Patents

Literature

59results about How to "Guarantee the quality of production and processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

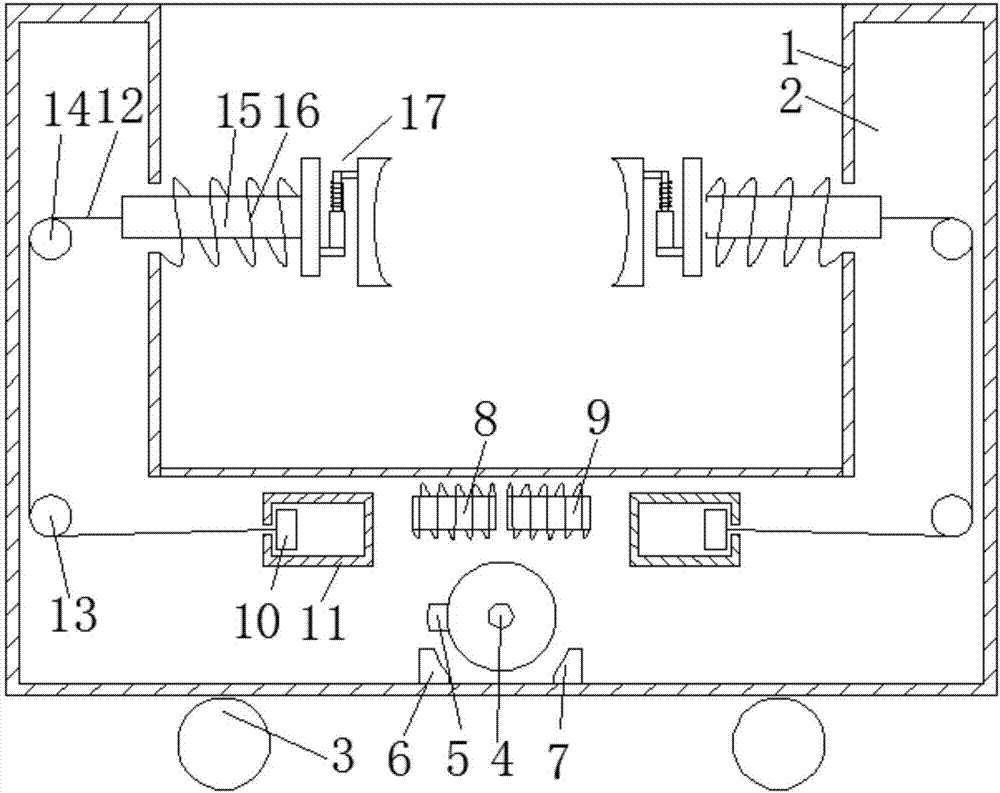

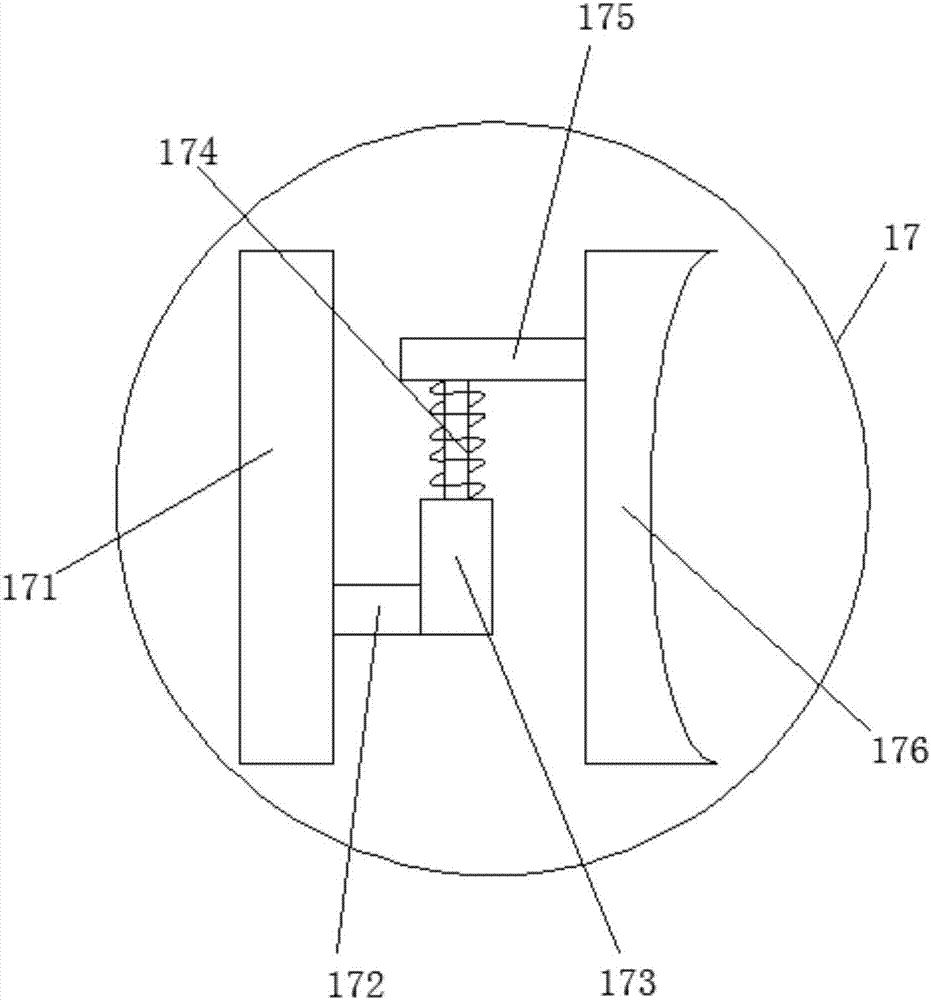

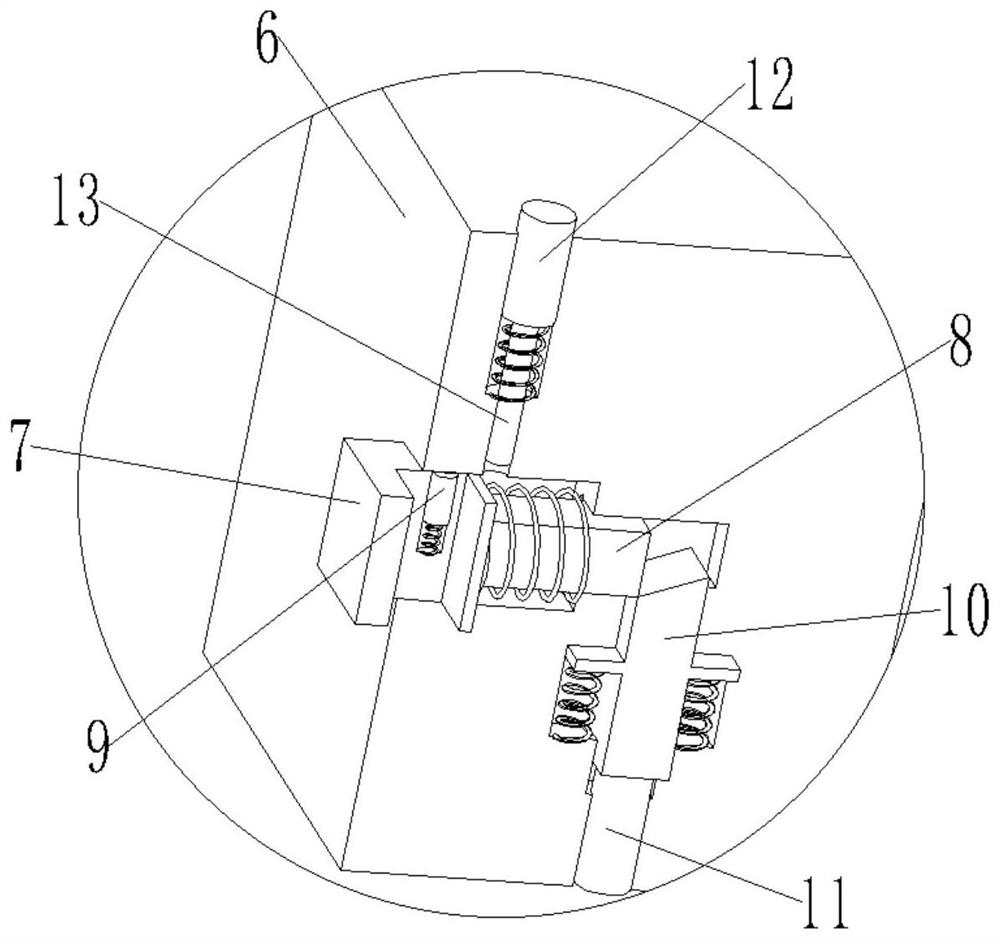

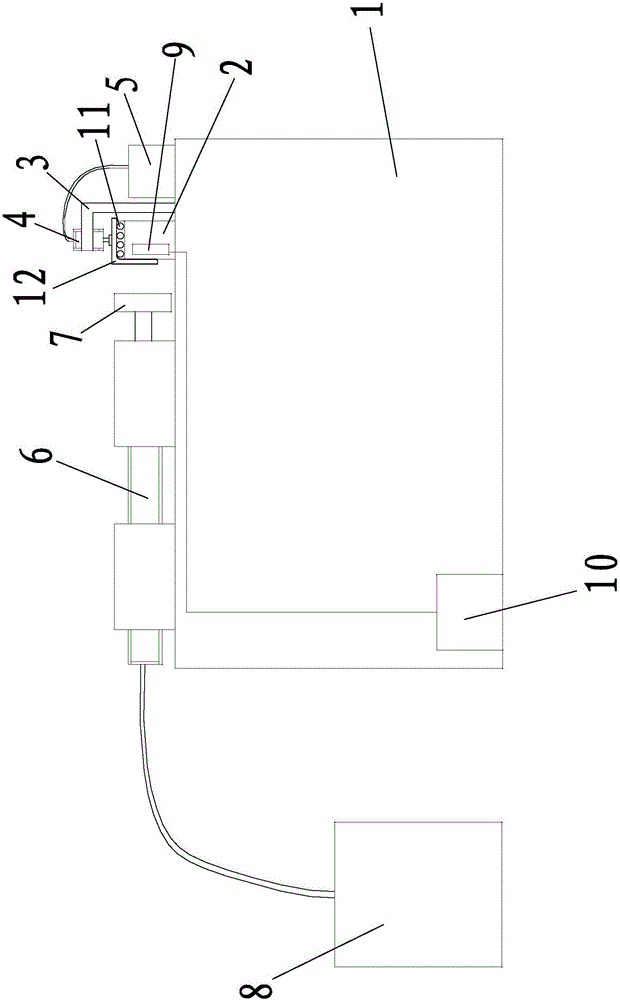

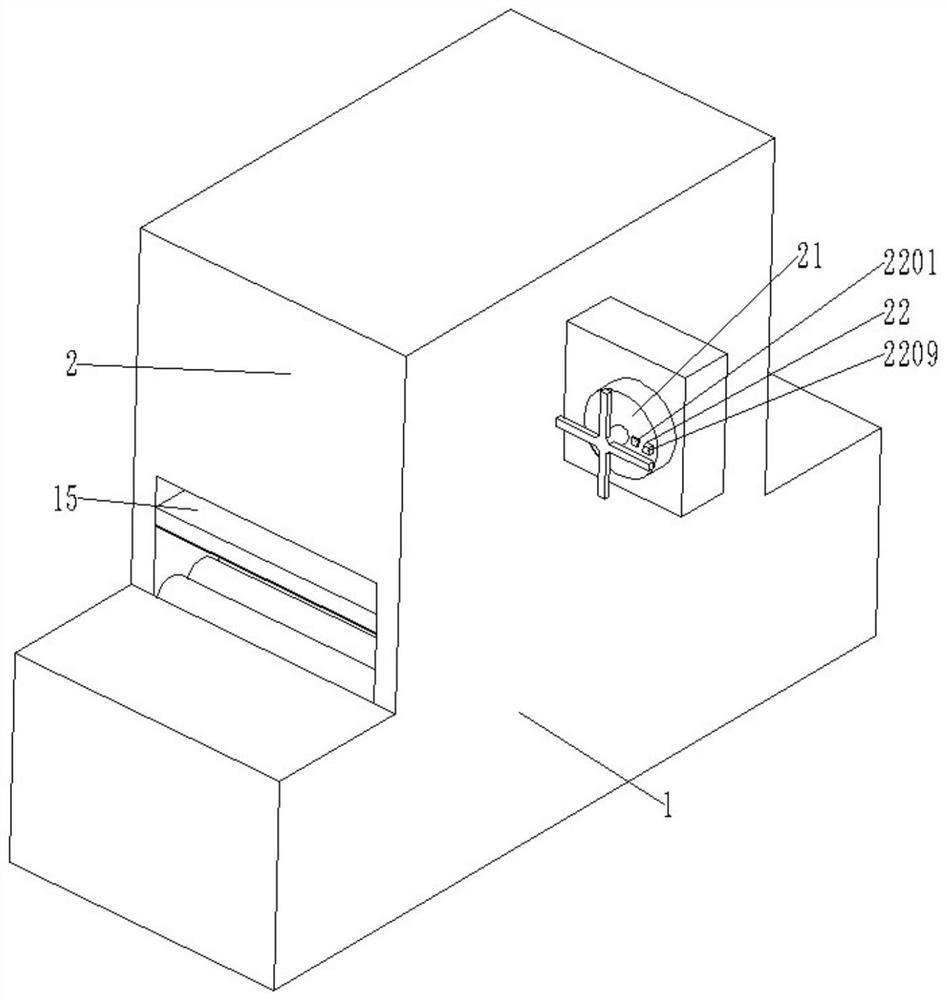

Copper product mould cleaning device

The invention discloses a copper product mould cleaning device. A mounting cavity is formed in the side wall of a cleaning tank body; a motor is connected with the side wall of the mounting cavity; a rotating shaft on the motor is connected with a disk; the outer ring of the disk is connected with a guide piece; a first contact piece and a second contact piece which are matched with the guide piece are arranged below the disk; and the first contact piece and the second contact piece are connected with the bottom wall of the mounting cavity. According to the copper product mould cleaning device, the structure is simple, a connecting rod is restored in place, when the guide piece is in contact with the second contact piece, a second electromagnet is electrified, an armature matched with the second electromagnet is attracted, the connecting rod moves back and forth, two clamping devices are matched with each other, a fixed mould and the connecting rod move alternately in a reciprocating mode to drive the mould to move. The copper product mould cleaning device has the advantages that automatic cleaning is realized, high-efficiency dust removal is realized, the mould is more fully and thoroughly cleaned, the service performance of the mould is greatly improved, and the production and processing quality of a copper product is effectively ensured.

Owner:程立章

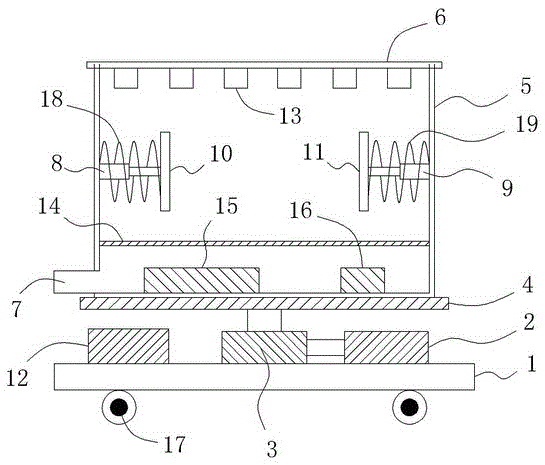

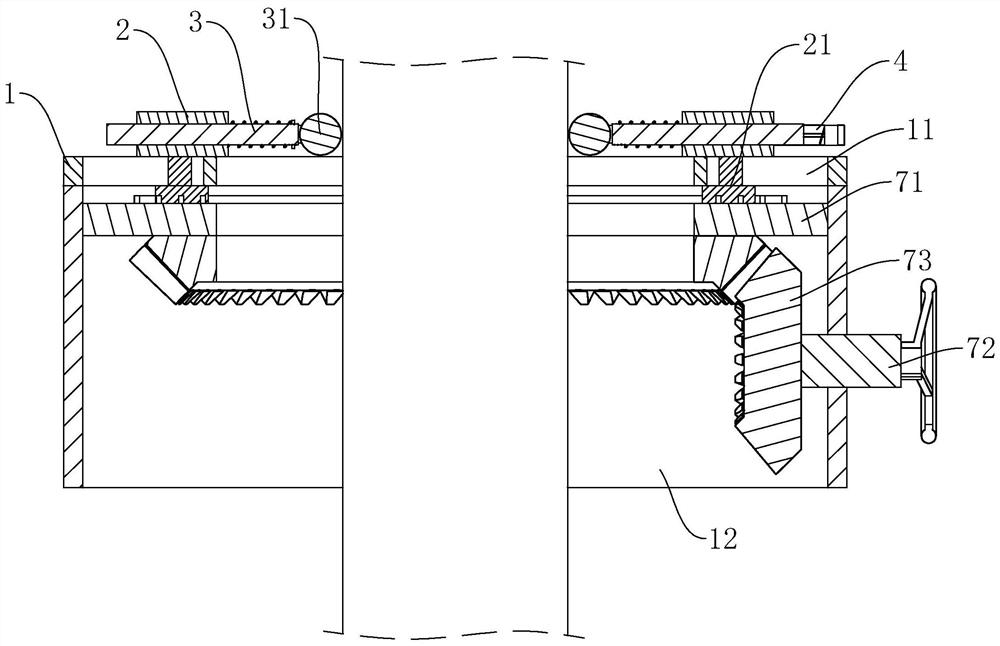

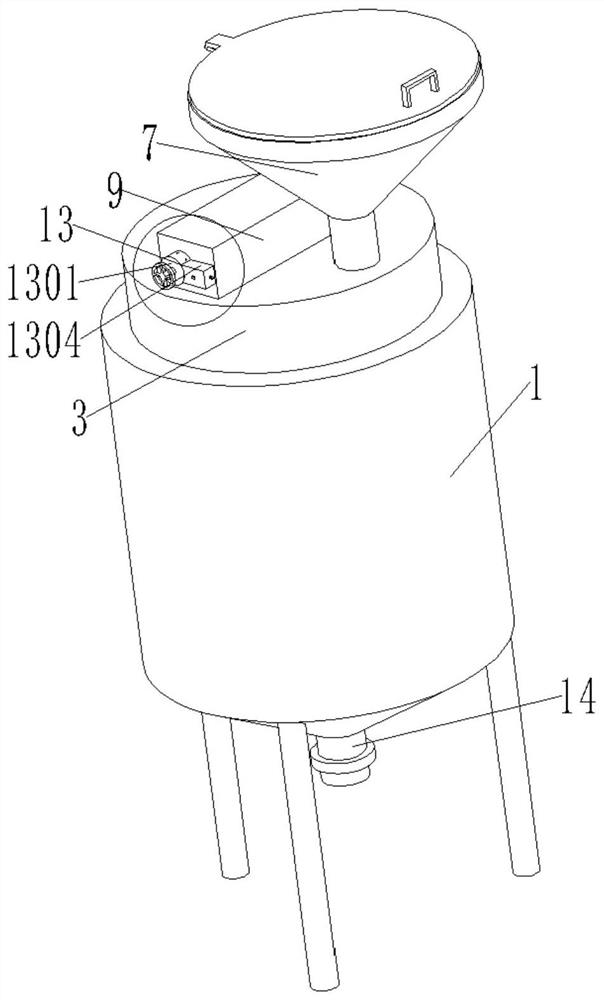

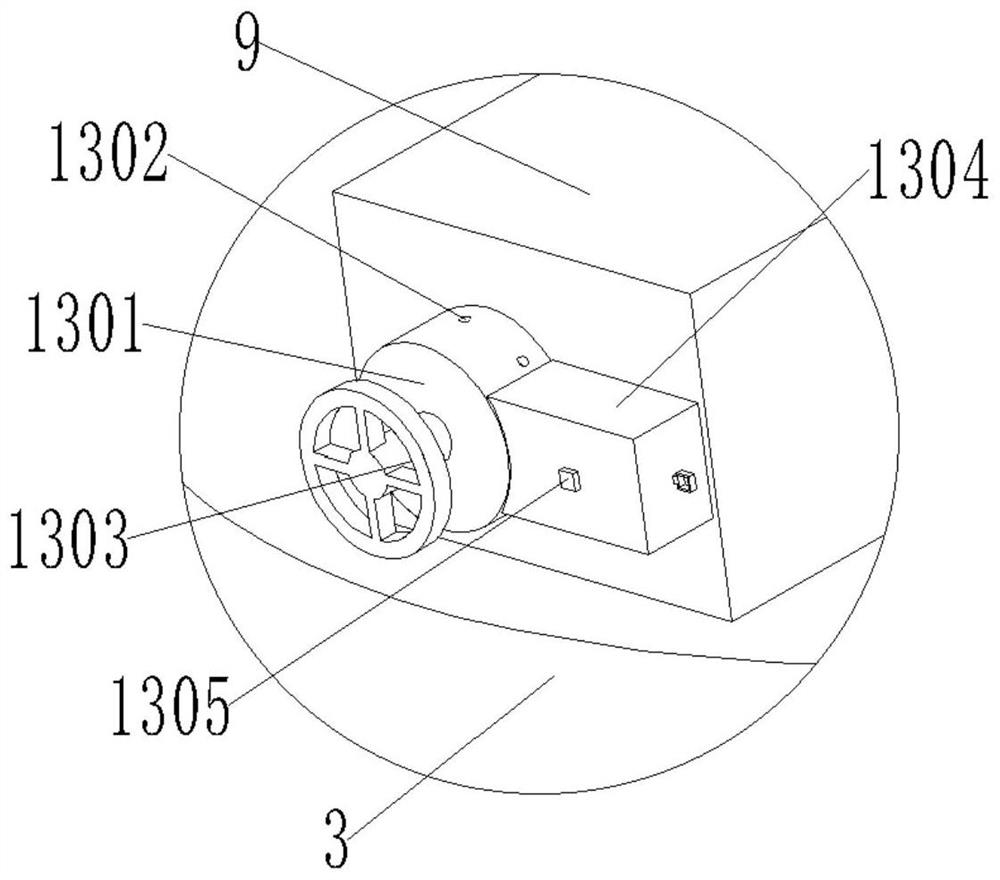

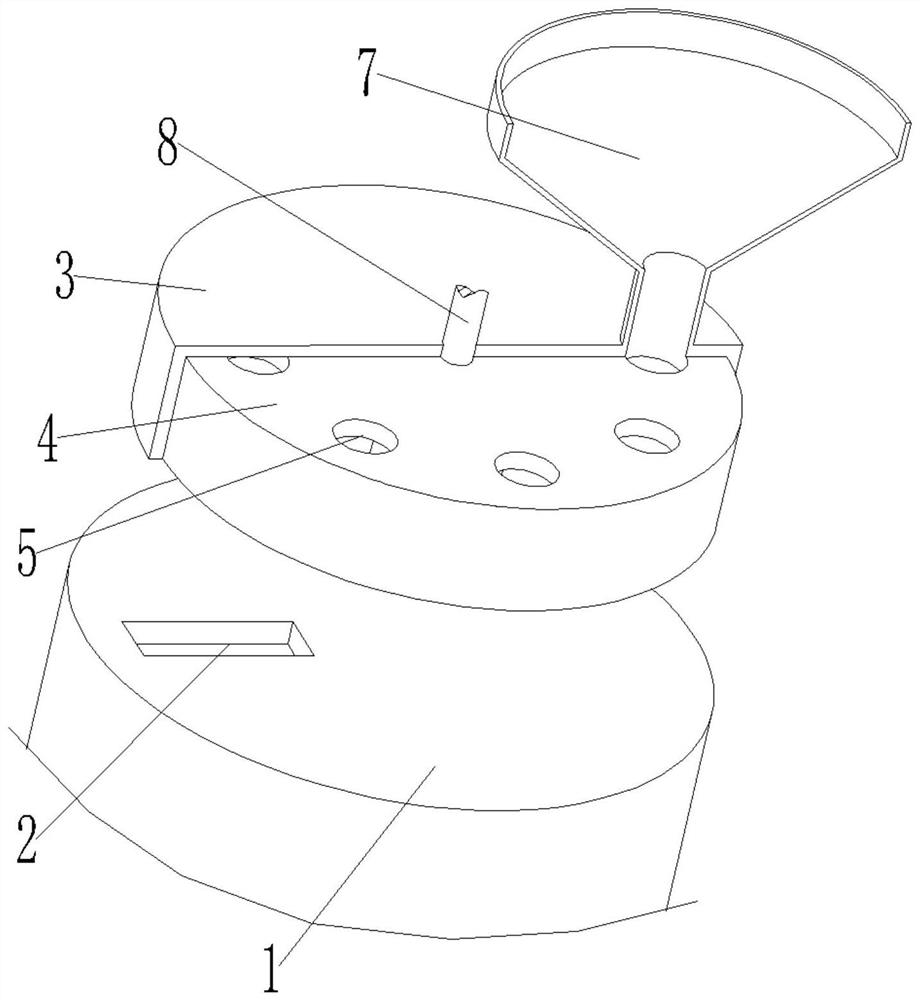

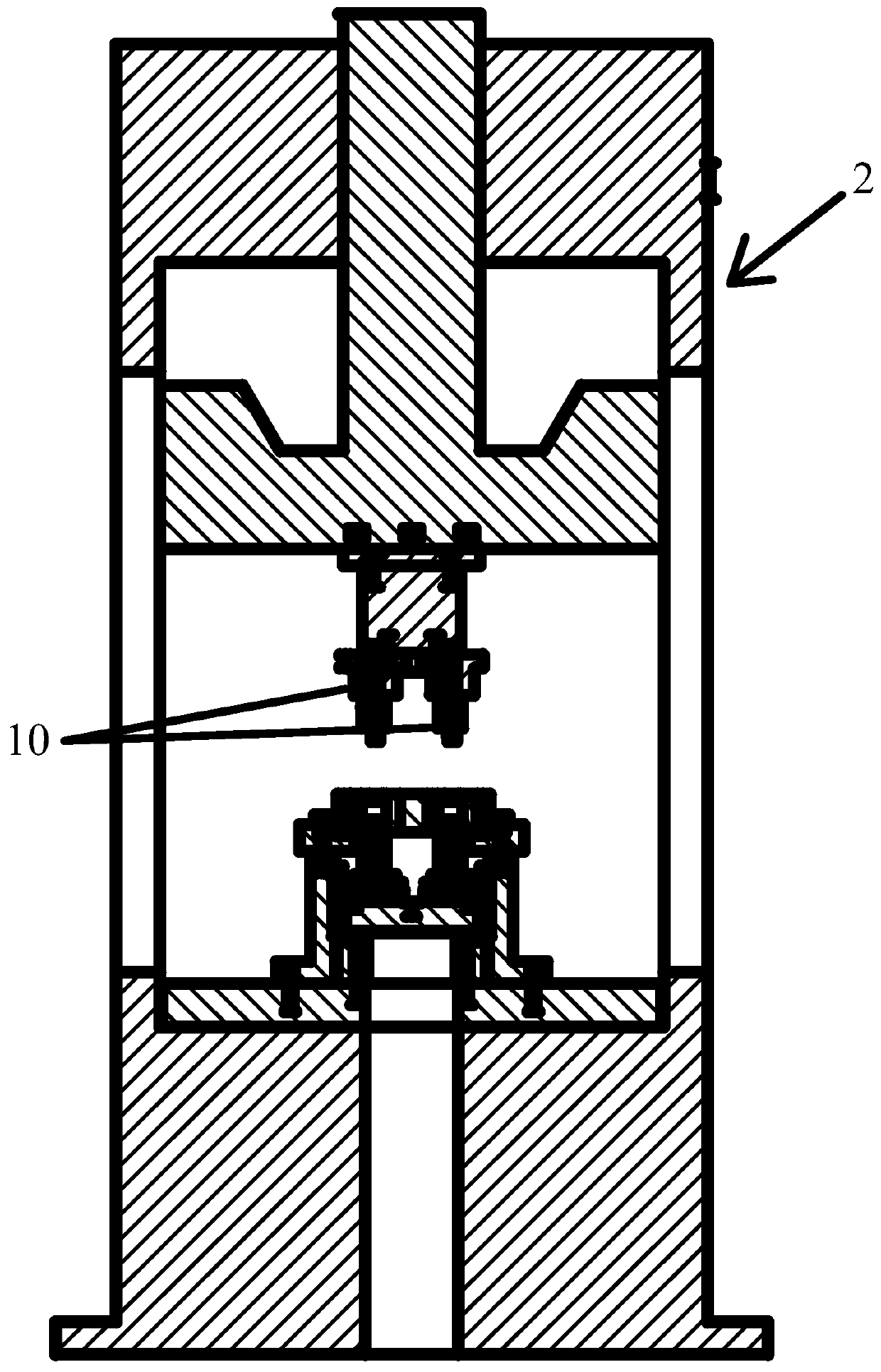

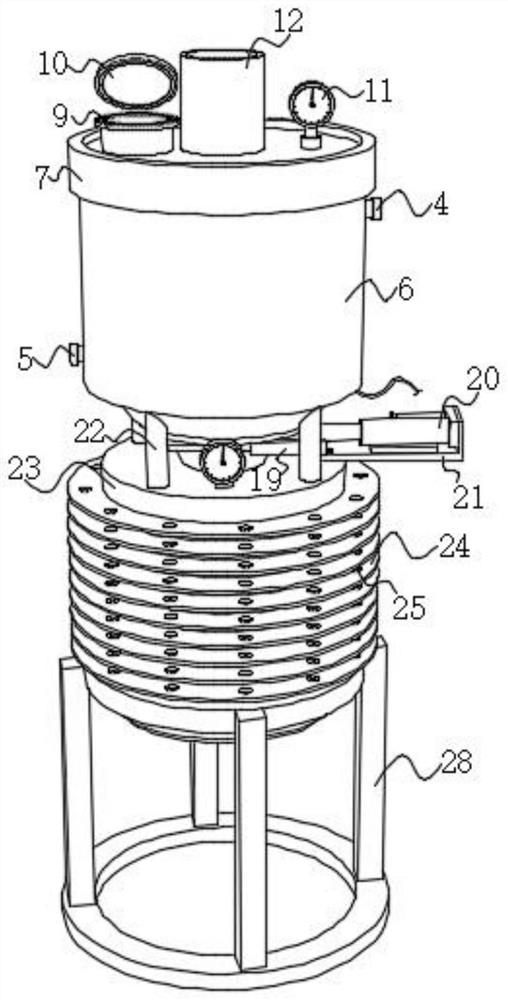

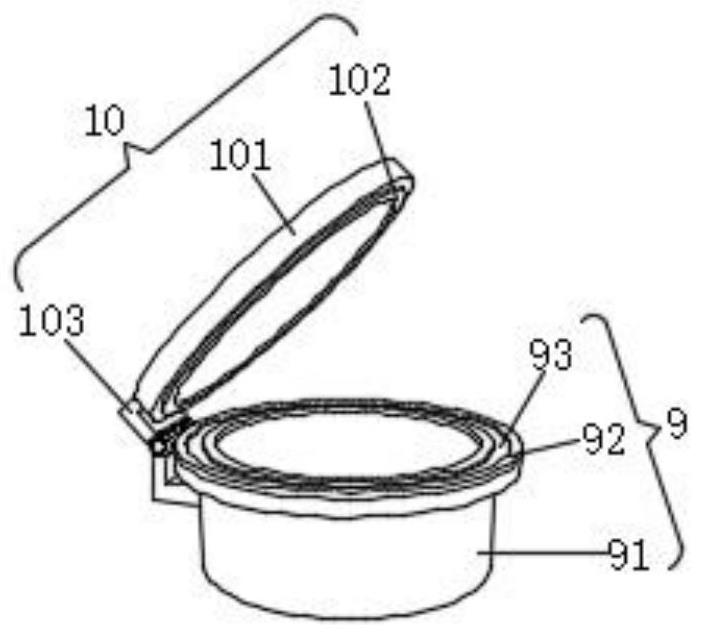

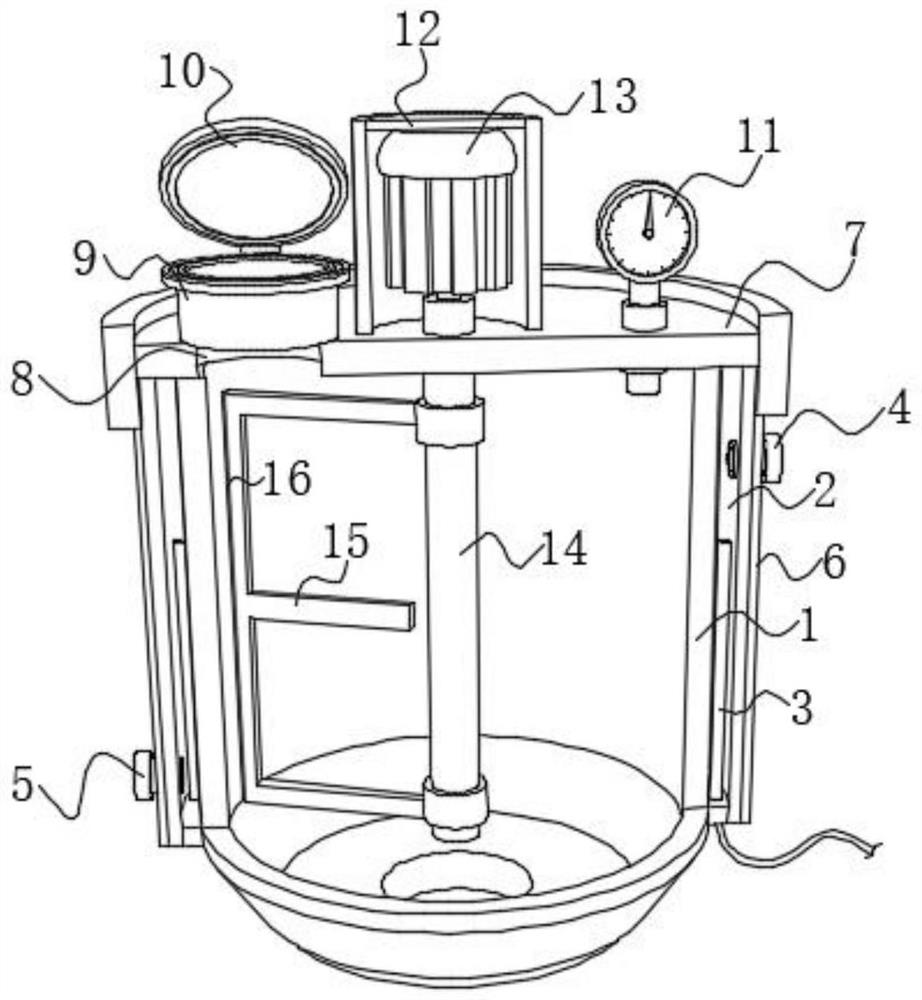

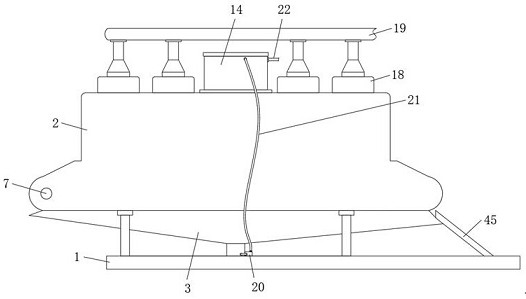

Novel casting mold cleaning device

InactiveCN105618426AFully cleanedWash thoroughlyCleaning using liquidsEngineeringUltrasonic vibration

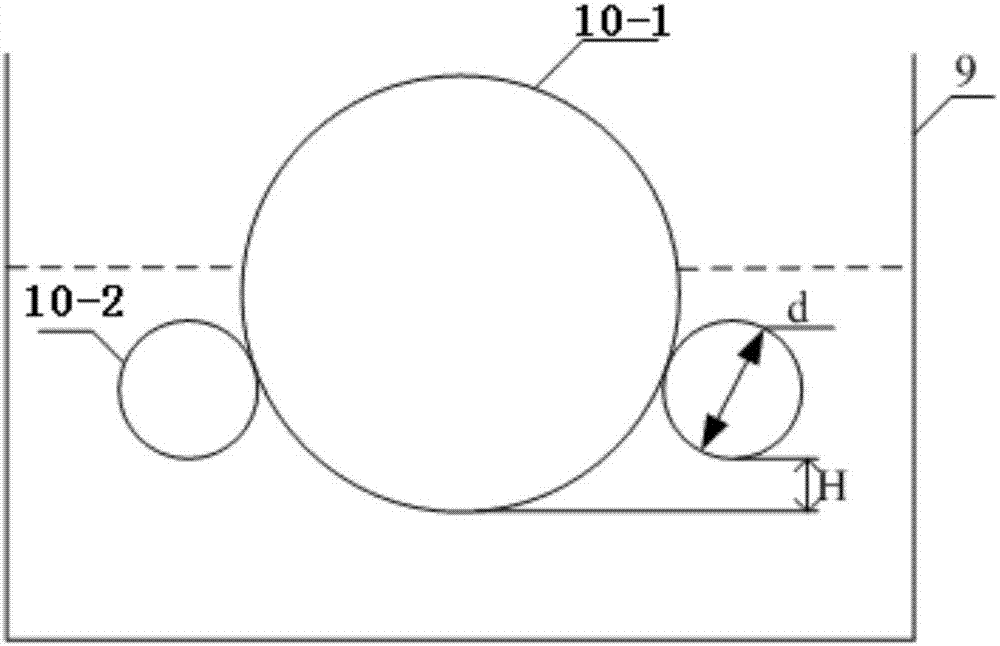

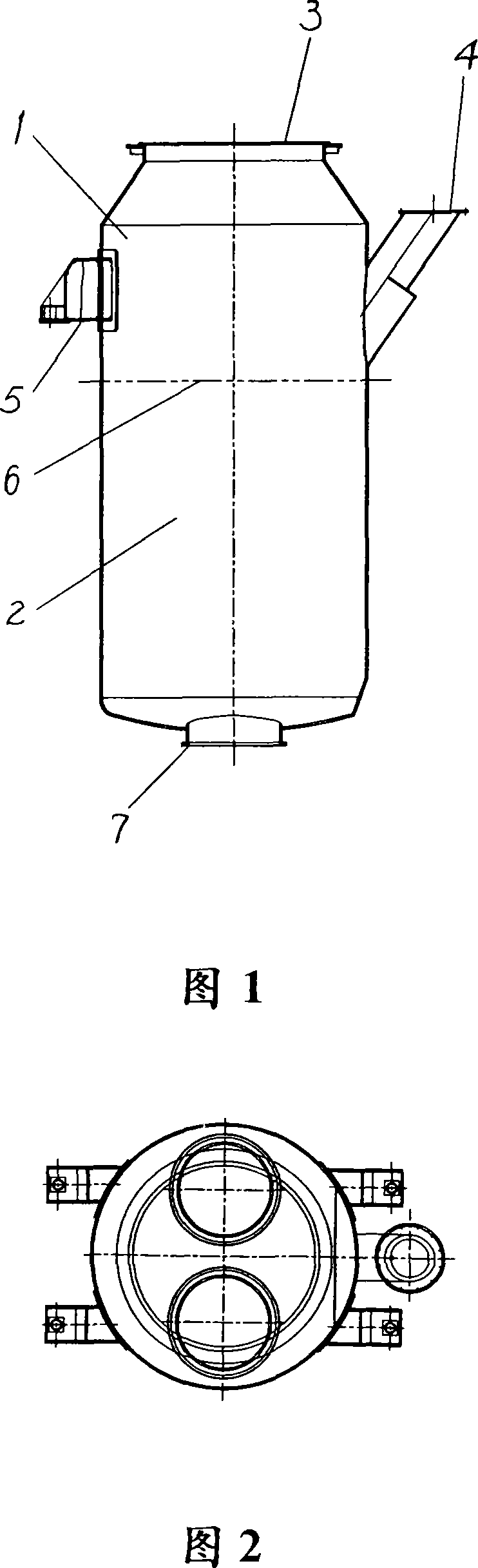

The invention relates to a novel casting mold cleaning device. The novel casting mold cleaning device comprises a base, and a motor and a speed reducer are arranged on the base; a tray is arranged at the output shaft end of the speed reducer, and a cleaning barrel is mounted on the tray; a barrel cover is arranged at the top end of the cleaning barrel, a water inlet is formed in the barrel cover, and a water draining opening is formed in the bottom of the cleaning barrel; a left telescopic rod is arranged on the left side inside the cleaning barrel, and a right telescopic rod is arranged on the right side inside the cleaning barrel; the left telescopic rod and the right telescopic rod are both provided with locking bolts; a left arc-shaped plate is further arranged at the right end of the left telescopic rod, and a right arc-shaped plate is further arranged at the left end of the right telescopic rod; an ultrasonic generator is arranged on the base, and a plurality of ultrasonic vibration heads connected with the ultrasonic generator are evenly distributed at the bottom end of the barrel cover; a partition plate is further arranged at the bottom inside the cleaning barrel, and a plurality of water passing holes are distributed in the partition plate; and an electric heater is further arranged below the partition plate. Through the above structure, a casting mold can be cleaned more sufficiently and thoroughly, and therefore the use performance of the device is greatly improved.

Owner:CHENGDU JUZHI IND DESIGN

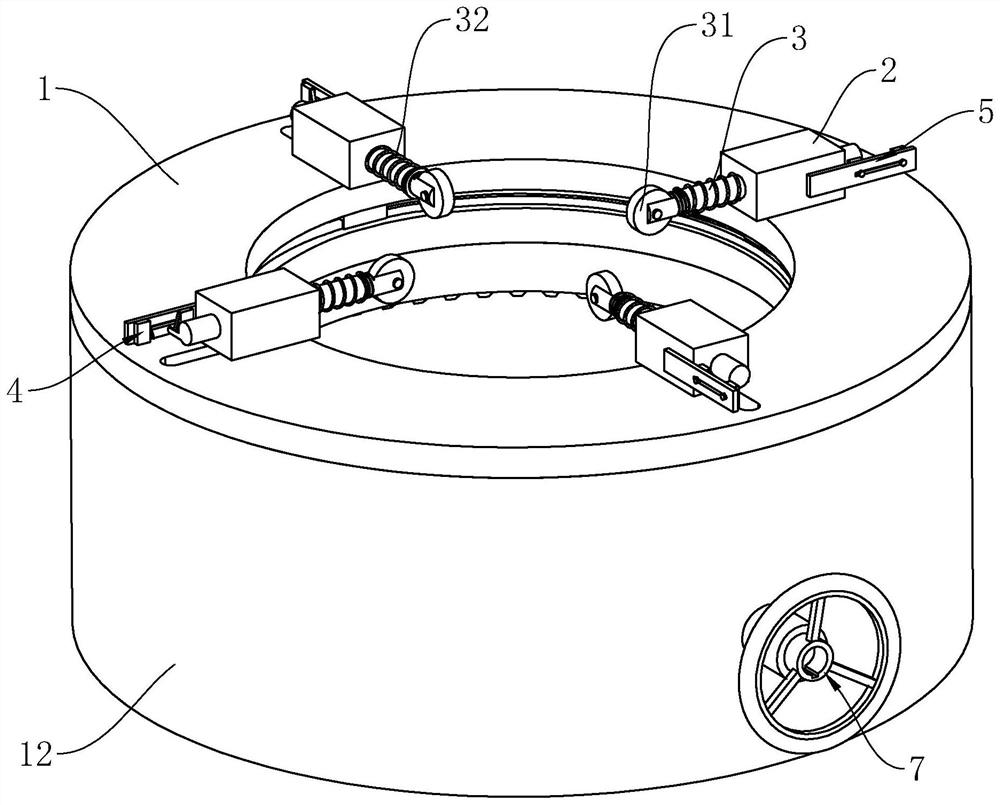

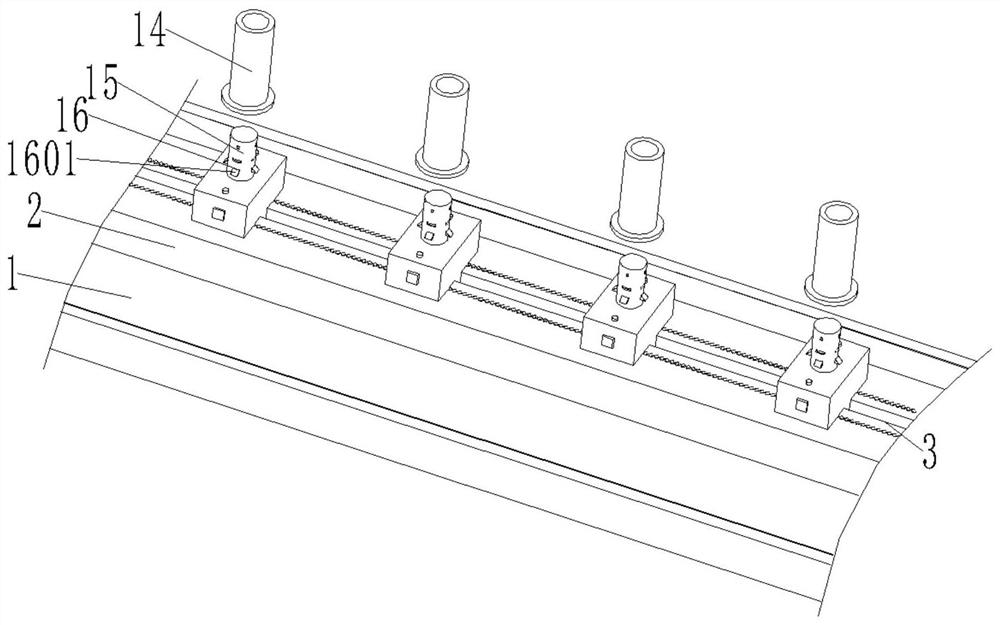

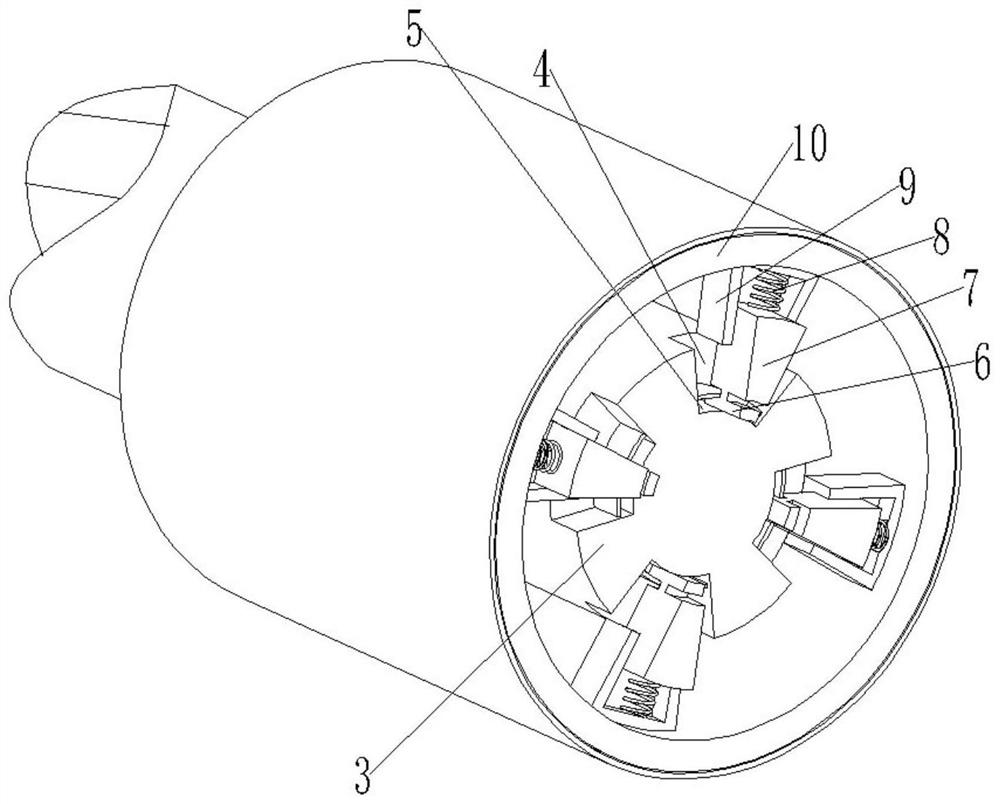

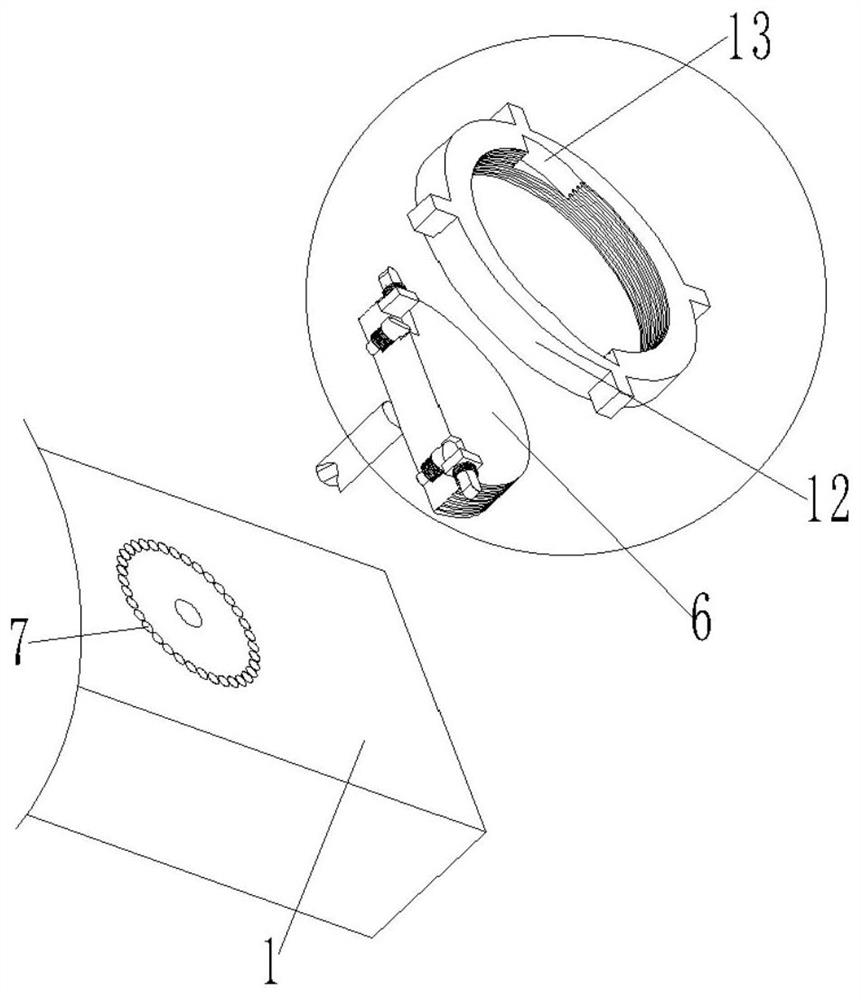

Detection device for high-temperature cable processing and processing technology thereof

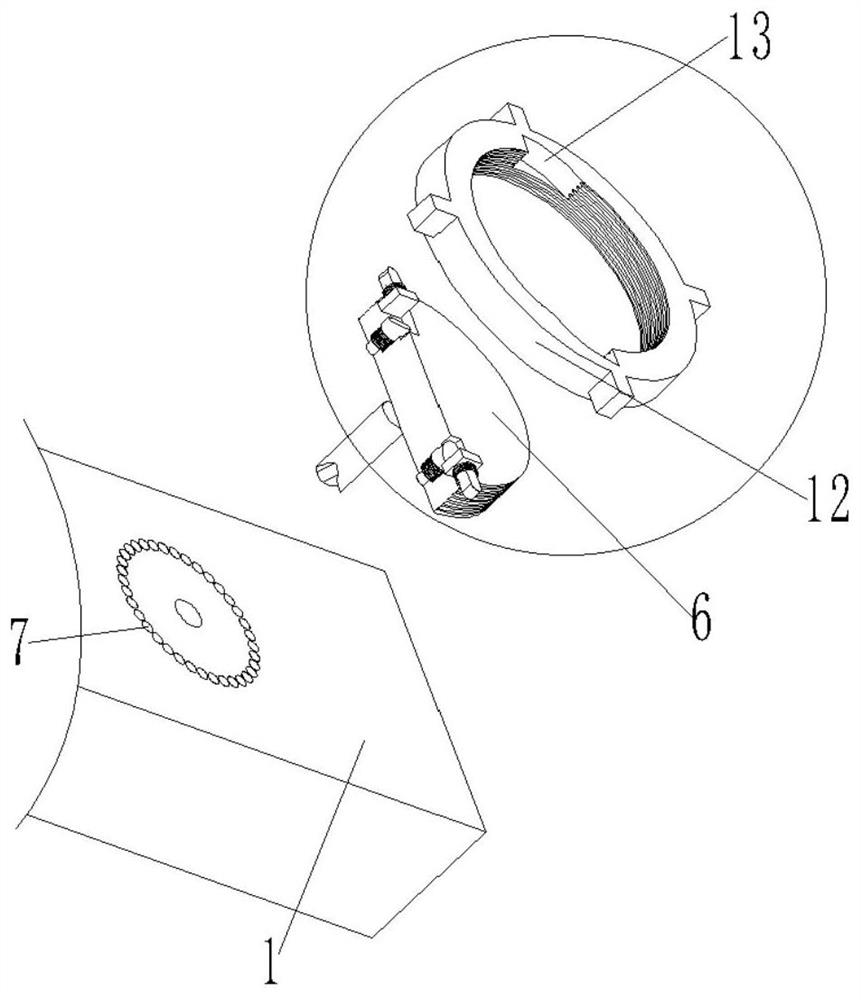

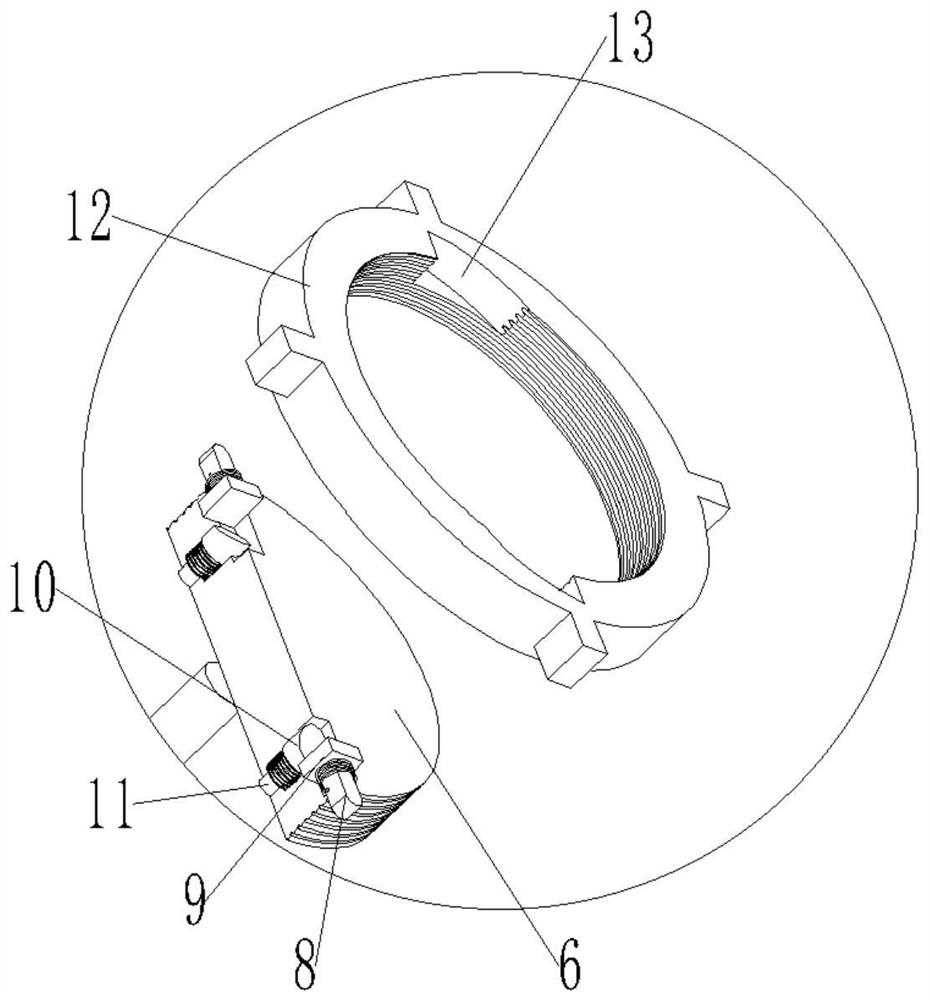

PendingCN113091678AGuarantee the quality of processing and productionIncrease the scope of applicationMeasurement devicesInsulating conductors/cablesEngineeringStructural engineering

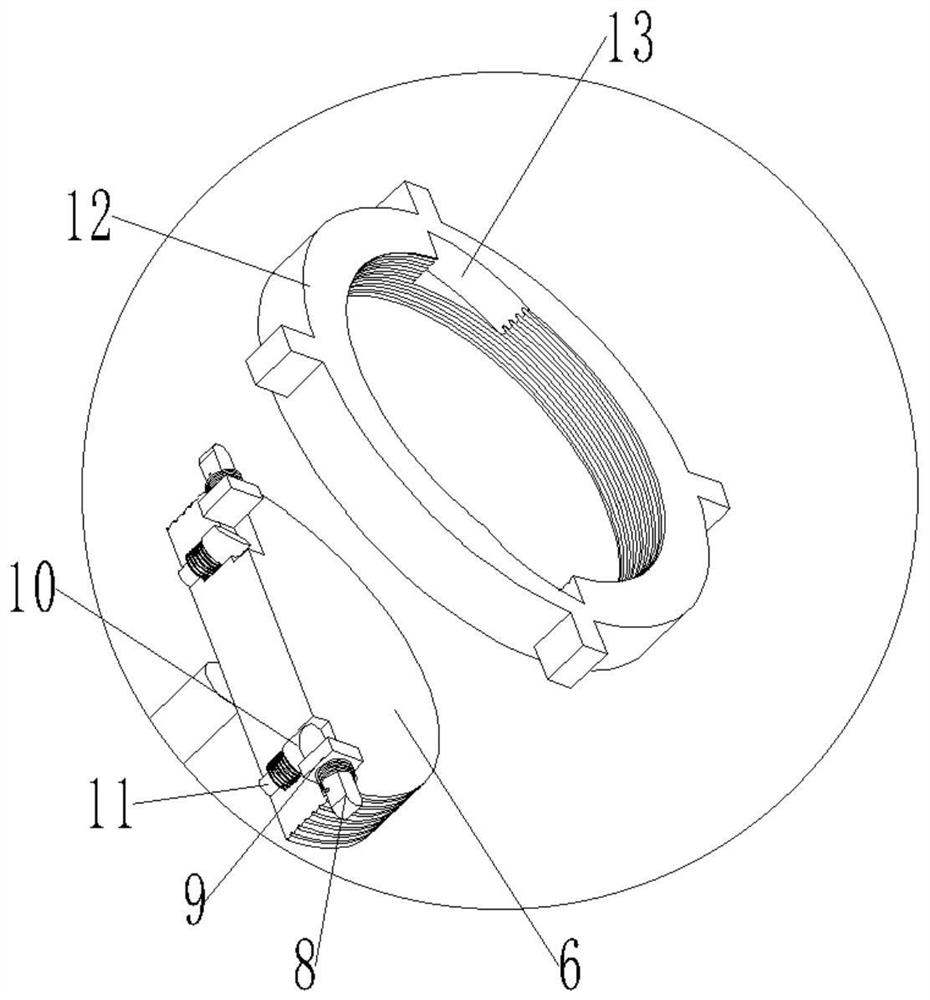

The invention relates to a detection device for high-temperature cable processing and a processing technology thereof, and belongs to the technical field of high-temperature cable processing, the detection device comprises a mounting ring, a plurality of mounting blocks arranged on the mounting ring, and detection rods arranged on each mounting block; the inner diameter of the mounting ring is greater than the diameter of a processed cable, and the mounting blocks and the detection rods are distributed at intervals along the circumferential direction of the mounting ring; and the detection rods can slide on the corresponding installation blocks in the radial direction of the installation ring, elastic pieces and displacement detection mechanisms are arranged between the detection rods and the installation blocks, the elastic pieces provide thrust for the detection rods to slide in the axis direction of the installation ring, and the displacement detection mechanisms are used for measuring the displacement amount of the detection rods. Through the contact between the plurality of detection rods and the cable insulation skin and the movement of the detection rods along with the change of the cable diameter, the purpose of real-time detection of the cable diameter is achieved, the abnormal position of the cable insulation skin can be found in time, and the processing and production quality of the cable is ensured.

Owner:上海申巨高温线有限公司

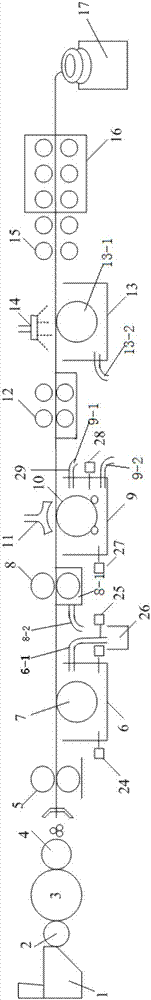

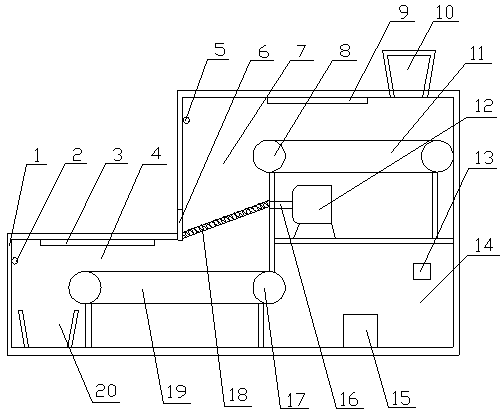

Continuous indigo dyeing device and dyeing method for cotton sliver

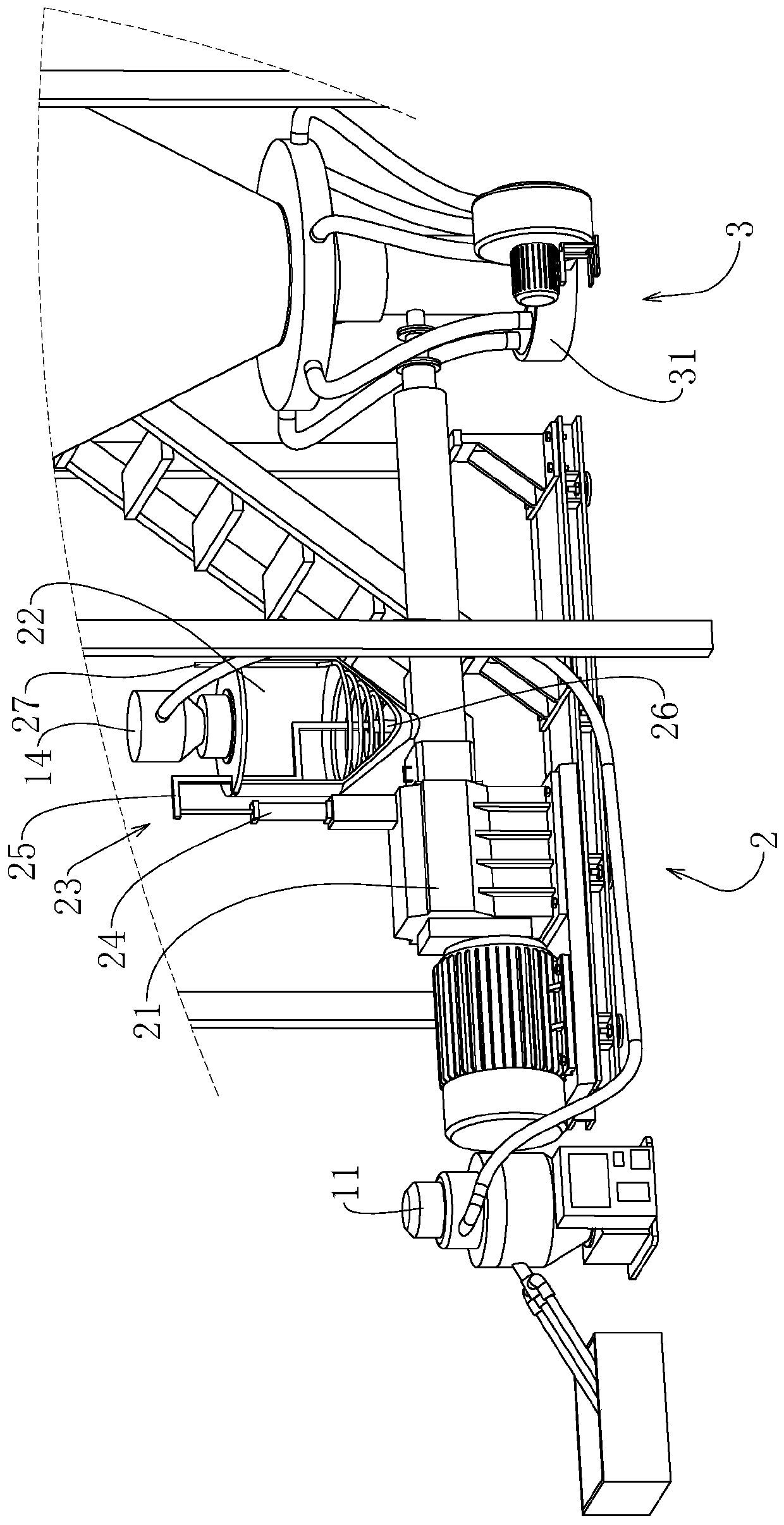

InactiveCN107059284AIncreased production flexibilityReduces unintended draft tension effectsLiquid/gas/vapor removal by squeezing rollersFibre cleaning/openingEngineeringPre treatment

The invention discloses a continuous indigo dyeing device for cotton sliver. The device comprises a pre-treatment device, a dyeing device, a raw cotton feeding device and a post-treatment device, all of which are orderly arranged. The pre-treatment device comprises the raw cotton feeding device, a loosening roll, a carding roll, a collection and slivering device, a cotton sliver wetting device, a scouring groove, a scouring rotary drum and a pair of liquid pressing rolls A. The continuous indigo dyeing device for cotton sliver has the following beneficial effects: sliver equipment, sliver scouring, sliver dyeing and water scrubbing and drying processes are effectively integrated so that phenomena in the prior art are avoided during a sliver processing and production process such as non-uniformity and broken ends due to accidental stretching; and high efficiency short-flow production of denim indigo is achieved. The invention further discloses a method for dyeing with the dyeing device.

Owner:XI'AN POLYTECHNIC UNIVERSITY

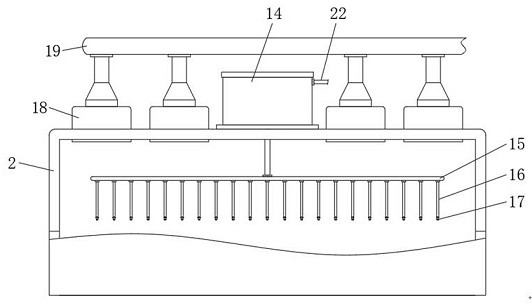

Drying device for LED aluminum substrates

InactiveCN106403552ADry evenly and fullyGuarantee the quality of production and processingDrying gas arrangementsDrying chambers/containersEngineeringAluminum substrate

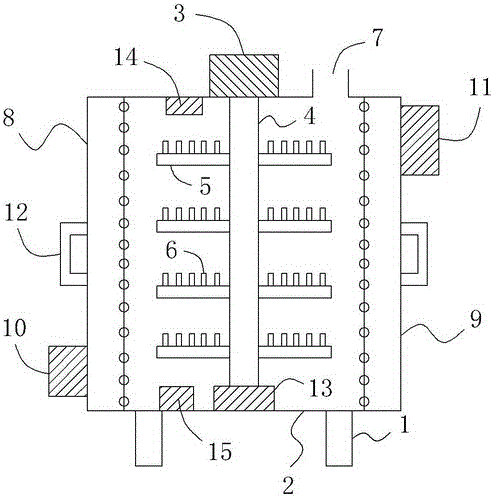

The invention relates to a drying device for LED aluminum substrates. The drying device comprises a support and a cabinet body; a cabinet door is arranged on the front side wall of the cabinet body; a rotating motor is arranged at the top end of the outer part of the cabinet body; the bottom end of an output shaft of the rotating motor is connected with a rotating shaft extending vertically downwards; the rotating shaft is fixedly sleeved with circular trays; tray ventilating holes are formed in the circular trays; needle-like bulges extending vertically upwards are uniformly distributed on top planes of the circular trays; an exhaust port is formed in the top wall of the cabinet body; a left cavity and a right cavity are formed in the left side and the right side of the cabinet body respectively; multiple left ventilating holes and multiple right ventilating holes are uniformly formed in the left side wall and the right side wall of the cabinet body; a left air heater is arranged at the lower part of the left side of the left cavity; a right air heater is arranged at the upper part of the right side of the right cavity; an air outlet of the left air heater communicates with the left cavity; and an air outlet of the right air heater communicates with the right cavity. With the adoption of the structure, the aluminum substrates placed in the device can be dried sufficiently and uniformly, so that the production and machining quality and the service life of LED lamps are greatly guaranteed.

Owner:CHENGDU JUZHI IND DESIGN

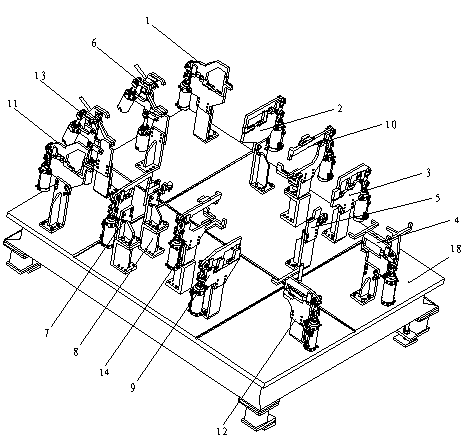

Clamp for automobile top cover assembly

InactiveCN103624446AEasy to fixGood and effective fixationWelding/cutting auxillary devicesAuxillary welding devicesEngineeringProduction quality

The invention provides a clamp for an automobile top cover assembly. The clamp comprises a platform and a clamping mechanism which is arranged on the platform. The clamping mechanism comprises an air window pull rod support left reinforcement plate clamping mechanism, a first top cover left support plate and a second top cover left support plate in sequence. An air window pull rod support right reinforcement plate clamping mechanism is arranged symmetrical to the air window pull rod support left reinforcement plate clamping mechanism, a first top cover right support plate clamping mechanism is arranged symmetrical to a first top cover left support plate clamping mechanism, a second top cover right support plate clamping mechanism is arranged symmetrical to a second top cover left support plate clamping mechanism, and a top cover right reinforcement plate clamping mechanism is arranged symmetrical to a top cover left reinforcement plate clamping mechanism. In the process of arranging positions of all the clamping mechanisms, according to production needs, the clamp for the automobile top cover assembly symmetrically, sufficiently and effectively fixes the automobile top cover assembly in a segmenting mode according to portions, and on the premise that a good fixing effect is guaranteed, machining operation performed on the assembly is not affected, and production quality is guaranteed.

Owner:JIANGSU KAWEI SPECIAL PURPOSE VEHICLE MFG

Product marinating equipment integrated with feeding and discharging, and feeding method thereof

ActiveCN113023387AEasy to addEasy dischargeClimate change adaptationFood shapingEconomic benefitsProcess engineering

The invention discloses product marinating equipment integrated with feeding and discharging, and a feeding method thereof. The marinating equipment comprises a marinating equipment main body, a feeding port, a containing cavity, a storage bin, a control mechanism and a discharging port. The product marinating equipment provided by the invention is provided with the feeding port and the discharging port, feeding and discharging are very convenient in the production process, and therefore the processing production efficiency is further improved; the economic benefit is improved; according to the feeding method of the product marinating equipment integrated with feeding and discharging, through arrangement of the containing cavity, the storage bin and the control mechanism, feeding can be controlled according to actual preparation requirements during feeding of the product marinating equipment, and equivalent feeding can be further achieved; and therefore, the processing production quality of the marinated products is ensured, and the production quality of the marinated products is ensured.

Owner:六安市胜缘食品有限公司

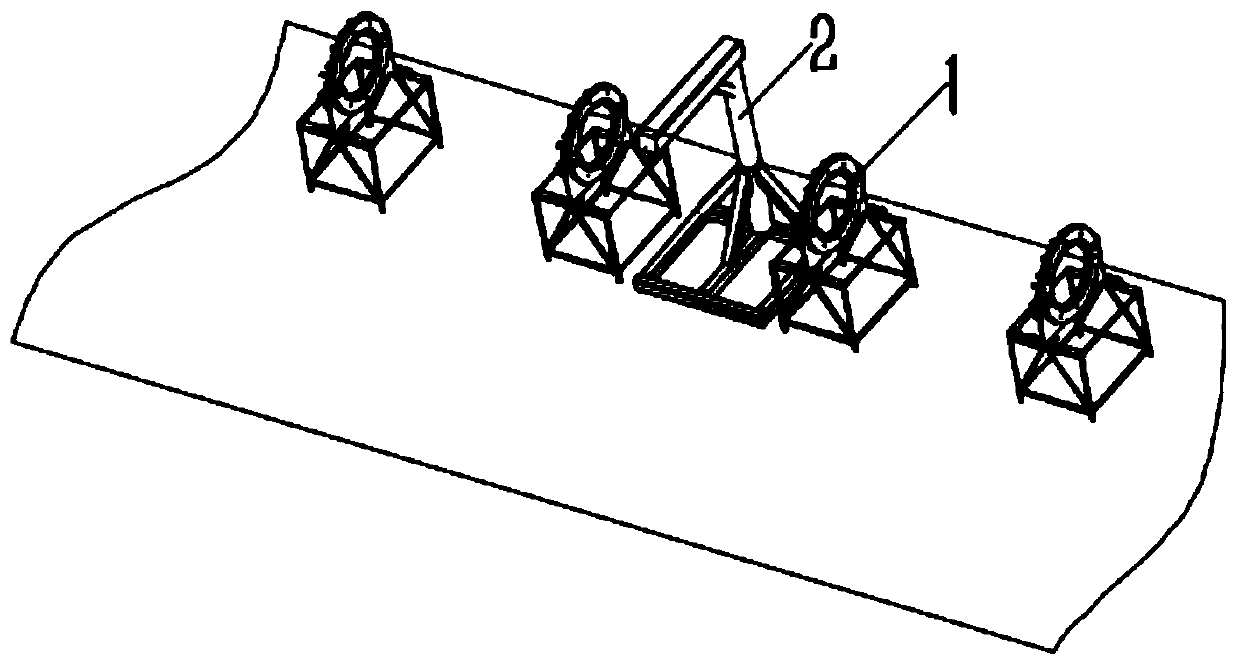

Construction site reinforcement cage machining and manufacturing device and technology

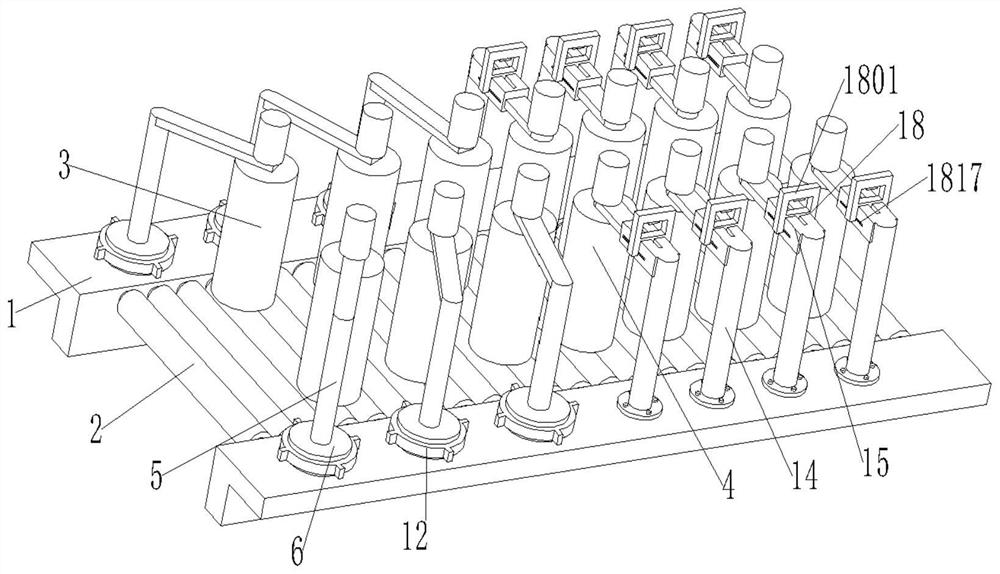

ActiveCN109954824AReduce configuration timeReduce repetitive and complicated actionsWire networkRebarMachining

The invention discloses a construction site reinforcement cage machining and manufacturing device and a technology. The machining device is mainly composed of a plurality of reinforcement cage machining bed jigs and a main reinforcement hoisting device, the reinforcement cage machining bed jigs are composed of brackets and main reinforcement positioning moulding bed discs, the reinforcement cage machining bed jigs are placed linearly and equidistantly, the main reinforcement hoisting device is arranged on the middle part of the reinforcement cage machining bed jigs, and machined main reinforcement, reinforced reinforcement and spiral stirrups are assembled in the reinforcement cage machining bed jigs. By adopting the construction site reinforcement cage machining and manufacturing device and the technology, the operating conditions of workers can be improved, and the machining quality and production efficiency of a reinforcement cage are obviously improved.

Owner:BEIJING TIANHENG CONSTR

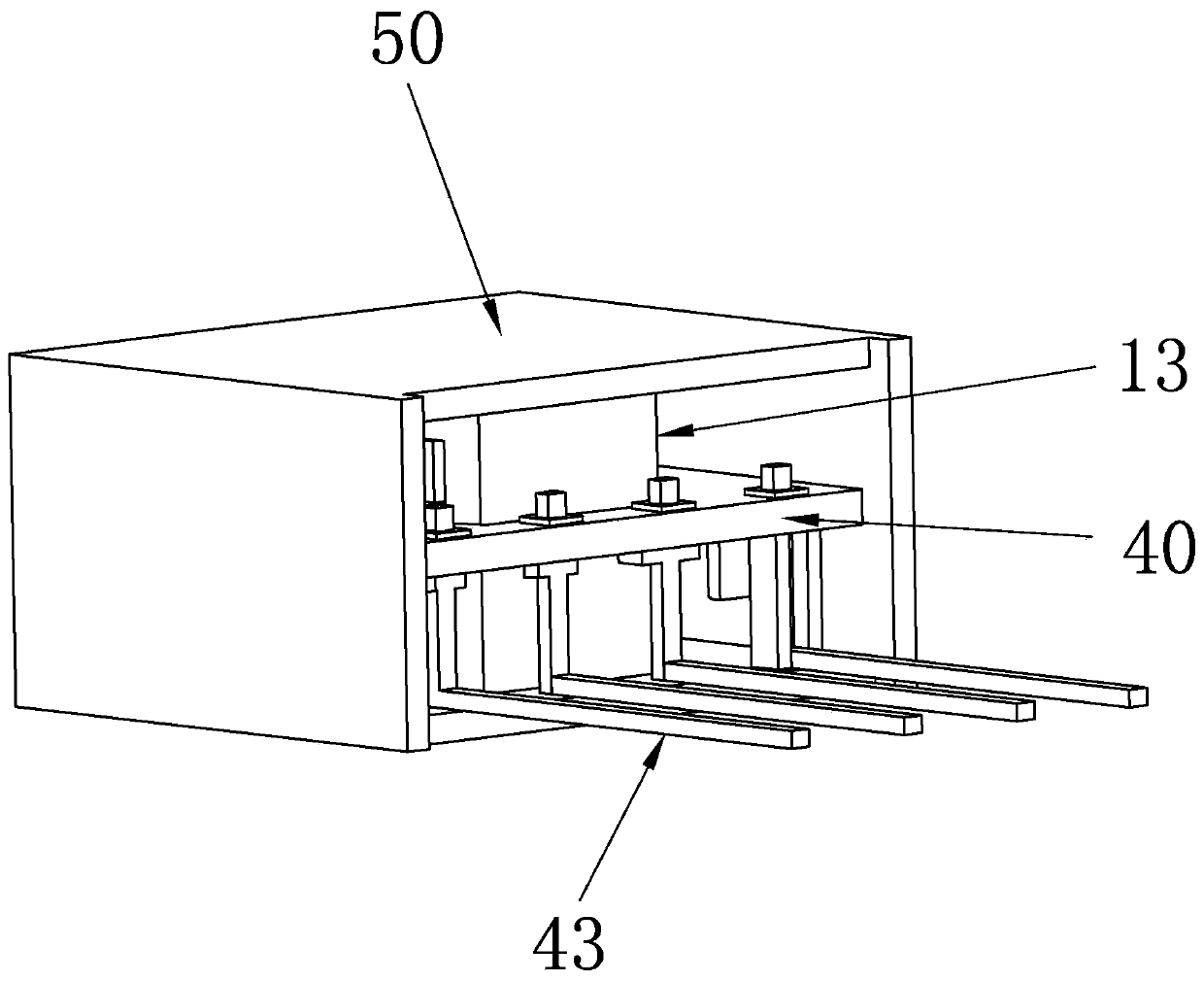

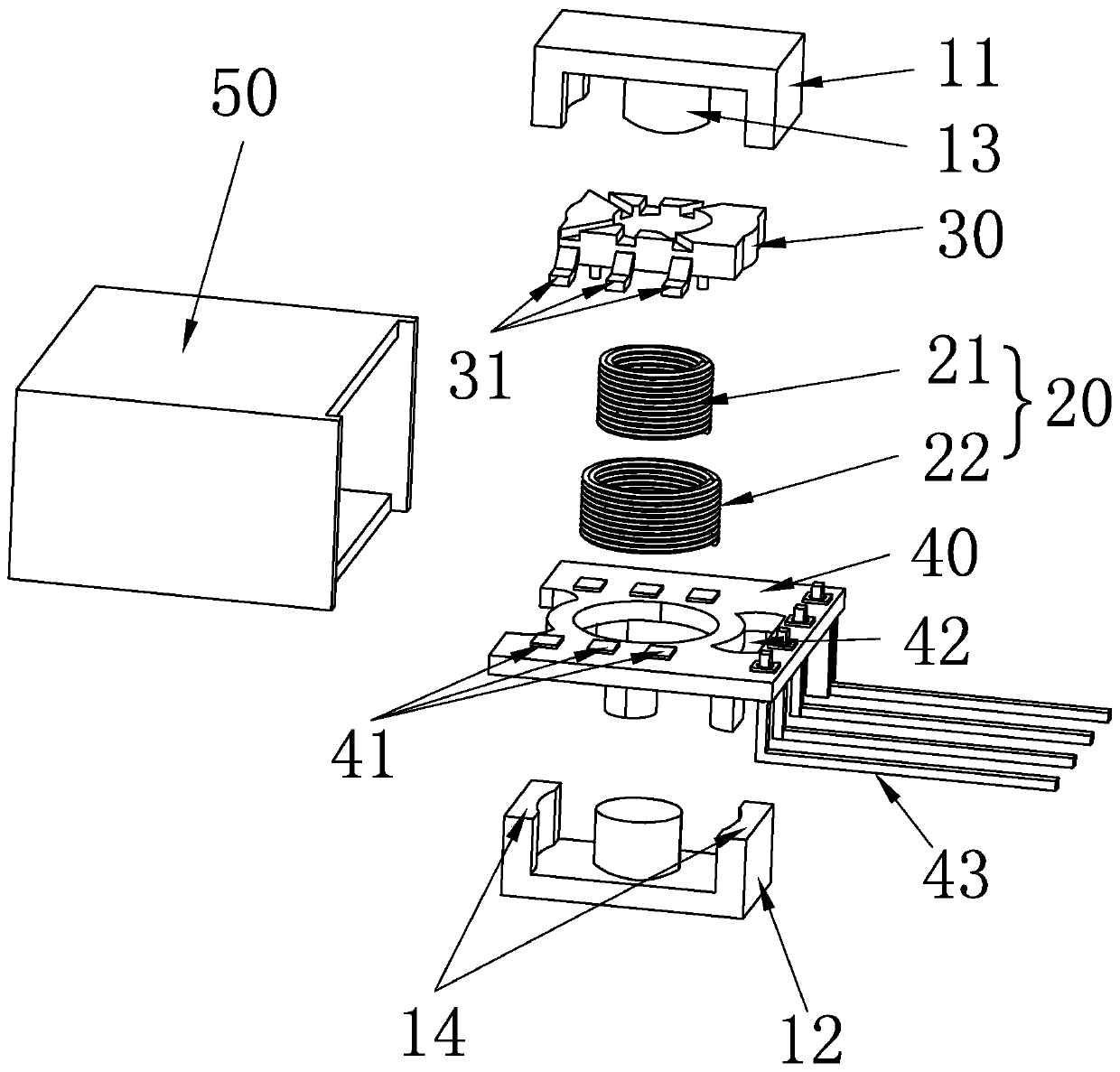

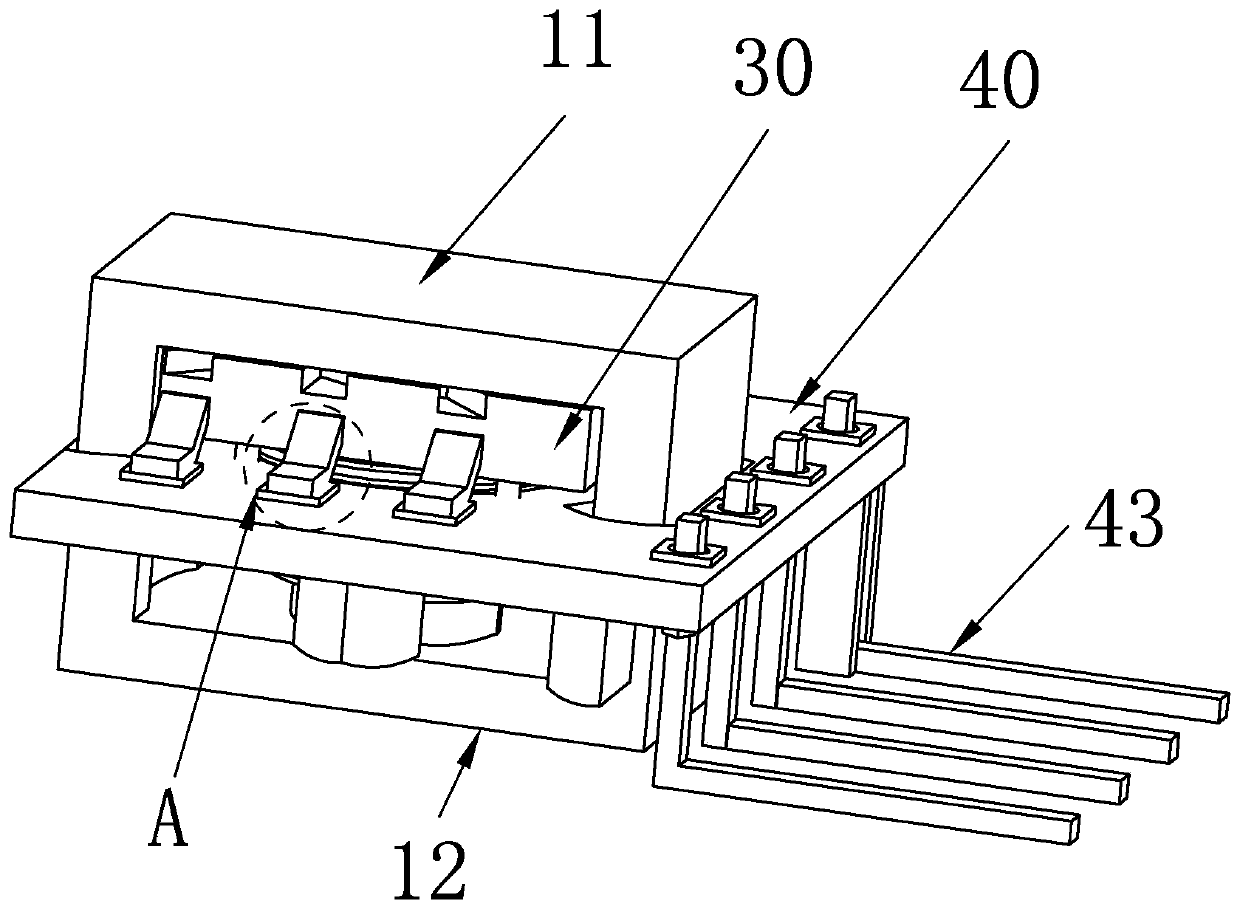

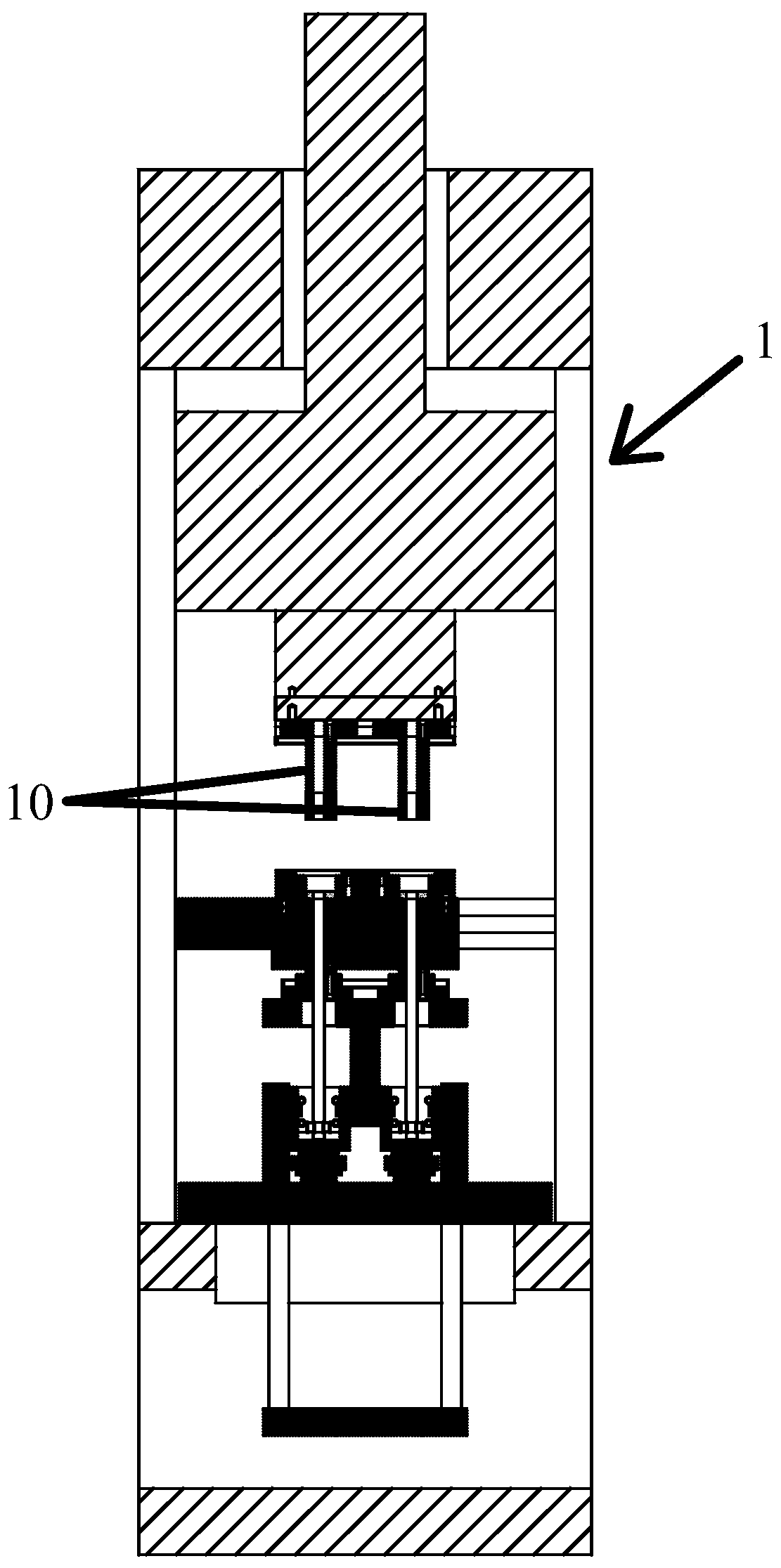

Power supply module

PendingCN111048292AGuarantee the quality of production and processingImprove production and processing efficiencyTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresMiniaturizationSpot welding

The invention discloses a power supply module. The power supply module comprises a pair of magnetic cores, a coil assembly, a PCB and a wiring base, wherein a magnetic core middle column is arranged between the pair of magnetic cores; the coil assembly is arranged on the magnetic core middle column in a sleeving manner and is provided with a plurality of pins; the PCB is arranged on the coil assembly in the sleeving manner and is provided with a plurality of chip mounting tables; the wiring base is arranged above the PCB and is provided with a plurality of wiring seats correspondingly bindingthe pins, and the wiring seats are in one-to-one correspondence with the chip mounting tables; and the plurality of pins are welded with the plurality of chip mounting tables in a one-to-one correspondence manner. According to the power supply module, full-automatic welding and rapid assembling can be realized; and a traditional mode that the pins on a coil are welded to the PCB through spot welding is omitted, quality problems that enameled wires are fused and broken when the pins of the coil are subjected to spot welding and so on are solved, meanwhile, a requirement for a production and assembly process is simplified, and a capacity of the power module is greatly improved. The whole power supply module is compact in structure, reliability of electronic devices in the module is improved,and design requirements for miniaturization, lightness and thinness of the power supply module in the market are met.

Owner:ZHUHAI HAIWER ELECTRIC APPLIANCE CO LTD

Packaging device for spinning yarns

The invention discloses a packaging device for spinning yarns. When work of packaging yarn ball single bodies is carried out, by means of the cooperation effect of an arranged placing belt, an inverted-T-shaped sliding groove and an inverted-T-shaped sliding block, the distance among the yarn ball single bodies can be well controlled, by means of fixedly clamping of arranged positioning columns and positioning circular grooves, the distance among the yarn ball single bodies is kept the same, moreover, the distance among the yarn ball single bodies can be controlled in a ball manner, then the package work can be carried out according to the actual requirement of package production and processing, and the quality of the package work is ensured. According to the device, by means of arranged sleeve columns and positioning mechanisms, the package processing quality of the device can be ensured, normal operation of a package processing and production line can be ensured, the processing and production quality is ensured, and economic benefits of the work are ensured.

Owner:安福风起科技有限公司

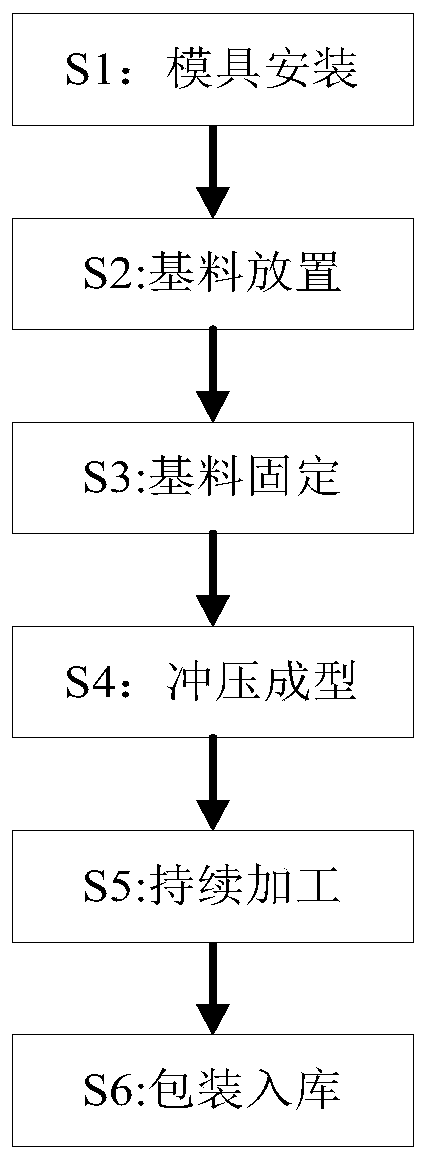

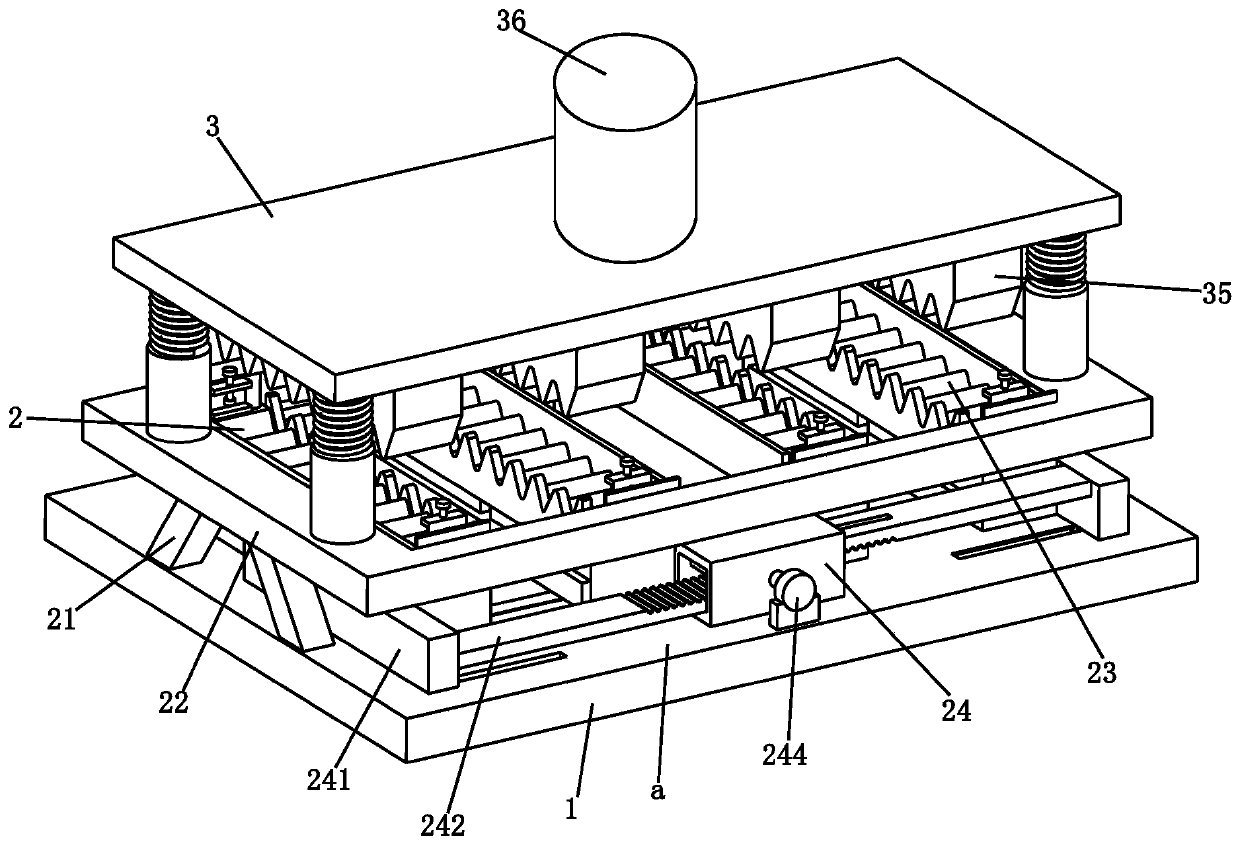

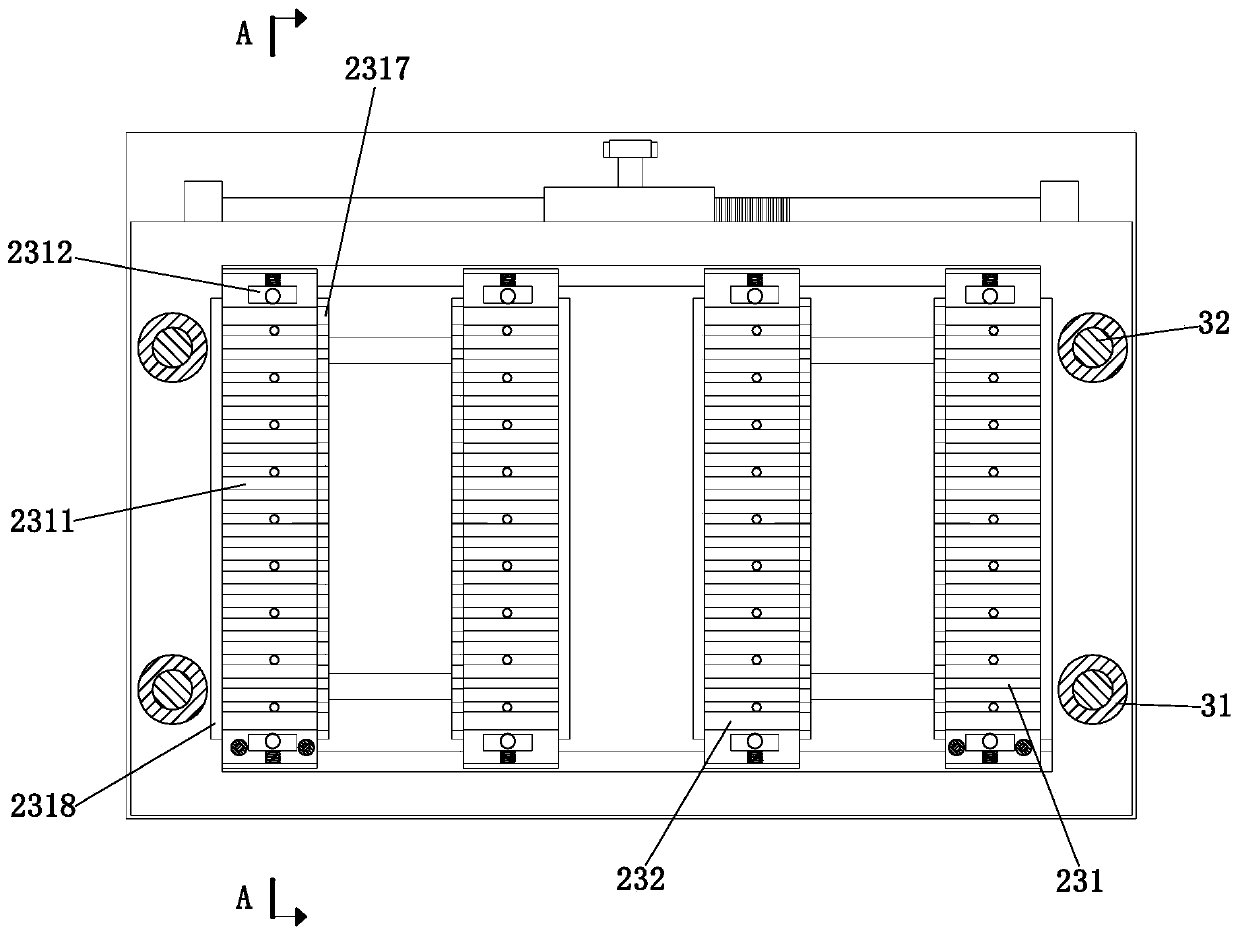

Air-conditioning condenser fin manufacturing and processing technology

ActiveCN110538940ASmall processing rangeReduce processing efficiencyShaping toolsHeat exchange apparatusEngineeringAir conditioning

The invention provides an air-conditioning condenser fin manufacturing and processing technology. A stamping die and the like are fully cooperated to complete manufacturing and processing of air-conditioning condenser fins. The problems that single-station processing is carried out on most existing equipment when the fins are processed by the equipment, different dies need to be replaced when thedifferent-size fins are processed, the processing range is small, and the processing efficiency is low; meanwhile, when the existing equipment is used for processing the fins, due to influences of special structures of the fins, the processed fins are tightly attached to the dies, and material taking after processing is not convenient to achieve; and raw materials can be stressed to retract back in the processing process of the fins, due to the improper restriction manner of the fins, the fins can offset during processing, and the fins deform and are broken after the fins are processed are solved.

Owner:SHANDONG MODERN LION AIR CONDITIONING EQUIP

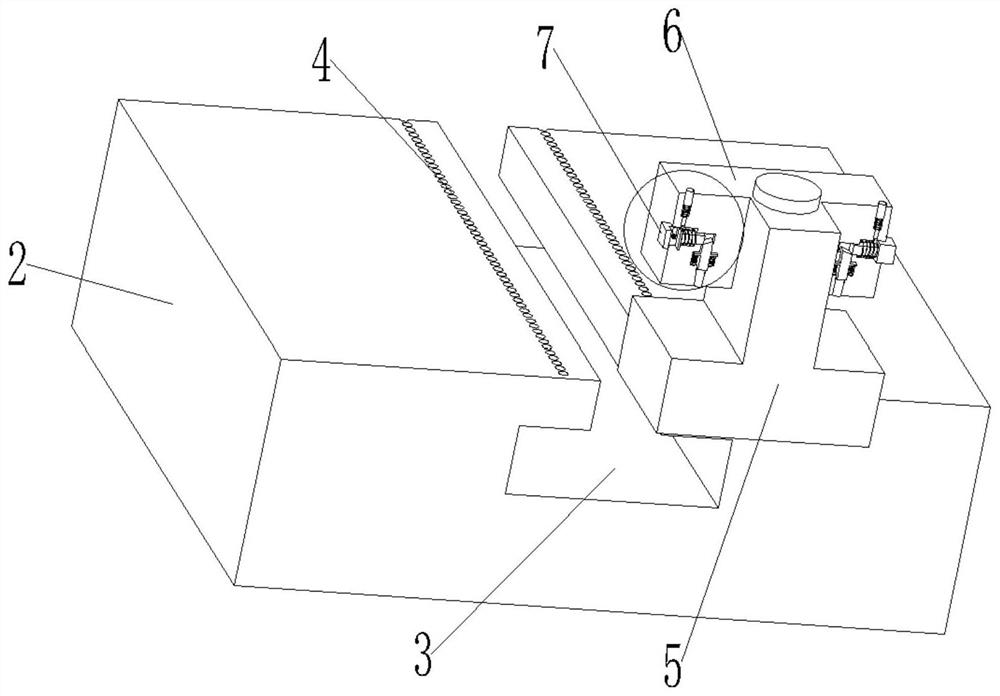

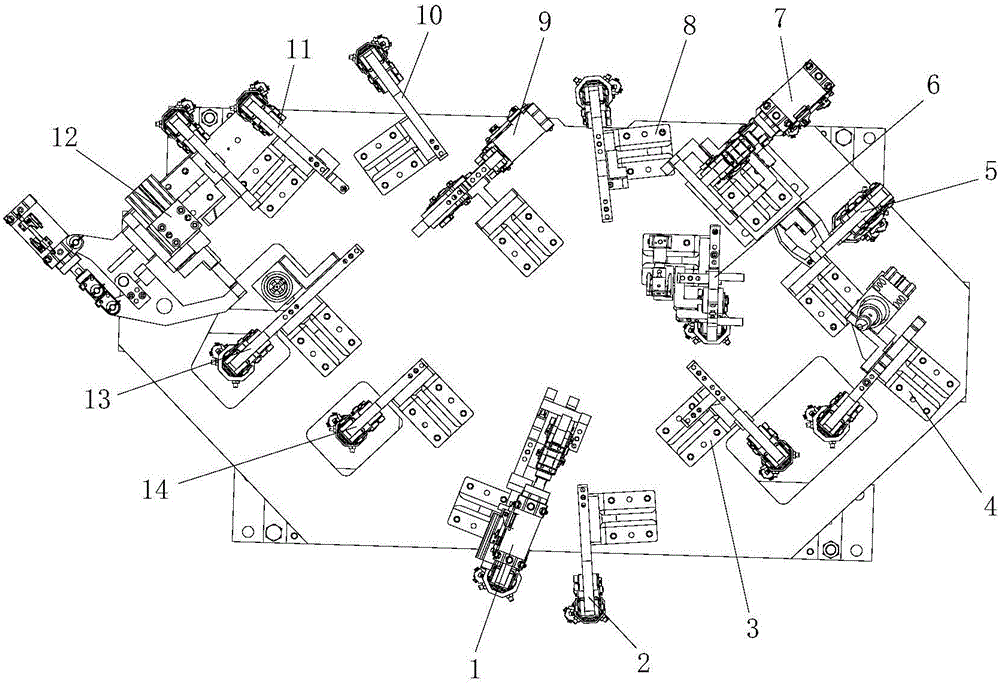

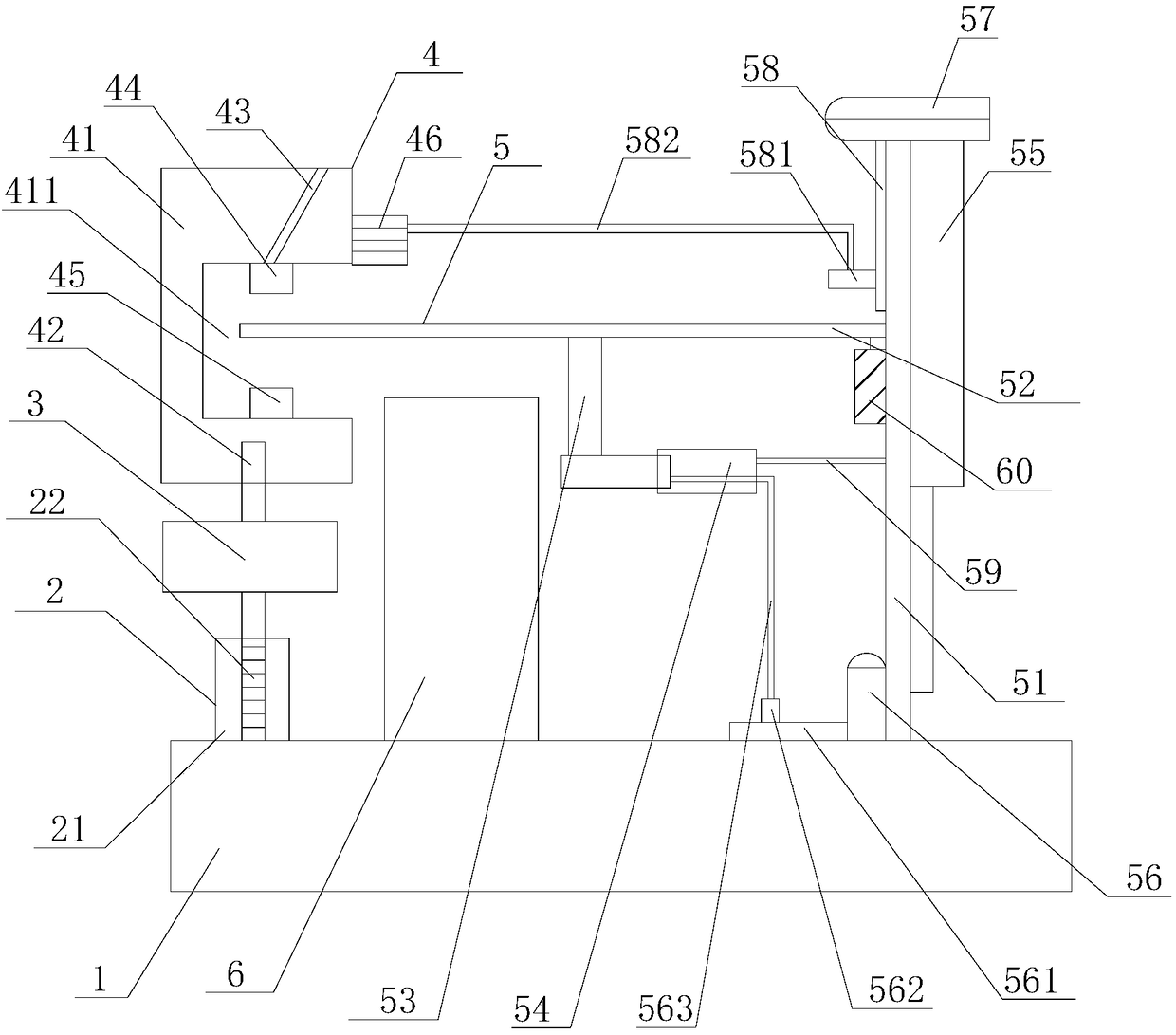

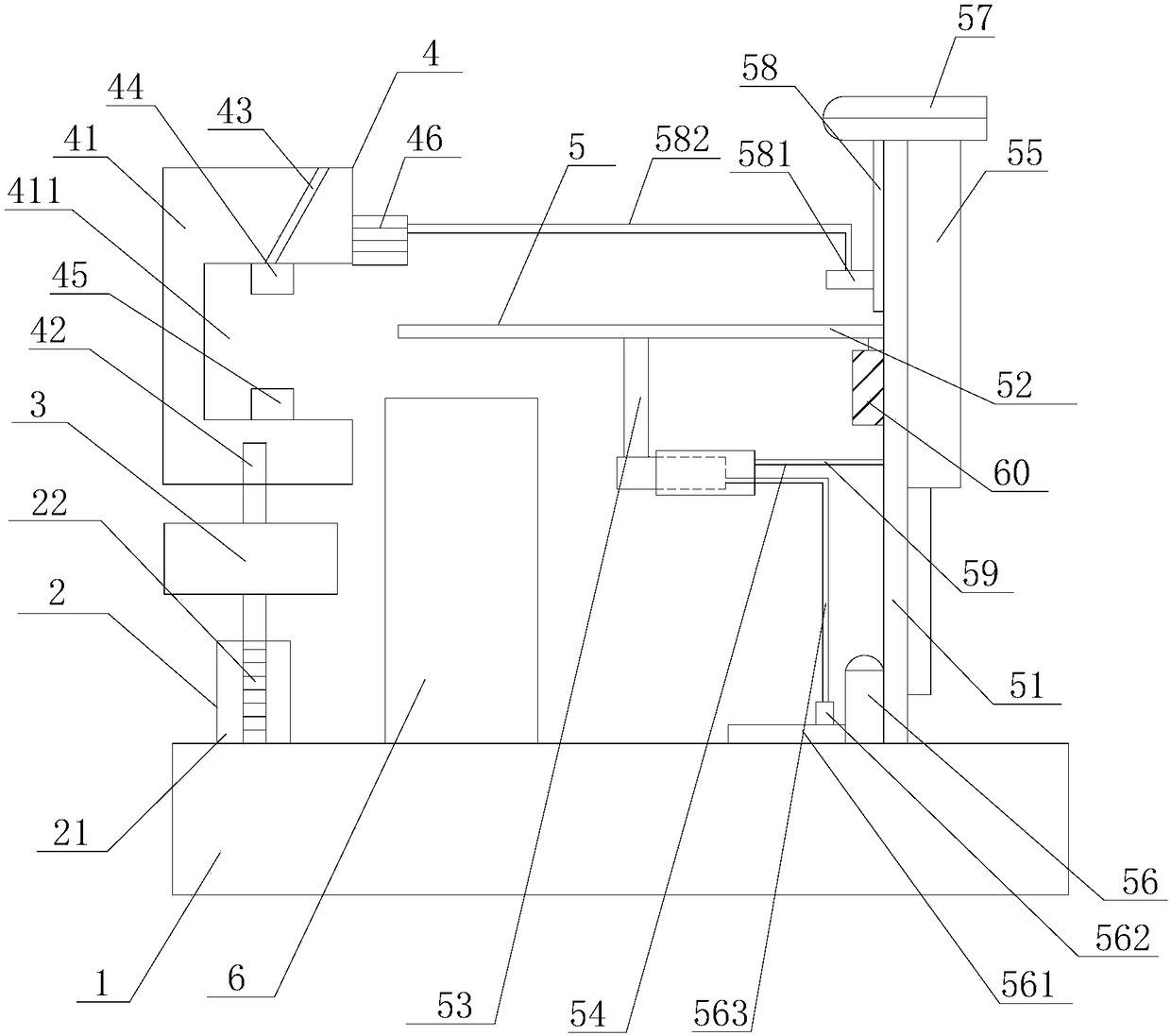

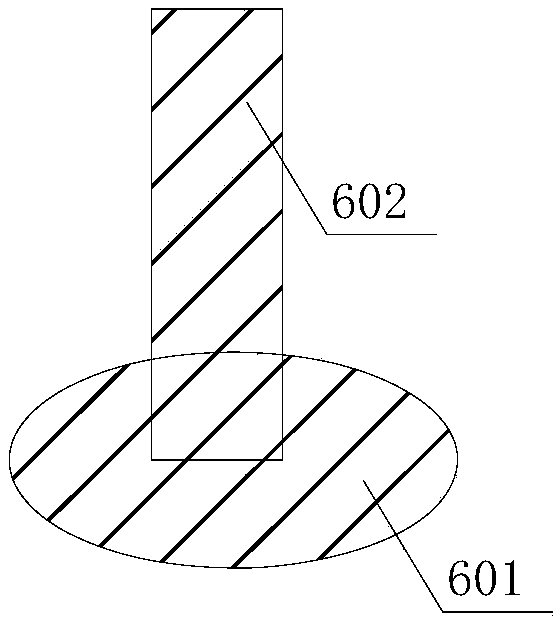

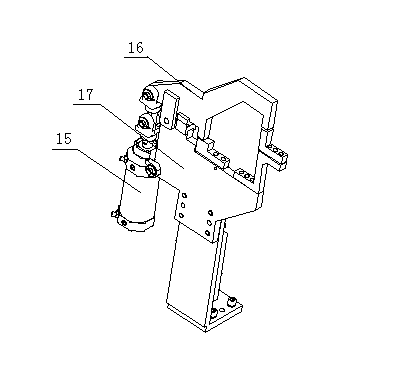

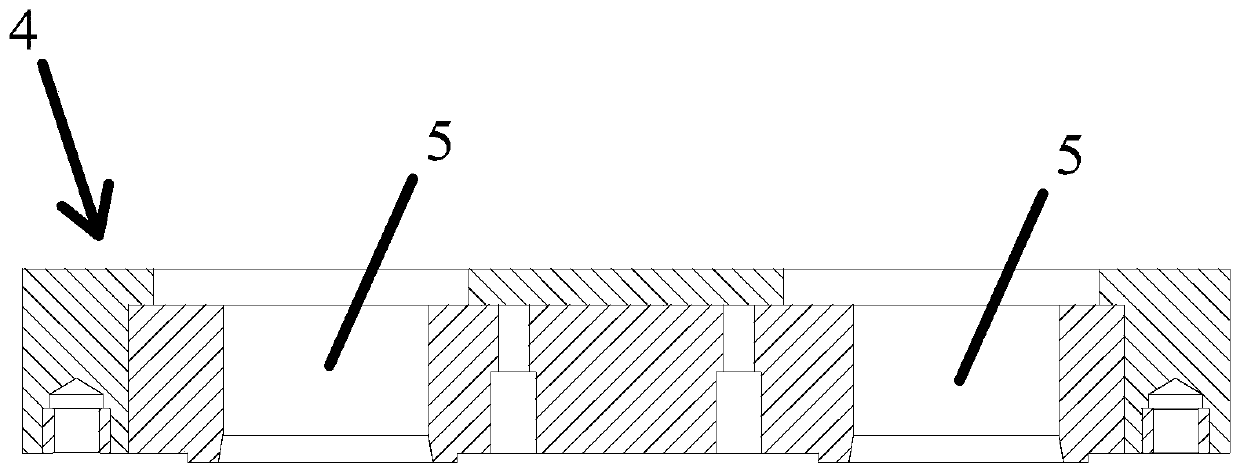

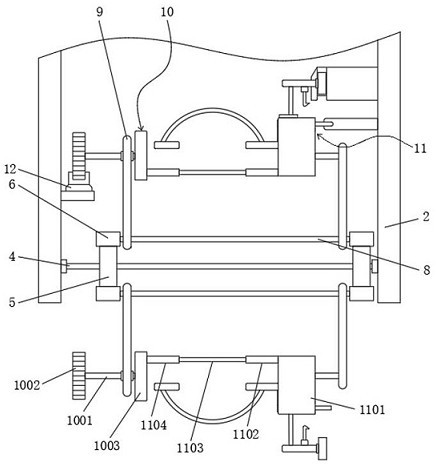

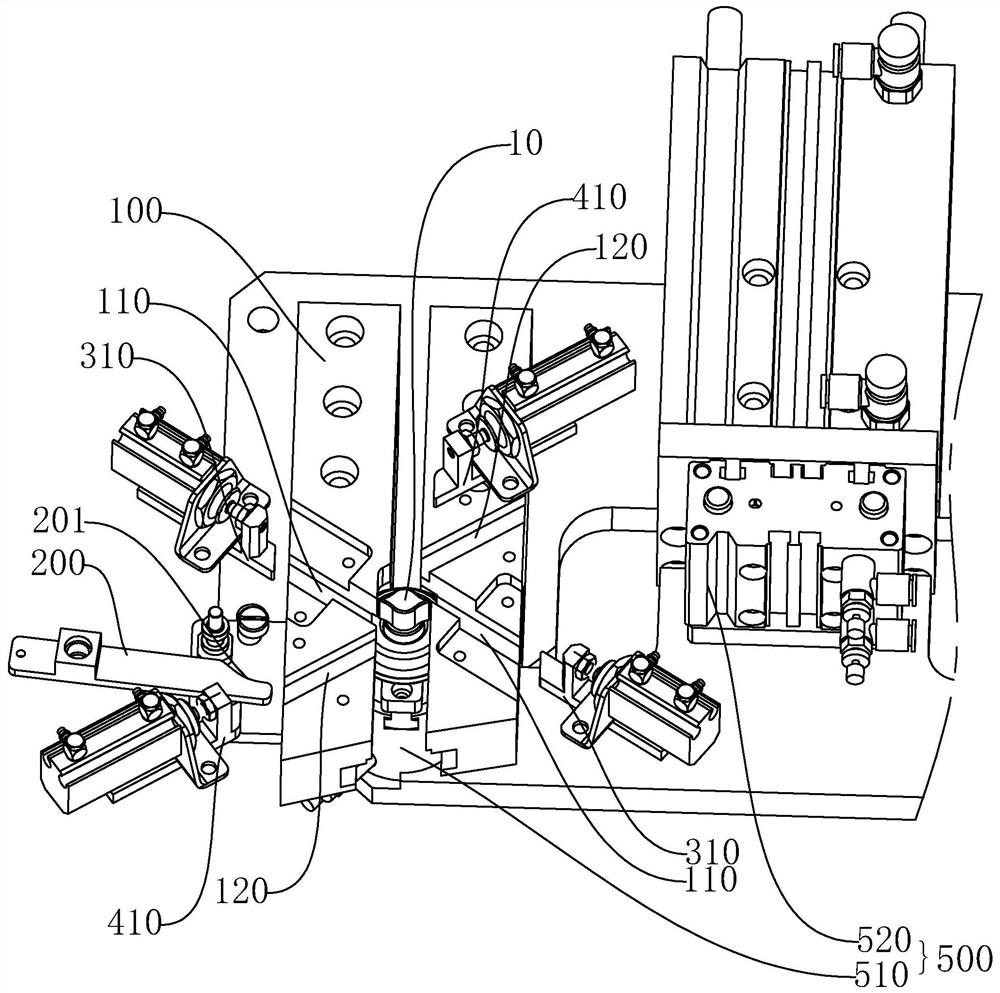

Synchronous drive fixture for automobile side coaming processing

InactiveCN105710686AGuarantee the quality of production and processingAvoid production errorsPositioning apparatusMetal-working holdersEnvironmental resistanceControl system

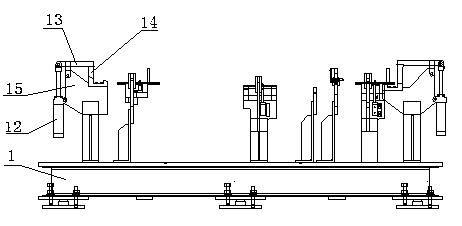

The invention discloses a synchronous driving fixture for processing an automobile side panel, comprising a support base, on which a plurality of installation holes and a plurality of installation grooves are opened, and a support column is arranged under the support base , a support plate is installed below the support column, and a support block is installed on the support plate; fourteen clamping devices are installed above the support base, and these fourteen clamping devices are synchronously hydraulically Controlled by the control system, these clamping devices are used to clamp the side panels of the vehicle. The fixture provided by the invention facilitates the processing operation of the automobile side panel assembly, and avoids the production error caused by the position movement of the automobile side panel assembly during processing, thereby ensuring the production and processing quality of the automobile side panel assembly; The synchronous hydraulic control system makes each clamping device act synchronously, which can improve the clamping efficiency; the hydraulic system uses water as the working medium, which is clean and environmentally friendly and reduces costs.

Owner:黄斌

PE film efficient blow molding production line

The invention relates to a PE film efficient blow molding production line. The production line comprises a material suction device, an extrusion device, a blow molding device, a cooling device, an extrusion device, a punching device, an edge cutting device and a material collecting device, wherein the material suction device comprises a material suction machine, the material suction end of the material suction machine is connected with a plurality of material suction pipes, the extrusion device comprises an extruder body, the blow molding device comprises a blow molding machine body, the cooling device comprises a support and a plurality of cooling air outlet pipes located in the support, the extrusion device comprises a herringbone plate located at the upper end of the support and a mainpressing roller and an auxiliary pressing roller which have a cooling effect, the punching device comprises a first punching roller and a second punching roller, the first punching roller and the second punching roller are each provided with a plurality of annular roller cutters, the edge cutting device and the material collecting device are located in a movable rack, and the material collecting device comprises a first material collecting roller and a second material collecting roller. According to the PE film efficient blow molding production line, a PE film is punched and trimmed from production to winding, and the production line has the effects of being high in machining efficiency, high in production efficiency, saving in cost and low in labor intensity.

Owner:苏州惠国塑料制品有限公司

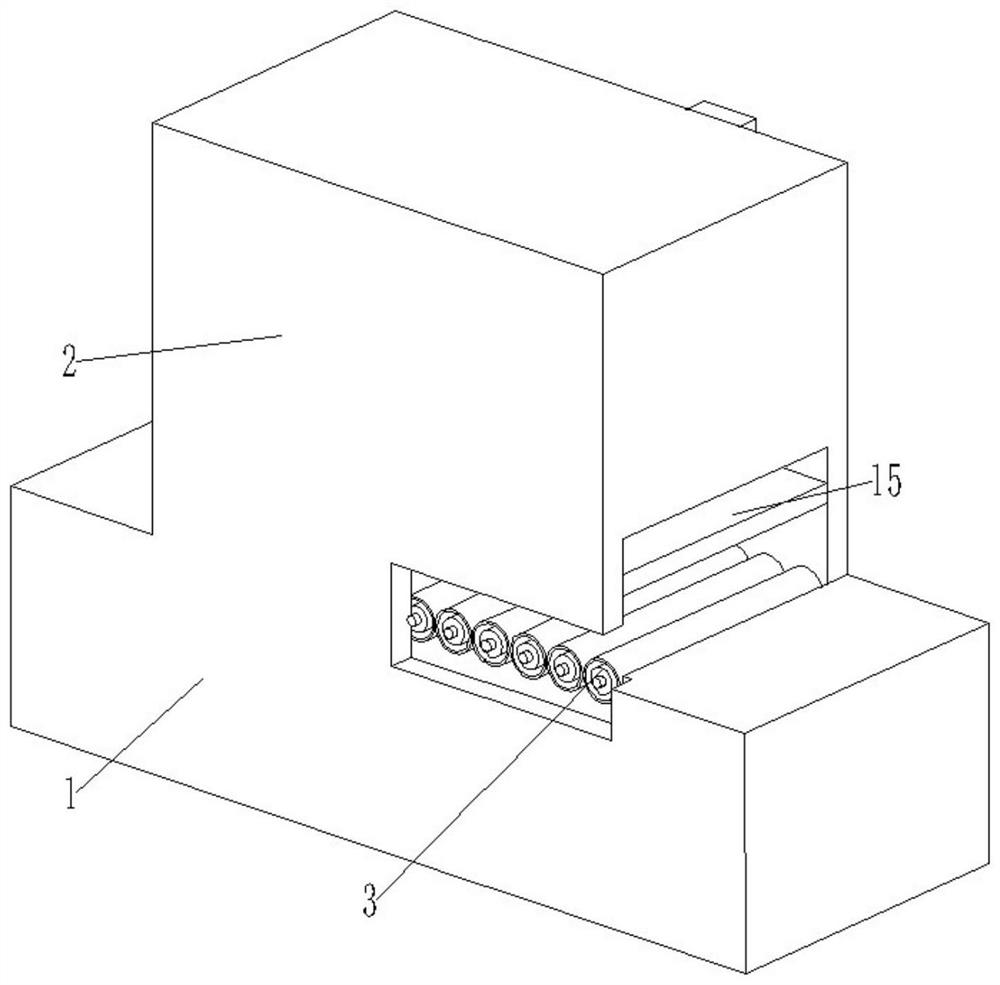

Full-automatic feeding device of industrial aluminum profile machining assembly line

ActiveCN112124841AGuarantee the quality of production and processingEnsure delivery stabilityConveyor partsRoller-waysMachine partsEconomic benefits

The invention discloses a full-automatic feeding device of an industrial aluminum profile machining assembly line. The full-automatic feeding device carries out conveying work through conveying rollers in the aluminum profile machining and production feeding process and limits the positions of aluminum profile machining raw materials through guide rollers and limiting rollers, and therefore it isensured that aluminum profiles do not deviate when being conveyed and can be conveyed to accurate positions in a next machining site without deviating, the conveying stability of aluminum profile machined parts is guaranteed, the production and machining quality of the aluminum profiles can be guaranteed, and machining and production economic benefits are guaranteed; and the positions of the guiderollers and the limiting rollers can be adjusted, adjustment can be made according to the actual sizes of the aluminum profiles, and therefore it can be better guaranteed that position guiding and limiting work can be better conducted on the aluminum profile machined parts.

Owner:JIANGXI TIAN YI ALUMINUM

Method for manufacturing integral vacuum chamber of vacuum refining device

InactiveCN101082073AGive full play to the processing abilitySatisfy the structural characteristicsButt weldingProcess engineering

The present invention relates to process of making integrated vacuum chamber for vacuum refining apparatus. The making process of integrated vacuum chamber includes the separate machining of two chamber sections, including one upper section of 3000-3400 mm height and one lower section, in a common large floor-type milling and boring machine; the subsequent butt welding of two sections and annealing; and final ultrasonic or ray detection. The making process has the advantages of low production cost and high production efficiency.

Owner:BAOSTEEL ENG & TECH GRP

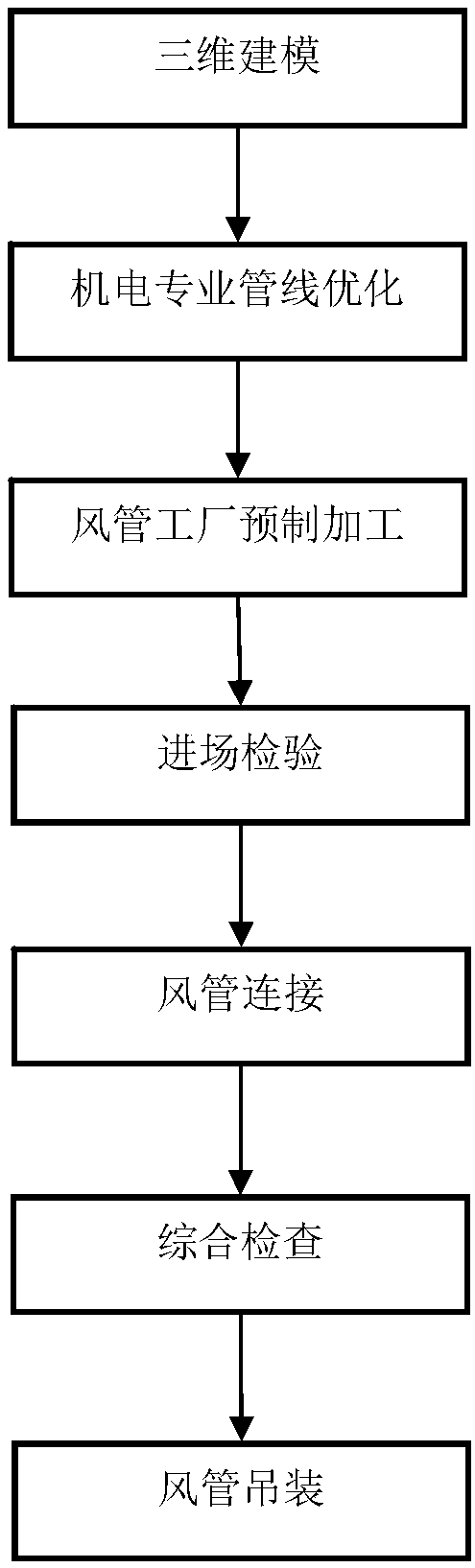

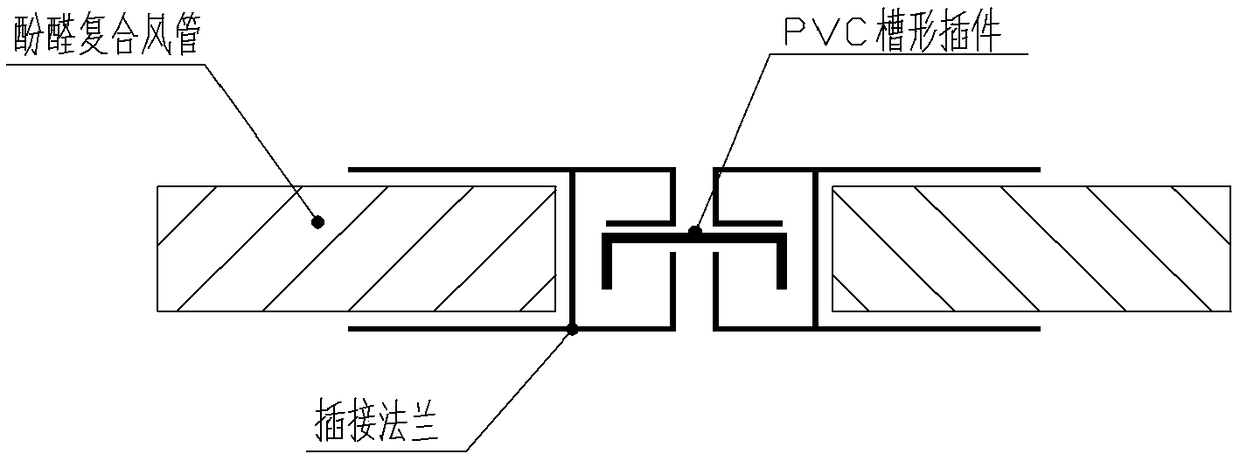

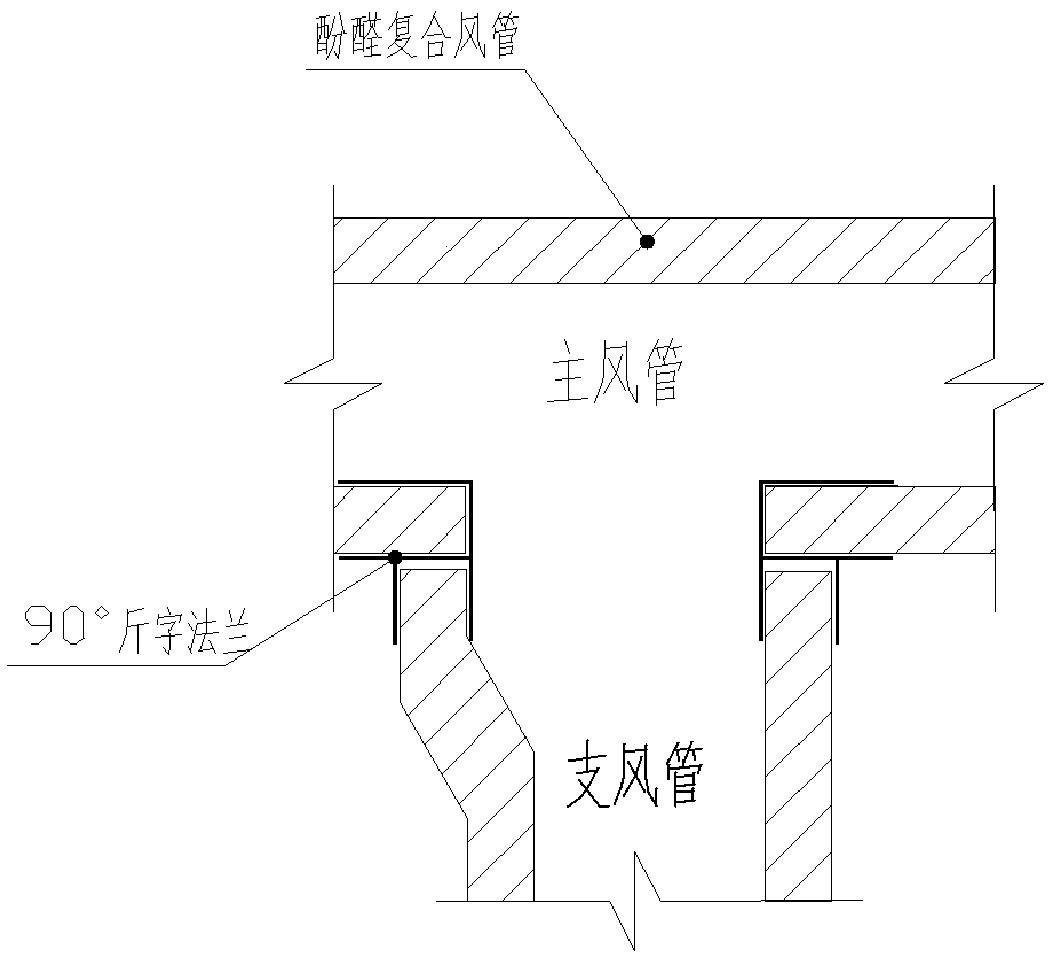

Pre-fabrication and installation method of phenol-formaldehyde composite air duct based on BIM platform

ActiveCN109033717AAvoid Duct ReworkGuarantee processing qualityGeometric CADPassive housesThree dimensional modelEngineering

The invention discloses a prefabrication and installation method of phenolic compound air duct based on BIM platform, which comprises the following steps: collecting drawings and applying Revit software to establish a three-dimensional model; the three-dimensional model is imported into Naviswork software, the pipeline of the three-dimensional model is arranged comprehensively, the net height is checked, and the pipeline of electromechanical specialty is optimized. The design drawings of the optimized air ducts are obtained, and the prefabrication of phenolic composite air ducts and plugging accessories is realized. After the prefabricated air duct enters the site for inspection, the air duct connection is carried out, and the air leakage and cold bridge plugging treatment are carried outat the flange connection of the air duct; after passing the comprehensive inspection, the hoisting of the air duct shall be completed. The invention can remarkably save energy, save phenolic compoundair duct plate, avoid air leakage and cold bridge at the air duct connection, and has no air pollution and health hazard caused by on-site blanking, cutting and bonding during installation, thereby reducing production cost and ensuring installation quality, and ensuring on-site safety of the constructor. It has a broad prospect of popularization and application.

Owner:GUANGZHOU HENGSHENG CONSTR ENG

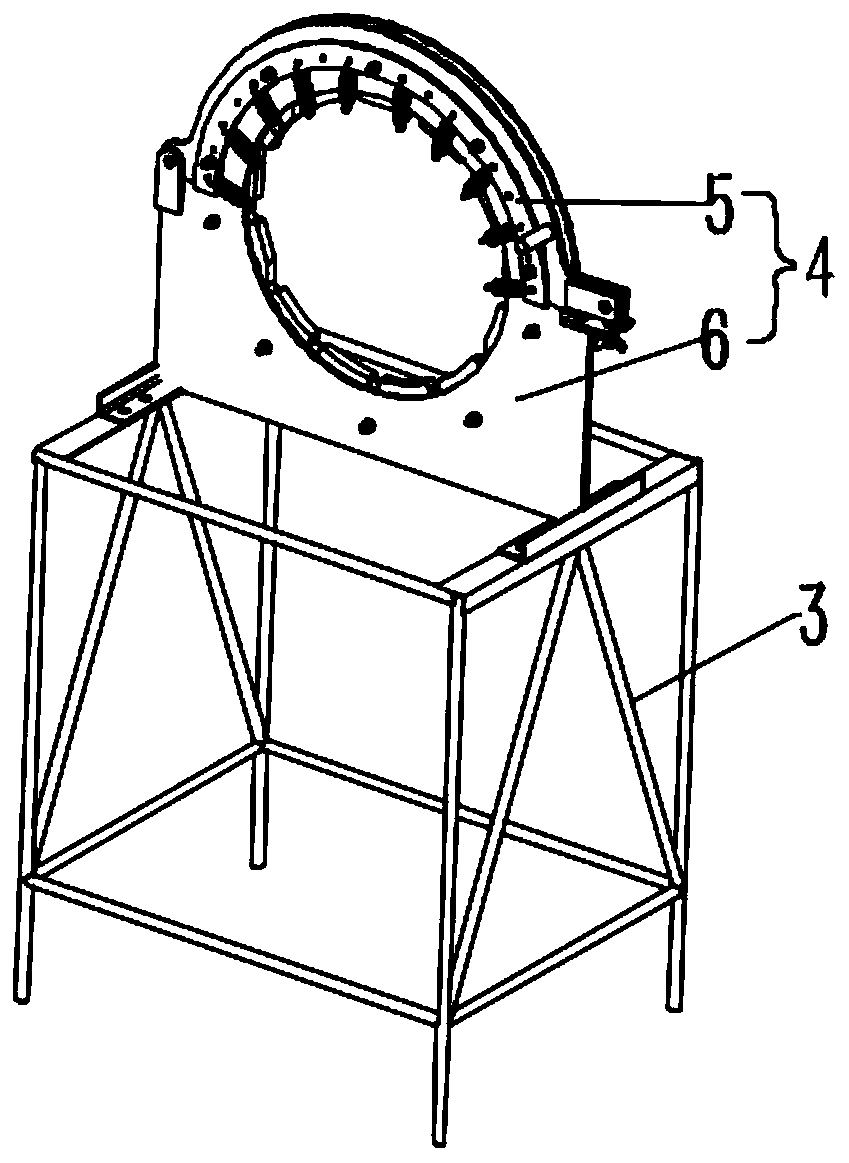

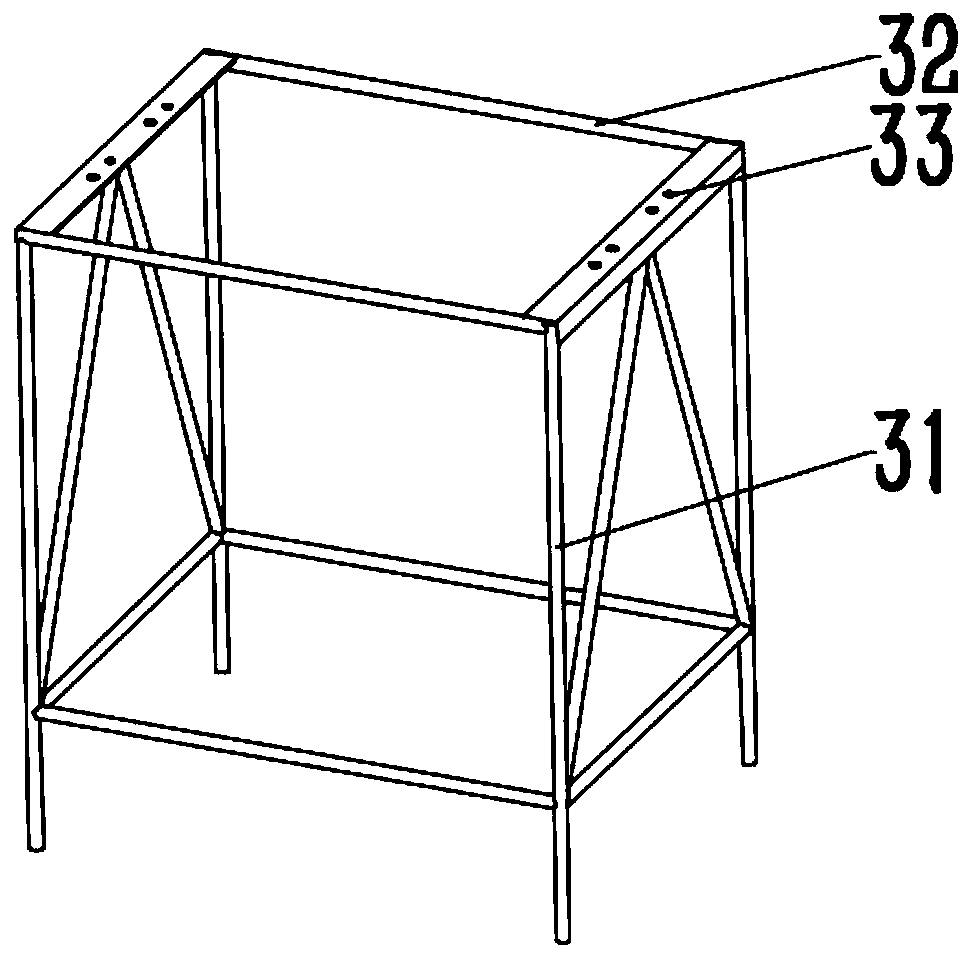

High-frequency preheating angle steel angle opening and closing machine

InactiveCN105750382AAvoid crackingGuarantee the quality of production and processingPunchingEngineering

The invention discloses a high-frequency preheating angle steel angle opening and closing machine. The high-frequency preheating angle steel angle opening and closing machine is characterized in that one side of the upper plane of a rack is provided with an angle steel supporting block; a pressing oil cylinder is longitudinally arranged above the angle steel supporting block in a supporting way through a support; an auxiliary hydraulic pressure station is arranged at the outer side of the support; a punching oil cylinder is horizontally arranged at the other side of the upper plane of the rack; a main hydraulic pressure station is arranged at one side of the rack, and the main hydraulic pressure station is connected with the punching oil cylinder through a high-pressure oil pipe. Through the arrangement, when the high-frequency preheating angle steel angle opening and closing machine disclosed by the invention is used for opening and closing an angle, a piece of angle steel is firstly heated by utilizing a heating block, then angle opening and closing punching can be carried out on the angle steel, the angle steel is enabled not easy to crack, the machining is once completed, and the machining production quality is ensured.

Owner:SHANDONG LUNENG TAISHAN TOWER

Full-automatic punch press facilitating feed collecting and unloading

InactiveCN108127013AFully automatedNo manual operationMetal-working feeding devicesStripping-off devicesPunch pressLeveling mechanism

The invention provides a full-automatic punch press facilitating feed collecting and unloading. The full-automatic punch press comprises a base, a feeding mechanism, a leveling mechanism, a punching mechanism, a feed collecting mechanism and a feed collecting box, the feeding mechanism comprises a feeding frame and a feeding guide groove located in the middle of the feeding frame, the punching mechanism comprises a punch press body, a feed guide plate, a knockout plate, an upper mold, a lower mold and a punch press slide block, the feed collecting mechanism comprises a feed collecting support,a feed collecting disc, a connecting rod and a telescopic rod, a first air cylinder is arranged at the lower end of the feed collecting support, a first slide rail is arranged at the left side of thefirst air cylinder and is connected with a telescopic rod, a second air cylinder is arranged at the upper end of the feed collecting support, and a second slide rail is arranged below the second aircylinder and is connected with the punch press slide block. By means of the full-automatic punch press facilitating feed collecting and unloading, full-automation of feed collecting and unloading is achieved, manual operation is not needed, the labor intensity is lowered, the production safety and the machining efficiency are improved, and the machining production quality is effectively guaranteed.

Owner:XINCHANG GENERAL MACHINERY

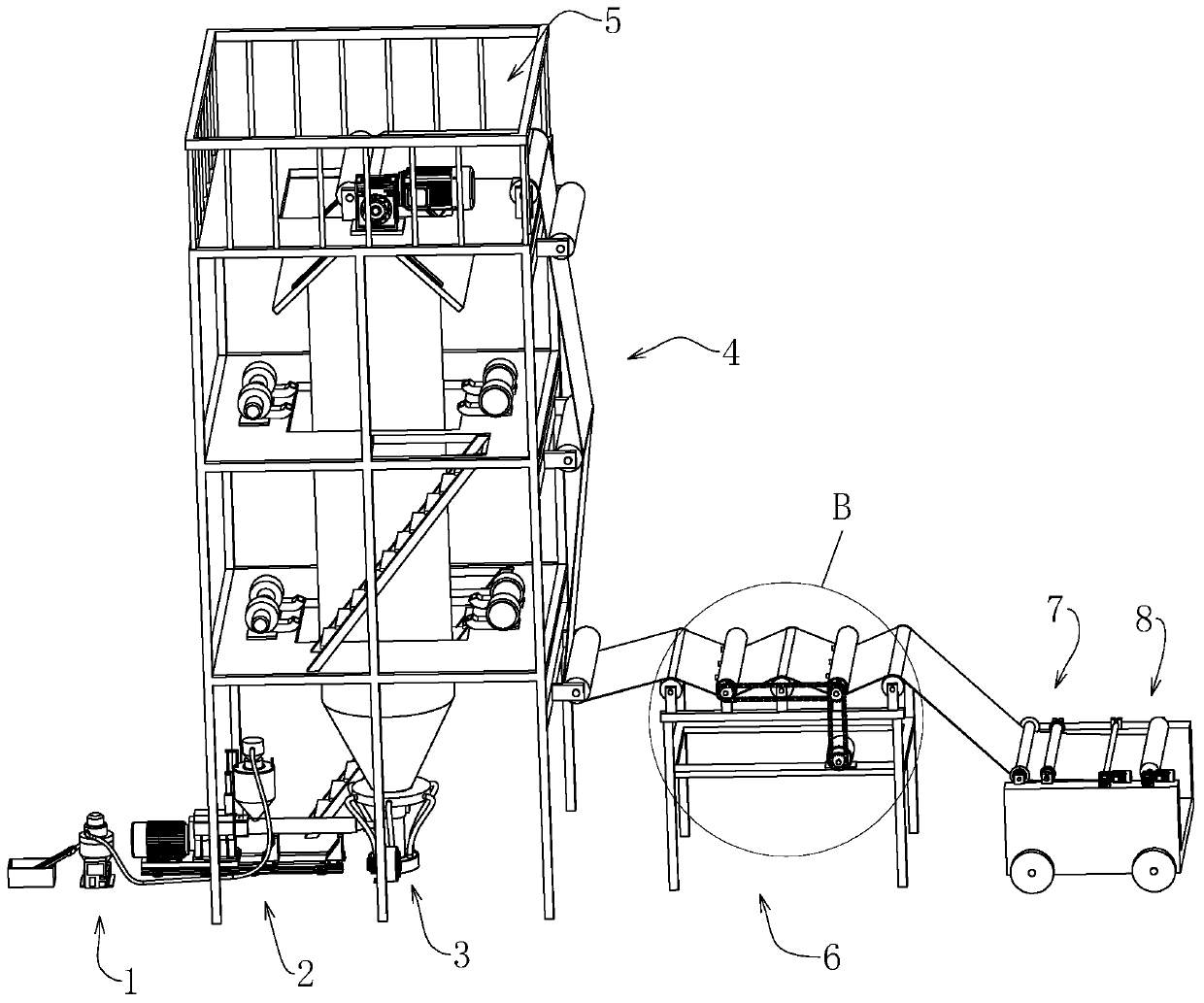

Sand screening and drying device for mortar production and processing

InactiveCN109092675AImprove screening efficiencyMeet the requirements of production and processingSievingSand dryingEngineeringConveyor belt

The invention discloses a sand screening and drying device for mortar production and processing. The sand screening and drying device comprises a device body, a second temperature sensor, a second heater, a drying room, a first temperature sensor, an outlet, a screening room, a first transmission motor, a first heater, a feed hopper, a first conveyor belt, a vibration motor, an operation display,an equipment room, a controller, a transmission shaft, a second transmission motor, a screening sieve, a conveyor belt and a material receiving bucket. The screening room is arranged on the middle portion in the device body, and the drying room is arranged on the left portion in the device body. The equipment room is arranged on the right portion in the device body, and the feed hopper is arrangedon the upper right portion of the device body. The first conveyor belt is arranged on the right portion in the device body and is located under the feed hopper, and the first transmission motor is arranged in the first conveyor belt. The first heater is disposed on the upper portion in the screening room, and the screening sieve is disposed on the middle portion of the screening room. The sand screening and drying device for mortar production and processing can better screen mortar for mortar production and processing, selected sand is high in consistency, and the sand screening efficiency isimproved.

Owner:贵州砂浆博士科技有限公司

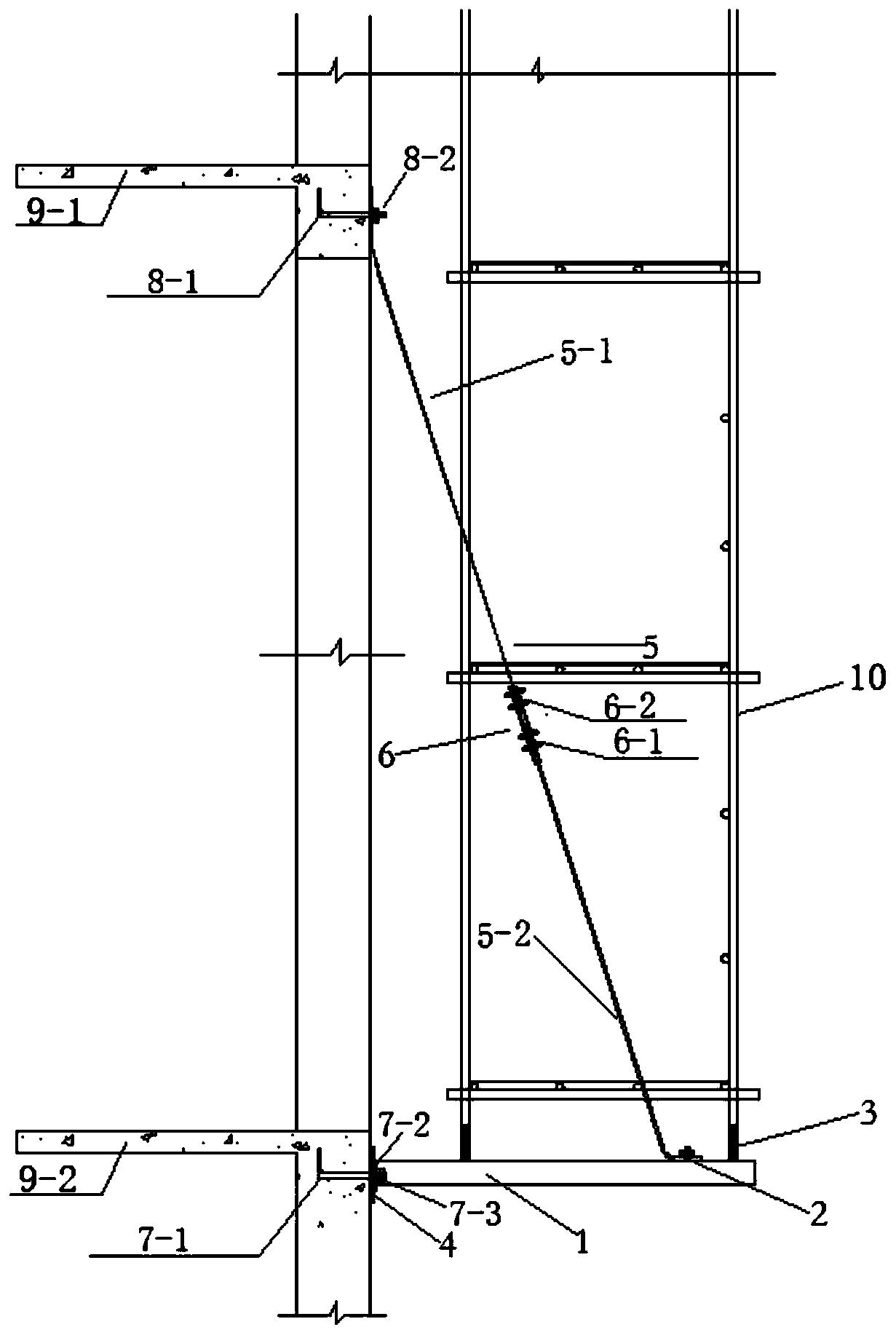

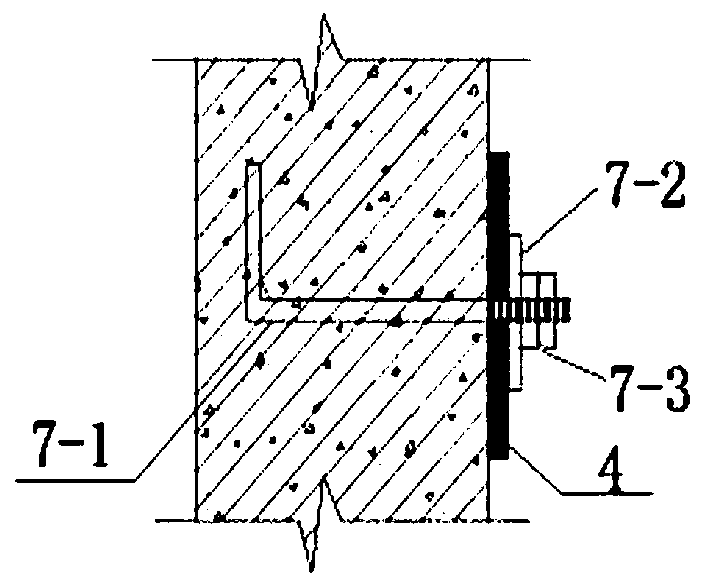

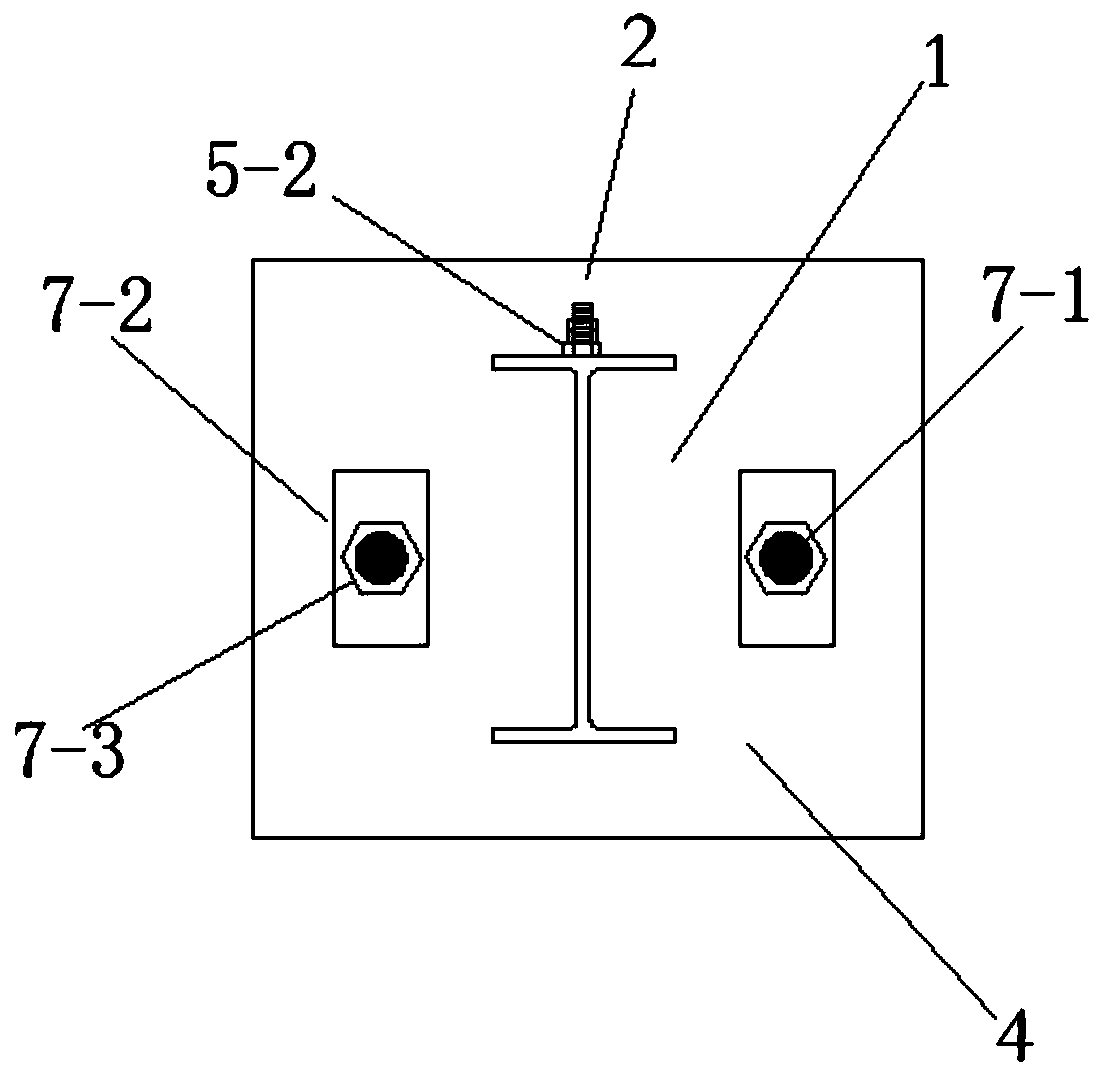

Supporting device for fabricated cantilever scaffold and construction method thereof

PendingCN110725525AGuarantee the quality of production and processingImprove turnover efficiencyScaffold accessoriesBuilding support scaffoldsPipeCantilever

The invention provides a supporting device of a fabricated cantilever scaffold and a construction method thereof. The supporting device comprises a first embedded anchoring part, a second embedded anchoring part, a cantilever steel beam and a splicing type diagonal member, wherein the cantilever steel beam comprises I-steel and a seal head steel plate, the seal head steel plate is welded to one end of the I-shaped steel, and the seal head steel plate is connected with the lower layer through the first embedded anchoring part; steel pipes used for positioning and connecting vertical rods of thecantilever scaffold are arranged in the I-shaped steel; bolts are arranged on the I-steel, the bolts are used for being connected with the splicing type diagonal member, one ends of the bolts are welded and fixed on the I-shaped steel side wing plate, and the bolts are arranged in a staggered mode with the steel pipes; and one end of the splicing type diagonal member is fixed to the upper layer through the second embedded anchoring part, and the other end of the splicing type diagonal member is connected with the bolts on the I-shaped steel, so that the other end of the splicing type diagonalmember is connected with the I-steel. According to the supporting device, suspension type steel beam component shaping machining and manufacturing are achieved, no welding operation is performed on the construction site, the machining and manufacturing quality of the welding node is guaranteed, and the using and circulating efficiency of the profile steel cantilever beam is increased through theuse of the shaping component.

Owner:SUNYOUNG CONSTR GROUP

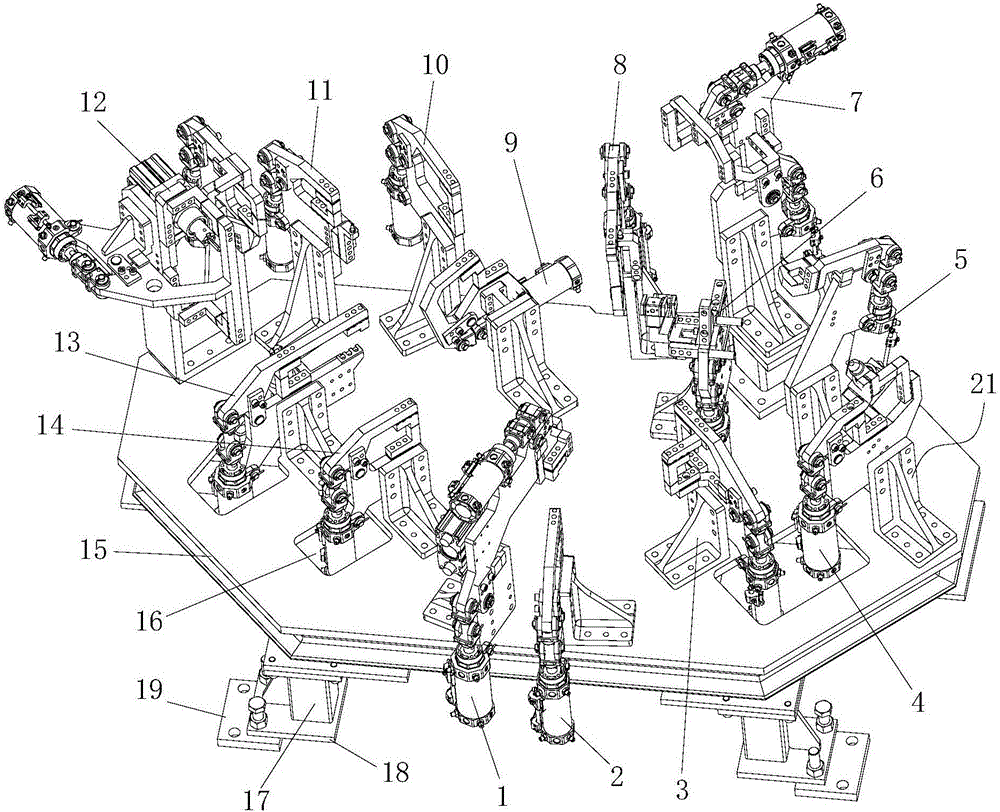

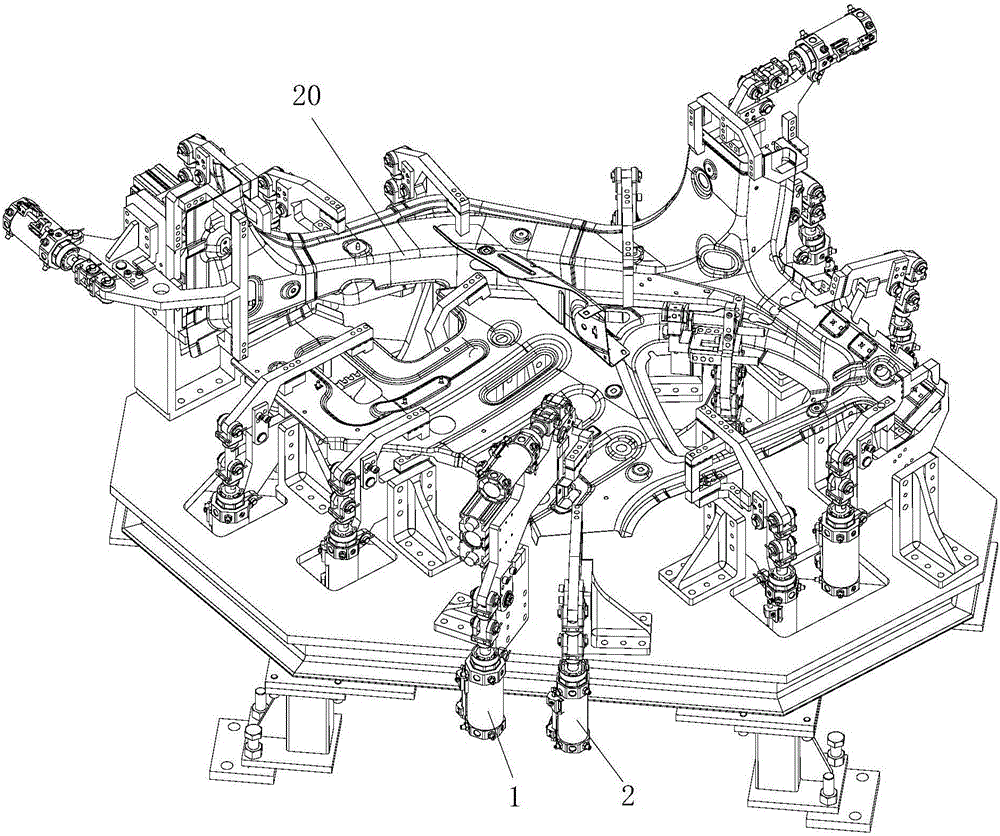

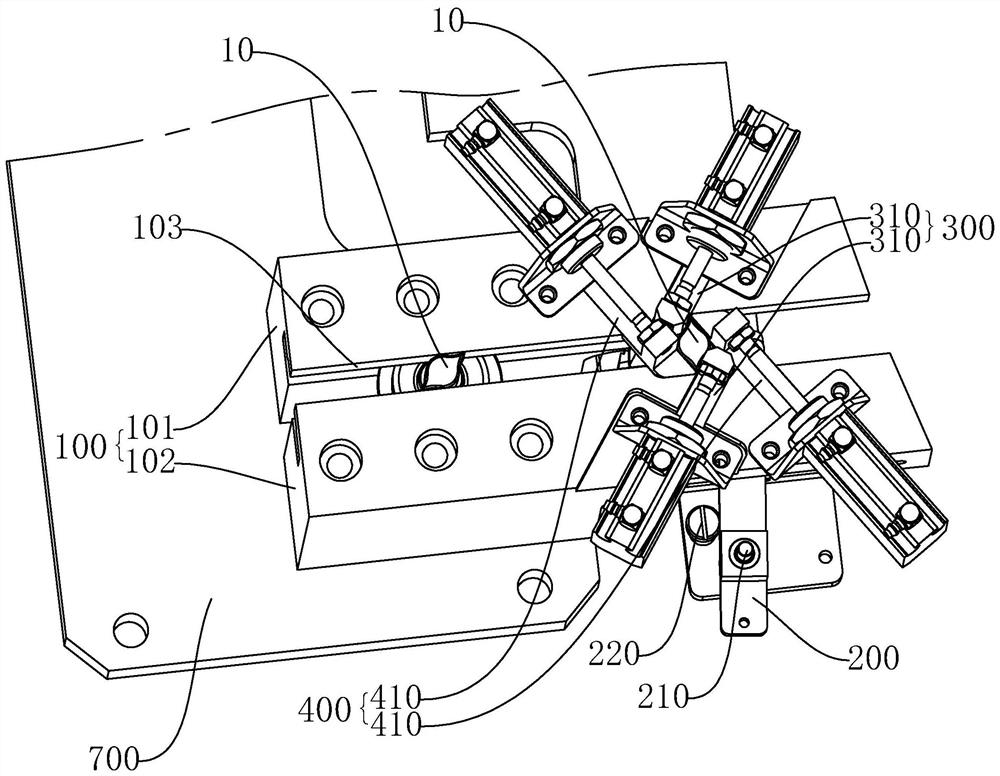

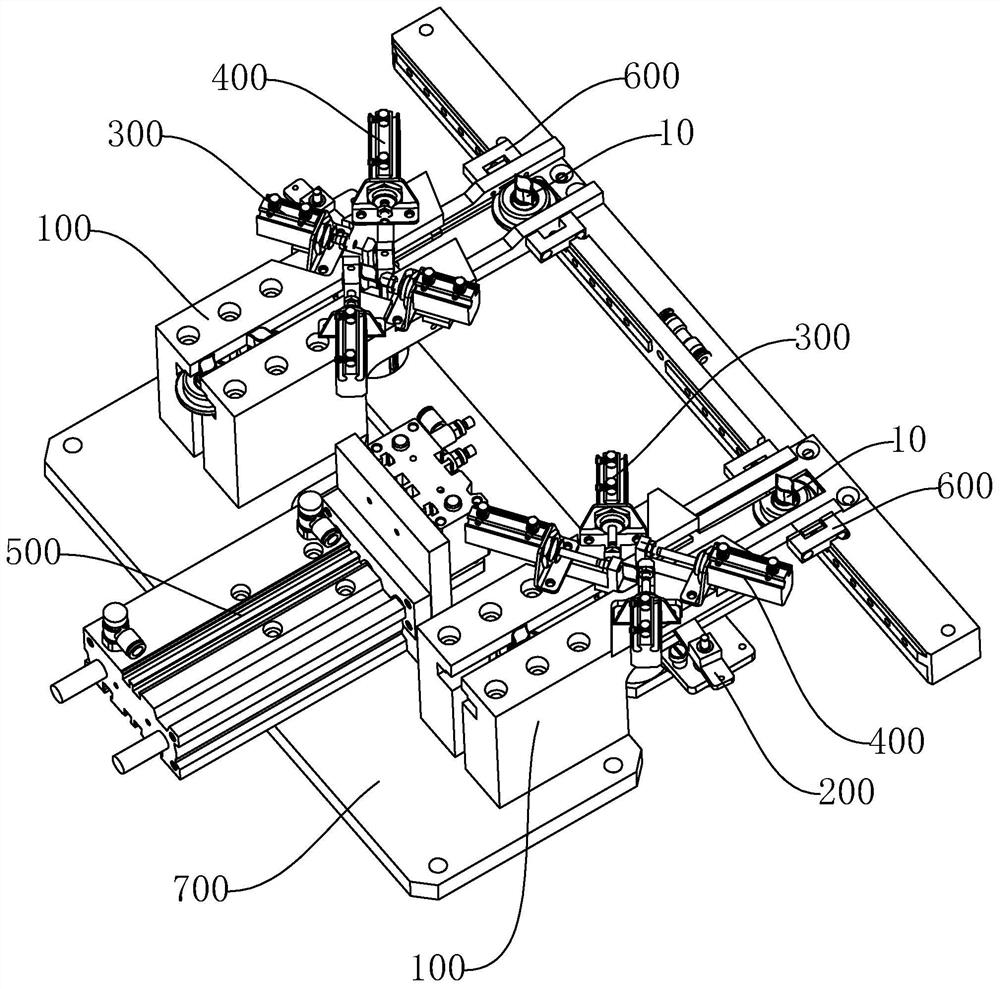

Automobile middle and rear floor assembly clamp

InactiveCN103624563AAvoid production errorsGuarantee the quality of production and processingWork holdersWork benchesSupport planeEngineering

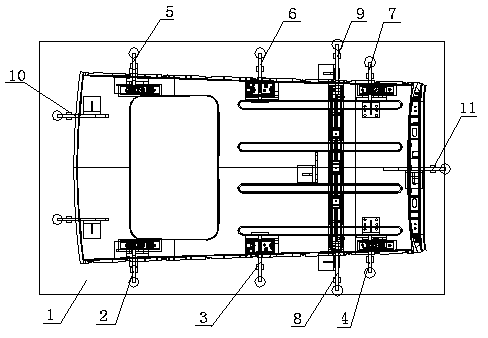

The invention provides an automobile middle and rear floor assembly clamp. The automobile middle and rear floor assembly clamp comprises a platform, and the platform is provided with clamping mechanisms. Each clamping mechanism comprises a power source, a chuck and a supporting frame. The first clamping mechanism, the second clamping mechanism, the tenth clamping mechanism, the third clamping mechanism and the fourth clamping mechanism are sequentially arranged at one end of the platform, the eleventh clamping mechanism, the seventh clamping mechanism, the fourteenth clamping mechanism, the ninth clamping mechanism and the twelfth clamping mechanism are sequentially arranged at the other end of the platform, and the fifth clamping mechanism is arranged in the middle of the platform. According to the automobile middle and rear floor assembly clamp, because a middle and rear floor assembly of an automobile is characterized by being special in structure and irregular in part of the shape, the clamping mechanisms are arranged on the periphery and the middle of the platform respectively according to production requirements when the positions of all the clamping mechanisms are arranged, the middle and rear floor assembly of the automobile can be reasonably fixed, and the machining operation on the middle and rear floor assembly of the automobile is not affected on the premise that a good fixing effect is guaranteed.

Owner:JIANGSU KAWEI SPECIAL PURPOSE VEHICLE MFG

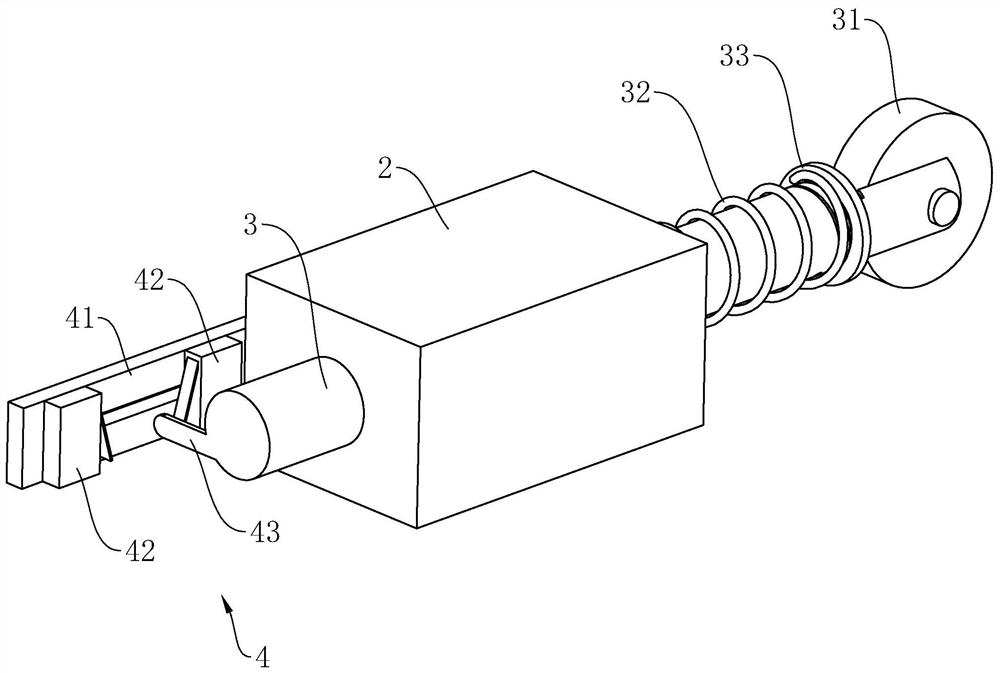

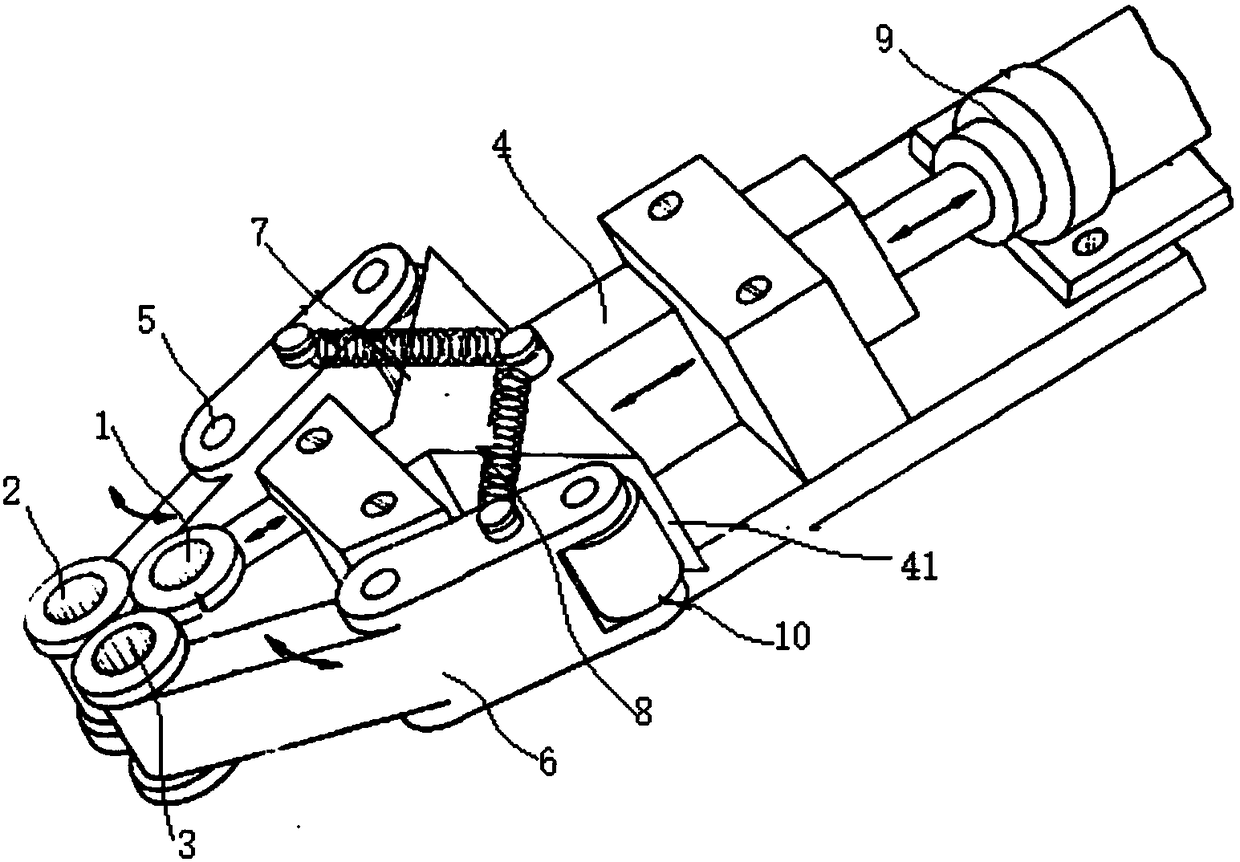

Self-aligning device for storage rack production

InactiveCN108214005ASimple structureIngenious designWork clamping meansPositioning apparatusEngineeringProduction quality

The invention discloses a self-aligning device for storage rack production. The self-aligning device for storage rack production comprises a first gripper jaw, wherein the gripper jaw is mounted in the starting end of a first clamping plate push plate, the tail end of the first clamping plate push plate is connected to a pusher, a second gripper jaw and a third gripper jaw are separately mounted in the starting ends of a second clamping plate and a third clamping plate, the left and right sides of the middle of the first clamping push plate are inclined surfaces inward, and the inclined surfaces are in contact with rollers; one end of a first spring is connected and mounted to the surface of the second clamping plate while the other end is connected and mounted to the surface of the middleof the first clamping push plate; one end of a second spring is connected and mounted to the surface of the third clamping plate while the other end is connected and mounted to the surface of the middle of the first clamping push plate. The clamp is simple in structure and skillful in design and can clamp workpieces with different dimensional specifications steadily, so that the processing and production quality is guaranteed while the production efficiency is improved.

Owner:广东添道仓储设备有限公司

Plastic bottle aluminum cap production raw material pretreatment device

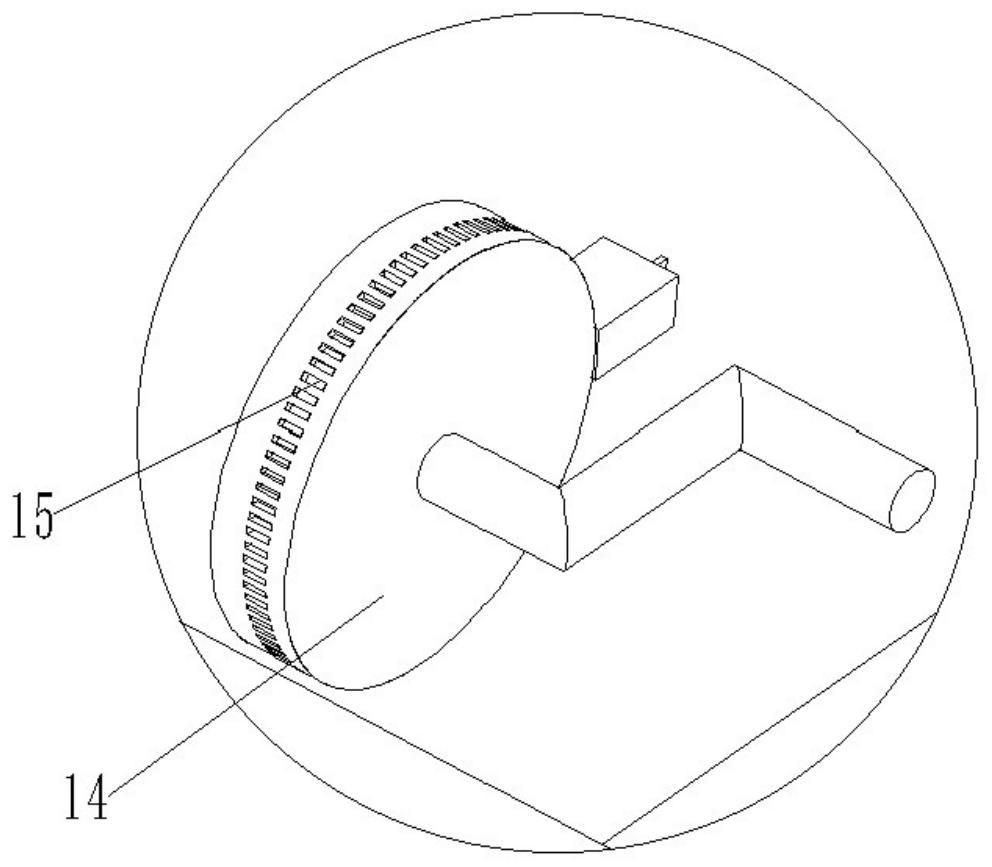

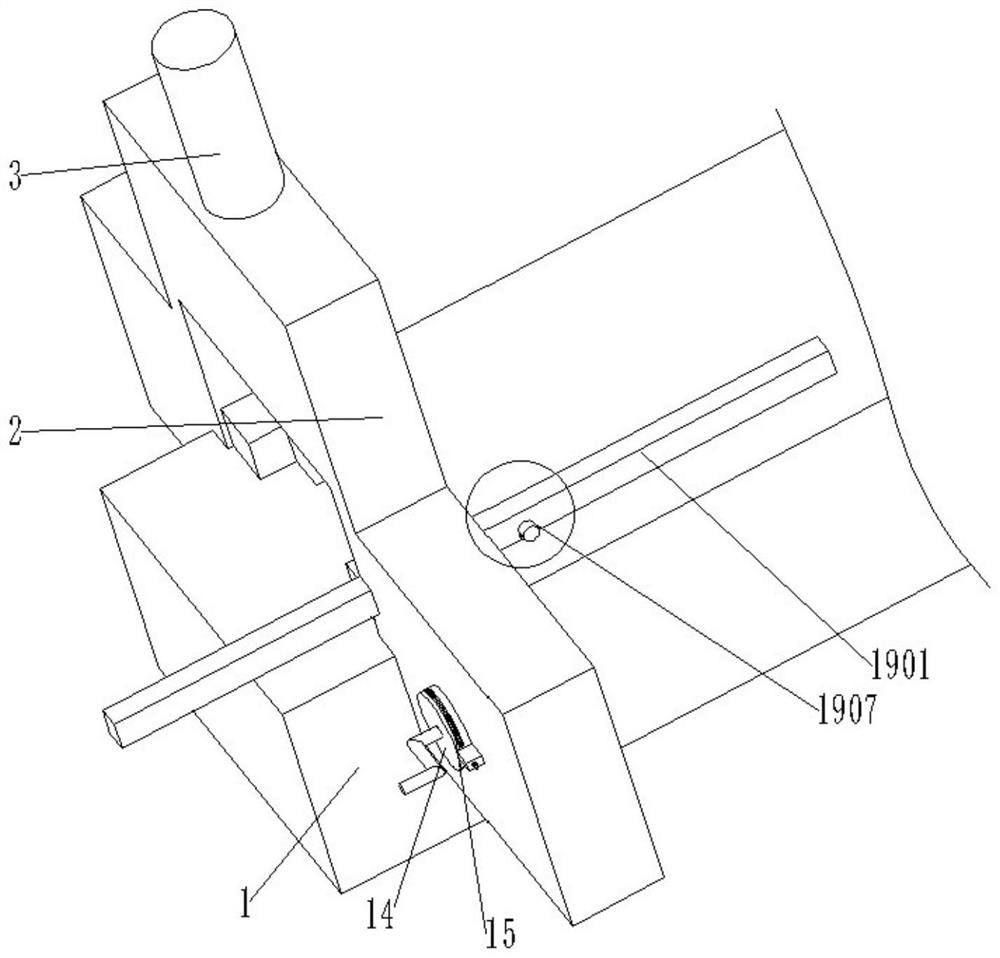

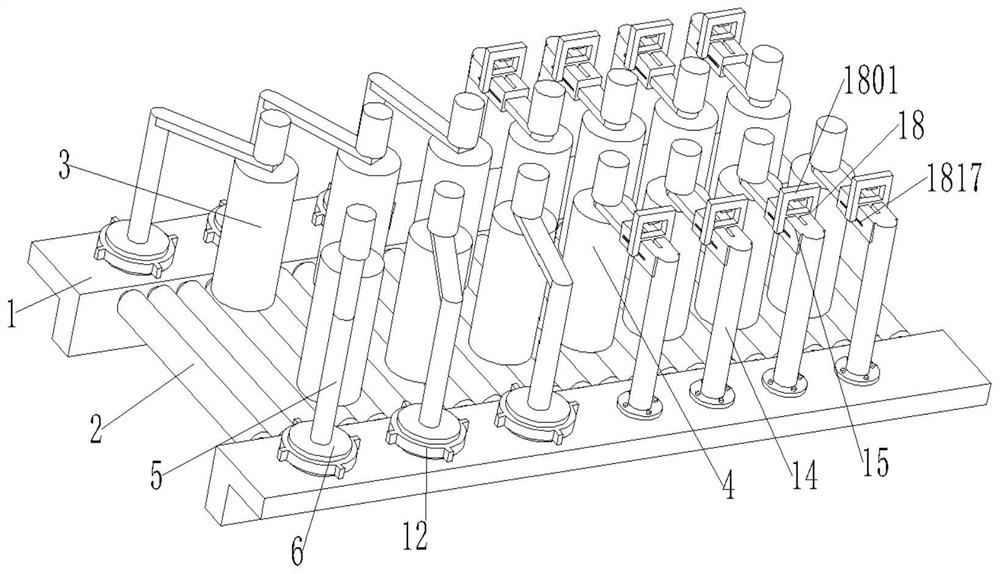

InactiveCN112058947AGuarantee the quality of production and processingProduction and processing quality is stableCleaning using toolsGear wheelEconomic benefits

The invention discloses a plastic bottle aluminum cap production raw material pretreatment device. On one hand, an aluminum cap plate is flattened through extrusion matching among an arranged extrusion plate, a rotary drum and a sleeve, so that the aluminum cap plate has very good flatness, stains on the surface of the plate can be well removed, and the quality of the plate is well guaranteed; andon the other hand, the pressing force for the extrusion plate can be well controlled through the arrangement of a first extrusion rod, a second extrusion rod and an auxiliary extrusion block, then pretreatment work can be carried out according to the actual situation of the plate, through an arranged positioning mechanism, a good positioning function is achieved for transmission among a transmission rack, a transmission gear and a rotation gear, plate flattening treatment and dust removal treatment are more stable, accordingly, the aluminum cap production machining quality is improved, and economic benefits are improved.

Owner:安徽天下盖包装有限公司

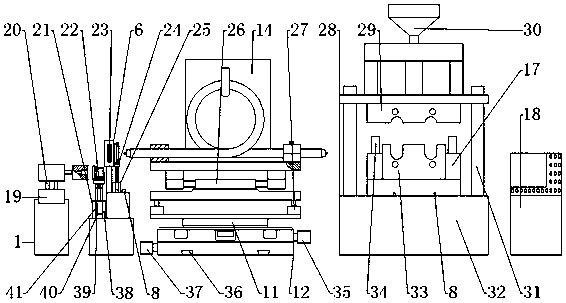

Friction block production device and friction block production method

PendingCN110788336ANo position shiftAccurate and effective pressingTurbinesOther manufacturing equipments/toolsMolding machineEngineering

The invention relates to a friction block production device and a friction block production method. The friction block production device comprises a mixing mechanism, a pressing and forming mechanismand a pressing and sintering mechanism, wherein the mixing mechanism mixes and stirs materials to form a mixed material; the pressing and forming mechanism comprises a pre-pressing mechanism and a primary pressing mechanism;, the pre-pressing mechanism pre-presses the mixed material, the primary pressing mechanism re-presses the pre-pressed mixed material and the pressure of the pre-pressing mechanism is smaller than a pressure value of the primary pressing mechanism; and the pressing and sintering mechanism pressurizes and sinters the pressed and formed mixed material. The friction block production device solves the problem that the compact density of a friction block is low and the friction block even has cracks as the compact will expands elastically to increase the volume as a result of release of elastic stress after an existing friction block is pressed.

Owner:BEIJING TIANYISHANGJIA NEW MATERIAL

Epoxy resin production and preparation equipment

InactiveCN114225873AGuarantee the quality of processing and productionAvoid pot situationTransportation and packagingMixer accessoriesPolymer chemistryThermal reaction

The invention discloses epoxy resin production and preparation equipment, and particularly relates to the technical field of epoxy resin processing equipment.The epoxy resin production and preparation equipment is characterized in that a heating cylinder is fixedly mounted on the outer wall of a reaction barrel, a heating pipe used for heating heating liquid is fixedly mounted in the heating cylinder, and a water inlet pipe is fixedly connected to the inner wall of the top of one side of the heating cylinder; a water outlet pipe used for replacing heating liquid is fixedly connected to the inner wall of the bottom of the other side of the heating cylinder, a heat preservation layer is fixedly connected to the outer wall of the heating cylinder, and a fixing cover is fixedly installed on the outer wall of the top of the reaction barrel. Heating liquid is preheated through the heating pipe in advance, after reaction materials are put in, the heating liquid is continuously heated, then the internal materials are uniformly heated through the heating cylinder arranged in a surrounding mode, meanwhile, the materials are uniformly heated to react through stirring of the stirring paddle, and then the dissolution reaction of the materials is accelerated; therefore, the processing and production quality of the epoxy resin is ensured, and meanwhile, the condensation condition caused by slow heating is avoided.

Owner:毛方虹

Melting and cooling device for metal casting

InactiveCN113477908AMeet the needs of useGuarantee the quality of production and processingGear wheelMetal machining

The invention relates to the technical field of metal processing equipment, discloses a melting and cooling device for metal casting, and solves the problem that the quality of a metal casting is affected due to different stresses on each surface of the metal casting due to the fact that conventional water-cooling cooling equipment for metal casting cannot comprehensively and uniformly cool the metal casting. The device comprises a base, a cooling box is mounted at the top of the base, a cooling water collecting cover is mounted at the top of the cooling box, rotating shafts are rotatably mounted between the lower portions of the inner side of the cooling box at equal intervals, first gears are fixedly mounted at two sides of each rotating shaft, and a transmission chain is mounted between the surfaces of the first gears at the same side of each rotating shaft. According to the melting and cooling device for metal casting, moving and rotating adjustment can be conducted on a metal casting part, and water spraying and cooling can be conducted on the metal casting part in the moving and rotating adjustment process so that it is guaranteed that each surface of the metal casting part can be uniformly and effectively cooled, and the production and processing quality of the metal casting part is also guaranteed.

Owner:扬州市华胜铸造有限公司

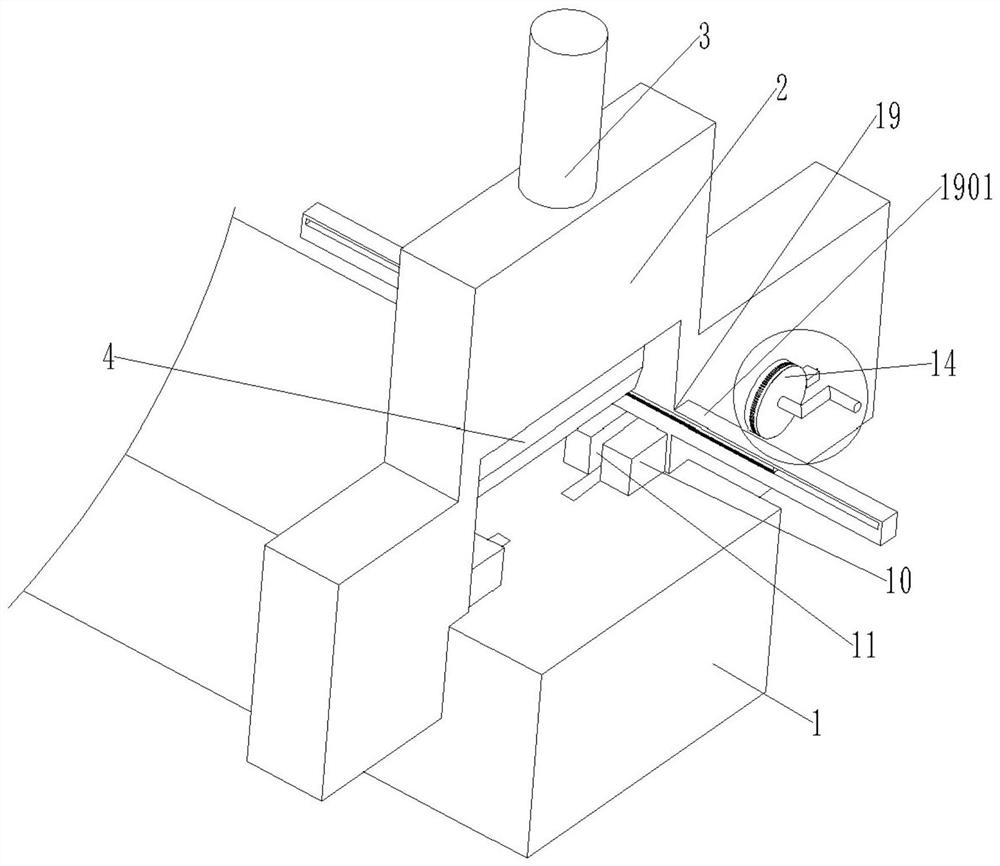

Fixed-size standard cutting mechanism for aluminum bottle cap production and processing

ActiveCN112059285AGuarantee the quality of production and processingImprove the quality of production and processingMeasurement/indication equipmentsNibbling shearing machinesProcess engineeringBottle cap

The invention discloses a fixed-size standard cutting mechanism for aluminum bottle cap production and processing. A workbench, a fixed frame, a telescopic rod, a cutter and a fixed-size mechanism areincluded. On one hand, through the arranged fixed-size mechanism, an aluminum sheet needing to be cut can be cut in an equal-size and fixed-size manner in the production and processing working process of an aluminum bottle cap, accordingly, it is guaranteed that cut aluminum pieces are the same in size, a guarantee is provided for later aluminum bottle cap production and processing quality, sizecutting of the aluminum sheet can be controlled according to different actual production requirements, and the size cutting precision can be guaranteed through a fine adjustment rack, a fine adjustment gear and an adjustment knob arranged on the fixed-size mechanism; and the production and processing quality of the aluminum bottle cap is improved.

Owner:安徽天下盖包装有限公司

A fully automatic feeding device for an industrial aluminum profile processing line

ActiveCN112124841BGuarantee the quality of production and processingEnsure delivery stabilityConveyor partsRoller-waysEconomic benefitsProcess engineering

The invention discloses a fully automatic feeding device for an industrial aluminum profile processing line. During the process of aluminum profile processing and production feeding, the conveying roller provided by the invention is used for conveying work, and the set guide roller and limit roller are suitable for aluminum profile processing. The position of the raw material is limited, that is, to ensure that the position of the aluminum profile will not be deflected during the transportation process, so as to ensure that the position of the aluminum profile can be accurately reached when it is transported to the next processing point, and there will be no position deviation, which not only ensures The conveying stability of aluminum profile processing parts can also ensure the production and processing quality of aluminum profiles, and ensure the economic benefits of processing and production; and the positions of guide rollers and limit rollers can be adjusted, and then can be adjusted according to the actual size of aluminum profiles. In this way, better position guidance and limit work for aluminum profile processing parts can be ensured.

Owner:JIANGXI TIAN YI ALUMINUM

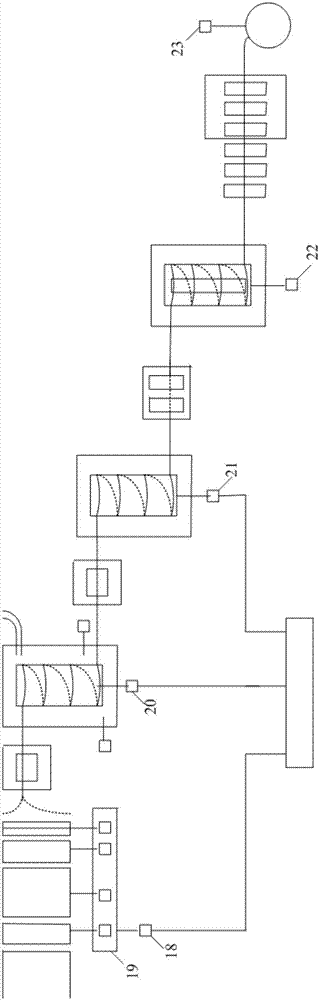

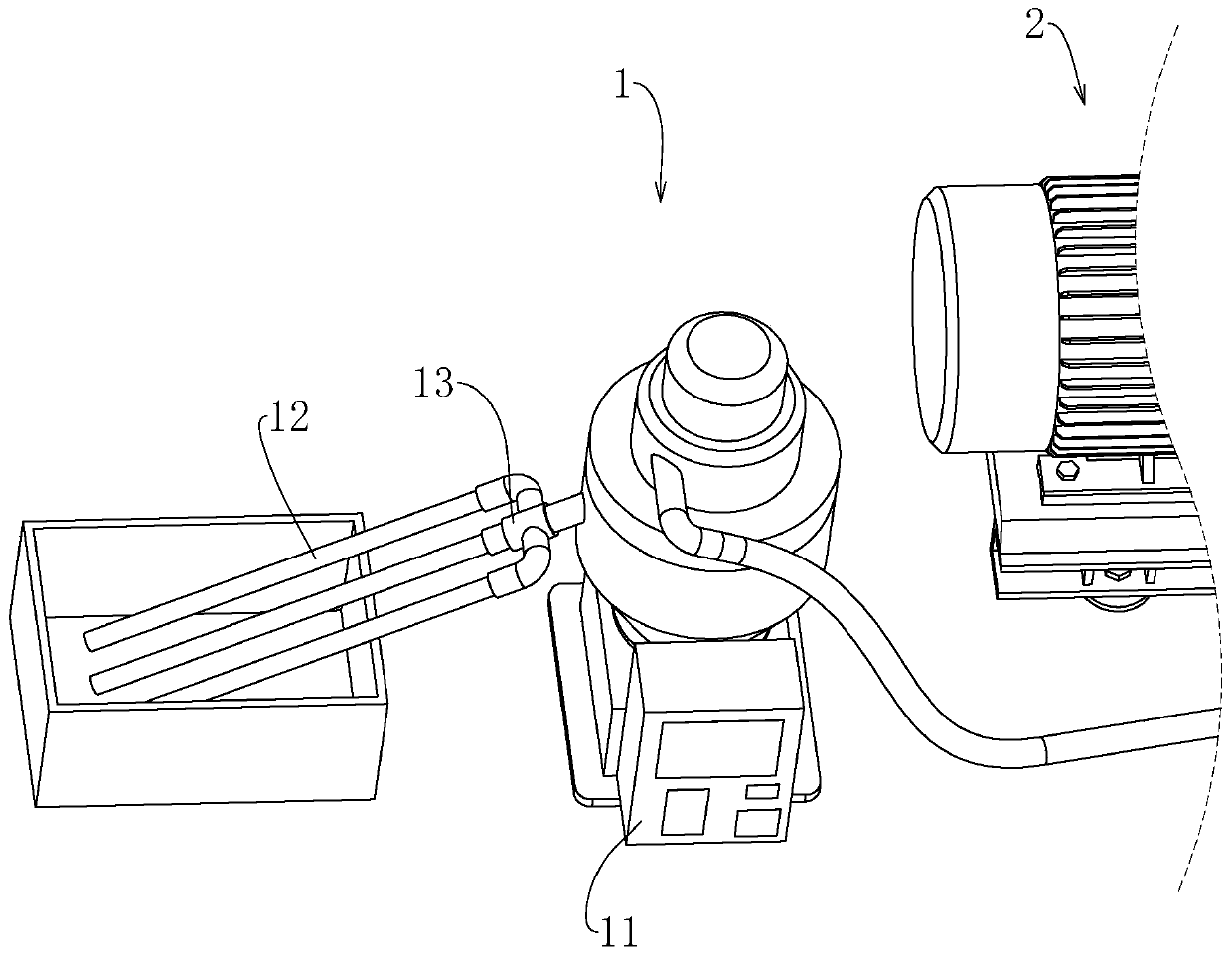

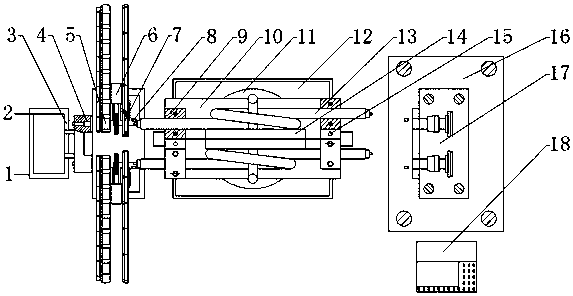

An automatic device for welding and injection molding processes of radio frequency coaxial jumper components

ActiveCN106444604BReduce inhalationGuarantee welding qualityProgramme control in sequence/logic controllersMeasuring instrumentClosed loop

The invention discloses an automatic device for welding and injection molding of a radio frequency coaxial jumper assembly. The automatic device comprises a feed device, a feeder A, an induction heater, a feeder B, a laser measuring instrument, a workbench, an injection molding machine and a feedback and main control system. The feed device is mainly composed of a cylinder A, a piston rod A, a cylinder B, a piston rod B and a vacuum workpiece support. The feeder A and the feeder B are straight feeders. The workbench is a lift rotary workbench, and comprises an electric motor, a motor A, a chute, a rotary disc, a cylinder C, a cylinder D, a tooling table A, a threaded hole, a buckle and a wire hanging stand in order from the bottom to the top. The feedback and main control system is a closed-loop control system which is used for controlling the operation of each component. According to the invention, the automatic device has the advantages of exquisite design, reasonable layout, rapid and reliable pneumatic control response, and good social and economic benefits; the labor intensity of a worker is reduced; and the production efficiency is improved.

Owner:JIANGSU TRIGIANT TECH

Suction nozzle piece correcting device and packaging equipment

PendingCN113371434AGuarantee the quality of production and processingBag making operationsPaper-makingControl engineeringProcess engineering

The invention discloses a suction nozzle piece correcting device and packaging equipment. The suction nozzle piece correcting device comprises a material guide rail, the output end of the material guide rail is provided with a correcting station and a blocking piece capable of abutting against a suction nozzle piece, the correcting station is movably provided with a first positioning clamping block set and a second positioning clamping block set which can drive the suction nozzle piece to move, and a clamping and positioning space matched with the mounting part of the suction nozzle piece is defined between the first positioning clamping block set and the second positioning clamping block set. After the suction nozzle piece is conveyed to the correction station through the material guide rail, the suction nozzle piece is limited and fixed in the clamping and positioning space through mutual cooperation of the first positioning clamping block set and the second positioning clamping block set, so that the suction nozzle piece is adjusted to the preset angle and position, the suction nozzle piece which is accurately positioned is provided for subsequent procedures, and the production and processing quality of packaging bags is guaranteed. The packaging equipment comprises the suction nozzle piece correcting device, and the packaging equipment is beneficial for improving the processing quality and stability of packaging bags and improving the production efficiency.

Owner:ZHONGSHAN NCA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com