Brushless electronic water pump

An electronic water pump and stator assembly technology, applied in the direction of pumps, pump devices, pump components, etc., can solve the problems of poor heat dissipation effect, shortened service life, and small water output of electronic water pumps, so as to avoid rust or lubrication failure, use Long life and low rotational resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below through specific examples.

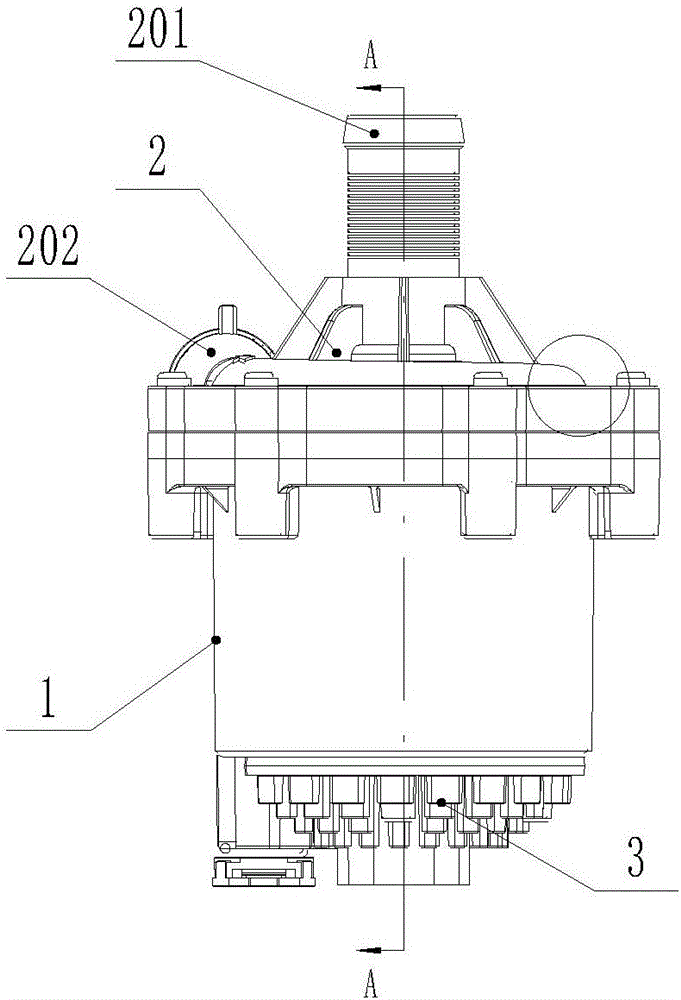

[0040] The up and down orientation in this embodiment is to place the electronic water pump according to figure 2 The placement position is determined.

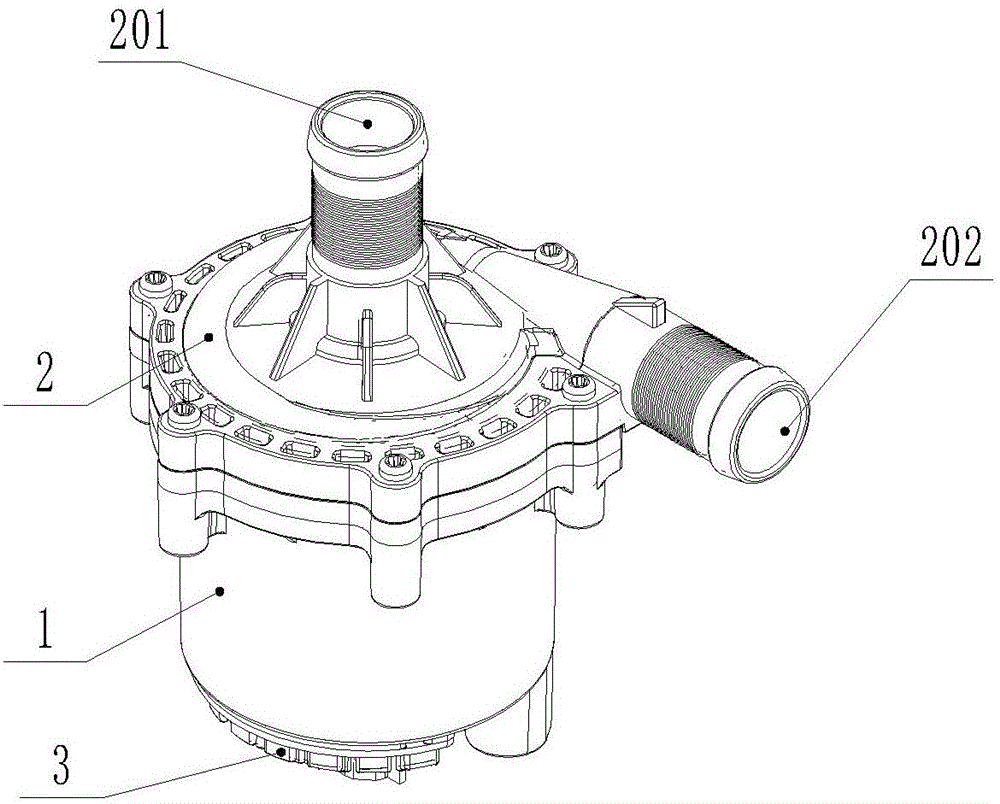

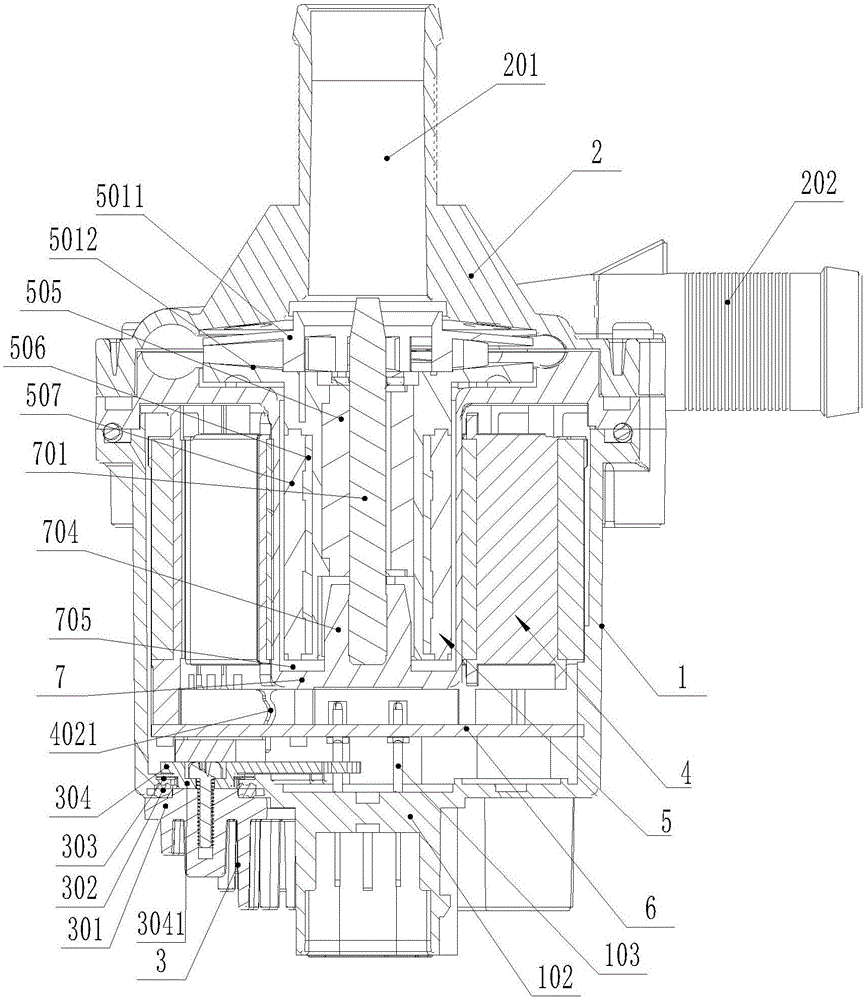

[0041] Such as Figure 1 to Figure 12 As shown, a brushless electronic water pump includes a detachable and fixed outer shell 1, a spacer 7 and an upper cover 2. The outer shell 1 is cylindrical, and the bottom of the outer shell 1 is provided with a through hole for installation. The cooling device 3 is installed, and the bottom of the outer casing 1 is also provided with a waterproof and breathable valve 101, which is used to increase the breathable effect and realize the waterproof effect at the same time. The upper cover 2 is provided with a water inlet 201 and a water outlet 202 , the upper cover 2 and the spacer 7 are sealed by an upper sealing ring 8 , and the spacer 7 and the outer shell 1 are also sealed. Screws ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com