Special-shaped part detection tool and method

A technology for detecting tooling and detection methods, applied in the direction of measuring devices, mechanical measuring devices, mechanical devices, etc., can solve the problems of difficult detection of special-shaped parts, and achieve the effects of convenient manufacturing and use, ensuring stability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

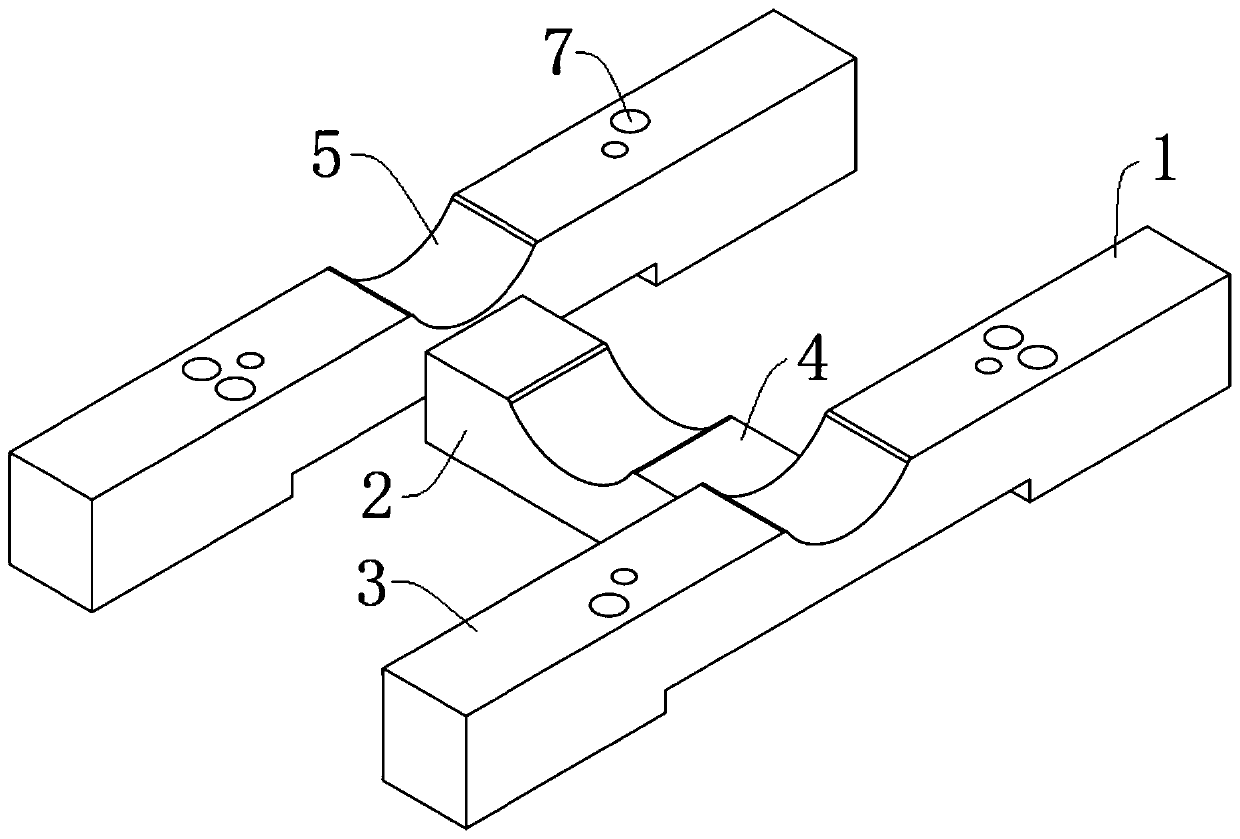

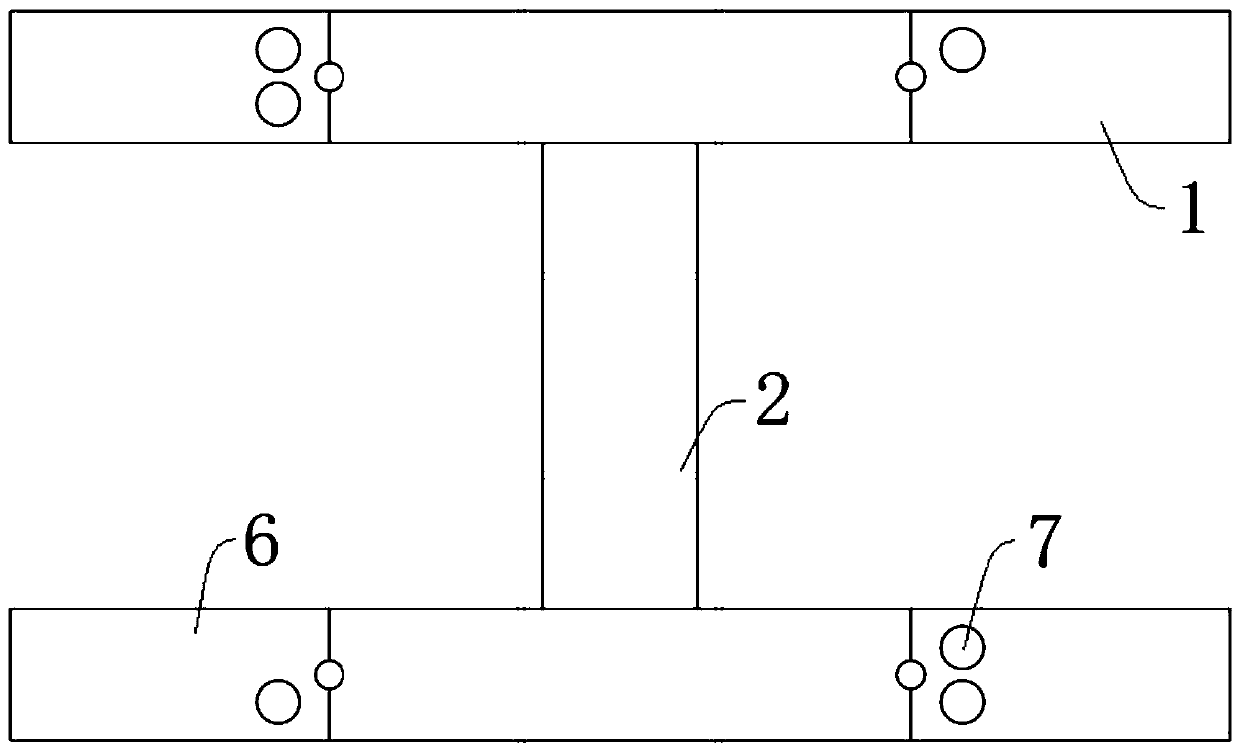

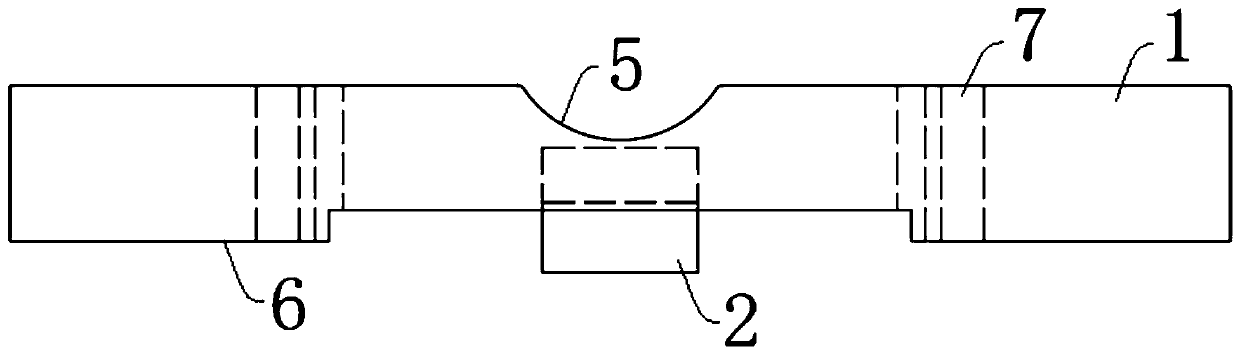

[0053] Such as figure 1 , figure 2 and image 3 As shown, a special-shaped piece detection tool in this embodiment is set based on the initial detection surface on the frame of the continuous casting segment.

[0054] The special-shaped piece detection tool of this embodiment includes a first detection block 1 and a second detection block 2, the number of the first detection block 1 is two, the number of the second detection block 2 is one, and the two ends of the second detection block 2 are respectively provided with The first detection block 1 and the special-shaped piece detection tooling are in the shape of "I" as a whole. In actual use, the materials for the first detection block 1 and the second detection block 2 should be selected with small elastic coefficient and small surface friction. In the process of measuring with special-shaped parts detection tooling, it is necessary to attach the dial indicator 9 or the magnetic base of the dial indicator (magnetic suction...

Embodiment 2

[0059] The structure of a special-shaped detection tool in this embodiment is basically the same as that in Embodiment 1. They are all aimed at the continuous casting segment frame, and the initial detection surface is convex. rise.

Embodiment 3

[0061] A special-shaped piece detection tool of this embodiment has basically the same structure as that of Embodiment 1, the difference is that the positioning surface 6 is adjacent to the first working surface 3 and the second working surface 4, the initial detection surface is a groove, and the positioning surface 6. The engaging structure on the surface is a protrusion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com