Dust removing and wrinkle integrated winding device for fabric

A winding device and wrinkle-removing technology, which is applied in the direction of winding strips, thin material processing, transportation and packaging, etc., can solve the problems of wrinkle generation, single function, no function of dust removal and wrinkle removal of fabrics, etc. The effect of folds and fabric flattening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

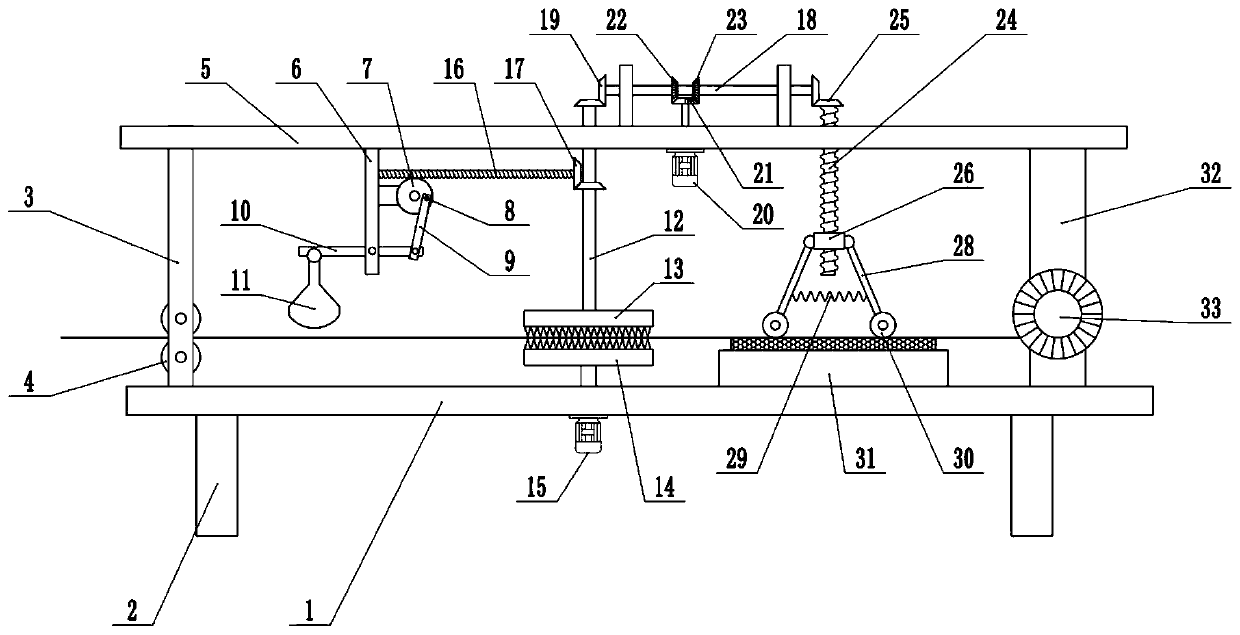

[0022] see figure 1 , 3 , 4. In the embodiment of the present invention, an integrated winding device for dust removal and wrinkle removal of fabrics, including a frame 1, a left support frame 3, a clamping roller 4, a right support plate 32 and a winding motor 33, the frame 1 The lower surface is fixedly connected with support feet 2, the upper surface of the frame 1 is fixedly connected with a left support frame 3, and the left support frame 3 is equipped with a clamping roller 4, and there are two clamping rollers 4, which are arranged symmetrically up and down, and the fabric is from two Pass between the clamping rollers 4, utilize the clamping rollers 4 to clamp the fabric, the top of the left support frame 3 is fixedly connected with a top plate 5, the top plate 5 runs through a rotating shaft 12, and the rotating shaft 12 is connected with the top plate 5 in rotation.

[0023] The left side of rotating shaft 12 is provided with beating mechanism, and beating mechanism ...

Embodiment 2

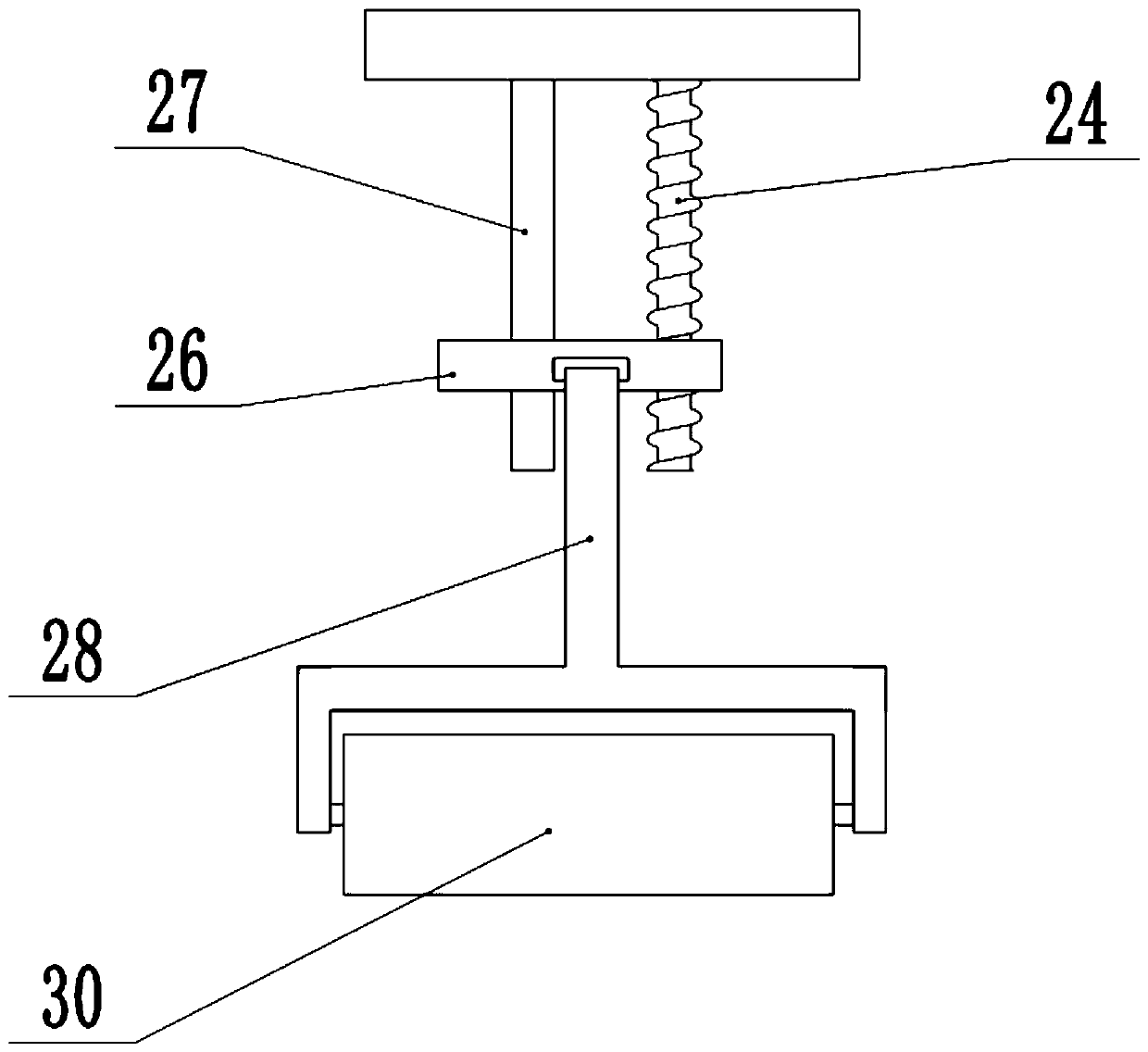

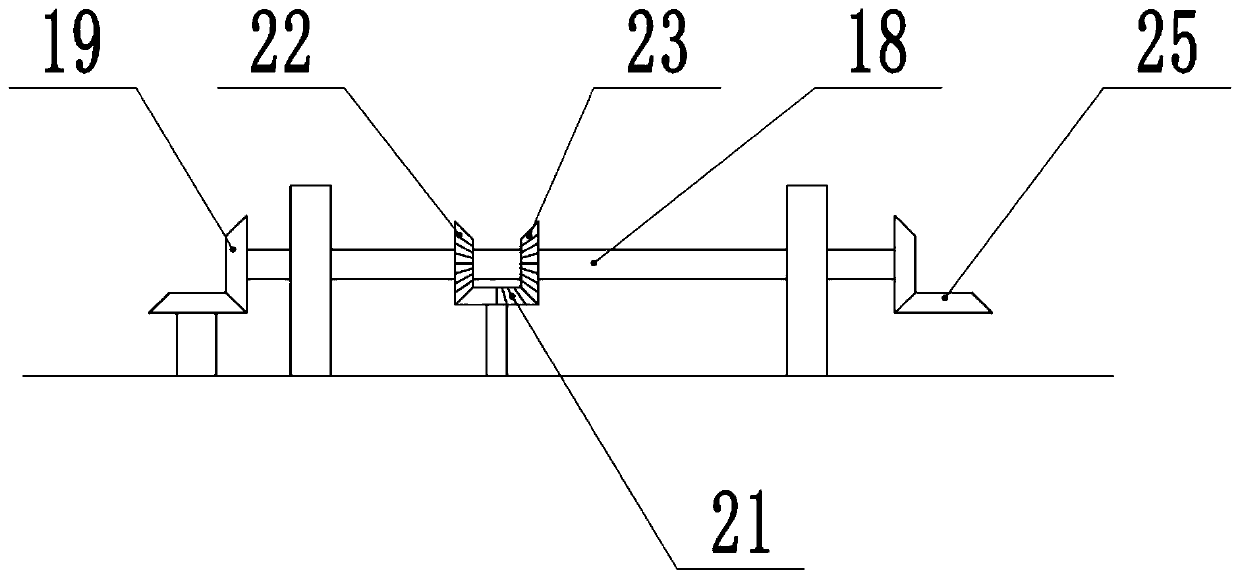

[0026] see figure 1 , 2 , on the basis of Embodiment 1, the right side of the transmission shaft 18 is provided with a screw mandrel 24, the screw mandrel 24 passes through the top plate 5 and extends to the bottom of the top plate 5, the screw mandrel 24 is rotationally connected with the top plate 5, and the upper end of the screw mandrel 24 passes through The third bevel gear set 25 is connected with the right end of the transmission shaft 18, and an ironing mechanism is installed on the screw mandrel 24, and the ironing mechanism includes a lifting plate 26, a guide rod 27, a support 28, an extension spring 29, a pressure roller 30 and an electric heating plate 31. The screw rod 24 runs through the lifting plate 26, the screw rod 24 is threadedly connected with the lifting plate 26, the lifting plate 26 runs through a guide rod 27, the guide rod 27 is slidingly connected with the lifting plate 26, and the top of the guide rod 27 is fixedly connected with the top plate 5 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com