Wallboard installation structure and method

A technology for installing structures and wall panels, which is applied in building construction, covering/lining, construction, etc., and can solve problems such as long installation periods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The preferred embodiments of this patent will be described in further detail below in conjunction with the accompanying drawings. The wallboard in this application is a buckle-type wallboard, and the wallboard is vertically pasted on the wall. Therefore, the description of the orientation in this application takes the wallboard installed on the wall as the reference standard. The wallboard and the wall The side where the body is bonded is the inner side, and the side opposite the inner side is the outer side.

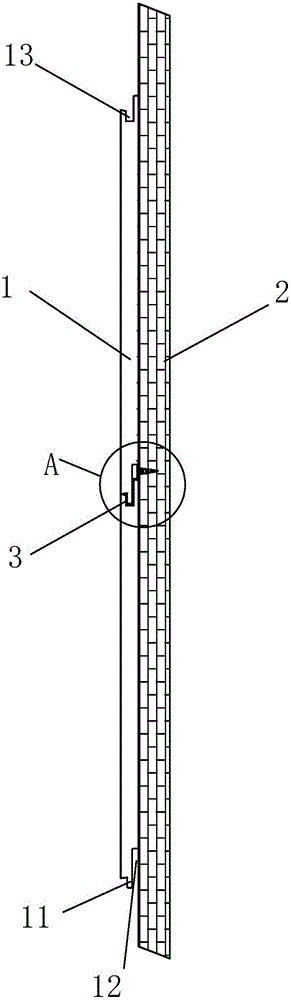

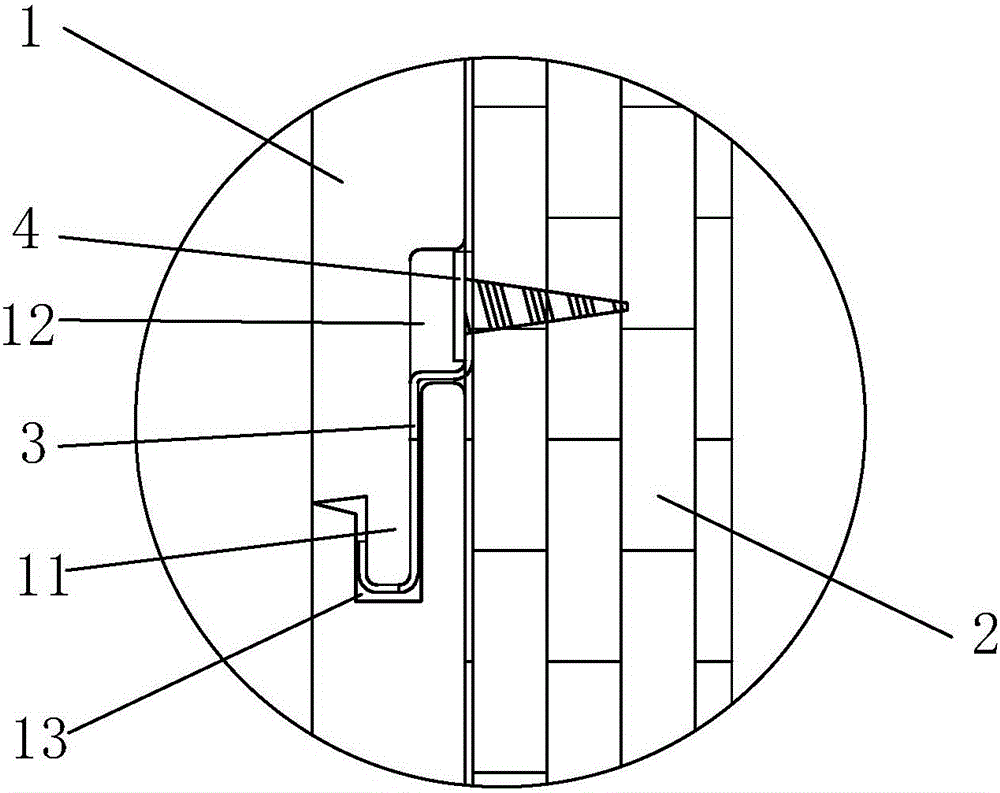

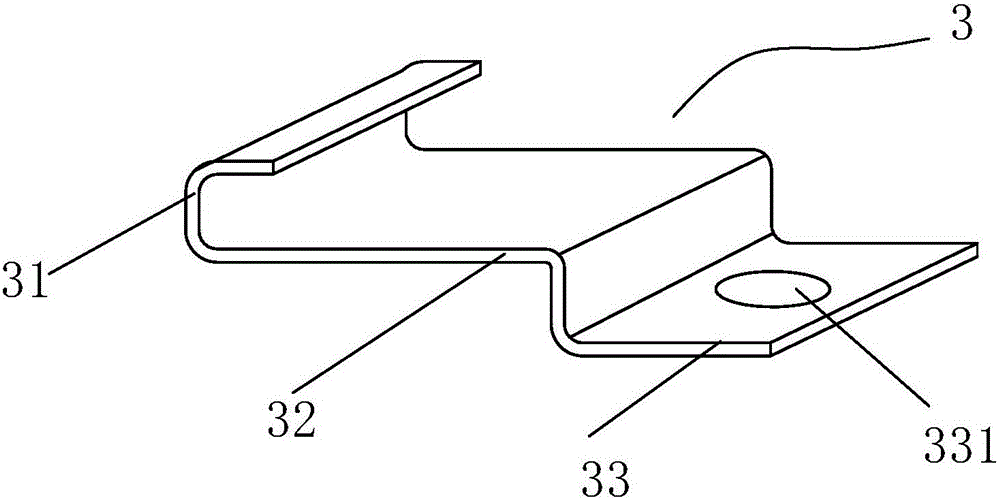

[0018] Such as figure 1 and figure 2 A wall panel installation structure shown includes a wall panel 1 , a wall body 2 and a wall panel installation buckle 3 . The wallboard 1 is strip-shaped, and the long side of the wallboard 1 is horizontally installed on the wall body 2 . One end of the wallboard 1 is a plug-in end, and the other end of the wallboard 1 is a socket end. A first protruding strip 11 protruding downward is provided at the plug-in end. 2. Adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com