A UV-curable coating adhesive for textile fabrics based on multifunctional polyurethane acrylate and its preparation method and application

A polyurethane acrylate, textile fabric technology, applied in textiles and papermaking, etc., can solve the problems of low water pressure resistance, rough hand feel, high recycling cost, and achieve the effect of improving curing speed, excellent mechanical properties, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

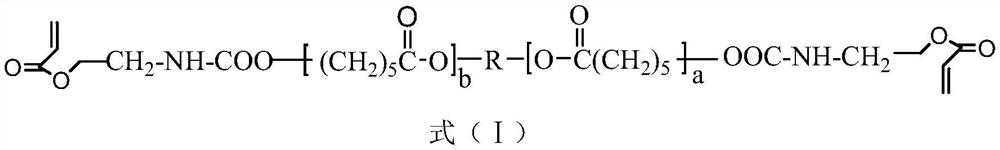

[0029] In a 1000mL four-necked flask, 500 grams of polycaprolactone diol (Perstorp CAPA2100, molecular weight 1000), 141 grams (1mol) of isocyanate ethyl acrylate, 0.1 gram of catalyst dibutyltin dilaurate, and polymerization inhibitor p-hydroxybenzene Take 0.7 g of methyl ether, slowly heat up to 80°C-85°C for 0.5-4 hours, heat-retain, stir and react for 3-5 hours, then discharge the material to obtain a bifunctional polycaprolactone urethane acrylate with the structure shown in formula (I).

[0030]

[0031] R is: That is, the diol starter in polycaprolactone diol is neopentyl glycol; a+b=(1000-104) / 114=7.8596.

Embodiment 2

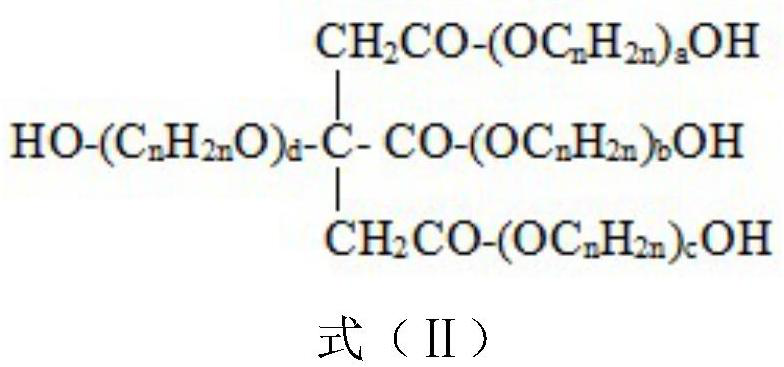

[0033] Drop into 1920 grams of anhydrous citric acid (C 6 h 8 o 7, molecular weight 192), 40 gram sodium formate, be warming up to 155 ℃, begin to drop ethylene oxide (C 2 h 4 O, molecular weight 44) 2200 grams of reaction, temperature control 155 ° C ~ 165 ° C, pressure 0.20 ~ 0.40 MPa, dropwise for 3 ~ 4 hours, after the drop is completed, 155 ° C ~ 165 ° C for 2 ~ 3 hours, and then cooled to 80 ° C The following, the crude product is obtained in discharging; after the crude product was added with 40 grams of activated clay and stirred for 30 minutes, it obtained clear and transparent tetrahydroxycitric acid polyether ester (C 16 h 28 o 12 , molecular weight 412) 4037.6 grams, structure as shown in formula (II).

[0034]

[0035] Wherein: n=2, a+b+c+d=5.

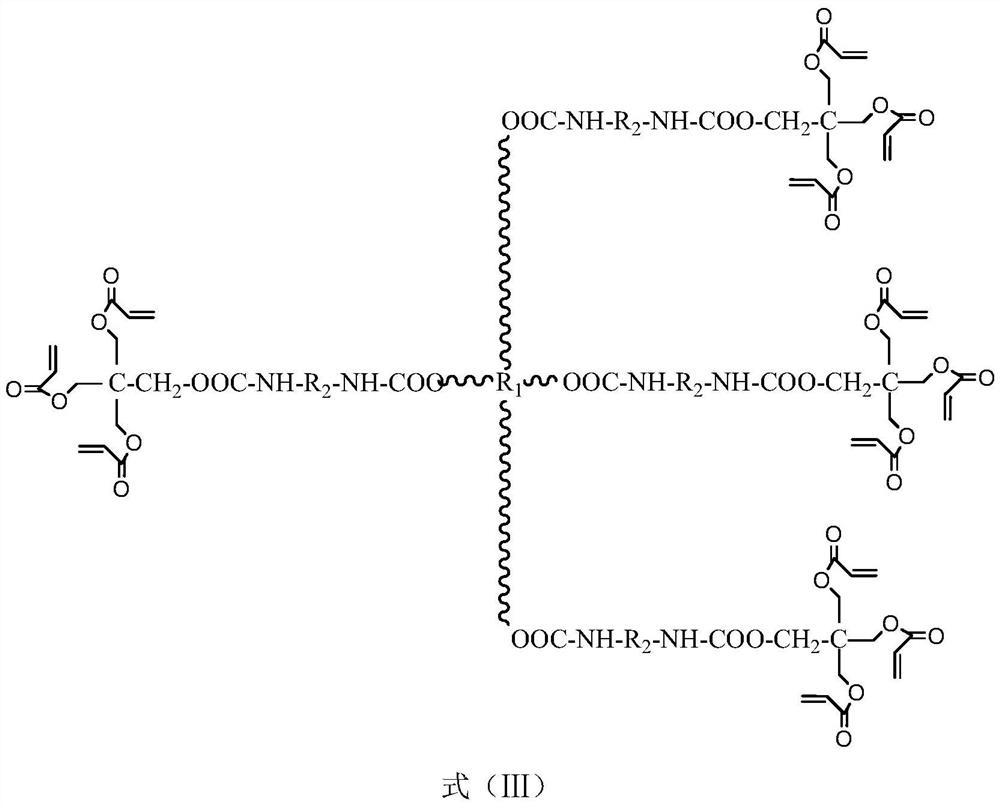

[0036] Put 206 grams of polyether tetrahydroxycitrate, 445 grams (2mol) of IPDI, and 0.2 grams of dibutyltin dilaurate into a 3000 mL four-neck flask, heat up to 60°C to 65°C, stir and keep warm for 2 to 3 hours,...

Embodiment 3

[0044] In the 3000L reactor, drop into 600 kilograms of toluene, 350 kilograms of normal hexane, ethoxylated glycerin (C 9 h 20 o 6 , molecular weight 224) 618 kilograms, 655 kilograms of acrylic acid, 8 kilograms of p-hydroxyanisole, 9 kilograms of sodium hypophosphite, 55 kilograms of methanesulfonic acid; Stirring is started, and compressed air is continuously fed into the kettle through the distributor at the bottom of the kettle, and the temperature is raised to Start reflux dehydration at 85-90°C, esterification reaction for 9-10 hours, kettle temperature 90-105°C, when reflux dehydration until no water comes out, detect acid value 25-30mgKOH / g, after the reaction is over, cool to 40°C; add 25 kg of caustic soda and 60 kg of water, stirred for 30 minutes; 6 kg of magnesium polysilicate was added, stirred and adsorbed for 30 minutes; then the water and solvent were distilled under reduced pressure at 50-95 ° C under a vacuum degree of -0.098 MPa, and the recovered water Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com