Positioning method of flexible tool in forming process of composite product

A composite material and positioning method technology, which is applied in the field of high-performance carbon fiber composite structural parts manufacturing, can solve the problems of scrapped parts, position deviation of soft tooling, position deviation of thickening area, etc., to ensure surface forming quality, The effect of improving the qualified rate and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

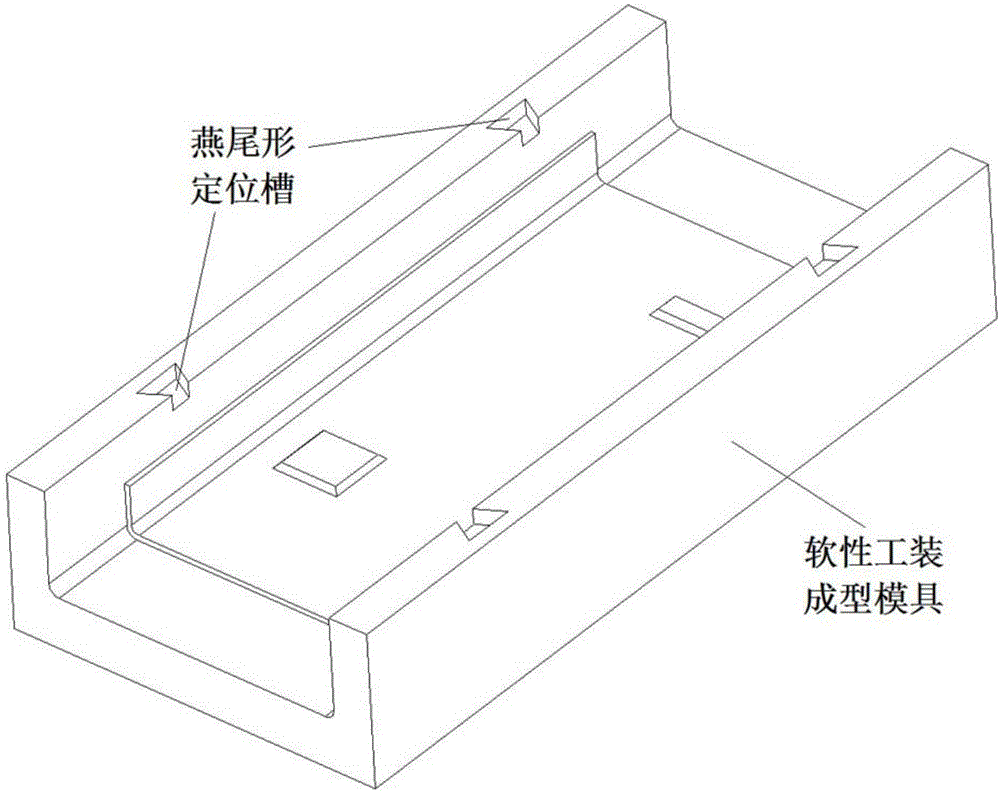

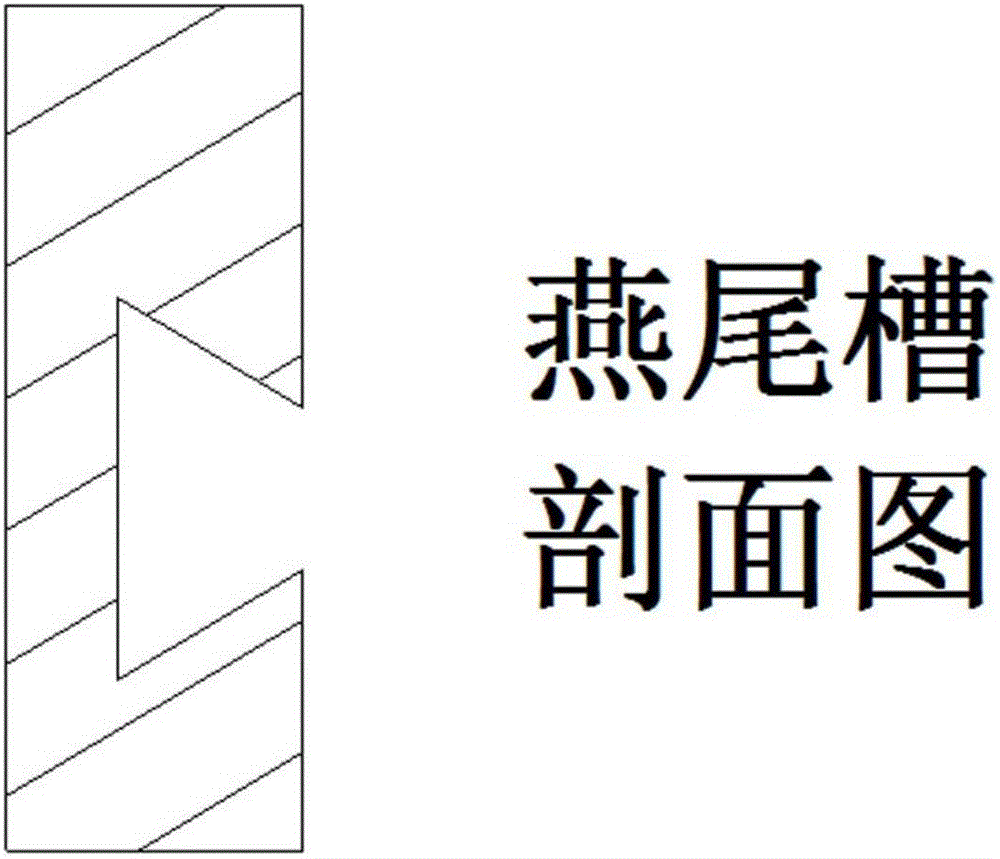

[0026] The present invention molds the soft tooling through a metal mold. The forming mold is provided with dovetail-shaped positioning grooves, and the positioning grooves are symmetrically distributed on both sides of the mould. The quantity and specifications need to be determined in combination with the size and structural complexity of the composite material parts, such as figure 1 and 2 .

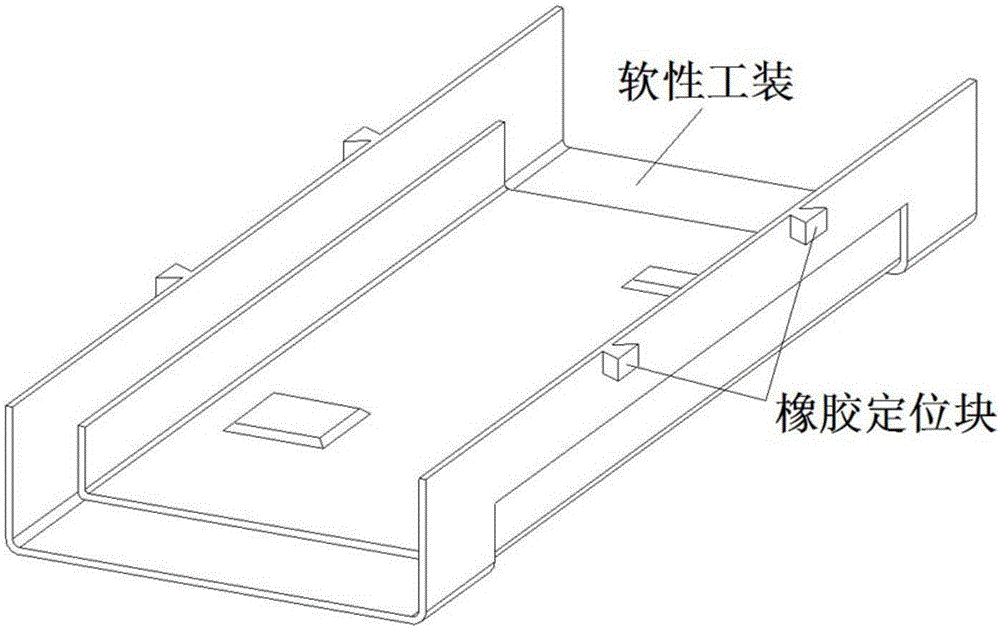

[0027] When laying soft tooling, fill the dovetail groove with rubber and connect it with the soft tooling, so that after the soft tooling is solidified, a certain number of dovetail-shaped rubber positioning blocks will be attached to the edge, such as image 3 .

[0028] There are also several dovetail-shaped positioning grooves on the molding die of composite material parts, and the size specifications and positions are consistent with the soft to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com