Steam box and method for preventing condensate water from dripping

A steam box and condensed water technology, applied in the field of pulp and paper making, can solve the problems of complex equipment and high cost, and achieve the effects of reducing equipment costs, low manufacturing and maintenance costs, and preventing condensed water from dripping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

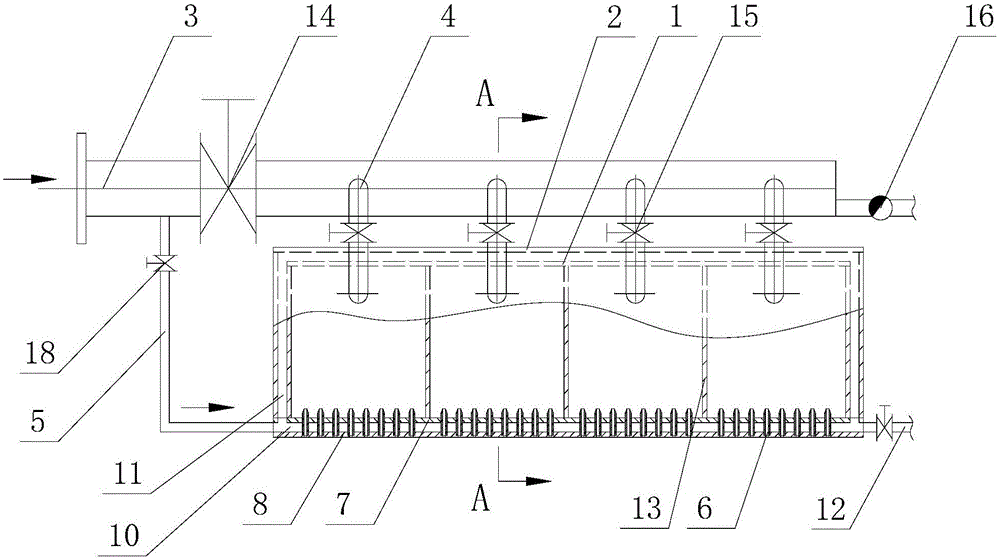

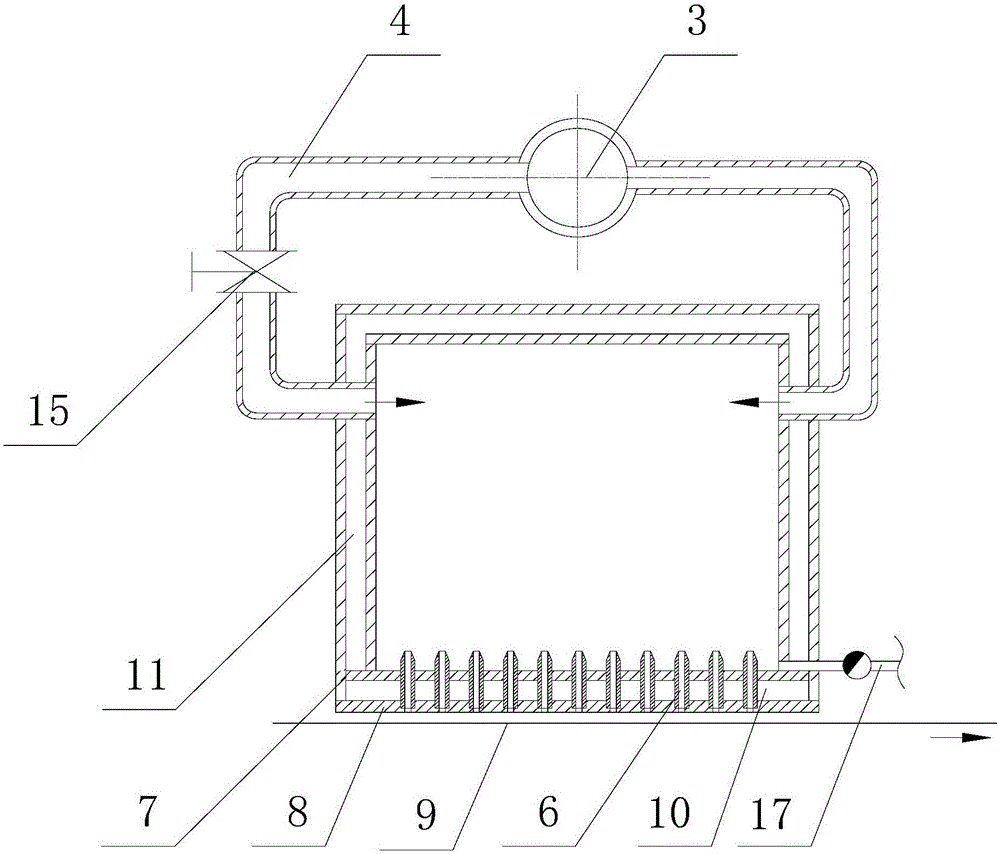

[0039] In this embodiment, a steam box that prevents condensed water from dripping, such as figure 1 or figure 2 As shown, it includes steam box 1, preheating box 2, steam main pipe 3, steam branch pipe 4 and preheating branch pipe 5. The preheating box is set on the periphery of the steam box, and A preheating compartment is formed, steam inlets are respectively provided on the opposite side walls of the steam box, the steam main pipe is connected to each steam inlet through a steam branch pipe, and the steam main pipe is connected to the preheating partition through a preheating branch pipe.

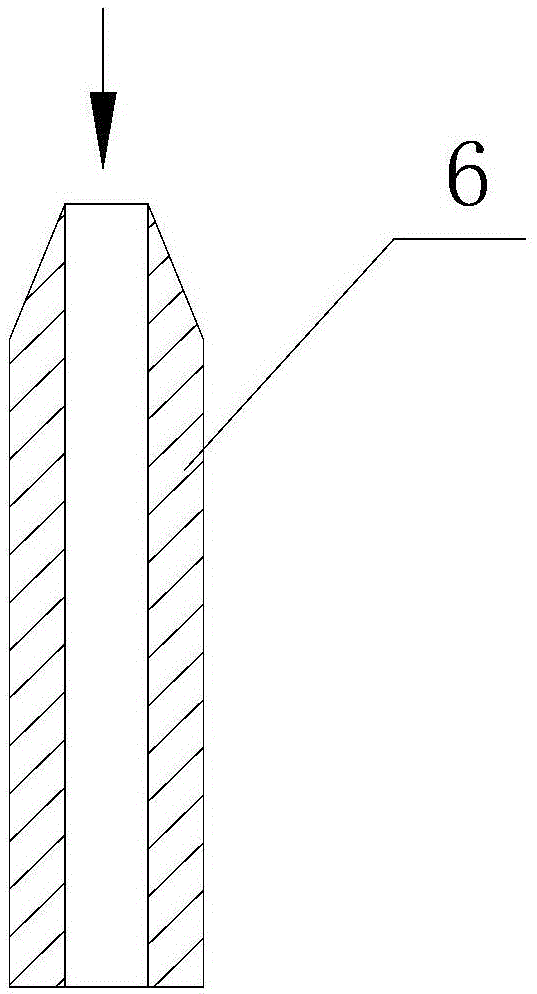

[0040] A plurality of steam injection pipes 6 are distributed at the bottom of the steam box. The upper end of the steam injection pipes is higher than the inner surface of the bottom of the steam box, which can prevent the condensed water that may form in the steam box from falling into the steam injection pipes and spraying on the surface of the paper. like image 3 As shown, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com