Donut bi-directional frying production device

A production device and doughnut technology are applied in the field of doughnut bidirectional frying production devices, which can solve the problems of affecting the taste of the doughnut, unable to achieve the consistency of the taste of the two sides of sweet and sweet, low efficiency, etc. The effect of frying for too long, improving taste and speeding up production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

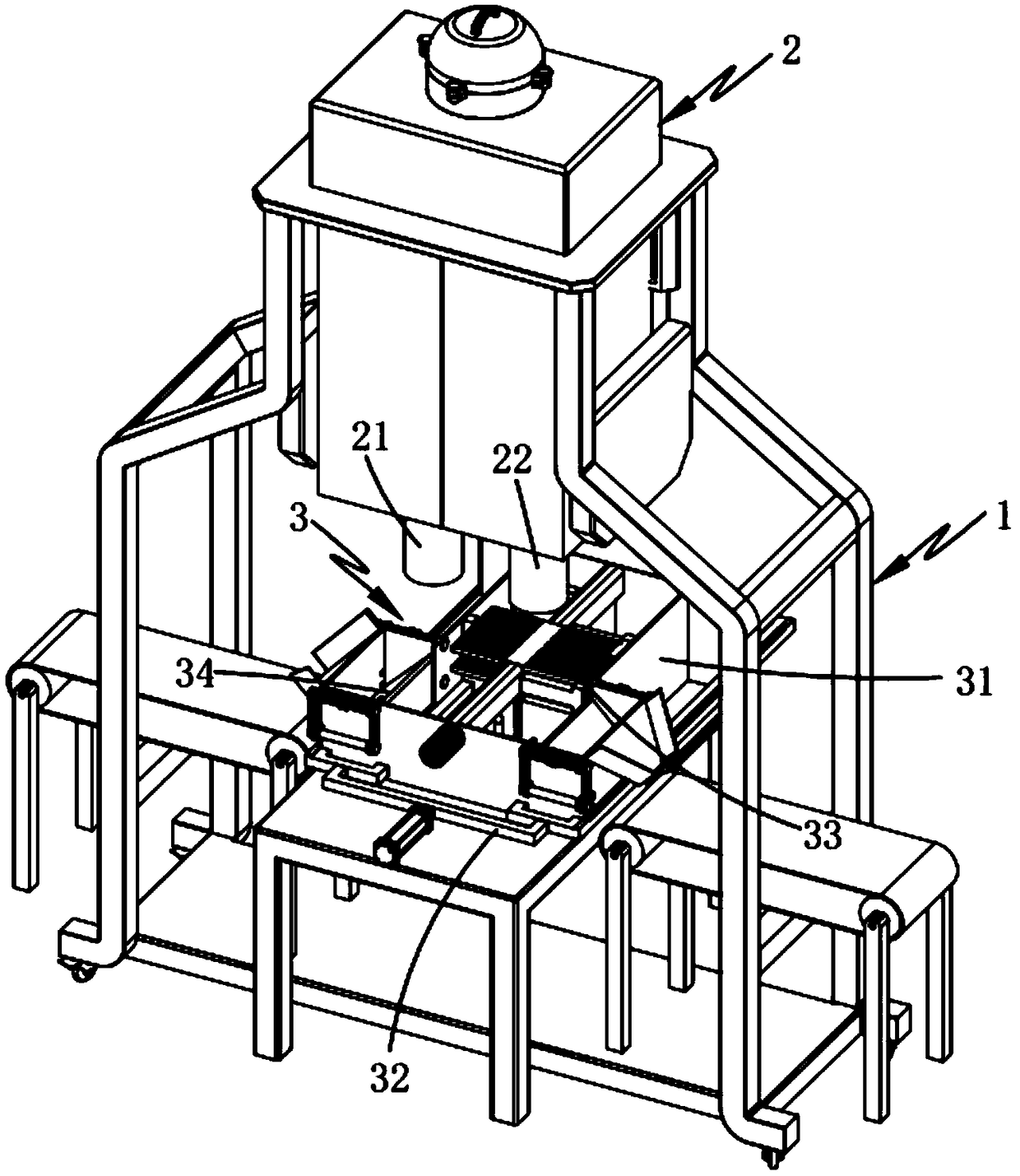

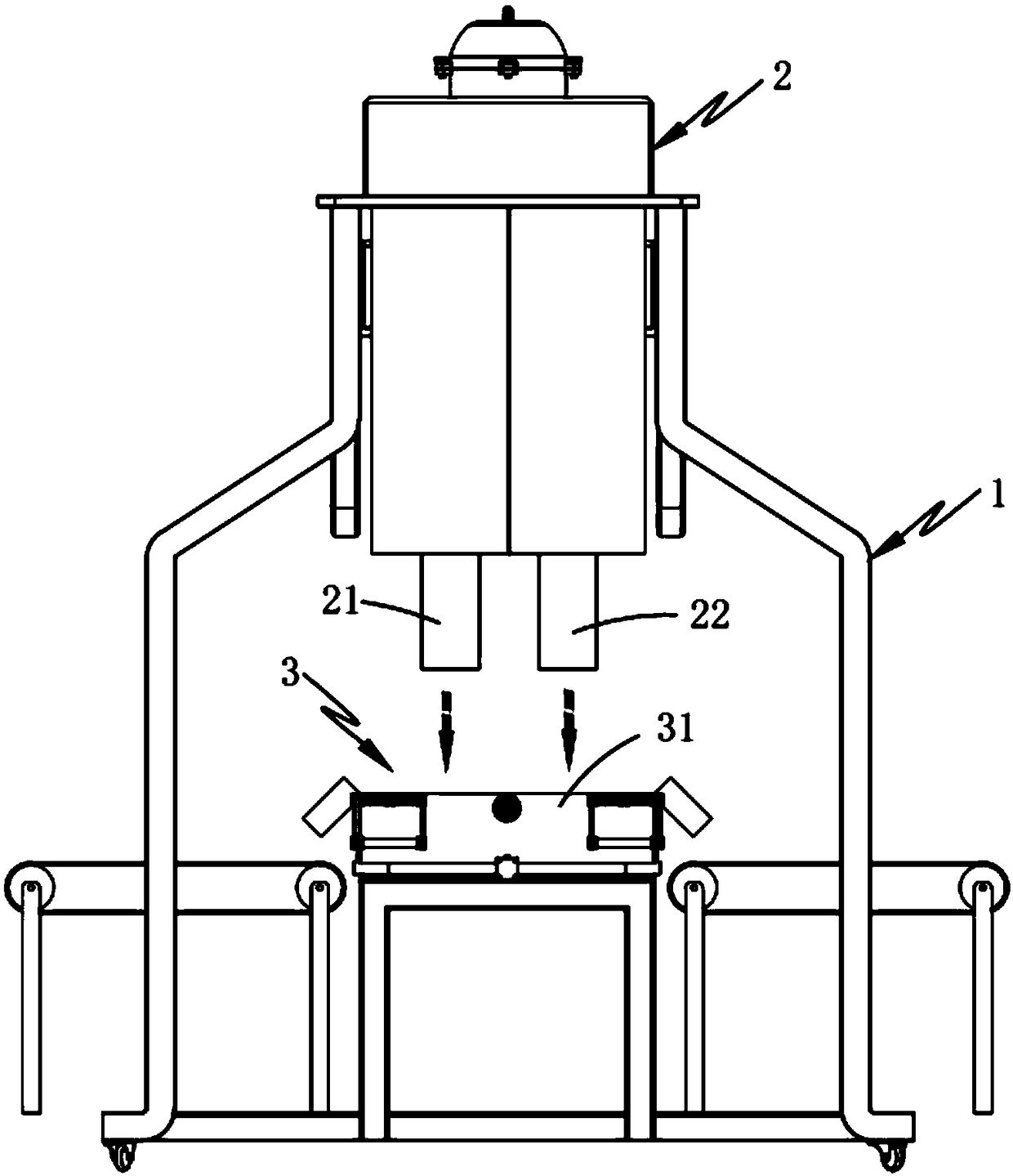

[0056] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 Shown, a kind of donut two-way fried production device, comprises support 1, the molding mechanism 2 that is installed on the described support 1, also comprises:

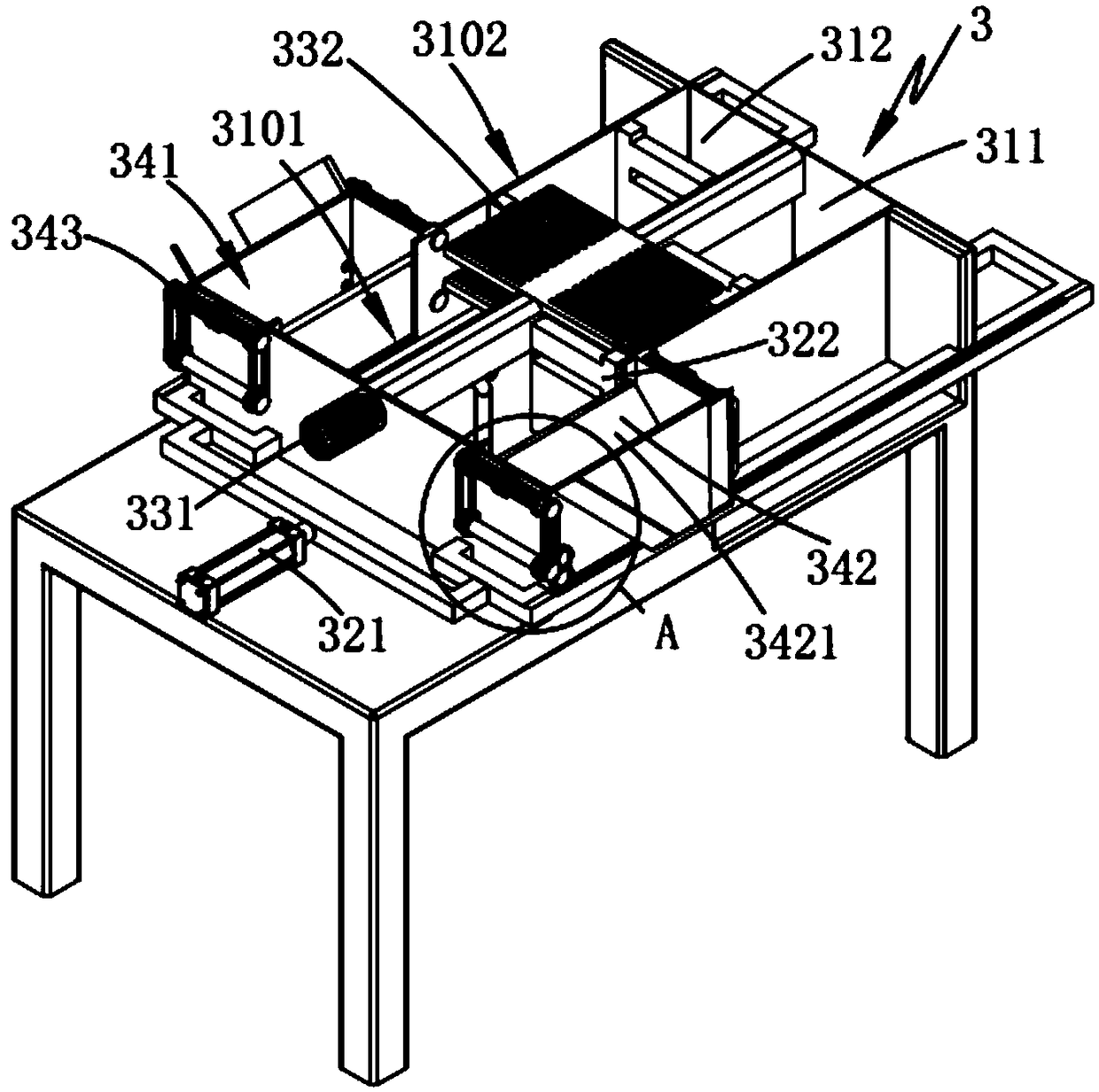

[0057] Frying overturning mechanism 3, described frying overturning mechanism 3 is arranged below described forming mechanism 2, and this frying overturning mechanism 3 comprises oil pot 31, guide assembly 32 that is arranged on described oil pot 31, is arranged on described The turning assembly 33 on the oil pan 31 and the discharge assembly 34 that is arranged on the one end of the oil pan 31 close to the forming mechanism 2, during work, the forming mechanism 2 carries out the blanking of the donut primary mold in the oil pan 31, and guides During the reciprocating motion, the component 32 guides the falling donut blank to the turning component 33 for turning over, and then the guiding component 32 cooperates wit...

Embodiment approach

[0064] As a preferred embodiment, the guide assembly 32 includes:

[0065] A guide driver 321, the guide driver 321 is arranged in the oil pan 31;

[0066] The guiding contact piece 322 is disposed on the guiding driving piece 321 and located in the oil pan 31 .

[0067] As a preferred embodiment, the turning assembly 33 includes:

[0068] Turn over driving part 331, described turning over driving part 331 is arranged on described oil pot 31;

[0069] The turning frame 332, the turning frame 332 is rotatably arranged between the first oil pan 311 and the second oil pan 312, and the turning frame 332 is placed between the first oil pan 311 and the second oil pan 312 during rotation. Rotate in the second oil pan 312 , and the turning frame 332 is set in cooperation with the guide contact piece 322 .

[0070] As a preferred embodiment, the number of the discharge assembly 34 is two groups, which are respectively arranged on one side of the first oil pan 311 and the second oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com