Steam device of supercalender and paper sheet moisture regulation method therefor

A super calender, steam technology, applied in calenders, wetting devices, papermaking, etc., can solve the problems of inaccurate temperature control of exhaust air, reducing the effect of steam humidification, and difficulty in achieving ideal results, and achieve lower temperature. , Simple structure, easy to control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

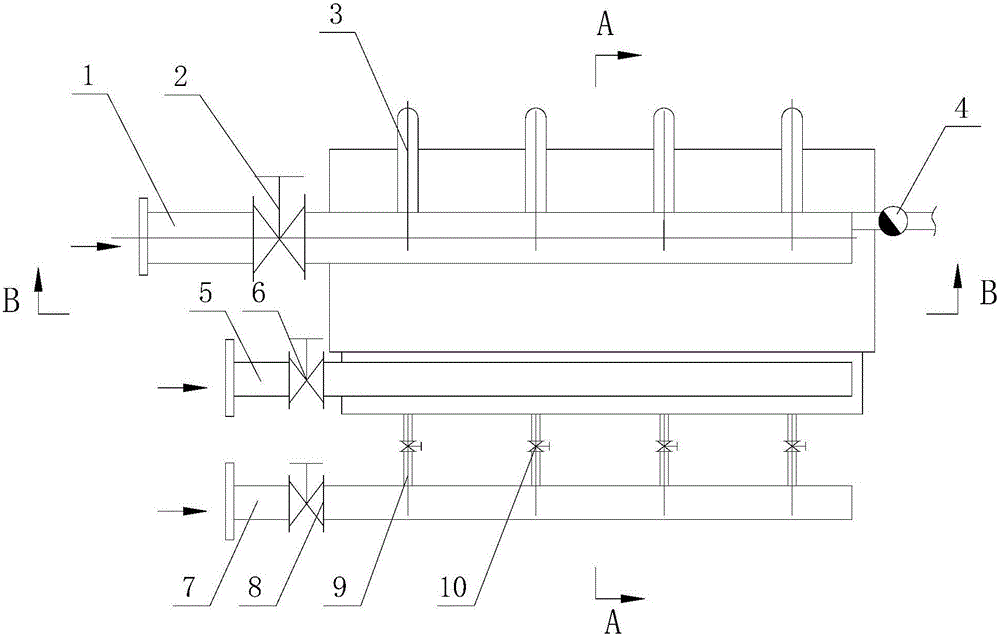

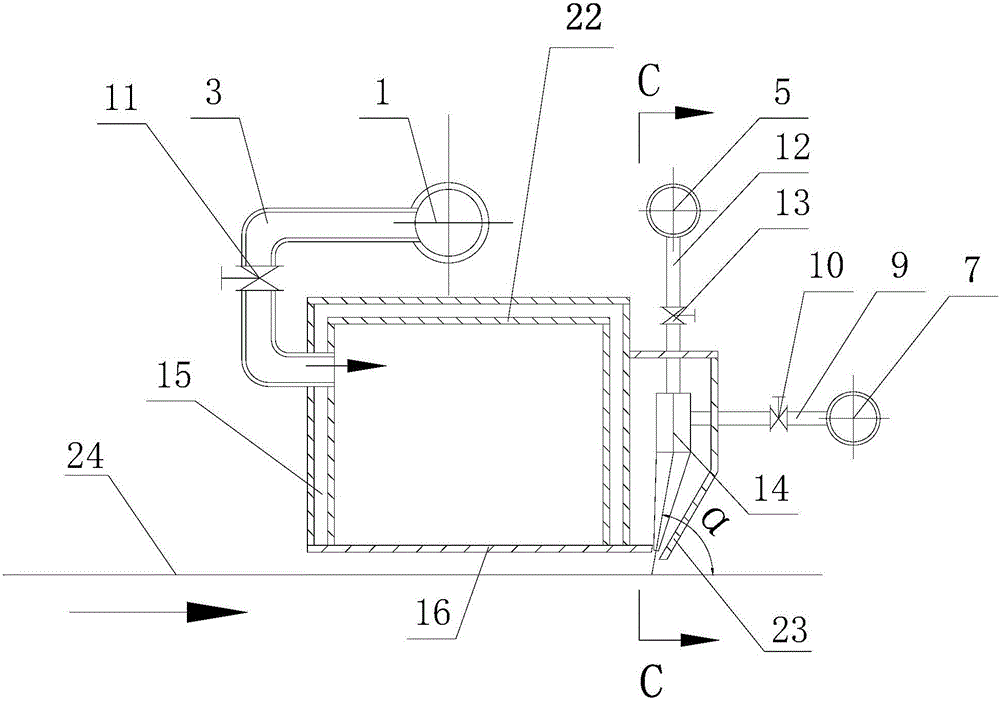

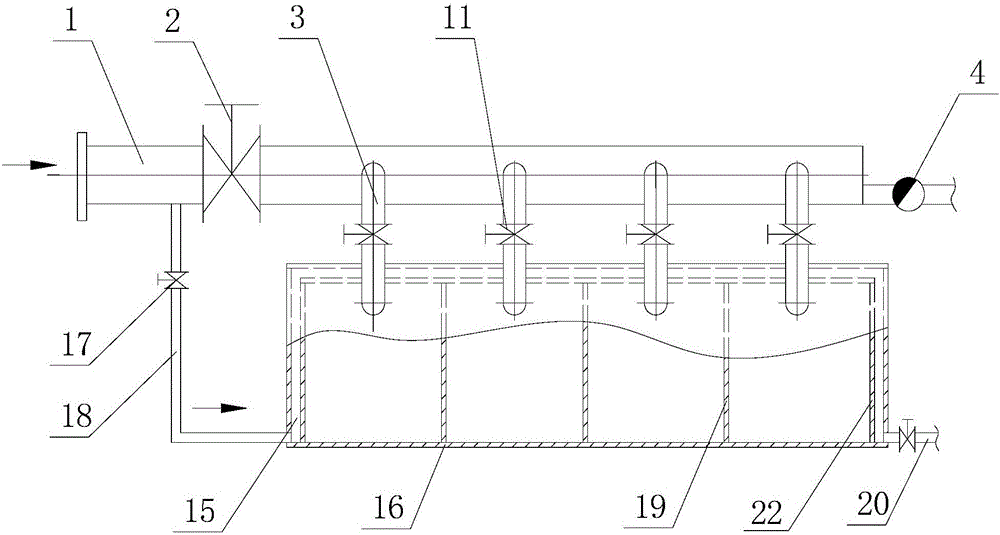

[0037] A kind of super calender steam device of present embodiment, as figure 1 or figure 2 As shown, it includes steam main pipe 1, steam branch pipe 3, compressed air main pipe 5, compressed air branch pipe 12, low-pressure water main pipe 7, low-pressure water branch pipe 9, steam box 22, spray box 23 and air atomizer 14, along the conveying of paper Direction, the steam box and the spray box are set in sequence, the air atomizer is set in the spray box, the steam main pipe is connected to the steam box through the steam branch pipe, the compressed air main pipe is connected to the air atomizer through the compressed air branch pipe, and the low-pressure water main pipe is connected to the low-pressure water main pipe. The branch pipe is connected with the air atomizer; a steam area is formed in the steam box, and a spray area is formed in the spray box. Among them, the combination of spraying steam and spray is used to control the humidity and temperature of the paper en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com