Friction block production device and friction block production method

A production device and friction block technology, which is applied to other manufacturing equipment/tools, mechanical equipment, turbines, etc., can solve the problem of low green compact density and achieve the effects of improving production processing speed, ensuring production processing efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A friction block production device is described, comprising:

[0053] The mixing mechanism is used to mix and stir the materials to form a mixed material;

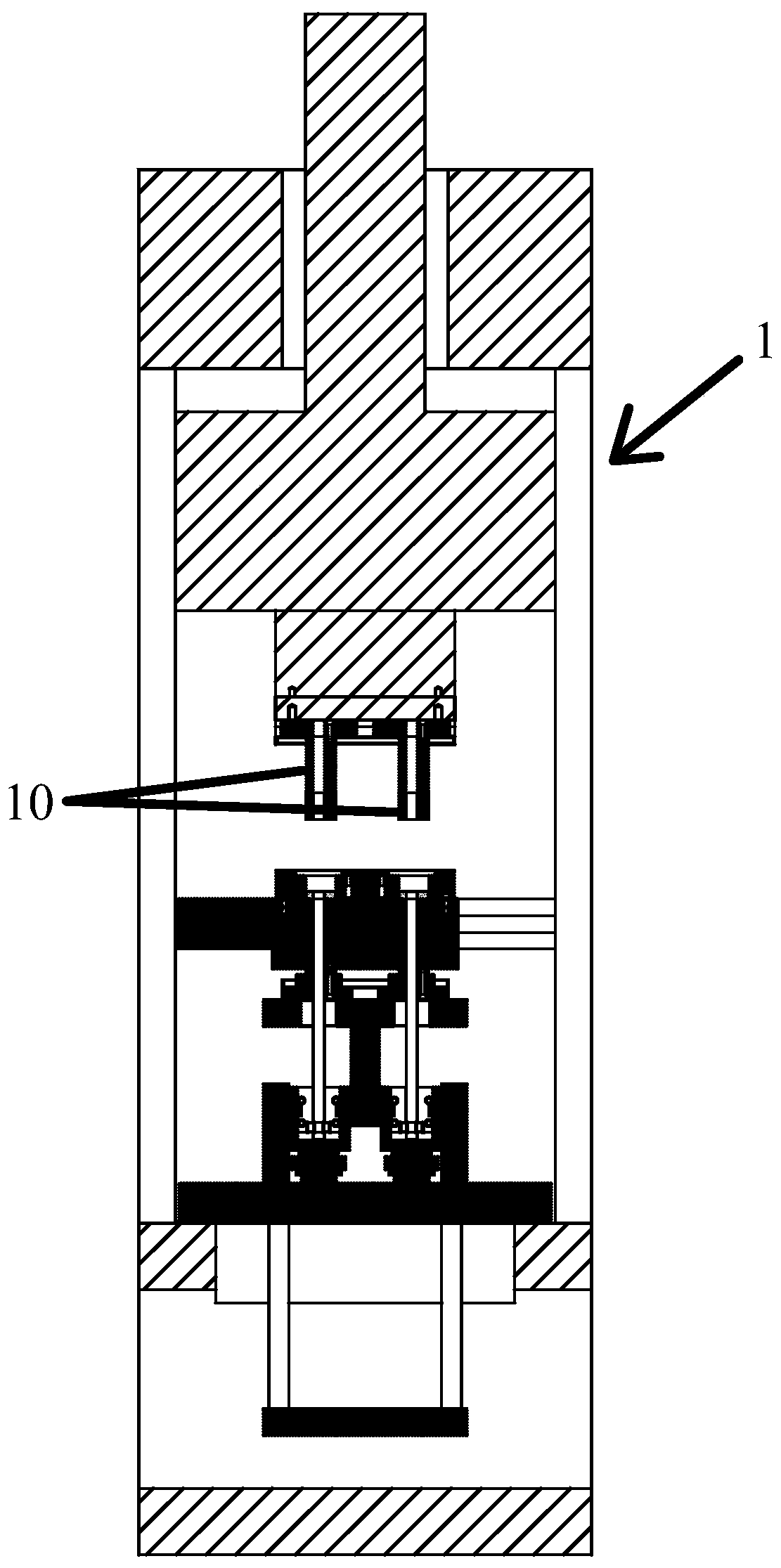

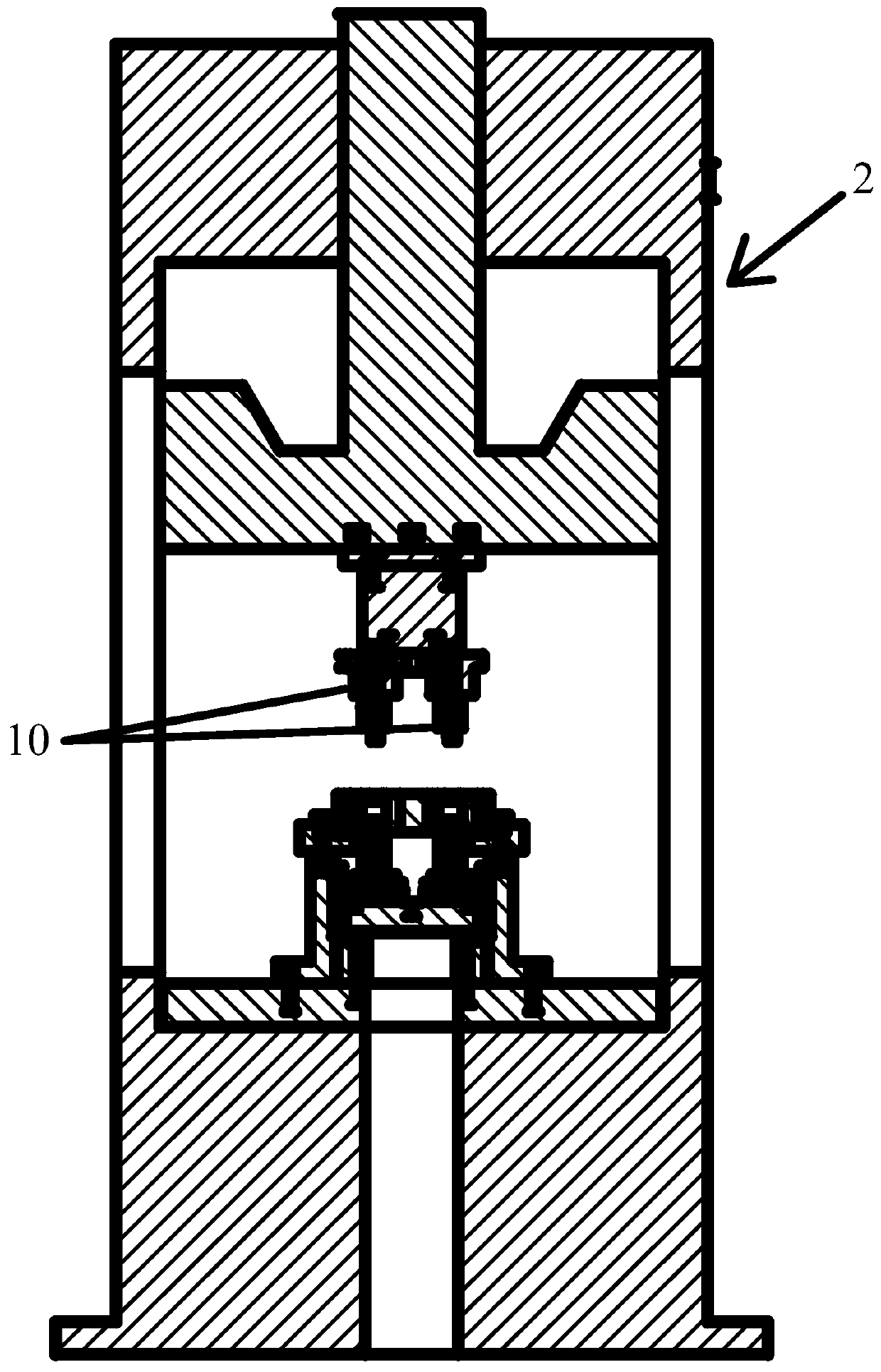

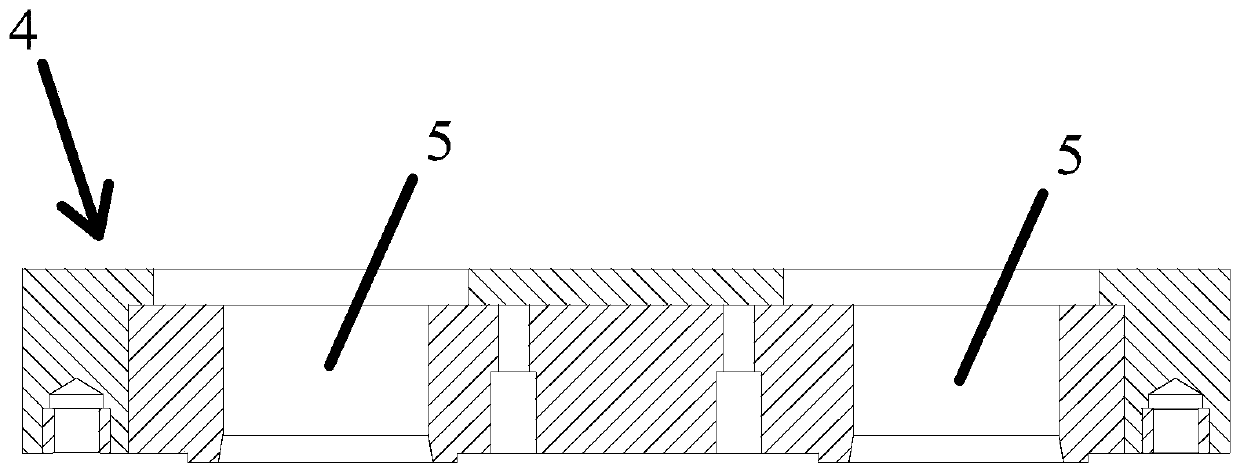

[0054] Press molding mechanisms such as figure 1 , figure 2 as well as Figure 7 As shown, the press-forming mechanism includes: a pre-pressing mechanism 1 and a main pressing mechanism 2; the pre-pressing mechanism 1 pre-presses the mixed material, and the main-pressing mechanism 2 pre-presses the mixture The material is pressed again, and the pressure of the pre-pressing mechanism 1 is lower than the pressure value of the main pressing mechanism 2; the main pressing mechanism 2 is provided with a positioning part for accommodating the steel back 3 of the friction block, and the main pressing mechanism 2 The mixed material and the friction block steel back 3 are pressed together; the present invention has a pre-pressing mechanism 1 and a main pressing mechanism 2 that cooperate with each other. After the pre-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com