Automatic coil material changing and connecting device and method

A technology of splicing device and coiling material, applied in the field of automatic rewinding splicing device and automatic rewinding and splicing of coil material, it can solve the problem of inability to maintain the tension state and position of the pole piece, the size of the cell and the instability of the winding tension , the influence of product production status, etc., to achieve the effect of improving material receiving efficiency and production efficiency, eliminating wrinkles or cracks, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

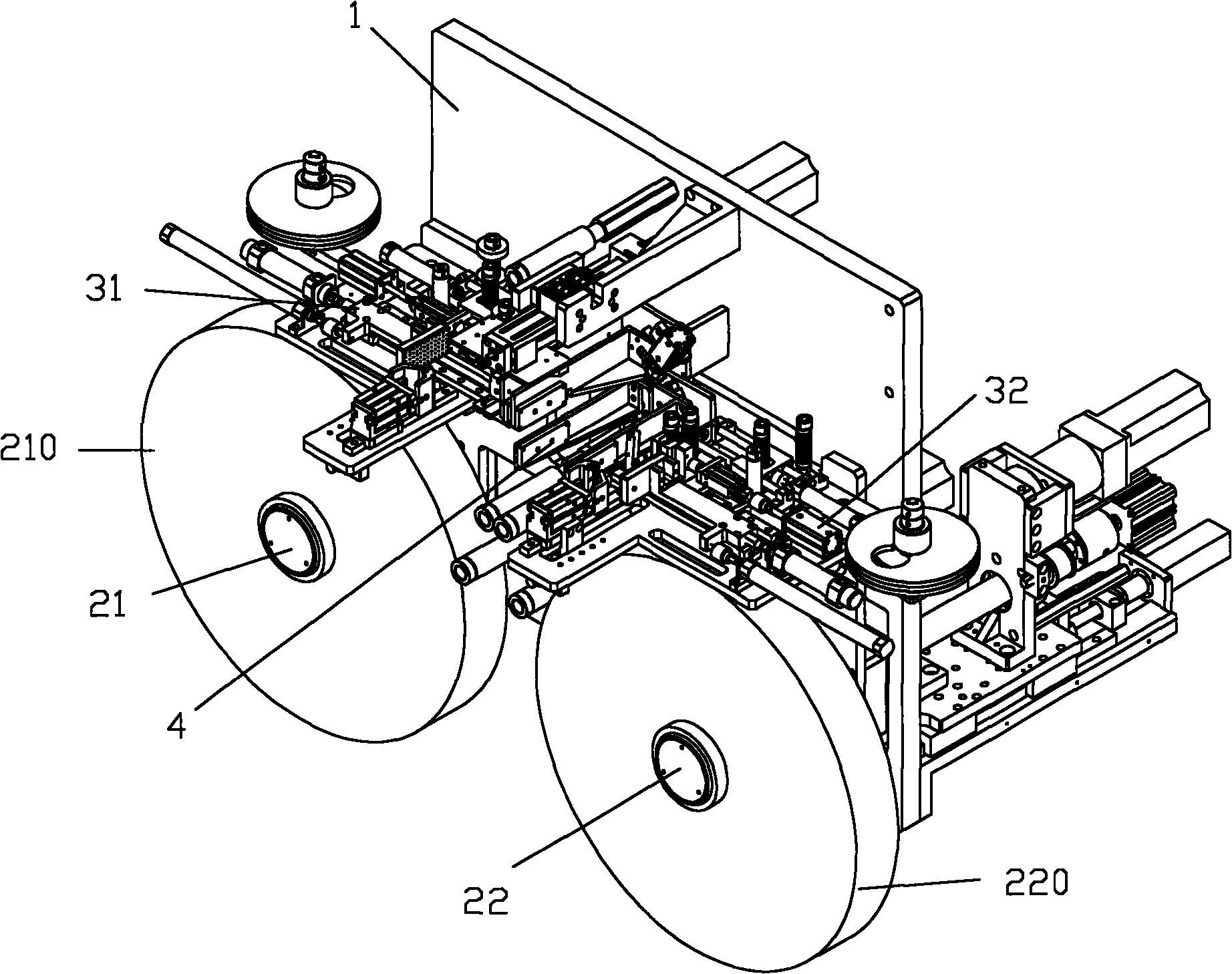

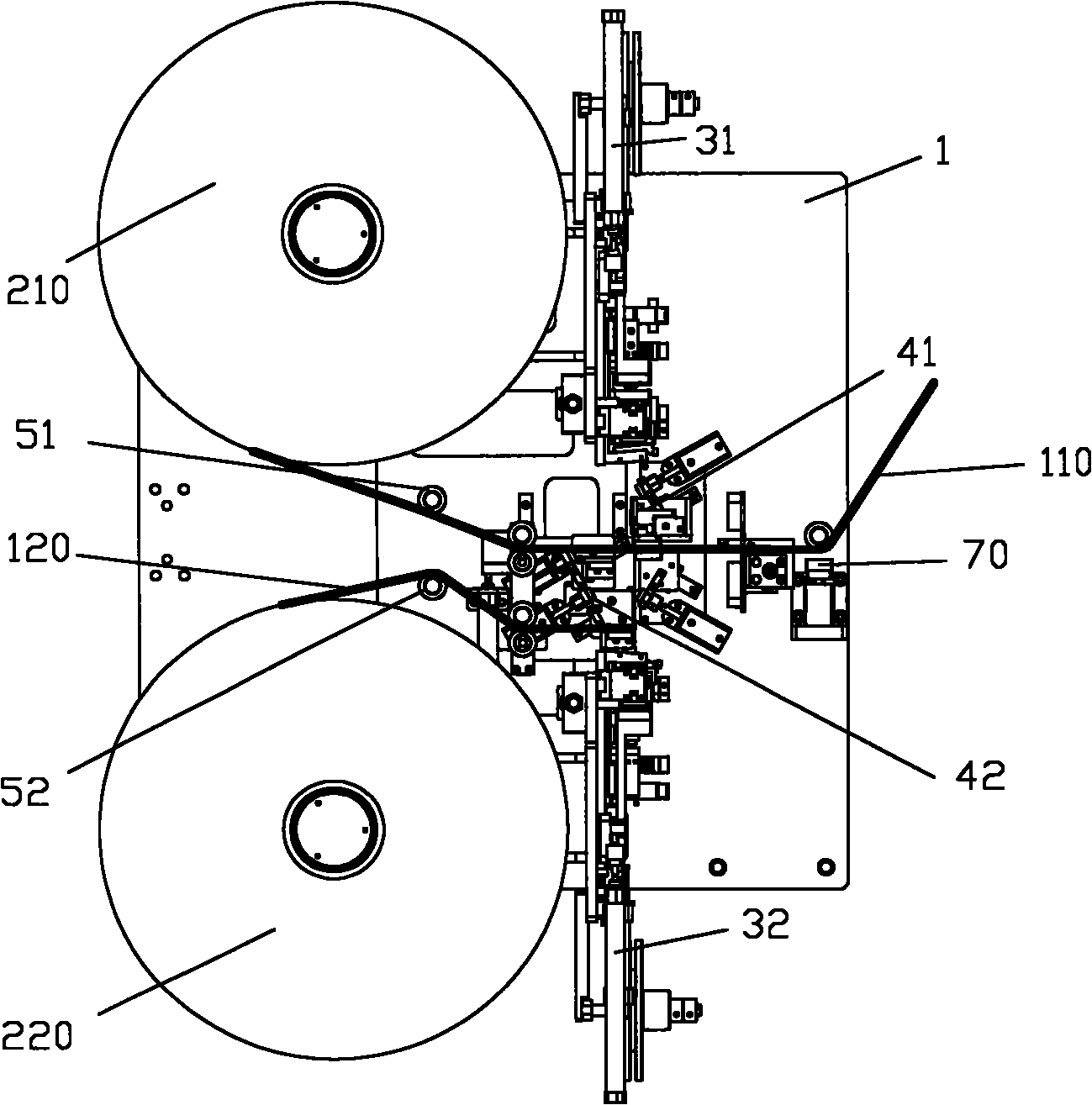

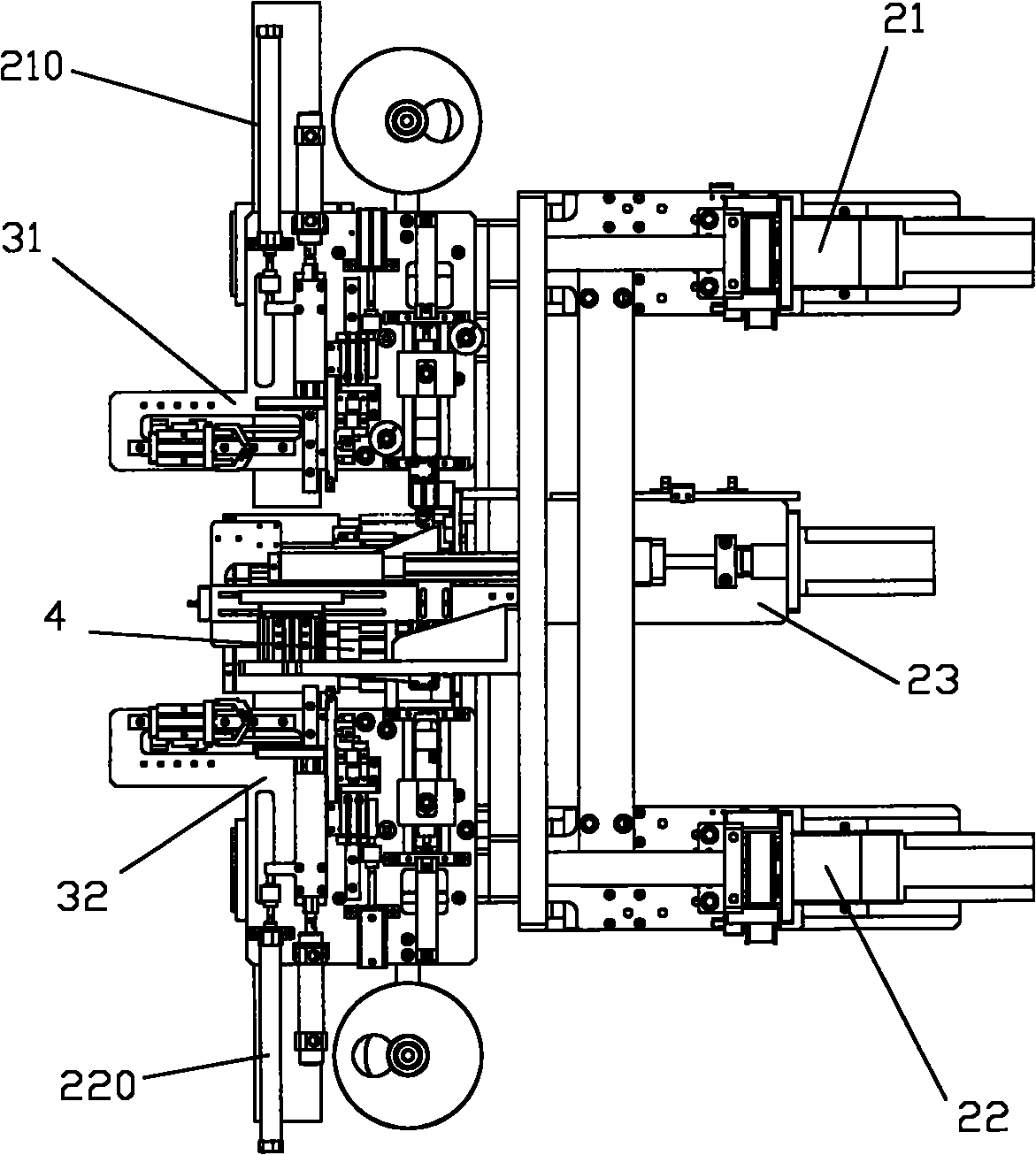

[0038] Please refer to Figure 1 to Figure 3 , the automatic roll changing and receiving device of coil material according to an embodiment of the present invention mainly includes a main feeding mechanism 21, a backup discharging mechanism 22, a docking mechanism 4, a first glue applying mechanism 31, and a second glue applying mechanism 32, As well as the control mechanism (not shown in the figure) that controls the above mechanism, the above mechanism can be installed on the base 1 in cooperation with each other, and the base 1 plays the role of fixing and structural support.

[0039] Wherein, the main unwinding mechanism 21 is used for clamping the first set of coils 210, thereby providing the main coils 110 used in normal product production, and correspondingly, the standby unwinding mechanism 22 is used for clamping the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com