Patents

Literature

289results about How to "No position shift" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

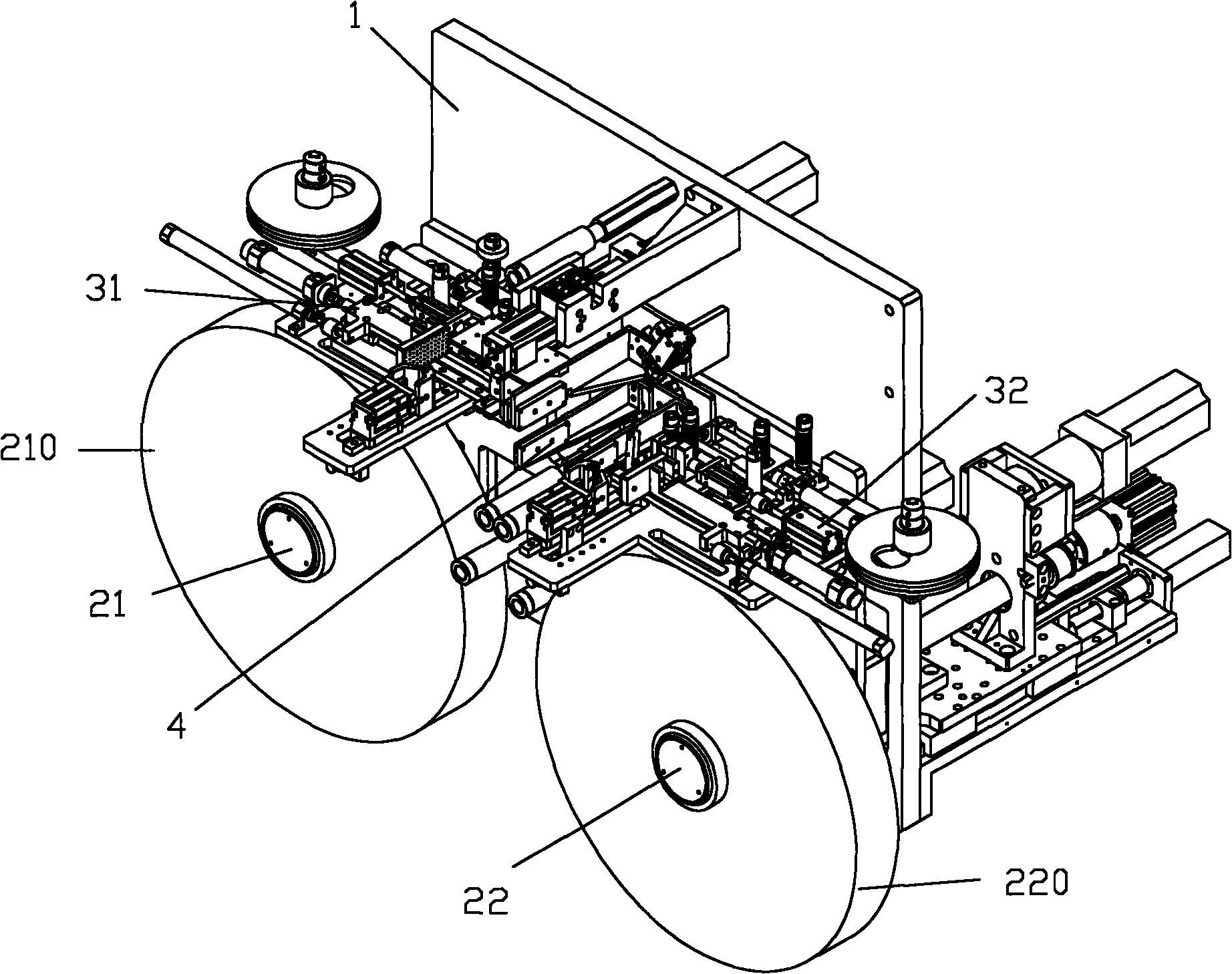

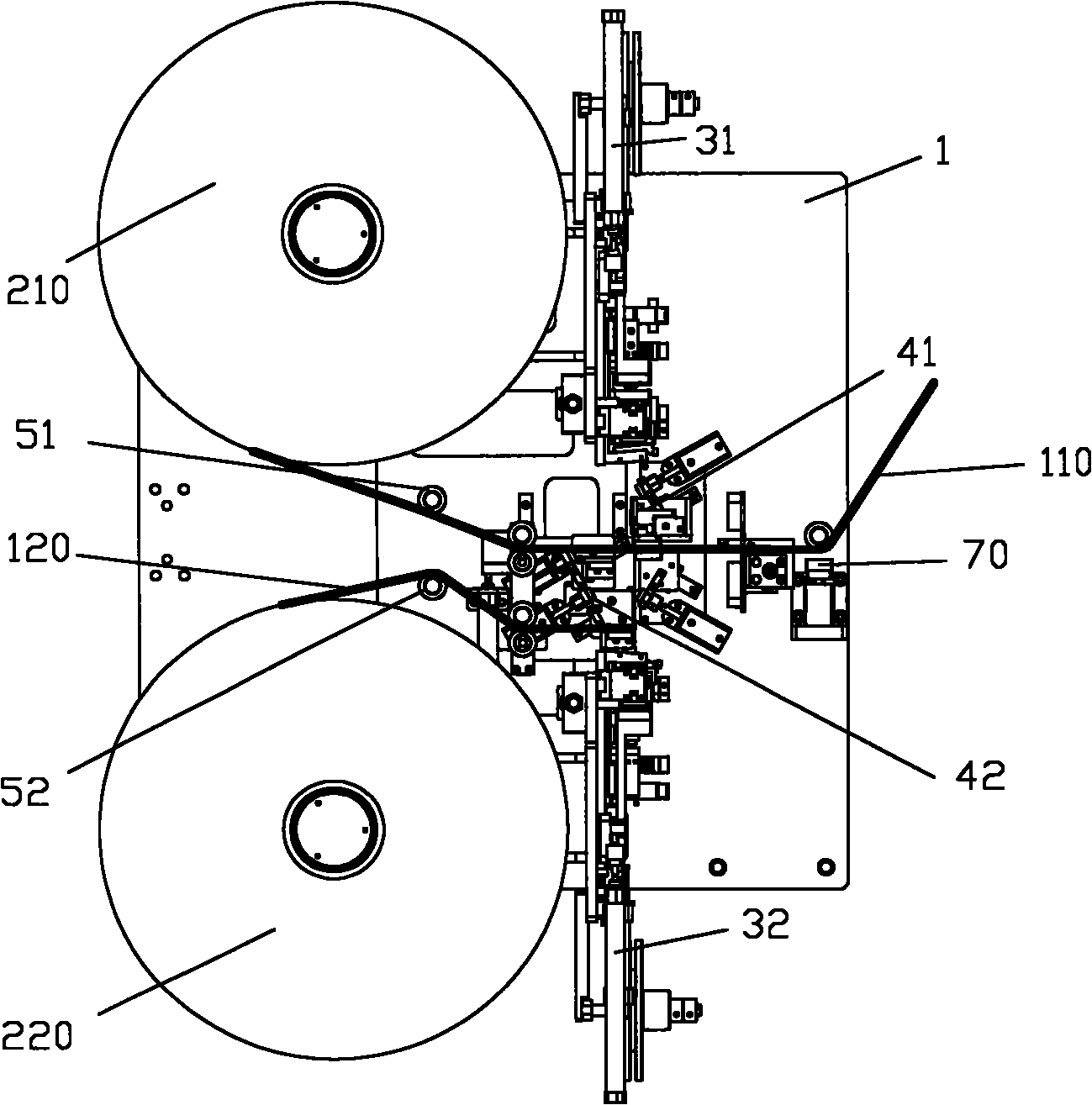

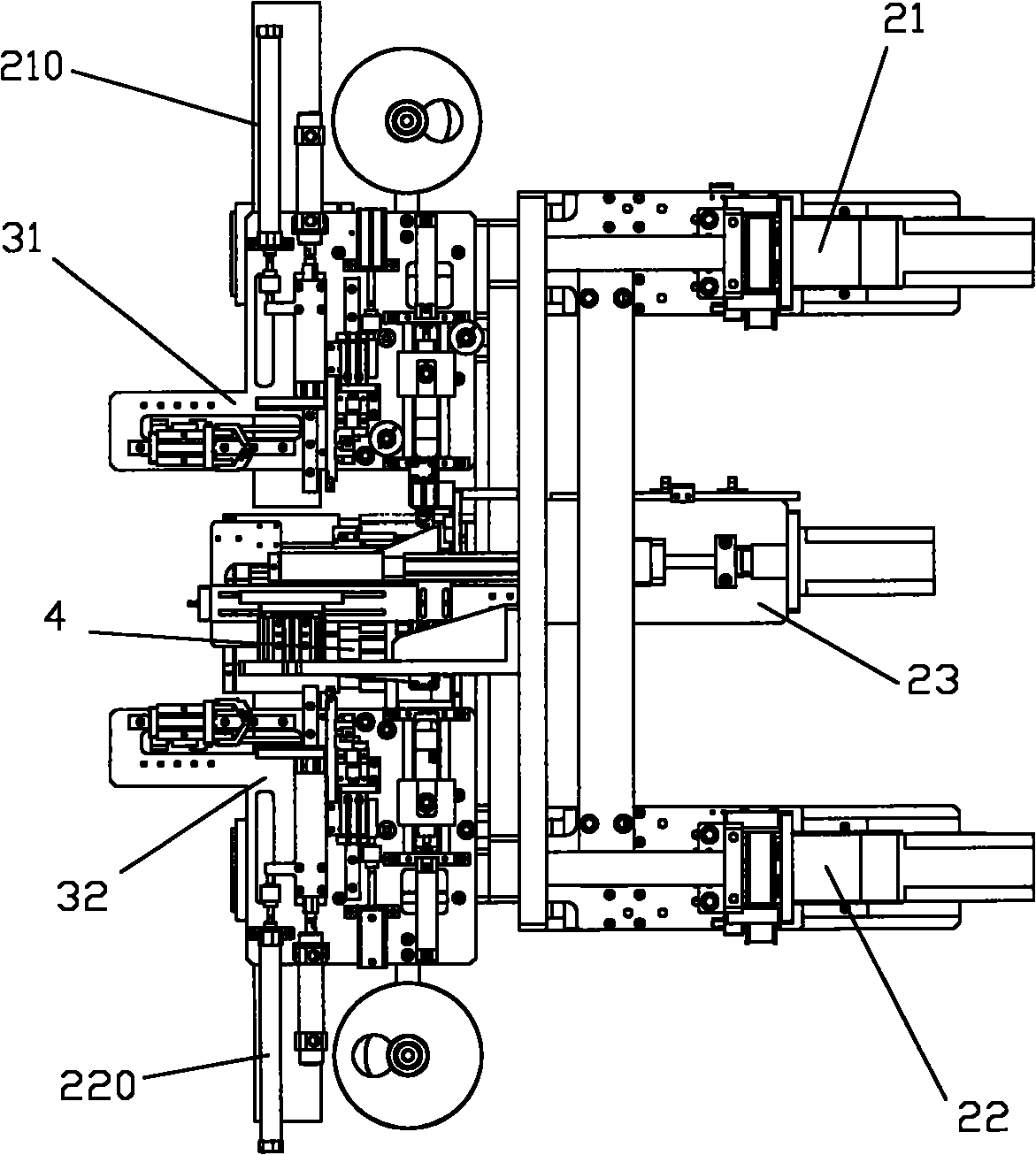

Automatic coil material changing and connecting device and method

ActiveCN101804922AEliminate wrinklesImprove protectionWebs handlingEngineeringMechanical engineering

The invention discloses an automatic coil material changing and connecting device and an automatic coil material changing and connecting method. The device comprises a primary loading mechanism, a standby loading mechanism, an aligning mechanism, a first adhesive sticking mechanism, a second adhesive sticking mechanism and a control mechanism, wherein the aligning mechanism comprises a first connecting part and a second connecting part, the first connecting part comprises a tail sucker, and the second connecting part comprises a head sucker; the head sucker sucks the head of a standby coil material in advance, and the tail sucker is used for sucking the tail part of a primary coil material under the control of the control mechanism when the primary coil material is used up; after the tail part of the primary coil material is sucked, the aligning mechanism aligns the tail part of the primary coil material and the head of the standby coil material; and under the control of the control mechanism, the first adhesive sticking mechanism and the second adhesive sticking mechanism stick adhesive tapes on two faces at the connecting part between the tail part of the primary coil material and the standby coil material. The device and the method can improve the connection rate greatly and avoid influencing the production state of normal products.

Owner:SHENZHEN GEESUN INTELLIGENT TECHNOLOGY CO LTD

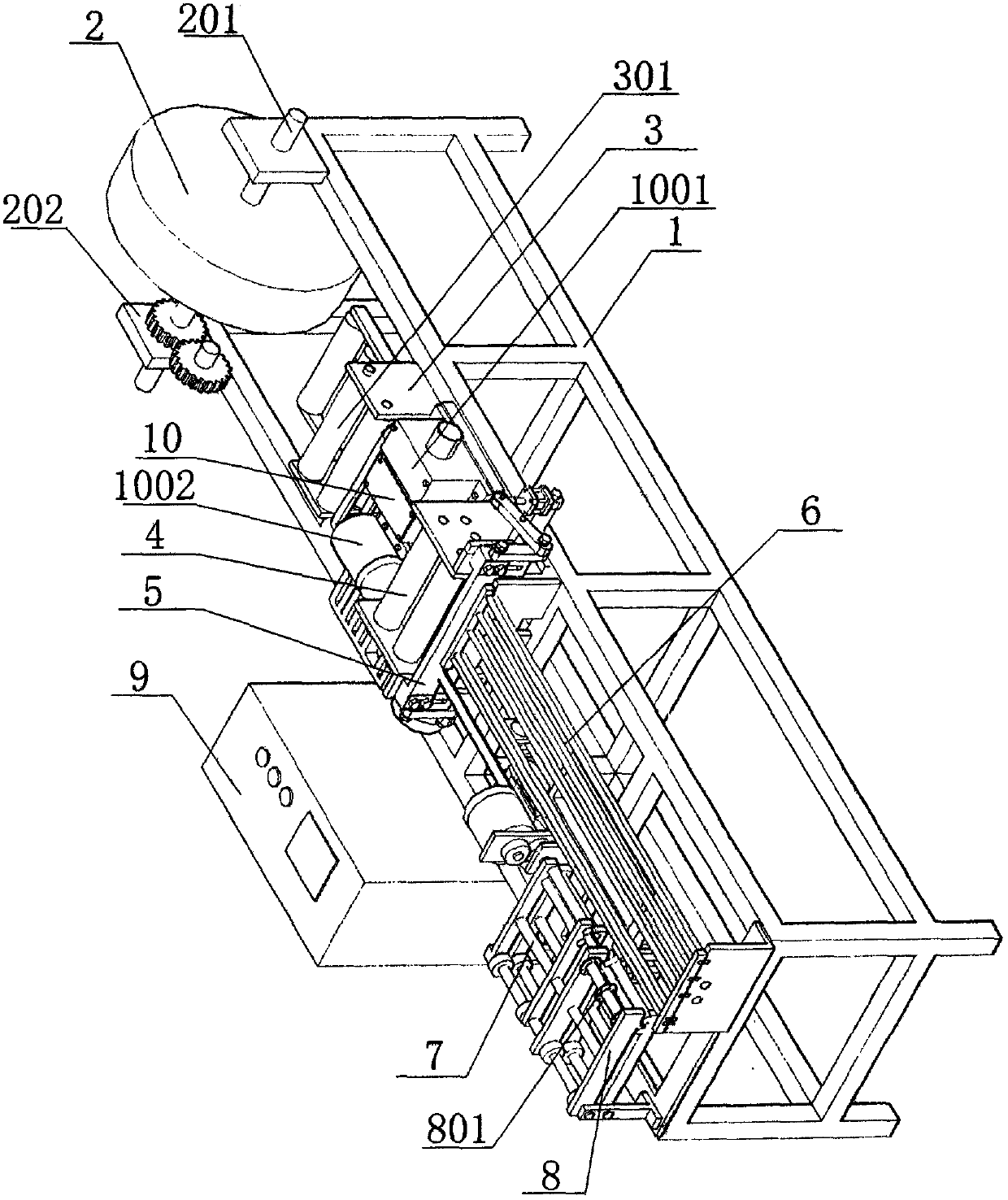

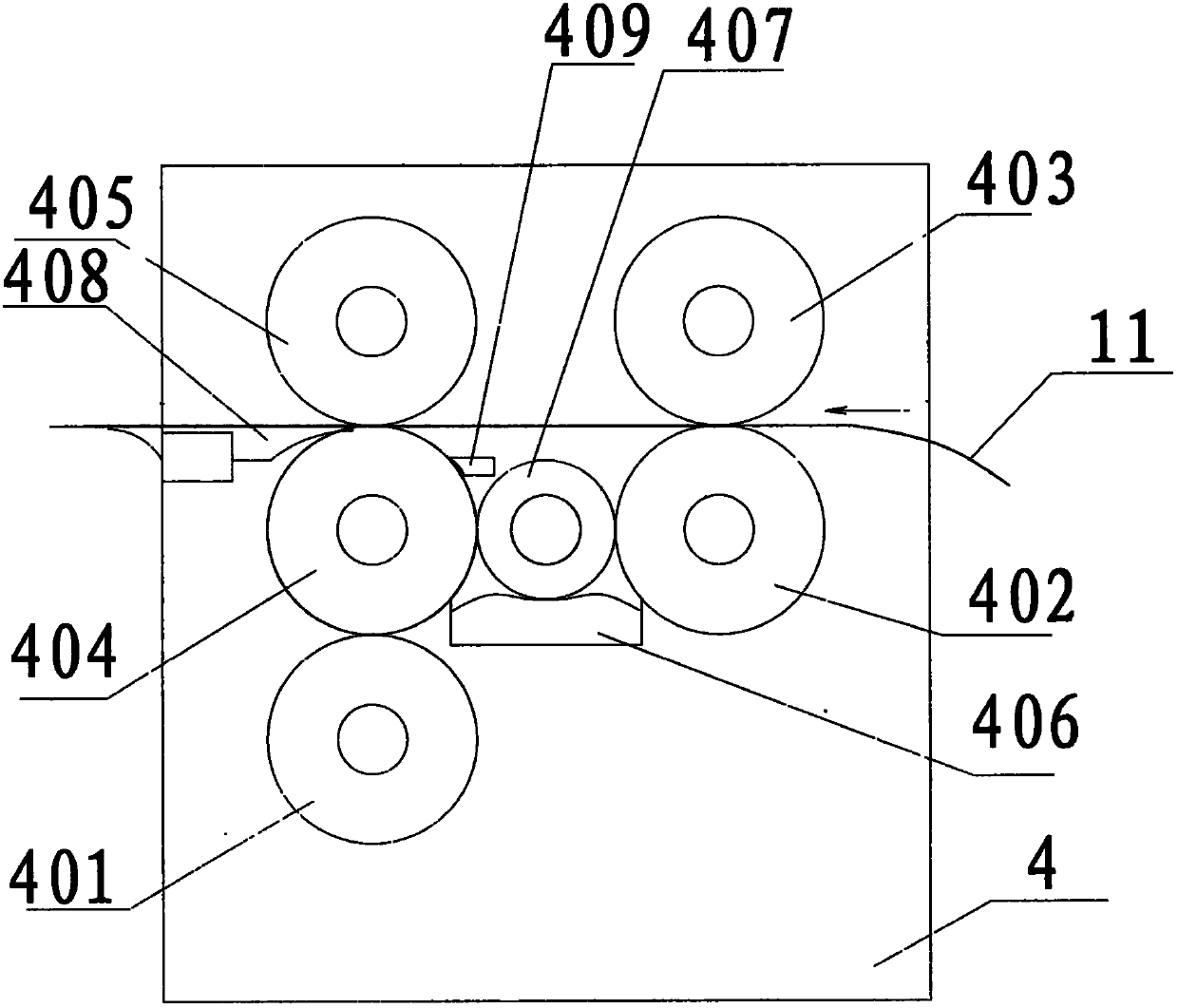

Flat paper tube reeling machine

InactiveCN102774035AReduce thicknessExcellent adhesionPaper/cardboard wound articlesPulp and paper industryPaper cut

The invention discloses a flat paper tube reeling machine, comprising a rack, a paper placing device which is connected to the rack, a paper guiding device, a pasting device, a, paper cutting device, a paper feeding detaching device, a tube reeling device and a tube cutting device, wherein the pasting device comprises a sizing roller; a paper passing device is fixedly arranged between the pasting device and the paper cutting device; an paper inlet surface of the paper passing device and the top surface of the sizing roller are in a same plane; and an paper outlet surface of the paper passing device and a paper cutting surface of the paper cutting device are in a same plane. According to the flat paper tube reeling machine provided by the invention, the thickness of paper can be reduced; and during the tube reeling, the adherence force between two pieces of paper is increased, so that the paper tube quality is improved.

Owner:GUANGZHOU ZHONGSHI PACKAGE PROD

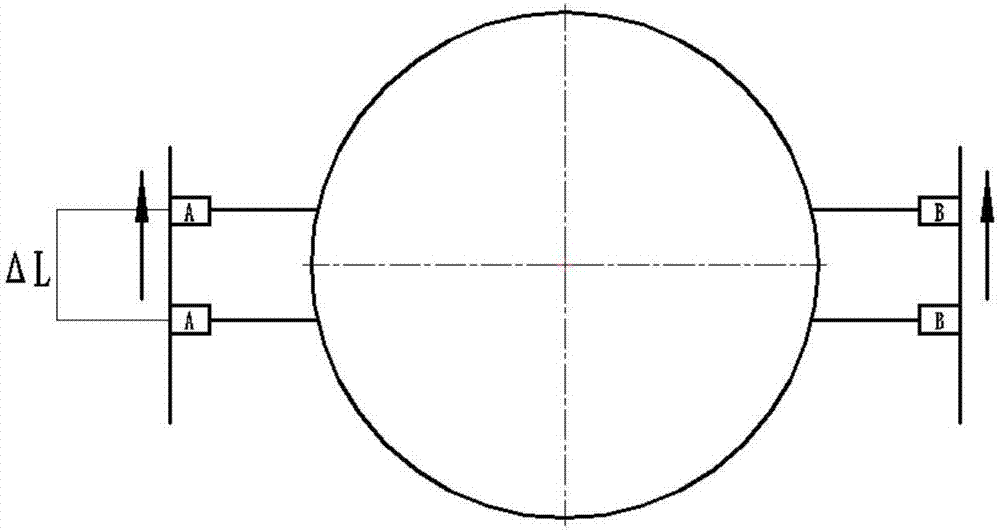

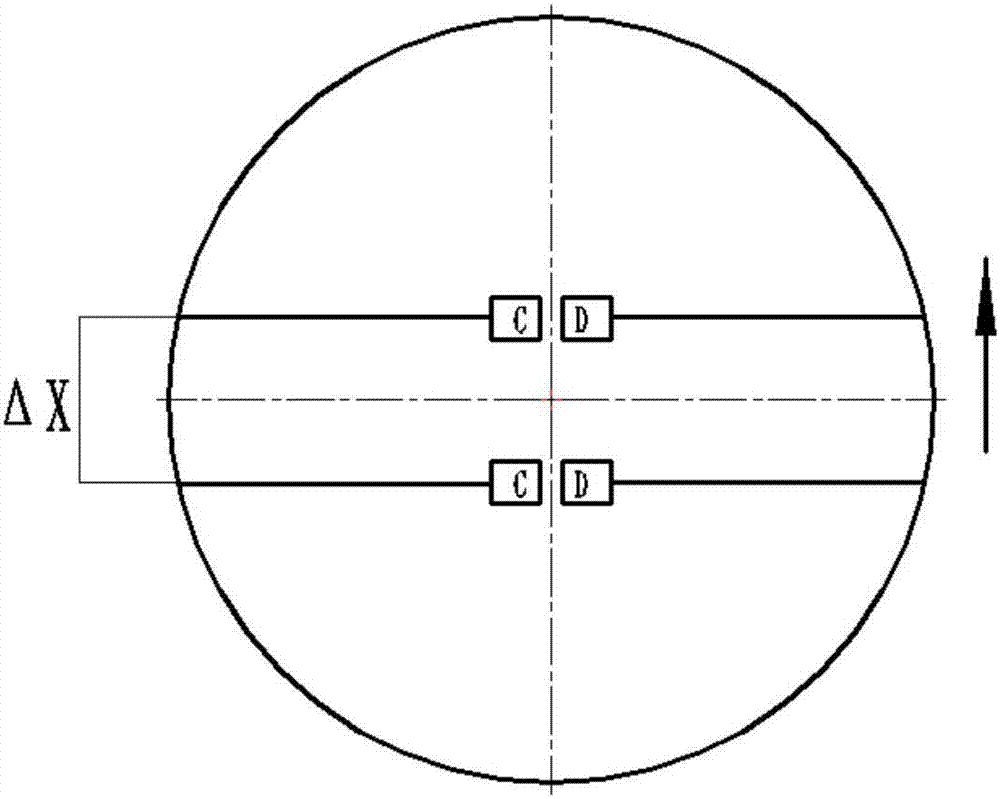

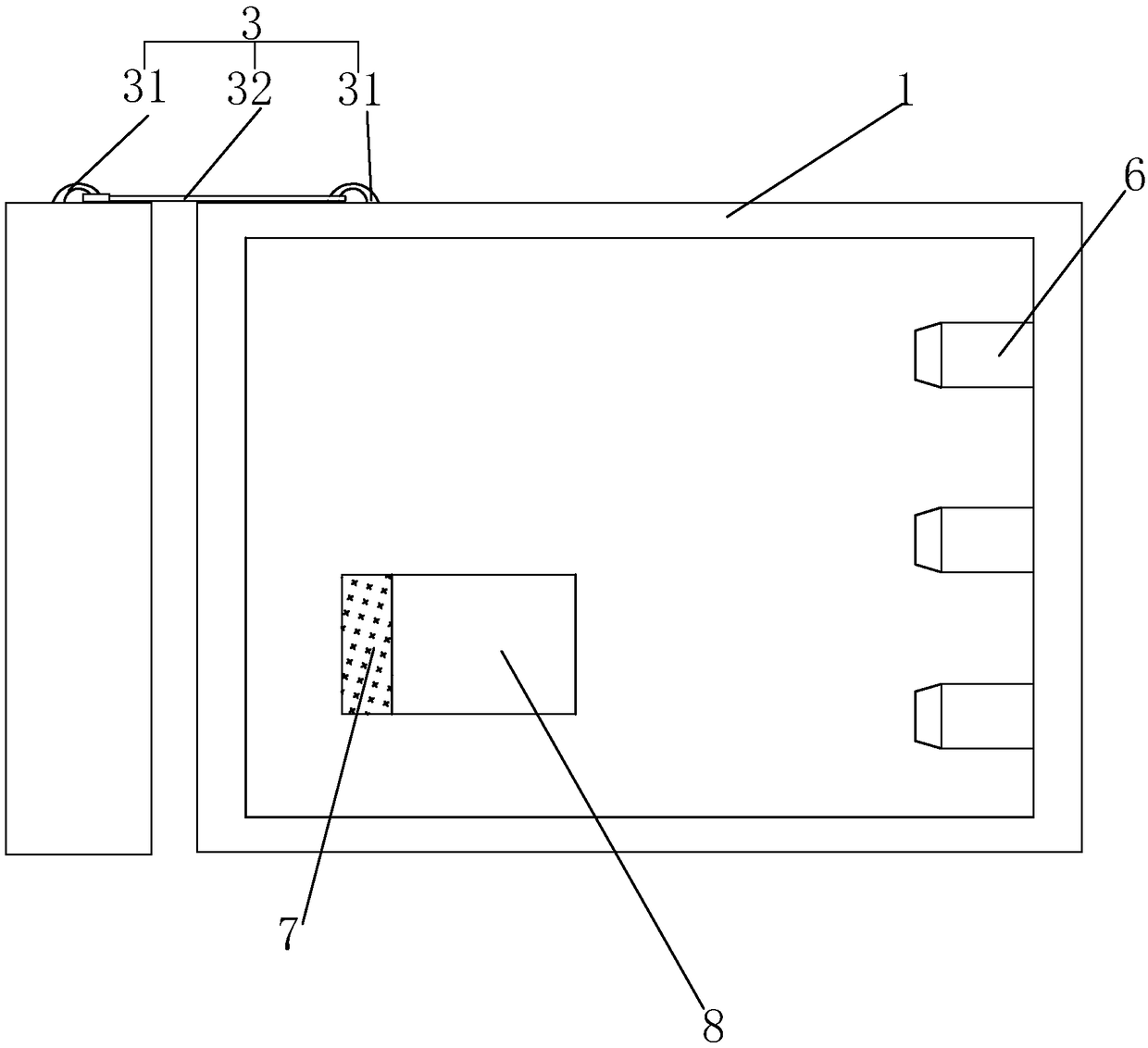

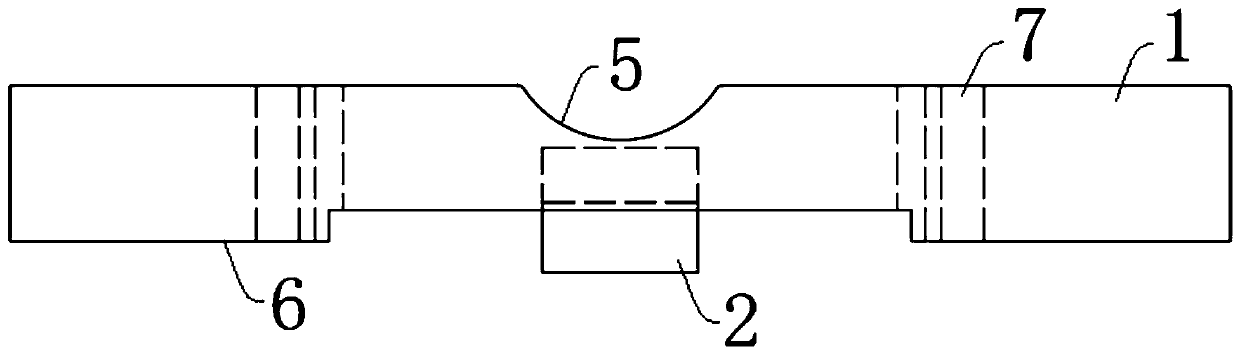

Detecting device and detecting method for measuring outer diameter and the inner diameter of wheel of motor train

InactiveCN107084673AMeasurement position does not occurPrecise control of measurement positionUsing optical meansEngineeringLaser

The invention discloses a detecting device and detecting method for measuring the outer diameter and the inner diameter of the wheel of a motor train. The device mainly comprises a wheel vertical detection platform, a horizontal detection platform, a fine reference support device, a coarse reference support device, a transportation platform, a rotary driving device. Four laser displacement sensors, including laser displacement sensors A and B installed on a crescent board tail end IV and laser displacement sensors C and D installed on the wheel vertical detection platform III, horizontally move a [delta]L and a [delta]X in the radial direction of the wheel of the motor train respectively. The scanning measured values in each length unit of the four laser displacement sensors are stored in an acquisition card. Then the maximum value of the measured data of each laser displacement sensor is selected to be compared with standard data to calculate the outer diameter and the inner diameter of the wheel. Then, the above operation is performed after a wheel rotary driving device is rotated by a certain angle. After measurement is performed three times, average values are acquired to be used as the measured values of the outer diameter and the inner diameter of the wheel.

Owner:CHANGCHUN INST OF TECH

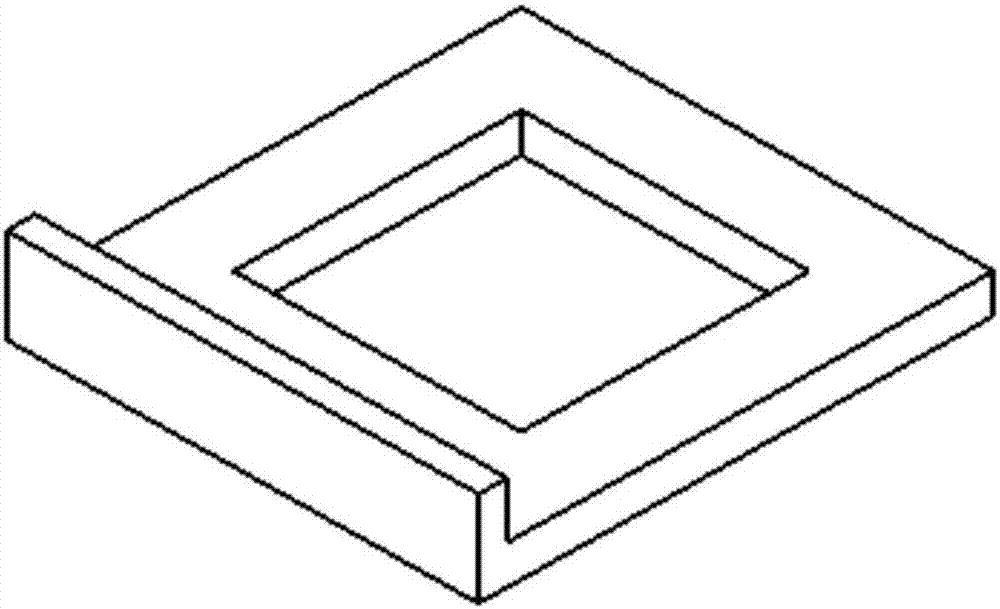

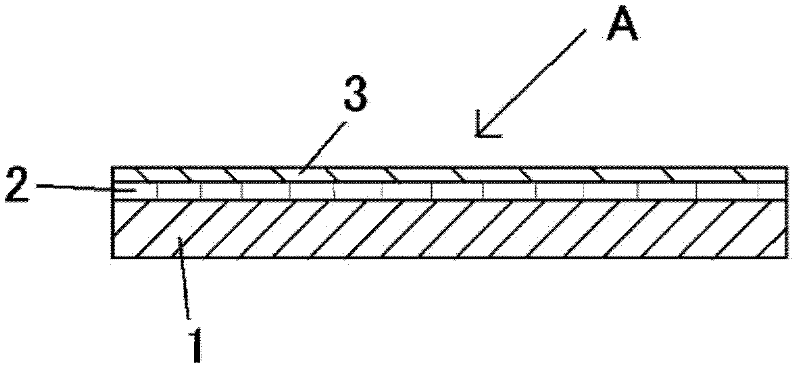

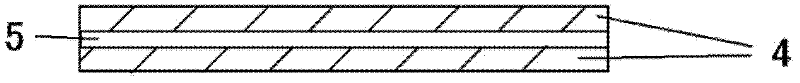

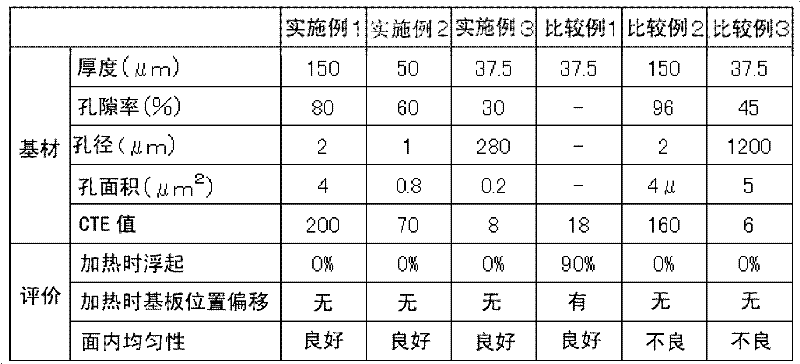

Tackiness adhesive sheet for thin-film substrate fixing

InactiveCN102653663AForm an efficient and stableImprove operating rateLayered productsFilm/foil adhesivesPorous substrateEngineering

The present invention provides a manufacturing method for efficiently and stably forming a pattern on a thin-film substrate. A thin-film substrate, a tackiness adhesive sheet for thin-film substrate fixing, and a hard substrate are laminated in this order and a porous base material functioning as a core material of the tackiness adhesive sheet for thin-film substrate fixing has bore holes. Therefore, even if preliminary heating and drying is not applied, air bubbles are not generated between the thin-film substrate and the tackiness adhesive sheet for fixing during pattern formation on the thin-film substrate. This makes it possible to stably and efficiently form a pattern.

Owner:NITTO DENKO CORP

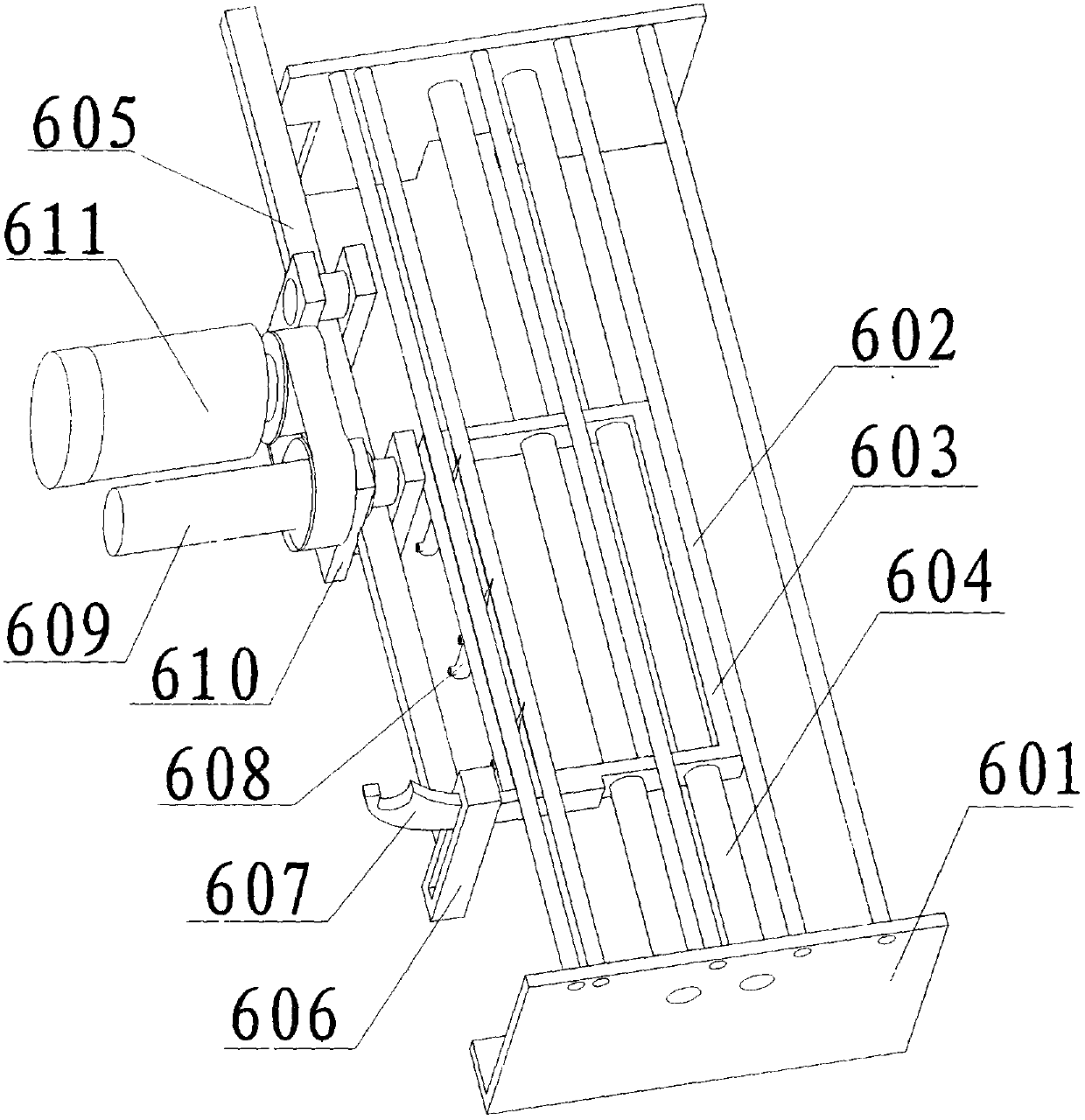

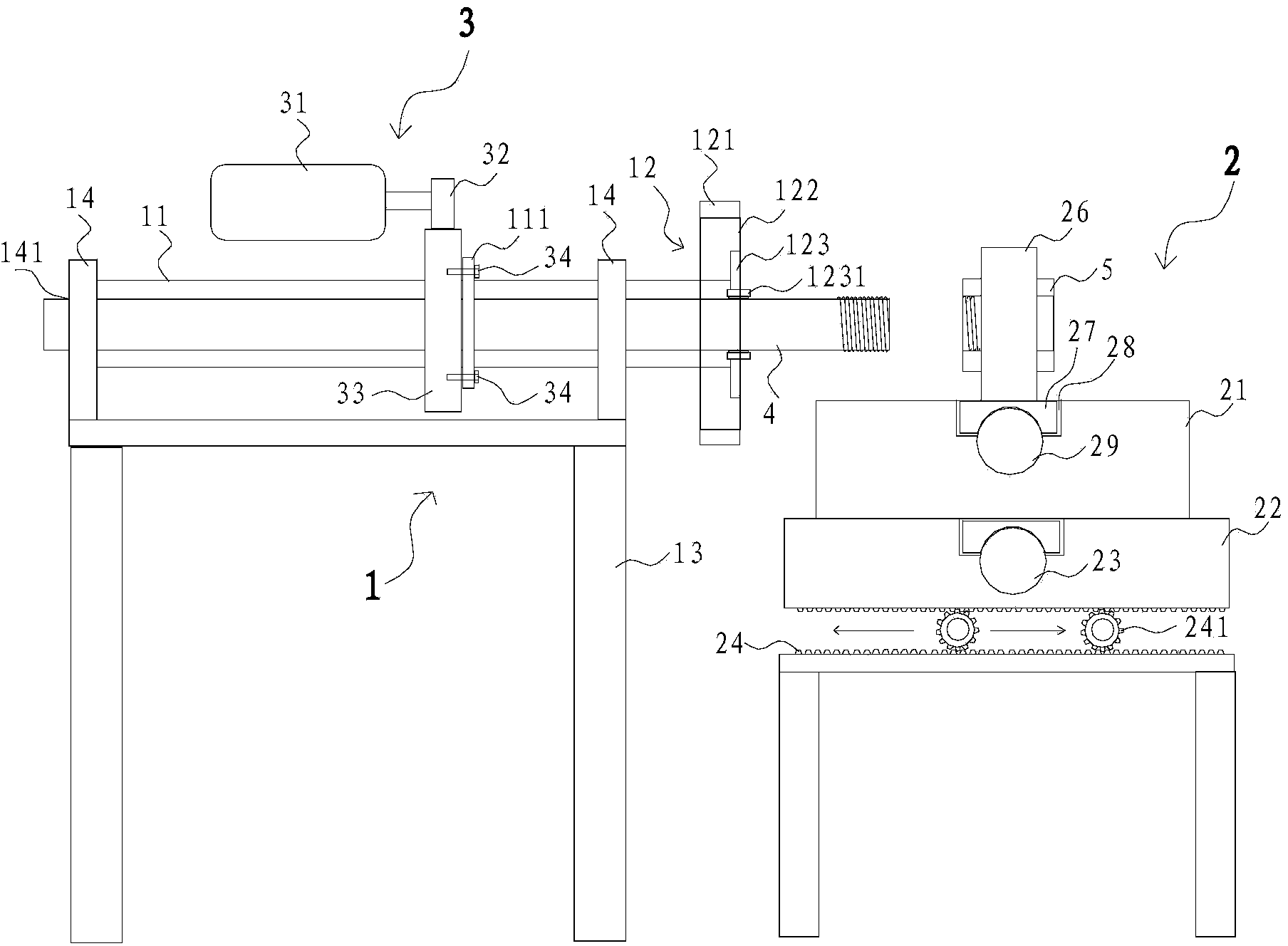

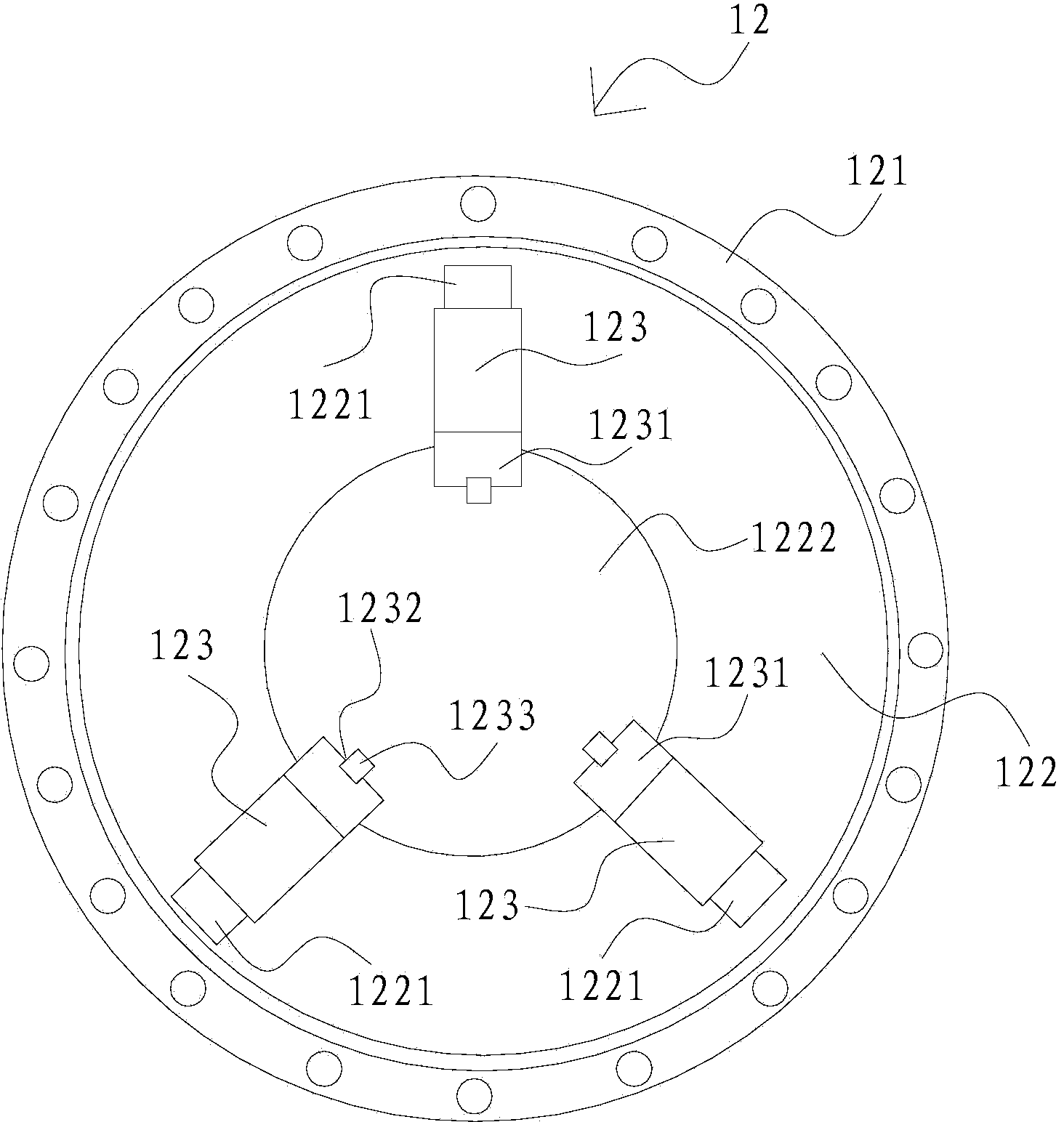

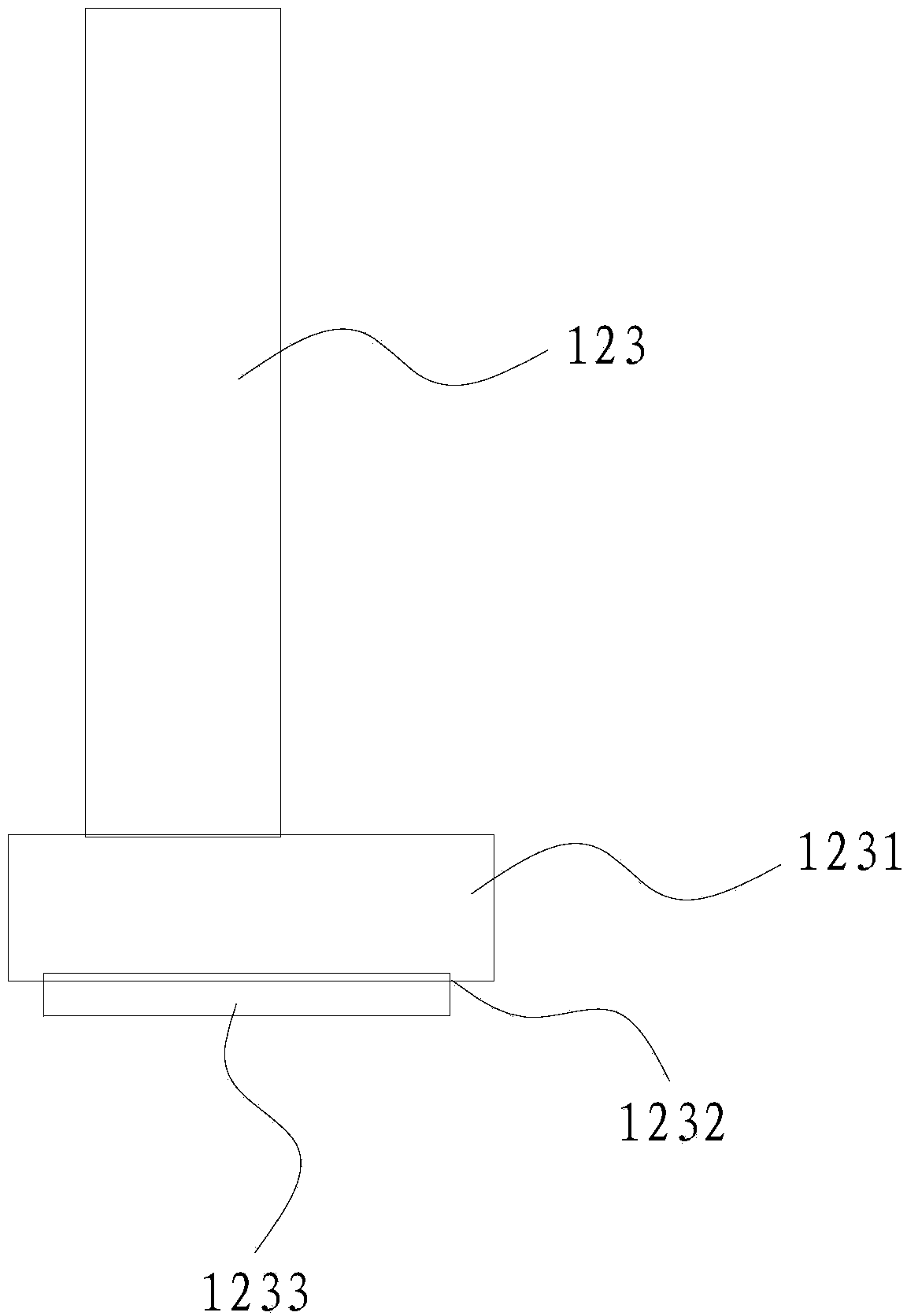

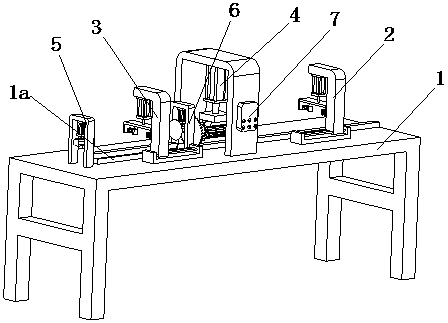

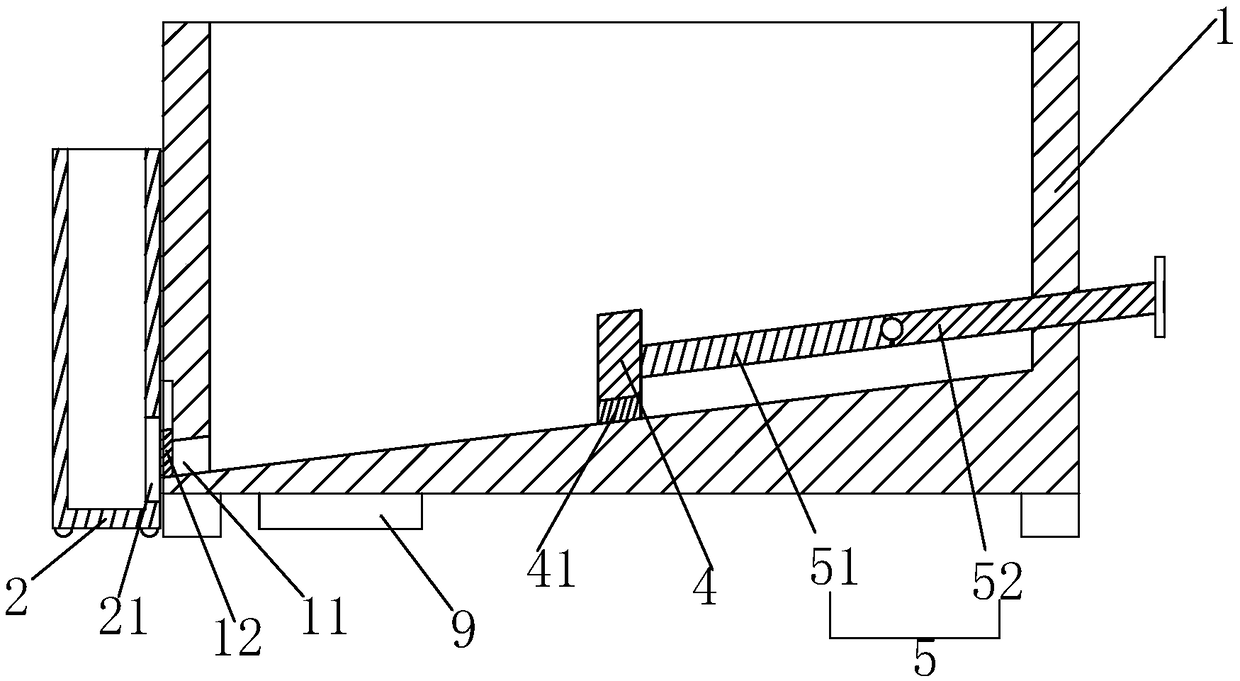

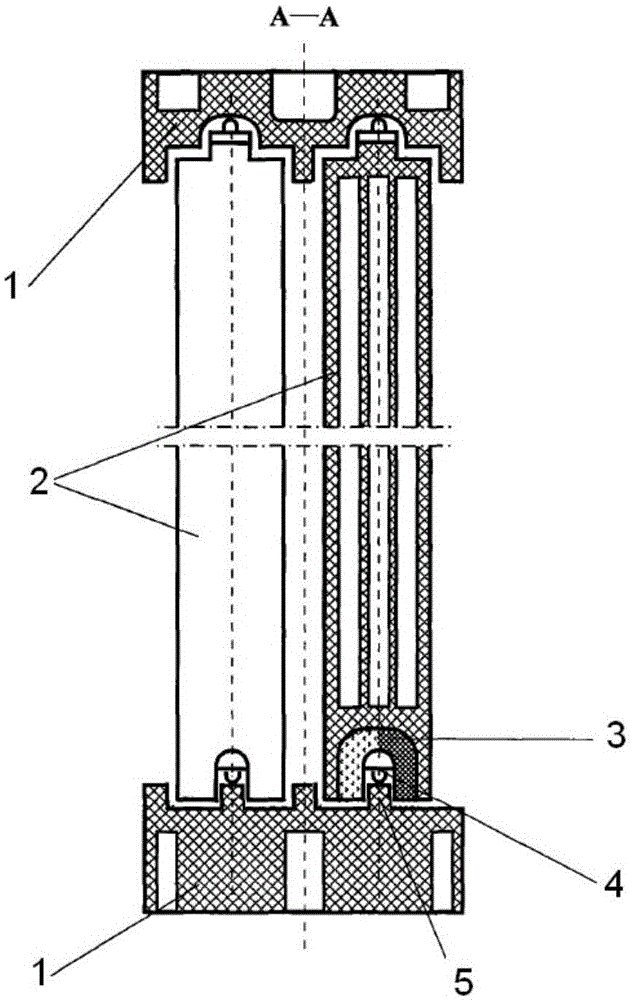

Threaded pipe assembly device

ActiveCN103659246AImprove tightening qualityGuarantee personal safetyMetal working apparatusThreaded pipeEngineering

The invention discloses a threaded pipe assembly device comprising a first fixing unit, a second fixing unit and a driving unit. The first fixing unit is used for fixing a pipe to be assembled. The second fixing unit is used for clamping a pipe joint to be assembled and capable of sliding along the horizontal direction. The driving unit is used for driving the pipe to rotate. The pipe and the pipe joint are oppositely arranged at the same horizontal height, the pipe is fixed through the first fixing unit, and when the driving unit drives the pipe to rotate, the second fixing unit clamps the pipe joint to get close to the pipe, and the pipe is matched with the pipe joint. The threaded pipe assembly device has the advantages that a traditional pure manual assembly mode is converted into the one with the driving unit providing force, so that labor force is saved; the driving unit can provide force in electric, pneumatic modes and the like, the force provided by the driving unit is stronger as compared with that of human beings, tightening quality between the pipe joint and the pipe is higher, bayonet pliers used by workers are omitted, skid danger is avoided, and personal safety of the workers can be greatly guaranteed.

Owner:商丘市天路工程机械有限公司

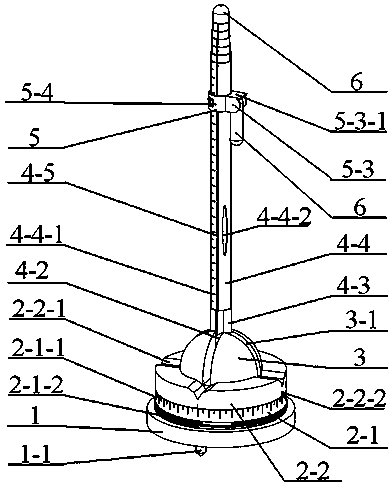

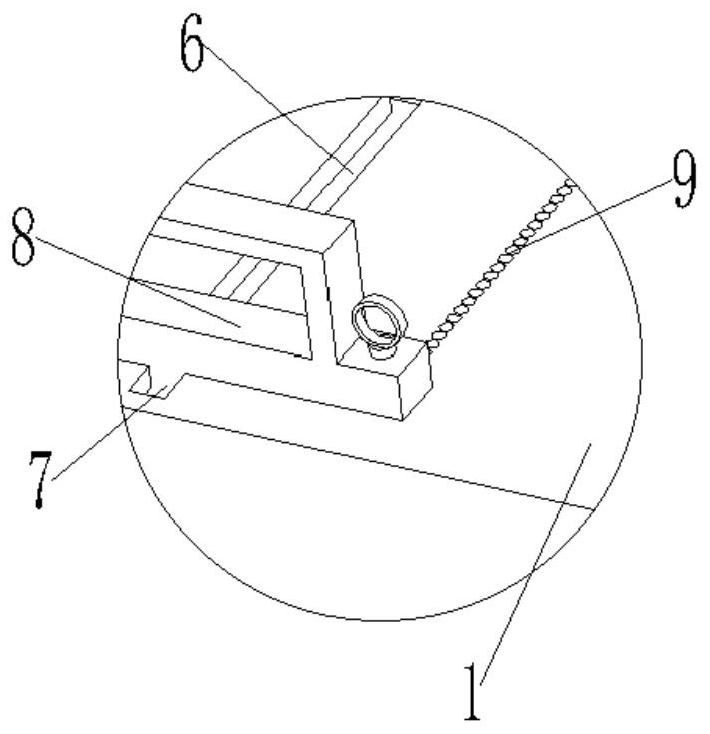

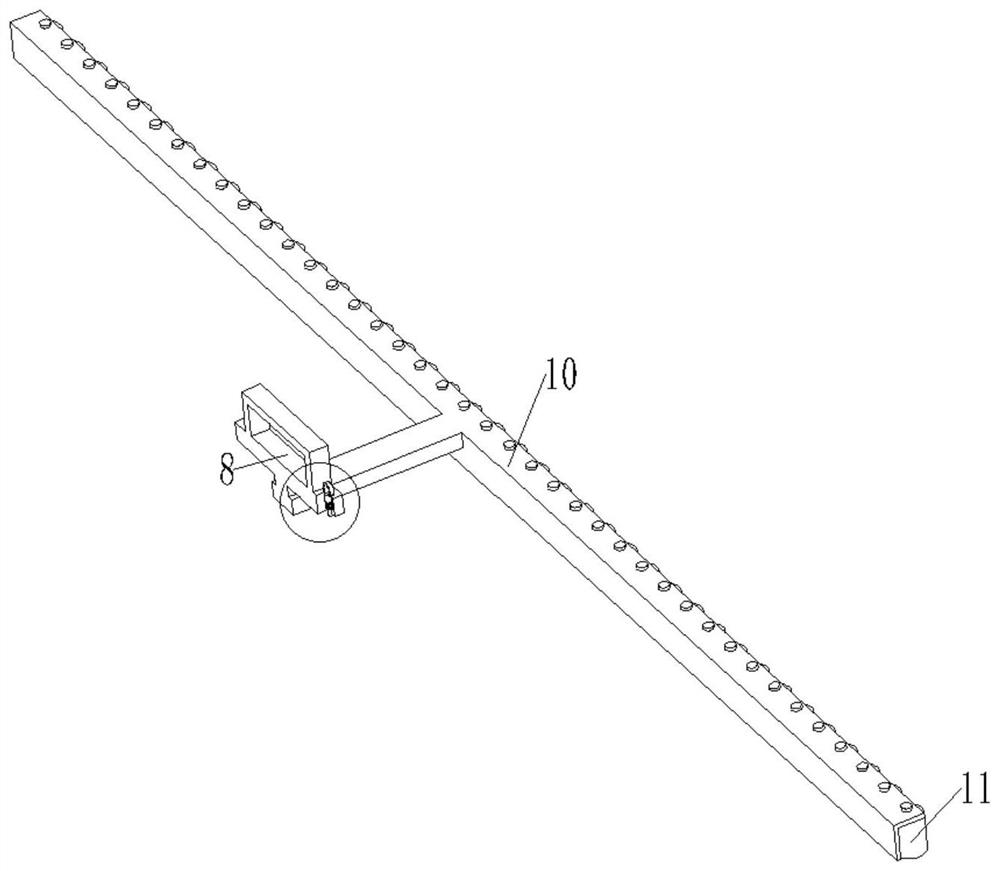

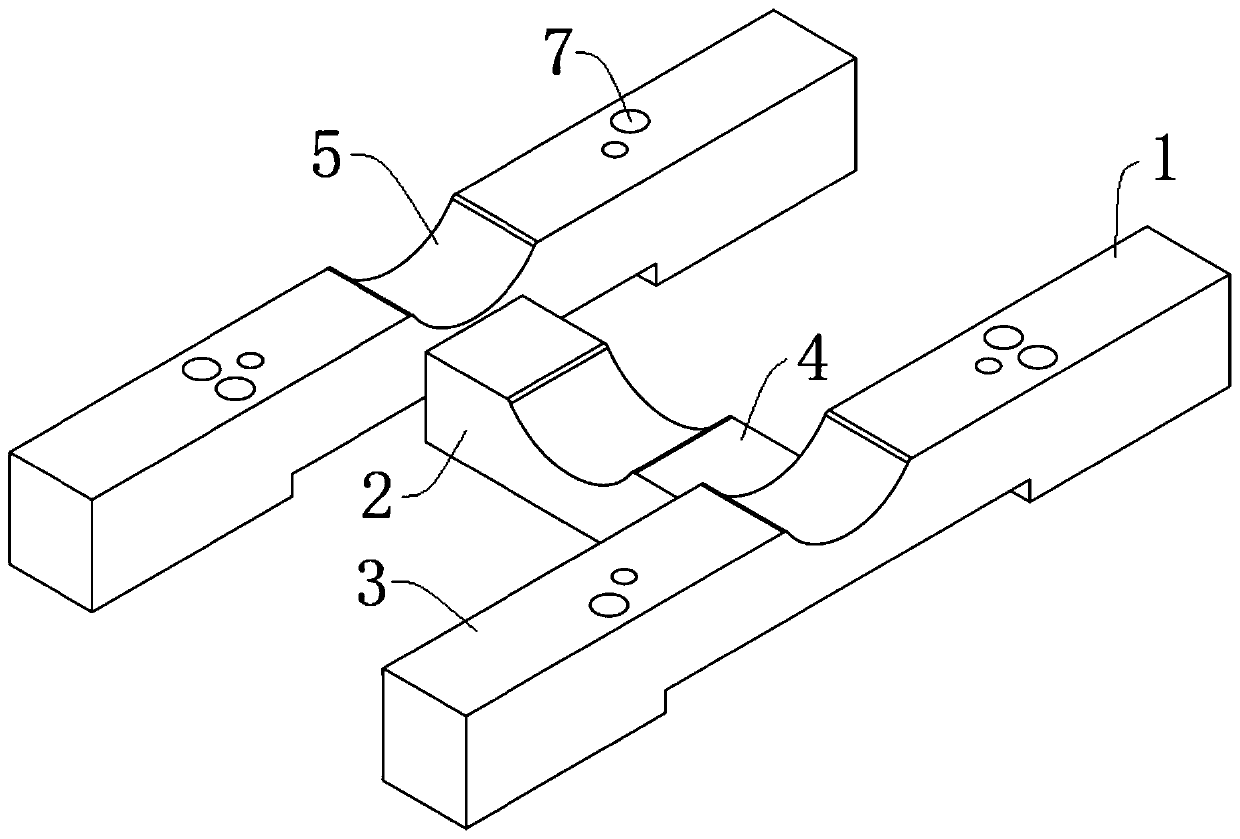

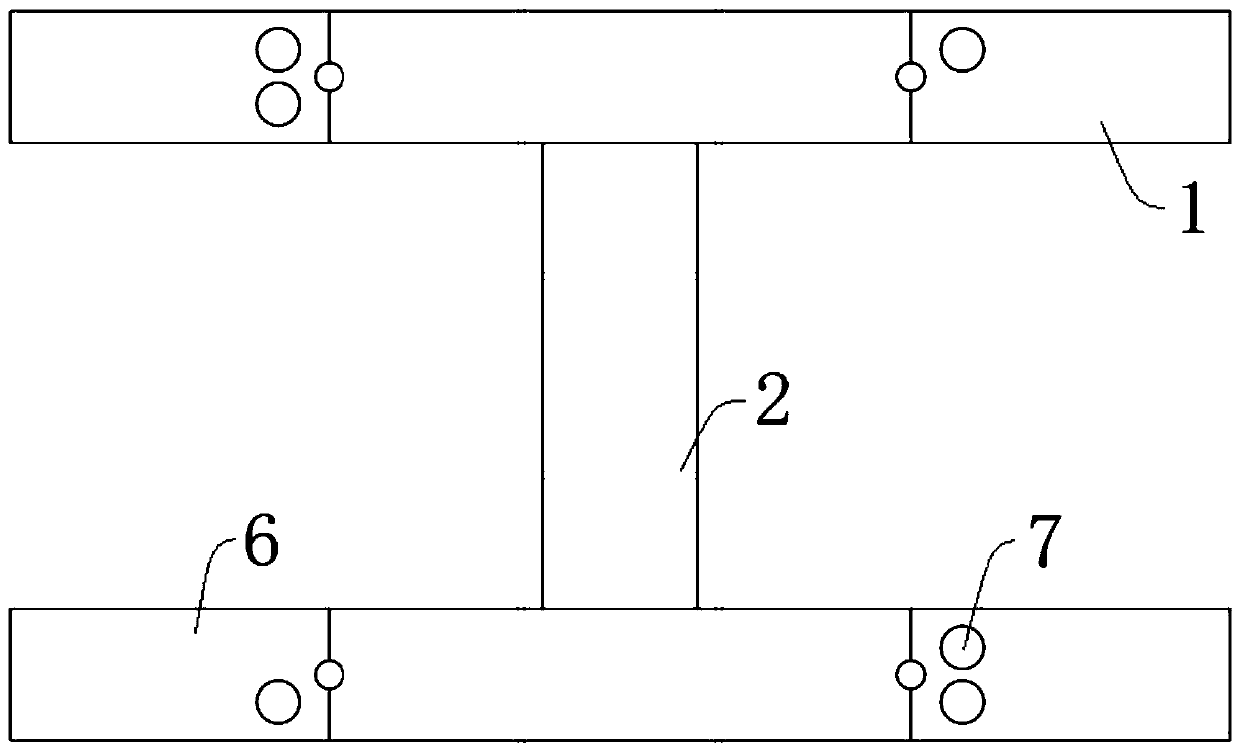

Multipoint positioning auxiliary device

ActiveCN104029192APrecise positioningSimple structureOther workshop equipmentEngineeringPositioning system

Owner:STATE GRID CORP OF CHINA +2

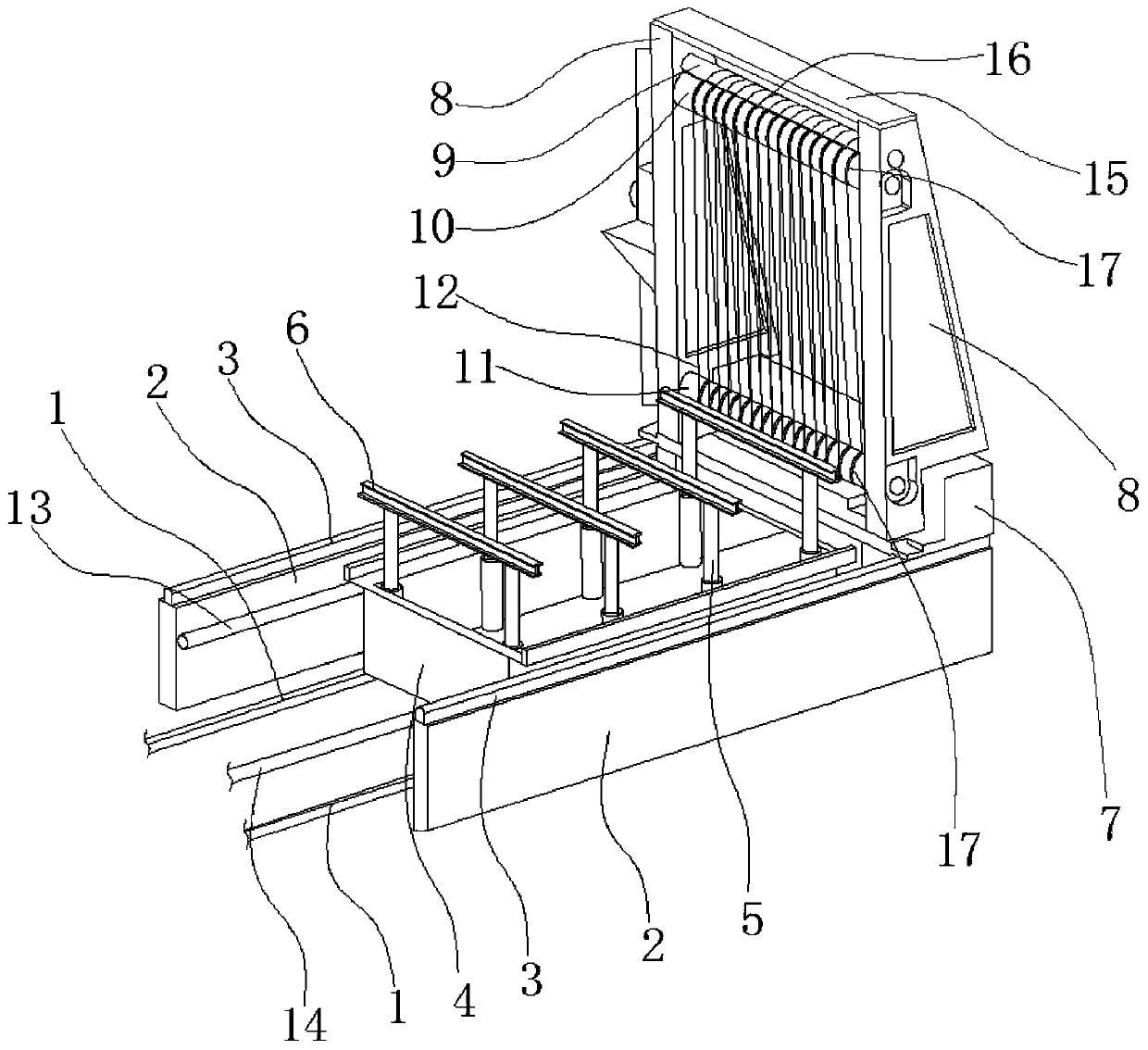

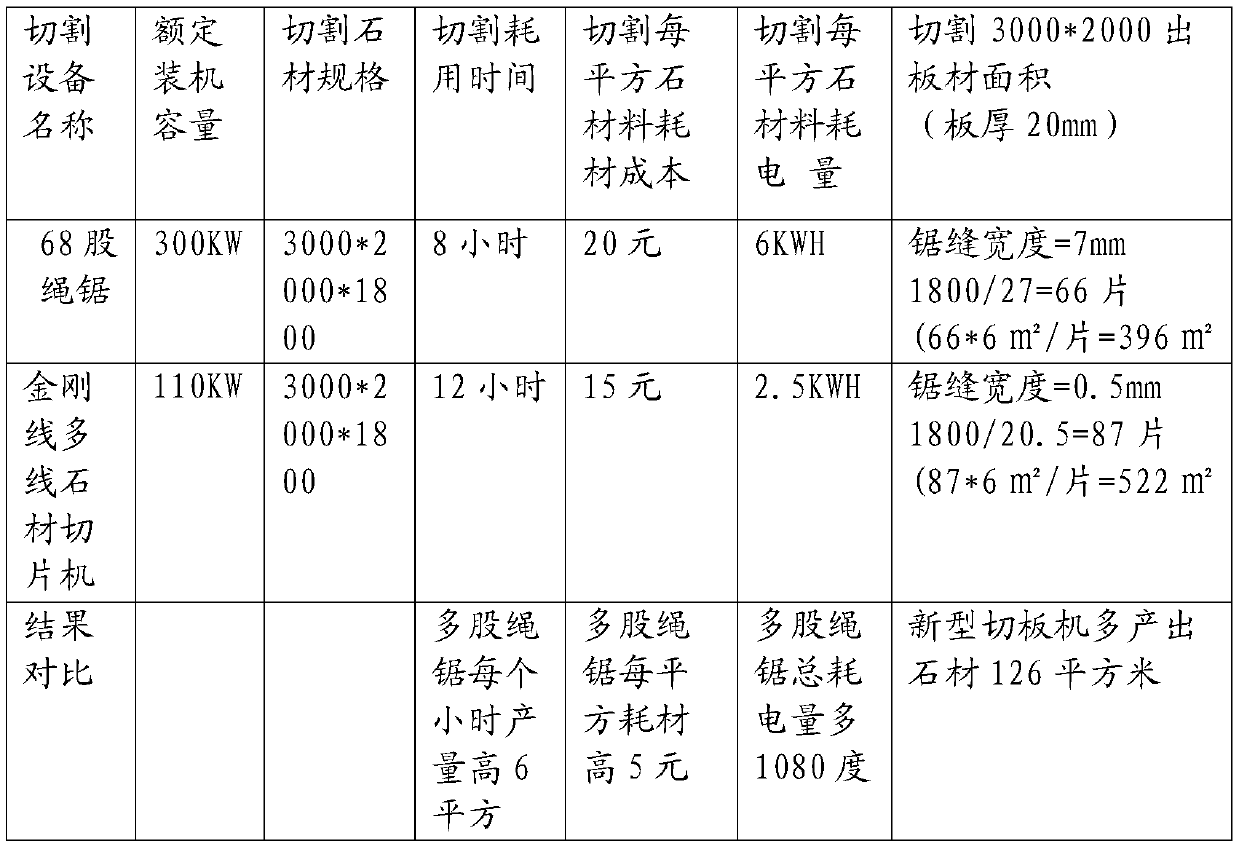

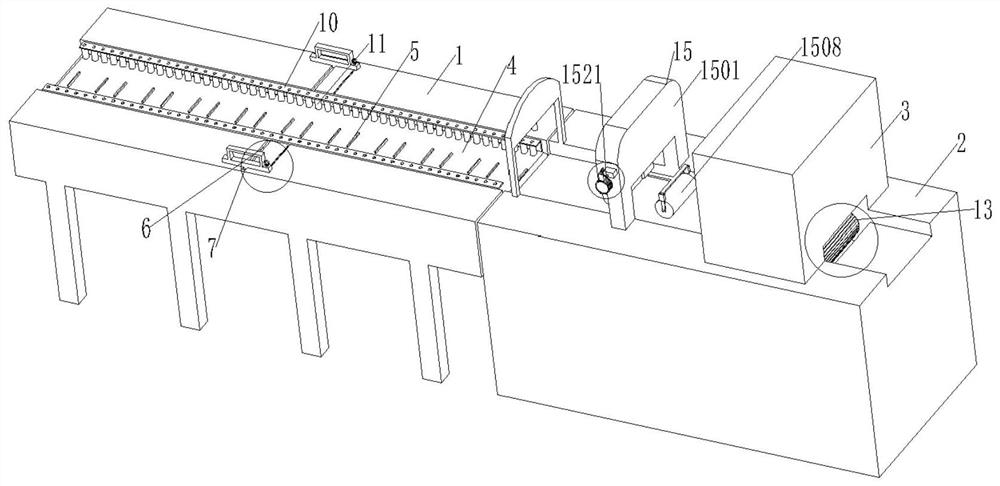

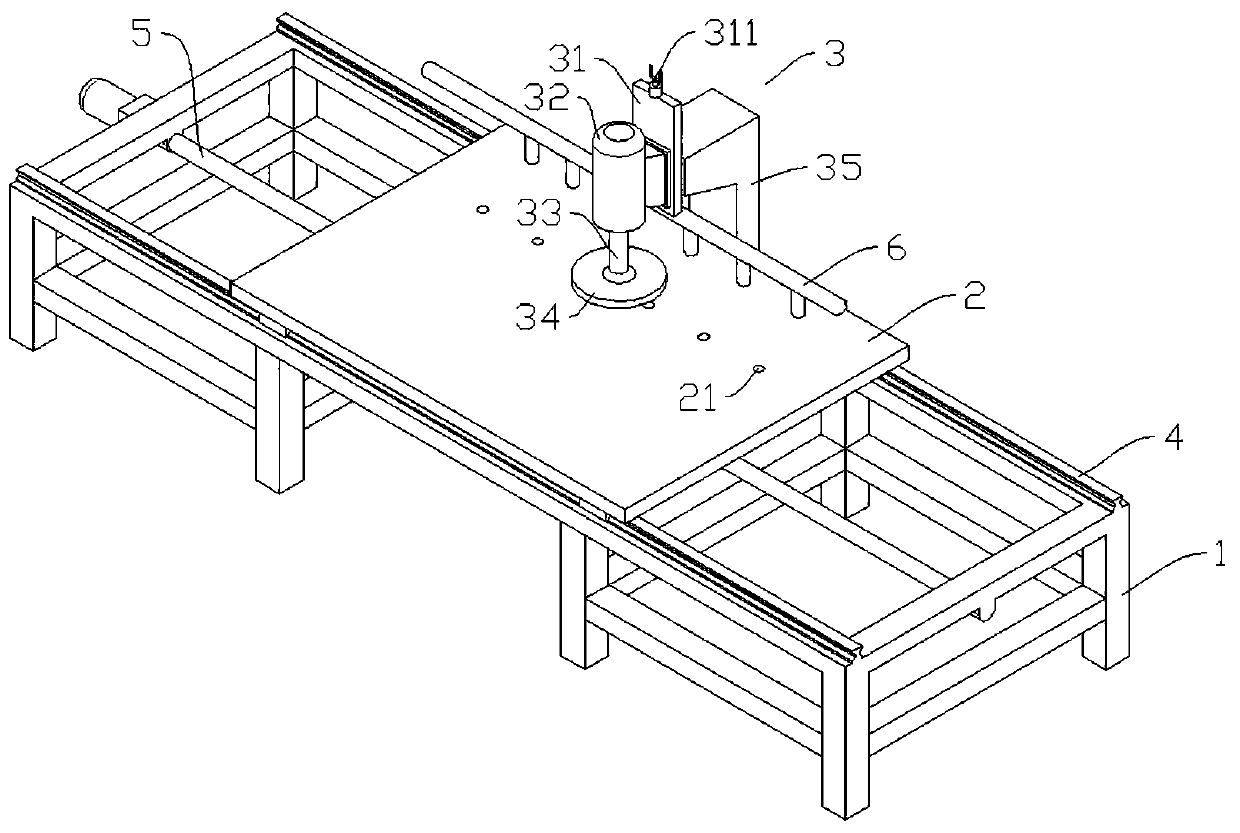

Novel stone cutting winding device and stone cutting sawing machine

ActiveCN109866338ASolve major problems with a one-time passSmall kerfStone-like material working toolsWire cuttingEngineering

The invention relates to a novel stone cutting winding device and a stone cutting sawing machine. A stone transferring trolley and two parallel cutting transferring supports are included, and cuttingtransferring guide rails are arranged at the top ends of the cutting transferring supports. The stone transferring trolley is evenly provided with a plurality of sets of vertically-arranged oil cylinders, and the tops of each set of oil cylinders are connected through a horizontal supporting rod. The cutting transferring guide rails are provided with a cutting base, installing bases are fixedly arranged at the two ends of the cutting base, and a wire passing guide wheel and a first cutting guide wheel which are horizontally arranged are arranged between the upper portions of the two installingbases, and a horizontally-arranged second cutting guide wheel is arranged between the lower portions of the two installing bases. Through a wire passing guide rail, the angle of a diamond cutting wire passing through the wire passing guide wheel changes, and accordingly, a front diamond wire cutting wire and a rear diamond wire cutting wire are located on the same plane. Each set of oil cylinderscan sequentially ascend and descend according to needs to support smooth passing of a cutting wire net, and accordingly, the wire net smoothly passes through a loading trolley under the situation that the loading trolley is not damaged.

Owner:厦门品河精密科技有限公司

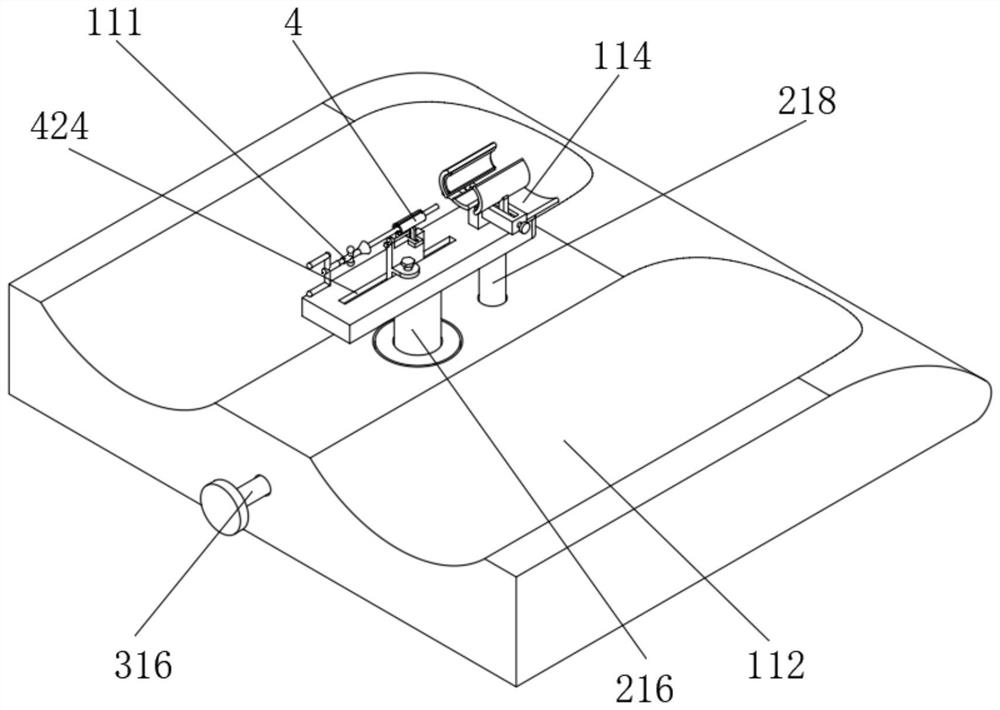

Deviation rectifying welding machine for battery assembly

PendingCN111941094AAvoid extrusion damageElastic regularizationWelding/cutting auxillary devicesAuxillary welding devicesElectrical batteryStructural engineering

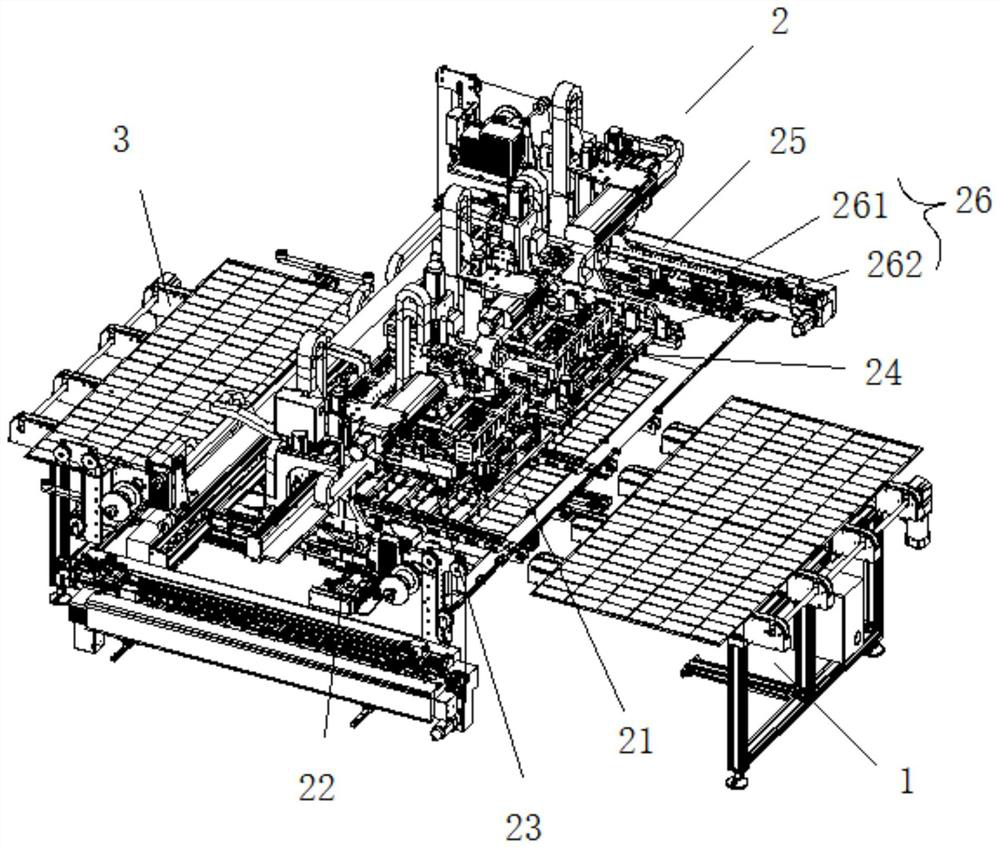

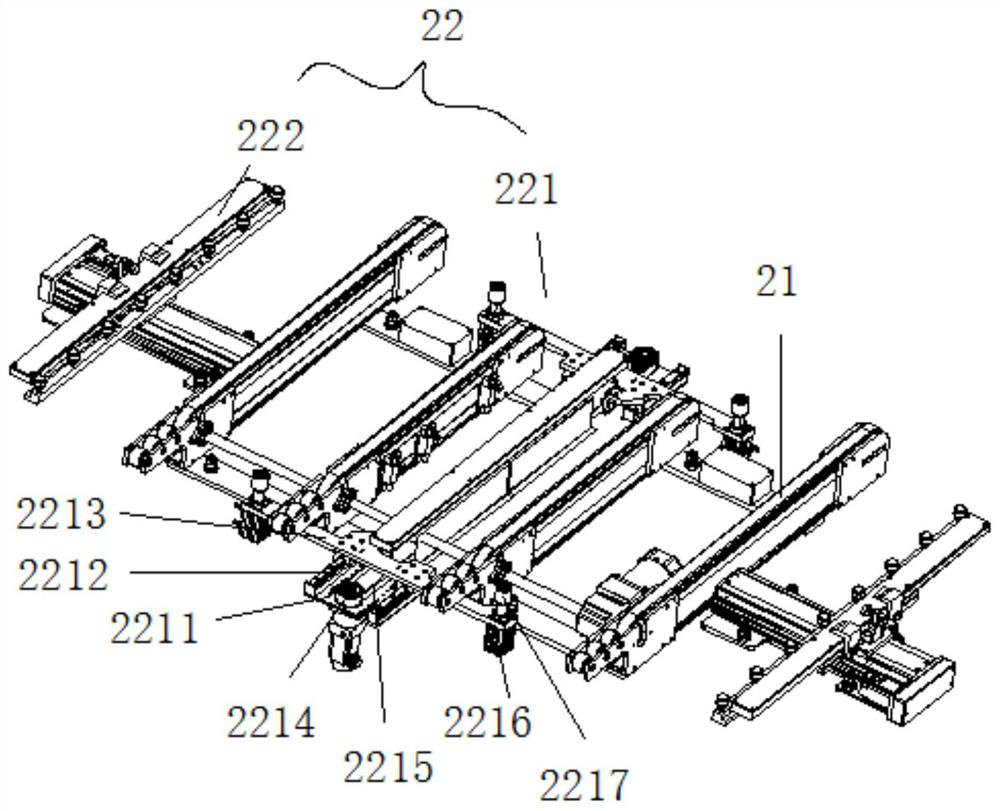

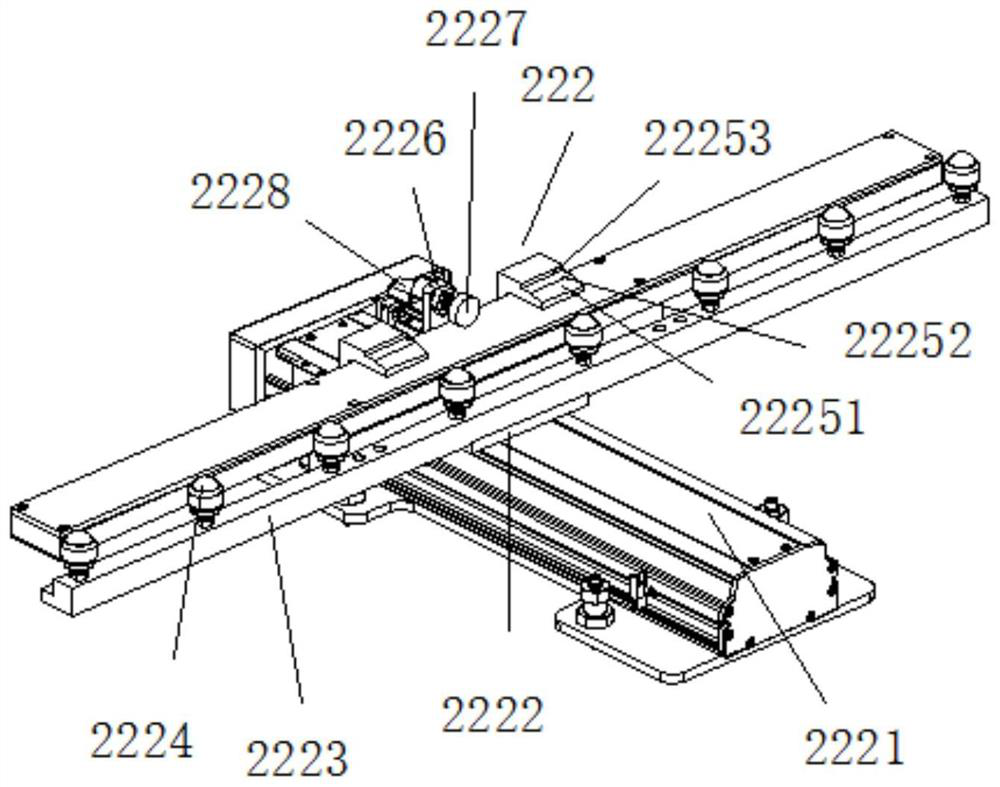

The invention discloses a deviation rectifying welding machine for a battery assembly. The deviation rectifying welding machine for the battery assembly comprises a feeding temporary storage conveyingbelt, a deviation rectifying welding line body and a discharging conveying belt which are sequentially arranged in a butt joint manner, and the deviation rectifying welding line body comprises a conveying belt, a tidying device, a visual positioning device, a deviation rectifying device, welding flow rod feeding devices and a welding device. A solar photovoltaic module is conveyed on the conveying belt, a battery string is arranged on glass, the tidying device is installed at the periphery of the conveying belt, the visual positioning device and the deviation rectifying device are arranged above the conveying belt, the welding flow rod feeding devices are arranged at the two sides of the conveying belt in a butt joint manner, and the welding device is installed on the conveying belt. By means of the manner, the battery assembly can be elastically tidied, horizontal deviation rectification can be conducted on products, and interference between every two adjacent sets of products is avoided; and a scaling powder sprayer is matched with a lead screw for spraying, the spraying requirements of different starting points are met, a welding rod can be stably connected, tight contact between a welding head and a welding point is guaranteed, and products are not damaged.

Owner:SUZHOU SHENGCHENG SOLAR EQUIP

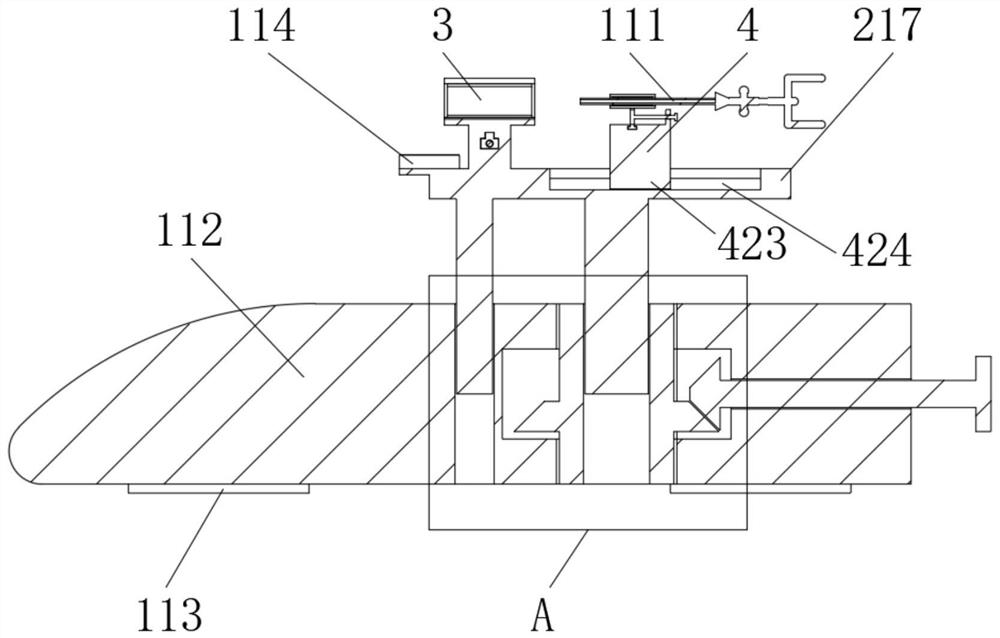

Positioning tool for chip welding

InactiveCN103567683ANo position shiftReduce void rateWelding/cutting auxillary devicesSemiconductor/solid-state device manufacturingDBcEngineering

The invention discloses a positioning tool for chip welding. The positioning tool comprises a base and a top cover positioned above the base, wherein a plurality of positioning holes are formed in the top cover, a positioning pin capable of sliding in each of the positioning holes vertically is arranged in each of the positioning holes, and one end of the positioning pin close to the base is used for abutting against chips to be welded. By arranging a plurality of positioning pins formed in the top cover and sliding freely to apply a certain pressure on the chips to be welded, the chips, welding lugs and a DBC base plate are fixed relatively, and the chips cannot be damaged by pressing. Therefore, position offset of the chips during welding is avoided, voidage of chip welding is reduced, the welding is firm, and quality and performance of welded products are effectively improved.

Owner:XIAN YONGDIAN ELECTRIC

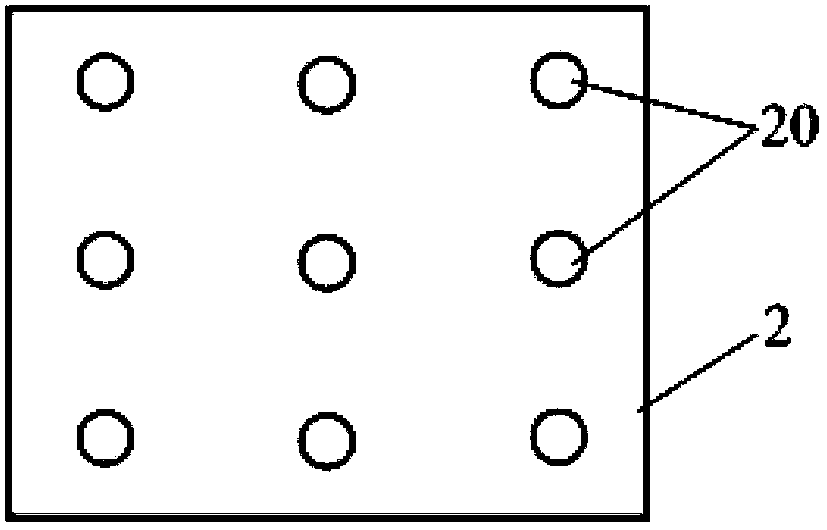

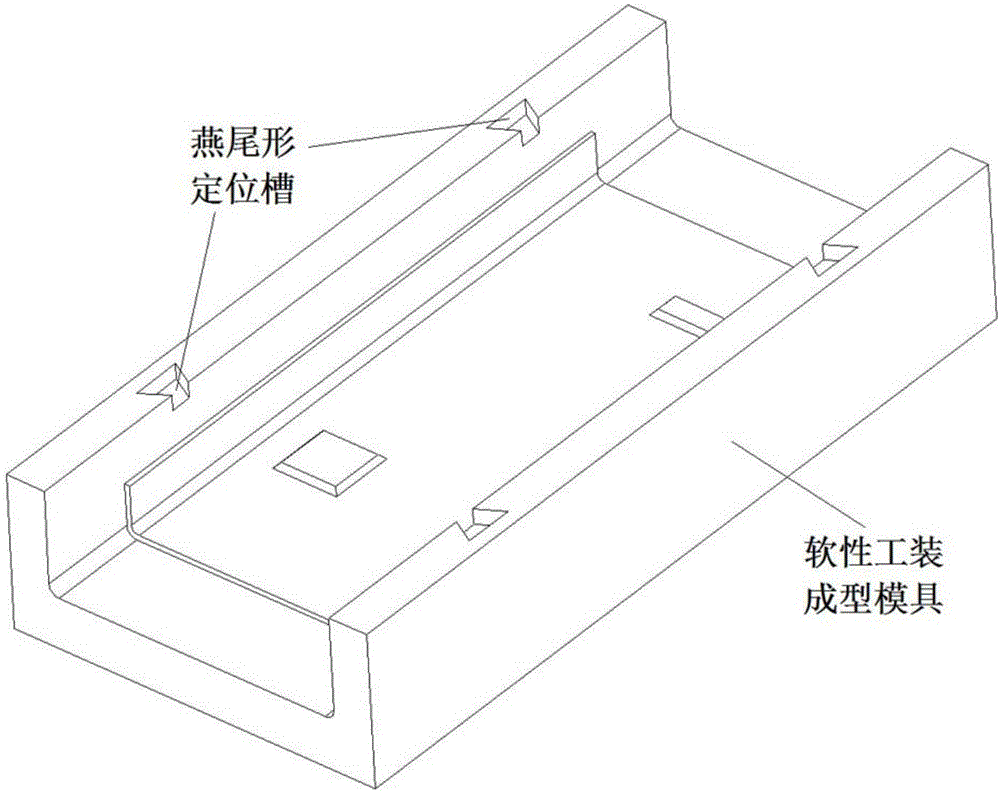

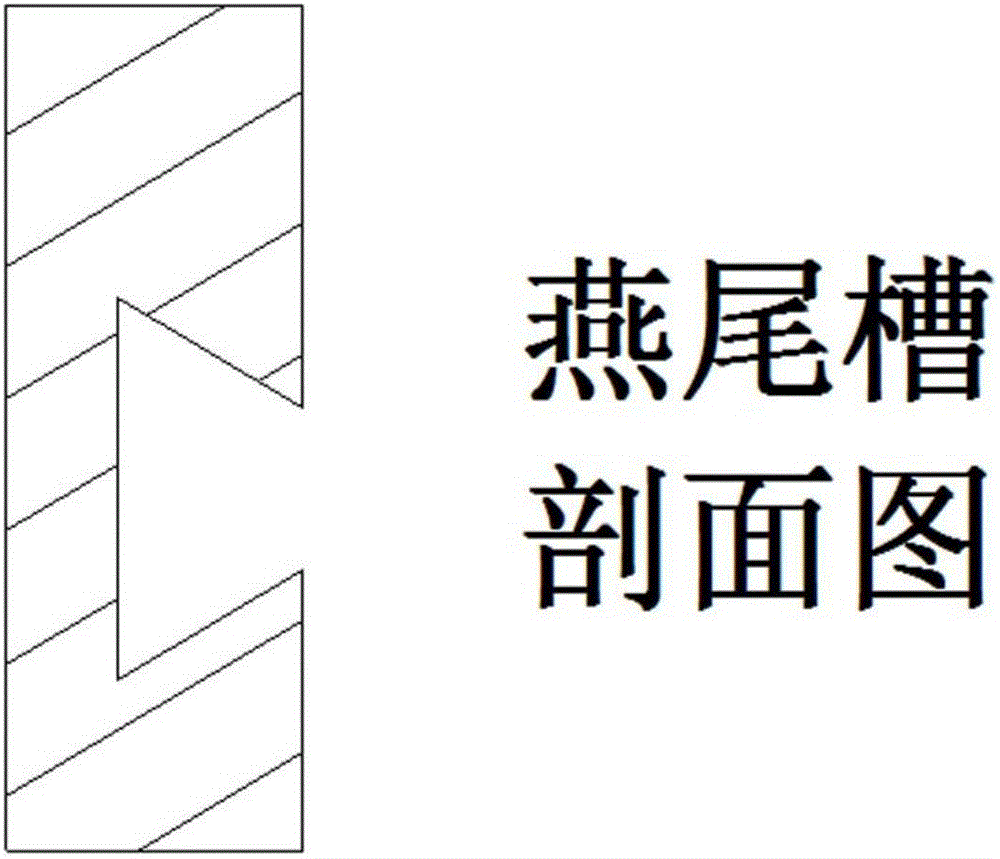

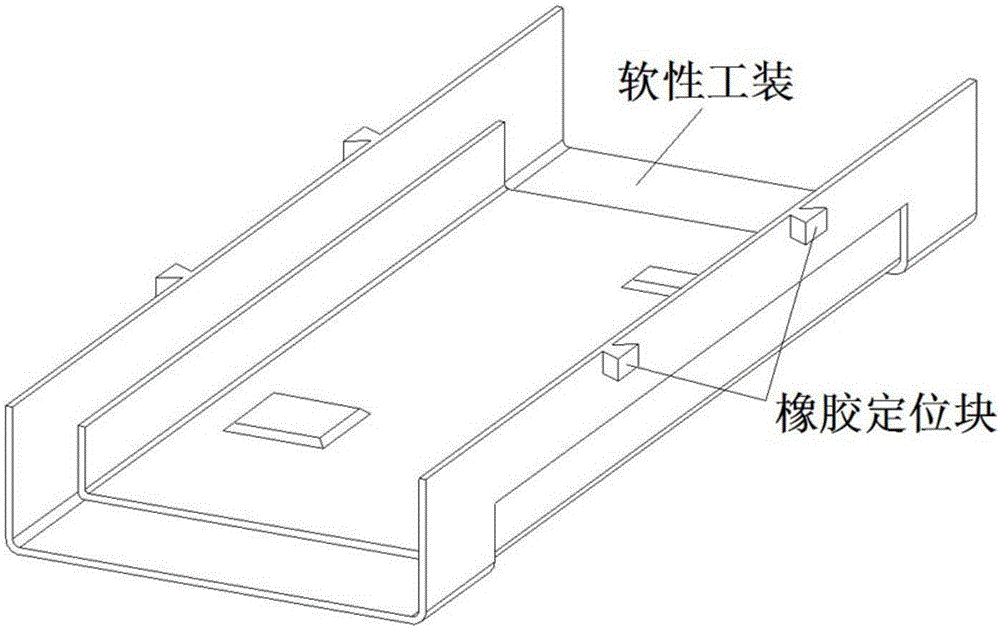

Positioning method of flexible tool in forming process of composite product

The invention discloses a positioning method of a flexible tool in a forming process of a composite product. The positioning method comprises the following steps: more than two dovetail-shaped positioning grooves are respectively formed in two sides of a flexible tool forming mold; a metal false piece is placed on the surface of the flexible tool forming mold; when the flexible tool is laid and adhered to the surface of the metal false piece, the dovetail-shaped grooves are filled with rubber, the rubber is connected with the flexible tool, the outside of the flexible tool is sealed under vacuum by a vacuum bag, and then the sealed flexible tool enters an autoclave for forming; after a rubber flexible mold is formed, the vacuum bag is removed, the metal false piece is taken out, the shaped flexible tool is filled with composites, then the outer layer of the shaped flexible tool is sealed under vacuum by the vacuum bag, and the flexible tool enters the autoclave for forming to obtain the composite product. By the dovetail-shaped positioning groove structure, positioning between the flexible tool and the forming mold is finished, the flexible tool is fixed and does not deviate in the forming process of the composite product, and therefore, the surface forming quality of the composite product is guaranteed.

Owner:航天海鹰(镇江)特种材料有限公司

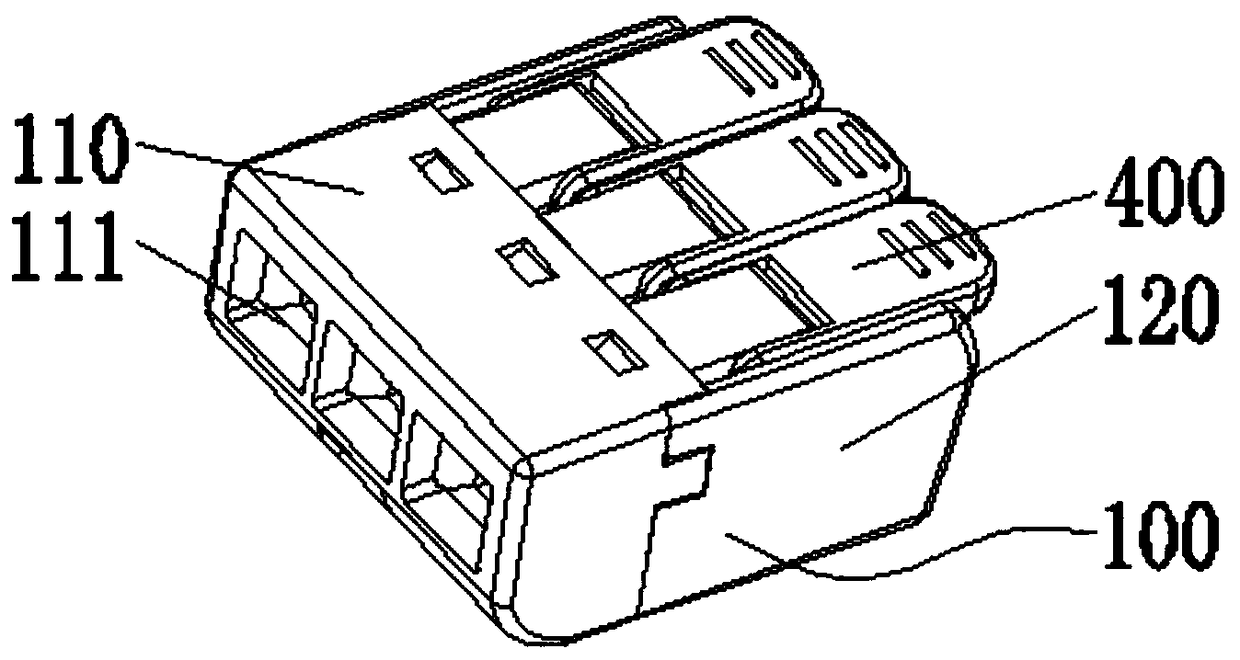

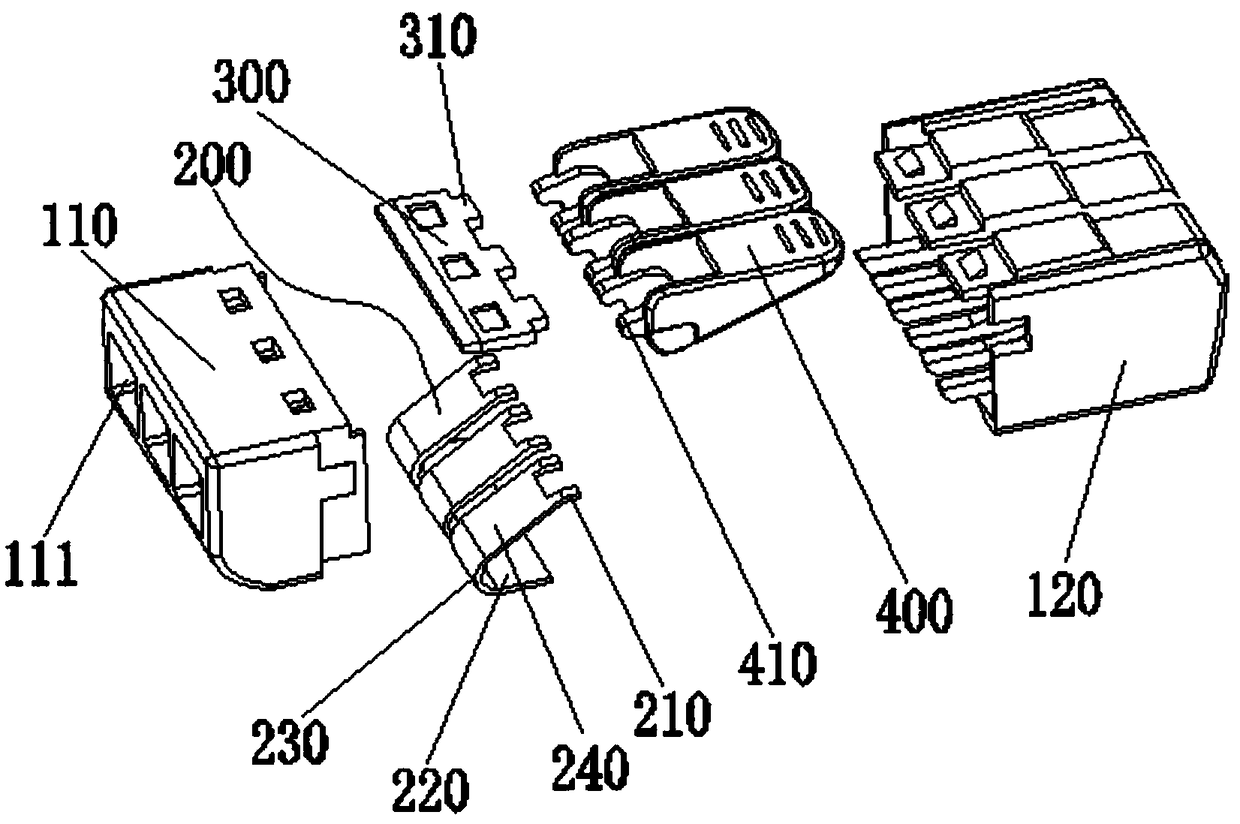

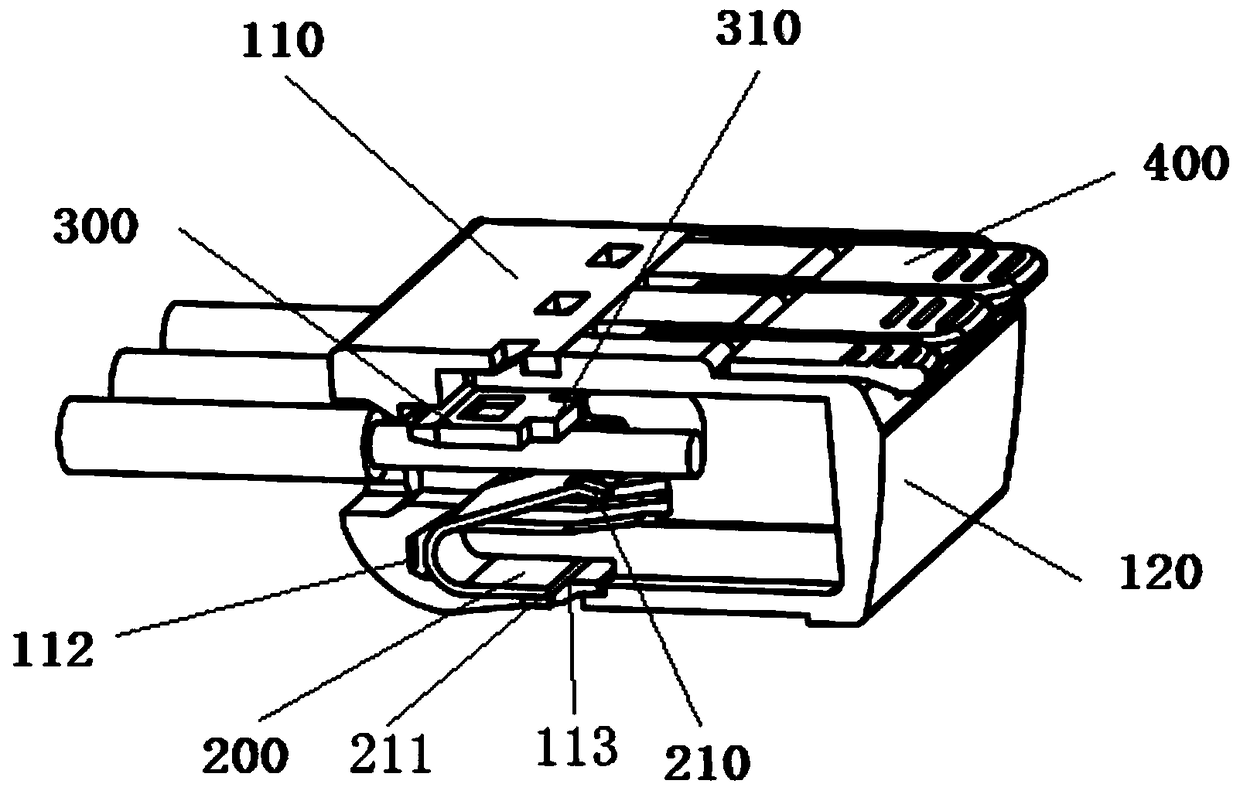

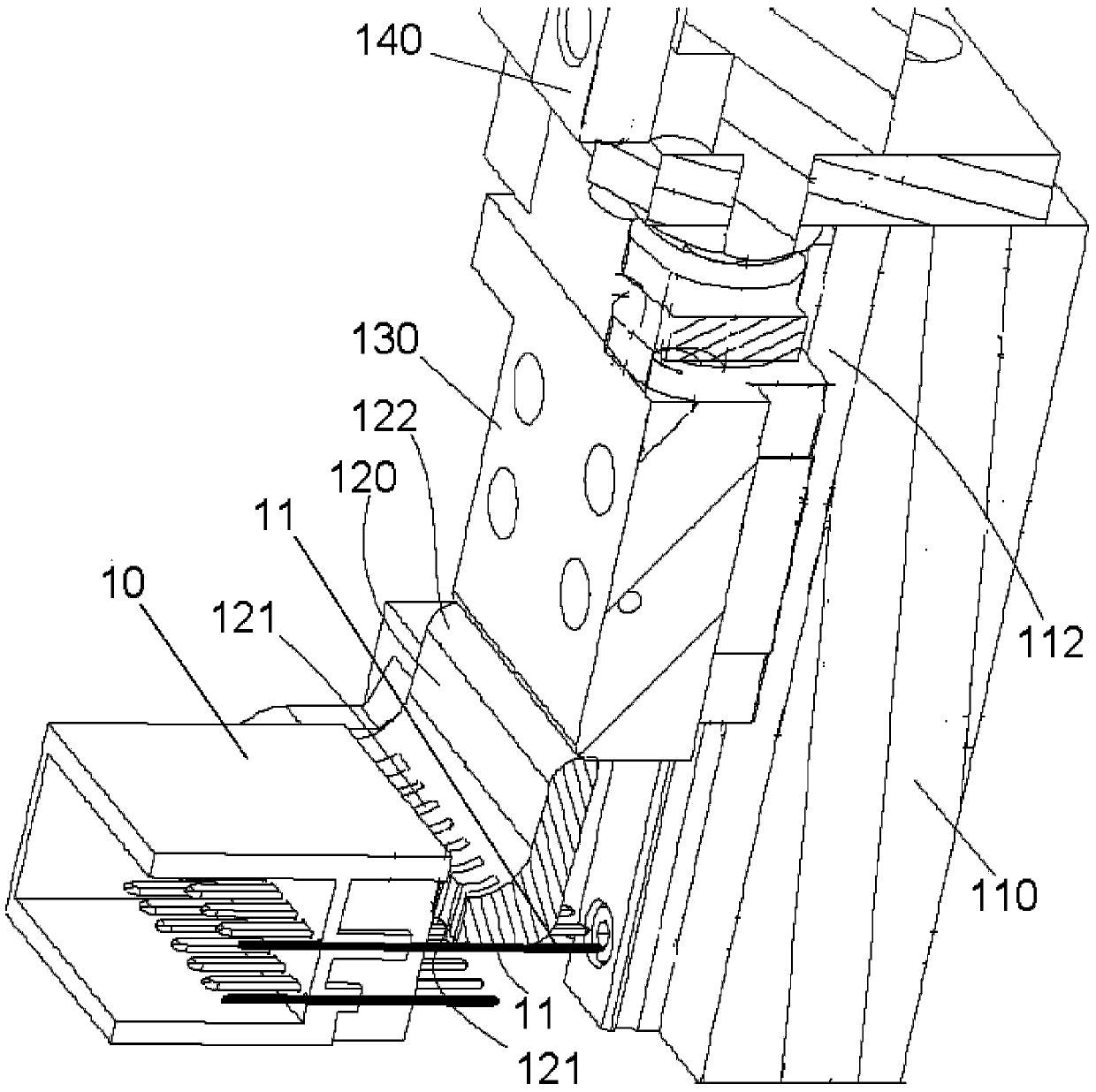

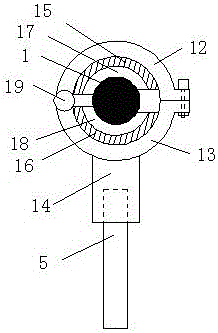

A terminal with an operating handle

PendingCN108987951AImprove stabilityNo position shiftClamped/spring connectionsEngineeringElectric wire

The invention provides a terminal with an operating handle including a housing, at least two independent chambers are arranged in the shell, and the cavity is provided with elastic fragments, however,that conductive sheet is also include, the conductive sheet penetrates all chambers and cooperates with the elastic sheet to clamp the wire, The upper end of the shell corresponds to the position ofthe chamber, and the handle is provided with a normal state and a working state. When the handle is in the working state, the handle presses the spring to cause elastic deformation of the spring, andbarbs are arranged on the spring, and the spring and the shell are assembled in a limited position. A conductive piece and a elastic piece are arranged in the connecting case to cooperate with the clamping wire, and barbs and convex teeth are arranged at the ends of the elastic piece and the conductive piece, and the electric wire can be clamped under the cooperation of the barbs and the convex teeth, the soft wire and the hard wire can be clamped, and the effect is very good, and the wiring and the drawing are very convenient.

Owner:浙江京红电器有限公司

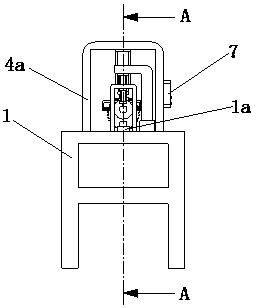

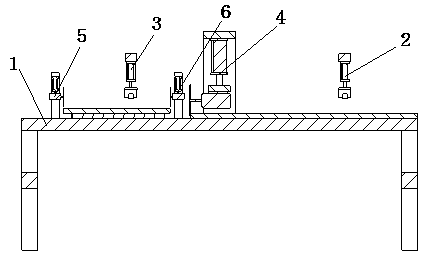

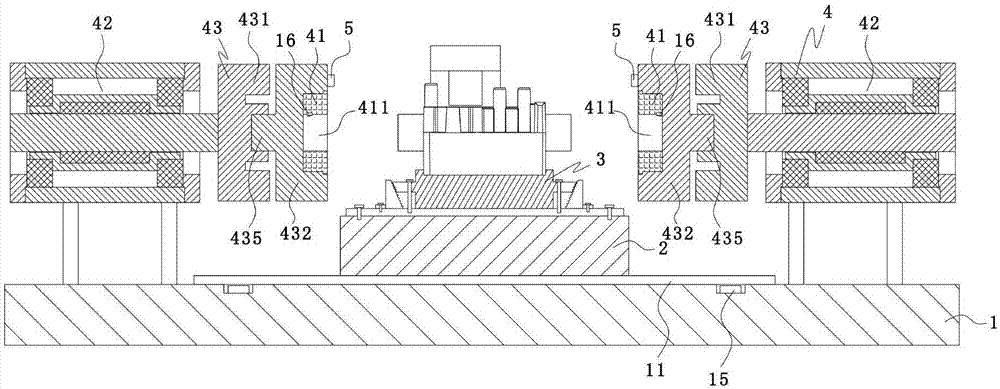

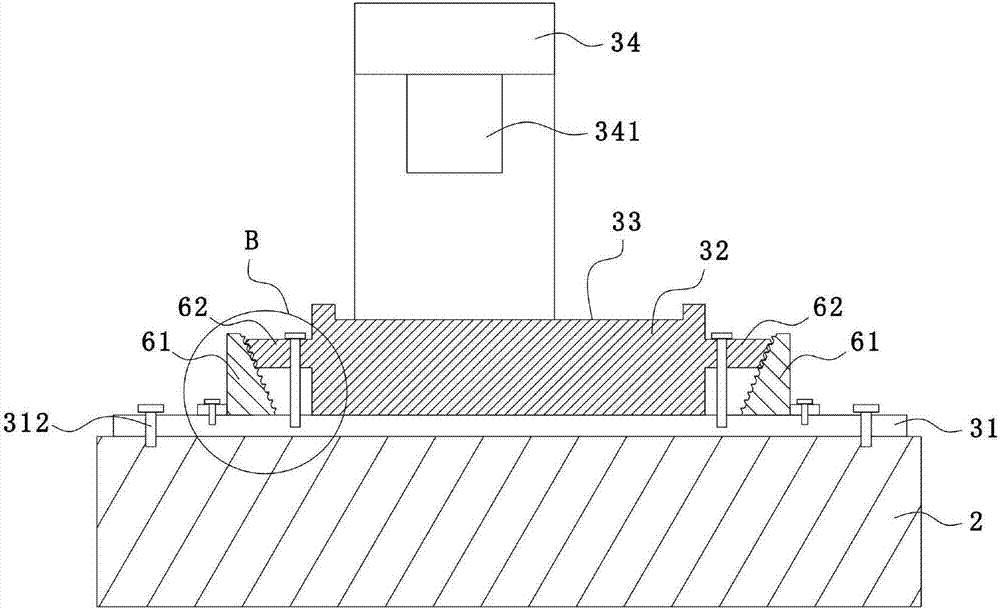

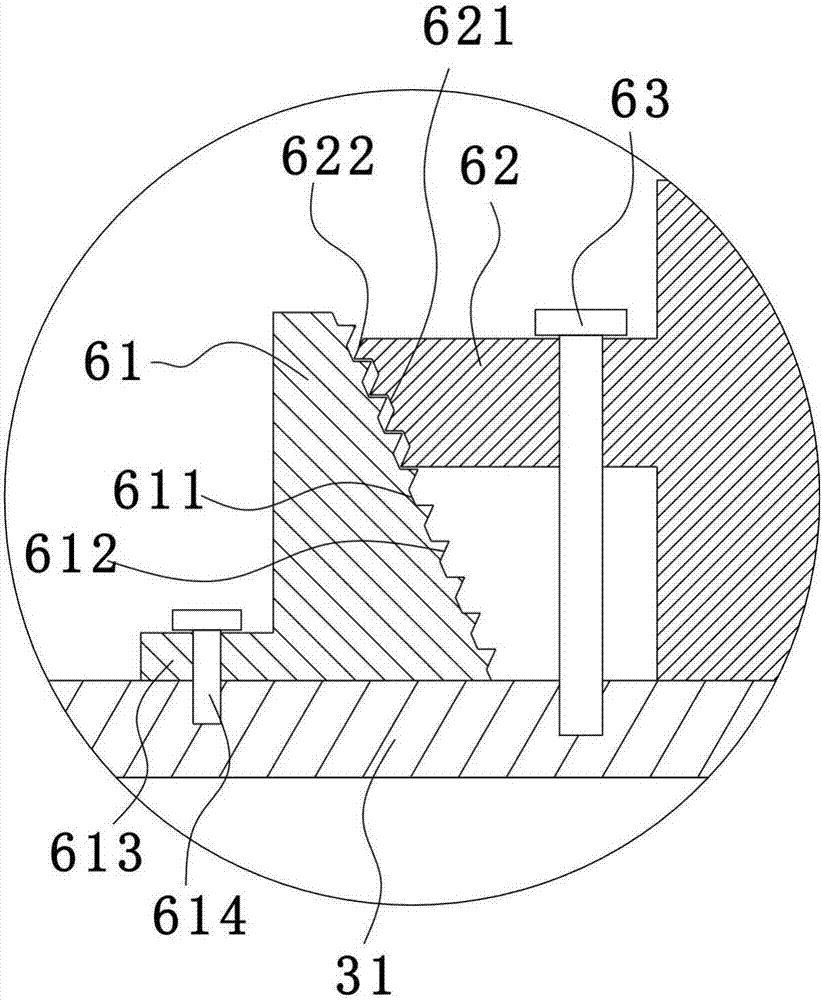

Semi-automatic machining equipment of steel materials

ActiveCN108637696ASave manpower and resourcesHigh precisionOther manufacturing equipments/toolsMetal working apparatusSemi automaticNumerical control

The invention relates to the field of machining apparatuses, in particular to semi-automatic machining equipment of steel materials. The semi-automatic machining equipment comprises a base, a first grabbing assembly, a second grabbing assembly, a cutting assembly, a first grinding assembly and a second grinding assembly, wherein the cutting assembly is arranged in the middle of the base; the firstgrabbing assembly and the second grabbing assembly are fixedly mounted on the base and are positioned on the left side and the right side of the cutting assembly; the first grinding assembly and thesecond grinding assembly are positioned on the same side of the cutting assembly and are positioned on the two sides of the second grabbing assembly; the first grinding assembly and the second grinding assembly are fixedly connected with the base, and a controller is also arranged on the cutting assembly; and the first grabbing assembly, the second grabbing assembly, the cutting assembly, the first grinding assembly and the second grinding assembly are electrically connected with the controller. According to the semi-automatic machining equipment of the steel materials disclosed by the invention, integration of cutting and grinding of the steel materials can be realized, and the precision of a product is higher under numerical control transportation.

Owner:赣州溢之远钢材有限公司

Medical mask machine capable of automatic packaging

ActiveCN111674612AImprove the limit effectGuarantee processing qualityPackagingArticle feedersEconomic benefitsProduction quality

The invention discloses a medical mask machine capable of automatic packaging. The machine comprises a transportation platform, a packaging processing platform, a packaging machine body, and a transportation belt. The arrangement of a limiting block and a limiting drum can realize a good limiting effect on a mask to be packaged, and ensure that no position deflection of the mask occurs in the conveying process, thereby guaranteeing the processing quality of the mask. Through the arrangement of a push rod, a fixed circular groove and a first spring pin, the position of the limiting drum can beadjusted, so position limiting can be realized based on the actual size of the mask, the application range is widened and benefits of application are increased. Through the arrangement of a compactingdevice, after the mask to be packaged is wrapped by a paper film, on the one hand, the mask can be duly compacted, the paper film is attached to the mask, i.e., extra space between the mask and the paper film is squeezed out, waste of the paper film is prevented, and economic benefits are improved, and on the other hand, tidiness of mask packaging is improved, the aesthetic property after packaging is guaranteed, and processing production quality is therefore improved.

Owner:滕春根

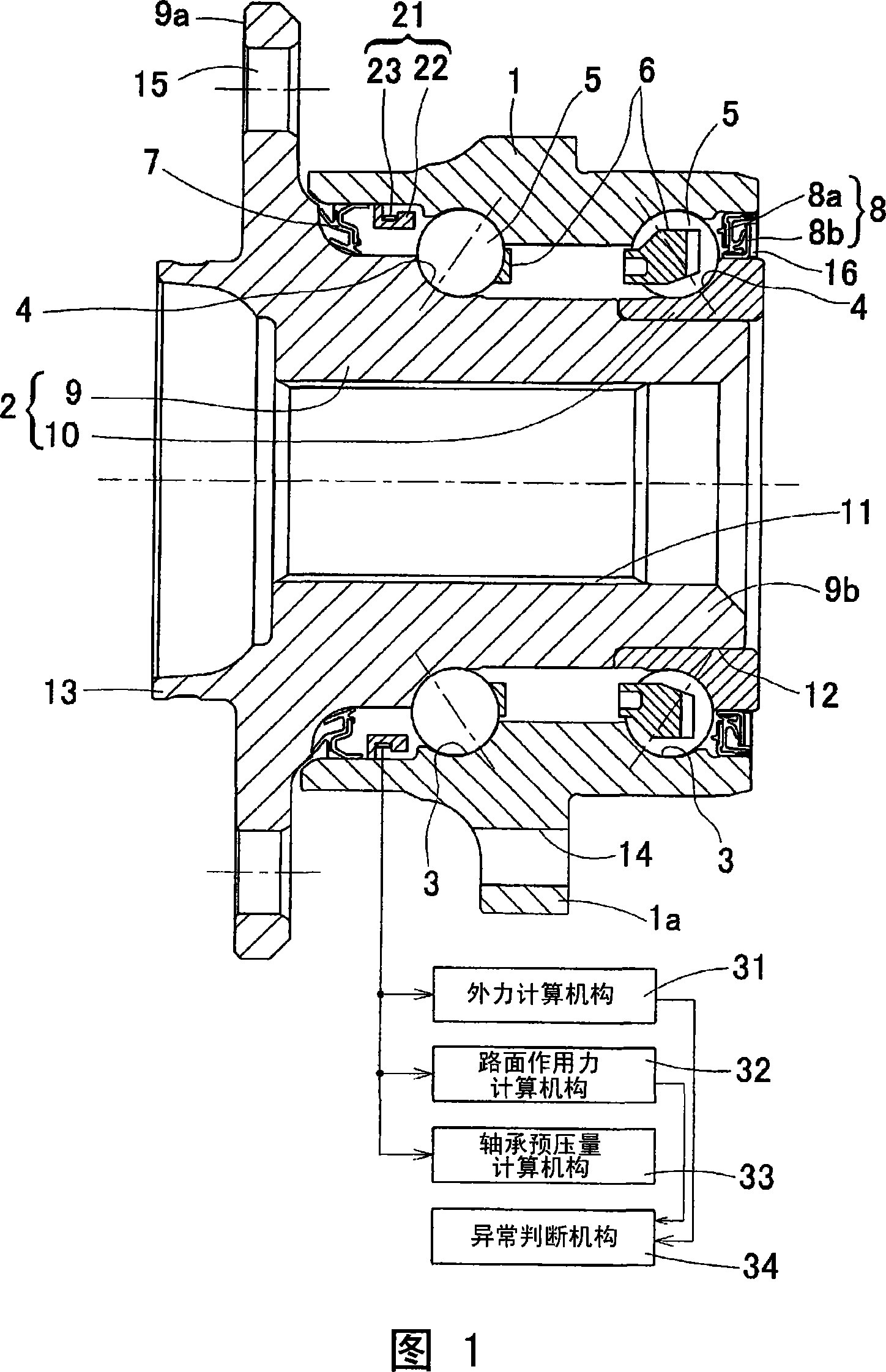

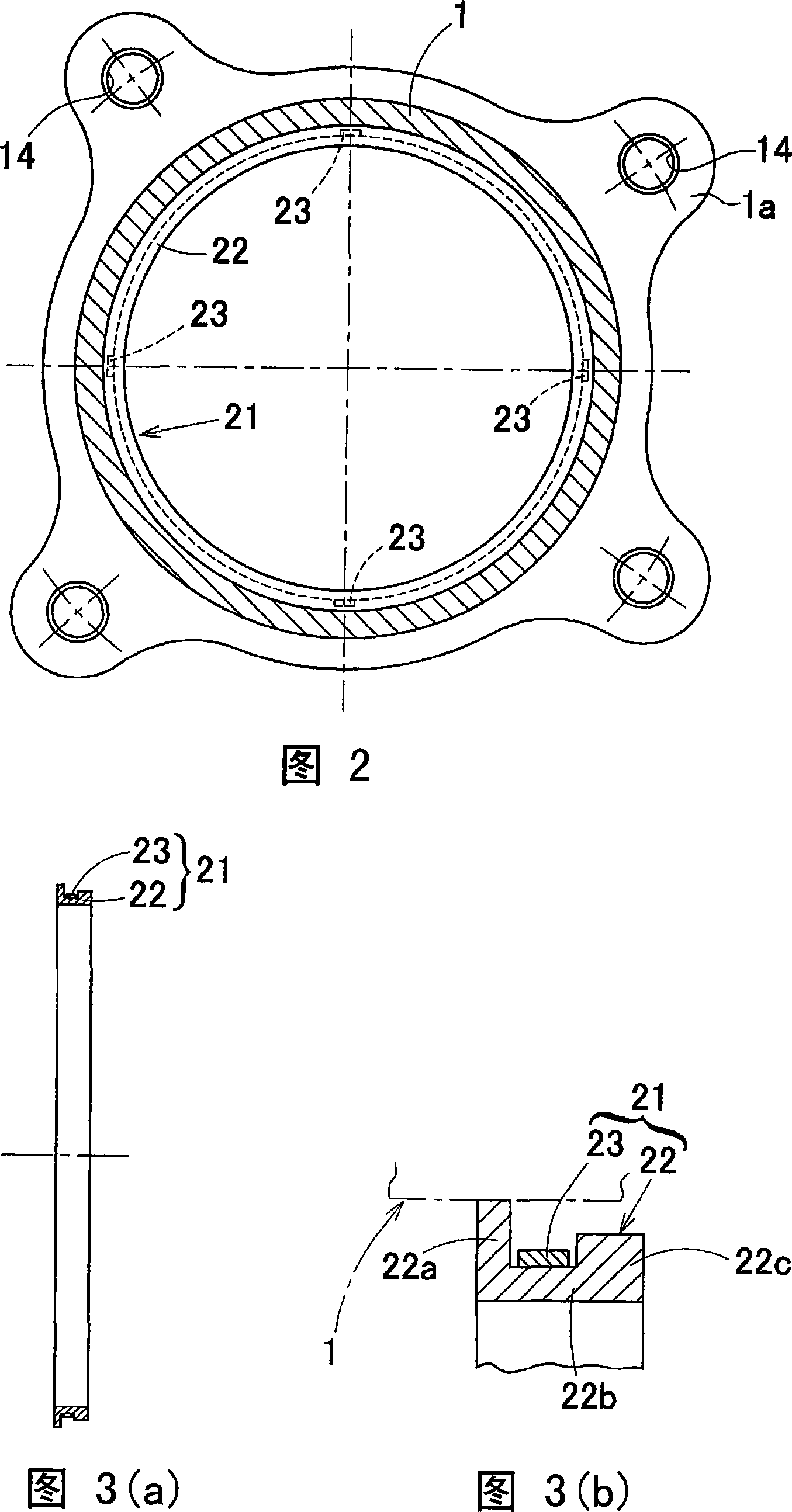

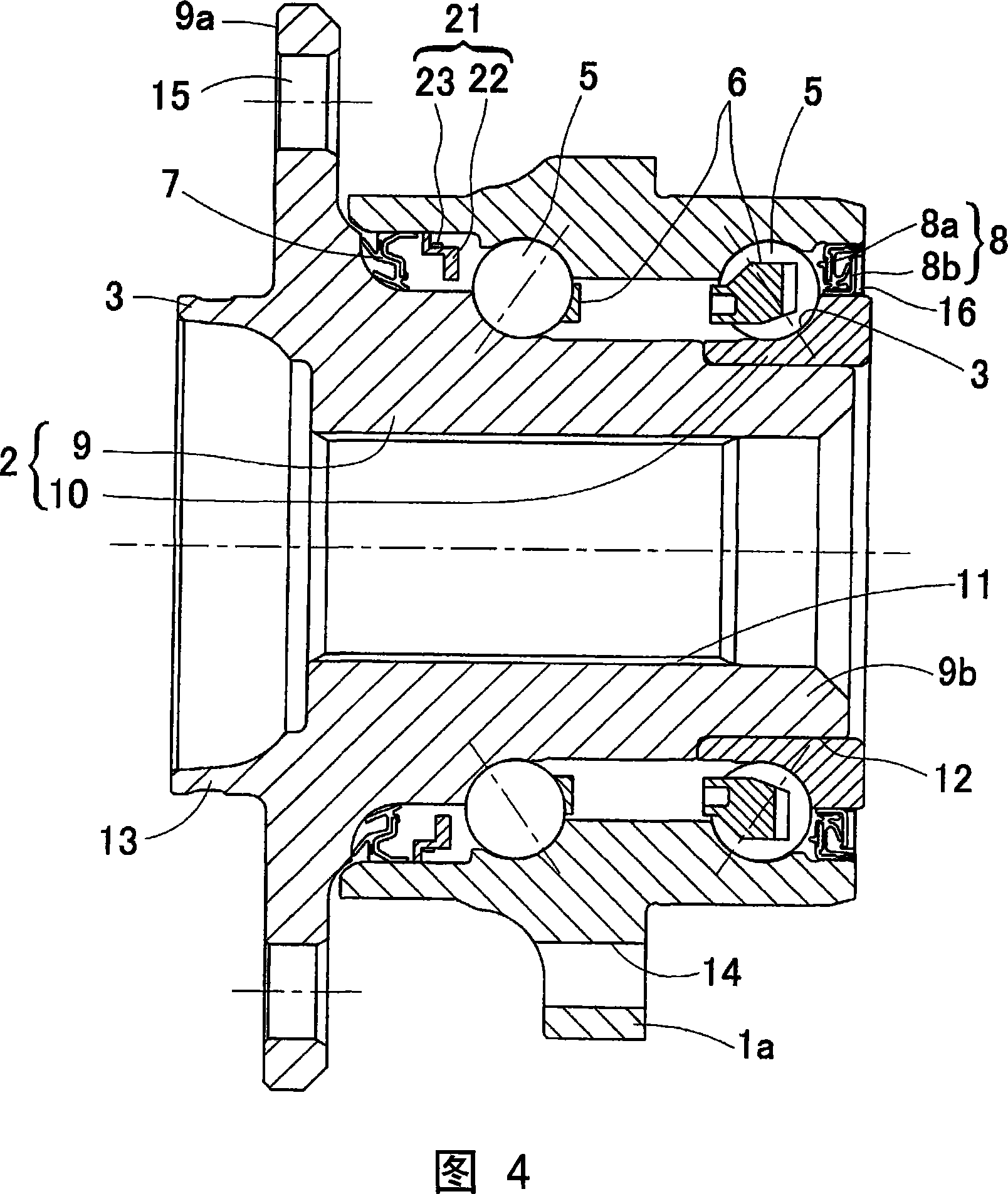

Sensor-equipped bearing for wheel

InactiveCN101243310AIncreased Design FreedomBig spaceRolling contact bearingsBearing assemblyBiomedical engineering

Owner:NTN CORP

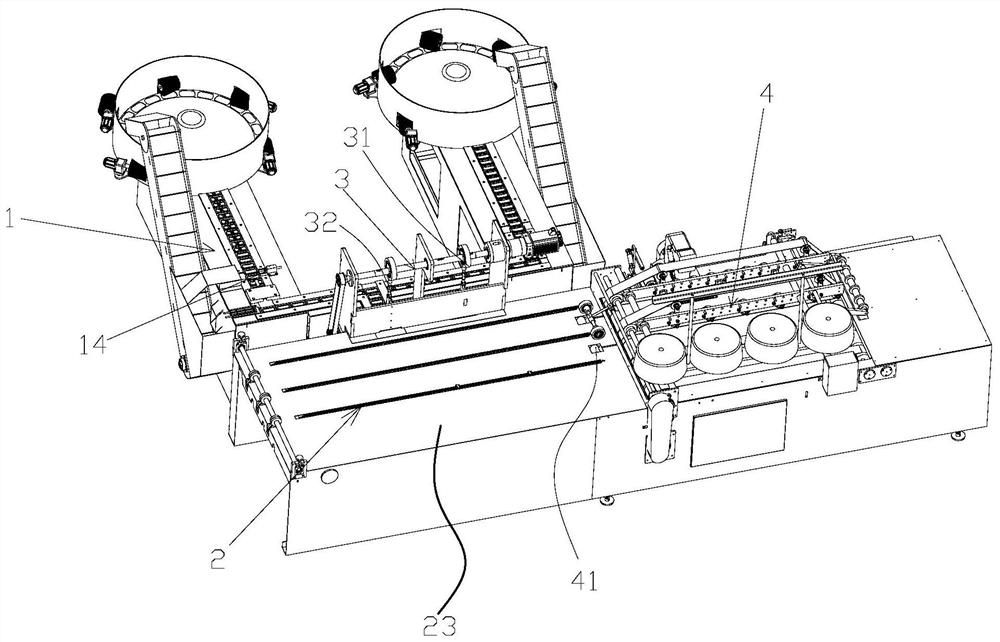

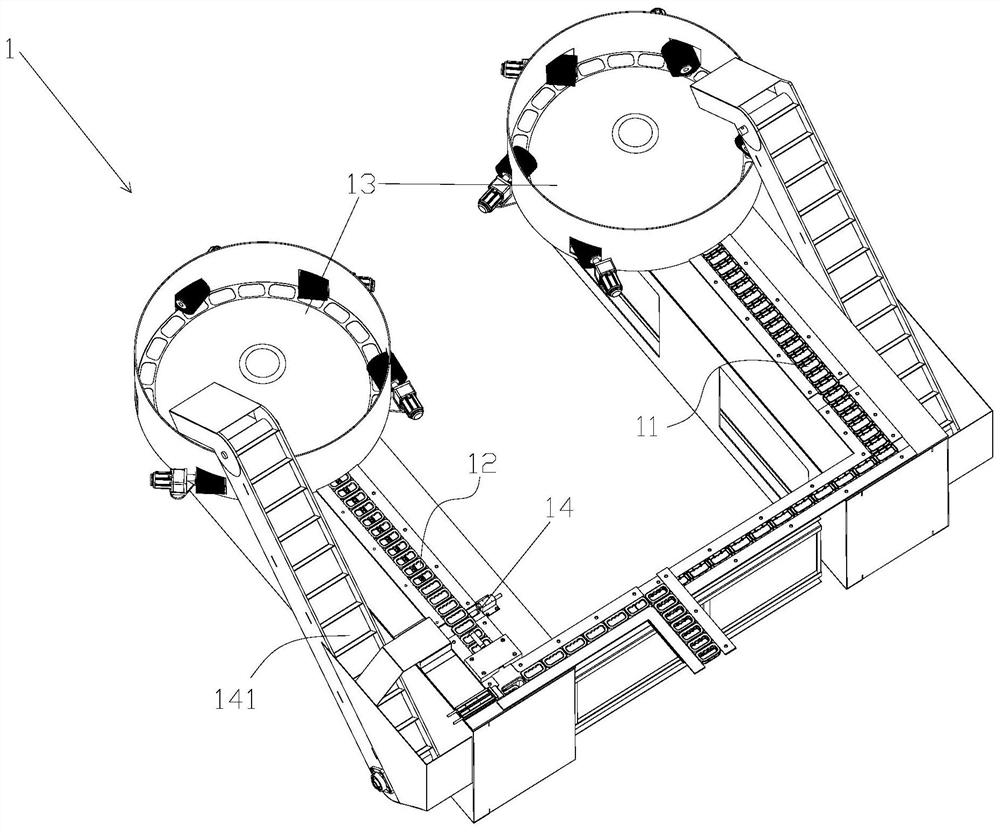

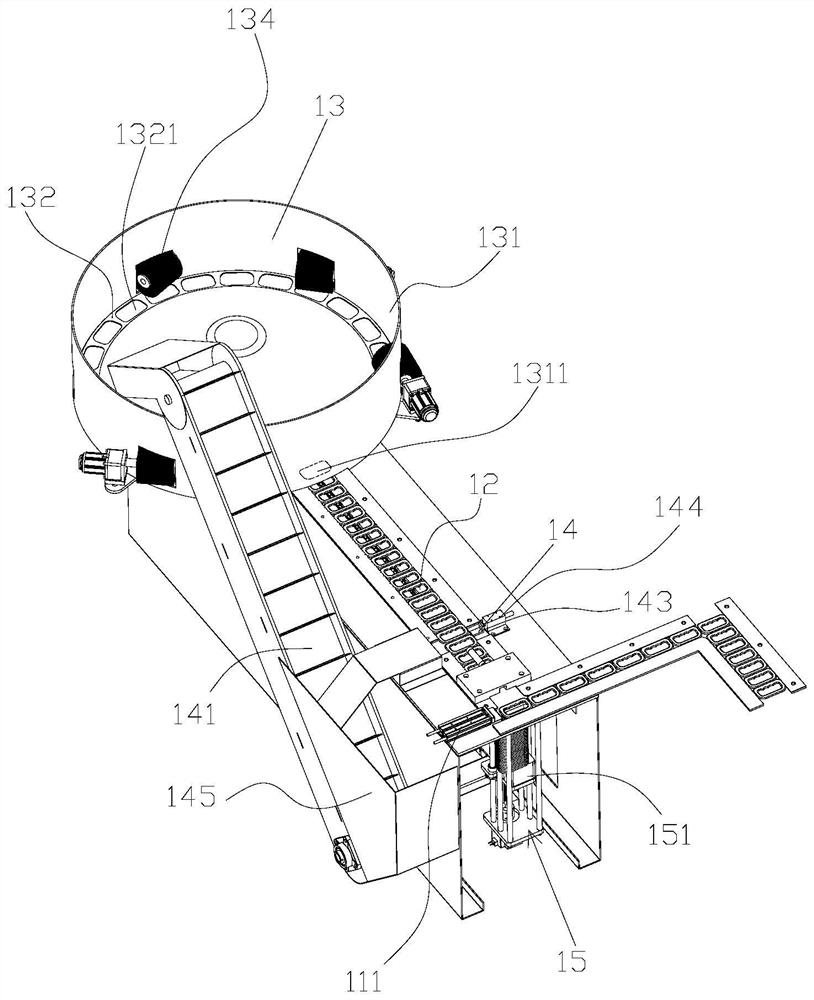

Automatic hand buckle buckling and pressing equipment

PendingCN112009028AAffect normal deliveryNormal delivery does not produceBag making operationsPaper-makingStructural engineeringIndustrial engineering

The invention discloses automatic hand buckle buckling and pressing equipment. The automatic hand buckle buckling and pressing equipment comprises a frame, wherein a hand buckle feeding device, a woven bag feeding device and a stamping device are arranged on the frame; the stamping device is provided with a stamping station and a pressing and buckling station; a primary buckle feeding track and asecondary buckle feeding track are respectively arranged on the upper end surface and the lower end surface of a woven bag, corresponding to the pressing and buckling station, of the hand buckle feeding device; the primary buckle feeding track and the secondary buckle feeding track are respectively provided with filling mechanisms for feeding primary buckles into the primary buckle feeding track and feeding secondary buckles into the secondary buckle feeding track; and sorting mechanisms used for distinguishing and sorting the front faces and the back faces of the primary buckles and the frontfaces and the back faces of the secondary buckles are arranged on track paths of the primary buckle feeding track and the secondary buckle feeding track respectively. The automatic hand buckle buckling and pressing equipment provided by the invention can perform automatic production, improves the production efficiency and is used for automatic processing and assembling of woven bag punching and automatic buckling of hand buckles.

Owner:WENZHOU KEWANG MACHINERY

Production method of valve workpiece

The invention discloses a production method of a valve workpiece. The production method comprises the following steps that (1), casting forming is conducted; (2), a charges handle is removed, specifically, the charges handle of a workpiece blank in the step (1) is subjected to workpiece cutting for burr removal through cutting equipment; (3), the workpiece is cleared; (4), tapping is conducted, specifically, the workpiece is subjected to automatic tapping operation through automatic tapping equipment, and outer threads are machined on two connecting columns of the workpiece are machined; (5),shot blasting is conducted, specifically, surface shot blasting treatment is conducted on the deburred workpiece through a shot blasting machine; and (6), acceptance check is conducted. According to the production method of the valve workpiece, full-automatic operation of valve body production is achieved, the work efficiency is high, the production speed of a valve body is high, and the supply and demand proportion is met; the qualification rate of an external thread of the workpiece is high, the condition of a defective product or a scrapped product is basically avoided, re-work of the product is reduced, and the production efficiency is improved to a great extent; and through a multi-step technique of burr removal, high-pressure air spraying for clearing, shot blasting and the like, theworkpiece is treated, and thus the overall aesthetic degree of the workpiece is high.

Owner:ZHEJIANG HAOLONG ELECTRIC CO LTD

Anti-fouling device for air conditioner accessory cutting device

InactiveCN108940950AGuaranteed cleanlinessAvoid pollutionCleaning using toolsMaintainance and safety accessoriesWorking environmentContamination

The invention discloses an anti-fouling device for an air conditioner accessory cutting device. The anti-fouling device comprises a waste bin, wherein one side wall of the waste bin is provided with adischarging outlet, a carrying trolley which communicates with the discharging outlet is arranged on one side of the waste bin, a feeding inlet of the carrying trolley is lower than the discharging outlet, and garbage bags are arranged in the carrying trolley; the carrying trolley is connected to the waste bin through a connection mechanism, the waste bin is internally provided with a pushing plate used for pushing waste chips into the carrying trolley, and a push rod is fixedly arranged on the pushing plate; and the push rod slides through the waste bin to communicate with the outside, and abrush layer which makes contact with the bottom surface of the waste box is arranged at the lower end of the pushing plate. According to the anti-fouling device, the waste chips can be easily treated, treatment is more thorough and cleaner, and the working environment contamination phenomenon is effectively prevented.

Owner:天长市永鑫制冷设备有限公司

Urinary calculus removing device for urinary surgery

InactiveCN112515734AIncrease laborEasy to operateDiagnosticsSurgical instrument supportMedical staffBiomedical engineering

The invention relates to the technical field of medical instruments, in particular to a urinary calculus removing device for urinary surgery. The urinary calculus removing device comprises a device main body; a supporting bottom plate is arranged below the device main body; a height adjusting mechanism is arranged above the supporting bottom plate; the height adjusting mechanism comprises an opengroove; the open groove is formed in the supporting bottom plate; threaded sleeve rods are movably connected to the upper side and the lower side of the interior of the open groove through bearings; first bevel gears are fixedly connected to the middles of the outer sides of the threaded sleeve rods; second bevel gears are fixedly connected to the ends, close to the first bevel gears, of rotatingrods; an adjusting limiting mechanism is arranged on the left side above the height adjusting mechanism; and a clamping mechanism is arranged on the right side above the height adjusting mechanism. When the device is used, the surgical site of a patient and the device main body can be fixed, manual holding by medical staff is not needed, therefore the labor amount of the medical staff is reduced,and operation is more convenient and faster.

Owner:CHANGZHOU NO 2 PEOPLES HOSPITAL

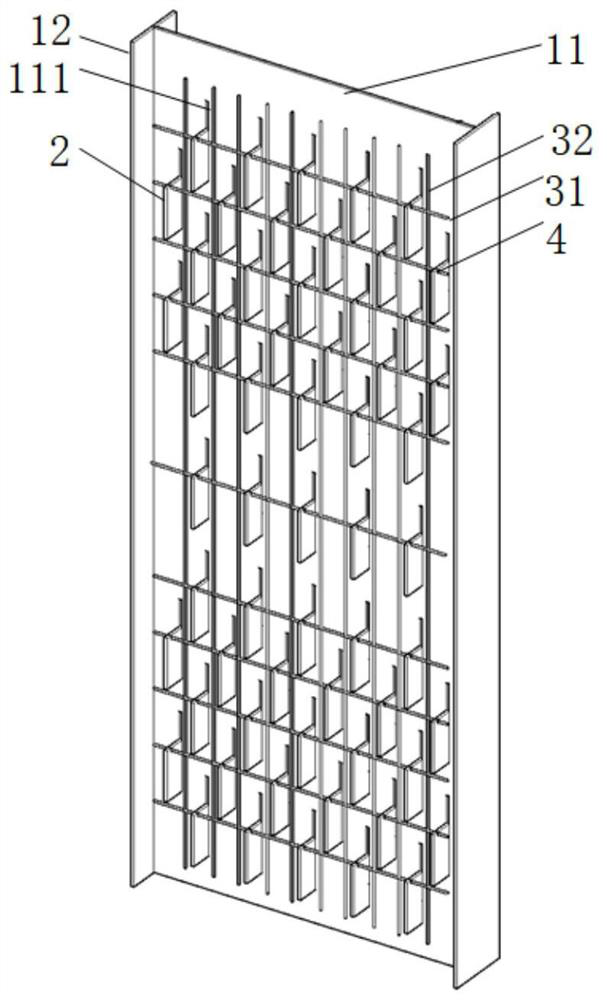

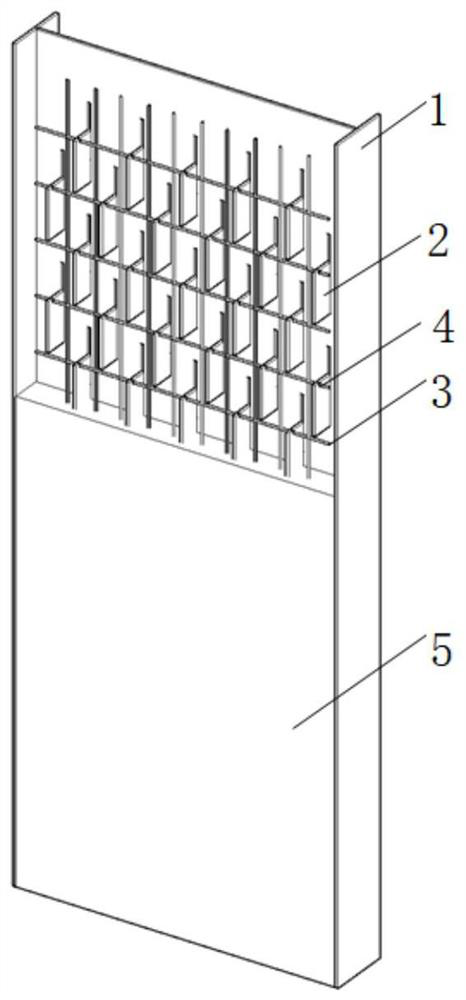

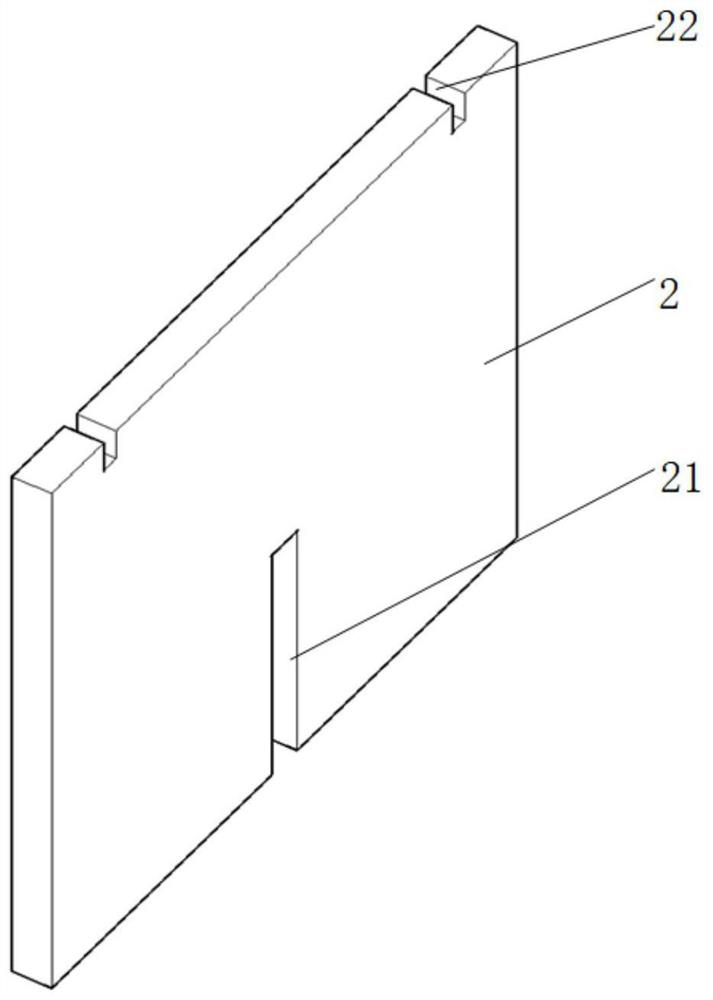

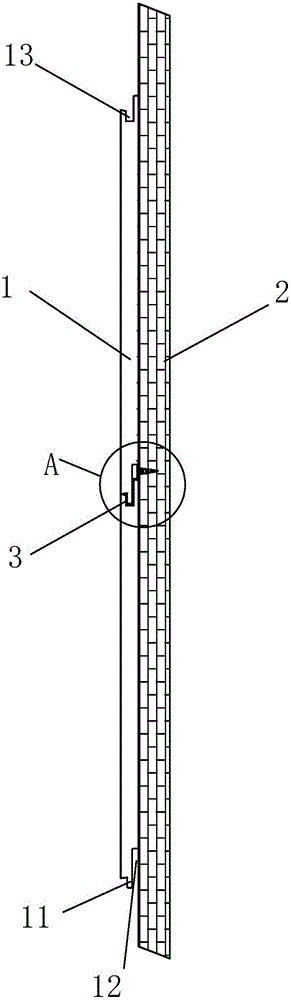

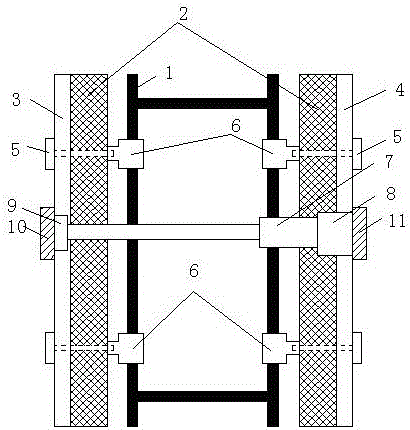

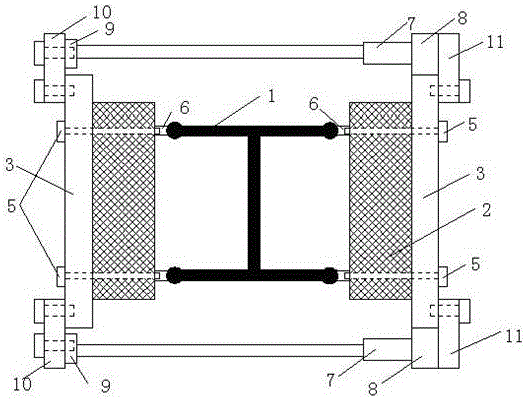

Pluggable longitudinal rib type sound insulation steel-concrete composite shear wall and assembly method thereof

ActiveCN112814225AQuick installationQuality assuranceWallsSound proofingMesh reinforcementClassical mechanics

The invention belongs to the field of structural engineering in civil engineering, and particularly relates to a pluggable longitudinal rib type sound insulation steel-concrete composite shear wall and an assembling method thereof. The pluggable longitudinal rib type sound insulation steel-concrete composite shear wall is characterized in involving an H-shaped steel body structure, rib plates and reinforcing meshes, wherein the H-shaped steel body structure comprises a web and two flanges symmetrically arranged on the two sides of the web, a plurality of rows of rib plates are arranged on the web plate from top to bottom, the rib plates are perpendicularly clamped on the web plate, reinforcing meshes are correspondingly arranged on two sides of the web, and the reinforcing meshes are hung on the rib plates. According to the pluggable longitudinal rib type sound insulation steel-concrete composite shear wall and the assembly method thereof, the rib plates are arranged on the web, the stability of the shear wall is improved, notches are formed in the rib plates, welding of steel bars in actual engineering is reduced, the structural integrity and the assembling efficiency are guaranteed on the basis of facilitating construction, meanwhile arranged materials can fully achieve the sound insulation effect, by means of the design of connecting joints and clamping grooves, connection among the structures is convenient and rapid, fastening is reliable, and the workload of on-site molding, installing and welding is reduced.

Owner:HEFEI UNIV OF TECH

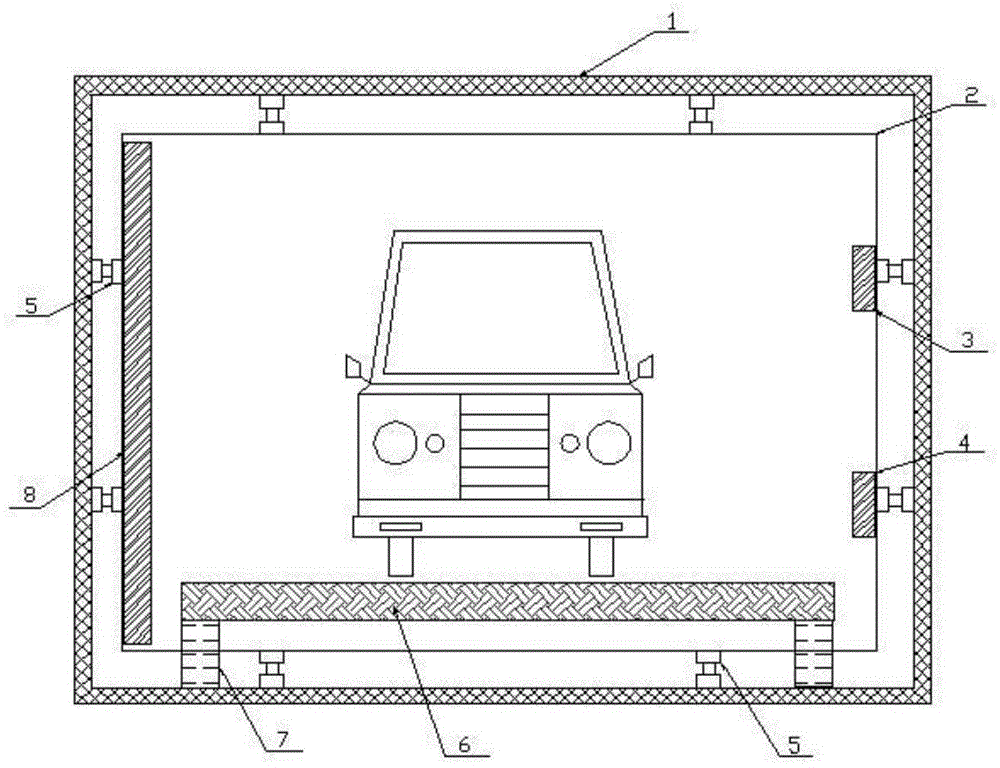

Identification system for scrap motor vehicle parts

ActiveCN104807418ANo position shiftStop the leakUsing wave/particle radiation meansMotor vehicle partPhysics

The invention discloses an identification system for scrap motor vehicle parts on the basis of a multi-energy X-ray material identification technology and an image processing technology. The identification system comprises a transmission unit, an X-ray detection system and an information processing system; the X-ray detection system comprises an X-ray detection frame, a dual-energy X-ray generator and a linear display detector; the dual-energy X-ray generator comprises a low-energy X-ray generator and a high-energy X-ray generator; the information processing system comprises a signal input module, a signal processing module, a signal logic analysis module and a signal output module and features in 3D (three-dimensional) modeling and image, part identifying and data redundancy processing. By the arrangement, a scrap motor vehicle can be vertically scanned, the parts can be identified rapidly to acquire space and geometry information of the same, and intelligent demounting of the scrap motor vehicle is favorably realized.

Owner:UNIV OF SCI & TECH BEIJING

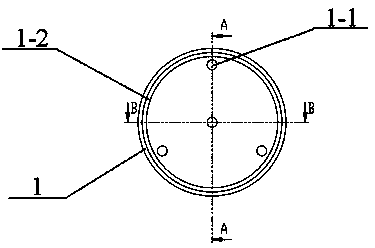

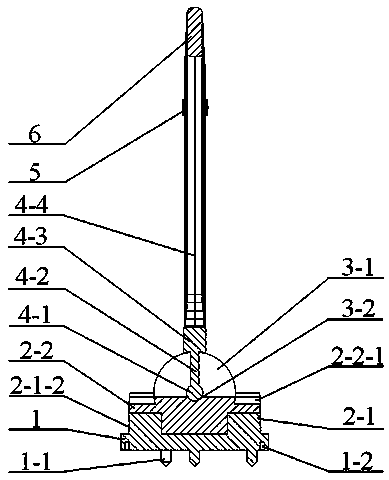

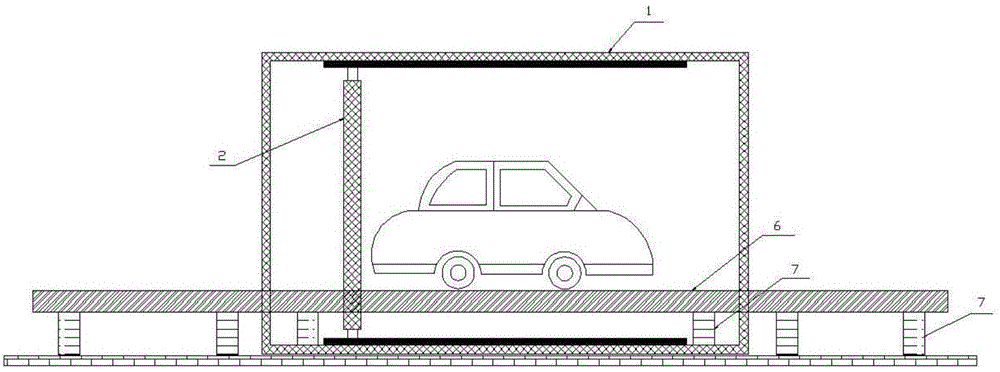

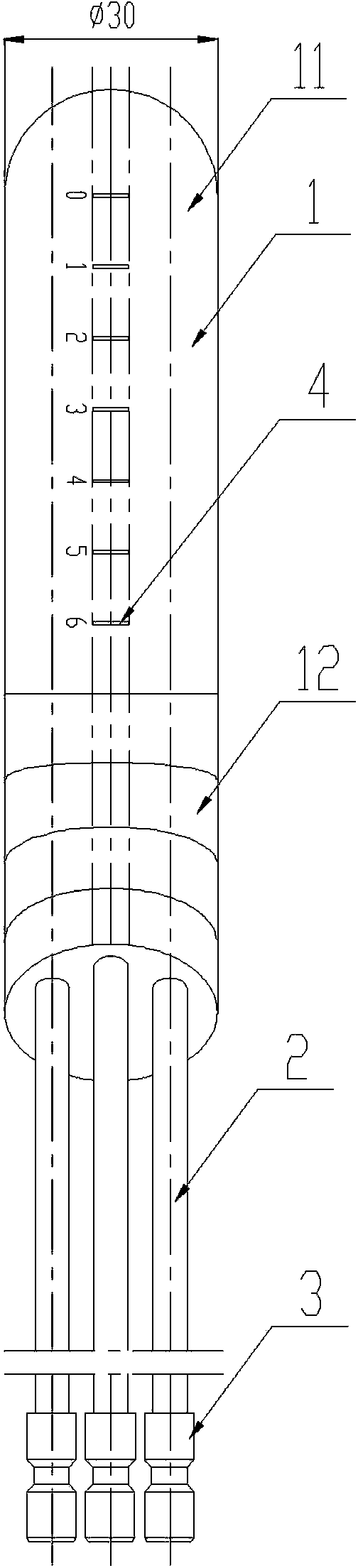

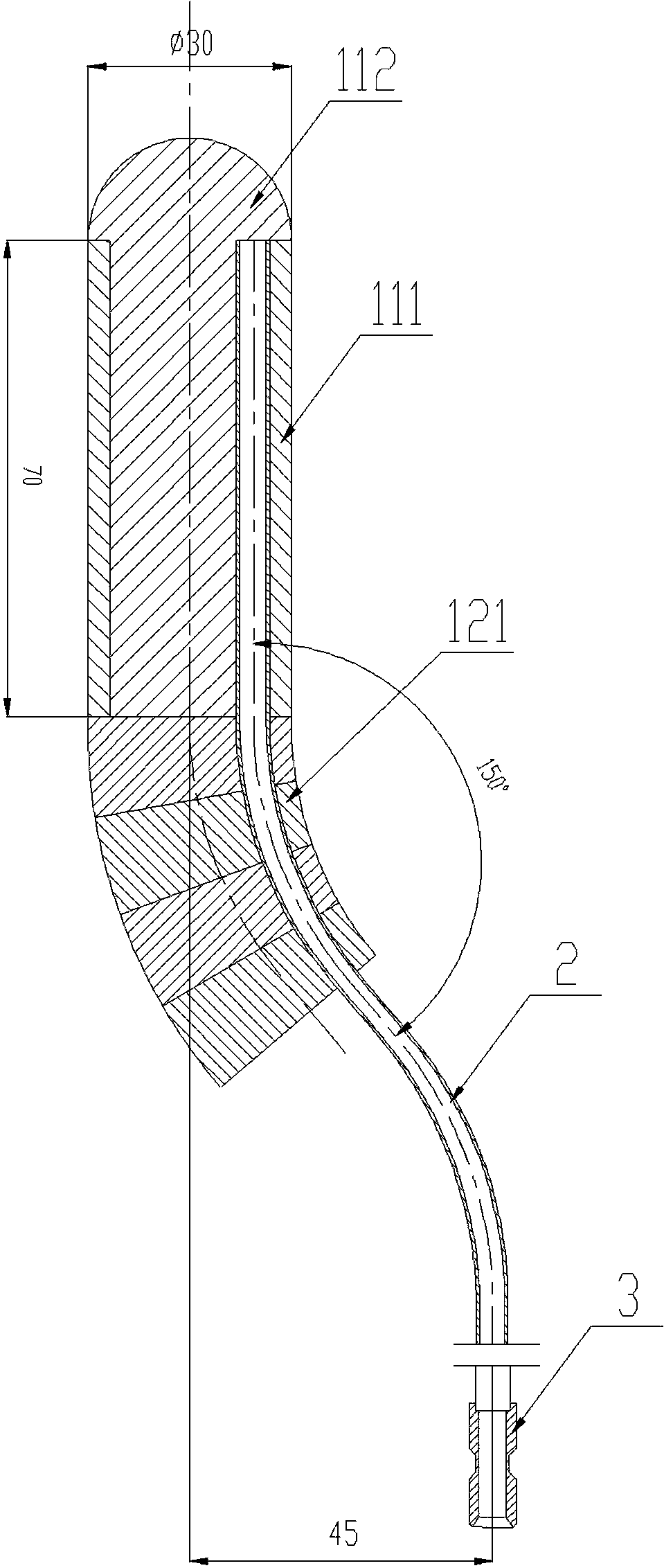

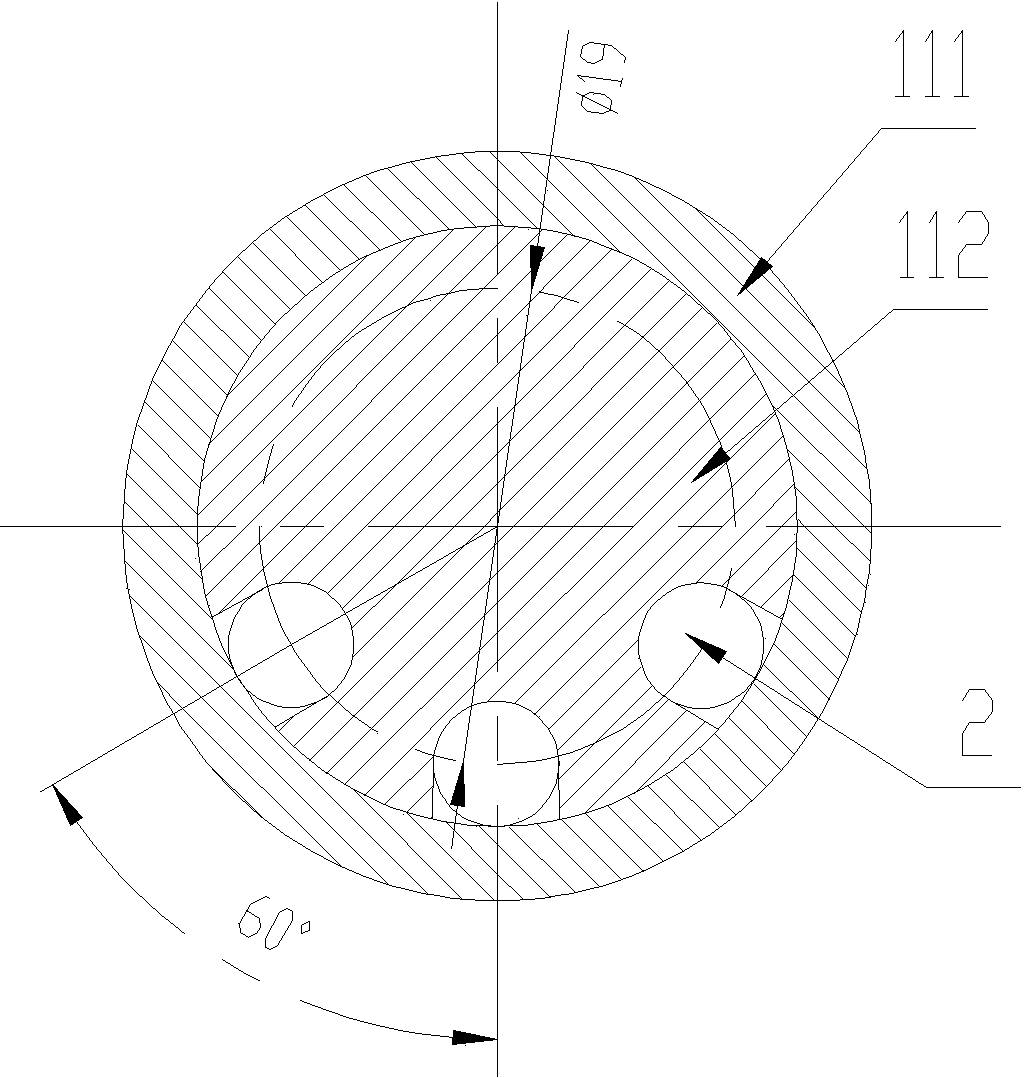

Source applicator for anal canal tumor radiotherapy

InactiveCN103845789AReduce the likelihood of relapseAvoid damageRadiation therapyAbnormal tissue growthTumor recurrence

The invention relates to a source applicator for anal canal tumor radiotherapy, the source applicator comprises a cylindrical source applicator body of which the diameter is 3cm, wherein the front end of the source applicator body is a spherical arc, the front segment of the source applicator body is a right cylinder segment of which the length is 8.5cm, the right cylinder segment comprises the spherical arc at the front end, the rear segment of the source applicator body is bent in a manner of a 150-degree arc, the arc length of an introvert of an arc-shaped bent segment is 5cm, the source applicator body is internally and axially provided with three source applying tubes which are eccentrically arranged in a semicircle of the introvert side of the cross section of the source applicator body and distributed in a manner of a circular curve, and the distance between the center of each source applying tube and the outer wall of the introvert side of the source applicator body is 5.5cm; an arc between the circle center of the first source applying tube and the circle center of the second source applying tube is equal to an arc between the circle center of the second source applying tube and the circle center of the third source applying tube, and a central angle corresponding to the arc is 60 degrees. The source applicator has a good radiotherapy effect on nidus that part carcinoma of the anal canal spreads outside the anus edge, reduces the possibility of tumor recurrence and facilitates radical cure of the tumor.

Owner:THE THIRD AFFILIATED HOSPITAL OF THIRD MILITARY MEDICAL UNIV OF PLA

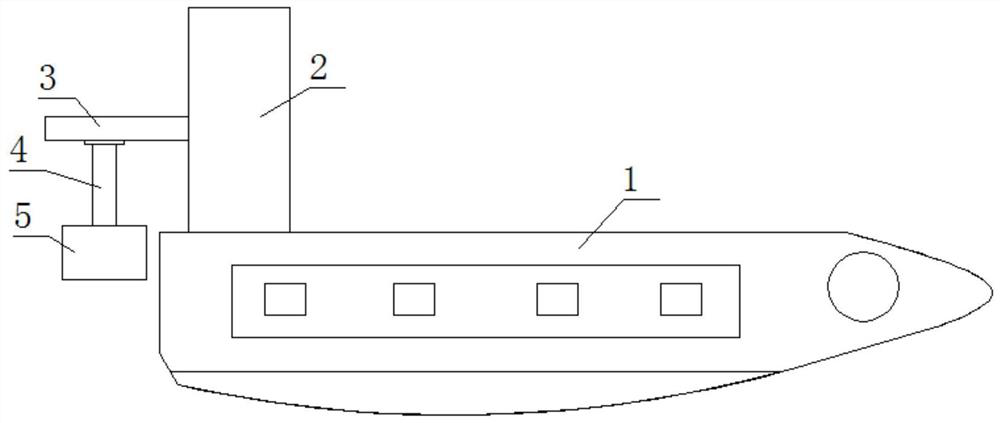

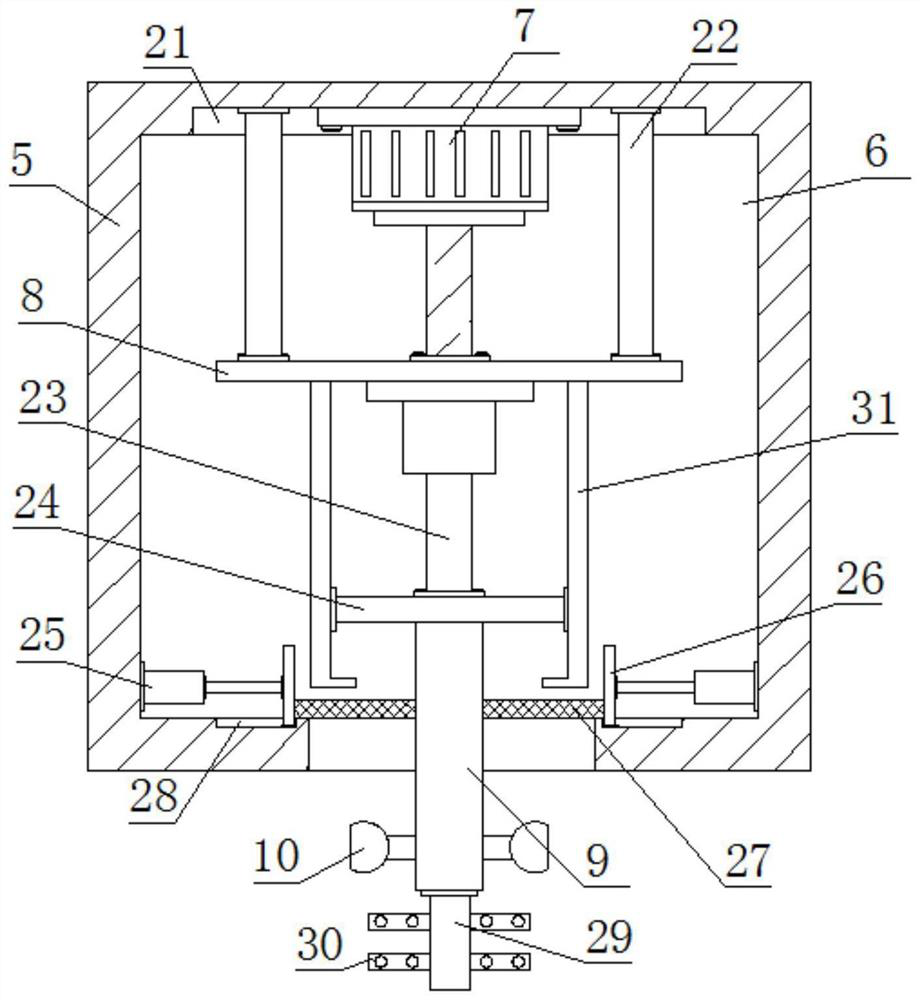

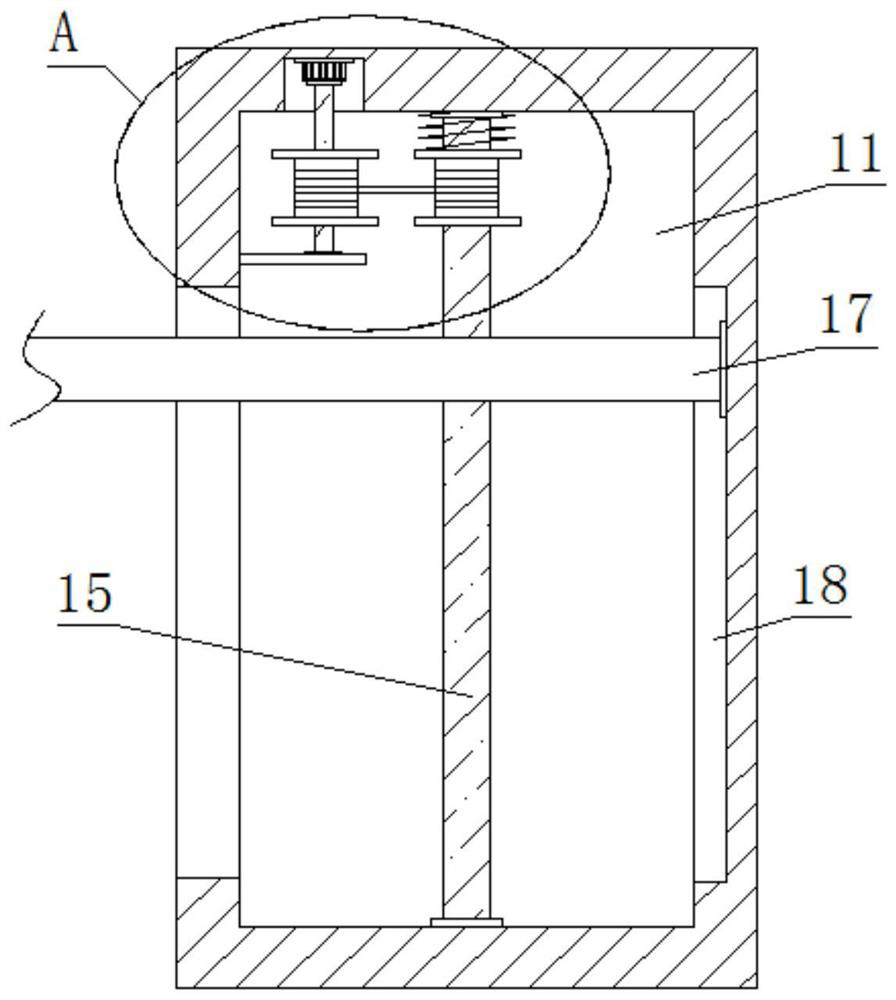

Device for detecting cracks of underwater building

PendingCN112061304AWon't hurtReduce shockVessel partsMaterial testing goodsClassical mechanicsWater flow

The invention relates to the field of detection of underwater buildings, in particular to a device for detecting cracks of an underwater building. A lifting assembly is arranged on a fixed base fixedly connected on a ship body, a connecting column is fixedly connected on the bottom of a movable plate in transmission connection on the lifting assembly, and a mounting cavity is arranged on a rectangular base fixedly connected to the bottom end of the connecting column; a first motor is fixedly connected on the top inner wall of a ring-shaped slot formed in the top inner wall of the mounting cavity, a rotary disc is fixedly connected on the output shaft of the motor, an electric push rod is fixedly connected on the bottom of the rotary disc, a connecting plate is fixedly connected on the output shaft of the electric push rod, and a fixed plate is fixedly connected on the bottom of the connecting plate; and the bottom of the fixed plate extends to a position below the bottom of a rectangular base; detectors are fixedly connected at the two sides of the fixed plate; and an anti-impact assembly is arranged on the rectangular base. The device solves the problems that a conventional detector has a detection dead corner, is liable to have a detection leakage phenomenon, and is easily damaged as a result of impact of water flow.

Owner:温州华志宇强科技有限公司

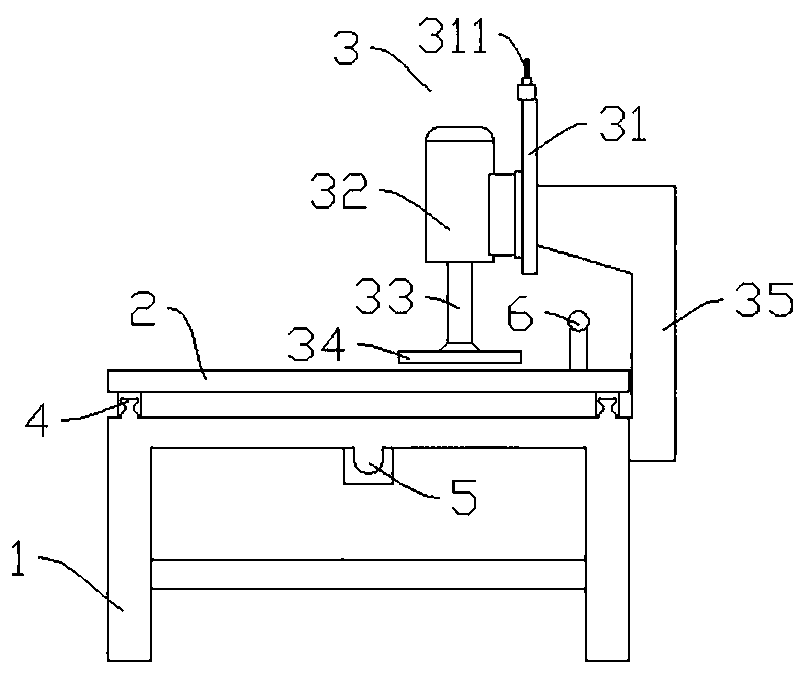

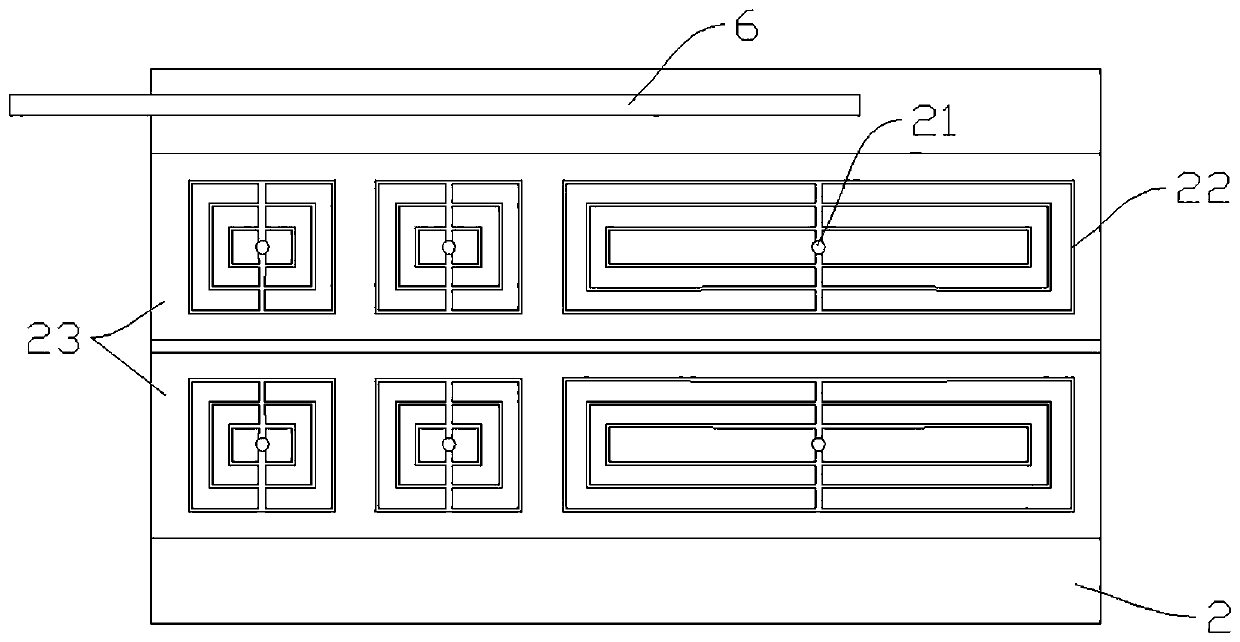

High-precision polishing equipment for graphite slices

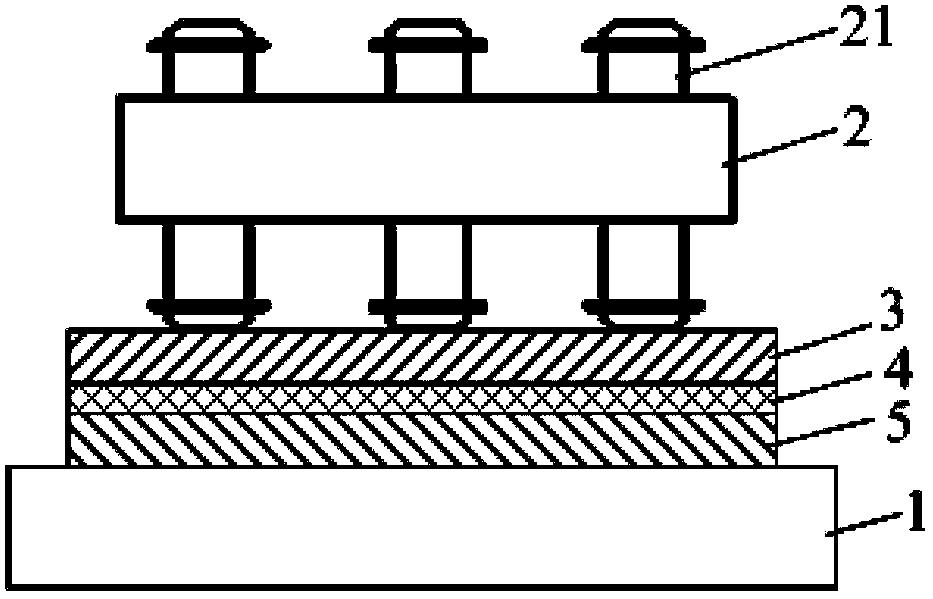

PendingCN111531452AAchieve level adjustmentHigh polishing precisionGrinding carriagesPolishing machinesPolishingEngineering

The invention belongs to the technical field of graphite product machining equipment, and particularly discloses high-precision polishing equipment for graphite slices. The high-precision polishing equipment for the graphite slices comprises a rack, a workbench and a grinding assembly. Small holes are formed in the surface of the workbench for vacuumizing to adsorb and fix the graphite slices, double sliding rails and the grinding assembly are arranged on the rack for adjustment of polishing positions, and the relatively high polishing precision is obtained preliminarily; annular channels communicating with the small holes are formed in the peripheries of the small holes to enhance the vacuum adsorption effect, with the arrangement of a concave area of the workbench combined, it is guaranteed that the graphite slices cannot deviate in position in the polishing process, and the polishing precision is improved; and through the three-layer structural design of a metal layer, a rubber layer and a polishing layer of a polishing disc, the stability of the grinding assembly is improved, and the polishing precision is further improved; in addition, the high-precision polishing equipment for the graphite slices also has the characteristics that the operation is easy, the safety is high, the polishing layer can be easily replaced, and the polishing efficiency is high.

Owner:ZHEJIANG HAROG TECH CO LTD

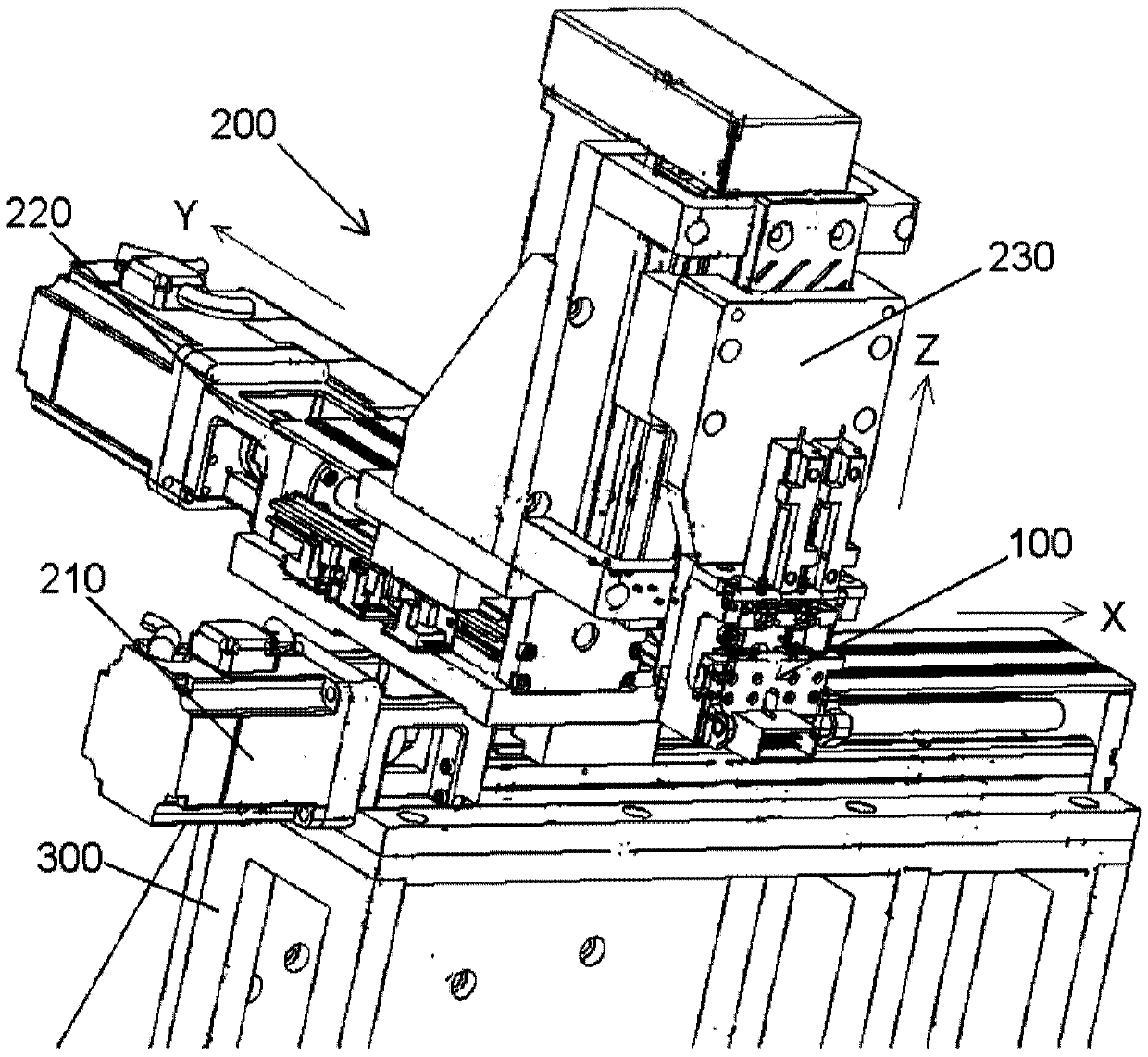

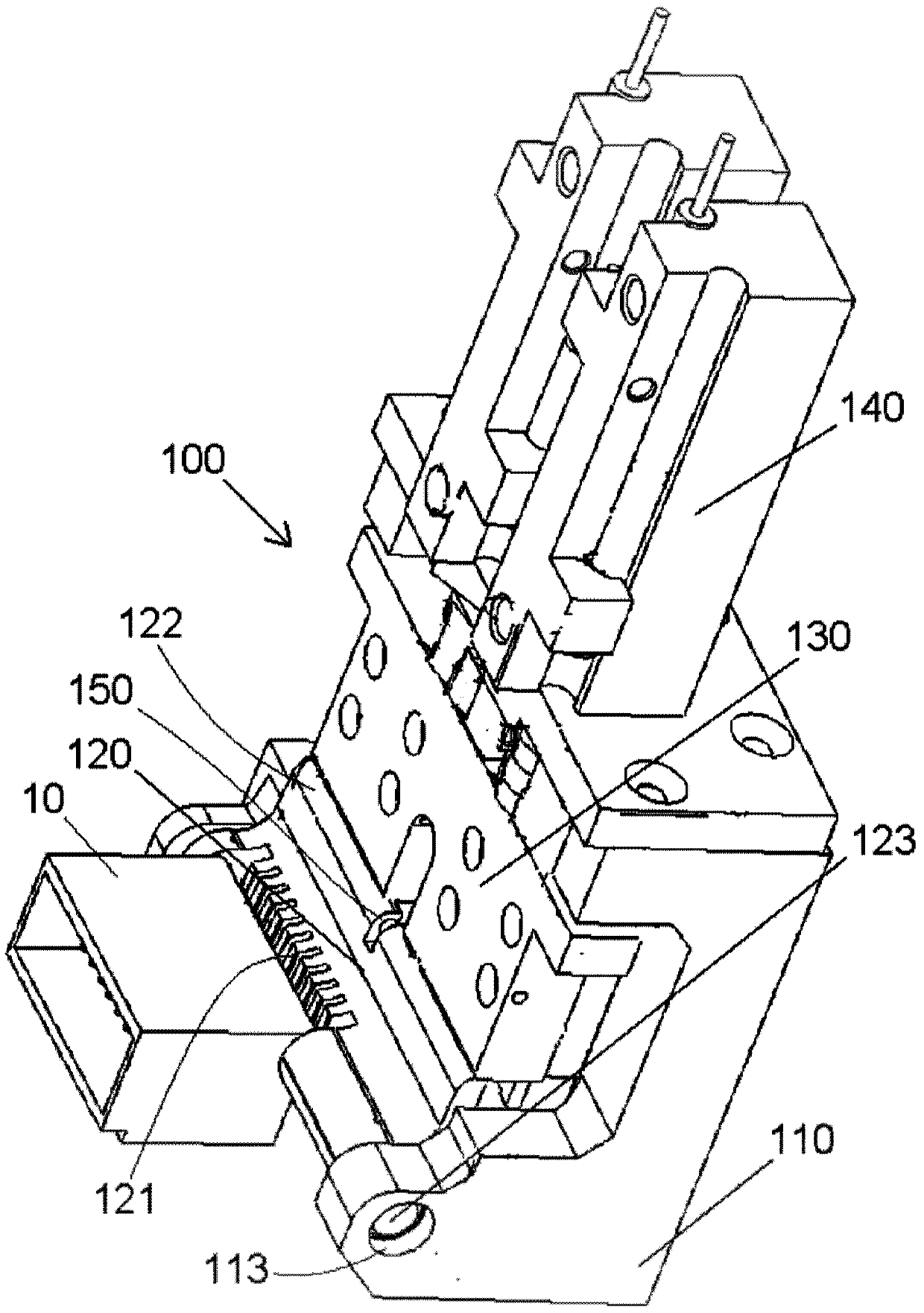

Terminal crimping devices and terminal crimping equipment

ActiveCN107516804BAchieve bendingImprove bending efficiencyContact member manufacturingConnection formation by deformationStructural engineeringMechanical engineering

Owner:TYCO ELECTRONICS (SHANGHAI) CO LTD +1

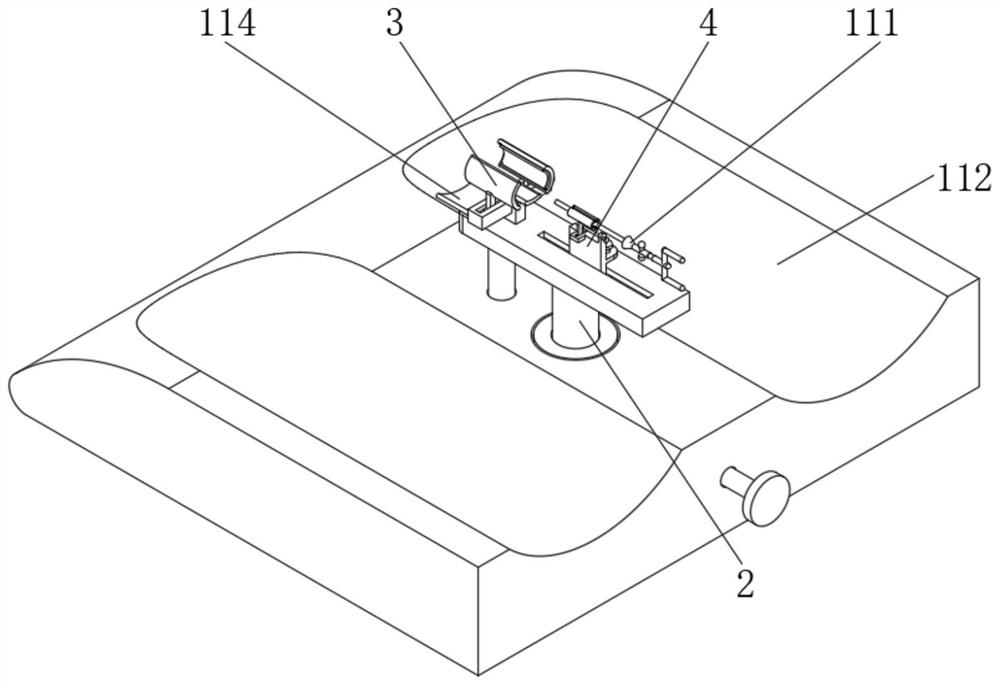

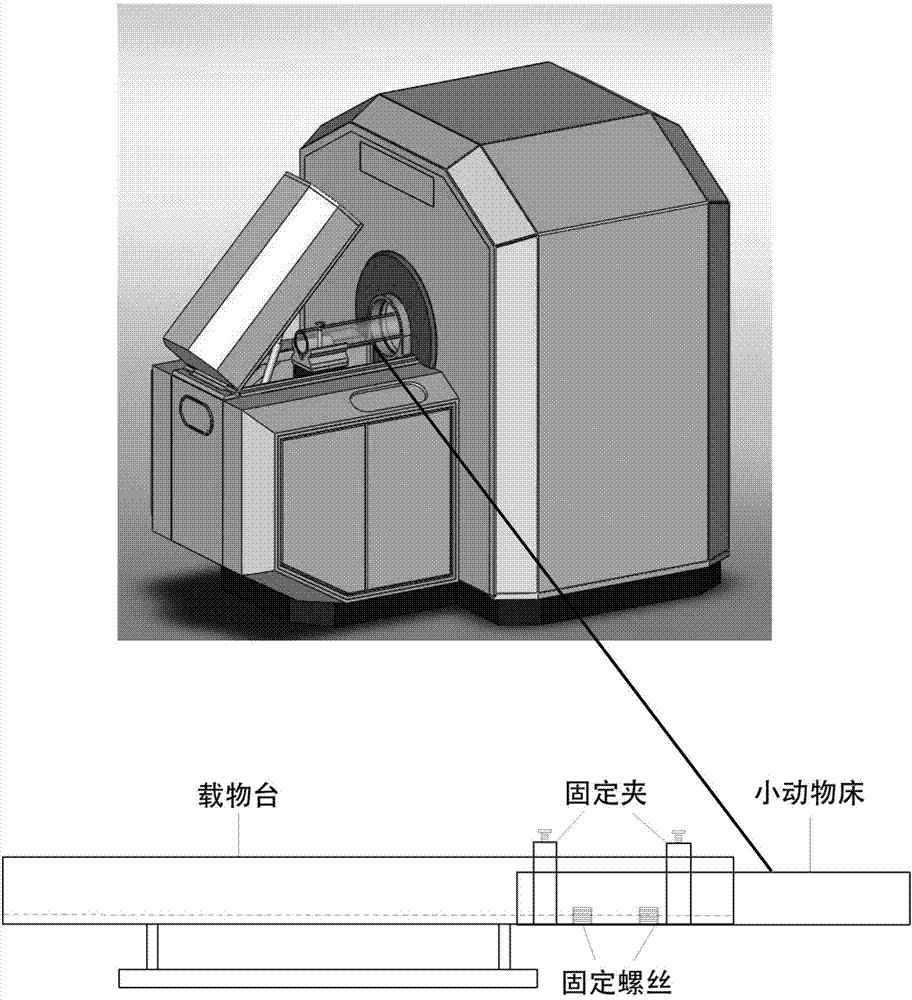

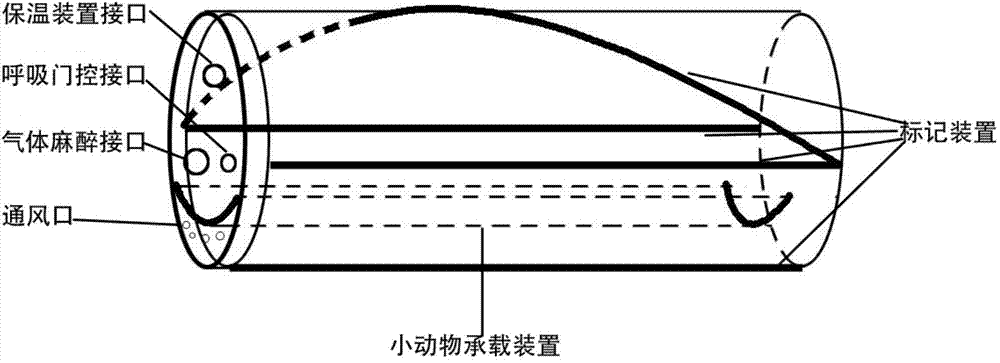

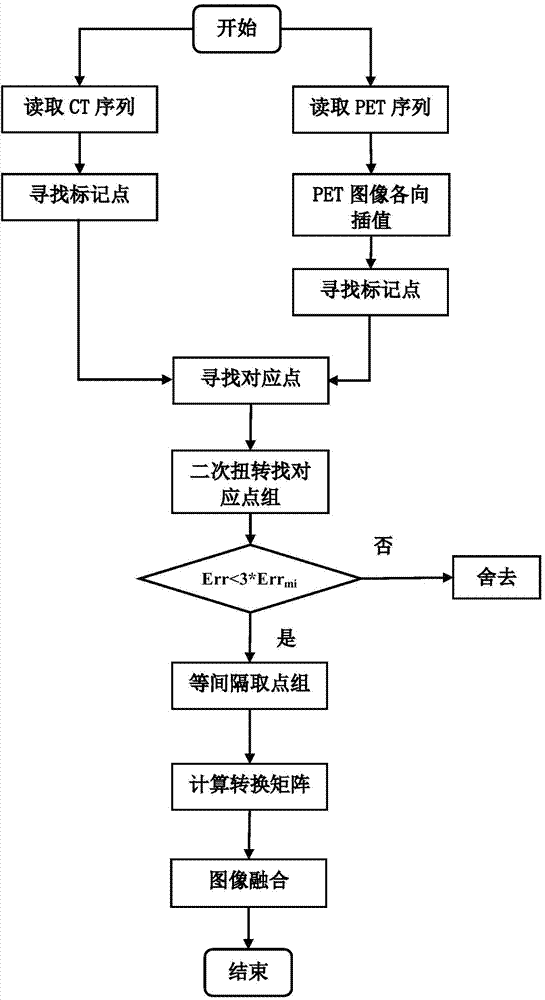

Multimodal medical small animal image registration and fusion system

ActiveCN104517293ACompatibleDoes not affect the scanning effectImage enhancementImage analysisDiagnostic Radiology ModalitySmall animal

The invention discloses a multimodal medical small animal image registration and fusion system. The multimodal medical small animal image registration and fusion system comprises a small animal bed transferred between two or more pieces of medical imaging equipment, and is characterized in that a device for developing images of multiple pieces of the medical imaging equipment is arranged on the outer side of the small animal bed; the multimodal medical small animal image registration and fusion system further comprises a software-based automatic image registration and fusion unit, and is characterized by adopting a fusion method based on spatial point rigid body registration. The multimodal medical small animal image registration and fusion system can achieve registration and fusion of multimodal medical images of a small animal, and can provide richer information for the images acquired by independent medical imaging equipment.

Owner:SOUTHEAST UNIV

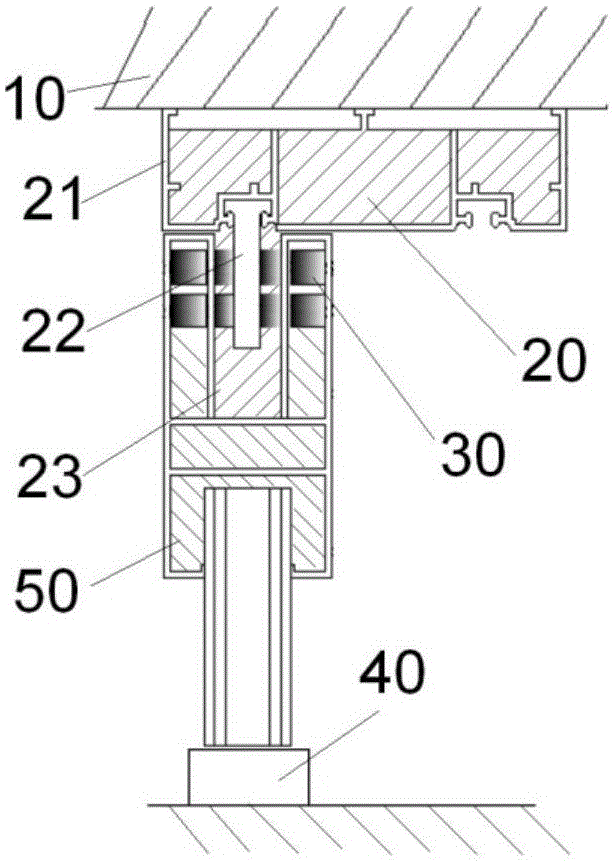

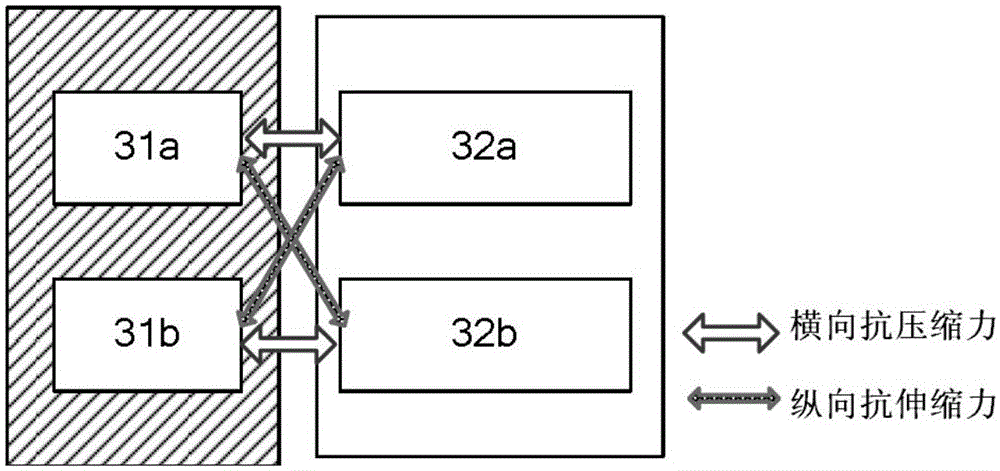

Magnetic suspension door and window for building structure

InactiveCN106703610AReduce frictionOffset self-weightWing arrangementsWing suspension devicesEngineeringTransverse compression

The invention discloses a magnetic suspension door and window for a building structure. The magnetic suspension door and window are characterized by comprising a frame, a door and window body and a supporting unit; the frame is used for being fixed to the building structure, the door and window body comprises at least one covering material, an excitation array is arranged between the frame and the door and window body and comprises a first excitation unit and a second excitation unit, the first excitation unit is fixed to the frame body, the second excitation unit is fixed to the door and window body, and longitudinal stretching resistance and transverse compression resistance are generated between the first excitation unit and the second excitation unit.

Owner:RUNYI SHANGHAI WINDOWS TECH CO LTD

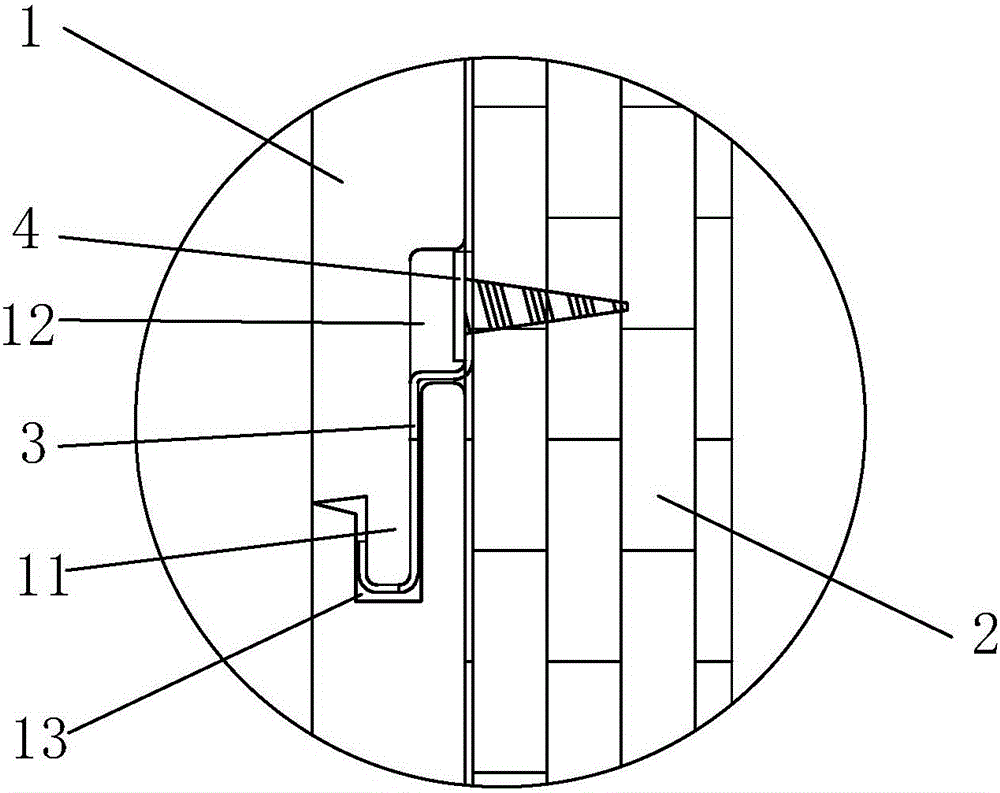

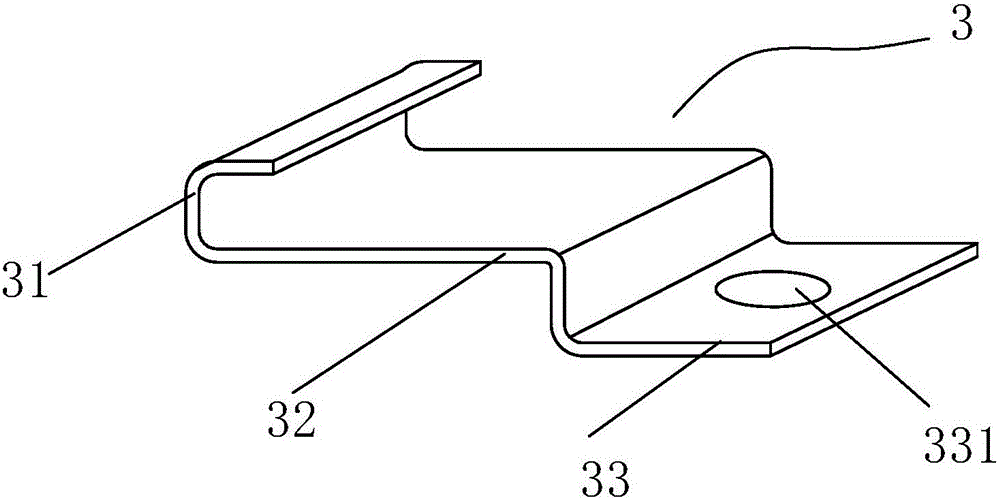

Wallboard installation structure and method

The invention relates to a wallboard installation structure and method. The structure comprises a wallboard, a wall body and a wallboard installation buckle. The wallboard is in a long-strip shape. The lower end of the wallboard installation direction is a plug-in end. The upper end of the wallboard installation direction is a bell end. A downward-protruding first protruding strip is arranged at the plug-in end. The inner side of the first protruding strip is provided with a first gap which extends upwards and is adjacent to the wall body. A positioning groove is formed in the bell end of the wallboard. The wallboard installation buckle comprises a supporting portion, an installation portion and a connecting portion for connecting the installation portion with the supporting portion. The supporting portion is located below the installation portion, a supporting groove is formed in the supporting portion, and a connecting hole is formed in the installation portion; the supporting portion is matched with the positioning groove, the first protruding strip is matched with the supporting groove, and the connecting portion of the wallboard installation buckle is fixed to the wall body through a self-tapping screw. Before an adhesive achieves the best adhesive strength, reliable connection of the wallboard is achieved.

Owner:ZHEJIANG HUAXIAJIE MACROMOLECULE BUILDING MATERIAL

Special-shaped part detection tool and method

PendingCN110779417AEasy to useSimple structureMechanical measuring arrangementsStructural rigidityManufacturing engineering

The invention discloses a special-shaped part detection tool and method, and belongs to the technical field of workpiece detection. The device comprises a first detection block and a second detectionblock, the first detection block is vertically connected with the second detection block, the first detection block is provided with a first working surface, the second detection block is provided with a second working surface, and the first working surface and the second working surface are provided with arc members respectively. The tool is simple in structure, high in structural rigidity and convenient to manufacture and use; and according to the detection method, use of complex machine parts are not needed, existing detection equipment can be used, a dial indicator needs not to change theposition in the detection process, and the detection method is simple and convenient to use.

Owner:安徽马钢重型机械制造有限公司

Novel form-removal-free concrete construction technology

InactiveCN106760528AEasy to installSimplified installation stepsWallsBuilding material handlingArchitectural engineeringRebar

Owner:HUANGHE S & T COLLEGE

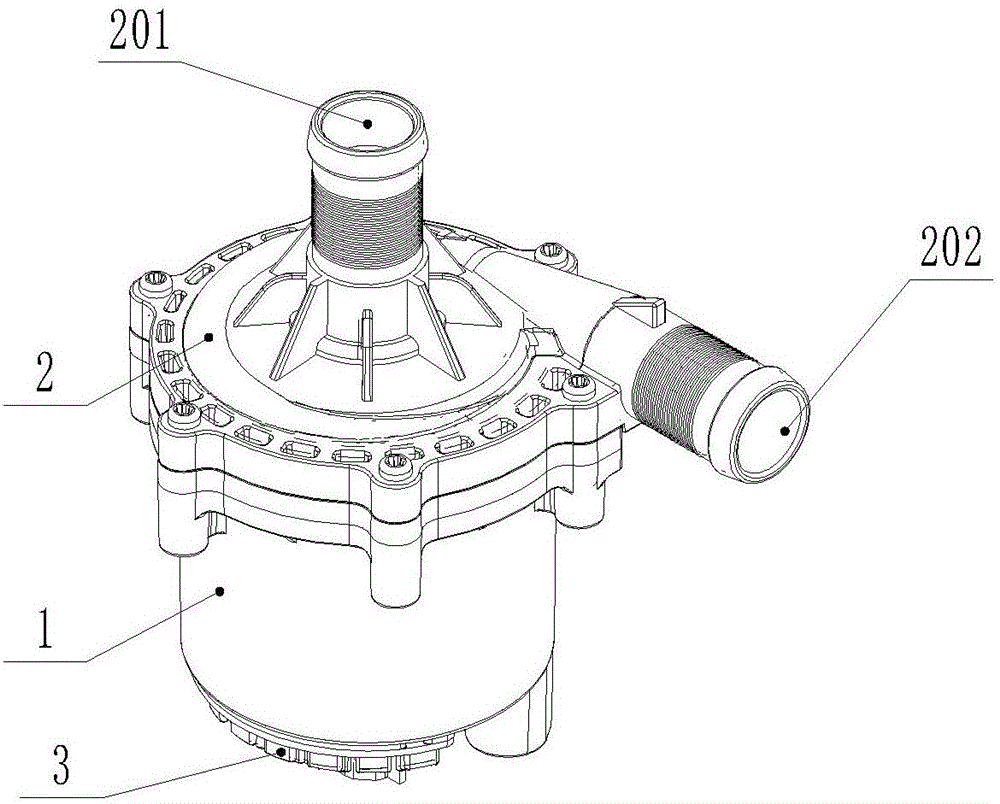

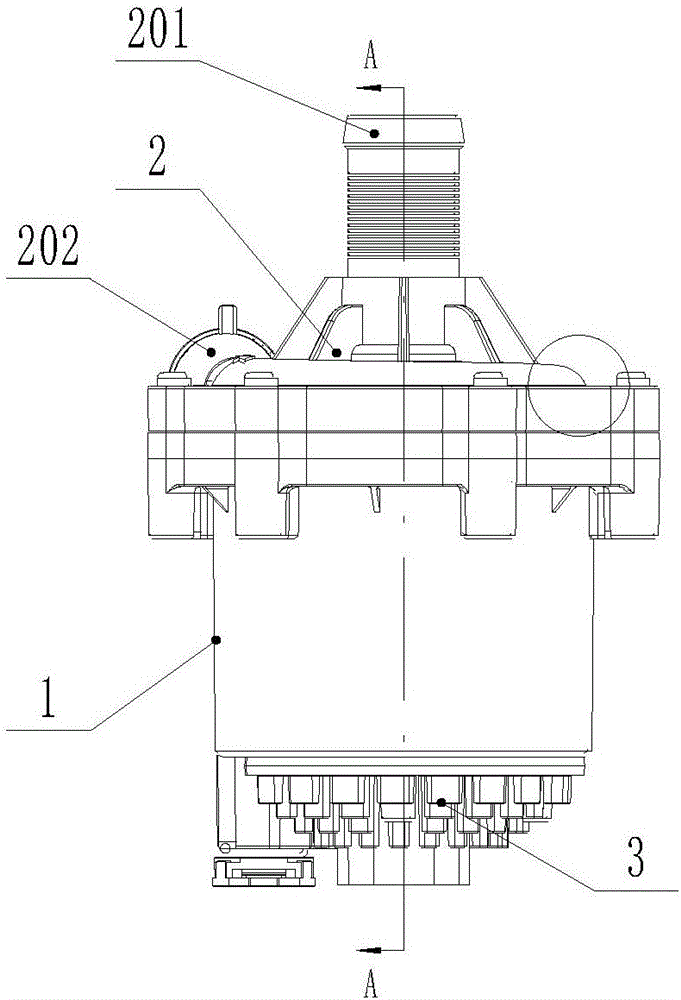

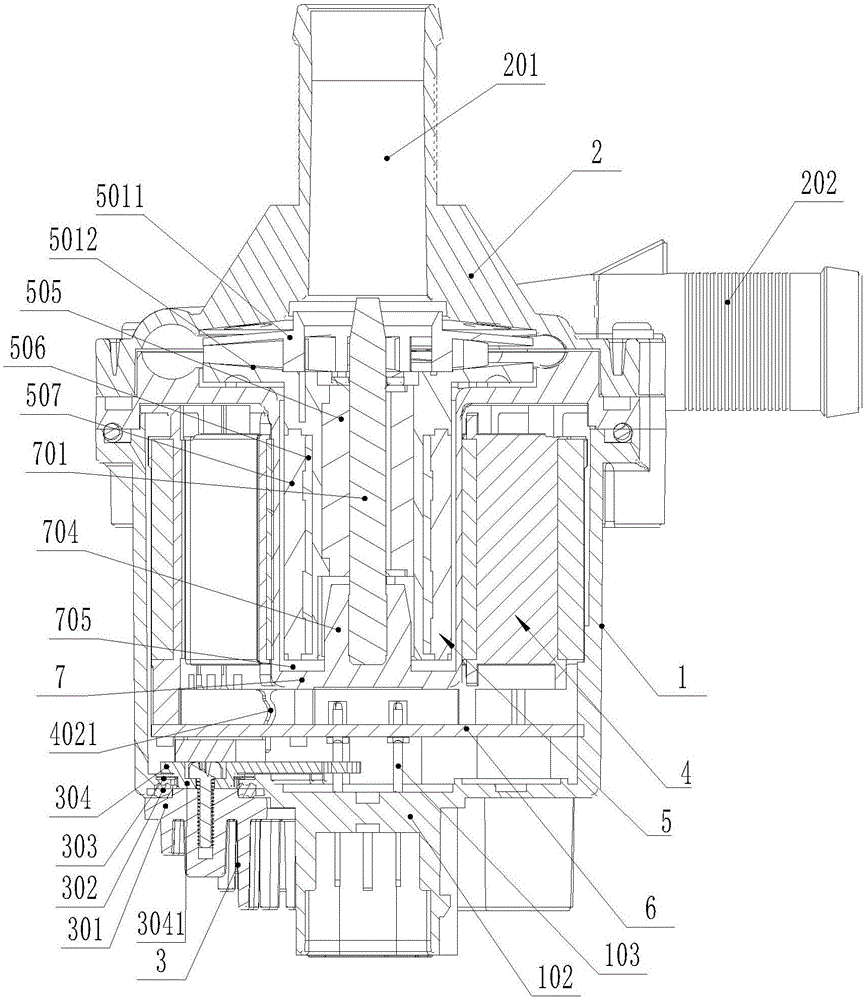

Brushless electronic water pump

PendingCN106640681ASmooth rotationLow rotational resistancePump componentsMechanical energy handlingImpellerHeat conducting

The invention discloses a brushless electronic water pump. The brushless electronic water pump comprises a shell body, an isolating sleeve and an upper cover which can be detachably fixed. The isolating sleeve divides the shell body and the upper cover into an installing chamber and a fluid chamber. A stator assembly and a PCB are fixed into the installing chamber. A rotor assembly is installed in the fluid chamber in a rotating manner. The upper cover is provided with a water inlet and a water outlet. The rotor assembly comprises an impeller and a connecting drum. A wear-resisting lubricating insert is fixedly inserted into an inner hole of the connecting drum. A center hole is formed in the wear-resisting lubricating insert. A magnet yoke drum is fixedly installed outside the connecting drum concentrically in a sleeving manner. A magnet ring drum is fixedly installed outside the magnet yoke drum concentrically in a sleeving manner. The isolating sleeve is provided with a locating center shaft which is inserted into the center hole. The shell body is provided with a heat dissipating device connected with the PCB in a heat-conducting manner. According to the brushless electronic water pump, a bearing does not need to be arranged on a rotor, no water inlet space is occupied, the reliability of the brushless electronic water pump is improved, and the service life of the brushless electronic water pump is prolonged.

Owner:JIANGSU LANGXIN ELECTRIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com