Tea seed oil pressing process

A technology of tea seed oil and tea seeds, which is applied in the field of tea seed oil pressing technology, can solve the problems of temperature drop, tea seed moisture resurgence, and limited amount of compression, and achieve the effect of preventing moisture resurgence and uniform frying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below by means of specific embodiments:

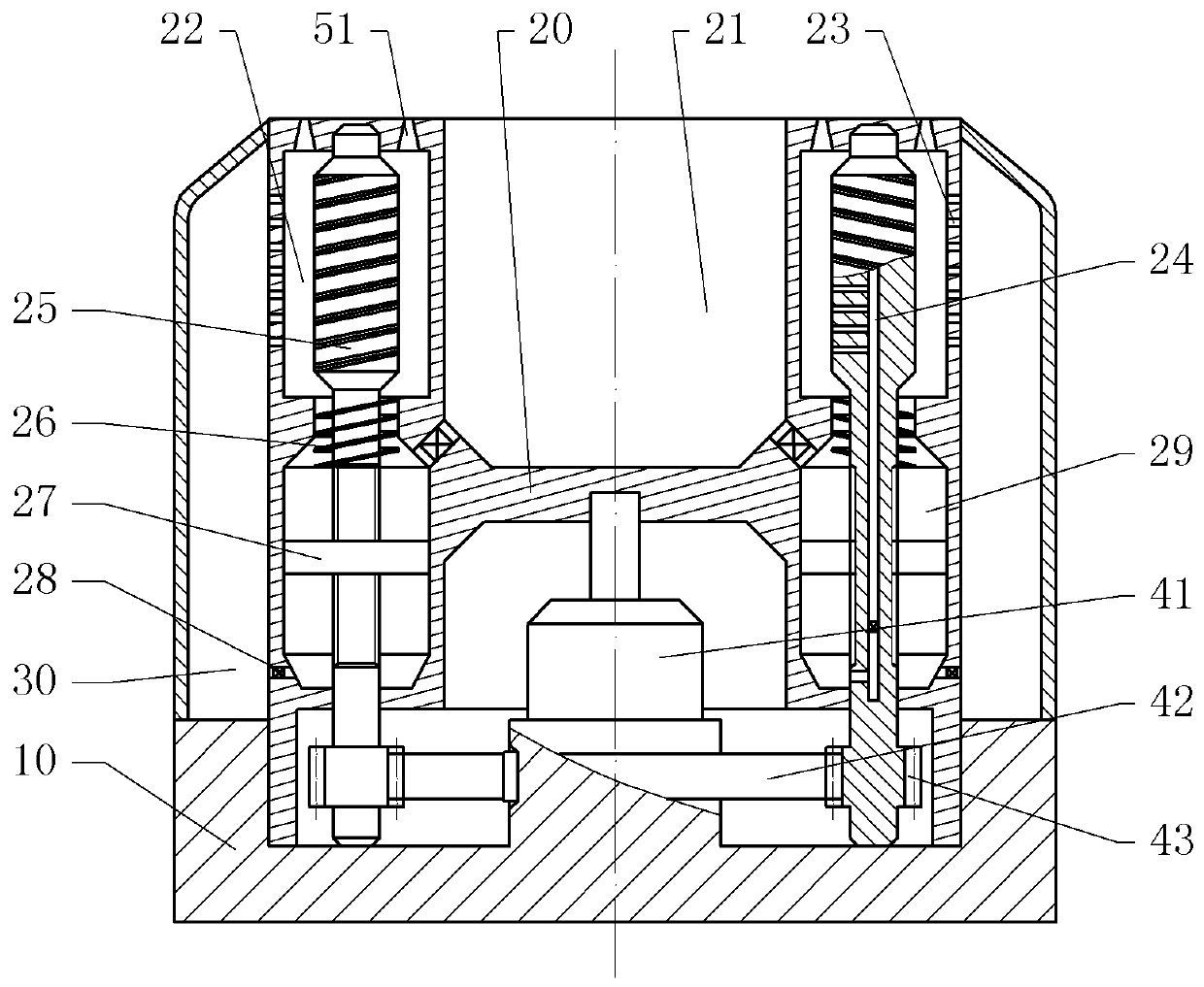

[0028] The reference signs in the accompanying drawings of the description include: seat body 10, rotating body 20, frying chamber 21, oil pressing chamber 22, oil outlet hole 23, oil guiding channel 24, oil pressing screw 25, material guiding screw blade 26, piston 27. Oil discharge port 28, feed chamber 29, oil cylinder 30, drive motor 41, first gear 42, second gear 43, slag outlet 51.

[0029] The tea seed oil pressing process of this embodiment uses a tea seed oil pressing device to squeeze the tea seed oil. Such as figure 1 As shown, the tea seed oil pressing device includes a base body 10, an oil cylinder 30 fixed on the base body 10, a rotating body 20 and a driving part that are rotatably connected to the base body 10; the rotating body 20 is arranged in the oil cylinder 30, and the rotating body The 20 is provided with a frying cavity 21, an oil pressing cavity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com