Frying cooking method

A technology of oil layer and oil surface, which is applied in the field of frying and cooking, can solve the problems of environmental protection and disposal cost, oil deterioration, and affecting the flavor of fried food, etc., and achieve the effect of good appearance and quality, and uniform oil temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Using the following test conditions, the center temperature of the cooked meatloaf was compared between a test fryer capable of carrying out the frying method of the present invention and a conventional fryer.

[0054] Test conditions:

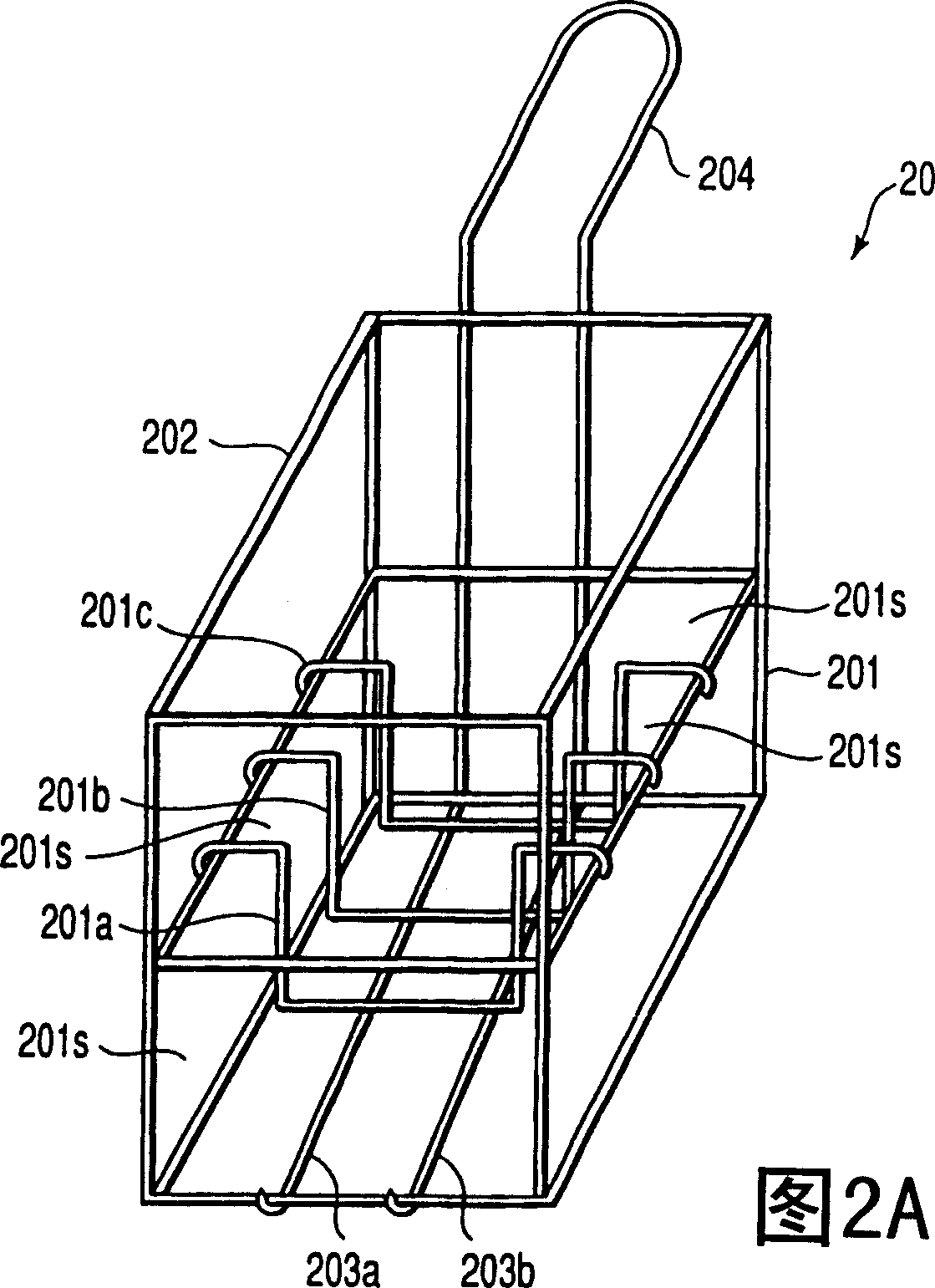

[0055] frying utensils

[0056] Experimental Fryer

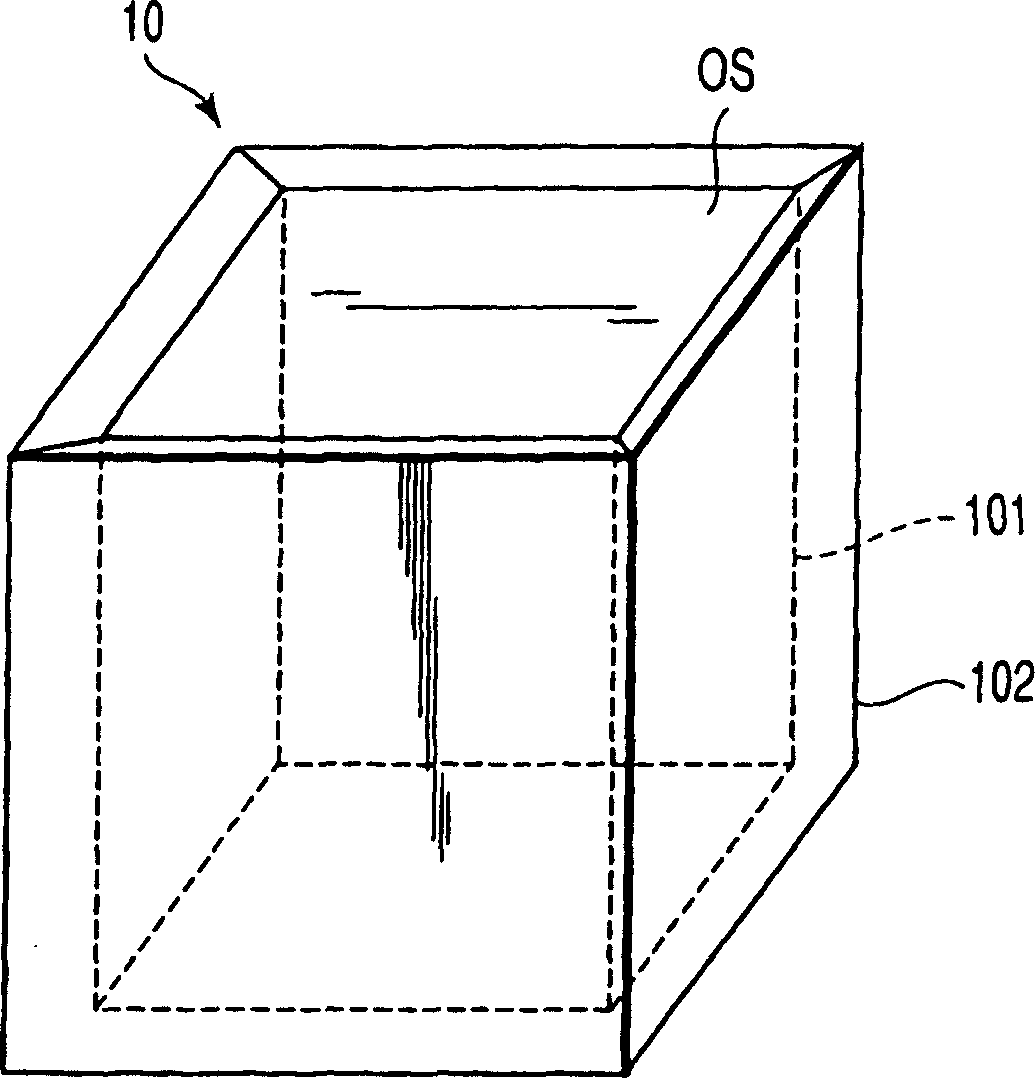

[0057] Oil tank shape: horizontal 10cm, vertical 18cm, height 21cm

[0058] Oil volume: 2.0 liters

[0059] Configuration of the main ingredients: make the large side of the meatloaf vertical to the oil surface, and fix it in a state completely submerged in the oil.

[0060] Conventional machine (commercially available 5L electric fryer, ェィシン electric EF-5 type)

[0061] Oil tank shape: width 25cm, weight 27cm, height 13cm

[0062] Oil volume: 5.0 liters

[0063] The configuration of the main ingredients: make the large surface of the meatloaf parallel to the oil surface, not fixed (the previous frying method).

[0064] Oil temperature: the temperature is 180°C when the main in...

Embodiment 2

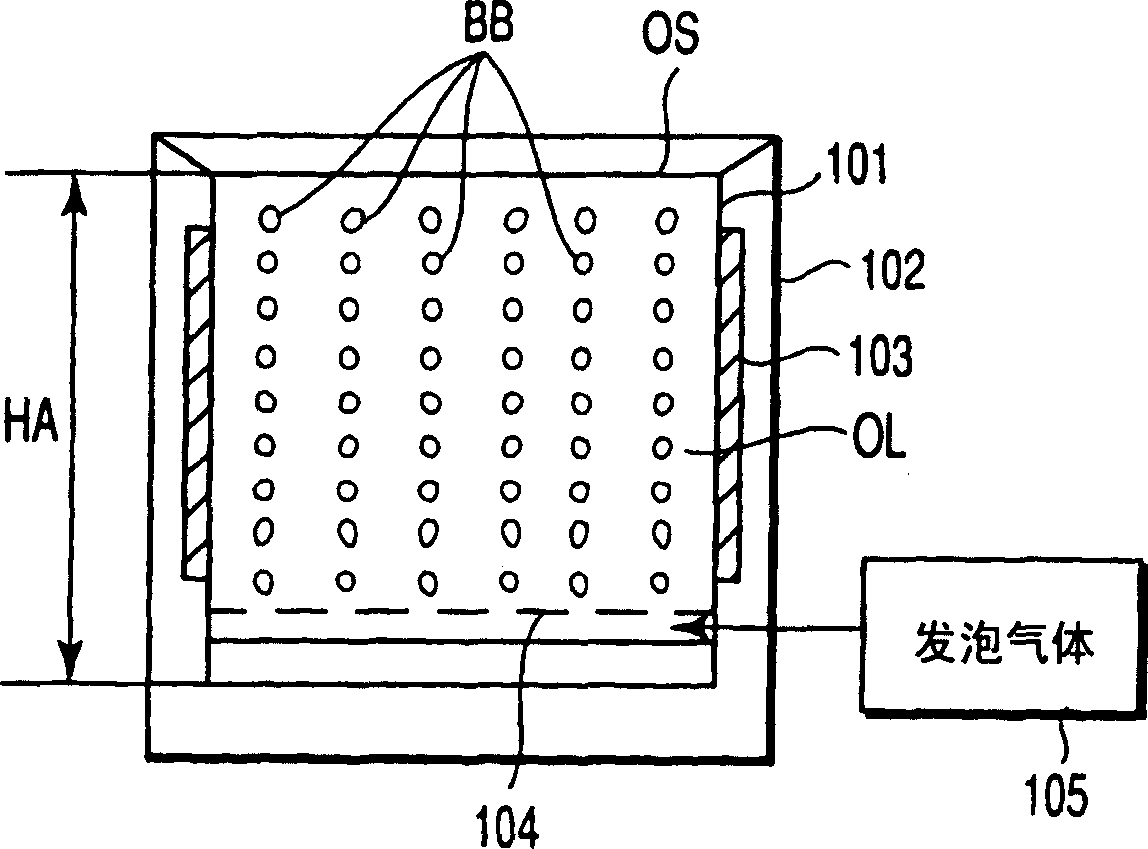

[0074] Using the following conditions, when using a test fryer that can implement the frying method of the present invention, and when using a conventional fryer, compare the state of the oil during frying and cooking (the ratio of air bubbles, flow rate) and after frying and cooking The state of the meatloaf (appearance, core temperature).

[0075] Test conditions:

[0076] frying utensils

[0077] The invention machine

[0078] Oil tank shape: horizontal 9cm, vertical 16cm, height 17cm

[0079] Flow: 1500mL

[0080] Heater: The heater is hidden in the left and right side walls of the oil tank, not exposed to the oil tank.

[0081] Configuration of the main ingredients: make the big side of the patty vertical to the oil side, and completely submerged in the oil to fix it.

[0082] (ェィシン Electric EF / 3L type)

[0083] Past machine:

[0084] Oil tank shape: horizontal 24cm, vertical 23cm, height 11cm

[0085] Oil volume: 3000mL

[0086] Heater: The heater is arranged in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com