Multipoint positioning auxiliary device

An auxiliary device, multi-point positioning technology, applied in manufacturing tools, workshop equipment, etc., can solve the problems of inconvenient operation, difficult to carry tools, large size, etc., to improve positioning accuracy, facilitate storage and portability, and expand the scope of application. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

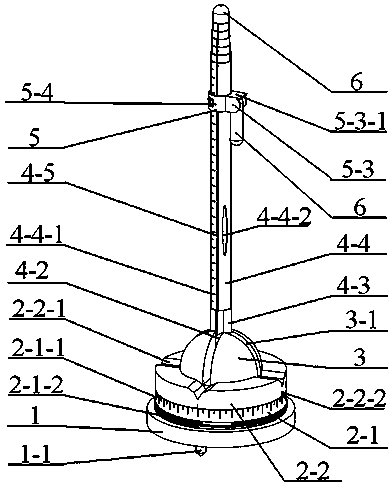

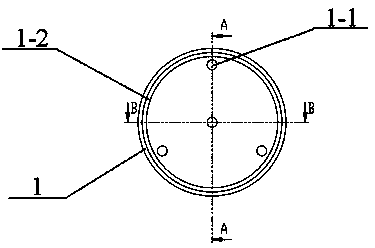

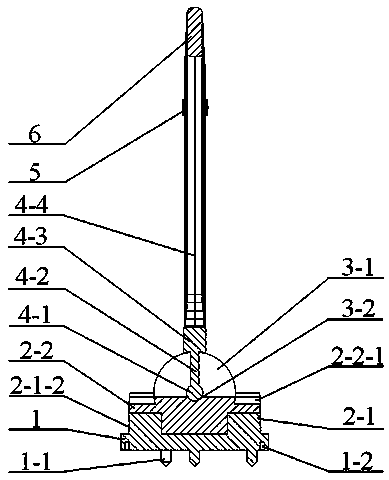

[0032] The structure diagram of the present invention is as figure 1 As shown, it includes a cylindrical base 1, a cylindrical indexing and positioning mechanism 2, a hemispherical positioning seat 3, a cylindrical scale rod 4, a positioning vernier 5, and a marking device 6.

[0033] The indexing and positioning mechanism 2 is arranged on the base 1, and the indexing and positioning mechanism 2 includes an indexing plate 2-1 and a counter-fixing plate 2-2, and the indexing plate 2-1 and the counter-fixing plate 2-2 are relatively rotatable; The circumferential scale scale 2-1-1 is set on the upper edge of the circumferential surface of the indexing plate 2-1, and the thread 2-1-2 is set on the lower edge of the circumferential surface of the indexing plate 2-1; the positioning is set on the fixed plate 2-2 The number of wing slots 2-2-1 and positioning wing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com