Brazing device and method capable of reducing solder overflow

A brazing method and solder technology are applied in the field of microwave hybrid integrated circuit generation equipment, which can solve the problems of inability to guarantee a low void rate and a large amount of solder overflow, and achieve the effects of improving reliability, reducing overflow and reducing void rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

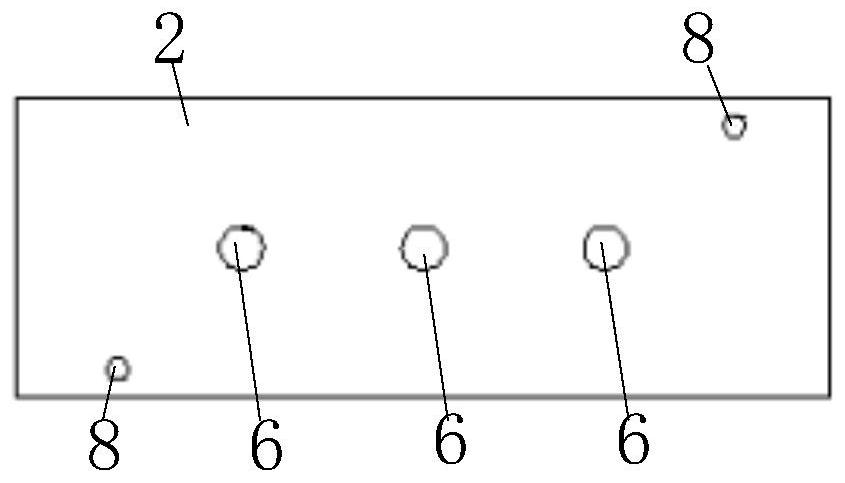

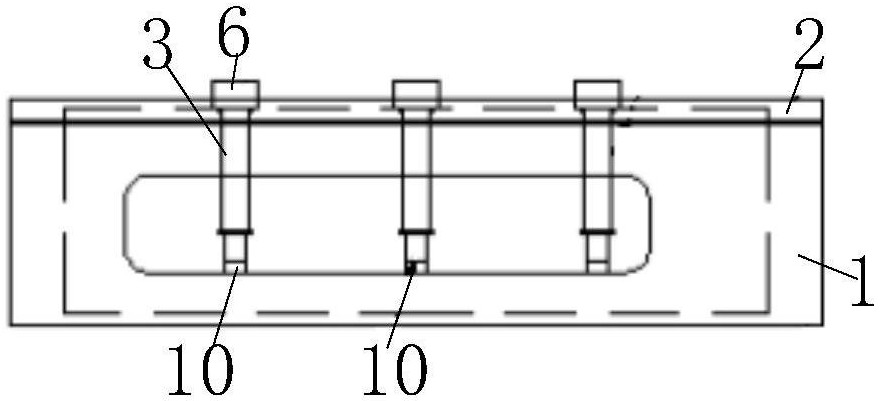

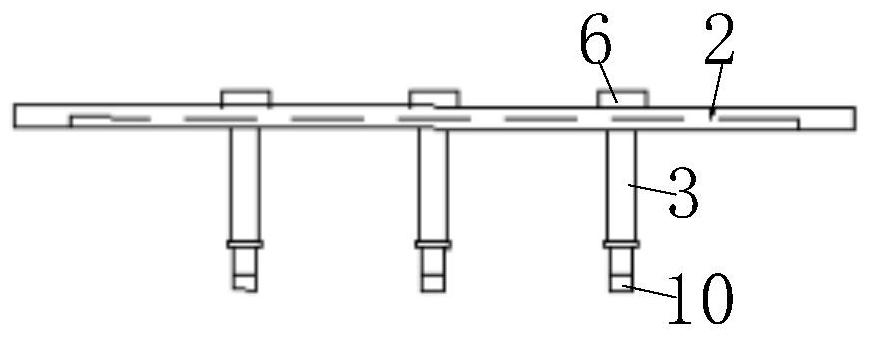

[0046] Such as Figure 1 to Figure 9 As shown, the embodiment of the present invention provides a soldering device for reducing solder overflow, which includes: a base 1 for loading parts to be soldered and a box body, a pressing plate 2, and at least one pressing pin for pressing parts to be soldered 3. The pressing plate 2 is detachably installed on the top of the base 1 , and the pressing pin 3 is slidably installed on the pressing plate 2 .

[0047] The beneficial effects of the present invention are: by designing a brazing device with a base, a pressing plate and a pressing needle to reduce the overflow of solder, the pressure of the parts to be welded is adapted to avoid the welding of the solder due to high p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com