Production equipment for fried small yellow croakers

A production equipment and technology for small yellow croaker, which is applied in oil/fat roasting and other directions, can solve the problems of excessive zooming and uneven heating of small yellow croaker in frying, and achieve the effects of convenient and fast discharging, uniform heating and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

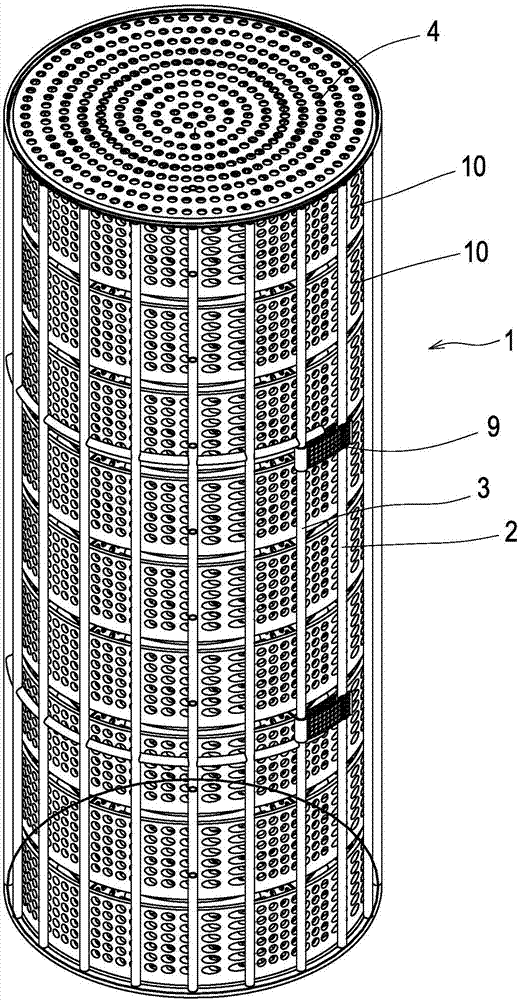

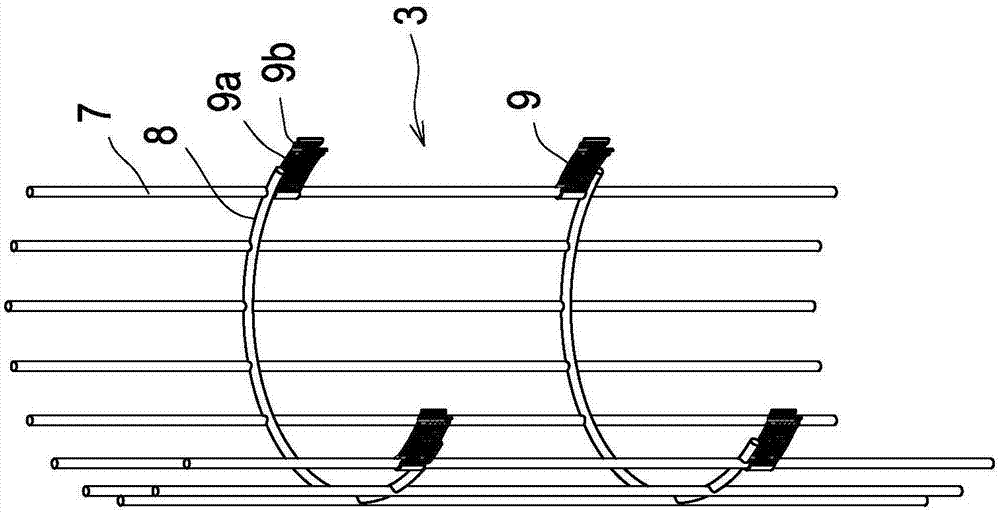

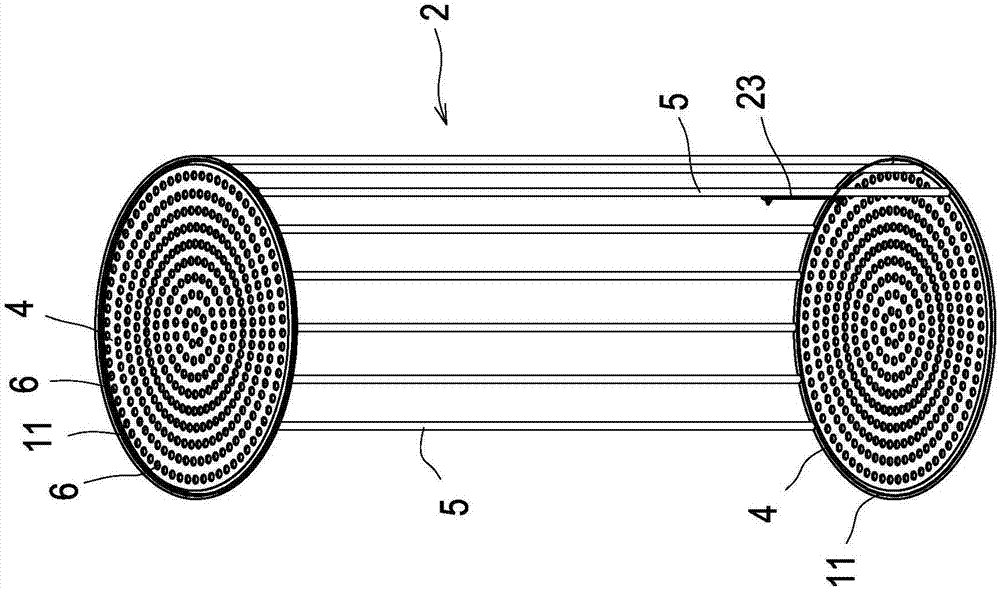

[0037] Such as Figure 7 As shown, a production equipment for frying small yellow croaker includes a base 30, the base 30 is provided with a frying chamber 31, and the base 30 is also provided with a heating mechanism 32 located below the frying chamber 31 One end of the frying chamber 31 is provided with a feed valve assembly 33, the other end of the frying chamber 31 is provided with a discharge valve assembly 34, and several cylindrical frying barrels 1 are arranged in the frying chamber.

[0038] In this embodiment, the frying cavity 31 is U-shaped with two ends high and the middle low. The inlet valve assembly 33 and the discharge valve assembly 34 are used to seal the two ends of the frying cavity 31 respectively, and the small yellow croaker is put into the frying barrel. 1, it can avoid contact with the stains at the bottom of the frying oil in the frying cavity 31, ensuring the safety and sanitation of the frying process.

[0039] The feed valve assembly 33 and the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com