Novel form-removal-free concrete construction technology

A concrete, formwork-free technology, which is applied to building components, walls, buildings, etc., can solve the problems of high noise in concrete construction, shifting of mesh positions, disturbing residents, etc., to ensure pouring effect, simplify installation steps, and good pouring effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

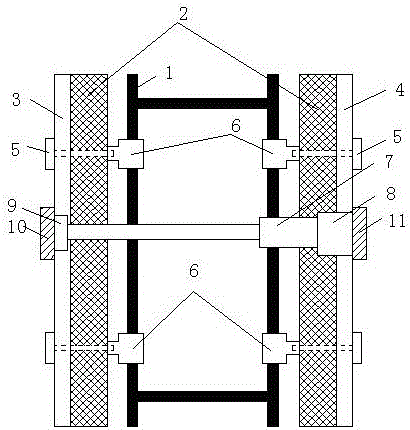

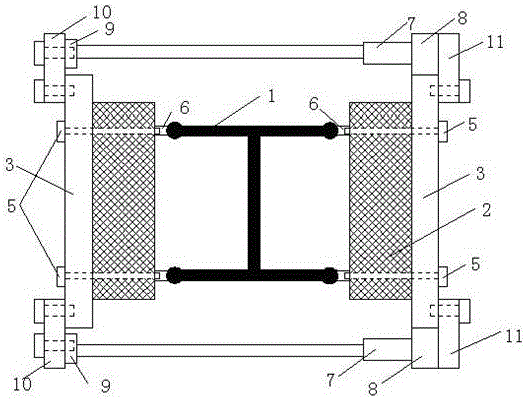

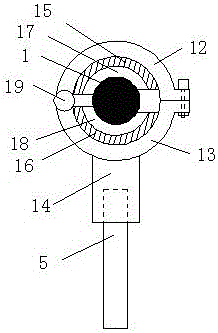

[0023] refer to Figure 1-3 In this embodiment, a new construction technique for concrete without form removal is proposed, which includes a first mesh 3, a second mesh 4 and a steel frame 1, and two clips 6 are set on both sides of the steel frame 1. , and the clips 6 located on both sides of the steel frame 1 are oppositely arranged, the clip 6 includes a first semicircular plate 13, and the two first semicircular plates 13 are respectively located on both sides of the steel bar frame 1, and the two first semicircular plates 13 are oppositely arranged , the first half-circle plate 13 is provided with a first buffer layer 16 near the side of the steel skeleton 1, and the first buffer layer 16 is provided with a first arc-shaped plate 18 on a side away from the first semi-circle plate 13, and the first arc-shaped plate 18 is in contact with the reinforcement skeleton 1, and the first semicircular plate 13 is provided with a rotating rod 19, and the first semicircular plate 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com