Three-station cut loop pile jacquard circular weft knitting machine and knitting method

A three-position, knitting machine technology, applied to weft knitting, circular knitting machines with individual action needles, knitting, etc., to achieve the effects of reducing napping, reducing production costs, and improving production efficiency

Pending Publication Date: 2022-06-10

泉州千镒机械有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003]However, the current cut loop pile fabric is difficult to achieve flexible conversion of various types on the same knitting machine, that is, the flexibility of hairless weaving, low wool weaving, and high wool weaving. Conversion, there are no high-hair cutting and pressing wheels, low-hair cutting and pressing wheels respectively, which cannot make the cutting smoother and more stable, the fabric is smoother, and the situation of pulling can not be reduced. The needle selector is used more, which greatly increases the cutting speed. The production cost and production efficiency of loop pile fabric are low

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

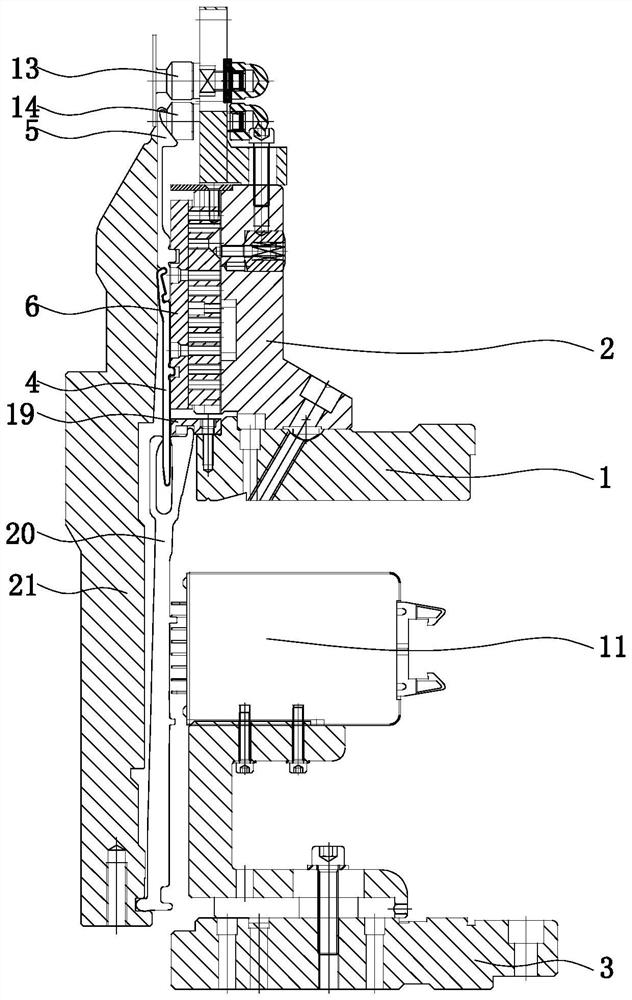

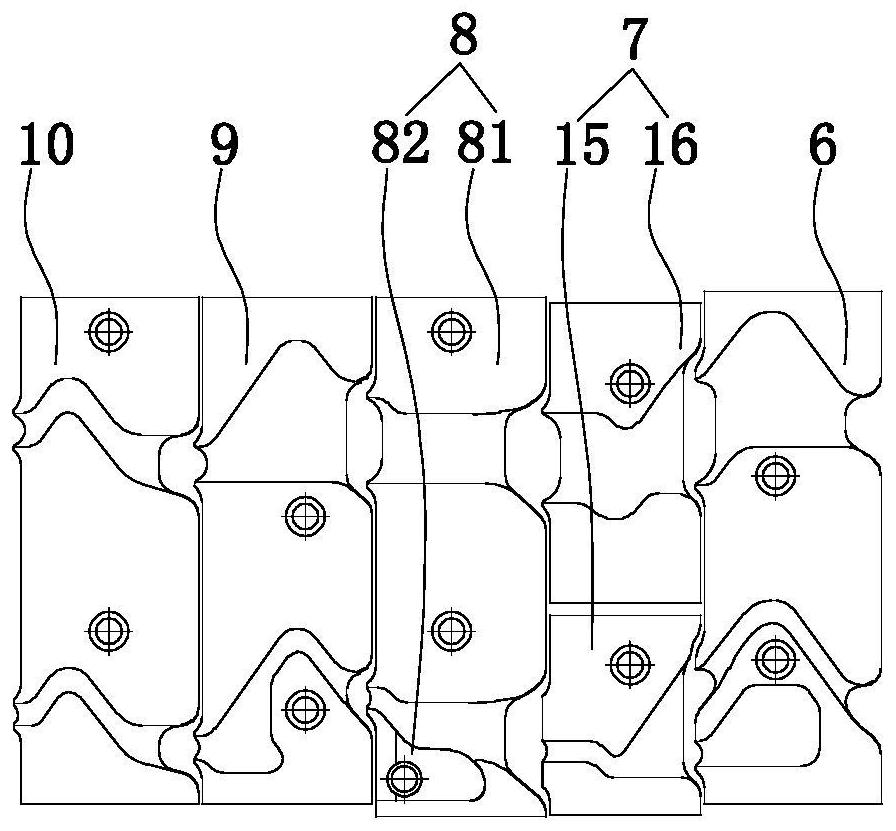

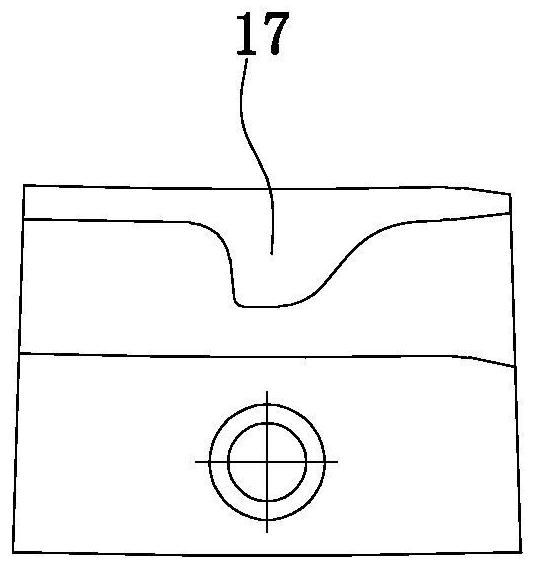

The invention provides a three-station cut loop pile jacquard circular weft knitting machine and a knitting method. The three-station cut loop pile jacquard circular weft knitting machine comprises a triangular base bottom ring, a triangular base arranged on the upper end face of the triangular base bottom ring and a needle selection bottom ring arranged below the triangular base bottom ring. The knitting machine further comprises needle raising triangles which are sequentially arranged on the triangular base in a communicating mode according to an assembly line and used for allowing the knife crochet needle to suck yarn after the connecting needle is connected and allowing the knife crochet needle not to suck yarn when the connecting needle is disengaged, and flexible conversion of various types can be achieved on the same knitting machine, namely flexible conversion of wool-free knitting, low-wool knitting and high-wool knitting can be achieved. The high-wool cutting and pressing wheel and the low-wool cutting and pressing wheel are arranged, so that wool cutting is smoother and more stable, the fabric is smoother, the galling condition is reduced, the number of used needle selectors is small, the production cost of the cut loop-pile fabric is reduced, and the production efficiency is improved.

Description

technical field [0001] The invention relates to the technical field of knitting machines, in particular to a three-position cut loop velvet jacquard circular knitting machine and a weaving method. Background technique [0002] According to the length of the fluff on the surface of the cut loop pile, it can be divided into three types: no hair, low hair and high hair. Weaving different lengths of fluff in different areas on the same piece of fabric can present a variety of patterns, so the cut loop pile fabric It is deeply loved by the public in the market. [0003] However, the current cut loop pile fabrics are difficult to realize flexible conversion of various types on the same knitting machine, that is, the flexible conversion of hairless knitting, low wool knitting, and high wool knitting. The hair cutting and pressing wheel cannot make the cutting more smooth and stable, the fabric is more flat, and it cannot reduce the situation of napping. The needle selector is used...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): D04B9/14D04B15/32D04B15/68D04B15/94

CPCD04B9/14D04B15/32D04B15/68D04B15/94

Inventor 俞祖光何小燕

Owner 泉州千镒机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com