Steam type highlight and traceless injection-molding and forming process for complex precise product

An injection molding process, high-gloss and non-marking technology, applied in coating and other directions, can solve the problems of affecting product surface quality, difficult to obtain quality effect, low molding yield rate, etc., to save energy and materials, reduce various defects, eliminate The effect of flow marks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

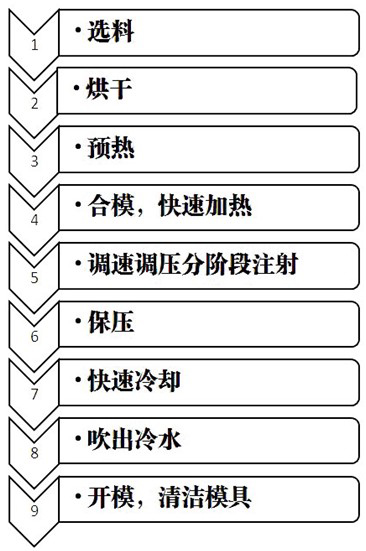

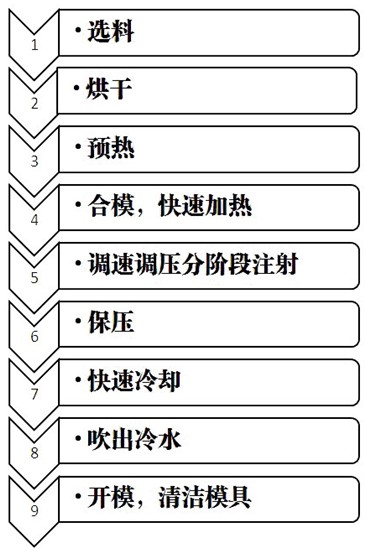

Method used

Image

Examples

Embodiment 1

[0032] 1) Use PMMA material as the injection material;

[0033] 2) Place the injection material in a vacuum drying oven and dry at 90°C for 2 hours to make the humidity less than 0.04%;

[0034] 3) Before starting injection molding, fix the mold on the injection molding machine, and preheat the mold before closing the mold. The preheating temperature is 80°C;

[0035] 4) When closing the mold, the high-temperature steam with a temperature of 160°C and a pressure of 0.2MPa passes through the optimized irregular water channel to instantly heat the mold to 110°C;

[0036] 5) After the mold clamping is completed, the injection machine injects the mold. When injecting, the injection pressure is divided into three injection pressure controls, namely 75% of the highest injection pressure, 50% of the highest injection pressure and 50% of the highest injection pressure. The injection stroke of the screw is divided into 3 stages. When the plastic first passes through the gate, the inje...

Embodiment 2

[0040] 1) PC / ABS material is selected as the injection material;

[0041] 2) Place the injection material in a vacuum drying oven at 110°C for 4 hours to make the humidity less than 0.04%;

[0042] 3) Before starting injection molding, fix the mold on the injection molding machine, and preheat the mold before closing the mold. The preheating temperature is 90°C;

[0043] 4) When closing the mold, the high-temperature steam with a temperature of 170°C and a pressure of 0.3MPa passes through the optimized irregular water channel to instantly heat the mold to 120°C;

[0044]5) After the mold clamping is completed, the injection machine injects the mold. During the injection, the injection pressure is divided into three injection pressure controls, namely 85% of the highest injection pressure, 60% of the highest injection pressure and 60% of the highest injection pressure, and the injection The injection stroke of the screw is divided into 3 stages. When the plastic first passes ...

Embodiment 3

[0048] 1) Select high-gloss ABS material as the injection material;

[0049] 2) Place the injection material in a vacuum drying oven and dry at 100°C for 3 hours to make the humidity less than 0.04%;

[0050] 3) Before starting injection molding, fix the mold on the injection molding machine, and preheat the mold before closing the mold. The preheating temperature is 85°C;

[0051] 4) When closing the mold, the high-temperature steam with a temperature of 150°C and a pressure of 0.25MPa passes through the optimized irregular water channel to instantly heat the mold to 115°C;

[0052] 5) After the mold clamping is completed, the injection machine injects the mold. During the injection, the injection pressure is divided into 3 times of injection pressure control, namely 80% of the highest injection pressure, 55% of the highest injection pressure and the highest injection pressure. The injection stroke of the screw is divided into 3 stages. When the plastic first passes through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com