Patents

Literature

177results about How to "Realize automatic removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

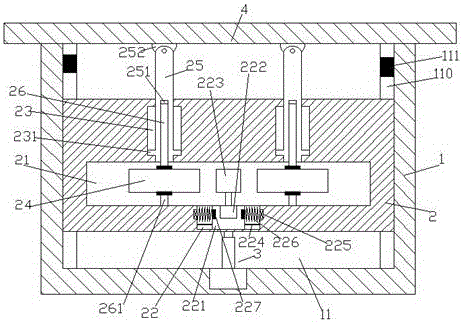

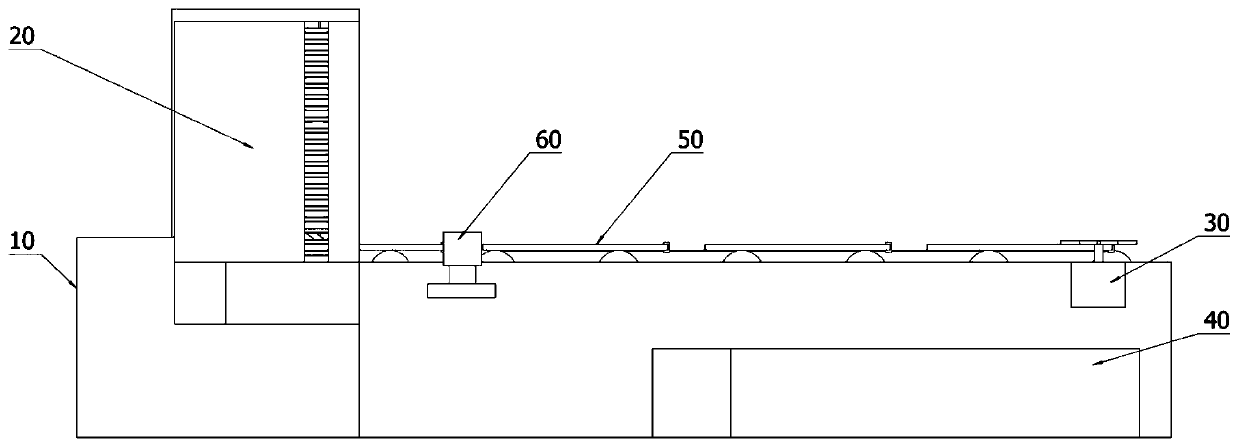

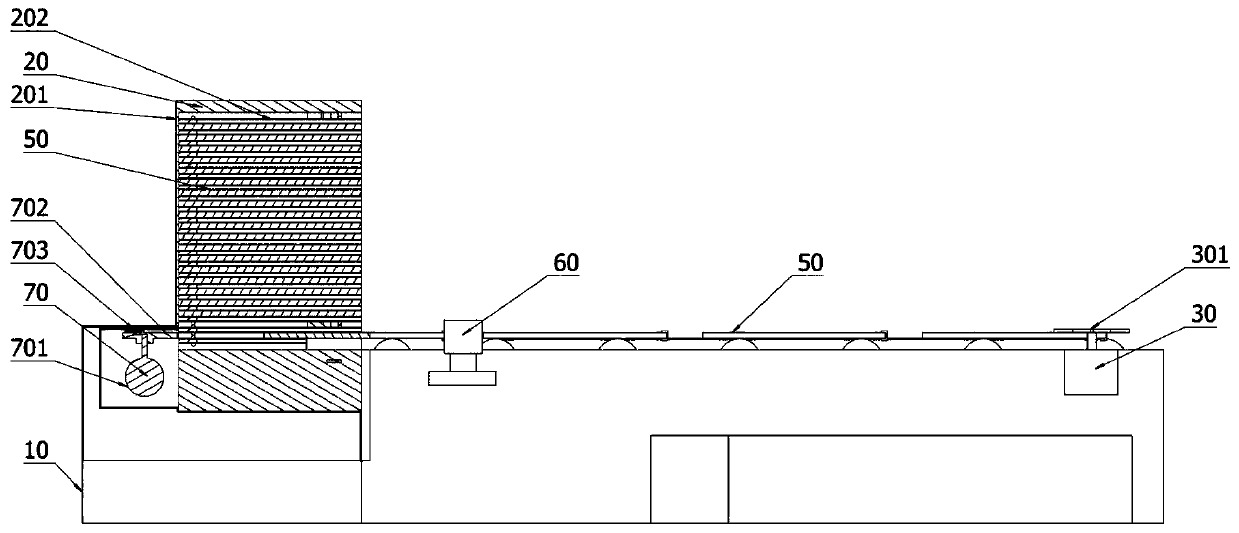

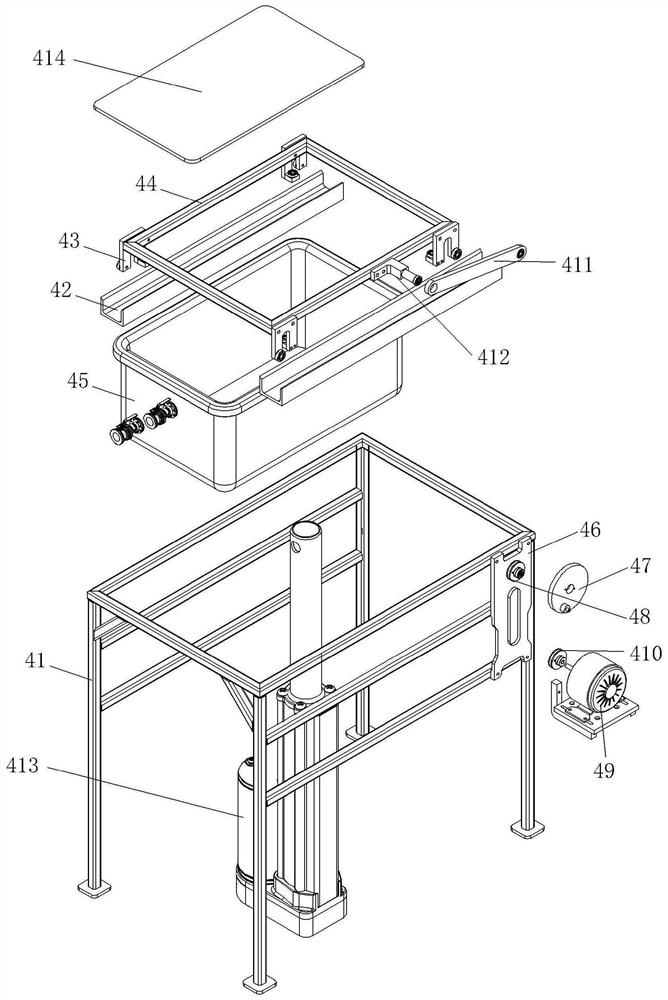

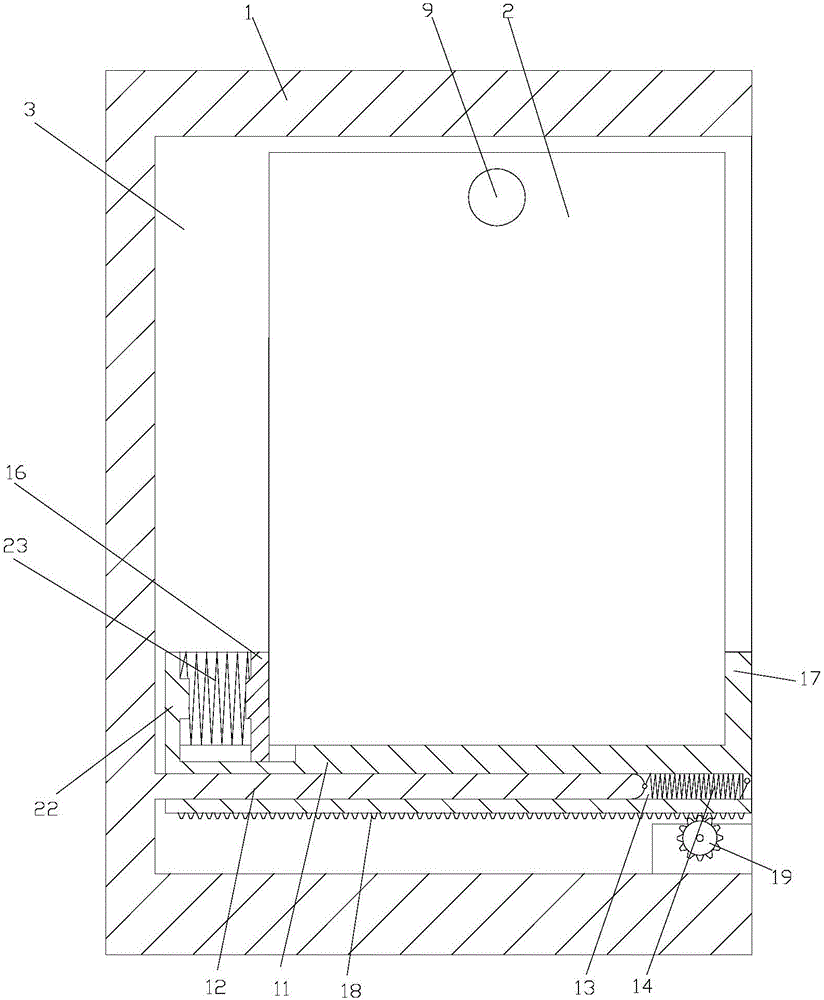

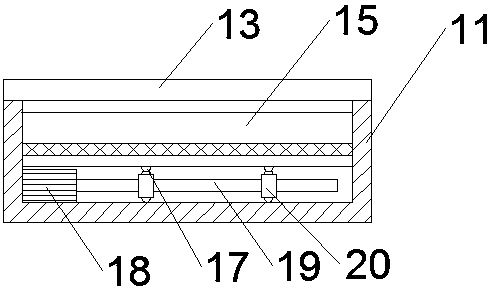

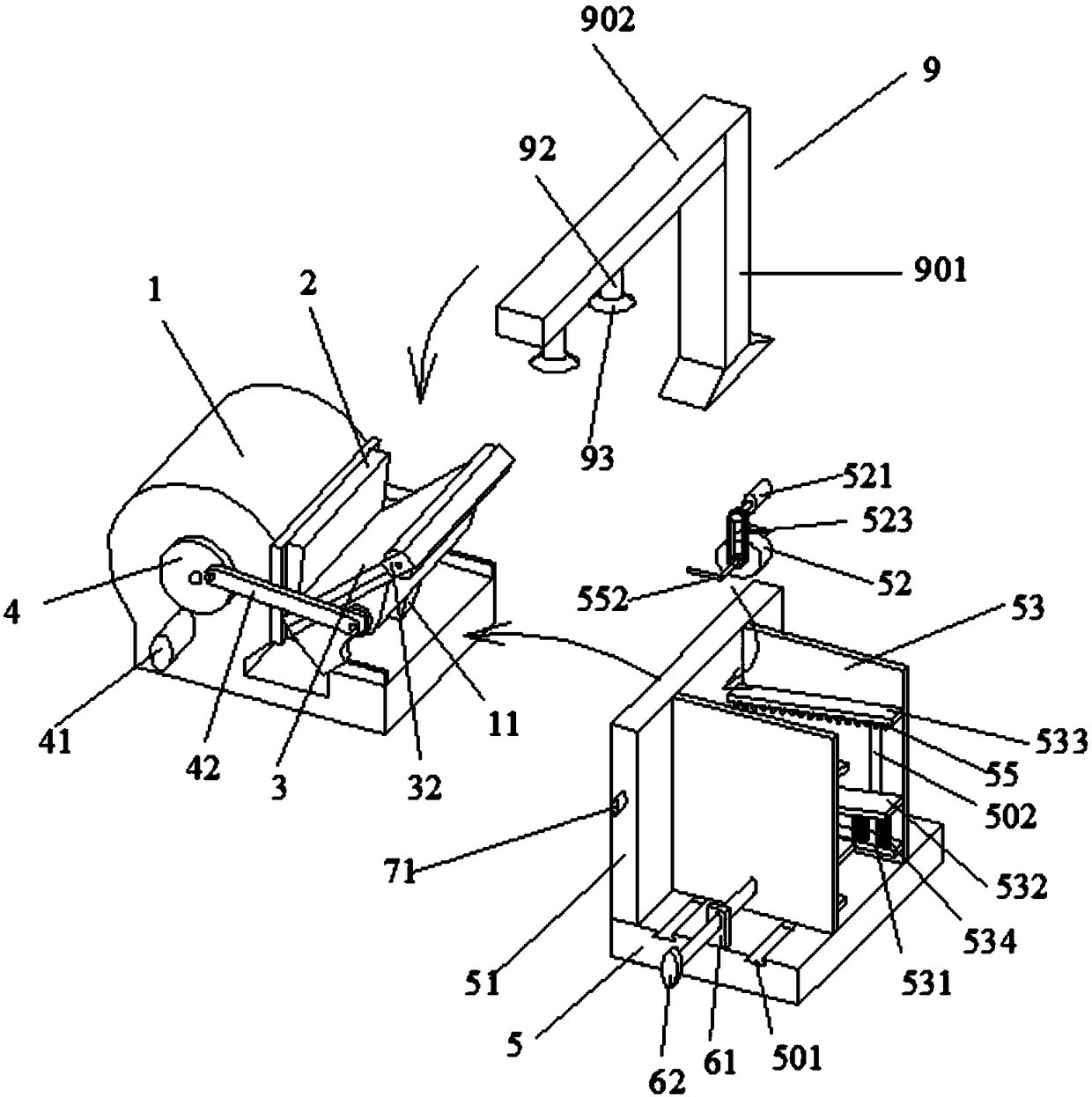

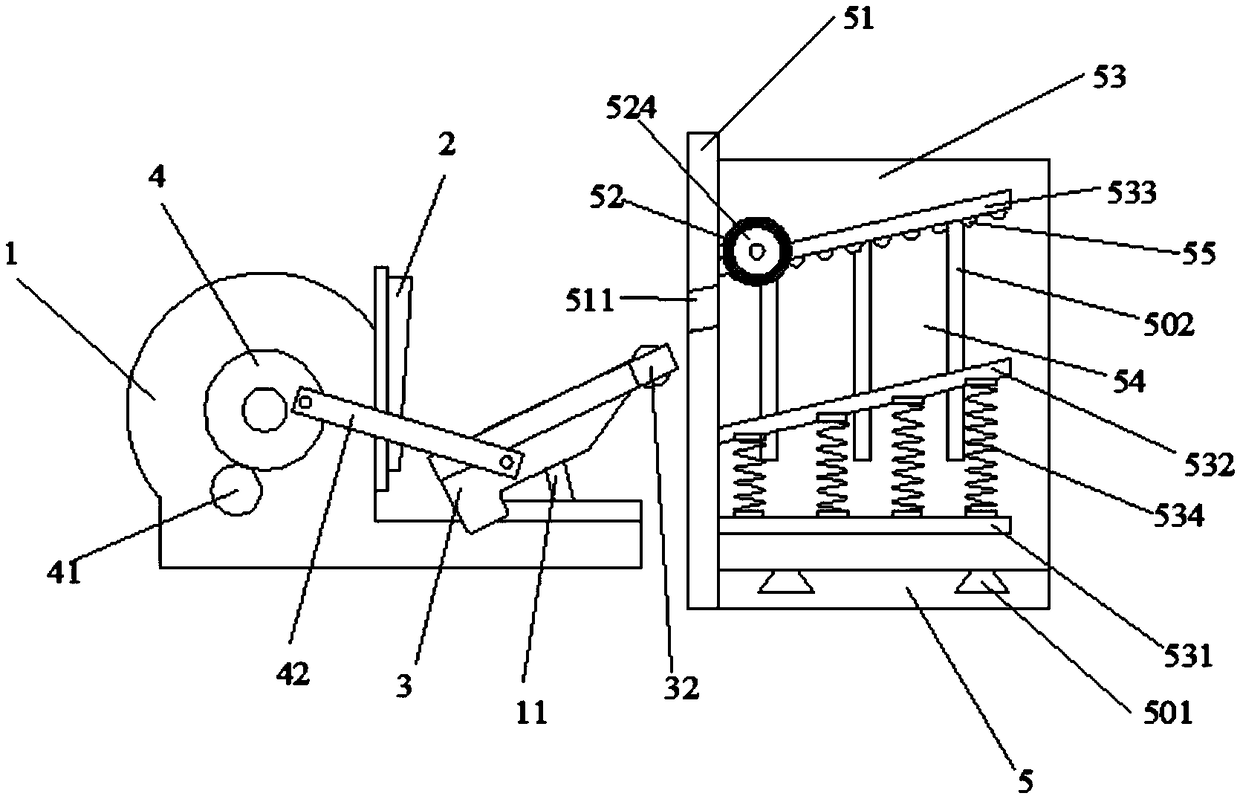

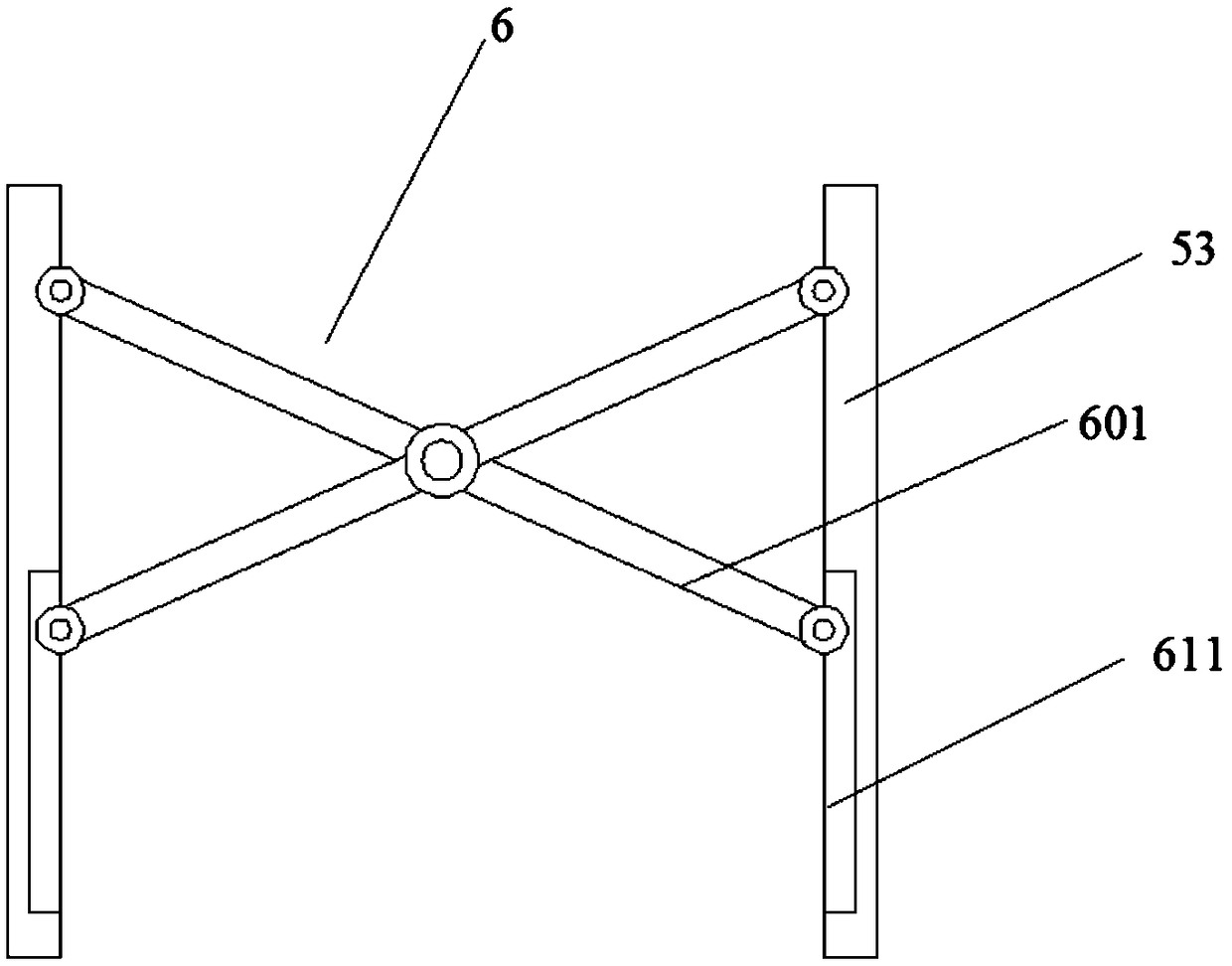

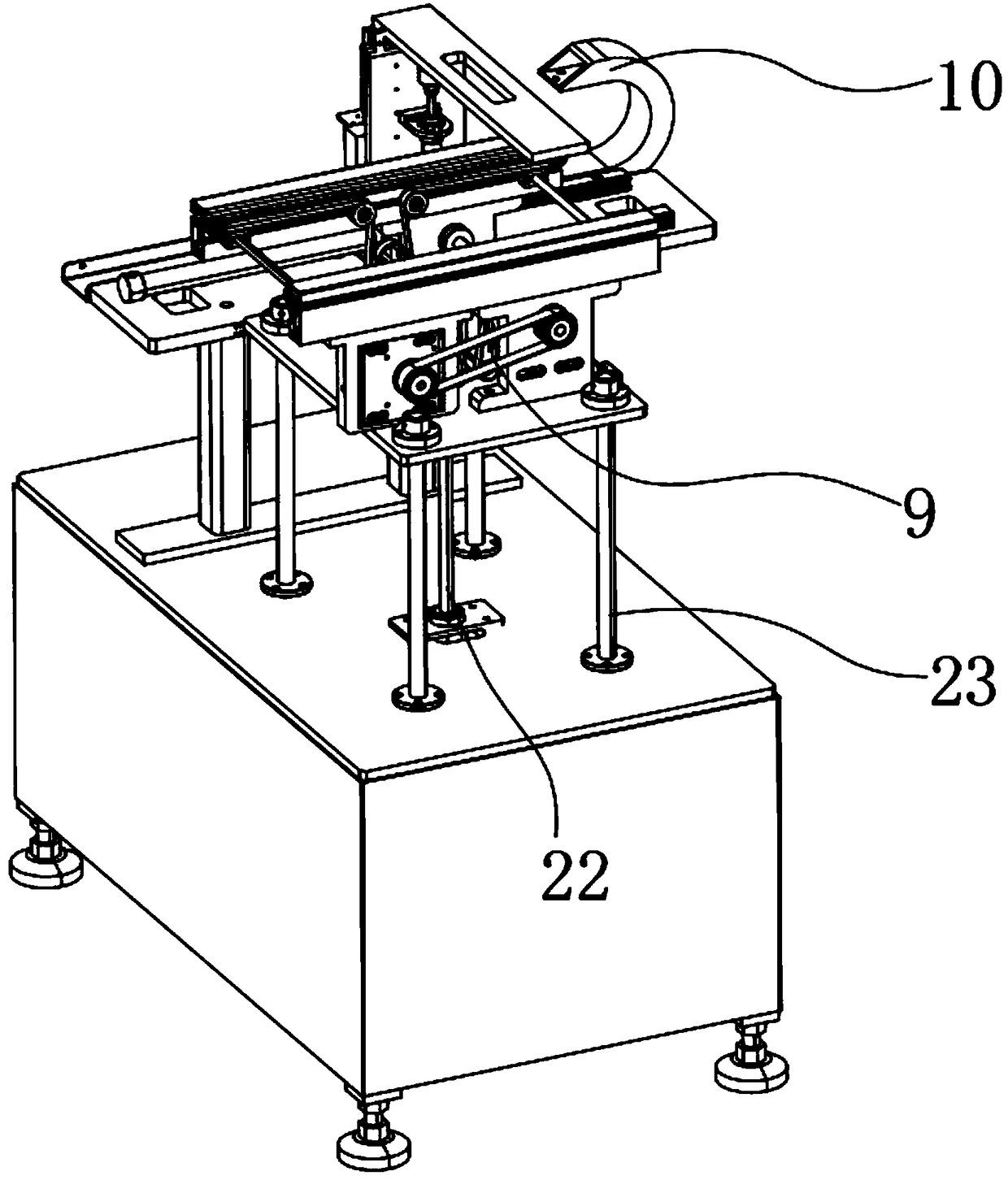

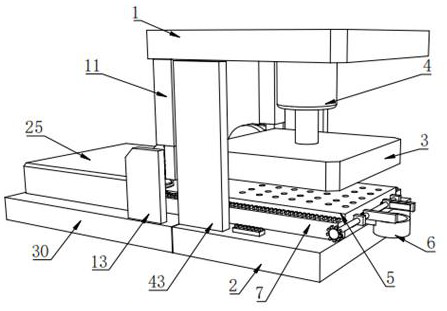

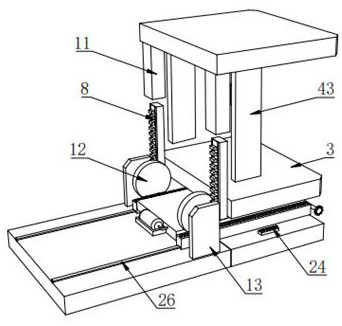

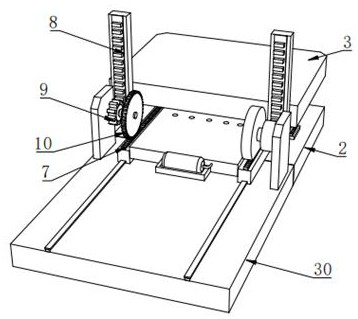

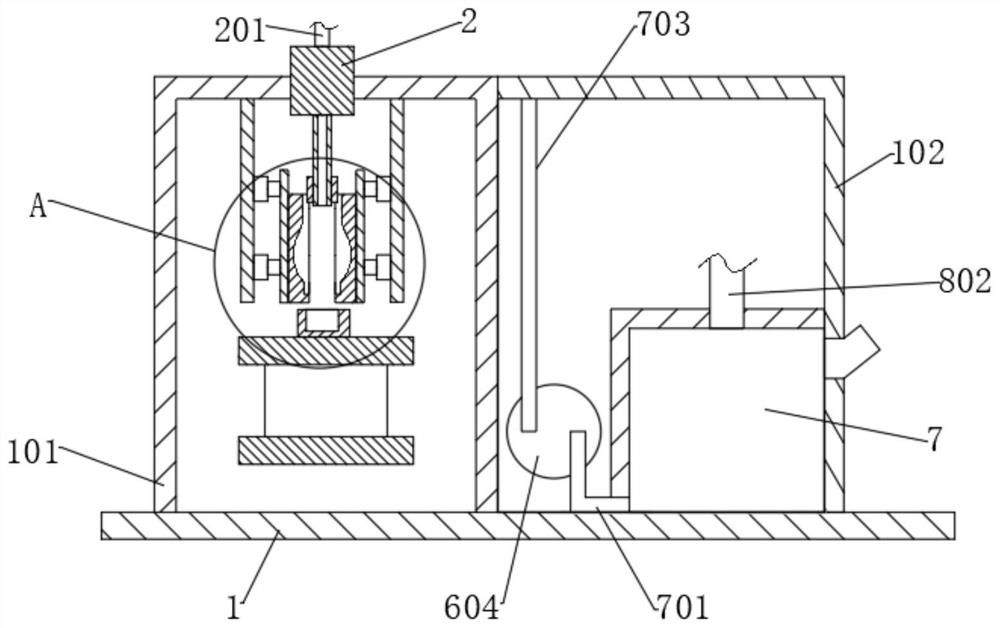

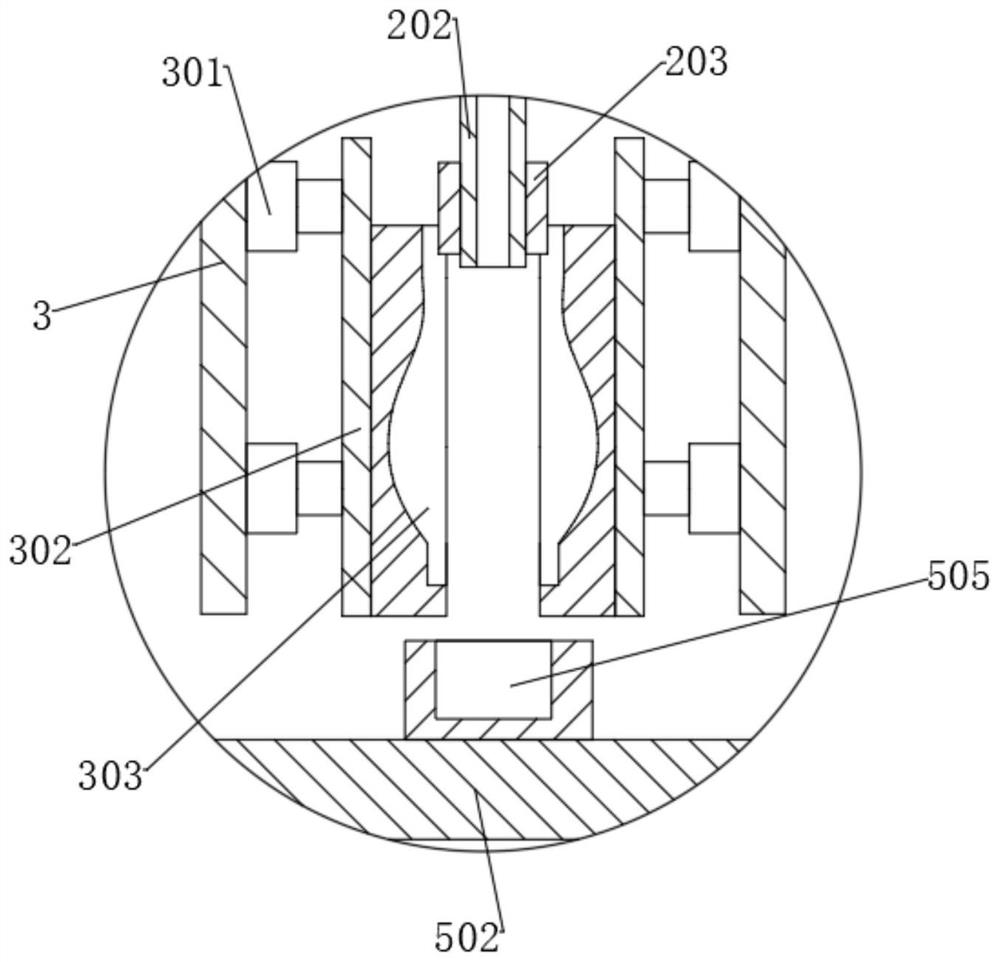

Workpiece processing table device

ActiveCN106584376ARealize automatic removalStable automatic lifting workWork benchesLarge fixed membersEngineeringMechanical engineering

The invention discloses a workpiece processing table device which comprises a processing table, wherein a cavity is formed in the processing table; slip grooves are formed in inner walls of two sides of the cavity; positioning plates are arranged at the upper side ends of the slip grooves; a sliding table is arranged in the cavity; two side ends of the sliding tables are arranged in the slip grooves and are in slip connection with the slip grooves in a matched manner; a push-press device is arranged at the bottom of the sliding table; an assembling cavity is formed in the sliding table; a placement groove is formed in the midpoint of the bottom of the assembling cavity; translation cavities are formed in the sliding table in the top end of the assembling cavity in a left-right equal manner; and sleeve shells are arranged in the translation cavities and stretch up and down along the translation cavities. The workpiece processing table device is simple in structure and convenient to operate, and can automatically adjust height and automatically move a workpiece out to greatly improve the working efficiency.

Owner:扬州市舜意机械有限公司

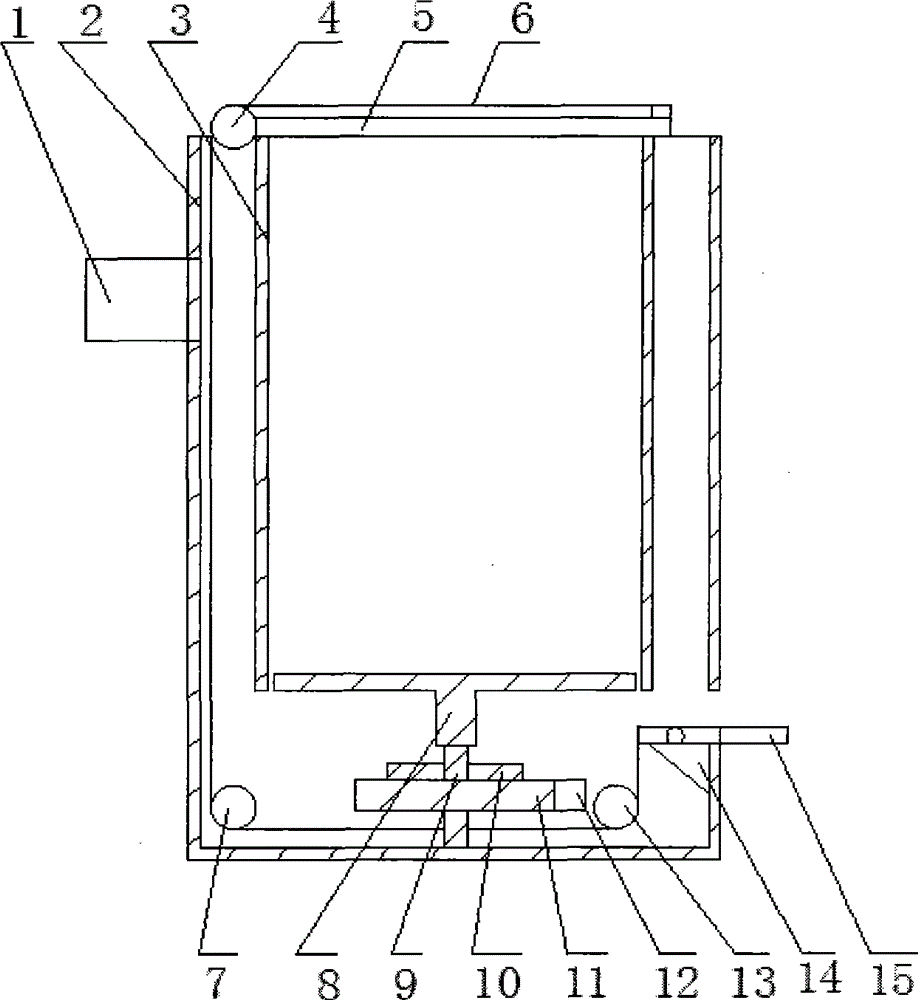

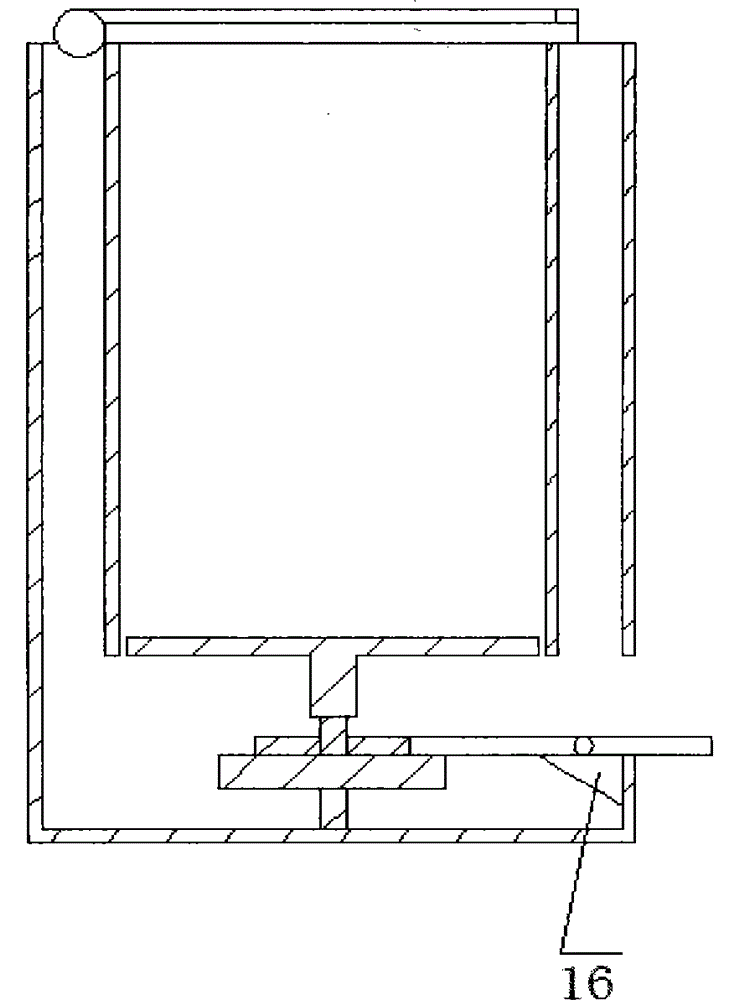

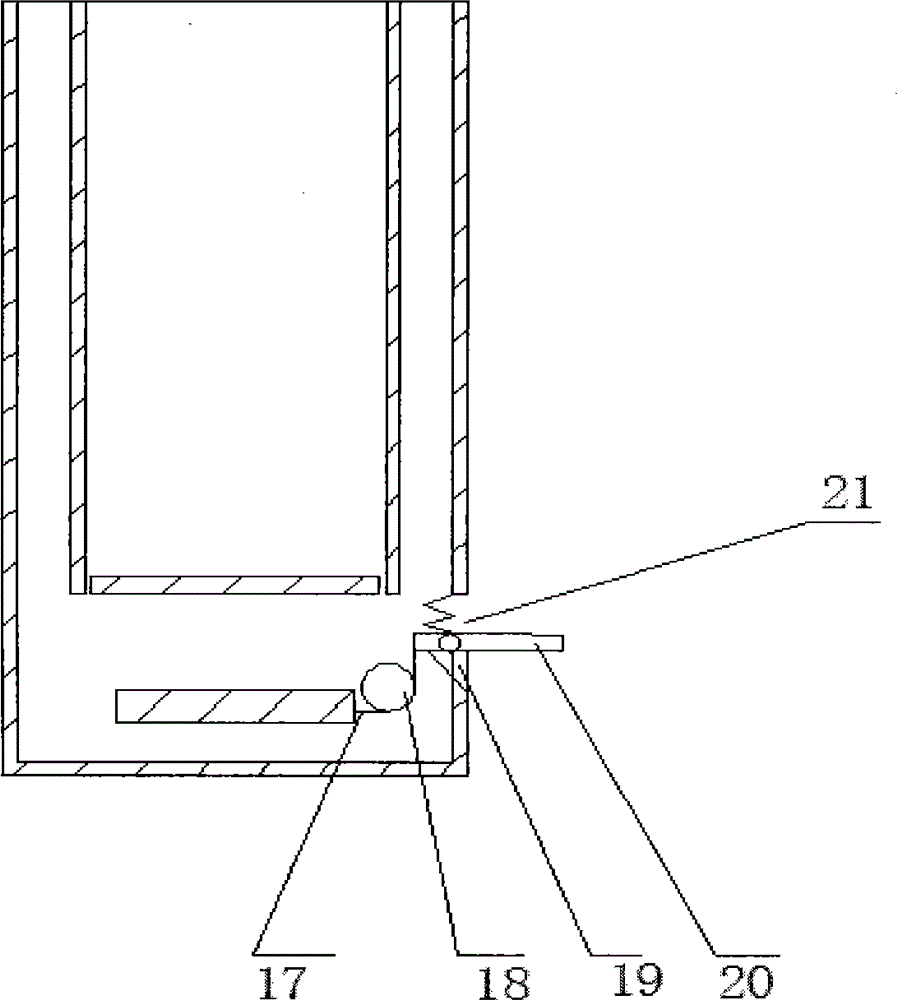

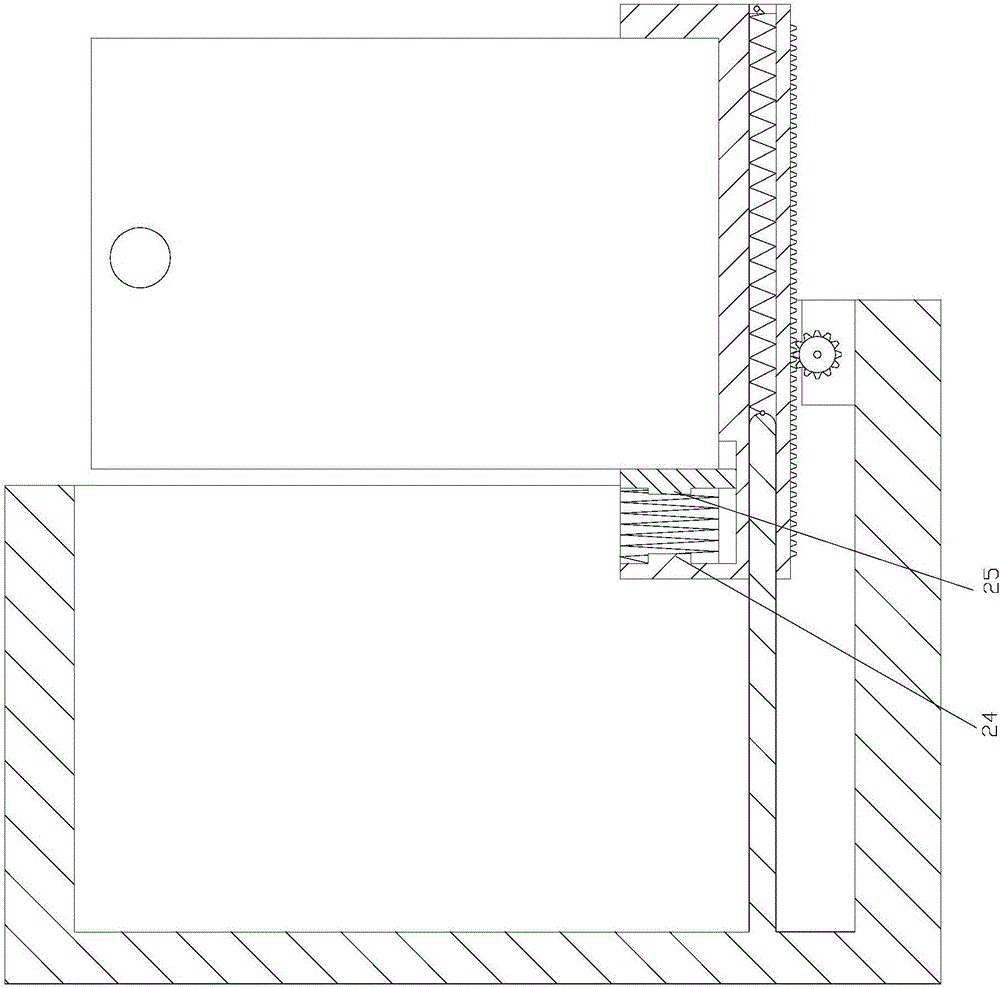

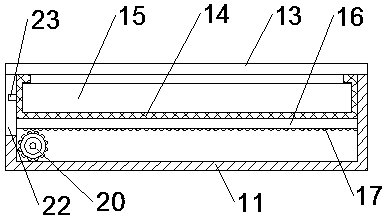

Foot-operated type automatic opening-tightening chip collector

InactiveCN104058162ARealize automatic removalRealize the function of automatic tight mouthRefuse receptaclesLidsEngineeringWire rope

The invention relates to a foot-operated type automatic opening-tightening chip collector which can realize automatic opening tightening of a collecting bag, automatic moving out of the collecting bag, automatic opening and closing of a collector cover and the placement of the collecting bag, and the collecting bag is attached to the collector. The foot-operated type automatic opening-tightening chip collector comprises a chip collector housing, a chip collector inner housing, a chip collector cover, a head end fixed pulley, an auxiliary fixed pulley, a tail end fixed pulley, a direction changing fixed pulley, an opening-closing pedal support frame, a lifting pedal support frame, a rotary pedal support frame, an opening-closing pedal, a lifting pedal, a rotary pedal, a collecting bag groove, a rotary table, a gear, a rack, a shaft, an opening-closing steel wire rope, a rotary steel wire rope and a return spring. According to the foot-operated type automatic opening tightening chip collector, the rotary table can be moved vertically, so that the function of moving the collecting bag out of the chip collector automatically can be realized; the rotary table is rotatable, so that the function of tightening the opening of the collecting bag automatically can be realized; through the steel wire rope pulley mechanism, the function of the opening and closing the chip collector cover automatically can be realized.

Owner:JIAMUSI UNIVERSITY

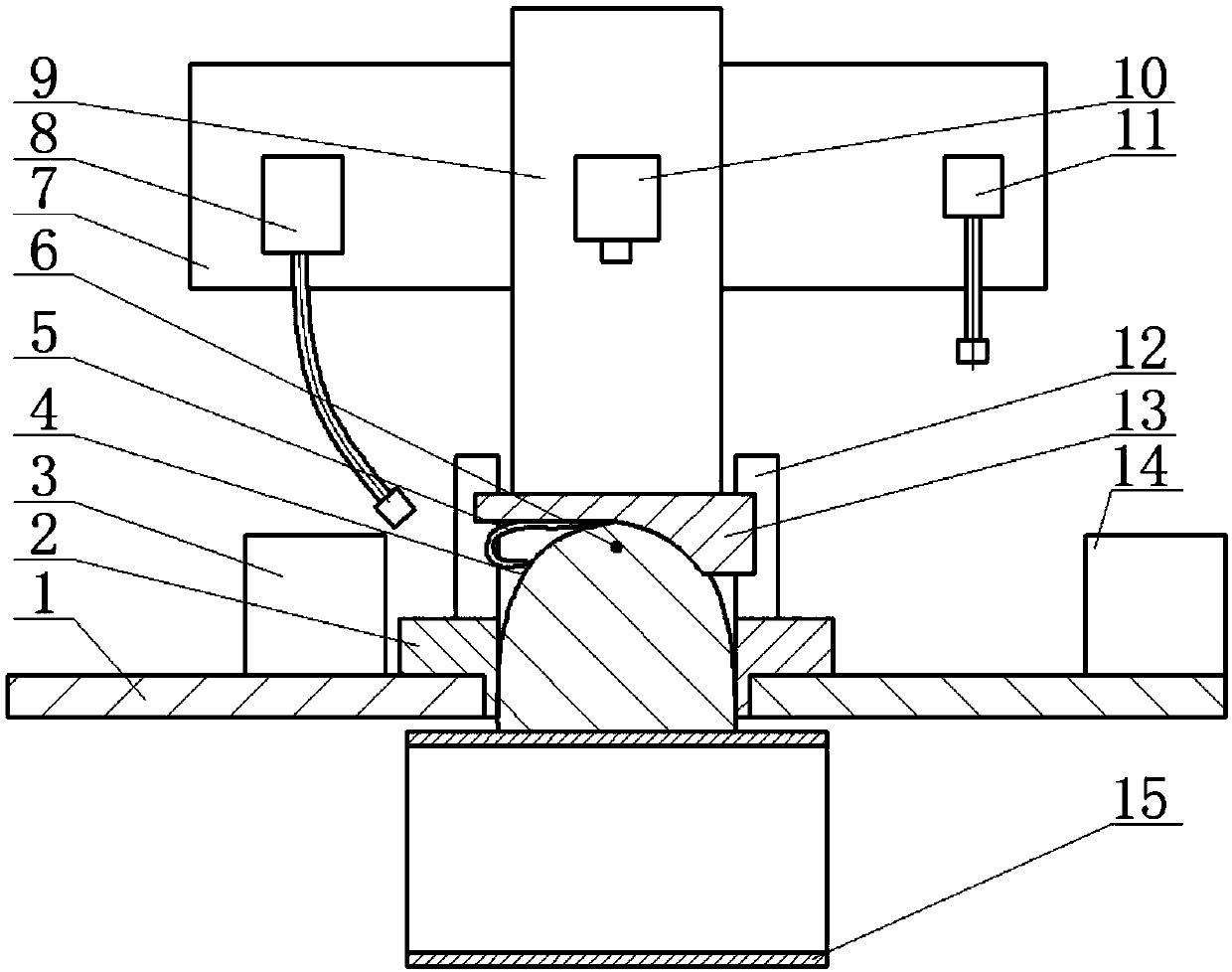

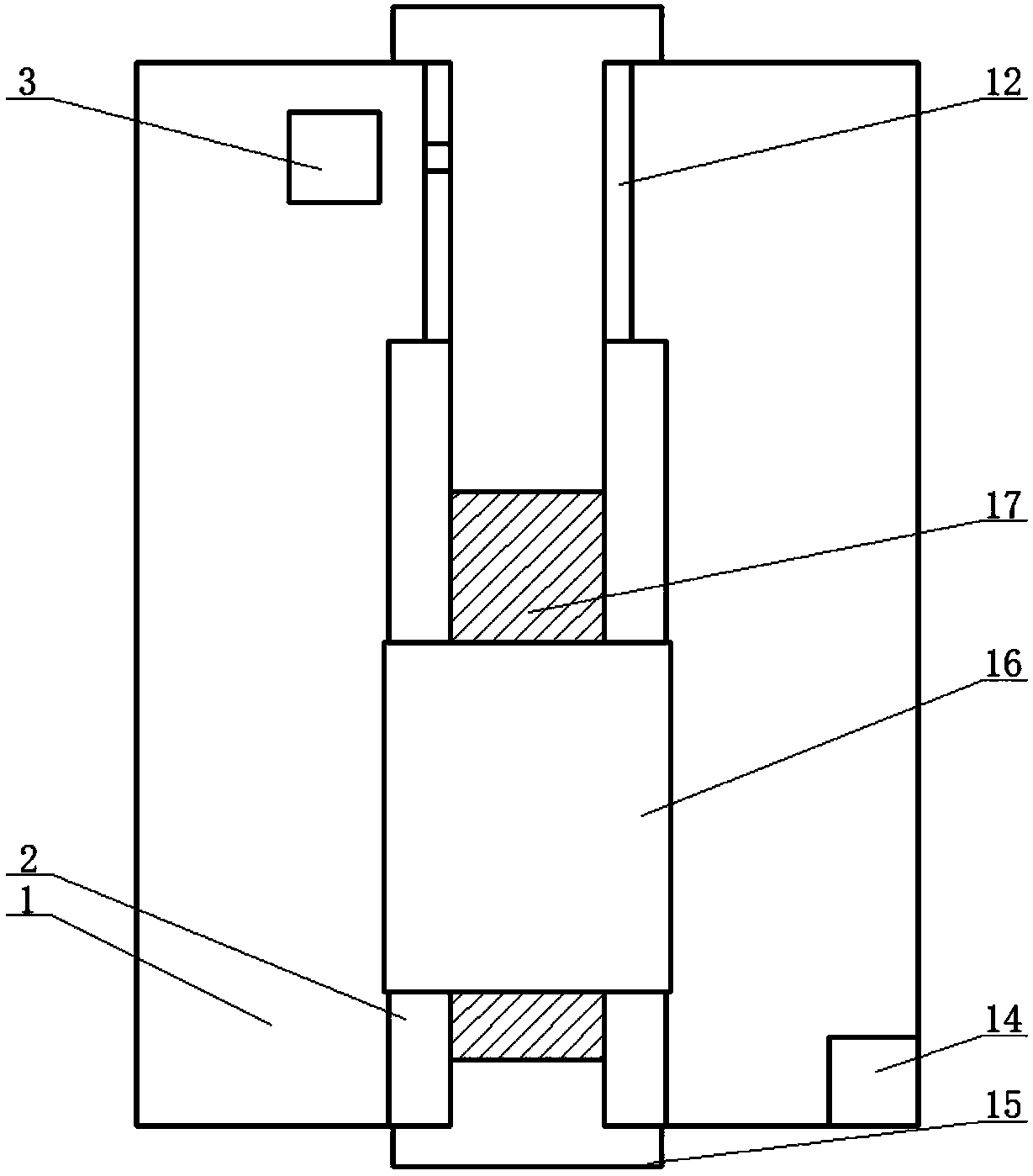

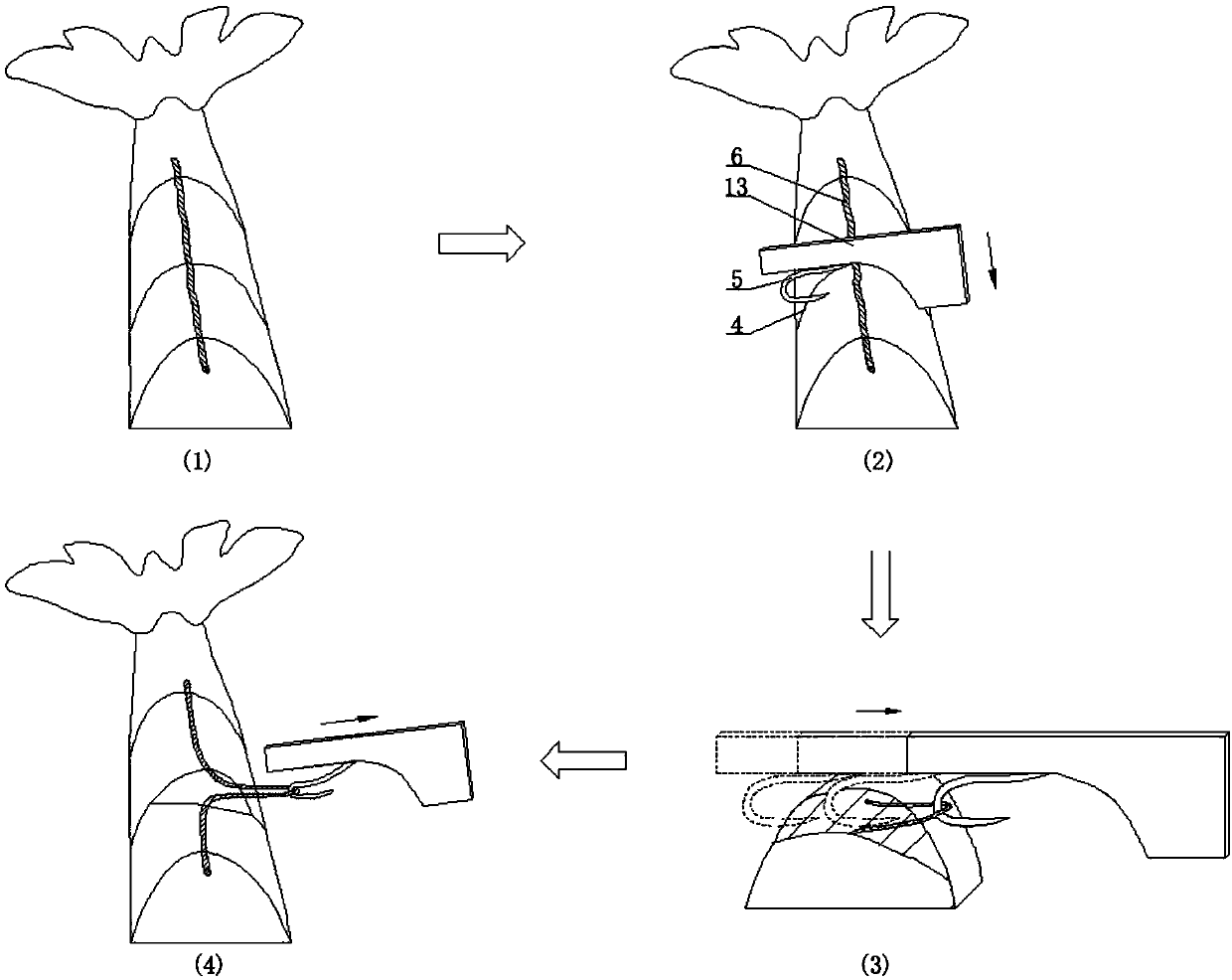

Device and method for automatically removing shrimp lines

ActiveCN109588466AGood removal effectIntegrity guaranteedShrimp/lobster processingShrimpColor recognition

The invention belongs to the field of mechanical design and relates to a device and method for automatically removing shrimp lines. According to the device and the method, by the use of a color difference between a shrimp section and the surrounding and the adoption of an optical fiber sensor for color recognition, a cutter is precisely located to a penultimate shrimp section from the shrimp tail.A special cutter is adopted, which has an arc-shaped edge fitted to the shape of the shrimp back; a small opening is formed in the shrimp back, and then the shrimp line is hooked out from the side ofthe shrimp with a shrimp line hook. The shrimp line hook is made of a shape memory alloy, and the shrimp line hook is in an open state at normal temperature and is in a closed state at a high temperature; when the shrimp line hook hooks the shrimp line, the temperature of the shrimp line hook is raised, and the shrimp line hook is closed to slightly clamp the shrimp line. The device is simple instructure and convenient to use and can ensure that the shrimp line cannot fall off in the hooking process and guarantee the integrity of a shrimp.

Owner:DALIAN UNIV OF TECH

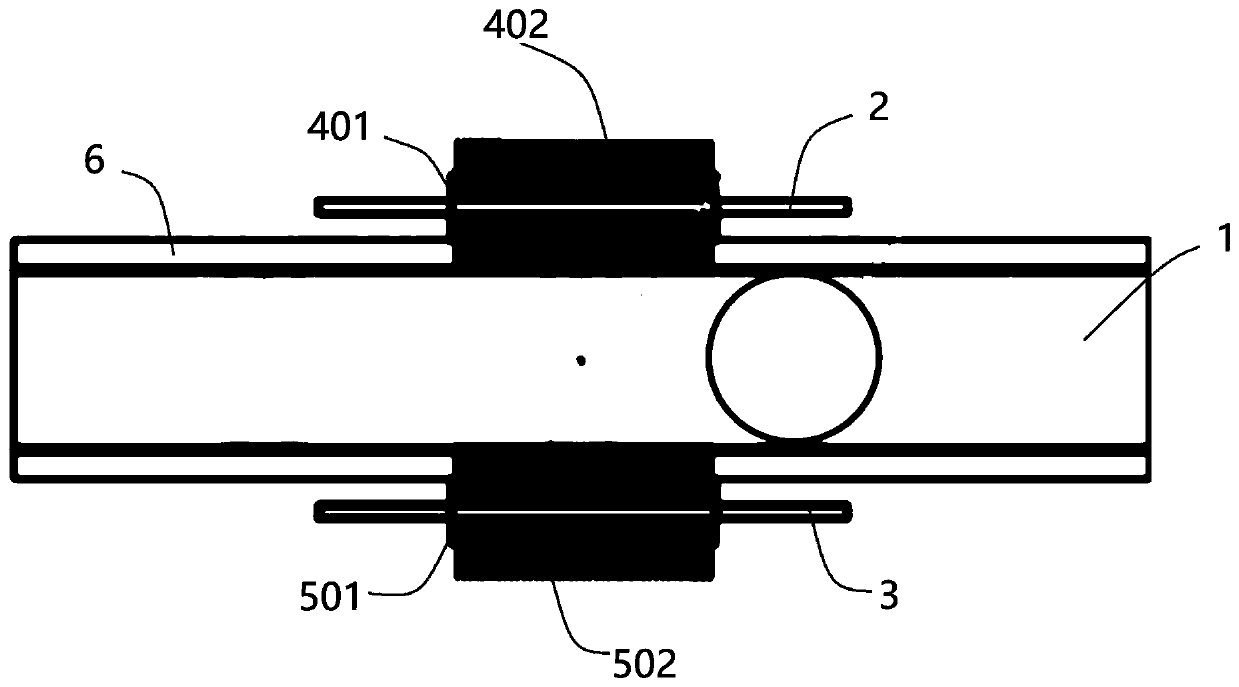

Pin bending device

ActiveCN108687264ASolve the problem of large deviation of bending degreeGuarantee the quality of production and processingEngineeringElectronic component

The invention relates to the field of manufacturing of electronic components, and discloses a pin bending device. The pin bending device comprises a feeding conveying belt provided with a metal blockand a plurality of through holes which are arranged at intervals. A bending mechanism is arranged above the feeding conveying belt. A conveying table and a slidable ejector rod are arranged below thefeeding conveying belt. A magnetic insertion block is slidably arranged on the conveying table and is located on the metal block. An oblique plate is hinged to the front end of the conveying table. The end, away from the conveying table, of the oblique plate is hinged to the ejector rod. An airbag which intermittently abuts against the oblique plate is arranged under the oblique plate and is connected with an air inlet pipe and an air outlet pipe. An air inlet one-way valve is arranged on the air inlet pipe. An air outlet one-way valve is arranged on the air outlet pipe. A feeding table is arranged on the ejector rod and right faces one through hole in the feeding conveying belt. A shifting mechanism right facing the ejector rod is arranged above the feeding conveying belt. By adoption ofthe pin bending device, the problem that certain pins of electronic components are excessively bent, the bending degrees of multiple pins are inconsistent, and consequentially, bending deviations arecaused is solved.

Owner:泸州龙芯微科技有限公司

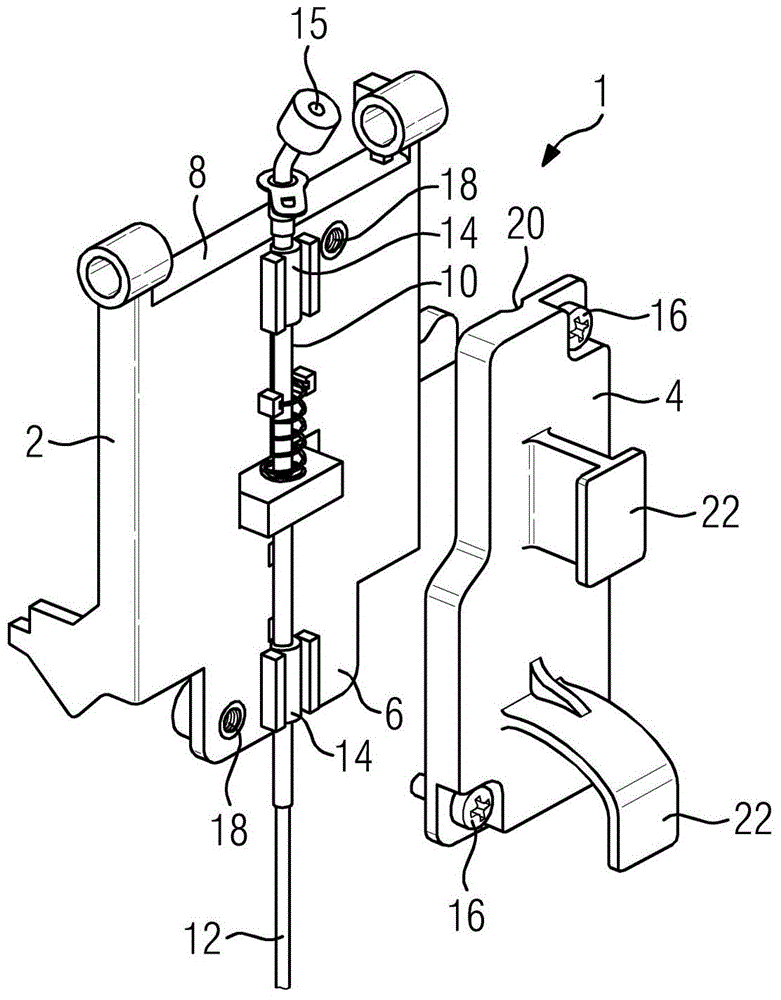

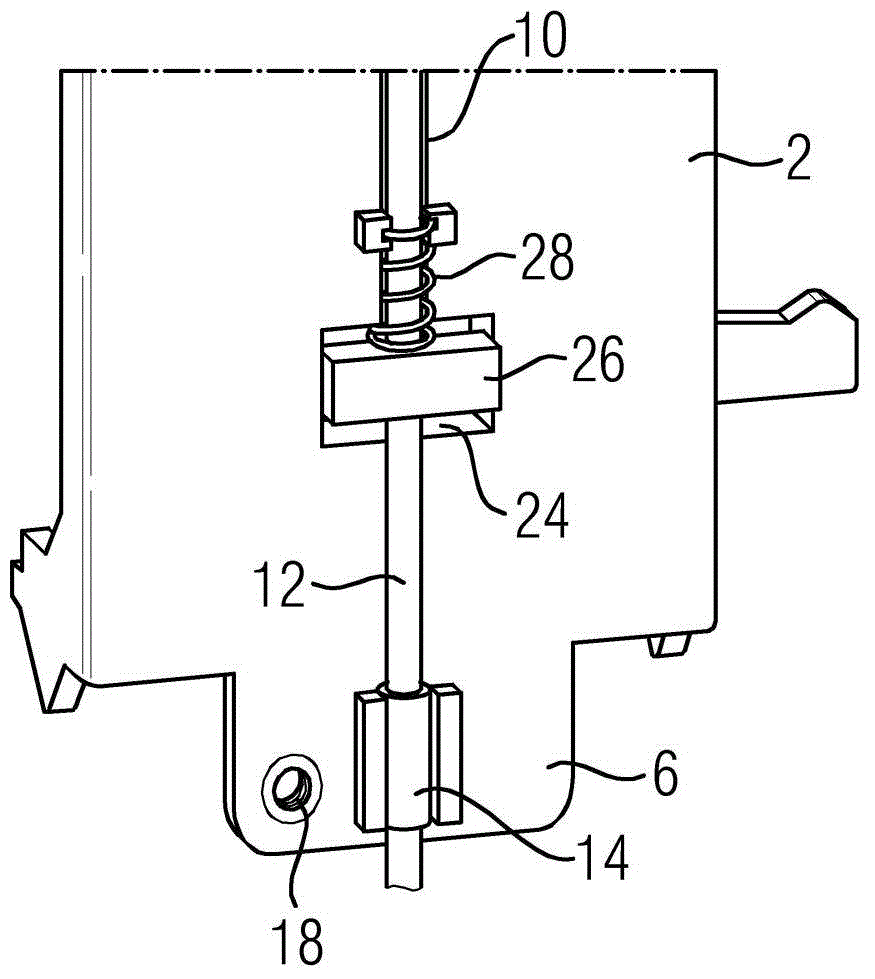

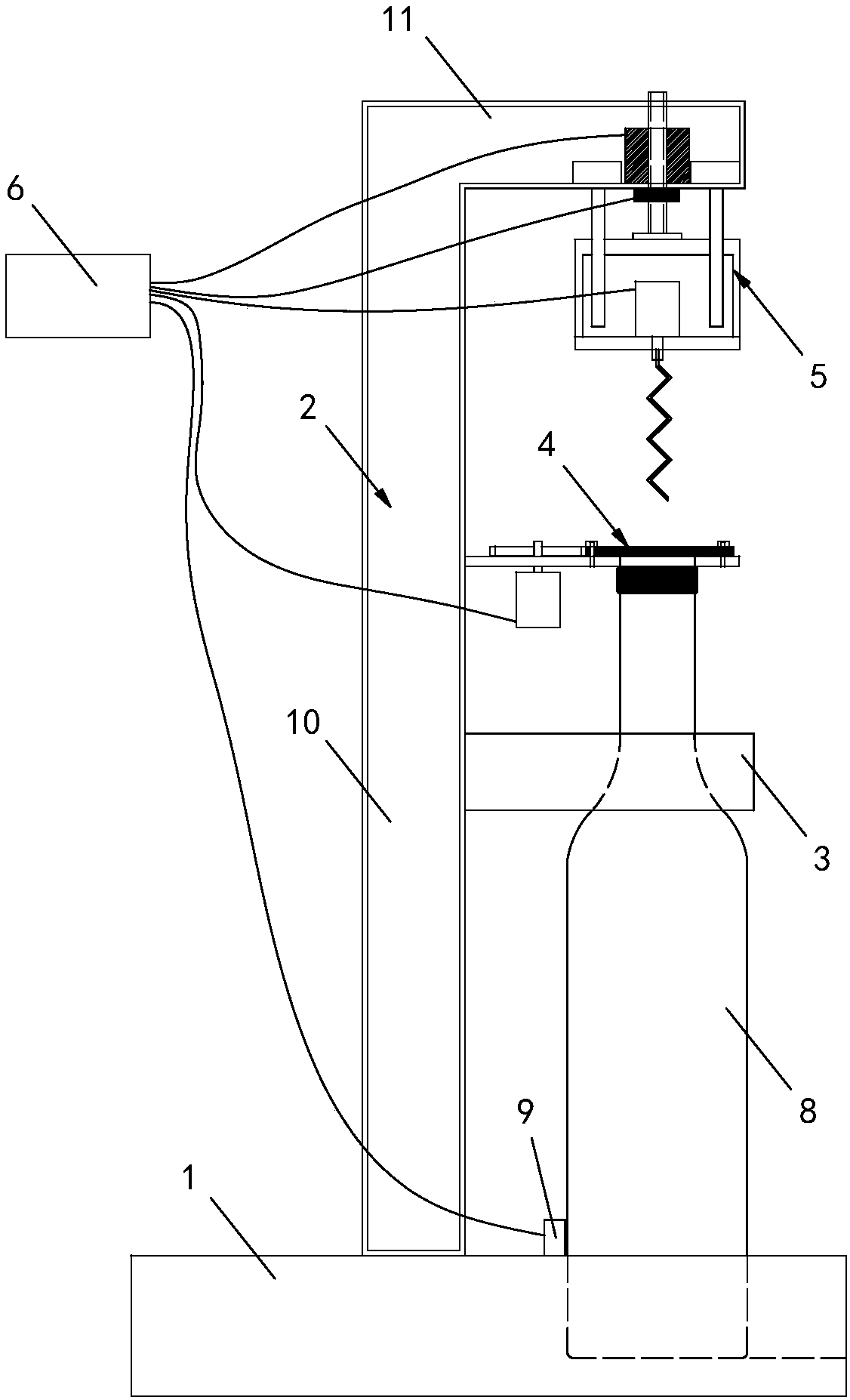

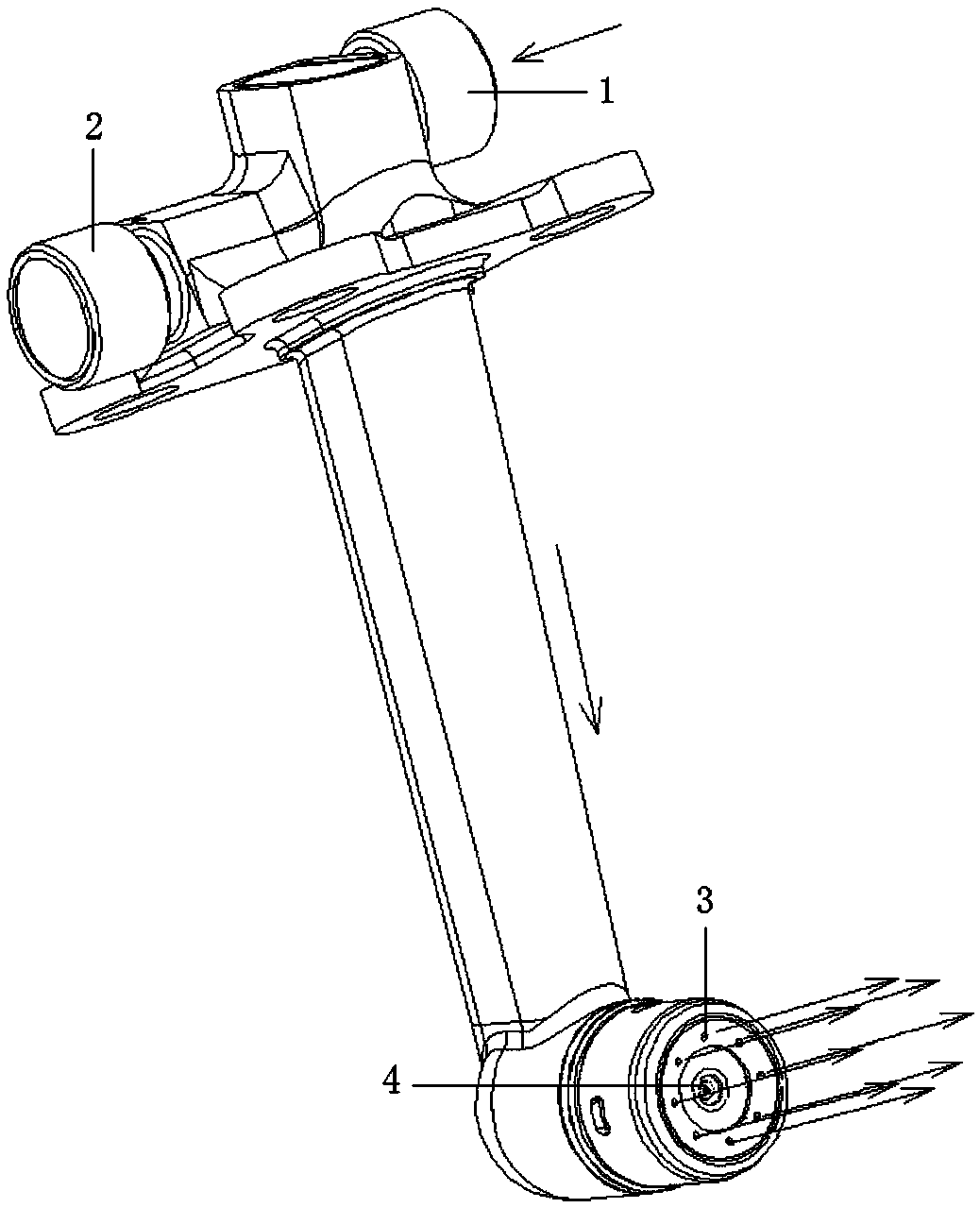

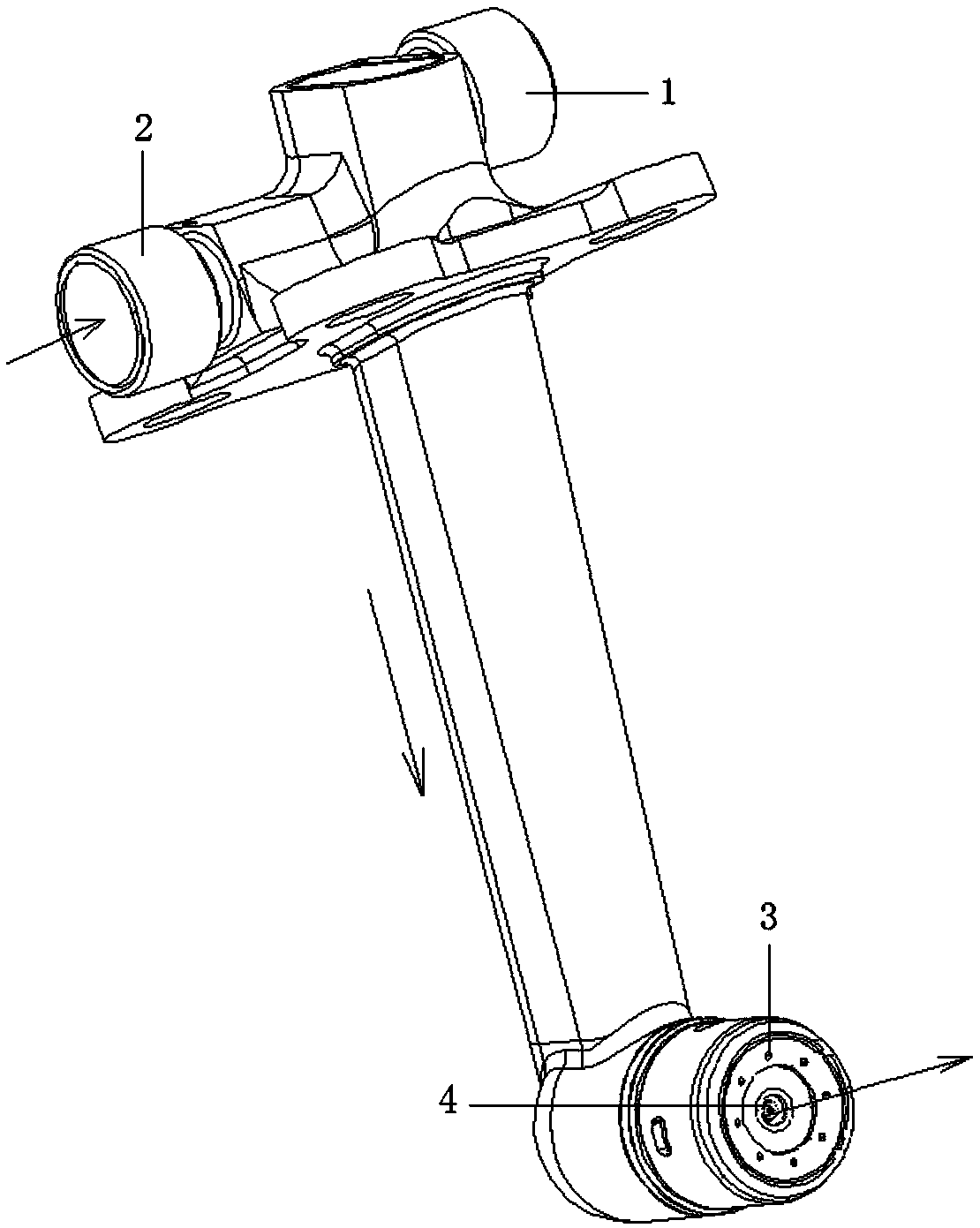

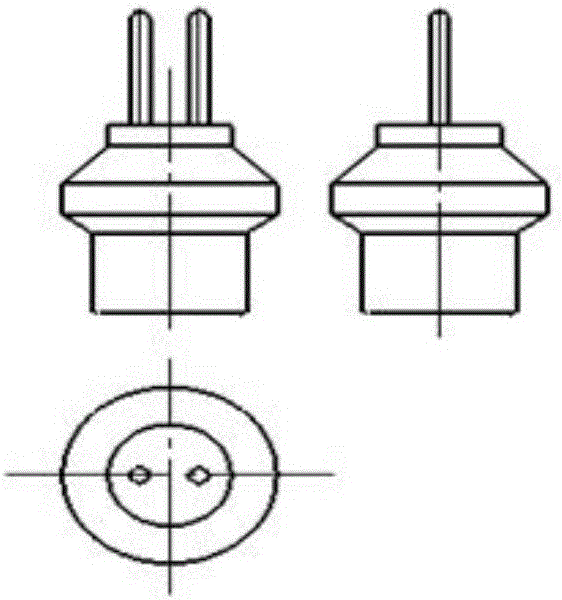

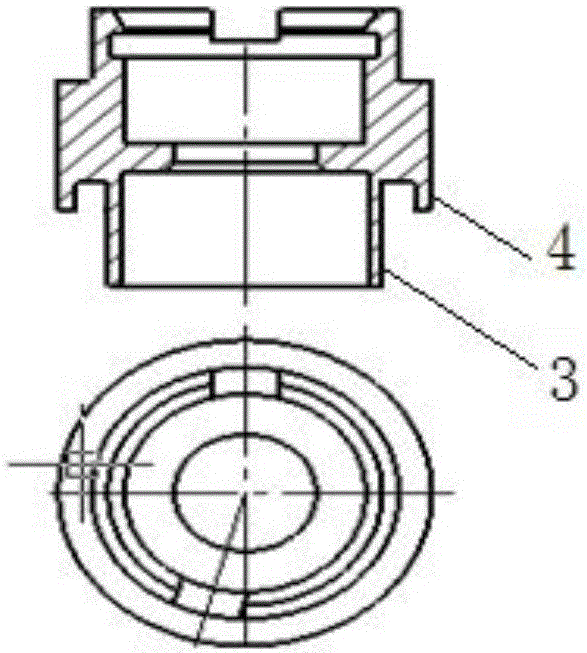

Holding device for a pipetting needle

ActiveCN104049092AGood supportRealize automatic removalLaboratory glasswaresMaterial analysisEngineeringMechanical engineering

The invention relates to a retaining device (1) for a hollow needle (12) of a pipetting device in an automatic analysis apparatus. The retaining device (1) comprises a first retaining element (2), which can be secured releasably on a base plate that is movable in an automated manner, and a second retaining element (4), which is connected to the first retaining element (2), wherein at least one bearing bushing (14) is provided, which is fixed between the retaining elements (2, 4) and in which the hollow needle (12) is mounted.

Owner:SIEMENS HEALTHCARE DIAGNOSTICS PRODS

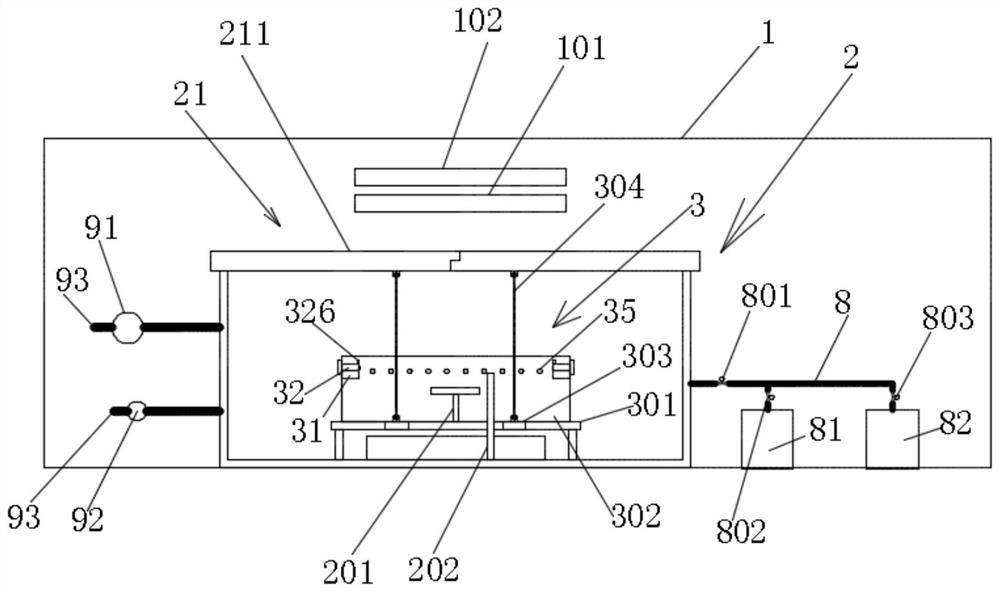

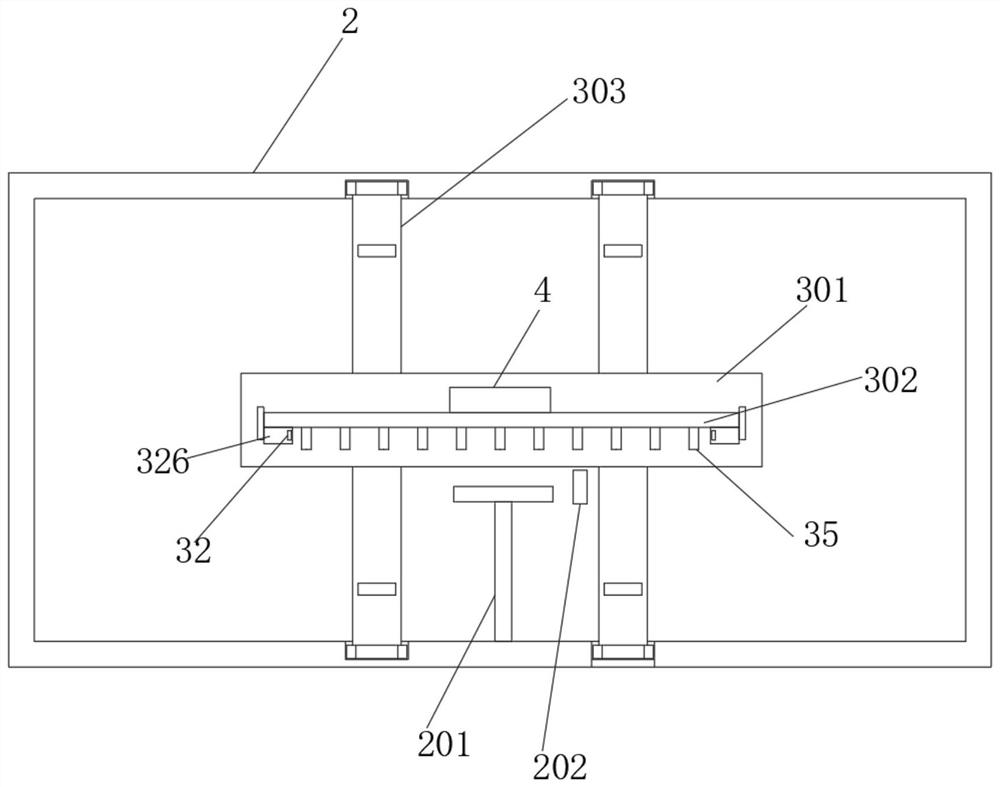

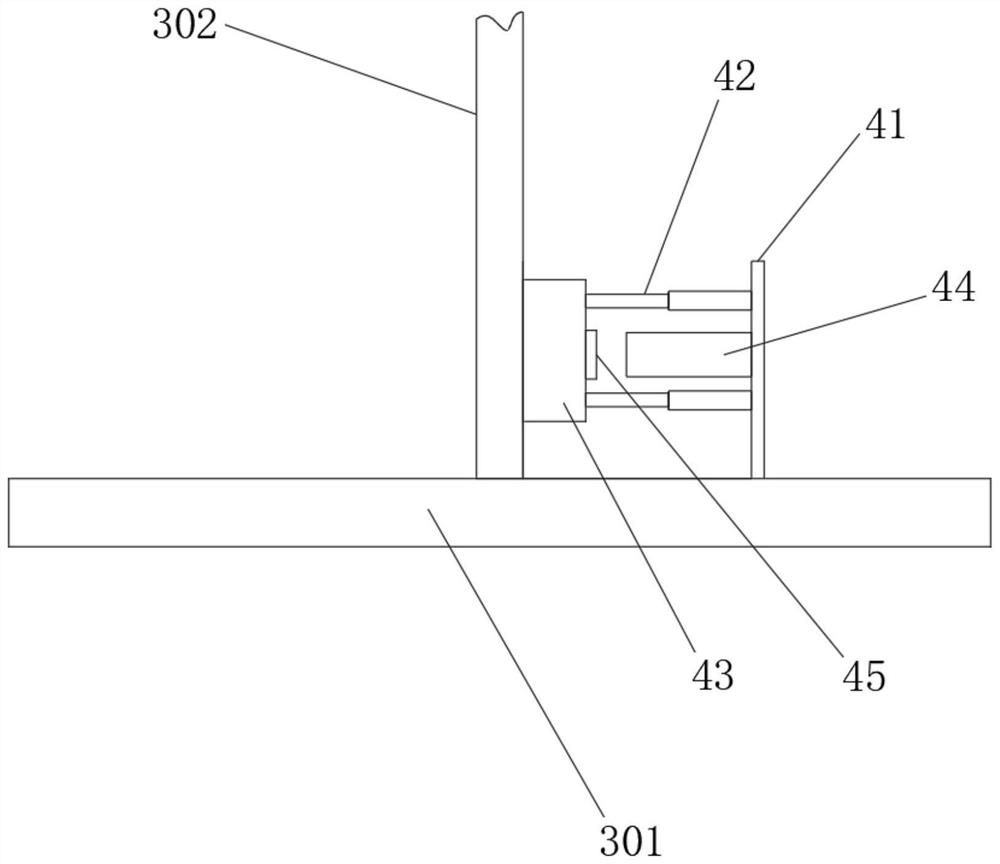

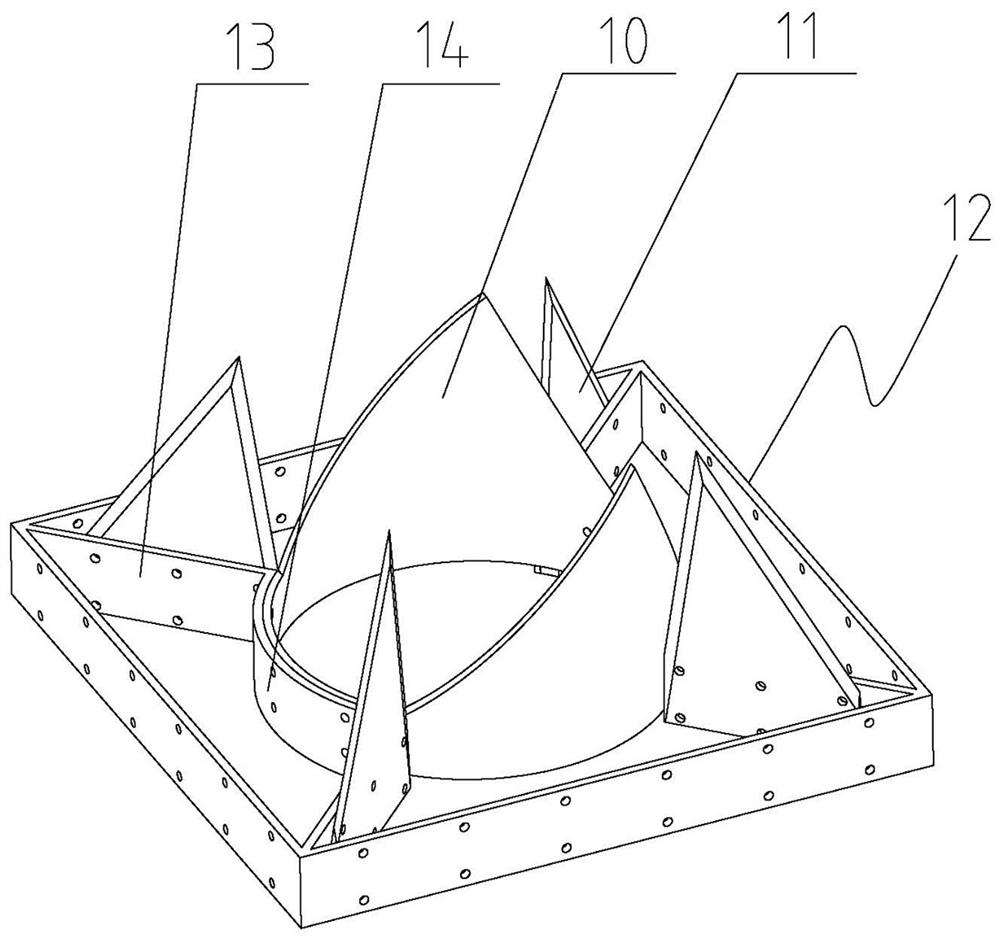

Fireproof cable combustion test device

ActiveCN112305147AImprove test efficiencyShorten the timeChemical analysis using combustionElectrical connectionStructural engineering

The invention relates to the technical field of cable test equipment, in particular to a fireproof cable combustion test device which comprises a test chamber, a test box and a controller, the test box is arranged in the test chamber, a cable fixing mechanism, a combustion mechanism and a water spraying mechanism are arranged in the test box, and the cable fixing mechanism comprises a fixing frame, a connecting plate and a clamping plate and is used for clamping and electrifying a cable; the base is provided with an impact mechanism, and the impact mechanism comprises a supporting plate, an elastic telescopic rod, an impact carbon block and an electromagnet and is used for providing impact force for the cable; the combustion mechanism and the water spraying mechanism are both arranged in the test box, and the combustion mechanism is used for combusting a cable; the water spraying mechanism is used for spraying the cable; and the controller is electrically connected with the combustionmechanism and the water spraying mechanism so as to control starting and stopping of the combustion mechanism and the water spraying mechanism. Mounting and dismounting of a cable combustion test canbe facilitated, and the test efficiency is improved.

Owner:广西顺业线缆有限公司

Silicon wafer conveying equipment on sputtering table and using method

PendingCN111403327AImprove processing efficiencyAvoid damageFinal product manufactureSemiconductor/solid-state device manufacturingEngineeringMachine

The invention discloses silicon wafer conveying equipment on a sputtering table, and relates to the technical field of silicon wafer processing. According to the silicon wafer conveying equipment on the sputtering table, a machine body is arranged on a plane, conveying wheels are arranged in the machine body, and the conveying wheels are fixedly connected with the machine body; a placing device isarranged on one side of the machine body, is connected with the machine body, and comprises a shell arranged above the machine body, the shell is connected with the machine body in a matched manner,and the interior of the shell is hollow; placing plates are arranged in the shell, and a gap is formed between the placing plates; the guide-out device is arranged in the machine body, is fixedly connected with the machine body, and comprises a guide-out plate arranged in the machine body, the guide-out plate is matched with the gap of the placing plate, and the guide-out plate can be inserted into the gap of the placing plate; and a driving device is arranged in the machine body. The silicon wafer conveying device is used for solving the problem that in the prior art, silicon wafers collide with a conveying device in the conveying process, the silicon wafers are damaged easily, and the silicon wafer machining efficiency cannot be effectively improved.

Owner:SUZHOU SAISEN ELECTRONICS TECH

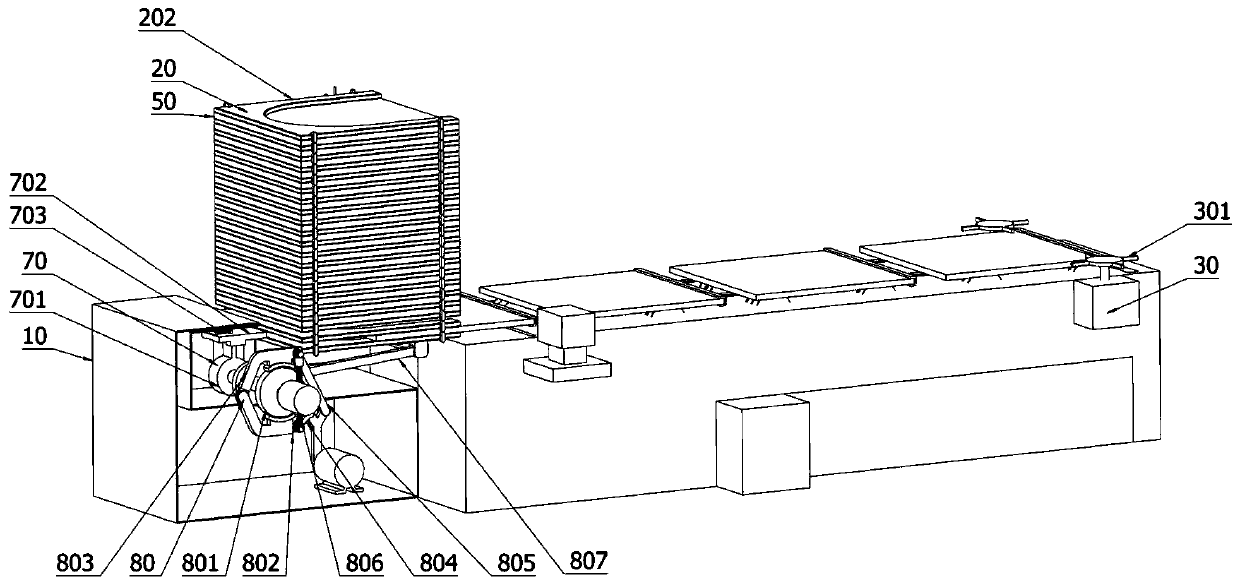

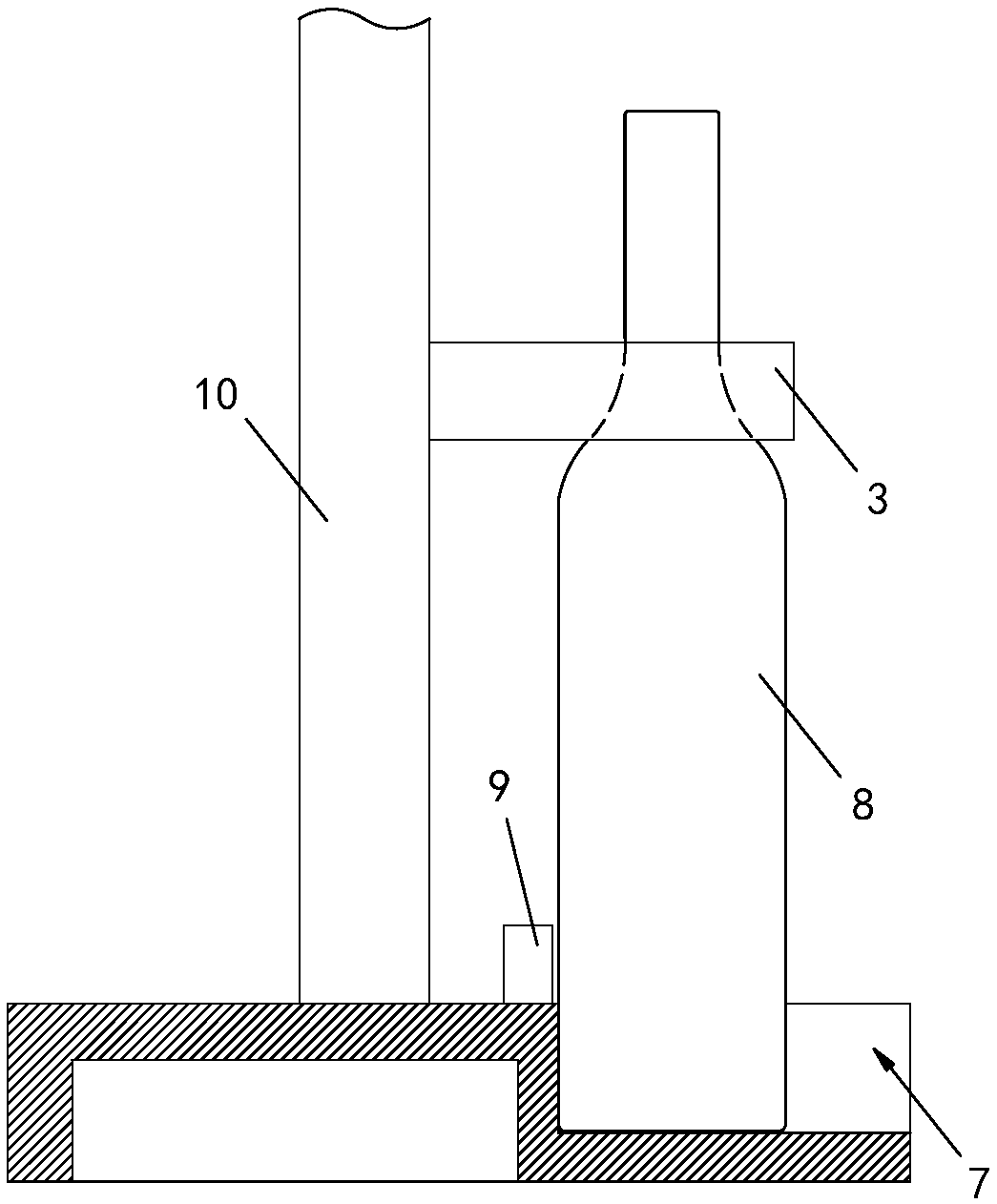

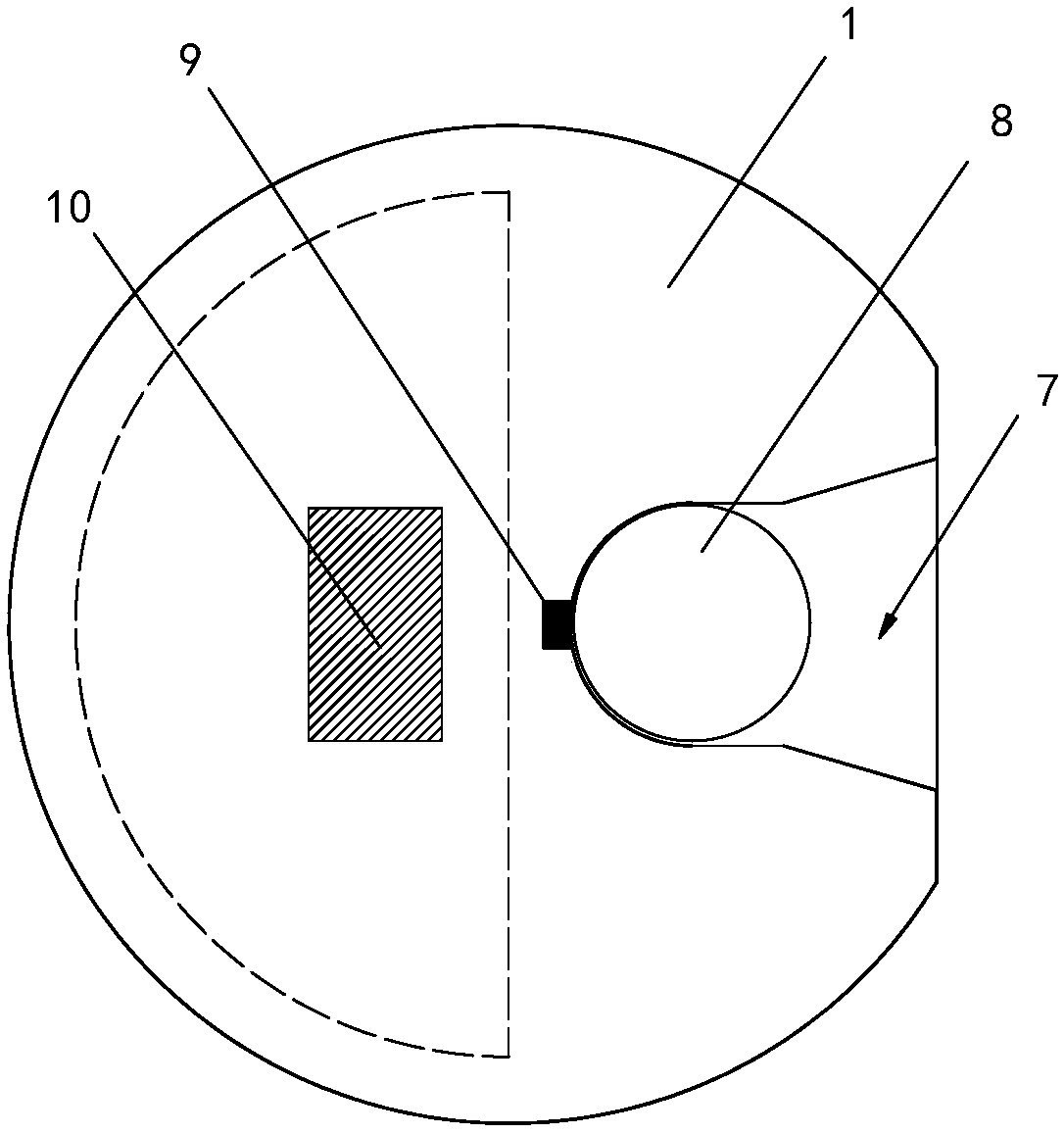

Automatic cork puller for cork of wine bottle

InactiveCN108083205ARealization of automatic plug removalRealize automatic removalBottle/container closurePower operated devicesPulling actionControl circuit

The invention discloses an automatic cork puller for a cork of a wine bottle. The automatic cork puller comprises a base, an L-shaped bracket, a bottle pressing plate, a sealing film removing mechanism, a cork pulling mechanism and a control circuit board. The bottle pressing plate, the sealing film removing mechanism, and the cork pulling mechanism are all installed on the L-shaped bracket and arranged in sequence from bottom to top. A wine bottle is placed on the base. The L-shaped bracket is arranged on the base. The bottle pressing plate is used for pressing the wine bottle. The sealing film removing mechanism is used for removing a sealing film on the wine bottle. The cork pulling mechanism is used for achieving automatic cork pulling. After the wine bottle is placed on the base, thebottle pressing plate is matched with a wine bottle storing groove in the base to fix the wine bottle well, the sealing film removing mechanism is controlled by the control circuit board to remove thesealing film of the wine bottle automatically, automatic cork pulling action is achieved through the cork pulling mechanism under the control of the circuit board, and the automatic cork pulling process of the cork is achieved through the automatic cork puller.

Owner:王馨浩

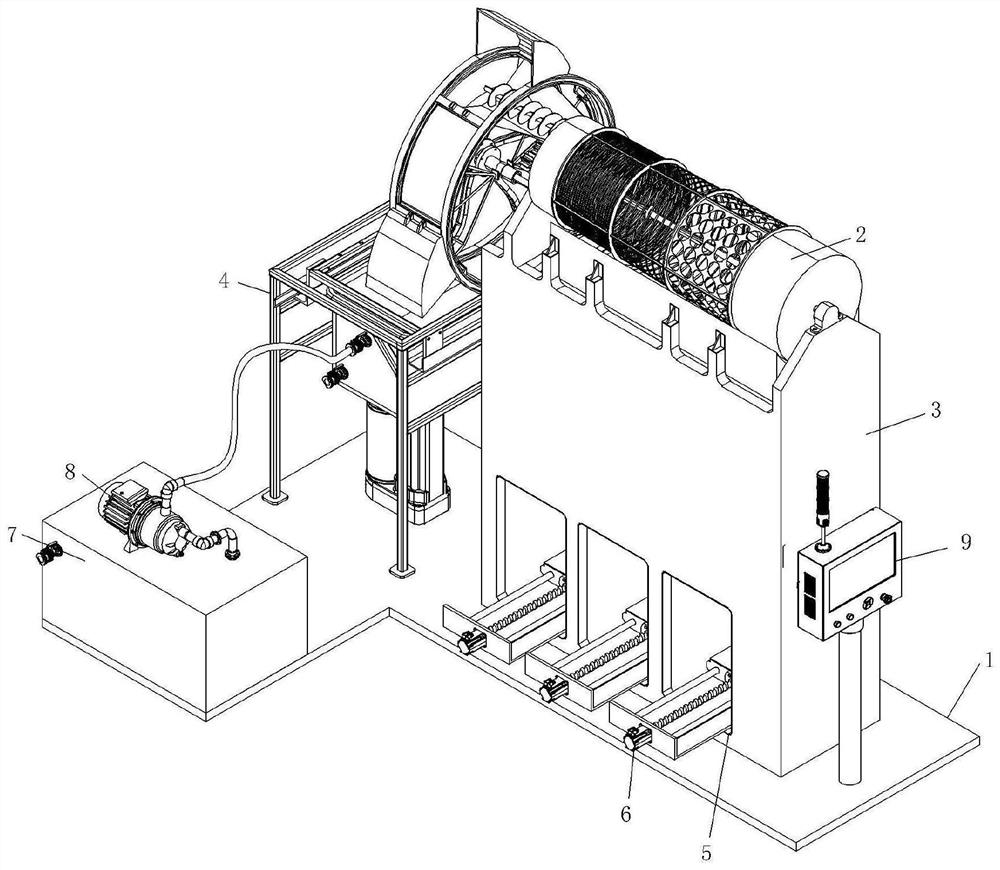

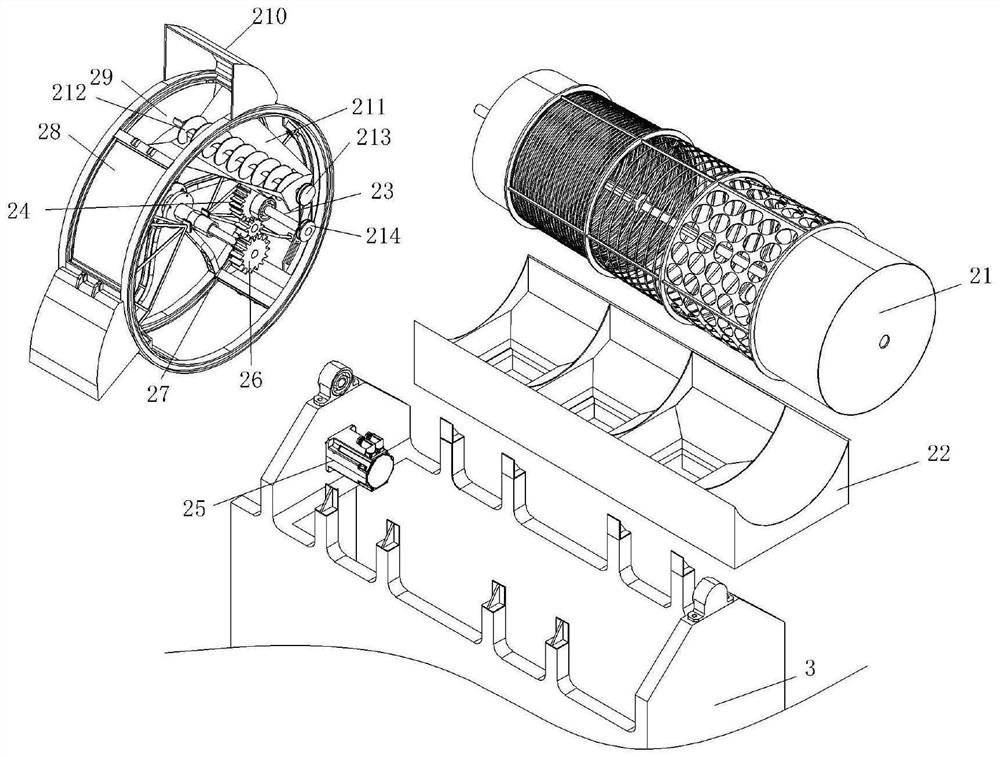

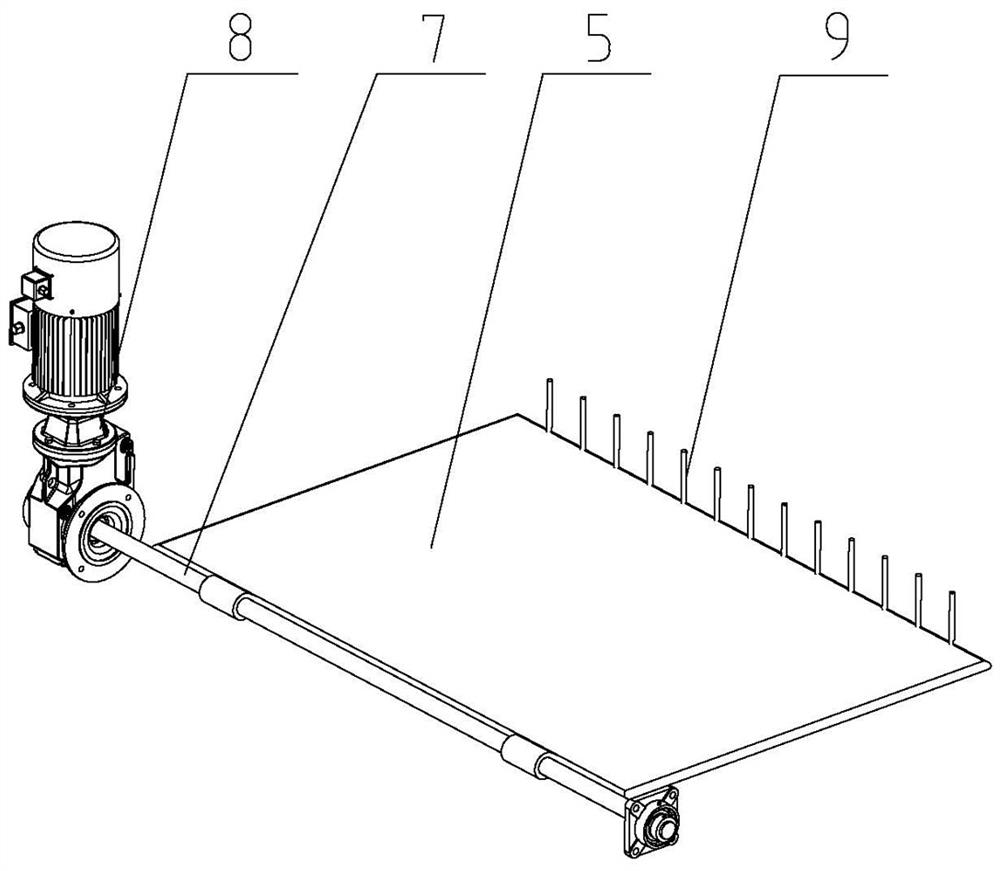

Agricultural efficient forest tree seed cleaning and grading device

InactiveCN112170364APreliminary cleaningRealize automatic removalSievingScreeningAgricultural scienceAgricultural engineering

The invention discloses an agricultural efficient forest tree seed cleaning and grading device which comprises a base, a box body, a grading mechanism, a cleaning mechanism, a discharge hole, discharging mechanisms, a water tank, a water pump and a controller; the box body is arranged on the rear right side of the top end of the base in a vertical direction; the grading mechanism is arranged at the top end of an inner cavity of the box body in a left-right direction. the cleaning mechanism is arranged at the top end of the base and located on the lower left side of the grading mechanism; and the three discharging mechanisms are separately arranged at the bottom end of the inner cavity of the box body from left to right at intervals in a front-back direction. By adopting the agricultural efficient forest tree seed cleaning and grading device, forest tree seed cleaning and grading operation integration can be achieved, and forest tree seeds are cleaned so as to prevent soils on the surfaces of the seeds from blocking meshes of a screen and affecting normal screening and grading of the forest tree seeds; and automatic taking out of the graded forest tree seeds can be achieved, so thatmanual operation items of workers are reduced, and the time and the labor are saved.

Owner:卢俊伟

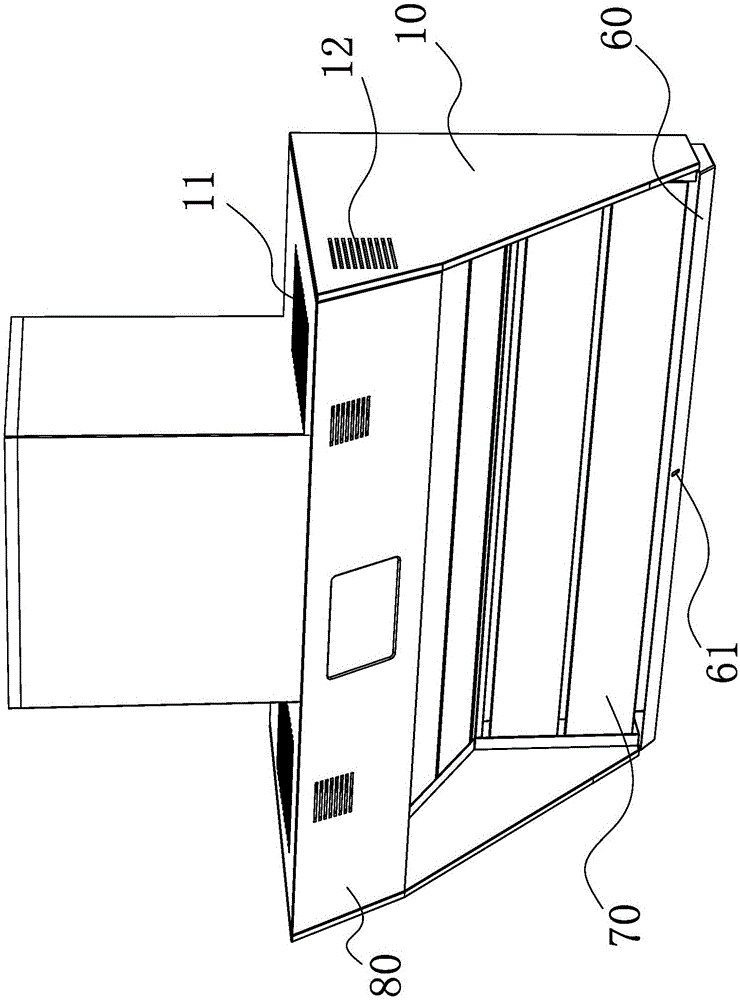

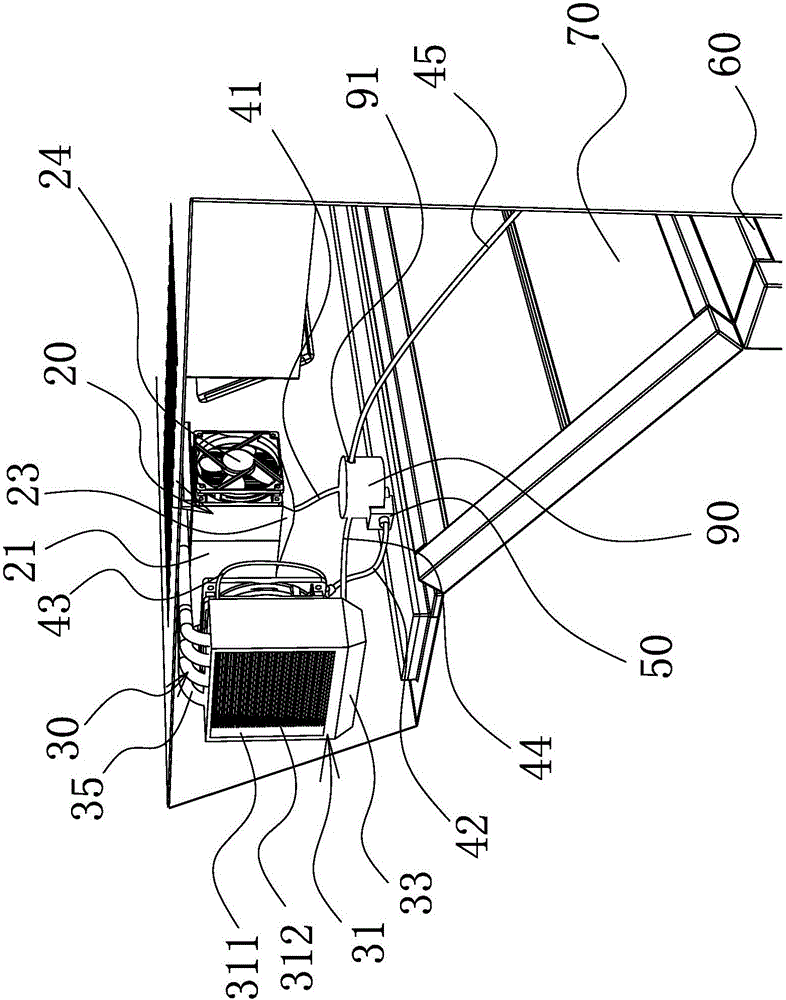

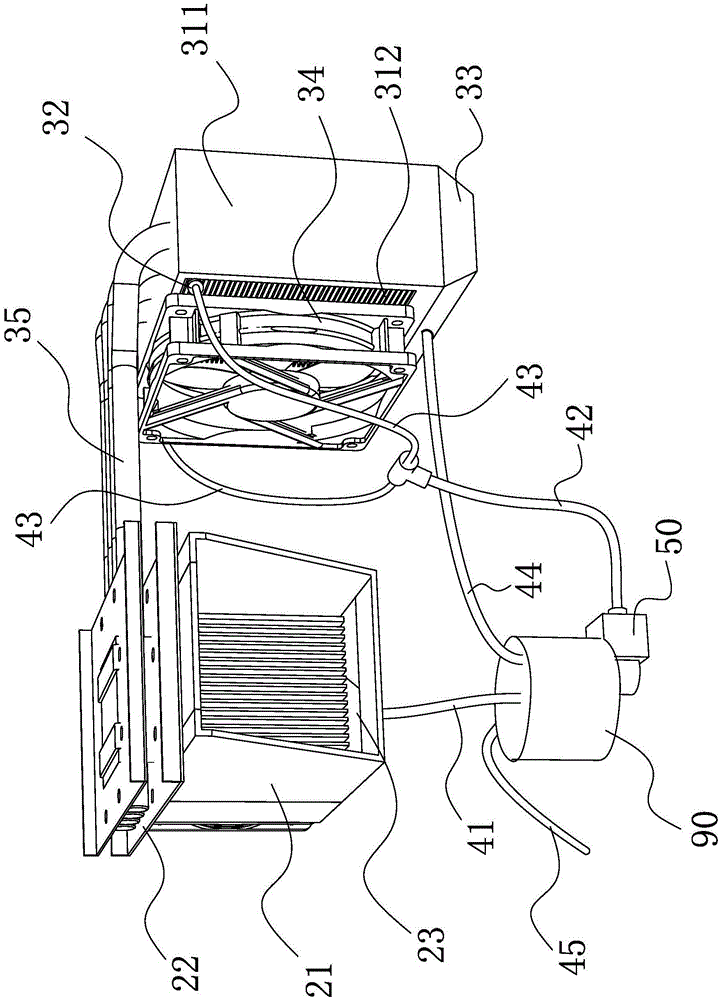

Improved range hood

ActiveCN106196222AButt tightHave storageDomestic stoves or rangesCooking fumes removalElectrical equipmentCondensed water

The invention provides an improved range hood and belongs to the technical field of kitchen electric appliances. The improved range hood comprises a machine shell, at least one refrigerating mechanism, an evaporating mechanism and a water accumulating cup. The refrigerating mechanism is installed on the machine shell. The evaporating mechanism is used for evaporating condensed water to the outside. The water accumulating cup is used for receiving the condensed water generated by the refrigerating mechanism and sending the condensed water into the evaporating mechanism. The improved range hood has the beneficial effect that the condensed water can be automatically removed.

Owner:NINGBO OULIN KITCHEN UTENSILS

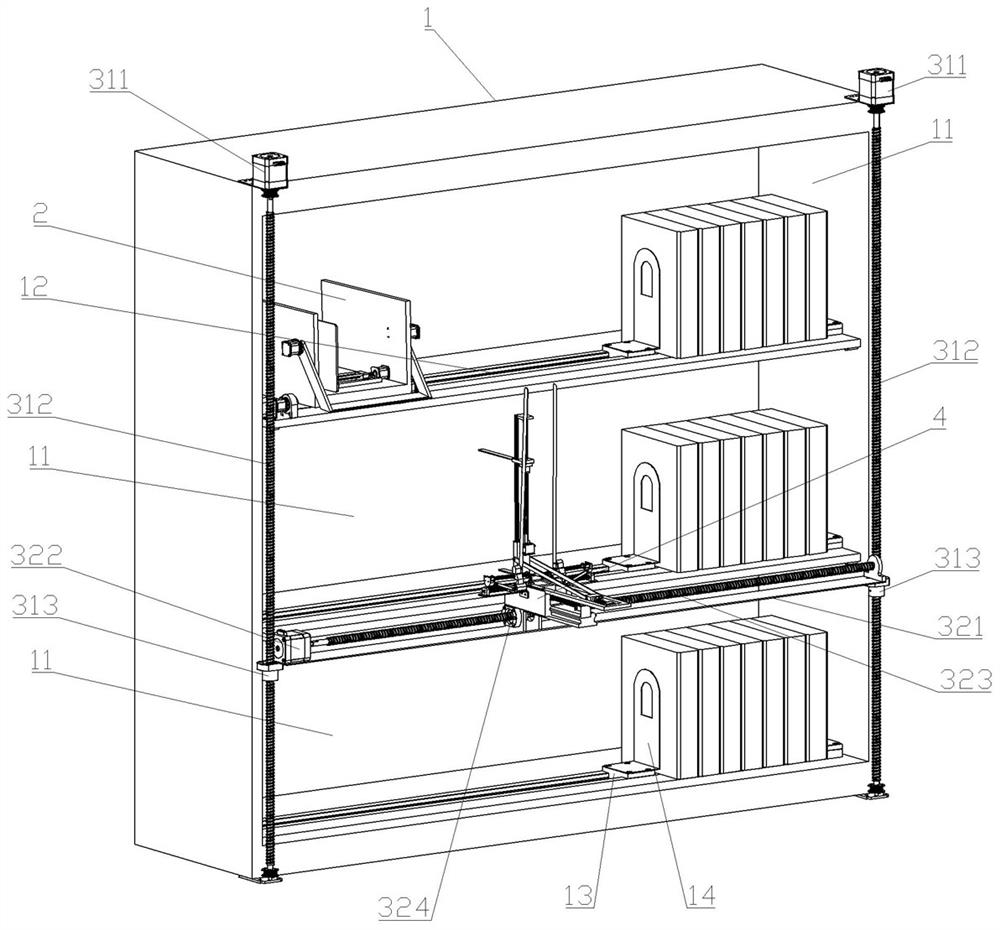

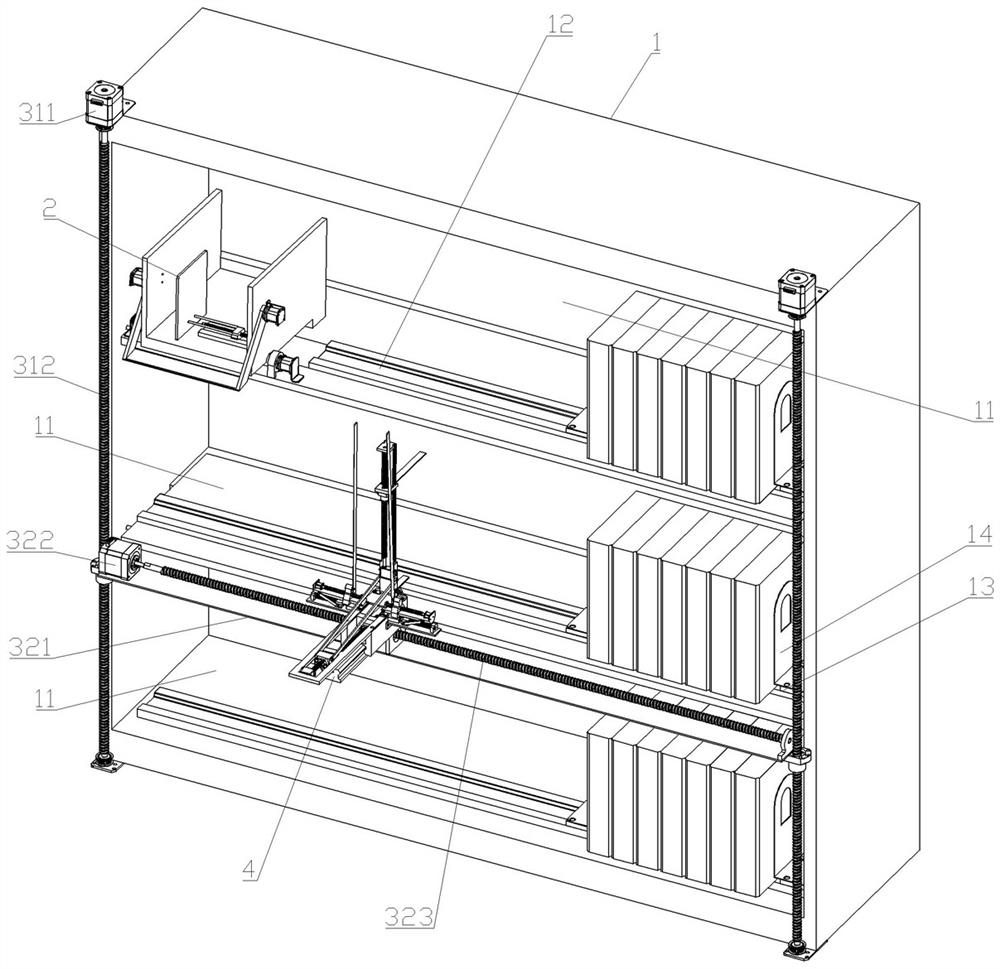

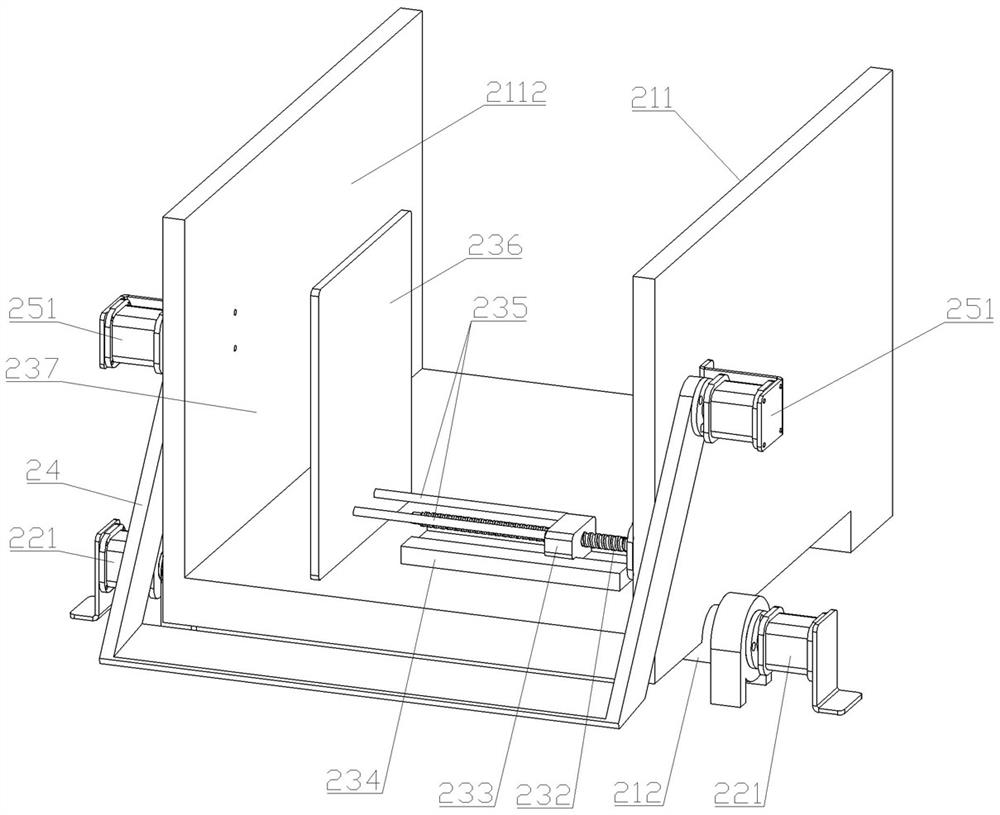

Intelligent taking and returning system for library books

ActiveCN112249569ARealize automatic removalImplement loadingBook cabinetsStorage devicesVertical planeSoftware engineering

An intelligent taking and returning system for library books comprises bookcases, book transfer devices, mechanical claw movement driving mechanisms and mechanical claws; each book transfer device isarranged in any book storage interval and are used for temporarily storing the books; the mechanical claw movement driving mechanisms are arranged at the front ends of the bookcases; and the mechanical claws are associated with the mechanical claw movement driving mechanisms and are driven by the mechanical claw movement driving mechanisms to move in a vertical plane, so that the books can be taken out of or put into any book storage interval through openings A. The intelligent library book taking and returning system is applied to book management of a library, on one hand, rapid retrieval andpositioning of specified books can be achieved, the book borrowing and returning efficiency is greatly improved, and on the other hand, the books in the bookcases can be automatically taken out and put in, and manpower consumption of librarians and readers is reduced.

Owner:NANHUA UNIV

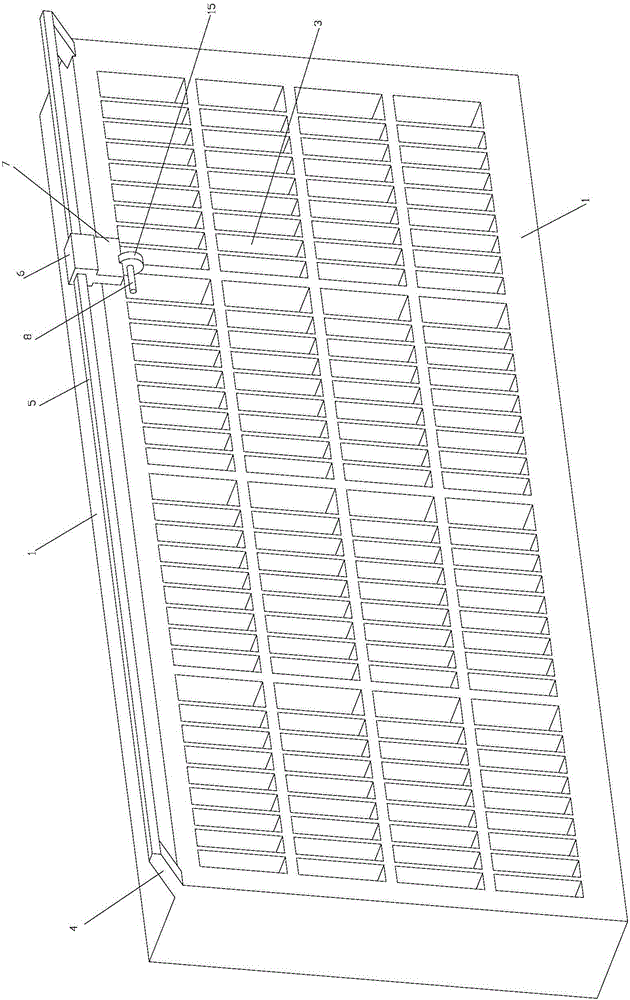

Compact shelf mechanism for taking out folder

Owner:NINGBO XINWANBAO SAFE EQUIP

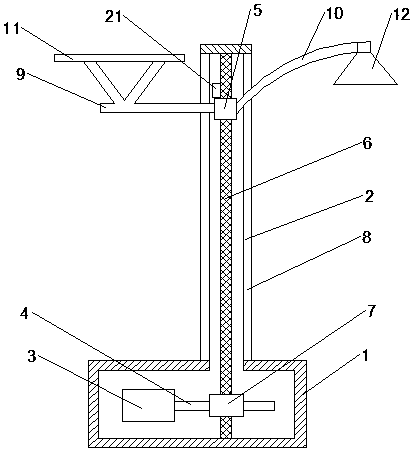

Solar street lamp convenient to maintain

InactiveCN110762464AAvoid working at heightsEasy to operateMechanical apparatusLighting support devicesStructural engineeringSolar street light

The invention discloses a solar street lamp convenient to maintain. The solar street lamp comprises a base and a main column arranged on the base, wherein a cavity is formed in the interior of the base; a servo motor is arranged in the cavity; the output end of the servo motor is connected with a worm through a coupler; a screw rod sleeve is arranged in the inner cavity of the main column; a screwrod is arranged in the screw rod sleeve; the screw rod and the screw rod sleeve are connected through threads; a worm wheel meshed with the worm is arranged on the screw rod; the bottom of the lead screw is rotatably mounted at the bottom of the inner cavity of the base; the left side of the lead screw sleeve is fixedly connected with a first support rod; the right side of the lead screw sleeve is fixedly connected with a second support rod; the first support rod is connected with a solar panel frame; and the second support rod is connected with a lamp body. The solar street lamp has the beneficial effects that the solar street lamp is simple in structure and convenient to maintain, parts of the solar street lamp are replaced conveniently, and the safety performance is high.

Owner:JIANGSU MINGYU NEW ENERGY RESOURCES

Automatic feeding mark pressing wire cutting machine

PendingCN109434915APrecise deliveryRealize automatic indentation and tangentMetal working apparatusWire cuttingEngineering

The invention relates to technical field of production of packaging bags, in particular to an automatic feeding mark pressing wire cutting machine. A rack, a cutting knife plate, an overturning plate,a driving mechanism and a feeding mechanism are included; the rack and the cutting knife plate are fixedly connected; the driving mechanism is used for driving the overturning plate to be pressed tothe cutting knife plate; the feeding mechanism comprises a first base body, a fixed plate, a feeding rolling wheel, a second motor, clamping plates, a first supporting plate, a second supporting plate, a pressing plate and an adjusting device; the fixed plate is close to the overturning plate and fixedly connected with the base body, and is provide with a material outlet; the clamping plates are located at the two ends of the first base body; the first supporting plate and the second supporting plate are used for pressing materials to the pressing plate through supporting springs; the feedingrolling wheel is used for conveying the materials out of the material outlet; and the adjusting device is used for adjusting the distance of the two clamping plates. The automatic feeding mark pressing wire cutting machine can achieve automatic feeding, and accidents are reduced.

Owner:GUANGXI POLYTECHNIC

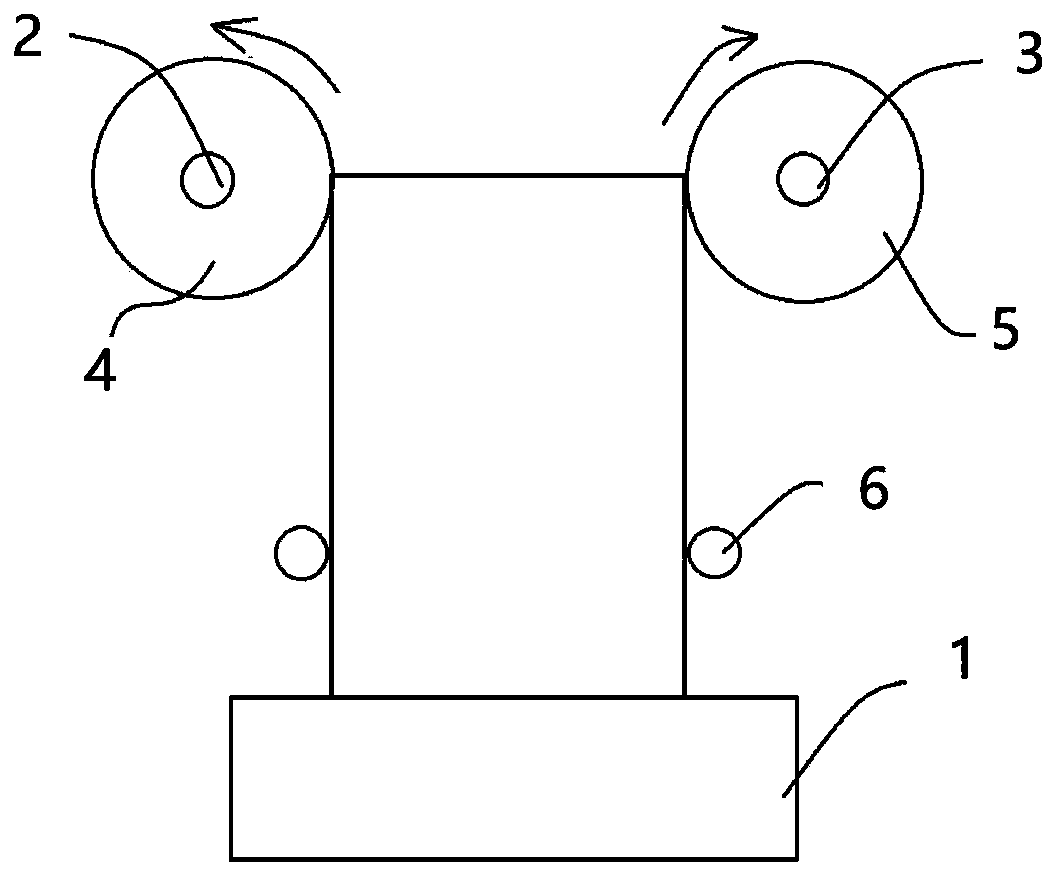

Automatic cover removal mechanism

PendingCN110885048ARealize automatic removalReduce work intensityOpening closed containersBottle/container closureRotational axisConveyor belt

The invention discloses an automatic cover removal mechanism. Compared with the prior art, the automatic cover removal mechanism includes a first rotation shaft arranged on one side of a conveyor belt, a second rotation shaft arranged on the other side of the conveyor belt, a first roller mechanism arranged on the first rotation shaft and a second roller mechanism arranged on the second rotation shaft; and the first roller mechanism and the second roller mechanism are used for rotating upward and reversely to open a plastic cover on a tank body. Compared with the prior art, the automatic coverremoval mechanism can automatically remove plastic covers from milk powder tanks with the plastic covers, the work intensity of personnel is reduced, and the operating efficiency is improved.

Owner:AUSNUTRIA DAIRY CHINA

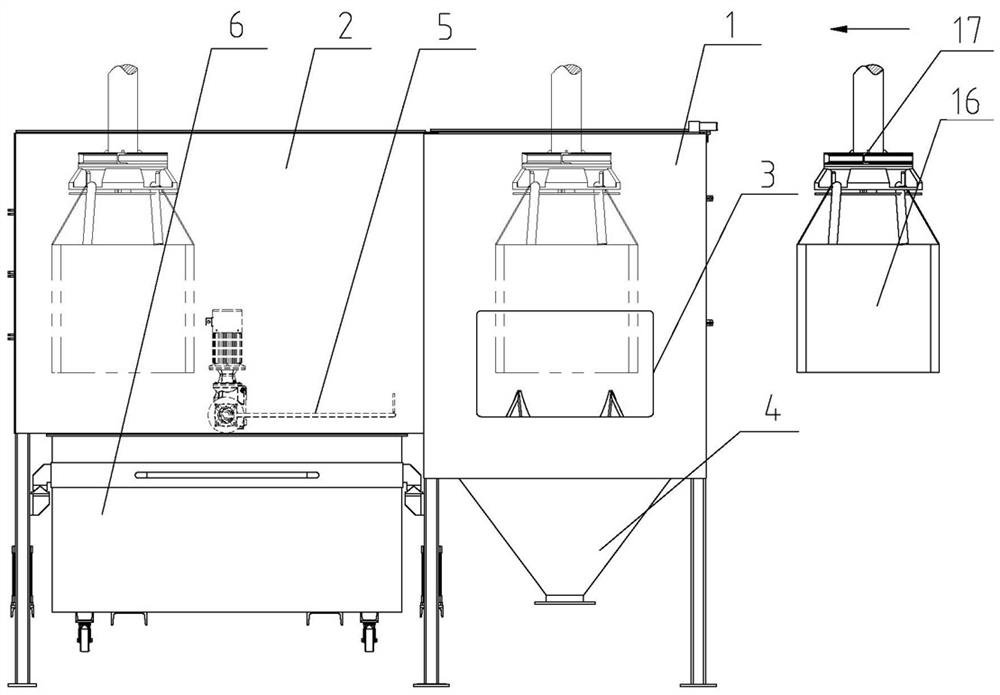

Automatic ton bag opening machine

PendingCN113955259ASmooth entryEnter the discharge bin, the spreader hangs the waste bag and enters smoothlyLoading/unloadingUnpacking by cuttingElectric machineryEngineering

The invention relates to the technical field of ton bag opening and blanking, in particular to an automatic ton bag opening machine which can achieve automatic ton bag opening and collecting, reduce labor intensity and improve efficiency and safety. The machine comprises a bag breaking cutter and a lifting appliance used for hanging ton bags, and is characterized by further comprising a bag opening bin and a bag collecting bin which are arranged side by side and integrated into a whole. The bag breaking cutter is installed in the bag opening bin, the bottom of the bag opening bin is connected with a discharging bin, a turnover pressing plate is installed in the bag collecting bin, one end of the pressing plate is connected with a driving motor through a rotating shaft, a row of teeth is installed at the other end of the pressing plate, and a waste bag collecting mechanism is arranged at the bottom of the bag collecting bin.

Owner:WUXI RICH INTELLIGENT EQUIP CO LTD

Automatic nozzle deburring and flow adjusting method

ActiveCN109434697ARealize automatic removalFull adjustmentAbrasive feedersAbrasive machine appurtenancesParticle flowWear particle

An automatic nozzle deburring and flow adjusting method comprises the steps that the initial flow value of a main / auxiliary oil spraying port of each nozzle is measured; grinding particle flow equipment is utilized for machining a main / auxiliary oil path of each nozzle, and burrs on each main / auxiliary oil path are removed; cleaning fluid is utilized for cleaning the main / auxiliary oil path of each nozzle; the cleaning fluid is utilized for cleaning the grinding particle flow equipment; the nozzle flow after machining is detected and then compared with the initial flow value, and the grindingparticle flow machining time and flow changing relation under corresponding machining parameters is determined; for nozzles with small flow, secondary grinding particle flow machining is conducted onthe nozzles according to the obtained grinding particle flow machining time and flow changing relation, the nozzle flow is further adjusted till the flow of all the nozzles is consistent, and the flowrequirement is met; the grinding particle flow equipment is cleaned; ultrasonic cleaning equipment is utilized for nozzle cleaning, and residual cleaning fluid is removed; and the weight of each nozzle is measured and compared with the initial weight of the nozzle before grinding particle flow machining, and it is ensured that the nozzle weight changing value does not exceed 50 g.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

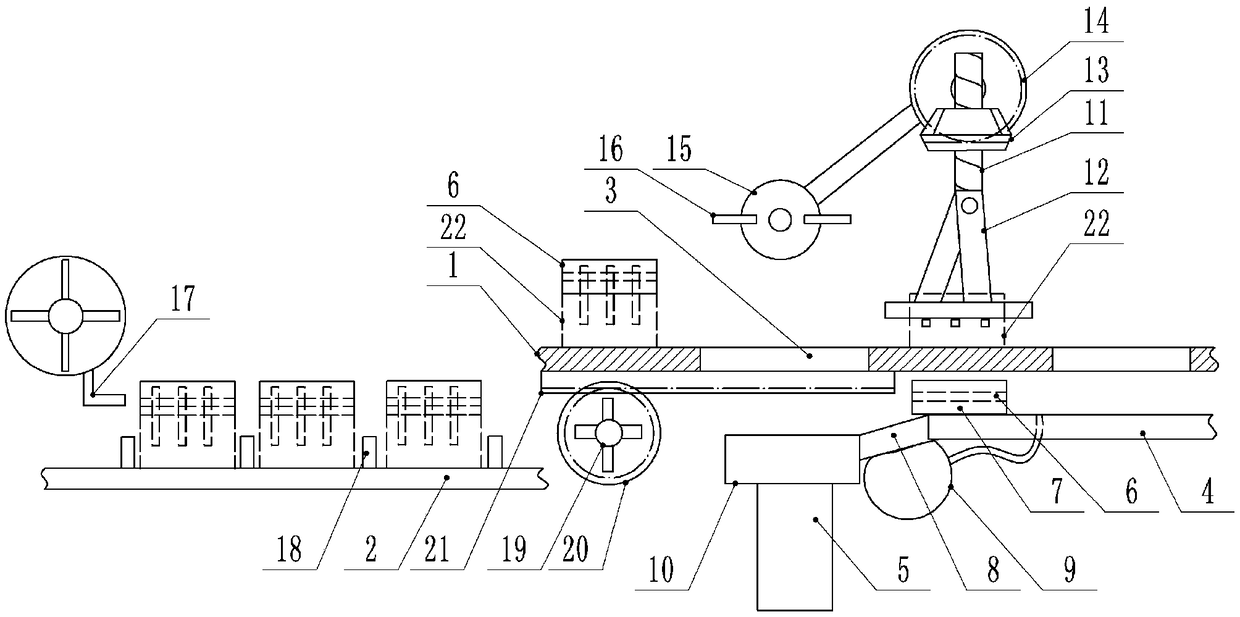

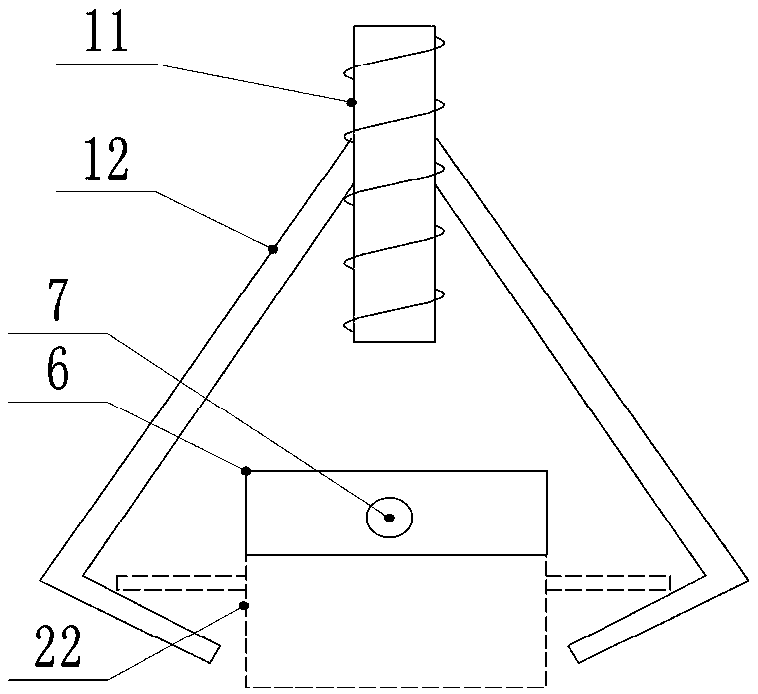

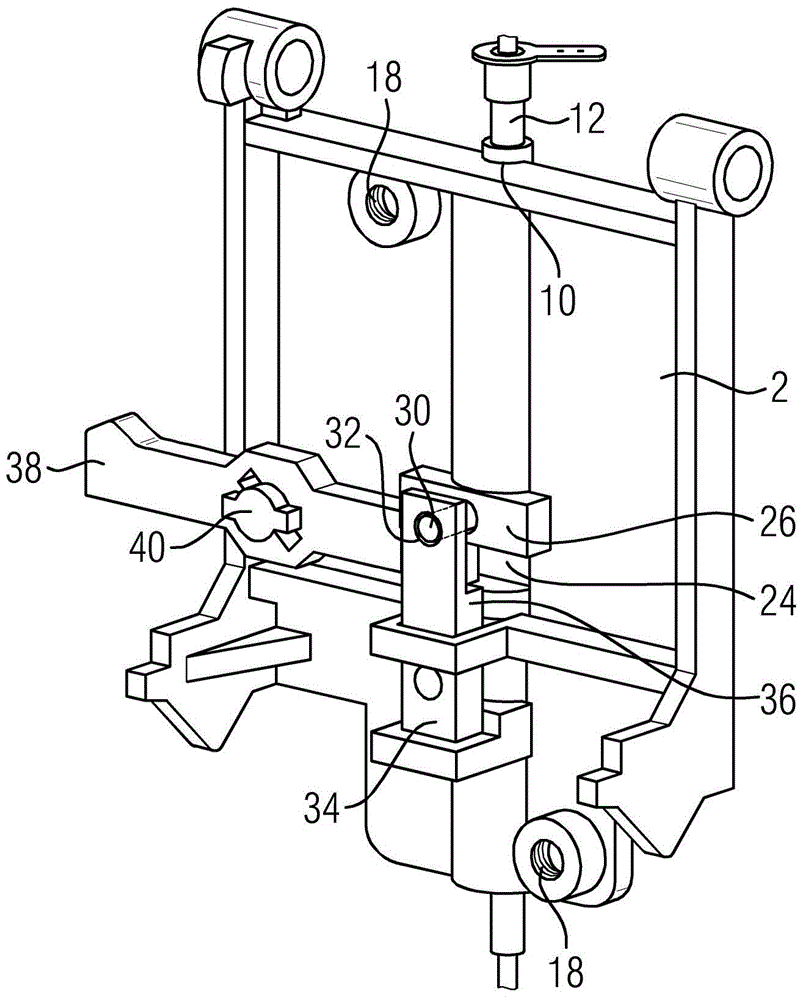

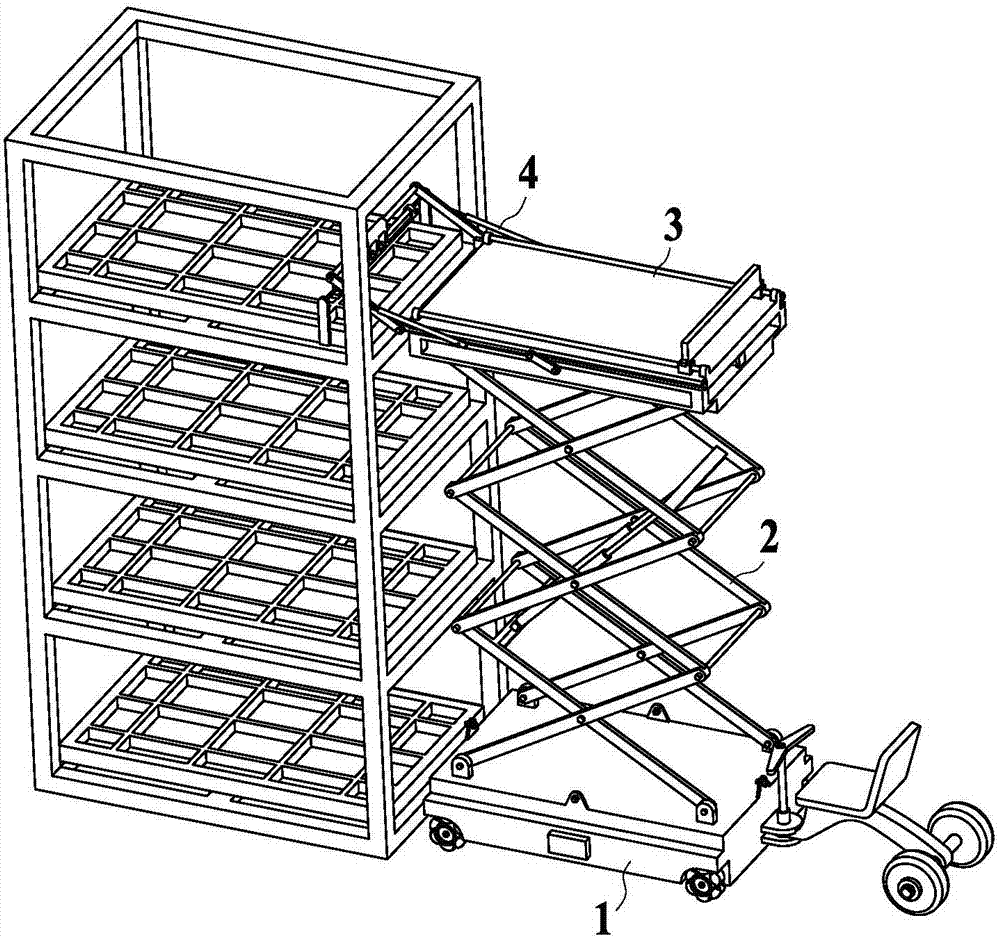

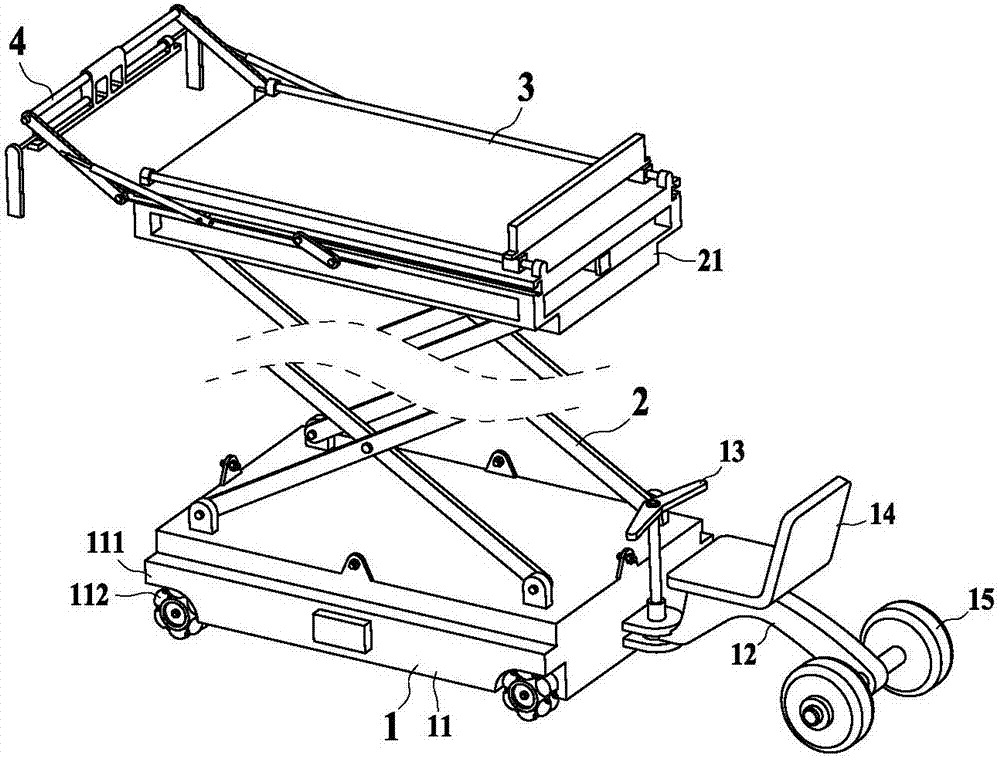

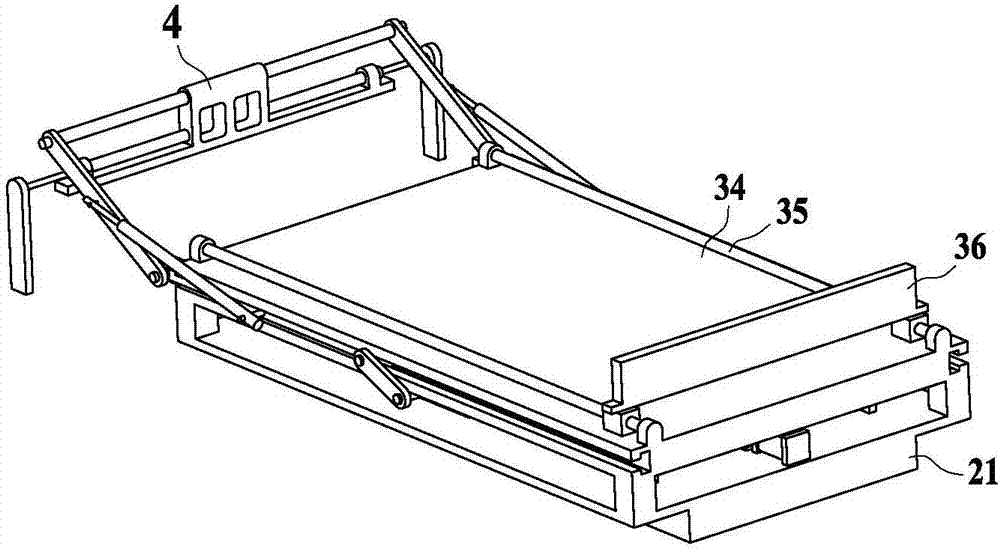

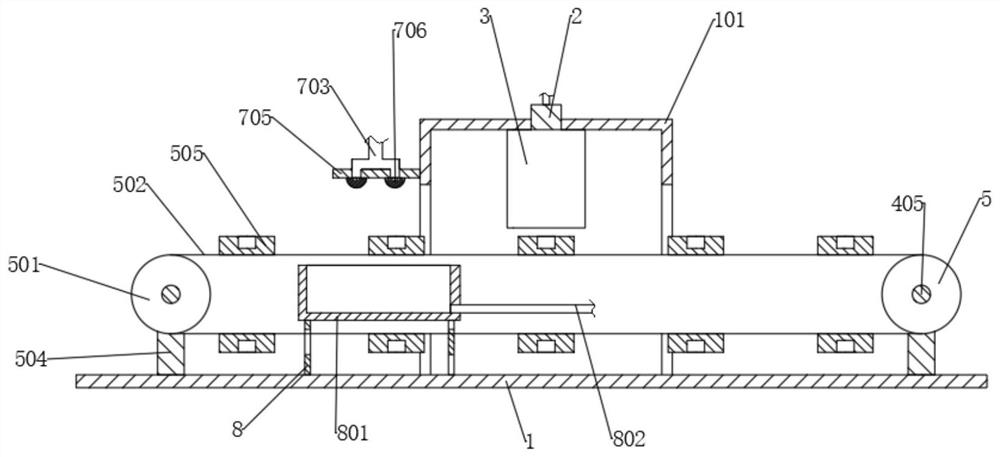

A scissor-type blister mold pick-and-place device

ActiveCN105712243BRealize automatic removalRealize automatic depositConveyorsLifting framesSteering wheelDrive wheel

The invention relates to the field plastic uptake equipment, in particular to a scissors type plastic uptake mold taking and putting device. The device comprises a running unit, a lifting mechanism, a function platform and a mold taking mechanism. The lifting mechanism is arranged on the running unit. The function platform is installed at the upper end of the lifting mechanism. The mold taking mechanism is installed on the function platform. The running unit comprises a driving unit, a running stand, a steering wheel, a seat and big driven wheels. The lifting mechanism is a conventional scissors type mechanism. The function platform comprises a translational screw, a rotating motor, a movable plate, a supporting table, rodless push cylinders and a push plate. The mold taking mechanism comprises a fixing round bar, a pair of adjusting units, a connecting rod, a supporting frame and a pair of clamping devices. The scissors type plastic uptake mold taking and putting device can automatically store a mold, manual mold conveying is not needed in the whole process, the labor intensity of workers is relieved, time and effort are saved, the production efficiency is improved, and the economic benefits are increased.

Owner:ANQING LIXIANG IND & TRADE

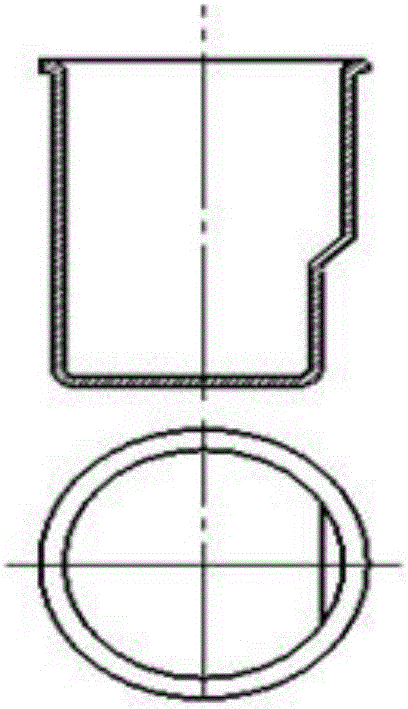

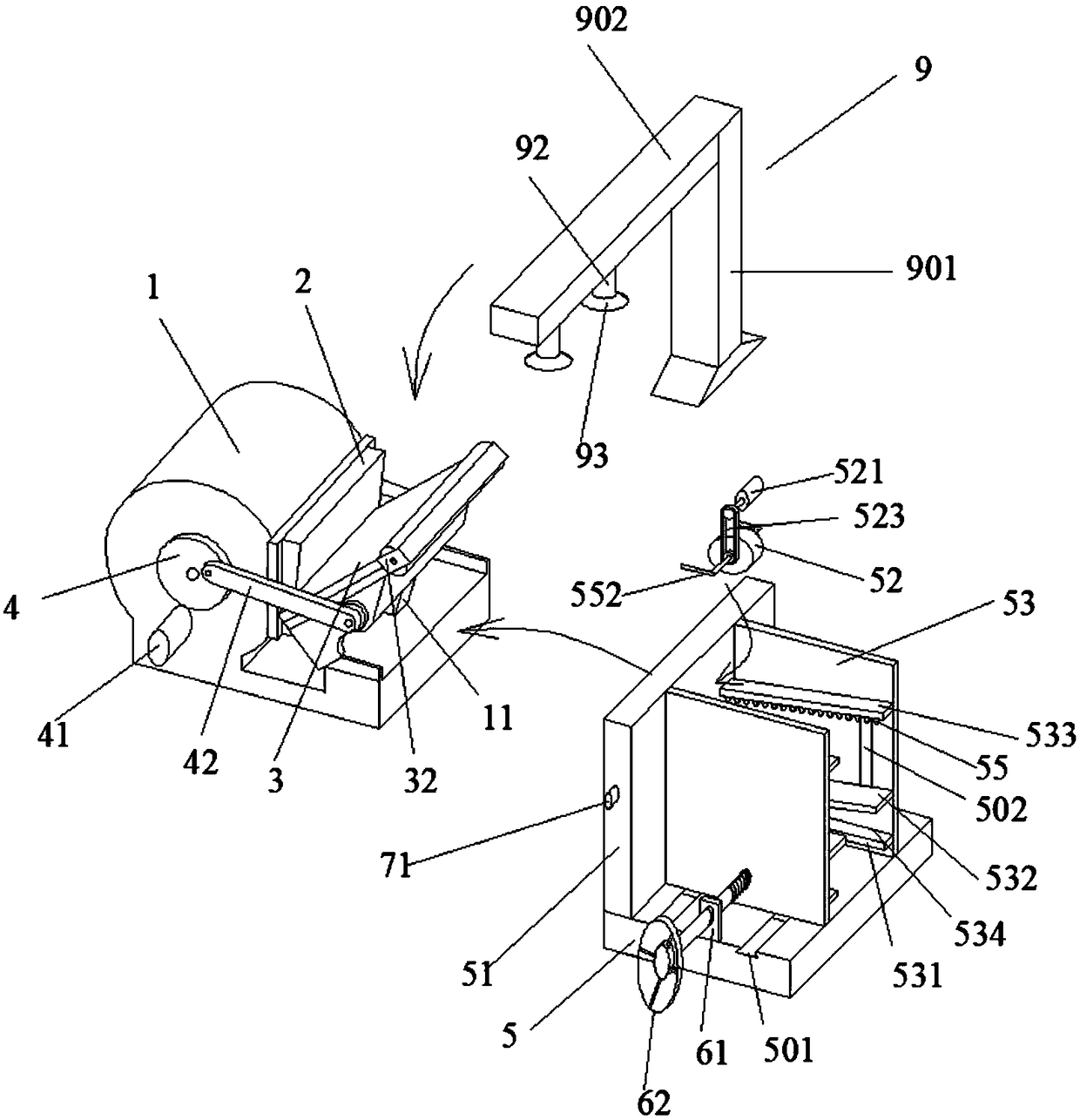

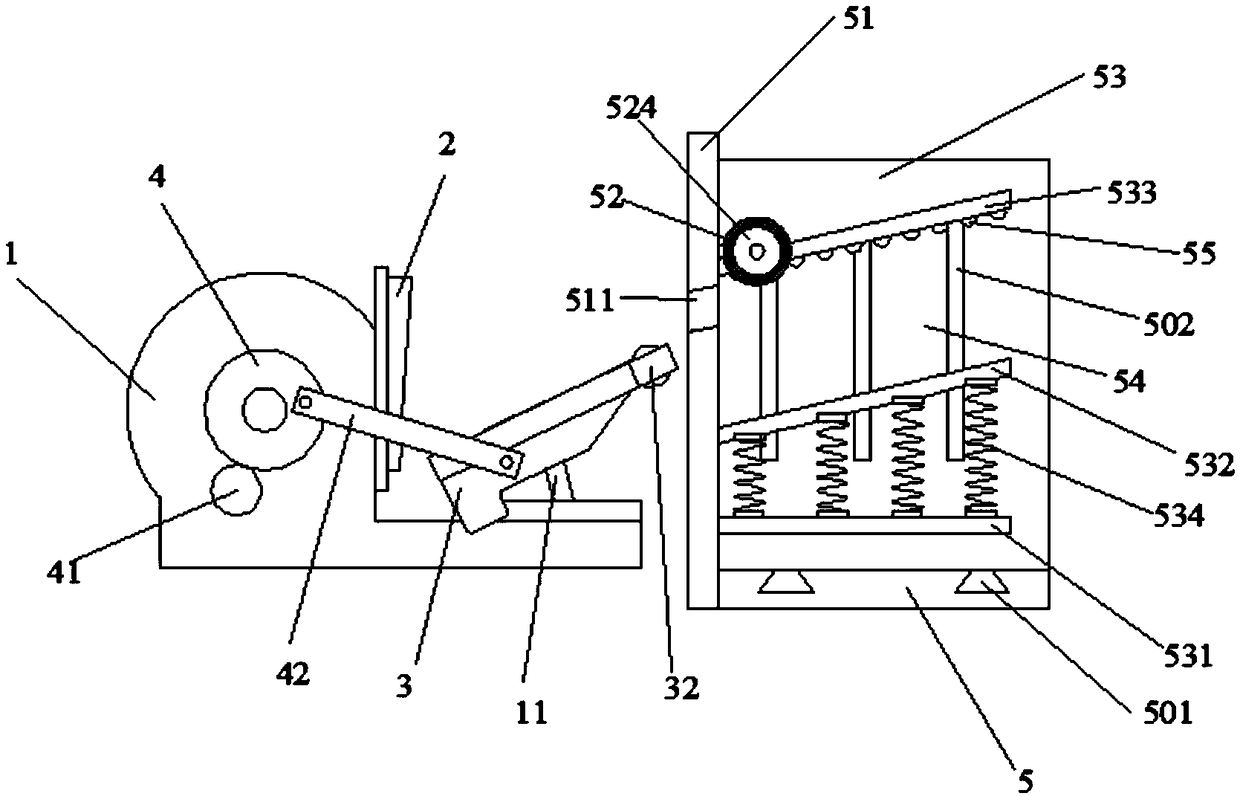

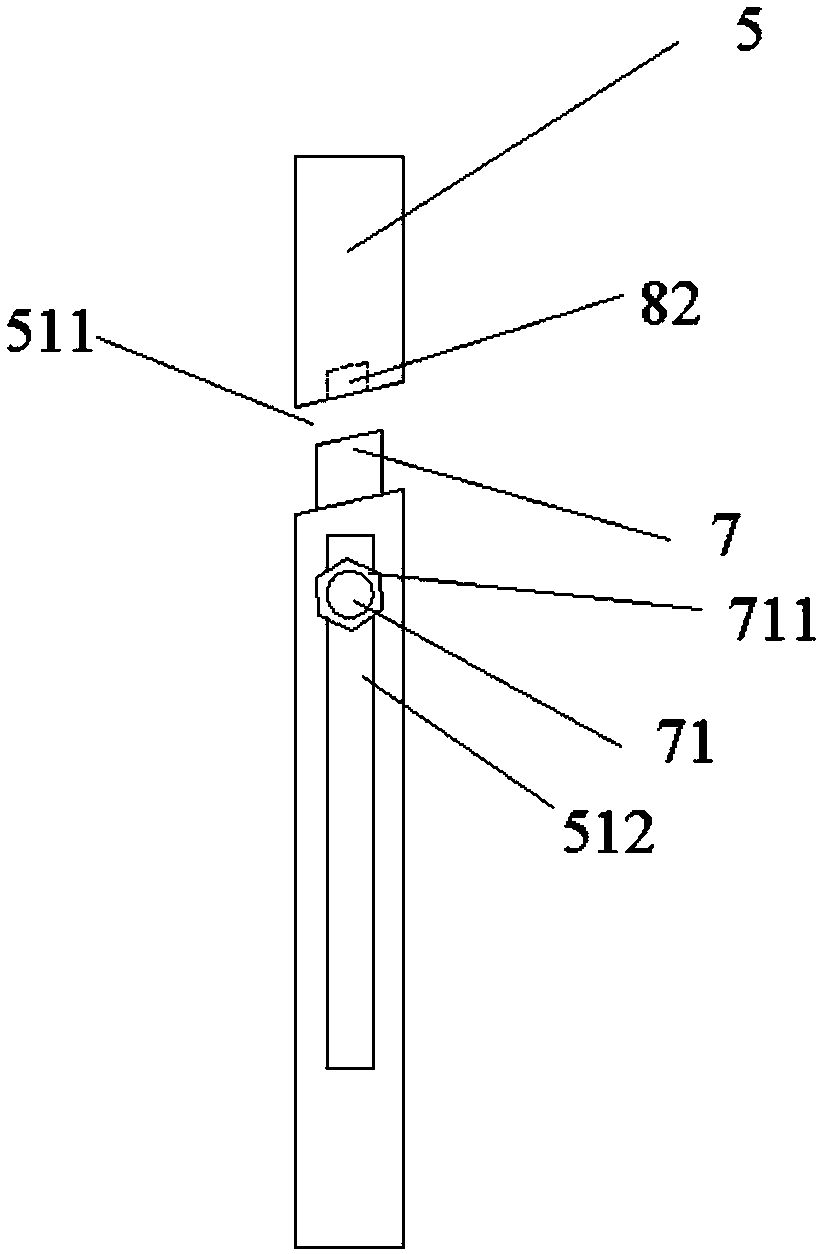

Gas generator forming device and method

ActiveCN106270279ALow priceReduce processing costsShaping toolsVehicle componentsElastic componentWork in process

The invention discloses a gas generator forming device. The gas generator forming device comprises an ignition body forming device and a finished product forming device which are used for closing of a die and a positioning base. The positioning base is used for fixing a base or a semi-finished product. The die is of a cylindrical structure provided with a hollow structure and provided with an opening in one end, the die can vertically move relative to the positioning base, and an annular concave face is arranged at the position of the opening of the die and used for extrusion closing of the base or a product. The invention further discloses a gas generator forming method. An electric ignition pipe or an ignition body is fixed to the base, a press is started, the die vertically moves relative to the positioning base, the base or the product is extruded through the annular concave face of the die, pressure maintaining is conducted for a certain time, and the assembled product is taken out. The gas generator forming device is high in automation degree and simple in structure, forming of a gas generator can be efficiently conducted with the high quality, and the burden of manpower is relieved. According to the device, automatic product taking out is achieved by further utilizing elasticity of elastic components.

Owner:陕西庆华汽车安全系统有限公司

Novel creasing and cutting machine

PendingCN109502378ARealize automatic indentation and tangentFall intoArticle deliveryArticle separationBlade plateEngineering

The invention relates to the technical field of production packaging bags, in particular to a novel creasing and cutting machine. The novel creasing and cutting machine comprises a rack, a cutter plate, a turning plate, a driving mechanism and a loading mechanism; the rack is fixedly connected with the cutter plate, the driving mechanism is used for driving the turning plate to press the cutter plate, the loading mechanism comprises a first base body, a fixed plate, a loading roller, a second motor, clamping plates, a first supporting plate, a second supporting plate, a pressing plate and an adjusting device, the fixed plate is close to the turning plate, is fixedly connected with the base body, and is provided with a discharging opening, the clamping plates are located on the two ends ofthe first base body, the first supporting plate and the second supporting plate are used for pressing materials to the pressing plate through bracket springs, and the loading roller is used for discharging the materials out of the discharging opening; and the adjusting device is used for adjusting the distance between the two clamping plates. The novel creasing and cutting machine can achieve automatic feeding, and accidents can be reduced.

Owner:GUANGXI POLYTECHNIC

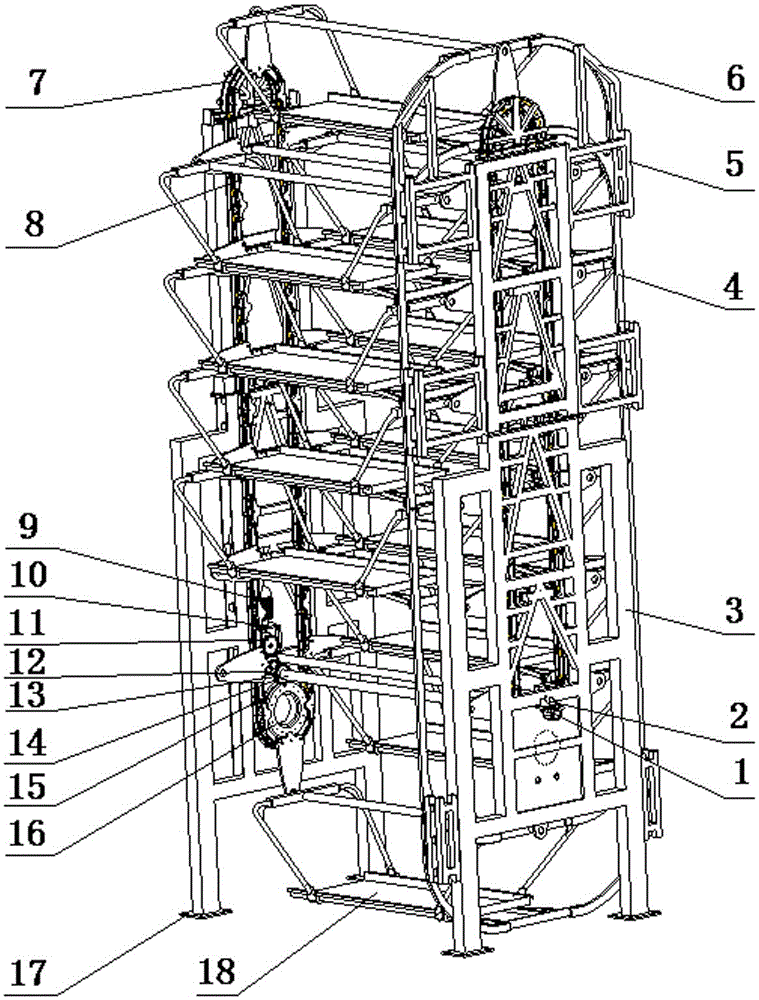

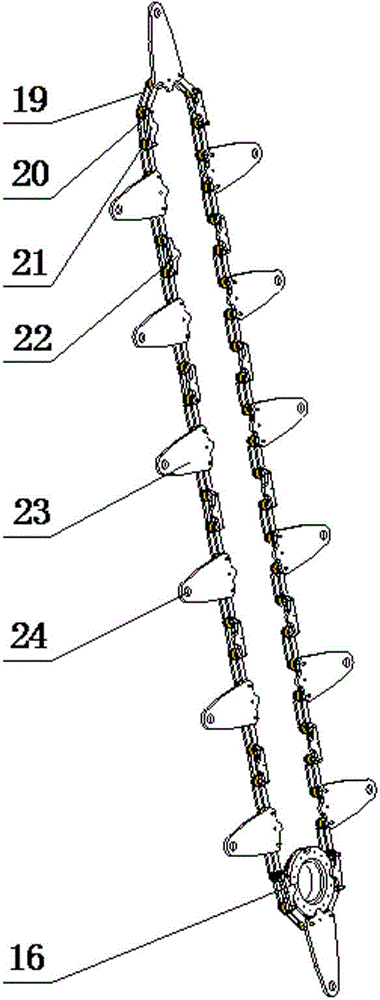

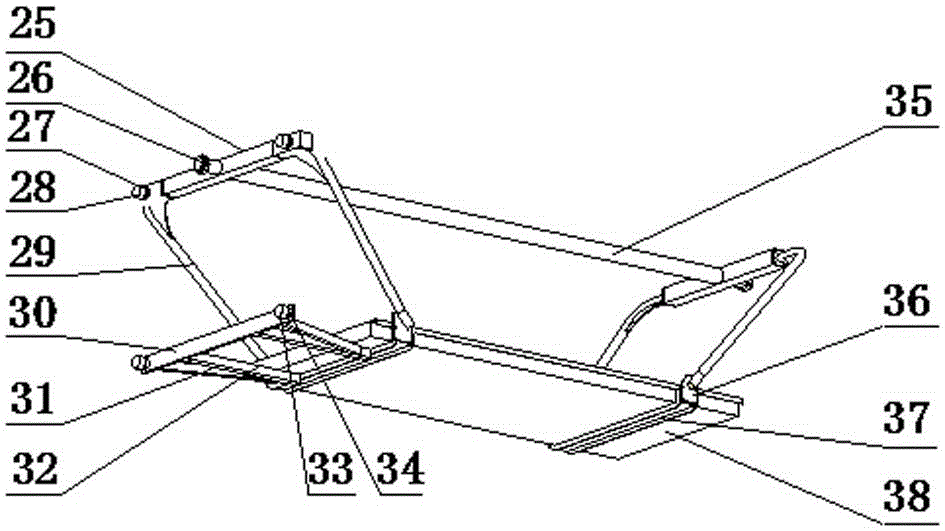

Chain type gear elliptic transmission stereo garage

InactiveCN105155888ARealize automatic storageRealize automatic removalParkingsDrive shaftParking space

The invention provides a chain type gear elliptic transmission stereo garage, which is characterized in that transmission chains in vertical rotation along transmission chain guide grooves formed in the two sides of a support frame are arranged at the two sides of the support frame; the transmission chain arranged at one side of the support frame is driven by a position change wheel; the position change wheel is driven by a motor positioned at the same side; the transmission chain arranged at the other side of the support frame is driven by a gear positioned at the same side on a transmission shaft arranged on the support frame through driving the position change wheel arranged on a gearwheel positioned at the same side; the two ends of a chain plate of each transmission chain are connected and provided with large position change plates and small position change plates; car carrying platforms are connected and arranged between the corresponding large position change plates arranged on the two transmission chains; an encoder controlled by a PLC (Programmable Logic Control) system is arranged on the support frame; and a car storing and taking control box controlled by the PLC system is also arranged on the support frame. The chain type gear elliptic transmission stereo garage has the advantages that the automatic storage and automatic taking of cars are realized; the problem of parking difficulty of the cars in a city is greatly solved; a great number of ground parking spaces are saved; and the traffic pressure of the city is relieved.

Owner:NANYANG TIANHE MACHINERY

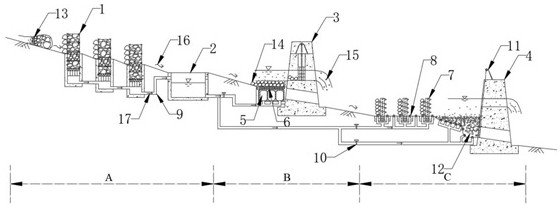

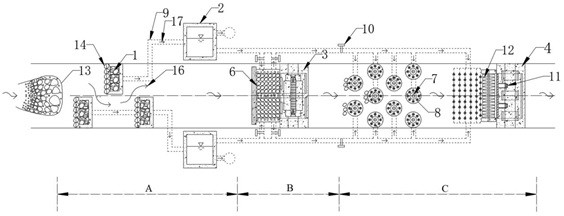

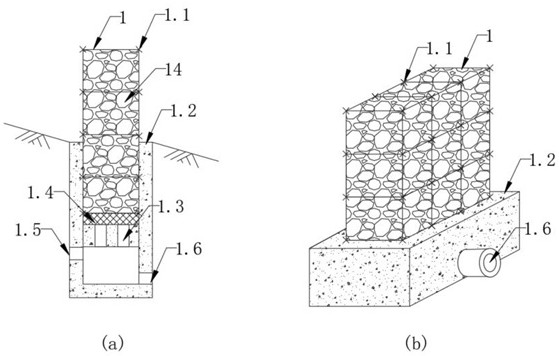

Debris flow blocking dam with automatic desilting function and building and using method

ActiveCN114108569AReduce impactRealize secondary useBarrages/weirsWater collectionPetroleum engineering

The invention relates to the technical field of debris flow protection engineering, and discloses a debris flow blocking dam with an automatic dredging function and a construction method of the debris flow blocking dam. A debris flow energy dissipation and water collection section, a large-particle stone blocking and cleaning section and a small-particle mud and sand blocking and cleaning section are sequentially arranged from upstream to downstream. The debris flow energy dissipation and water collection section realizes energy dissipation and solid-liquid separation of debris flow; the separated liquid, namely water, is used as a cleaning power source of the large-particle stone blocking and cleaning section and the small-particle mud and sand blocking and cleaning section, kinetic energy of debris flow is sequentially digested stage by stage, and stones and mud and sand are sequentially and respectively removed.

Owner:INST OF MOUNTAIN HAZARDS & ENVIRONMENT CHINESE ACADEMY OF SCI

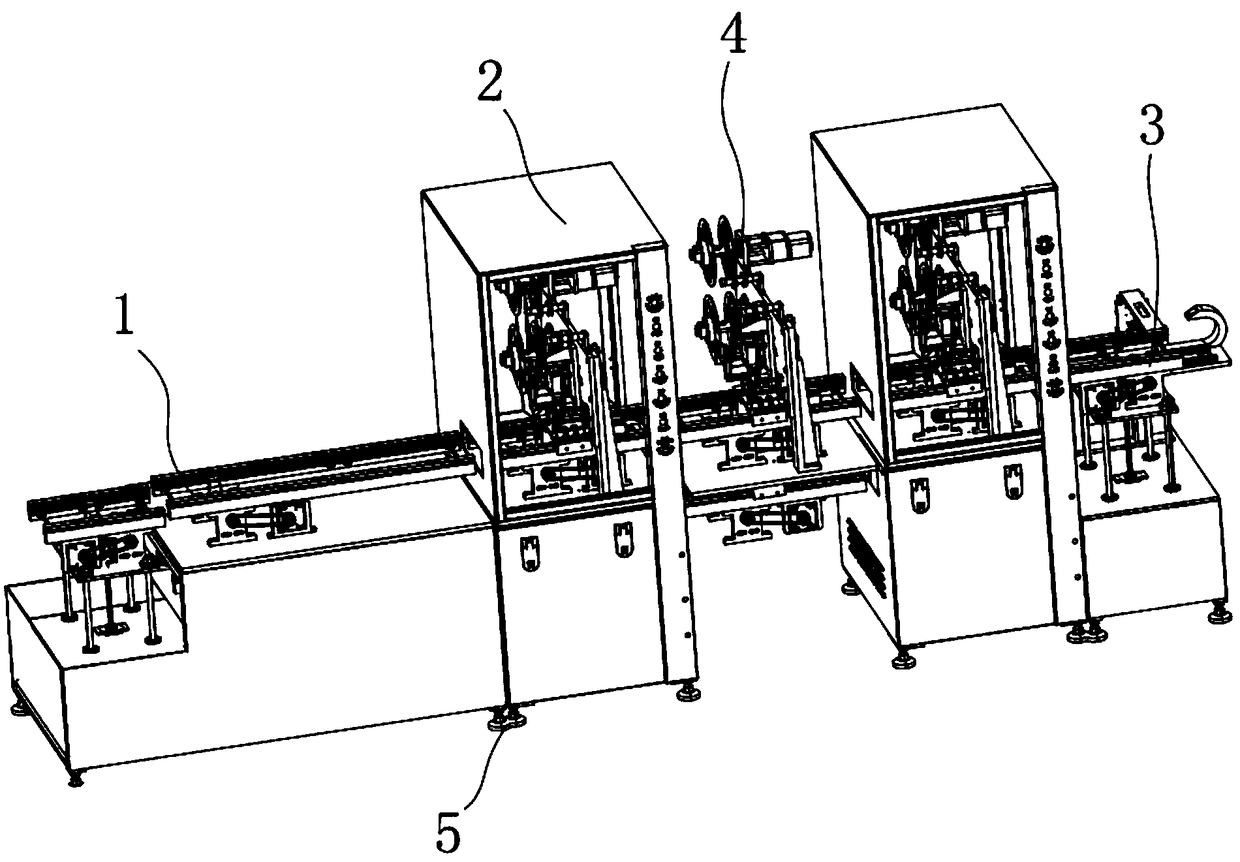

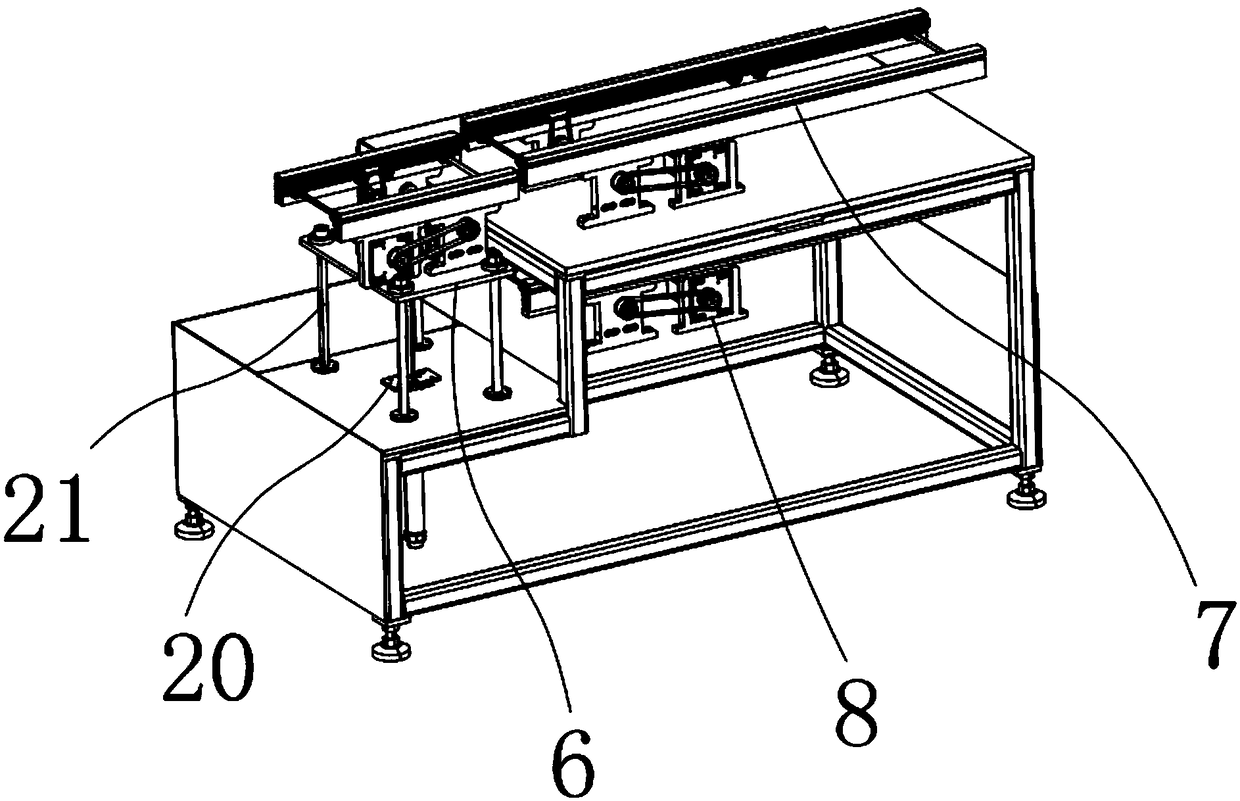

Full-automatic punching and pasting machine

The invention discloses a full-automatic punching and pasting machine which comprises a feeding mechanism, a punching and pasting machine and a discharging mechanism. The feeding mechanism comprises afeeding lifting reversing conveying belt, a feeding conveying belt and a discharging conveying belt. The punching and pasting machine comprises a gantry platform and an upper combined conveying belt.The gantry platform comprises a material collecting wheel, a dovetail groove, a punch and a material rolling wheel. The upper combined conveying belt comprises a material ejecting air cylinder. A positioning guide pillar is assembled at the upper end of the material ejecting air cylinder. A jig is arranged at the end portion of a piston rod of the material ejecting air cylinder. A handle screw isarranged on one side of the upper combined conveying belt, and a material blocking air cylinder is arranged on one side of the jig. A material baffle is fixed to the end portion of the piston rod ofthe material blocking air cylinder. By means of the structure, during punching and pasting work of products, automatic feeding, automatic punching and pasting and automatic discharging can be achieved, the punching and pasting technology can be completely automatic, labor force is saved, efficiency is also improved, the precision of the punching and pasting technology is also improved, and the full-automatic punching and pasting machine is worthy of being popularized.

Owner:深圳市鼎晖伟业自动化设备有限公司

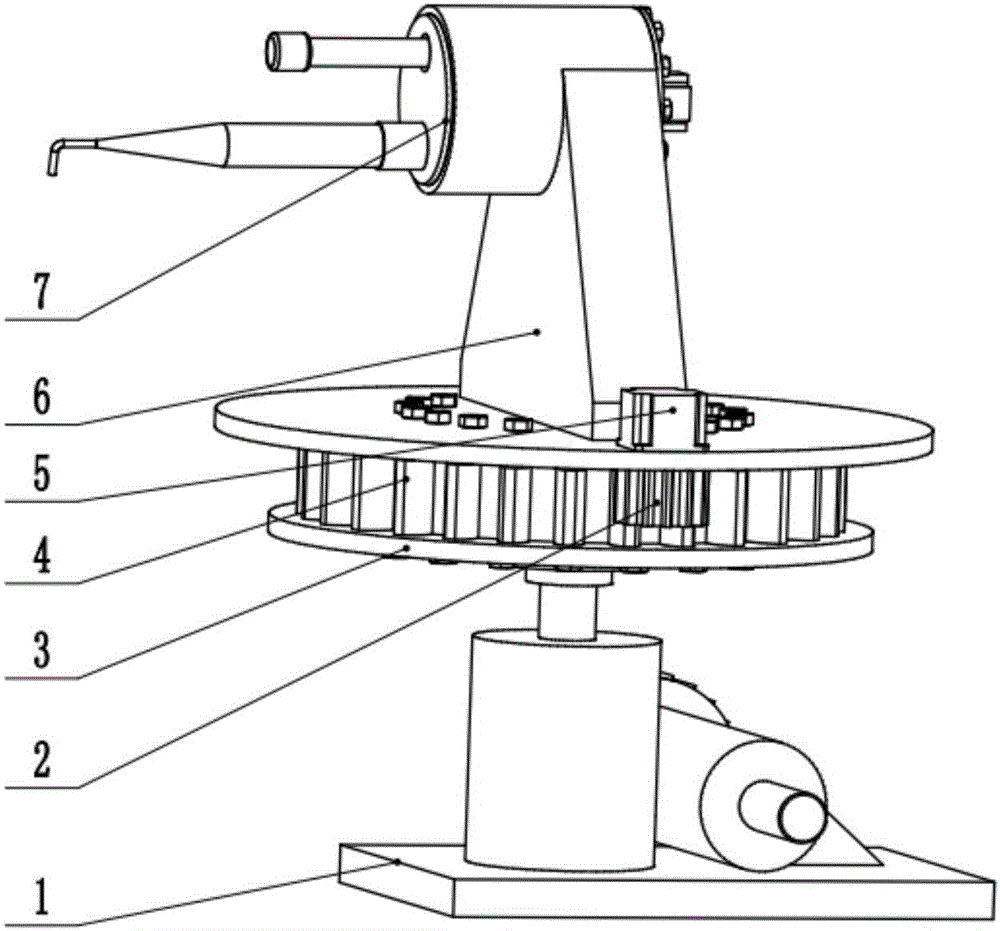

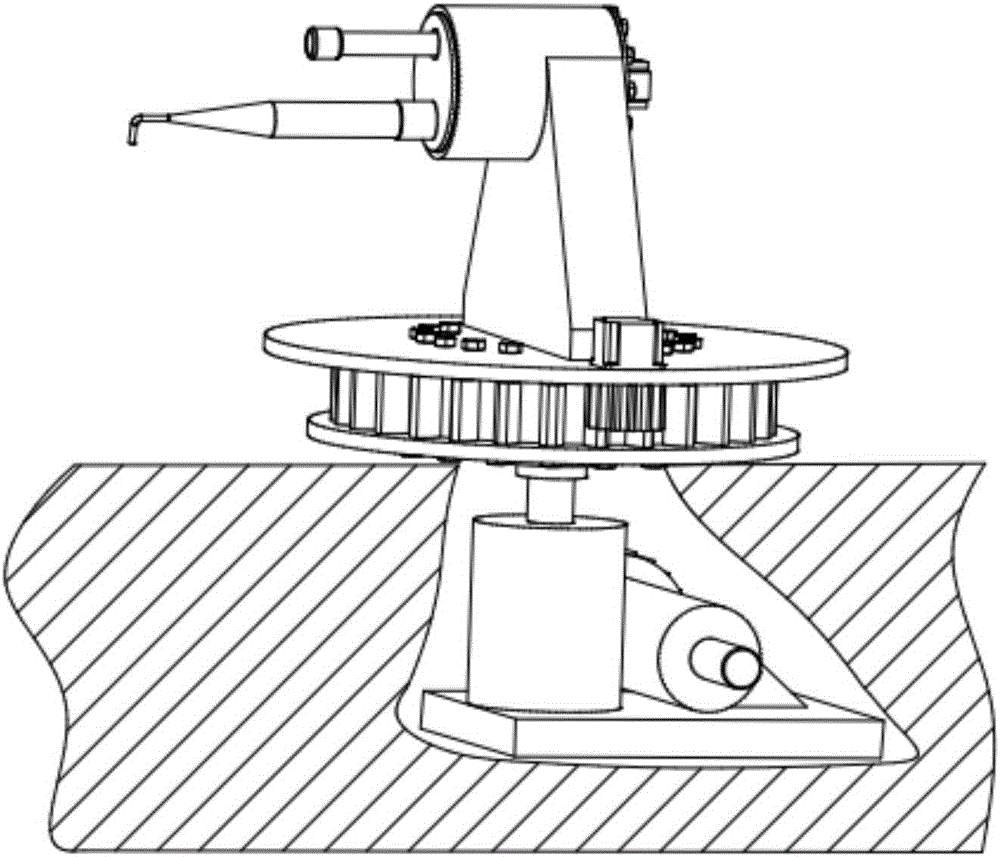

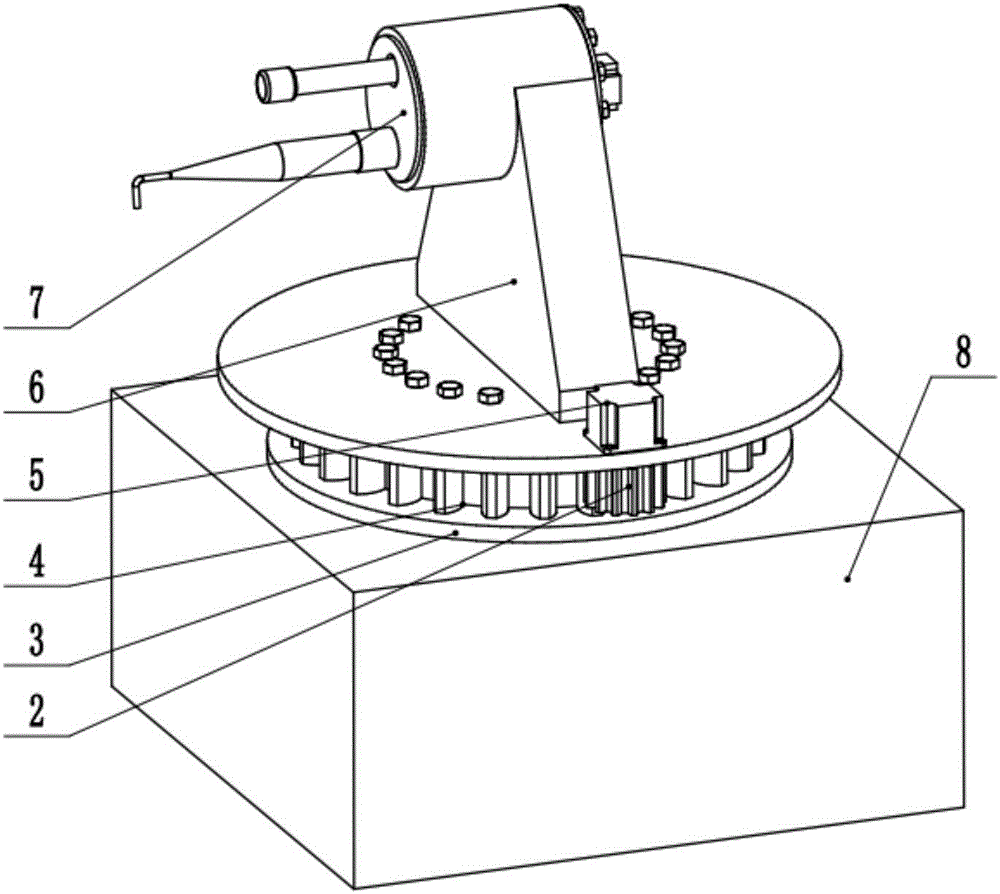

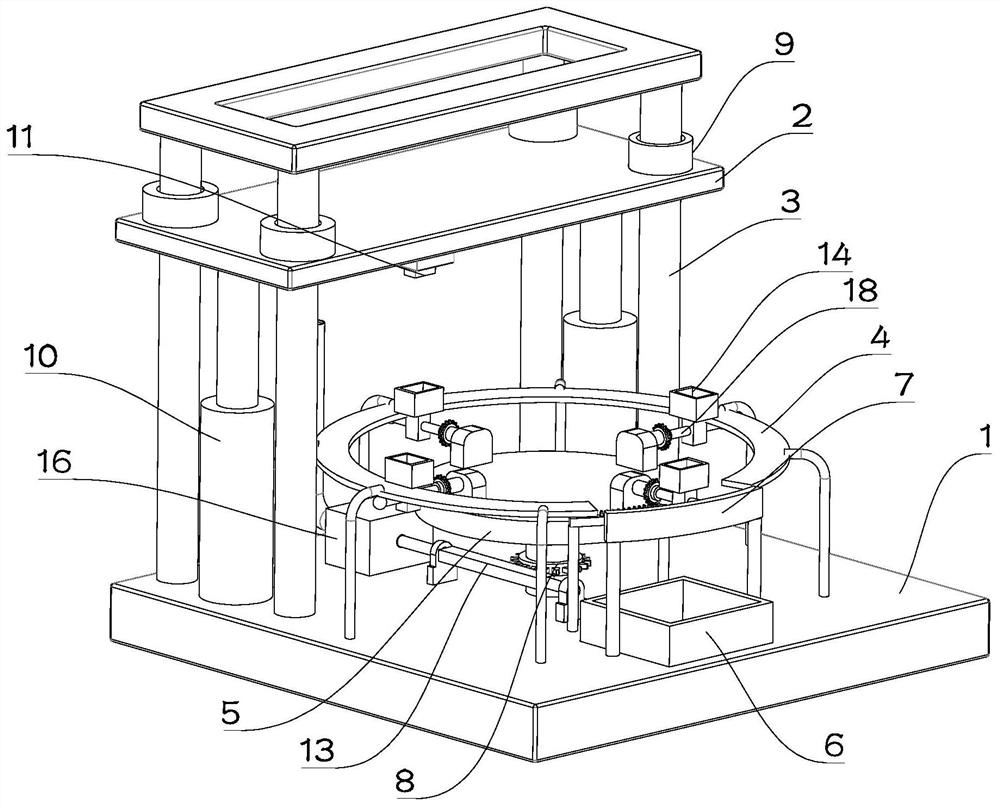

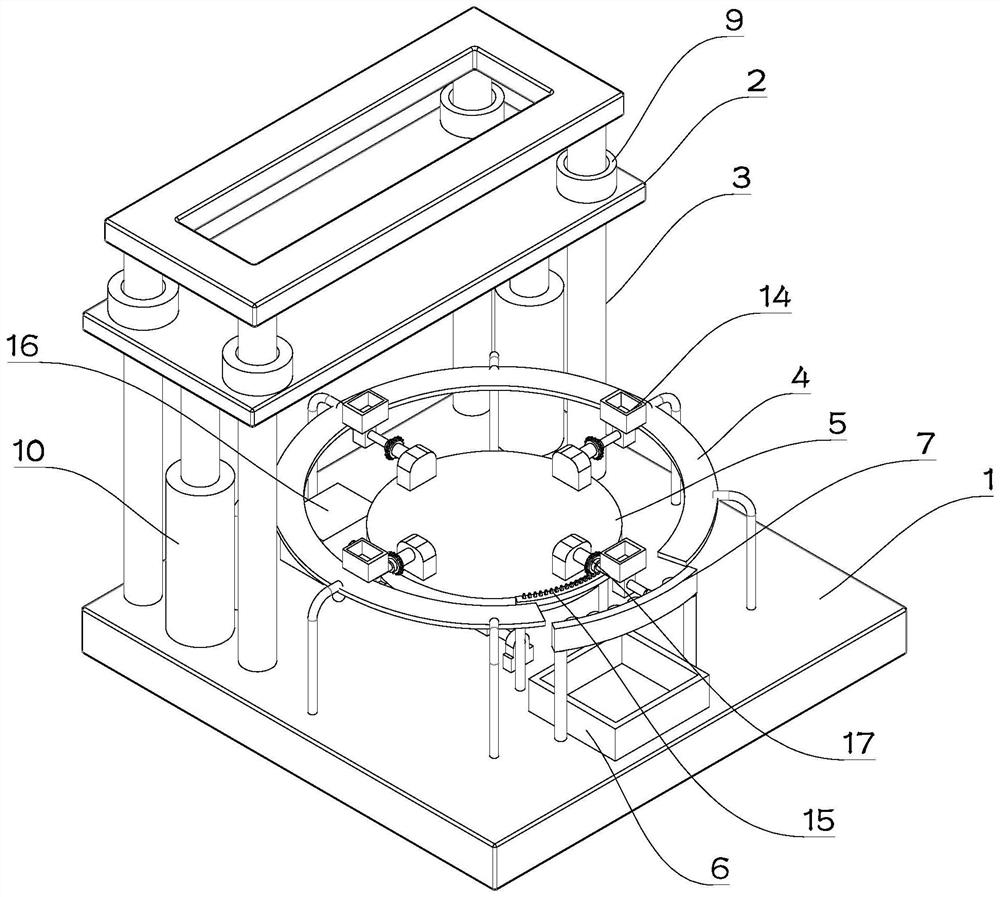

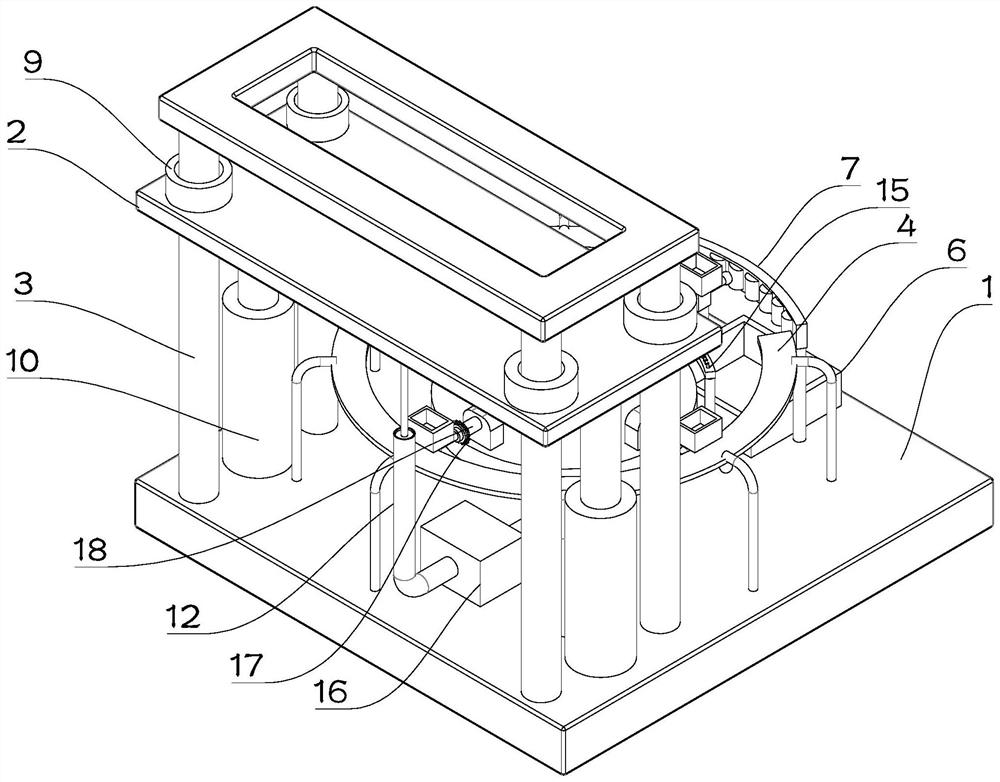

Device for taking out bearing ring casting parts

The invention discloses a device for taking out bearing ring casting parts and belongs to the field of bearing tool equipment. The device for taking out the bearing ring casting parts comprises a worm and gear lifting machine, a rotary support and a rotating device; the lower surface of a rotary support lower plate is arranged on the worm and gear lifting machine, and the upper surface of the rotary support lower plate is provided with the rotary support; a shell is arranged on the rotary support; a rotary support motor is arranged on the shell; a small gear is arranged on an output shaft of the rotary support motor; the rotating device is arranged in the shell; a rotating motor is arranged on a rotating cylinder; a telescopic device is arranged in the rotating cylinder; an air cylinder is installed on a air cylinder installing plate; one side of the air cylinder installing plate is fixedly connected on the rotating cylinder, and the other side of the air cylinder installing plate is fixedly connected on a plugging plate; and the plugging plate is arranged at an opening of the rotating cylinder. According to the device for taking out the bearing ring casting parts, the bearing ring casting parts can be automatically taken out, manual participation is not needed, and convenience and quickness are realized.

Owner:烟台九业机器人科技有限公司

Heating and cooling device of bonding machine

ActiveCN113471115AReduce the risk of burnsImprove securitySemiconductor/solid-state device manufacturingMetal working apparatusEngineeringHeating cooling

The invention relates to the technical field of bonding machines, in particular to a bonding machine heating and cooling device; the bonding machine heating and cooling device comprises a top seat and a bottom seat which are arranged up and down, the side end of the bottom seat is fixedly connected with a second heating and cooling seat matched with a first heating and cooling seat, and a conveying mechanism is arranged between the first heating and cooling seat and the second heating and cooling seat. The first heating and cooling seat is connected with a transmission mechanism, the transmission mechanism comprises a first rack and a gear set, the conveying mechanism comprises a push block and a second rack, and the first rack drives the second rack through the gear set to drive the push block to reciprocate between the base and the second heating and cooling seat. Through cooperation of the first rack, the gear set, the second rack and the push block, after wafer bonding is completed, the push block pushes the bonded wafer out of the second heating and cooling seat along with upward movement of the first heating and cooling seat, automatic taking-out of the wafer is achieved, the scalding danger coefficient in the wafer taking-out process is greatly reduced, and safety is higher.

Owner:烟台一诺电子材料有限公司

Blank moving device of blowing molding machine

The invention discloses a blank moving device of a blowing molding machine and belongs to the technical field of blowing molding machines. The blank moving device of the blowing molding machine comprises a base plate, a supporting frame and a box. A motor is arranged on the sidewall of the box. The output end of the motor is connected with a first rotary shaft. The first rotary shaft is connectedwith a cam and a first rotary disk. The first rotary disk is provided with a shifting tooth. The sidewall of the box is rotatably connected with a second rotary shaft. A driving wheel and a second rotary disk are arranged on the second rotary shaft. The second rotary disk is provided with a shifting groove matched with the shifting tooth. A driven wheel is further arranged on the base plate. A conveyor belt is connected between the driving wheel and the driven wheel. A piston is arranged in the box. The piston is connected with a connecting rod. The blank moving device is simple in structure and convenient to operate, can automatically move away blowing molded products through cooperation of the cam and the first rotary disk and can also implement rapid cooling treatment on the blowing molded products, and the working efficiency is greatly improved.

Owner:李旭燕

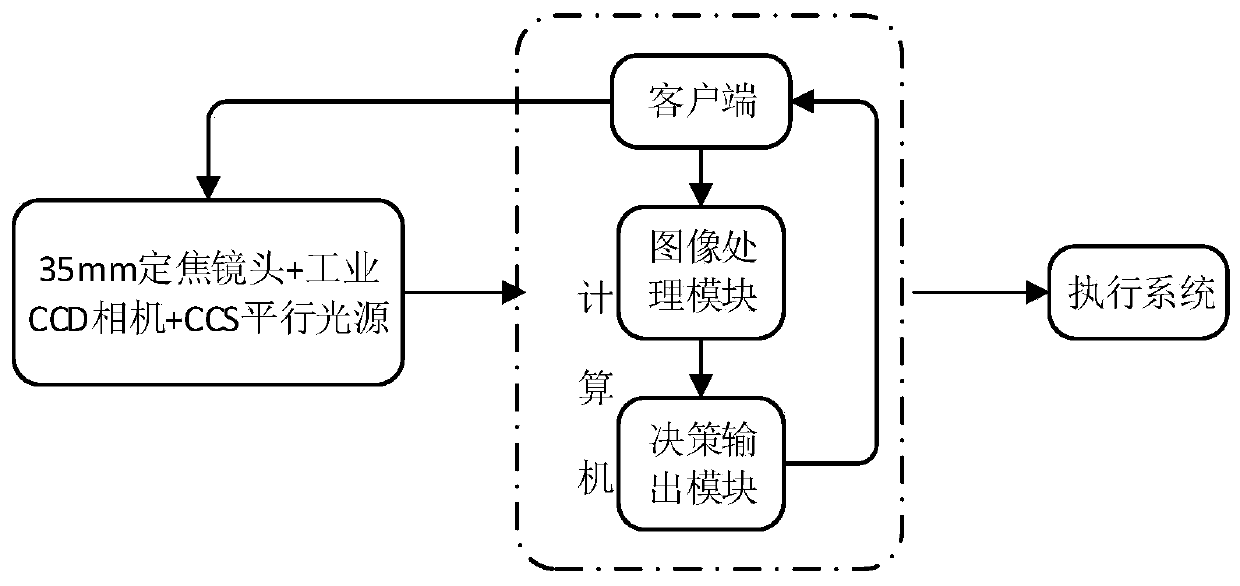

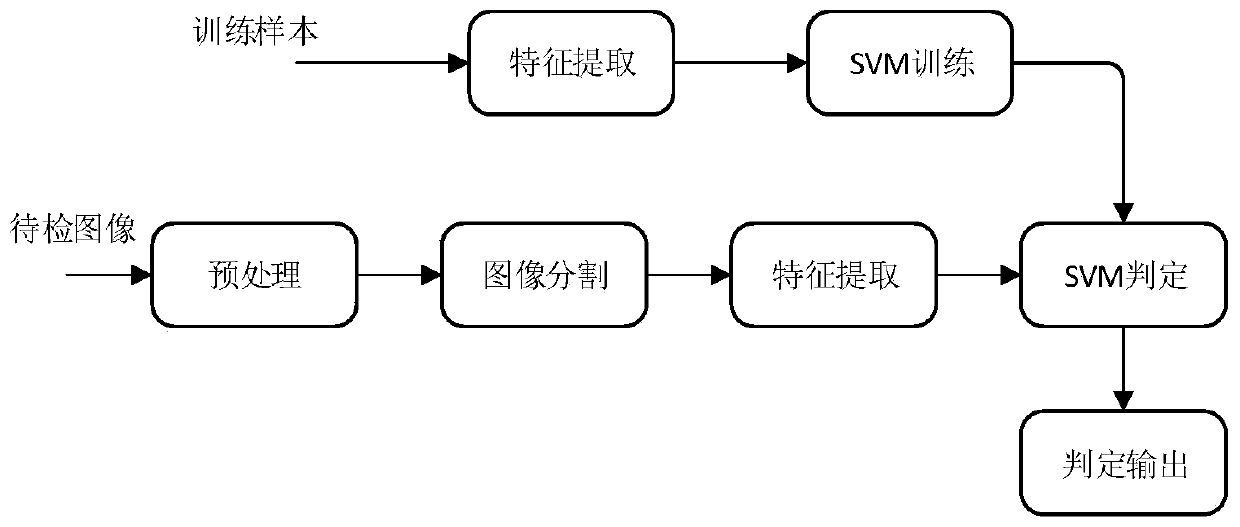

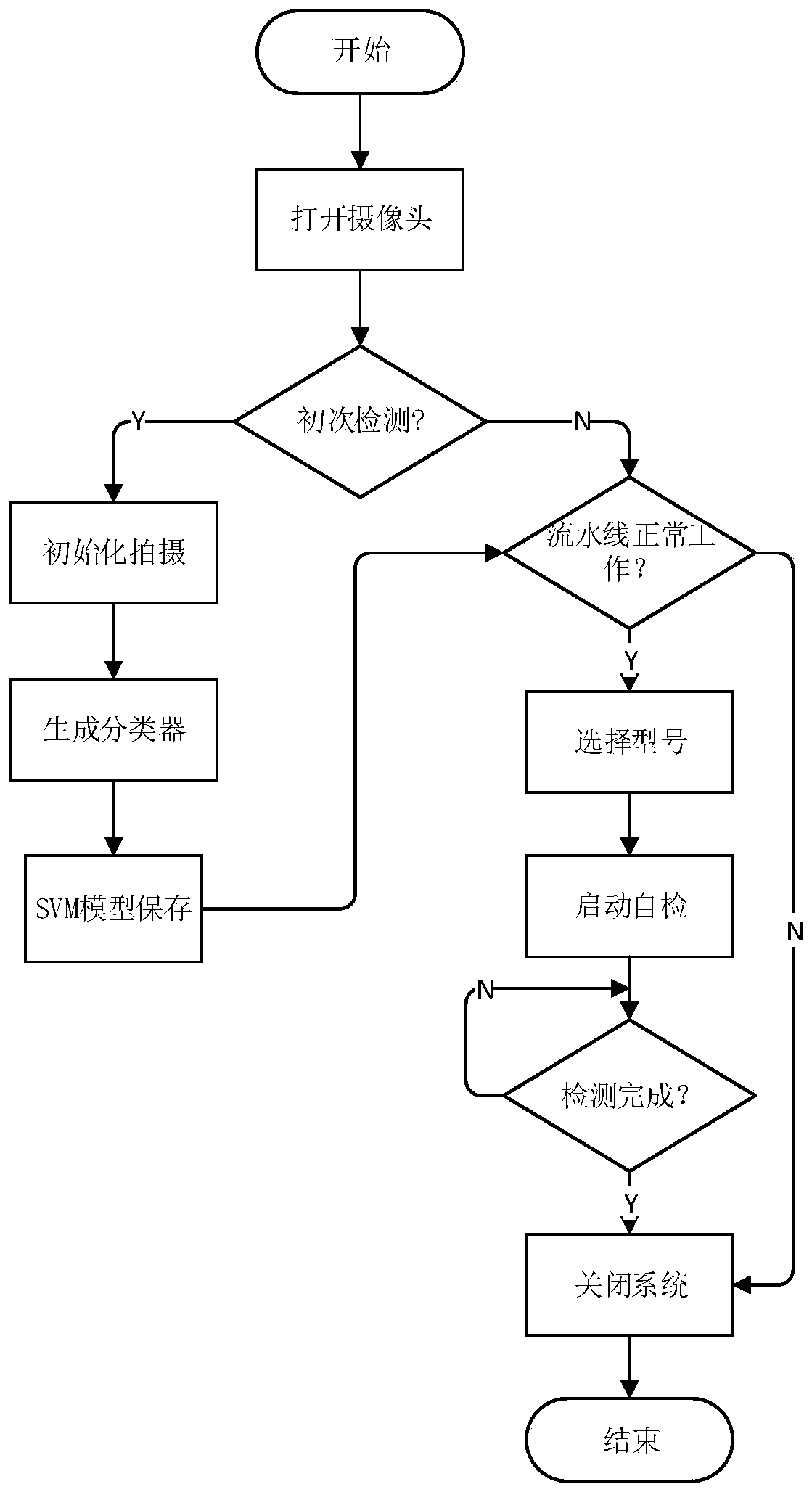

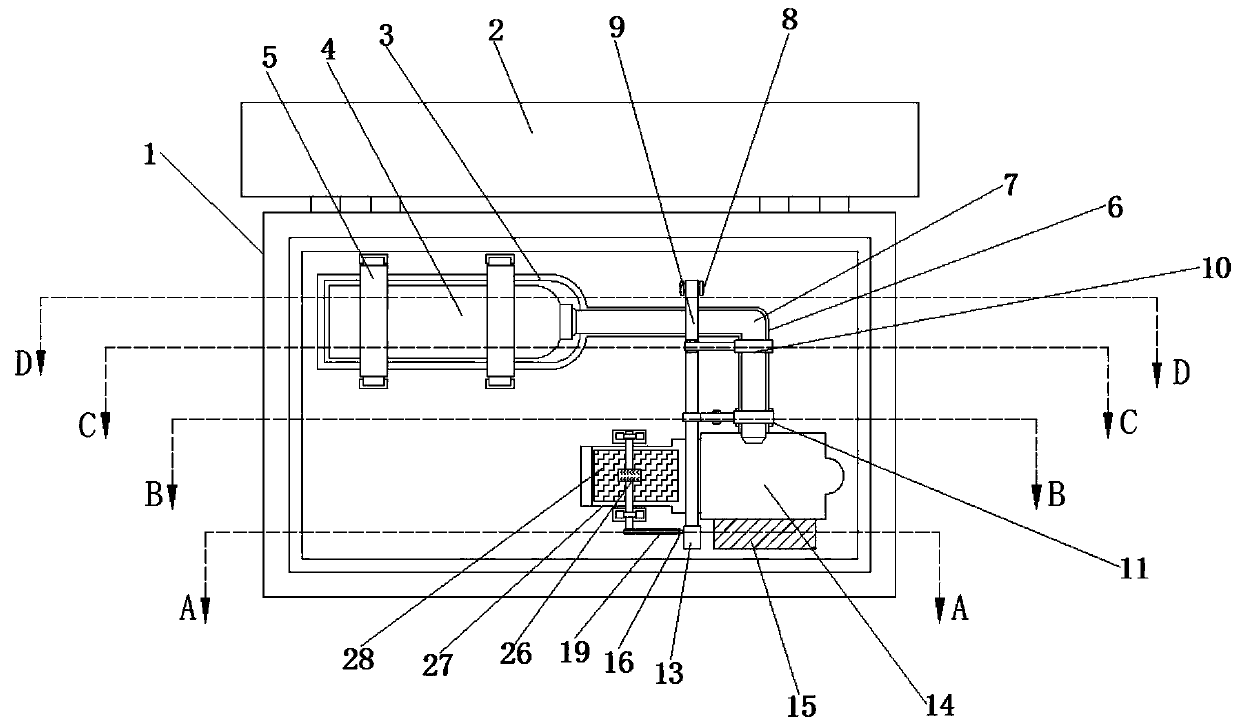

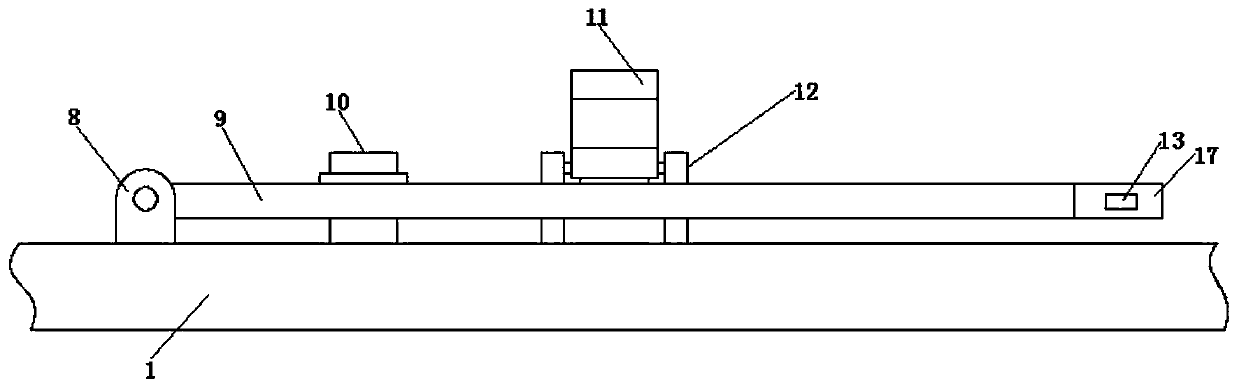

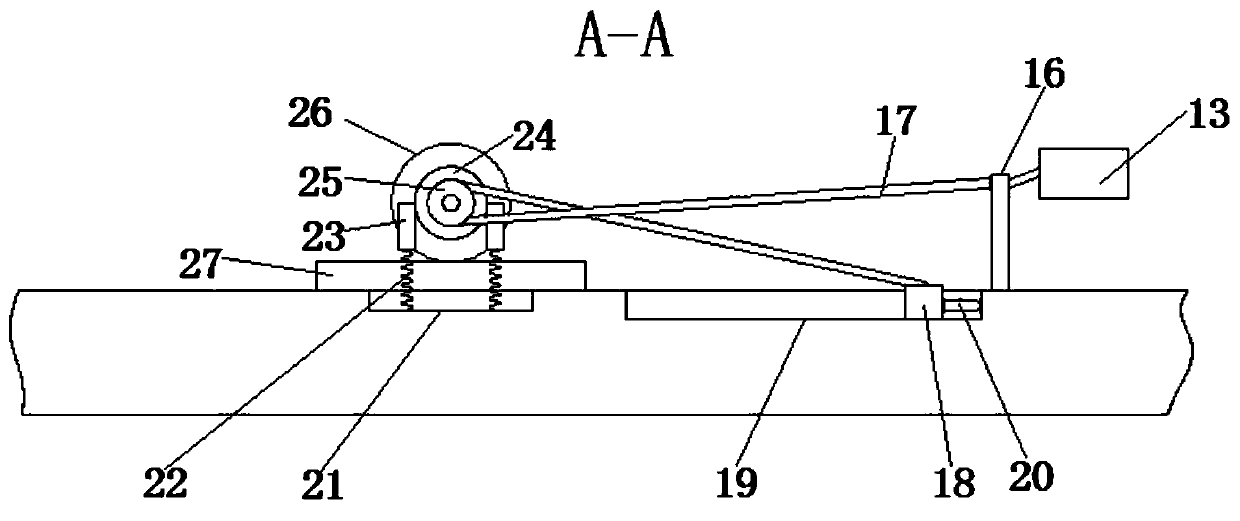

Bearing surface defect detection system based on statistical projection training and detection method

PendingCN109975307AUniform brightness distributionReduce the impact of projected feature extractionImage enhancementImage analysisBearing surfaceSystem structure

The invention discloses a bearing surface defect detection system based on statistical projection training and a detection method. The system comprises a front-end information acquisition device, a computer, and an execution system. The front-end information acquisition device comprises a camera and a light source, and is placed on a bearing line to be detected. The computer comprises a client, animage processing module, and a decision output module. The client controls and displays the system and is connected to the image processing module and the decision output module. The computer makes the execution system carry out screening and overturning of a bearing. The system adopts ordered peak value energy to calculate and construct a characteristic vector of a projection curve, and trains asupport vector machine SVM to obtain a defect classifier and realizes binary classification detection of normal and defective bearings. The image processing module carries out preprocessing, polar coordinate transformation, image segmentation, characteristic extraction, and SVM training. The decision output module detects whether the bearing is defective through the trained classifier. The structure of the system is simple, robustness is high, and a double-sided defect of a bearing dust cover can be detected in online and real-time modes and can be removed.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

Kit for pesticide residue detection reagents

ActiveCN110006890AEasy to compareEasy to collectMaterial analysis by observing effect on chemical indicatorHinge angleReagent bottle

The invention discloses a kit for pesticide residue detection reagents. The kit comprises a kit body; the top end of the kit body is hinged with a sealing cover through a hinge; a placing groove is formed on the left side of the top end of the kit body; a detection reagent bottle is arranged in the placing groove; a pressure lever is welded on the front of a first rotating shaft; a pressure sheetis welded at the top end of the pressure lever; a rotating shaft is mounted at the top end of the kit body through a second rotating shaft; a grip is welded at the end, far away from the first rotating shaft, of the pressure lever; a detection groove is formed on the right side of the upper surface of the kit body; and a comparison card is adhered to the upper surface of the kit body at the bottomend of the detection groove. The kit is ingenious in structure, and is capable of realizing automatic liquid taking through pressing the pressure lever and automatically placing test paper to facilitate the comparison and facilitate the test paper collection.

Owner:深圳三方圆检测监管服务有限公司

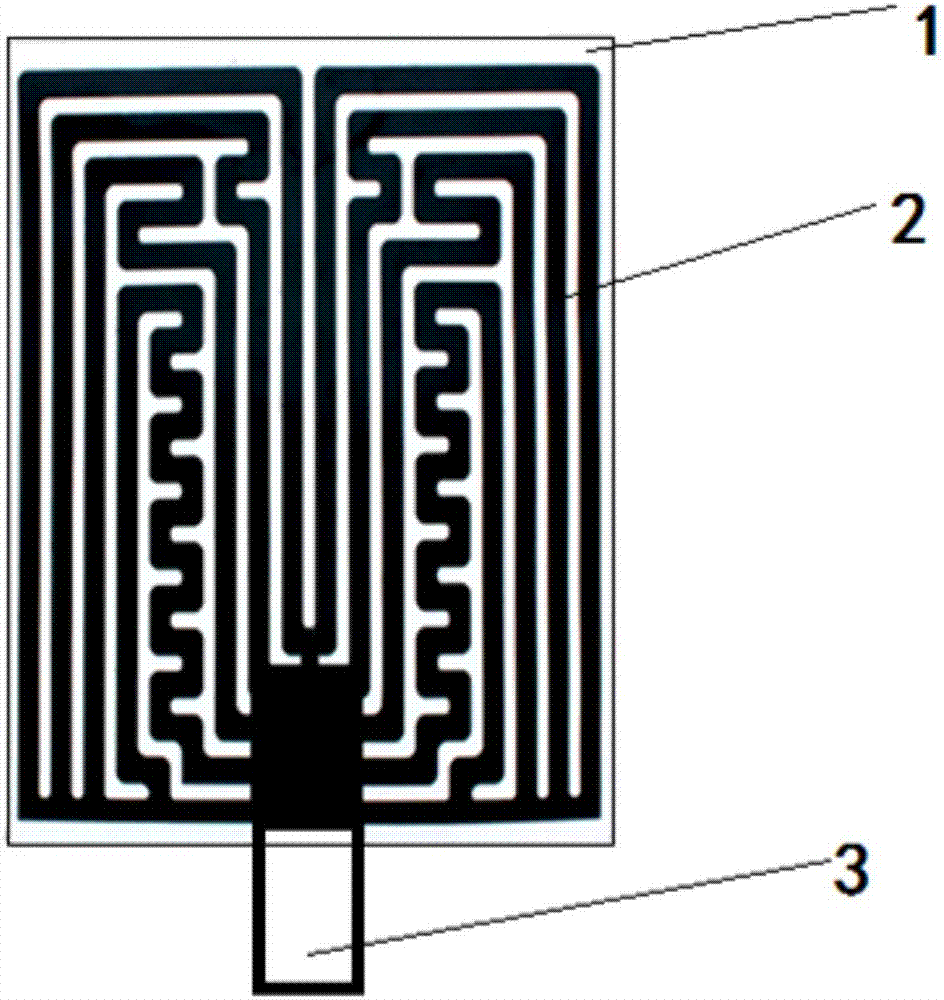

Automatic demisting shower room mirror

The invention discloses an automatic demisting shower room mirror. The automatic demisting shower room mirror comprises a shower room mirror, a humidity sensor and an electronic heating film, wherein the electronic heating film is adhered to the back surface of the shower room mirror; the humidity sensor is connected with the electronic heating film, and a power line is used for supplying power through 220 V commercial power; the electronic heating film is used for heating a mirror surface; and the humidity sensor is used for monitoring air humidity and controlling the turning-on and turning-off of the electronic heating film. According to the automatic demisting shower room mirror, the humidity sensor is used for monitoring the air humidity, the electronic heating film begins to work after target humidity is reached, and the mirror surface is heated, so that mist on the mirror surface is automatically evaporated, and the effect of removing the mist is reached.

Owner:ZHEJIANG UNIV

Forming die for stamping parts

InactiveCN113664110ARealize station conversionRun accuratelyShaping toolsStripping-off devicesMachiningIndustrial engineering

The invention is suitable for the technical field of machining equipment, and provides a forming die for stamping parts. The forming die for the stamping parts comprises an upper die part, a lower die part, a transmission mechanism, a rotating mechanism and a collecting tank, wherein the upper die part is arranged on the lower die part in an up-down sliding mode; the lower die assembly comprises a rotating base and a rotating table; the rotating table is rotationally mounted on the base; multiple rotating lower forming dies are arranged on the rotating table in an array mode; the transmission mechanism is arranged between the upper die part and the lower die part and used for driving the upper die part to drive the rotating table to rotate intermittently in the ascending process; the rotating mechanism is arranged on the lower die part and used for driving the lower forming dies to turn over, and used for driving the lower forming dies to turn over, so that the formed parts can be automatically unloaded; and the collecting tank is arranged on the base and used for collecting the automatically unloaded parts. According to the forming die for the stamping parts provided by the invention, automatic unloading is achieved, and operation is stable.

Owner:安徽沪鼎轴承有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com