Patents

Literature

138results about "Damping devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

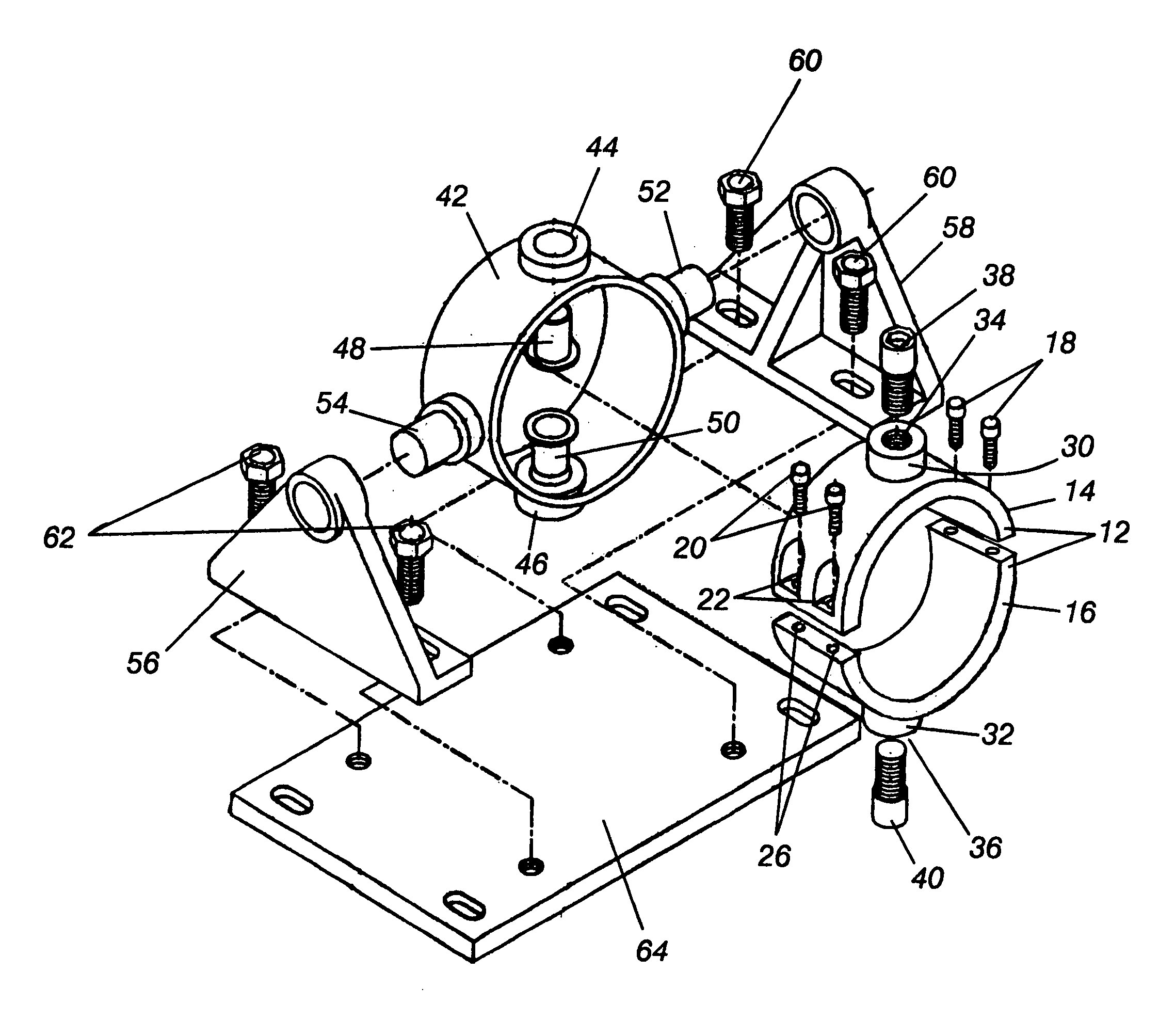

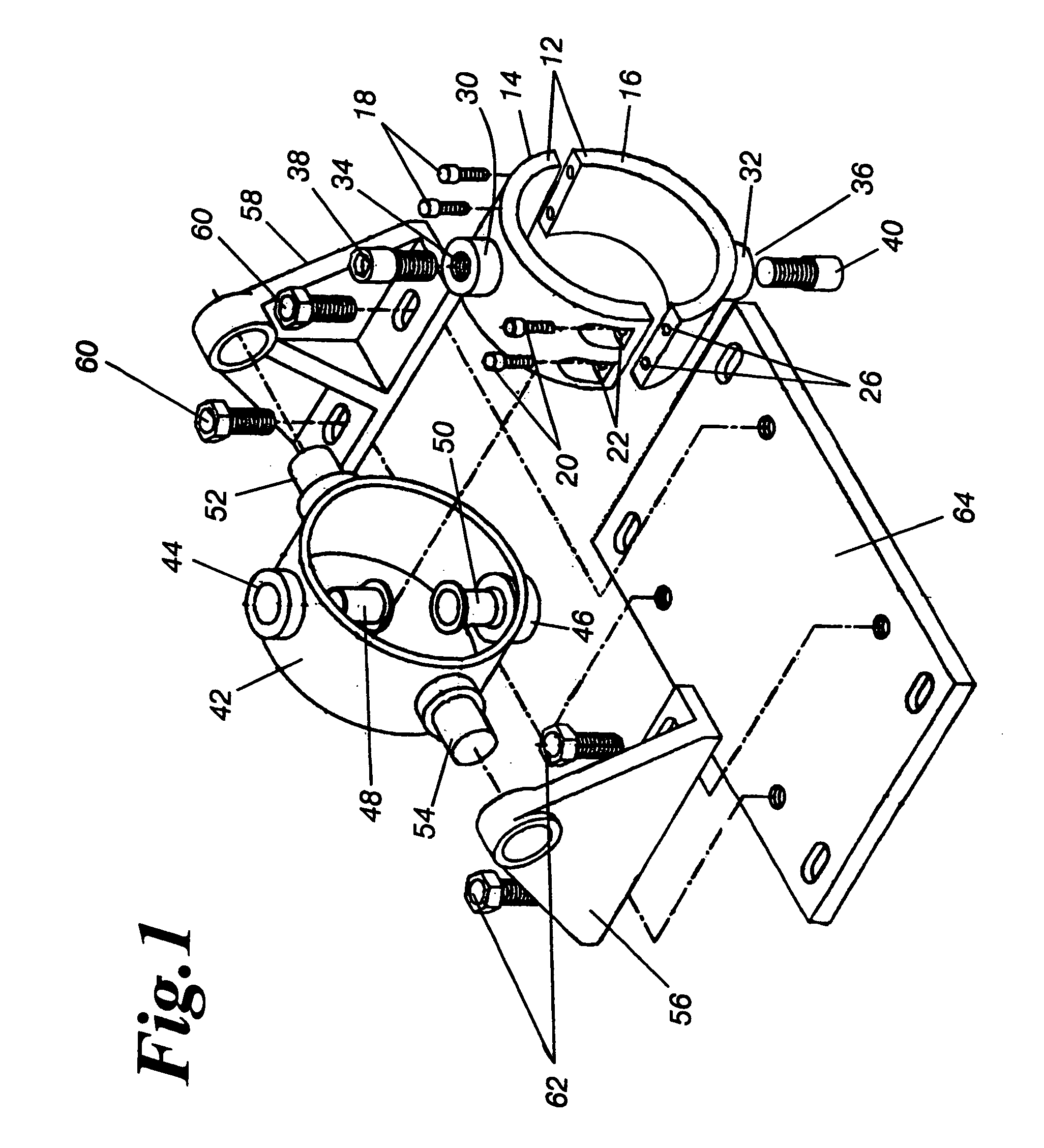

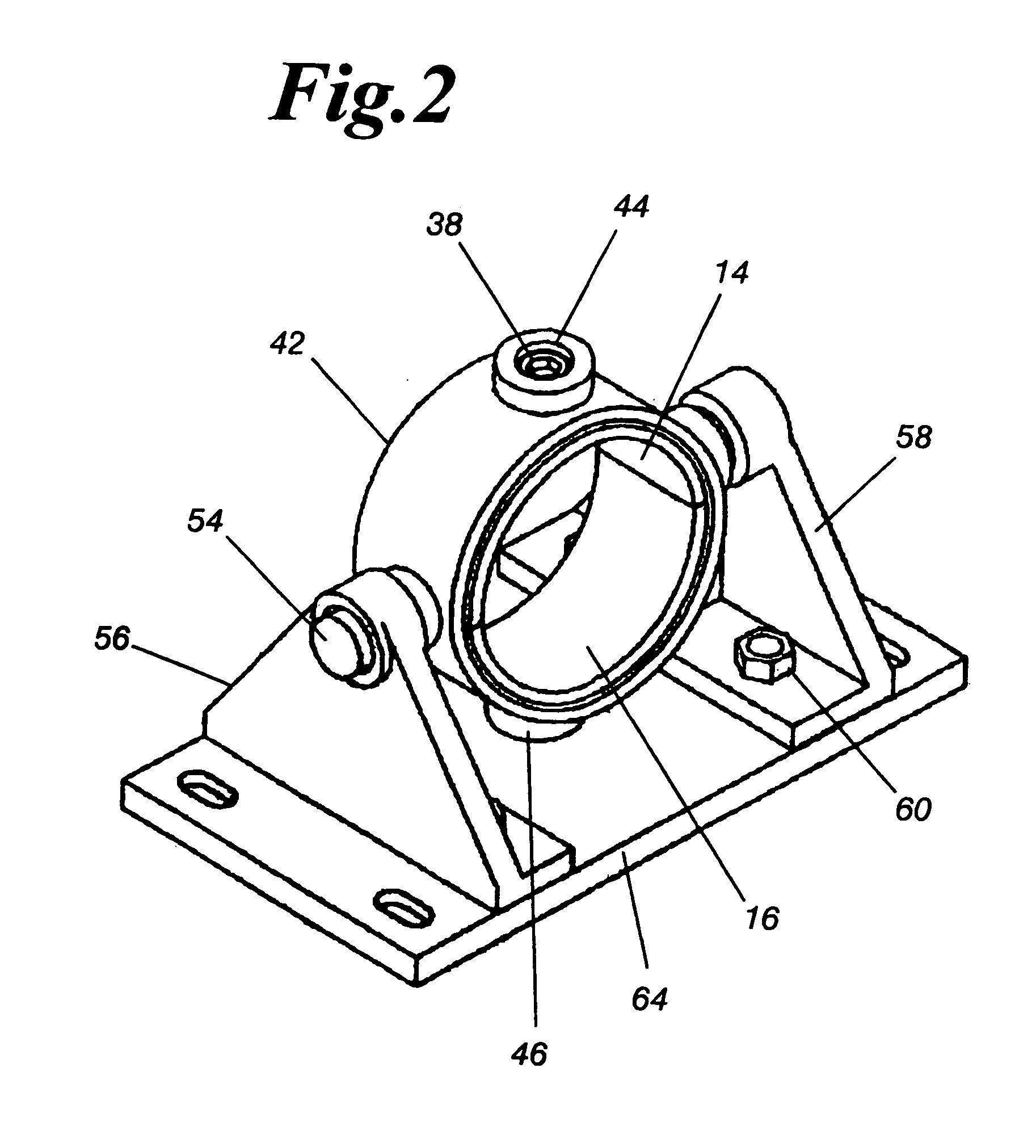

Gimbaled mounting bracket

ActiveUS20060065801A1Quick installationMinimal alignmentPipe supportsDisposition/mounting of recording headsRotational axisEngineering

A gimbaled mounting bracket apparatus for aligning an actuator with a receptacle is disclosed, having a mounting ring rotatable around a pair of gudgeons. A concentric rotation ring attached to the pair of gudgeons. The concentric ring is mounted to a base along a rotational axis orthogonal to the gudgeons. The mounting ring retains a shower actuator that is to be aligned with a piping apparatus. The shower actuator can be angularly adjusted relative to piping apparatus to produce a collinear relationship, but is free of any translational movement relative to said receptacle, so as to minimize stresses exerted on said actuator.

Owner:VOONER FLOGARD CORP

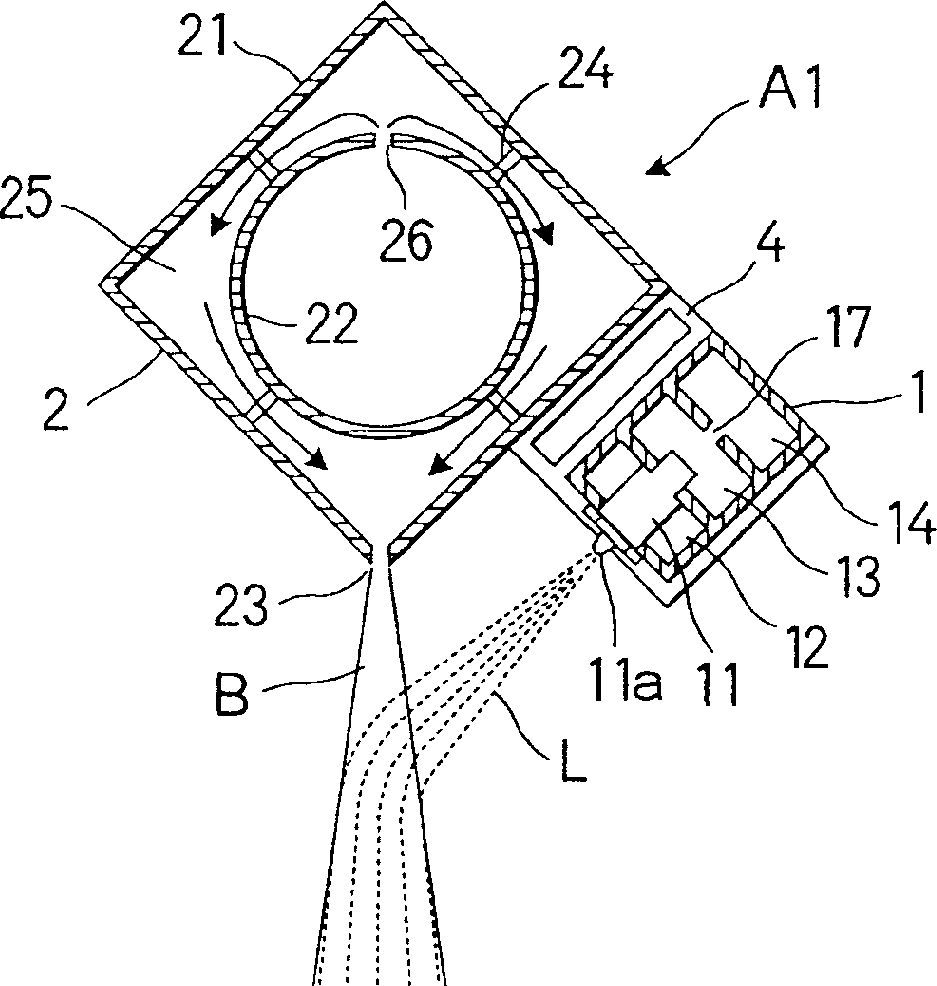

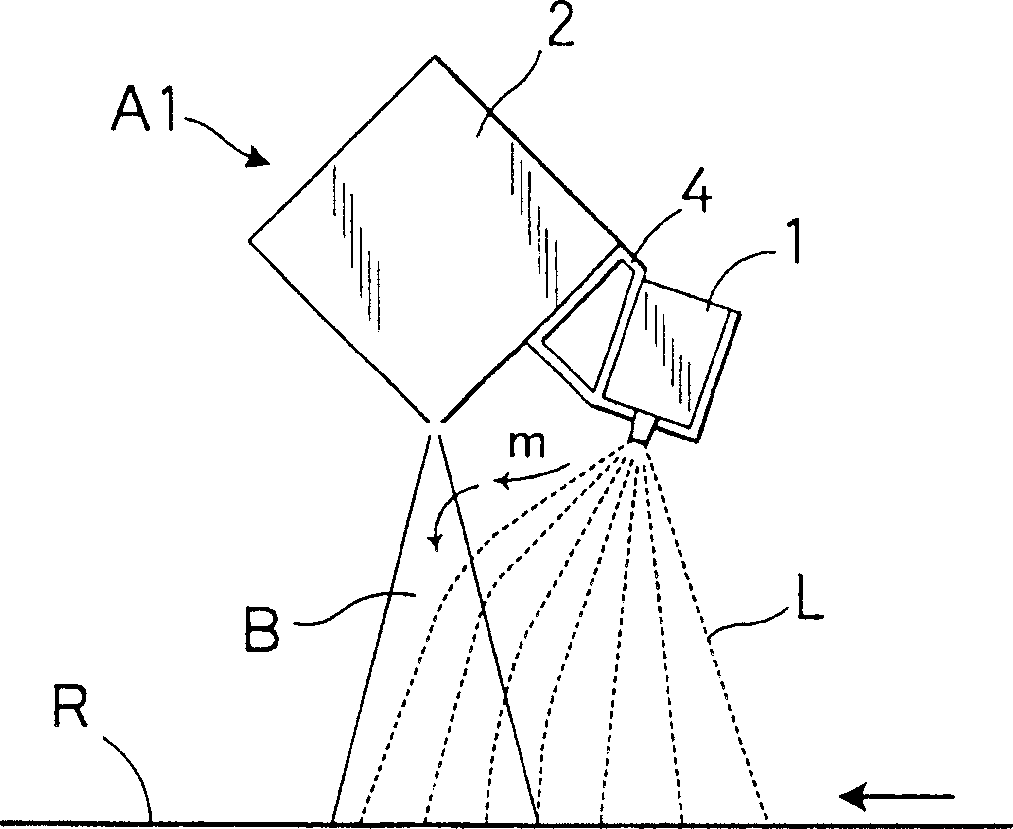

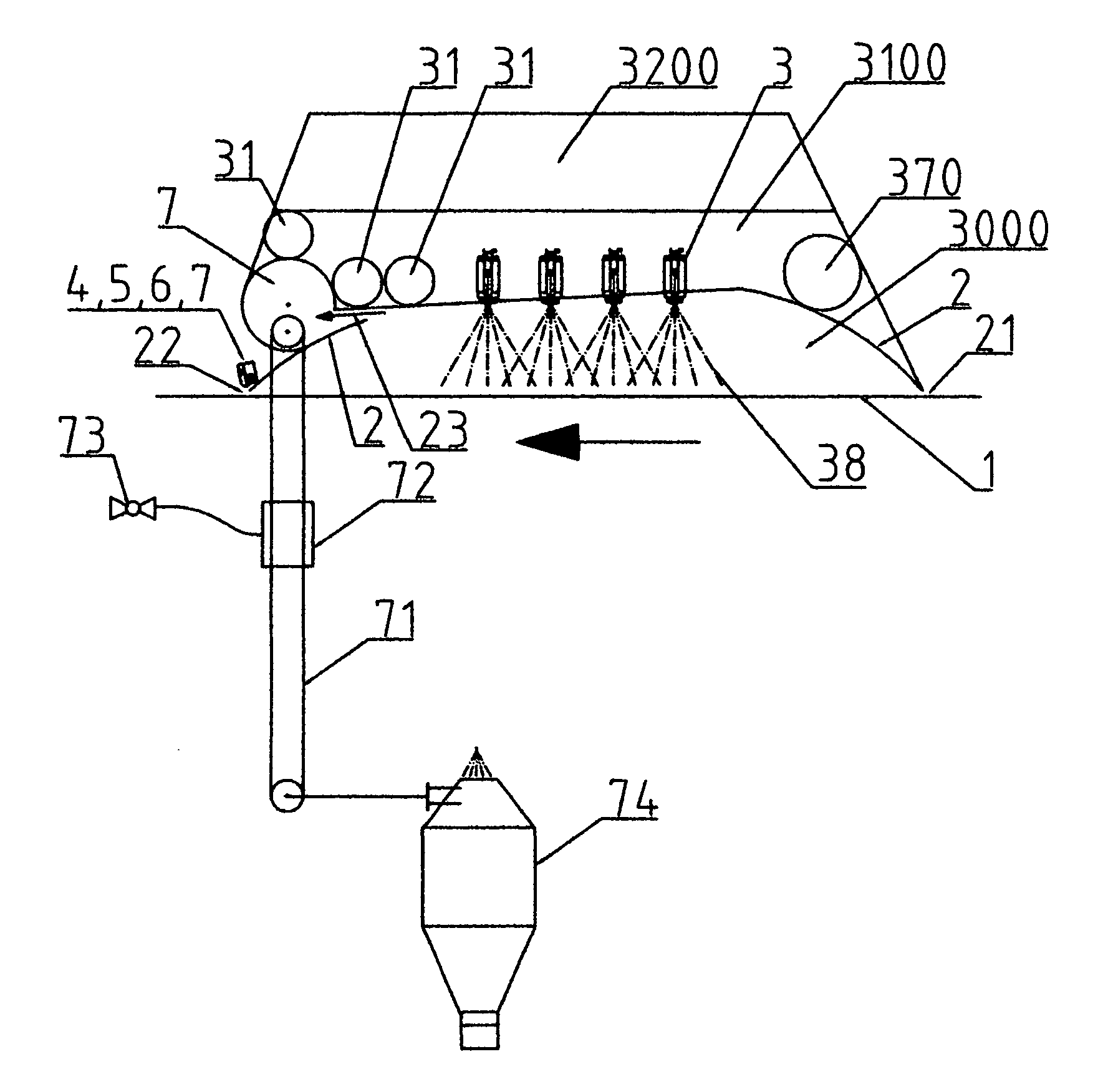

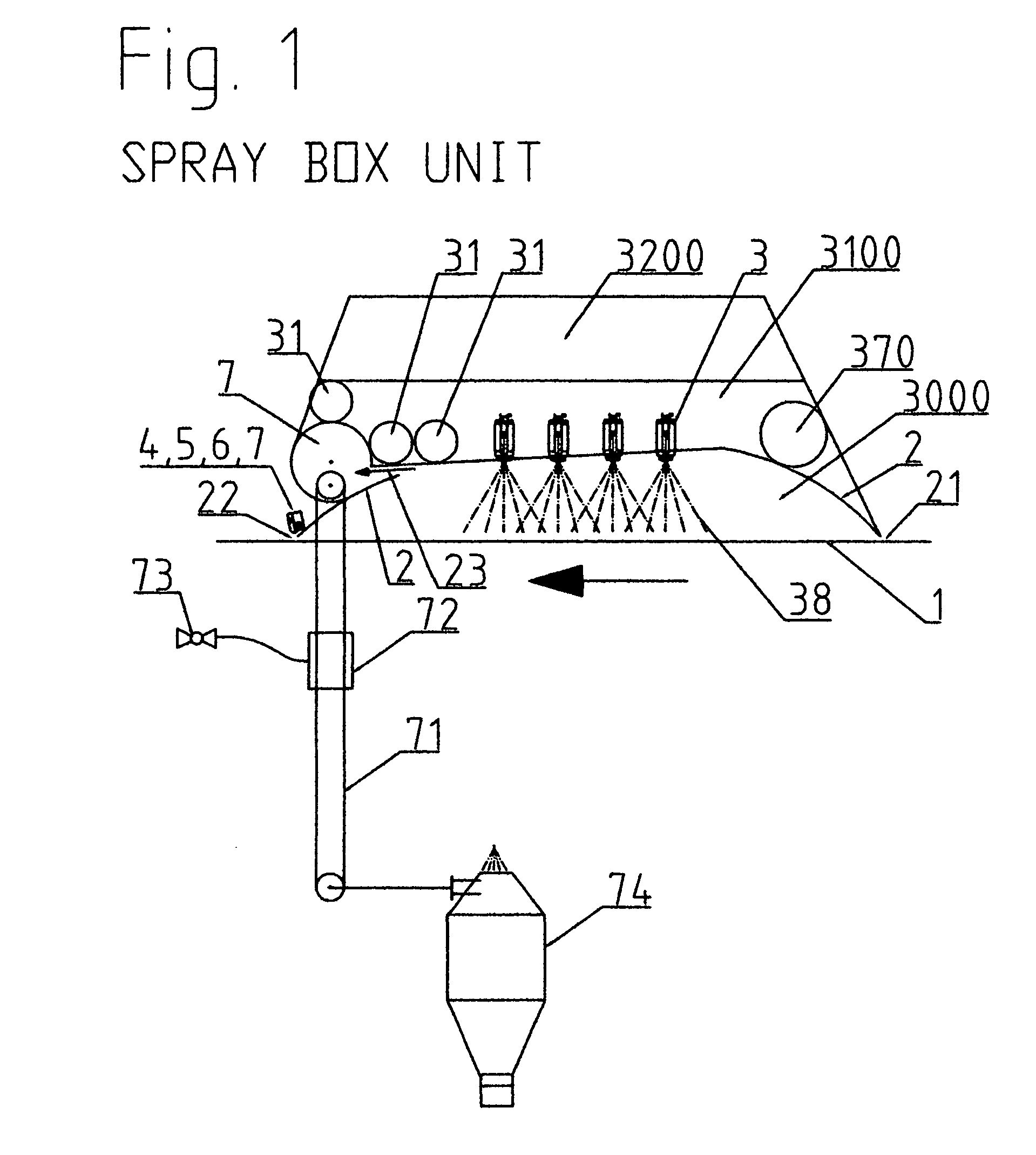

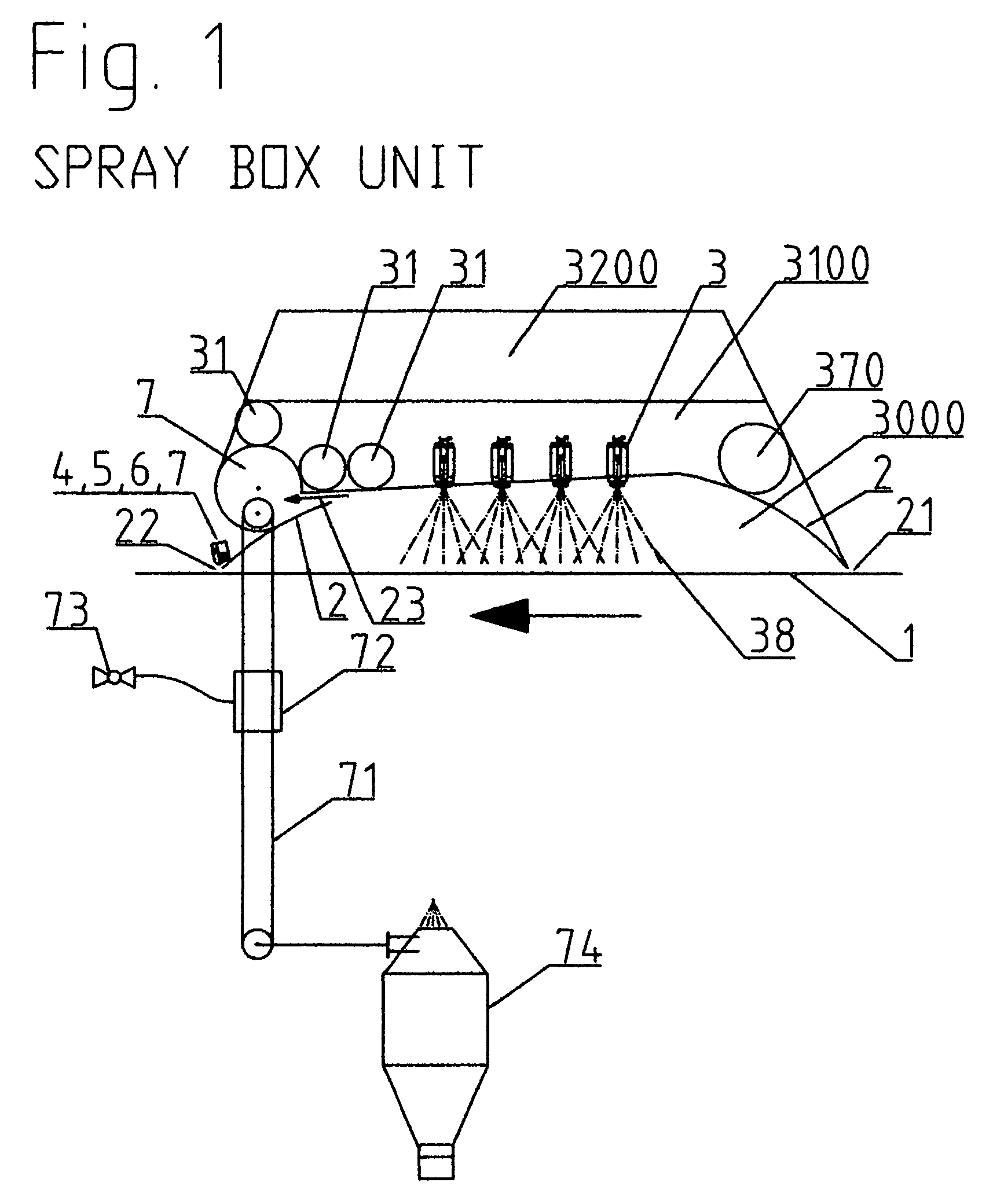

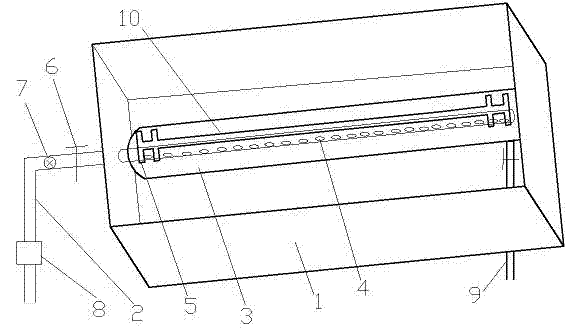

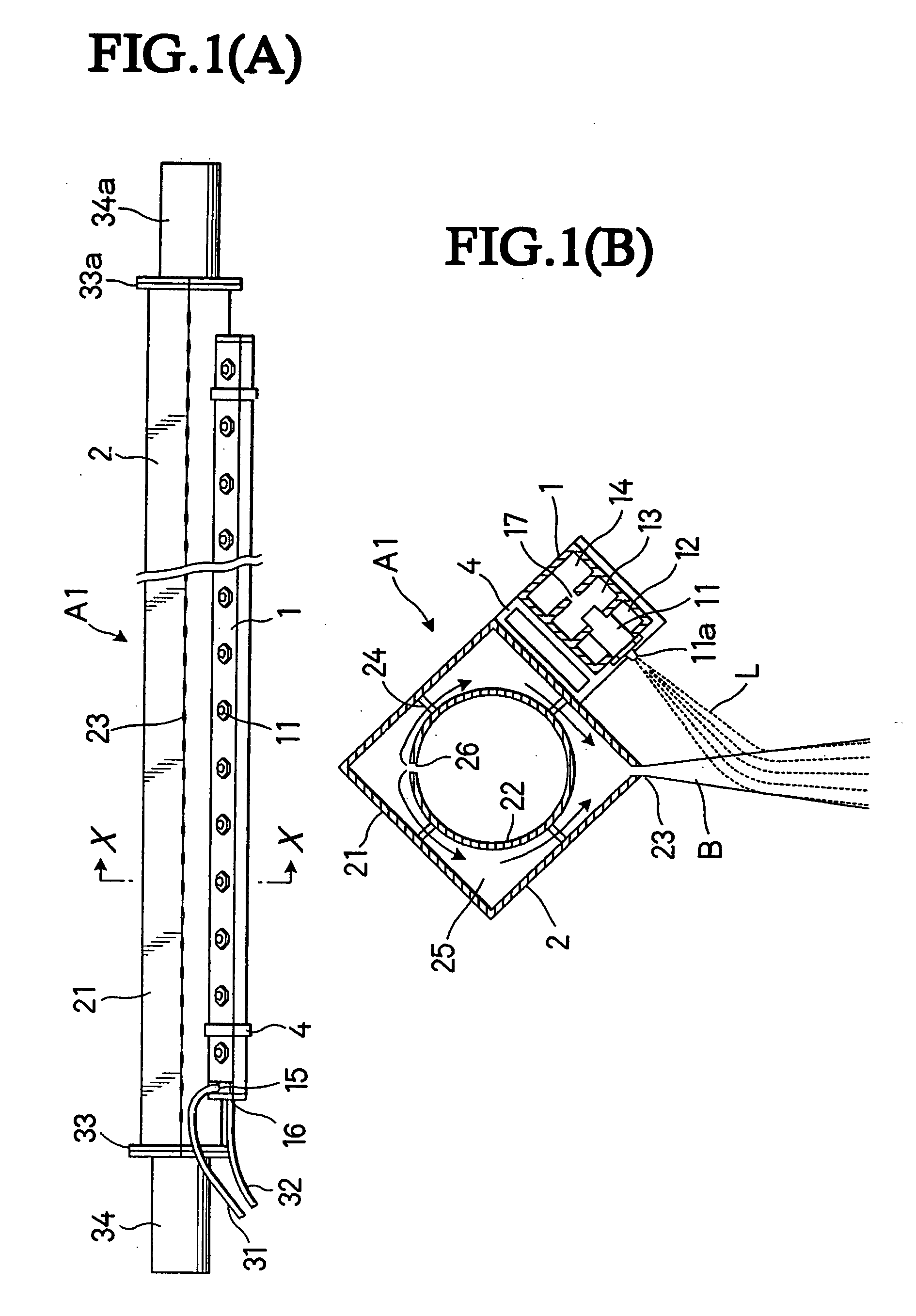

Liquid spray unit, method for spraying liquid using it, and chemical

InactiveCN1668382ASpeed up sprayingApply stabilityWater-repelling agents additionReinforcing agents additionInterior spaceSpray nozzle

A liquid spray unit which can impart liquid (treating liquid, medicine, or the like) surely to a traveling body even in a high speed paper making machine. The liquid spray unit for spraying liquid to a traveling body comprises a spray tube provided with a nozzle for spraying liquid, and an air box provided with an opening for jetting an air flow, wherein the spray tube and the air box are arranged such that the air flow is jetted from the air jet opening toward the liquid sprayed from the spray nozzle and the sprayed liquid can be blown to the traveling body after being accelerated by the air flow. The liquid can be sprayed more effectively to the traveling body by making compact the unit depending on the quantity of liquid being imparted or the inner space of a paper making machine, or the like, or by employing a unit of a type of reciprocating a single nozzle.

Owner:明答克株式会社

Apparatus for paper making and paper surface enhancement

InactiveUS20050098291A1Easy to manufactureImprove propertiesBurnersNon-fibrous pulp additionPulp and paper industry

A process that can utilize current paper manufacturing facilities by adding consecutive spray apparatuses that can make and / or enhance the manufacture of a multitude of specific paper products on-line, or improve the properties of already formed paper products with consequent spraying steps on-line or off-line.

Owner:KANGAS MARTTI Y O +1

Process for improving the surface of offset paper

Application device for a paper machine, a paper machine, a nozzle dampener, and a process for improving the surface of offset paper. The application device includes a plurality of nozzles distributed across a machine width as at least one row of nozzles, such that the plurality of nozzles are oriented to spray a passing paper web. The at least one row of nozzles is adapted for an alternative selective throughput of water and binding agent. The paper machine includes the application device. The nozzle dampener includes a plurality of nozzles distributed across a machine width as at least one row of nozzles, such that the plurality of nozzles are oriented to spray a passing paper web. The at least one row of nozzles are adapted to improve paper properties of offset paper by applying a binding agent onto the passing paper web. The process includes supplying a binding agent to at least one nozzle located within at least one of a drying section of a paper machine and a calender of the paper machine, and applying the binding agent across a width of a moving paper web in the at least one of the drying section and the calender.

Owner:VOITH PATENT GMBH

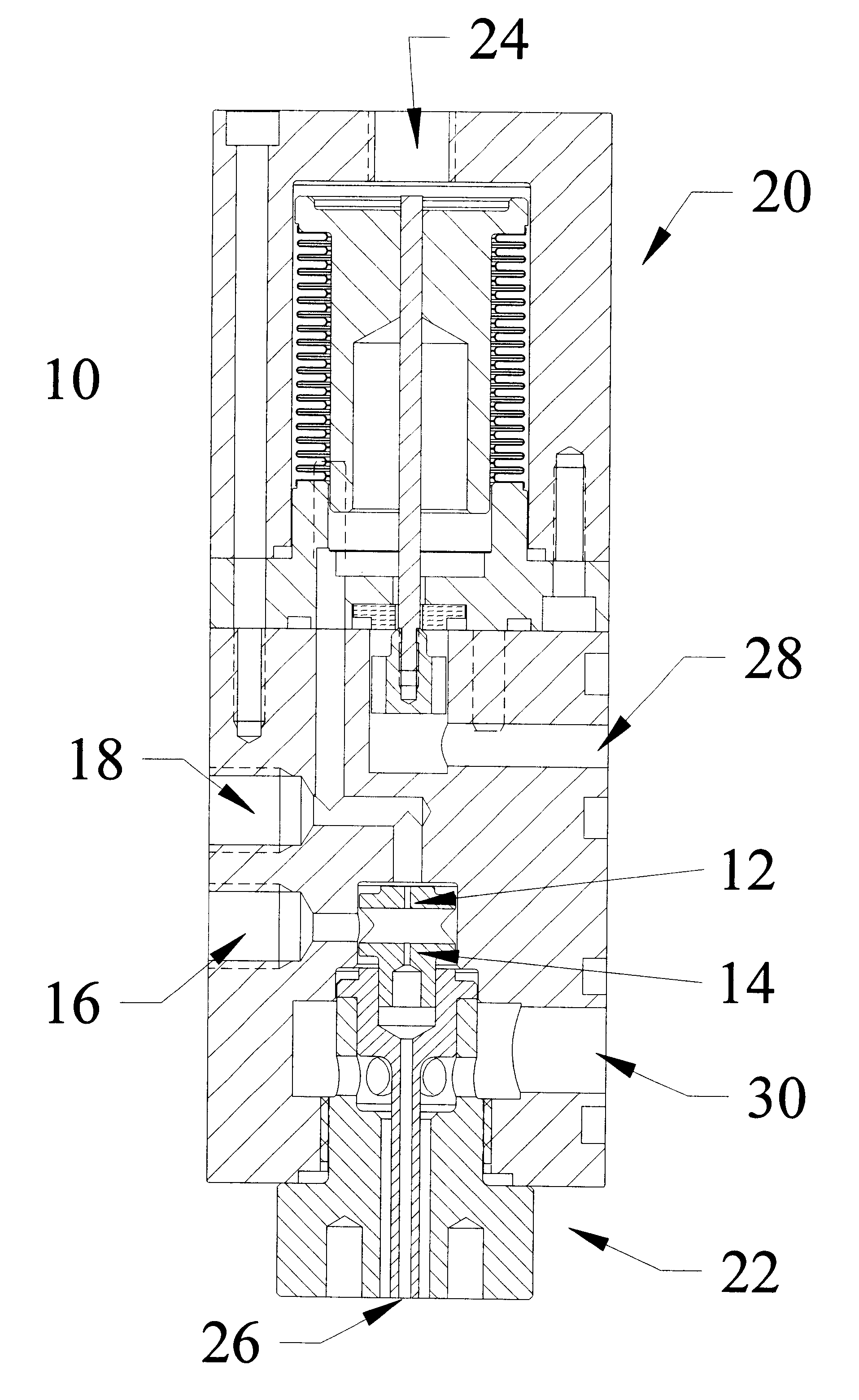

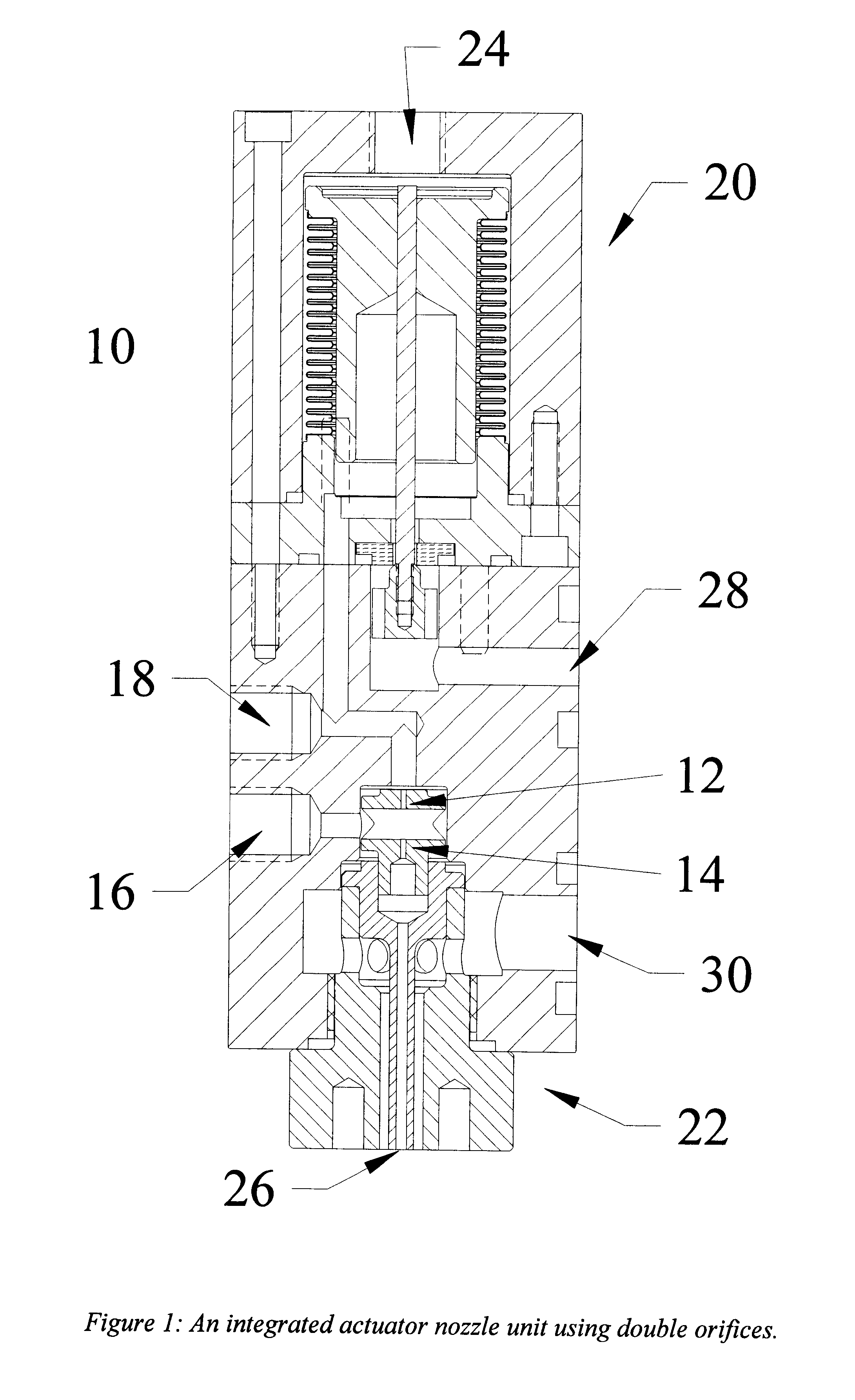

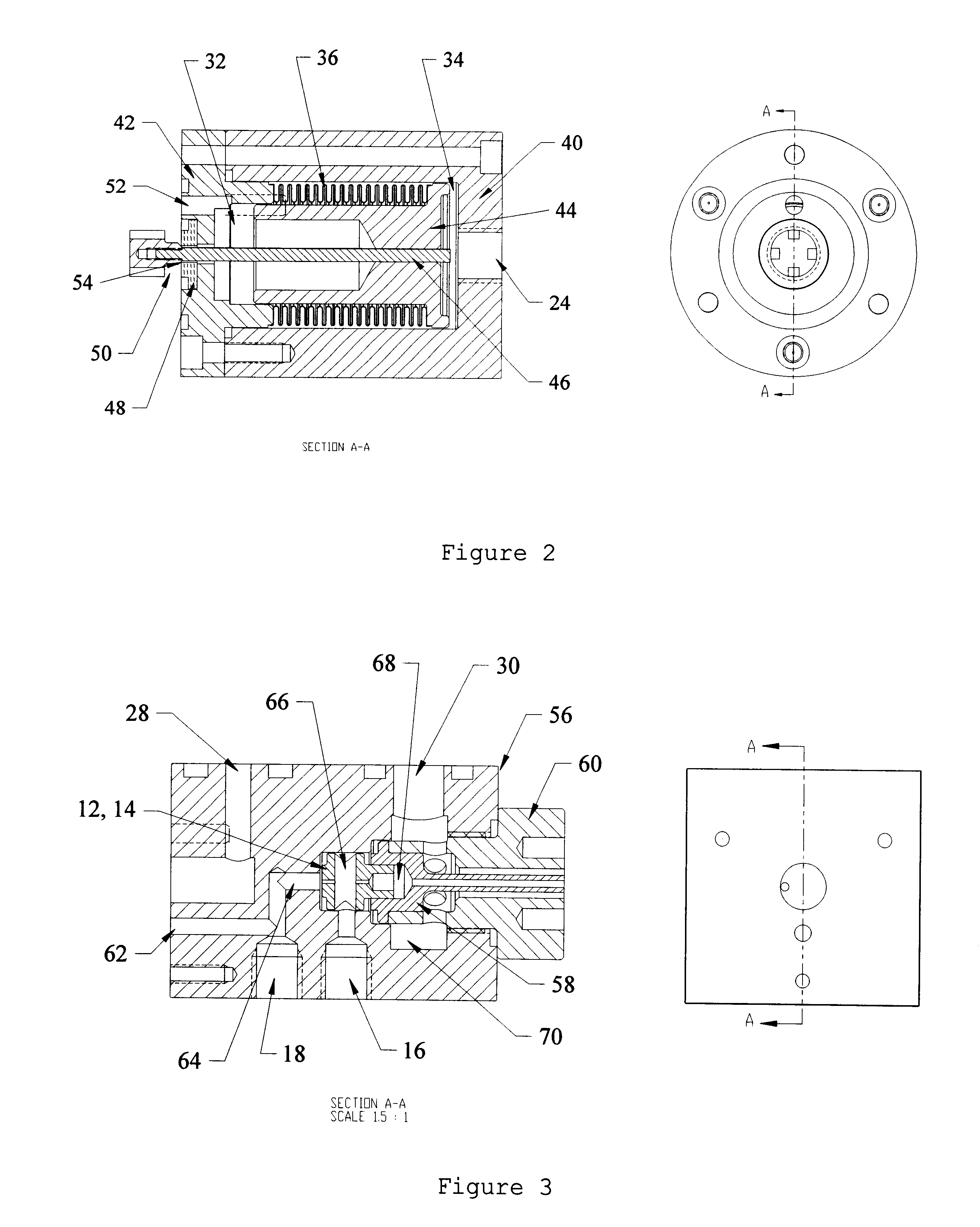

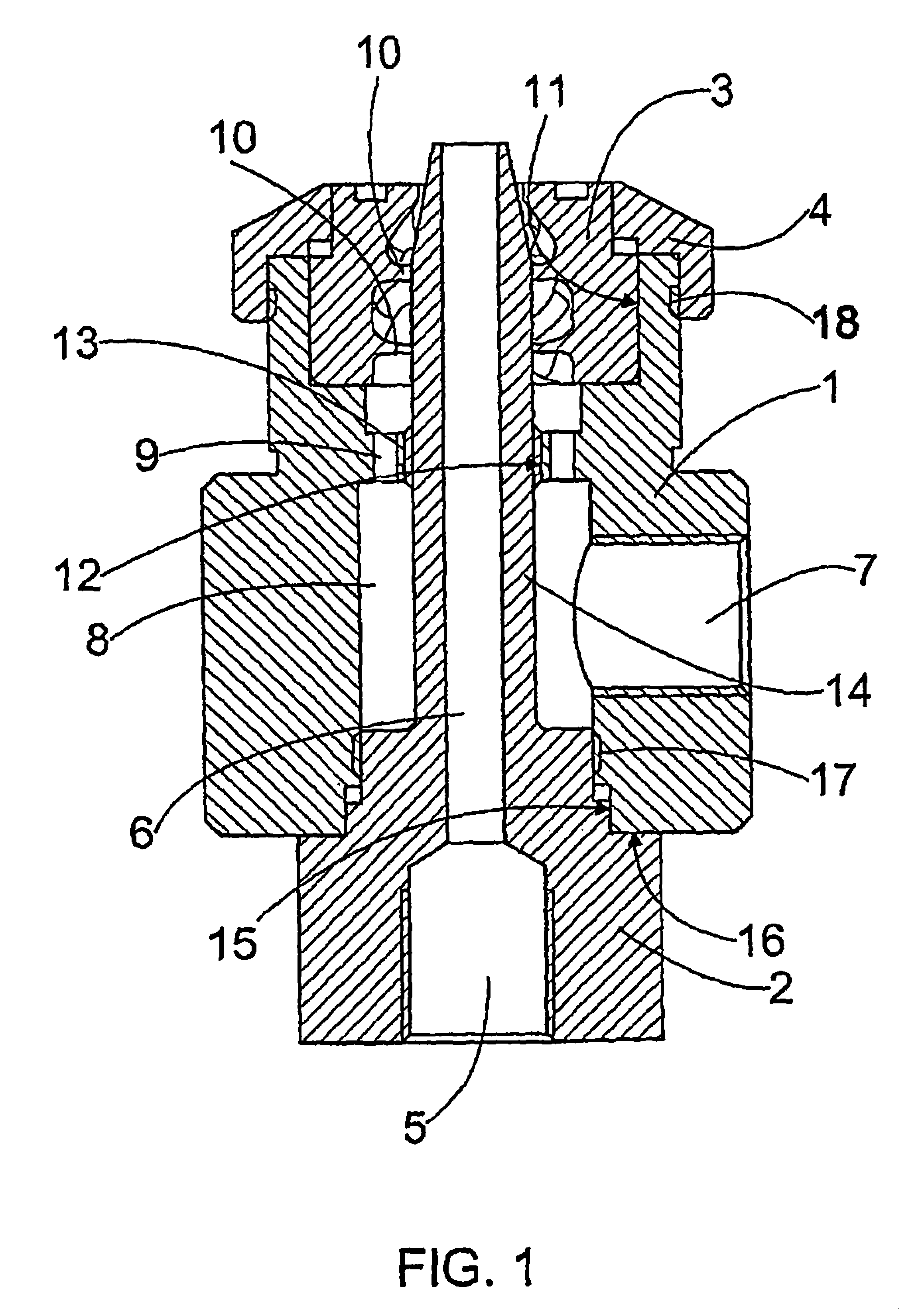

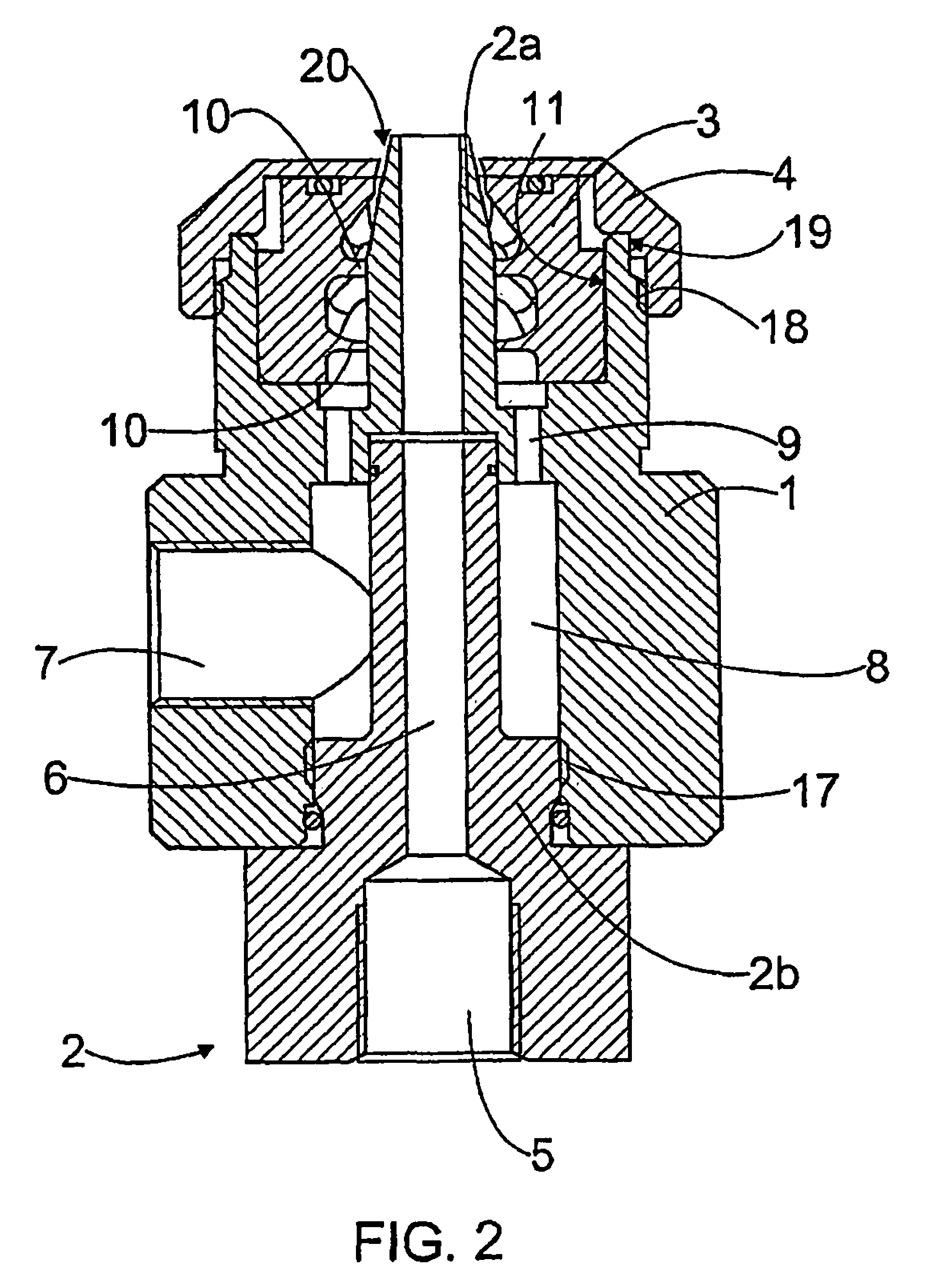

Flow monitor for rewet showers

An atomizing nozzle for use with a rewet shower or a steam box. The nozzle has first and second orifices and a pressure port which allows the pressure between the orifices to be measured. The nozzle also has a pressure port upstream of the two orifices that allows for the measuring of the regulated water pressure from an actuator attached to the atomizing unit. The measured pressures can be used to determine if either orifice is completely blocked or if one orifice is partially blocked or the other orifice is worn.

Owner:ABB LTD

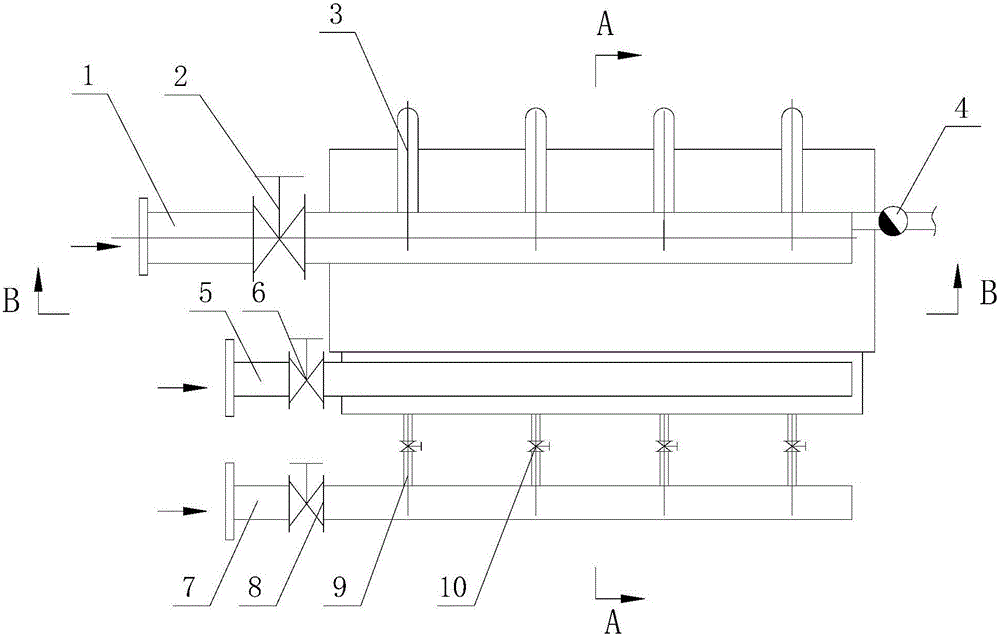

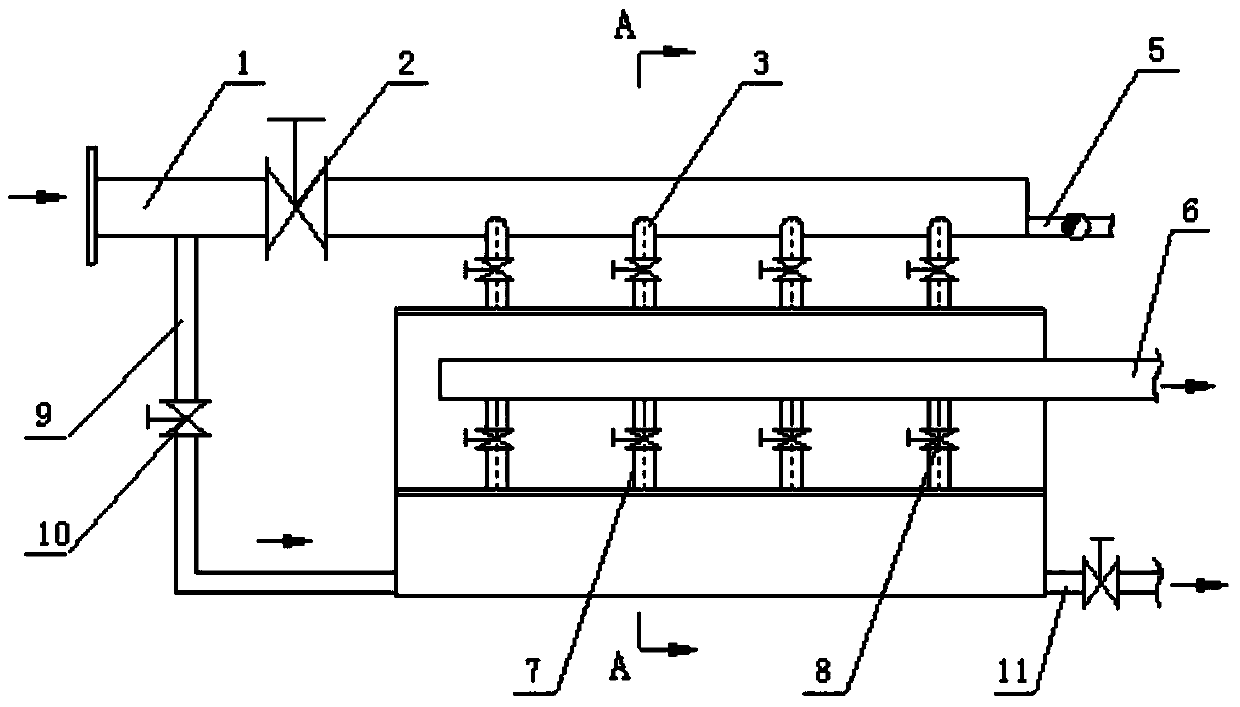

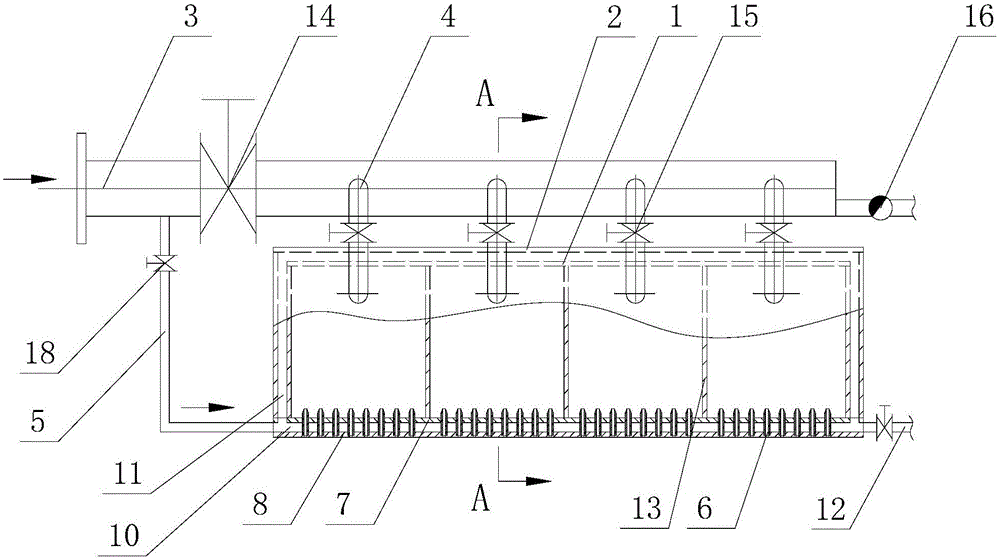

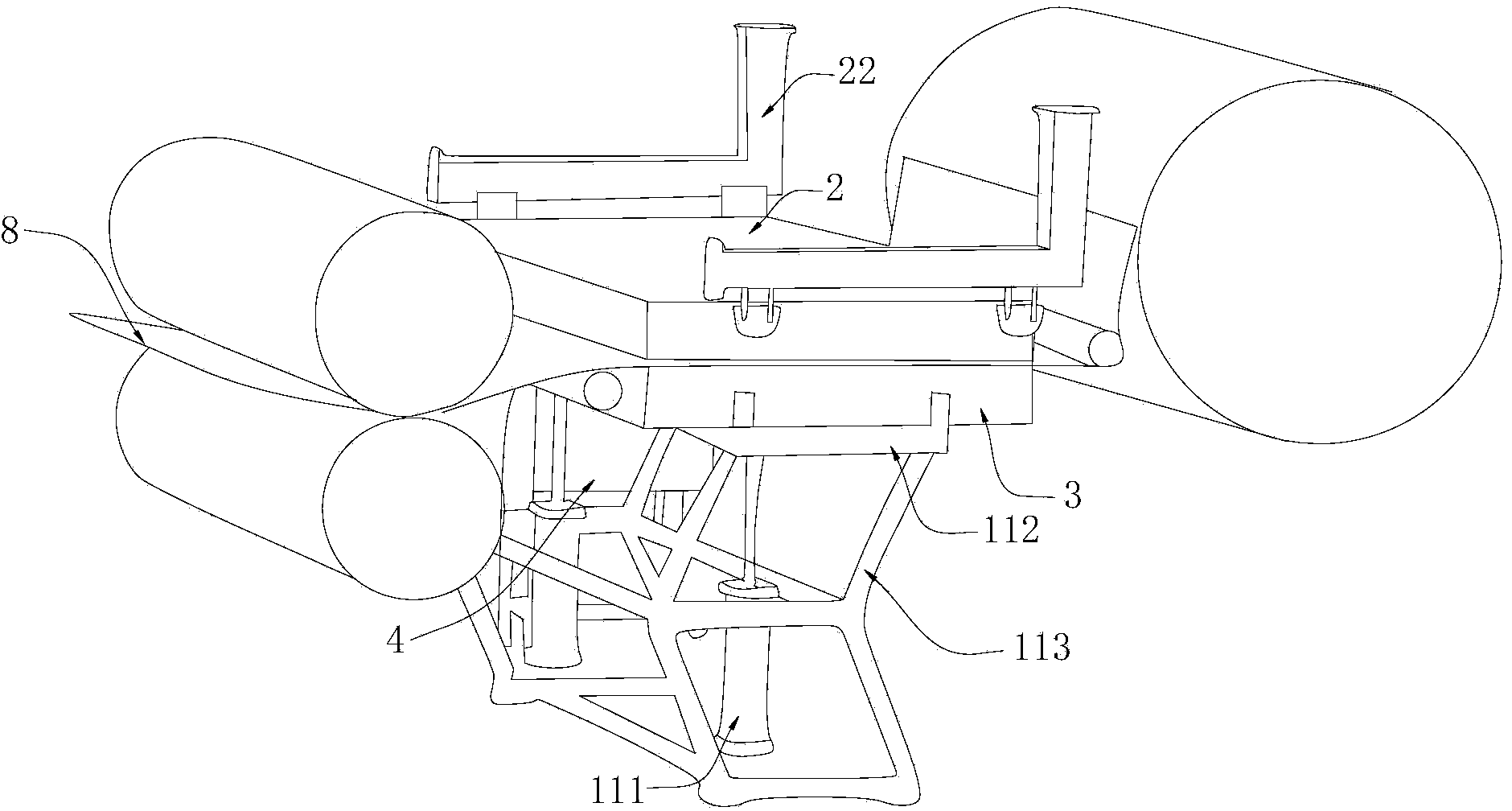

Steam device of supercalender and paper sheet moisture regulation method therefor

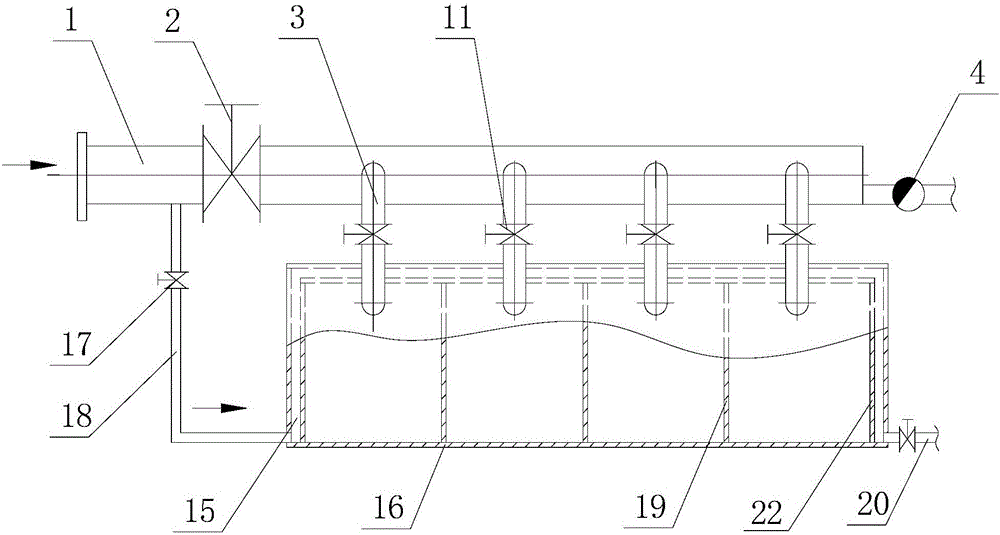

InactiveCN104988786APrevent spillageReduce dosageCalendersDamping devicesPulp and paper industryMoisture

The invention discloses a steam device of a supercalender and a paper sheet moisture regulation method therefor. In the steam device, a steam box and a spray box are arranged sequentially along paper sheet conveying direction, air atomizers are arranged in the spray box, a steam header pipe is connected with the steam box through steam branch pipes, a compressed air header pipe is connected with the air atomizers through compressed air branch pipes, and a low-pressure water header pipe is connected with the air atomizers through low-pressure water branch pipes. According to the paper sheet moisture regulation method, steam is conveyed into the steam box by the steam header pipe through the steam branch pipes and is sprayed to the surface of a paper sheet through through holes in a bottom plate; and meanwhile, compressed air is conveyed into the air atomizers by the compressed air header pipe through the compressed air branch pipes, low-pressure water is conveyed into the air atomizers by the low-pressure water header pipe through the low-pressure water branch pipes, and water mist is formed by the compressed air and the low-pressure water in the air atomizers and is sprayed to the surface of the paper sheet so as to further regulate the temperature and humidity of the paper sheet. According to the steam device of the supercalender and the paper sheet moisture regulation method therefor, the temperature and humidity of the paper sheet can be effectively regulated so as to improve the calendering effect.

Owner:SOUTH CHINA UNIV OF TECH

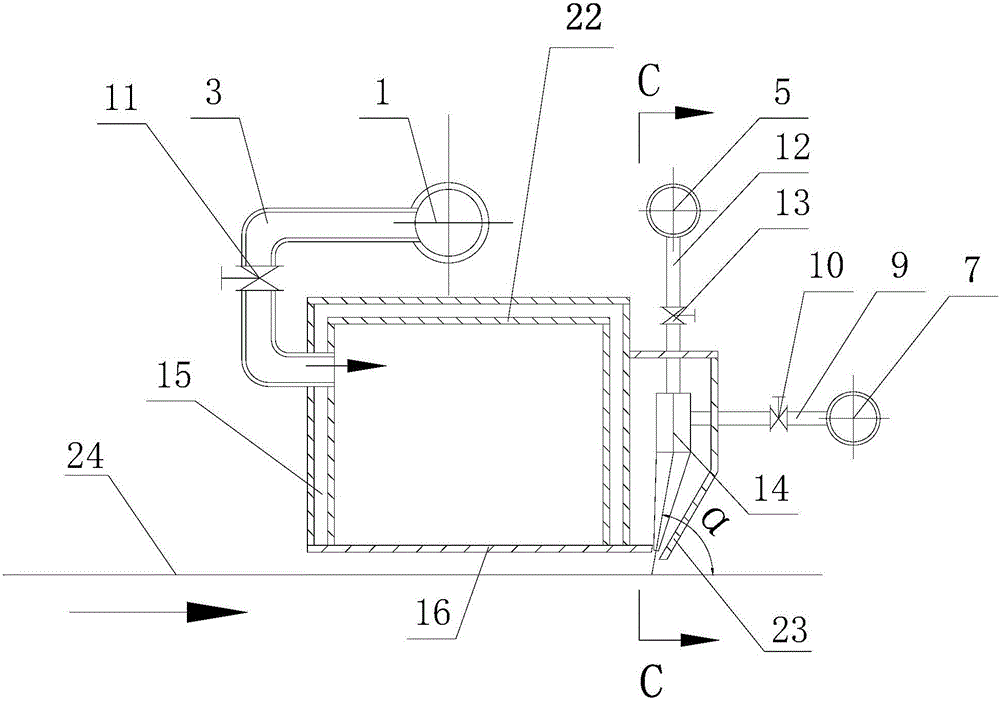

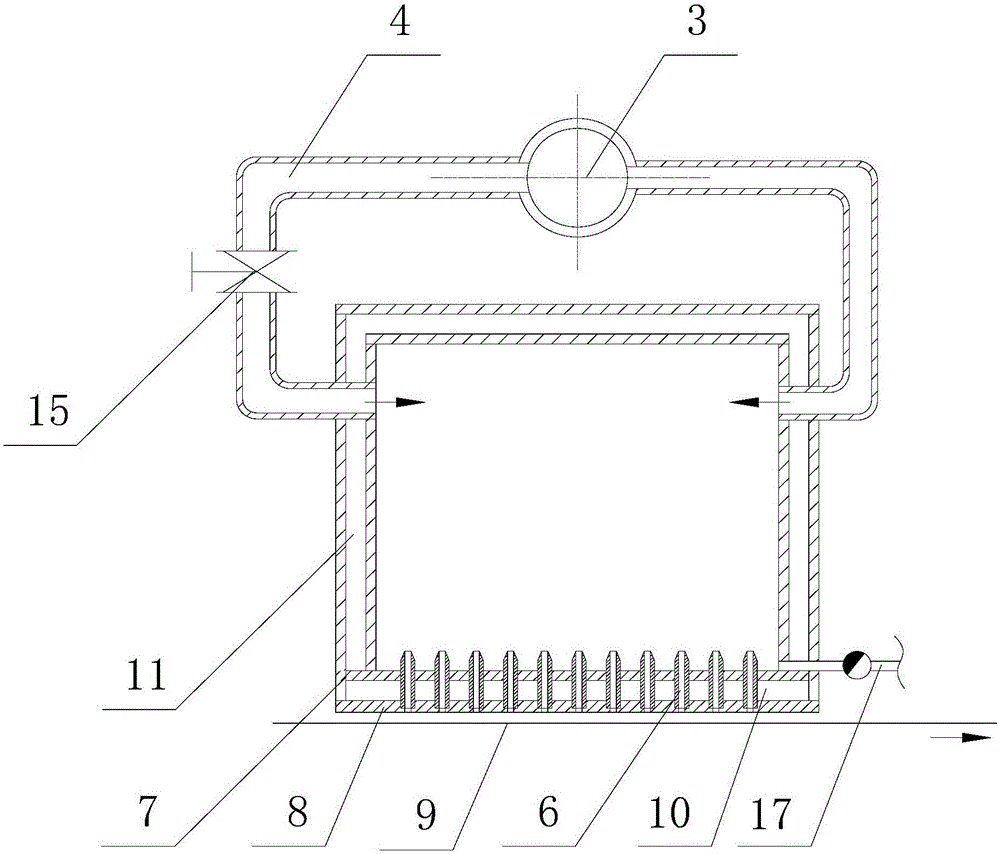

Steam device and method for adjusting moisture of paper sheet by using vacuum degree

InactiveCN104988787AIncrease profitQuality improvementDamping devicesPulp and paper industryMoisture

The present invention discloses a steam device and a method for adjusting moisture of a paper sheet by using a vacuum degree. The steam device comprises a steam box and a vacuum box which are matched for use; the steam box is arranged above a wet paper sheet and the vacuum box is arranged below the wet paper sheet; the bottom surface of the steam box is a steam spraying region; the top surface of the vacuum box is a pumping region; and the area of the pumping region is larger than that of the steam spraying region. The method comprises: continuously conveying the wet paper sheet between the steam box and the vacuum box; providing steam to the surface of the wet paper sheet in the direction from the upper side of the wet paper sheet by the steam box so as to improve the temperature and humidity of the wet paper sheet; pumping the wet paper sheet from the lower side of the wet paper sheet by the vacuum box; and controlling the temperature and humidity of the wet paper sheet by controlling pumping amount. According to the steam device and the method, disclosed by the present invention, the temperature and humidity of the wet paper sheet are adjusted by using a vacuum degree adjusting manner; the device has a simple structure and the utilization rate of the steam is high; and the better moisture adjusting effect can be realized and the quality of the paper sheet is effectively improved.

Owner:SOUTH CHINA UNIV OF TECH

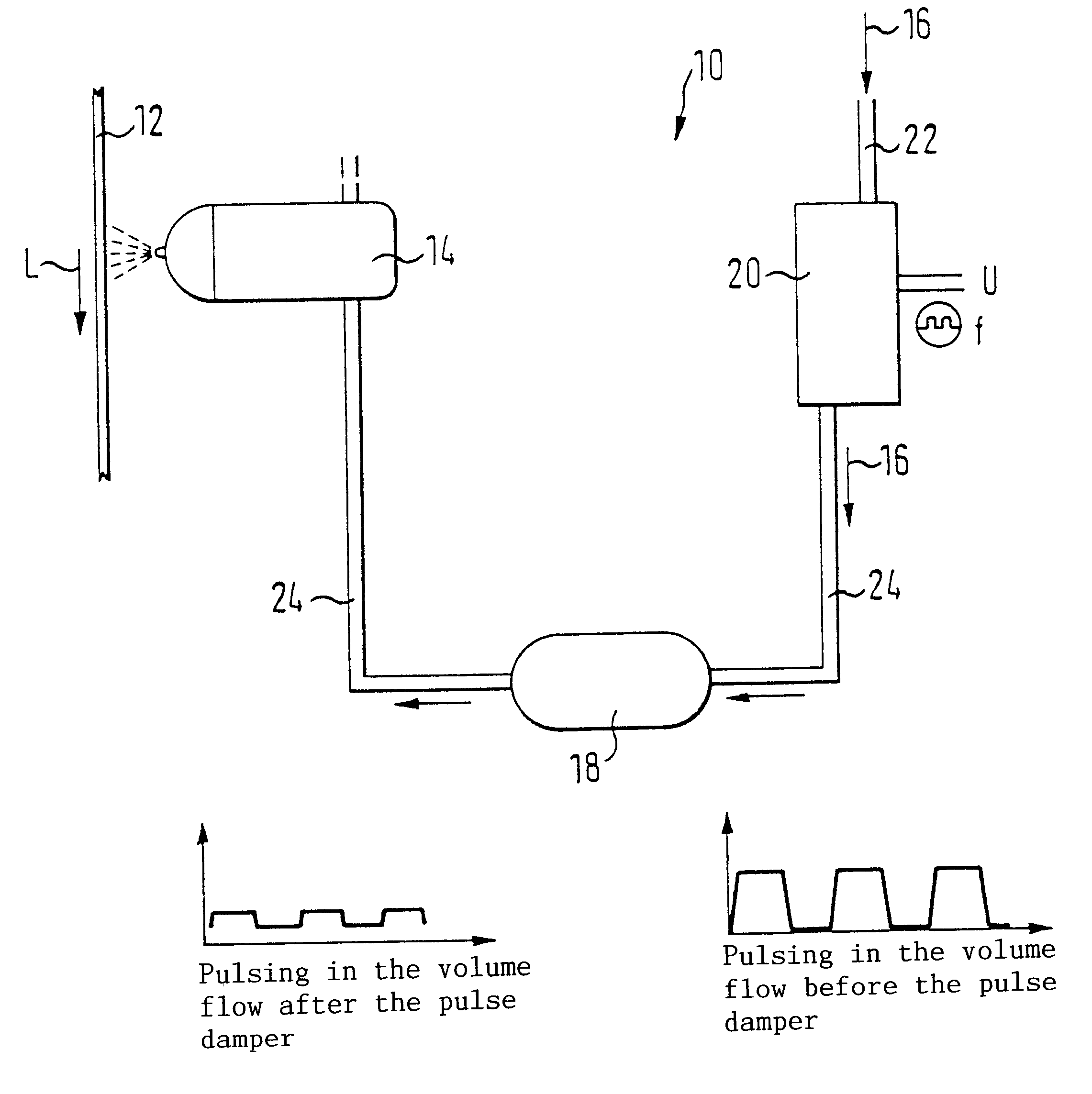

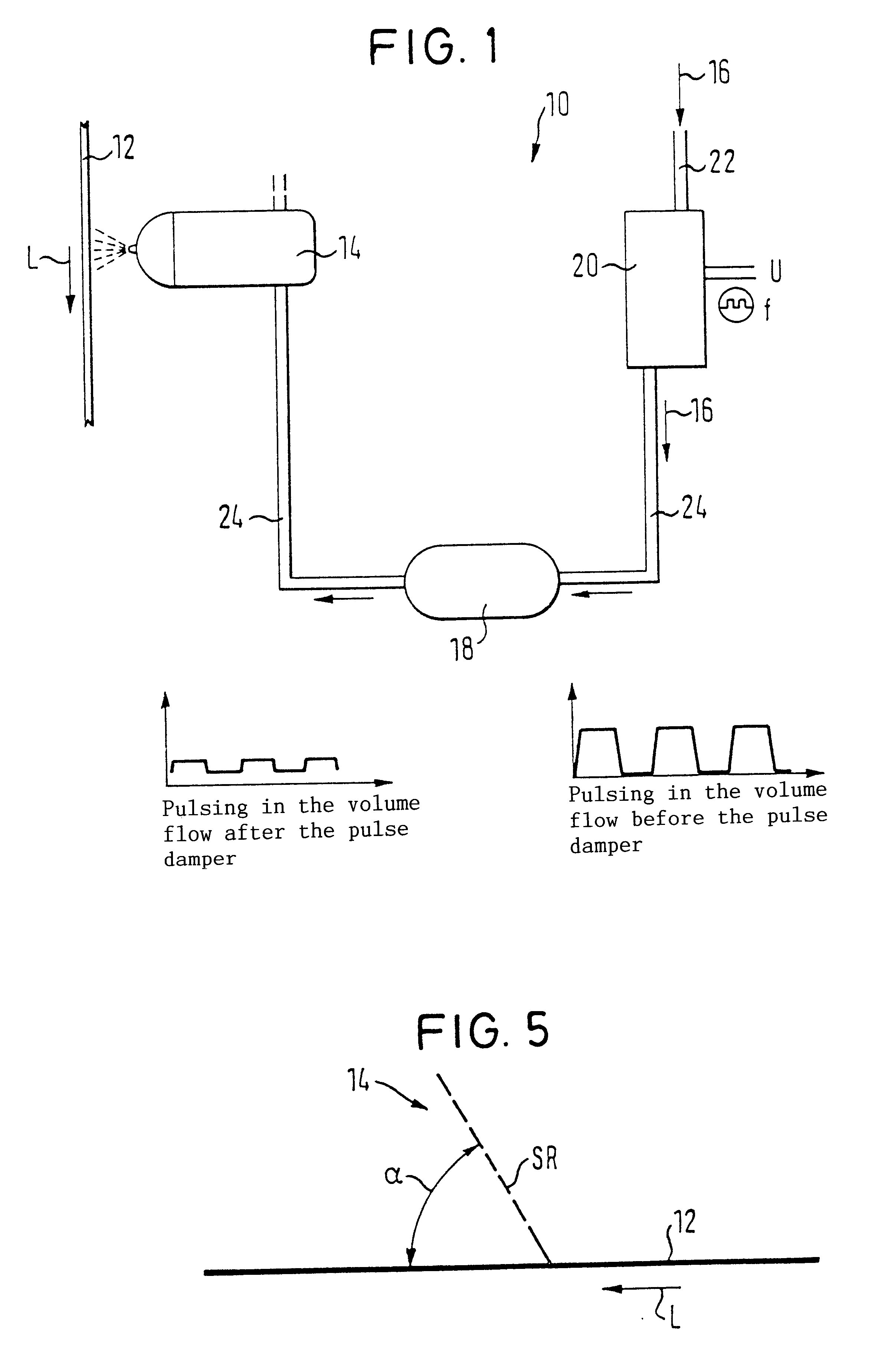

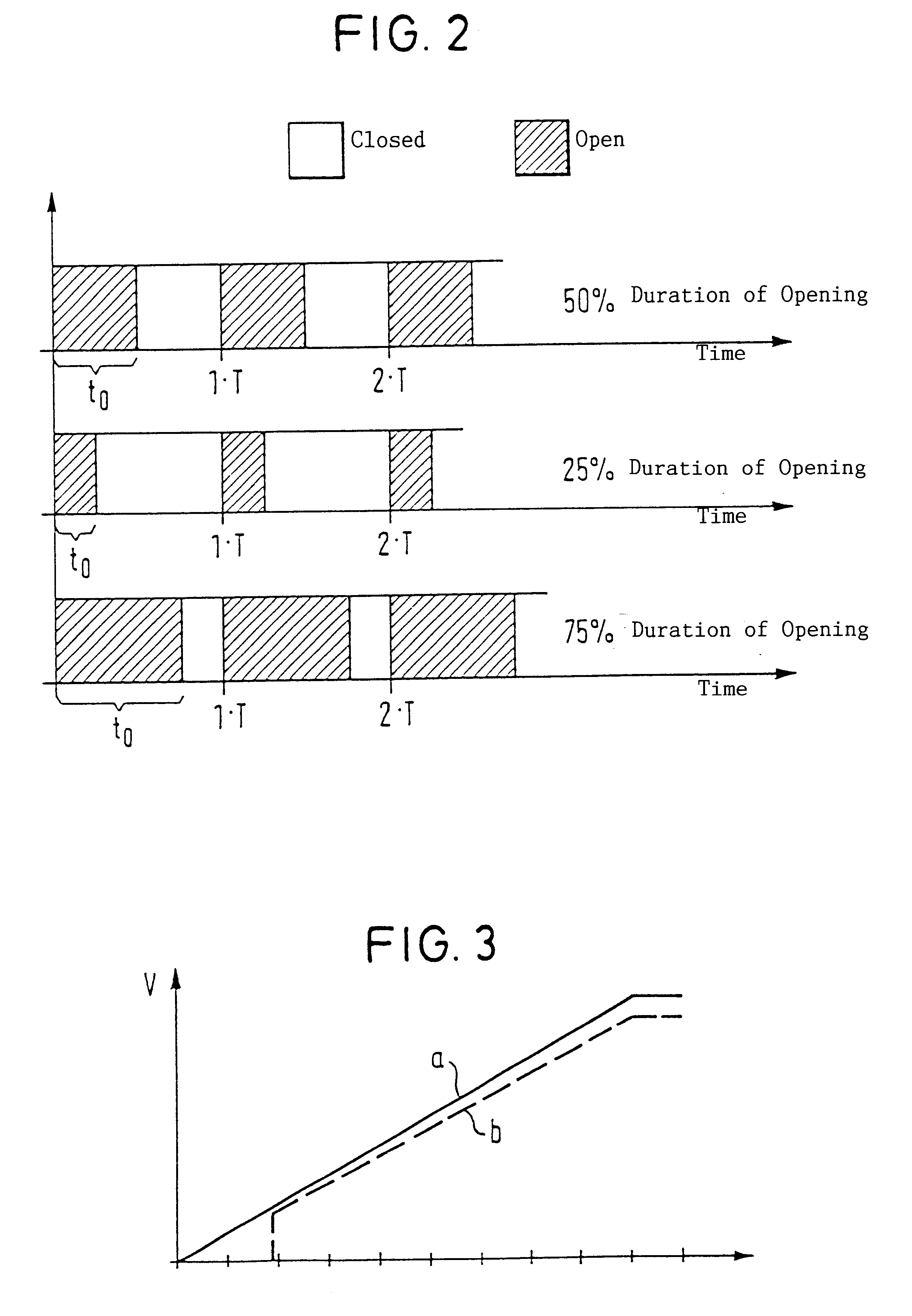

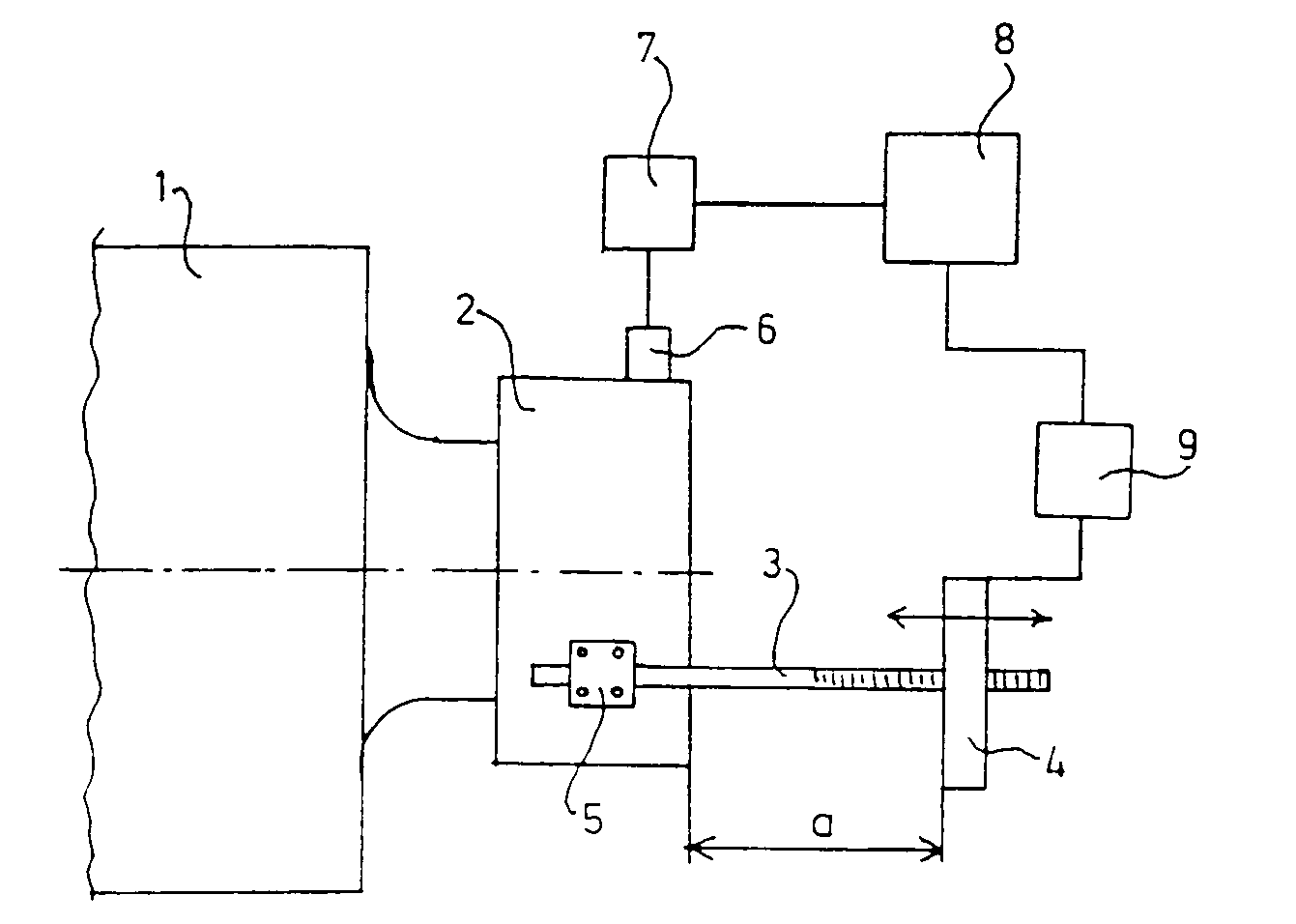

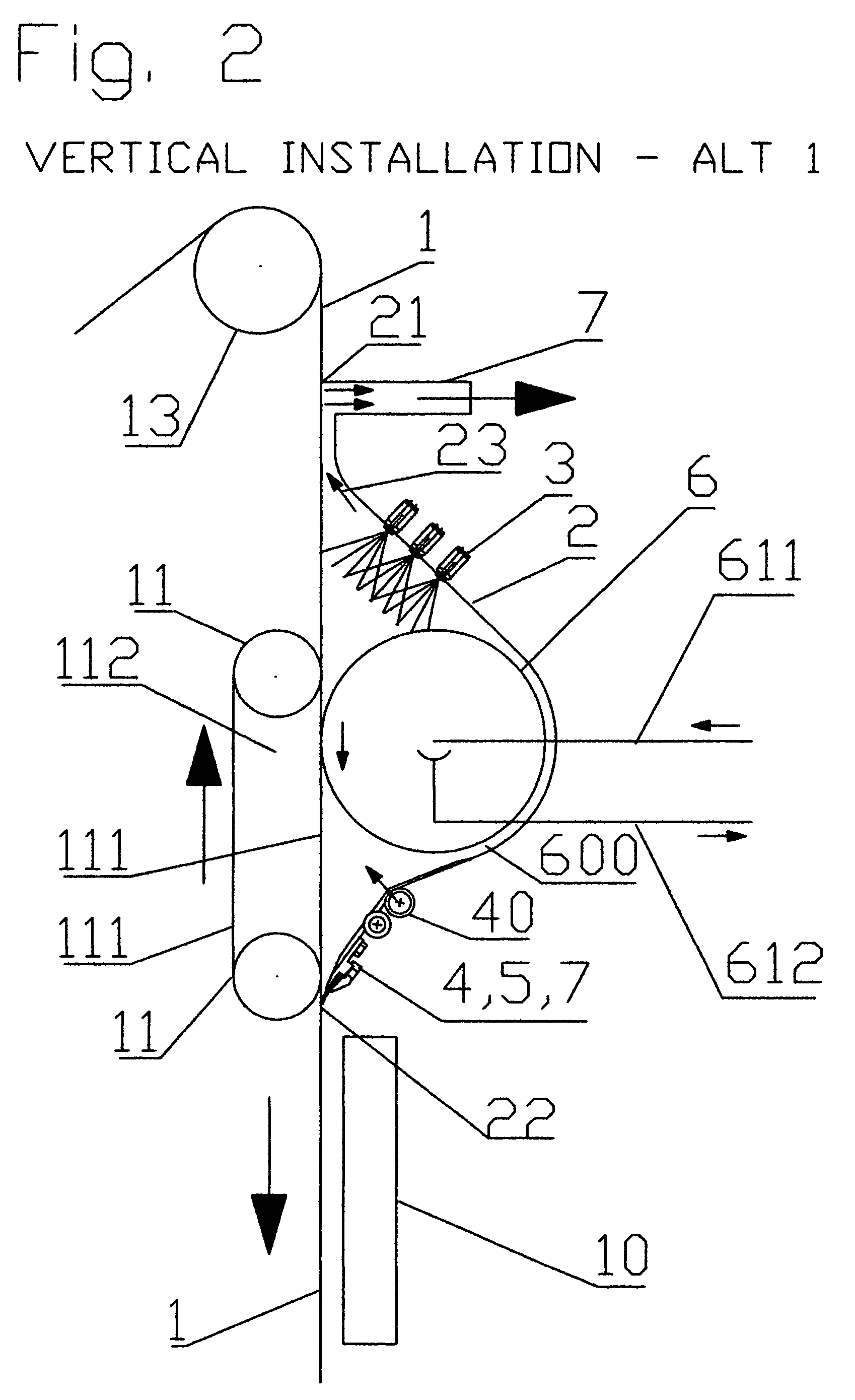

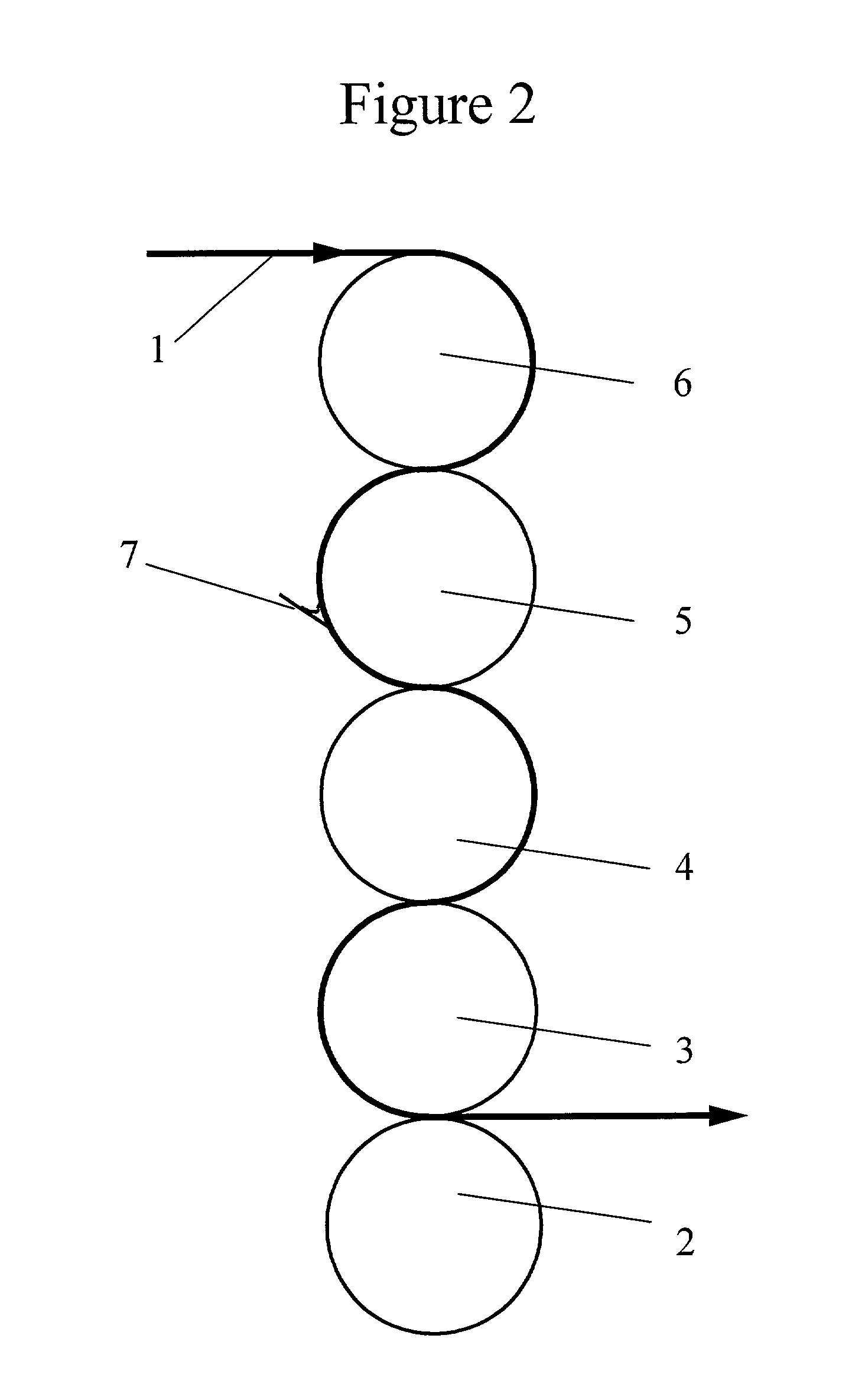

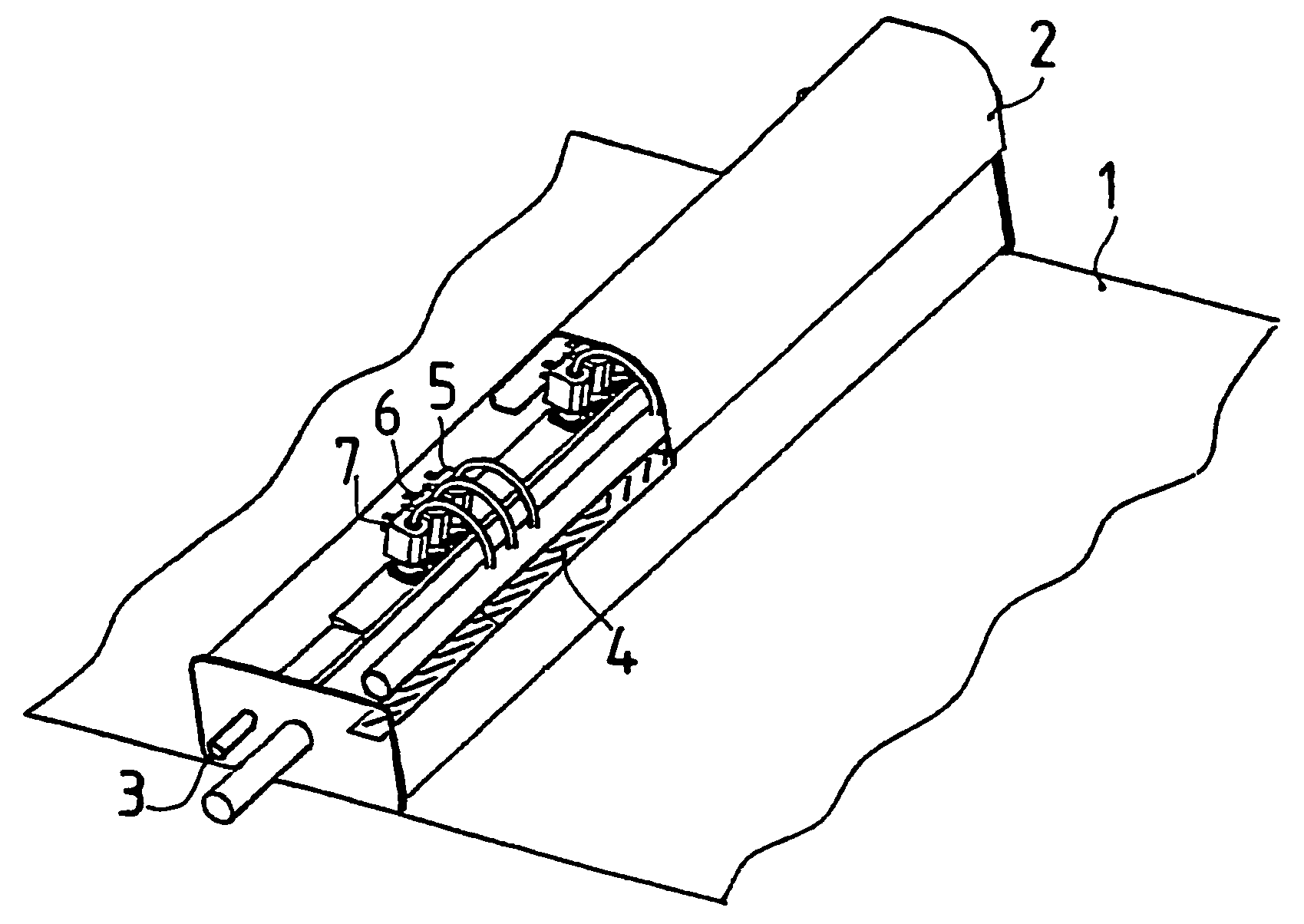

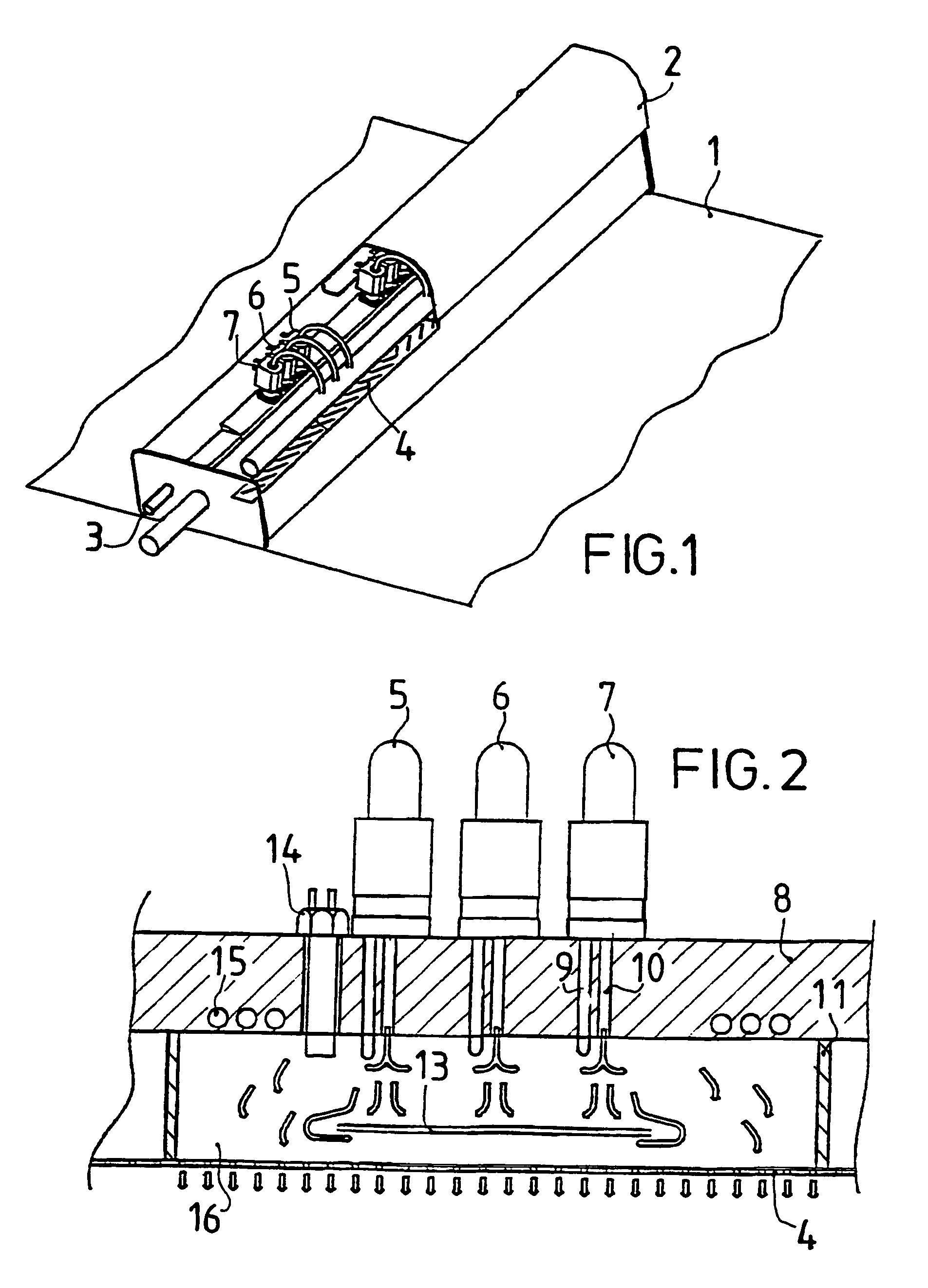

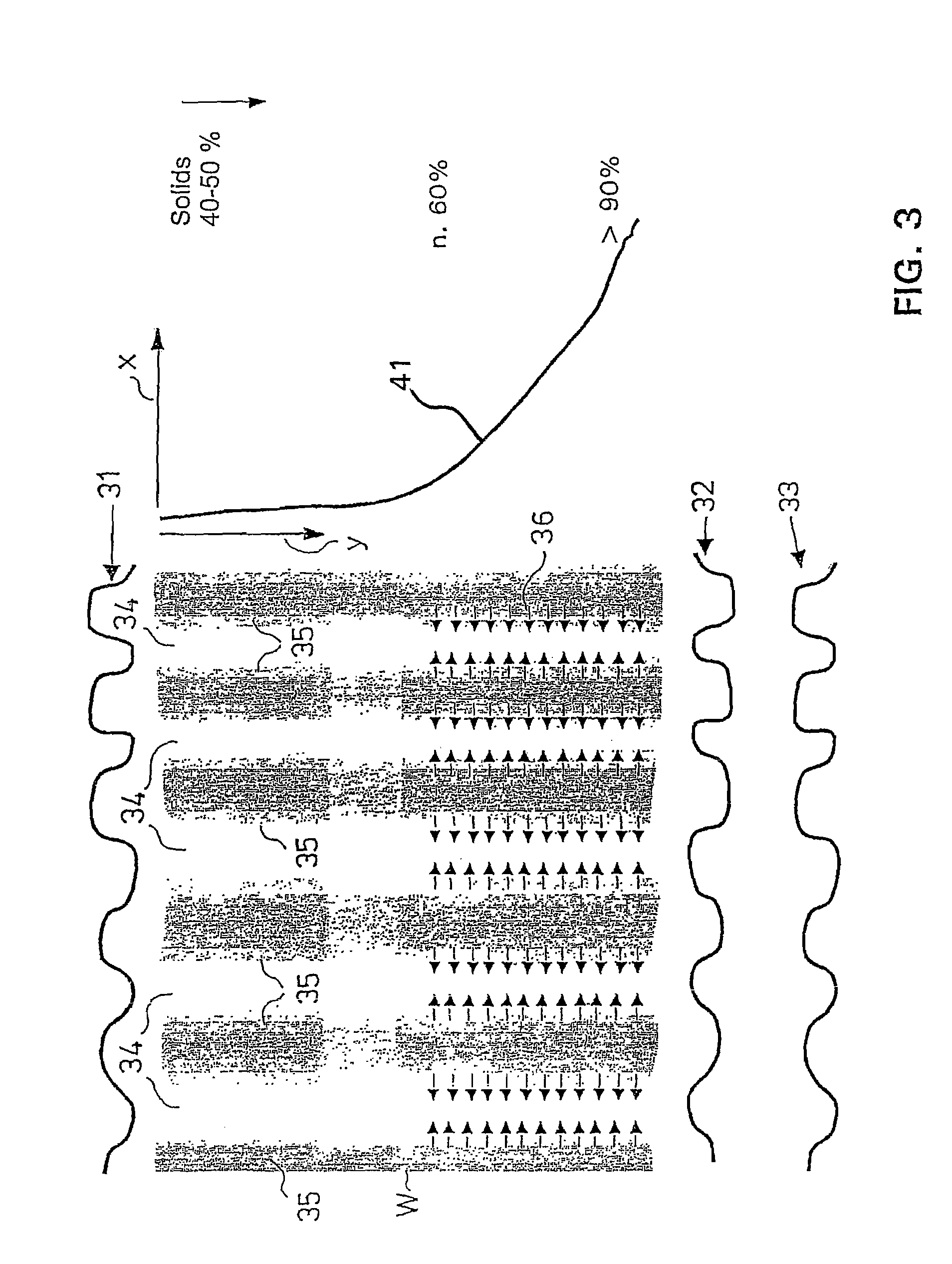

Process and device for spraying a moving fibrous web

InactiveUS6444090B1Reducing pulses occurringNon-fibrous pulp additionNatural cellulose pulp/paperInjectorEngineering

Process and apparatus for spraying a moving fibrous web with at least one jet. The process includes feeding a controlled volume flow of a spray agent to the at least one jet through at least one pulsing valve, and damping and reducing pulses occurring in the controlled volume flow of the spray agent. The apparatus includes at least one jet arranged to be fed with a controlled volume flow of a spray agent, at least one pulsing valve which feeds the controlled volume flow of the spray agent to said at least one jet, and at least one pulse damper arranged to damp or reduce pulses occurring in the controlled volume flow of the spray agent.

Owner:VOITH PATENT GMBH

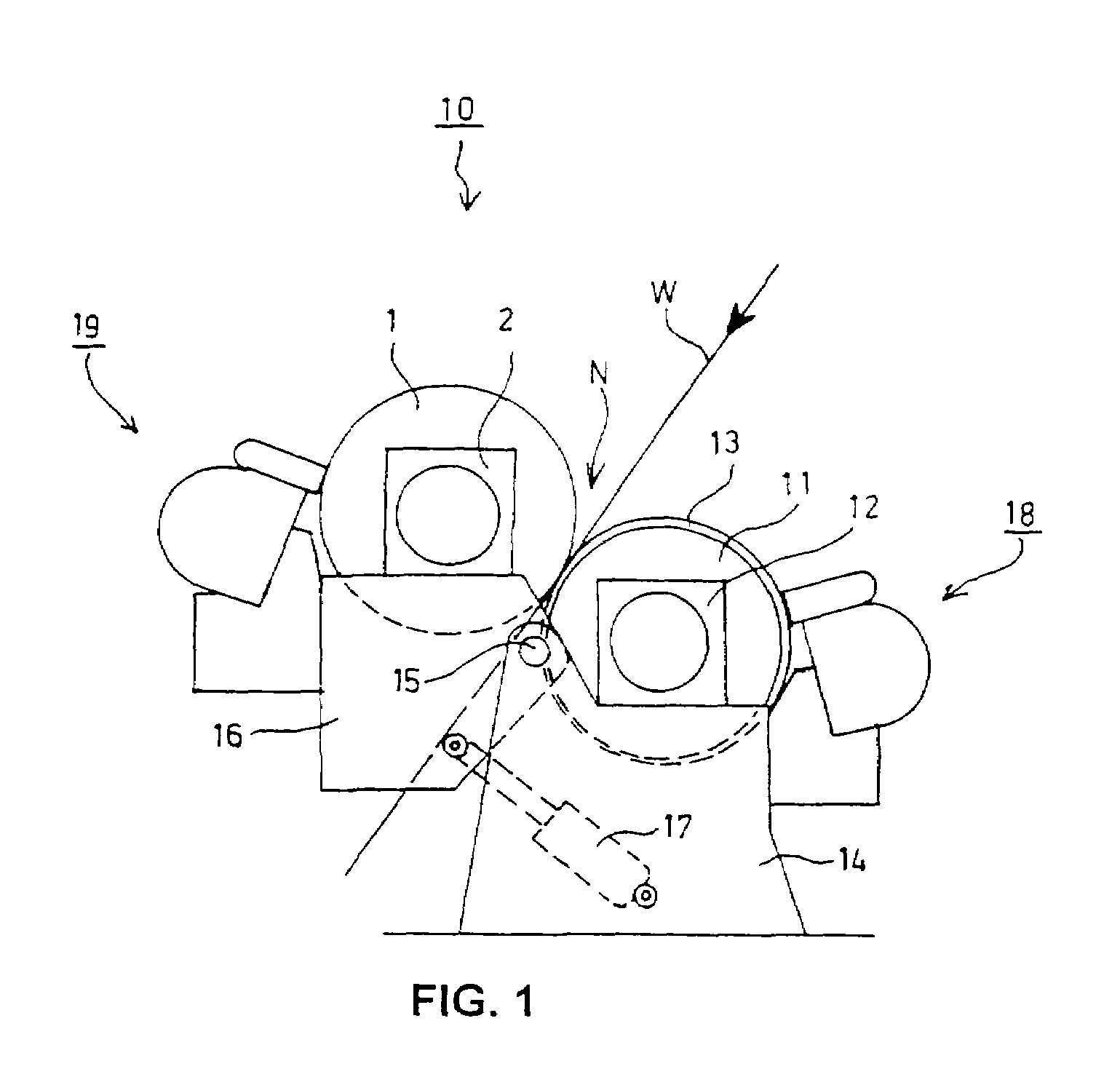

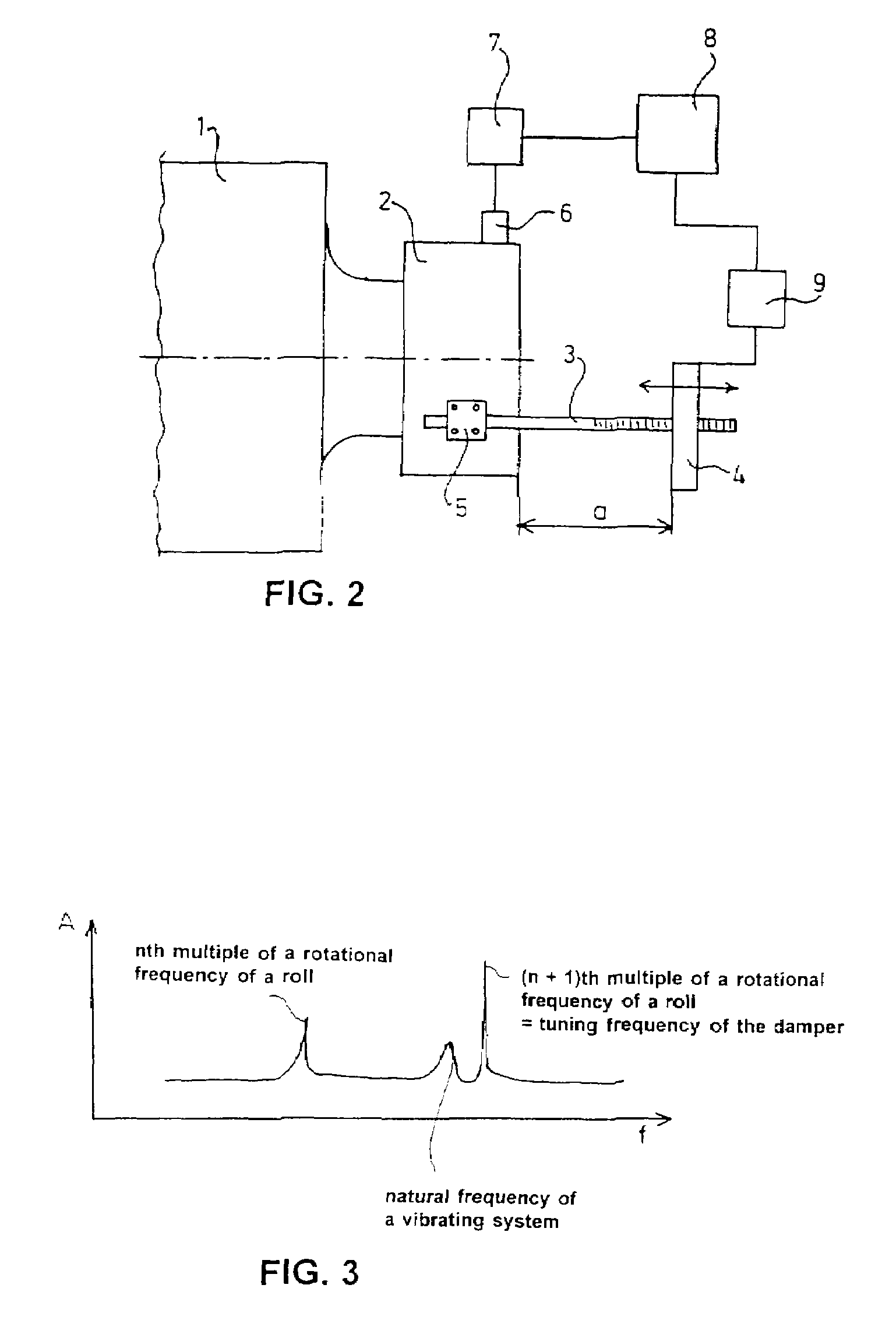

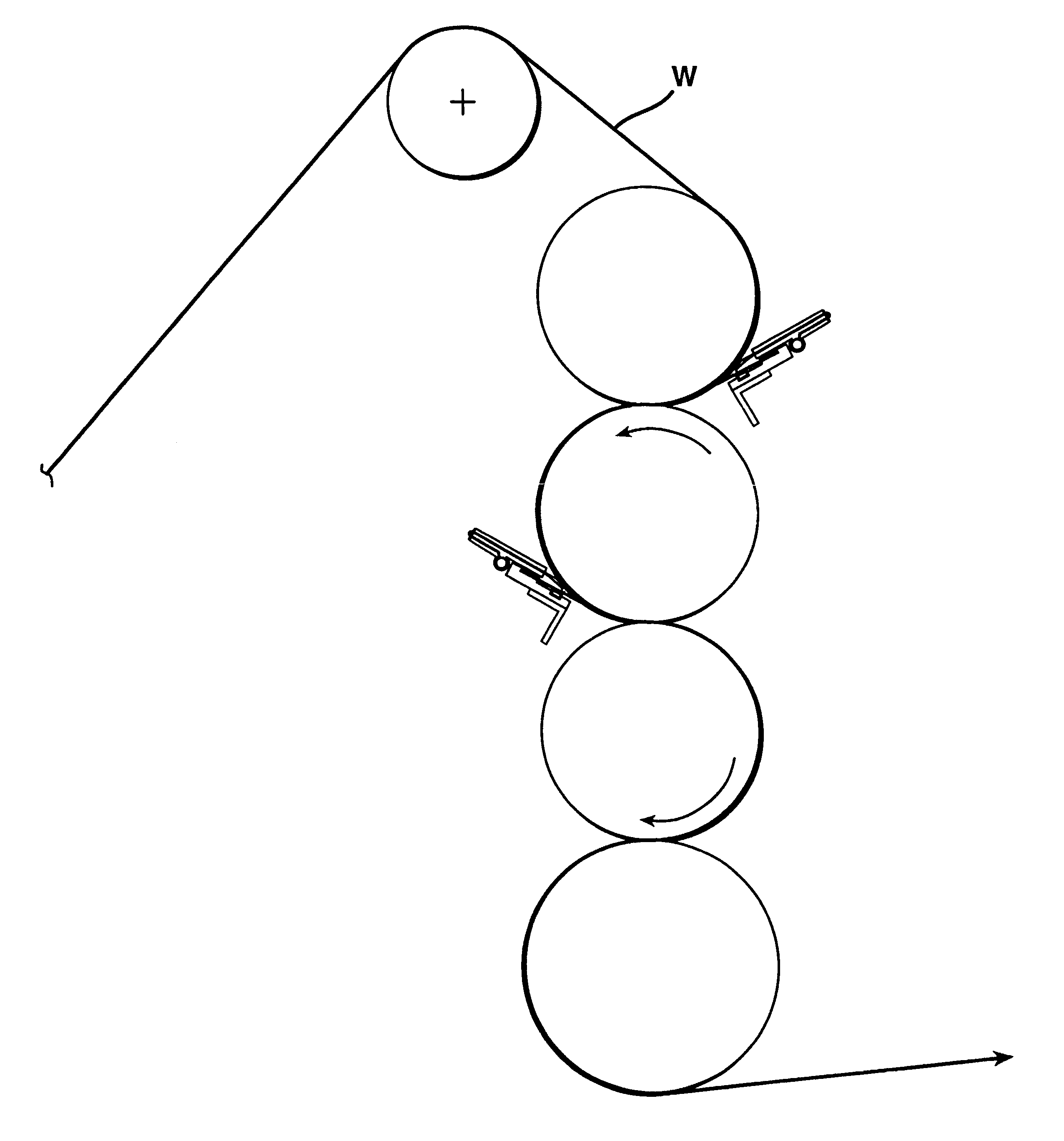

Method and equipment for attenuation of oscillation in a paper machine or in a paper finishing device

InactiveUS6911117B1Easy constructionSimple in its construction and in its mode of implementationPortable framesStands/trestlesUltrasound attenuationEngineering

A method and apparatus for damping vibration in a paper machine. The apparatus having a dynamic damper which includes a weight suspended by a spring. The spring constant of the spring is changed by means of a control device in order to tune the natural frequency of the dynamic damper. The dynamic damper is tuned to a frequency that is substantially equal to a multiple of the rotational frequency of the roll in the paper machine that is being damped.

Owner:VALMET TECH INC

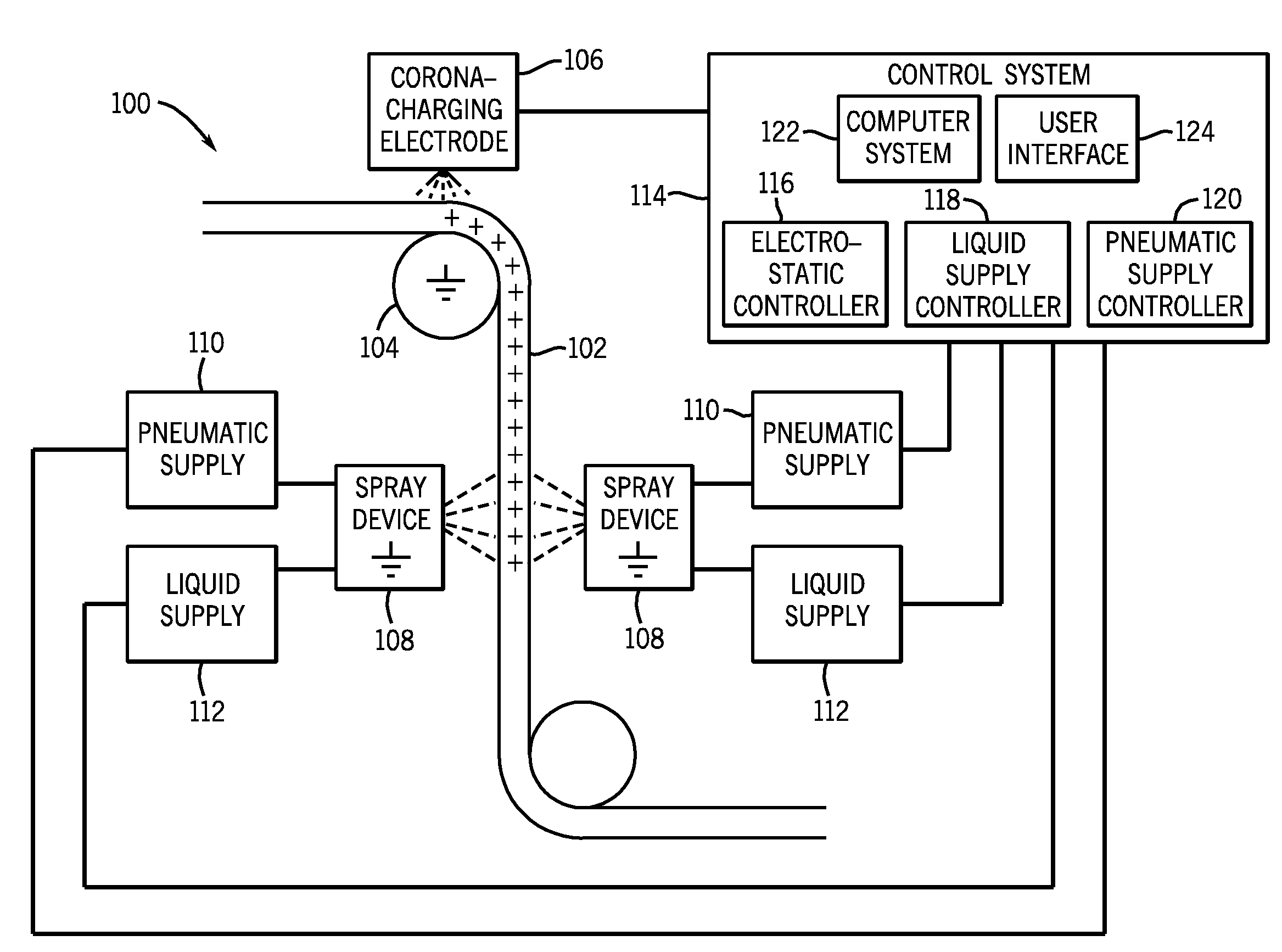

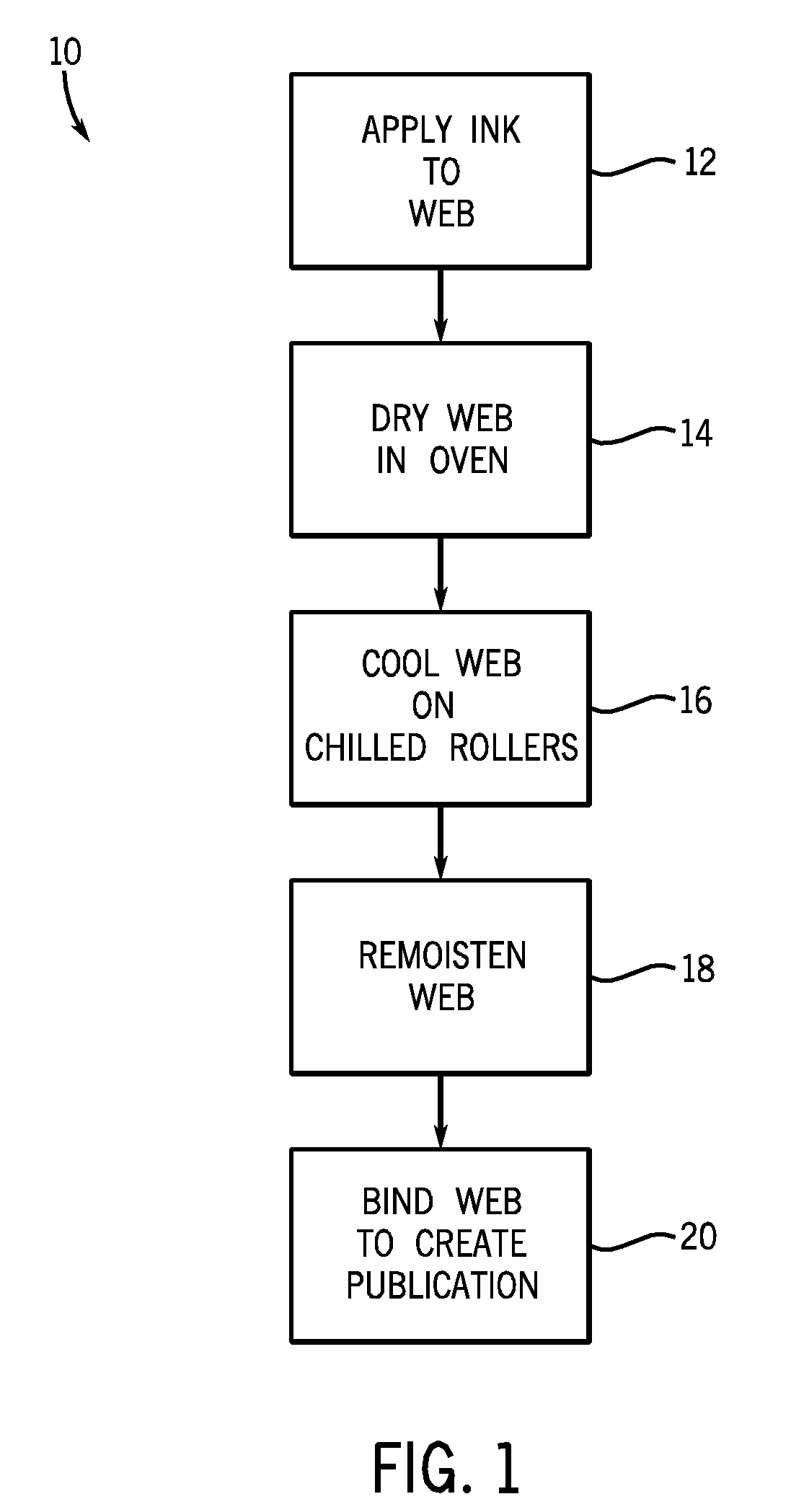

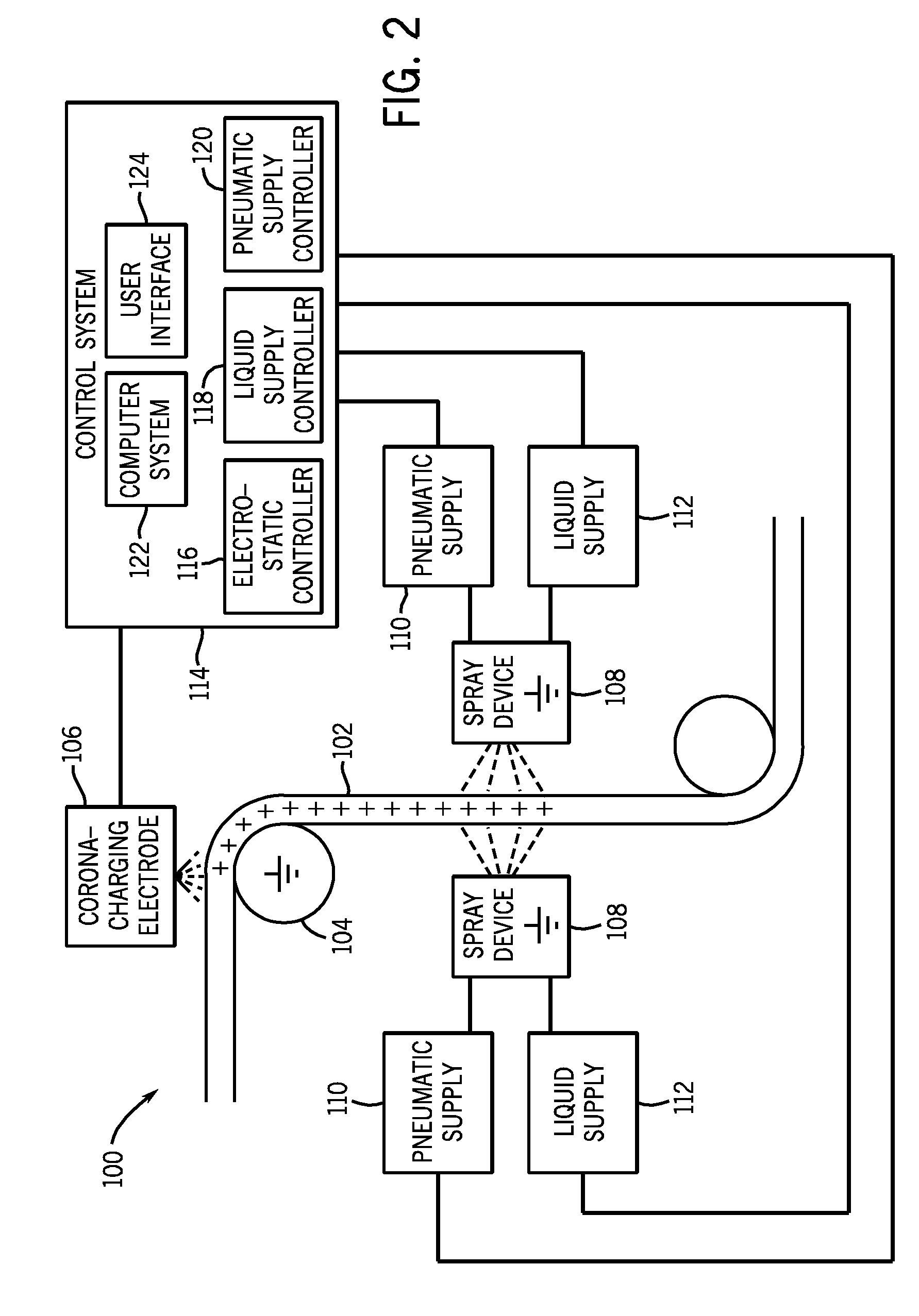

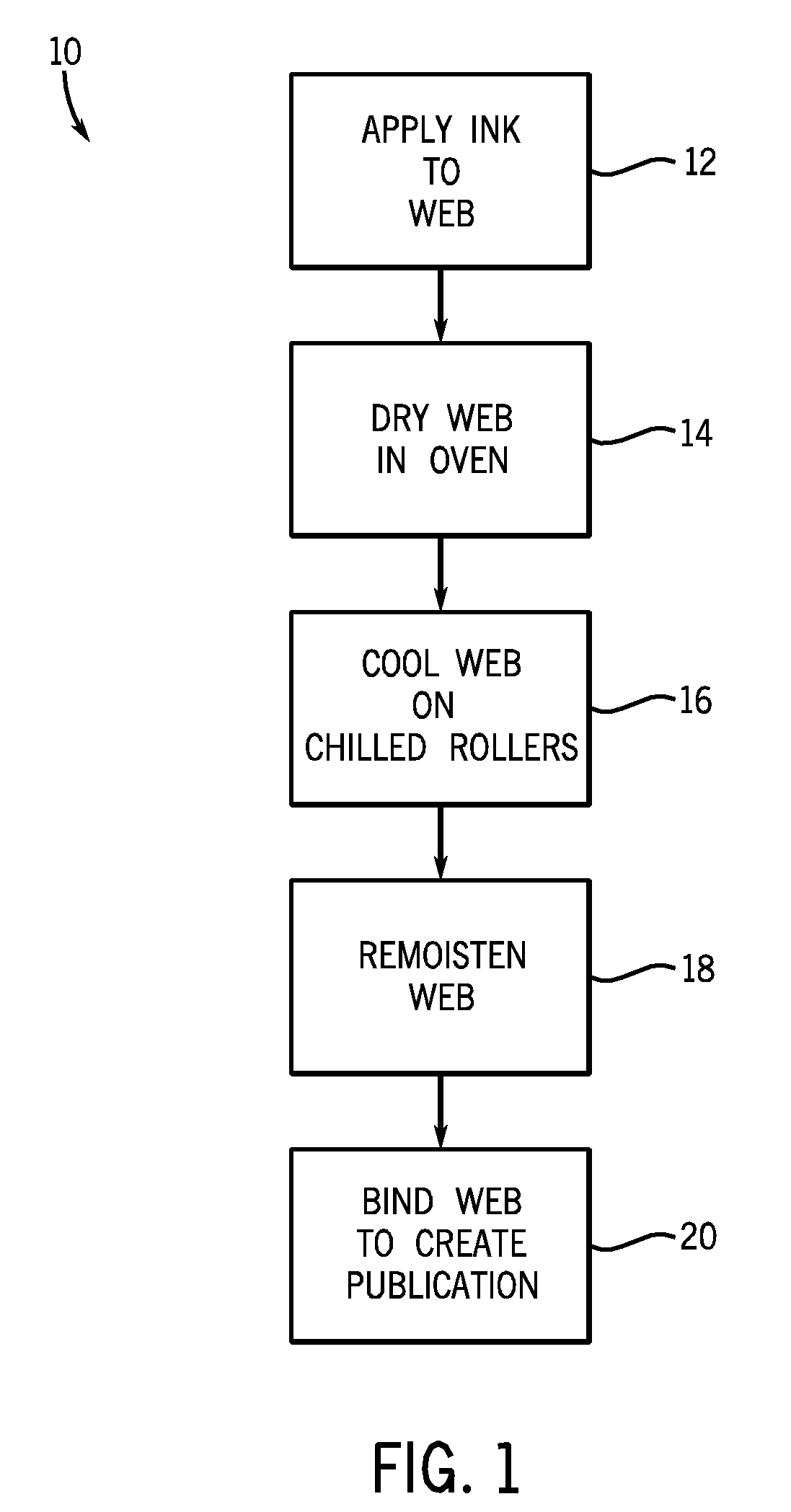

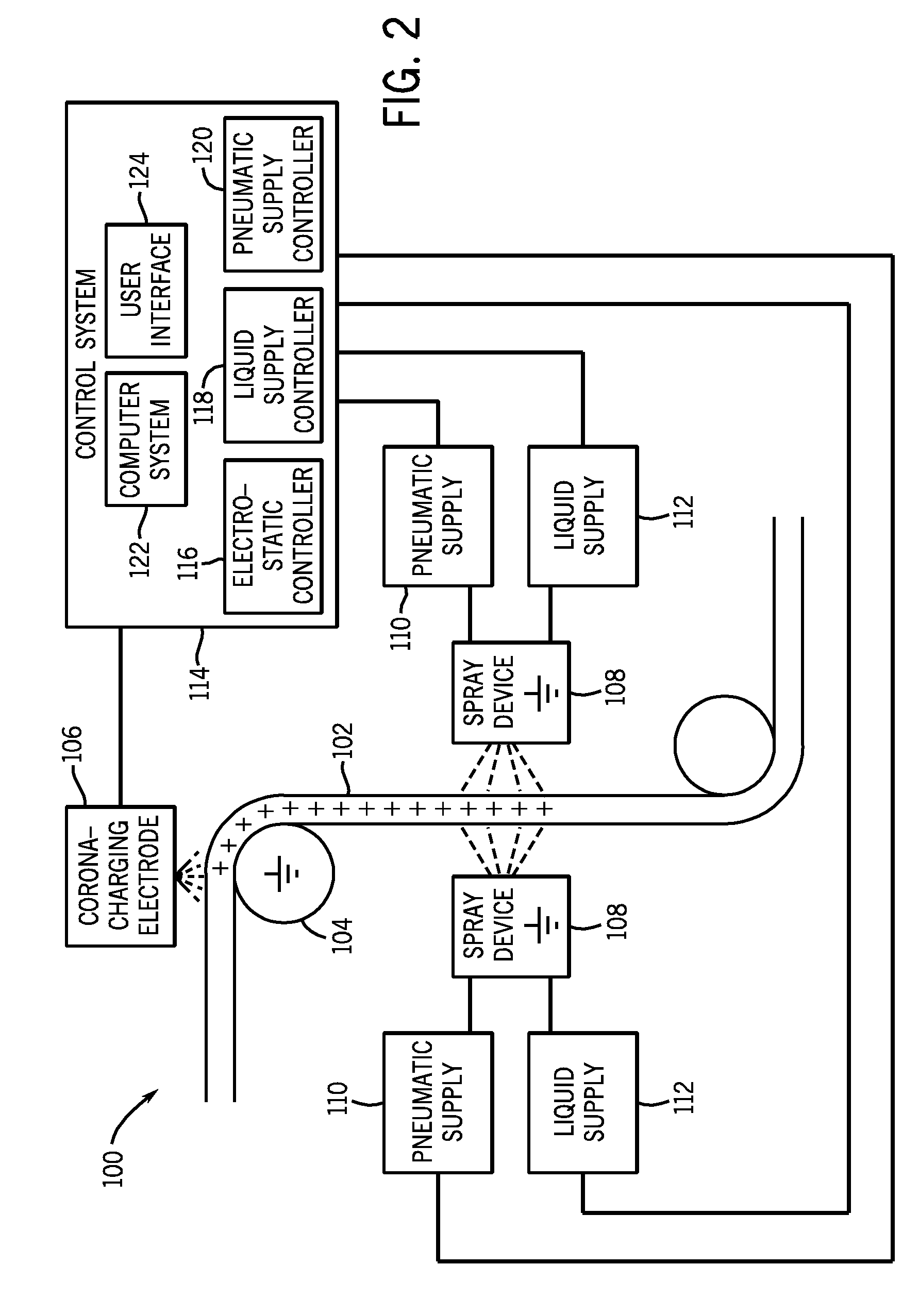

Moisture application system for a paper web

InactiveUS6280574B1Improve performanceReduce thickness lossNon-fibrous pulp additionNatural cellulose pulp/paperPulp and paper industryMoisture

The moisture application system of the present invention comprises in combination a first means for applying liquid to a paper web and a second means in contact with the web for scraping off excess liquid and spreading the liquid uniformly across the paper web. The moisture application system of the present invention is particularly useful when combined with a machine calender for finishing a paper web.

Owner:MEADWESTVACO CORP

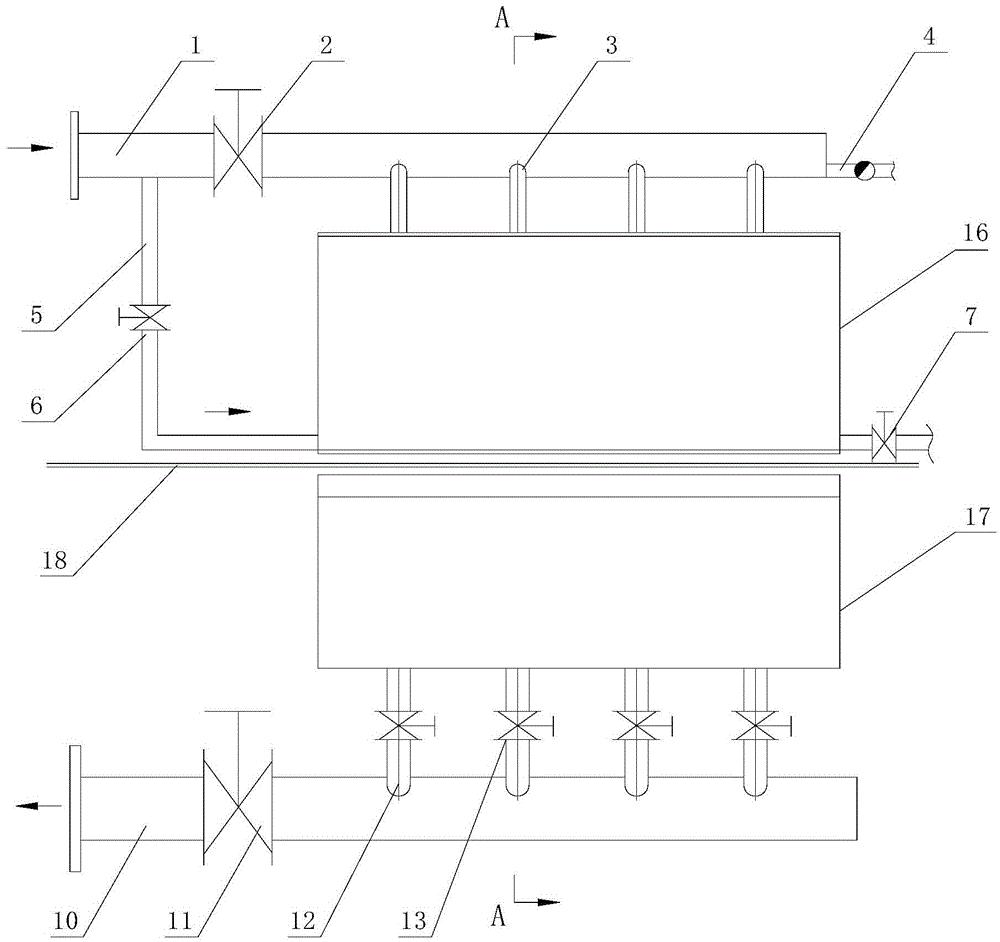

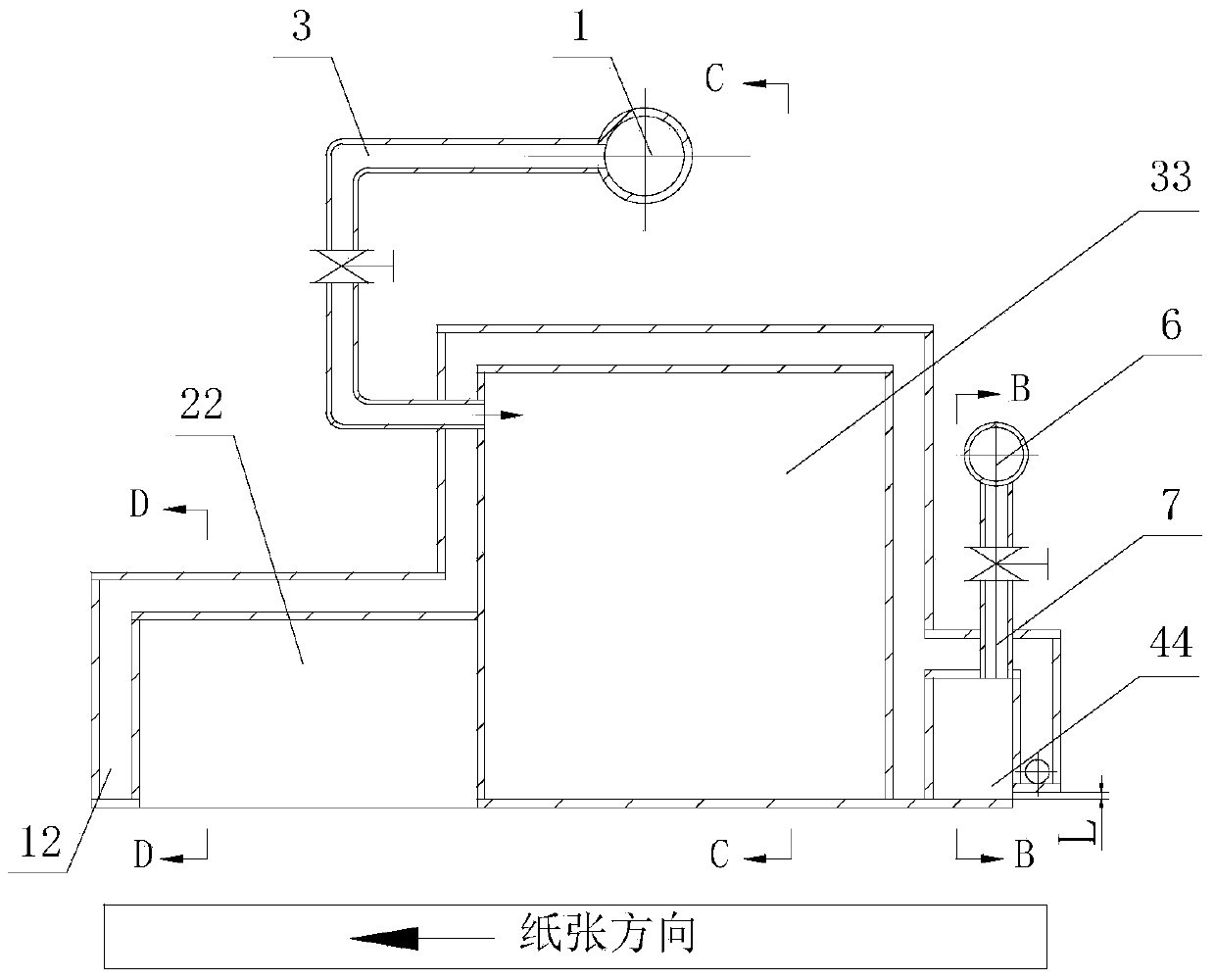

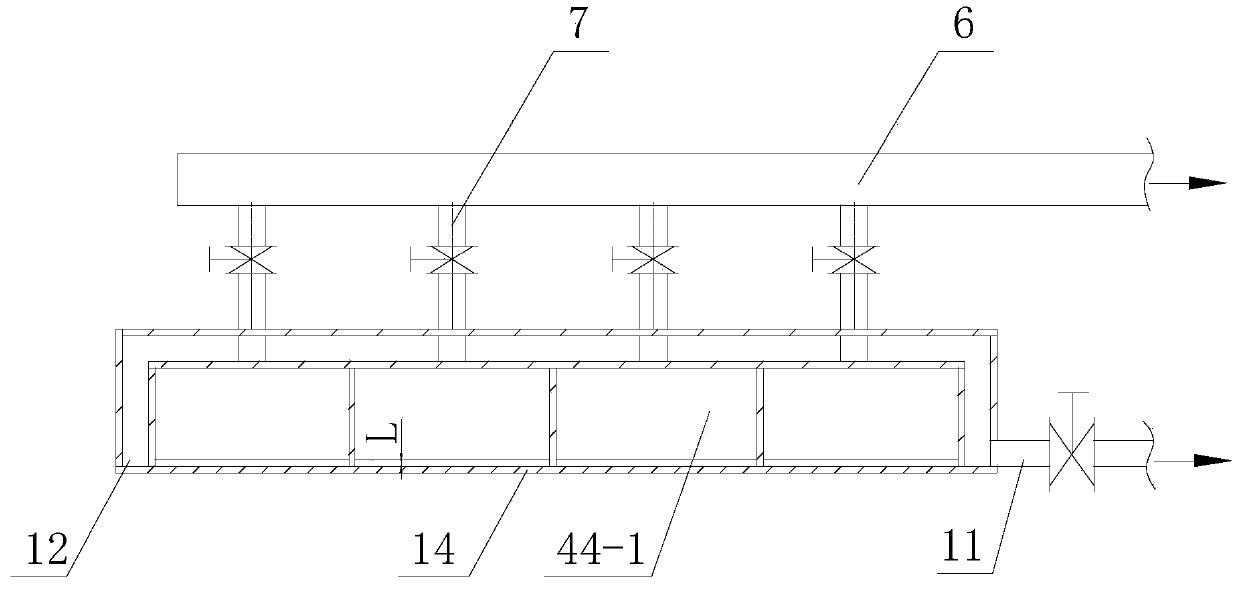

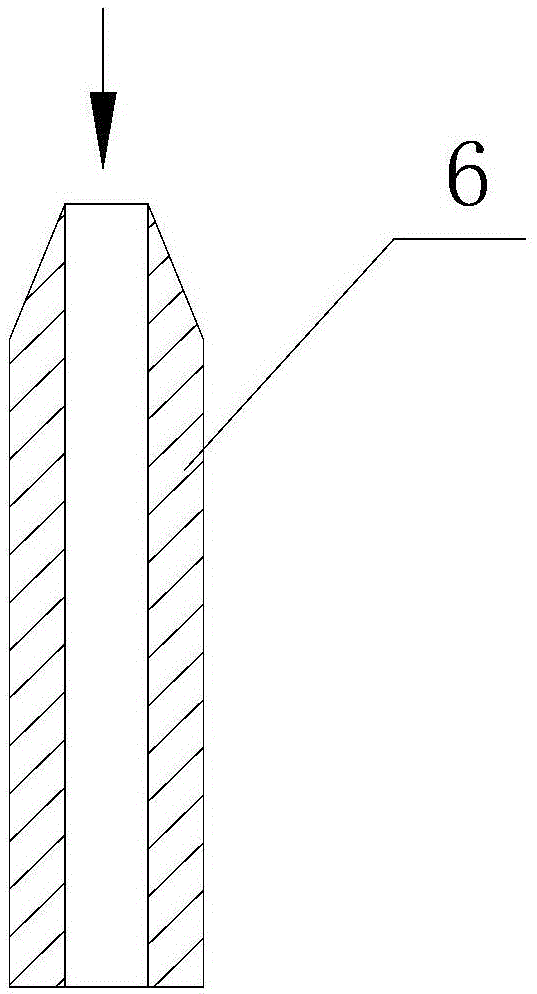

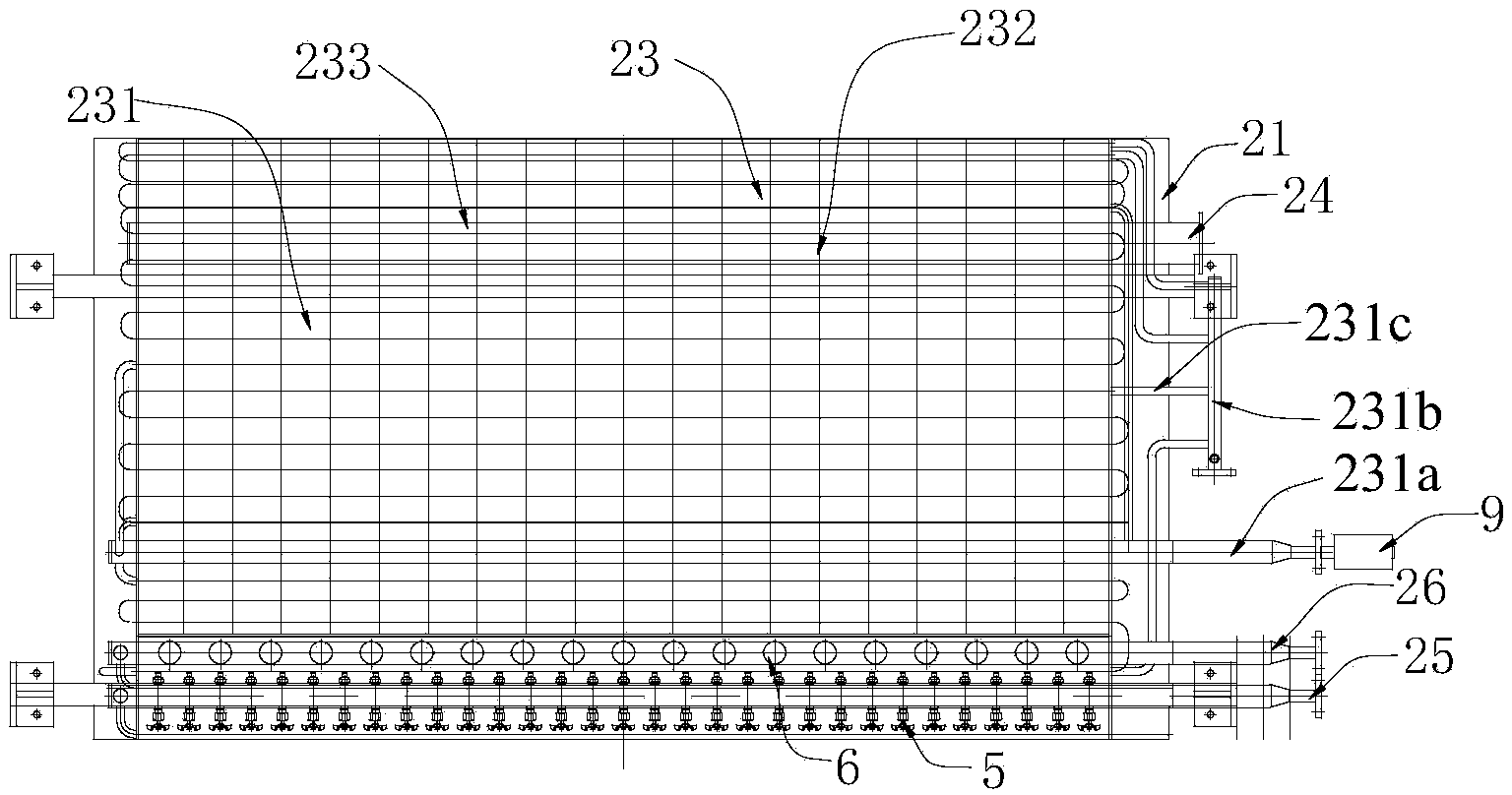

Secondary adjusting steam box and method for adjusting paper horizontal web water content

InactiveCN104195866ASolve the influence of heat transfer effectAvoid flowDamping devicesAir entrainmentPulp and paper industry

The invention discloses a secondary adjusting steam box and a method for adjusting the paper horizontal web water content. The secondary adjusting steam box comprises a steam box body, a master steam pipe and a master air exhaust pipe. A master pipe control valve is arranged at the inlet end of the master steam pipe. A preheating chamber is arranged outside the steam box body. The preheating chamber is arranged on a pipeline between the inlet end of the master steam pipe and the master pipe control valve in a communicating mode through a preheating branch pipe. The steam box body is sequentially provided with an air exhaust area, a steam spray area and a retention area in the advancing direction of paper, wherein the bottom of the air exhaust area is provided with a porous plate or a gap-type plate, the bottom of the steam spray area is provided with a porous plate or a gap-type plate and the bottom of the retention area is opened. Primary adjusting is conducted by using air carried by the paper, so that the problem that the steam heat transfer effect is affected by the air carried by the paper is solved and the secondary adjusting amount is reduced; secondary adjusting is conducted through steam flows of steam chambers of the steam box body, so that the purpose of adjusting the paper horizontal web water content is achieved. Due to the fact that the secondary adjusting amount of the steam flows is small, the flow difference between all the steam chambers is greatly reduced, steam is prevented from flowing among all the steam chambers and the adjusting effect is guaranteed.

Owner:SOUTH CHINA UNIV OF TECH

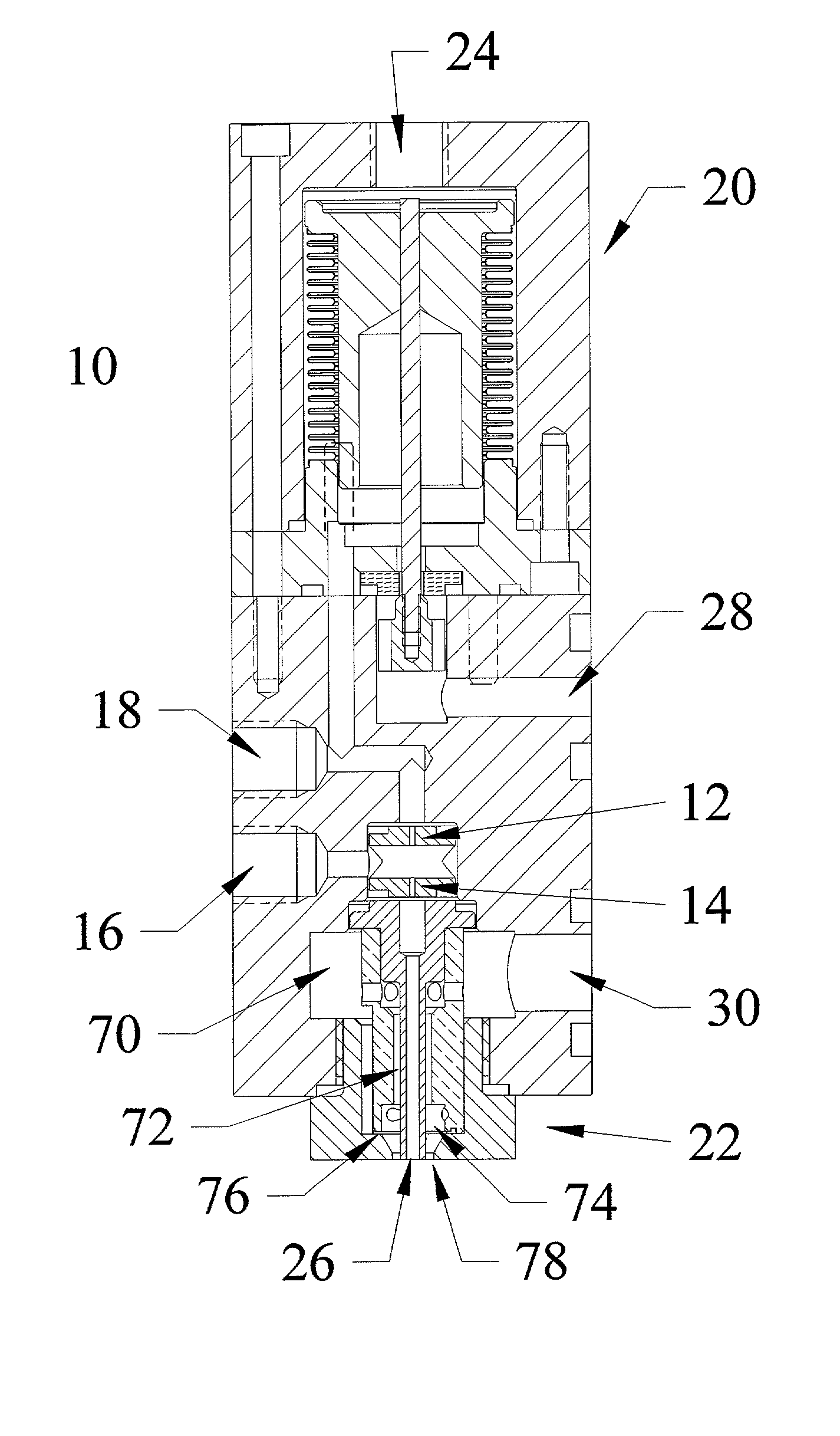

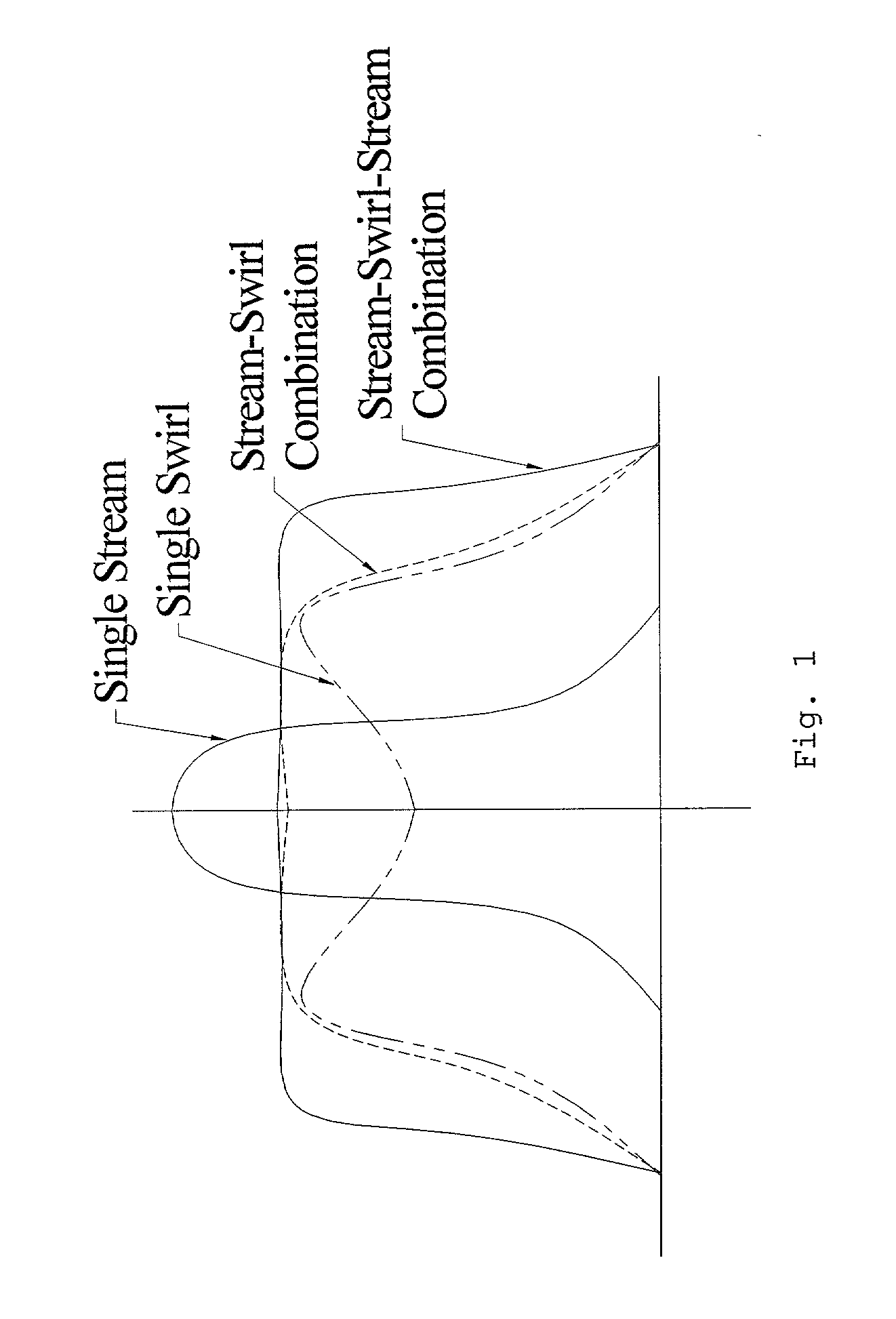

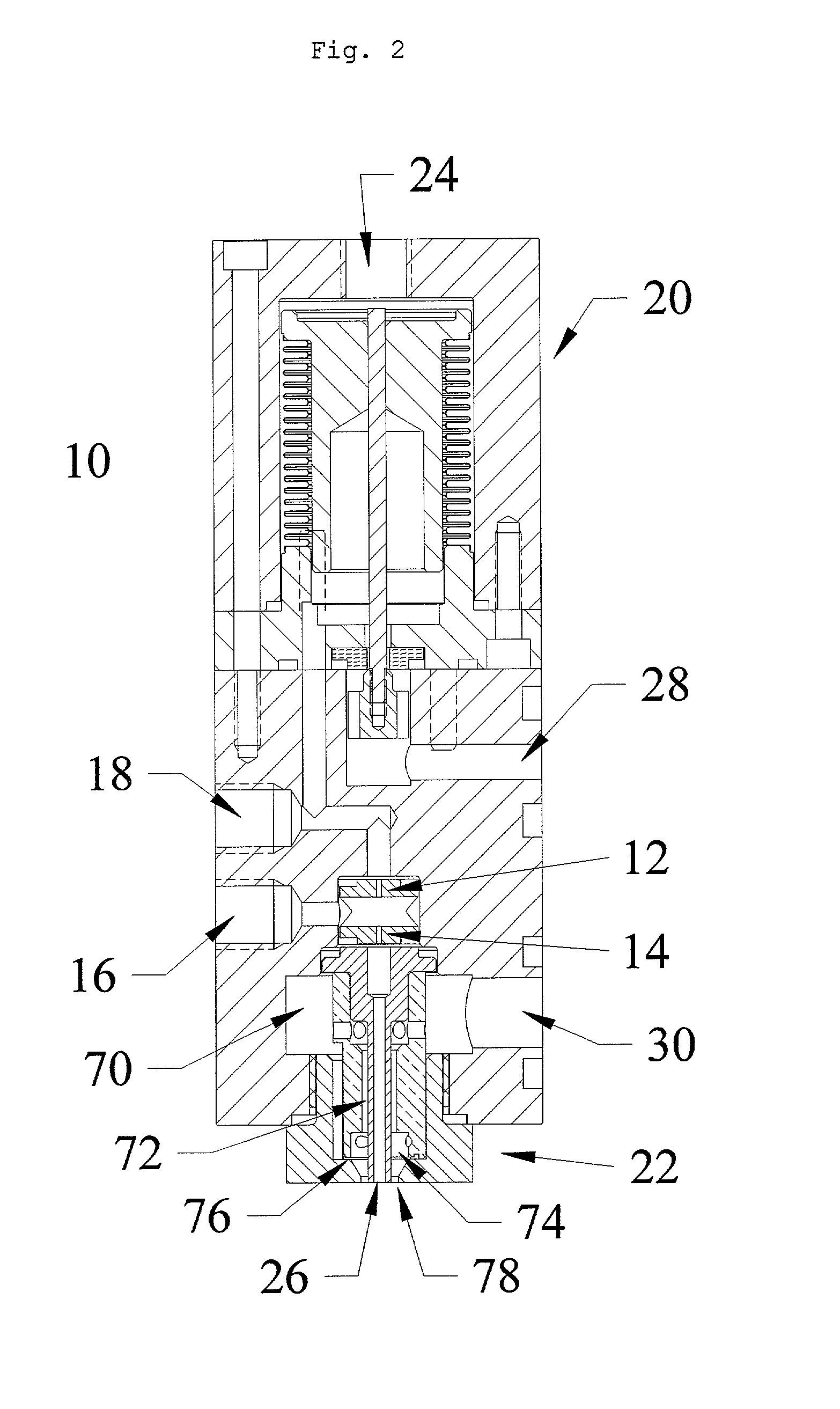

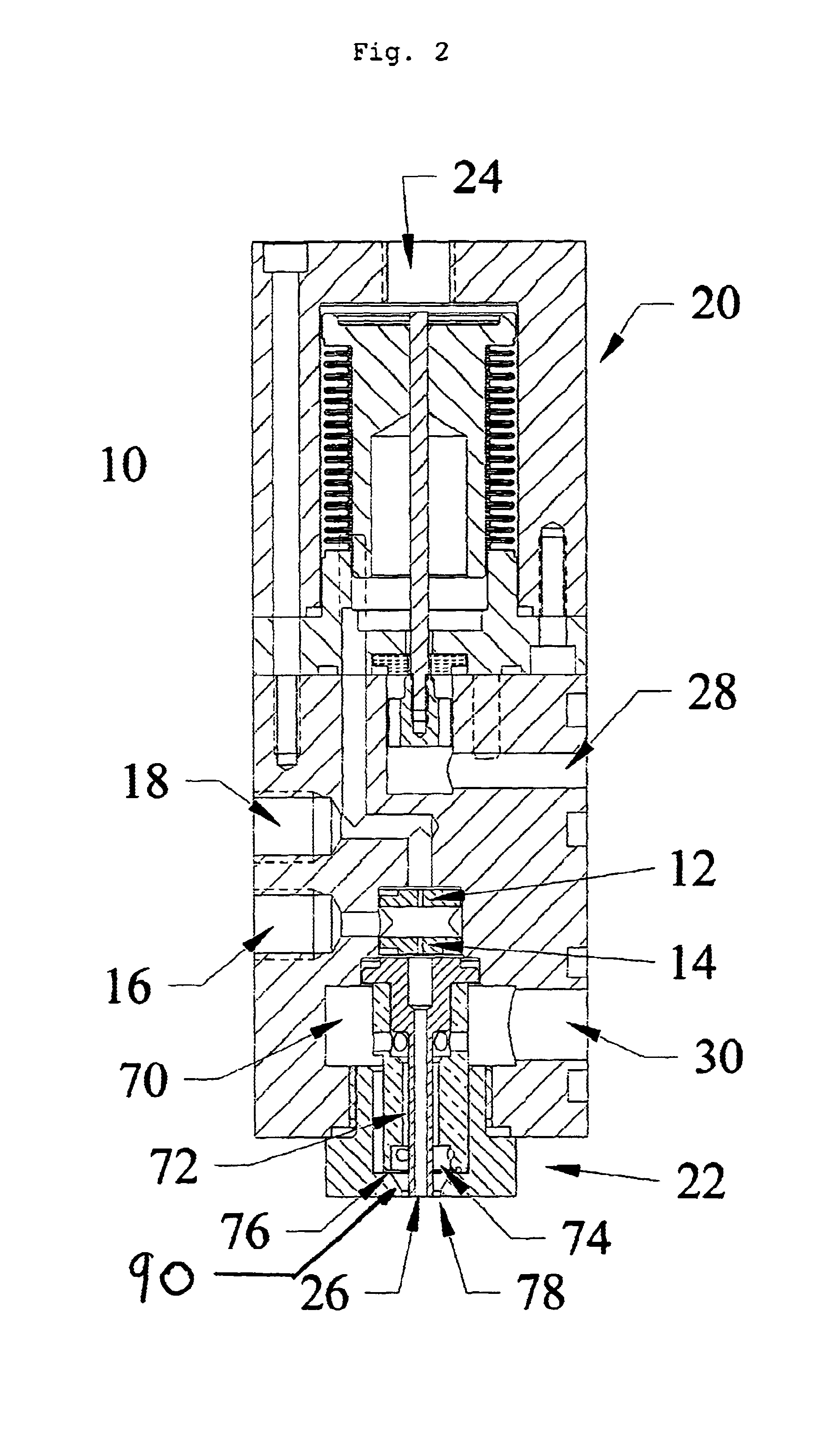

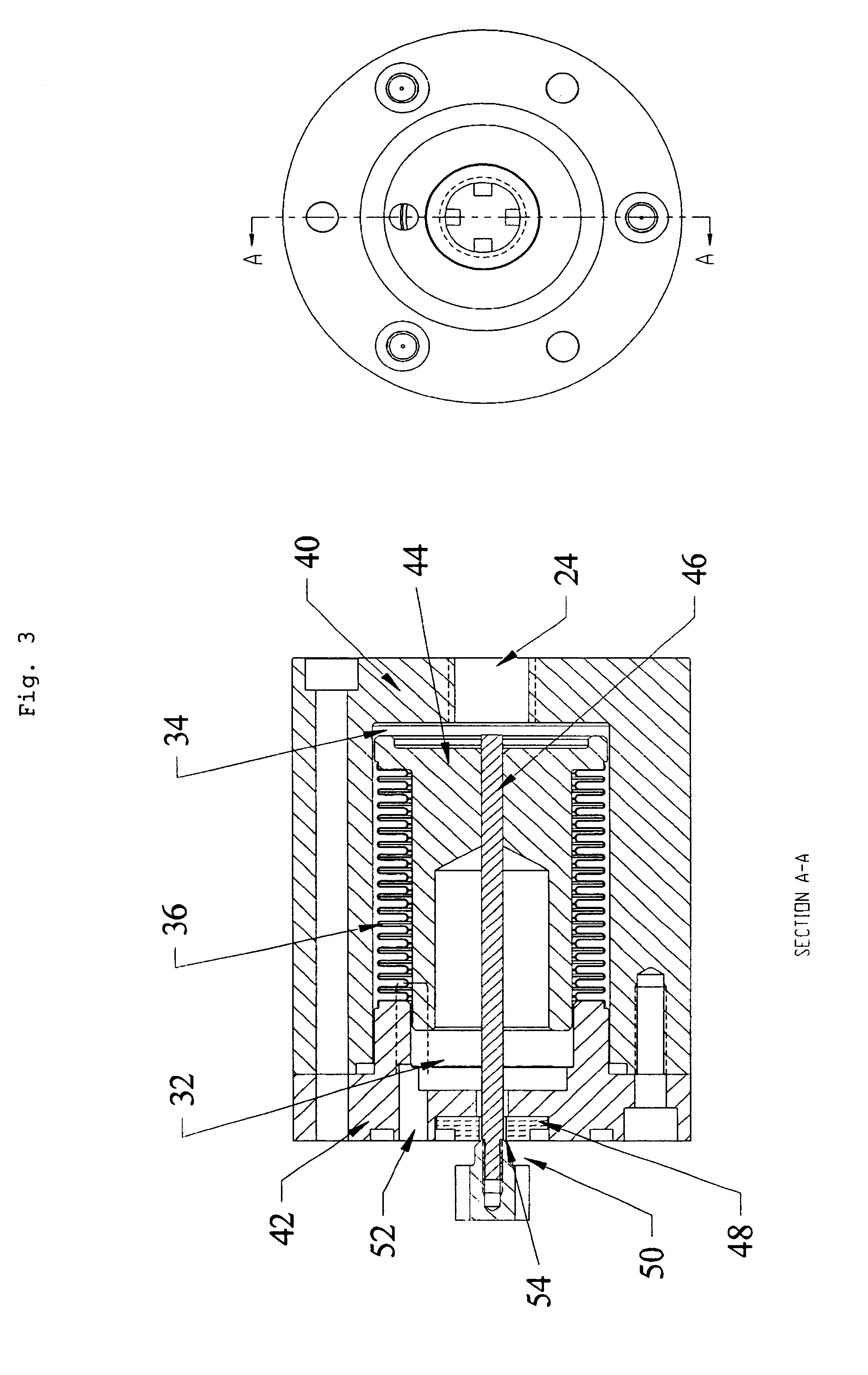

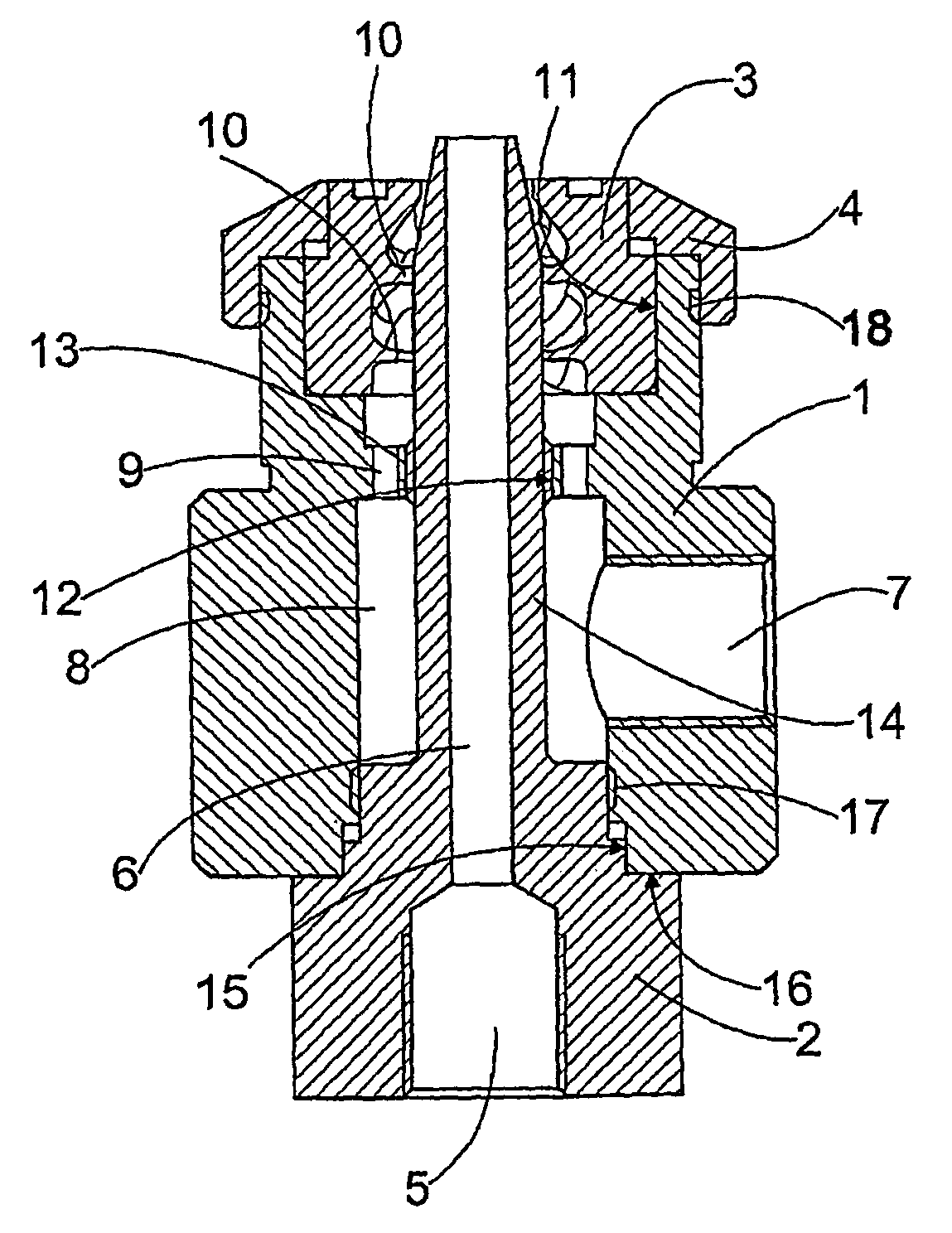

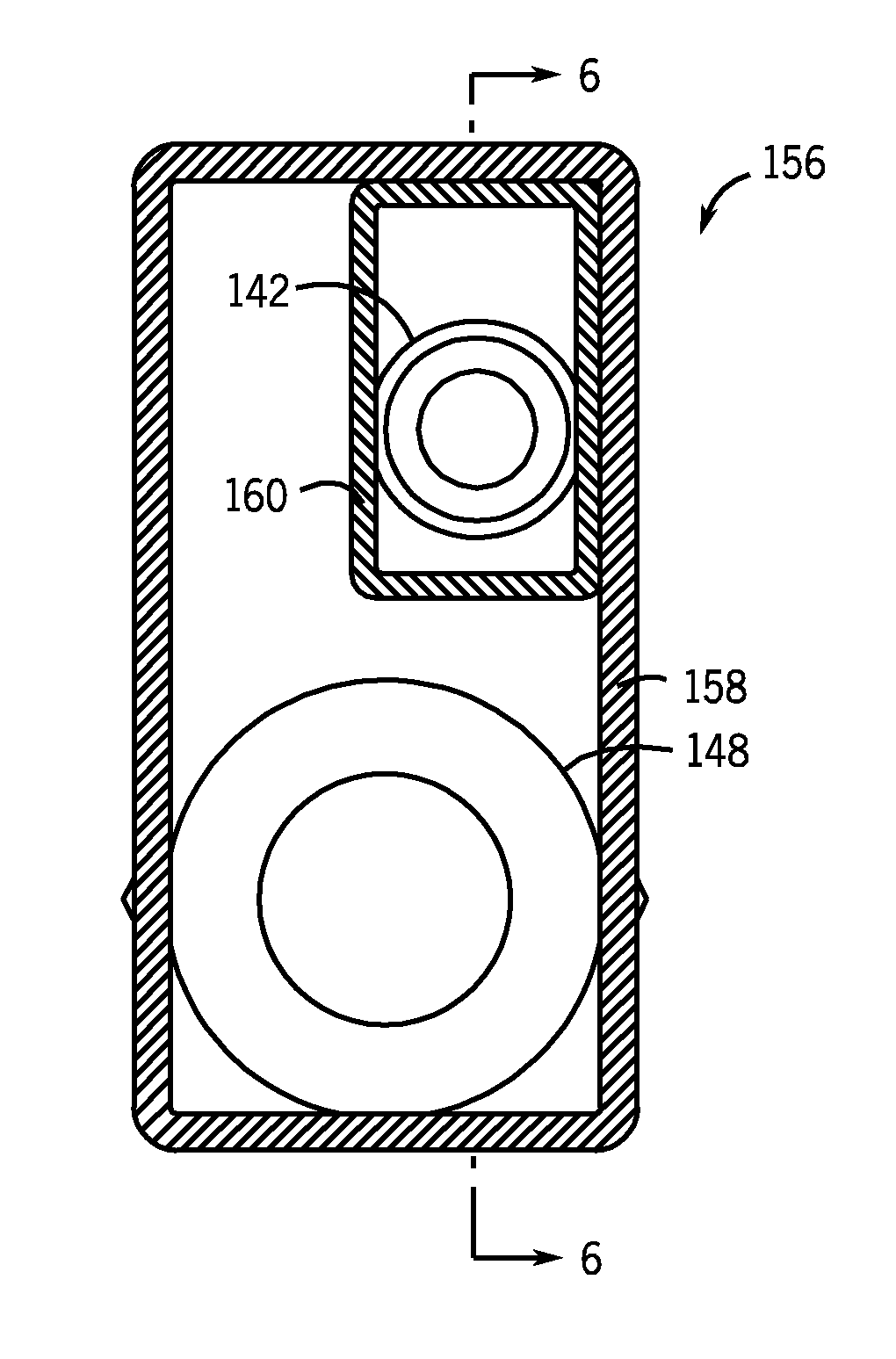

Spraying nozzle for rewet showers

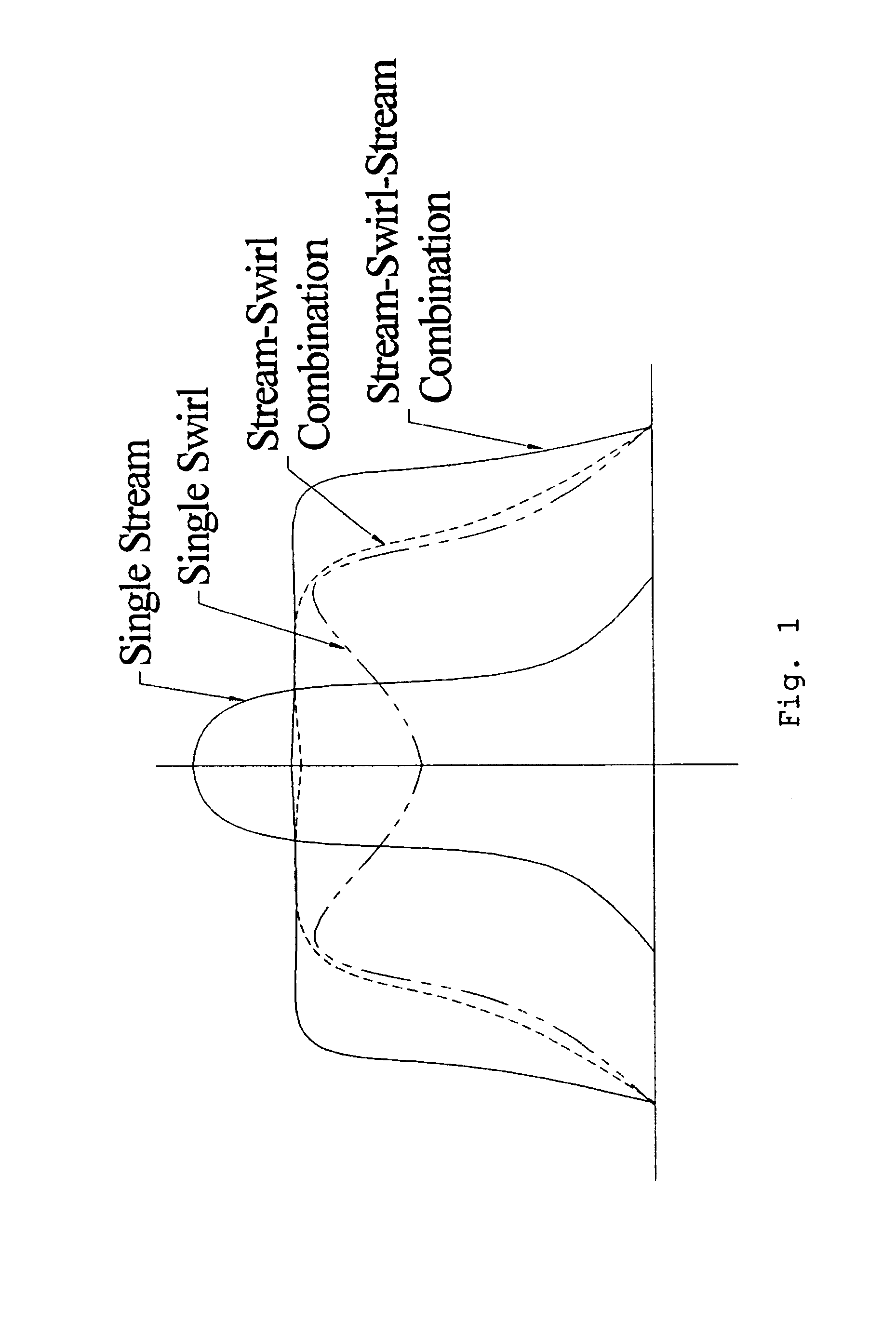

This invention relates to a three-stream atomizing nozzle for use with a rewet shower. The nozzle has an air stream divider that separates the atomizing air from the source into three streams. The first stream is a straight air stream staying closest to and around the atomized water jet. The second stream is a swirl running around the first straight stream. The third stream is also a straight stream that wraps around the first straight stream and the second swirl. The nozzle also has a mixing chamber in which the three air streams are mixed together for the atomizing purpose. The nozzle can from the combination of the three air streams produce fine water droplets that are suitable for a paper rewet shower and more importantly creates a tailorable water mass profile. The mass profile can be tailored into a shape that is close to a square shape which is ideal for rewet showers as a square profile creates minimal coupling between adjacent zones.

Owner:ABB LTD

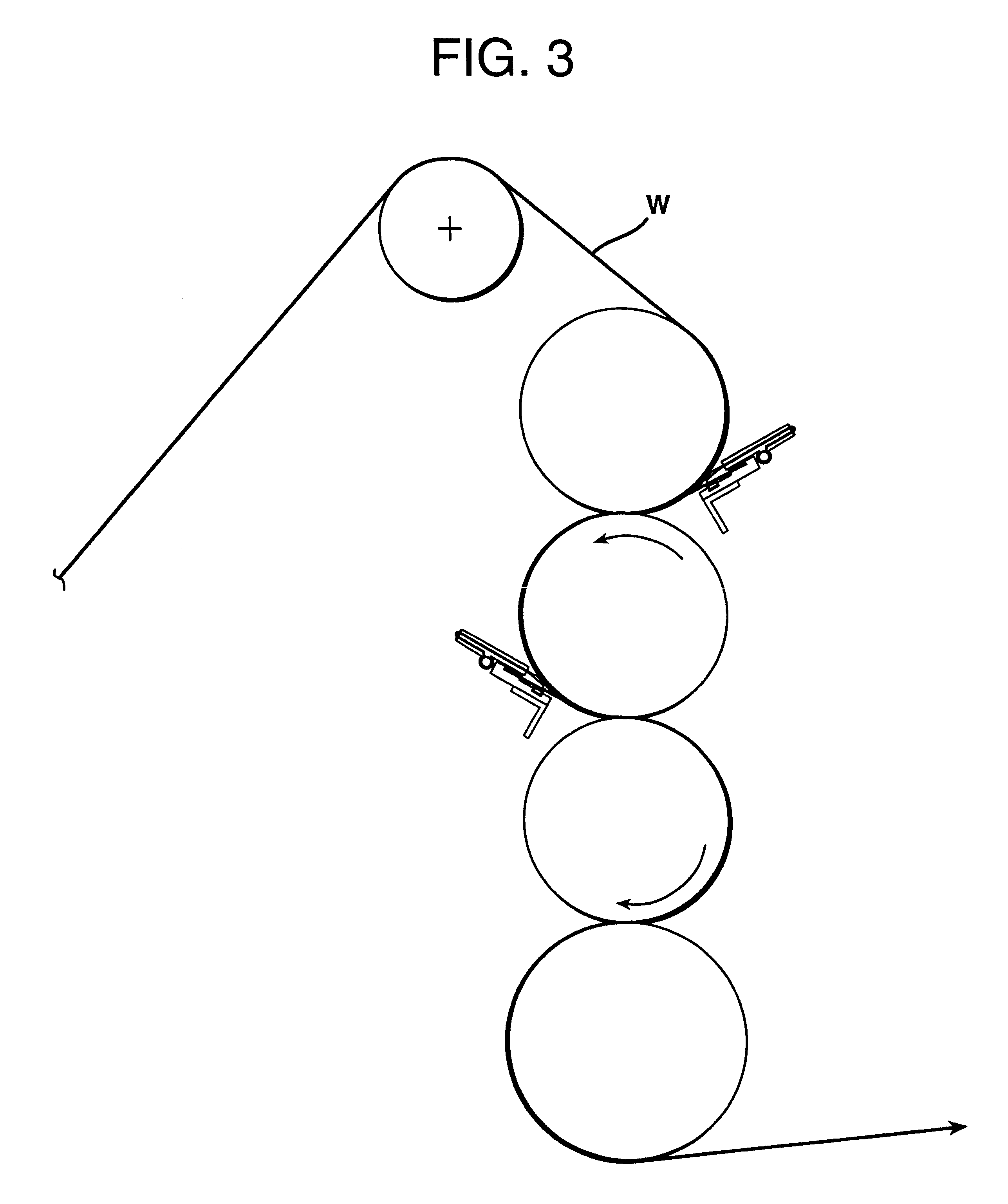

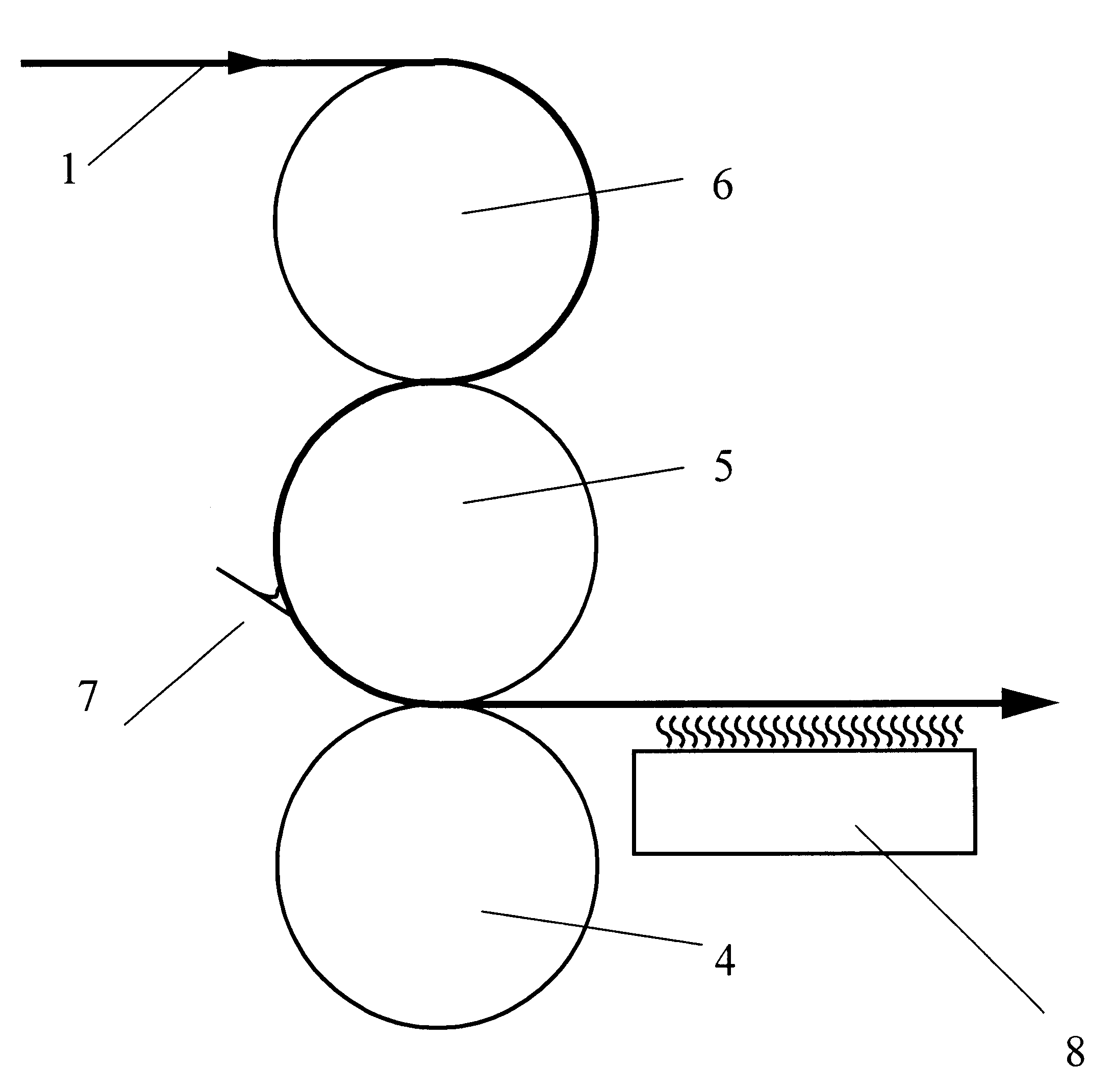

Method for smoothening a paper web before coating

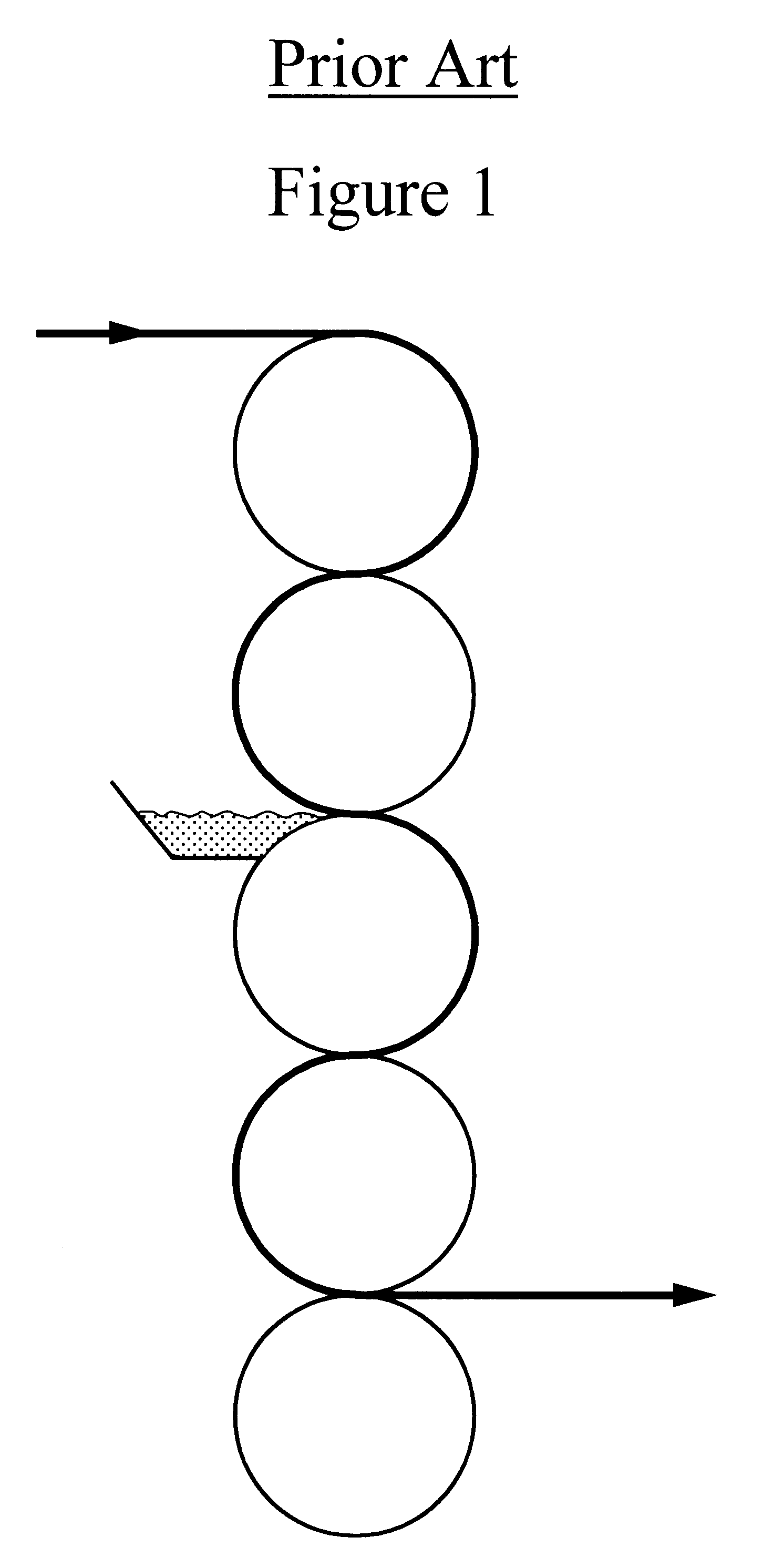

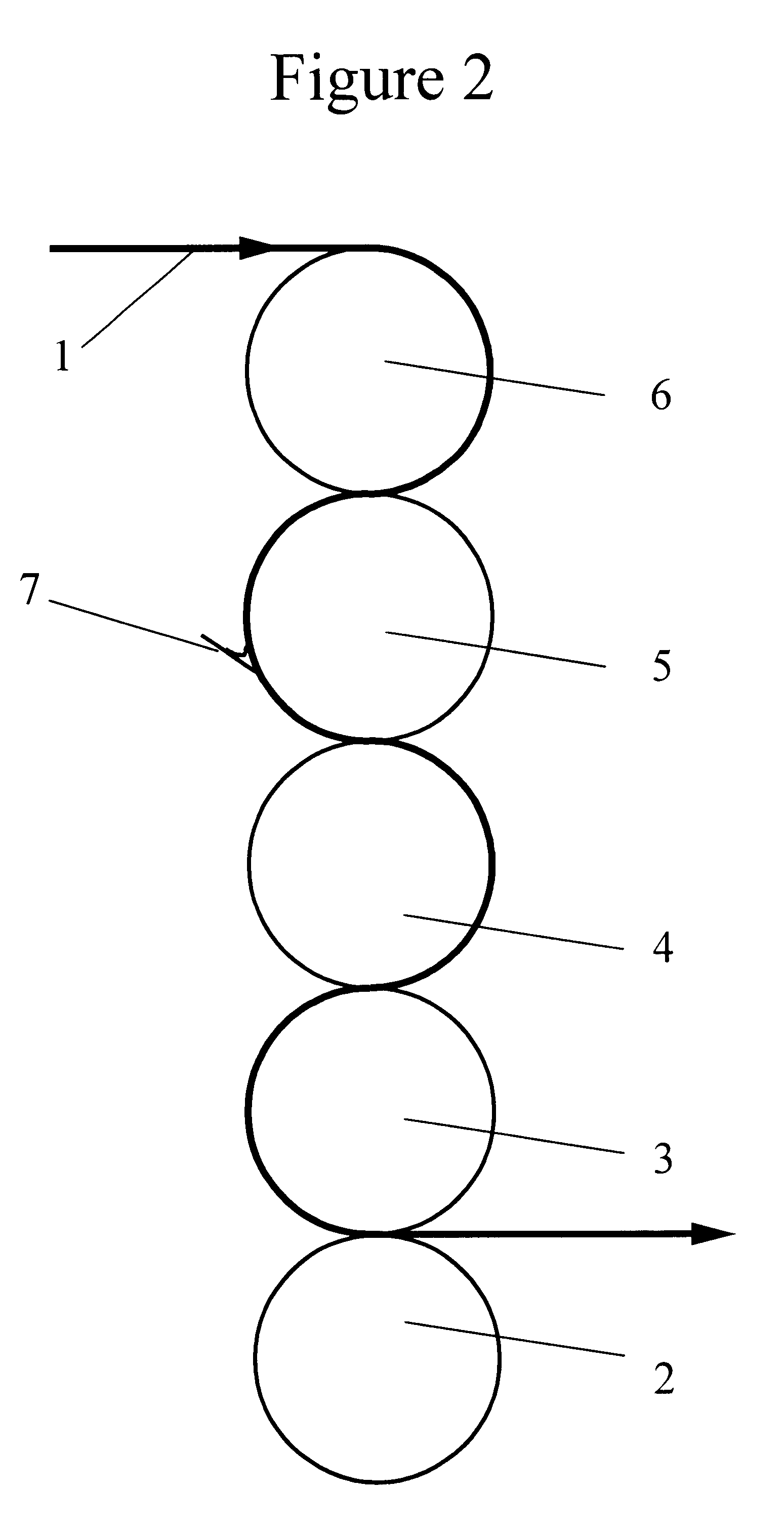

InactiveUS6485611B2Eliminate the effects ofPromote resultsNon-fibrous pulp additionNatural cellulose pulp/paperPaper sheetCoating

A paper web is smoothened by passing the web through a pre-calender device on a paper machine before the application of a coating. The pre-calender device comprises at least one pair of steel rolls, one of which is heated, and a liquid application device which applies a thin film of water to the surface of the web which contacts the heated roll before the web enters the nip between the rolls. The web is then dried after exiting the nip either by wrapping the heated roll and / or by applying heat externally to the web.

Owner:MEADWESTVACO CORP

Apparatus for paper making and paper surface enhancement

InactiveUS7217342B2Easy to manufactureImprove propertiesBurnersNon-fibrous pulp additionPulp and paper industry

A process that can utilize current paper manufacturing facilities by adding consecutive spray apparatuses that can make and / or enhance the manufacture of a multitude of specific paper products on-line, or improve the properties of already formed paper products with consequent spraying steps on-line or off-line.

Owner:KANGAS MARTTI Y O +1

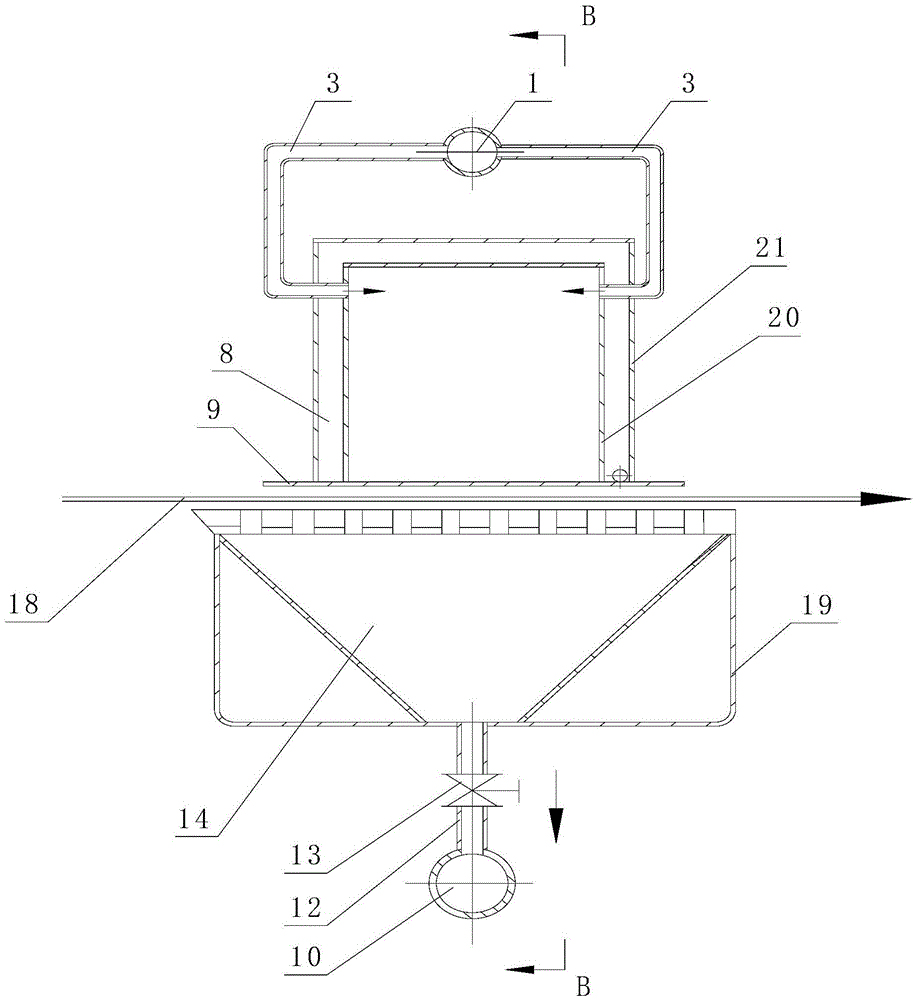

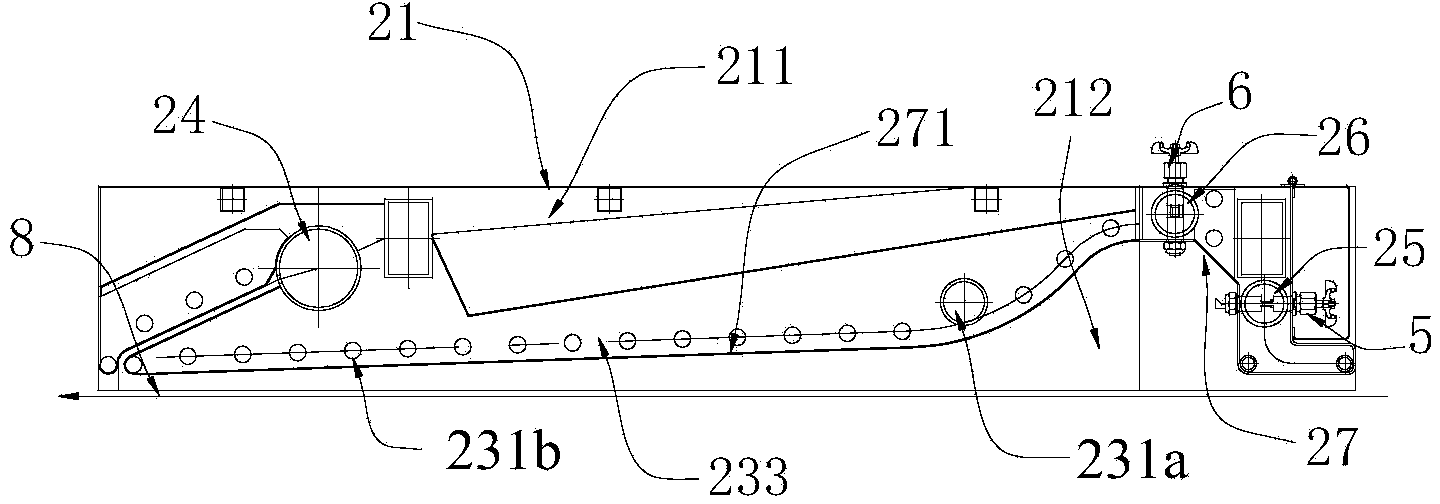

Steam box and method for preventing condensate water from dripping

InactiveCN105088852ASimple structureReduce manufacturing costDamping devicesEngineeringControl valves

The invention discloses a steam box and a method for preventing condensate water from dripping, wherein the steam box comprises a steam box body, a pre-heat box body, a steam main pipe, steam branch pipes and a pre-heat branch pipe; the pre-heat box body is set at the periphery of the steam box body and a pre-heat interlayer is set between the pre-heat steam box body and the steam body body; two side walls opposite to the steam box body are respectively provided with steam inlets; the steam main pipe is connected to the steam inlets through the steam branch pipes; and the steam main pipe is connected to the pre-heat interlayer through the pre-heat branch pipe. The method is that the steam main pipe is used to provide steam for the pre-heat branch pipe firstly; after steam goes into the pre-heat interlayer, the steam box body and a steam spay pipe are pre-heated; after the pre-heated process is finished, a control valve of the pre-heat branch pipe is regulated so as to reduce steam flow inside the pre-heat branch pipe; at the same time, the steam main pipe is used to convey steam to the steam box body through the steam branch pipes; and after steam goes into the steam box body, the steam spray pipe is used to spray steam on the surface of a piece of paper. The steam box provided herein has the advantage of simple structure and low manufacture and maintenance cost; and at the same time, the steam box provided herein also has the advantages of preventing the condensate water from dripping effectively.

Owner:SOUTH CHINA UNIV OF TECH

Method of wetting webs of paper or other hygroscopic material

This invention relates to a three-stream atomizing nozzle for use with a rewet shower. The nozzle has an air stream divider that separates the atomizing air from the source into three streams. The first stream is a straight air stream staying closest to and around the atomized water jet. The second stream is a swirl running around the first straight stream. The third stream is also a straight stream that wraps around the first straight stream and the second swirl. The nozzle also has a mixing chamber in which the three air streams are mixed together for the atomizing purpose. The nozzle can from the combination of the three air streams produce fine water droplets that are suitable for a paper rewet shower and more importantly creates a tailorable water mass profile. The mass profile can be tailored into a shape that is close to a square shape which is ideal for rewet showers as a square profile creates minimal coupling between adjacent zones.

Owner:ABB LTD

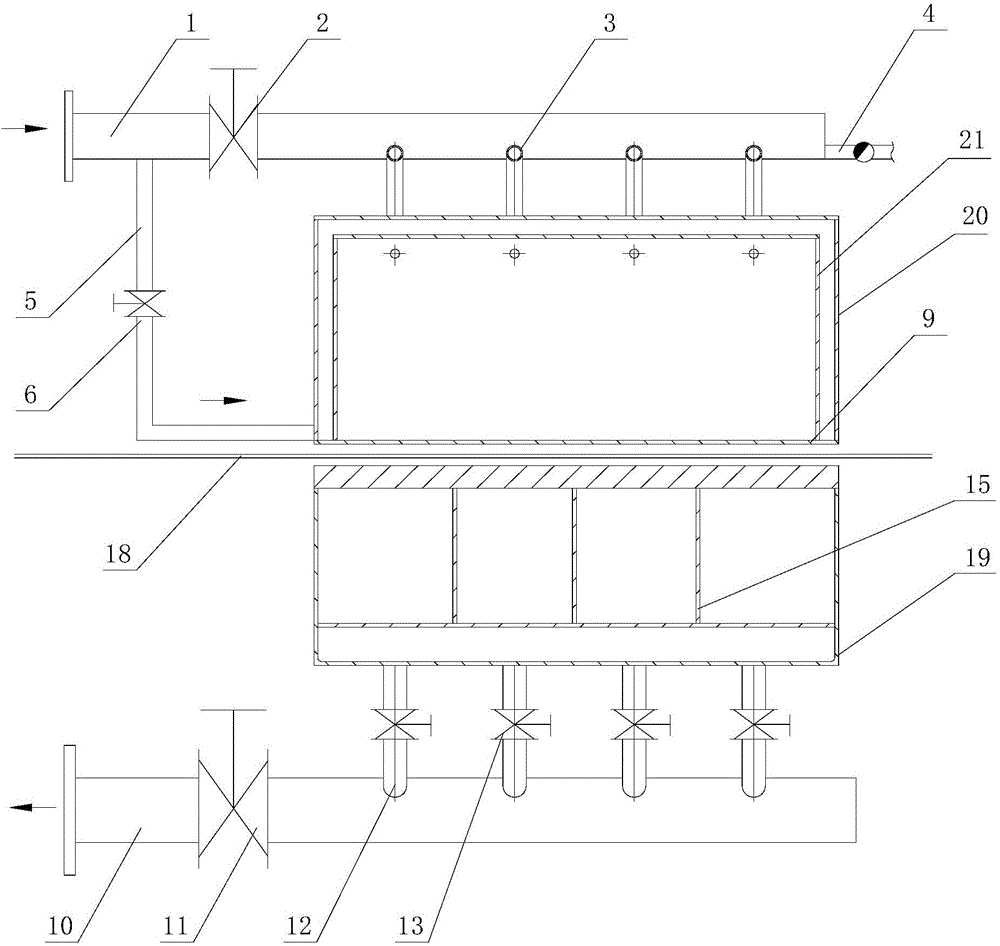

Steam humidification device suitable for multilayer corrugated paper

ActiveCN103696317AImprove humidification qualityImprove the humidification effectDamping devicesAir pumpPulp and paper industry

The invention provides a steam humidification device suitable for multilayer corrugated paper. The steam humidification device comprises a humidification groove which is internally provided with a humidification steam pipe; steam holes are arranged at the lower end of the part of the humidification steam pipe arranged in the humidification groove; the humidification steam pipe is connected with an air pump; the humidification steam pipe is provided with a humidification switch and a steam regulating valve at the outer end of the humidification groove; a humidification sleeve is arranged at the part of the humidification steam pipe arranged in the humidification groove; the upper end of the humidification sleeve is provided with a humidification strip-shaped groove; the two ends of the humidification strip-shaped groove are respectively provided with a humidification branch groove; the bottom of the humidification sleeve is provided with a condensate water recovery pipe. The steam humidification device has the beneficial effects that the corrugated paper is humidified by the steam, and the water is promoted and driven to rapidly permeate into an interlayer of the corrugated paper by the heat of the steam, so that the humidification effect of the corrugated paper can be improved; enhanced humidification can be carried out on the edge part of the corrugated paper by the humidification branch grooves arranged at the two ends of the humidification sleeve, so that the edge of the corrugated paper is prevented from being broken and damaged. The steam humidification device is simple in structure and good in using effect.

Owner:惠州市国鹏文化创意有限公司

Paper humidifying device

ActiveCN103924474AUniform humidificationEnhanced HumidificationDamping devicesPulp and paper industryNozzle

The invention relates to the field of papermaking devices, in particular to a paper humidifying device. The paper humidifying device comprises a humidifying box. The humidifying box comprises a box body, a dummy plate and a steam pipeline, wherein the dummy plate and the steam pipeline are arranged in the box body. The box body is arranged above paper conveyed by a roll shaft, the box body is divided into an upper part and a lower part by the dummy plate, the upper part is an installation chamber, the space between the dummy plate and the paper is a humidifying chamber, the steam pipeline is arranged in the installation chamber, a steam valve is arranged on the steam pipeline, and a nozzle of the steam valve is located in the humidifying chamber. The invention aims to provide an upward side humidifying device, the upward side humidifying device overcomes the technical defects that the steam flow direction of rising steam can not be controlled, and the humidifying effect of the paper is poor.

Owner:浙江汉普新材料技术有限公司

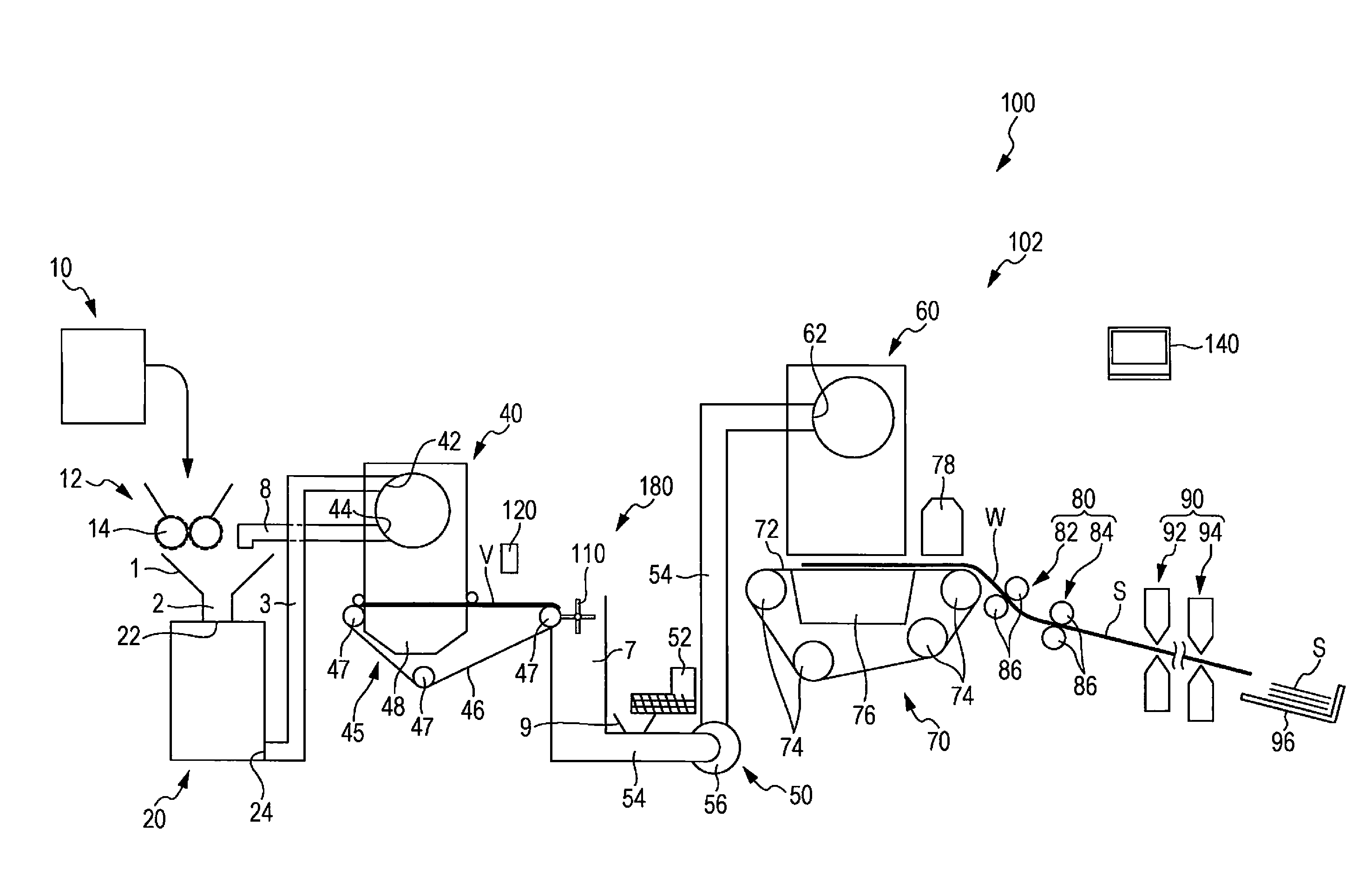

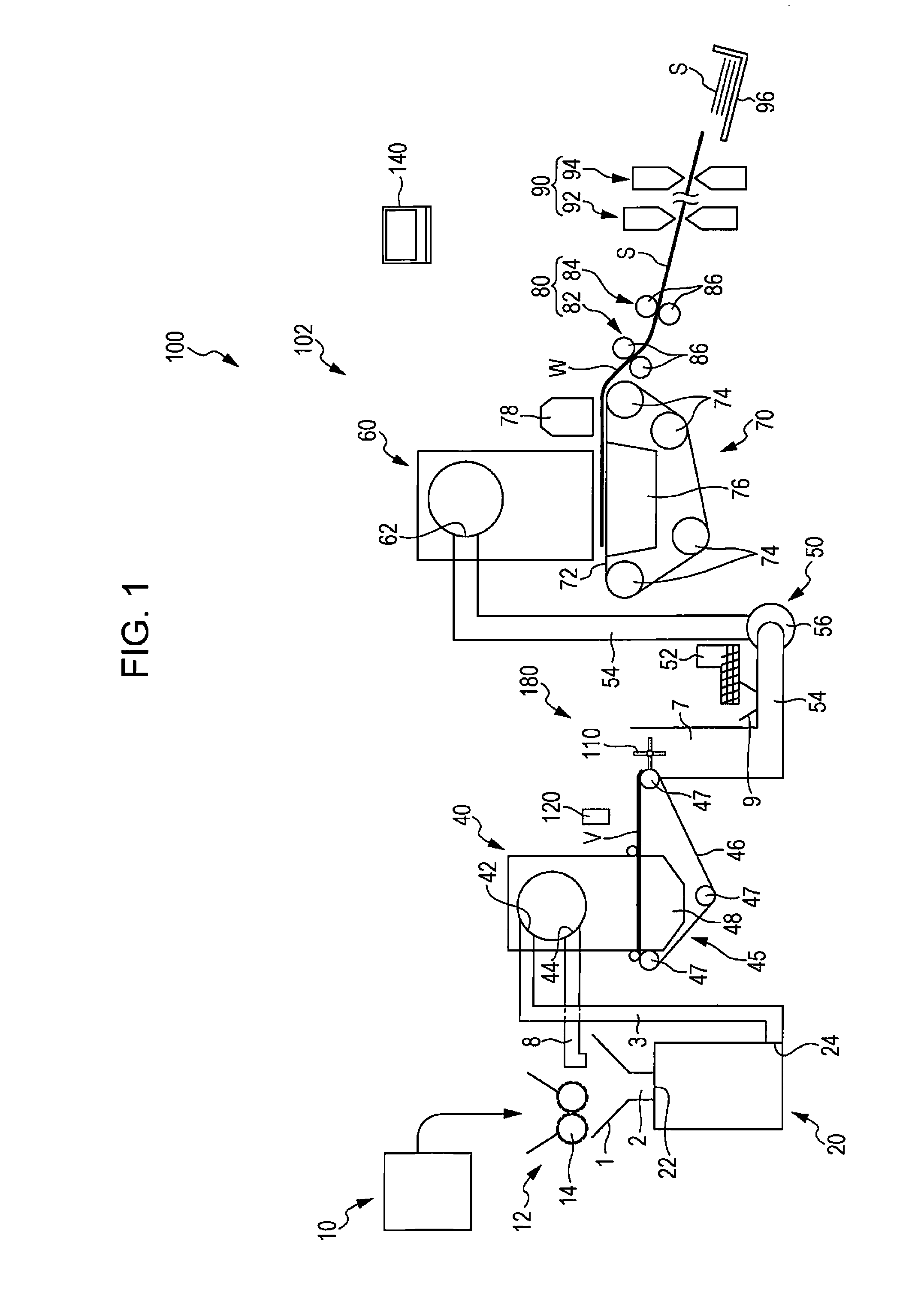

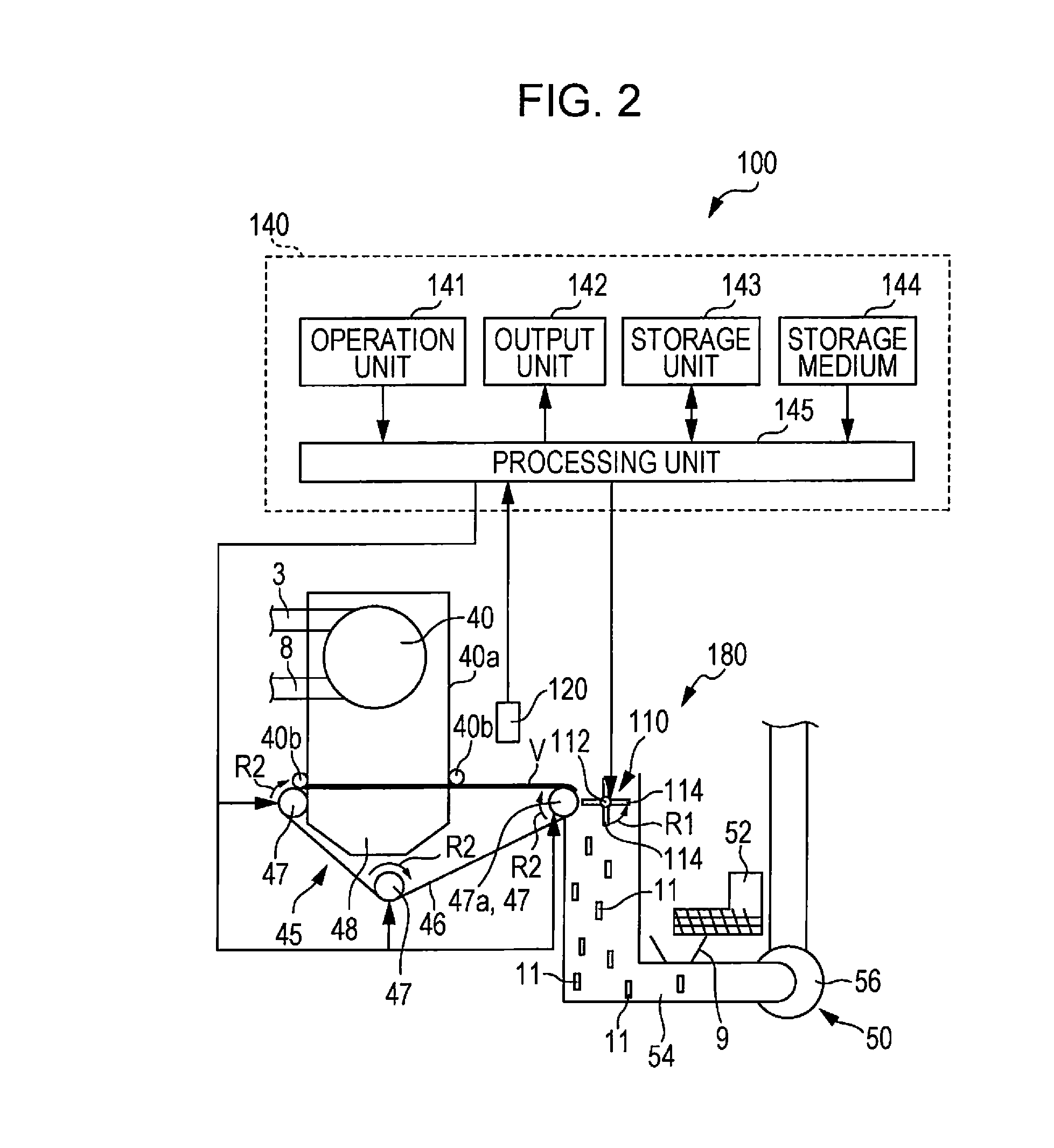

Sheet manufacturing apparatus and sheet manufacturing method

ActiveUS20160273164A1High uniformity in density and thicknessPaper recyclingMechanical paper treatmentFiberManufactured apparatus

A sheet manufacturing apparatus includes a defibrating unit configures to defibrate a raw material containing fiber into a defibrated material; a screening unit configured to screen the defibrated material that is defibrated by the defibrating unit; a web forming unit configured to form a web on which the defibrated material screened by the screening unit is deposited; a rotary body that includes a protrusion unit for forming a subdivided body by dividing the web formed by the web forming unit; a deposition unit configures to deposit the defibrated material configuring the subdivided body; and a forming unit configured to form the sheet by pressurizing and heating the defibrated material deposited by the deposition unit.

Owner:SEIKO EPSON CORP

Method for smoothening a paper web before coating

InactiveUS20020060022A1Eliminate the effects ofPromote resultsNon-fibrous pulp additionNatural cellulose pulp/paperPaper sheetCoating

A paper web is smoothened by passing the web through a pre-calender device on a paper machine before the application of a coating. The pre-calender device comprises at least one pair of steel rolls, one of which is heated, and a liquid application device which applies a thin film of water to the surface of the web which contacts the heated roll before the web enters the nip between the rolls. The web is then dried after exiting the nip either by wrapping the heated roll and / or by applying heat externally to the web.

Owner:MEADWESTVACO CORP

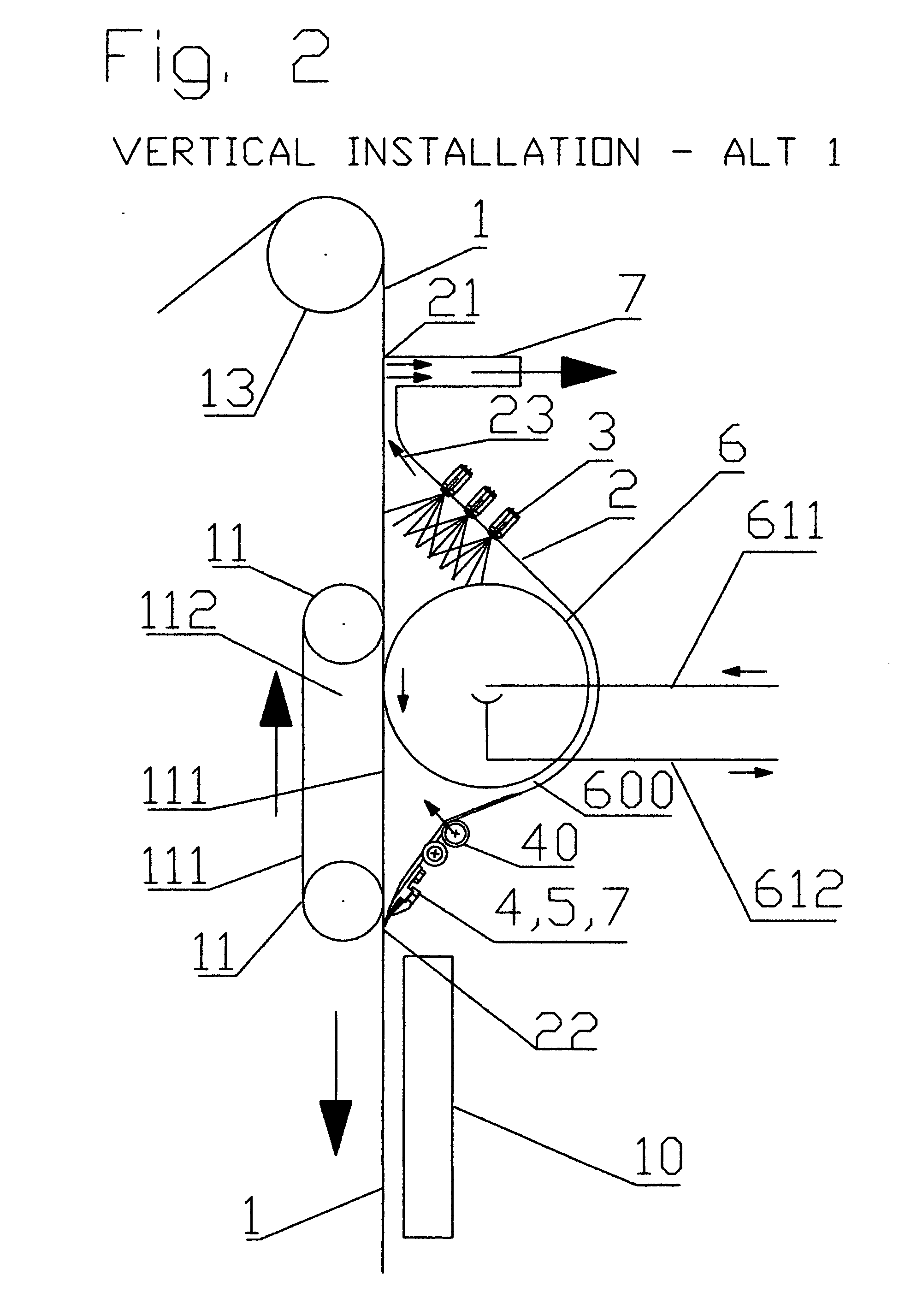

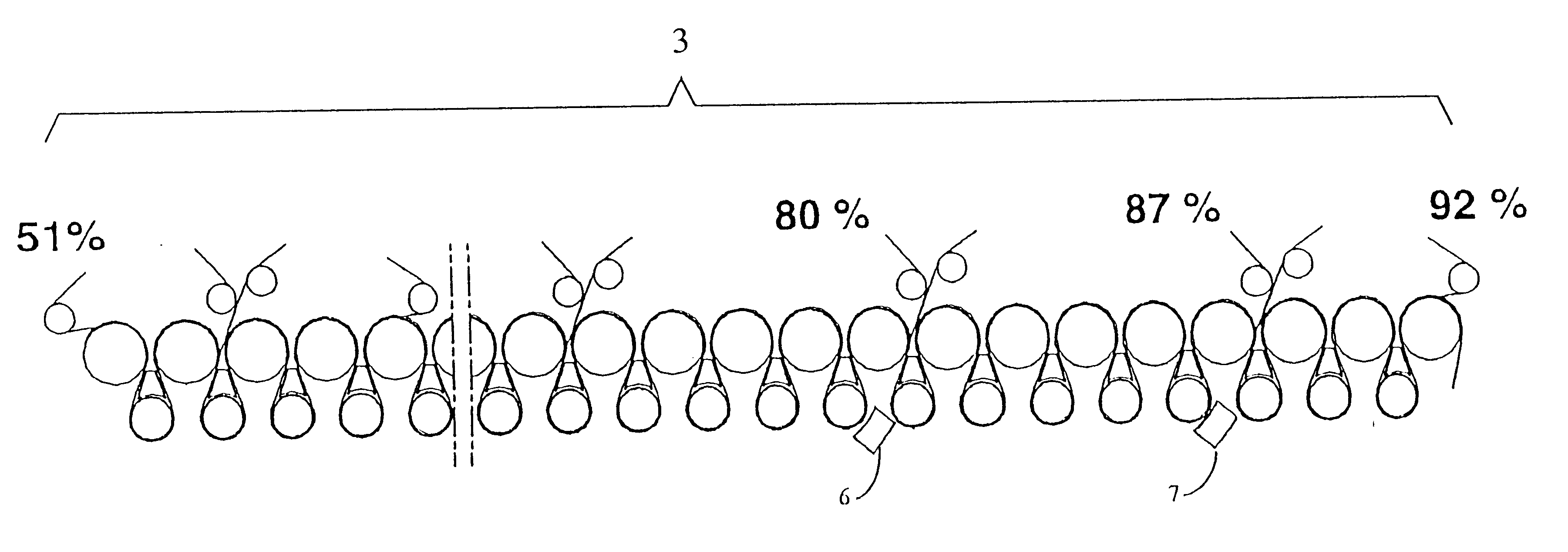

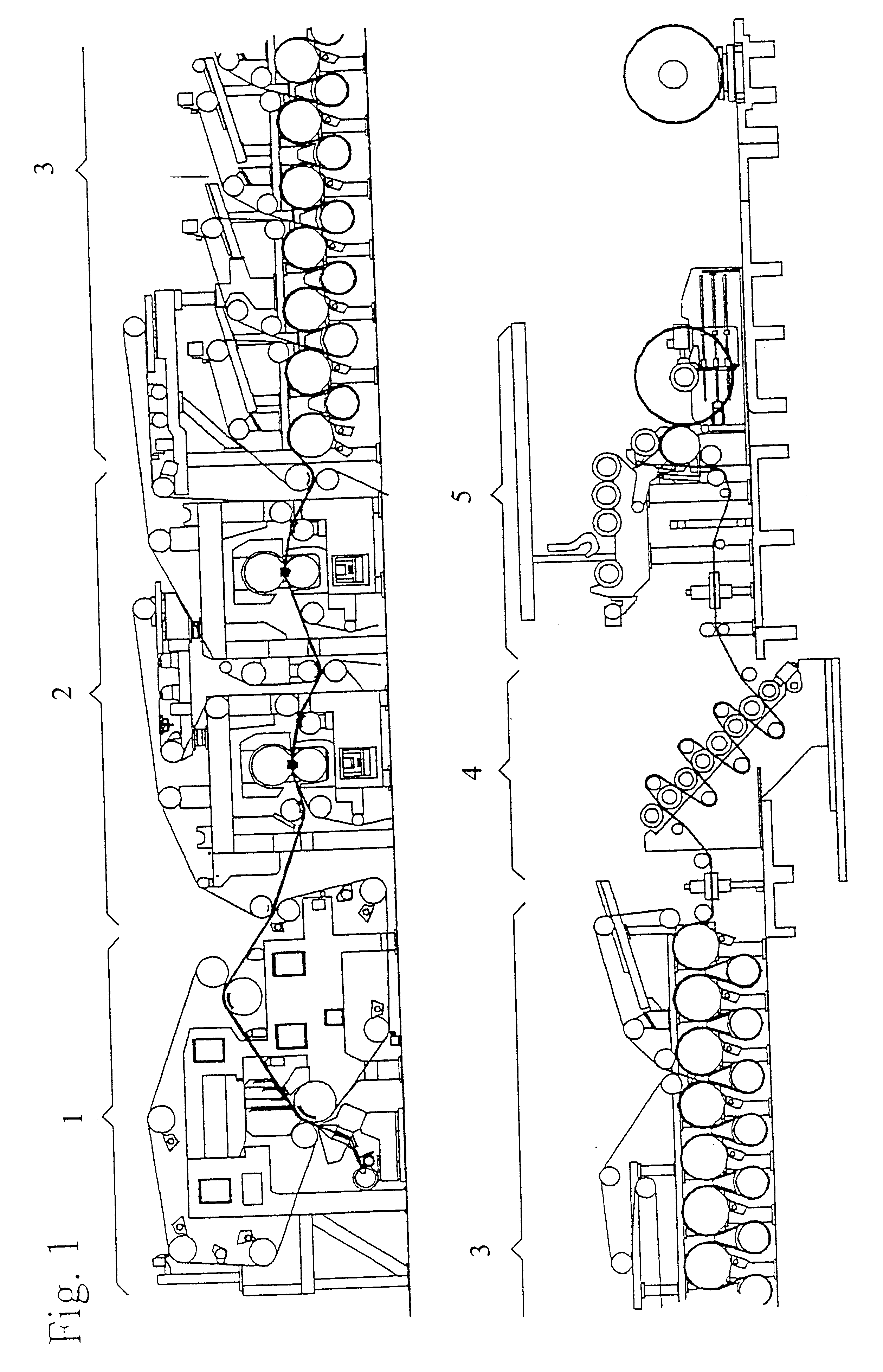

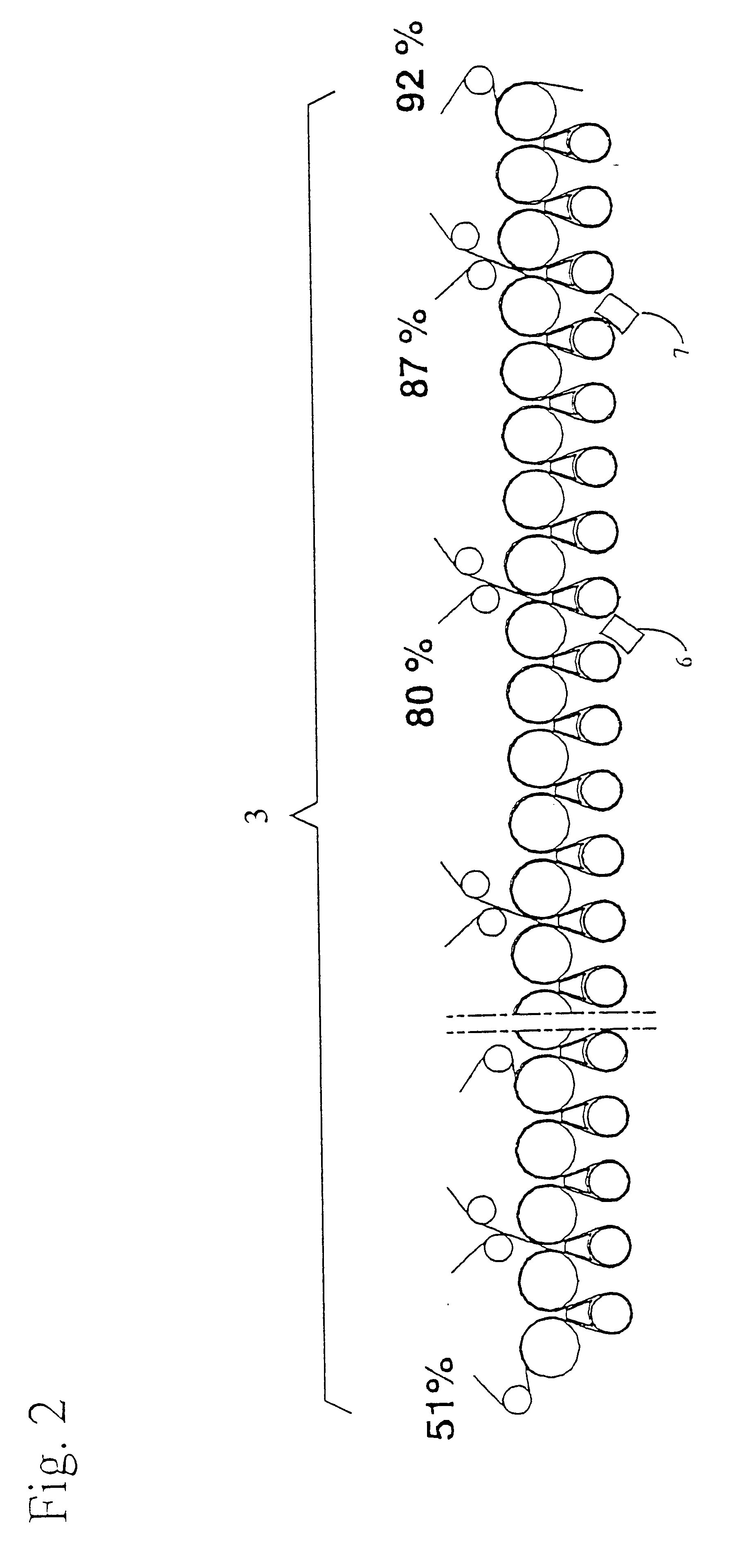

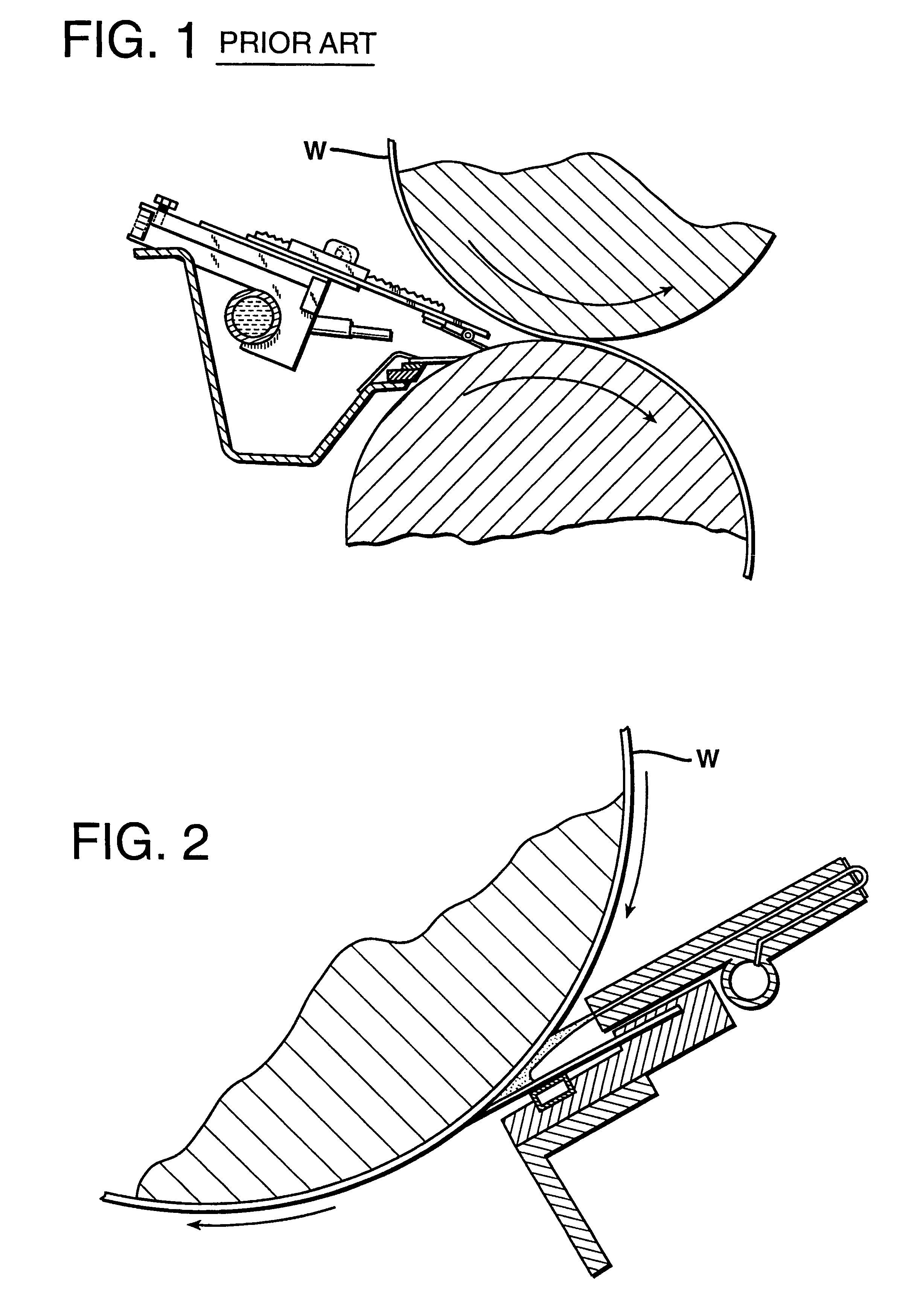

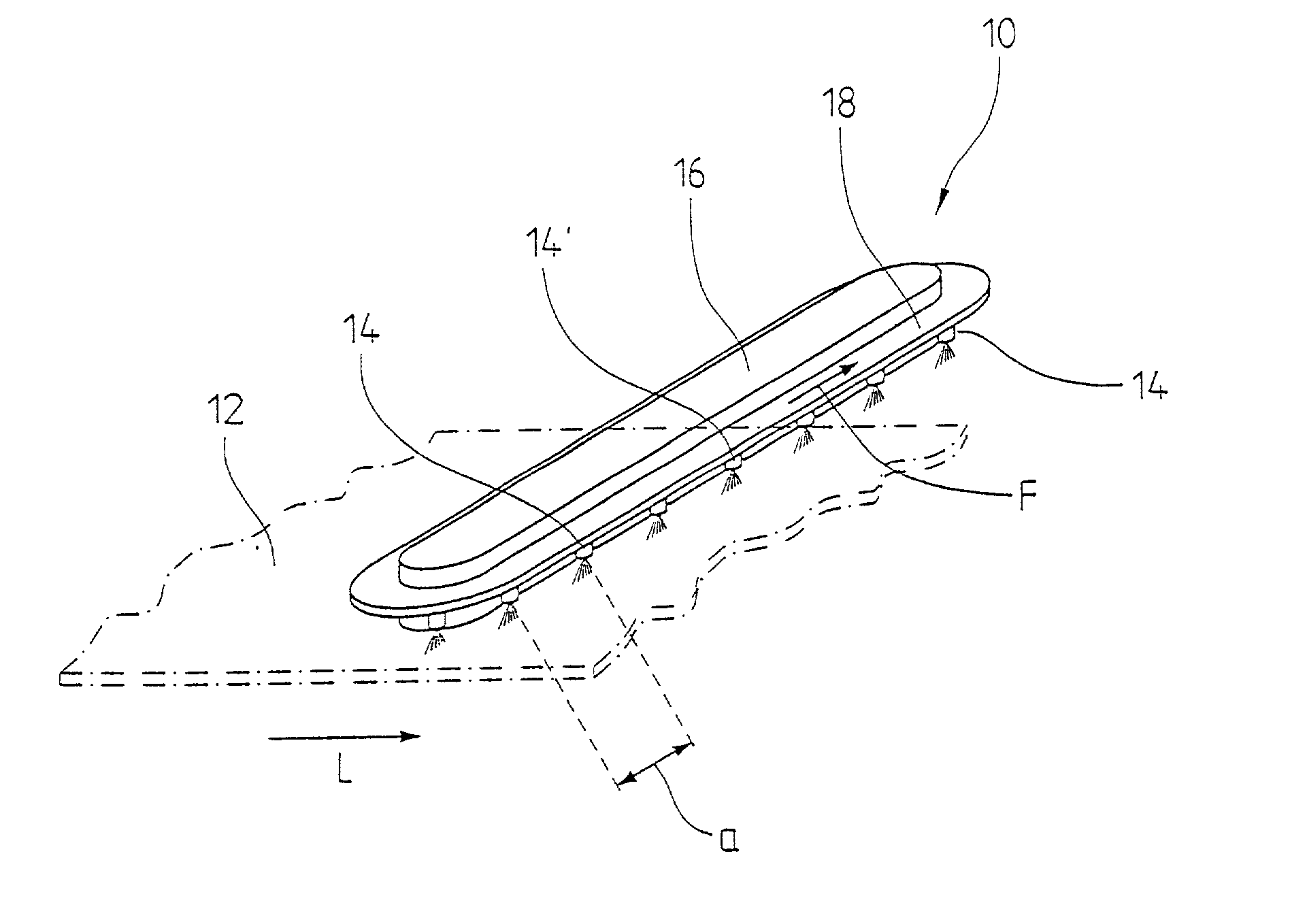

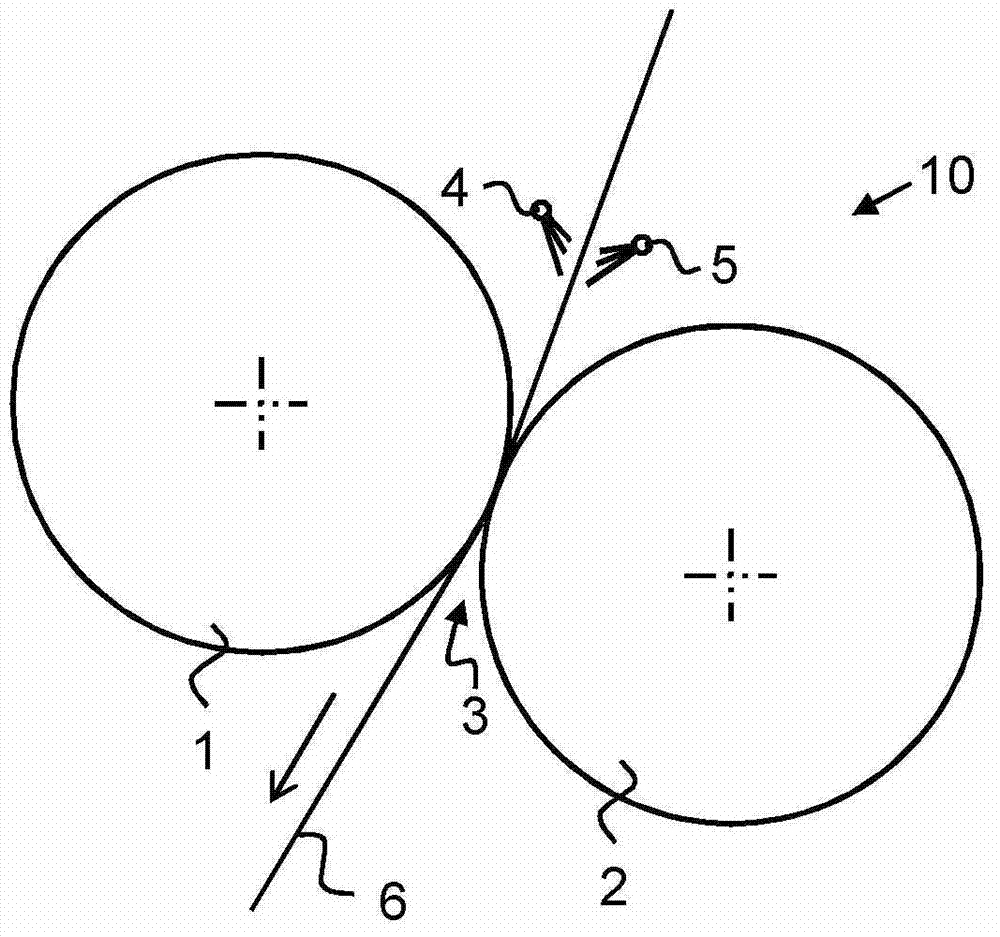

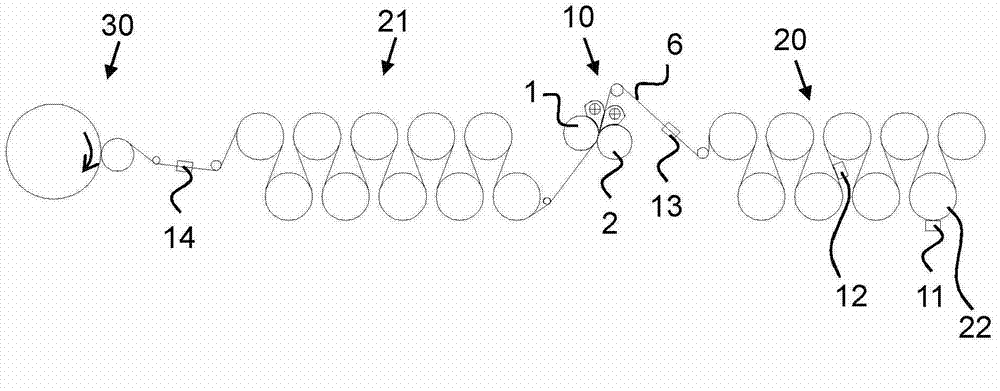

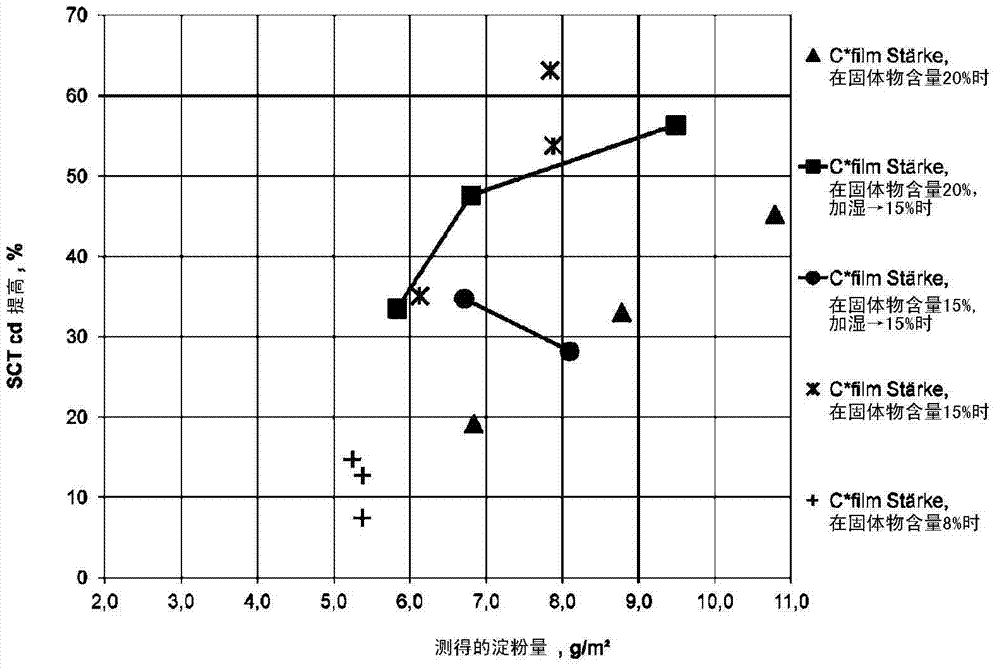

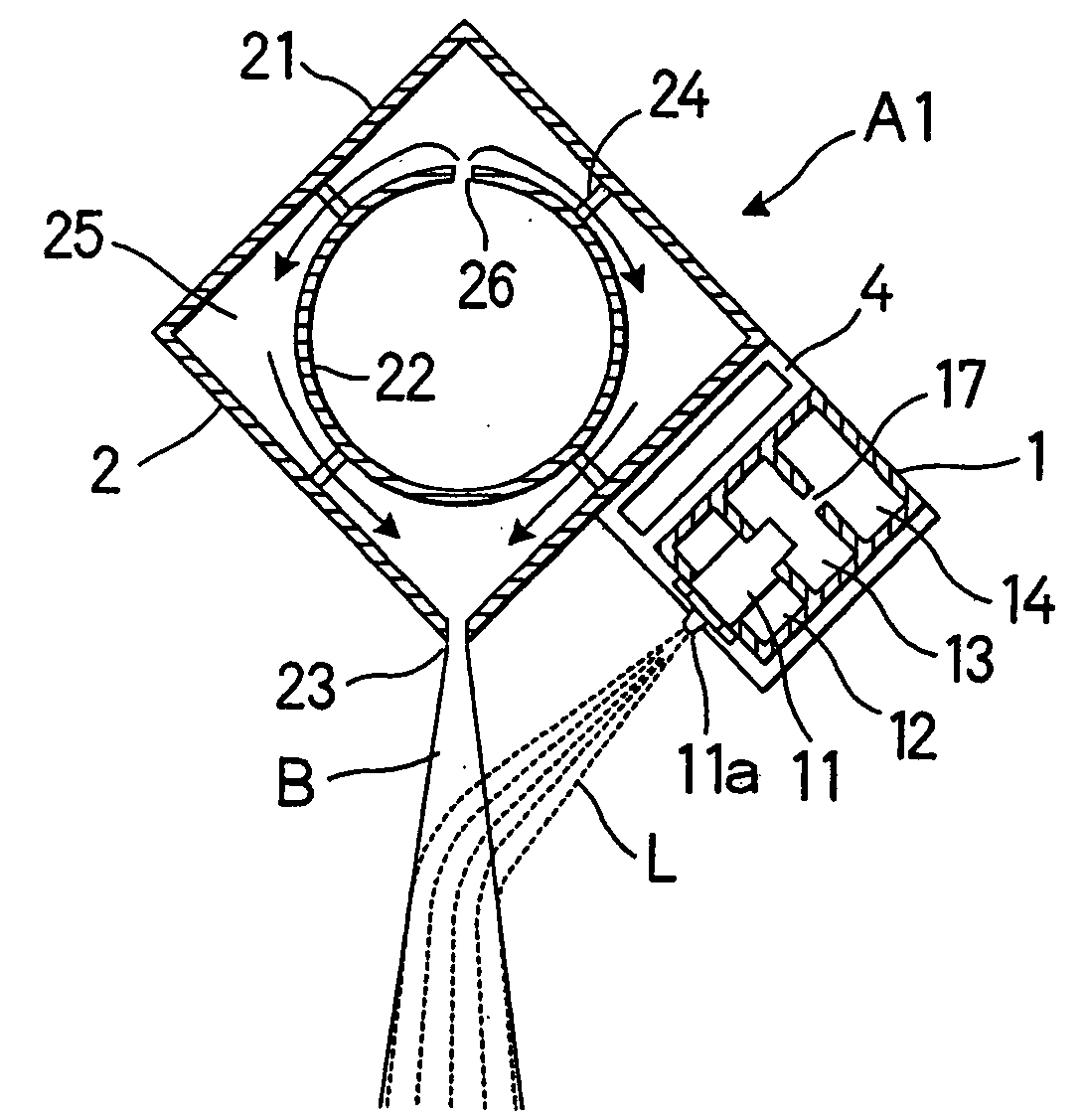

Apparatus and method for manufacture of paper and cardboards

InactiveCN102965996AHigh speedIncrease humidityWater-repelling agents additionPaper/cardboardCardboardSpray nozzle

The invention provides an apparatus for manufacture of paper and cardboards. The apparatus comprises a spray application plant (10) comprising spray nozzles (4, 5) for spraying an adhesive composition to at least one surface of a trajectory (6) and a press nip (3) for pressing the trajectory after the spraying of the adhesive composition, where the press nip is formed by two mutually resilient rotatable press elements (1, 2). The apparatus also comprises a first drying plant (20) before the spray application plant (10) for drying the trajectory, before spray application. The arrangement before the spray application plant (10) comprises a humidifying plant (11, 12), in which the trajectory (6) is configured before the spray application to profile with moisture, and when the inlet moisture of the trajectory before the spray application plant is 15%, the humidifying plant configured the trajectory on the intake moisture of 15-50% before the spray application to moisturize. The invention also relates to a method for manufacture of the paper and cardboards.

Owner:VALMET TECH OY

Liquid spray unit, method for spraying liquid using it, and chemical

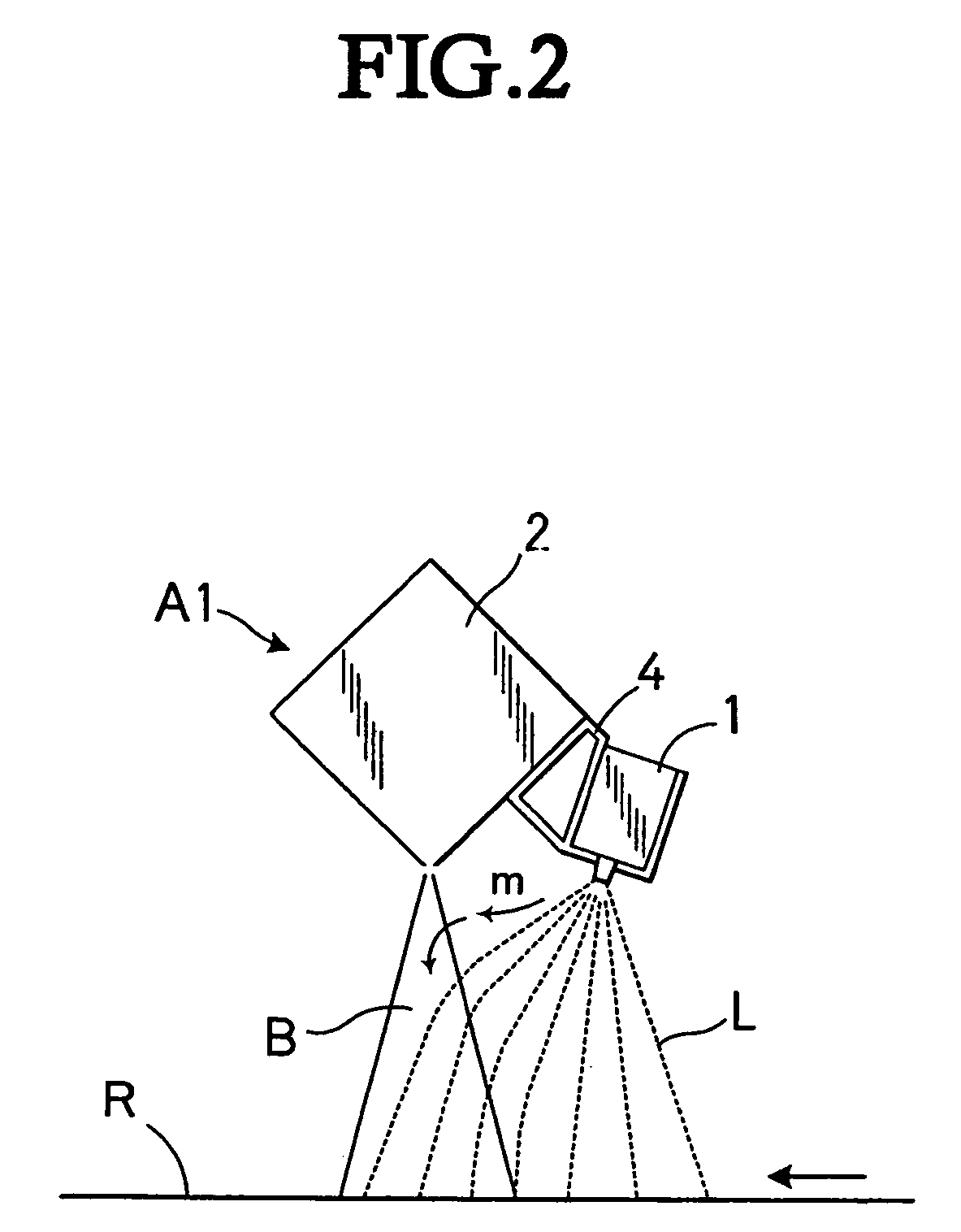

InactiveUS20060086827A1Effectively spray the liquidWater-repelling agents additionSpray nozzlesCompound (substance)Spray nozzle

A liquid spray unit which can impart liquid (treating liquid, medicine, or the like) surely to a traveling body even in a high speed paper making machine. The liquid spray unit for spraying liquid to a traveling body comprises a spray tube provided with a nozzle for spraying liquid, and an air box provided with an opening for jetting an air flow, wherein the spray tube and the air box are arranged such that the air flow is jetted from the air jet opening toward the liquid sprayed from the spray nozzle and the sprayed liquid can be blown to the traveling body after being accelerated by the air flow. The liquid can be sprayed more effectively to the traveling body by making compact the unit depending on the quantity of liquid being imparted or the inner space of a paper making machine, or the like, or by employing a unit of a type of reciprocating a single nozzle.

Owner:MAINTECH

Making method for glassine paper

InactiveCN104947511AImprove penetration resistanceImprove smoothnessSpecial paperCalendersPulp and paper industryMachining system

The invention relates to field of paper making technology, and provides a making method for glassine paper. The tension between surface molecules of the glassine paper is high, and the glassine paper is good in oil resistance. The method includes the following steps: 1, body paper making; 2, coating and wetting, wherein a wetting machine is adopted for moisture adjustment, a heating device is installed in a wetting machine system, hot water is adopted for wetting, the temperature of the hot water is controlled within 30 DEG C-90 DEG C, the moisture content of the paper is controlled, and wetting is stopped when the moisture content of the paper reaches 20%-21%; 3, storage; 4, excessive calendaring, wherein a calender is adopted for calendaring, at least three calendaring areas are arranged on the calender, the pressure is 1000 KN / m<2>-1200 KN / m<2>, and the temperature is 180 DEG C-220 DEG C; 5, storage heat dissipation; 6, rewinding; 7, packaging and warehousing.

Owner:福建省晋江优兰发纸业有限公司

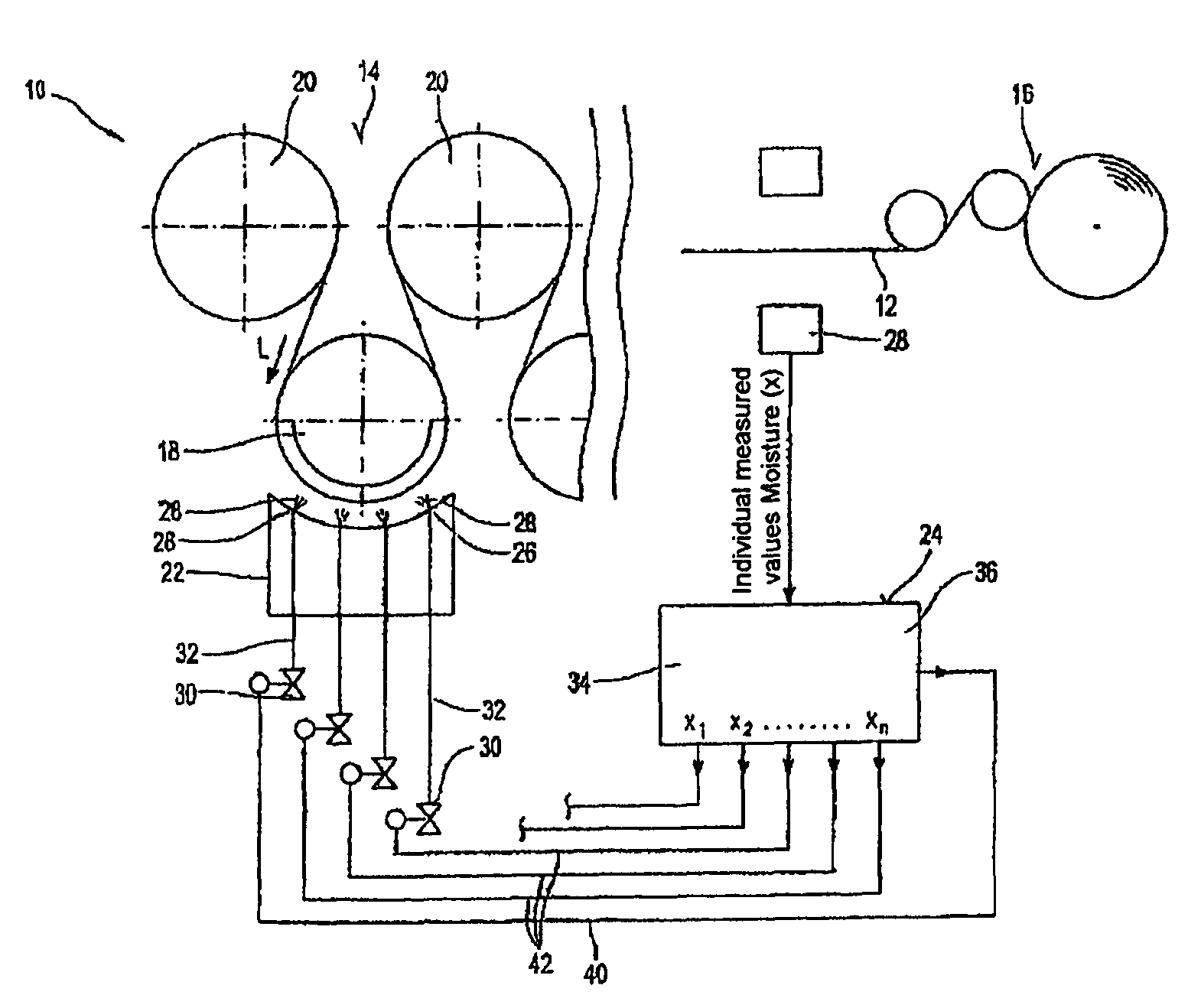

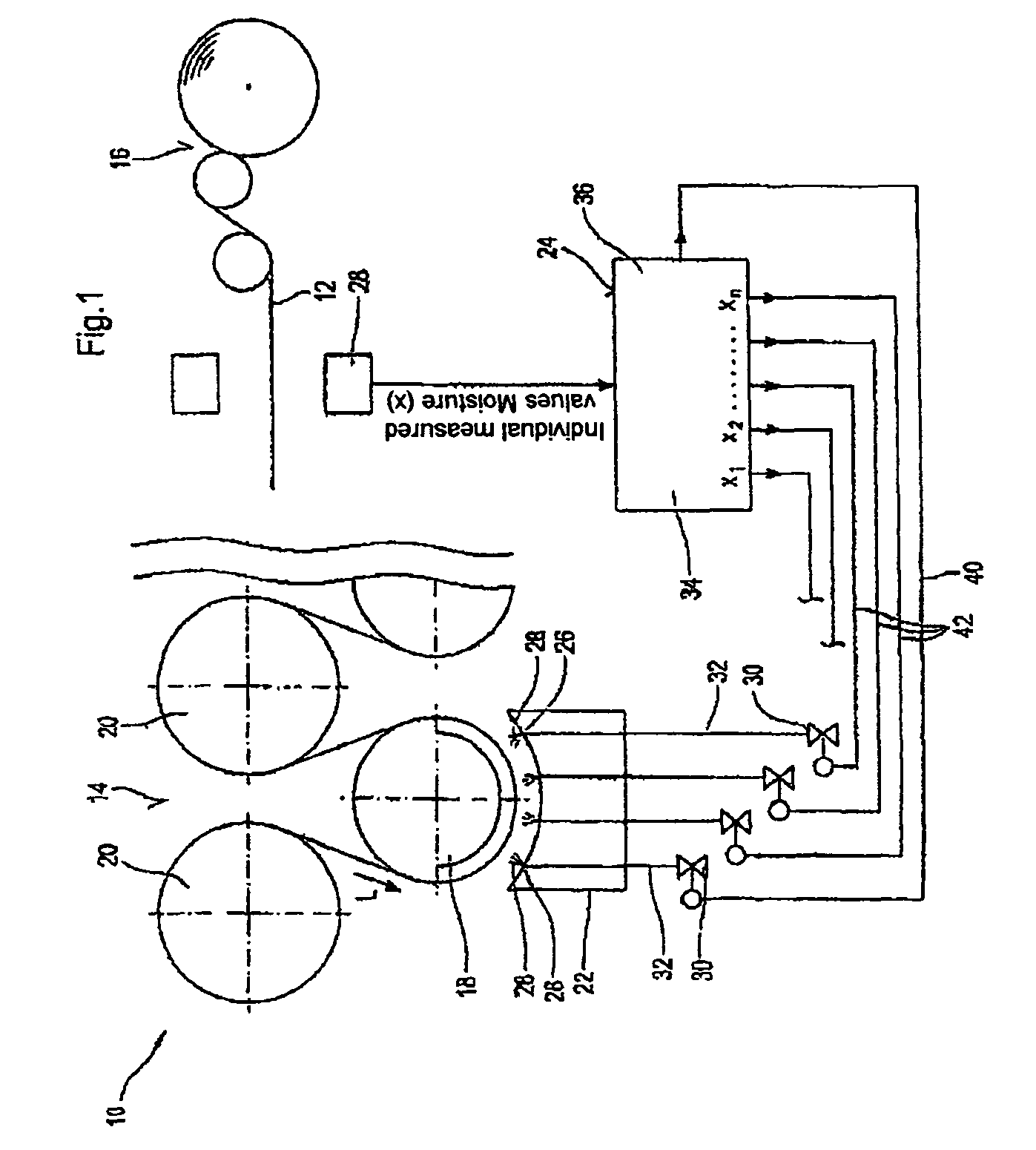

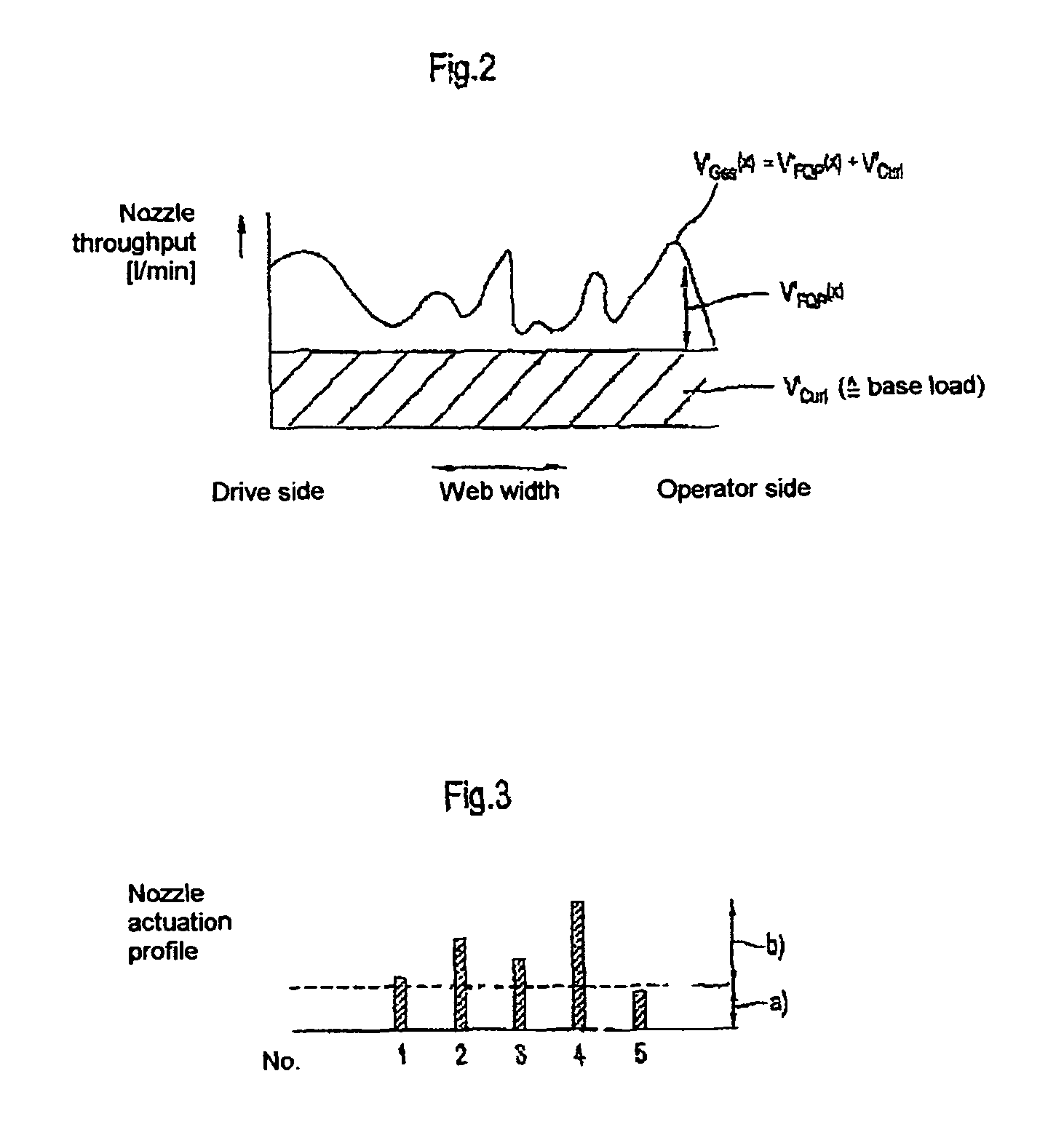

Equipment and method for producing and/or treating a fibrous web

InactiveUS8261465B2Improve flatnessFine surfaceLiquid surface applicatorsDryer sectionEngineeringUnit structure

Device and process for producing and treating a fibrous web. The device includes a moistening unit structured and arranged to simultaneously influence a cross machine moisture profile of the web and the curl of the web independently of each other. The instant abstract is neither intended to define the invention disclosed in this specification nor intended to limit the scope of the invention in any way.

Owner:VOITH PATENT GMBH

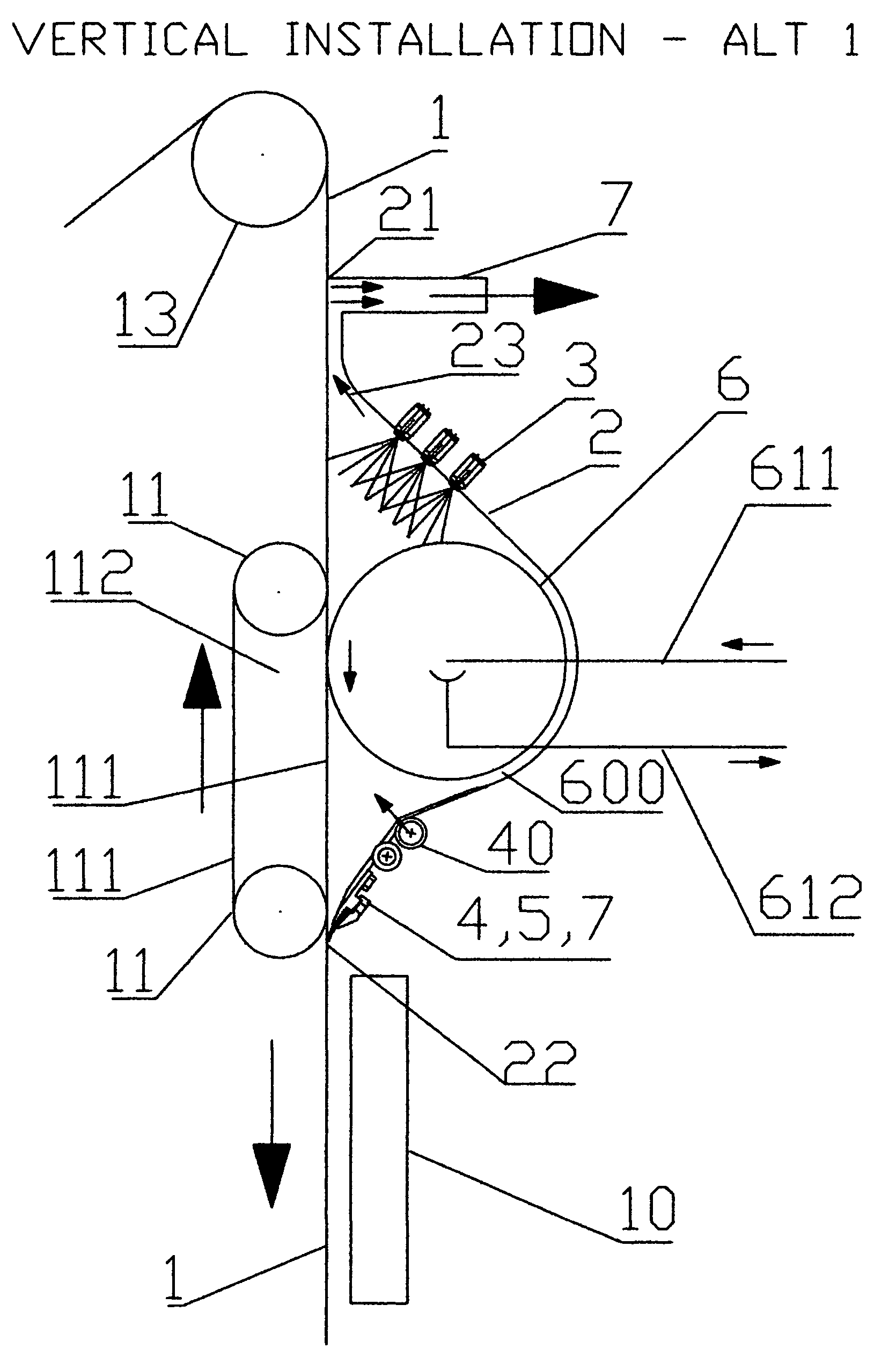

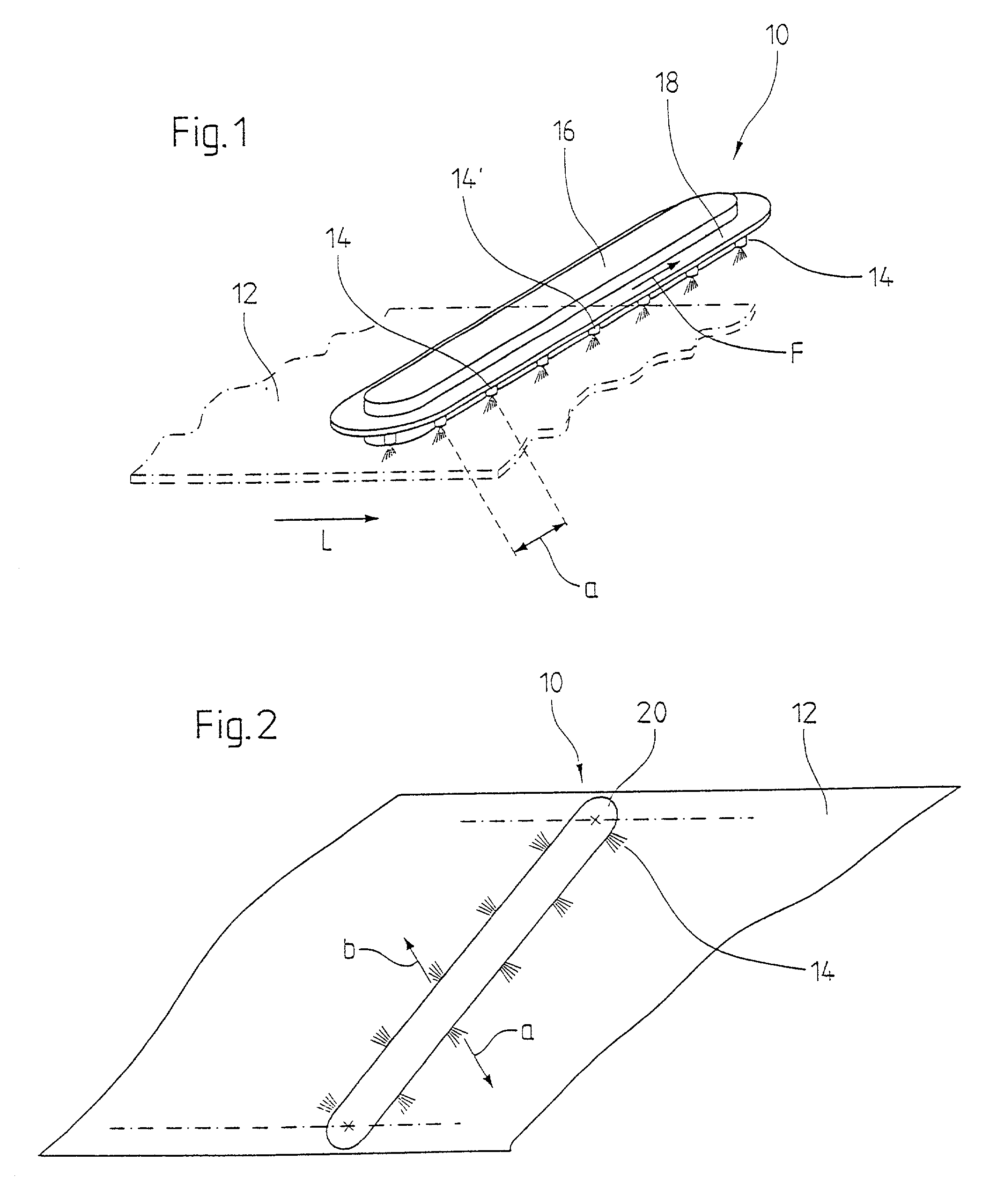

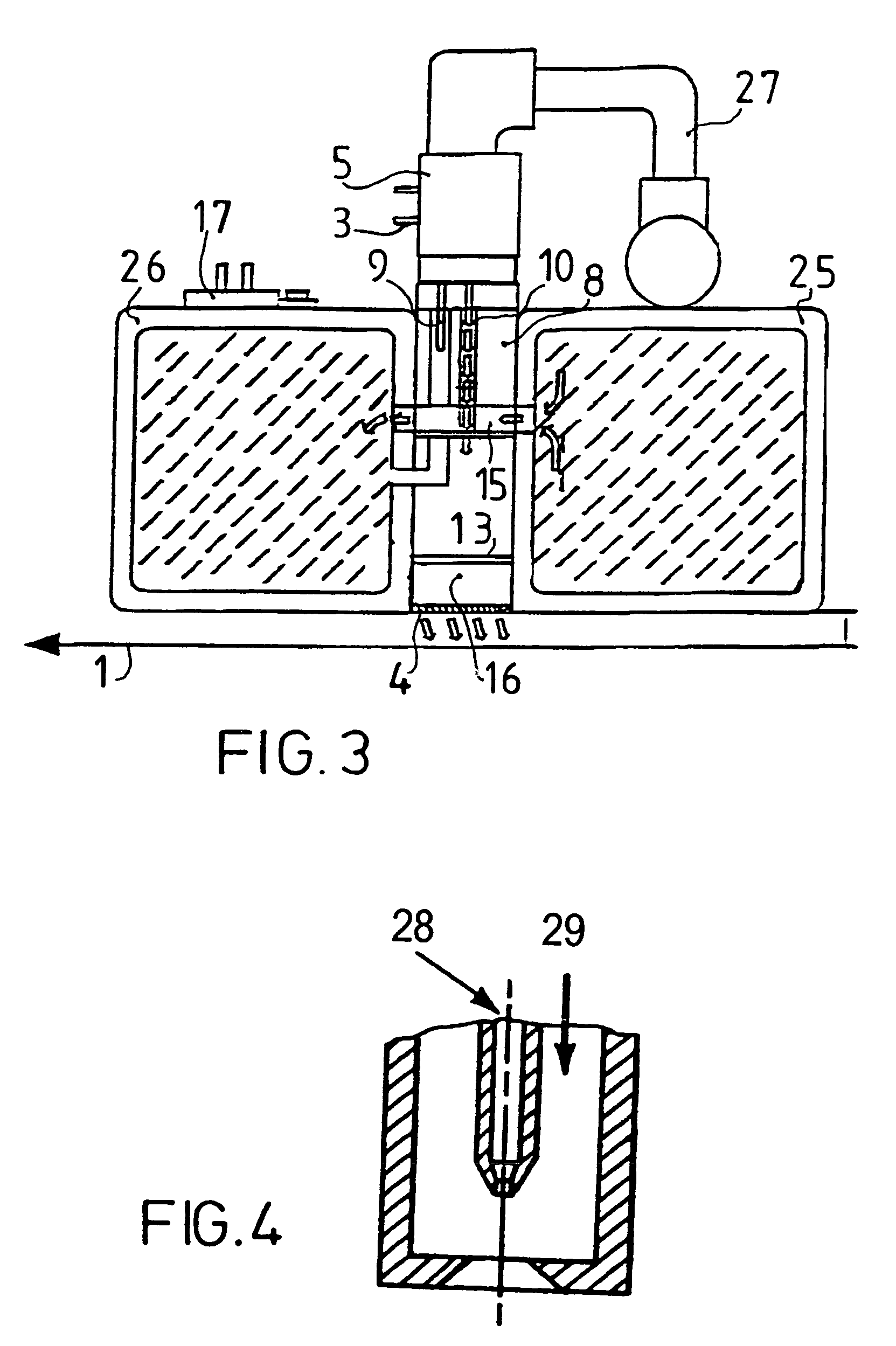

Method and assembly for moistening a moving web or paperboard

InactiveUS7429311B2Reduce surface tensionLow viscosityDryer sectionSpray nozzlesPaperboardEngineering

A method and assembly is disclosed for moistening a web of paper or paperboard, the assembly comprising a steam blow cavity open toward a moving web (1). The steam blow cavity houses spray nozzles (5, 6, 7) at least for injecting steam into the cavity so as to form a steam atmosphere therein. Additionally, the steam blow cavity houses spray nozzles (5, 6, 7) for spraying a mist of a heated liquid onto the web (1) within the thus formed steam atmosphere.

Owner:VALMET TECH INC

Moistening nozzle of a paper web

Owner:METSO AUTOMATION OY

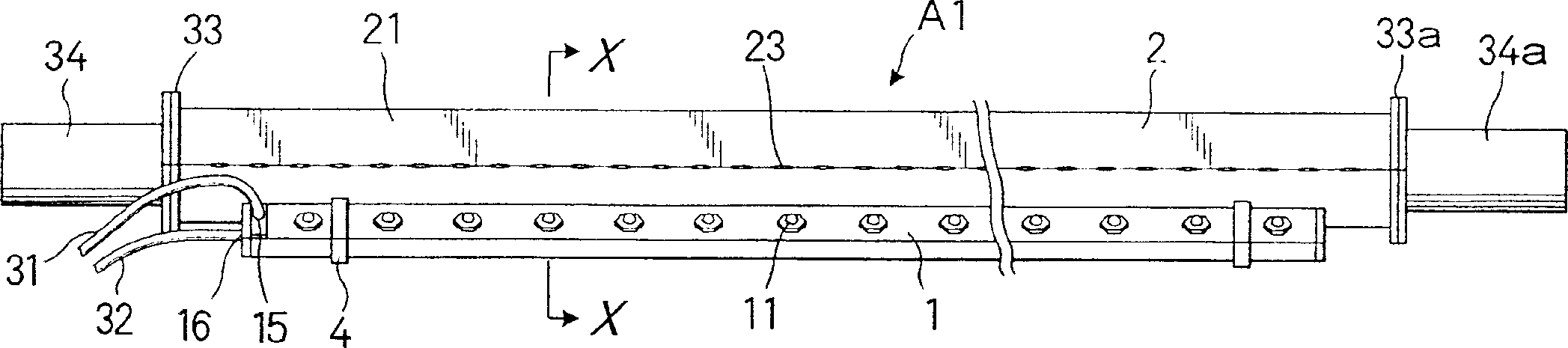

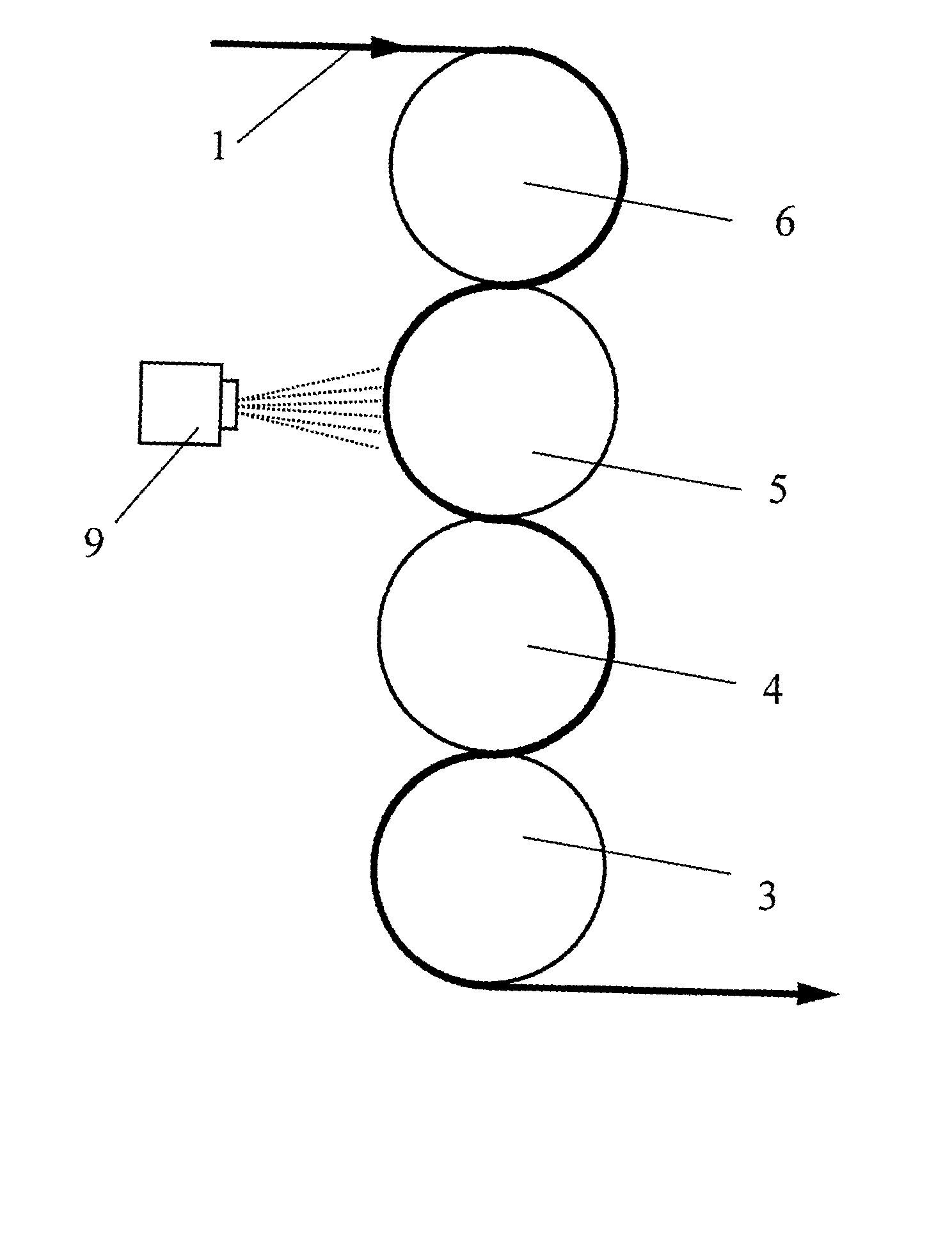

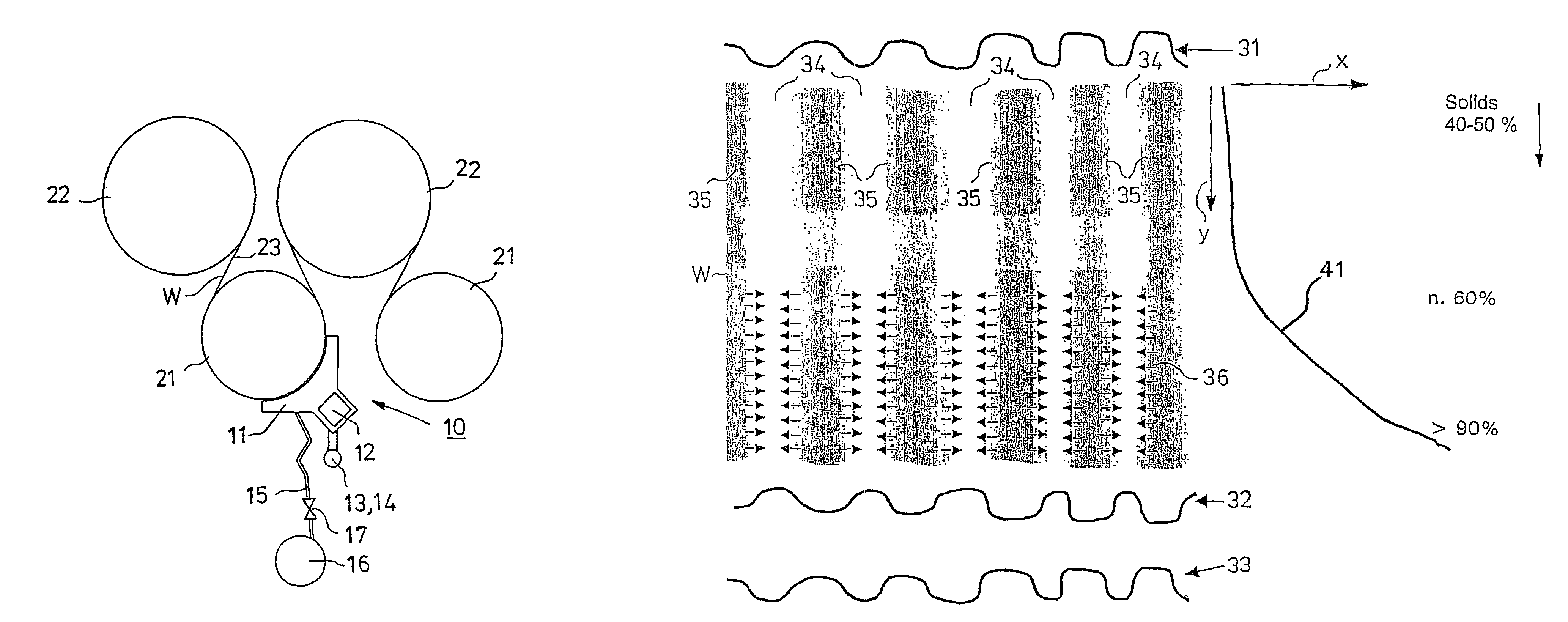

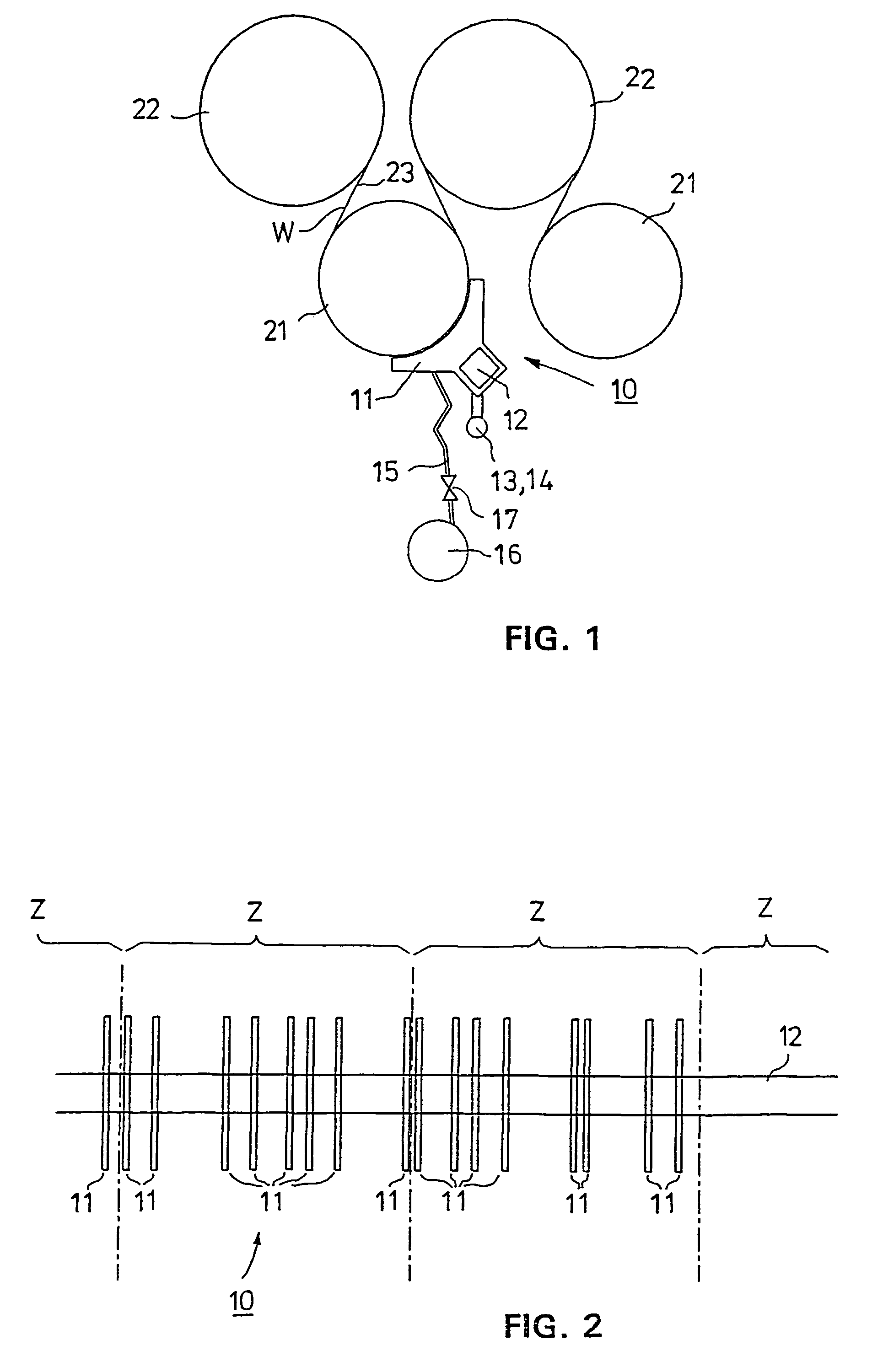

Method and device for controlling the moisture or coating quantity profile in a paper web

InactiveUS7249424B2Eliminating the undesired phenomenonDrying solid materials with heatDrying machines with progressive movementsEngineeringMoisture

The narrow-scale moisture profile of a paper web is controlled by profiling nozzles (11) of a profiling device (10) which cover part of the width of the web and desired variations of the moisture profile are corrected by the profiling nozzles (11). Coating quantity profile of a paper web may also be controlled. The narrow-scale coating quantity profile is controlled by profiling nozzles (11) of a profiling device (10) which cover part of the width of the web and desired variations of the coating quantity profile are corrected by the profiling nozzles (11). The device (10) for controlling the moisture profile or the coating quantity profile of a paper web has profiling nozzles (11) for controlling narrow-scale moisture profile variation, which cover a desired part of the width of the web, to correct desired variations occurring in the profile in the width direction of the web.

Owner:VALMET TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com