High-temperature oil frying machine

A frying machine and high-temperature technology, which is applied in food forming, food science, application, etc., can solve the health hazards of operators and other problems, achieve uniform frying, avoid burns, and ensure health effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

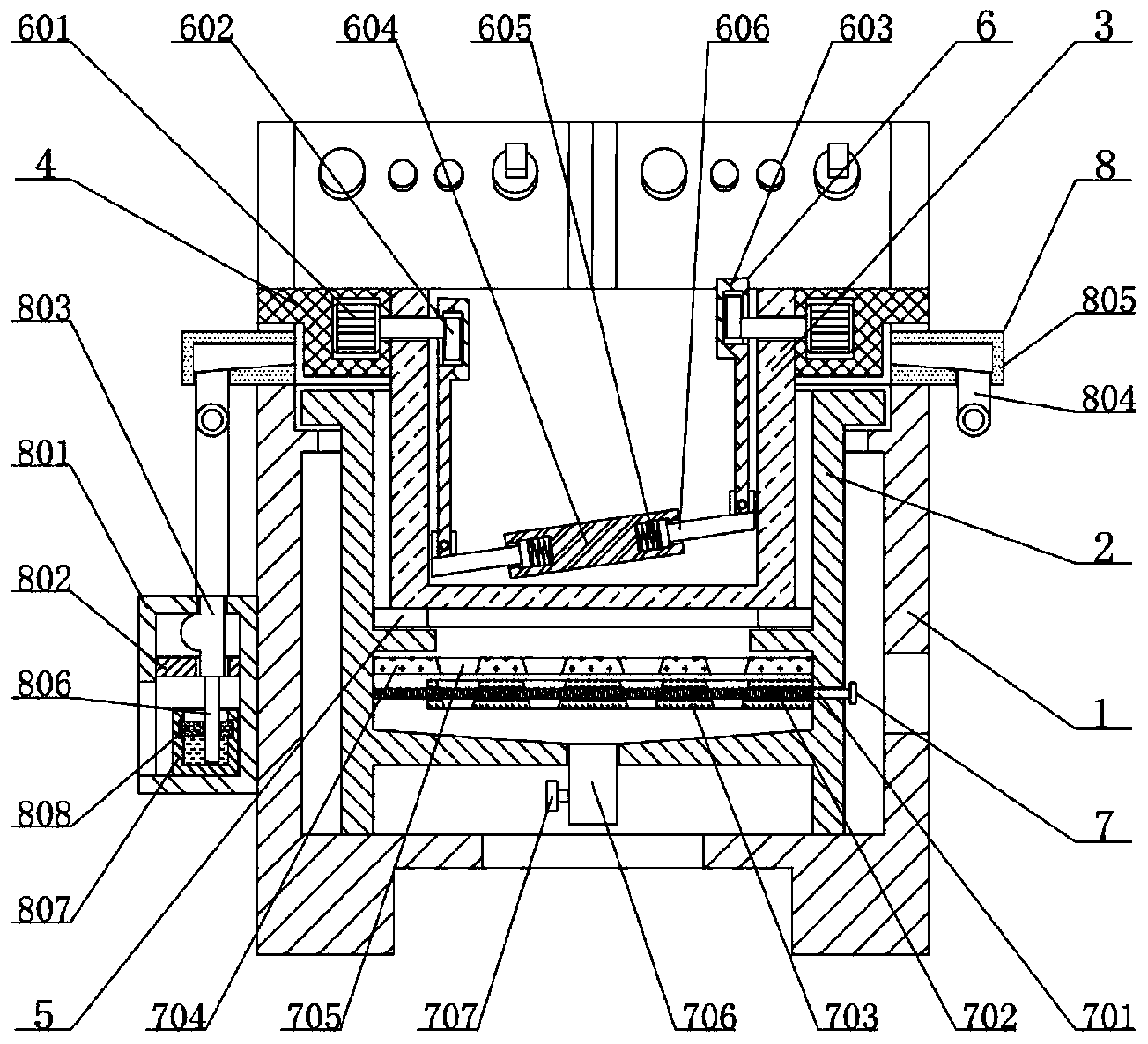

[0026] See figure 1 , image 3 , Figure 4 with Figure 5 , The present invention provides a technical solution:

[0027] A high-temperature fryer includes a fryer 1, a shaking device 6, a separating device 7 and a processing device 8. An oil cylinder 2 is arranged on the inside of the fryer 1, and the oil cylinder 2 is slidingly connected to the fryer 1, and the top of the inner side of the oil cylinder 2 There is a frying screen 3, the oil tank 2 is slidingly connected with the frying screen 3, the top of the outside of the frying screen 3 is fixedly connected with a bracket 4, the bracket 4 is slidingly connected with the fryer 1 and the oil tank 2, and the bottom end of the frying screen 3 is slidingly connected with heating The assembly 5, the heating assembly 5 is slidably connected with the oil cylinder 2, a shaking device 6 is provided inside the frying screen 3, and the shaking device 6 is fixedly connected with the bracket 4, the shaking device 6 includes a first motor ...

Embodiment 2

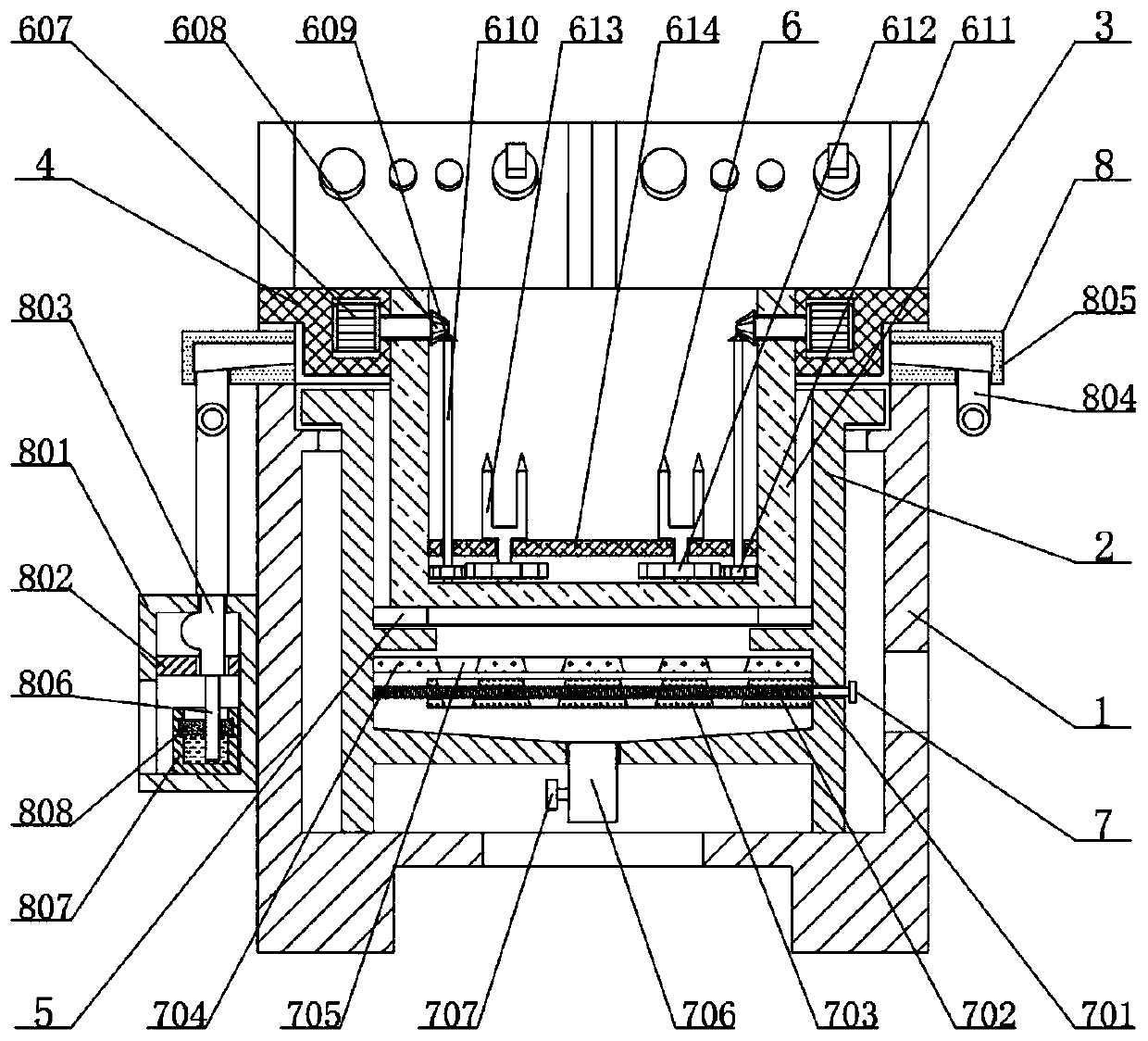

[0031] See figure 2 , image 3 with Figure 4 , The present invention provides a technical solution:

[0032] A high-temperature fryer includes a fryer 1, a shaking device 6, a separating device 7 and a processing device 8. An oil cylinder 2 is arranged on the inner side of the fryer 1, and the oil cylinder 2 is slidingly connected to the fryer 1, and the inner top of the oil cylinder 2 There is a frying screen 3, the oil tank 2 is slidingly connected with the frying screen 3, the top of the outside of the frying screen 3 is fixedly connected with a bracket 4, the bracket 4 is slidingly connected with the fryer 1 and the oil tank 2, and the bottom end of the frying screen 3 is slidingly connected with heating Component 5, the heating component 5 is slidably connected with the oil cylinder 2, a shaking device 6 is provided inside the frying screen 3, and the shaking device 6 is fixedly connected to the bracket 4, the shaking device 6 includes a second motor 607, a driving bevel ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com