Flexible screen rotating structure and flexible screen

A rotating structure and flexible screen technology, which is applied in the direction of shafts and bearings, instruments, identification devices, etc., can solve the problems of wrinkles in the folded part of the flexible screen, flexible screens that cannot be laid flat, and unfavorable storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

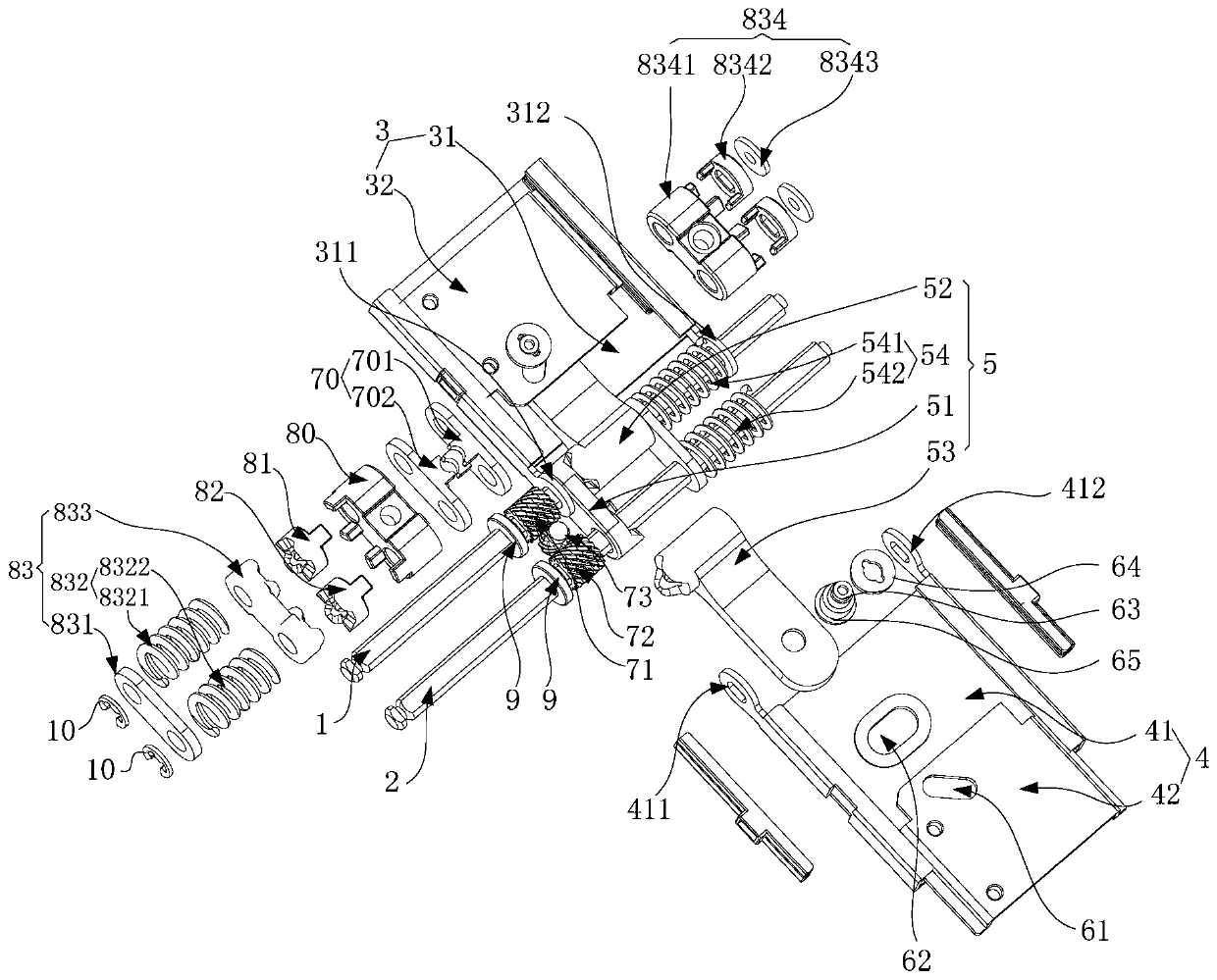

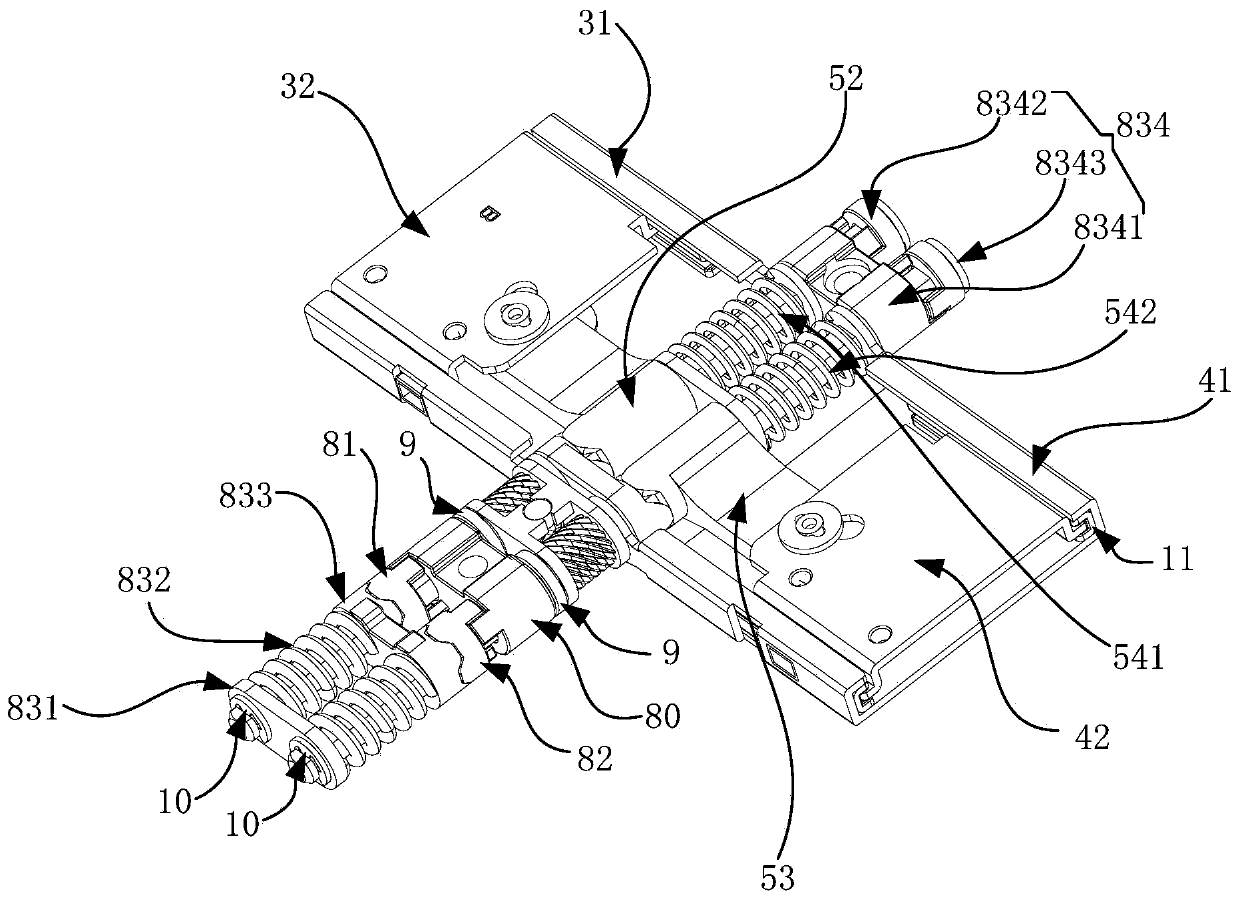

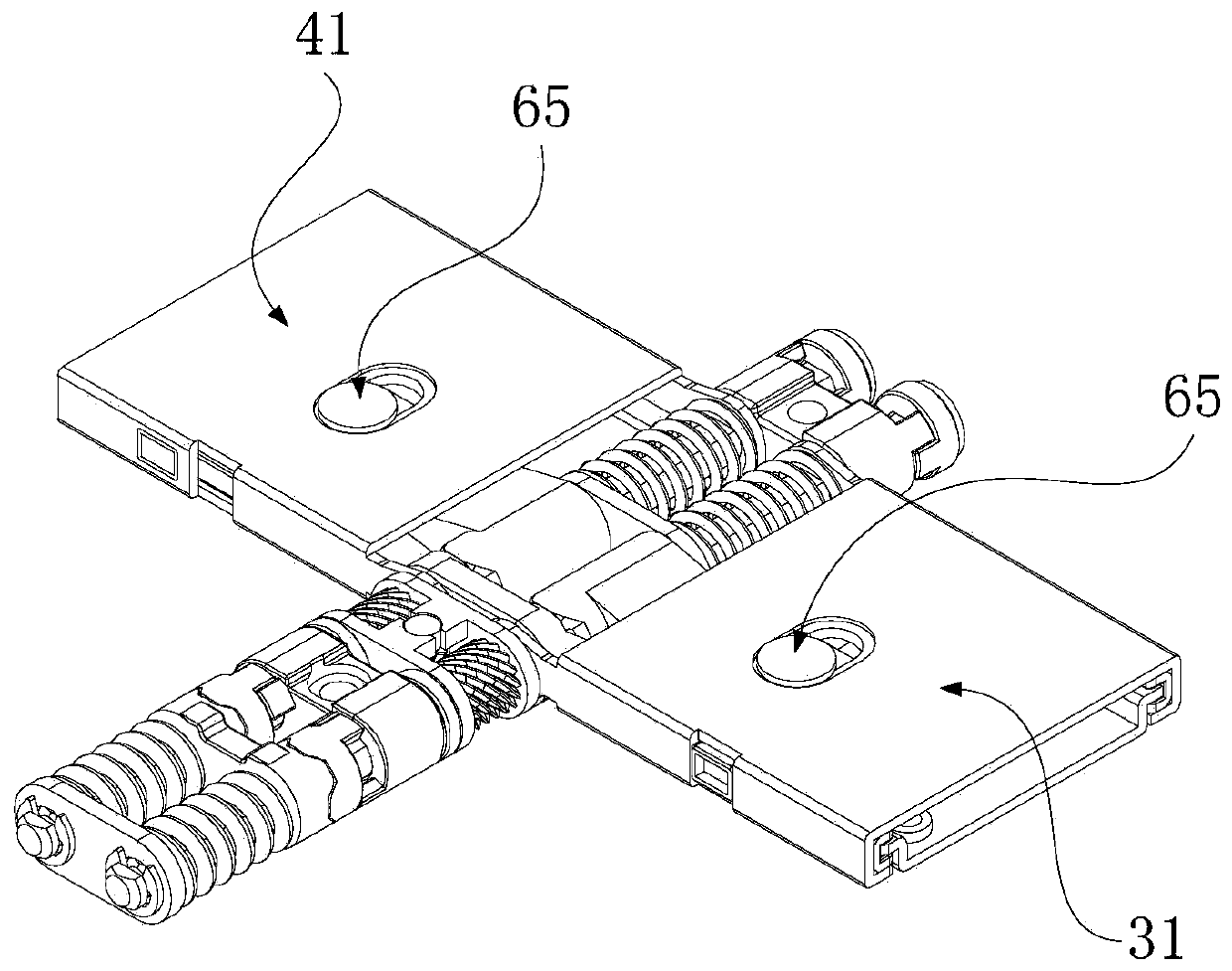

[0066] This embodiment provides a flexible screen rotation structure, refer to figure 1 , combined with Figure 2 to Figure 6 , the flexible screen rotating structure includes a first rotating shaft 1 , a second rotating shaft 2 , a first screen connection assembly 3 , a second screen connection assembly 4 and a rotation linkage assembly 5 . The first rotating shaft 1 and the second rotating shaft 2 are parallel to each other and can rotate relative to each other. The first screen connection assembly 3 includes a first fixing part 31 and a first moving part 32. The first fixing part 31 is connected to the first rotating shaft 1 in a manner of synchronous rotation with the first rotating shaft 1, and the first moving part 32 is slidably connected to the first rotating shaft 1. A fixed part 31; the second screen connection assembly 4 includes a second fixed part 41 and a second moving part 42, the second fixing part 41 is connected to the second rotating shaft 2 in a manner of ...

Embodiment 2

[0086] This embodiment provides a flexible screen, which includes a first casing, a first screen, a second casing, a second screen, and a flexible screen rotation structure.

[0087] Among them: refer to figure 1 , combined with Figure 2 to Figure 6 , the flexible screen rotating structure includes a first rotating shaft 1 , a second rotating shaft 2 , a first screen connection assembly 3 , a second screen connection assembly 4 and a rotation linkage assembly 5 . The first rotating shaft 1 and the second rotating shaft 2 are parallel to each other and can rotate relative to each other. The first screen connection assembly 3 includes a first fixing part 31 and a first moving part 32. The first fixing part 31 is connected to the first rotating shaft 1 in a manner of synchronous rotation with the first rotating shaft 1, and the first moving part 32 is slidably connected to the first rotating shaft 1. A fixed part 31; the second screen connection assembly 4 includes a second fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com