Patents

Literature

121results about How to "Reduce void rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

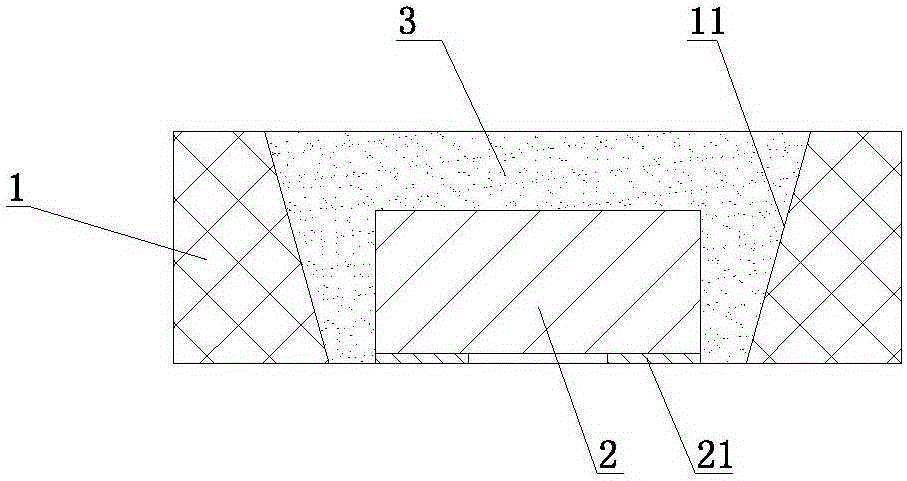

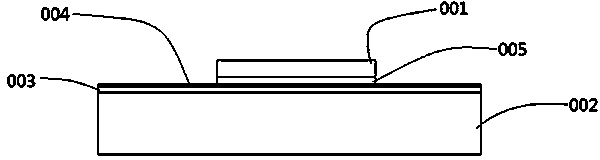

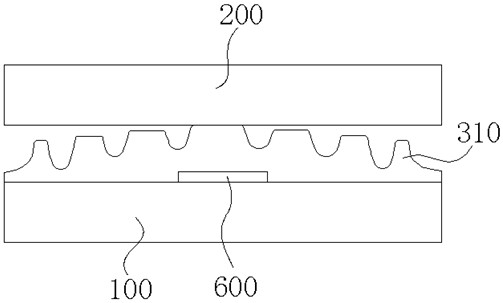

LED packaging structure and manufacturing method thereof

ActiveCN105006512AThe process steps are simpleReduce manufacturing costSemiconductor devicesAdhesiveElectrical connection

The invention discloses an LED packaging structure and a manufacturing method thereof. The manufacturing method comprises the steps of providing a carrier on which concave cavities are formed, laying an isolation film on the carrier, fixing flip chips in the concave cavities, and carrying out glue injection, curing, cutting and separation. The LED packaging structure comprises a flip chip which is provided with electrodes at the bottom, the sides and top of the flip chip are coated with packaging adhesive, and the lower surface of the packaging adhesive is higher than the lower surfaces of the electrodes. By adopting the manufacturing method, an LED packaging structure with a step between each electrode and the packaging adhesive can be manufactured. The void ratio of connection between the LED packaging structure and a substrate is reduced, the reliability of LED packaging structure fixing is improved, and the reliability of electrical connection between the LED packaging structure and the substrate is improved.

Owner:HONGLI ZHIHUI GRP CO LTD

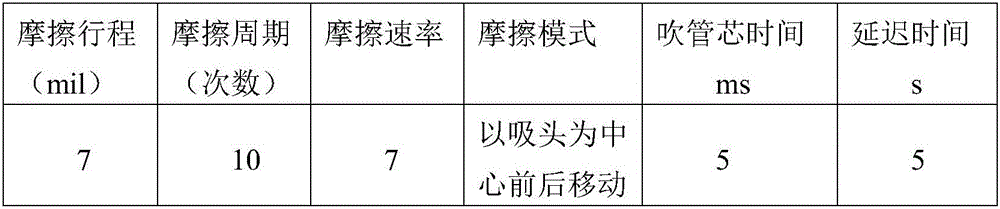

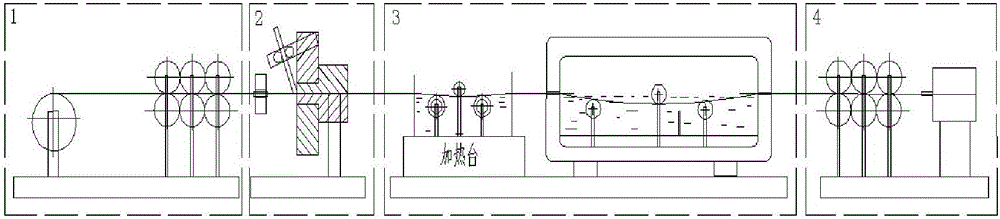

Semi-automatic eutectic soldering method of GaAs microwave power amplifier chip and product

ActiveCN105965120ASolve surface oxidationImprove solderabilitySolid-state devicesSoldering apparatusTin platingSoldering

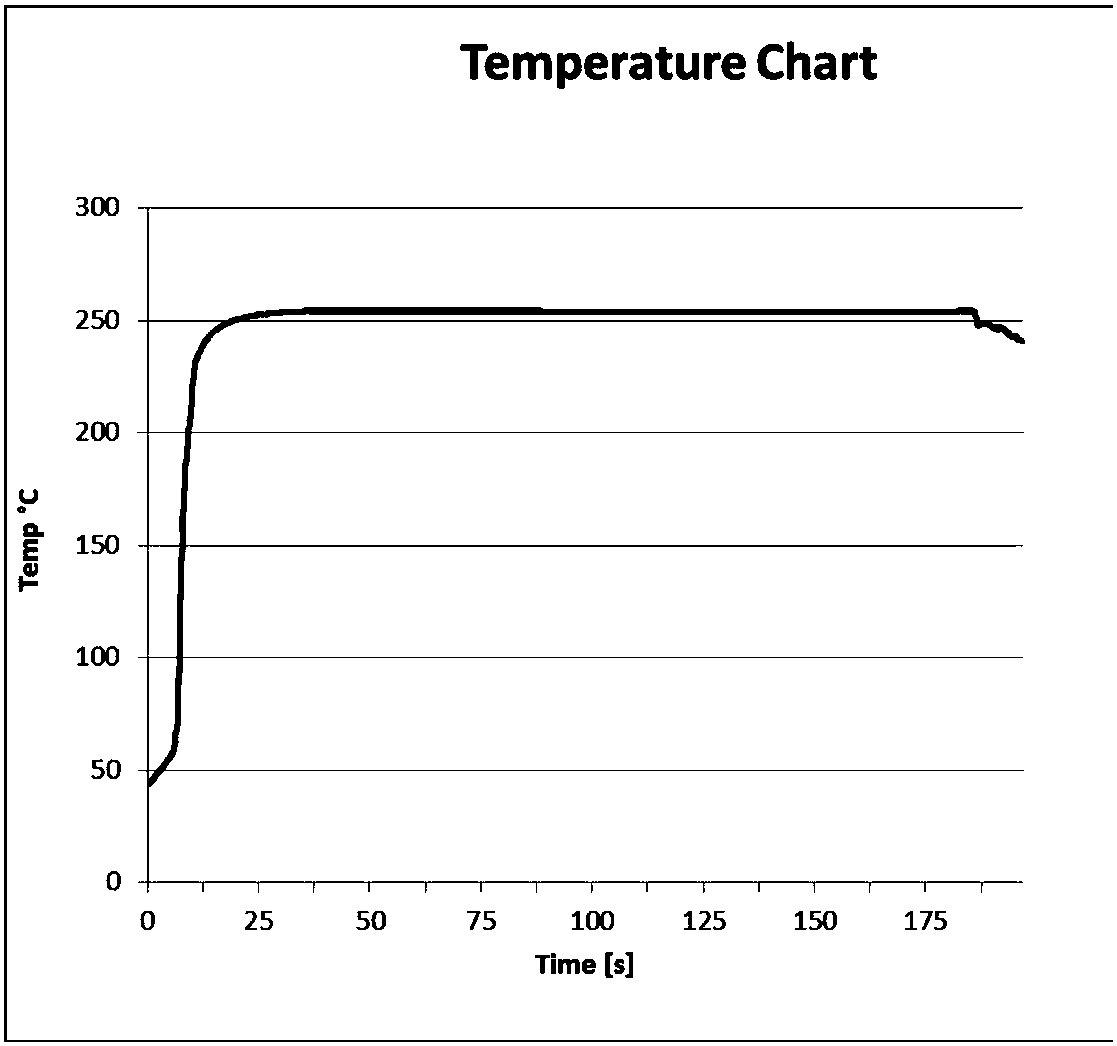

The invention discloses a semi-automatic eutectic soldering method of a GaAs microwave power amplifier chip. The method comprises the following steps: (1) a carrier, a solder and a bare chip are cleaned; (2) the power amplifier bare chip is plated with tin; (3) the carrier is plated with tin; and (4) the eutectic soldering is performed, that is, the tin-plated bare chip is preheated; an eutectic heating soldering table provided with the tin-plated carrier is heated; meanwhile, nitrogen is opened for protection; the bare chip is absorbed; an auxiliary heating table is stopped heating; when the eutectic heating soldering table is heated above a certain temperature, the bare chip is eutectically rubbed on the carrier after accurate alignment; and the carrier is cleaned after natural cooling in air. The invention further discloses the GaAs microwave power amplifier chip prepared by the method. The method can prepare the chip with lower voidage, less pseudo soldering and excellent performances through controlling such process details as cleaning, preheating and tin plating in specific process and optimizing process parameters therein, and largely increases the welding success rate.

Owner:HUBEI SANJIANG SPACE XIANFENG ELECTRONICS&INFORMATION CO LTD

Process for preparing low thermal resistance ceramic copper-clad plate used for IGBT (Insulated Gate Bipolar Transistor) module

ActiveCN101814439AImprove thermal efficiencyReduce thermal resistanceSemiconductor/solid-state device manufacturingVoid ratioMicrometer

The invention specifically relates to a process for preparing a low thermal resistance ceramic copper-clad plate used for an IGBT (Insulated Gate Bipolar Transistor) module. The process is characterized by comprising the following steps of: firstly, cleaning and activating a ceramic substrate, and depositing a layer of copper film of 1-2 micrometers on the surface of the ceramic substrate by using a PVD (Physical Vapor Deposition) process; secondly, cleaning and activating copper foil, and depositing cuprous oxide with a thickness of 0.1 micrometer and copper with a thickness of 0.1 micrometer on the surface of the copper foil by using a CVD (Chemical Vapor Deposition)process, wherein the thickness of the deposited cuprous oxide and copper is 0.5-10 micrometers; thirdly, prepressing and molding the copper foil, and placing the copper foil formed in an arc along the width direction and the ceramic substrate in a bonding furnace for high-temperature bonding at 1060-1076 DEG C; and finally, cooling the bonded copper-clad plate. Compared with a circuit board in the prior art, the copper-clad plate prepared by the process has the advantages of ultra thinness, high strength, low void ratio, high heat conduction efficiency and low thermal resistance.

Owner:淄博市临淄银河高技术开发有限公司

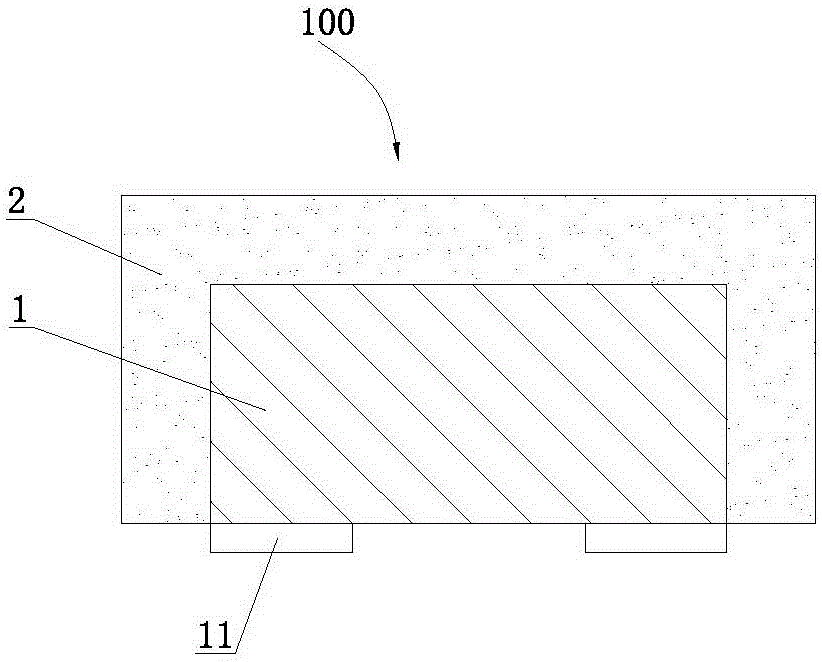

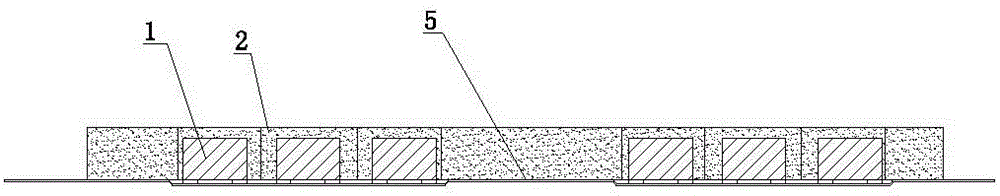

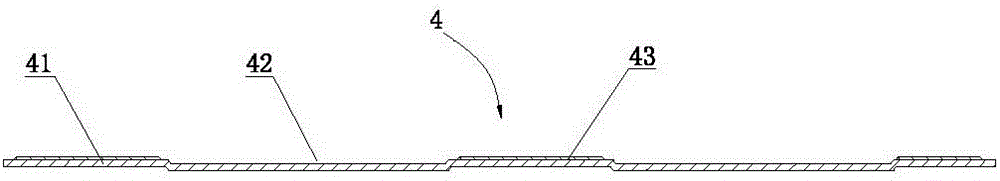

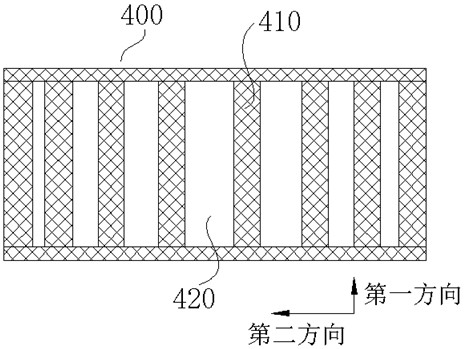

Injection molding based CSP packaging structure and manufacturing process

ActiveCN105161598AEasy to shapeGood thickness consistencySemiconductor devicesFluorescenceEngineering

The invention discloses an injection molding based CSP packaging structure and a manufacturing process. The packaging structure comprises an injection molding body formed through injection molding, the injection molding body is provided with through holes, the through holes are internally provided with LED chips, the LED chips are provided with electrodes, and the lower surfaces of the electrodes are in flush with the lower surface of the injection molding body or project out of the lower surface of the injection molding body; and the through holes are filled up with fluorescent glue covering the side surfaces and the top surfaces of the LED chips. The manufacturing method is as follows: injection-molding an injection molding, arranging a fixation membrane on a support plate, arranging the injection molding on the fixation membrane, fixing the LED chips, filling the through holes with the fluorescent glue, cutting, and separating the support plate from an isolation membrane. According to the invention, the technical problems of difficult control of the shape and the application amount of the fluorescent glue, difficult control of thickness uniformity of the fluorescent glue at each position, and difficulty in ensuring the quality of a chip scale package LED are solved.

Owner:HONGLI ZHIHUI GRP CO LTD

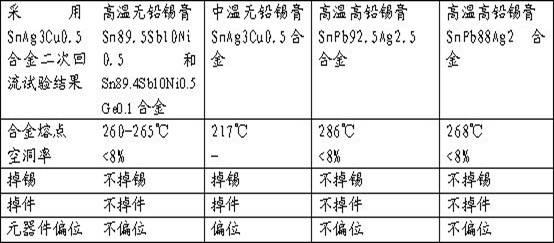

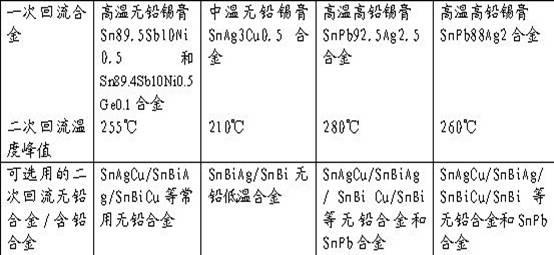

High-temperature lead-free halogen-free solder paste and preparation method thereof

InactiveCN102513739AChemically stableImprove antioxidant capacityWelding/cutting media/materialsSoldering mediaDevice materialAlloy

The invention provides a high-temperature lead-free halogen-free solder paste and a preparation method thereof. The high-temperature lead-free halogen-free solder paste is prepared from the components in percentage by weight: 80-91 percent of solder powder and 20-90 percent of flux paste, wherein the solder powder is tin-nickel-antimony or tin-nickel-antimony alloy powder. The high-temperature lead-free halogen-free solder paste has the beneficial effects that 1, the solder paste provided by the invention does not contain lead and is environmentally friendly, and the solder paste replaces a high-lead solder paste to be used for packaging semiconductor devices, particularly power devices and LED (Light Emitting Diode) in high temperature operation, packaging high-density integrated circuits and welding circuit boards needing secondary backflow; 2, the solder paste provided by the invention has stable chemical property and strong antioxidant capacity and is easily stored; 3, after the high-temperature lead-free halogen-free solder paste provided by the invention is adopted for welding, no solder ball exists, residues are less, the welding position is transparent, the surface impedance is high, and the safety performance of a product working in a high temperature and humid environment is effectively increased; the wetting property of gold-plated, silver-plated and nickel-plated devices is good, and the welding strength is large; 4, a precision device adopts the high-temperature lead-free halogen-free solder paste provided by the invention, a needle tube glue-dispensing process has uniform and smooth flow, and the void content after welding is lower than 8%.

Owner:深圳市晨日科技股份有限公司

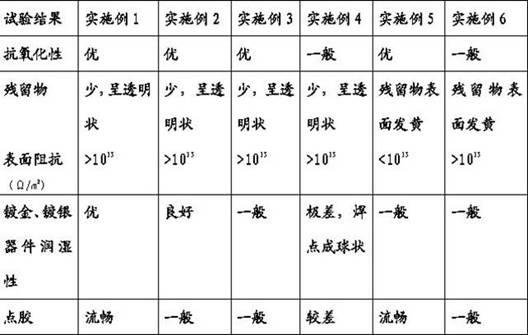

A high brazing rate vacuum welding method based on plasma cleaning

ActiveCN106134330BFast heat conductionEfficient removalWelding/cutting media/materialsSoldering mediaRoom temperatureSoldering

A high brazing rate vacuum welding method based on plasma cleaning, the steps are as follows: (1) plasma cleaning the solder sheet; The shape of the parts is the same, and the middle is hollowed out to form a gasket shape; (3) The welded workpiece, the solder piece, and the carrier are superimposed together in sequence, and a certain weight of tooling is added to exert pressure on the welded workpiece; (4) The superimposed good The workpiece is placed on the heating platform at room temperature, and the heating platform is placed in the vacuum furnace cavity, and the vacuum is started until the vacuum degree is less than 100Pa. At this time, the temperature of the solder piece is at room temperature; (5) The heating platform preheats the workpiece, and keep warm; (6) continue heating until the melting point of the solder sheet is 30-40°C above, and keep warm; (7) backfill the vacuum furnace cavity with the atmosphere, so that the air pressure in the cavity where the workpiece is located returns to atmospheric pressure; (8) cool down until the solder Below the melting point of the sheet, the welding is completed.

Owner:BEIJING SATELLITE MFG FACTORY

Manufacturing method of metal-ceramic composite substrate and composite substrate manufactured through manufacturing method

ActiveCN107546132ASmall electrical impedancePromote wettingSemiconductor/solid-state device detailsSolid-state devicesComposite substrateCopper foil

The invention discloses a manufacturing method of a metal-ceramic composite substrate and the composite substrate manufactured through the manufacturing method and belongs to the technical field of ceramic metallization. The manufacturing method comprises the following steps of forming a first brazing material layer on the surface of a ceramic substrate, wherein the first brazing material layer isa copper, silver and active metal brazing material layer; forming a second brazing material layer on the surface of the first brazing material layer, wherein the second brazing material layer is a copper and silver brazing material layer; forming a copper layer on the surface of the second brazing material layer; and sintering a metal-ceramic composite substrate precursor in vacuum. According tothe manufacturing method, an active metal in the first brazing material layer reacts with ceramic during vacuum sintering, so that the binding force is high and the thermal shock resistance is high. Copper and silver in the second brazing material layer are subjected to eutectic reaction with copper foil, so that the copper and the silver are tightly combined with the copper foil; and meanwhile, by adopting two brazing material layers, on one hand, the content of the silver is reduced and the cost is lower, and on the other hand, the content of the active metal is reduced, electrical impedanceis reduced and the metal-ceramic composite substrate is higher in high voltage resistance and high current resistance.

Owner:ZHEJIANG TC CERAMIC ELECTRONICS

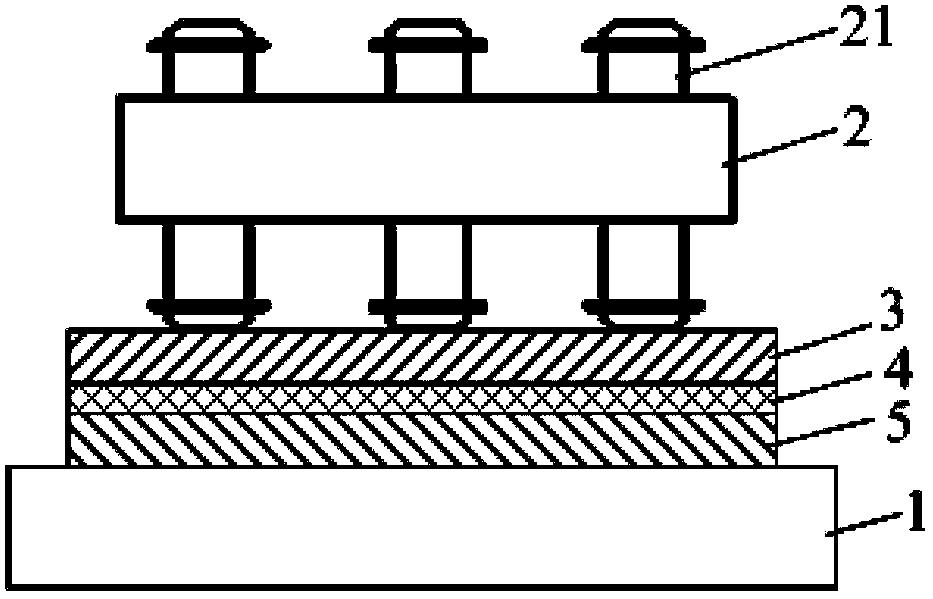

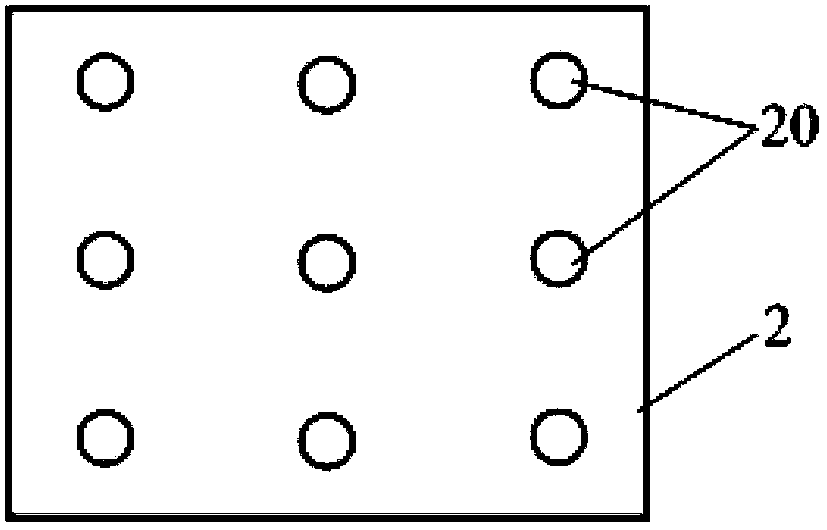

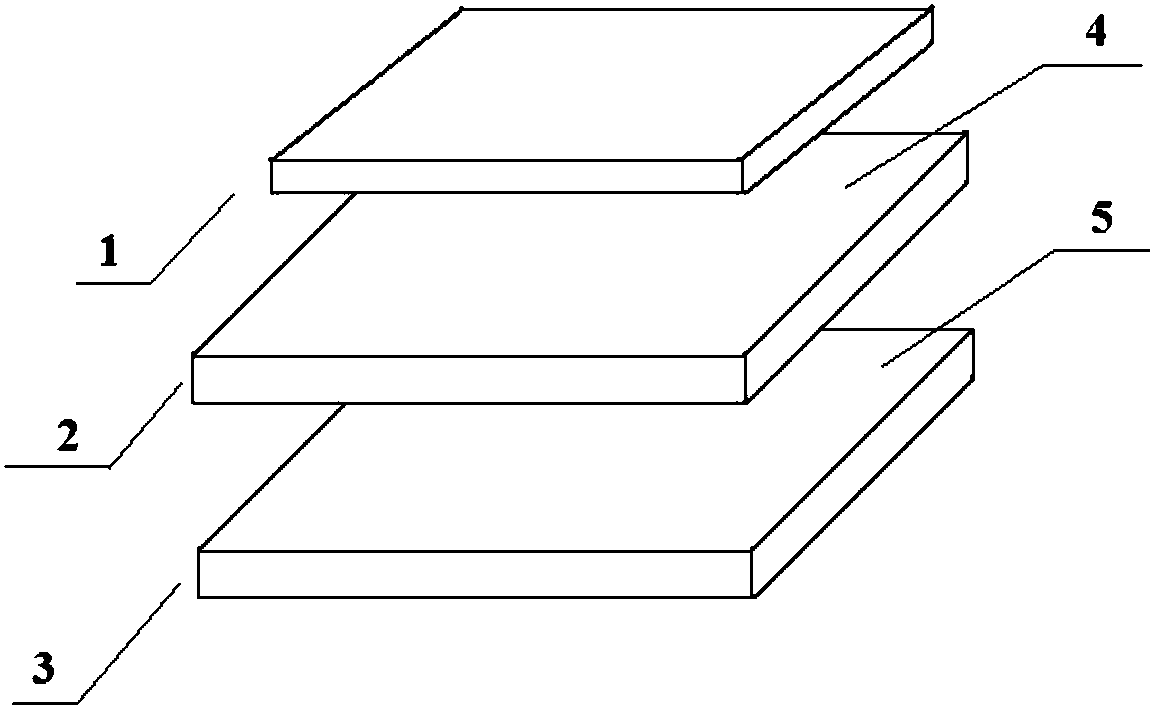

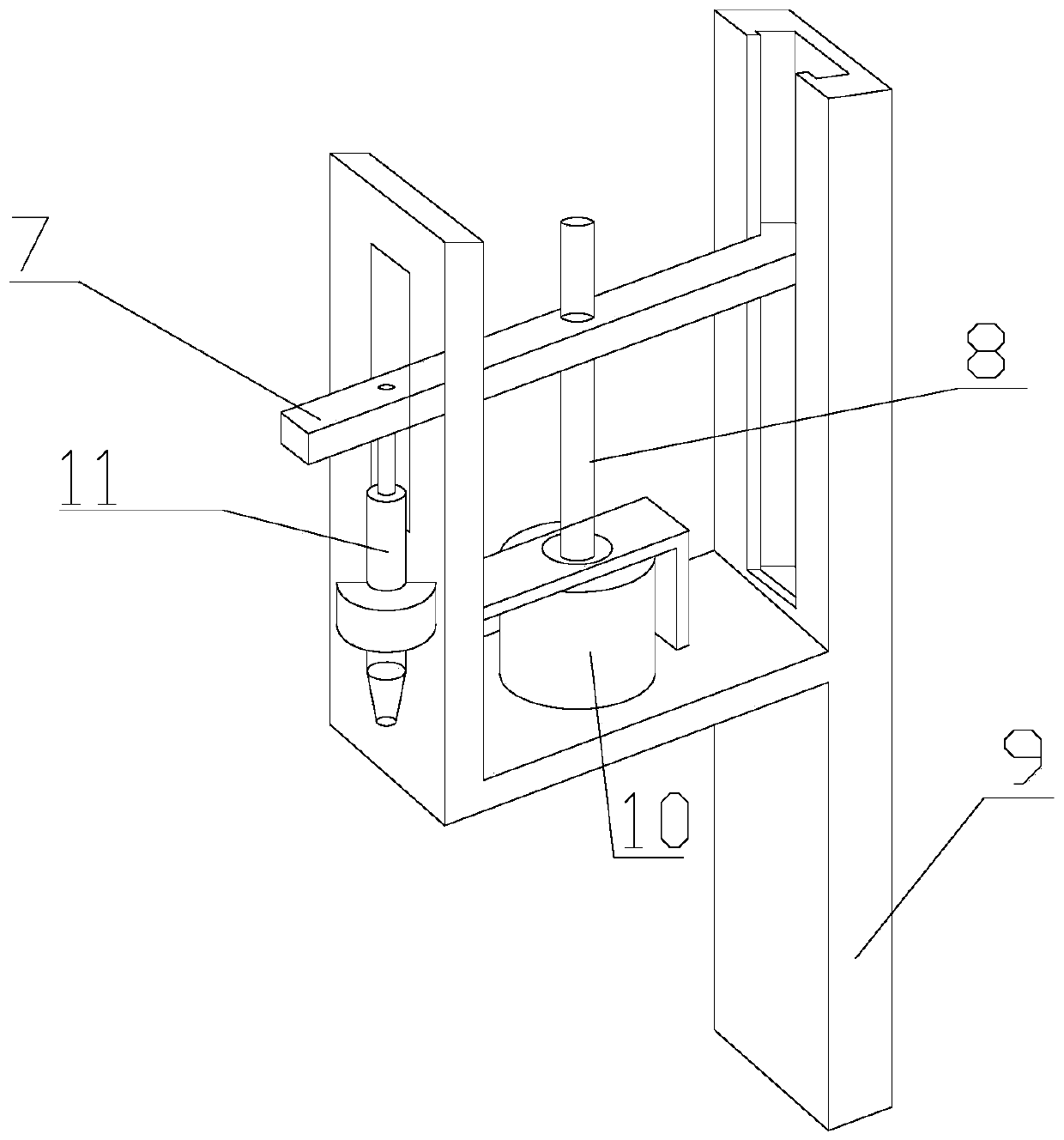

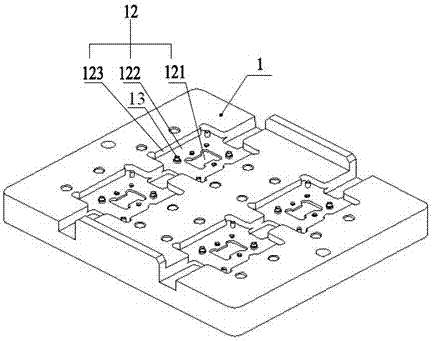

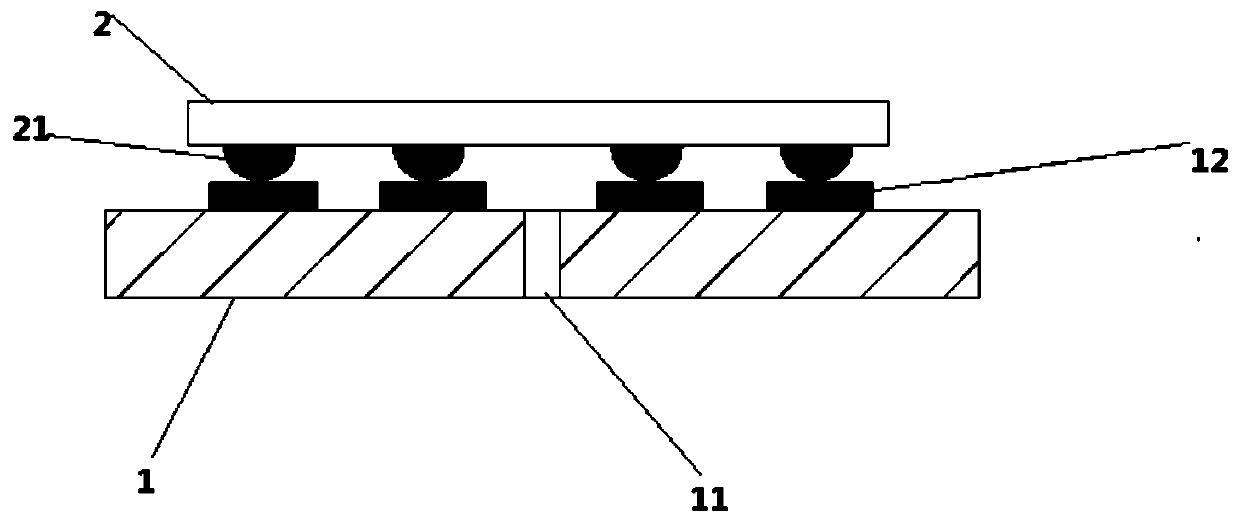

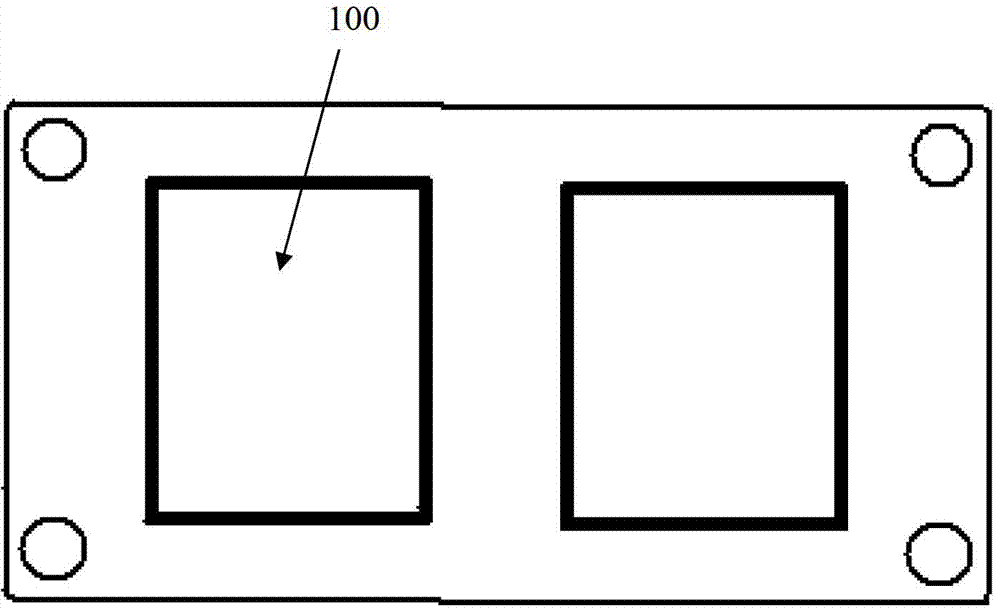

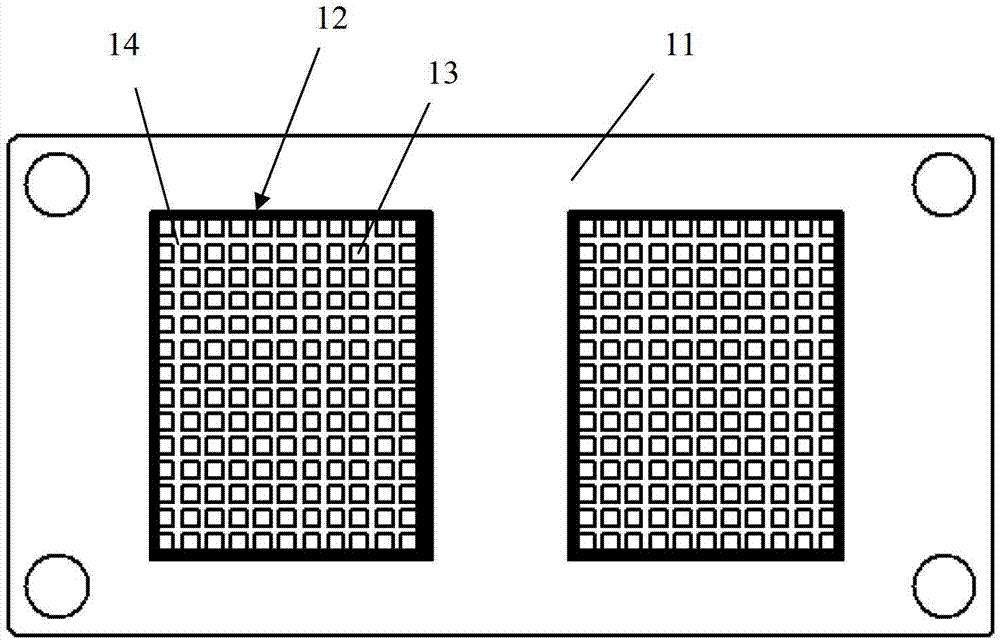

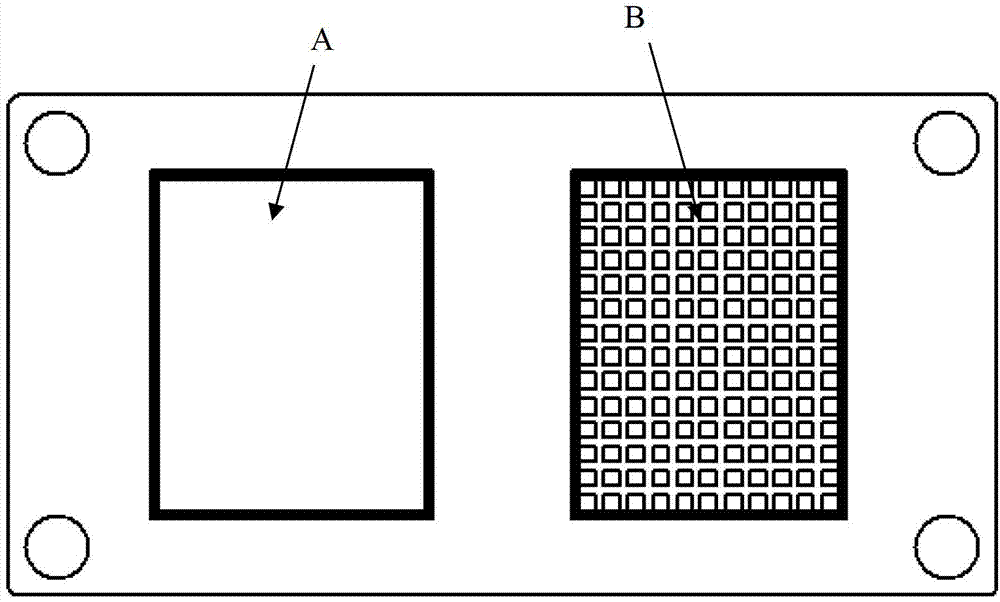

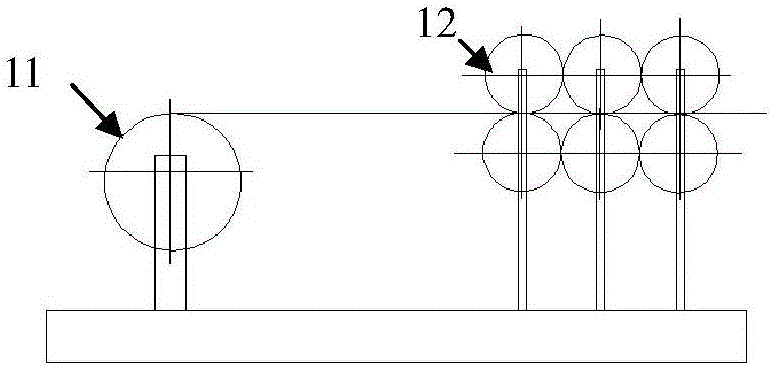

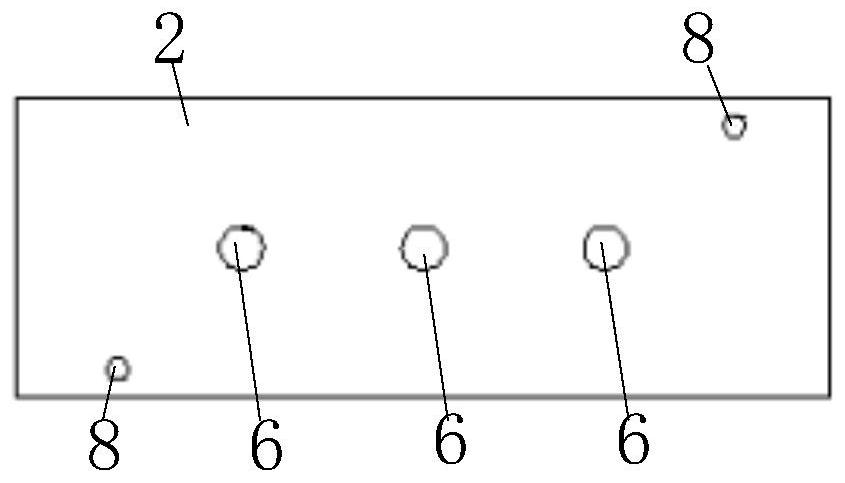

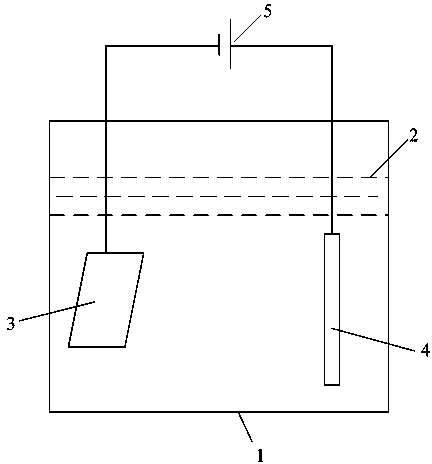

Positioning tool for chip welding

InactiveCN103567683ANo position shiftReduce void rateWelding/cutting auxillary devicesSemiconductor/solid-state device manufacturingDBcEngineering

The invention discloses a positioning tool for chip welding. The positioning tool comprises a base and a top cover positioned above the base, wherein a plurality of positioning holes are formed in the top cover, a positioning pin capable of sliding in each of the positioning holes vertically is arranged in each of the positioning holes, and one end of the positioning pin close to the base is used for abutting against chips to be welded. By arranging a plurality of positioning pins formed in the top cover and sliding freely to apply a certain pressure on the chips to be welded, the chips, welding lugs and a DBC base plate are fixed relatively, and the chips cannot be damaged by pressing. Therefore, position offset of the chips during welding is avoided, voidage of chip welding is reduced, the welding is firm, and quality and performance of welded products are effectively improved.

Owner:XIAN YONGDIAN ELECTRIC

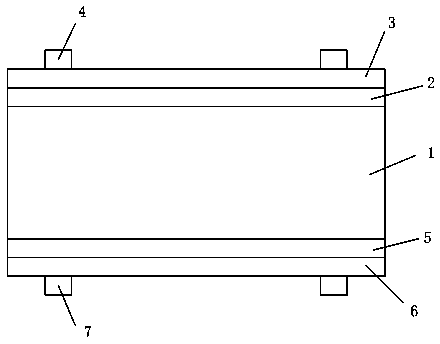

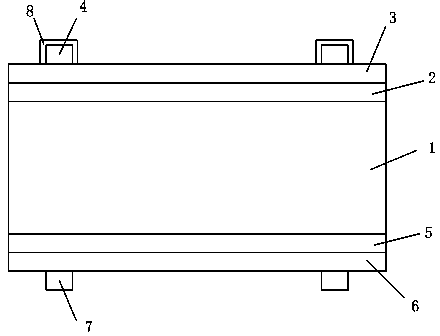

Crimping-type IGBT module with independently-formed chip and manufacturing method thereof

ActiveCN108183090AAvoid pollutionAvoid destructionSemiconductor/solid-state device detailsSolid-state devicesElectrical resistance and conductanceComputer module

The invention discloses a crimping-type IGBT module with an independently-formed chip and a manufacturing method thereof, which relate to the technical field of electrical element manufacturing and particularly relate to the technical field of high-power crimping-type IGBT module packaging. According to the chip structure provided in the invention, through carrying out insulated shell coating on the semiconductor chip sintered with a first conductive plane and a second conductive plane, the semiconductor chip can be protected to a maximum degree, the chip can be prevented from being polluted and damaged by the environment, the chip storage environment requirement severity can be reduced, and the risk of possible damages to the semiconductor chip during storage and packaging processes can be reduced to the minimum. The chip structure provided in the invention is convenient to store, the environment is loose, and the whole device reliability can be effectively improved. According to thecrimping-type IGBT module provided in the invention, the thermal contact resistance and the contact resistance are lower, the device reliability is high, the early failure rate is low, and when any parallel chip unit goes wrong, replacement can be carried out easily.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

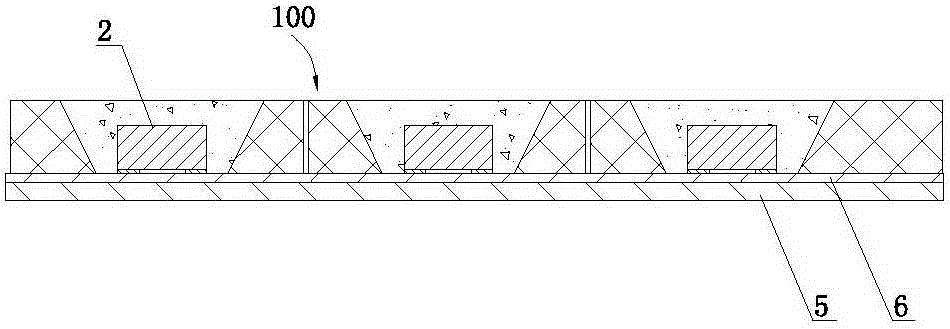

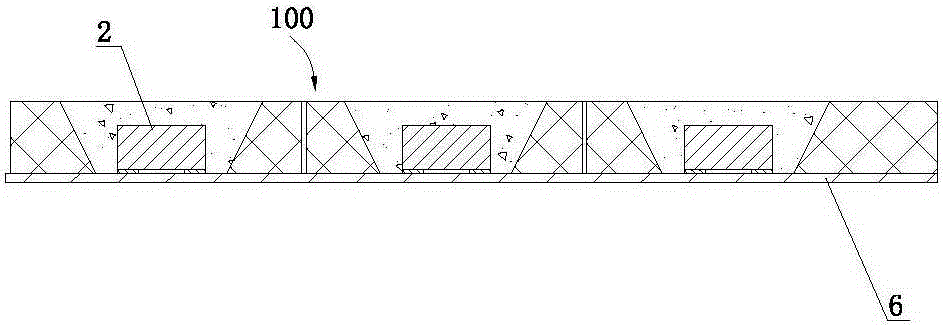

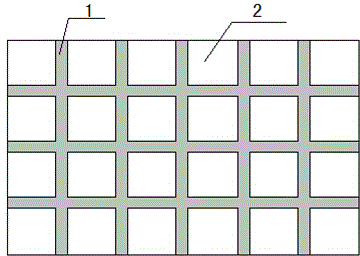

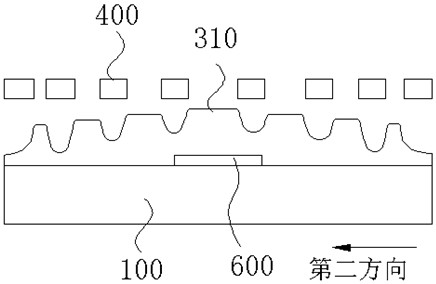

Method for reducing welding hollows of LTCC substrate and metal base plate and LTCC substrate structure

ActiveCN104093271AReduce void rateReduce void formationElectrical connection printed elementsSolder pasteWeld zone

The invention discloses a method for reducing welding hollows of an LTCC substrate and a metal base plate. The method comprises the following steps: presetting criss-cross resistance welding grid lines on a metalization layer of the surface of the substrate, and then welding the LTCC substrate and the metal base plate by adopting welding paste. As the grid lines are printed on the metalization layer of the welding surface of the LTCC substrate, discharge of fluxes and gas can be increased during welding of the LTCC substrate and the metal base plate, the formation of the hollows is reduced, and the voidage is reduced. As the grid lines are printed on the metalization layer of the welding surface of the LTCC substrate, more fluxes and gas can be discharged during welding, the accumulation of fluxes and gas is prevented, the welding area is increased, and the area of the biggest hollow is reduced. The design of multi-layer substrates and high-density grounding through holes does not need to be changed, many times of printing alignment for thickening of the rectangular-block metalization layer is avoided, and the grid lines are directly printed on the large-area metalization layer of the substrate. The printing is simple, the grid lines are clear and reliable, and the discharge channel of the fluxes can be ensured.

Owner:NO 43 INST OF CHINA ELECTRONICS TECH GRP CETC

Low-cost high-power electronic device packaging technology

ActiveCN104078369AReduce the cost of gold platingGuaranteed cooling efficiencySemiconductor/solid-state device manufacturingSurface mountingInterface layer

The invention discloses a low-cost high-power electronic device packaging technology. The technology comprises the steps that a chip and flange for packaging a high-power electronic device are prepared, a thick gold layer or a gold-tin layer is manufactured on the back face of the chip, a nickel layer and a thin gold layer are plated on the surface of the flange in sequence, and the chip and the flange are in surface mounting through gold-silicon eutectic welding or gold-tin eutectic welding. According to the low-cost high-power electronic device packaging technology, the thick gold layer or the gold-tin layer is manufactured on the back face of the chip, and the thin gold layer is plated on the surface of the flange, so that the good effect of gold-silicon eutectic welding or gold-tin eutectic welding is achieved, the void content of a hot interface layer between the chip and the flange is reduced, the radiating efficiency of the chip is ensured, the gold plating cost in the packaging technology is greatly reduced, and the number of working procedures is reduced.

Owner:长沙瑶华半导体科技有限公司

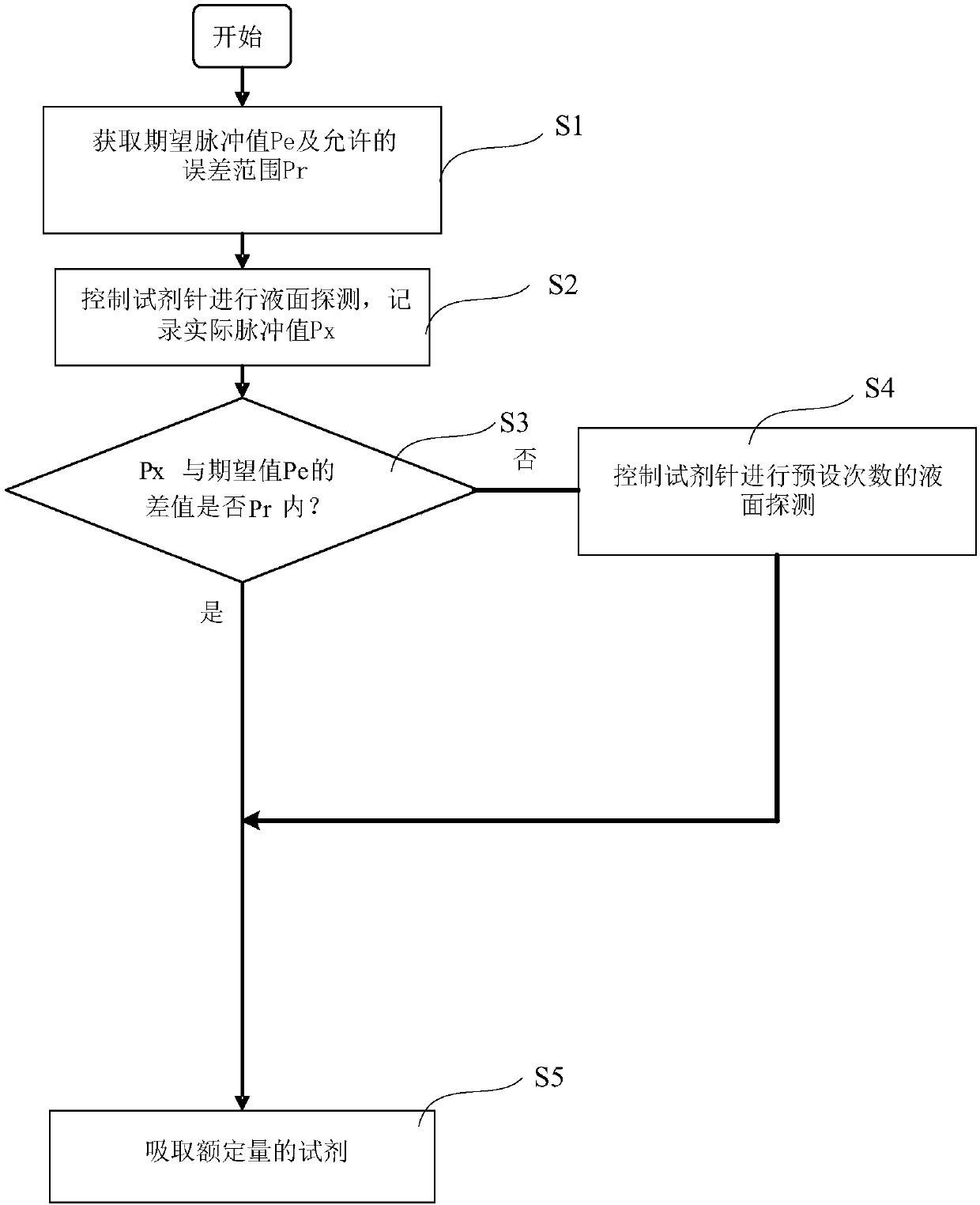

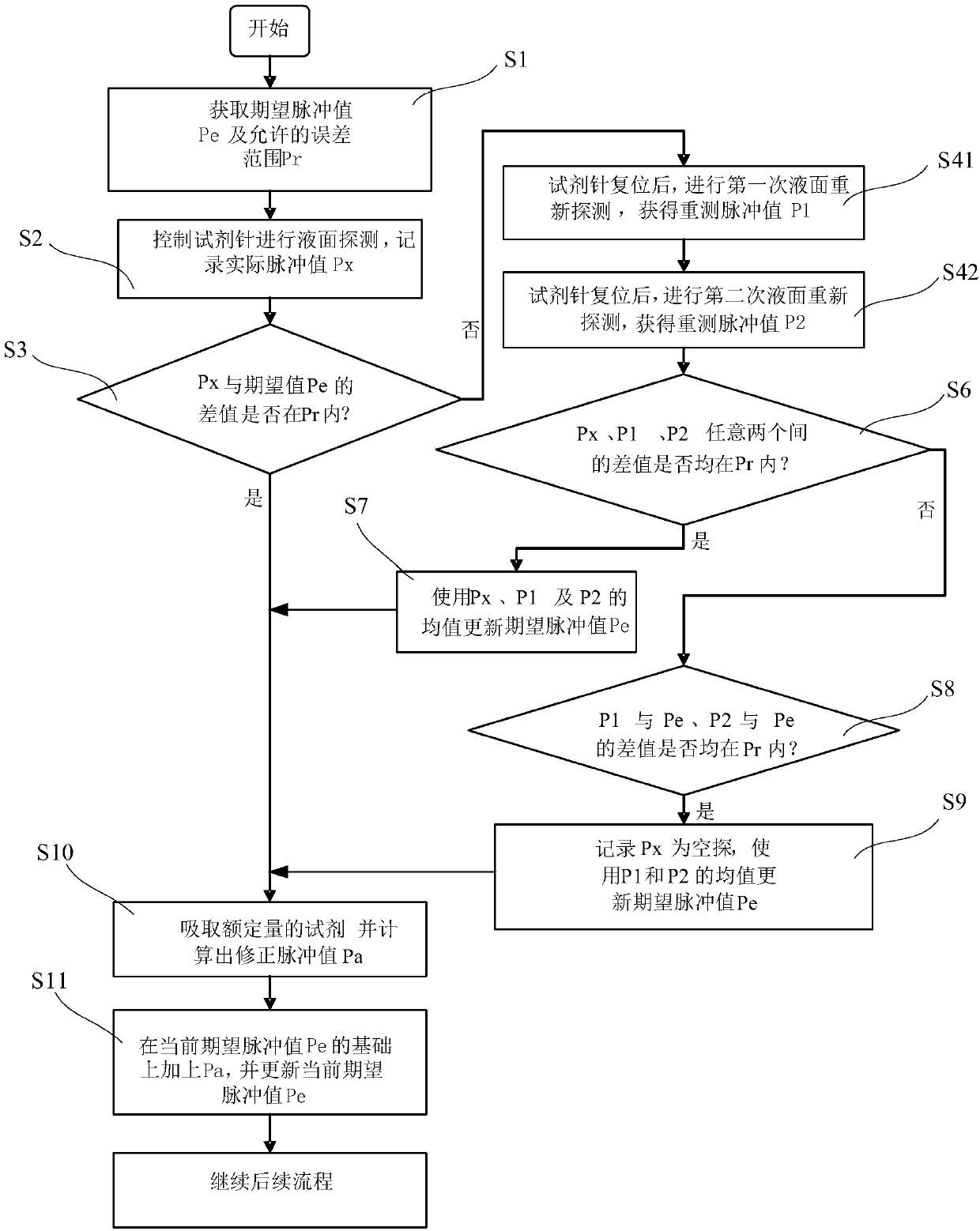

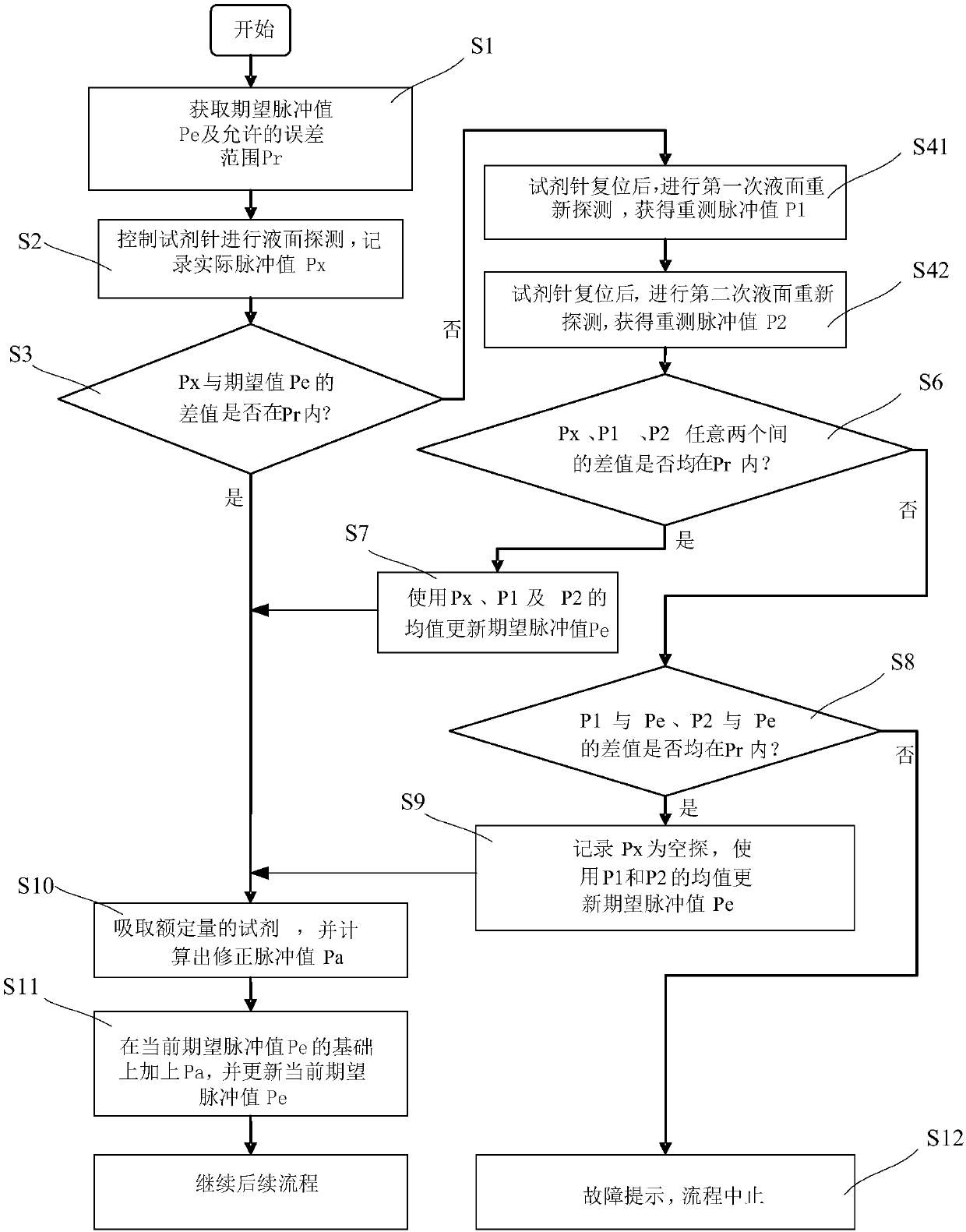

Liquid taking control method and device, and liquid taking system

ActiveCN107643699AReduce void rateGuarantee normal absorptionProgramme control in sequence/logic controllersEngineeringReagent

The invention relates to a liquid taking control method, which comprises the steps of: recording an actual pulse value Px given to a driving device when a reagent needle detects a liquid level; comparing the actual pulse value Px with a desired pulse value Pe, and controlling the reagent needle to suck rated quantity of reagent if a difference value between the Px and the Pe is within a set rangeT; otherwise, controlling the reagent needle to suck the rated quantity of reagent after re-detecting the liquid level for a preset number of times. The liquid taking control method can effectively ensure the contact of the reagent needle and the liquid, thus the probability of empty suction caused by empty detection is greatly reduced, thereby further ensuring that the reagent needle sucks sufficient reagent and improving the reliability of test or experimental results. The invention further discloses a liquid taking control device capable of implementing the liquid taking control method, anda liquid taking system adopting the liquid taking control method.

Owner:MACCURA MEDICAL INSTR CO LTD

Manufacturing method of metal-ceramic composite substrate and composite substrate manufactured by manufacturing method

InactiveCN106328543AImprove conductivityStrong high pressure resistanceSemiconductor/solid-state device detailsSolid-state devicesHigh resistanceComposite substrate

The invention discloses a manufacturing method of a metal-ceramic composite substrate and a composite substrate manufactured by the manufacturing method, and belongs to the technical field of ceramic metallization. The manufacturing method comprises the following steps: forming a first brazing filler metal layer on the surface of a ceramic substrate, wherein the first brazing filler metal layer is a copper and active metal brazing filler metal layer; forming a second brazing filler metal layer on the surface of the first brazing filler metal layer, wherein the second brazing filler metal layer is a copper and silver brazing filler metal layer; forming a copper layer on the surface of the second brazing filler metal layer in order to form a metal-ceramic composite substrate precursor; and sintering the metal-ceramic composite substrate precursor in vacuum. In the manufacturing method, an active metal of the first brazing filler metal layer reacts with ceramic during vacuum sintering, so that high bonding force and high thermal shock resistance are achieved. Copper and silver of the second brazing filler metal layer undergo a eutectic reaction with a copper foil, so that the copper and the silver are combined tightly with the copper foil, and the metal-ceramic composite substrate has higher resistance to high voltages and heavy current at the same time.

Owner:ZHEJIANG TC CERAMIC ELECTRONICS

Epoxy adhesive integrated potting system and method satisfying anti-hard target requirement

ActiveCN110139495AImpact resistanceAbility to meet vibrationNon-metallic protective coating applicationTemperature controlEngineering

The invention discloses an epoxy adhesive integrated potting system satisfying an anti-hard target requirement. The integrated potting system comprises a perfusion system, a vacuum system, a temperature control system and a vibration system. The epoxy adhesive integrated potting system, by using a potting way integrating vibration, temperature control and vacuumizing, solves the problem that a closed cavity built-in printed board component is complex in structure and still has void defects after vacuum potting, further improves the fluidity of the epoxy adhesive, improves the wetting ability of the printed board component and other structural parts, basically realizes the non-hole potting of the epoxy adhesive, and satisfies the anti-impact and anti-vibration abilities of aerospace products under a large-overload condition.

Owner:湖北三江航天红林探控有限公司

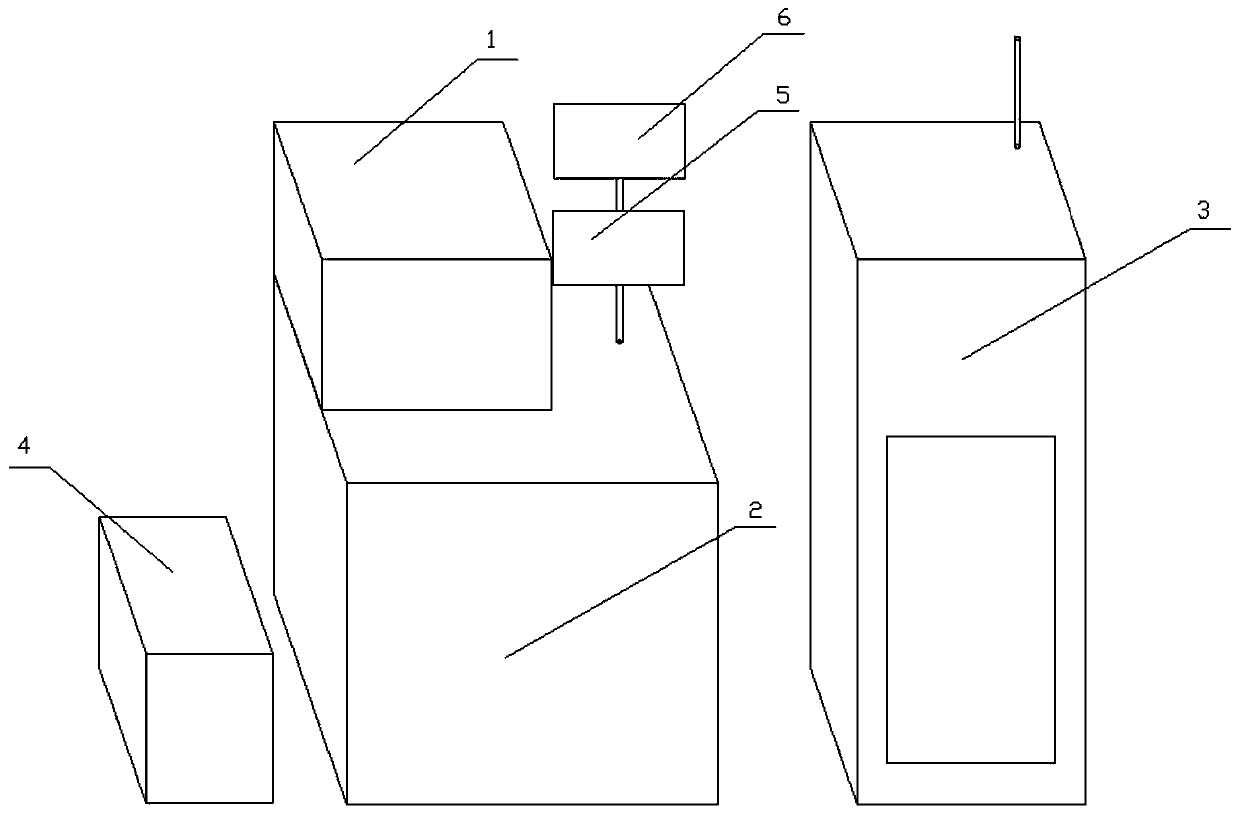

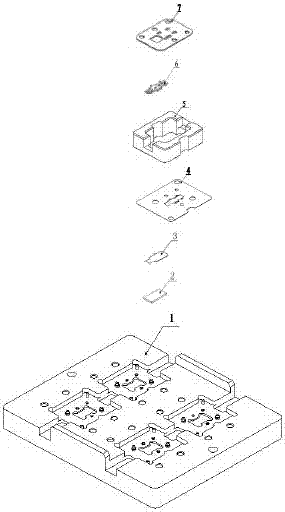

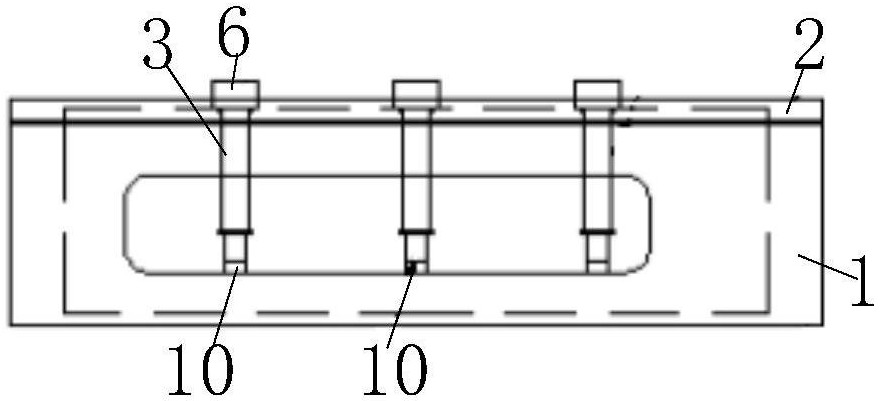

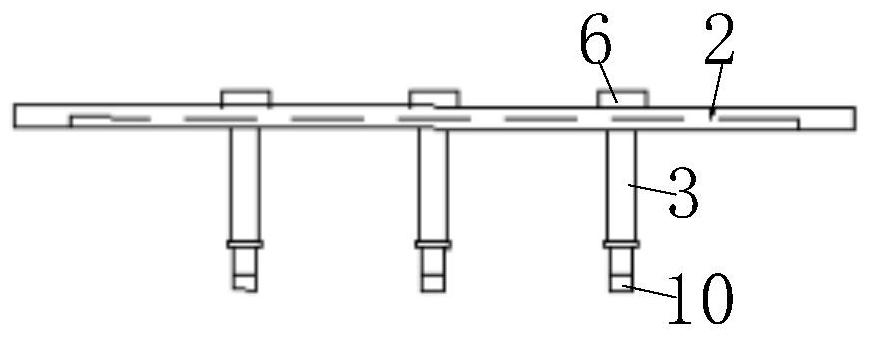

TR module pressing and carrying device and installation method thereof

ActiveCN107548277AImprove alignment accuracyReduce solder void rateElectrical componentsMicrowaveHeat sink

The invention relates to the field of microwave, in particular to a TR module pressing and carrying device and an installation method thereof. The TR module pressing and carrying device comprises a base, wherein a plurality of eutectic grooves are formed in the base, each eutectic groove comprises a substrate, a positioning surface and a limitation step, a heat sink carrying plate and a formationwelding sheet are arranged in the substrate, the positioning surface is used for placing a positioning steel sheet, the limitation step is used for arranging a loosen-prevention press block, the loosen-prevention press block is used for preventing the positioning steel sheet from being deformed and shaking, a chip counterweight press block is arranged on the loose-prevention press block, a capacity discharging via hole and a radio frequency microstrip via hole are respectively formed in a chip press sheet coverage capacity discharging region and a radio frequency microstrip region, and a capacity discharging counterweight piece and a radio frequency microstrip counterweight piece are respectively arranged in the capacity discharging via hole and the radio frequency microstrip via hole. Thedevice is simple in structure and is convenient to operate, a plurality of TR modules can be eutectically welded in one time, and the welding void rate of the TR module is reduced.

Owner:成都雷电微力科技股份有限公司

Flip device packaging method and structure

InactiveCN110660891AReduce void rateImprove work efficiencySemiconductor devicesSolder ballEngineering

The invention provides a flip device packaging method, and the method at least comprises the steps: enabling a substrate to be placed at a preset position, wherein the substrate is provided with at least one hole which is through from the top to the bottom; placing a flip chip on the substrate, wherein the solder balls on the flip chip are correspondingly connected with the bonding pads on the substrate; welding the bonding pads on the substrate and the solder balls of the flip chip, and carrying out cooling treatment; and injecting filling materials into the holes. Besides, the invention alsoprovides a flip device packaging structure, and by applying the embodiment of the invention, the problem that holes of different degrees are generated due to the influence of the flowing speed and the like when filling materials are injected around the chip in the prior art is solved.

Owner:宁波安芯美半导体有限公司

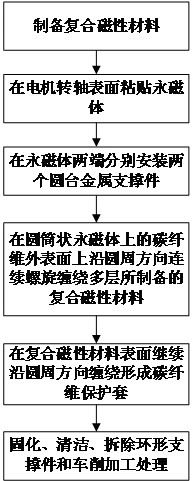

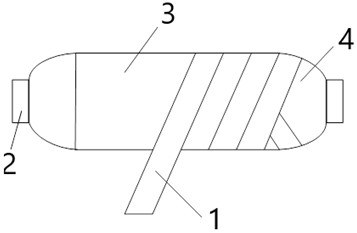

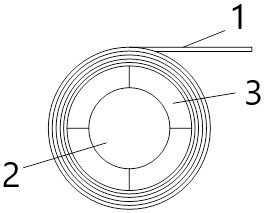

High-speed permanent magnet synchronous motor composite rotor spiral winding preparation method

ActiveCN111835161AReduce concentrated stressWinding is effectiveManufacturing stator/rotor bodiesCoils manufactureAutomotive engineeringMagnetic powder

The invention belongs to the field of motor rotor manufacturing, and particularly relates to a high-speed permanent magnet synchronous motor composite rotor spiral winding preparation method which comprises the following steps: preparing a composite magnetic material; adhering the inner surface of the permanent magnet to the surface of the motor spindle; connecting and mounting circular truncatedcone metal supporting pieces at two ends of the permanent magnet; continuously and spirally winding multiple layers of prepared composite magnetic materials on the outer surface of the carbon fiber ofthe permanent magnet in the circumferential direction, and applying a pre-tightening force in the winding process; and after winding of the composite magnetic material is completed, continuously performing winding at the surface of the composite magnetic material to form a carbon fiber protective sleeve, then performing curing, cleaning, circular truncated cone metal supporting piece dismountingand turning treatment sequentially, and preparing the composite rotor. In the spiral winding process, it can be guaranteed that each layer of magnetic powder adhesive film is evenly distributed, particularly, the problem of interlayer continuous winding can be solved, and the problem that due to continuous winding, the end of the rotating shaft is wrinkled in a winding mode or time is wasted in the cutting and re-winding process is fundamentally solved.

Owner:BEIHANG UNIV +1

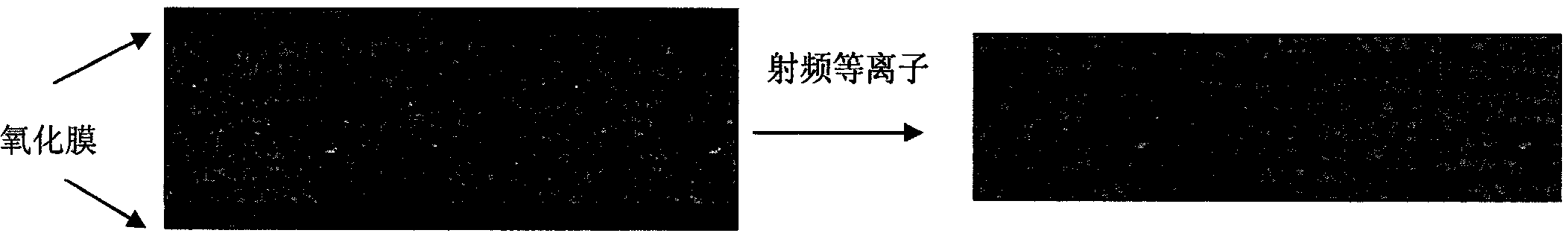

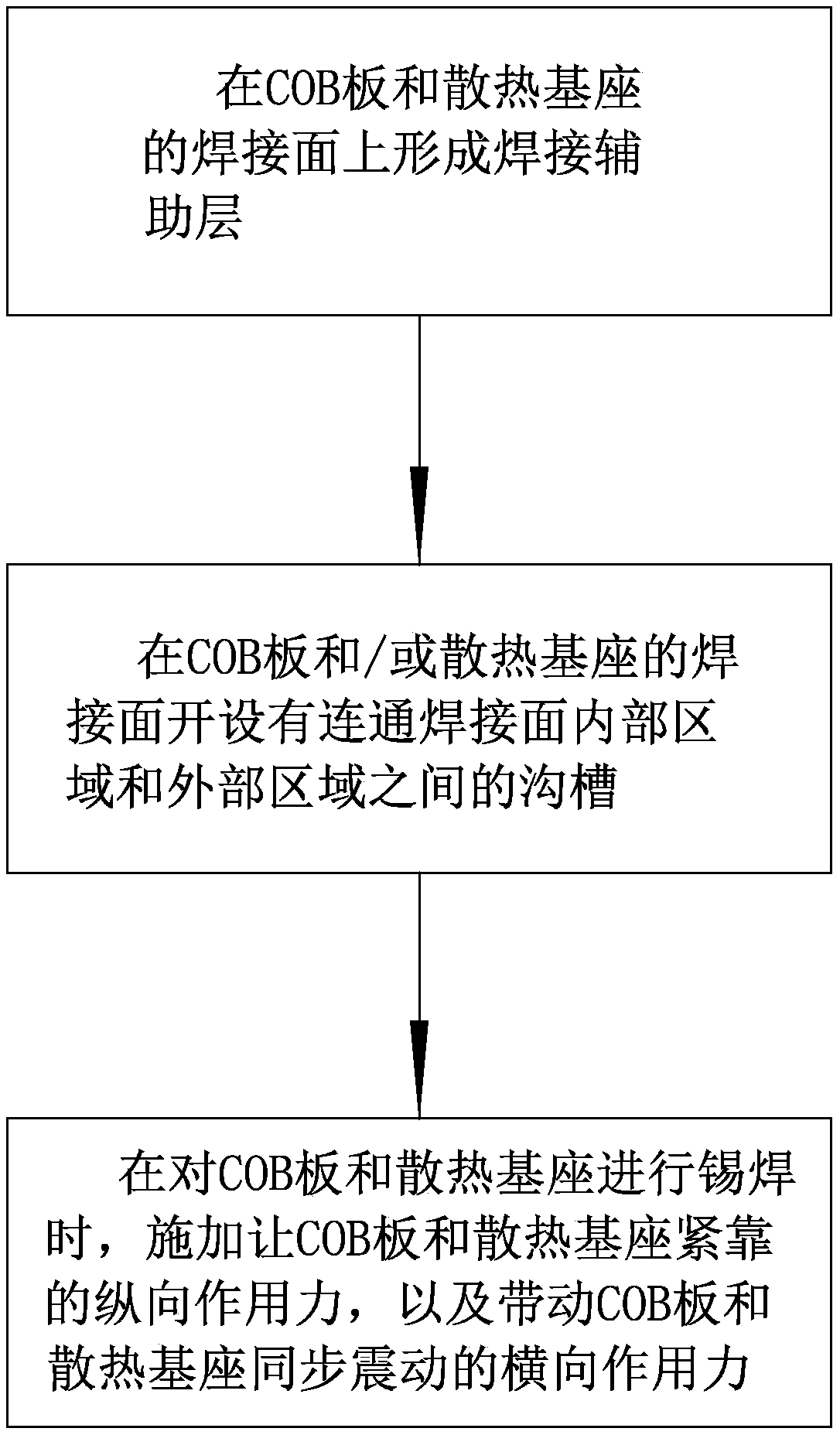

Method of reducing tin soldering voidage between COB (chip on board) and heat-dissipation base

InactiveCN109079274AIncrease success rateEnsure the promotion of industrializationSolder feeding devicesSoldering auxillary devicesSolderingHigher Power

The invention discloses a method of reducing tin soldering voidage between a COB (chip on board) and a heat-dissipation base. The method comprises the following steps of: (1) forming a soldering assistance layer on a soldering face of the heat-dissipation base, (2) forming a groove communicating an internal area and an external area of the soldering face in the COB or the soldering face of the heat-dissipation base, (3) applying a longitudinal acting force to allow the COB to close to the heat-dissipation base and a transverse acting force to drive the COB to rock during tin soldering of the COB and the heat-dissipation base, wherein the depth of the groove is greater than or equal to the thickness of the soldering assistance layer and less than the thickness sum of the soldering assistance layer and the COB or the heat-dissipation base. The method can greatly increase an actual soldering success rate; high efficiency of a heat conduction bridge between the COB and the heat-dissipationbase is guaranteed; and actual industrial popularization of the high-power COB is guaranteed.

Owner:厦门吉来特光电有限公司

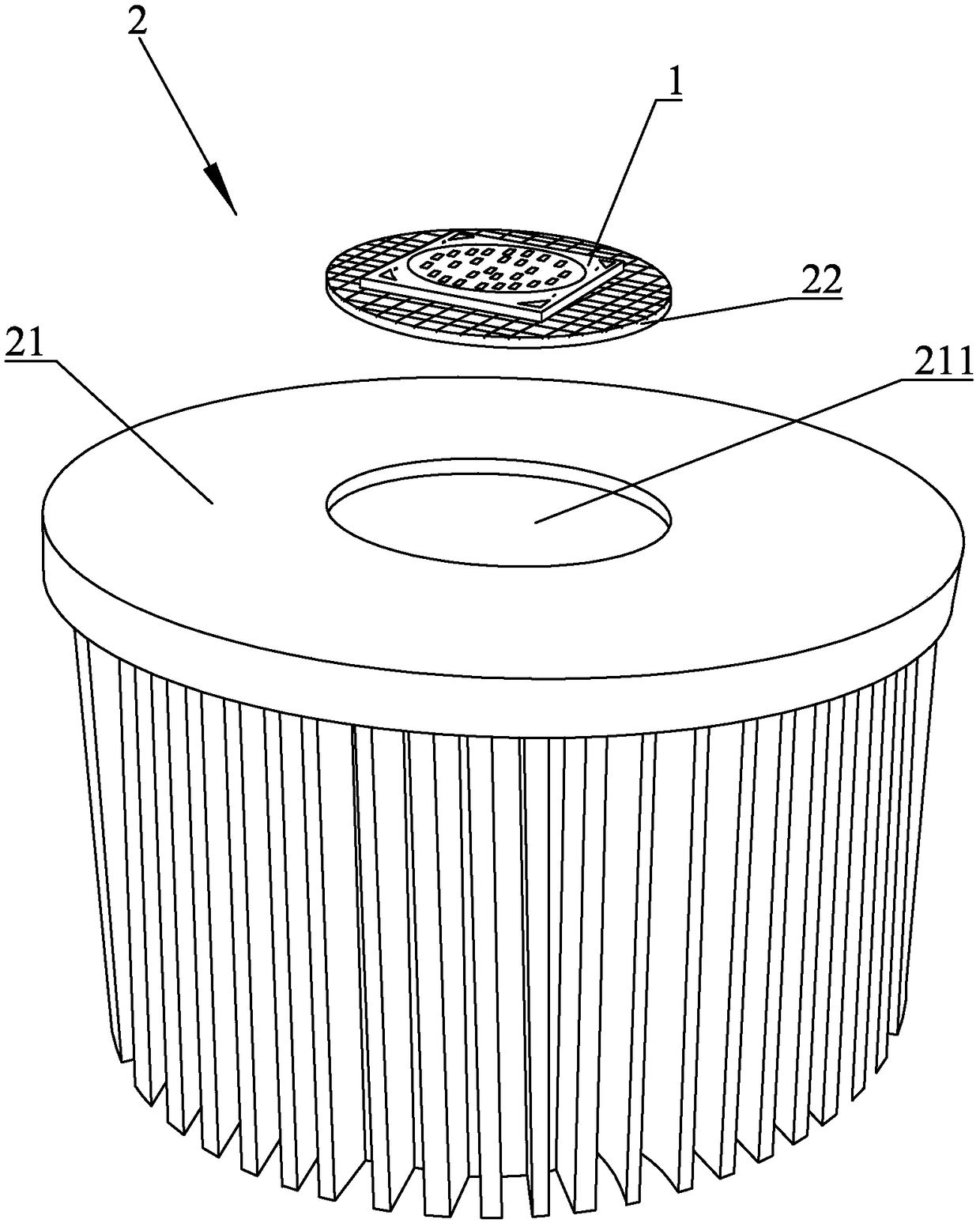

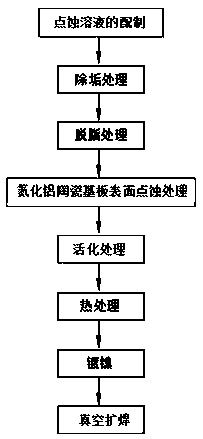

Method for manufacturing copper-plated aluminum nitride ceramic substrate

The invention relates to a method for manufacturing a copper-plated aluminum nitride ceramic substrate. The method comprises the following steps: (1) preparing a pitting solution; (2) carrying out descaling treatment; (3) carrying out degreasing treatment; (4) carrying out pitting treatment on the surface of an aluminum nitride ceramic substrate, namely soaking the aluminum nitride ceramic substrate into the pitting solution, and treating with an ultrasonic process; (5) carrying out activation treatment, namely coating the surface of the aluminum nitride ceramic substrate with an activator, wherein the activator is prepared from copper sulfate, sodium persulfate, boric acid and potassium citrate through mixing; (6) carrying out thermal treatment; (7) carrying out nickel plating; (8) carrying out vacuum welding expansion. By adopting the method, the problems that a conventional copper foil is insufficient in binding force with an aluminum nitride ceramic substrate, high in porosity, lowin peeling strength, and the like, can be solved, by reducing the porosity of the copper foil and the aluminum nitride ceramic substrate, the binding force of the two components can be increased, andthe strength of the copper-plated aluminum nitride ceramic substrate can be improved.

Owner:合肥市闵葵电力工程有限公司

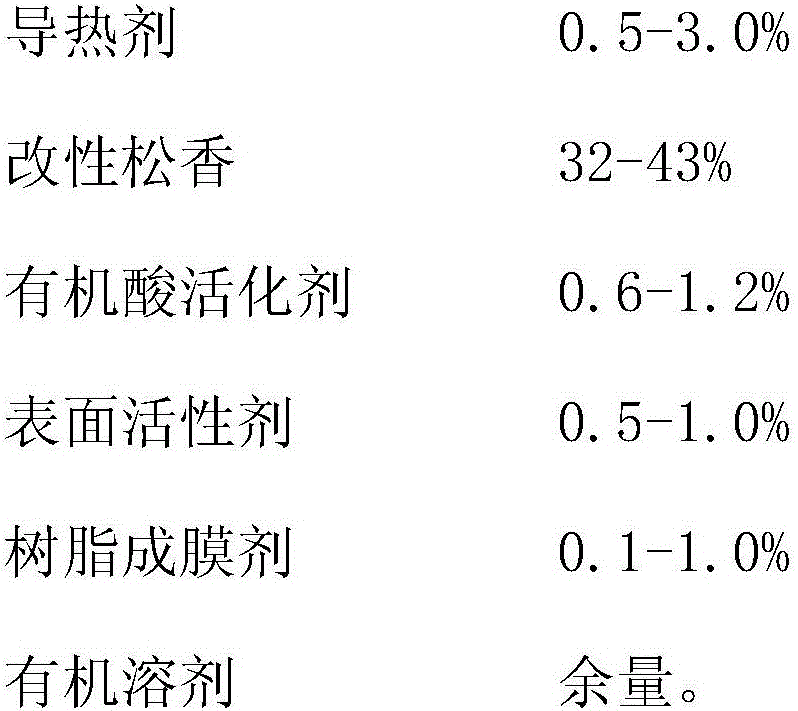

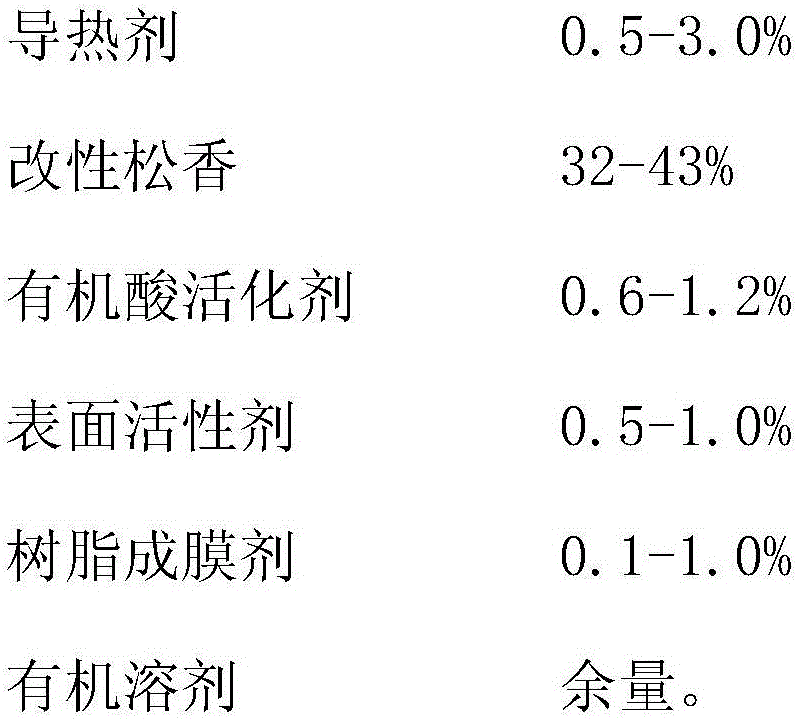

Soldering flux which generates few concaves after welding and is used for pre-formed soldering lug

ActiveCN105921911AResidue reductionConvenient coatingWelding/cutting media/materialsSoldering mediaOrganic acidOrganic solvent

The invention provides soldering flux. The preparation raw materials of the soldering flux comprises a heat conducting agent, and preferably further comprises modified rosin, an organic acidic active agent, a surface active agent, a resin film forming agent and organic solvent. The soldering flux is applied to the pre-formed soldering lug, and is good in coating performance, good in wettability and high in weldability. Besides, a little active material is left after welding, and an ultra-low voidage rate is kept after welding.

Owner:深圳市唯特偶新材料股份有限公司

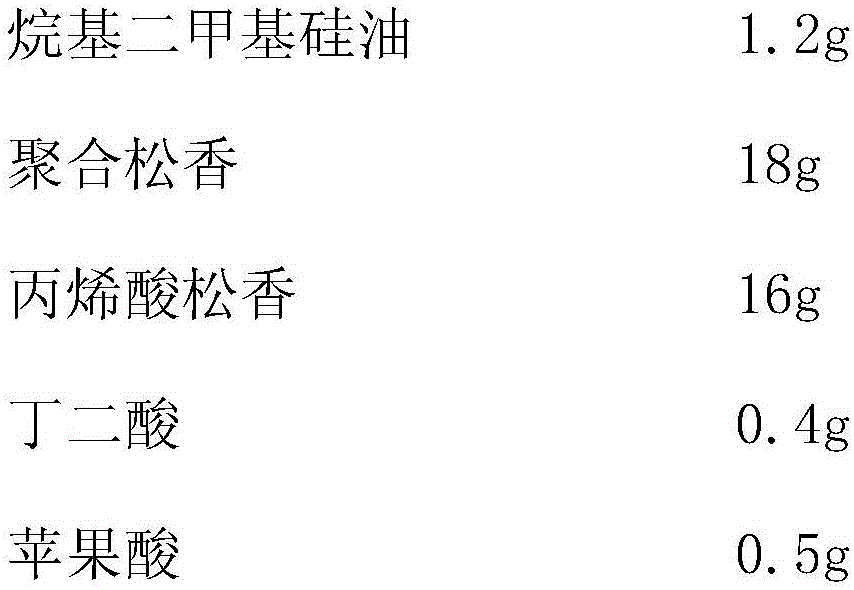

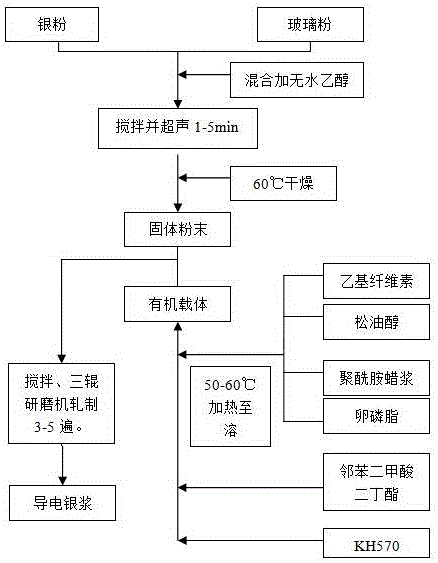

Car rear windshield heating wire silver paste and preparation method thereof

InactiveCN105764168AGuaranteed performanceMeet the requirements of energy saving and environmental protectionTransparent/reflecting heating arrangementsHeating element materialsWater bathsSilver paste

The invention discloses a car rear windshield heating wire silver paste and a preparation method thereof, which belong to the technical field of material preparation. The silver paste is prepared by the following raw materials, by mass percentage, 60% to 80% of silver powder, 2% to 10% of lead-free glass powder, 0.5% to 2% of macromolecule resin, 1.5% to 4% of an organic additive and 16% to 25% of an organic solvent. The method of the invention comprises steps: the macromolecule resin, the organic additive and the organic solvent are heated for 5 to 30 min in a water bath at a temperature of 50 to 60 DEG C, stirring is carried out to realize complete dissolution, and after cooling, an organic carrier is obtained; the uniformly-mixed silver powder, the lead-free glass powder and the organic carrier are mixed and stirred uniformly, a three-roll grinder is used for rolling for three to five times until the fineness of the slurry to be uniform, and thus, the car rear windshield heating wire silver paste is obtained. The prepared silver paste has small sheet resistance, low voidage, high acid resistance, and strong adhesion of the silver paste film layer after sintering, is used for the car rear windshield and has good mist eliminating effects.

Owner:KUNMING UNIV OF SCI & TECH

Insulated gate bipolar transistor (IGBT) module

InactiveCN103165588AImprove cooling effectImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesDBcEngineering

The invention discloses an insulated gate bipolar transistor (IGBT) module which comprises a direct bonded copper (DBC) substrate and a base plate welded with the DBC substrate through welding materials. A welding area is formed on a welding surface of the base plate in a defined mode. The welding area is divided into a plurality of area units through grooves. The area of each area unit is smaller than or equal to a hundredth of the area of the whole welding area. The IGBT module can reduce a void rate of a welding layer between the base plate and the DBC substrate of the IGBT module, improves welding quality and ensures stability of the welding quality.

Owner:XIAN YONGDIAN ELECTRIC

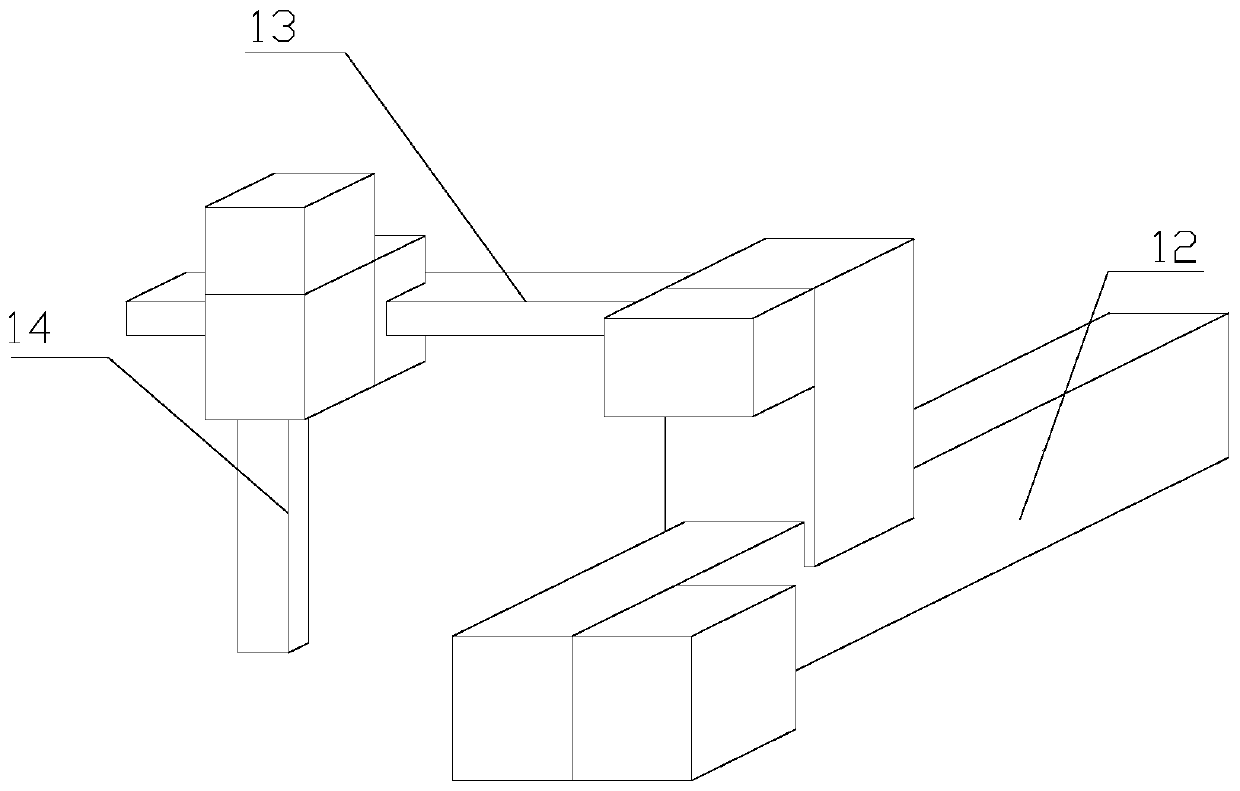

Device and method for manufacturing enhanced type welding columns

ActiveCN106624423ARealize mass productionSimple and fast operationSolid-state devicesSemiconductor/solid-state device manufacturingDip solderingWire cutting

The invention provides a device and method for manufacturing enhanced type welding columns and belongs to the field of ceramic electron component packaging. The device comprises a welding wire supplying mechanism, a copper strip winding mechanism, a copper strip dip soldering mechanism and a welding wire cutting-off mechanism. Straight welding wires are supplied by the welding wire supplying mechanism, and copper strips with a certain thickness are wound on the welding wires by the copper strip winding mechanism, the whole outer surfaces of the welding wires are subjected to tin dipping through the copper strip dip soldering mechanism, and enhanced type welding wires are obtained; the enhanced type welding wires are conveyed to the welding wire cutting-off mechanism for leveling and cutting off, and a plurality of enhanced type welding columns are obtained. The gap that currently the enhanced type welding columns can not be independently manufactured in domestic is filled up, and the device and method are simple in operation and can ensure that the manufactured welding columns are good in surface state and end face smoothness.

Owner:BEIJING MXTRONICS CORP +1

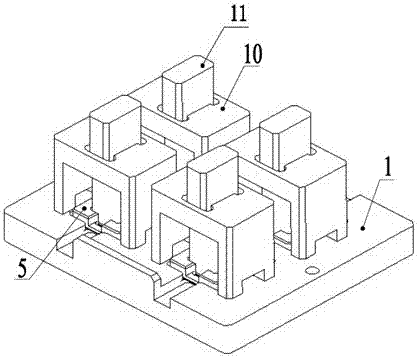

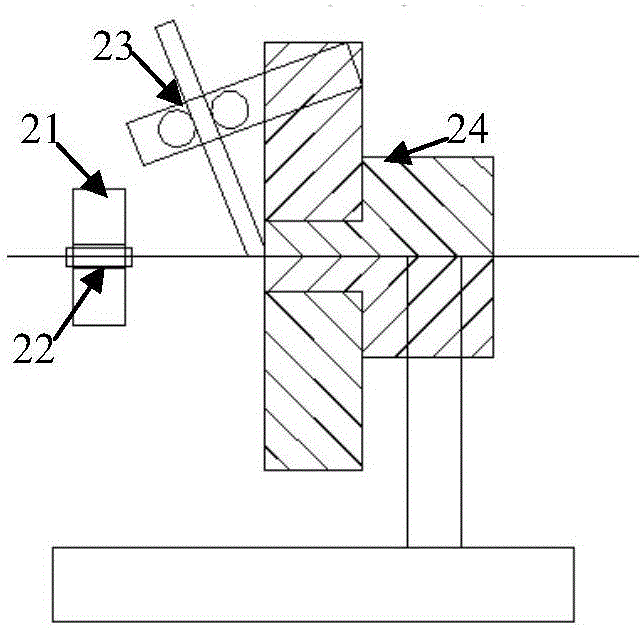

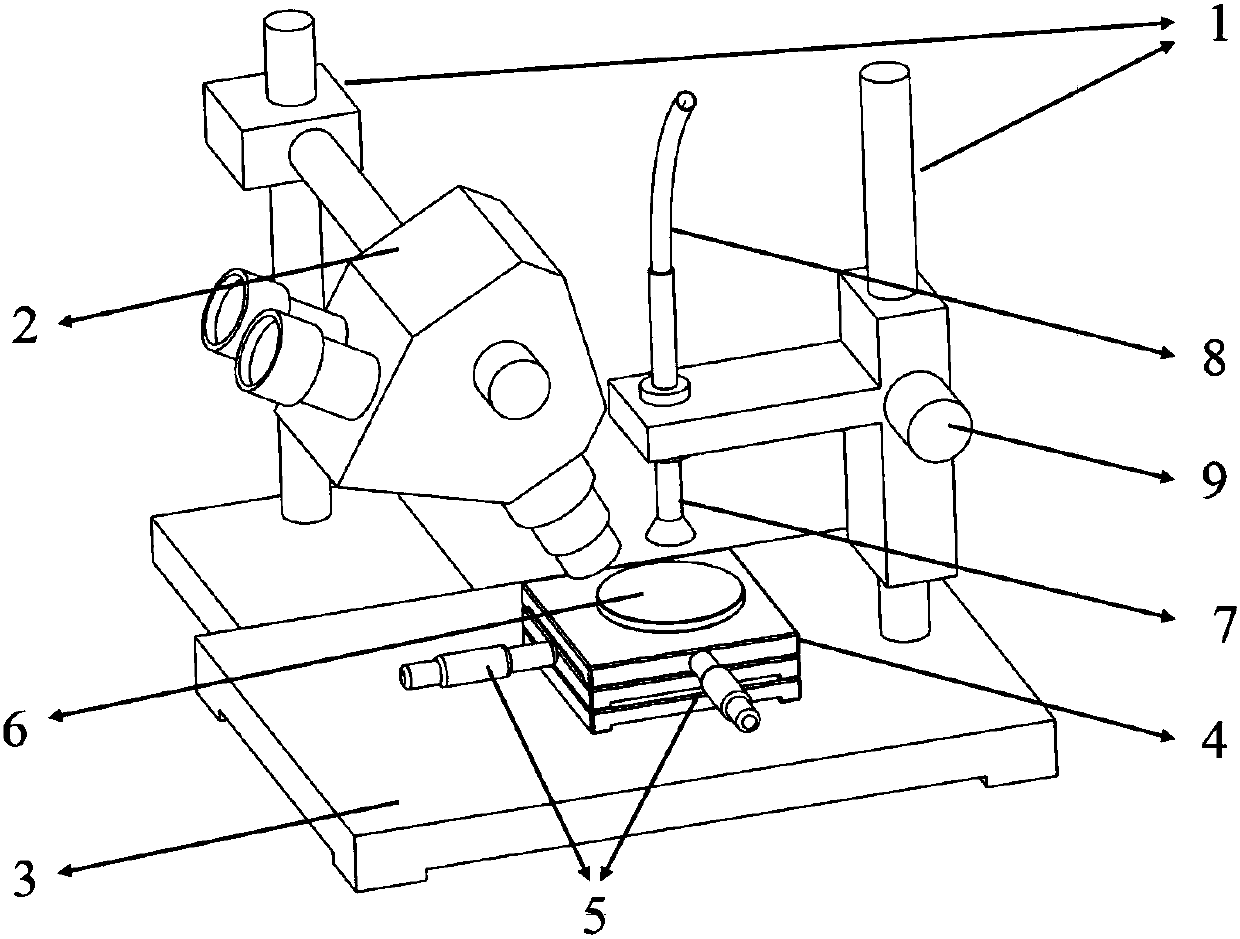

Surface mounting device and method for silver solder paste connection

PendingCN107734959AReasonable structureEasy to operatePrinted circuit assemblingElectrical componentsVision processingSurface mounting

The invention relates to a surface mounting device and method for silver solder paste connection. The surface mounting device comprises an optical adjustment rack and a vision processing system fixedon the rack, wherein a precise mobile platform is arranged on a base plate at the lower part of the vision processing system; the precise mobile platform is provided with high-precision micrometer heads on the horizontal plane along X-axis and Y-axis directions separately; the precise mobile platform is provided with a sample platform; a vacuum nozzle is arranged above the sample platform; the upper part of the vacuum nozzle can be connected with a vacuum pump through a sealing pipeline; the vacuum nozzle and a displacement adjustment knob are fixed on the optical adjustment rack; and the optical adjustment rack is fixed on the base plate. According to the surface mounting device, high-precision chip mounting at the position, at which solder paste is printed, on a substrate can be achievedby combining the vision processing system through multi-axis coordination work; and high vacuum can be achieved by the vacuum nozzle, so that the surface mounting device is suitable for chips of allsizes and shapes, and is reasonable in structure and simple in operation.

Owner:TIANJIN UNIV

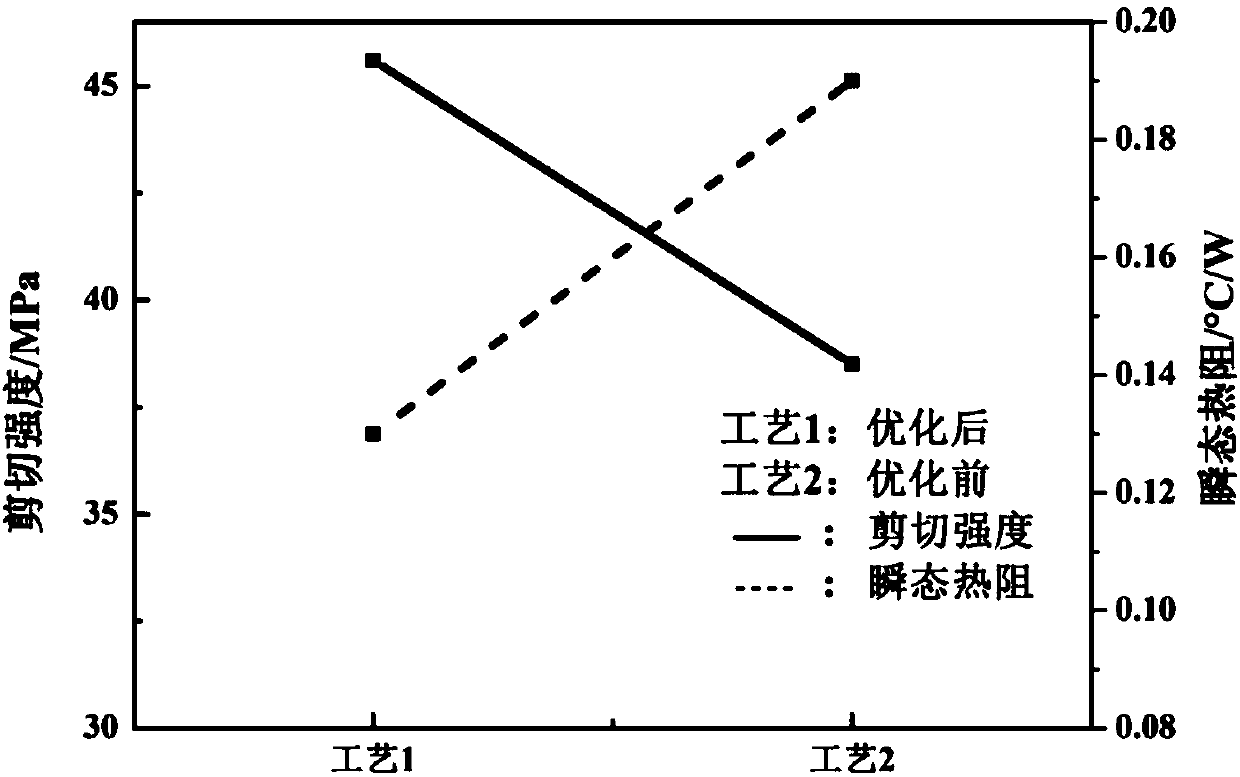

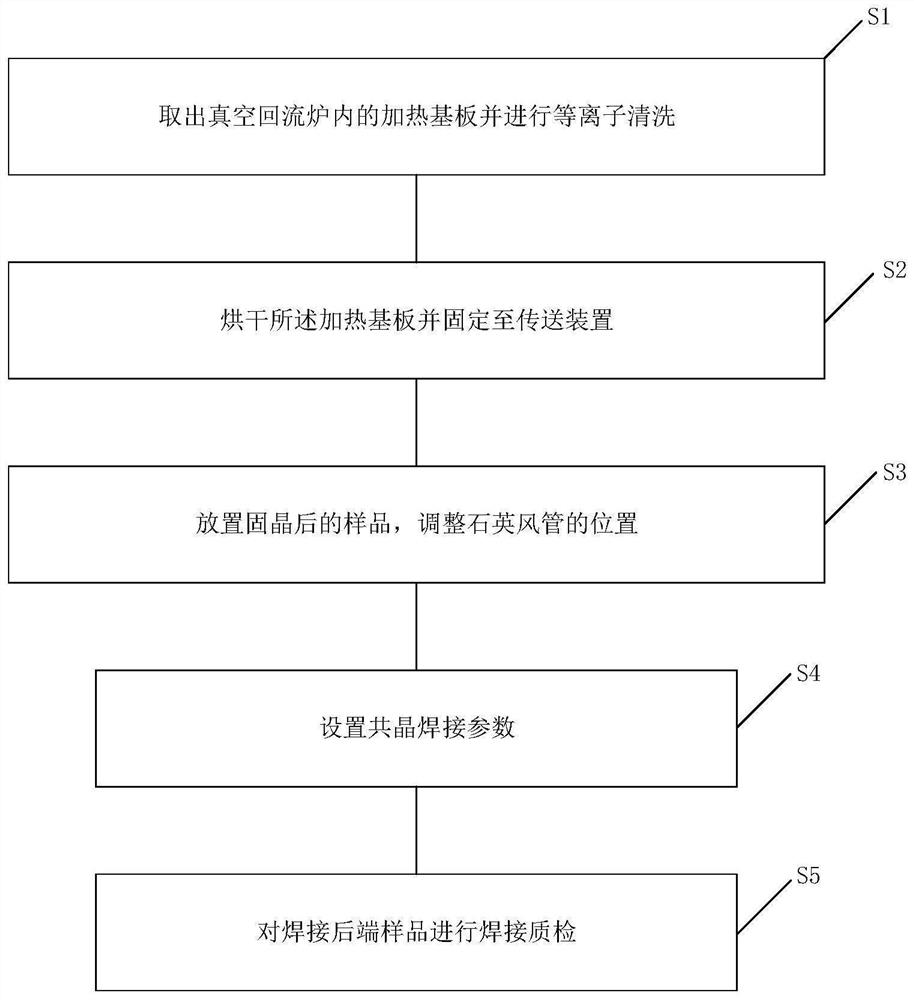

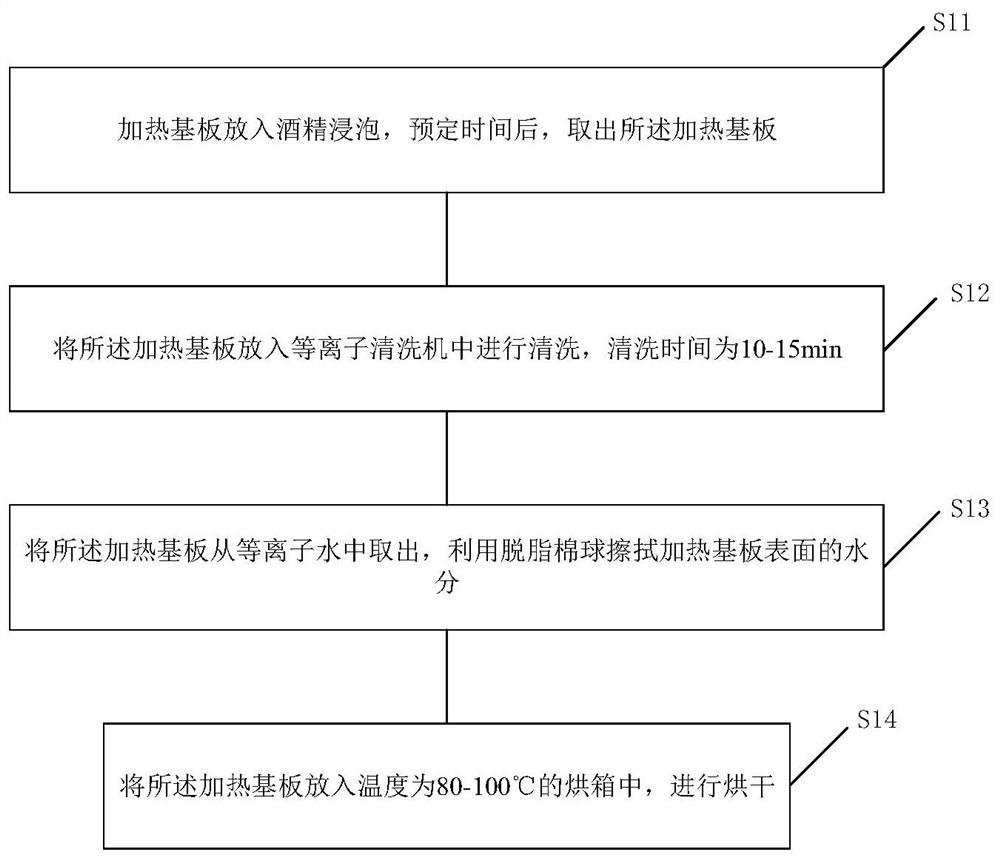

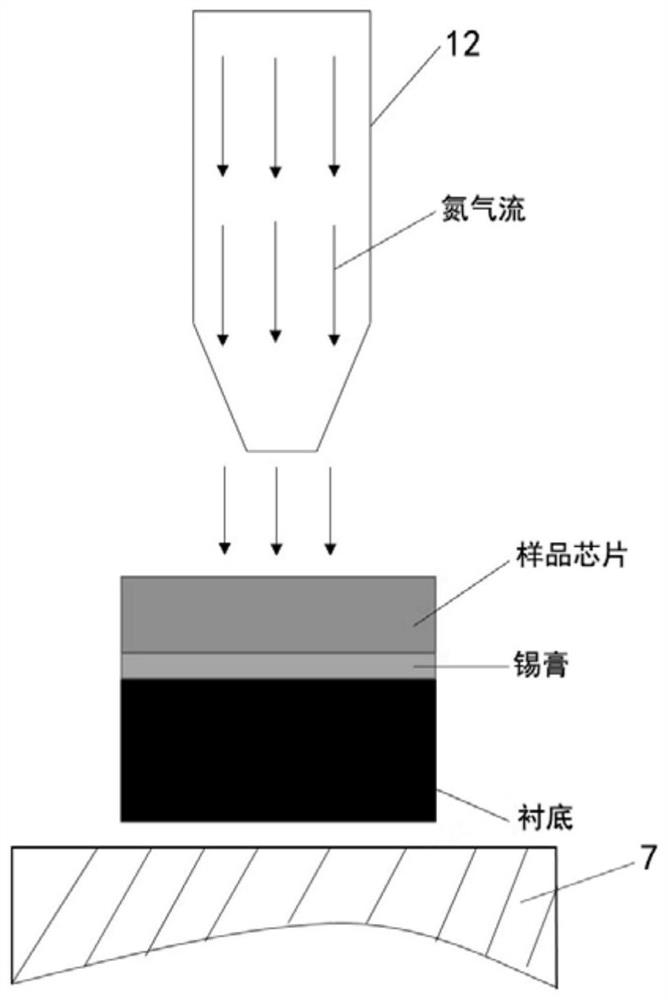

Process method for vacuum reflow eutectic welding

InactiveCN112002650AImprove welding qualityHeating up fastSemiconductor/solid-state device detailsSolid-state devicesRadiative heatingRadiant heat

The invention discloses a process method of vacuum reflow eutectic welding. The method comprises the steps of S1, taking out a heating substrate in a vacuum reflow furnace and carrying out plasma cleaning; S2, drying the heating substrate and fixing the heating substrate to a conveying device; S3, placing a sample after die bonding, and adjusting the position of a quartz air pipe; S4, setting eutectic welding parameters; and S5, carrying out welding quality inspection, wherein an improved vacuum reflow furnace is adopted for eutectic welding, the vacuum reflow furnace adopts a first heat source and a second heat source to provide heat required by sample welding, the first heat source provides hot air for heating, and the second heat source provides radiant heat. According to the invention,heat needed by eutectic welding is provided in a hot air heating mode and a radiation heating mode at the same time, the effect of rapid temperature rising can be achieved, the welding quality of a sample is improved, and the welding void ratio is reduced. The process method provided by the invention is simple to operate, high in safety, universal and suitable for production of small-batch and multi-variety products.

Owner:SHANGHAI INST OF TECH

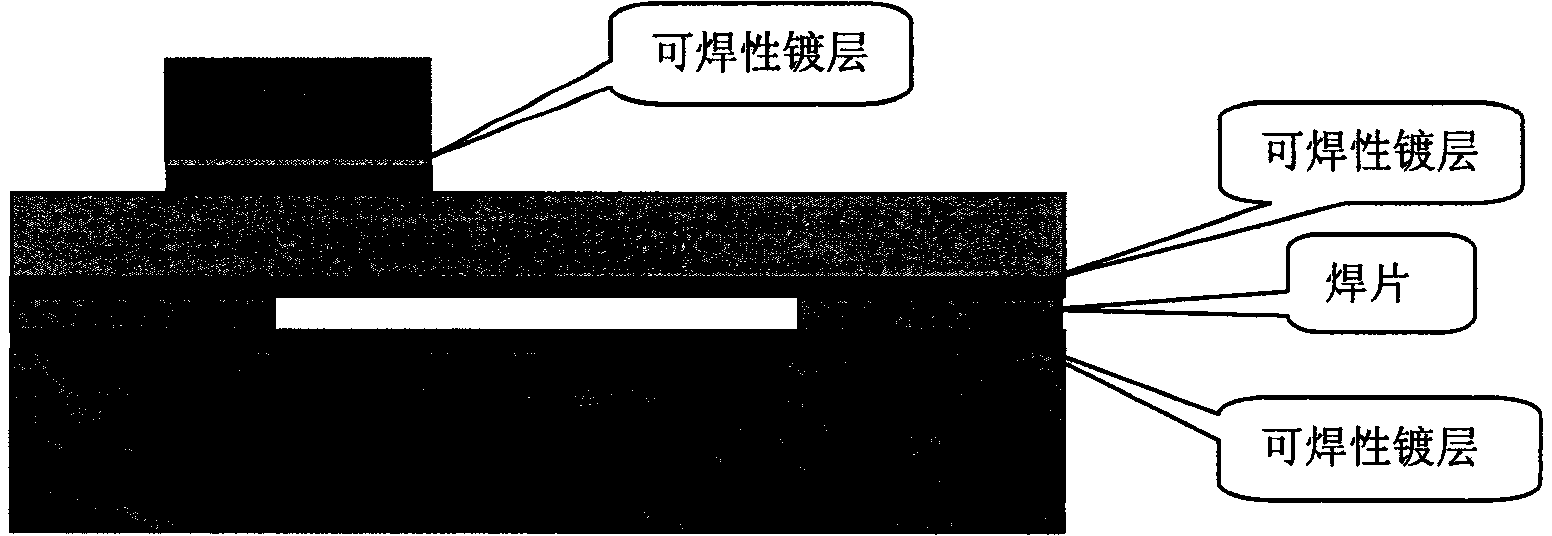

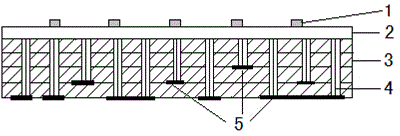

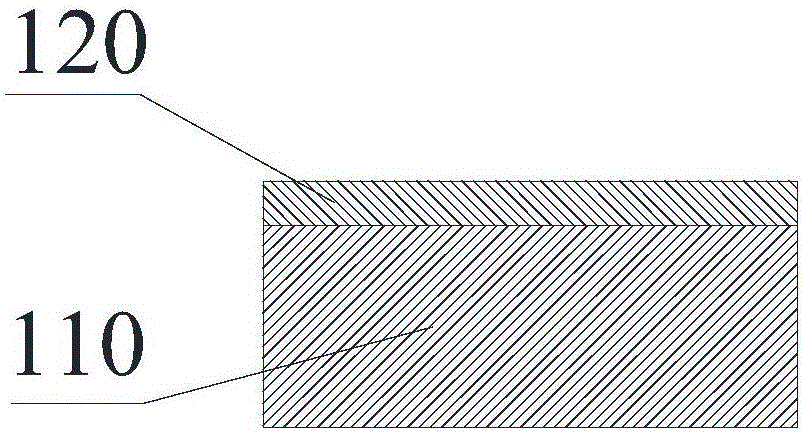

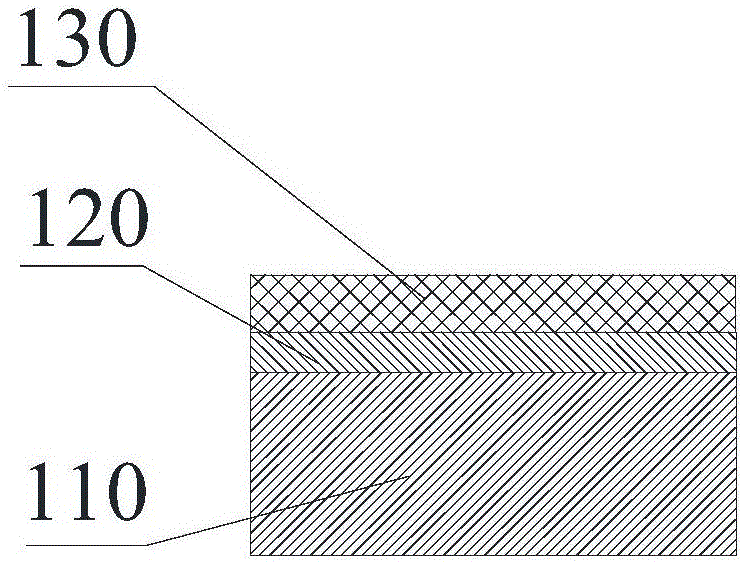

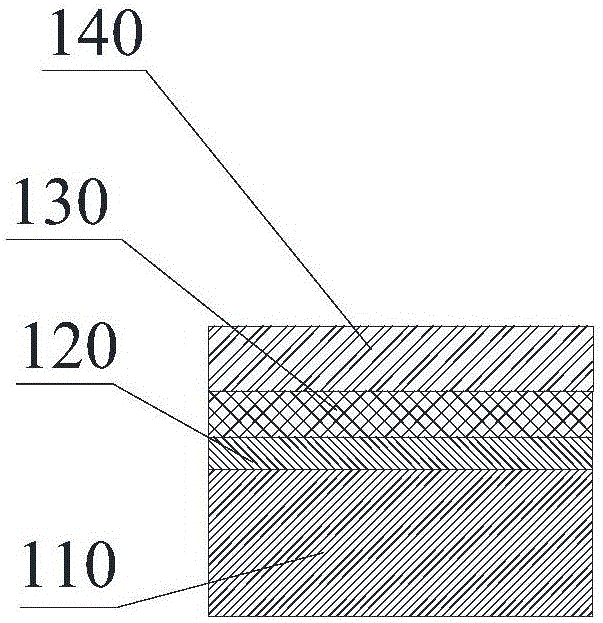

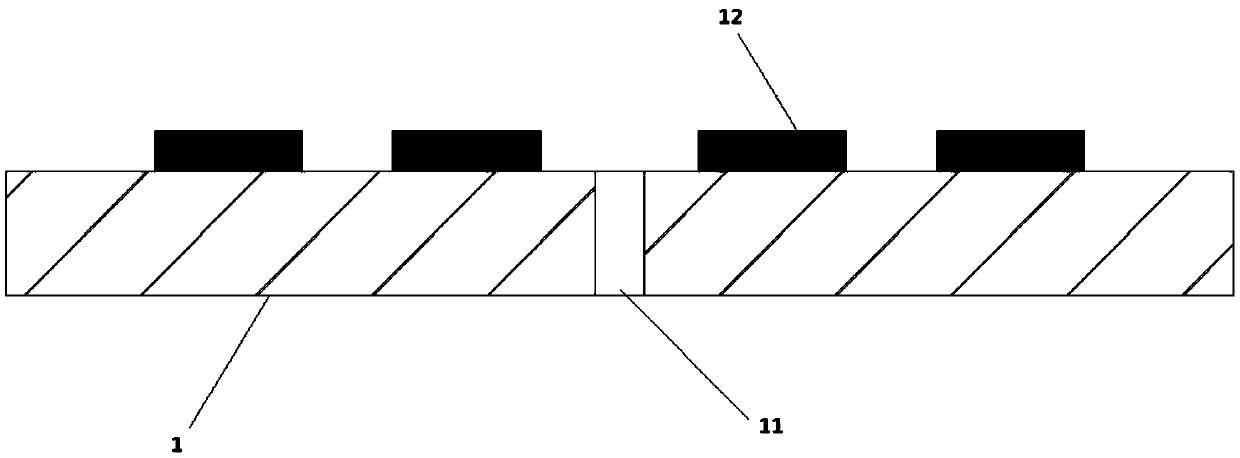

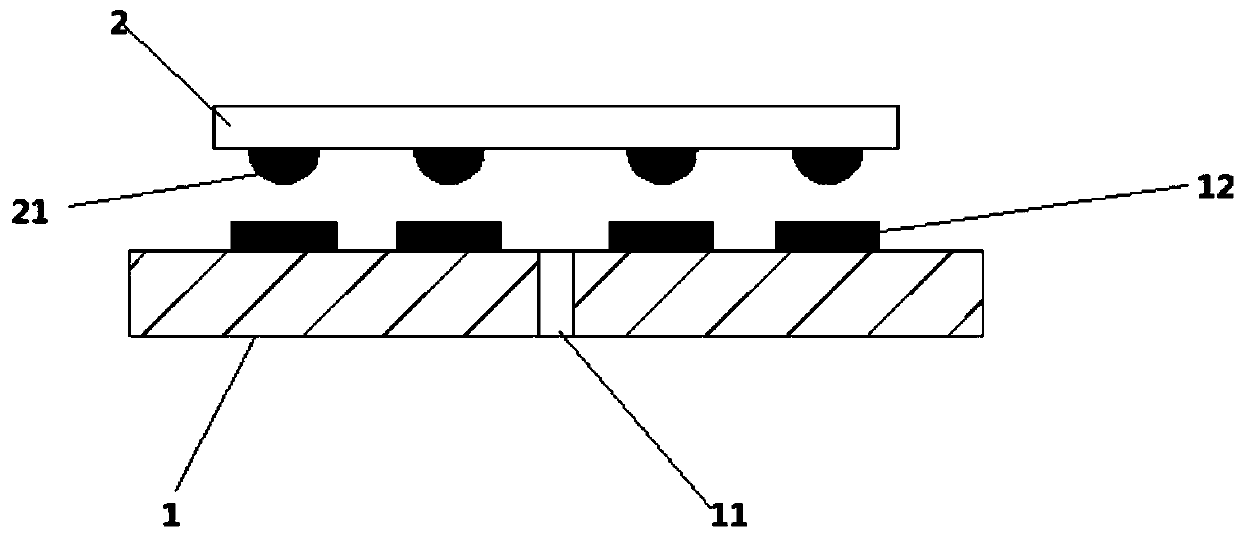

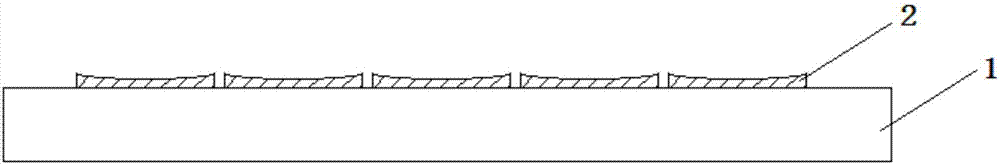

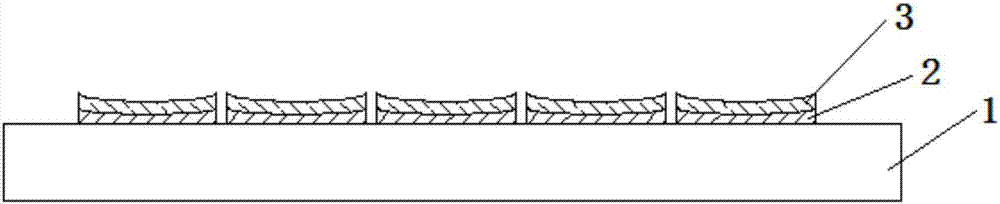

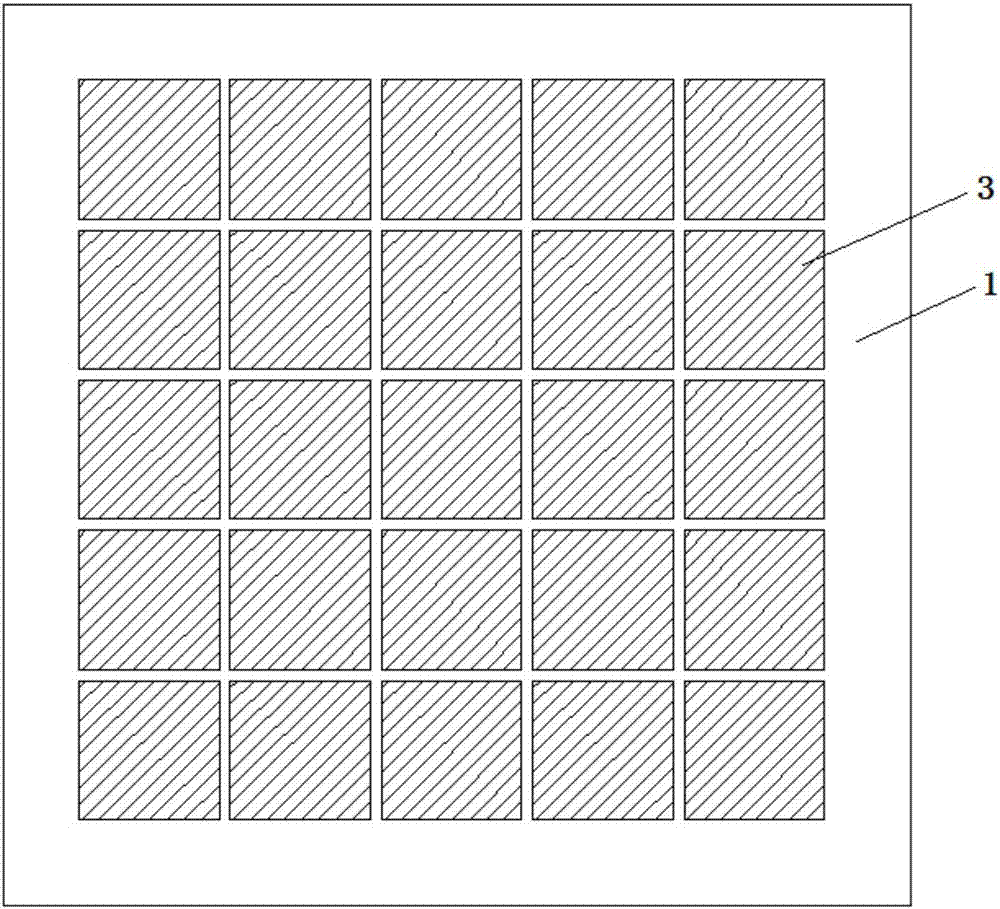

Thick film substrate having low void content and high reliability and manufacturing method thereof

ActiveCN107039358AGuaranteed mechanical reliabilityImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesMechanical reliabilityProcess manufacturing

The invention relates to a thick film substrate having low void content and high reliability and a manufacturing method thereof. The thick film substrate comprises a ceramic substrate, a first grid layer arranged on the ceramic substrate, a second grid layer arranged on the first grid layer and an emboss layer arranged on the second grid layer, wherein each emboss in the emboss layer is located in the center of each grid of the second grid layer. The emboss layer can effectively reduce the void content of a circuit and improve the heat dissipation of the substrate; meanwhile, the structure can be manufactured by adopting high-palladium silver-palladium paste, so that the binding force between the substrate and a tube shell is guaranteed while the low void content is guaranteed, and the mechanical reliability of the substrate is ensured. The method for manufacturing the thick film substrate is simple and effective, does not have special control requirement in the process manufacturing link, can realize manufacturing by three times of printing and burning, and can be used for large-scale production.

Owner:NO 24 RES INST OF CETC

Packaging method of semiconductor device and semiconductor device

ActiveCN112992701AReduce thermal resistanceReduce the chance of voidsSemiconductor/solid-state device detailsSolid-state devicesDevice materialFusion welding

The invention provides a packaging method of a semiconductor device and a semiconductor device, and relates to the technical field of semiconductor device packaging. A mask plate with a plurality of first holes is used for evaporating solder on a to-be-welded surface of a first structure, therefore, a plurality of solder protrusions with the heights gradually reduced from the middle of the first structure to the two sides of the first structure are formed on the surface of the solder; in the welding process, the high solder protrusions located in the middle contact with a second structure and are subjected to fusion welding, the low solder protrusions contact with the second structure and achieve welding, and sequential welding is achieved in the direction from the middle to the two sides; gas generated in the welding process and air between the first structure and the second structure can be exhausted from the gaps (a solder groove structures) between two adjacent solder protrusions or the second structure and the top areas of the solder protrusions with the smaller height, so that the probability that holes appear in a solder layer after welding is reduced, the thermal resistance of an interface is reduced, and the heat dissipation effect is improved.

Owner:度亘激光技术(苏州)有限公司

Brazing device and method capable of reducing solder overflow

ActiveCN113814506AReduce overflowReduce spillageFinal product manufactureMetal working apparatusEngineeringMaterials science

The invention provides a brazing device and method capable of reducing solder overflow. The brazing device capable of reducing solder overflow comprises a base used for loading a to-be-welded part and a box body, a pressing plate and at least one pressing needle used for extruding the to-be-welded part, the pressing plate is detachably installed at the top end of the base, and the pressing needle is installed on the pressing plate in a sliding manner. By designing the brazing device capable of reducing the solder overflow, the brazing device is provided with the base, the pressing plate and the pressing needle, the pressure borne by the to-be-welded part during welding is adapted, the situation that the solder overflows too much due to large or uneven pressure after melting is avoided, the overflow amount of the solder is effectively reduced, the voidage of low-temperature brazing is reduced, and the reliability of low-temperature brazing is improved.

Owner:BEIJING INST OF RADIO MEASUREMENT

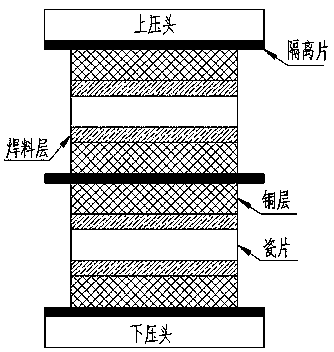

Method for preparing ceramic copper-clad plate by hot-pressing active brazing method

InactiveCN110064808AReduce void rateImprove pullout forceWelding/cutting media/materialsSoldering mediaVoid ratioAdditive ingredient

The invention discloses a method for preparing a ceramic copper-clad plate by a hot-pressing active brazing method. The method comprises the following steps that 1, a ceramic chip is ultrasonically cleaned with pure water under the condition of 70 DEG C for 1-10min and then dried in a drying oven at the temperature of 100 DEG C; 2, the two faces of the dried ceramic chip are evenly coated with silver-copper welding flux containing active metal ingredients and dried in the drying oven at the temperature of 60-90 DEG C; 3, the two faces, coated with the welding flux, of the ceramic chip are in fit with copper sheets to form a set A; 4, multiple sets A are stacked, and every two adjacent sets A are isolated through an isolation sheet; 5, the structure of the multiple stacked sets A is placedinto a hot pressing furnace, and 0-30 MPa pressure is applied to the two ends of the structure; 6, heating along with the furnace is started when vacuum is pumped to 10<-3>Pa, heat preservation is carried out for 30-90min at the temperature of 400-500 DEG C, then, glue discharge is carried out, and heat preservation is carried out for 10-60min at the temperature of 800-950 DEG C for brazing. By adopting vacuum hot-pressing active brazing, the prepared ceramic copper-clad plate has the characteristics of extremely low void ratio, high drawing force, solder saving, high production efficiency, simple operation in the preparation process and the like.

Owner:WUXI TIANYANG ELECTRONICS

Solar cell and preparation method thereof

InactiveCN104201216AFacilitate depositionImprove conductivityFinal product manufacturePhotovoltaic energy generationSilver electrodeP type silicon

The invention discloses a solar cell. The solar cell comprises P type silicon, an N type emitter is formed on the front surface of the P type silicon through diffusion, the front surface of the N type emitter is provided with a passivation film, the front surface of the passivation film is provided with a positive electrode which is a silver electrode, the back surface of the P type silicon is provided with a back passivation layer, the back passivation layer is provided with a back electric field and a back electrode, the silver electrode is electroplated with at least one silver layer, and the silver layer covers the silver electrode. Accordingly, the invention also provides a method of preparing the solar cell. The solar cell is simple in structure, the silver layer can fill voids in the surface of the silver electrode, so that the void ratio of the silver electrode of a traditional solar cell is effectively reduced, the conductivity of the silver electrode is improved, and further the photoelectric conversion efficiency of the cell is enhanced.

Owner:GUANGDONG AIKO SOLAR ENERGY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com