Steam device and method for adjusting moisture of paper sheet by using vacuum degree

A vacuum and steam technology, applied in the wetting device, paper making, paper machine and other directions, can solve the problems of increasing investment and maintenance costs, increasing control complexity, etc., to improve utilization efficiency, improve paper quality, reduce equipment investment and The effect of the cost of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

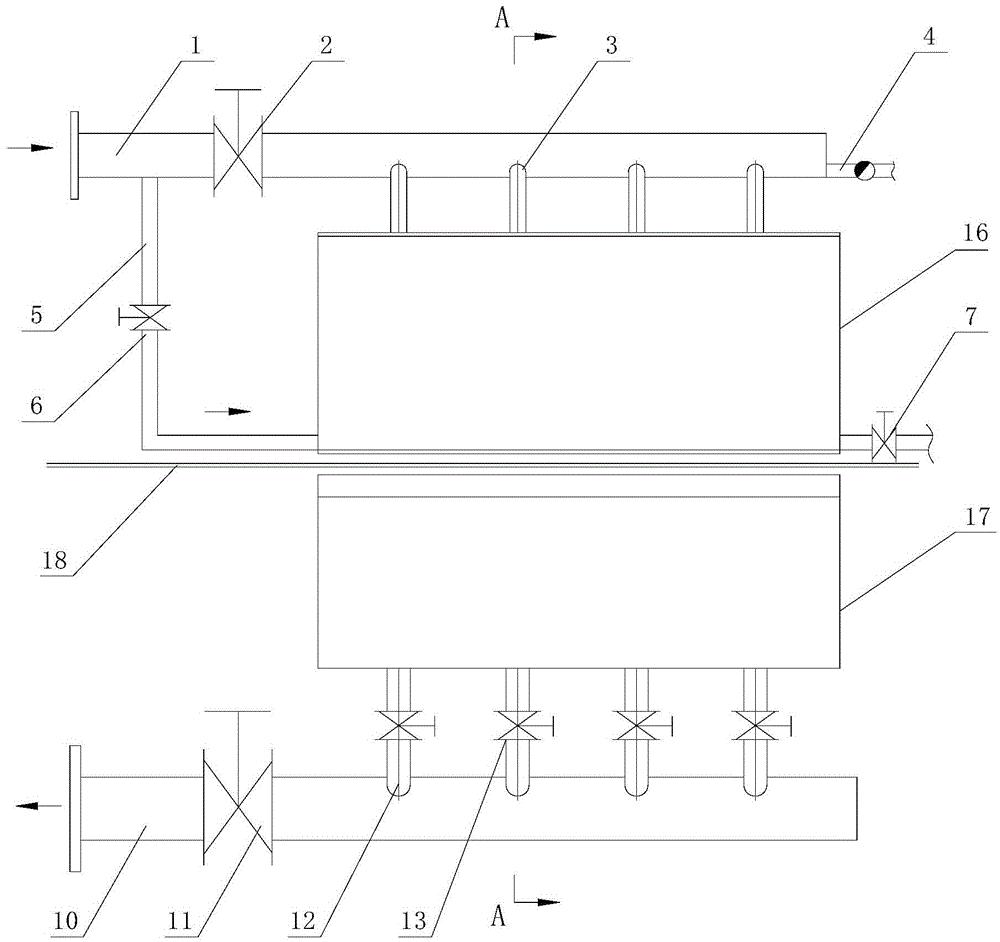

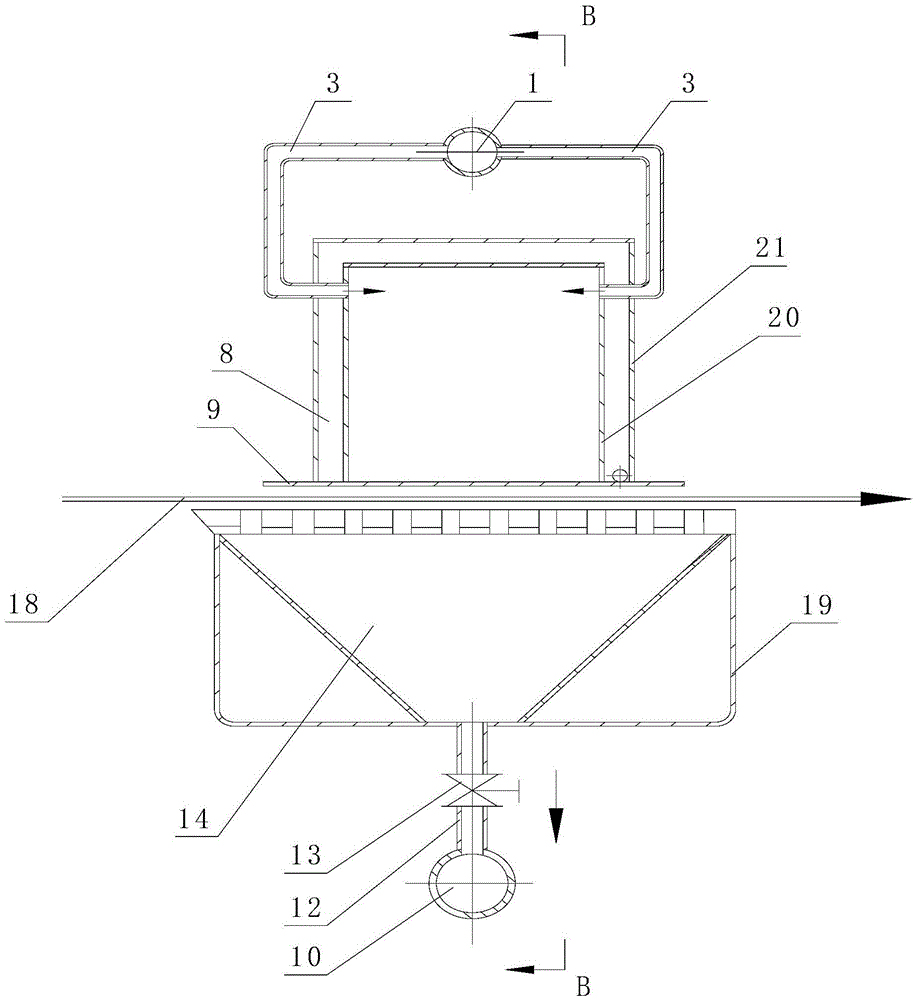

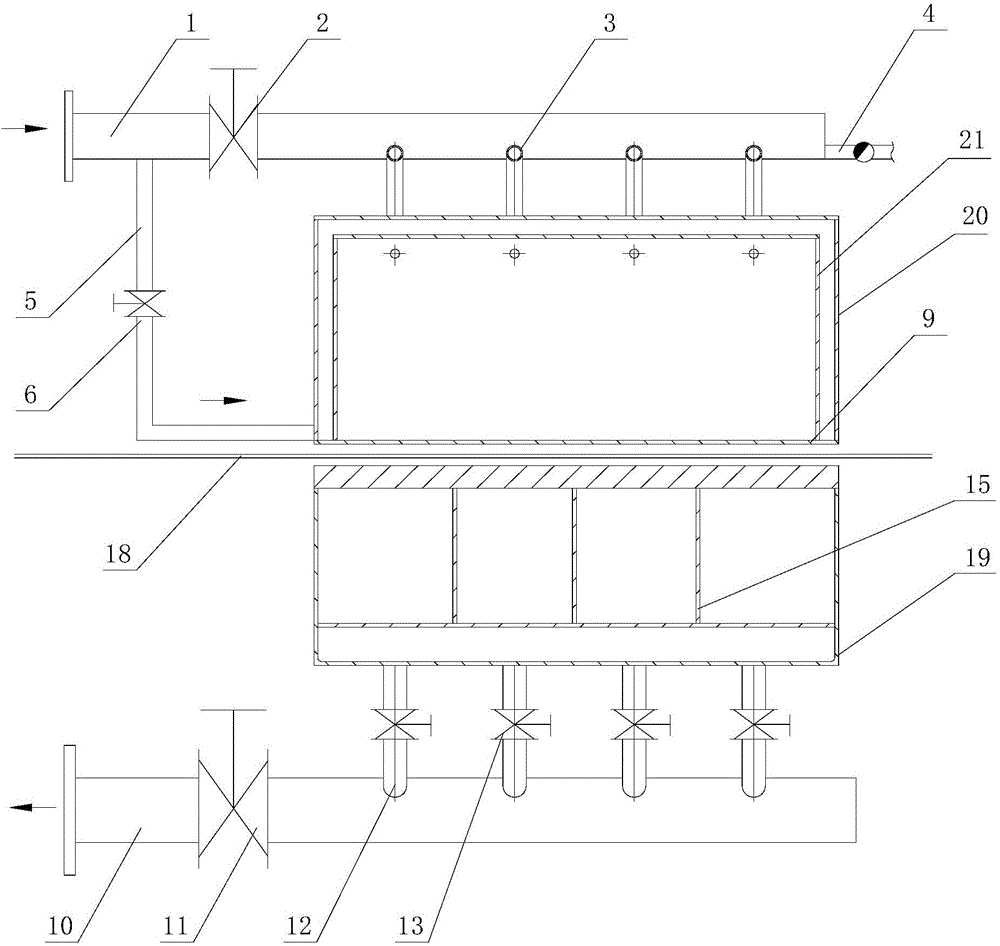

[0035] In this embodiment, a steam device that utilizes vacuum to regulate paper moisture, such as figure 1 , figure 2 or image 3 As shown, it includes a paired steam box 16 and a vacuum box 17, the steam box is arranged above the wet paper page 18, and the vacuum box is arranged below the wet paper page; the bottom surface of the steam box is the steam injection area, and the top surface of the vacuum box is the suction area , the area of the air extraction area is larger than the area of the steam injection area.

[0036] The vacuum box includes a vacuum main pipe 10, a vacuum branch pipe 12 and a vacuum box body 19, the vacuum main pipe is connected with the vacuum box body through a plurality of vacuum branch pipes, and the inside of the vacuum box body is a vacuum area. A plurality of partitions are arranged inside the vacuum box, and the plurality of partitions divide the vacuum area into a plurality of independent vacuum chambers 14 . The vacuum area is divided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com