Semi-automatic machining equipment of steel materials

A kind of processing equipment and semi-automatic technology, which is applied in the field of mechanical processing equipment, can solve the problems of complexity, danger, and roughness of the end of the steel surface, and achieve the effects of high precision, improved precision, and saving manpower and resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

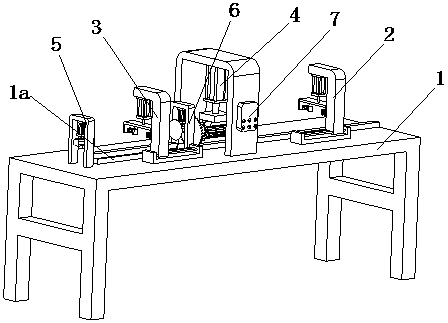

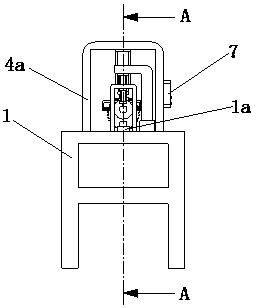

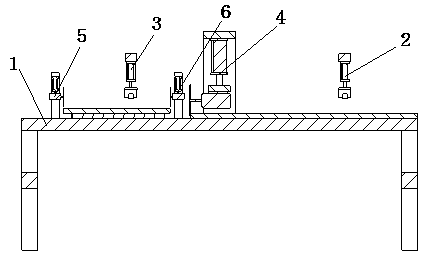

[0020] refer to Figure 1 to Figure 6 The shown semi-automatic steel processing equipment includes a base 1, a first grabbing assembly 2, a second grabbing assembly 3, a cutting assembly 4, a first grinding assembly 5 and a second grinding assembly 6, and the cutting assembly 4 is set In the middle part of the base 1, the first grabbing assembly 2 and the second grabbing assembly 3 are fixedly installed on the base 1 and located on the left and right sides of the cutting assembly 4. The first grabbing assembly 2 includes a first motorized Screw slide table 2a, inverted L-shaped first support frame 2b, first cylinder 2c, inverted U-shaped first clamping plate 2d, first clamping cylinder 2e and second clamping cylinder 2f, first electric wire The rod slide 2a is fixedly connected with the base 1, the first support fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com