Patents

Literature

769results about How to "Reduce spillage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

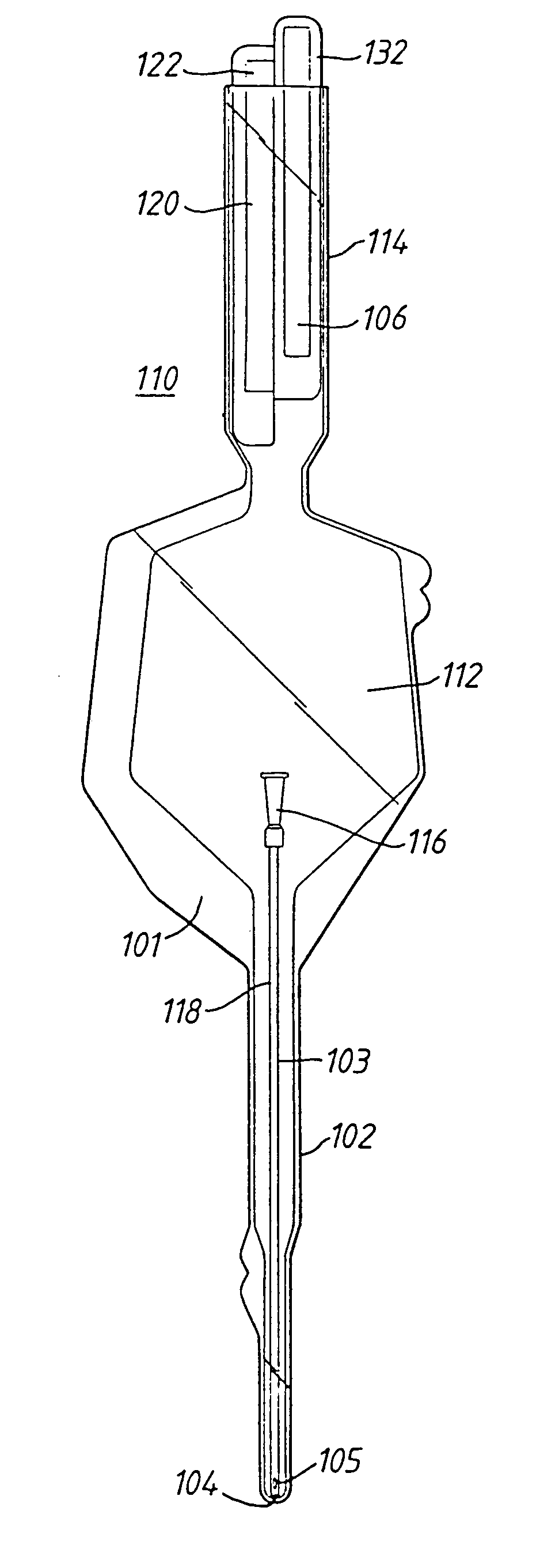

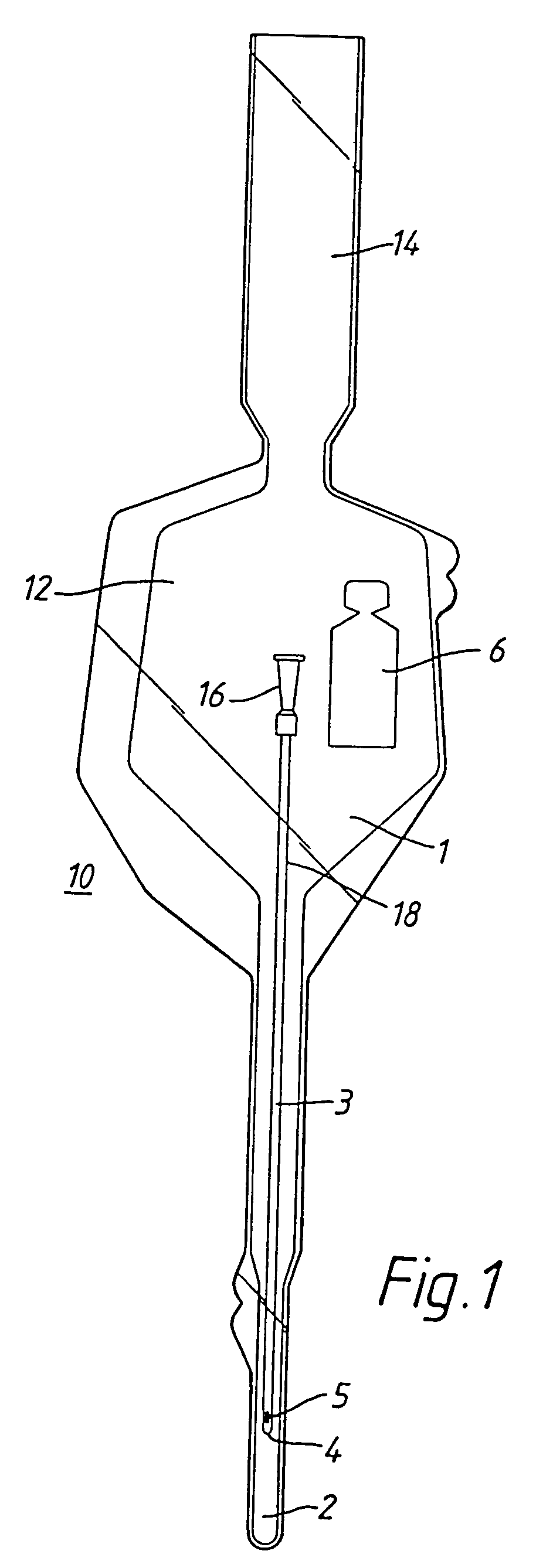

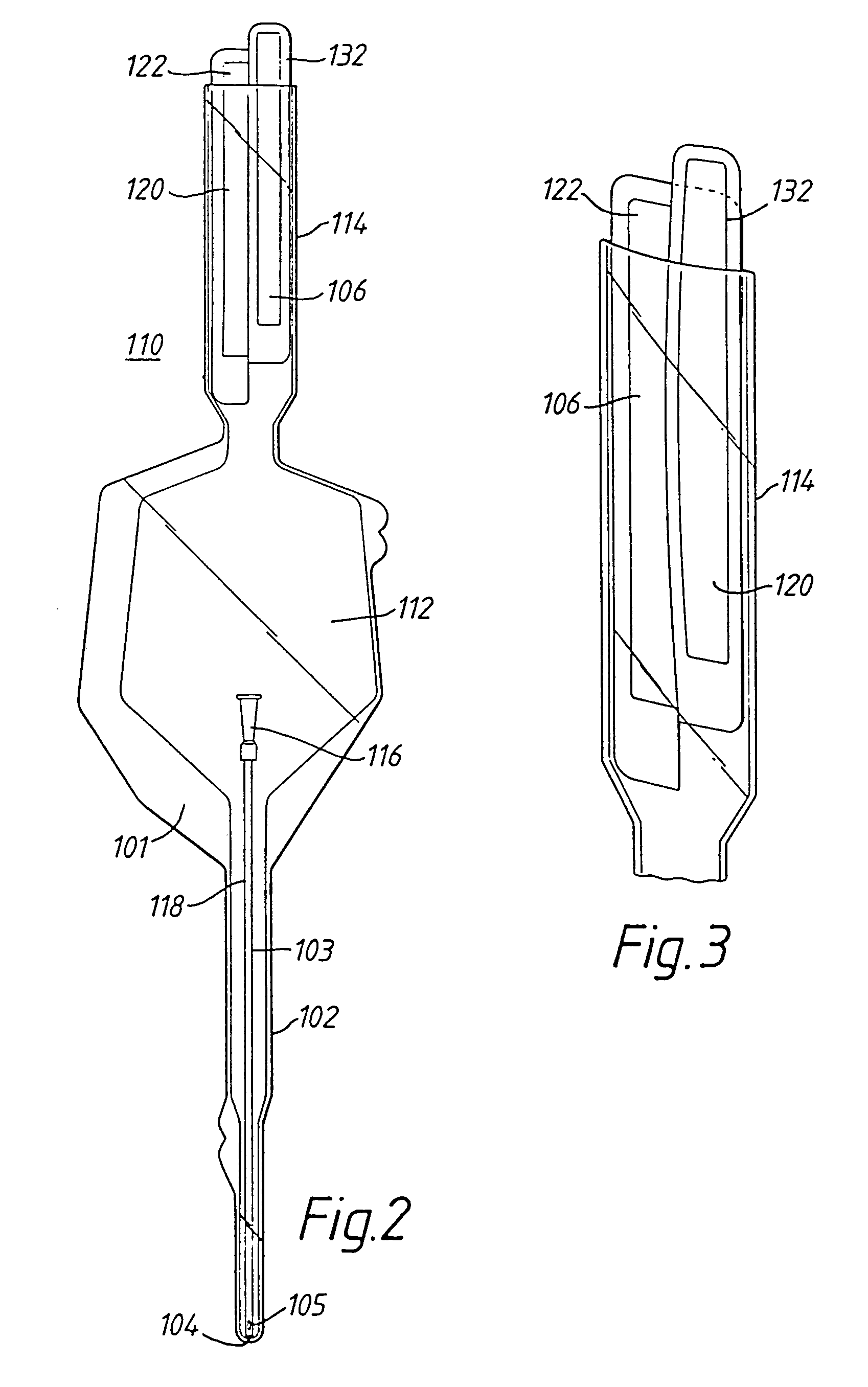

Hydrophilic urinary catheter having a water-containing sachet

InactiveUS7087048B2Easy to handleAvoiding and alleviating riskWound drainsCatheterUrinary catheterWetting

A wetting apparatus (110) for wetting a hydrophilic urinary catheter (103) comprises a wetting receptacle (101) which defines a wetting fluid receiving area (102) for receiving the hydrophilic urinary catheter and a hydrophilic urinary catheter wetting fluid container (106) having a discharge outlet (126) movable from a closed position to an open position on application of a predetermined condition thereto to enable the wetting fluid to be discharged from the wetting fluid container. The wetting fluid container provided can be positioned in the wetting receptacle in an operational position in which at least the discharge outlet of the wetting fluid container is disposed within the bounds of the wetting receptacle, the wetting receptacle being so constructed and the wetting fluid container being so disposed relative to the wetting receptacle when in the operational position that application of the predetermined condition to the discharge outlet of the wetting fluid container when in the operational position enables the wetting fluid to be discharged into the wetting fluid receiving area for wetting of the hydrophilic urinary catheter.

Owner:ASTRAZENECA AB

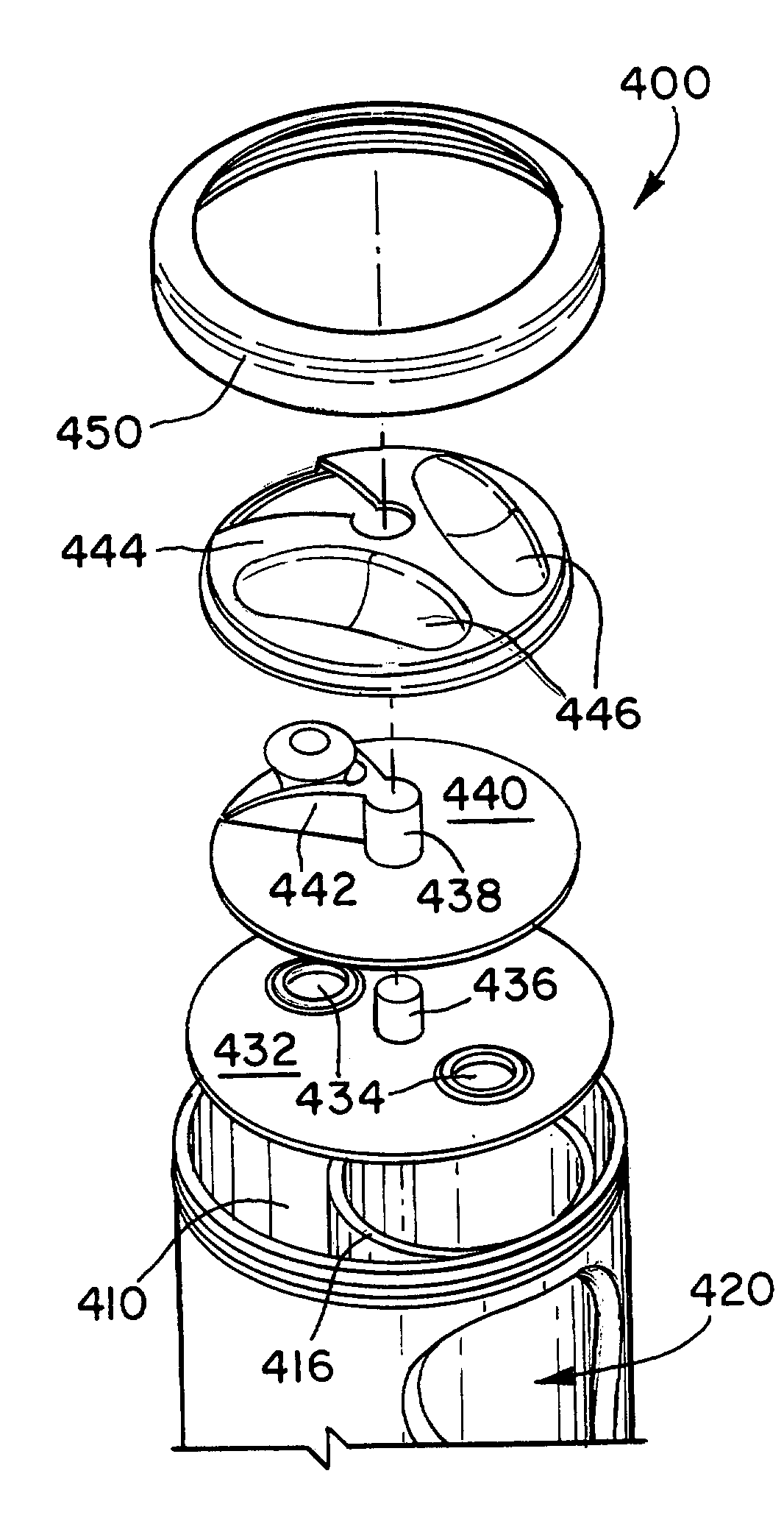

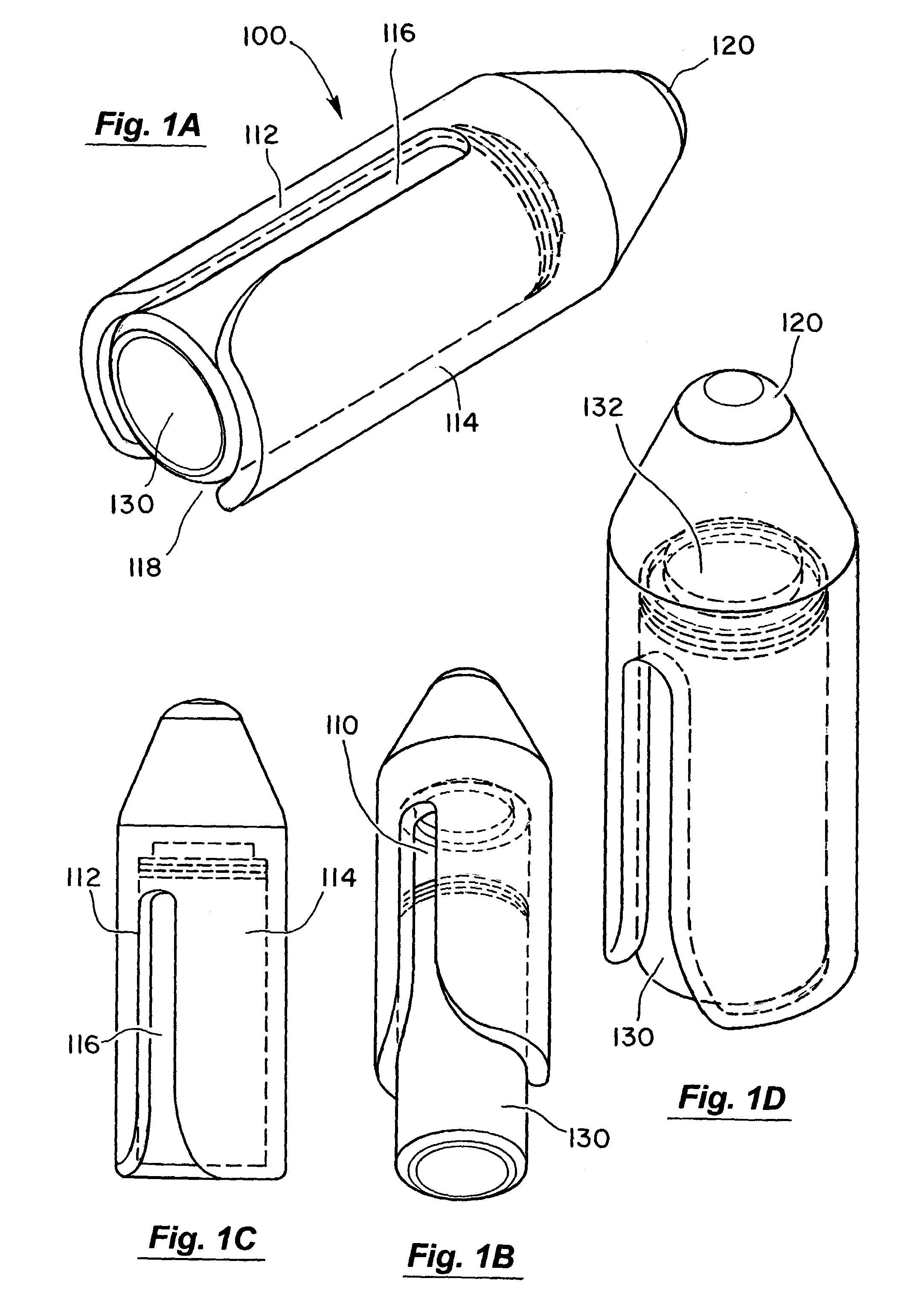

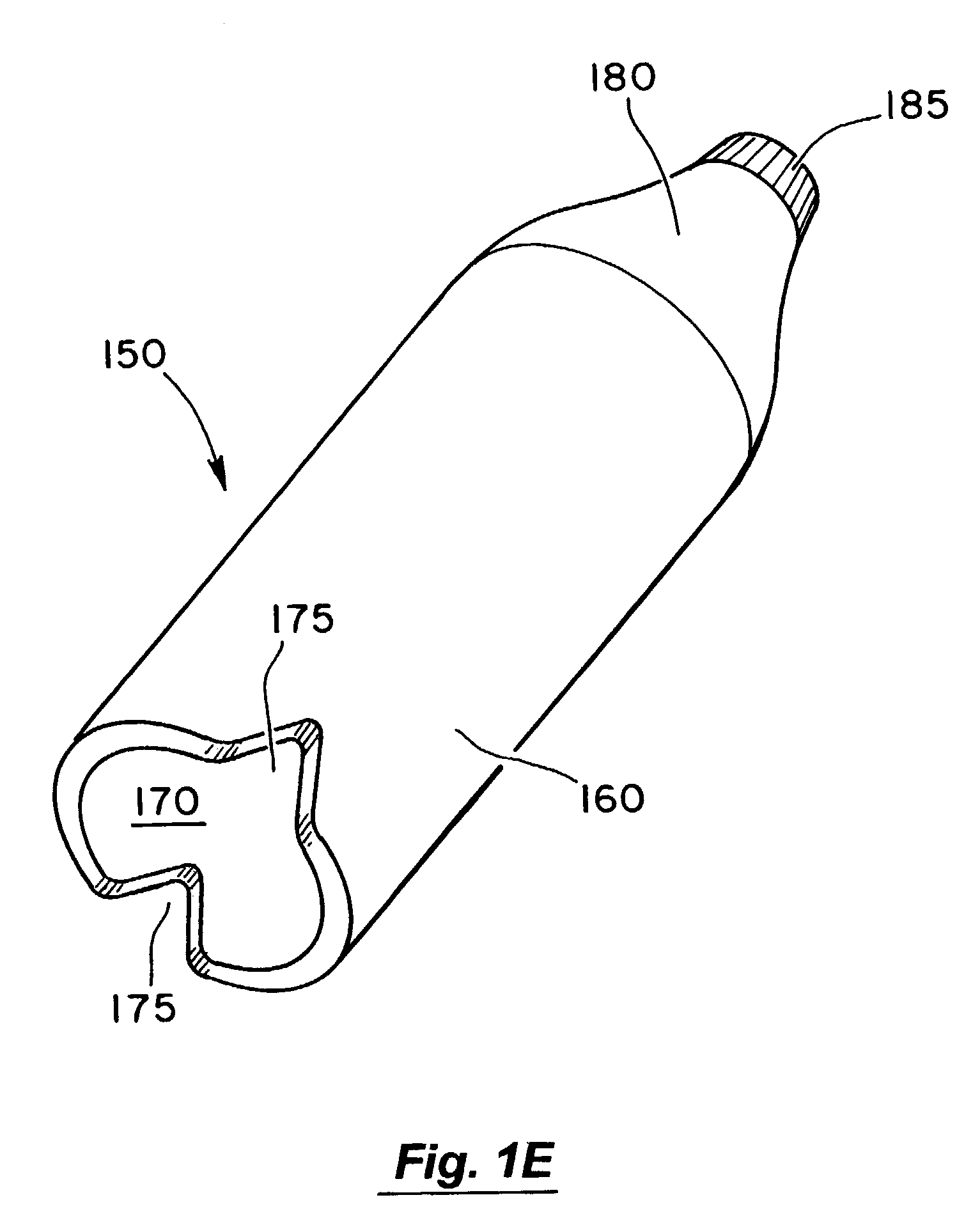

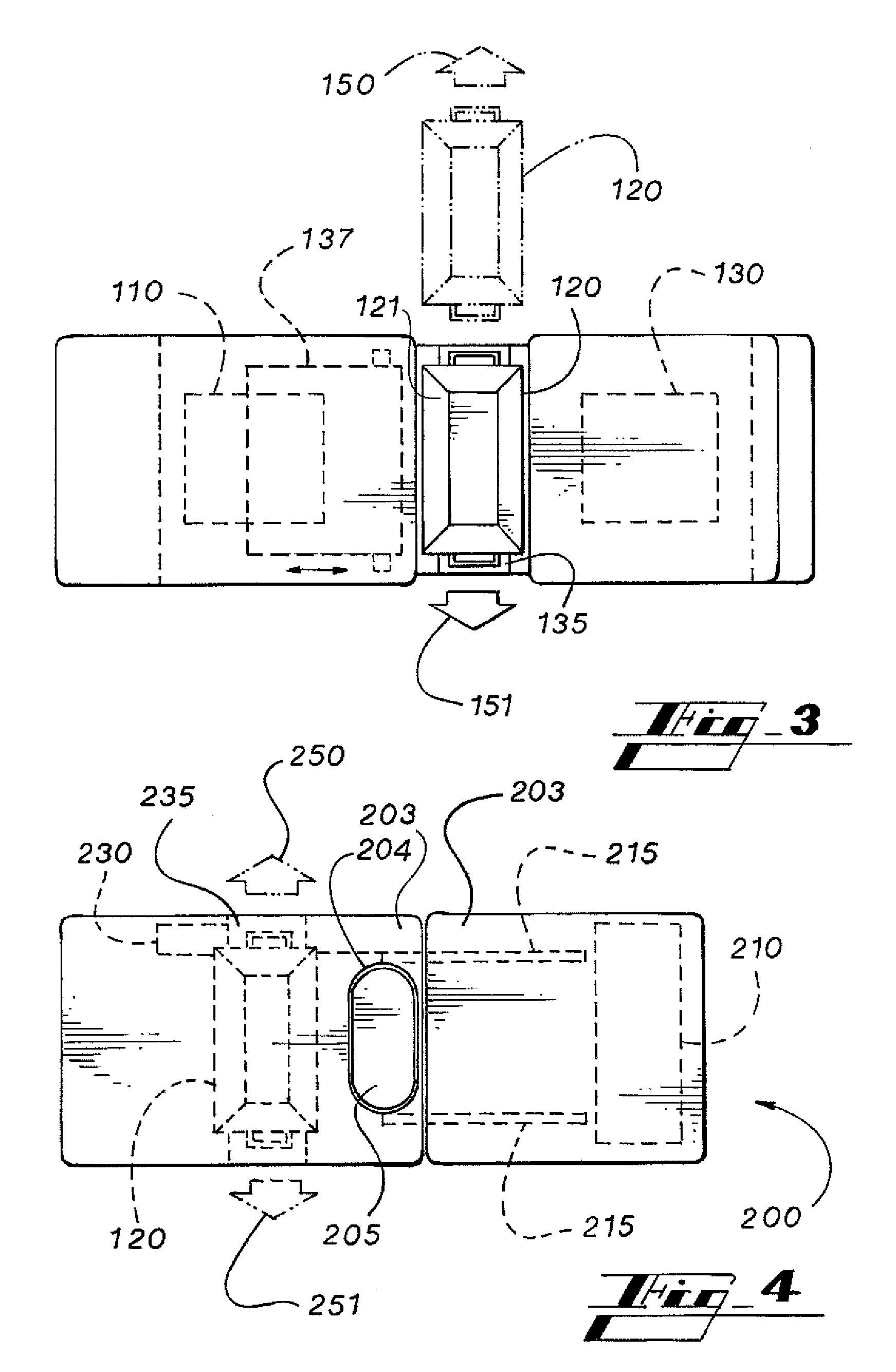

Beverage transporting and dispensing systems and methods

InactiveUS6971551B2Leakage of fluid is reduced and eliminatedEliminates spillageLiquid flow controllersLiquid transferring devicesEngineeringMechanical engineering

In one embodiment, a beverage dispensing container (100) includes a primary chamber (112, 114) for holding a first liquid and a fluid dispensing device (430) coupled to the primary chamber. The fluid dispensing device is adapted to provide access to the primary chamber when in a first position, and is adapted to fluidly seal the primary chamber when in a second position. The primary chamber further defines a cavity (110) adapted to receive a second container (130) therein. The second container holds a second liquid in a second chamber, and has a fluid port adapted to be opened to provide fluid access to the second chamber. A sealing mechanism (200) is adapted to fluidly seal the fluid port when the second container is disposed in the cavity. The sealing mechanism permits the removal of the second container from the cavity and the reinsertion of the second container into the cavity to fluidly reseal the open fluid port. In this manner, a second container, such as an energy drink container, can be opened and then stored in the sports fluid dispensing container of the present invention in a manner which reduces or eliminates spillage from the open second container.

Owner:GO FAST SPORTS & BEVERAGE

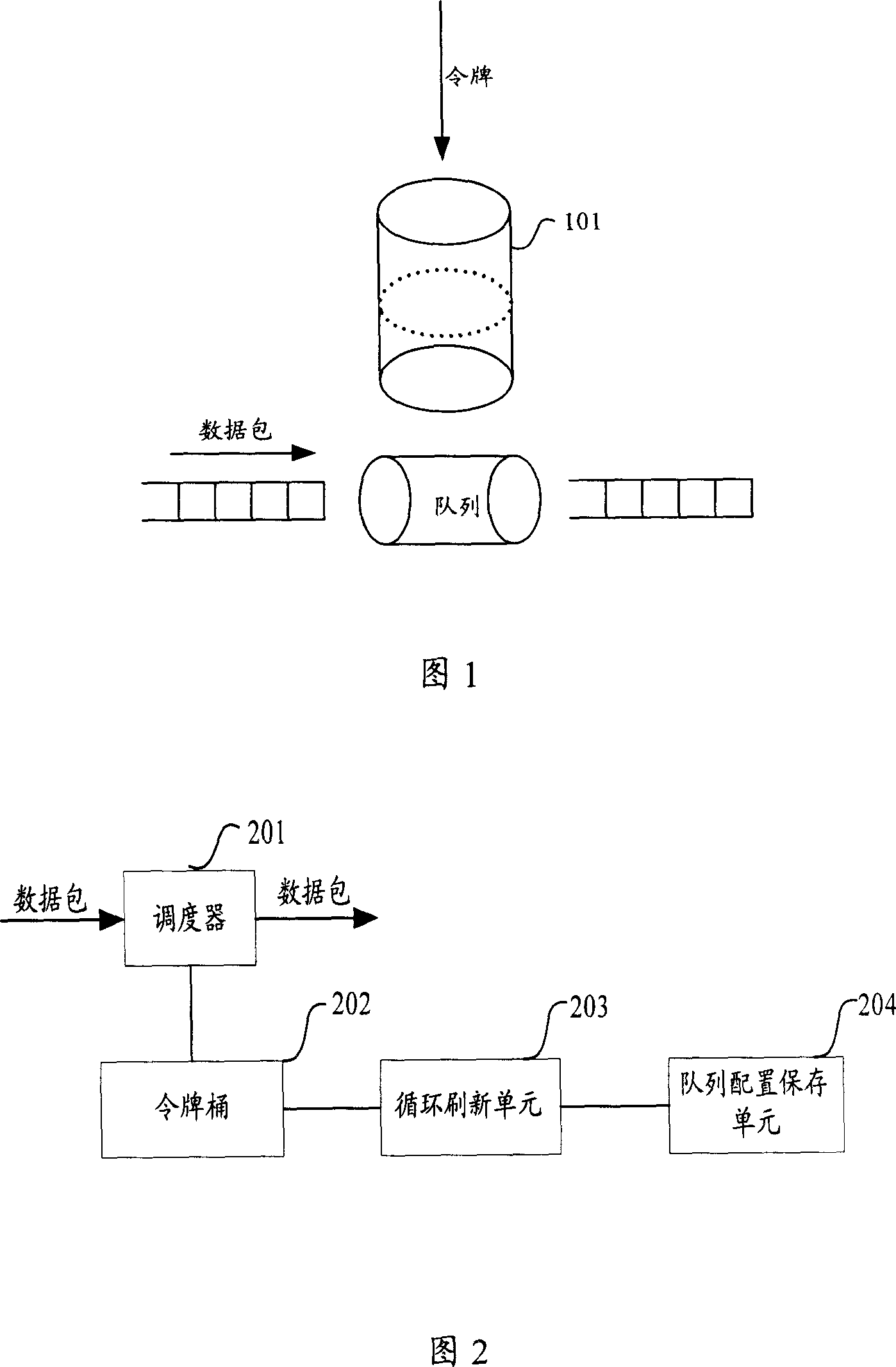

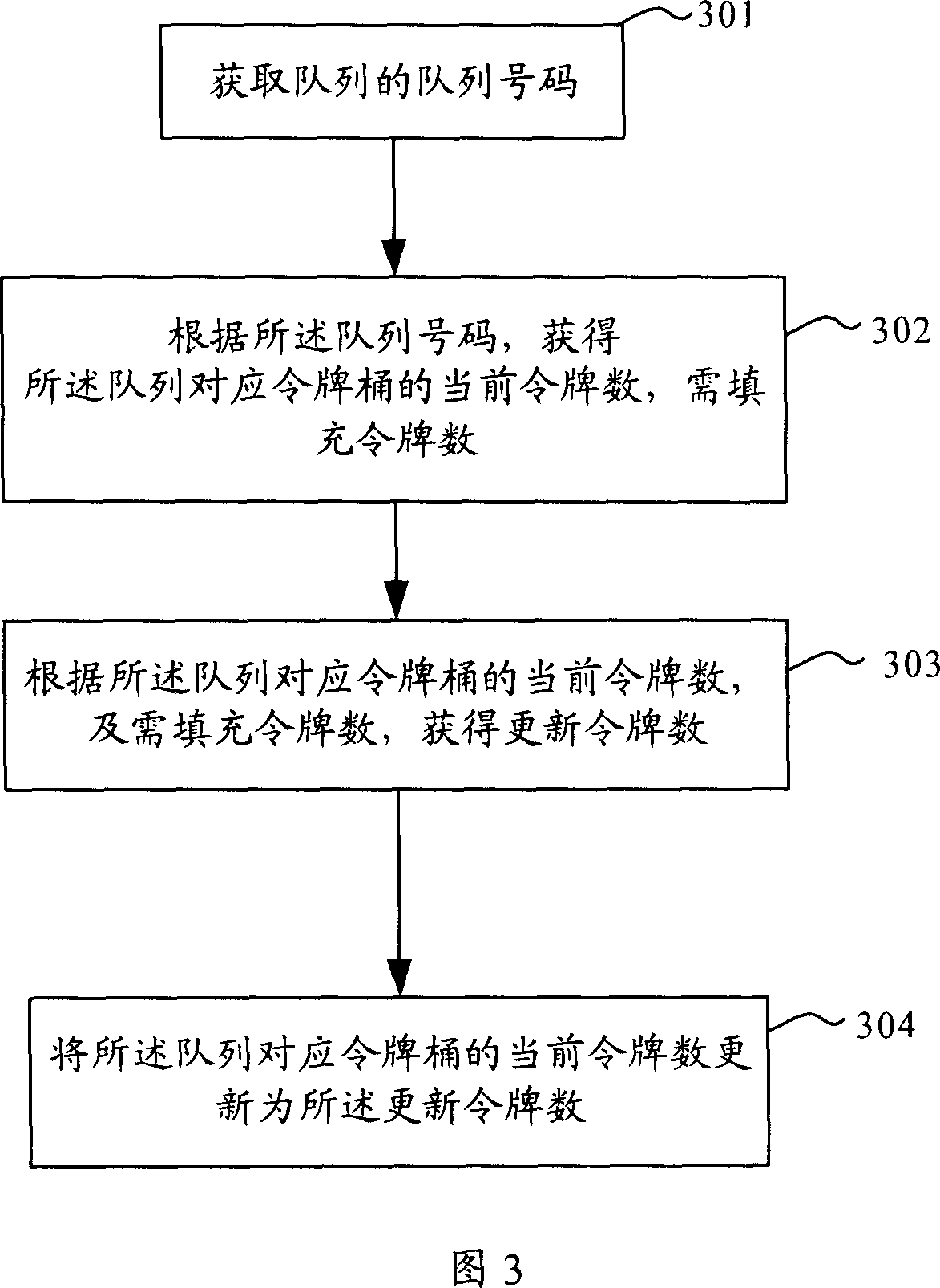

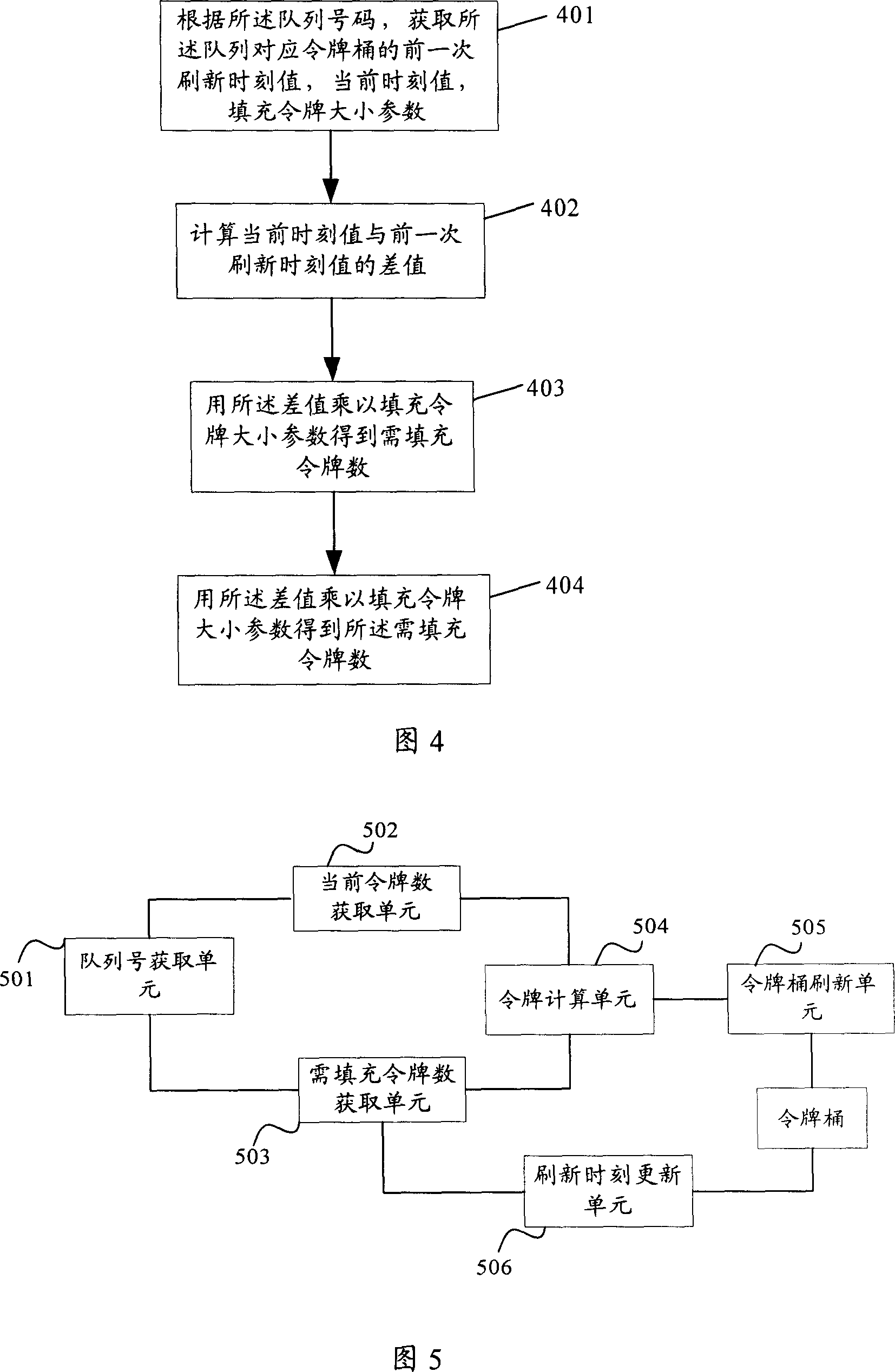

Method and device for refreshing token bucket in flow limiting technology

ActiveCN101005453AAvoid Bandwidth LossAvoid excessive traffic burstsData switching networksTraffic volumeDistributed computing

The method is used in the process of packet queuing and scheduling, and comprises: getting the queue number; according to queue number, getting the amount of current tokens and the amount of tokens to be filled up, both corresponds to the token-bucket; according to the amount of current tokens and the amount of token to be filled up, getting the amount of renewing tokens; renewing the amount of current tokens corresponding to the token bucket into the amount of renewing tokens. The invention also reveals an apparatus thereof.

Owner:HUAWEI TECH CO LTD

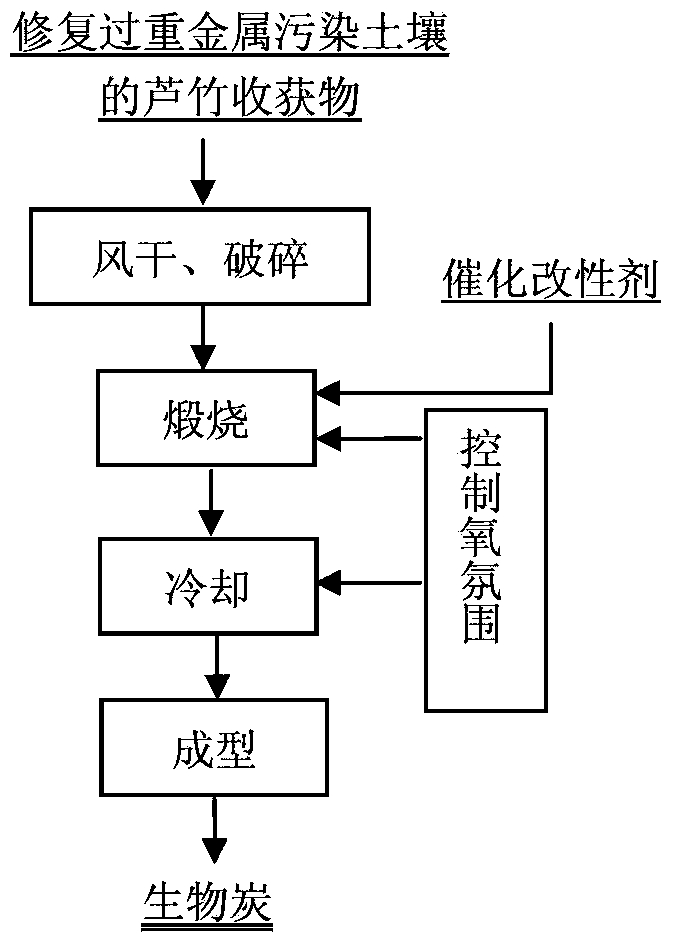

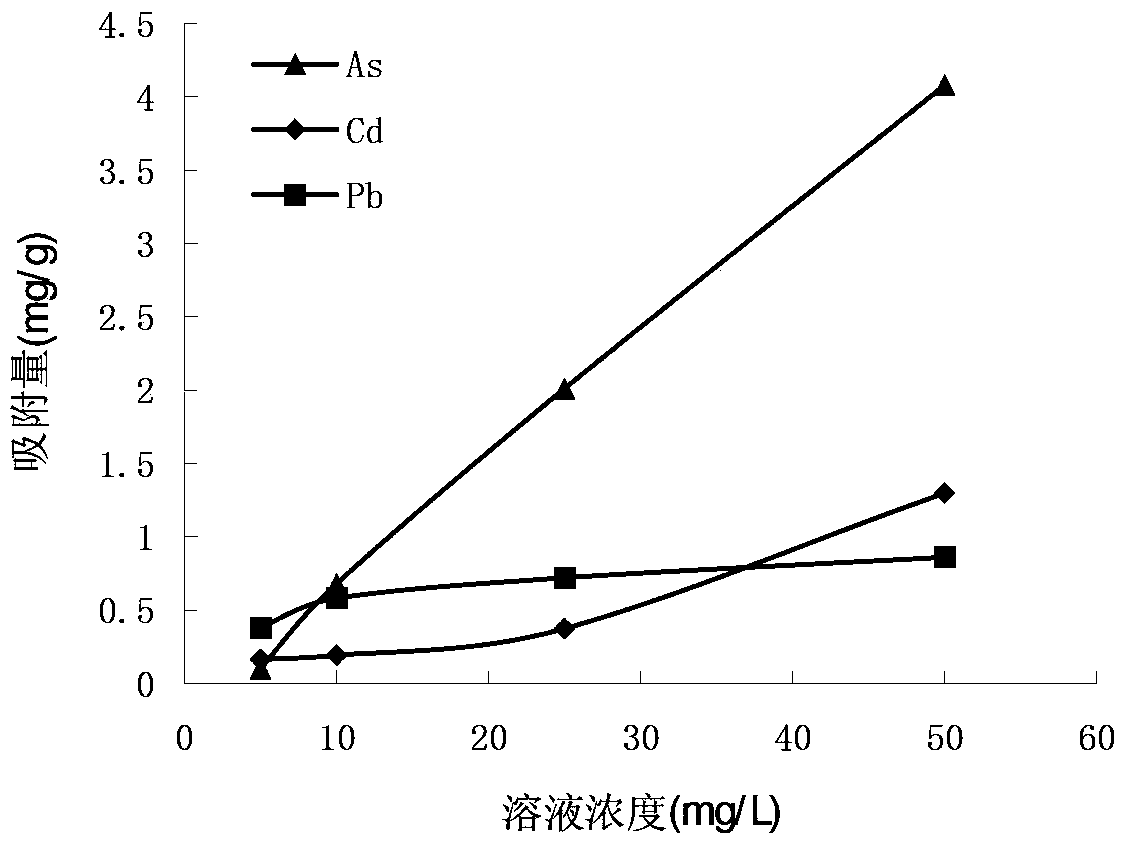

Resource utilization method of plant bamboo reed after restoring heavy metal contaminated soil

ActiveCN103464101APrevent proliferationRealize deep purificationOther chemical processesDispersed particle separationResource utilizationBiochar

The invention discloses a resource utilization method of plant bamboo reed after restoring heavy metal contaminated soil. The method comprises the following steps: air-drying and crushing the harvested plant bamboo reed used for restoring heavy metal contaminated soil, adding a catalytic modifier under a condition of controlling oxygen atmosphere, calcining the plant bamboo reed at 200-800 DEG C for 0.5-4 h, and cooling the plant bamboo reed to obtain charcoal, wherein the yield of the bamboo reed charcoal is 25-75%. When the bamboo reed charcoal is used for adsorbing heavy metals and compounds thereof in contaminated soil, wastewater or waste gases, the adsorption capacity reaches 0.4-6.0 mg / g; meanwhile, the bamboo reed charcoal can be used as an energy source raw material or a reducing agent to be comprehensively utilized by metallurgy enterprises. The invention provides an engineering approach for biomass resource utilization of contaminated soil restoring plants and solving the problem of potential secondary pollution.

Owner:CENT SOUTH UNIV

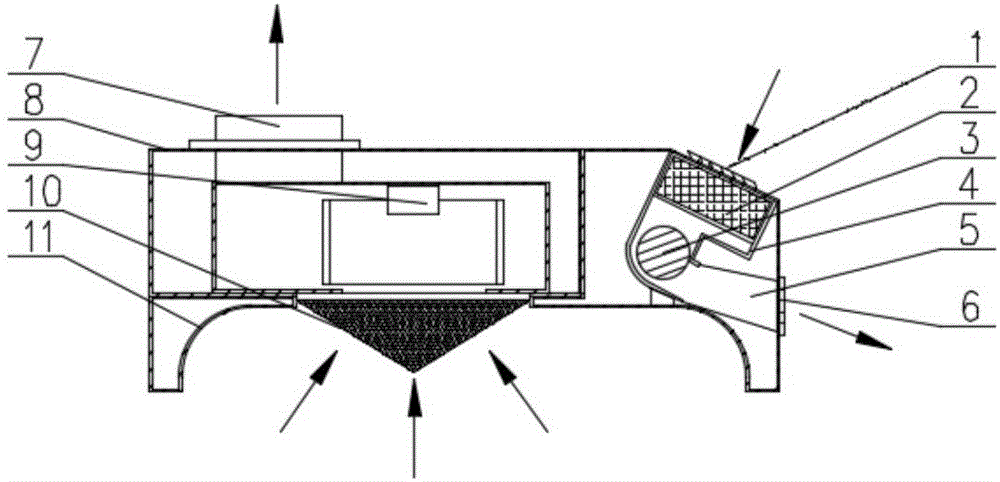

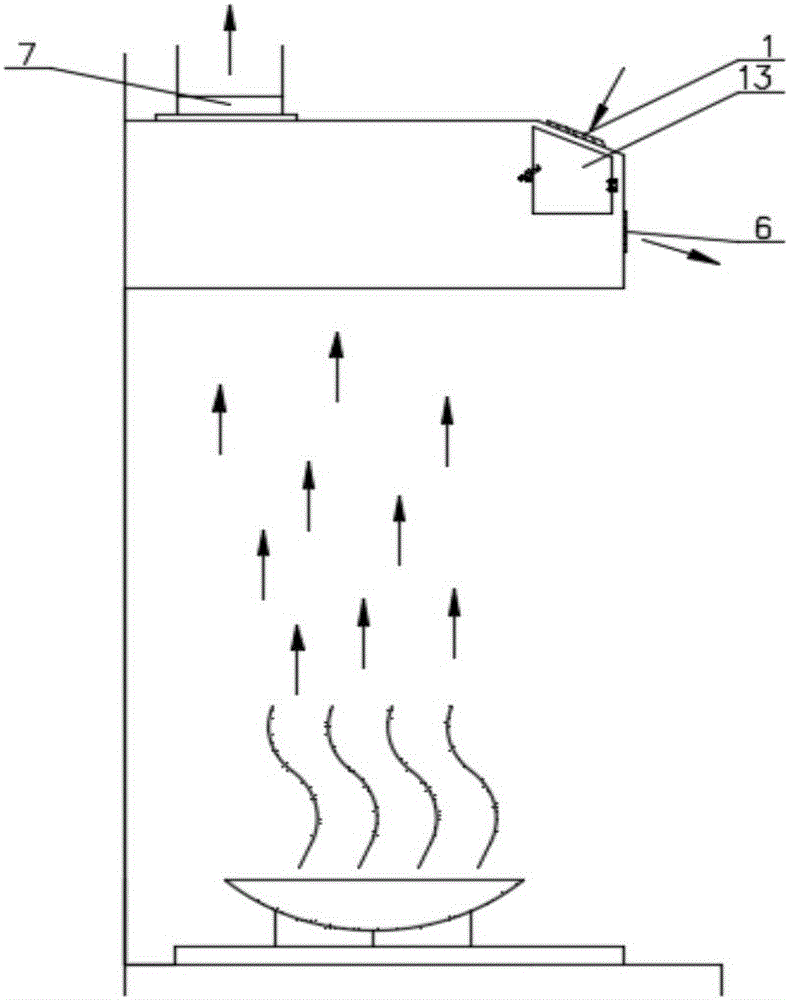

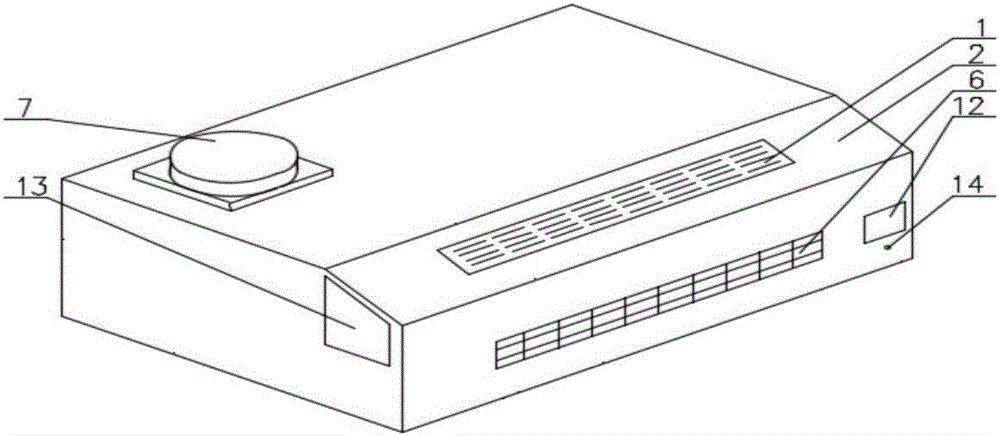

Range hood with personalized air purifier

InactiveCN106225037AGuaranteed aestheticsReduce spillageDomestic stoves or rangesLighting and heating apparatusControl systemEngineering

The invention discloses a range hood with a personalized air purifier. The range hood comprises a shell and a control system. A self-balance type air inlet is formed in the front side of a top plate of the shell. A double-layer shutter air supply outlet is formed in a front face plate of the shell. A controller and a PM2.5 mass concentration sensor are installed on the front face plate of the shell. In the flowing direction, from the top of a kitchen to a human body breathing area, of primary air, a combined multilayer filter and a silent cross-flow fan are sequentially installed in the air purifier, and an air outlet is formed in the exhaust direction of the silent cross-flow fan. Due to the adoption of the device, it is ensured that the fan is stable and low in noise in the running environment, detection and overall control of the air quality in a human body head breathing area are achieved, harm of cooking fume particles and gas to human bodies is reduced, and meanwhile overflow of the cooking fume can be reduced through a lateral lower air supply curtain.

Owner:TIANJIN UNIV

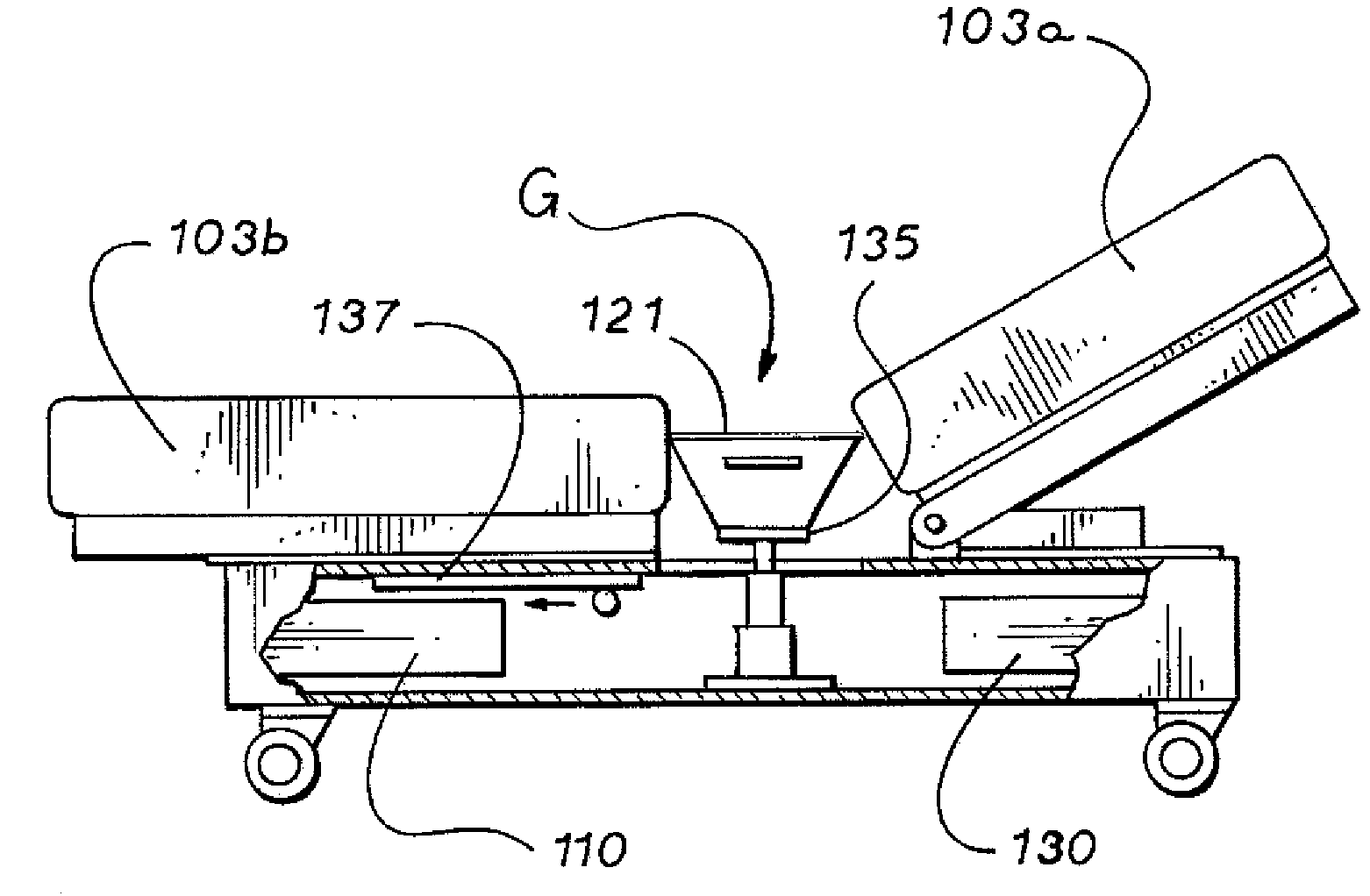

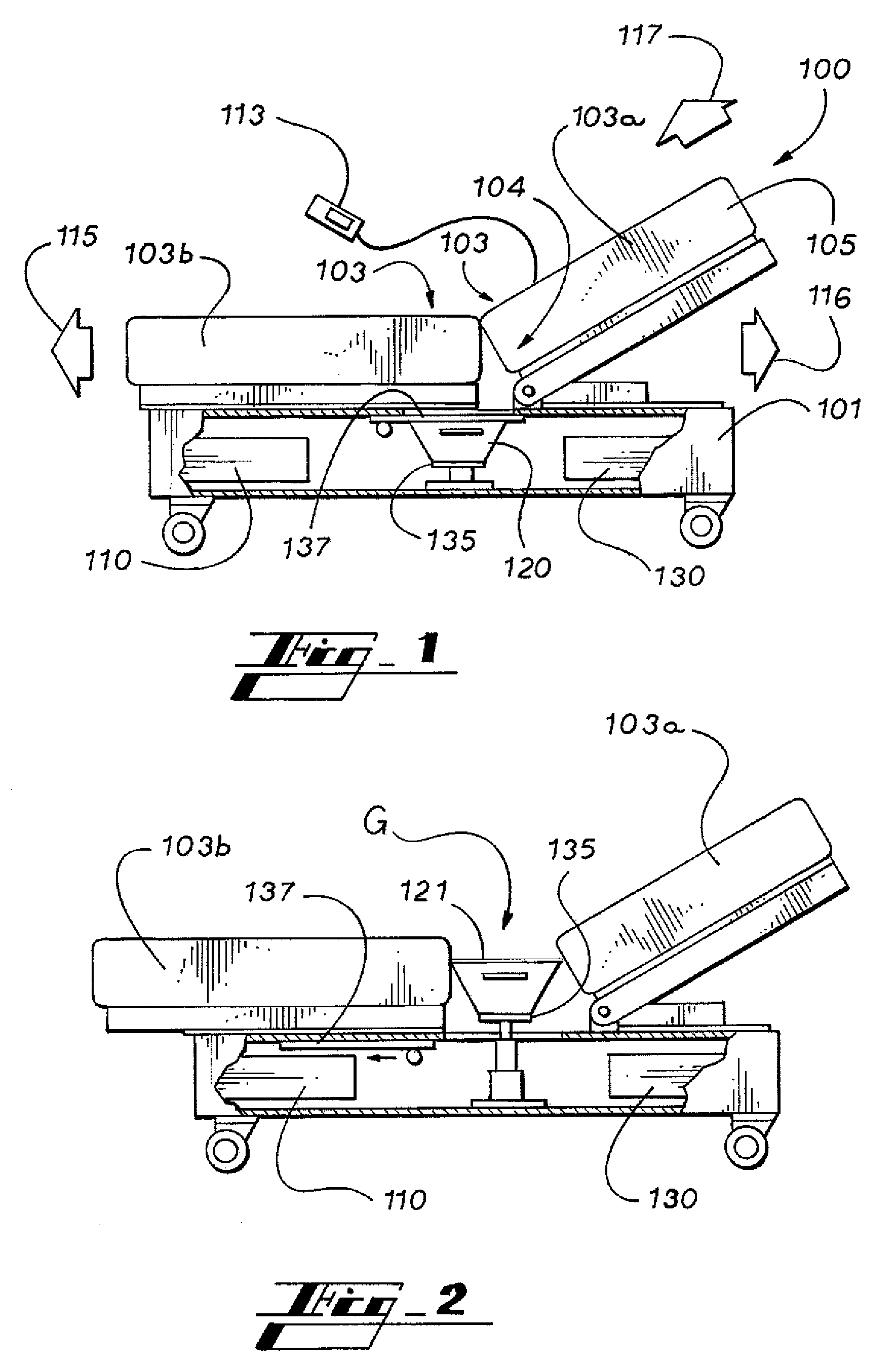

Automated bedpan system and method therefor

InactiveUS20080229502A1Prevent overflowReduce and preventNursing bedsRigid tablesProximateEngineering

An automated bedpan system for selectively moving a bedpan between a first storage position, such as beneath a bed, and a second use position, such as proximate an opening in the bed, such that an individual in the bed may use the bedpan with or without assistance, in a safe, convenient, and comfortable manner, with reduced risk of spillage of waste material, and such that after use the bedpan may be stored without spillage of waste material and without leakage of odor from the bedpan.

Owner:JOHNSON WILLIAM

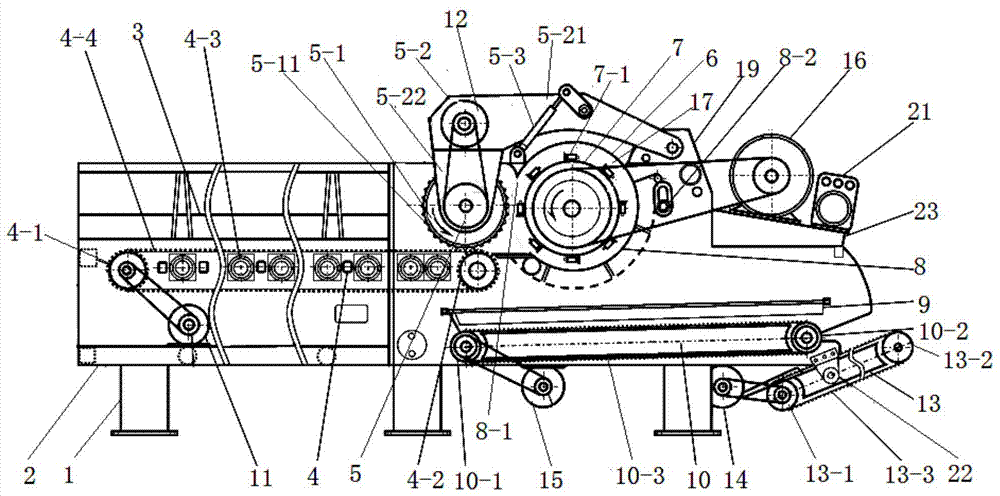

Biomass fuel crusher

The invention discloses a biomass fuel crusher. The biomass fuel crusher comprises a supporting base, wherein a rack is arranged on the supporting base, a feeding bin is arranged at the front part of the rack, a crawler-type feeding conveyer is horizontally distributed in the feeding bin, a forced feeding roll is arranged at the top part of the rear end of the crawler-type feeding conveyer, a crushing compartment is arranged on the rack at the rear part of the forced feeding roll, a crushing roll is arranged in the crushing compartment, a crushing cutter bit is arranged on the surface of the crushing roll, a crushing separating screen is coaxially sheathed at the periphery of the crushing roll, a crushing feeding hole matched with the forced feeding roll is formed at the front part of the crushing separating screen, a discharging compartment communicated with the crushing compartment is arranged at the bottom of the crushing compartment, a discharging hole is formed at the bottom of the discharging compartment, and a discharging conveyer is arranged under the discharging hole. According to the biomass fuel crusher, the universality of the crusher is improved, various biomass fuels in wastes in the fields of agriculture, forest industry, industry, construction industry and the like can be subjected to crushing processing, the operating efficiency and the crushing quality of the crusher are improved, the service life of the crusher is prolonged, the power consumption is reduced, and the using cost and the operating expense are reduced.

Owner:格薪源生物质燃料有限公司

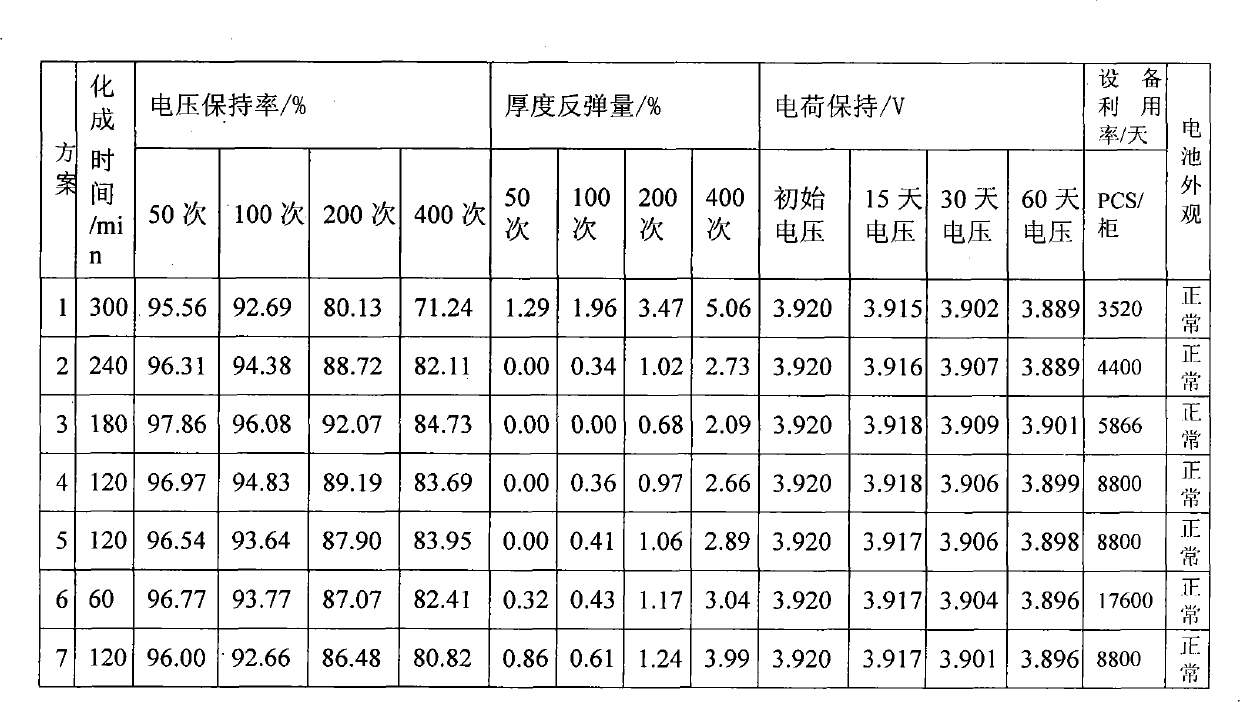

Negative pressure formation method of lithium ion battery and battery thereof

InactiveCN101908647AReduce the impactDegree of eliminationFinal product manufactureElectrolyte accumulators manufactureCurrent rangeInternal resistance

The invention relates to a negative pressure formation method of a lithium ion battery and the battery thereof. The negative pressure formation method comprises the following steps: sticking a hydrophobic permeable membrane on a liquid filling hole of the battery, adopting the negative pressure formation technology for carrying out formation on the battery, controlling the battery internal pressure in the range of vacuum degree of minus 0.01MPa-minus 0.1MPa, charging in the current range of 0.01C-1.5C, and carrying out the formation through the time control of the charging volume of the lithium ion battery. The battery formed by the method has high capacity playing of active substances, small internal resistance, small probability of shell bulging, long cycle life and long shelf life and is not affected by environmental humidity. Simultaneously, the method has the advantages of short formation time, high utilization rate of equipment, small energy consumption and small electrolyte loss, and is the high-efficient formation method which is conductive to environmental protection and suitable for mass production of the lithium ion batteries.

Owner:广东省惠州市泰格威电池有限公司 +1

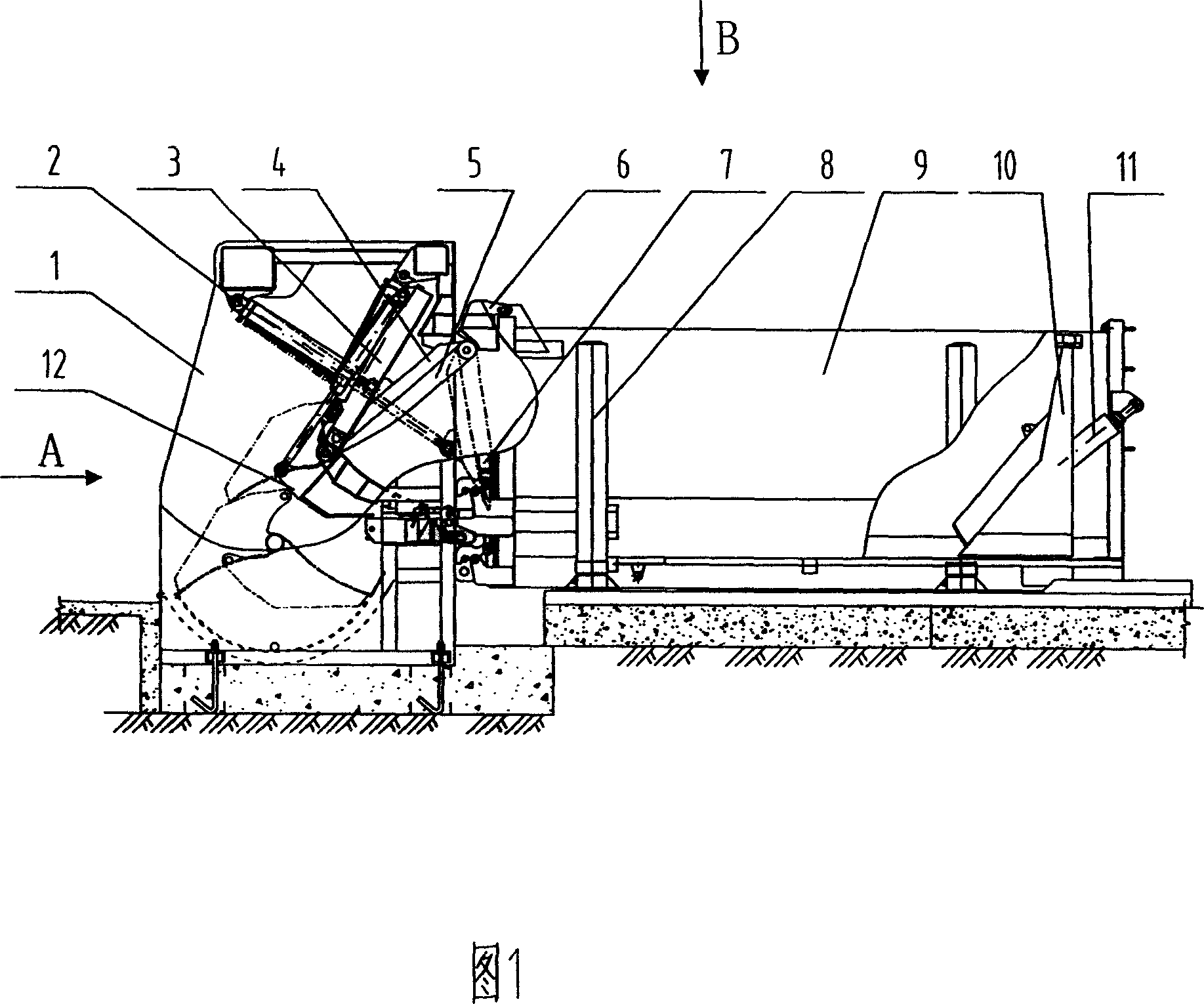

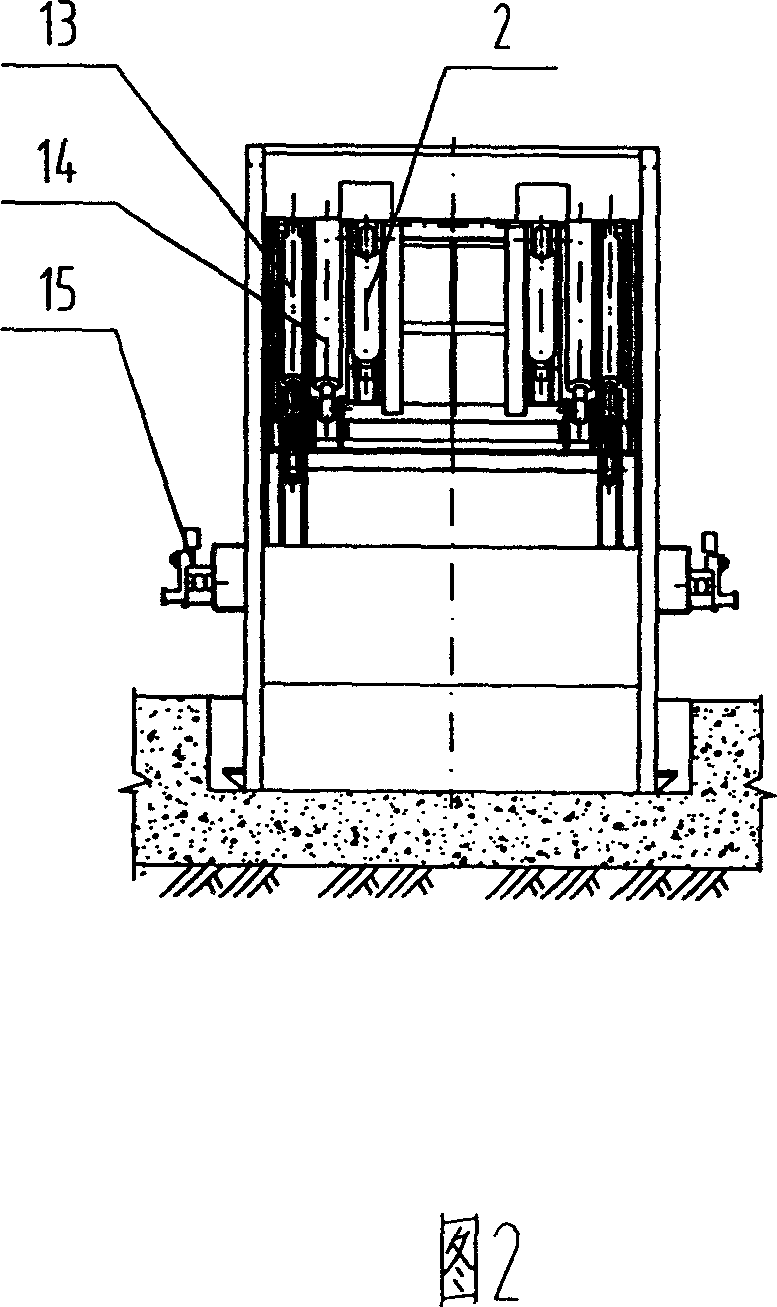

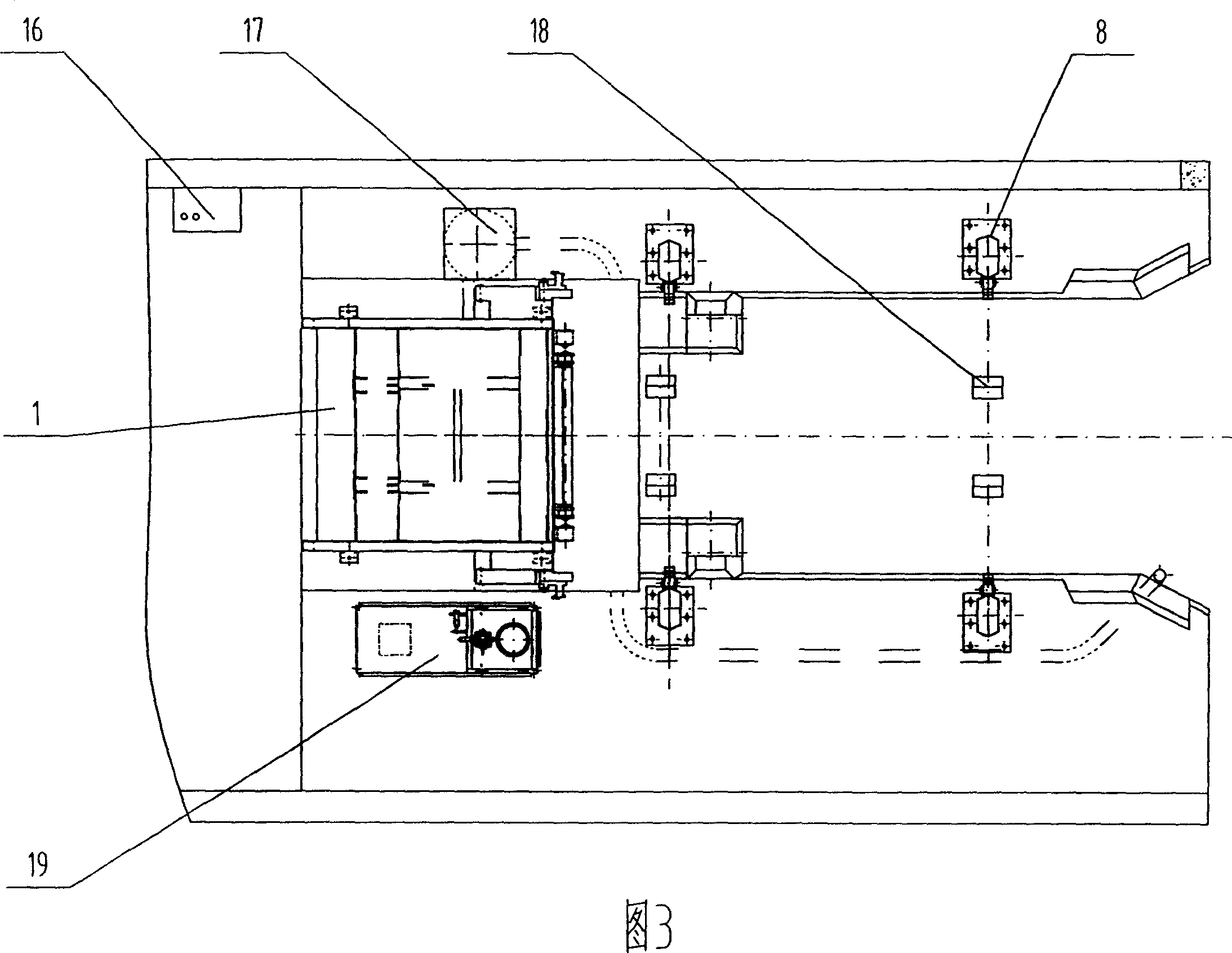

Two-stage scraper type garbage compression and transfer apparatus

InactiveCN1919703AGarbage to reasonableThe mechanism is evenly stressedRefuse transferringLoading/unloadingSewageControl system

The invention discloses a two-grade scraper-typed rubbish compressing rotary device, which comprises the following parts: wagon, rubbish compressor, wagon mobile locating device, hydraulic dynamic system and electric appliance control system, wherein the rubbish elevation mechanism of rubbish compressor possesses certain separation angle of vertical direction for rubbish compressor bulk, the pushing board locking mechanism of rubbish compressor and joint scraper board constitutes rubbish press-loading mechanism with rubbish elevating mechanism and loading mechanism individually, the effluent collecting and draining structure is set on the back door of wagon.

Owner:广西玉柴专用汽车有限公司

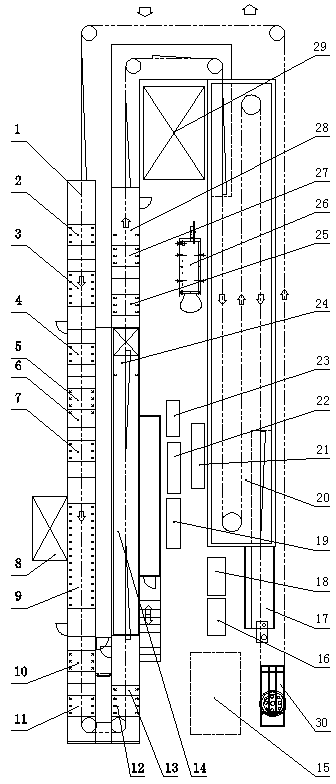

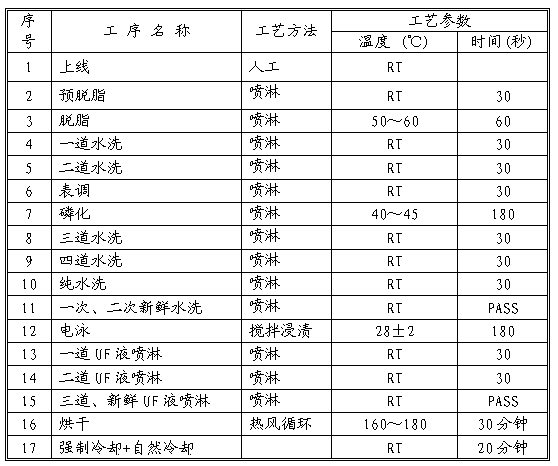

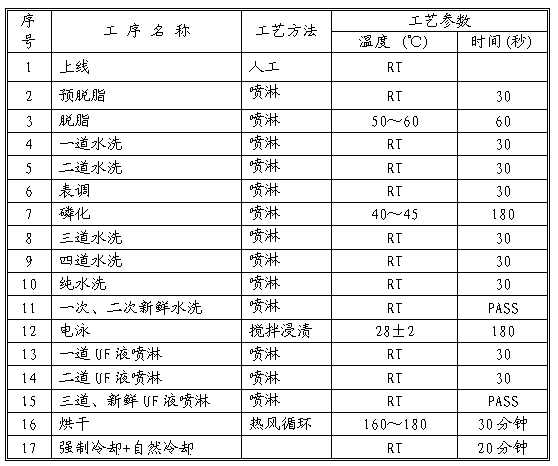

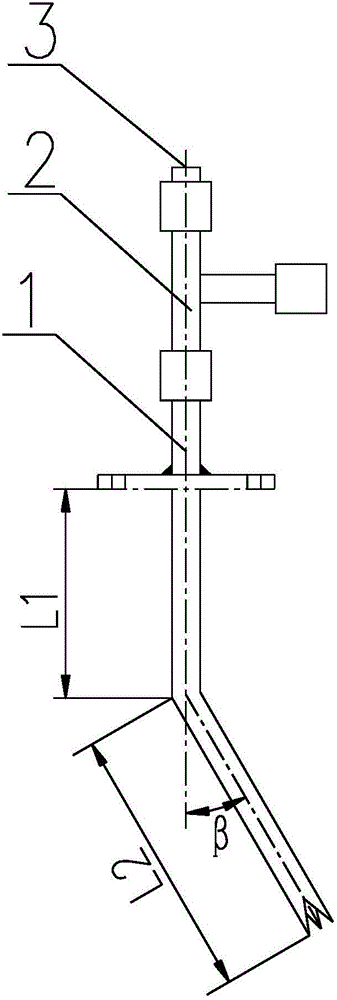

Electrophoresis apparatus and process suitable for automobile leaf spring

ActiveCN103436941AImprove adsorption capacityImprove heat exchange capacityElectrophoretic coatingsSheet steelElectrophoresis

The invention discloses an electrophoresis apparatus and process suitable for an automobile leaf spring. Ball-blasted reeds are subjected to degreasing, parkerizing, water washing and other pretreatments through a conveying chain, then enter an electrophoresis trough, are automatically dried, subjected to strong cold and cooled down after electrophoresis and are finally off-line; the reeds are assembled into a leaf spring assembly after electrophoresis, and the assembly is subject to surface paint spraying through an electrostatic painting line so as to meet the requirements on product corrosion protection and surface colors of clients. The invention overcomes the shortcomings of a conventional leaf spring coating technology, and creates a brand-new leaf spring coating technology-the process route and production equipment adopting leaf spring uniwafer electrophoresis plus assembly surface painting. The process saves energy and labor, achieves high utilization ratio of paint, enables the salt fog resisting capability of the leaf spring to be higher than 300 h, and simultaneously improves and prolongs the surface quality and the service life of the reeds.

Owner:安庆安簧汽车零部件有限公司

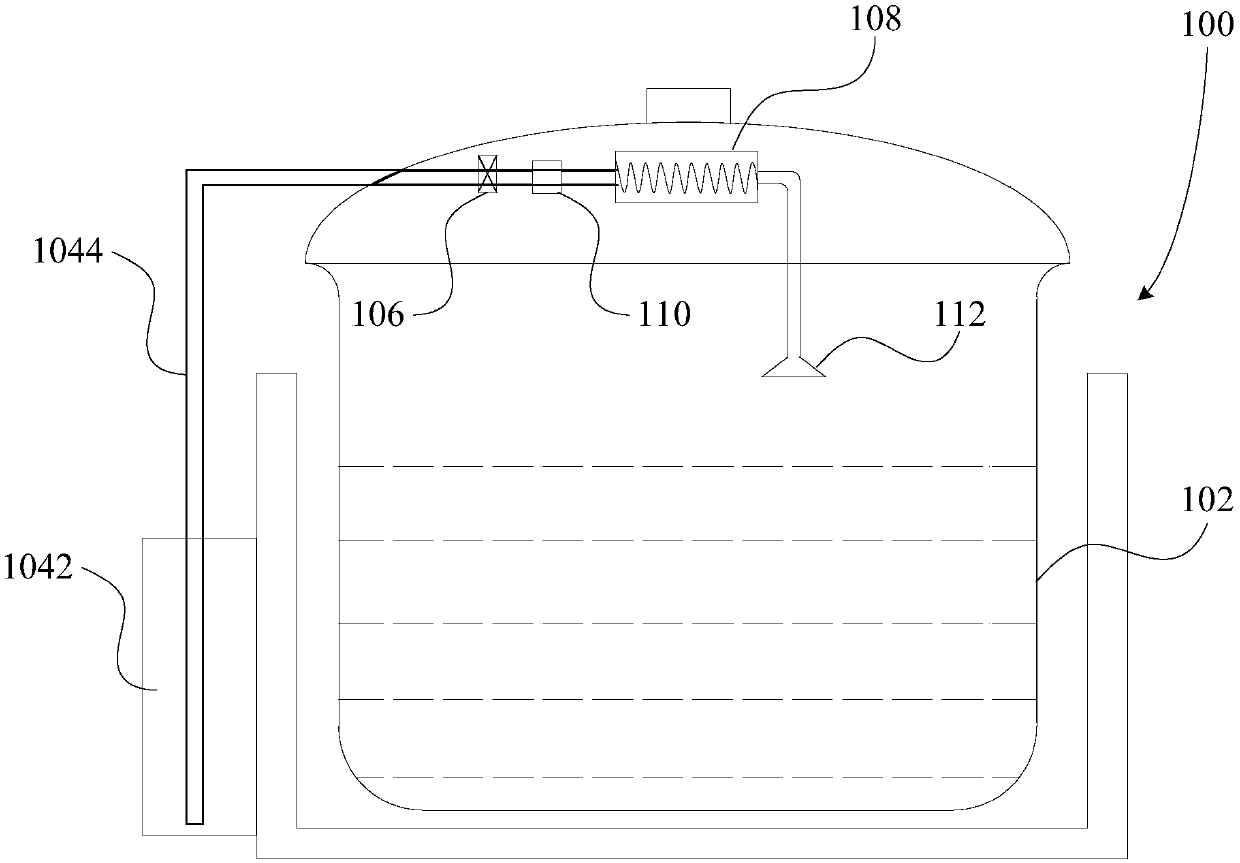

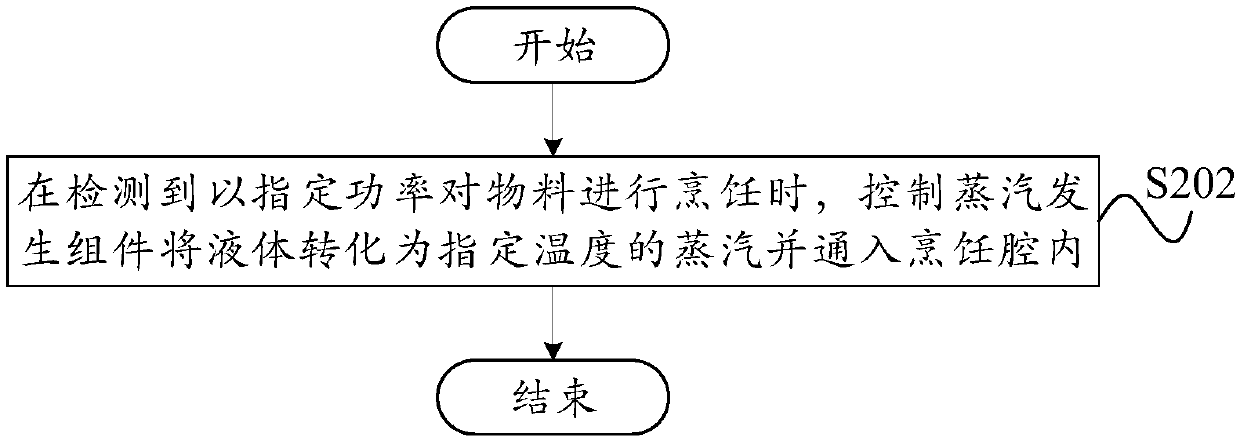

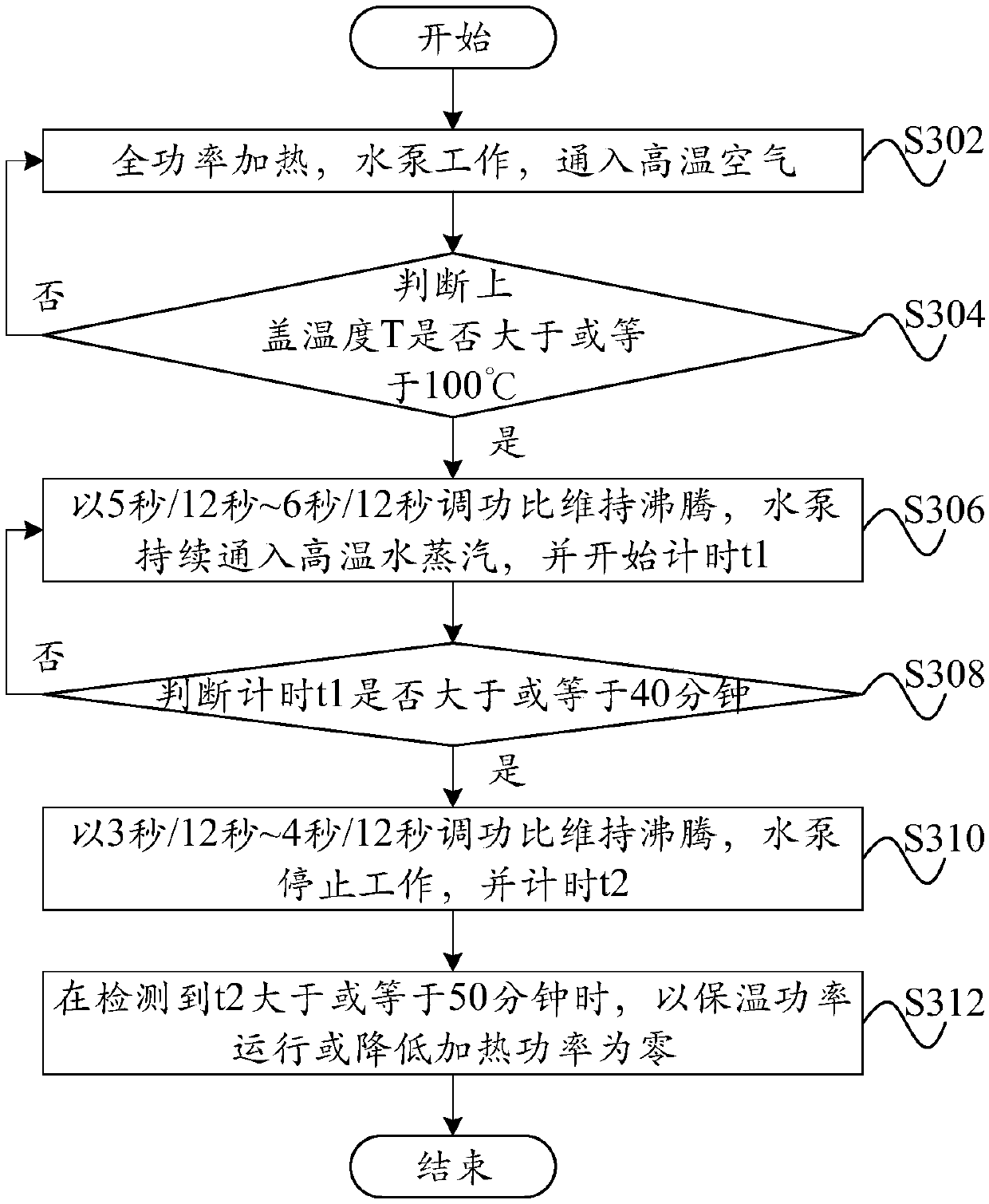

Cooking utensil, cooking method and computer readable storage medium

ActiveCN110547671AImprove accuracyGreat tasteSteam cooking vesselsVessels with intergral heatingProcess engineeringFood material

The invention provides a cooking utensil, a cooking method and a computer readable storage medium, wherein the cooking utensil comprises a cooking cavity and a steam generating assembly; the cooking cavity is used for containing materials to be cooked; the steam generating assembly comprises a liquid storage part and a steam passage; the liquid storage part is arranged at the outer side of the cooking cavity and is used for storing liquid used for generating steam; and the steam passage is arranged in a way of communicating with the liquid storage part and the cooking cavity and is used for converting liquid into steam with the specific temperature and introducing the steam into the cooking cavity. By using the technical scheme of the invention, the cooking temperature rise speed in the cooking cavity is accelerated; the content of oxygen gas in the cooking cavity is improved so as to promote oxidization decomposition of fat in food materials; the eating mouthfeel of the food materialsis further improved; and the use experience of a user is comprehensively improved.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

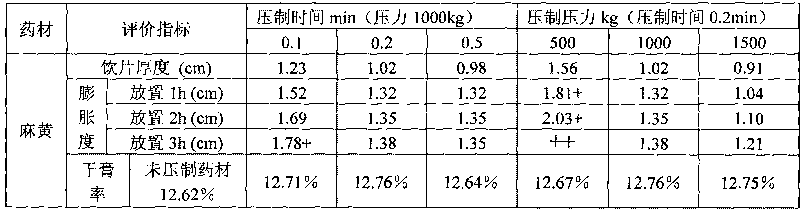

Method for preparing quantitatively-pressed traditional Chinese medicinal tablets or traditional Chinese medicinal materials

InactiveCN101716193AQuality assuranceEasy to storeUnknown materialsPlant ingredientsPharmacyCurative effect

The invention provides a method for preparing quantitatively-pressed traditional Chinese medicinal tablets or traditional Chinese medicinal materials. The method comprises the following steps of: a, selecting the traditional Chinese medicinal tablets or the traditional Chinese medicinal materials; b, mechanically pressing the traditional Chinese medicinal tablets or the traditional Chinese medicinal materials into cubes with specified weight; c, packaging the cubes with packing materials after the cubes are molded; and d, adding an identification mark on the package of the pressed traditional Chinese medicinal tablets or traditional Chinese medicinal materials. According to the method, the traditional Chinese medicinal tablets or the traditional Chinese medicinal materials are pressed into quantitative single parts, so the preparation process is simple, and auxiliary materials, and other processes of wetting, drying, and the like are not needed; the equipment is simple and can be easily operated; the method is in favor of the mechanized production and the automatic packaging of the traditional Chinese medicinal tablets or the traditional Chinese medicinal materials; the volume of the pressed traditional Chinese medicinal pieces is reduced by 3 to 5 times, so the appearance is beautiful, the needed areas of a storage and a pharmacy are reduced, and the pressed traditional Chinese medicinal pieces are convenient to carry, transport and store; and the quality is controlled accurately, so that the prescription dosage is accurate and reliable and the prescription can be easily regulated. The original characteristics of the traditional Chinese medicinal tablets or the traditional Chinese medicinal materials are not changed, so the medicinal property and the original decoction effect are not changed. The method has wide promotion and application prospect in the convention traditional Chinese medicinal prescription, which keeps the therapeutic effect.

Owner:TEACHING HOSPITAL OF CHENGDU UNIV OF T C M

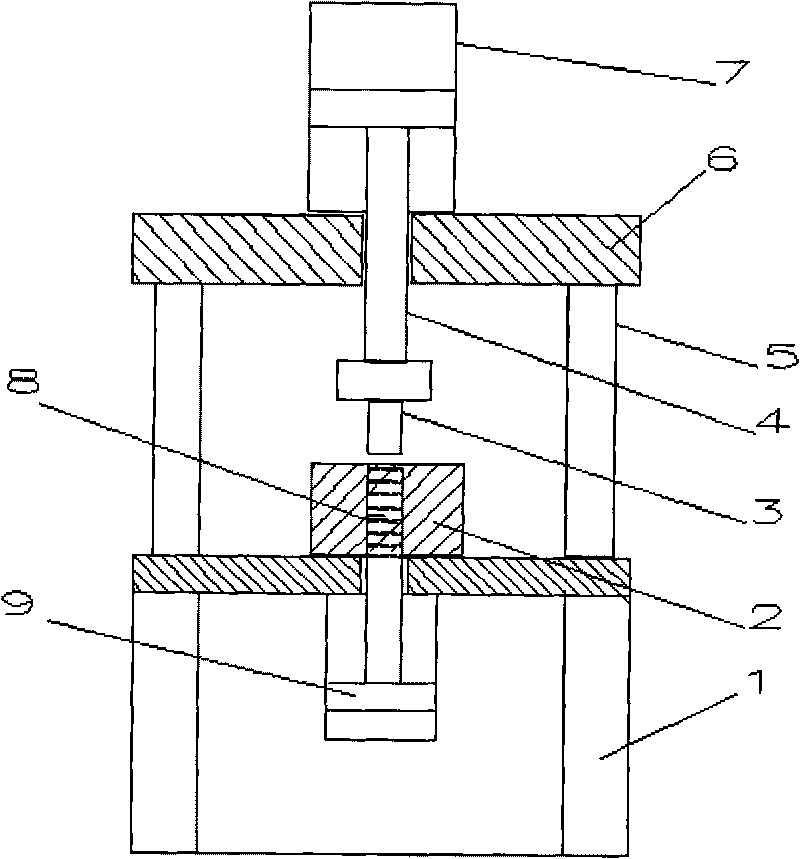

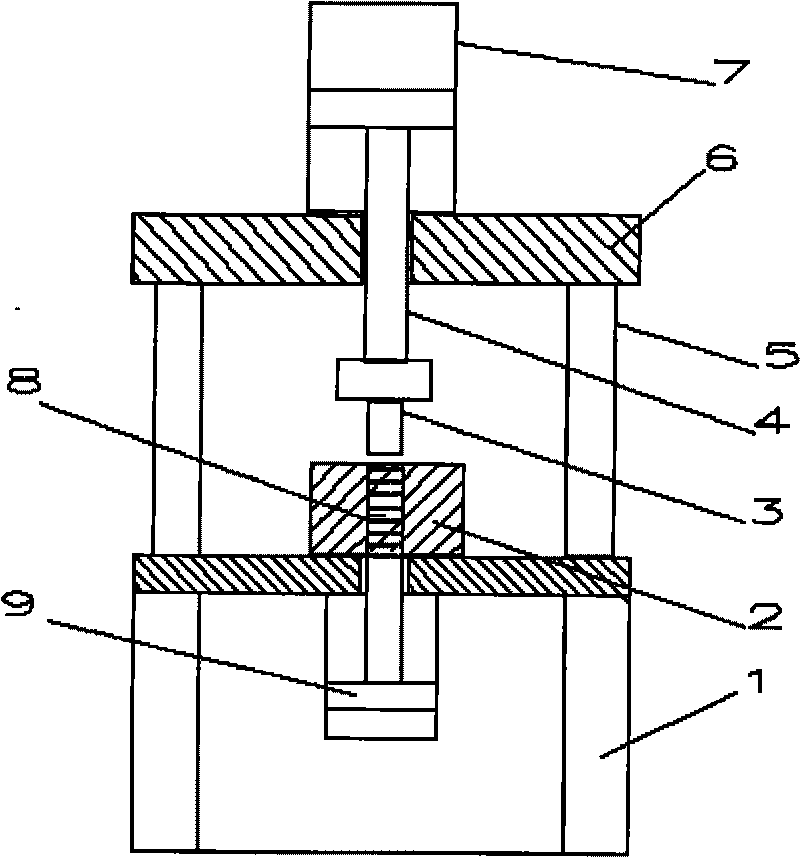

Spot soldering fixture and spot soldering process

InactiveCN102581458APrecise positioningHeight adjustableResistance welding apparatusEngineeringSoldering process

The invention belongs to the technical field of soldering, and particularly relates to a spot soldering fixture, which is used in a spot soldering process capable of avoiding pseudo soldering, false soldering and bursting, and is high in soldering efficiency. The spot soldering fixture comprises a fixture body, a cell storage area and a fuse storage area, and an avoidance hole is reserved between the cell storage area and the fuse storage area. Compared with the prior art, the spot soldering fixture has the advantages that a fuse and a metal strap can be effectively positioned, the height of a soldering pin can be adjusted, spot soldering quality can be improved, soldering reject ratio can be decreased, production efficiency can be improved, and cost can be saved. Besides, the invention further discloses the spot soldering process using the spot soldering fixture.

Owner:DONGGUAN NVT TECH

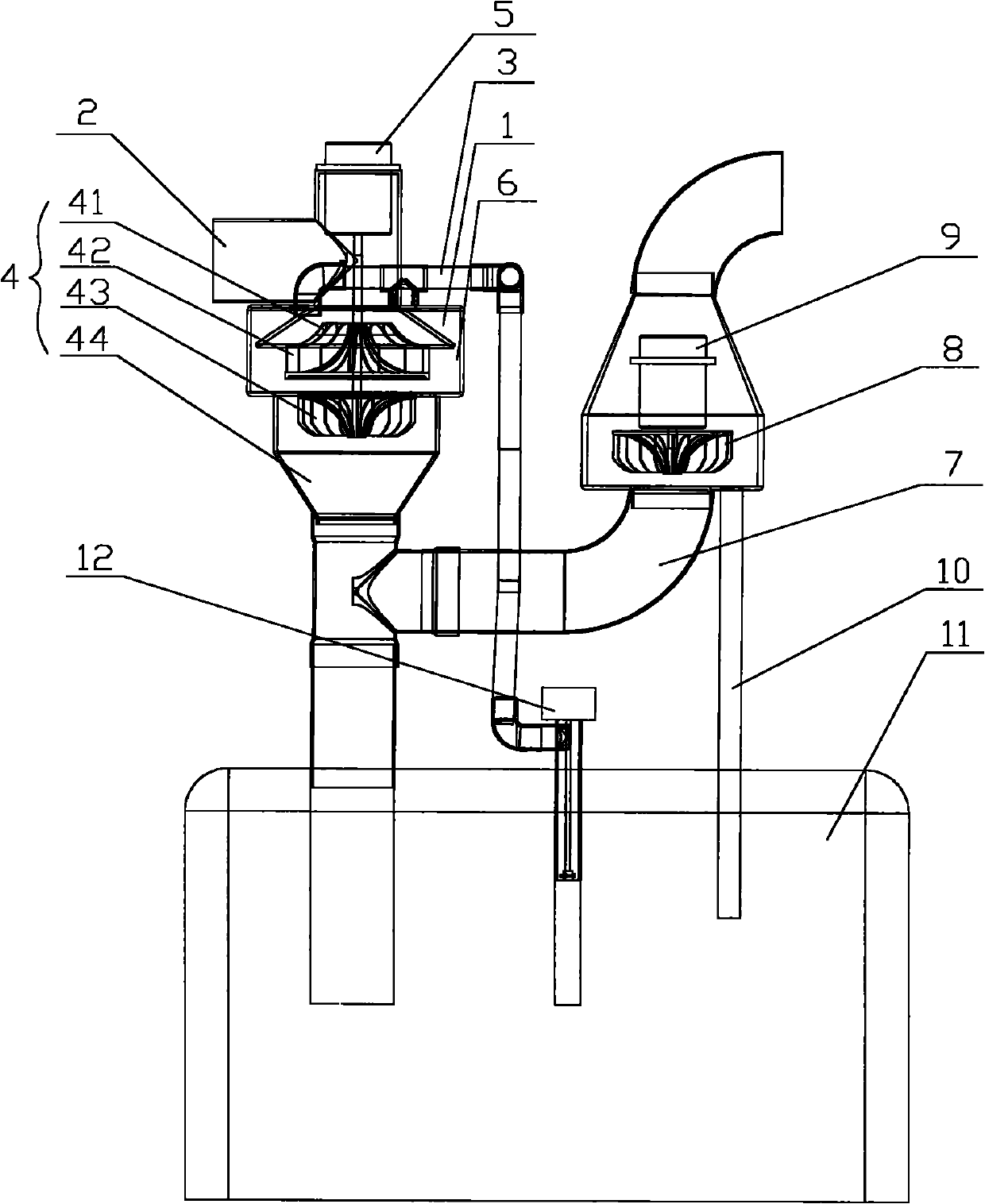

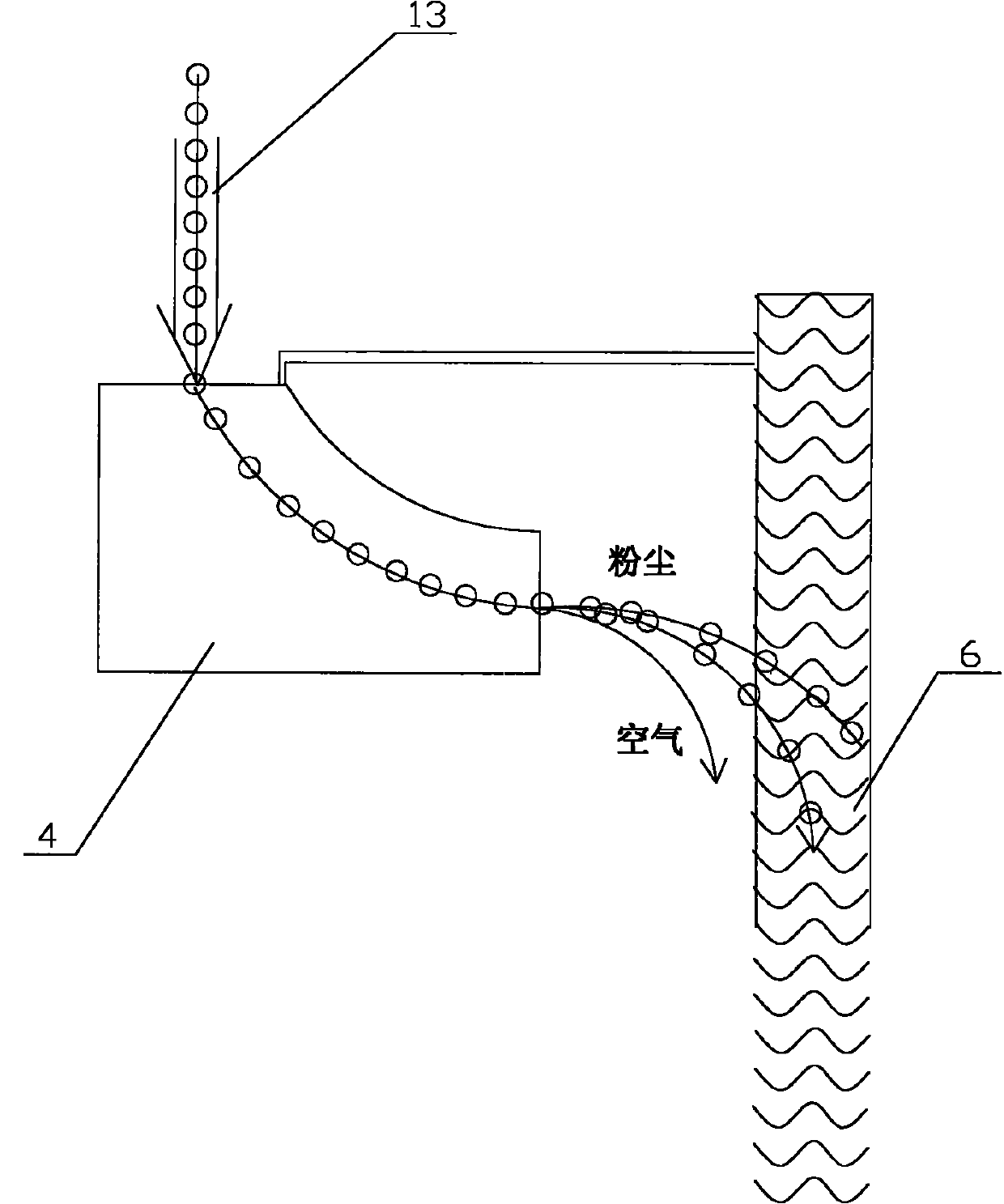

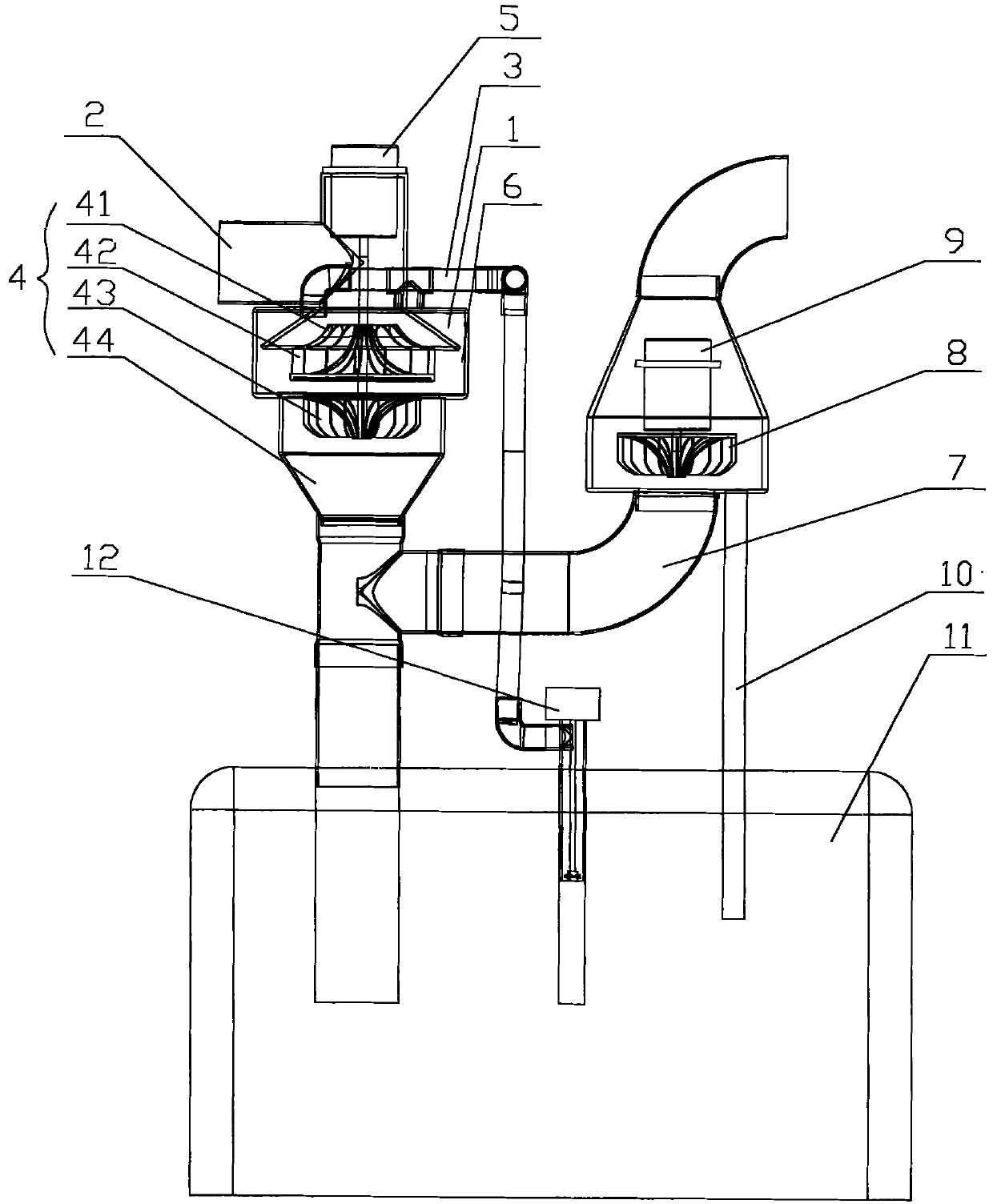

Cyclone water bath air cleaning device and cleaning method thereof

ActiveCN102000469AIncrease the diameterEasy to adjustUsing liquid separation agentWater bathsHigh concentration

The invention relates to the field of air purification, in particular to a cyclone water bath air cleaning device and a cleaning method thereof. The air with dust enters a centrifugal device through an air inlet pipe; extraneous water or circulating water forms a water curtain wall supported by the inner wall of the cavity of the device and coaxial with the centrifugal device under the action of the centrifugal device; the solid tiny dust or the liquid substance in the air with dust is instantaneously accelerated by the centrifugal device, then cut into the water curtain wall along the centrifugal direction and caught by the water curtain wall and flows out together with the water flow of the water curtain wall; the air is forced to turn quickly; and the dust removed air is led out through an air duct. The device has the function of treating high-flow and high-concentration dust by using small space; and the function has significance for places of gallery dust removal, working environment air purification, restaurant kitchen soot removal, commercial or household air cleaning and the like.

Owner:广州市合联科技发展有限公司

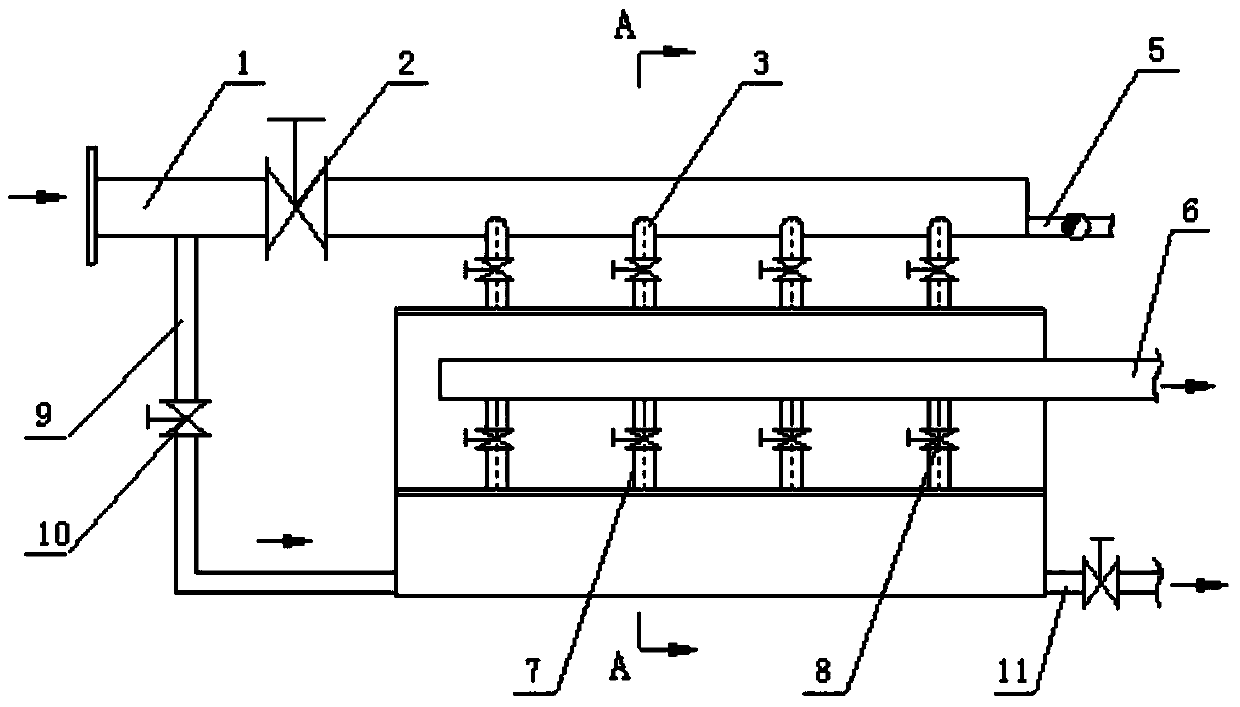

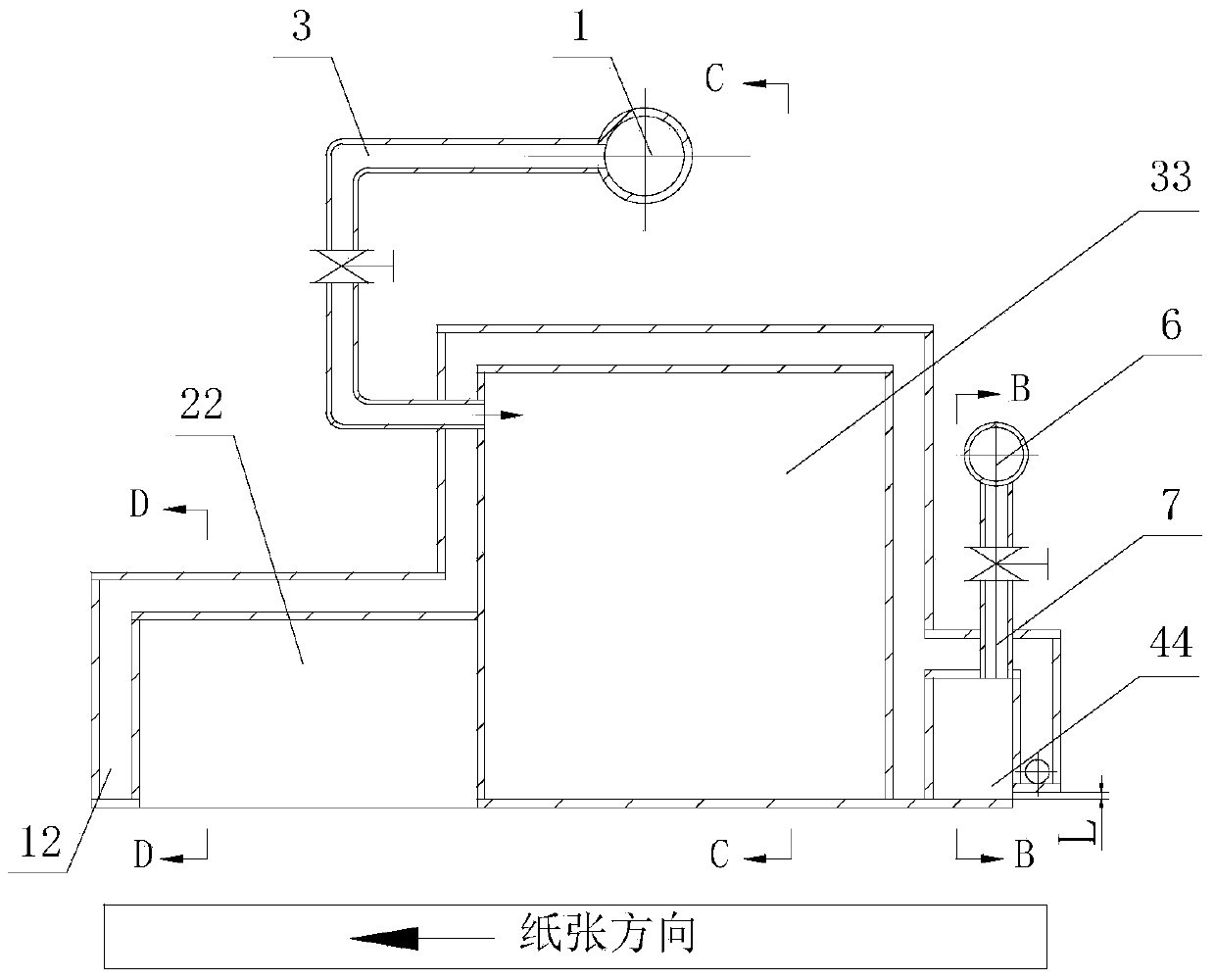

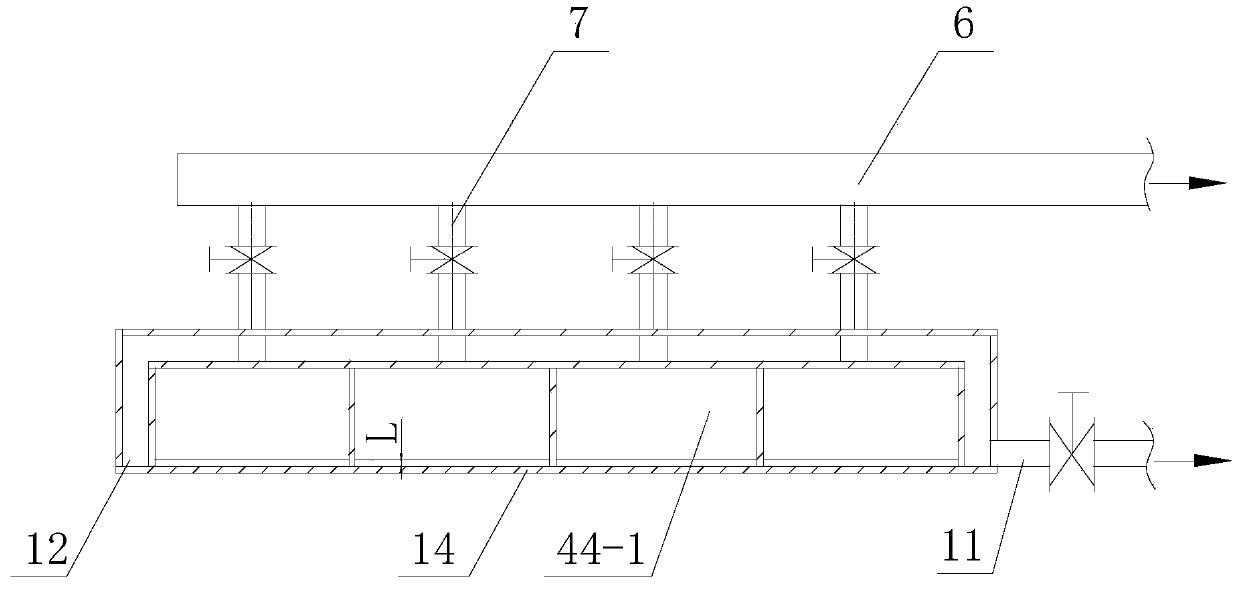

Secondary adjusting steam box and method for adjusting paper horizontal web water content

InactiveCN104195866ASolve the influence of heat transfer effectAvoid flowDamping devicesAir entrainmentPulp and paper industry

The invention discloses a secondary adjusting steam box and a method for adjusting the paper horizontal web water content. The secondary adjusting steam box comprises a steam box body, a master steam pipe and a master air exhaust pipe. A master pipe control valve is arranged at the inlet end of the master steam pipe. A preheating chamber is arranged outside the steam box body. The preheating chamber is arranged on a pipeline between the inlet end of the master steam pipe and the master pipe control valve in a communicating mode through a preheating branch pipe. The steam box body is sequentially provided with an air exhaust area, a steam spray area and a retention area in the advancing direction of paper, wherein the bottom of the air exhaust area is provided with a porous plate or a gap-type plate, the bottom of the steam spray area is provided with a porous plate or a gap-type plate and the bottom of the retention area is opened. Primary adjusting is conducted by using air carried by the paper, so that the problem that the steam heat transfer effect is affected by the air carried by the paper is solved and the secondary adjusting amount is reduced; secondary adjusting is conducted through steam flows of steam chambers of the steam box body, so that the purpose of adjusting the paper horizontal web water content is achieved. Due to the fact that the secondary adjusting amount of the steam flows is small, the flow difference between all the steam chambers is greatly reduced, steam is prevented from flowing among all the steam chambers and the adjusting effect is guaranteed.

Owner:SOUTH CHINA UNIV OF TECH

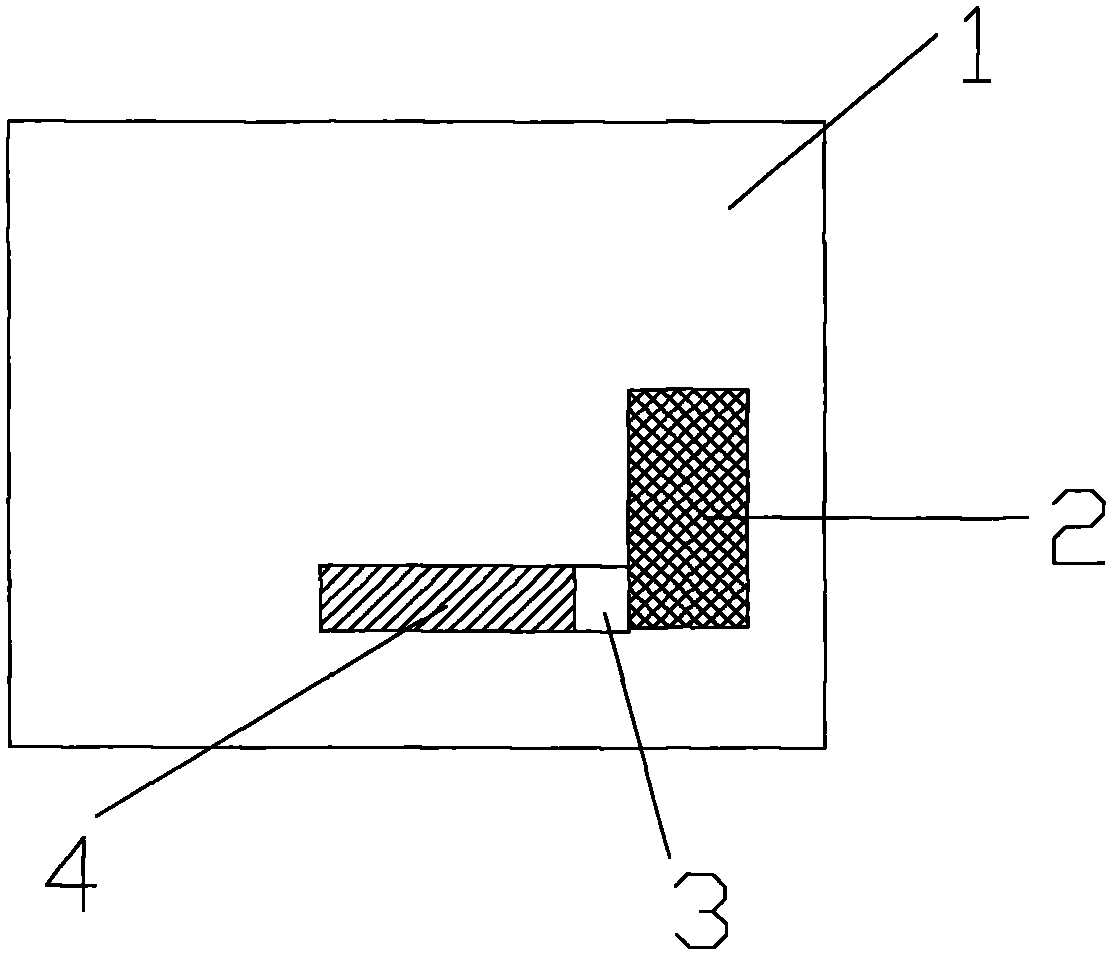

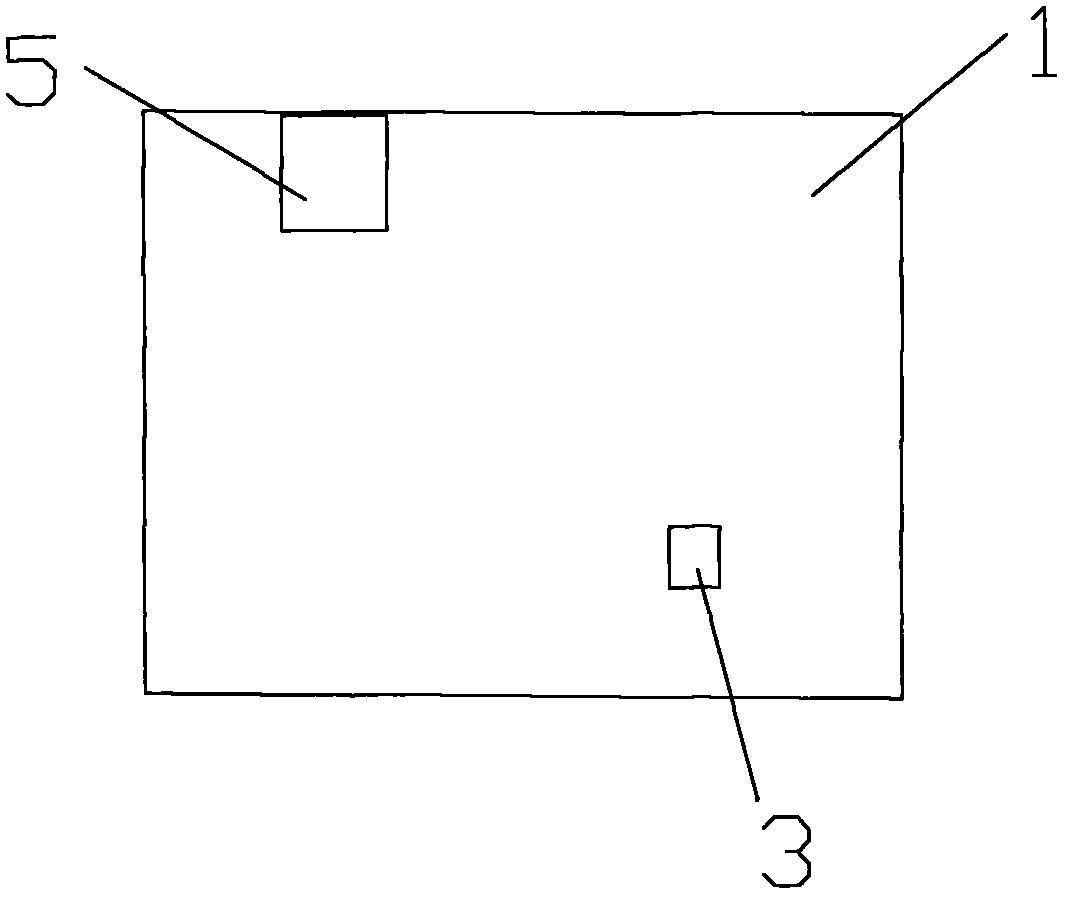

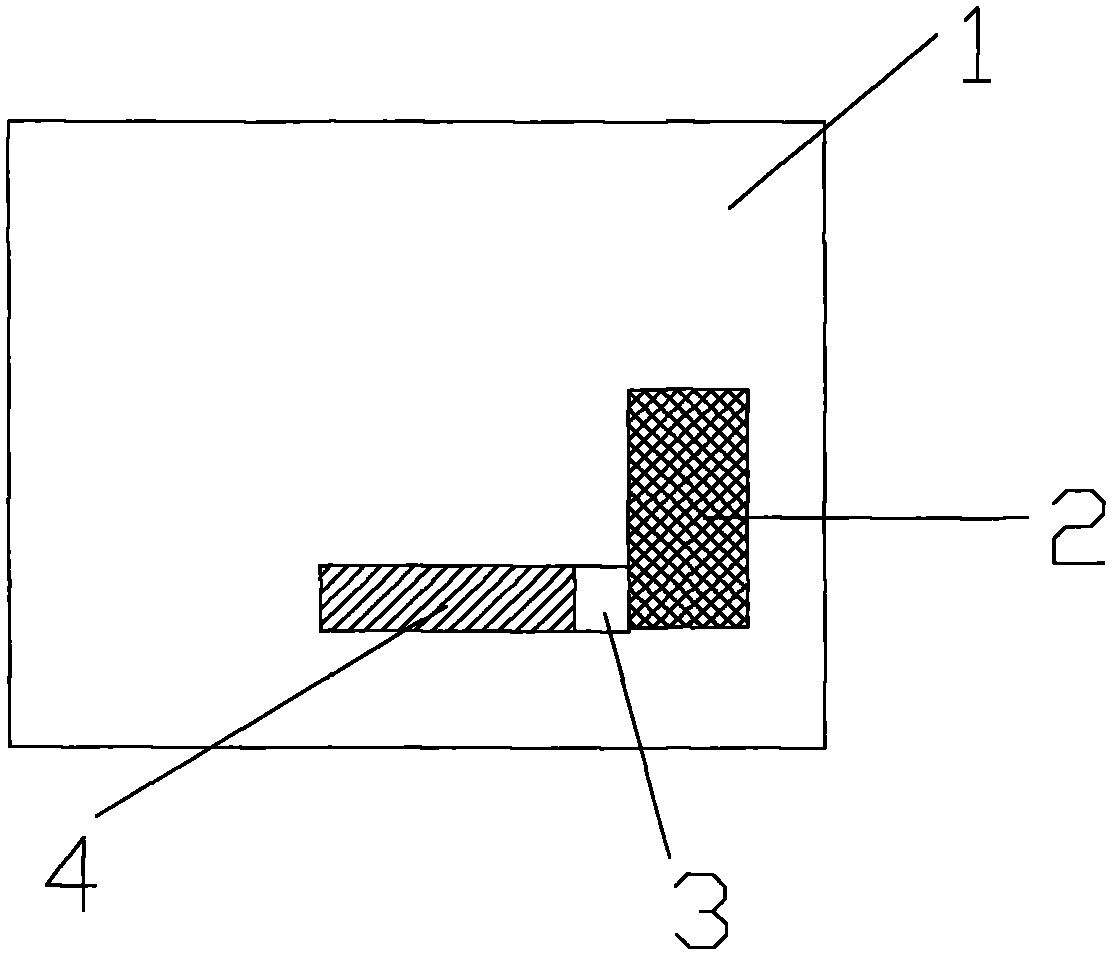

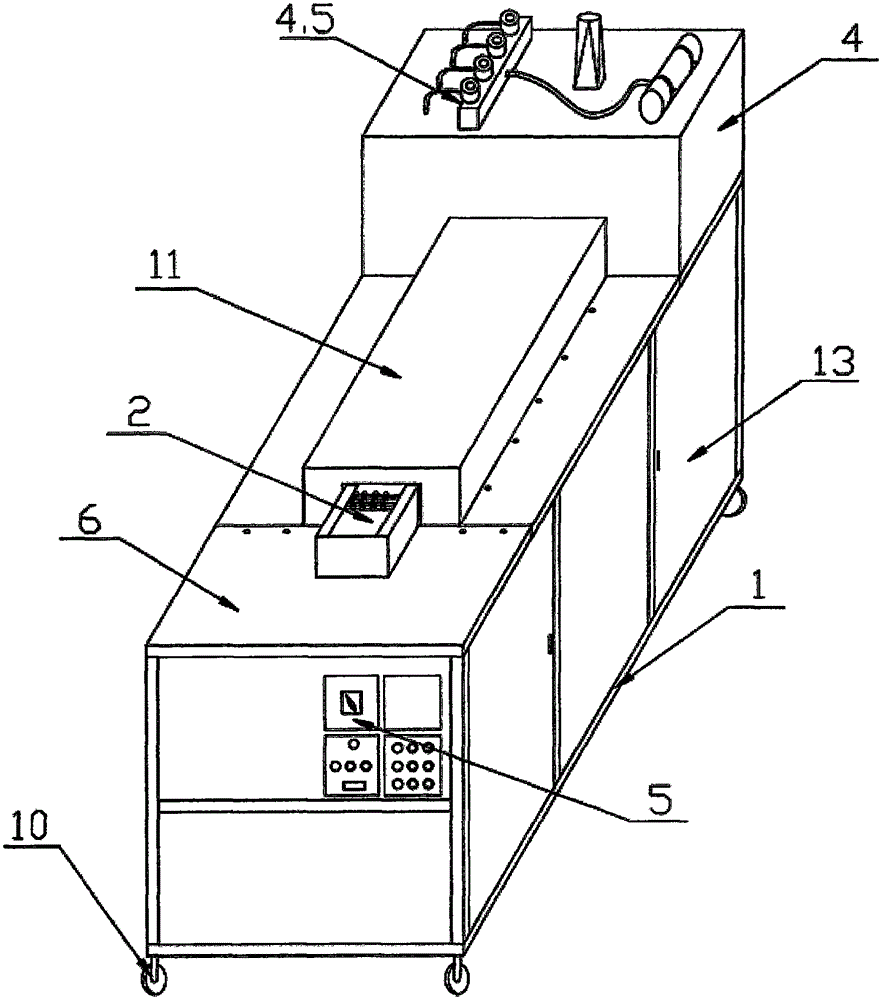

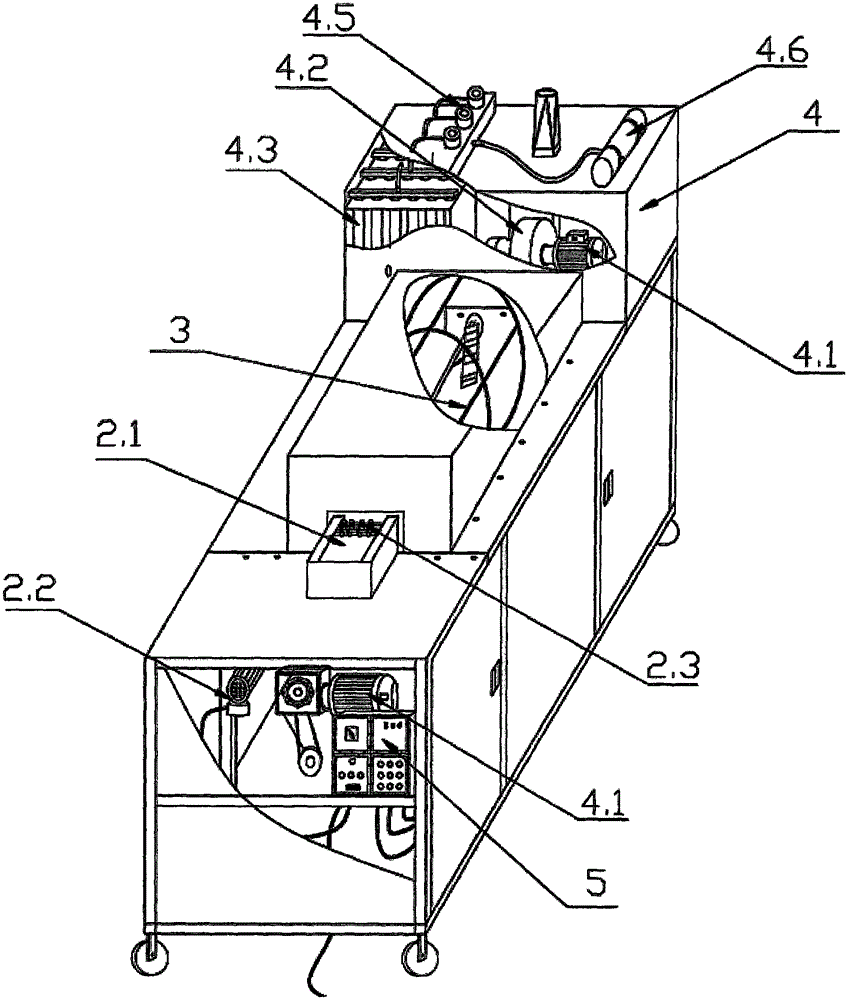

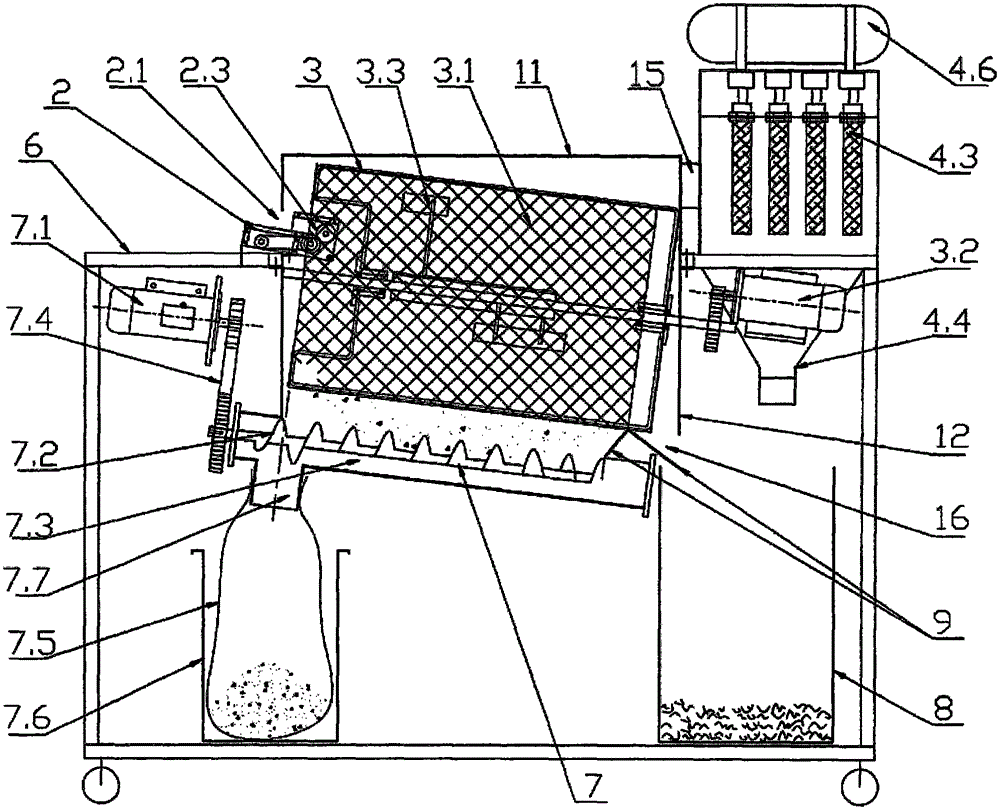

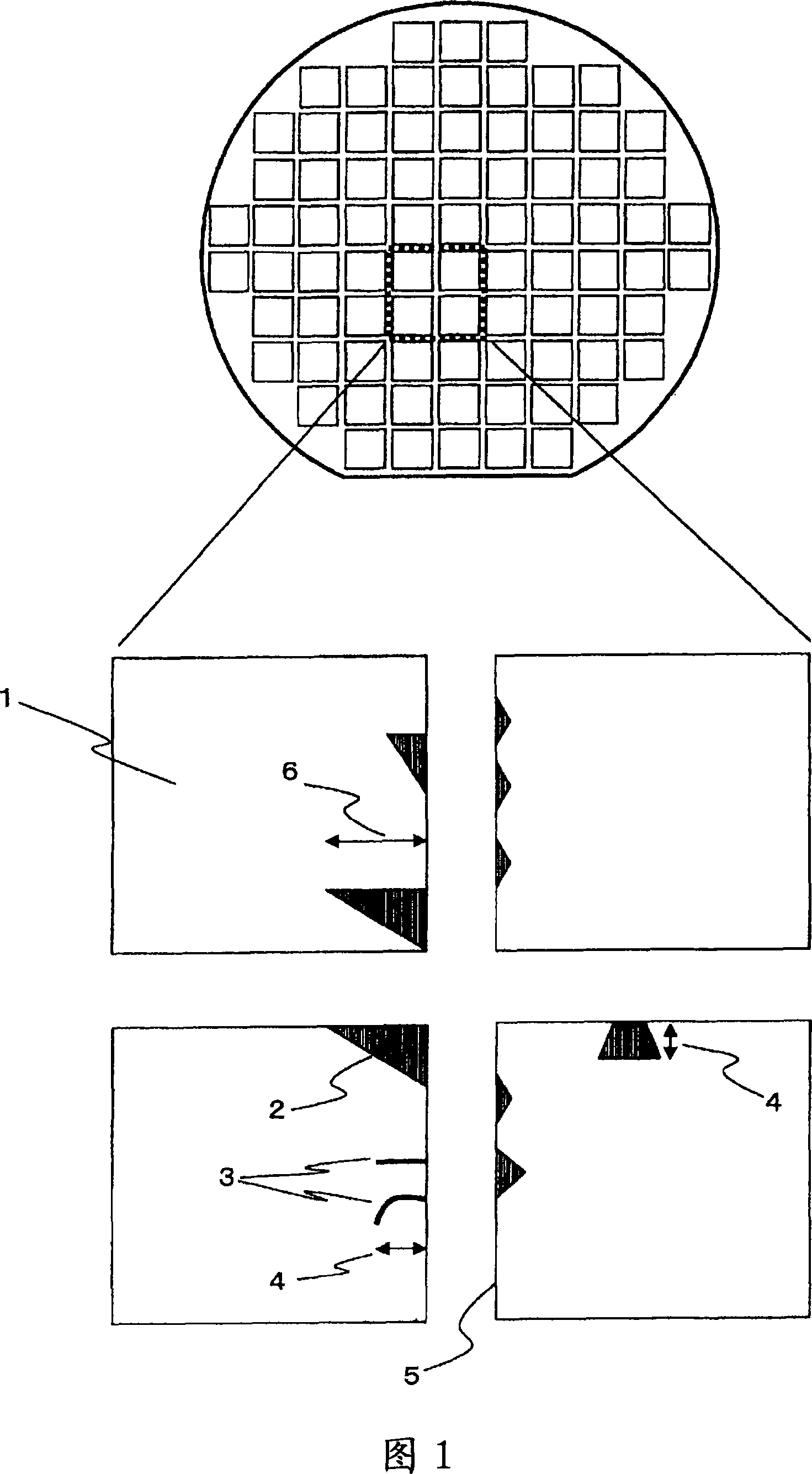

Powder packaging bag crusher screen

The invention discloses a powder packaging bag crusher screen which is characterized by comprising a rack (1), a crushing mechanism (2), a screening mechanism (3), a material collecting device, a fan filter (4) and an anti-explosion control box (5), wherein the screening mechanism (3) comprises a screen cage (3.1) obliquely arranged on the rack (1), a workbench (6) is arranged at the relatively high end part of the screen cage (3.1), the crushing mechanism (2) is arranged between the screen cage (3.1) and the workbench (6), and the fan filter (4) is arranged at the end part, far away from the crushing mechanism (2), of the screen cage (3.1). When the powder packaging bag crusher screen is used, a packaging bag just needs to be arranged at a bag feeding hole directly, materials can be shaken out from a shredded bag sufficiently due to the arrangement of the screen cage, and a negative pressure state is kept in the screen cage all the time due to the arrangement of the fan filter, so that harmful dust cannot diffuse to the working environment, and therefore, material recovery rate is high and safety performance is high.

Owner:安徽万秀园生态农业集团有限公司

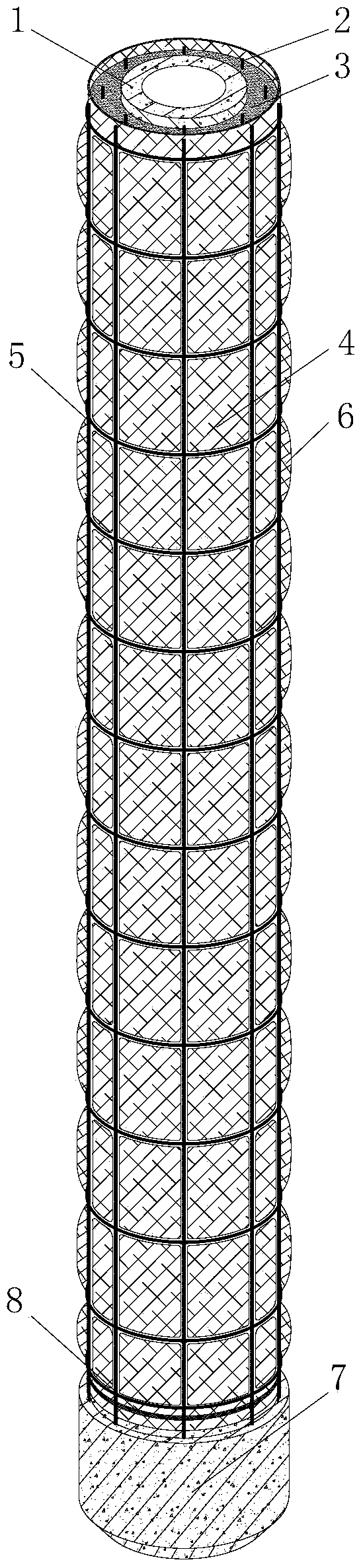

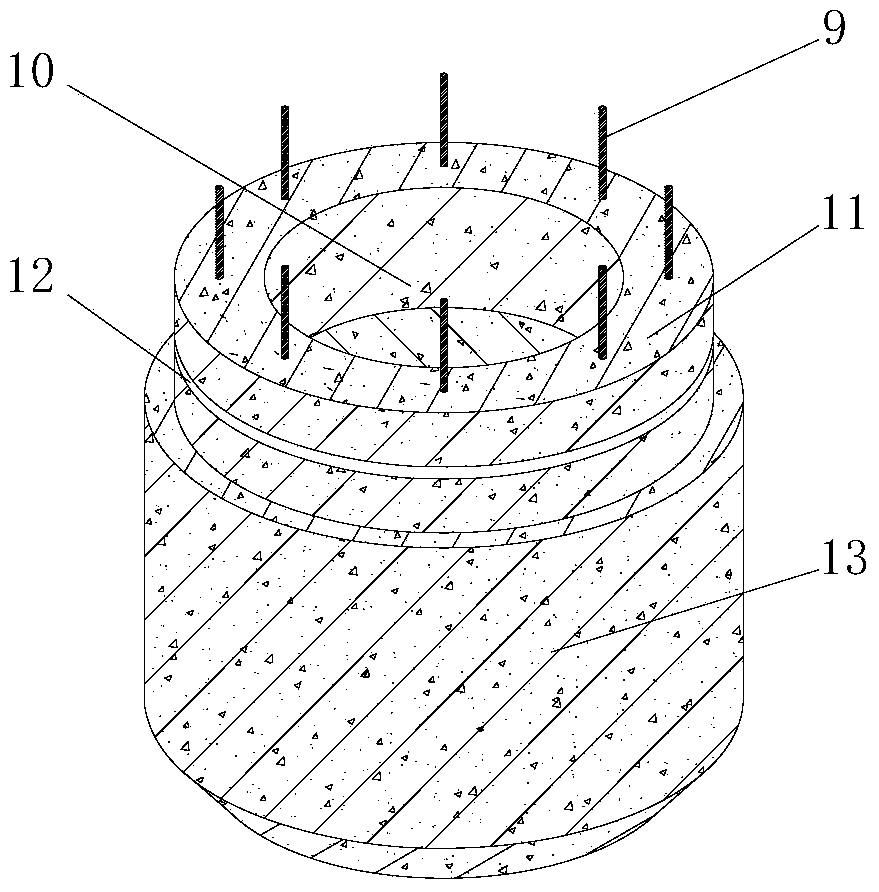

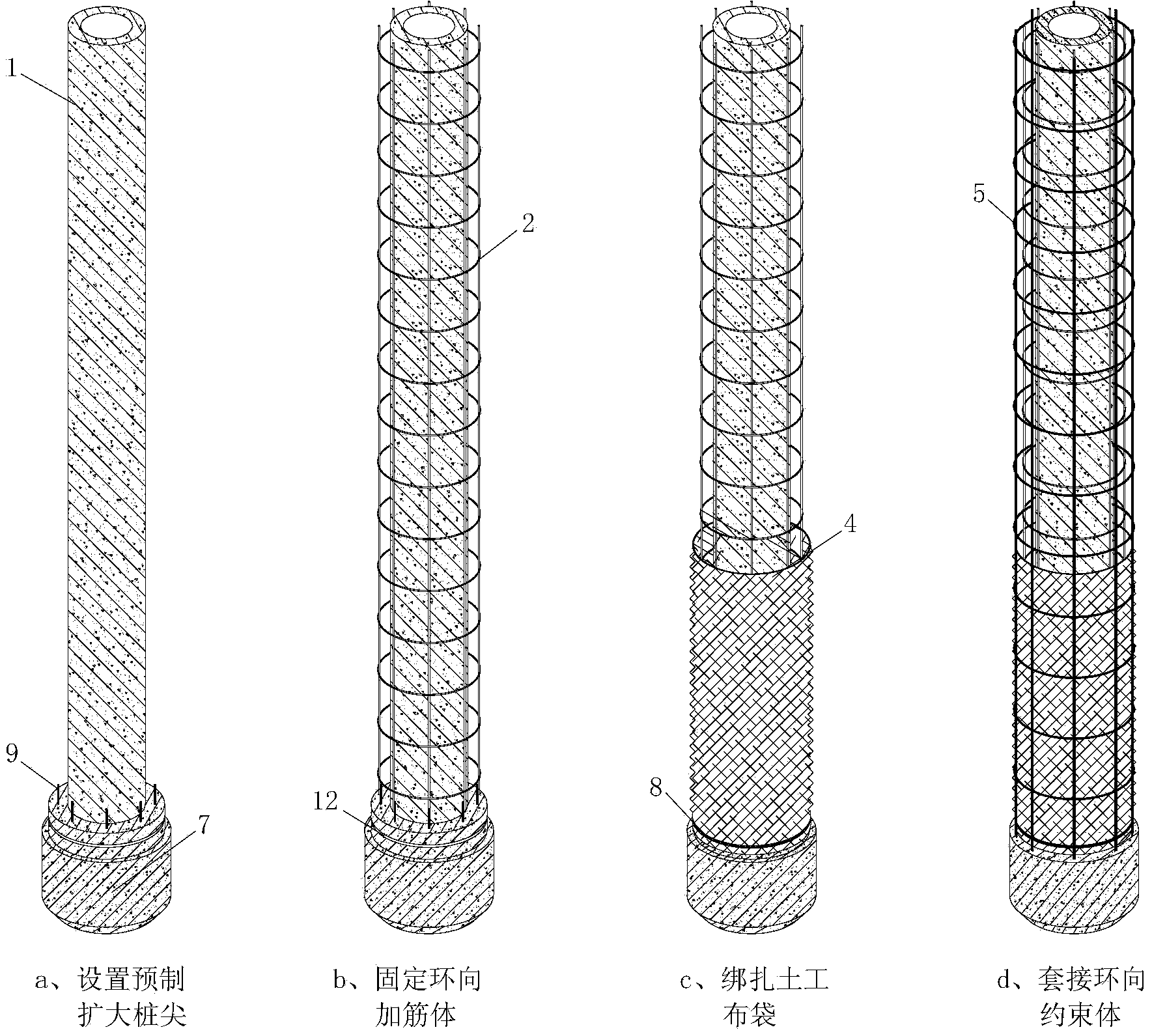

Prestressed pipe pile coated with active material pile body and construction method

ActiveCN104005404ALarge bearing capacityHigh side frictionBulkheads/pilesEconomic benefitsStructural engineering

The invention relates to a prestressed pipe pile coated with an active material pile body. The prestressed pipe pile is characterized in that the prestressed pipe pile is coated with a geotechnical cloth bag in the whole pile length, the bottom end of the pile is provided with a precast enlarged pile tip, the bottom of the geotechnical cloth bag is fixed to the precast enlarged pile tip in a binding mode, an annular reinforcing rib body is arranged inside the geotechnical cloth bag, the bottom of the annular reinforcing rib body is fixedly connected with a connecting rib on the precast enlarged pile tip, a meshed annular constraint body is tightly clamped to the exterior of the geotechnical cloth bag, the portion between the prestressed pipe pile and the geotechnical cloth bag is filled with active materials, and after absorbing water and swelling, the active materials are tightened by the meshed annular constraint body to form block-shaped protrusions. According to the prestressed pipe pile coated with the active material pile body, the active material hydration swelling effect is utilized, the geotechnical cloth bag and the meshed annular constraint body with which the geotechnical cloth bag is coated are matched for shaping, and the performance of the pile body can be improved; after the prestressed pipe pile is coated with the active material pile body, pile body concrete can be prevented from being corroded by underwater, and the higher technical and economic benefits are obtained. The invention further discloses a construction method of the pile body.

Owner:德达交通建设发展集团有限公司

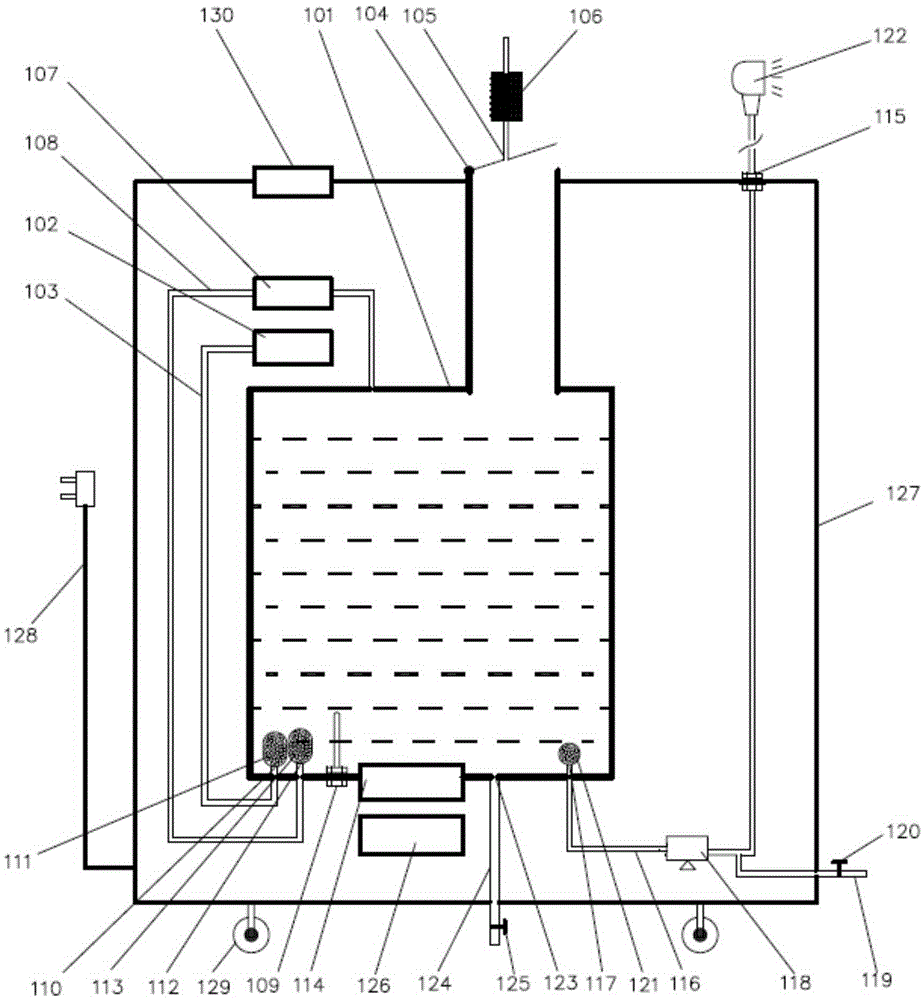

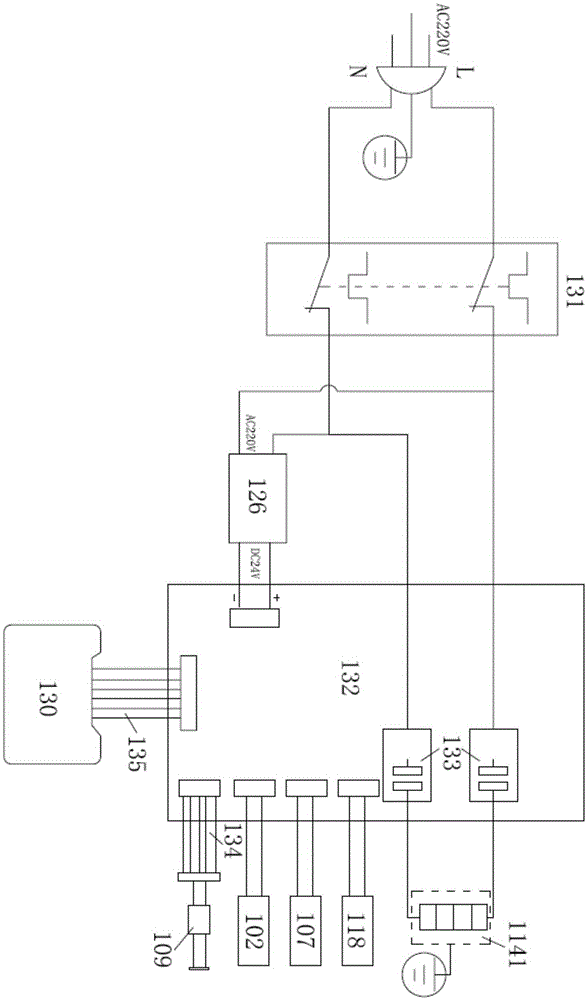

Bathing nursing equipment

The invention discloses bathing nursing equipment which comprises a water tank and an ozone generator. The ozone generator is communicated with the water tank. The bathing nursing equipment is characterized in that the water tank is a closed water tank, an exhaust pressure relief hole is formed in the water tank, and an ozone tail gas treatment device is arranged on the exhaust pressure relief hole; the bathing nursing equipment is further provided with an ozone gas circulating pump, so that un-dissolved ozone which is gathered above liquid level of the water tank can be injected into water again to be recycled. The bathing nursing equipment is further provided with a temperature and water level sensor, so that water level can be monitored, the water storage quantity of the water tank can be computed, the temperature of the water can be monitored, the ozone generator can generate the ozone under the control of the water storage quantity of the water tank and the temperature of the water, and the ozone can have set dissolved concentration; the bathing nursing equipment is further provided with a controller, and the controller is connected with the ozone generator, the ozone gas circulating pump and the temperature and water level sensor. The bathing nursing equipment has the advantages that the quantity of ozone which overflows to the atmosphere can be effectively reduced, accordingly, the human health can be prevented from being impaired by excessive ozone in the air, and the bathing nursing equipment is safe, is high in efficiency and has high market value.

Owner:于华新

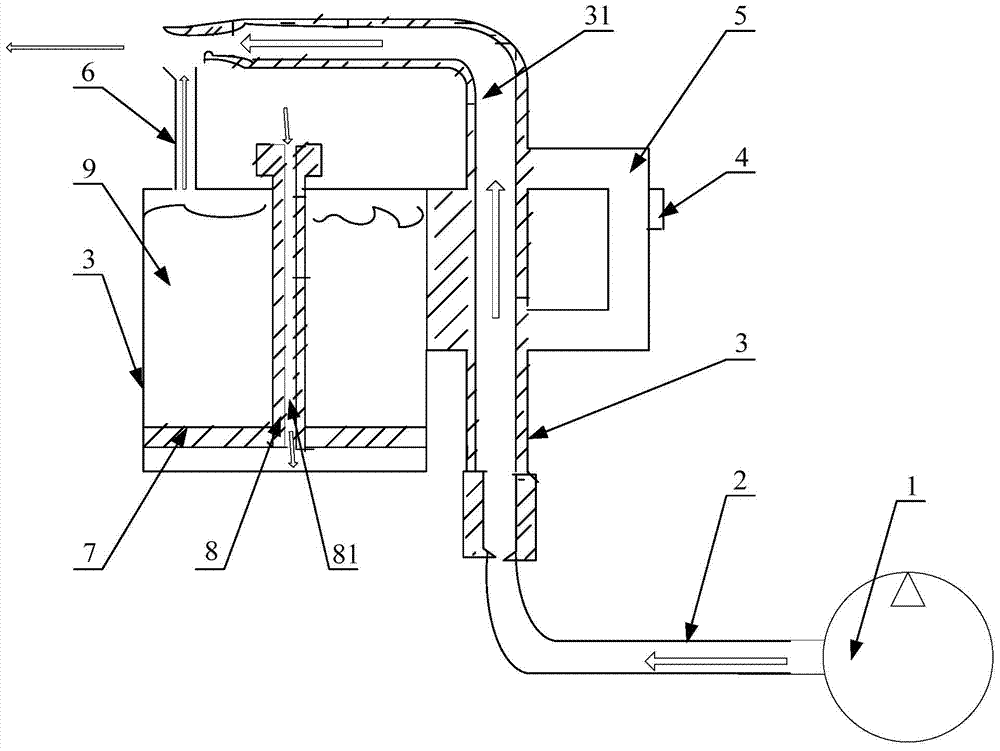

A device for water level control and waste heat removal of passive spent fuel storage pool

InactiveCN102280155AEasy to controlReduced risk of meltingPower plant safety arrangementNuclear energy generationFloating chargeNuclear engineering

The invention discloses a water level control and waste heat discharge device of a passive spent fuel storage pool, which belongs to the technical field of nuclear power plant safety equipment. The device of the present invention includes two loops of float filling and draining and natural circulation cooling. The water level of the spent fuel pool is controlled by the float, and at the same time, the cooling function of the water in the spent fuel storage pool can be completed by passive natural circulation. The two loops complement each other. Together, they guarantee the water level control and cooling process of the spent fuel pool. There are many passive modes such as natural circulation, gravity action and pressure action in the device, which are convenient to implement, simple to control, high in reliability, safe and stable.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

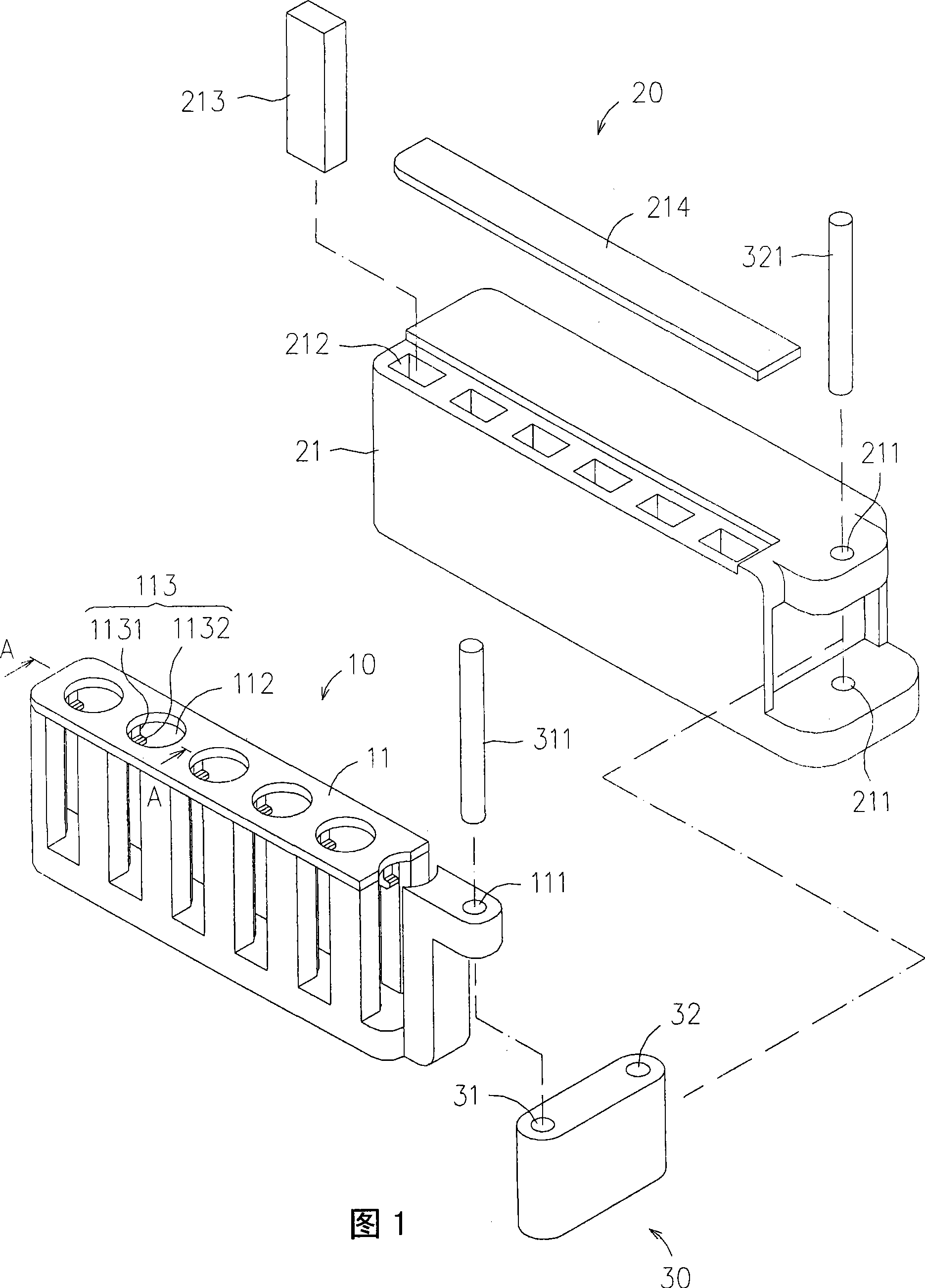

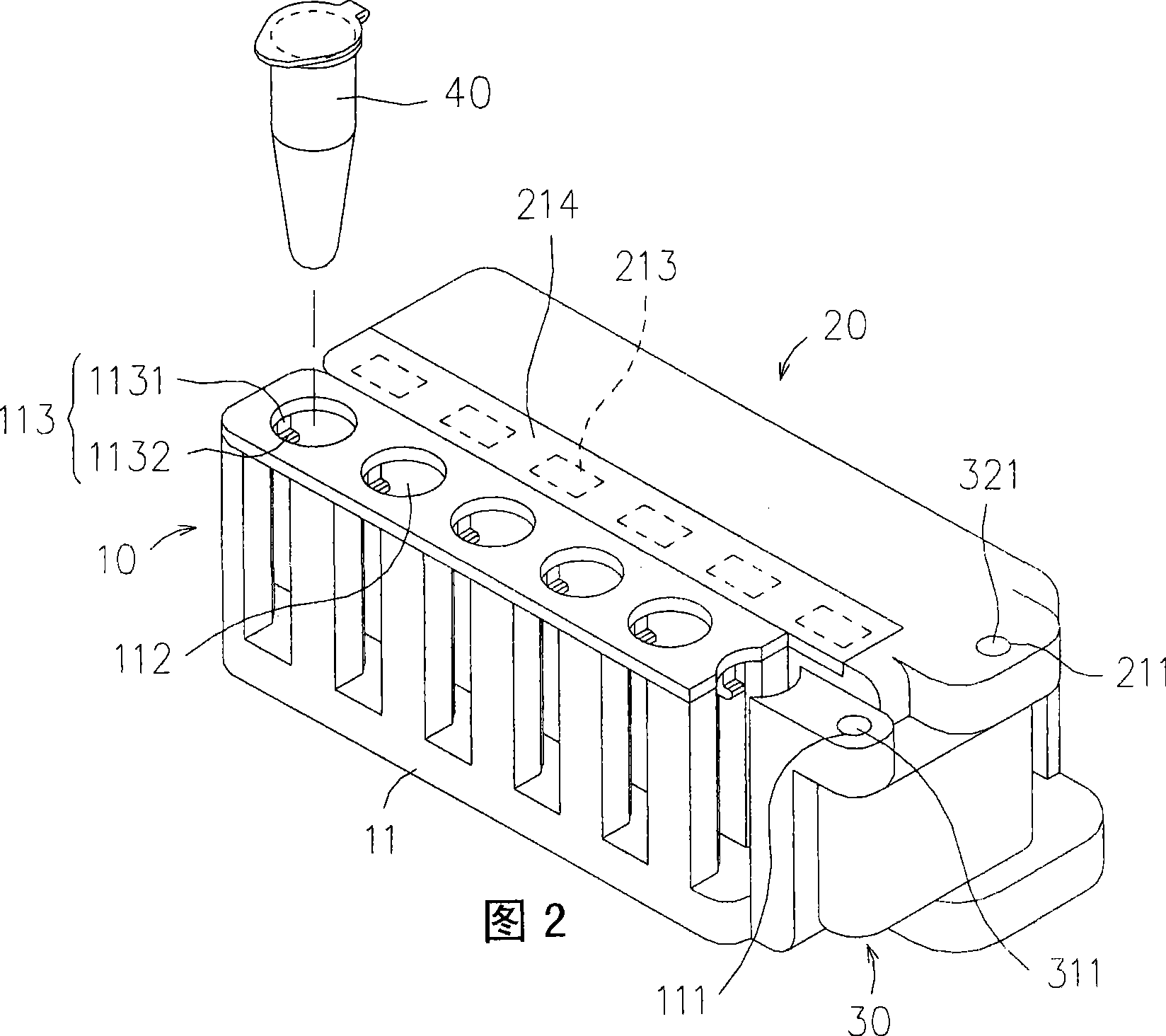

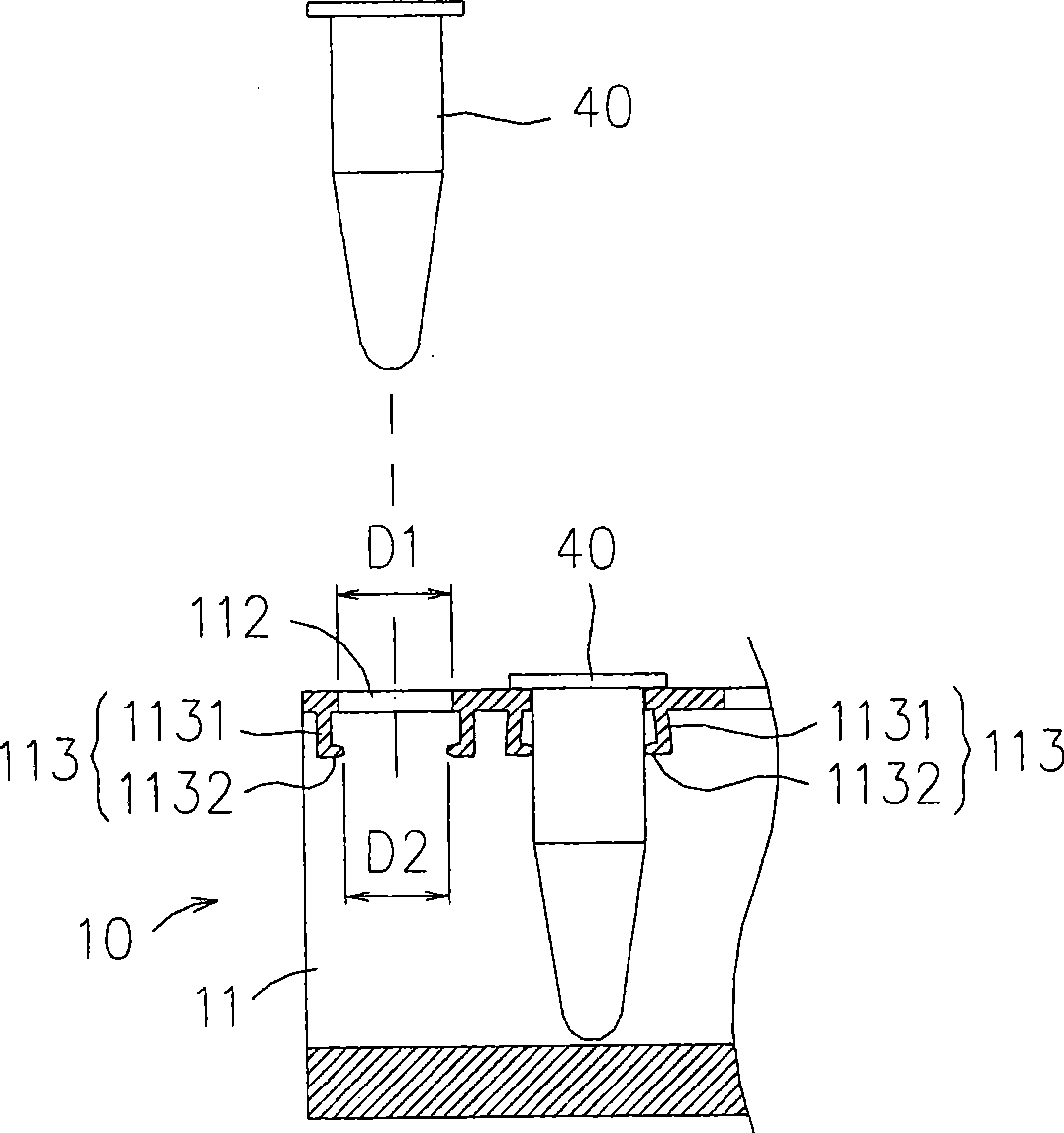

Magnetic conversion separation device

InactiveCN101368951AReduce processing timeReduce spillagePreparing sample for investigationLaboratory glasswaresMagnetic tension forceEngineering

The invention discloses a magnetic conversion and separation device, which is mainly composed of at least a test tube holder and a magnetic piece; the test tube holder is used to arrange at least a test tube; the magnetic piece can produce magnetic suction; the magnetic piece is mutually pivoted with the test tube holder; therefore, the test tube holder and the magnetic piece can be rotated by taking the pivot end as the center, so that the test tube arranged in the test tube holder can be relatively separated from the magnetic piece or can get relatively near the magnetic piece to adjust the magnetic intensity generated by the magnetic piece onto the mixture in the test tube.

Owner:IND TECH RES INST

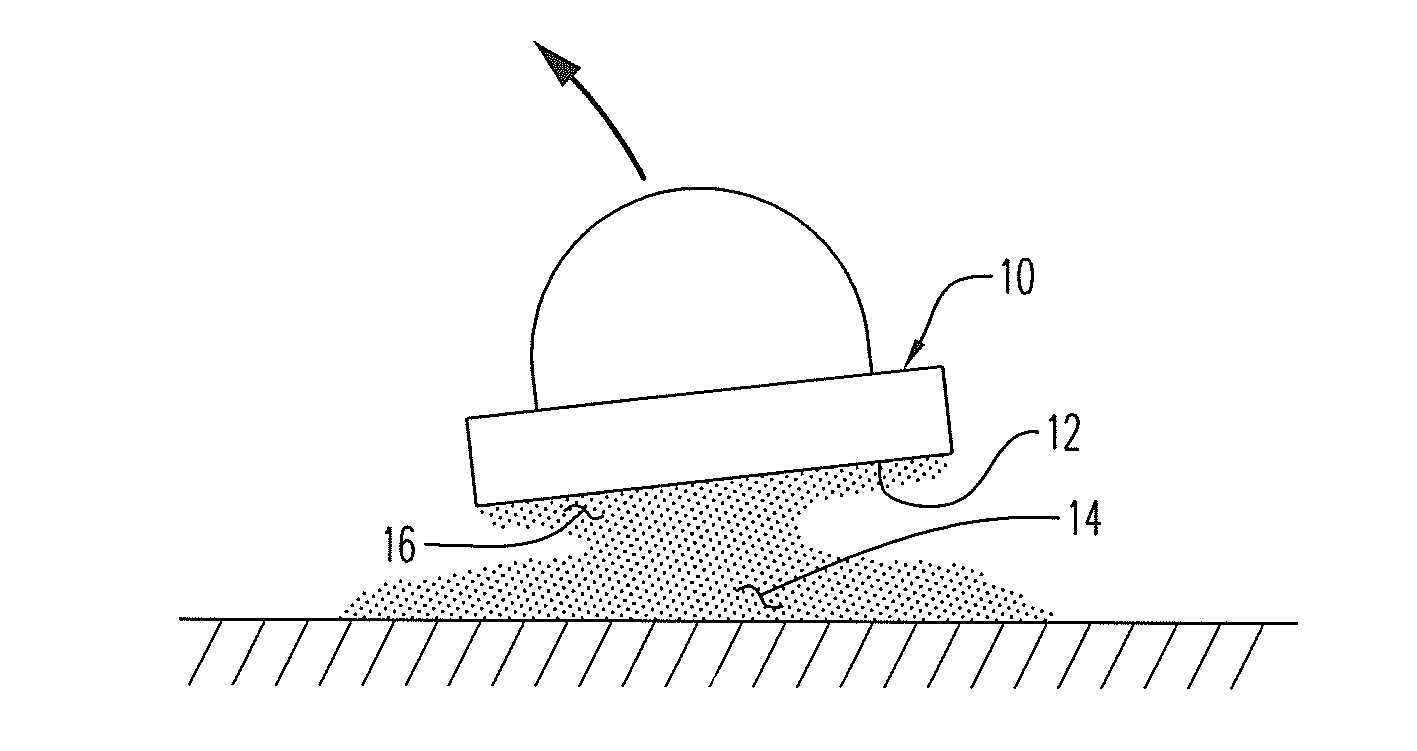

Hemostatic Composition with Magnetite

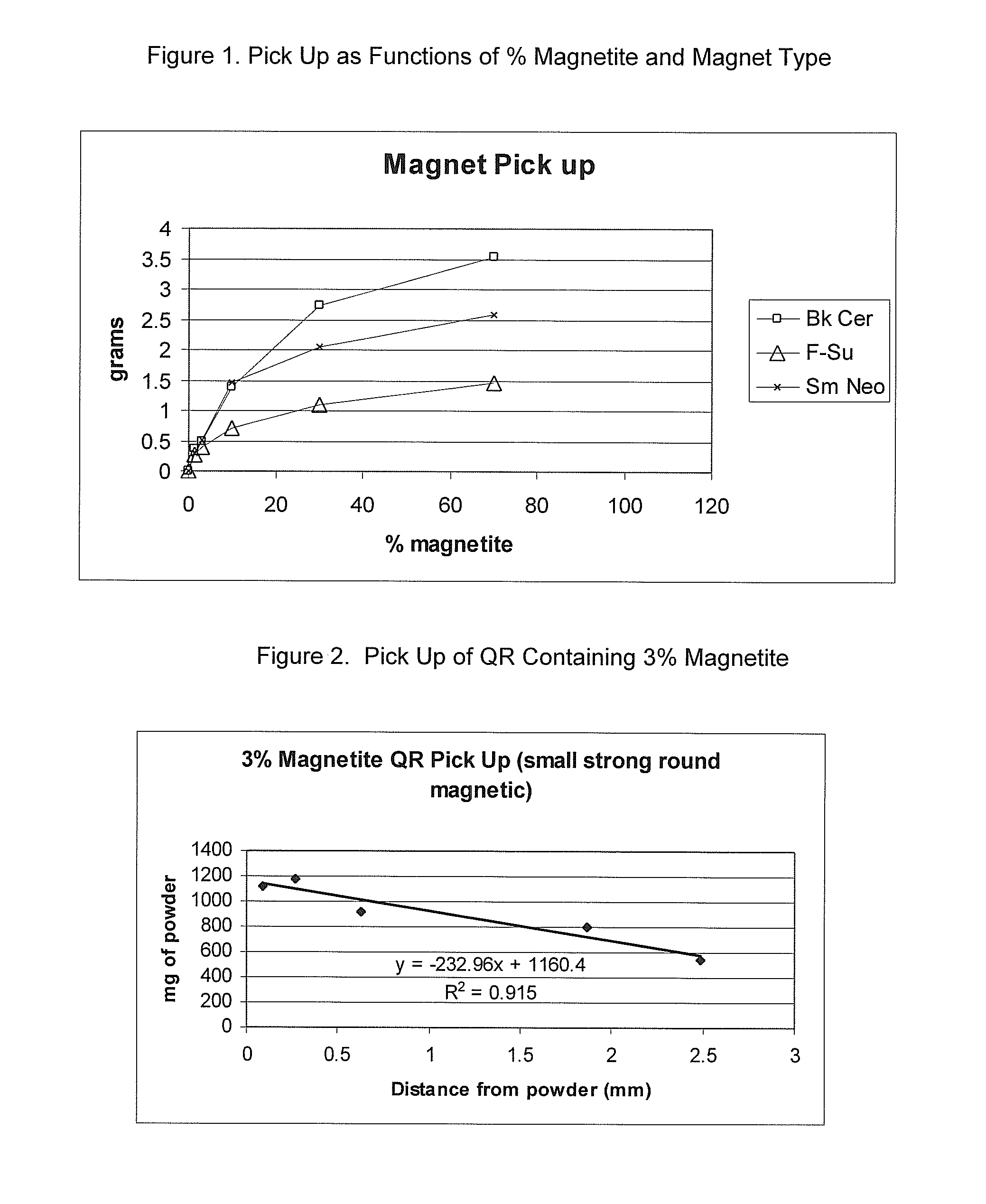

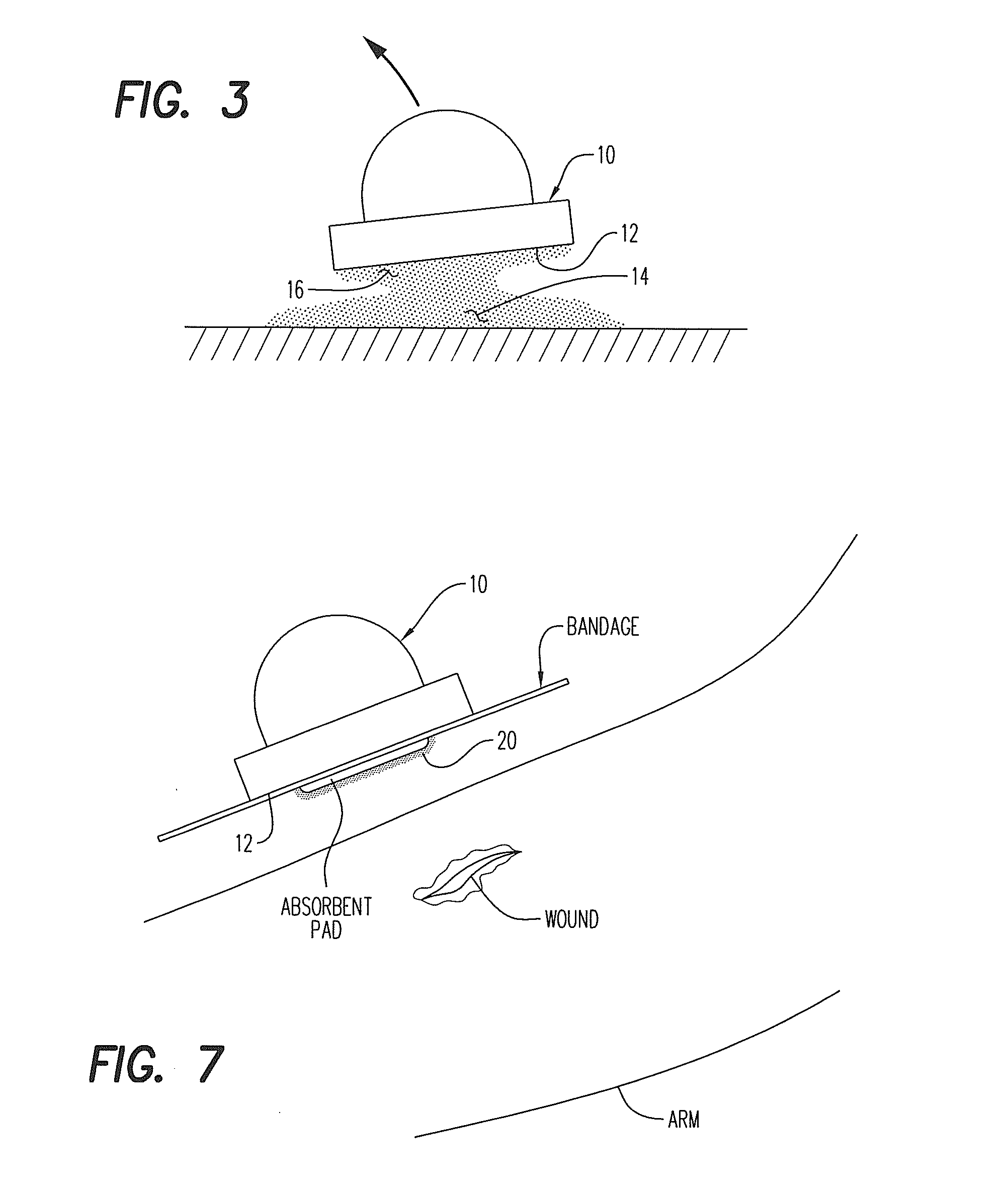

InactiveUS20100226873A1Reduce spillageImprove delivery and controlHeavy metal active ingredientsBiocidePowder mixtureMagnet

A composition and method of arresting the flow of blood from a bleeding wound. The composition preferably includes an anhydrous salt ferrate compound preferably combined with an effective amount of an insoluble cation exchange material and an effective amount of anhydrous Magnetite mixed uniformly together. Povidone iodine may be added for enhanced antimicrobial properties. In the method, a quantity of the composition is magnetically attached to a surface of a magnet, after which the powderous mixture is applied to the wound by pressing the surface covered with the powderous compound against the wound for a time sufficient to clot the blood to arrest substantial further blood flow from the wound.

Owner:BIOLIFE

Zero-power consumption steel-making method using electric-arc furnace

ActiveCN103205529AIncrease profitPromote rapid formationProcess efficiency improvementElectric furnaceElectric arc furnaceSmelting process

The invention discloses a zero-power consumption steel-making method using an electric-arc furnace. The zero-power consumption steel-making method specially comprises the following steps of: controlling the proportion of steel scrap in a furnace burden structure at 20%-30% and the proportion of molten iron at 70%-80%; pushing the steel scrap in a vertical shaft into the furnace by a hydraulic device, wherein the pushing speed is 1-3t / min; adding the molten iron to the furnace at twice through a molten iron adding chute for the furnace wall, wherein the primary molten iron accounts for 40%-80% of the total amount of the molten iron, the iron addition speed is 15-30t / min, the secondary molten iron accounts for 20%-60% of the total amount of the molten iron, and the iron addition speed is 4.5-6.5t / min; simultaneously adding lime to the furnace for slagging, and blowing oxygen for smelting; and when the temperature and components of the molten iron meet the technological requirements, finishing smelting in the electric-arc furnace. The zero-power consumption steel-making method can prevent the molten iron and furnace slag from overflowing from a furnace gate, thus reducing the consumption of slag charges and steel in the smelting process.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

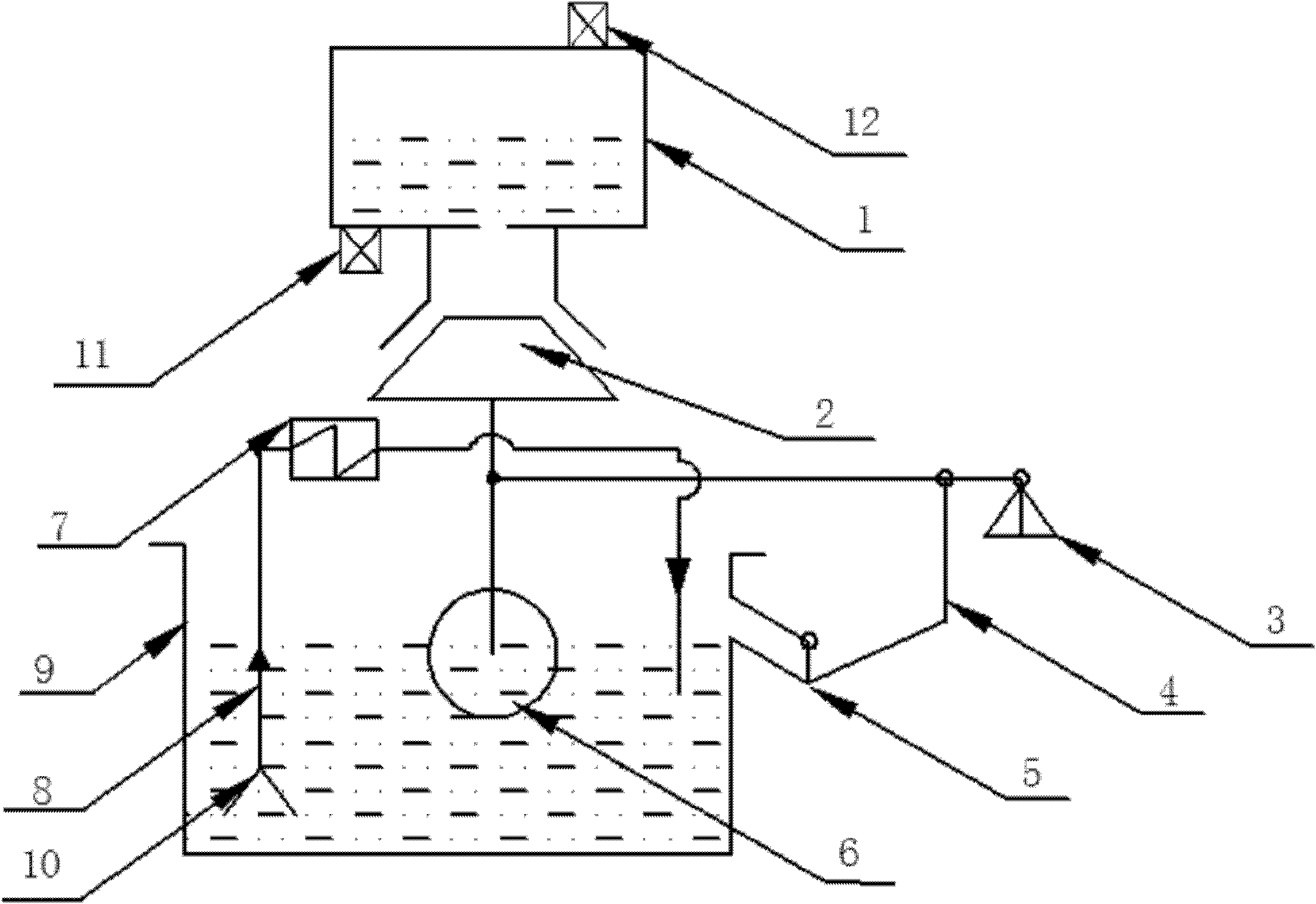

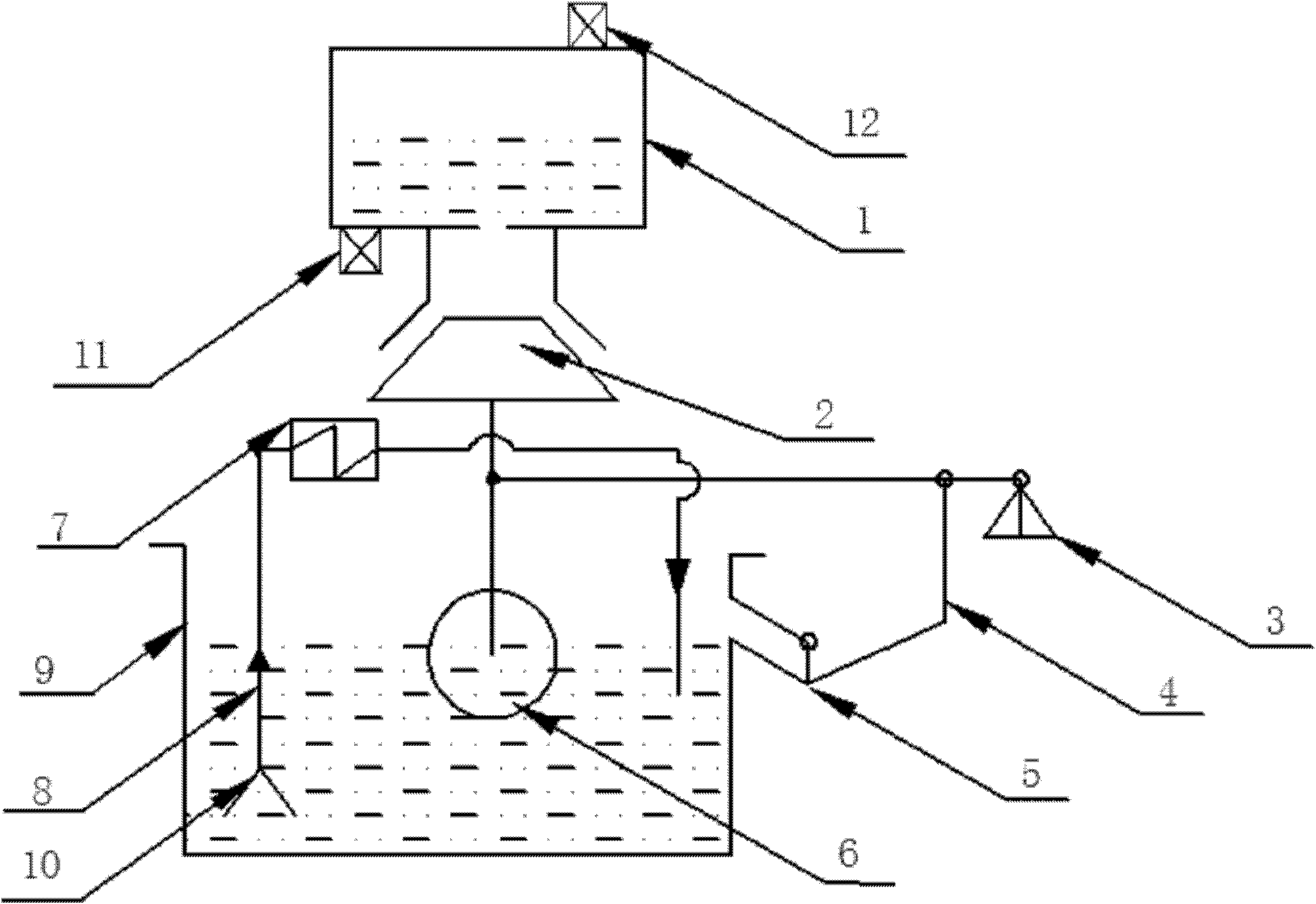

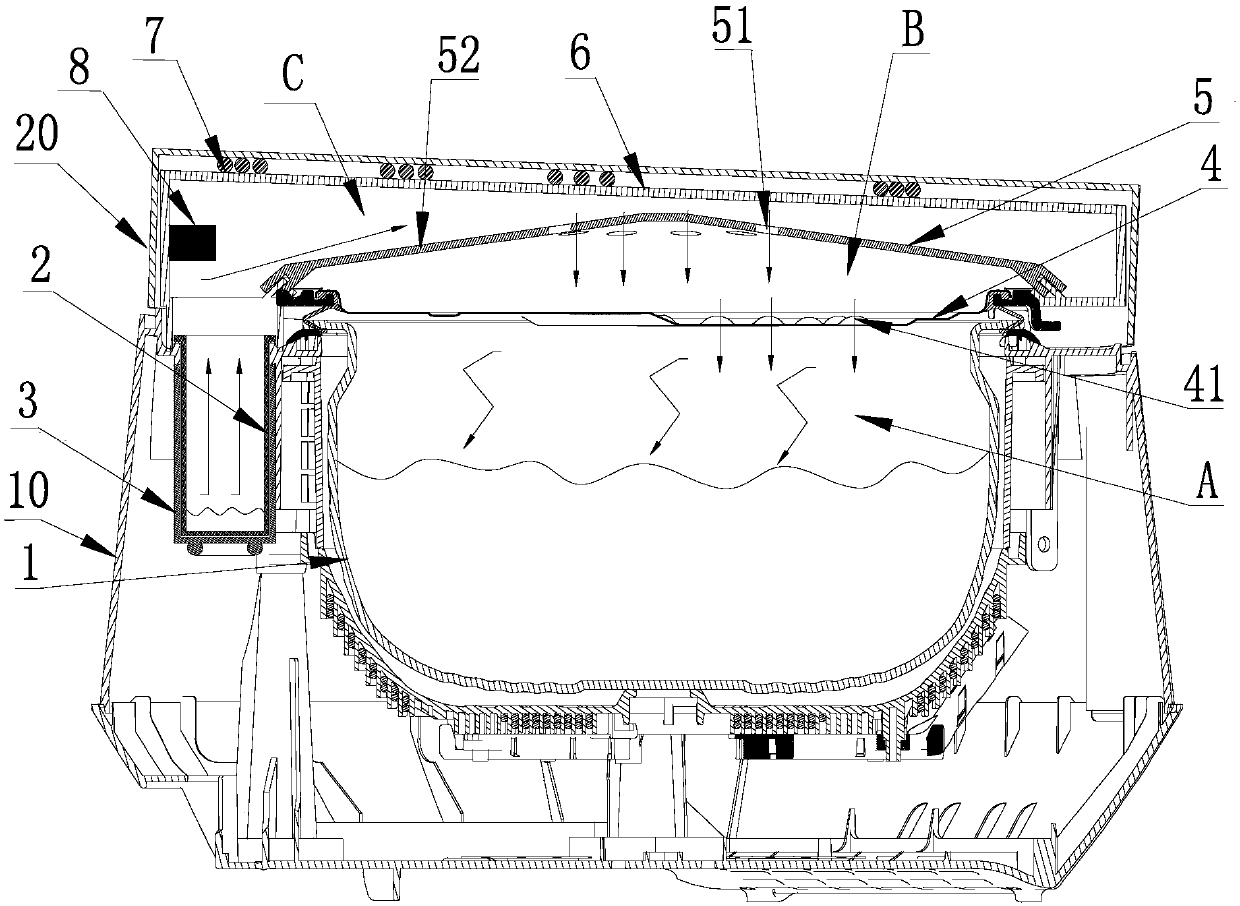

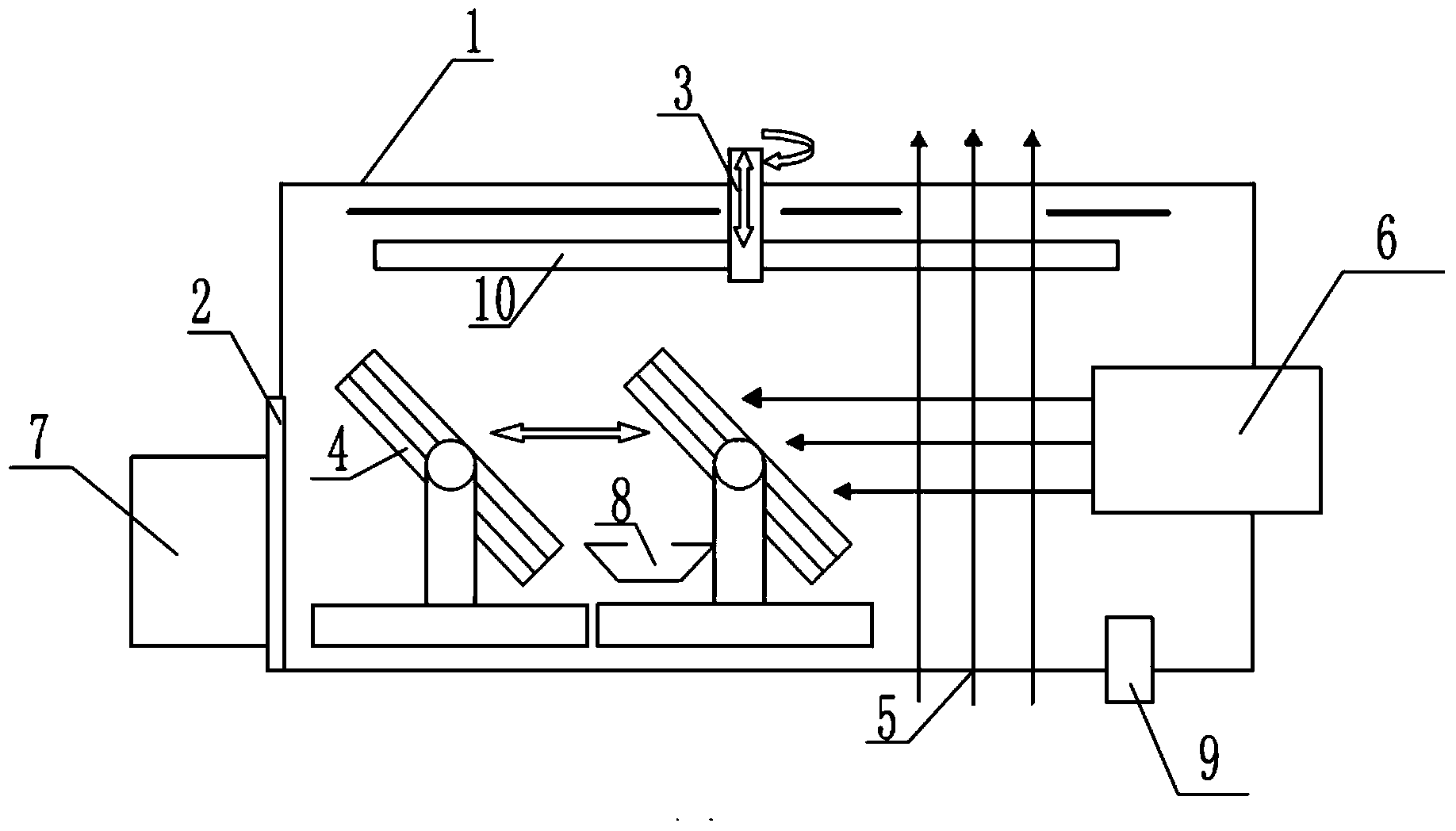

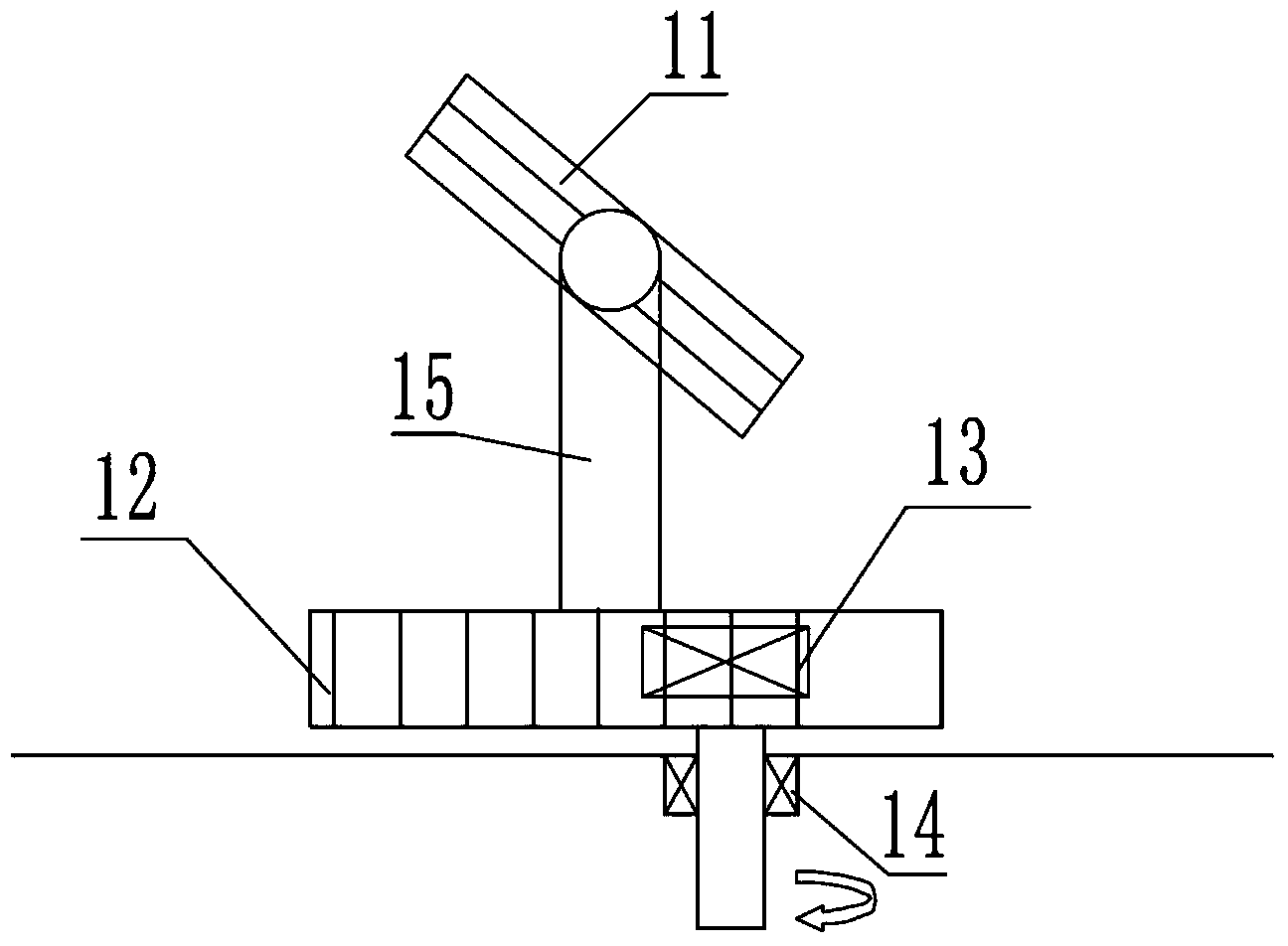

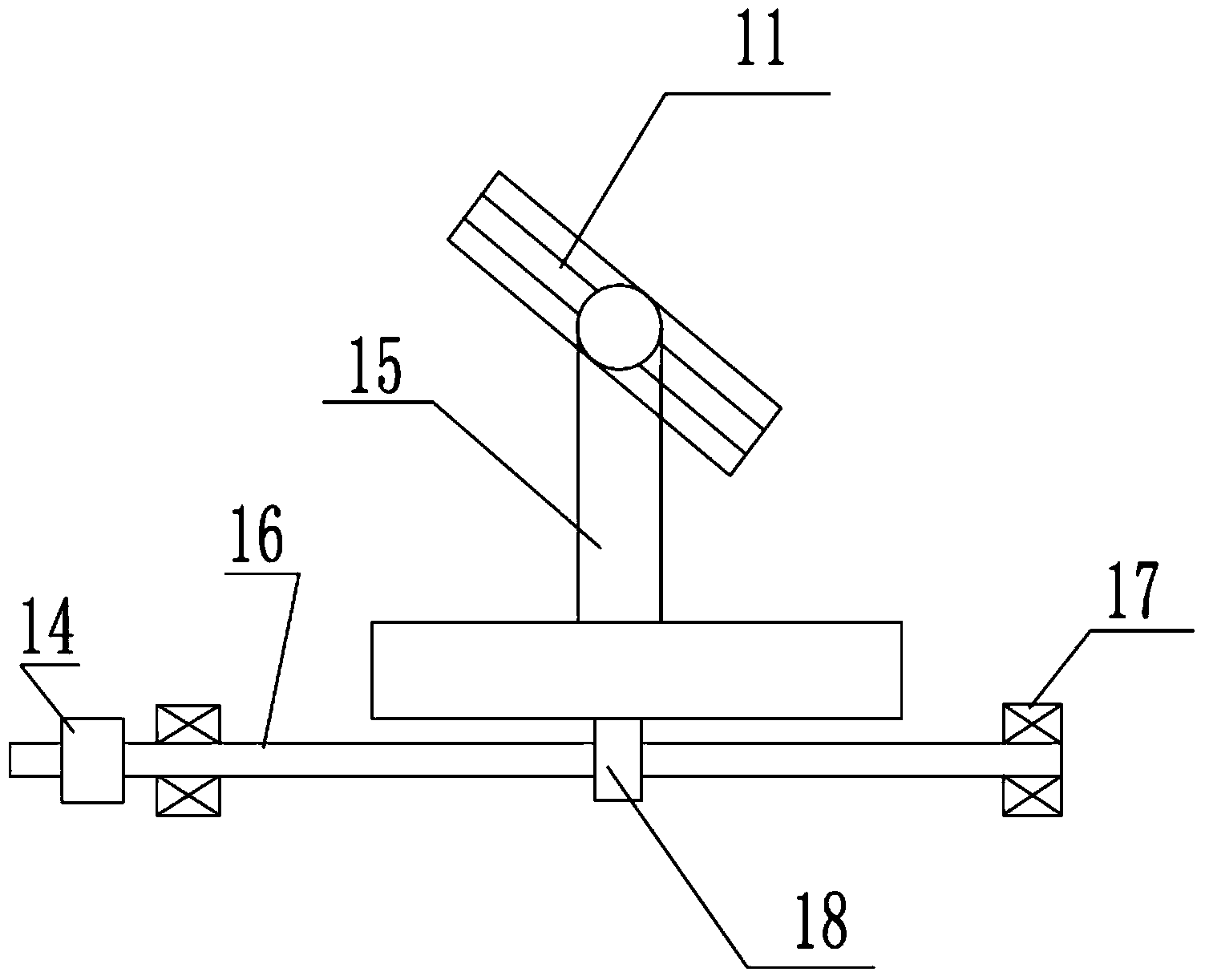

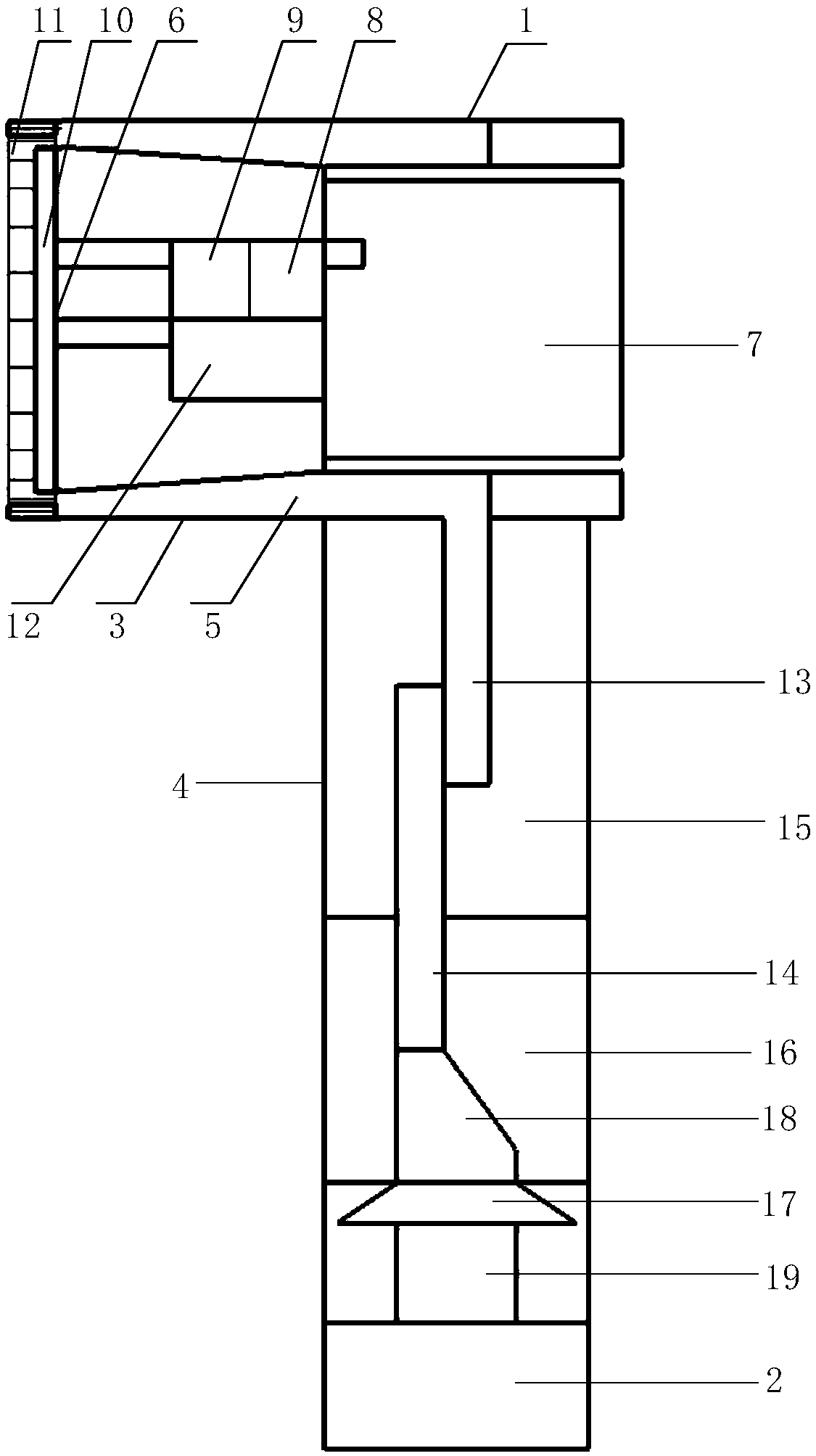

Electric cooker and steam supplementary cooking method thereof

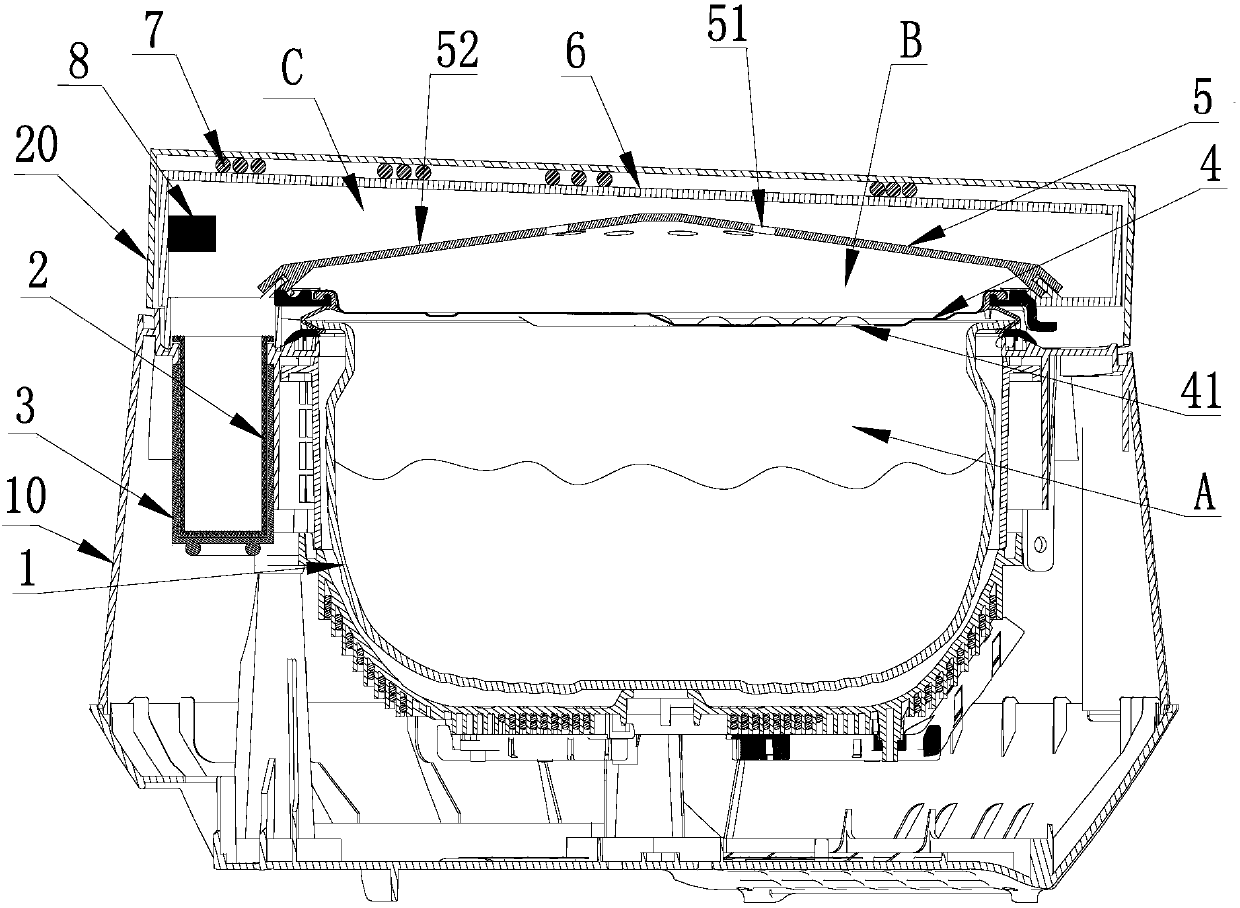

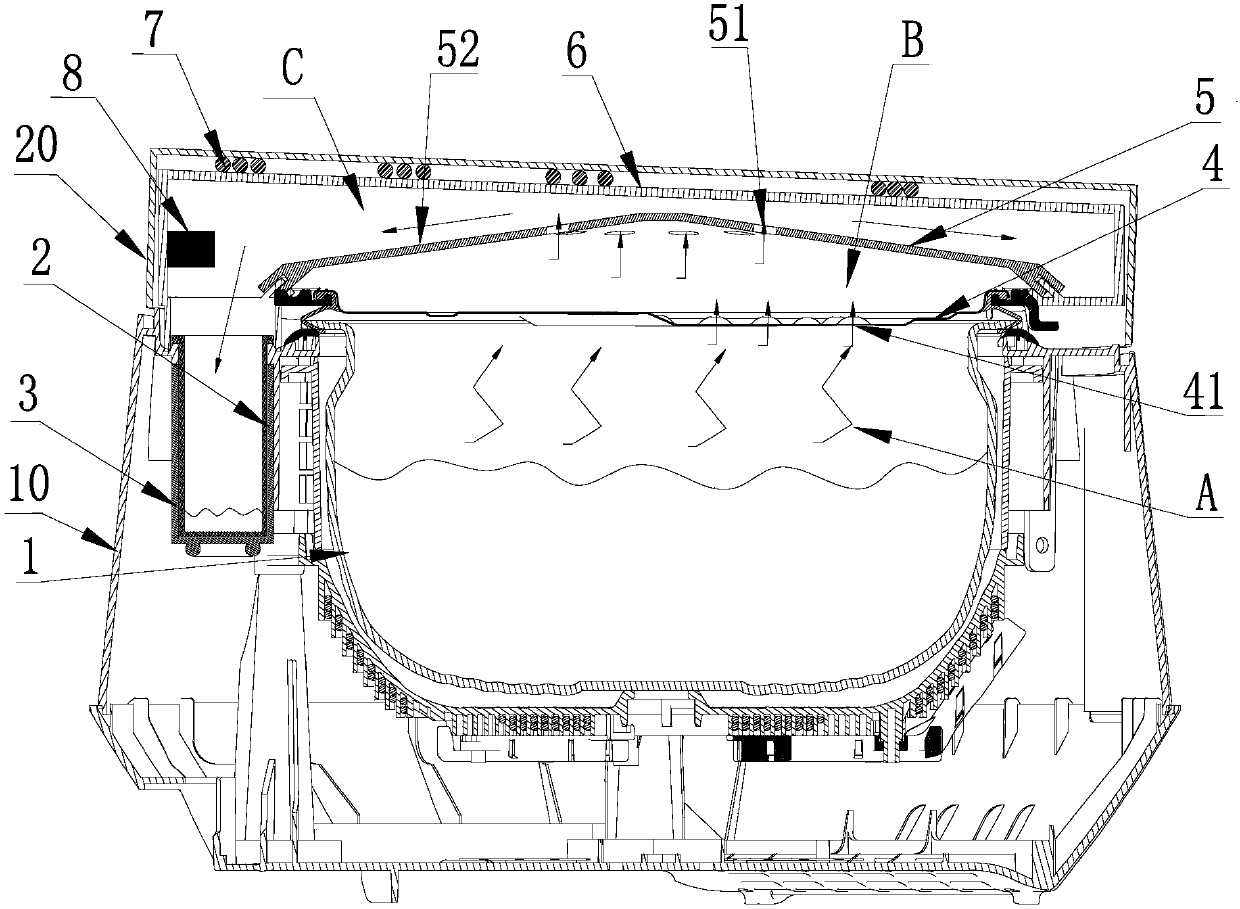

PendingCN107802172ARecovering needs are metReduce spillageWarming devicesVessels with intergral heatingEngineeringCooking methods

The invention discloses an electric cooker and a steam supplementary cooking method thereof. The electric cooker comprises a cooker body (10) and a cooker cover (20), wherein an inner pot (1), a waterdrop collection cup (2) and a water cup heating device (3); a steam condensing cavity (C) is formed in the cooker cover, wherein the electric cooker is provided with a steam condensing device; steam,which is generated from the interior of the inner pot, can at least partially enter the steam condensing cavity and can get condensed into condensed water by virtue of the steam condensing device; the condensed water is collected in the water drop collection cup; and by virtue of the water cup heating device, the condensed water in the water drop collection cup is heated, so that supplementary steam, which flows back into the inner pot, is formed. The steam supplementary cooking method comprises a condensed water collecting step and a steam supplementing step, wherein according to the condensed water collecting step, in a cooking and heating stage, the steam is at least partially condensed into the condensed water by virtue of the steam condensing device and is collected in the water dropcollection cup; and according to the steam supplementing step, in a heat-insulating stage, the condensed water in the water drop collection cup is heated, so that steam is formed and is supplementedinto the inner pot. The electric cooker, which avoids the special addition of water, is simple and convenient to operate, and effects of saving water and saving energy can be achieved.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

Ion sputtering film-plating machine

ActiveCN104294232ASolution areaSolve for uniformityVacuum evaporation coatingSputtering coatingLinear motionVacuum pump

The invention relates to an ion sputtering film-plating machine, which belongs to an ion sputtering vacuum film-plating facility. The ion sputtering film-plating machine is designed for mainly solving the technical problems that existing ion sputtering film-plating machines are small in effective film-plating area, not easily controlled in film thickness uniformity, and poor in surface quality of plated films. The technical scheme of the invention is as follows: the ion sputtering film-plating machine comprises a vacuum chamber, a large valve, an ion source, an observation window of a multi-beam optical film thickness gauge, a high-vacuum pump, a heater, an ion neutralizer, a movable film-plating target and a rotating substrate holder, wherein the movable film-plating target is arranged at the bottom of the inside of the vacuum chamber and located below a film-plating fixture in the rotating substrate holder, the movable film-plating target can carry out a linear motion in the vacuum chamber, the rotating substrate holder is arranged on the upside of the inside of the vacuum chamber and can move upwards and downwards, and the observation window of the multi-beam optical film thickness gauge is arranged on the outer wall of the vacuum chamber and located on the rotating radius of the rotating substrate holder.

Owner:杰莱特(苏州)精密仪器有限公司

Paint coating device

ActiveCN103657921AReduce spillageImprove spraying efficiencyLiquid spraying apparatusSiphonSpray nozzle

The invention provides a paint coating device. The paint coating device comprises a paint tank, a piston, a piston handle, a spraying nozzle and a high-pressure fluid pump, wherein a cavity of the paint tank is filled with paint, a paint outlet is formed in the top end of the paint tank, the piston is arranged inside the paint tank in a vertical sliding mode, the piston handle extends into the paint tank from a top plate of the paint tank, the bottom end of the piston handle is fixedly connected with the piston, the piston handle is provided with a ventilation hole communicated between the outside and a lower cavity, the spraying nozzle is arranged at one side of the paint tank and provided with a fluid passage, an outlet of the fluid passage is located above the paint outlet, the high-pressure fluid pump is used for guiding high-pressure fluid into the fluid passage, and an outlet of the high-pressure fluid pump is communicated with an inlet of the fluid passage. Pressure difference is generated between the cavity, filled with the paint, of the paint tank and the outside, the paint inside the paint tank is automatically pressed into the paint outlet based on the siphon principle, and then automatic coating is achieved. The paint coating device can be applied to coating of paint with different viscosities, and therefore the paint coating device can replace manual coating, is used for coating anti-corrosion paint or fire retardant or the like with high viscosity, and improves coating efficiency.

Owner:STATE GRID CORP OF CHINA +1

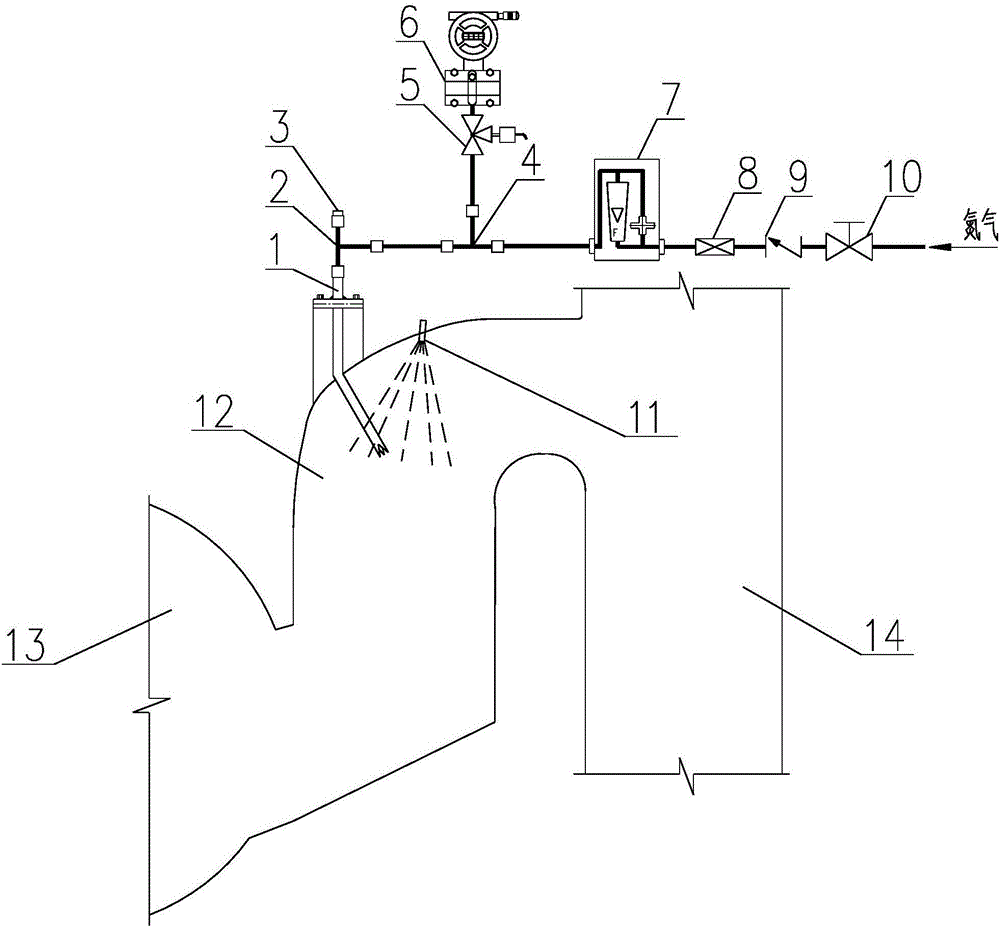

Coke oven bridge pipe raw gas pressure detection device

PendingCN106595948ASolve the blockageEasy to controlFluid pressure measurementObservational errorDifferential pressure

The present invention relates to a coke oven bridge pipe raw gas pressure detection device. The device comprises a pressure tapping probe, a differential pressure transmitter and a nitrogen gas blowing system. The pressure tapping probe is installed on a coke oven bridge pipe, the pressure tapping of the pressure tapping probe is stretched into the coke oven bridge pipe, a front-end pressure tapping port is located in the ammonium hydroxide spraying range, and the pressure output end is connected with a first tee joint and a second tee joint in order; the other branch of the first tee joint is connected with a drain plug or maintenance; and one branch of the second tee joint is connected with the differential pressure transmitter though a 3-way ball valve, and the other branch of the second tee joint is connected with the nitrogen gas blowing system formed through the connection of a constant flow gas blowing device, a filtering reducing valve, a one-way valve, a ball valve for air supply and a nitrogen pipeline in order. The coke oven bridge pipe raw gas pressure detection device employs the air blowing method to perform bridge pipe raw gas pressure detection to effectively solve the problem that the pressure tapping pipeline is obstructed caused by the substances such as the dust, the tar, the naphthalene and the like in the raw gas and perform long-term stable operation; and moreover, the accurate detection of the coke oven bridge pipe raw gas pressure is performed, and the measurement error does not exceed the range from -5Pa to +5Pa through test calibration so as to facilitate the pressure control of a coking chamber.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

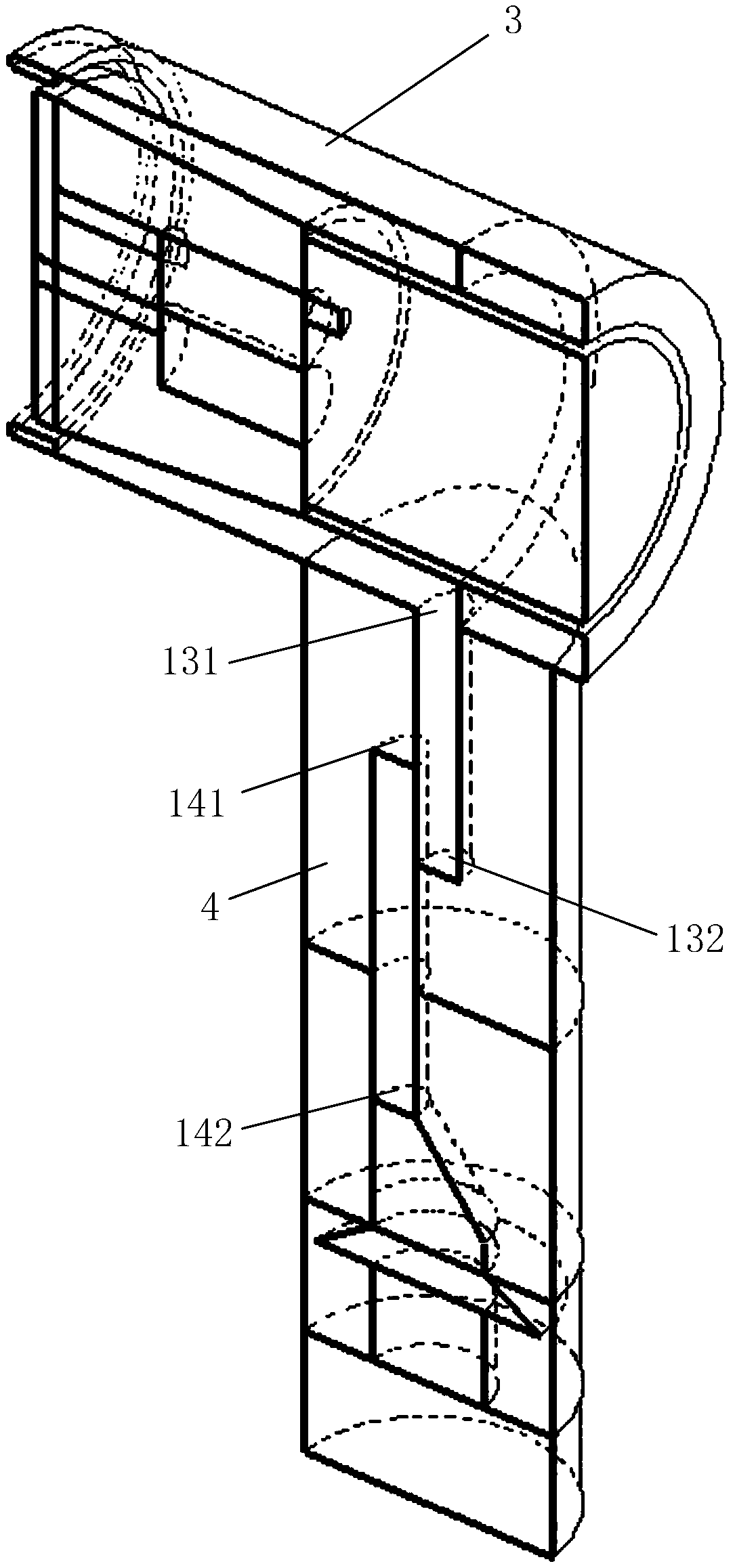

Portable cleaning device and cleaning system

The invention discloses a portable cleaning device and a cleaning system, and particularly relates to a portable cleaning device. The portable cleaning device comprises a shell, a cleaning mechanism,a cleaning fluid recycling mechanism and a battery, wherein the cleaning mechanism, the cleaning fluid recycling mechanism and the battery are arranged in the shell. The shell comprises a cleaning part and a hand-held part which is rotationally connected with one end of the cleaning part, the cleaning mechanism is arranged in the cleaning part, and the cleaning fluid recycling mechanism and the battery are arranged in the hand-held part. A recycling channel used for recycling cleaning fluid is arranged between the cleaning mechanism and edge of the cleaning part and is in connection with the cleaning fluid recycling mechanism, and the battery is used for supplying power for the cleaning mechanism and the cleaning fluid recycling mechanism. The portable cleaning device and the cleaning system have the advantages that the portable cleaning device is simple in structure and convenient to operate, an included angle between the cleaning part and the hand-held part can be adjusted in a rotating manner, and the portable cleaning device is not required to be connected with an external power supply through a power line, so that the portable cleaning device is convenient to carry and has a wide application range; and while ensuring cleaning efficiency and cleaning experience, the portable cleaning device can also be used to save water and reduce water overflow, prevent users from slipping due to the water overflow in cleaning process, and improve use safety.

Owner:董潇晓

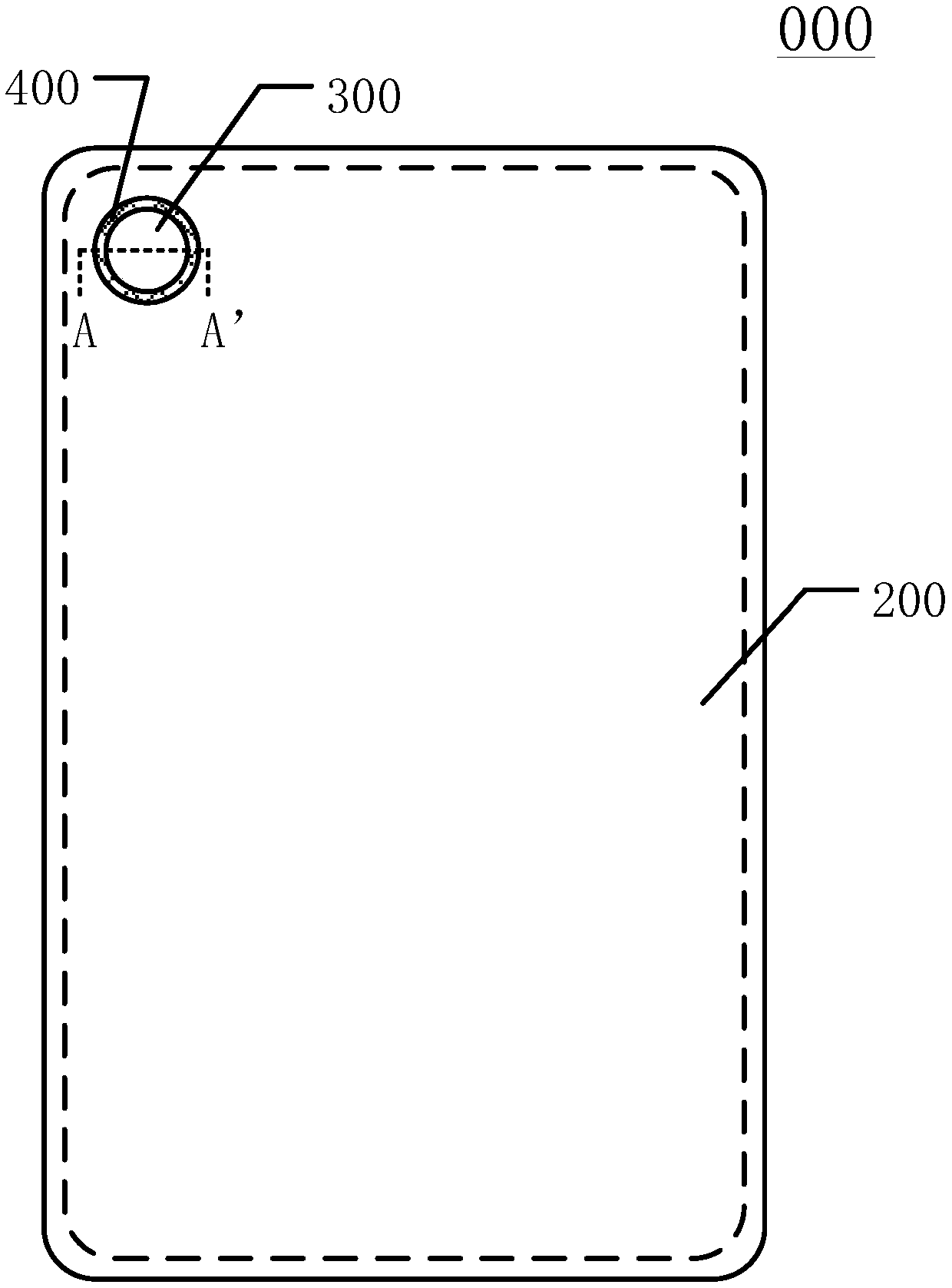

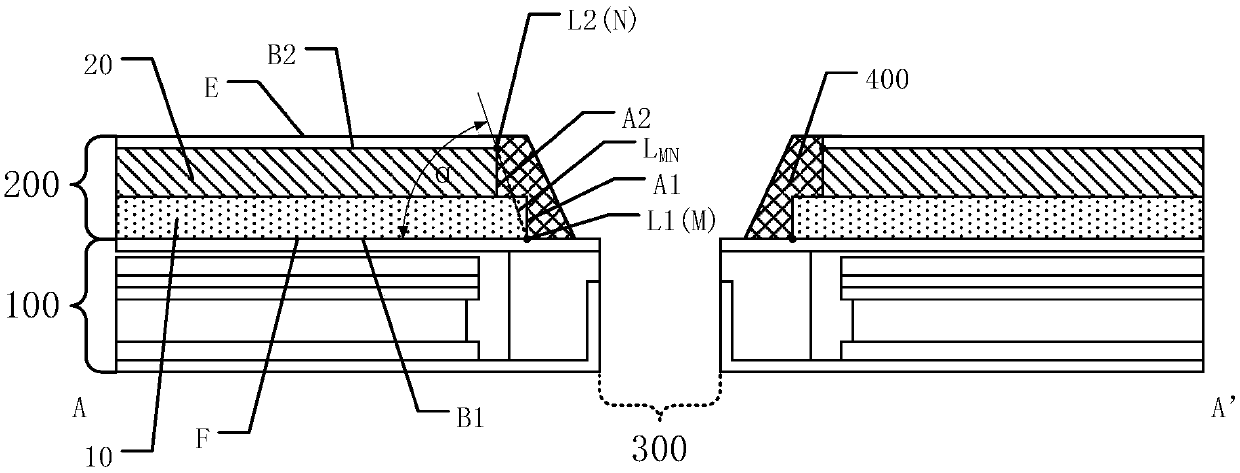

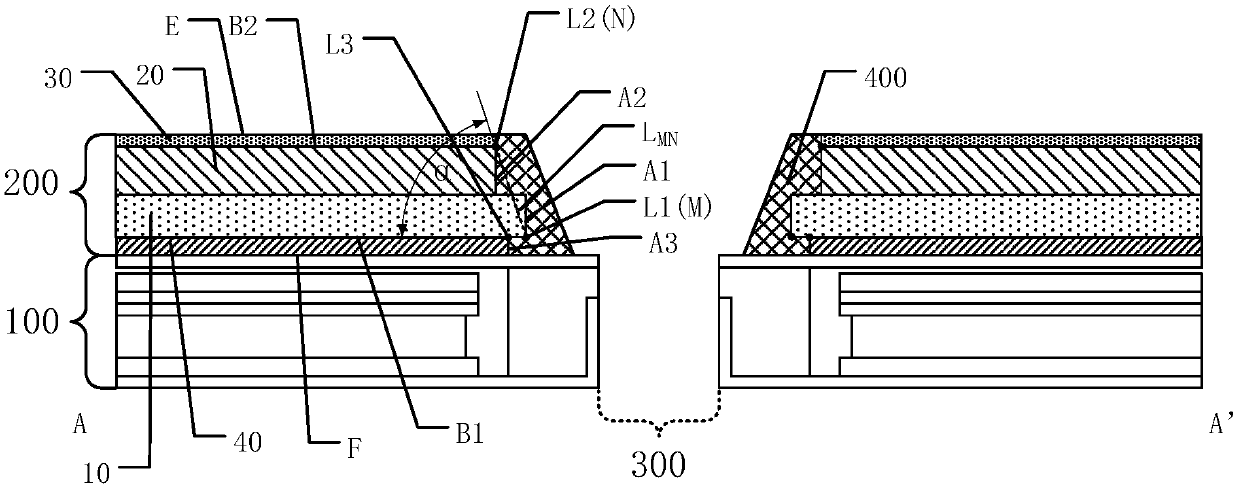

Display module and display device

ActiveCN109637373AImprove the display effectAffect the shooting effectTelevision system detailsColor television detailsAcute angleDisplay device

The invention discloses a display module and a display device, and belongs to the technical field of display. The display module comprises a backlight module and a display panel which are oppositely arranged and a through hole, the display panel at least comprises a first substrate and a second substrate which are oppositely arranged, the first substrate comprises a first side surface and a firstsurface, the second substrate comprises a second side surface and a second surface, the intersection line of the first side surface and first surface is a first intersection line, the intersection line of the second side surface and second surface is a second intersection line; the display panel comprises a first cross section which passes through the through hole and is vertical to a light emitting surface, the intersection point of the first cross section and first intersection line is a first intersection point, the intersection point of the first cross section and second intersection lineis a second intersection point, and the connecting line of the first intersection point and the second intersection point forms an acute angle with the first surface. The display device comprises thedisplay module. According to the invention, light leakage in the through hole can be avoided, the influence of the overflow of a shading sealant on the display and shooting functions of the camera arranged in the through hole can be reduced, and the product quality is improved.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

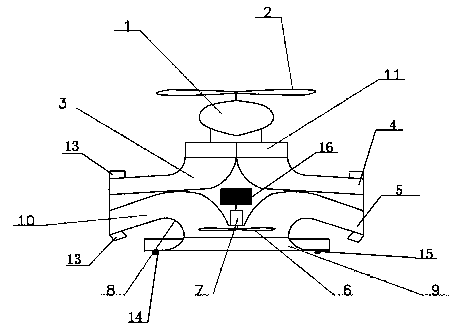

Unmanned aerial vehicle pollination device and method thereof

ActiveCN108353784AGuarantee the effectiveness of collectionIncrease profitAircraft componentsAgriculturePollinationPollen

The invention belongs to an unmanned aerial vehicle pollination device and a method thereof. The unmanned aerial vehicle pollination device comprises an unmanned aerial vehicle, wherein a rotor wing is arranged above the unmanned aerial vehicle; an air outlet flow passage is hung under the unmanned aerial vehicle; a pollen outlet passage is arranged under the air outlet passage; an air outlet of the air outlet flow passage is arranged above a pollen outlet of the pollen outlet flow passage; the air outlet and the pollen outlet are in horizontal arrangement; an air suction fan is arranged at apollen inlet of the pollen outlet flow passage; an air inlet of the air outlet flow passage is arranged under the rotor wing. The unmanned aerial vehicle pollination device can suck the pollen and horizontally spray out the pollen to the two sides of the unmanned aerial vehicle; the pollen can be diffused to a wider space through an airflow sprayed out from the air outlet. The unmanned aerial vehicle pollination method can improve the pollen utilization rate and can improve the artificial pollination efficiency.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

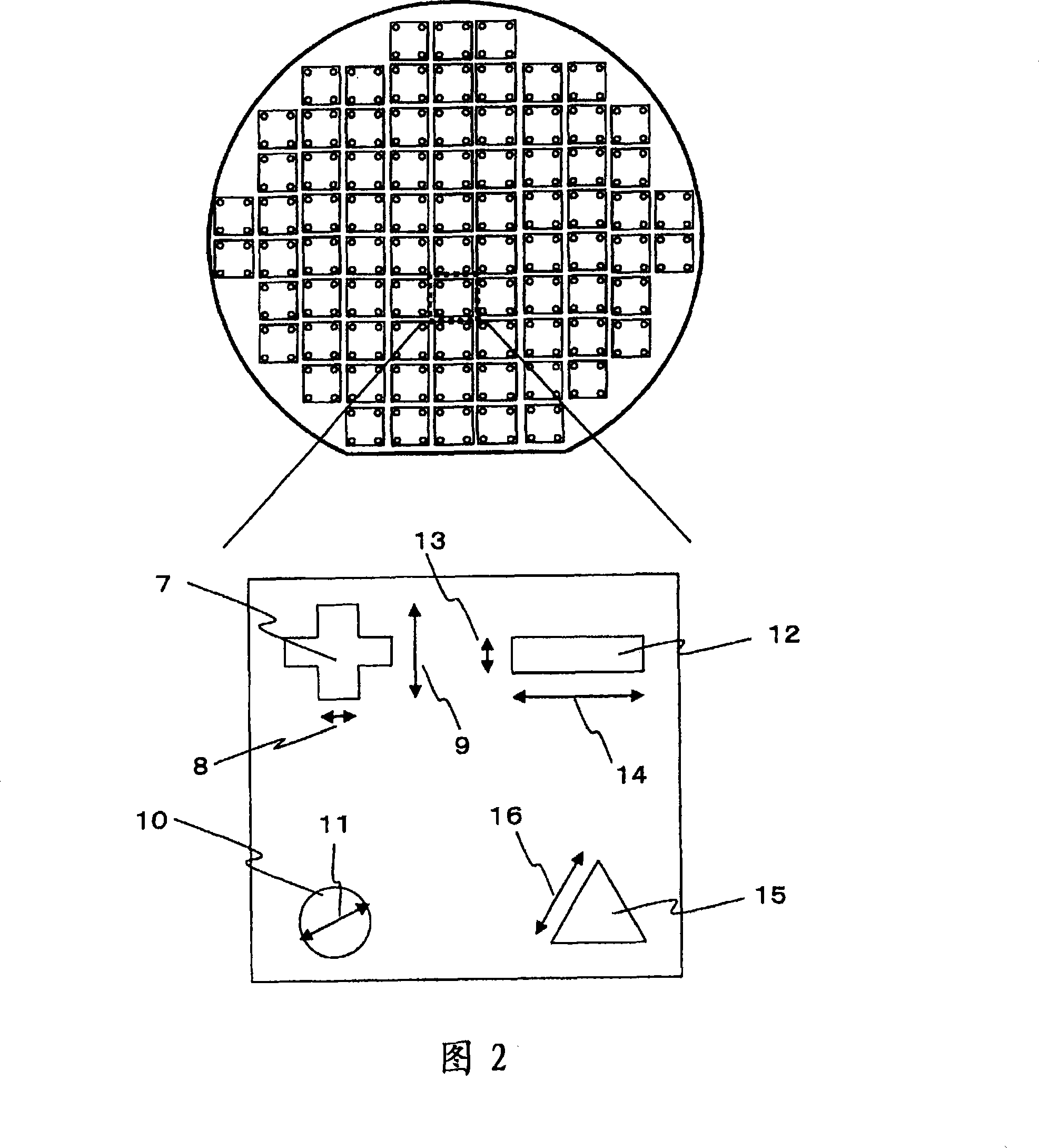

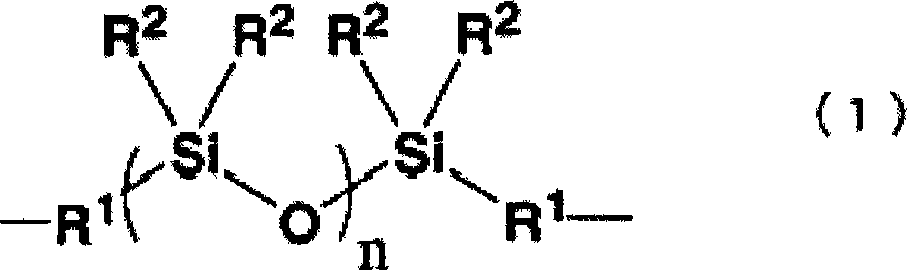

Adhesive composition for semiconductor, semiconductor device using the same and method for producing semiconductor device

ActiveCN101228621AEasy to thinImprove reliabilityNon-macromolecular adhesive additivesFilm/foil adhesivesEpoxyOrganic solvent

The present invention provides an adhesive composition for a semiconductor that does not break or peel off even when it is bent during handling, and that can be laminated with a narrow pitch and a high number of pins. The bump electrode is laminated on the electrode side of the semiconductor wafer, and high-speed dicing can be performed without contamination or defects of cutting powder during dicing, and alignment marks can be easily recognized during dicing and flip-chip mounting. An adhesive composition for semiconductors containing (a) an organic solvent-soluble polyimide, (b) an epoxy compound, and (c) a curing accelerator, wherein, relative to 100 parts by weight of the (b) epoxy compound, Containing 15 to 90 parts by weight of (a) organic solvent-soluble polyimide, 0.1 to 10 parts by weight of (c) curing accelerator, and (b) epoxy compound containing a compound that is liquid at 25°C and 1.013×105N / m2 For compounds that are solid at 25°C and 1.013×105N / m2, the proportion of liquid compounds in all epoxy compounds is 20% by weight or more and 60% by weight or less.

Owner:TORAY IND INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com