Automatic deep-frying and oil-filtering device for sweet potato slice processing

An oil filtering device and technology of sweet potato slices, which are applied in the direction of filtration and separation, oil/fat baking, fixed filter elements, etc., can solve the problems of inability to filter clean, reduce practicability, and a lot of waste residue in frying equipment, etc., to ensure oil quality The effect of frying quality, ensuring hygiene, and facilitating cleaning of debris

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

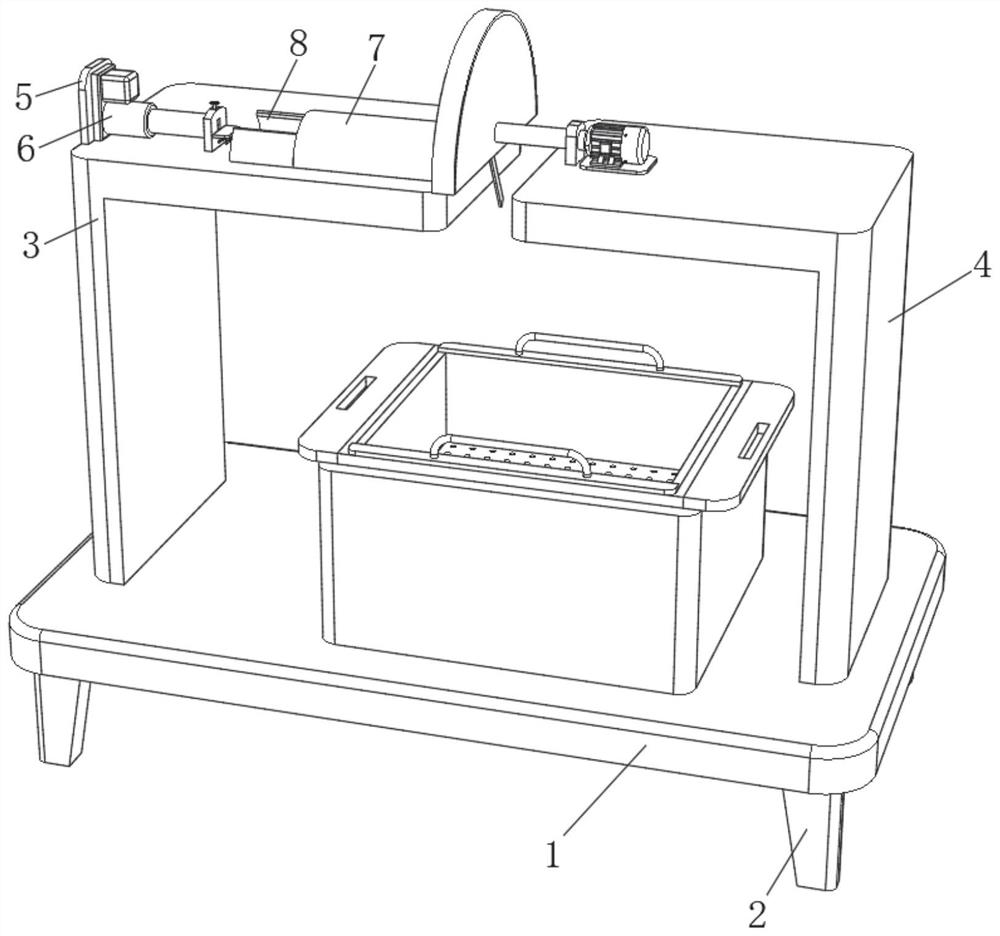

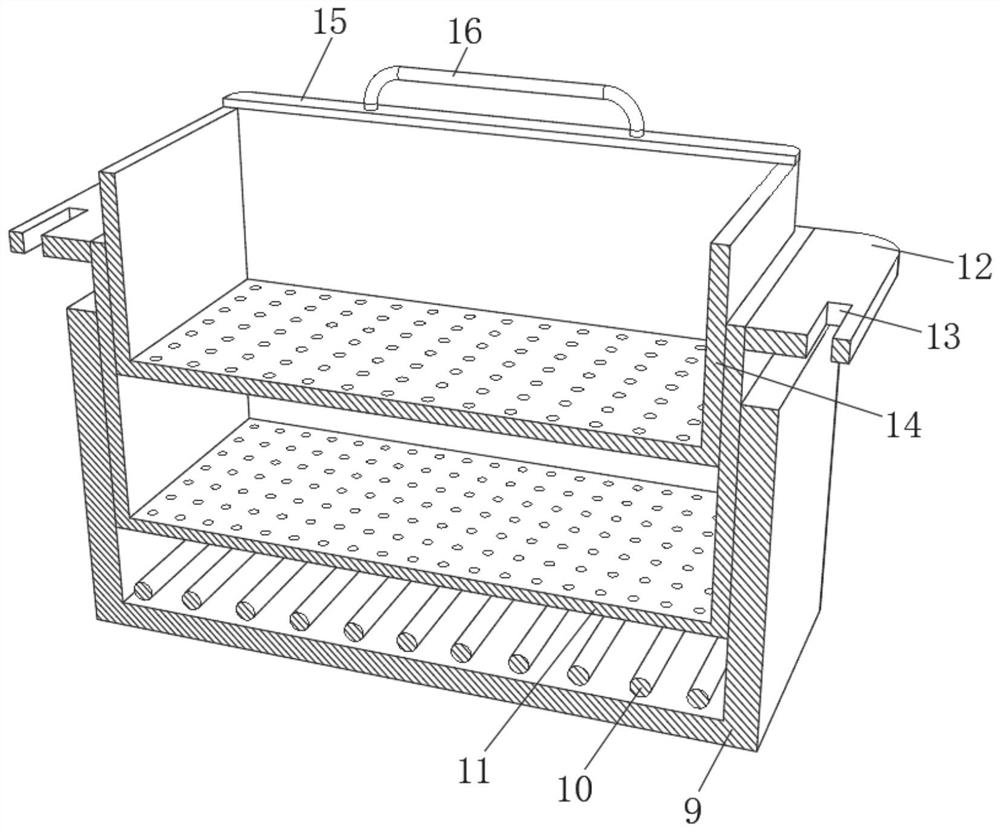

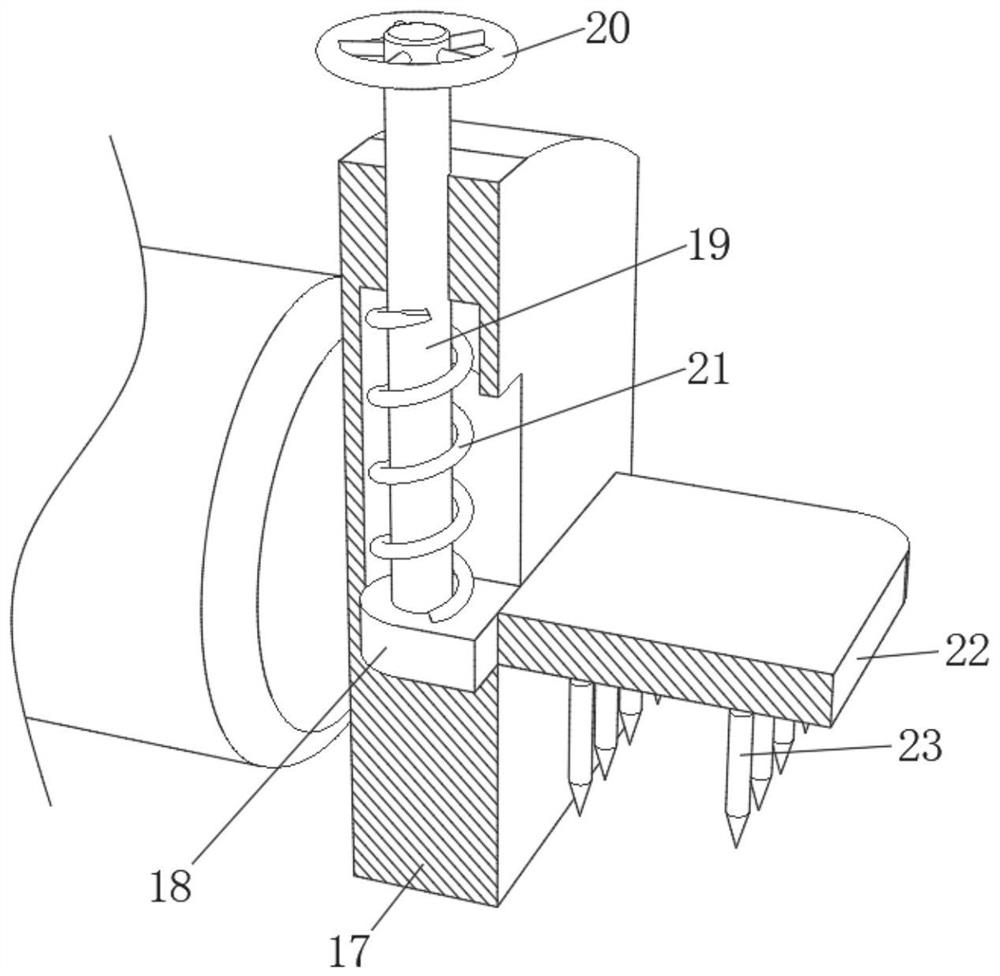

[0027] see Figure 1-4 , the present invention provides a technical solution: an automatic frying oil filtering device for processing sweet potato slices, comprising a support plate 1, the four corners of the lower surface of the support plate 1 are fixedly connected with support legs 2, and the left side of the upper surface of the support plate 1 The first riser 3 is fixedly connected, the right side of the upper surface of the support plate 1 is fixedly connected with the second riser 4, the left side of the upper surface of the first riser 3 is fixedly connected with the push rod support plate 5, and the push rod support plate 5 The right side of the first vertical plate 3 is fixedly connected with an electric push rod 6, and the model of the electric push rod 6 is SD146-85DJ. The right front side of the upper surface of the first vertical plate 3 is fixedly connected with an arc-shaped plate 7, and the front of the left side of the arc-shaped plate 7 The side and the rear...

Embodiment 2

[0035] see Figure 1-3 and Figure 5 , the present invention provides a technical solution: an automatic frying oil filtering device for processing sweet potato slices, comprising a support plate 1, the four corners of the lower surface of the support plate 1 are fixedly connected with support legs 2, and the left side of the upper surface of the support plate 1 The first riser 3 is fixedly connected, the right side of the upper surface of the support plate 1 is fixedly connected with the second riser 4, the left side of the upper surface of the first riser 3 is fixedly connected with the push rod support plate 5, and the push rod support plate 5 The right side of the first vertical plate 3 is fixedly connected with an electric push rod 6, and the model of the electric push rod 6 is SD146-85DJ. The right front side of the upper surface of the first vertical plate 3 is fixedly connected with an arc-shaped plate 7, and the front of the left side of the arc-shaped plate 7 The si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com