Insulated gate bipolar transistor (IGBT) module

A welding area and substrate technology, which is applied to electrical components, electrical solid devices, circuits, etc., can solve the problems of complex process adjustment, unstable soldering layer void rate, and difficult technical control of soldering layer void rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

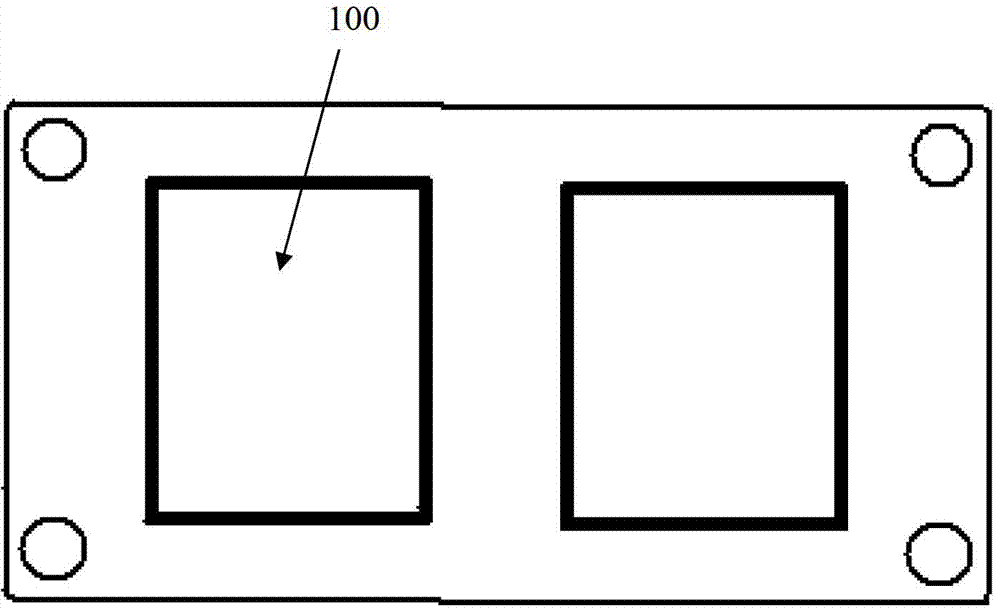

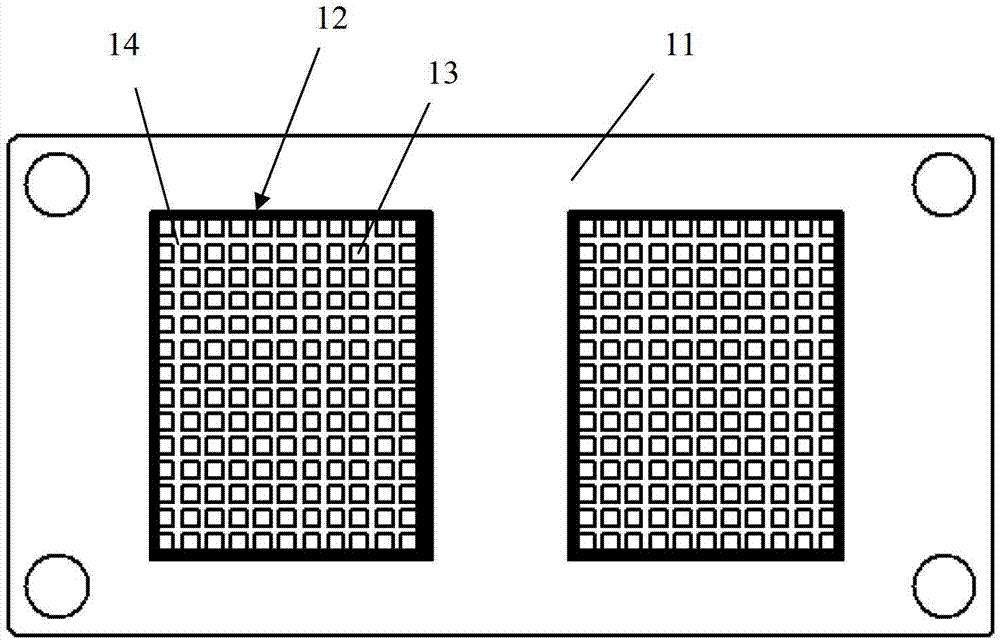

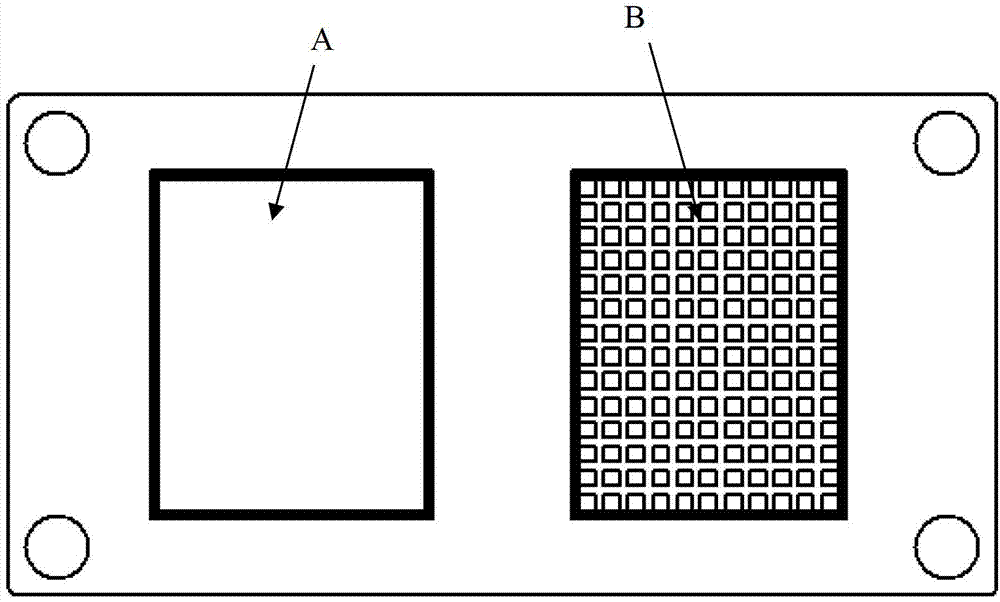

[0024] The embodiment of the present invention discloses an IGBT module, which includes a DBC substrate and a bottom plate welded to the substrate by solder, a welding area is defined on the welding surface of the bottom plate, and the welding area is divided into a plurality of area units by grooves, The area of each area unit is less than or equal to 1 / 100 of the area of the entire welding area.

[0025] Compared with the base plate (original base plate) in the prior art, the IGBT module base plate (grid base plate) designed in this application does not make any changes to the overall structural design of the original base plate, and the main difference from the original base plate design Yes, the grid design is carried out on the surface of the welding area of the original base plate, specifically, a certain shape of grid grooves is carried out on the surface of the welding area of the base plate, and the grooves in the welding area of the base plate are divided in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com