A remote control device for manually operating a hydraulic reversing valve

A technology of remote control device and hydraulic reversing valve, which is applied in the direction of valve operation/release device, valve device, valve details, etc., which can solve the problem that the furnace top valve cannot operate normally, the furnace top cannot be fed and distributed, and the wind can be reduced or even To achieve the effect of highlighting substantive features, restoring normal operation and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

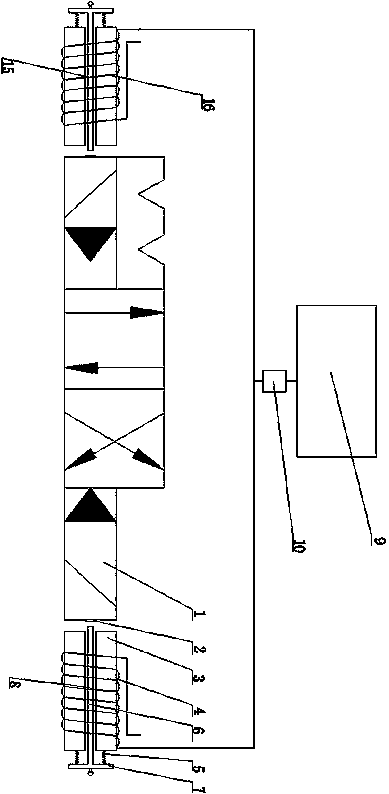

[0016] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

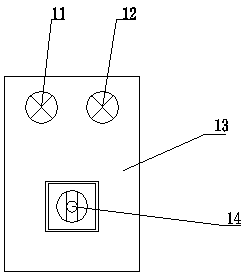

[0017] It can be seen from the accompanying drawings that a remote control device for manually operating a hydraulic reversing valve includes a control box 9 and an opening valve device 15 and a closing valve device 8 fixed at both ends of the hydraulic reversing valve 1. The valve device 15 is exactly the same as the valve device 8 for closing and poking. Both the valve device 15 for opening and the valve device 8 for closing and poking include an iron core 3, and the outer surface of the iron core 3 is wound with electromagnetic coils 4 and electromagnetic coils in an orderly manner. 16. The electromagnetic coil is a DC24V coil, and an AC220V coil can also be selected. The electromagnetic coil 16 of the valve opening device 15 and the electromagnetic coil 4 of the valve closing devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com