Patents

Literature

35results about How to "Realize automatic oil filling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

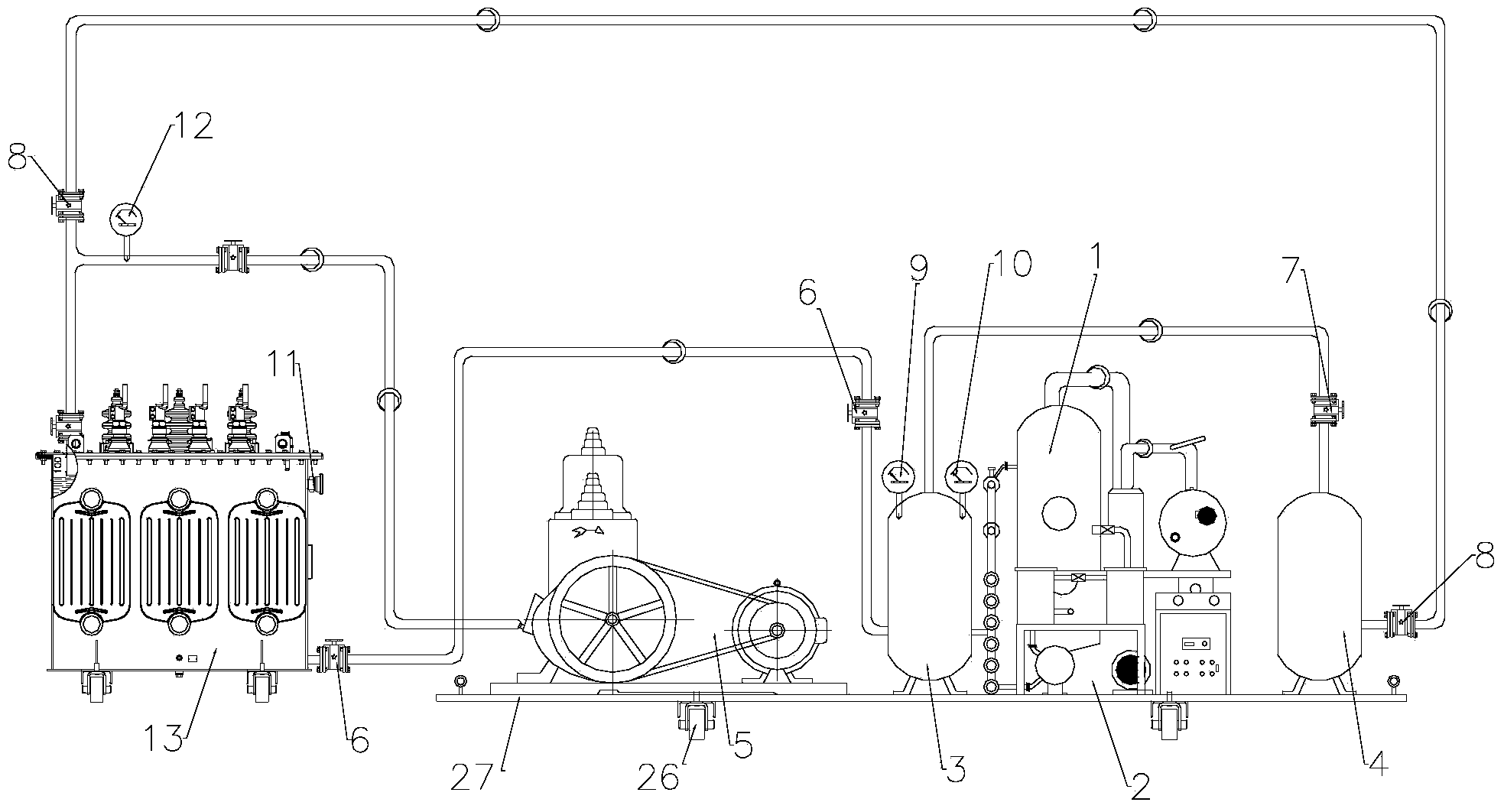

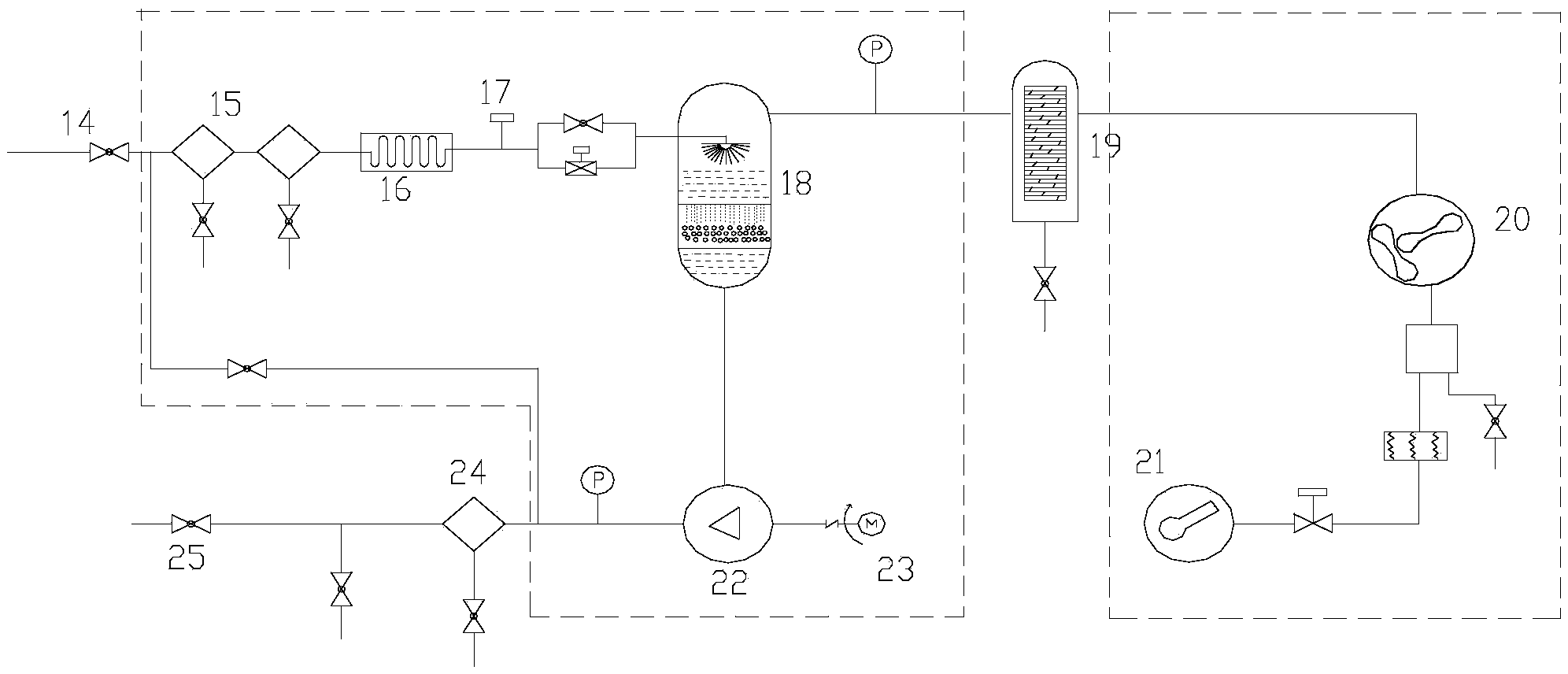

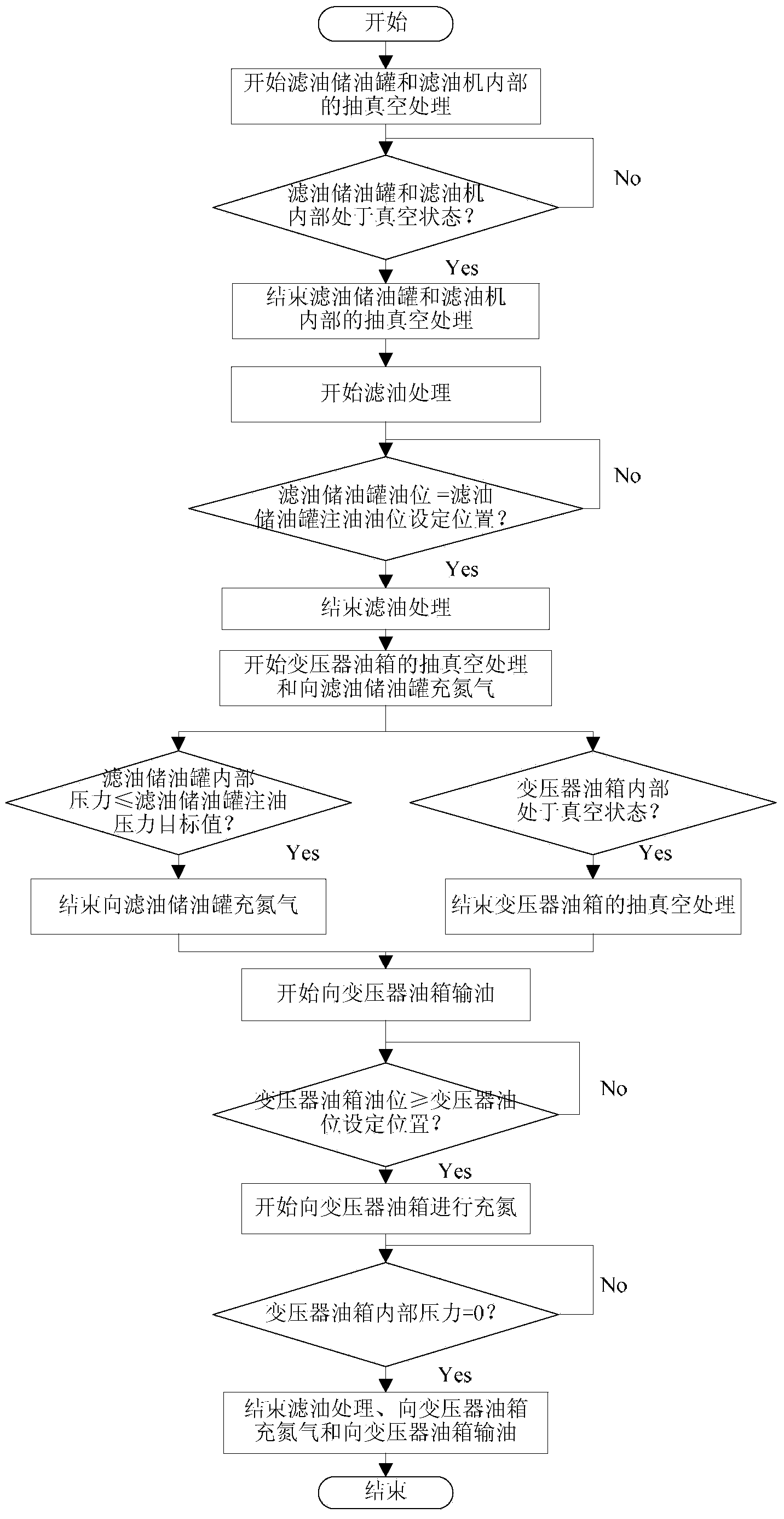

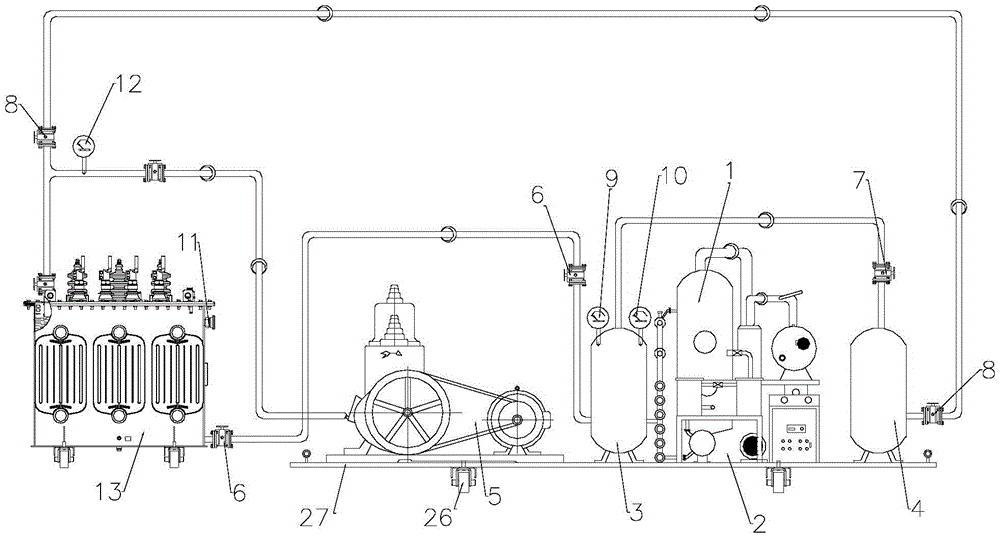

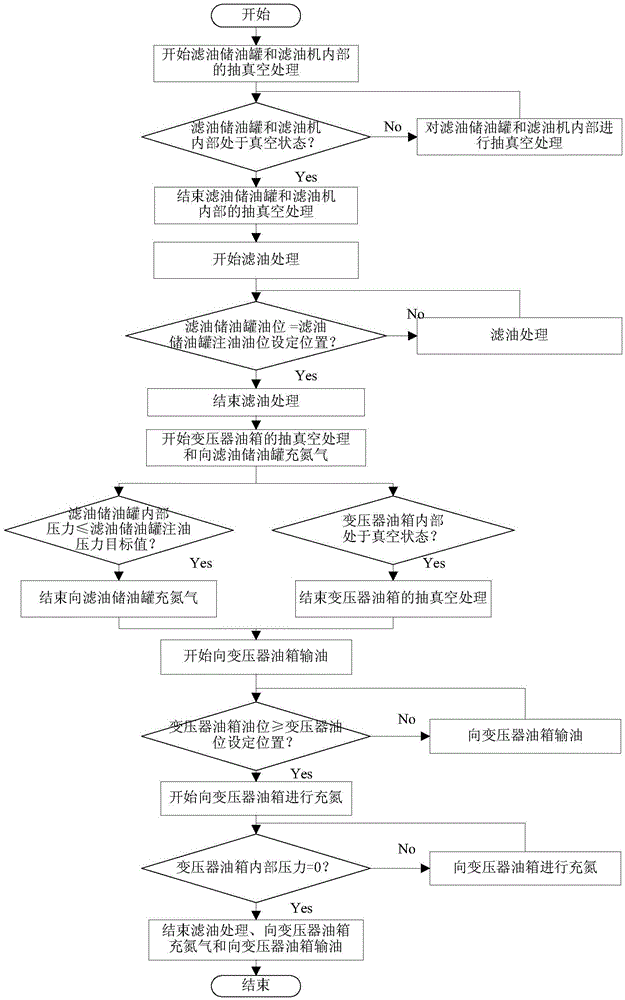

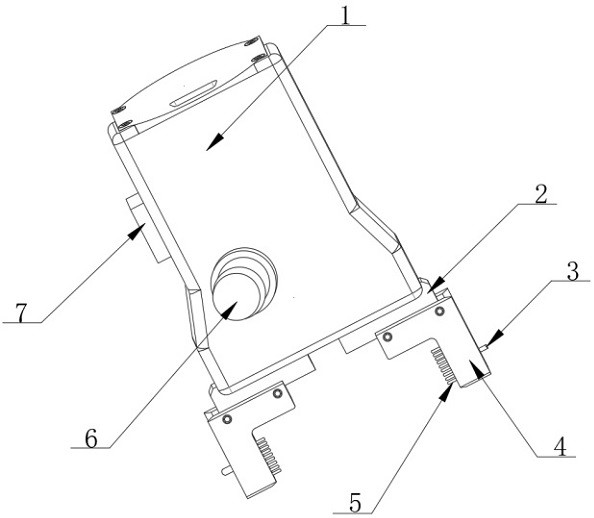

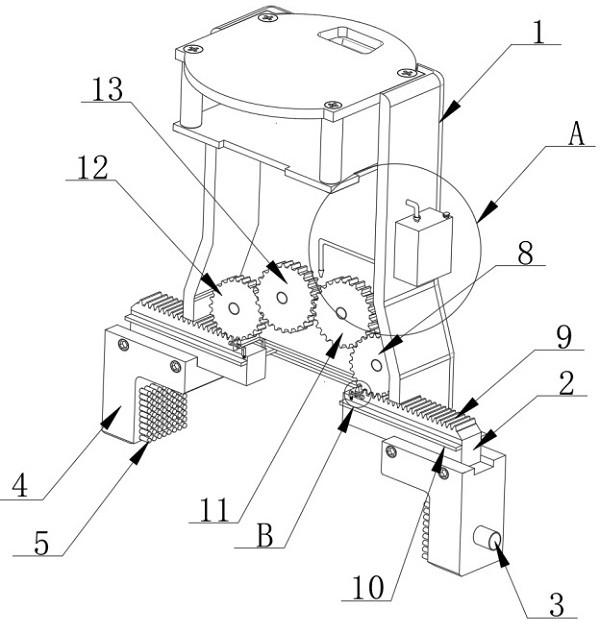

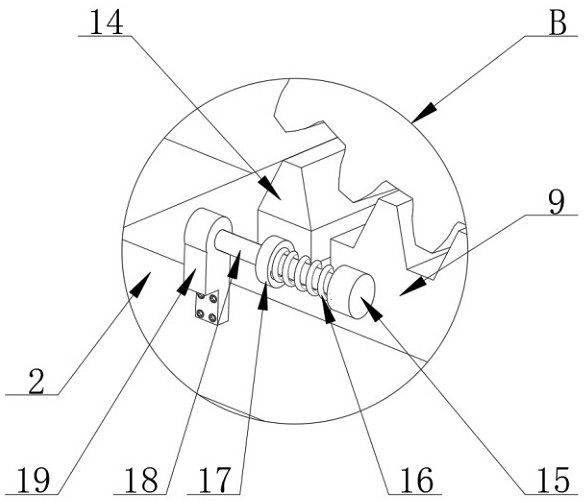

Transformer vacuum oiling device and oiling method thereof

ActiveCN103824679ARealize automatic oil fillingImprove insulation performanceTransformers/inductances coolingNitrogenFuel tank

The invention provides a transformer vacuum oiling device which is characterized in that a crude oil storage tank, an oil filter, a oil filtering and storing tank, a nitrogen tank and a main controller are included, and the transformer vacuum oiling device further comprises a filtered oil storage tank sensing device, a transformer oil tank sensing device, an oil storage tank oil outlet control device, an oil storage tank nitrogen filling control device, a transformer nitrogen filling control device and a vacuum device vacuumizing a transformer oil tank, wherein the sensing devices and the control devices are in signal connection with the main controller, the crude oil storage tank is connected with the oil filter and the filtered oil storage tank in sequence, and the vacuum device vacuumizing the transformer oil tank is directly connected with the transformer oil tank in a sealed mode. By means of the transformer vacuum oiling device, automatic transformer oiling can be achieved, the oiling speed is high, safety and reliability are achieved, on-site oiling can be achieved, moving is convenient, and cost is low. The invention further provides an oiling method, and on-site quick and automatic oiling can be achieved.

Owner:GUANGDONG CHAMPON ELECTRIC CO LTD

Air conditioner oiling device

InactiveCN104389763ASimple structureEasy to operatePositive displacement pump componentsPositive-displacement liquid enginesDifferential pressureFuel tank

The invention discloses an air conditioner oiling device, and belongs to the technical field of air conditioners. The air conditioner oiling device is designed for solving the problems that an existing air conditioner oiling device wastes time and labor in oiling, is low in oiling efficiency and the like. The air conditioner oiling device comprises an oiling tank, wherein the oiling tank is connected with an oil tank through an oil pipe, the oiling tank is connected with an exhaust port end of an air condition compressor through a first connection pipe, the oiling tank is connected with an air inlet end of the air condition compressor through a second connection pipe, a pressure increasing valve is arranged on the first connection pipe, and an oil discharge valve is arranged on the second connection pipe. The air conditioner oiling device uses differential pressure to achieve an oiling mode of automatically injecting lubricating oil into the air condition compressor, is simple in structure and convenient to operate, improves oiling efficiency, and saves time and labor.

Owner:GREE ELECTRIC APPLIANCES INC

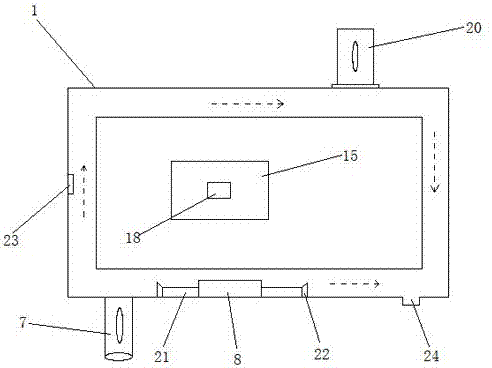

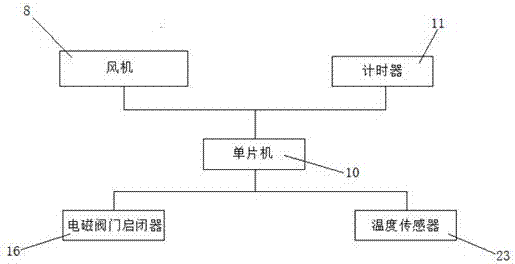

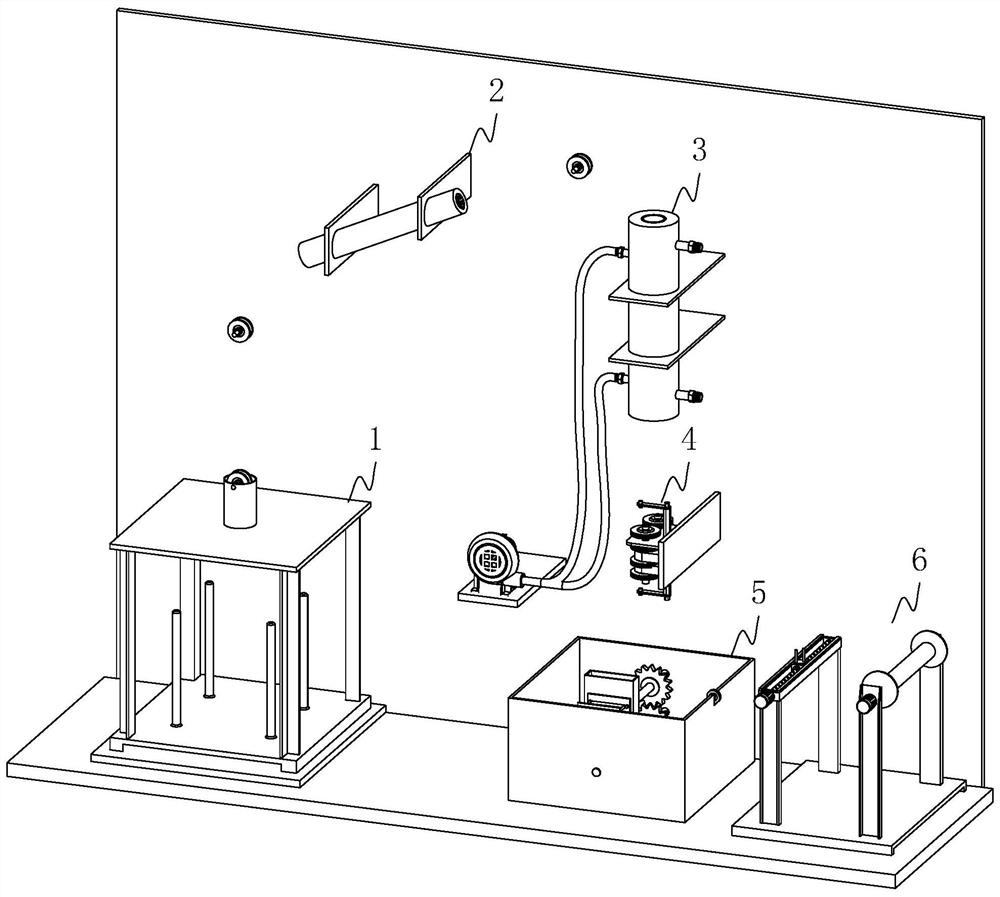

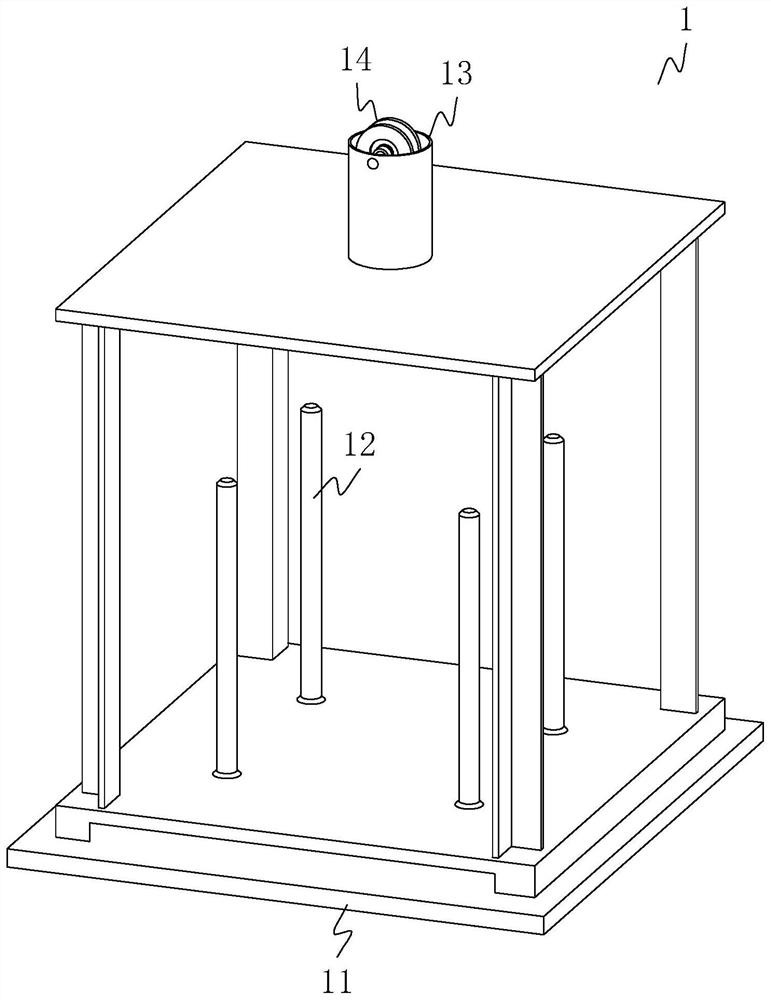

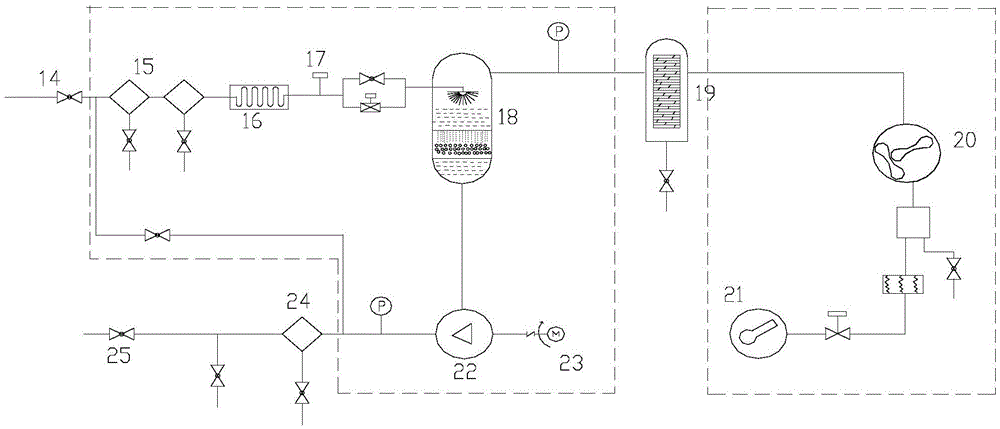

Low-temperature deep frying device and method for deep frying food

ActiveCN104170903ARealize automatic oil fillingReal-time detection of temperatureOil/fat bakingDeep fryingEngineering

The invention provides a low-temperature deep frying device and a method for deep frying food to be deep fried. The low-temperature deep frying device comprises a deep frying groove, a material inlet / outlet door, an oil inlet / outlet, a heating tube arranged in the deep drying groove, a vacuum device for making the interior of the deep frying groove reach a vacuum state, a deep frying main air cylinder for adjusting the deep frying position, a material inlet / outlet door air cylinder a for driving the material inlet / outlet door to descend or ascend, a material inlet / outlet door air cylinder b for driving the material inlet / outlet door to be opened or closed, an oil level meter for detecting the height of the oil level, a temperature gauge for detecting the oil temperature, and an electromagnetic valve used for receiving an oil temperature signal and controlling the deep frying main air cylinder, the material inlet / outlet door air cylinder a and the material inlet / outlet door air cylinder b, wherein the material inlet / outlet door and the oil inlet / outlet are communicated with the deep frying groove. According to the low-temperature deep frying device, the amount of oil injected into the deep frying groove and the temperature of the oil in the deep frying groove can be known through the oil level meter and the temperature gauge; through the deep frying main air cylinder, the position of a material inlet basket can be adjusted so that articles, to be deep fried, in the material inlet basket can make full contact with the oil.

Owner:BEIJING KAIDA HENGYE AGRI TECH DEV

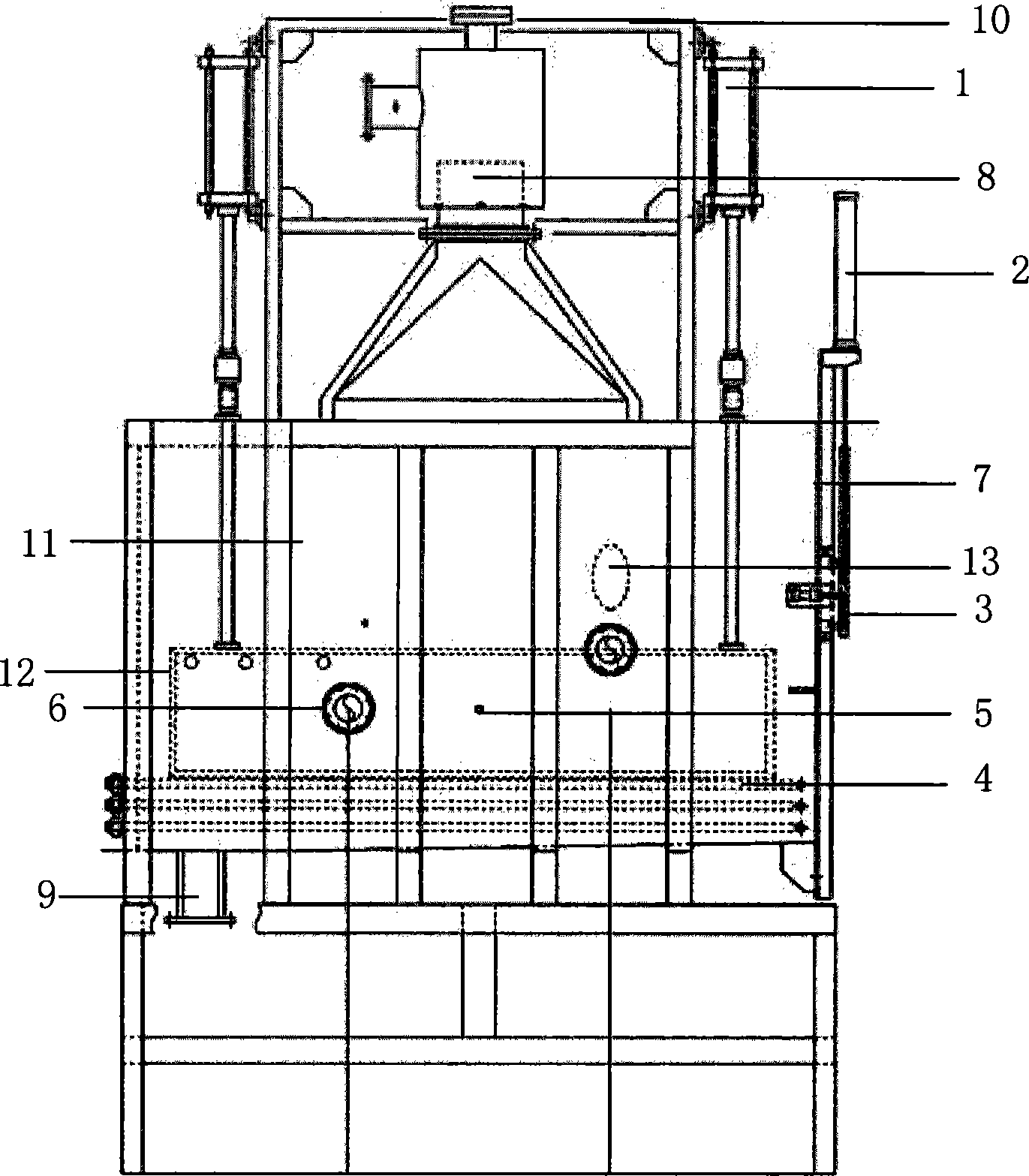

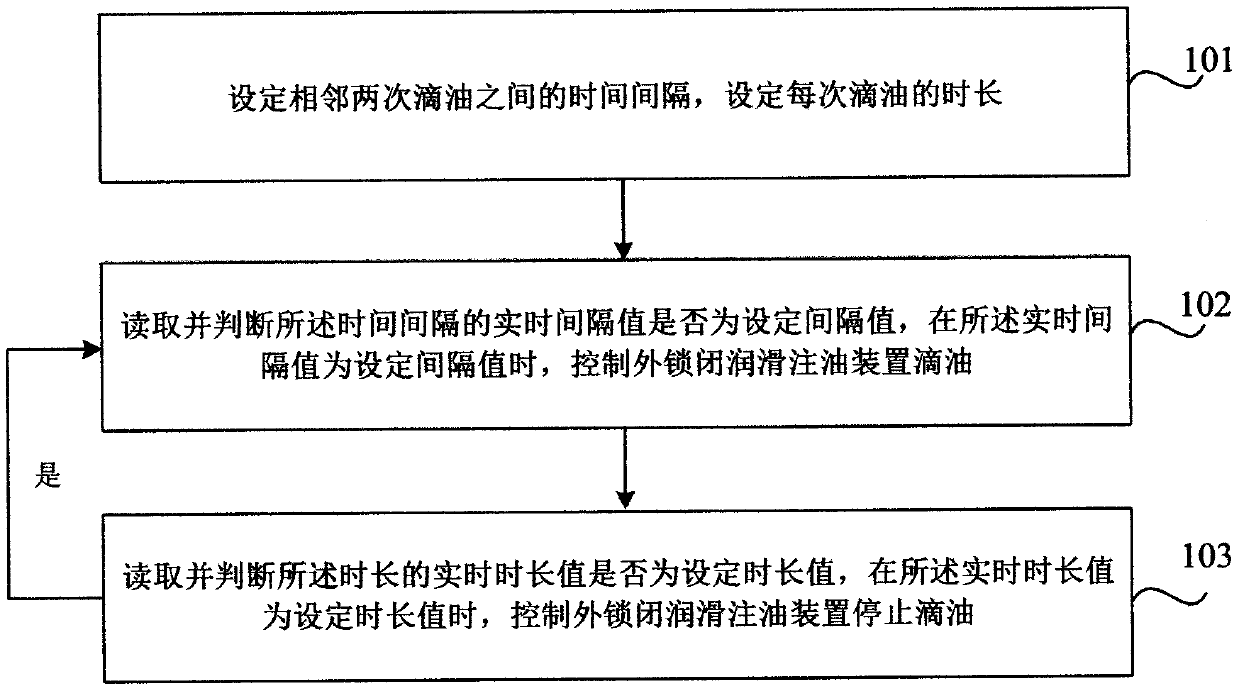

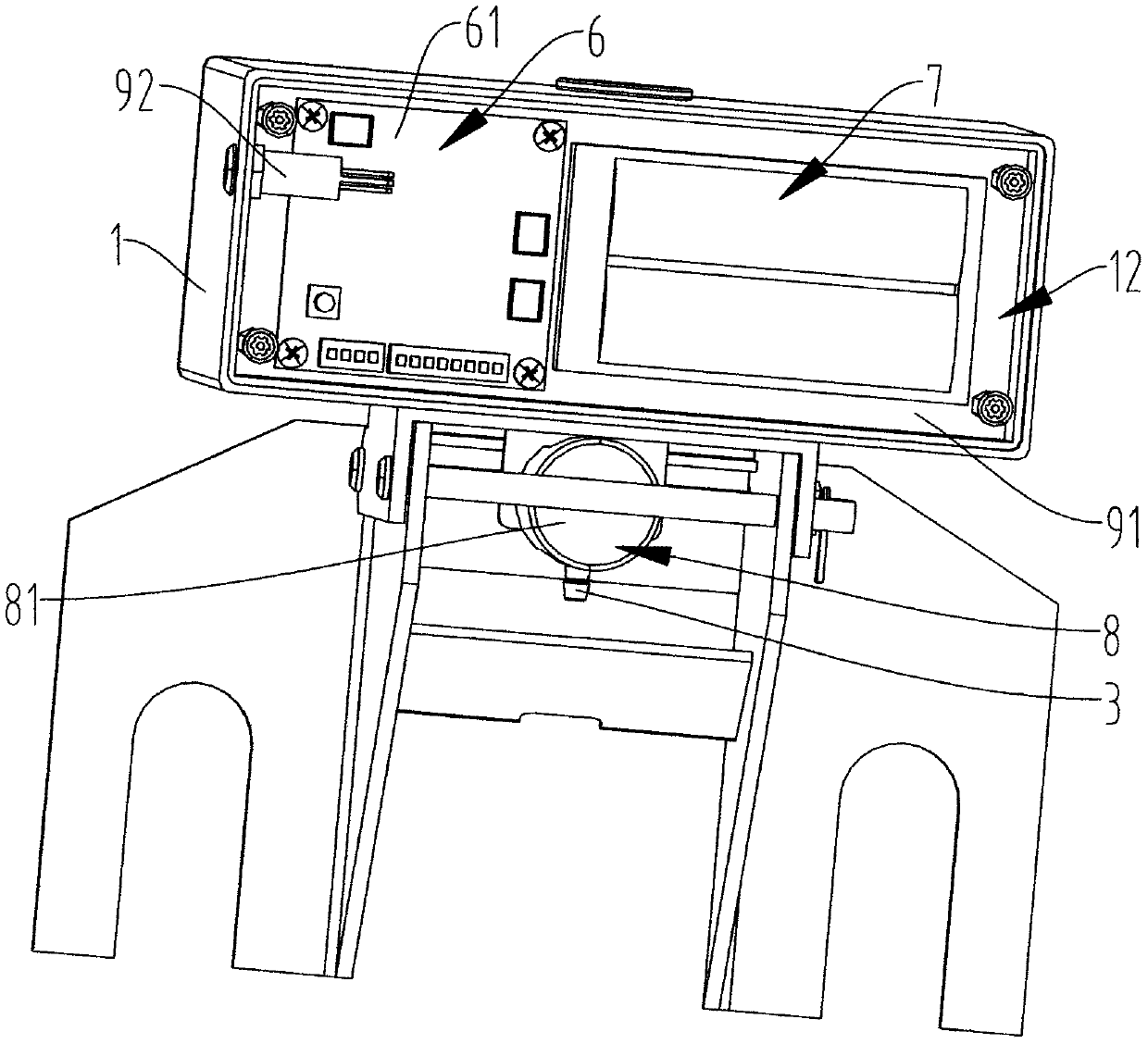

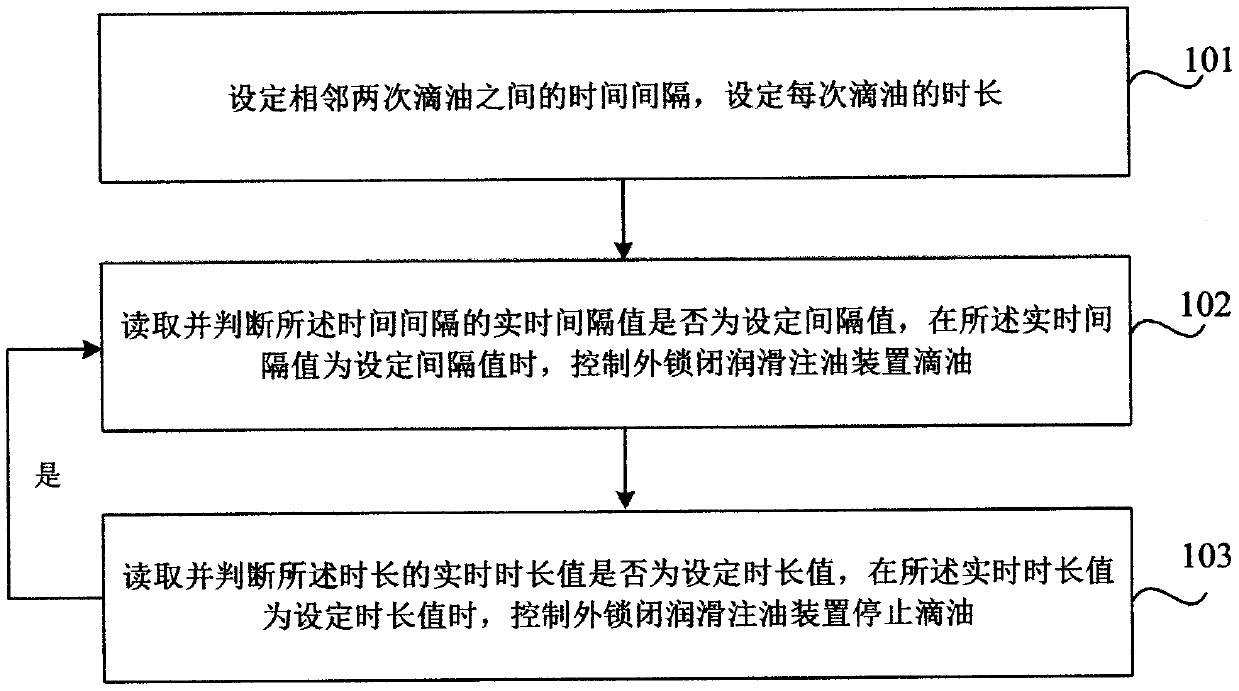

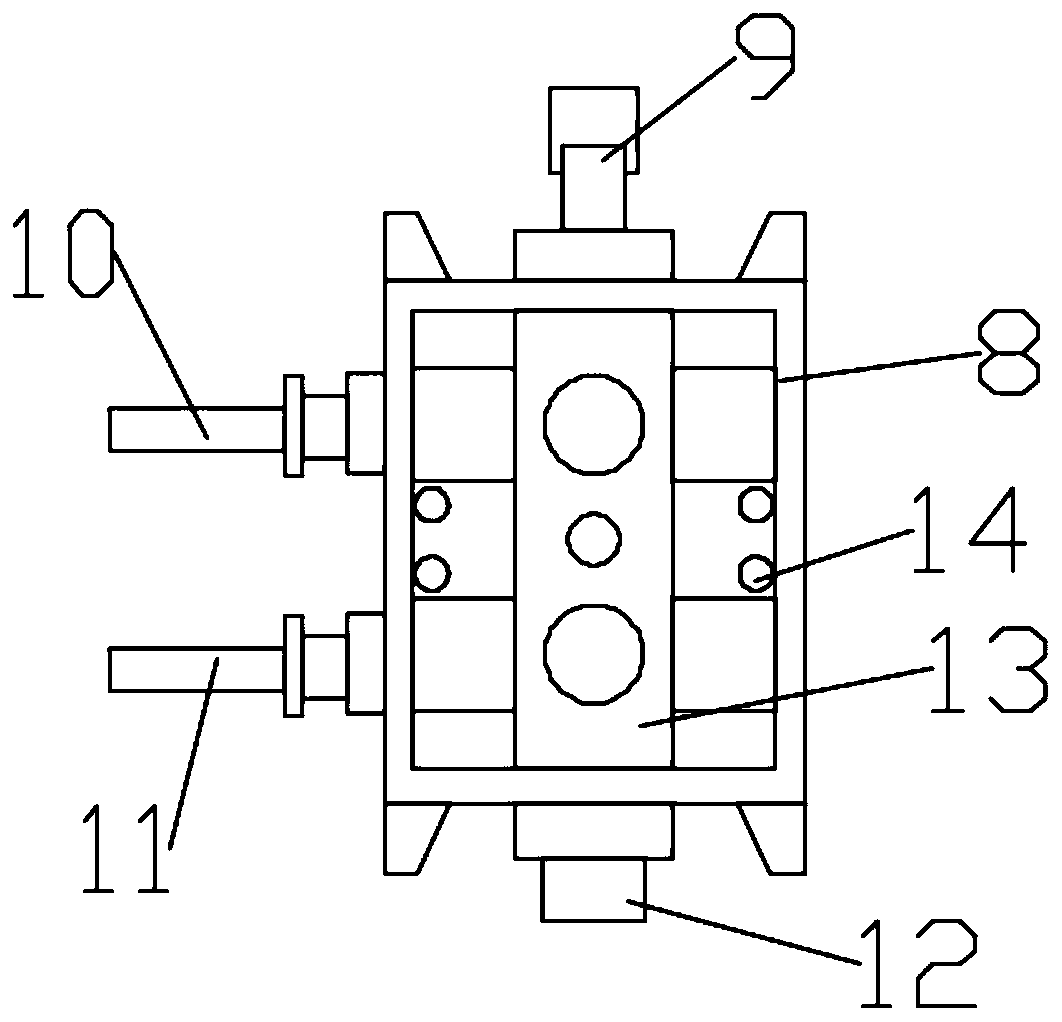

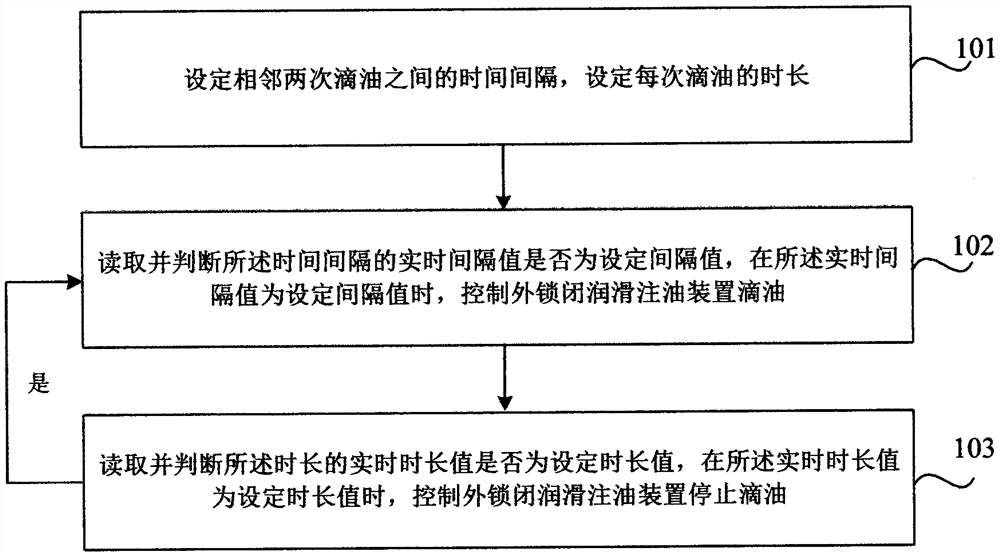

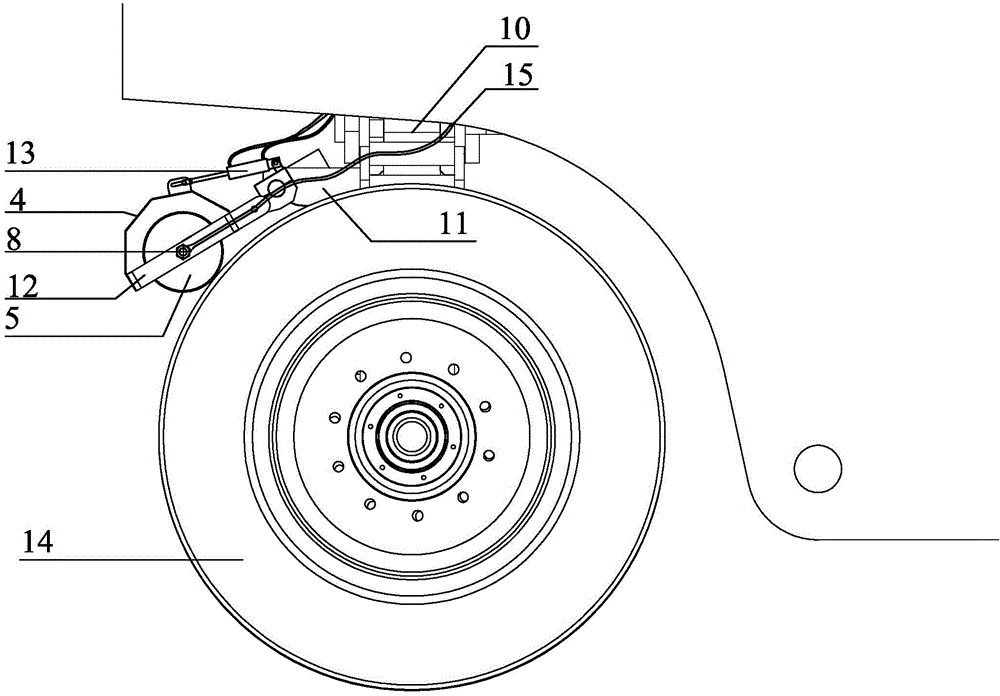

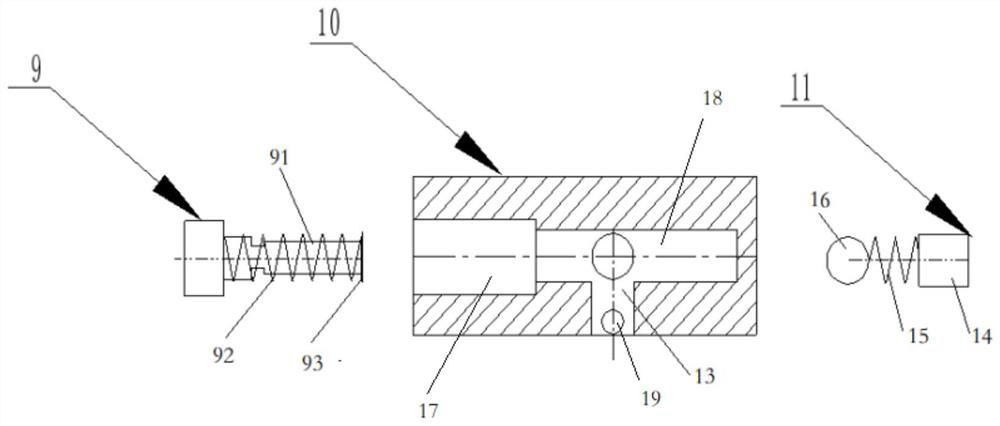

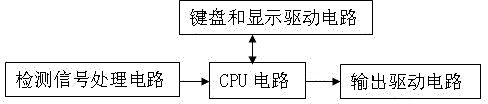

Oil dripping control method for external locking lubricating oil injection device and external locking lubricating oil injection device

ActiveCN111156399ARealize automatic oil fillingAvoid wastingSafety/regulatory devicesConduits/junctionsProcess engineeringTime duration

The invention relates to an oil dripping control method for an external locking lubricating oil injection device and the external locking lubricating oil injection device. The oil dripping control method comprises the steps that the time interval between two adjacent oil dripping times is set, and the duration of each oil dripping time is set; whether the real-time interval value of the time interval is the set interval value or not is read and judged, and when the real-time interval value is the set interval value, the external locking lubricating oil injection device is controlled to drip oil; and whether the real-time duration value of the duration is the set duration value or not is read and judged, when the real-time duration value is the set duration value, the external lance lubricating oil injection device is controlled to stop oil dripping, and the previous step is executed again. According to the oil dripping control method, automatic oil dripping of the external locking lubricating oil injection device can be achieved, and the oil dripping amount is controllable.

Owner:陕西夸克自控科技有限公司

Industrial robot reducer facilitating radiating

InactiveCN107401600AReasonable structural designEasy to operateGear lubrication/coolingReducerEngineering

The invention discloses an industrial robot reducer facilitating radiating. The industrial robot reducer comprises a reducer box. The reducer box comprises a lower box body and an upper box body. An input shaft is arranged on the surface of the left portion of the outer side of the reducer box. A fan is fixed to the right side of the input shaft. An output shaft is arranged on the surface of the right potion of the inner side of the reducer box. An oil filling box is fixed to the upper portion of the reducer box. An electromagnetic valve open-close device is arranged on the lower portion of the interior of the oil filling box. A valve is connected with the right side of the electromagnetic valve open-close device. Mounting holes are fixedly formed in the left side and the right side of the upper portion of the reducer box. A control device is fixedly arranged on the surface of the left side of the lower portion of the reducer box. An oil bottom shell is fixedly connected with the right side of the lower portion of the reducer box. A waste oil outlet is formed in the lower portion of the right side of the oil bottom shell. A waste oil collection box is arranged on the right side of the oil bottom shell. The industrial robot reducer facilitating radiating is simple in structure, high in automation degree and good in radiating effect.

Owner:JIANGSU TAILONG MACHINERY GRP CO CO LTD

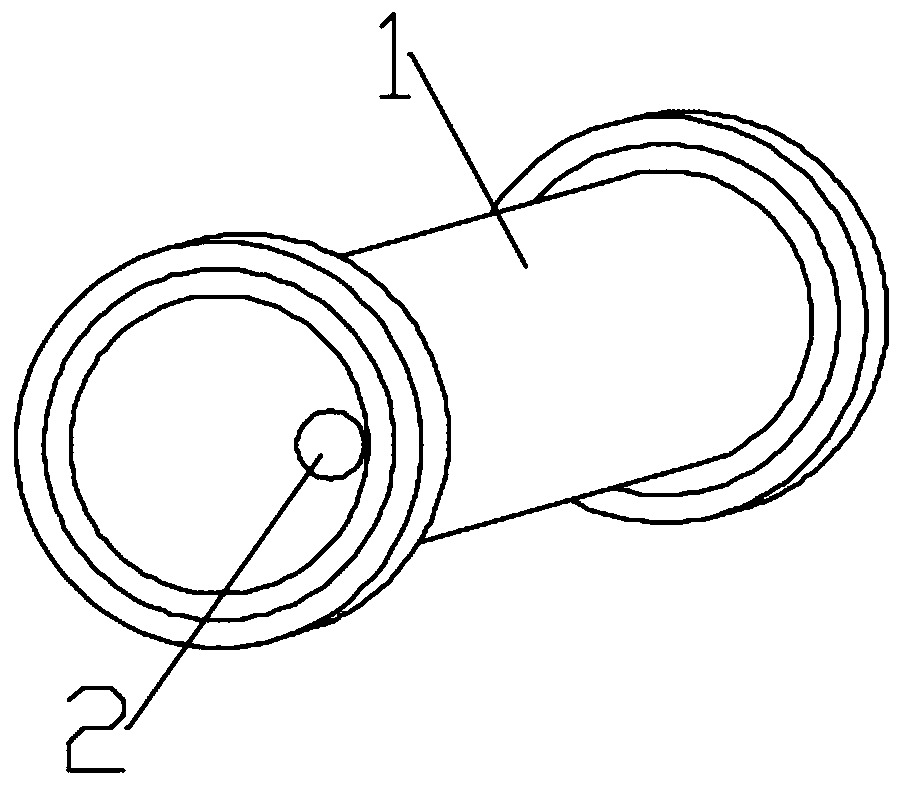

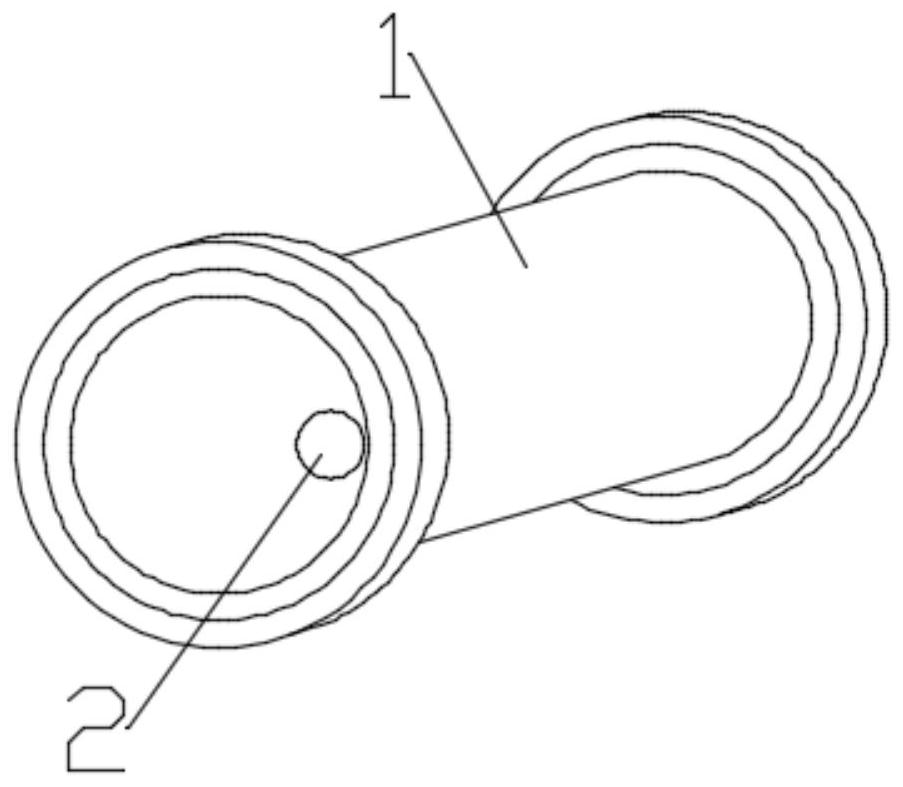

a texturizing machine

The invention discloses an elasticizer and relates to the technical field of spinning. The elasticizer comprises a yarn conveying device, a heating device, a cooling device, a false twister, an oil immersion device and a yarn rolling device. The oil immersion device comprises an oil storage tank, a drive shaft rotatably arranged on the inner wall of the oil storage tank and a guide wheel arrangedon the drive shaft, oil liquid is arranged on the oil storage tank, and an oil injection pipe is arranged on the oil storage tank; a driven shaft is rotatably arranged in the oil injection pipe, an oil injection wheel is arranged on the outer wall of the driven shaft, and the outer wall of the oil injection wheel abuts against the inner wall of the oil injection pipe; an oil groove is formed in the outer wall of the oil injection wheel, a drive gear is arranged on the outer wall of the drive shaft, and a driven gear meshed with the drive gear is arranged on the driven shaft. The elasticizer has the advantages that when yarn is subjected to oil immersion, the guide wheel is used for pressing yarn to be immersed in the oil liquid, the oil immersion operation of the yarn is achieved, and theworking efficiency of the whole elasticizer is improved. The guide wheel is also used for driving the oil injection wheel to rotate, the oil groove is used for conducting automatic and discontinuous oil injection on the interior of the oil storage tank, and the high working efficiency of the elasticizer is achieved.

Owner:杭州华远特种纤维有限公司

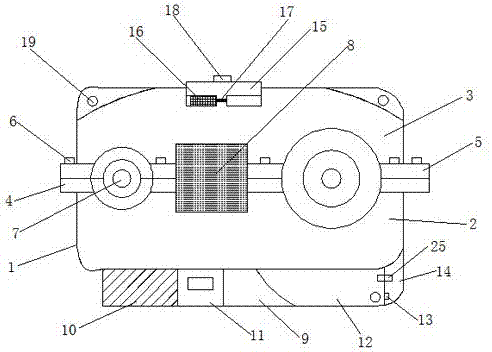

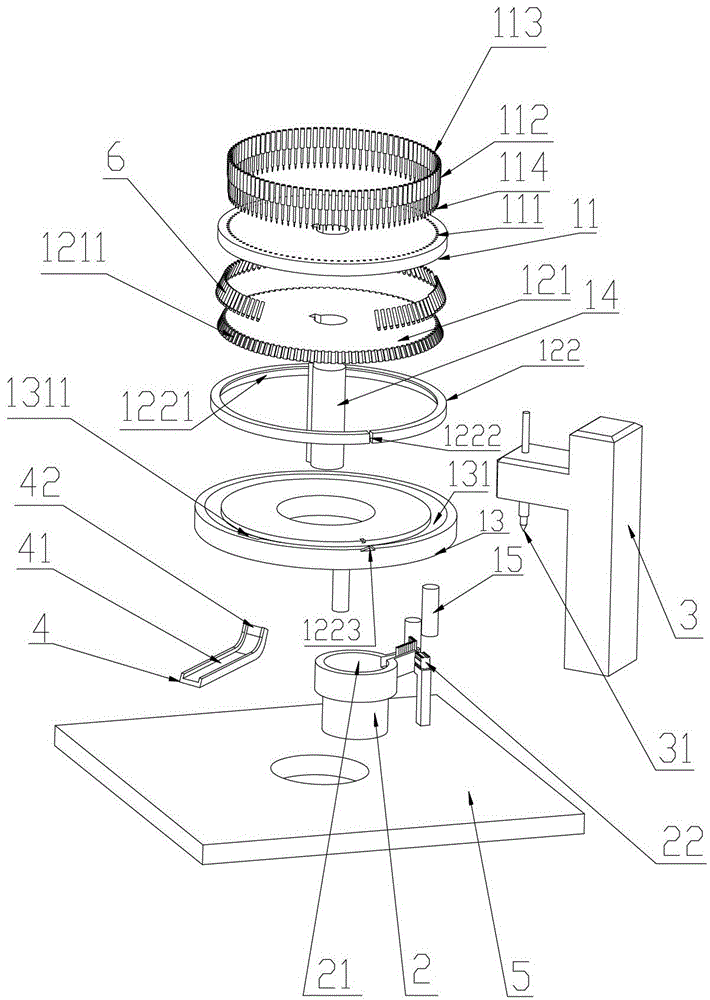

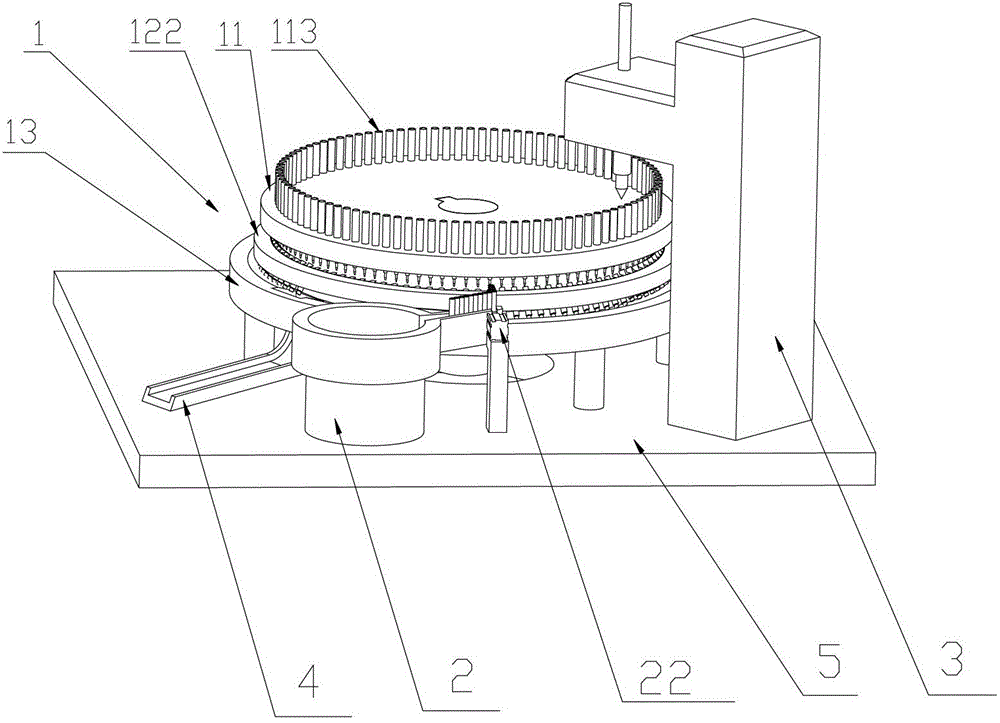

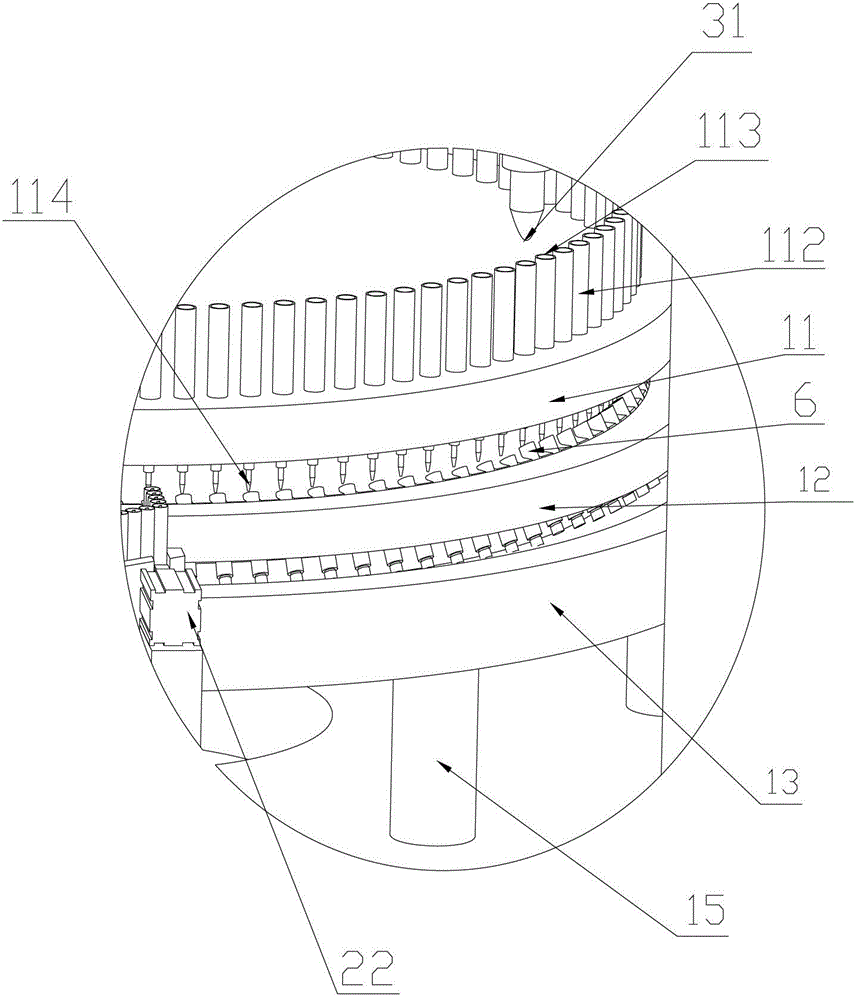

Oil spreading machine

ActiveCN105790518AFully automatedRealize automatic oil fillingLiquid surface applicatorsManufacturing stator/rotor bodiesNumerical controlRolling resistance

The invention relates to an oil spreading machine. The oil spreading machine comprises a rack, wherein an oil spreading device and a rotor arrangement device are arranged on the rack, an inclined groove guide rail is arranged between the oil spreading device and the rotor arrangement device, the oil spreading device comprises a numerical control oil injector and a synchronous belt, the synchronous belt is controlled by a speed reduction motor, a rotor preparation groove is formed in the end surface of the inclined groove guide rail and is communicated with the inclined groove guide rail, a support is arranged on the rotor preparation groove and is used for fixing the synchronous belt, and the rotor preparation groove is connected with the numerical control oil injector through an oil transmission pipeline. With the adoption of the numerical control oil injector, an oil liquid is enabled to be continuously input into the rotor preparation groove, the numerical control oil injector starts operation when a rotor enters the rotor preparation device so as to achieve automatic oil injection; and the synchronous belt is arranged at the bottom of the rotor preparation groove and is controlled by the speed reduction motor, rolling friction is carried out on the surface of the rotor, the oil liquid is promoted to be in uniform and full contact with the rotor, the automatic oil spreading of the rotor is achieved, the production efficiency is improved, and the labor cost is reduced.

Owner:NINGBO YINLI ELECTROMECHANICAL

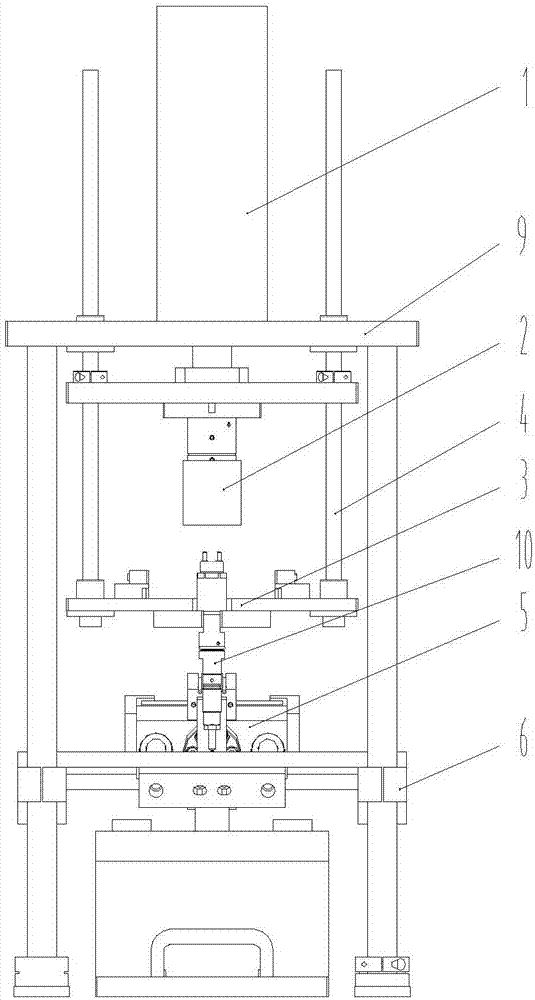

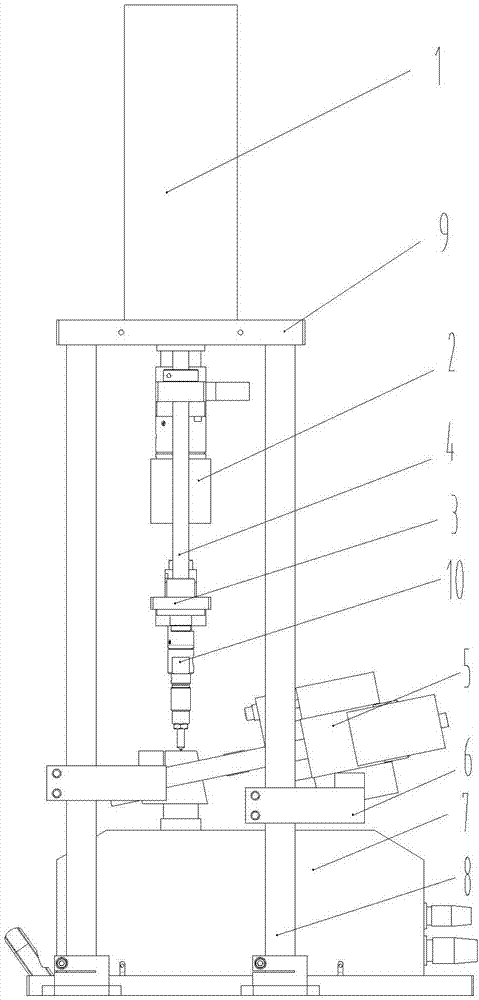

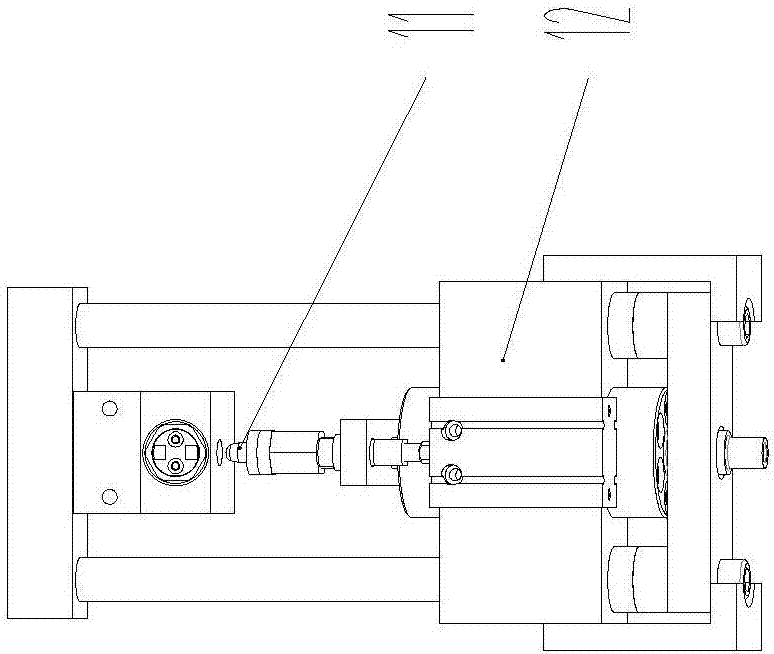

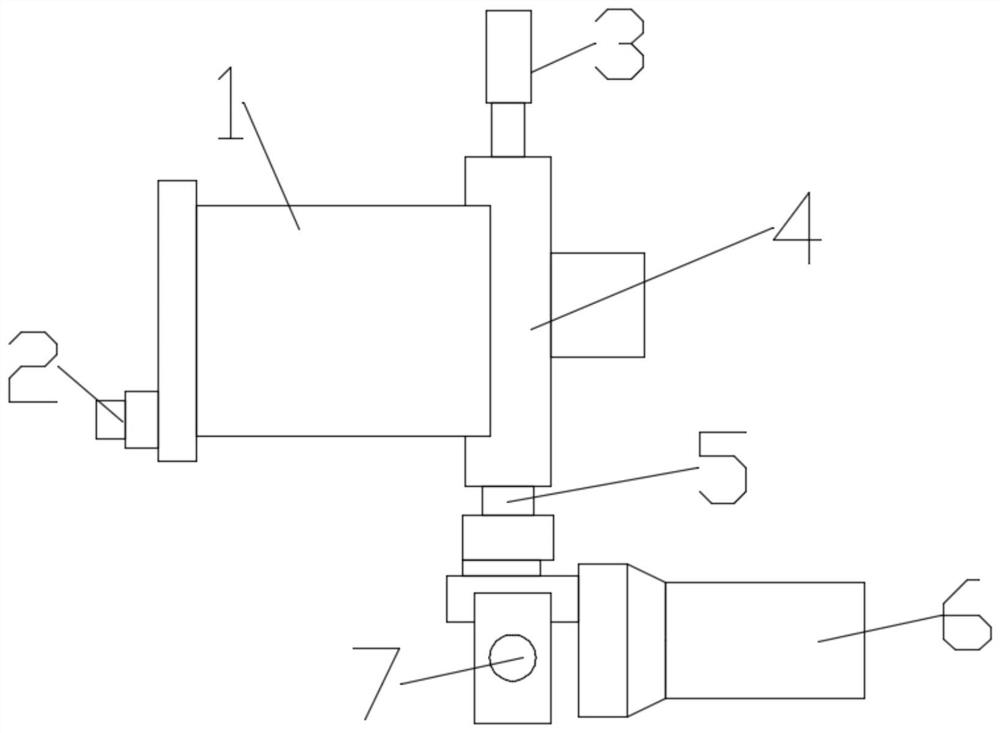

An automatic high-pressure oil injection mechanism for a common rail injector

The invention discloses an automatic high-pressure oil injection mechanism for a common rail fuel injector, which comprises a plurality of evenly distributed supporting optical axes, a top plate is fixed on the top of the supporting optical axes, an upper pressure cylinder is fixed on the top surface of the top plate, and the top plate A guide rod is movably connected to the bottom surface, and an upper pressure head is installed on the guide rod. At the same time, a workpiece positioning assembly is movably connected to the bottom end of the guide rod and below the upper pressure head. An oil injection component and a measurement sealing cavity are provided in sequence, wherein both the oil injection component and the measurement sealing cavity are fixed on the supporting optical axis. Beneficial effects of the present invention: the oil injection mechanism is exquisite in structure, strong and reliable, reasonable in cost and fully automatic, and can be used in a detection instrument for common rail injectors to realize automatic oil injection for common rail injectors with high cracking pressure, and There will be no leaks.

Owner:BEIJING BRANCH JIKE DEV SCI & TECH

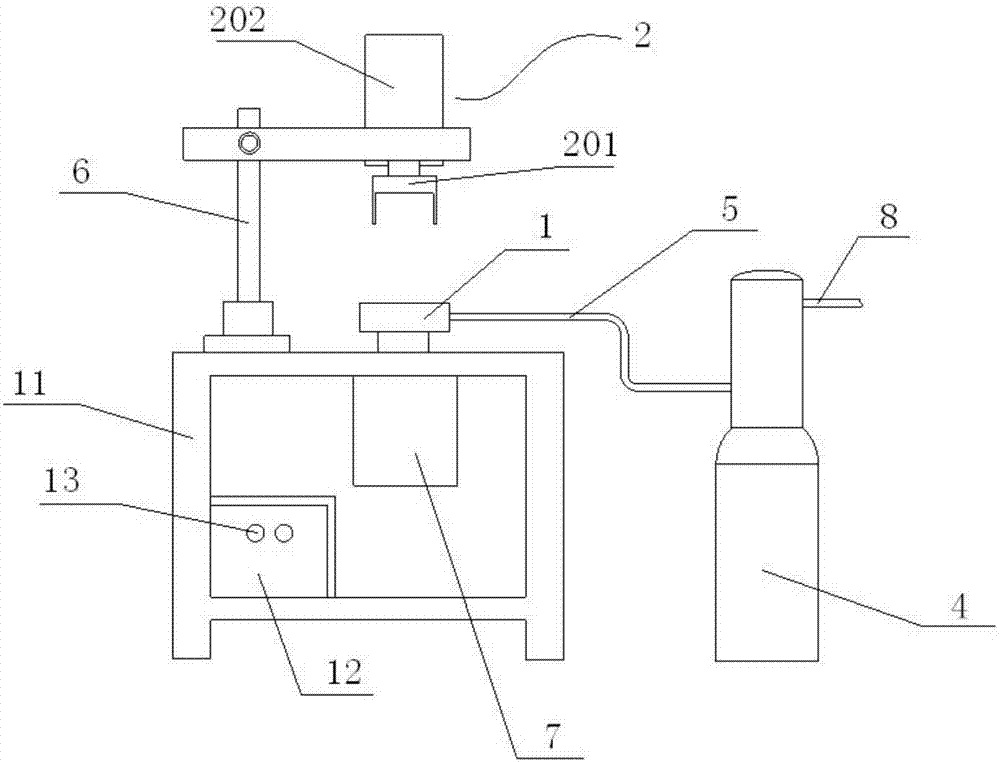

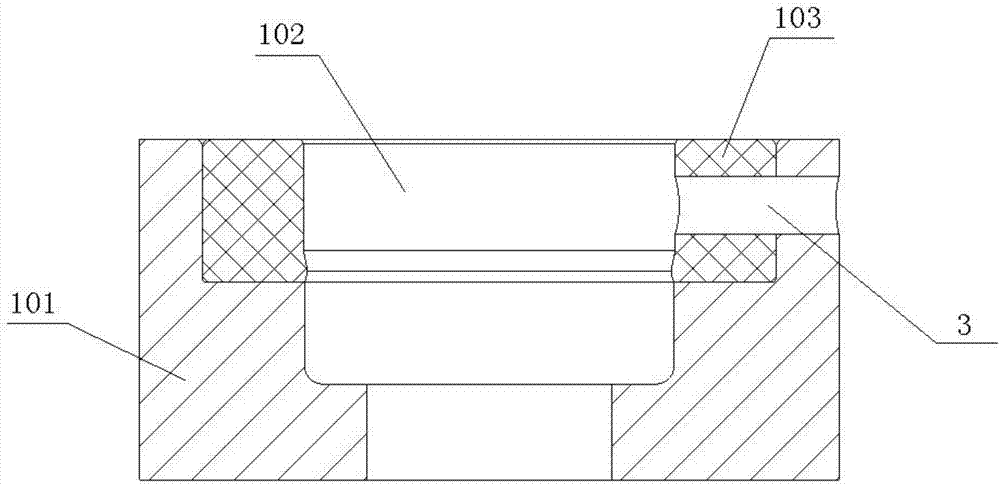

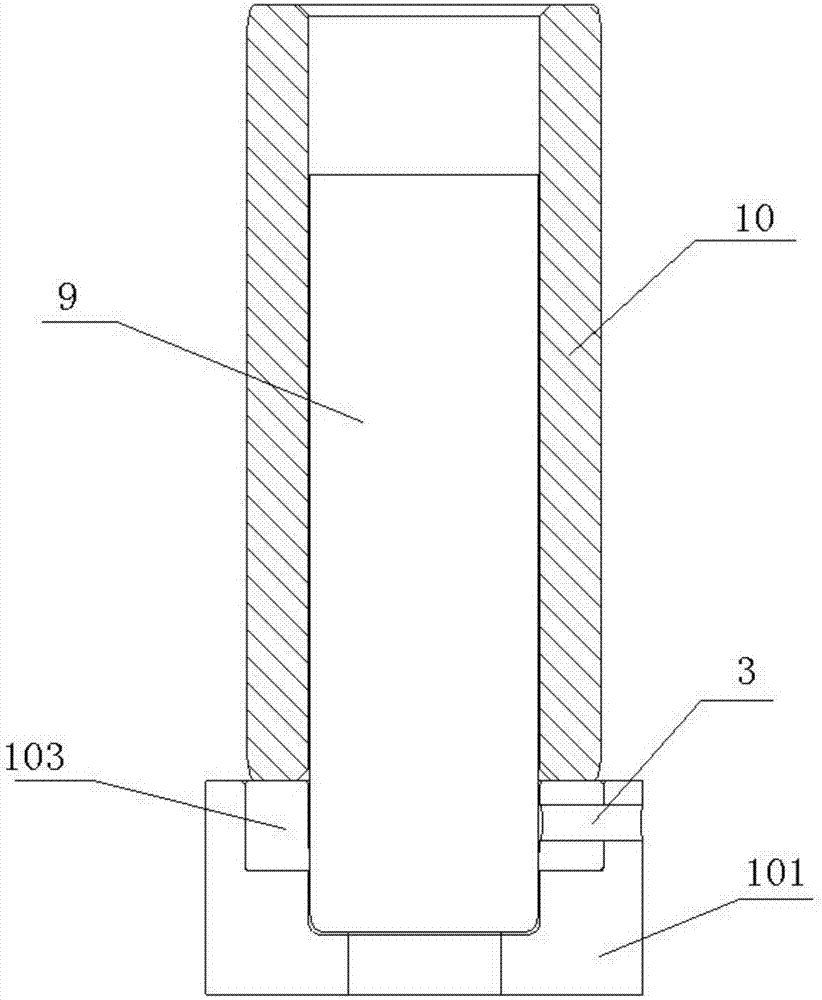

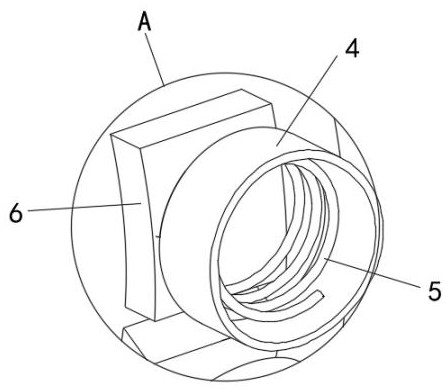

Oil injecting equipment

ActiveCN107477343AEvenly distributedRealize automatic oil fillingProportioning devicesConduits/junctionsOil and greaseOil tank

The application discloses oil injecting equipment. The oil injecting equipment comprises a clamping mechanism and an oil injecting mechanism; the clamping mechanism comprises a clamping seat and a clamping cover; the clamping cover and the clamping seat and are matched and are used for clamping two ends of each of a shaft sleeve and a shaft; an oil injecting port is formed in the clamping seat and is used for injecting oil to the position between shaft and the shaft sleeve; the oil injecting mechanism comprises an oil tank and an oil injecting power part; the oil injecting part communicates with the oil injecting port through an oil way; and the oil injecting power part is used for outputting lubricating oil from the oil tank through the oil way. According to the oil injecting equipment, the assembled shaft and shaft sleeve are only required to be placed between the clamping seat and the clamping cover, the two ends of each of the shaft and the shaft sleeve are clamped by matching the clamping cover and the clamping seat, then, the oil injecting power part is started to output the lubricating oil from the oil tank through the oil way and inject the lubricating oil to the position between the shaft and the shaft sleeve from the oil injecting port, so that automatic oil injecting is realized; the work efficiency is high; the injected oil amount is controllable; and grease is uniformly distributed between the shaft and the shaft sleeve.

Owner:HUNAN SANTER MACHINERY MFG

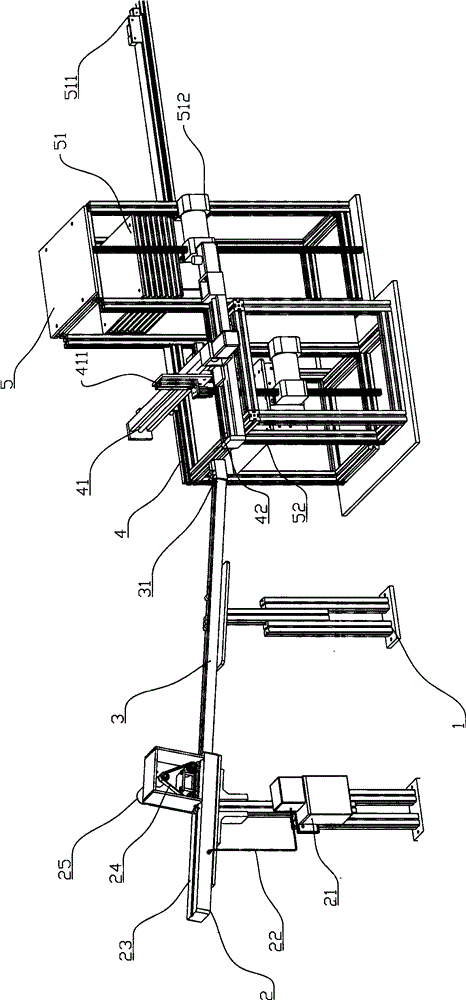

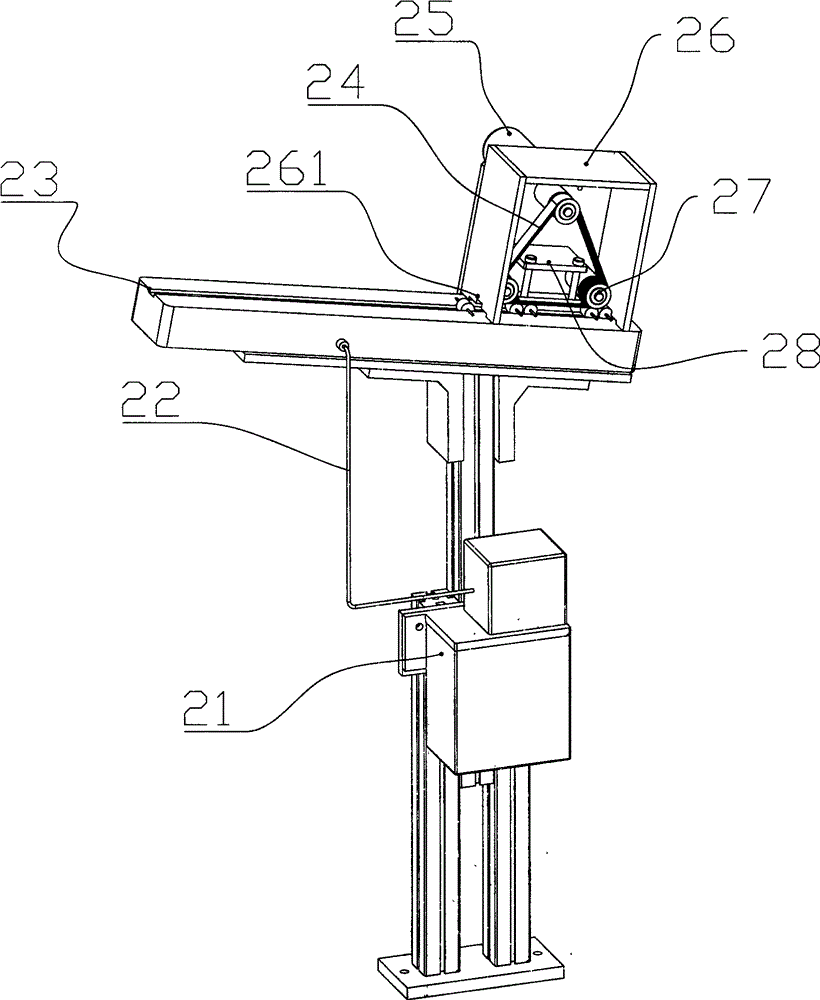

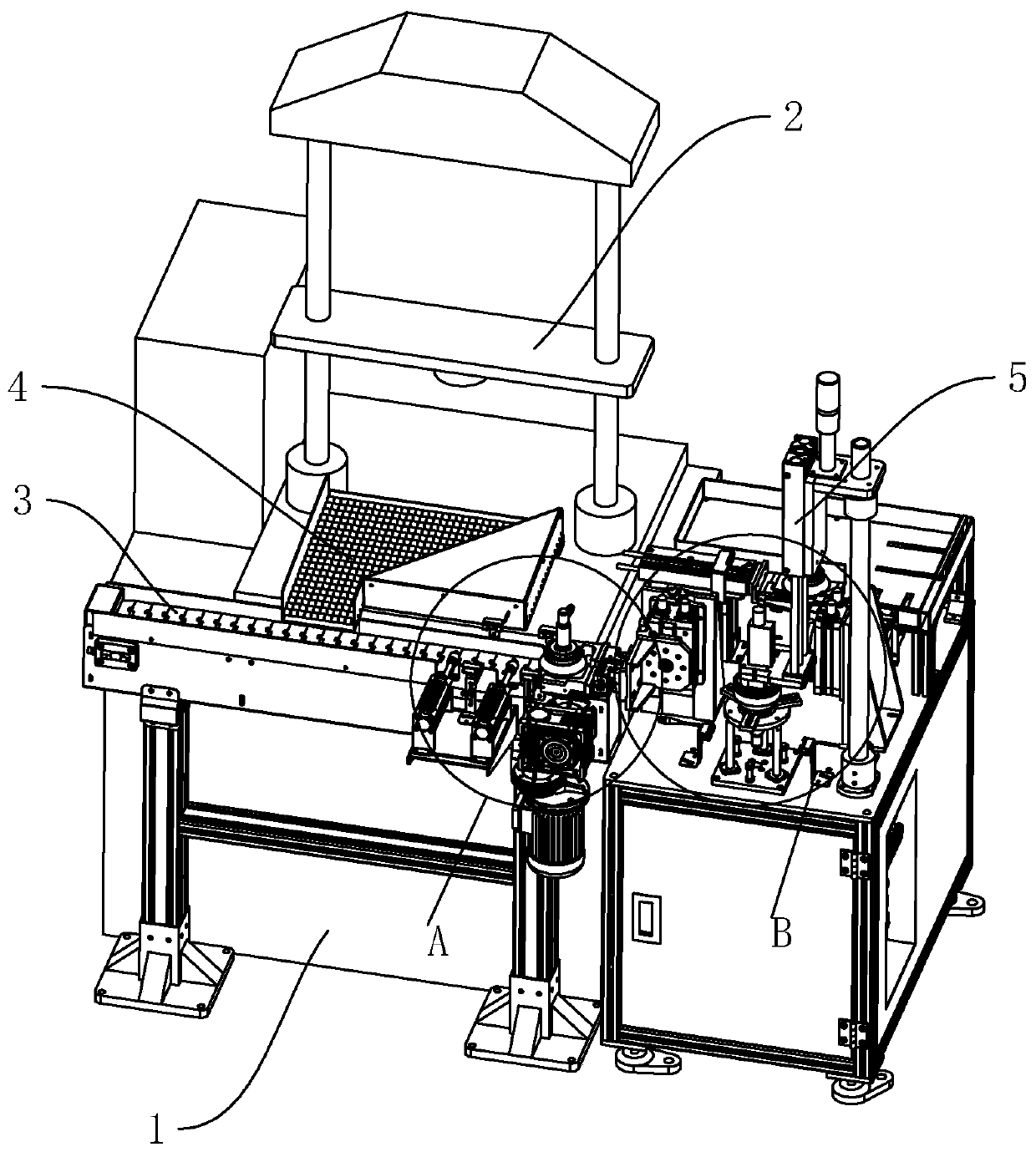

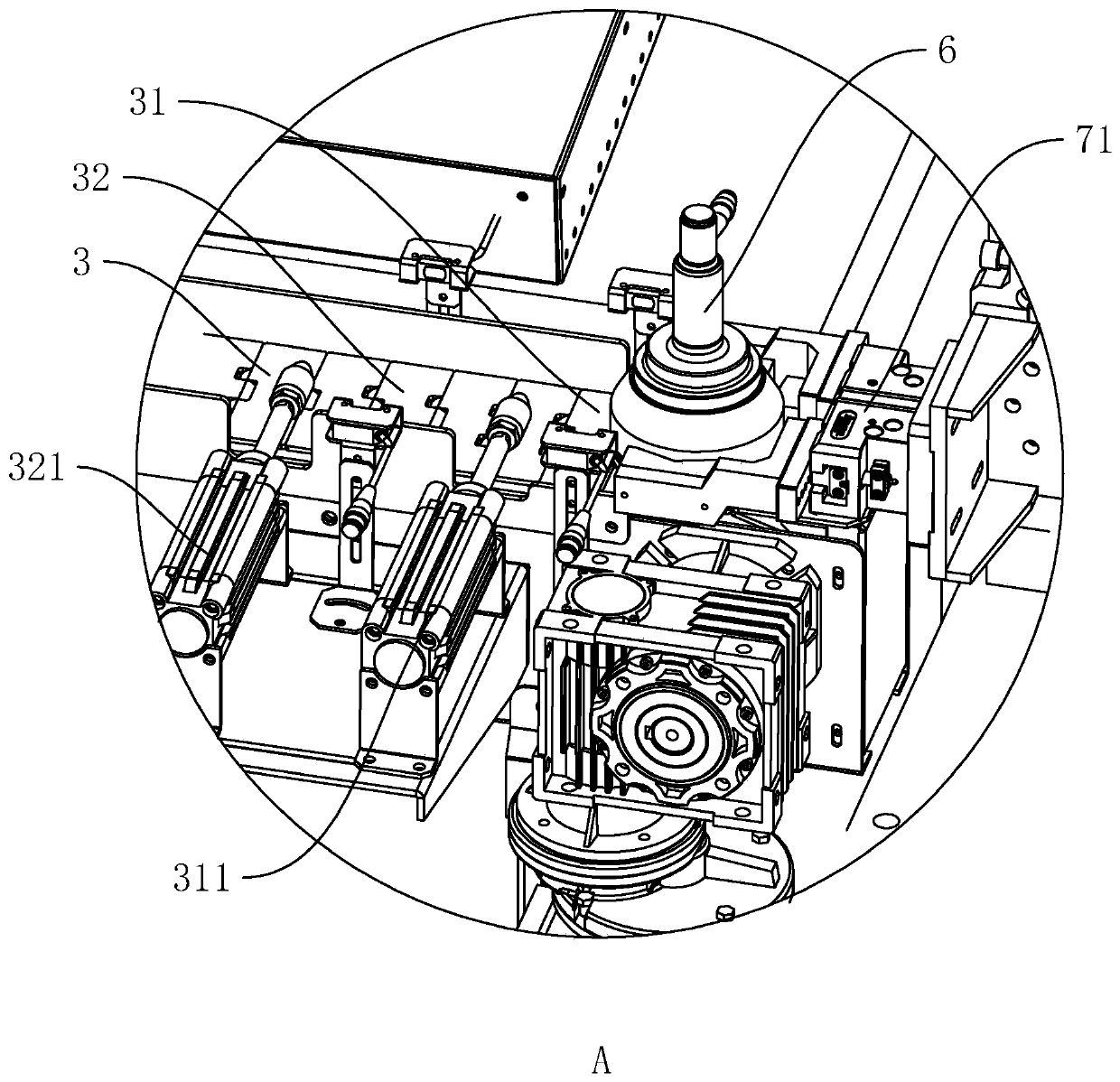

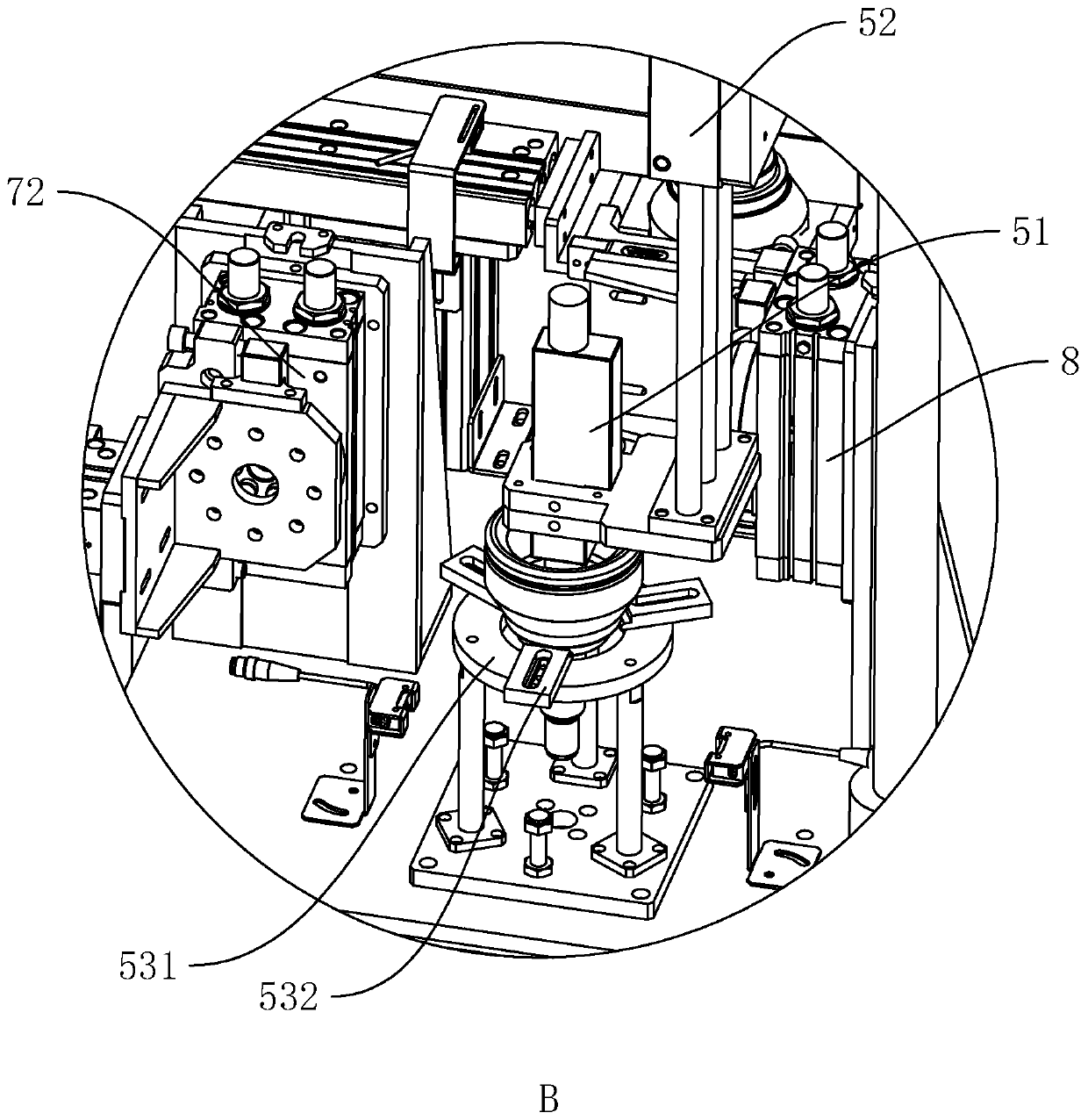

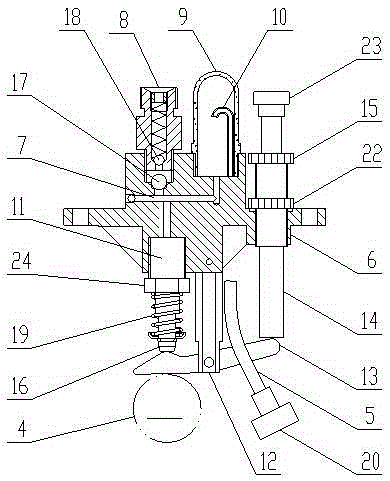

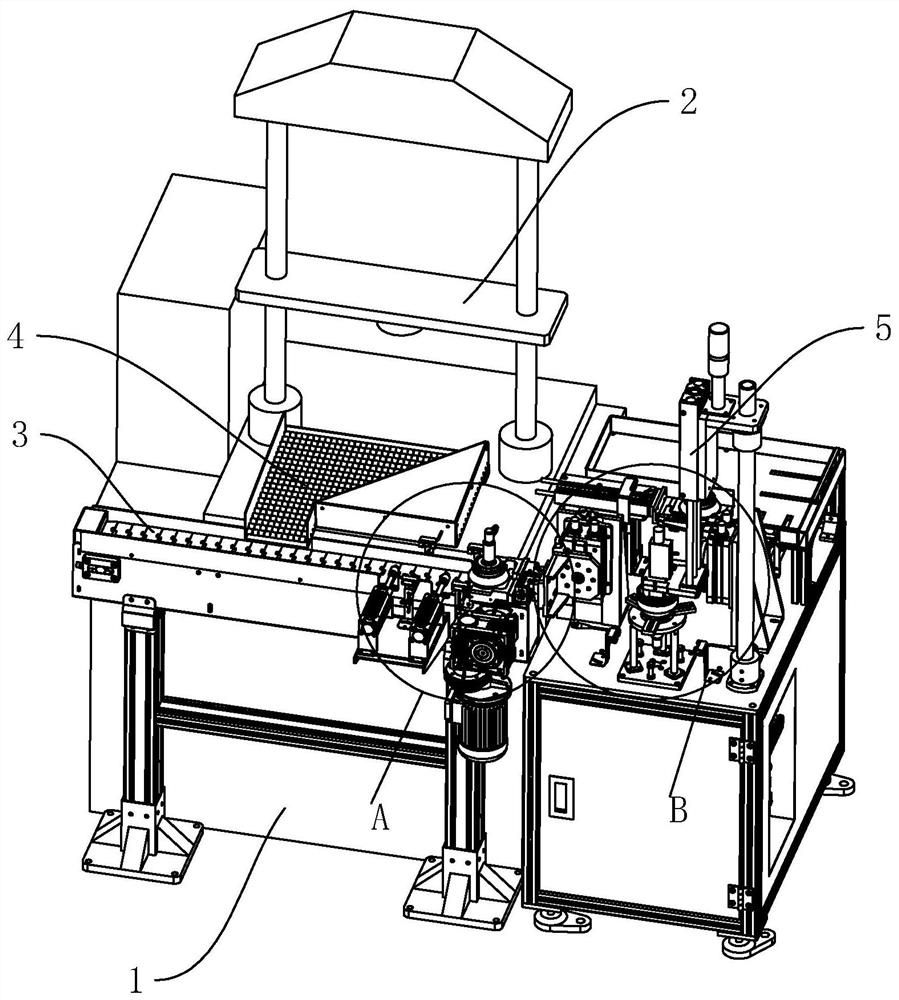

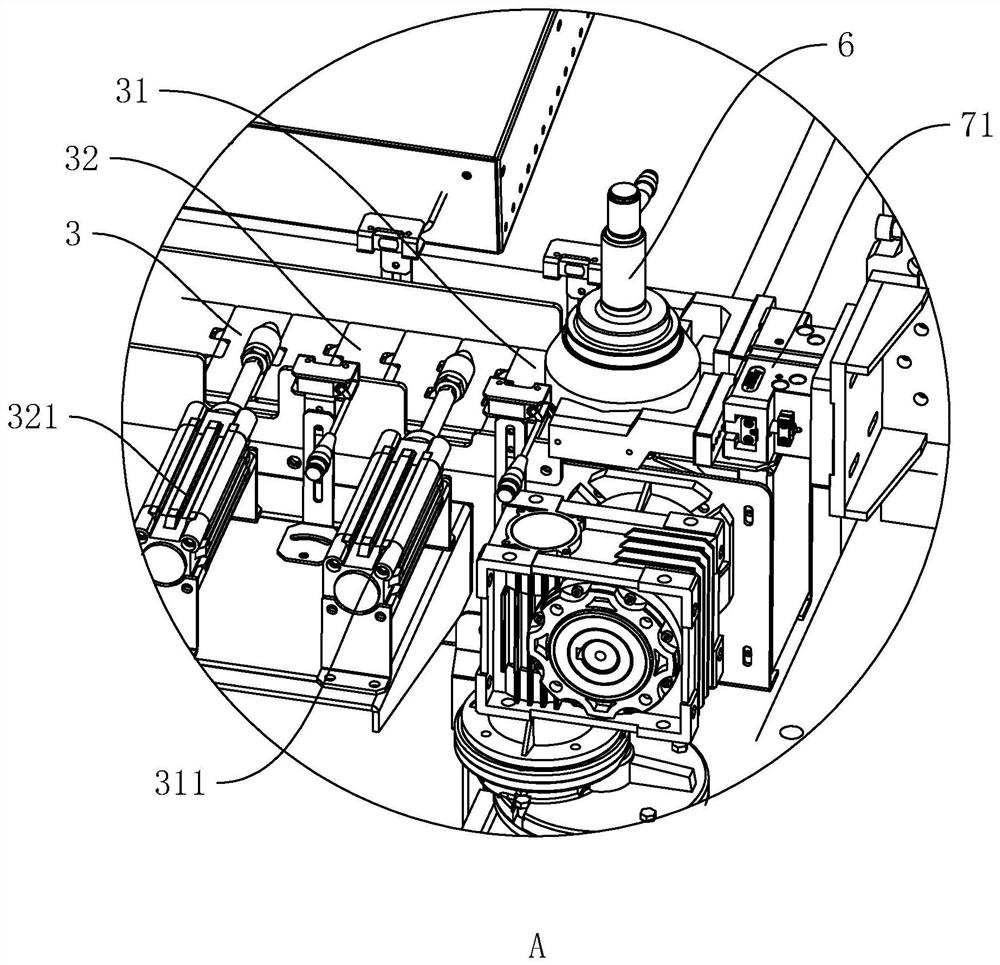

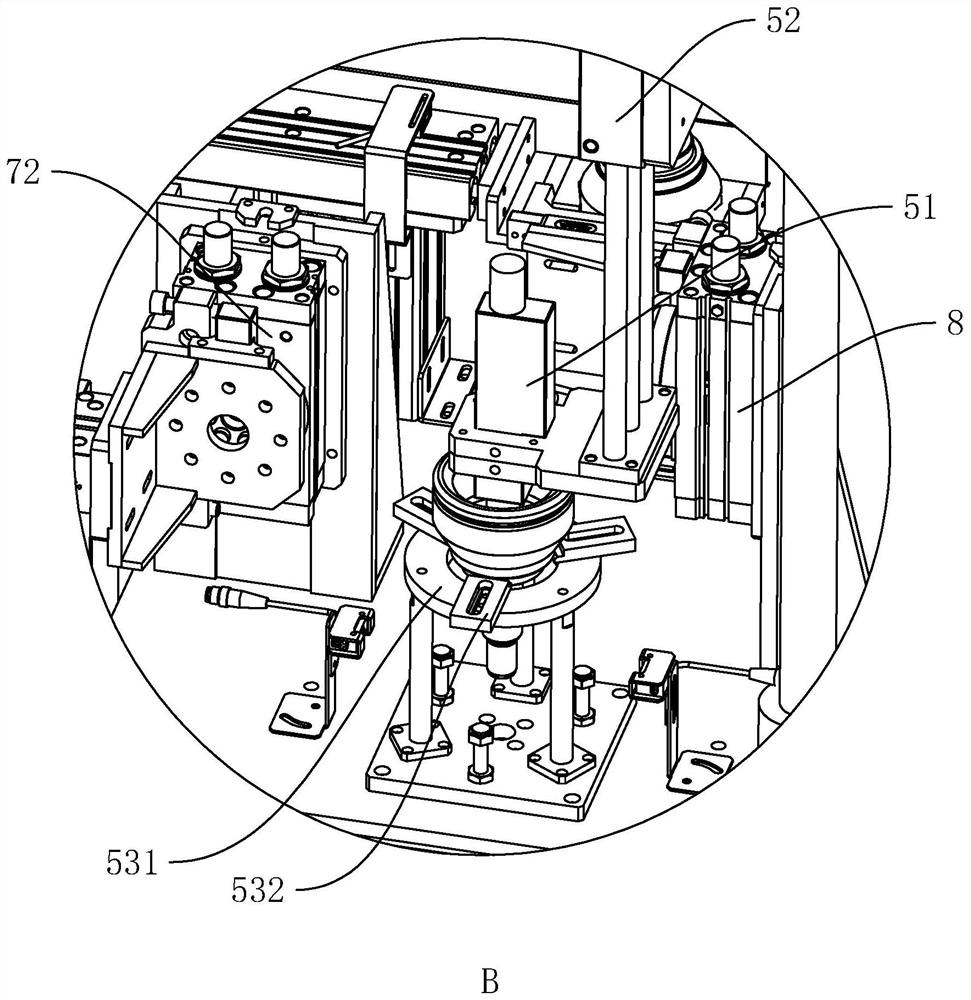

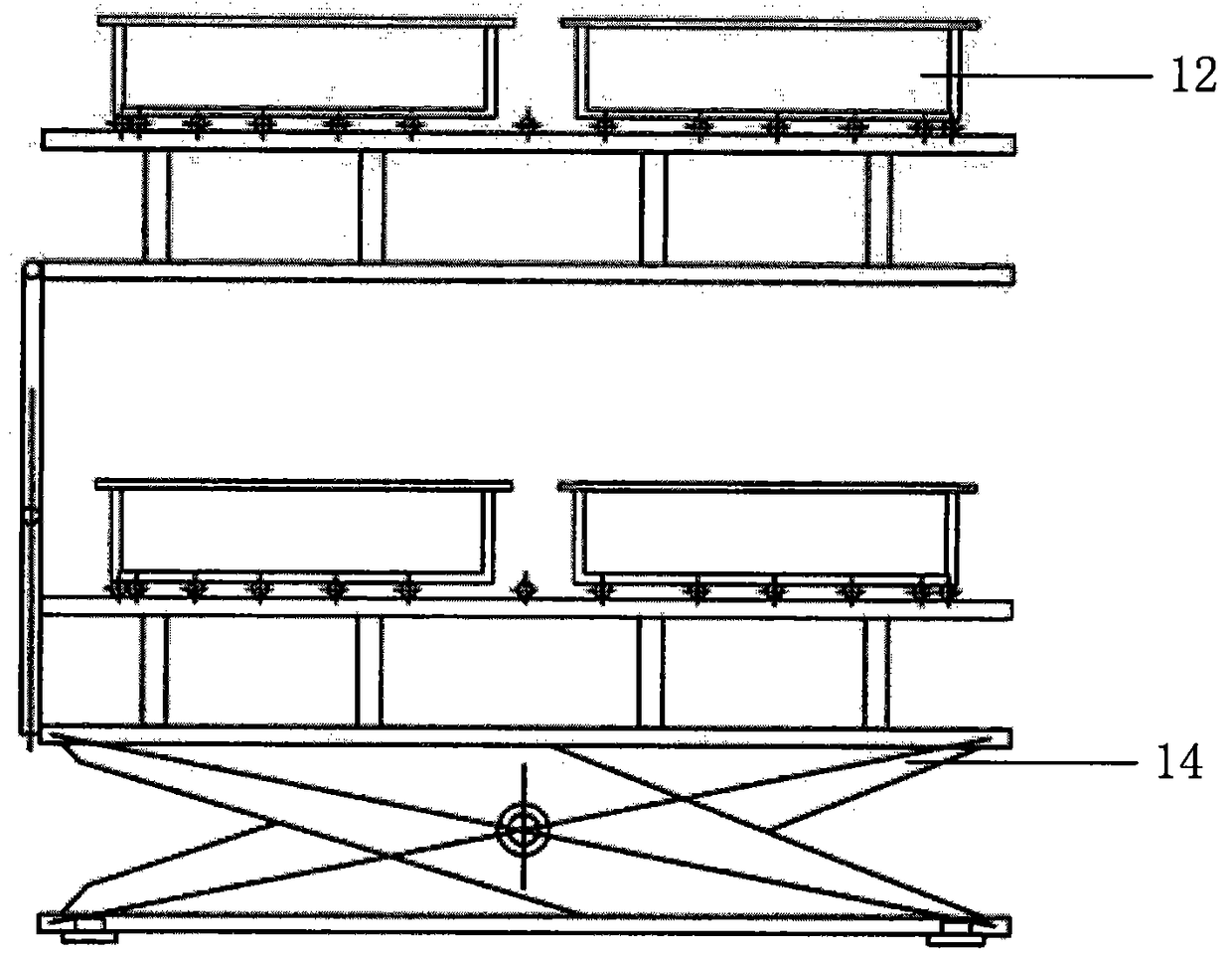

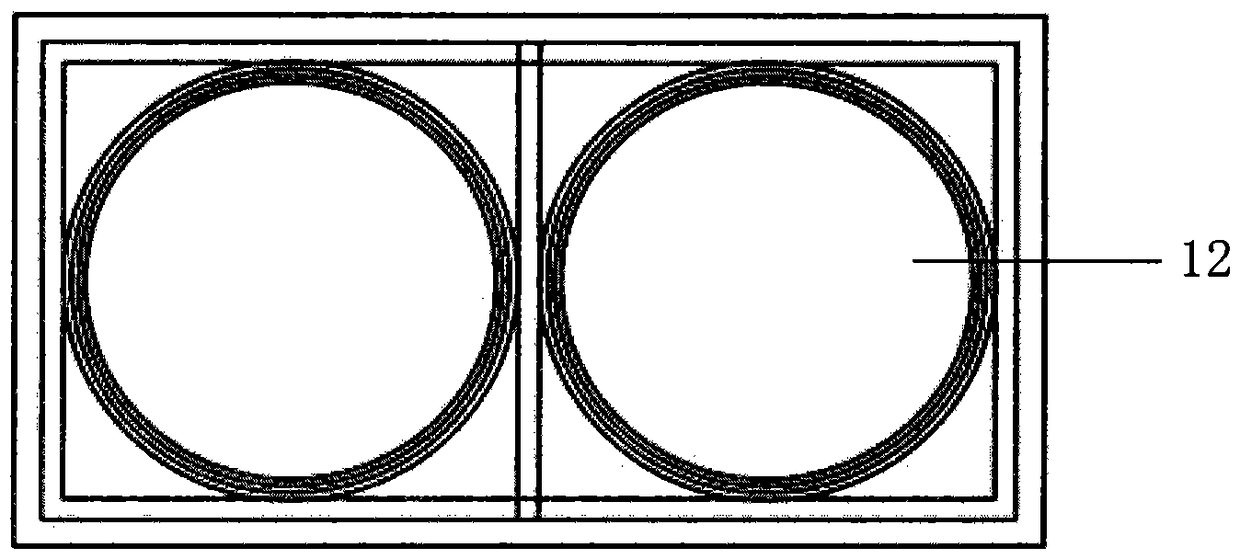

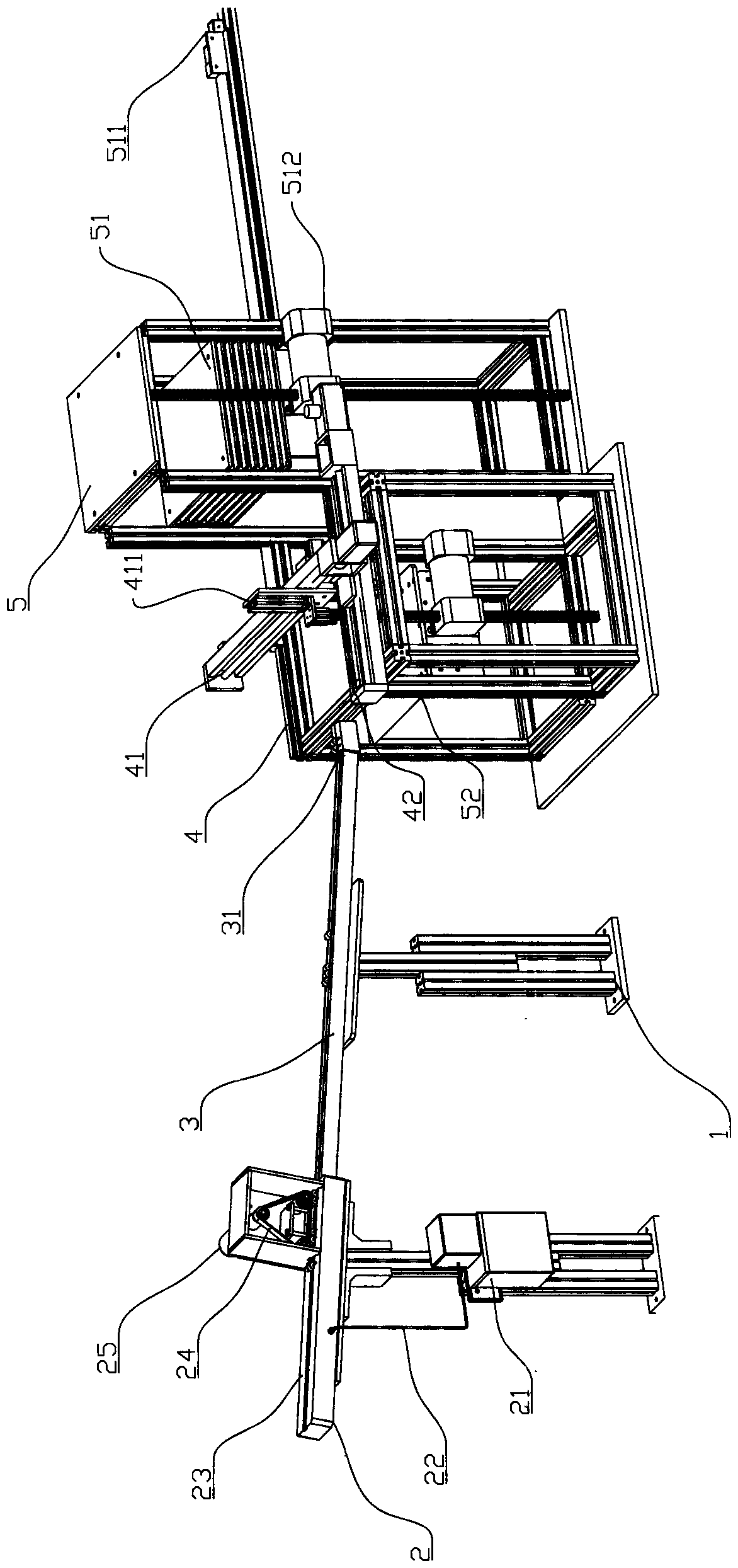

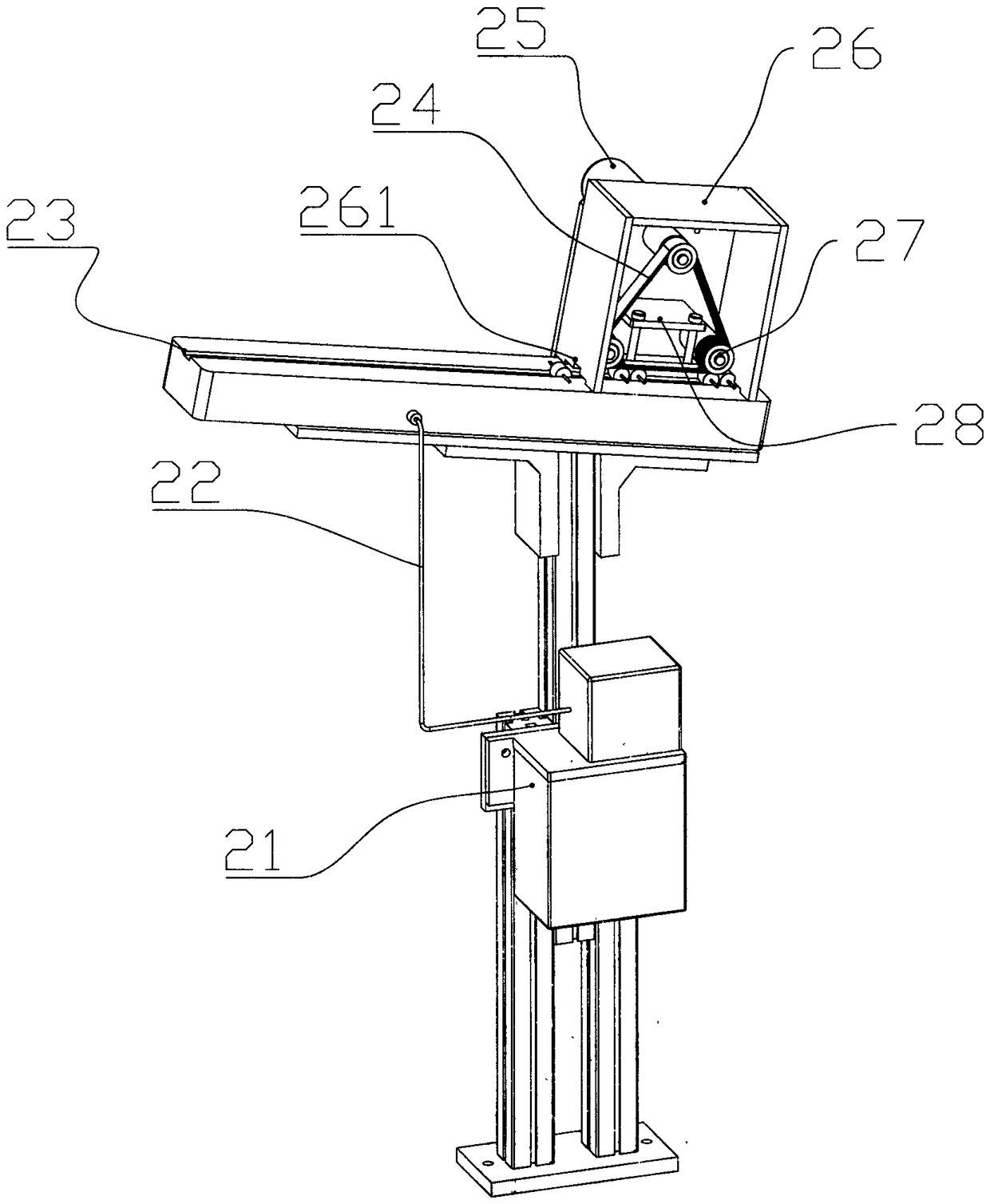

Ball cage automatic assembling and oil injecting integrated machine

ActiveCN111347233ARealize automatic oil fillingRealize automatic removalLiquid surface applicatorsGripping headsUniversal jointProcess engineering

The invention discloses a ball cage automatic assembling and oil injecting integrated machine. The ball cage automatic assembling and oil injecting integrated machine comprises a rack, the rack is provided with a pressing machine and an oil injecting mechanism, the oil injecting mechanism comprises an oil injecting fixture, an oil injecting head and a first lifting air cylinder, the oil injectinghead is arranged on the first lifting air cylinder and is located above the oil injecting fixture, a transfer conveyor belt is arranged beside the pressing machine, and a first overturning mechanicalclaw is arranged between the transfer conveyor belt and the oil injecting fixture. By means of the ball cage automatic assembling and oil injecting integrated machine, a pressed and assembled ball cage type universal joint can be automatically transferred to an oil injecting position to be subjected to automatic oil injecting, the production efficiency is improved, and the automatic oil injectingis realized to make the product quality be uniform and the quality stability be high.

Owner:浙江屹立机器人科技有限公司

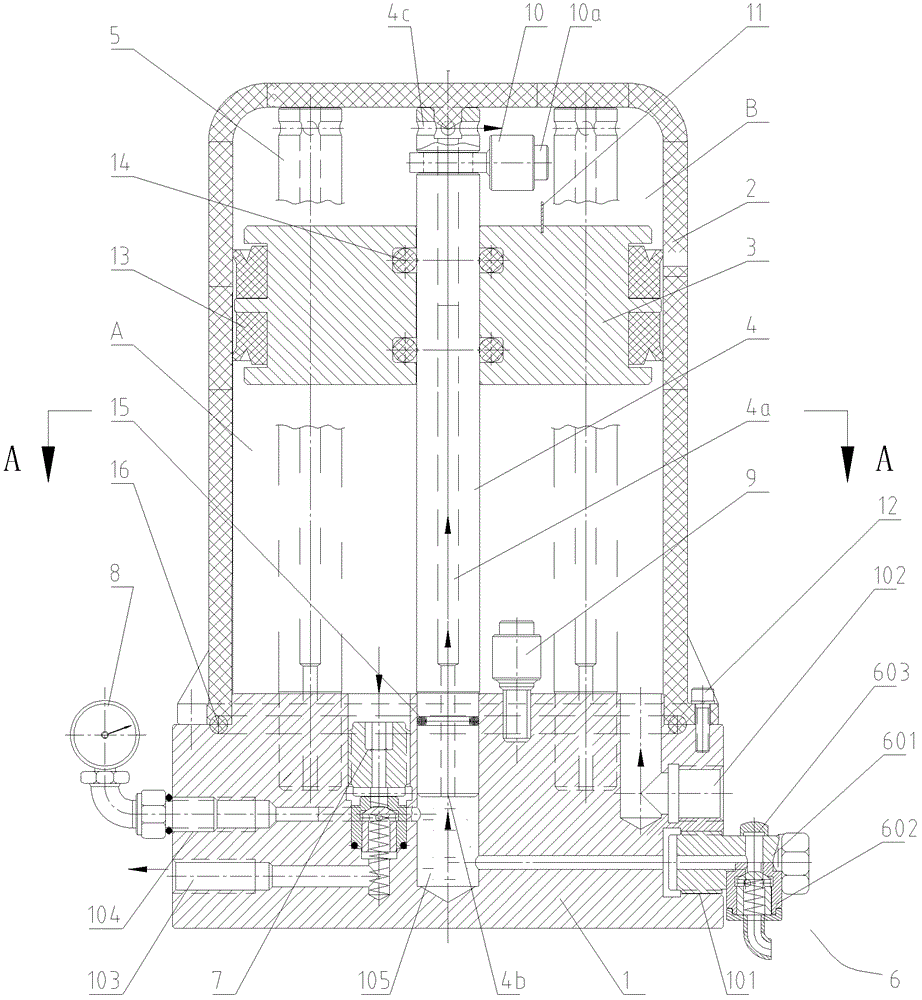

Oil injection pump

InactiveCN105276356ARealize automatic oil fillingImprove work efficiencyLubricating pumpsInjection pumpPlunger

The invention discloses an oil injection pump and belongs to the technical field of mechanical lubricating. The oil injection pump comprises a pump body, an oil channel, an oil outlet, a vacuum hood, an oil dripping pipe, an oil suction pipe, a plunger cavity, a supporting column, a lever, an adjusting rod and an adjusting nut. The lower portion of the plunger cavity is provided with a plunger capable of sliding up and down. An oil storage chamber is arranged on the upper portion of the plunger cavity. The plunger cavity and the adjusting rod are arranged on the two sides of the supporting column respectively. The two ends of the upper side of the lever abut against the plunger and the adjusting rod respectively. The oil suction pipe is communicated with the oil dripping pipe through the oil channel and a first one-way valve is arranged on the oil suction pipe. The vacuum hood is communicated with the oil storage chamber through oil holes. The oil outlet is communicated with the oil storage chamber through the oil channel and a second one-way valve is arranged on the oil outlet. A spring capable of making the plunger reciprocate is arranged between the plunger and the pump body. The adjusting nut is arranged between the adjusting rod and the pump body. The oil injection pump can achieve automatic oil injection and is high in working efficiency, safe and reliable.

Owner:HUBEI SHENYING LUBRICATION EQUIP

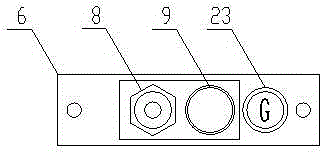

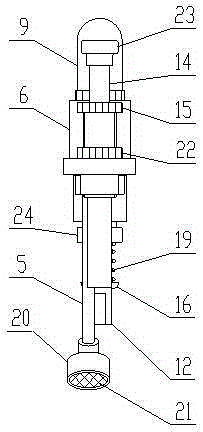

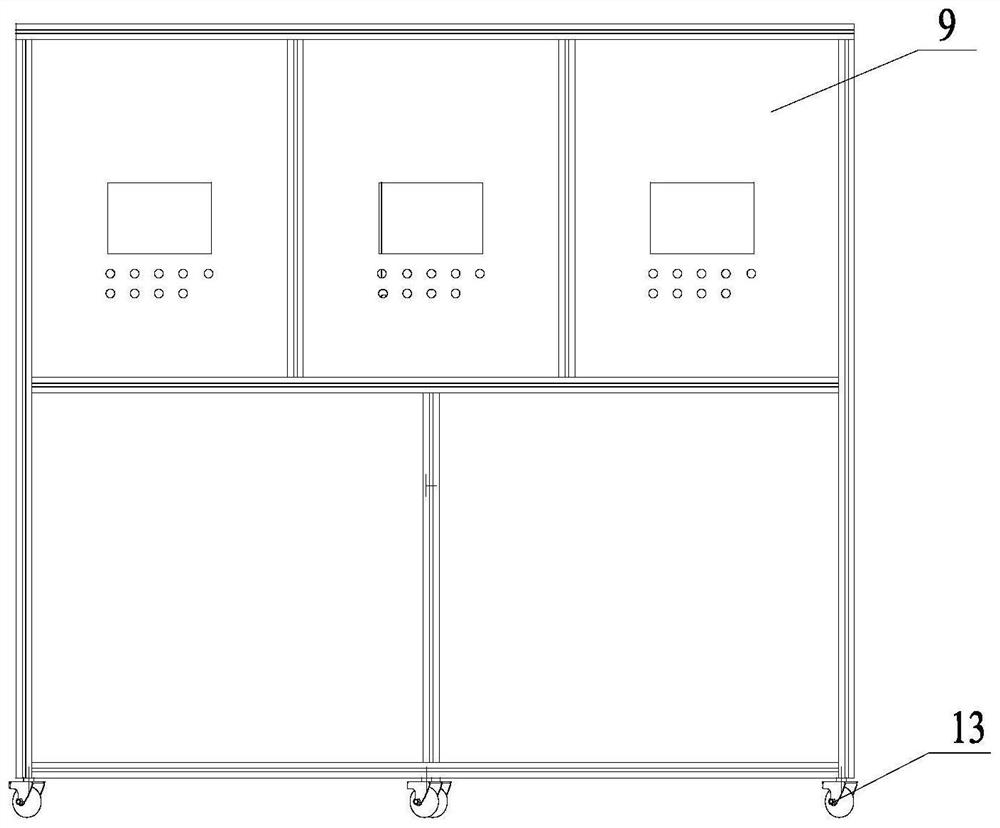

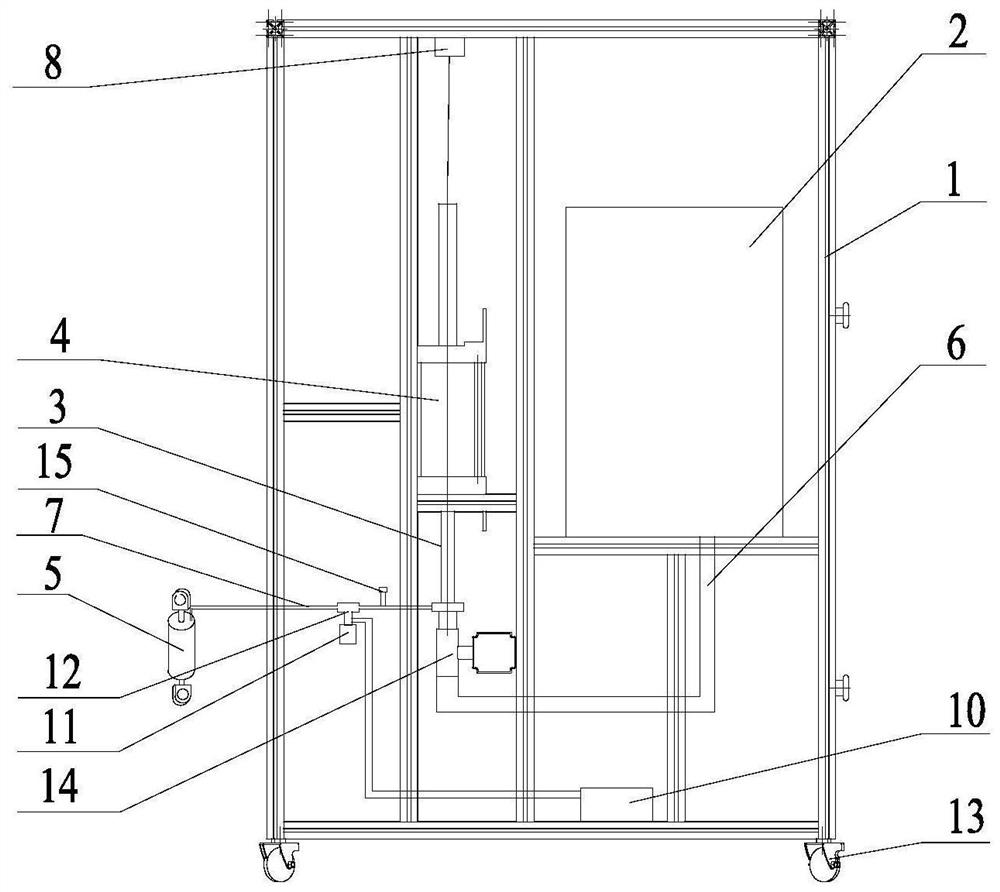

Full-automatic circulating oil injector

PendingCN112081859AHigh precisionStable jobSpringsSprings/dampers design characteristicsInjectorFuel tank

The invention relates to an oil injector, in particular to a full-automatic circulating oil injector. The full-automatic circulating oil injector comprises a frame, an oil injecting assembly, a metering assembly and a control assembly; the frame is provided with a housing; the oil injecting assembly comprises an oil storage tank, oil injecting oil cylinders and oil injecting air cylinders mountedin the frame; an oil inlet pipe connected with the oil injecting oil cylinders is provided at the bottom of the oil storage tank; the oil injecting oil cylinders are connected with the oil injecting air cylinders, and are provided with oil injecting pipes; the outlet ends of the oil injecting pipes extend out of the frame; the metering assembly comprises encoders; two groups of oil injecting oil cylinders, two groups of oil injecting air cylinders and two groups of encoders are correspondingly arranged; and the control assembly comprises a control panel and a controller. The oil injector metering system of the invention is high in precision and stable in work; the damper weighing procedure during oil injection is canceled; the oil injecting efficiency is improved; silicone oil having different viscosities can be injected at any time according to different design requirements, so that the adaptability is high; and a new oil injecting system is adopted to implement infinite circulation full-automatic oil injection.

Owner:JIANGSU HONGFENG AOKAI ELECTROMECHANICAL

Automatic assembly and oiling machine for ball cage

ActiveCN111347233BRealize automatic oil fillingRealize automatic removalLiquid surface applicatorsGripping headsUniversal jointControl engineering

The invention discloses an automatic assembly and oiling integrated machine for ball cages, which comprises a frame, on which a press and an oiling mechanism are arranged, and the oiling mechanism includes an oiling fixture, an oiling head and a first lifting cylinder, and the oiling head It is arranged on the first lifting cylinder, the oil injection head is located above the oil injection fixture, a transfer conveyor belt is arranged beside the press, and a first turning mechanical claw is arranged between the transfer conveyor belt and the oil injection fixture. The assembled ball cage universal joint is transferred to the oil injection place for automatic oil injection to improve production efficiency, and the realization of automatic oil injection makes the product quality uniform and high in quality stability.

Owner:浙江屹立机器人科技有限公司

Automatic lubricating oil injection device

ActiveCN110375183AReduce the burden onRealize automatic oil fillingLubrication check valvesOil canOil and grease

The invention discloses an automatic lubricating oil injection device, and belongs to the technical field of oil injection devices. The problem that an existing device is low in lubricating oil injection speed is solved. According to the technical scheme, the device comprises an oil injection cavity and a pressurizing assembly, an oil injection assembly used for automatic oil injection is arrangedin the oil injection cavity, the oil injection assembly is fixedly mounted on an oil injection assembly mounting base, the oil injection assembly mounting base is fixedly arranged on the inner wall of the oil injection cavity through a bolt, the oil injection cavity is fixed to the oil injection cavity mounting base, the pressurizing assembly is connected below the oil injection cavity, the oil injection cavity is connected with a grease detector used for detecting grease, lubricating oil can be automatically added, the damage to equipment due to lacking of the lubricating oil can be avoided,meanwhile, operation is easy, the failure rate is low, the oil injection speed is high, and the efficiency is high.

Owner:上海泽煦智能科技有限公司

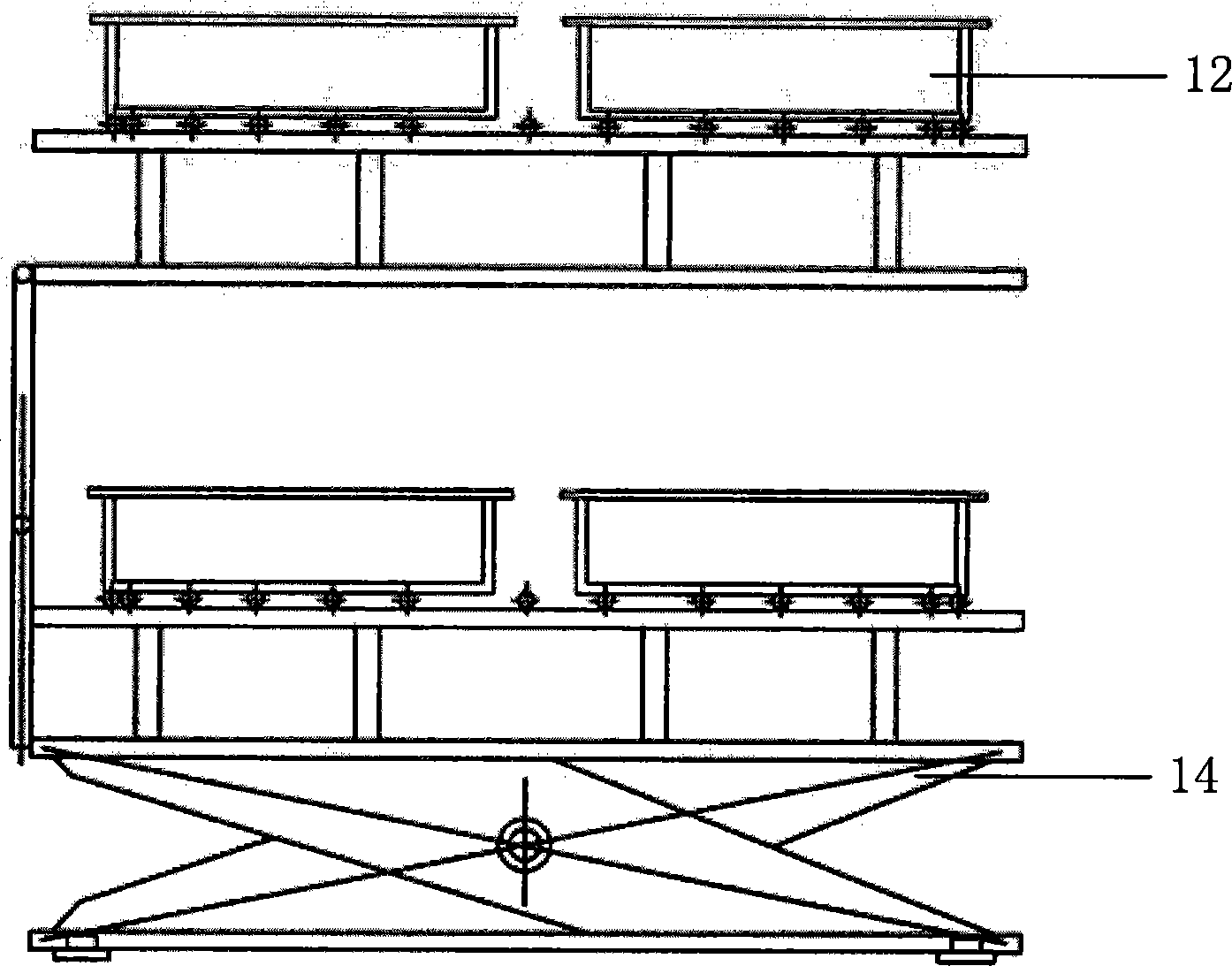

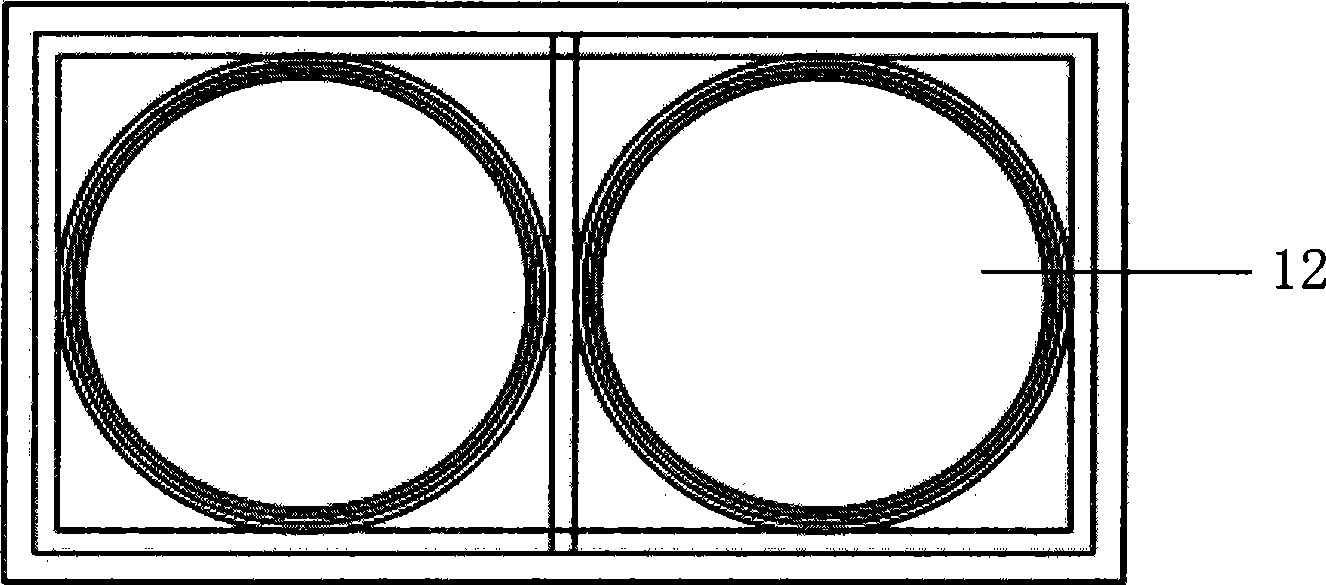

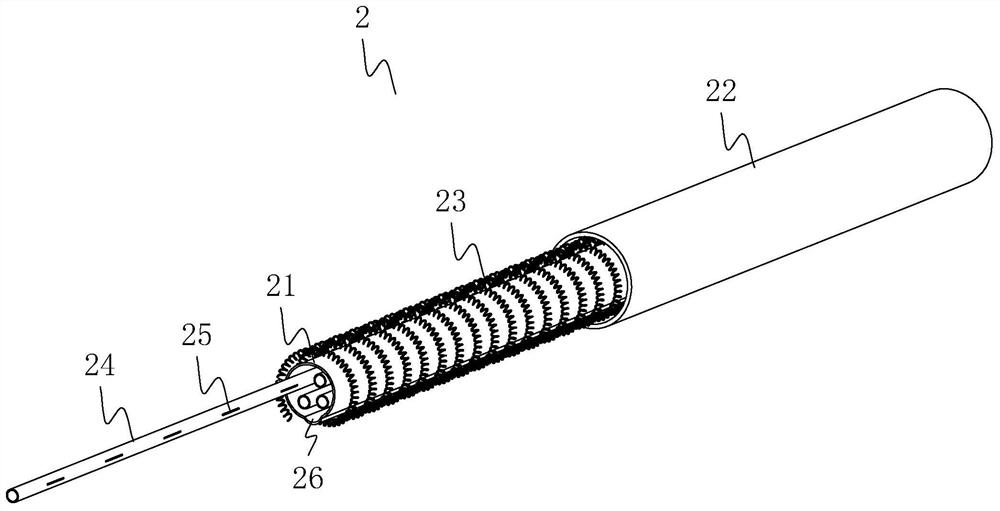

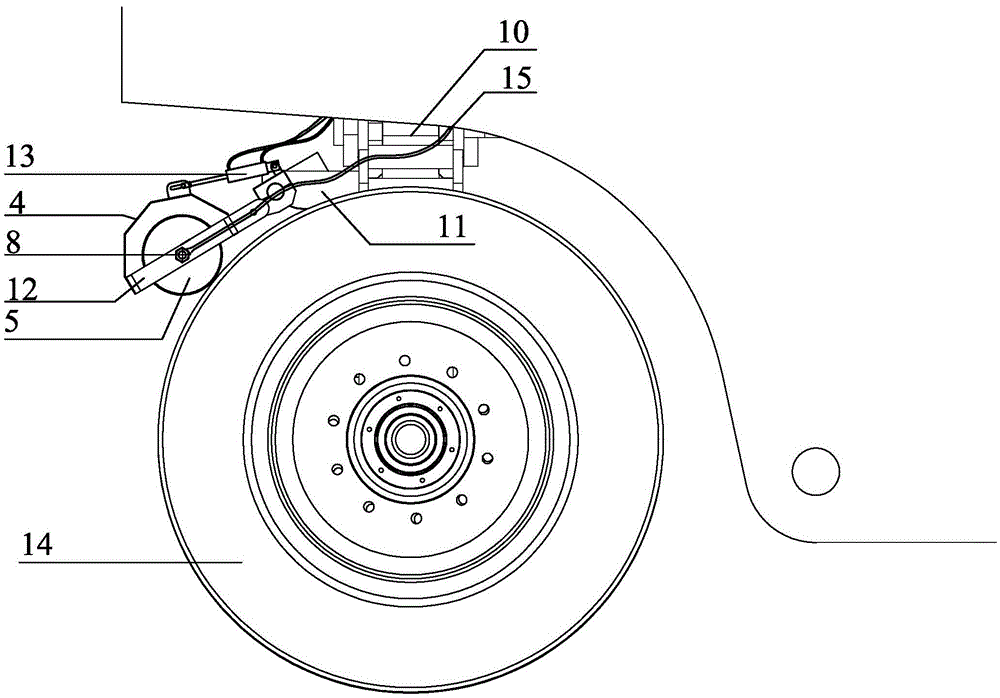

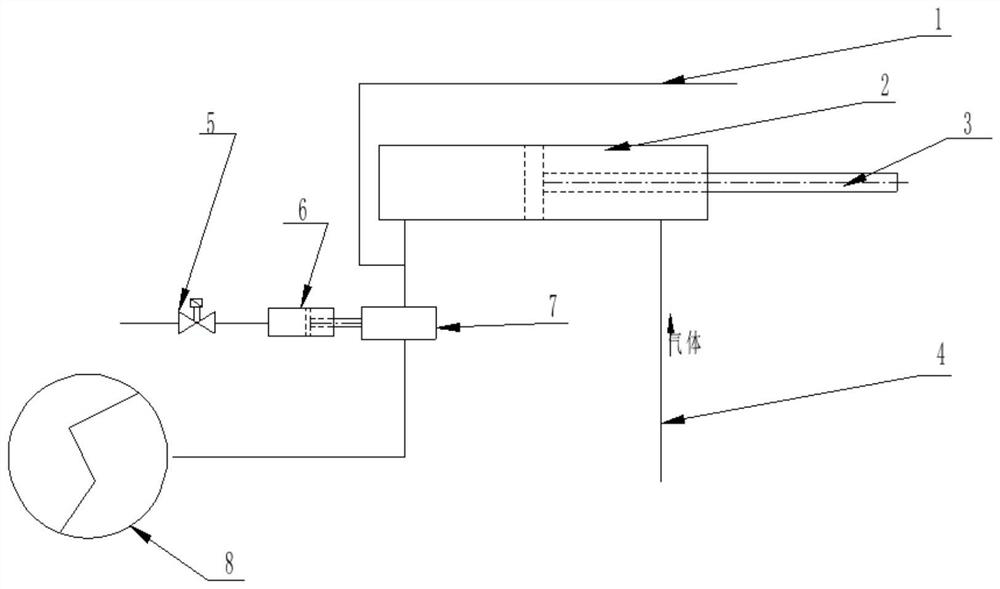

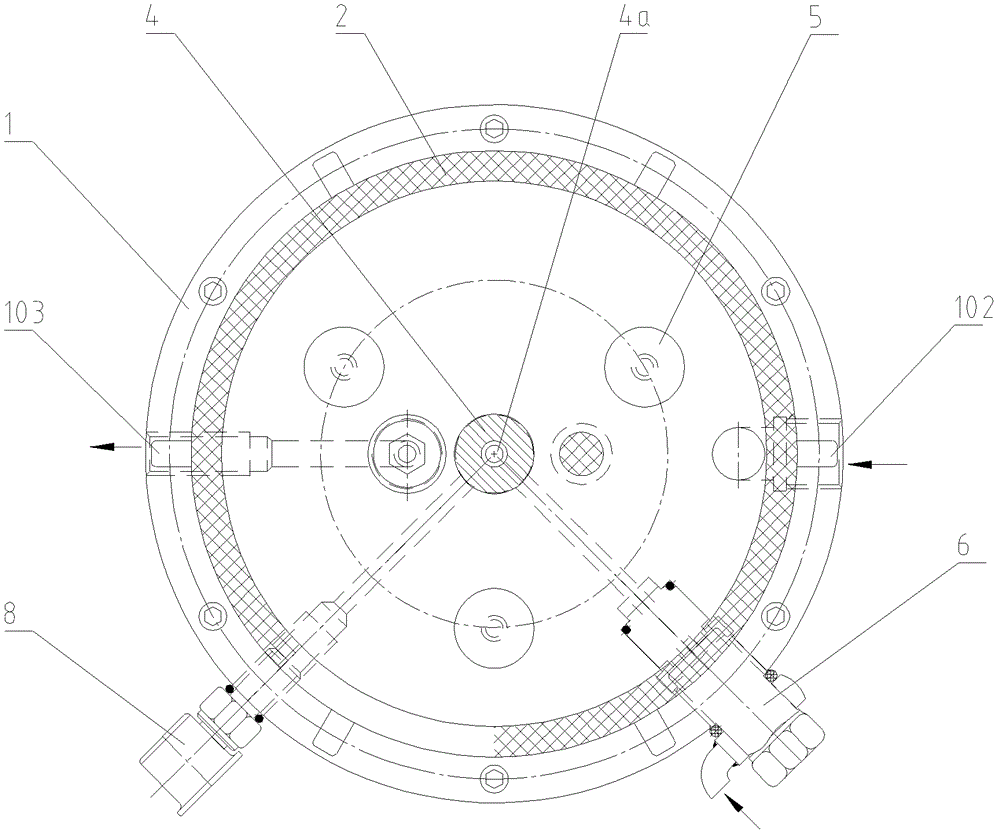

Roller oiling device and its control system and operation method

ActiveCN104128290BRealize automatic oil fillingRigorous structureLiquid surface applicatorsRoads maintainenceControl systemRoad surface

The invention belongs to the field of road machinery, and in particular to a rolling oiling station and a control system and an operation method thereof. The rolling oiling station has the following structure: the central part of a support frame is hinged with a hollow oiling roll, the oiling roll surface is provided with a through hole, an oil blocking cover is arranged on both sides of the oiling roll and outside the oiling roll, the top of the oil blocking cover is connected with one end of a cylinder, and the other end of the cylinder is hinged with a mounting seat; the surface of the oiling roller is provided with an oil immersing oil roll asphalt felt layer with side thickness greater than the central thickness; and the oiling roll is provided with a hollow through shaft with through holes on the surface, one side of the through shaft is fixedly connected with a support frame through an elastic cushion, a fastening nut and a fixed bolt, and the other side is provided with a speed plug join with a fine oil pipe connected inside. The system includes a circuit system and a gas oil system. The operation method is as below: closing eh switch; releasing the oiling roll; starting an oil filling electromagnetic valve; reliving the oiling roll from a wheel; repeating the cycle; and turn off the switch. The invention has the advantages of rigorous structure, controllable whole circulation process, efficiency and safety.

Owner:青岛科泰重工机械有限公司

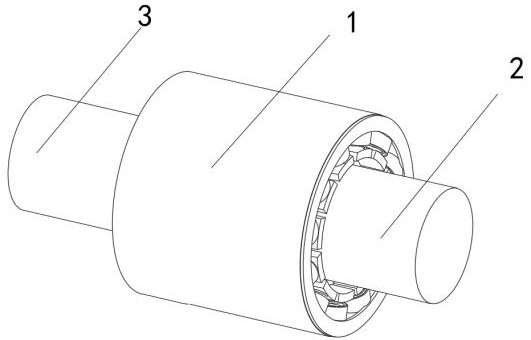

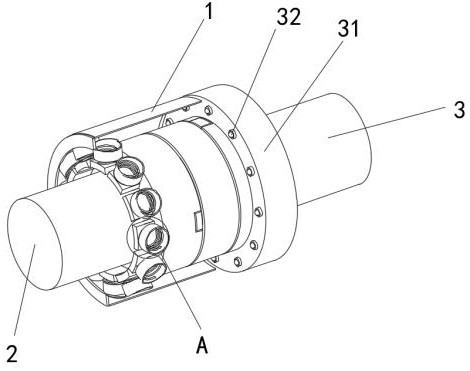

Coupler lubricating device

ActiveCN114060420AOpen in timeRealize the effect of automatic refuelingYielding couplingOperating means/releasing devices for valvesOil canDrive shaft

The invention relates to the technical field of couplers, and discloses a coupler lubricating device, which comprises a driving shaft, a driving disc, a driven shaft and a driven disc, wherein a bush is connected to the outer side of the driven disc in a sleeving mode, a second limiting cylinder is fixedly connected to the inner wall, close to one side of the driving disc, of the bush, the side, close to the bush, of the inner wall of the second limiting cylinder is fixedly connected with a third spring, the other end of the third spring is fixedly connected with a piezoelectric block, and a center sliding block is arranged between the driving disc and the driven disc. According to the invention, the current of an electromagnet on the corresponding side is adjusted in time according to the magnitude of piezoelectric current so as to open an electromagnetic valve in an oil guide cylinder in time, so that the automatic oil adding effect can be achieved; an oil outlet can be opened in time through cooperative arrangement of a conductive sheet, a conductive block and a first spring, so that the oil can be filled in the offset area of a cross sliding block in time, the torque transmission capacity in the transmission process is improved, and the loss of the central sliding block is reduced.

Owner:南通启重润滑设备有限公司

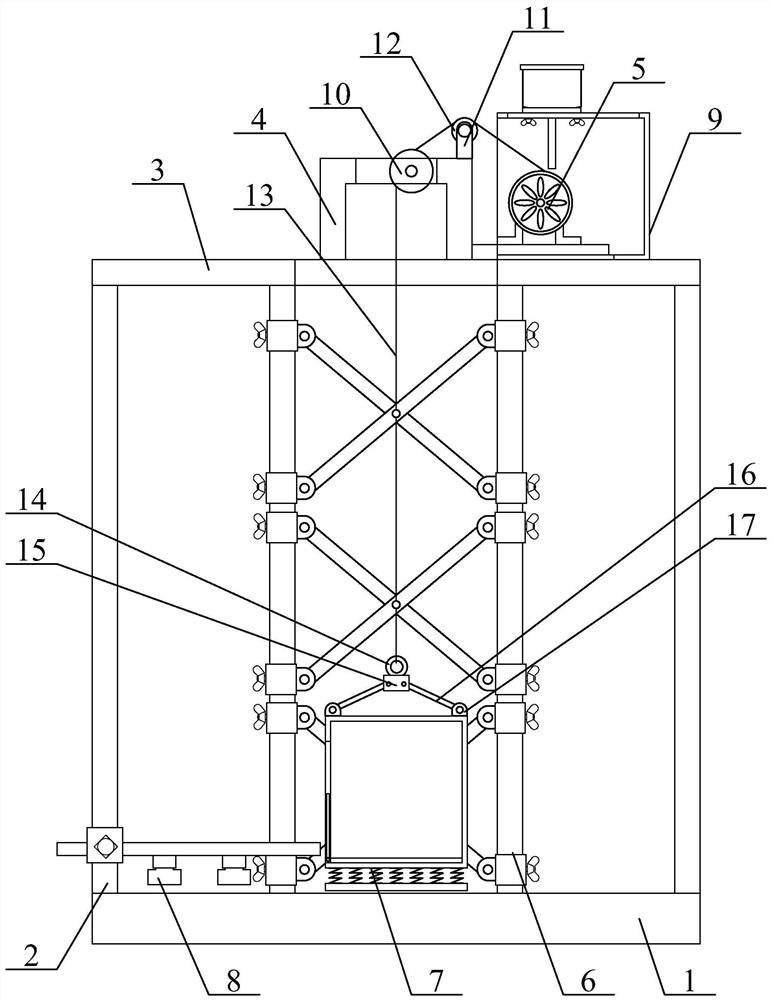

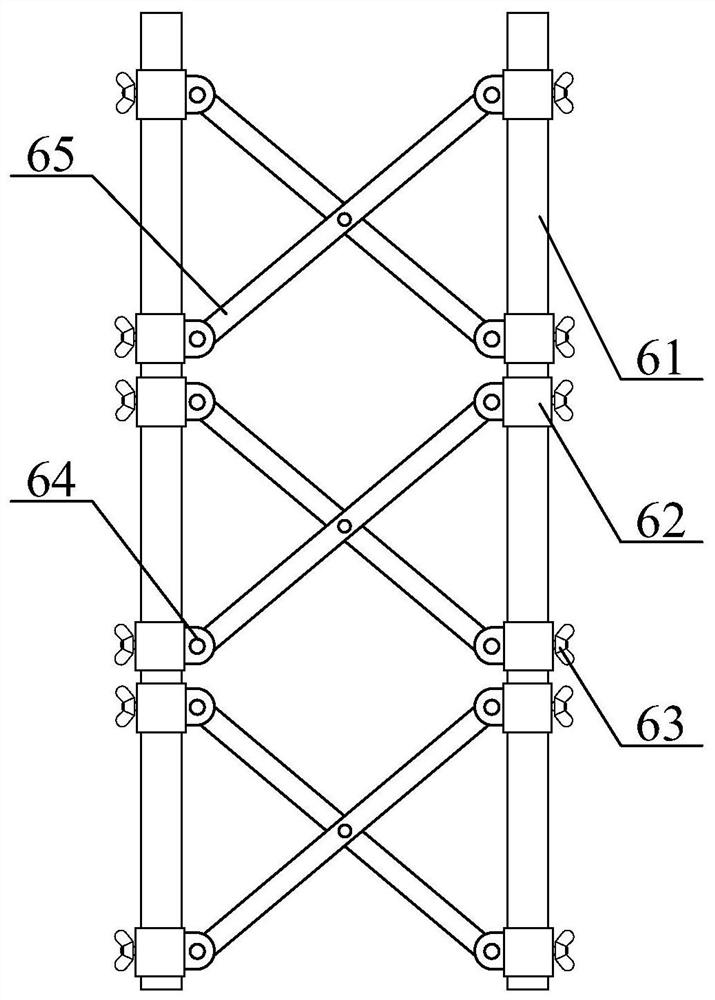

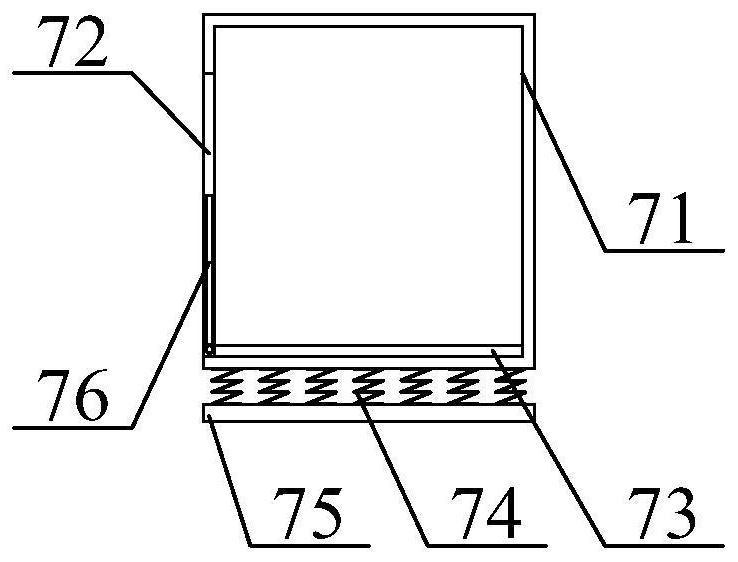

Multifunctional safety elevator for house building construction

PendingCN114148857AGood bufferingEasy to adjust workElevatorsBuilding liftsHouse buildingColumn structure

The invention provides a multifunctional safety lifter for house building construction, which comprises a base, a support column, a top plate, a support frame, a lifting mechanism, an adjustable reinforced connecting column structure, a liftable buffer storage box structure, an adjustable support lap plate structure, a shielding protective filling cover structure, a support wheel, a U-shaped frame, a guide wheel, a steel wire rope, a connecting ring and a connecting frame, the supporting columns are connected to the four corners of the upper end of the base through bolts correspondingly, and the upper ends of the supporting columns are connected to the four corners of the lower end of the top plate through bolts correspondingly. The protective cover, the sliding hole, the sliding plate, the storage box, the dustproof cover, the output pipe, the top plate and the lifting mechanism are arranged in a matched mode, grease can fall to the proper position of the upper end of the lifting mechanism through the output pipe by means of the weight of the grease and vibration of the device during working in the using process, and automatic grease injection work can be conveniently achieved in the using process.

Owner:安徽绿泉生态环境建设有限公司

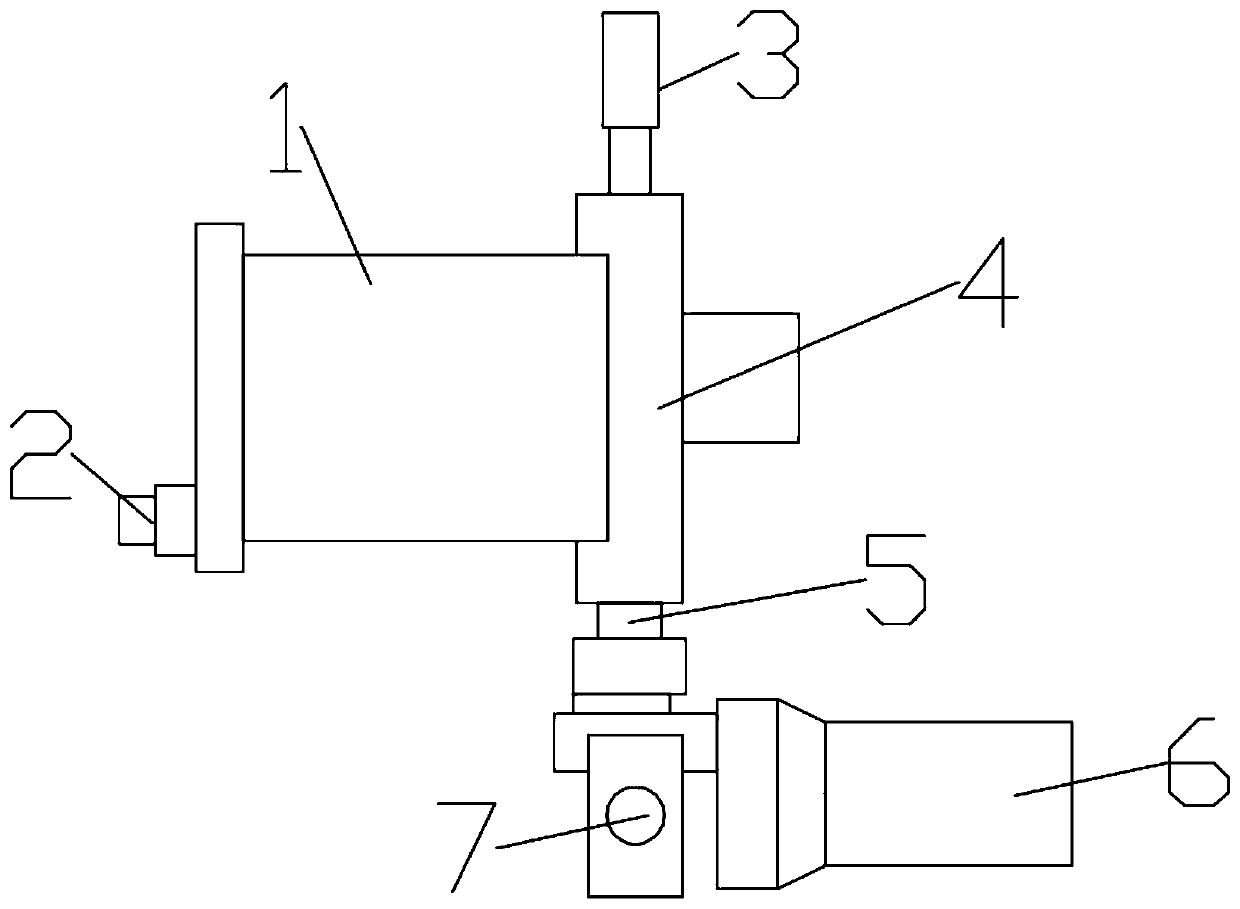

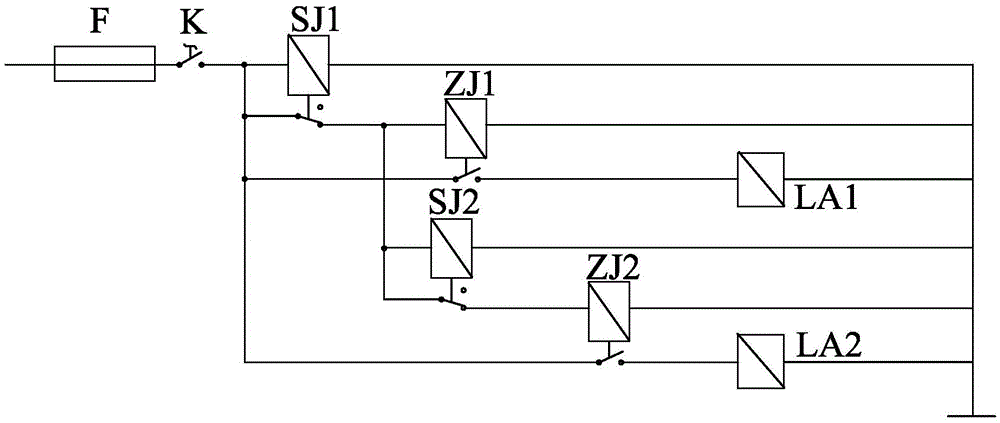

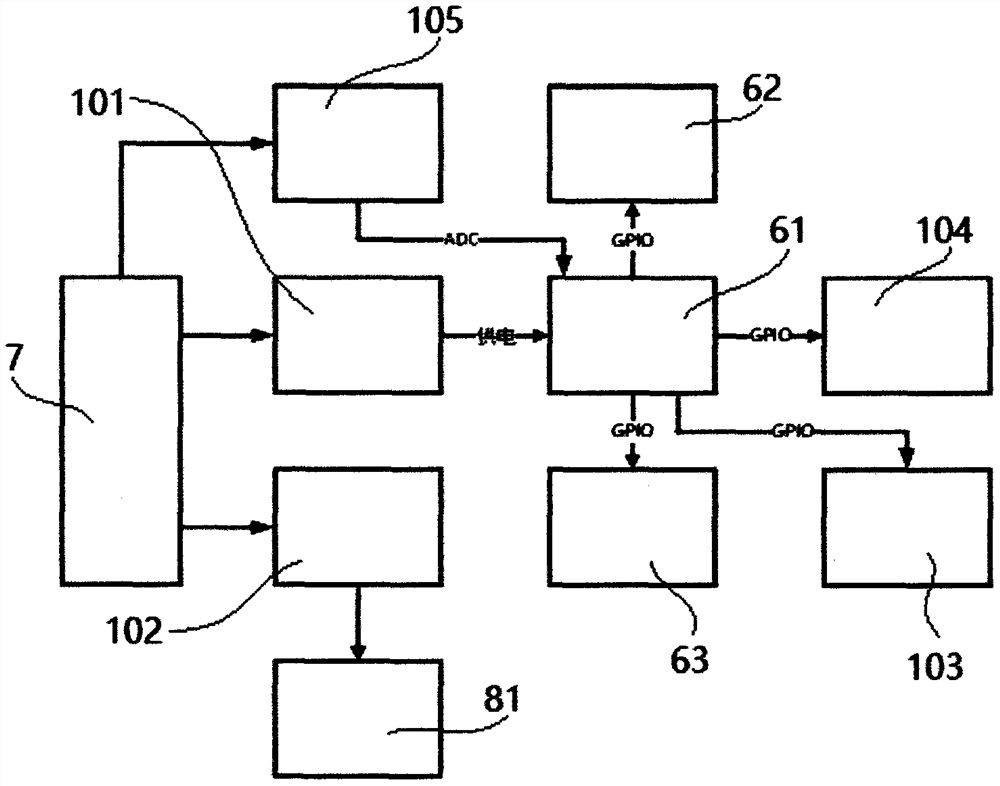

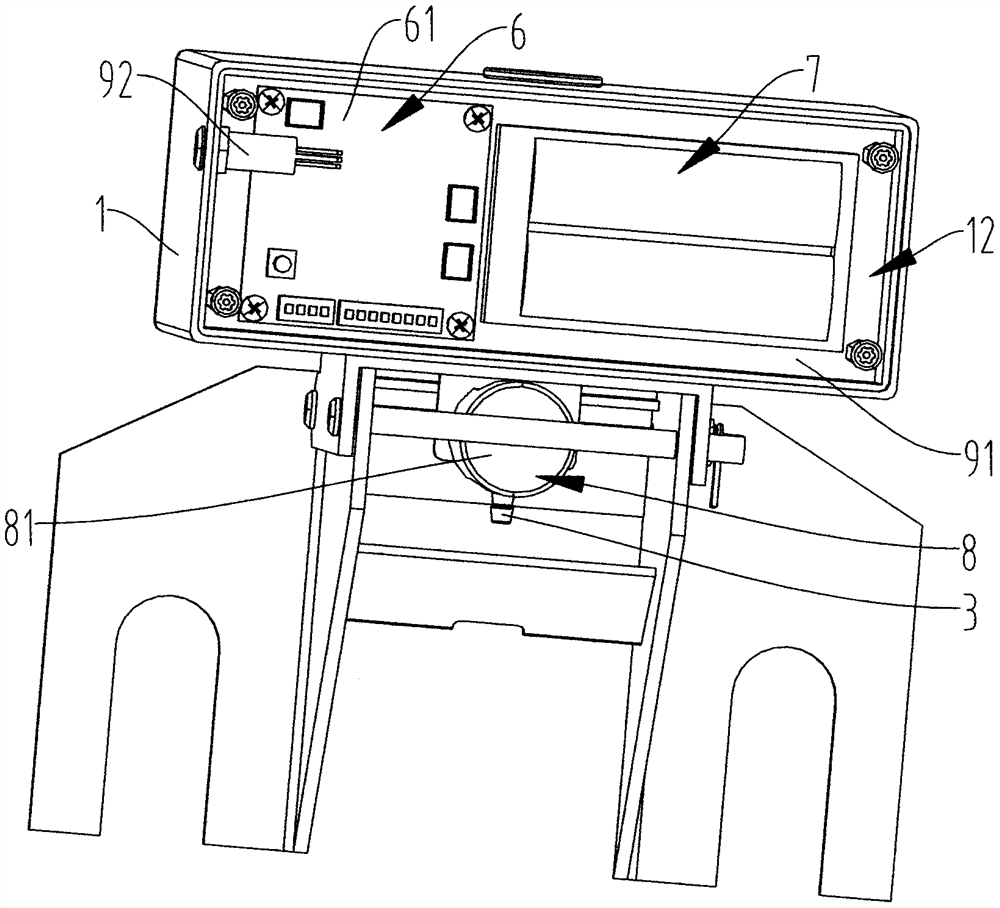

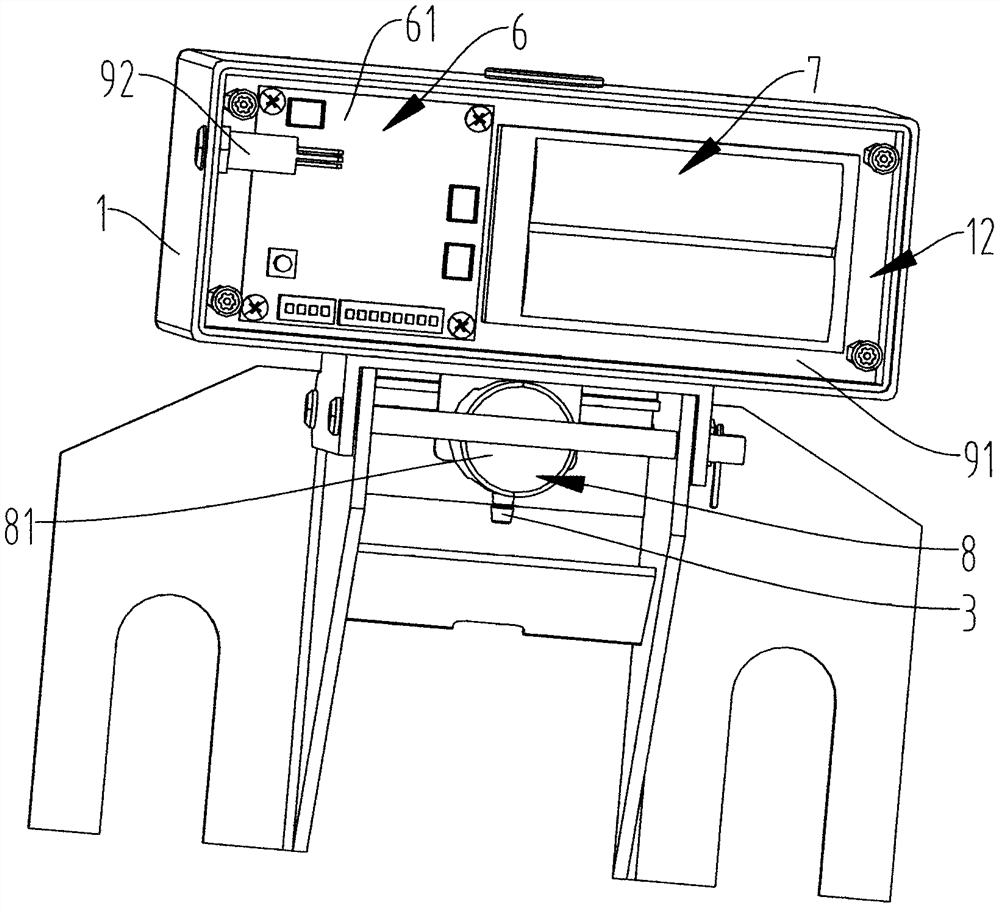

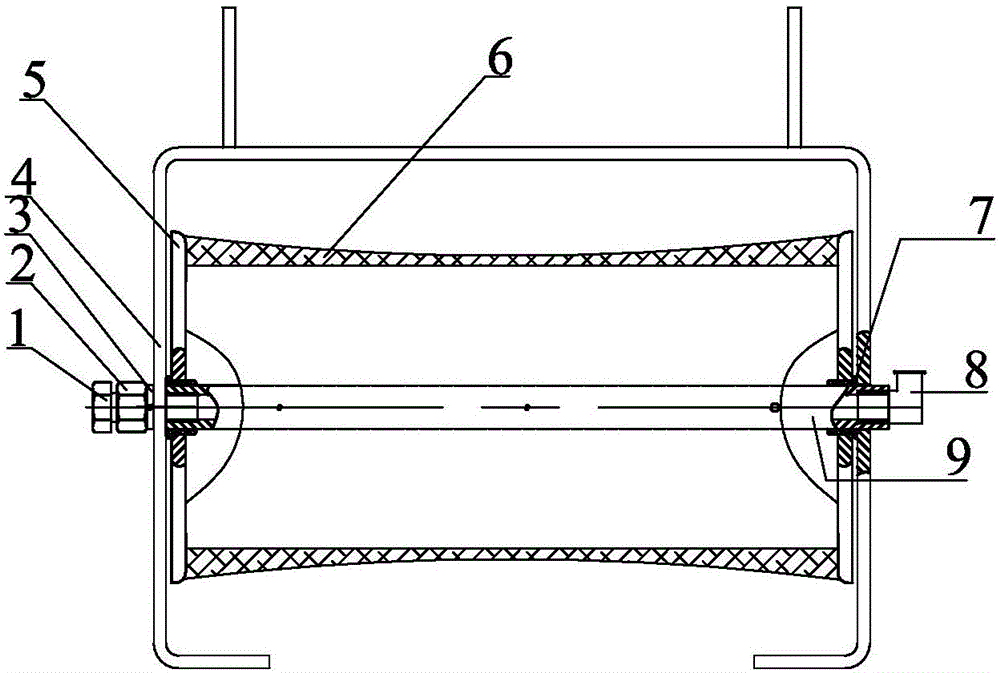

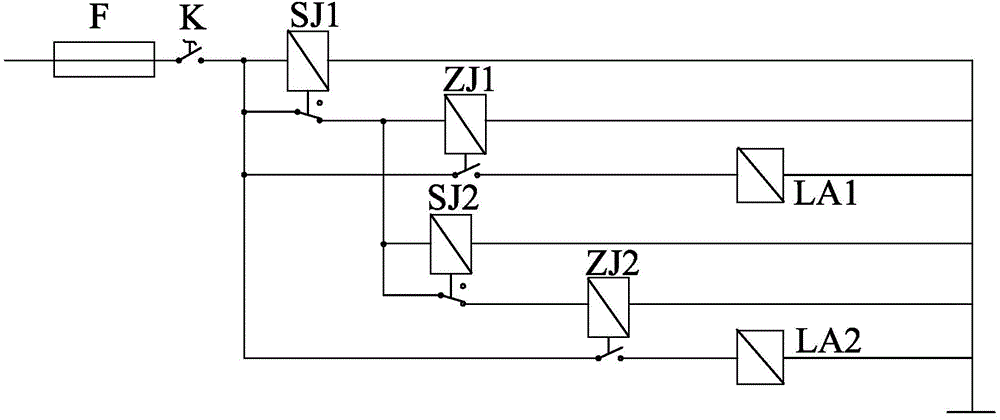

External locking lubricating and oiling device oil drop control system and external locking lubricating and oiling device

ActiveCN111188980BRealize automatic oil fillingAvoid wastingValve arrangementsSignal processingSolenoid valveControl system

The disclosure relates to an oil dripping control system of an external locking lubricating oil filling device and an external locking lubricating oil filling device. The oil dripping control system includes: a control module (6), a power supply module (7) and an execution module (8), and the control module includes The main control chip (61), the execution module includes a solenoid valve (81) communicated with the oil storage box (1) of the externally locked lubricating and oiling device, and a first power supply circuit (101) is electrically connected between the power supply module and the main control chip A second power supply circuit (102) is electrically connected between the power supply module and the solenoid valve, the control module includes a first dial switch (62) and a second dial switch (63) that are communicatively connected to the main control chip, and the main control chip One of the first dial switch and the second dial switch controls the time interval between two adjacent oil drops of the solenoid valve, and the other of the first dial switch and the second dial switch controls the solenoid valve every time The duration of each drop of oil is controlled, so as to realize the automatic dripping of the external locking lubricating and oiling device, and the amount of dripping oil is controllable.

Owner:陕西夸克自控科技有限公司

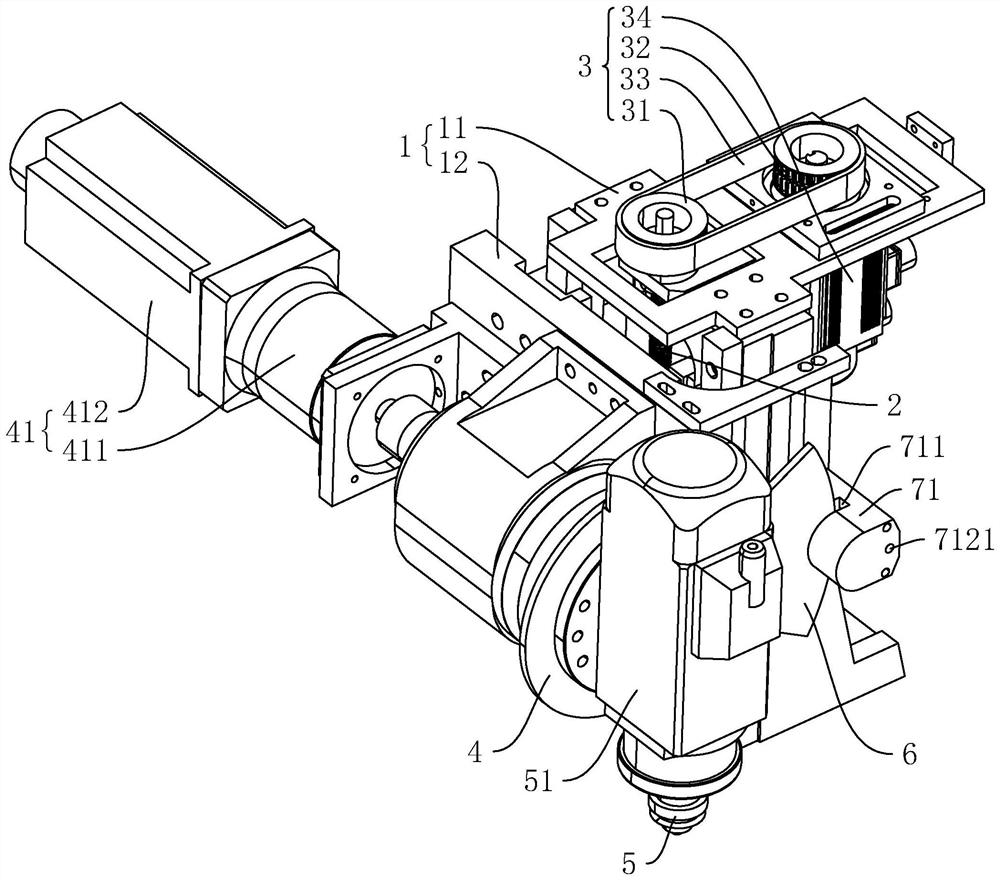

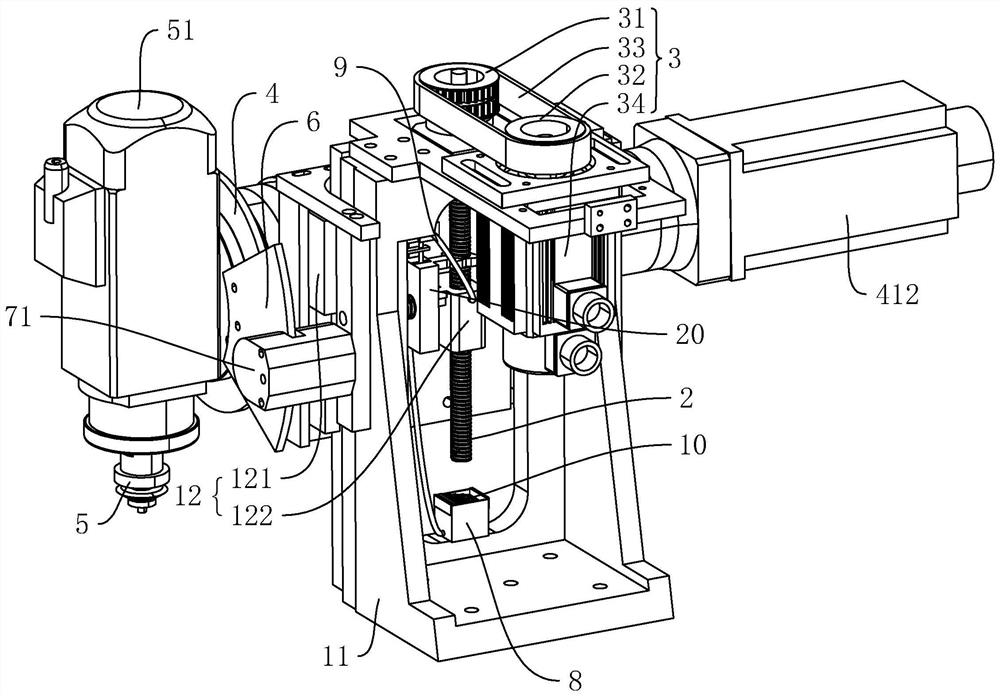

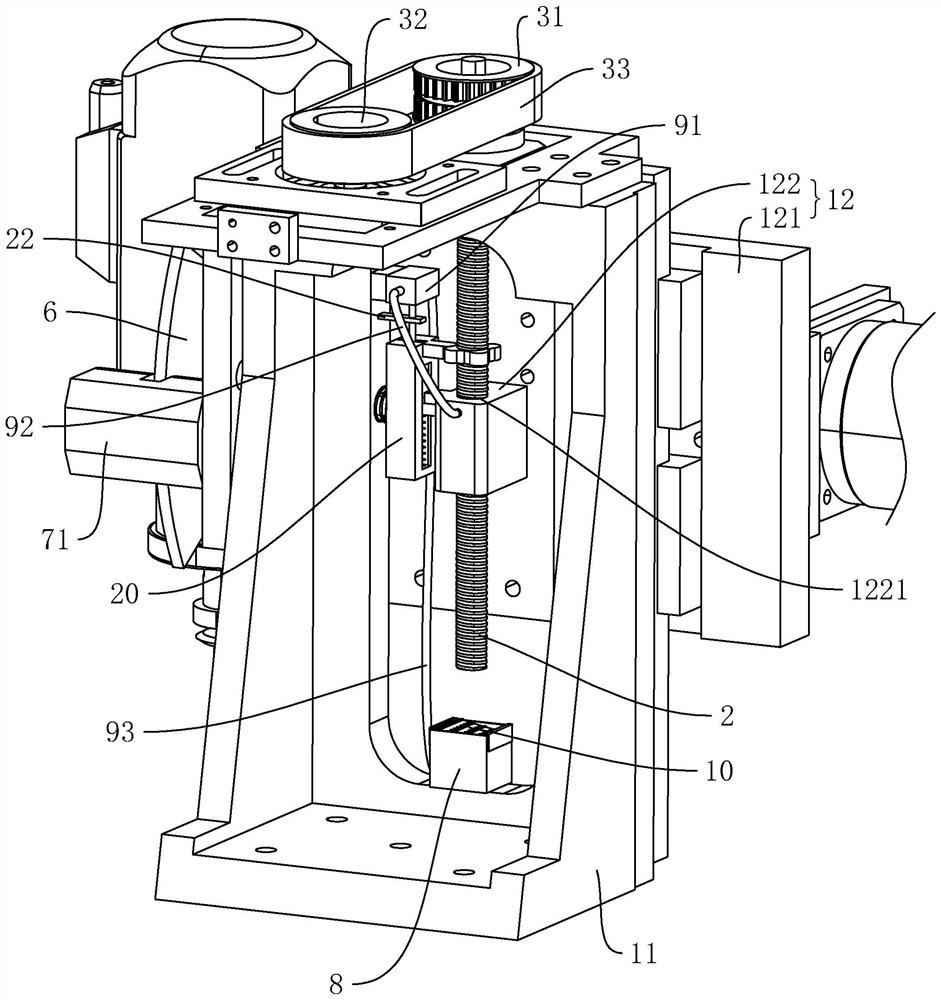

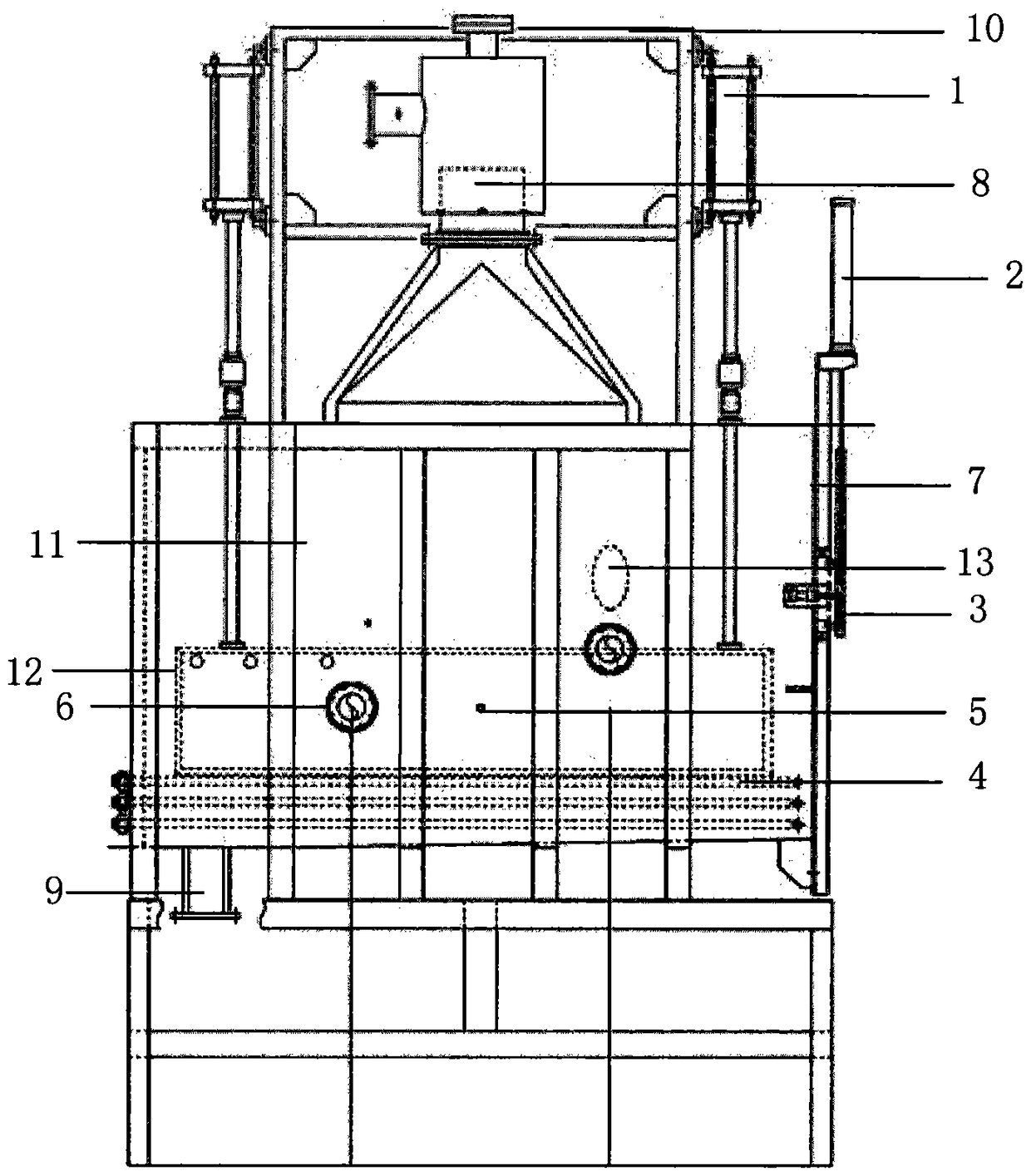

Rotary table

ActiveCN114700761AIncrease freedomImprove applicability and practicalityGrinding machine componentsLarge fixed membersEngineeringMachine tool

The invention relates to a rotary table, and relates to the field of workpiece machining equipment, the rotary table comprises a base, the base is rotatably connected with a rotary table, the base is further provided with a first driving part, the first driving part drives the rotary table to rotate, the rotary table is rotatably connected with a main shaft, the main shaft is used for installing a cutter, the rotary table is further provided with a second driving part, and the second driving part drives the main shaft to rotate. A brake plate is arranged on the second driving piece, and a fixing assembly is further arranged on the base and used for fixing the brake plate. When a workpiece is machined, the first driving piece can be controlled to drive the rotating disc to rotate, then the cutter on the main shaft is driven to move, and therefore the workpiece is machined at different angles, the freedom degree of workpiece machining is improved, more requirements of workpiece machining can be met, and the applicability and practicability of the machine tool are improved; and the brake plate is positioned through the fixing assembly, so that the main shaft can be further fixed, the stability of the main shaft during workpiece machining is improved, and the workpiece machining precision is improved.

Owner:WENLING KEYU AUTOMATION EQUIP CO LTD

Oil dripping control method for external locking lubricating and oiling device and external locking lubricating and oiling device

ActiveCN111156399BRealize automatic oil fillingAvoid wastingRail switchesSafety/regulatory devicesThermodynamicsMechanical engineering

The present disclosure relates to an oil dripping control method for an external locking lubricating oil filling device and the external locking lubricating oil filling device. The oil dripping control method includes: setting the time interval between two adjacent oil drips, setting the time interval between each dripping The duration of the oil; read and judge whether the real-time interval value of the time interval is the set interval value, and when the real-time interval value is the set interval value, control the external locking lubricating and oiling device to drip oil; read and judge Whether the real-time duration value of the duration is the set duration value, when the real-time duration value is the preset duration value, control the externally closed lubricating and oiling device to stop dripping oil, and return to the previous step. The oil dripping control method can realize the automatic oil dripping of the external locking lubricating oil injection device, and the oil dripping amount is controllable.

Owner:陕西夸克自控科技有限公司

Rolling oiling station and control system and operation method thereof

ActiveCN104128290AEasy maintenanceEasy to installLiquid surface applicatorsRoads maintainenceControl systemRoad surface

The invention belongs to the field of road machinery, and in particular to a rolling oiling station and a control system and an operation method thereof. The rolling oiling station has the following structure: the central part of a support frame is hinged with a hollow oiling roll, the oiling roll surface is provided with a through hole, an oil blocking cover is arranged on both sides of the oiling roll and outside the oiling roll, the top of the oil blocking cover is connected with one end of a cylinder, and the other end of the cylinder is hinged with a mounting seat; the surface of the oiling roller is provided with an oil immersing oil roll asphalt felt layer with side thickness greater than the central thickness; and the oiling roll is provided with a hollow through shaft with through holes on the surface, one side of the through shaft is fixedly connected with a support frame through an elastic cushion, a fastening nut and a fixed bolt, and the other side is provided with a speed plug join with a fine oil pipe connected inside. The system includes a circuit system and a gas oil system. The operation method is as below: closing eh switch; releasing the oiling roll; starting an oil filling electromagnetic valve; reliving the oiling roll from a wheel; repeating the cycle; and turn off the switch. The invention has the advantages of rigorous structure, controllable whole circulation process, efficiency and safety.

Owner:青岛科泰重工机械有限公司

Quantitative, timed, accurate and automatic oil injection device for wire drawing machine

ActiveCN114484248ACode of PracticeRealize automatic oil fillingProportioning devicesLubrication check valvesOil canPhotoswitch

The invention relates to a quantitative, timed and accurate oil injection device for a wire drawing machine, which comprises an oil inlet pipeline, an oil cylinder, an air inlet pipeline and an oil quantity adjusting unit, a piston is arranged in the oil cylinder, a cavity of the oil cylinder is divided into a lubricating grease cavity and a compressed air cavity by the piston, the lubricating grease cavity is communicated with the oil inlet pipeline, and the compressed air cavity is communicated with the oil inlet pipeline. And the compressed air cavity is communicated with the air inlet pipeline. The invention has the advantages that: the original mode of singly replacing the oil pot is changed, automatic oil injection is realized, and the cost is saved; the oil cylinder is provided with a liquid level indicating rod, a photoelectric switch for collecting photoelectric signals is arranged at the position of the liquid level indicating rod, the photoelectric switch is connected into the control panel, the photoelectric switch transmits the real-time oil level to a background signal data processing center, and when the oil level reaches a specified critical value, an alarm signal is output. Therefore, personnel can be reminded to carry out accurate machine refueling, and accurate information transmission is realized.

Owner:TAISHAN FIBERGLASS INC

Electronic cigarette filling device

Owner:中山市合沃电子科技有限公司

Low-temperature frying equipment and method for frying fried food

ActiveCN104170903BRealize automatic oil fillingReal-time detection of temperatureOil/fat bakingDeep fryingEngineering

Owner:BEIJING KAIDA HENGYE AGRI TECH DEV

an oiling machine

ActiveCN105790518BFully automatedRealize automatic oil fillingLiquid surface applicatorsManufacturing stator/rotor bodiesNumerical controlRolling resistance

The invention relates to an oil spreading machine. The oil spreading machine comprises a rack, wherein an oil spreading device and a rotor arrangement device are arranged on the rack, an inclined groove guide rail is arranged between the oil spreading device and the rotor arrangement device, the oil spreading device comprises a numerical control oil injector and a synchronous belt, the synchronous belt is controlled by a speed reduction motor, a rotor preparation groove is formed in the end surface of the inclined groove guide rail and is communicated with the inclined groove guide rail, a support is arranged on the rotor preparation groove and is used for fixing the synchronous belt, and the rotor preparation groove is connected with the numerical control oil injector through an oil transmission pipeline. With the adoption of the numerical control oil injector, an oil liquid is enabled to be continuously input into the rotor preparation groove, the numerical control oil injector starts operation when a rotor enters the rotor preparation device so as to achieve automatic oil injection; and the synchronous belt is arranged at the bottom of the rotor preparation groove and is controlled by the speed reduction motor, rolling friction is carried out on the surface of the rotor, the oil liquid is promoted to be in uniform and full contact with the rotor, the automatic oil spreading of the rotor is achieved, the production efficiency is improved, and the labor cost is reduced.

Owner:NINGBO YINLI ELECTROMECHANICAL

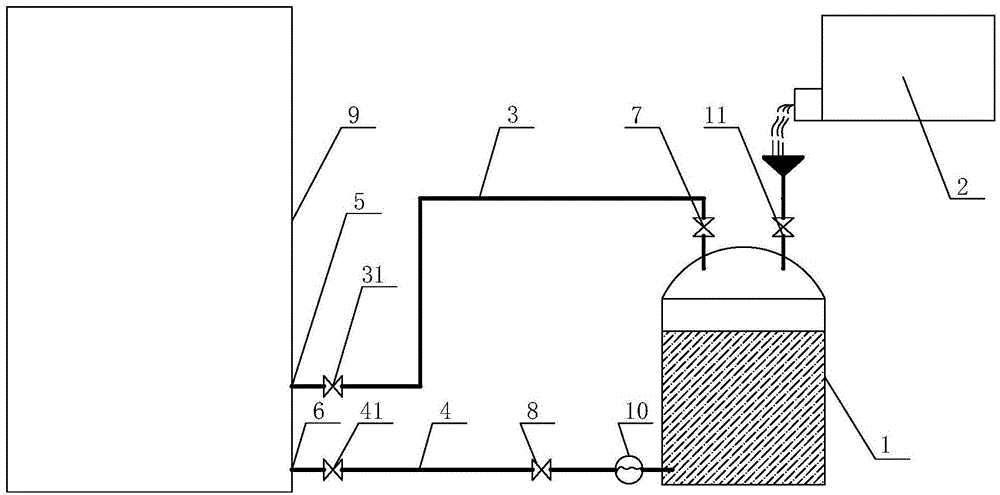

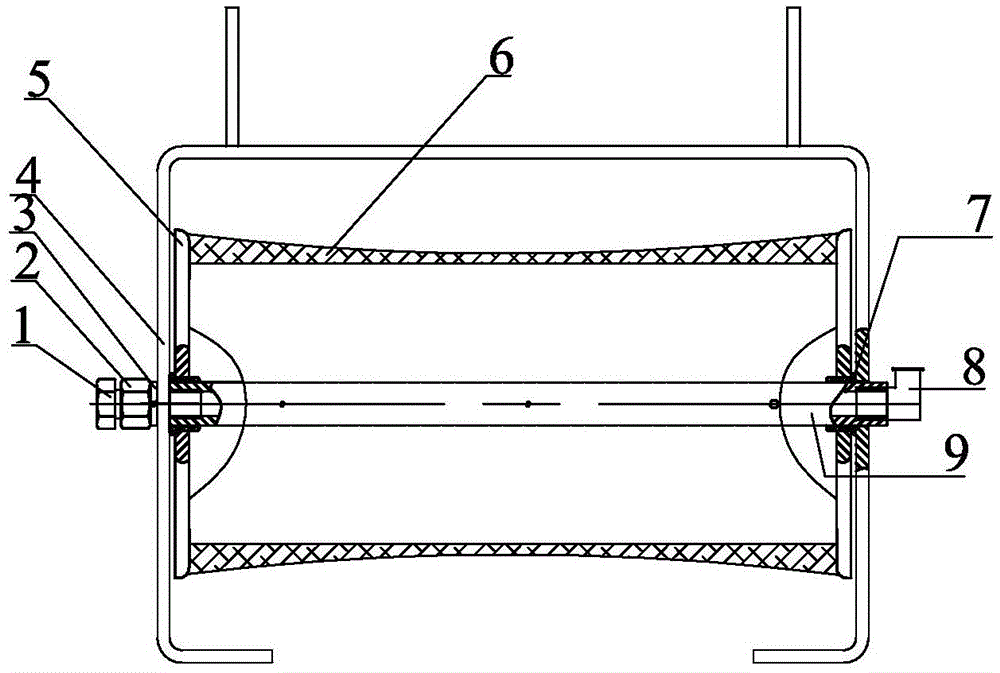

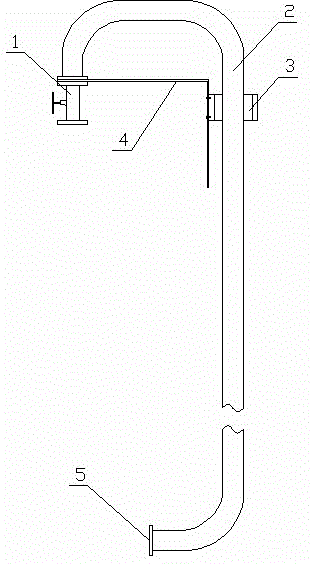

Oil level detection alarming device during vacuum oil injection of transformer

ActiveCN102853880BPrecisely controlled vacuum oilingReduce labor intensityMachines/enginesLubrication indication devicesTransformerUltimate tensile strength

The invention discloses an oil level detection alarming device during vacuum oil injection of a transformer. The oil level detection alarming device comprises a communication pipe and a valve, wherein the communication pipe is connected with the bottom valve of the transformer and a top flange; and the oil level detection alarming device is arranged on the upper part of the communication pipe and is fixed by a fixed piece. By utilizing the device, vacuum oil injection of the transformer is accurately controlled under an unmanned operation condition, and the oil level of the injected oil is adjusted according to the specific condition; and meanwhile, the manual attendance is realized under the condition of a damaged instrument and the device is accurately controlled, so that the labor intensity of operation personnel is lightened, the automatic oil injection is realized, and a requirement on modern automation production is met.

Owner:STATE GRID CORP OF CHINA +2

Vacuum oiling equipment and oiling method for transformer

ActiveCN103824679BRealize automatic oil fillingImprove insulation performanceTransformers/inductances coolingNitrogenFuel tank

Owner:GUANGDONG CHAMPON ELECTRIC CO LTD

A flexible grasping device for industrial robots

The invention relates to the technical field of flexible grabbing devices, in particular to a flexible grabbing device for industrial robots. The bottom end of the housing is symmetrically slidably connected to two sliding seats, and a driving motor is installed on the front side of the housing. , the inside of the housing is rotatably connected with a drive gear connected to the drive shaft of the drive motor. The invention is novel in design and ingenious in structure. It adopts the principle that multiple groups of clamping columns cooperate with magnets to repel each other at the same pole, so that the clamping columns can completely fit the surface of the workpiece, satisfying the grasping of workpieces of different shapes, and effectively improving the work efficiency. At the same time, the magnets simultaneously The distance difference between the poles is used to adjust the clamping strength to avoid damage to the workpiece. The anti-detachment mechanism can prevent the tooth plate from derailing and reduce maintenance costs. The oil injection mechanism can realize automatic oil injection, reduce the friction coefficient between gears, and avoid gear A problem of reduced service life due to wear and tear.

Owner:FOSHAN ZHIANG TECH CO LTD

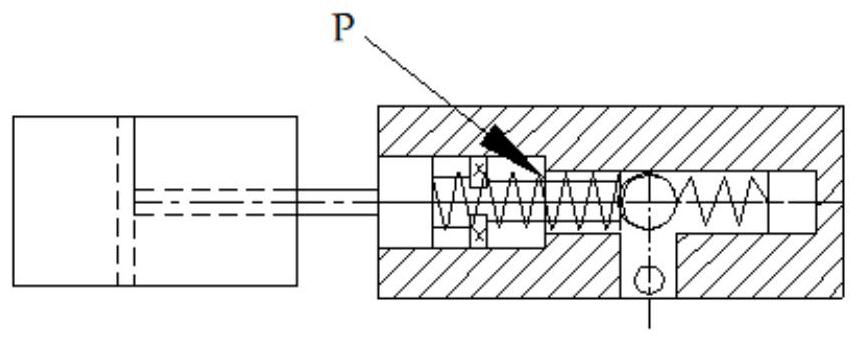

Air pressure lubricating oil injector and its oiling method

InactiveCN103123039BSimple structureEasy maintenanceLubricating pumpsEngineeringMechanical engineering

The invention discloses an air pressure lubricating oil injecting device and an oil injecting method thereof. The air pressure lubricating oil injecting device comprises a fixing seat, an oil storing barrel with an opening portion, a hollow first guide pillar and a piston, wherein an air inlet-vent mouth, an oil inlet and at least one oil injecting mouth are formed in the fixing seat, the opening portion of the oil storing barrel is connected with the fixing seat in a sealed mode, a first mouth and a second mouth are respectively formed at a first end and a second end of the first guide pillar, wherein the first mouth and the second mouth are respectively communicated with inner holes of the first end and the second end of the first guide pillar, the first guide pillar is installed inside the oil storing barrel, the first end of the first guide pillar is fixed on the fixing seat, the first mouth of the first end of the first guide pillar is communicated with the air inlet-vent mouth, the piston is arranged on the first guide pillar in a sliding mode, an inner cavity of the oil storing barrel is divided into an oil cavity and an air cavity by the piston, the oil cavity is communicated with the oil inlet and the oil injecting mouth, and the air cavity is communicated with the second mouth of the second end of the first guide pillar. According to the air pressure lubricating oil injecting device, air pressure is utilized to drive the piston to inject oil, and a traditional mode that a motor is depended to drive a pump body to supply oil is replaced. The air pressure lubricating oil injecting device is simple in structure, convenient to repair and low in overall price.

Owner:ZHUHAI LIZHUN ELECTRONICS SCI & TECH CO LTD

An automatic lubricating oil injection equipment

ActiveCN110375183BReduce the burden onAchieve superchargingLubrication check valvesOil and greaseInjection equipment

The invention discloses an automatic lubricating oil injection device, which belongs to the technical field of oil injection equipment and solves the problem of slow injection speed of lubricating oil in the existing device; There is an oil injection assembly for automatic oil injection. The oil injection assembly is fixedly installed on the installation seat of the oil injection assembly. The installation seat of the oil injection assembly is fixed on the inner wall of the oil injection chamber through bolts. There is a pressurized component connected to the bottom of the oil injection chamber, and a grease detector for detecting grease is also connected to the oil injection chamber; the invention can automatically add lubricating oil, avoiding the loss of the equipment caused by the lack of lubricating oil, and at the same time, the operation is simple and the failure rate is low , Fast oil injection and high efficiency.

Owner:上海泽煦智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com