Patents

Literature

481results about How to "Quick seal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

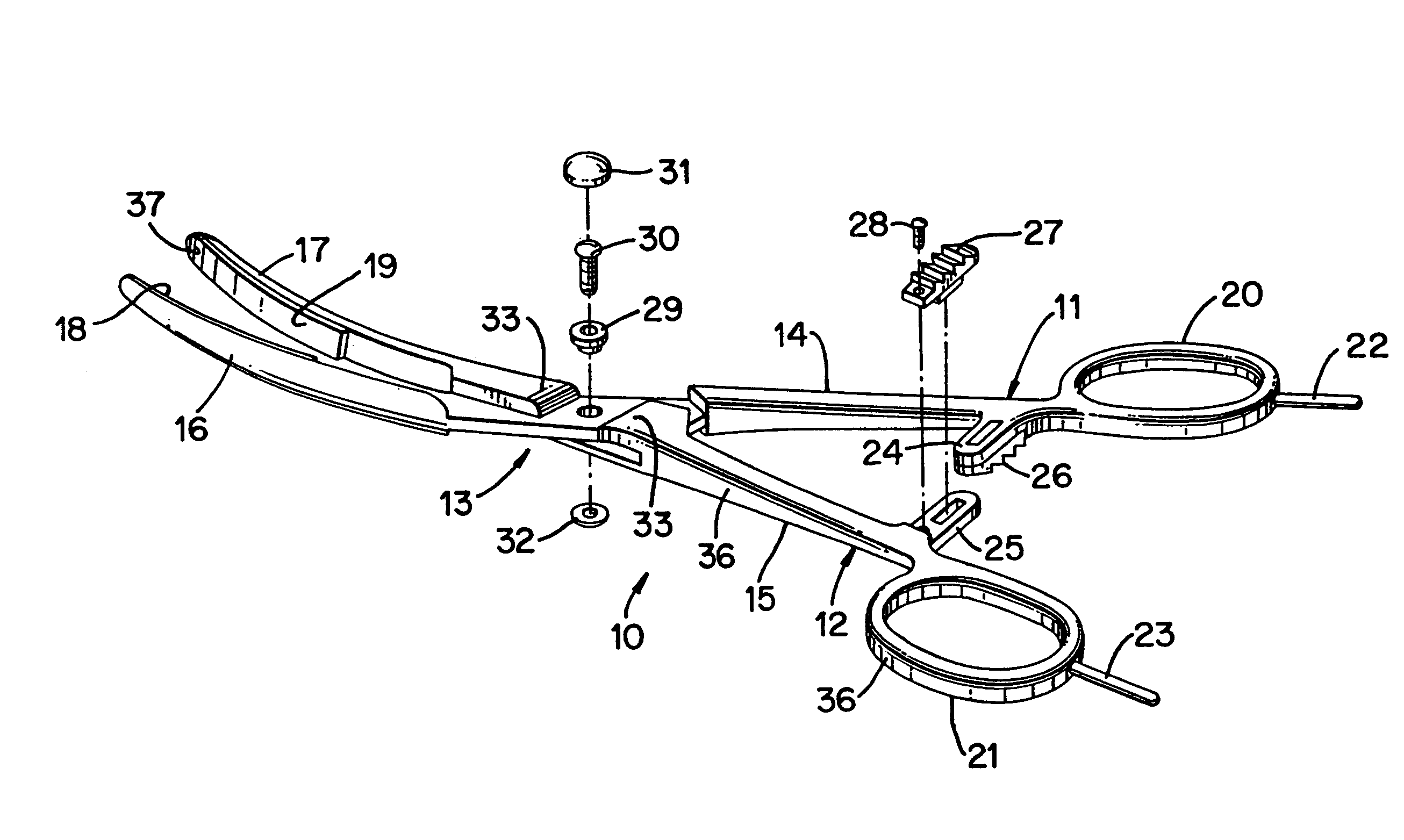

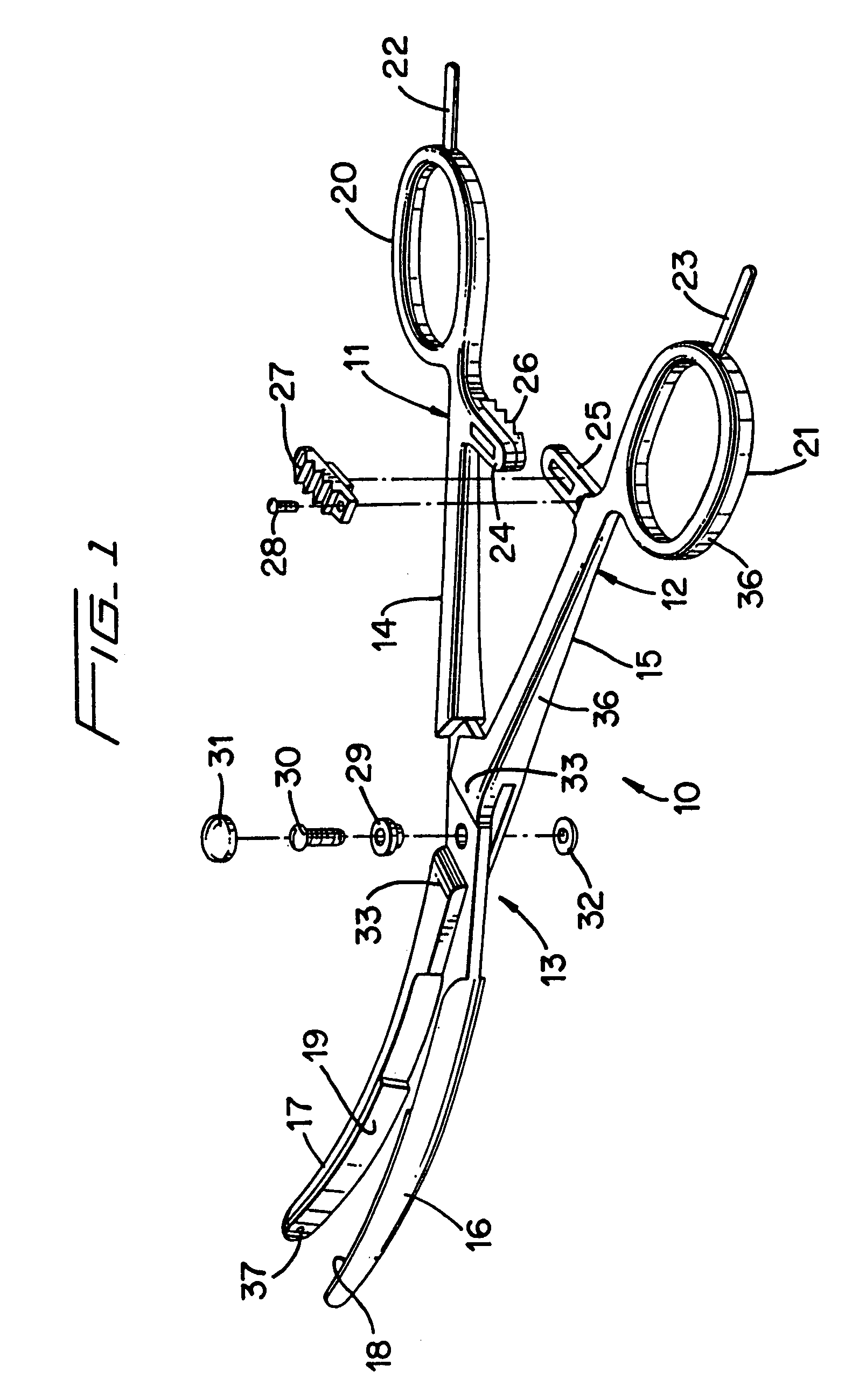

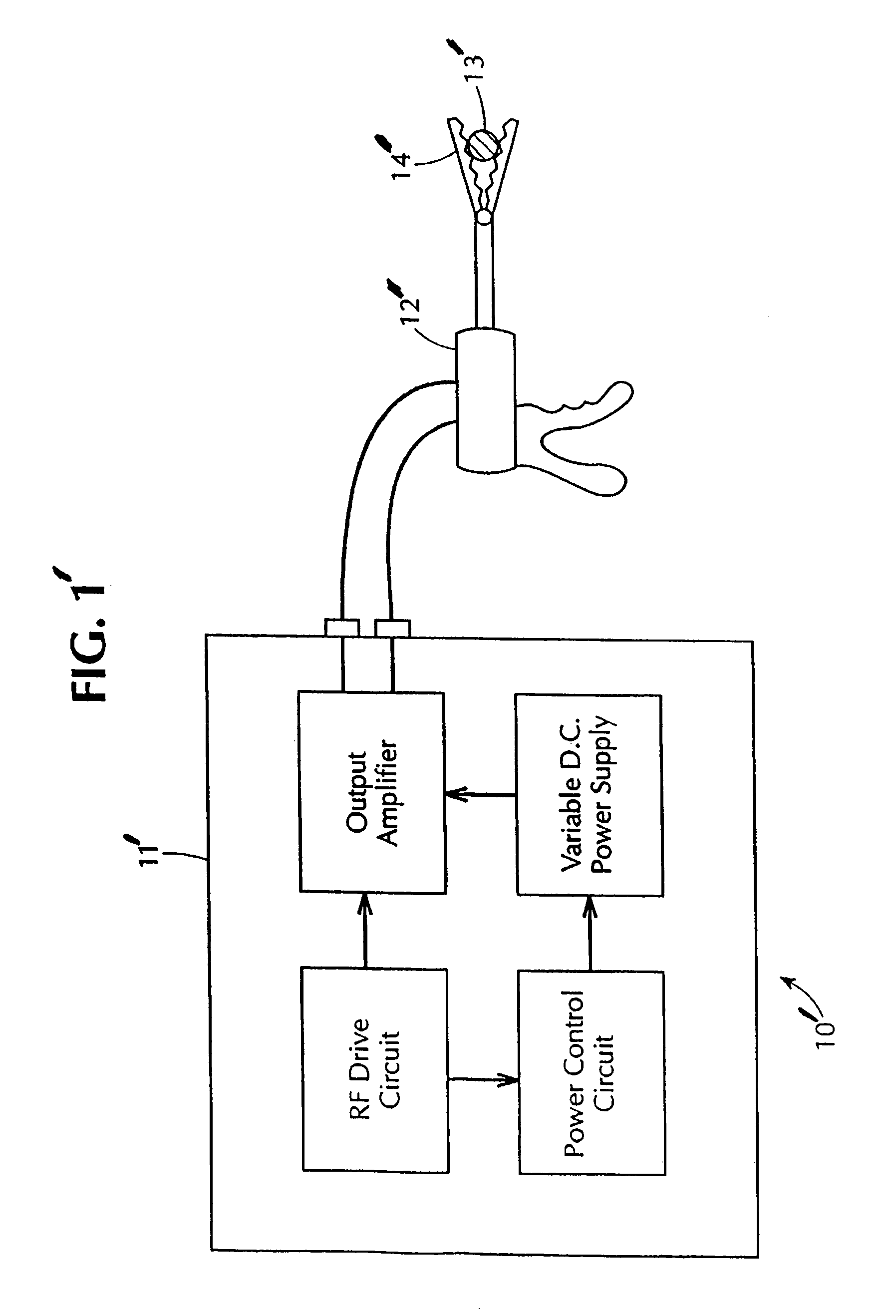

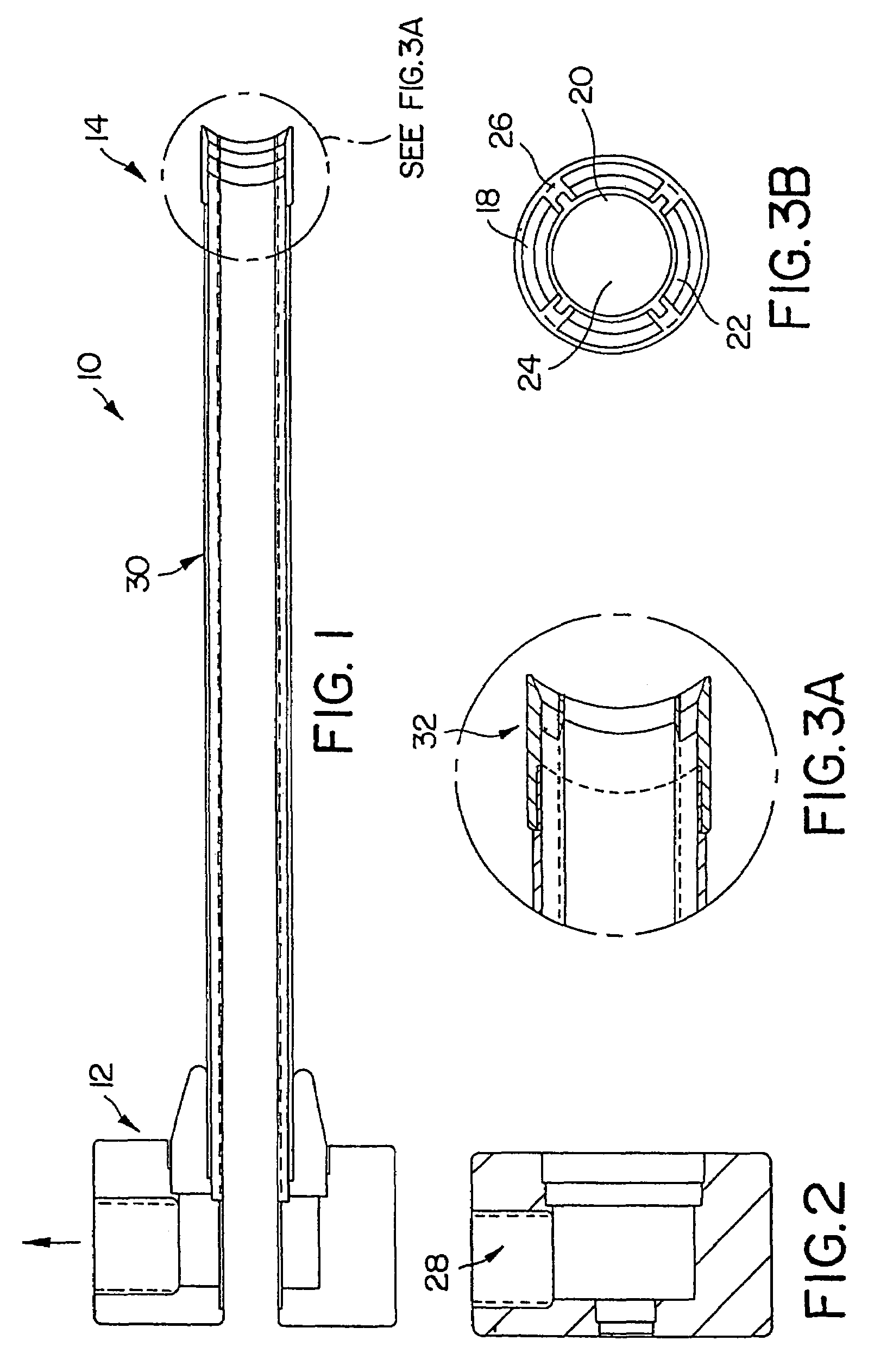

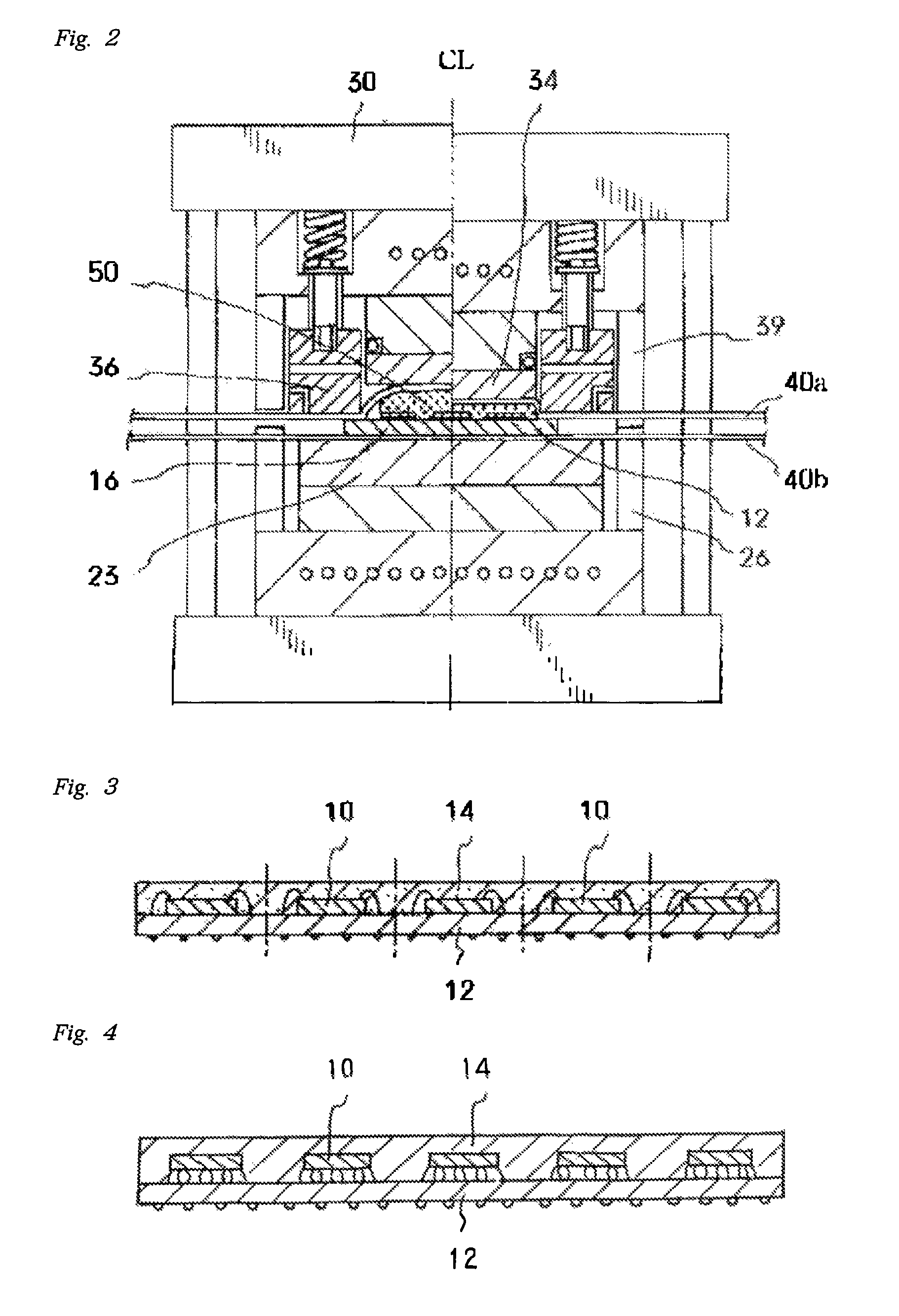

Bipolar electrosurgical instrument for sealing vessels

InactiveUS7179258B2Shorten the timeExpand accessSurgical instruments for heatingSurgical forcepsBipolar electrosurgeryVascular tissue

A bipolar electrosurgical instrument has opposable seal surfaces on its jaws for grasping and sealing vessels and vascular tissue. Inner and outer instrument members allow arcuate motion of the seal surfaces. An open lockbox provides a pivot with lateral support to maintain alignment of the lateral surfaces. Ratchets on the instrument members hold a constant closure force on the tissue during the seal process. A shank portion on each member is tuned to provide an appropriate spring force to hold the seal surfaces together. During surgery, the instrument can be used to grasp and clamp vascular tissue and apply bipolar electrosurgical current through the clamped tissue. In one embodiment, the seal surfaces are partially insulated to prevent a short circuit when the instrument jaws are closed together. In another embodiment, the seal surfaces are removably mounted on the jaws.

Owner:COVIDIEN AG

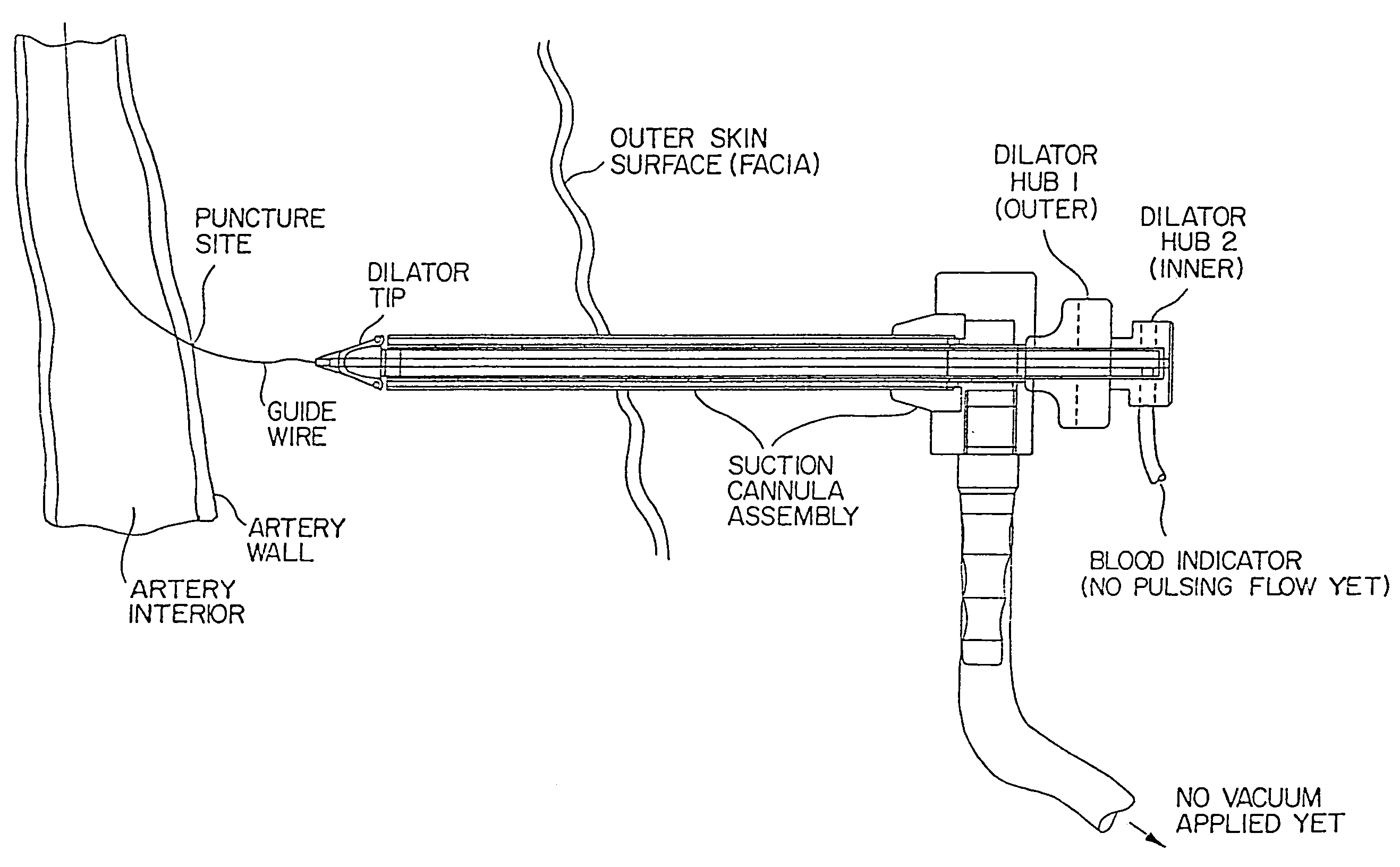

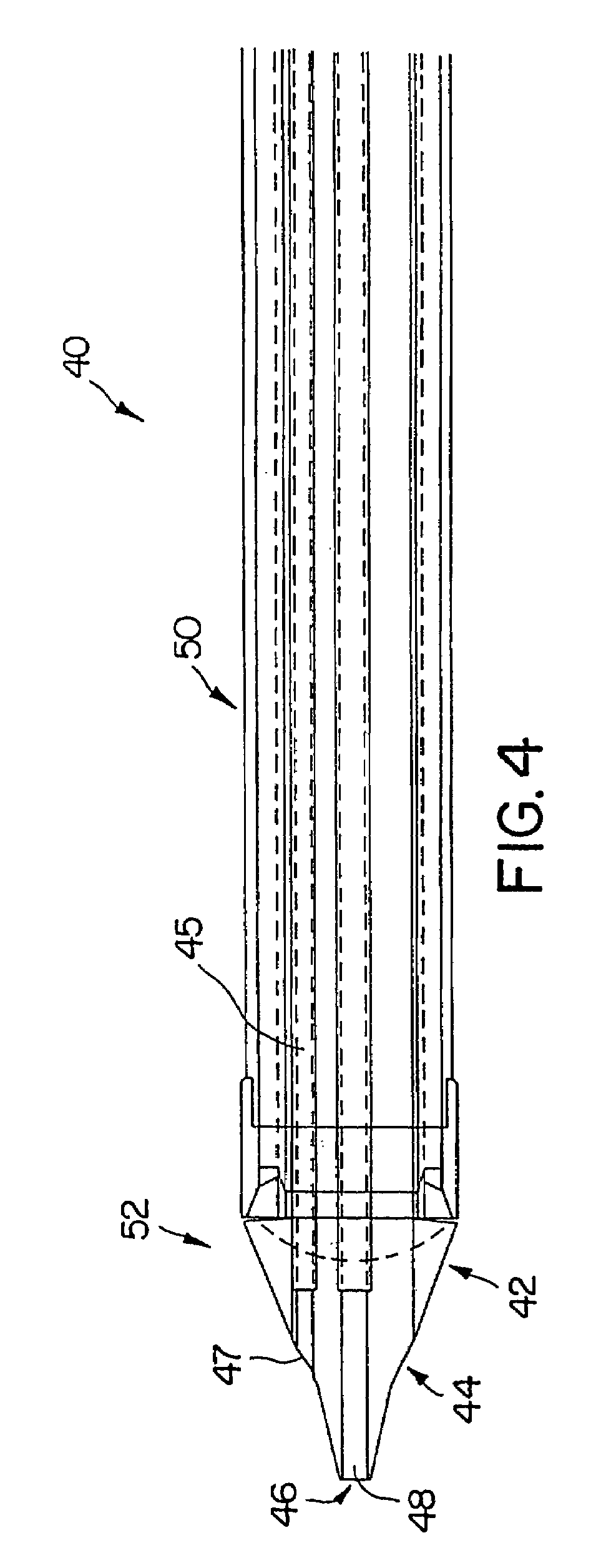

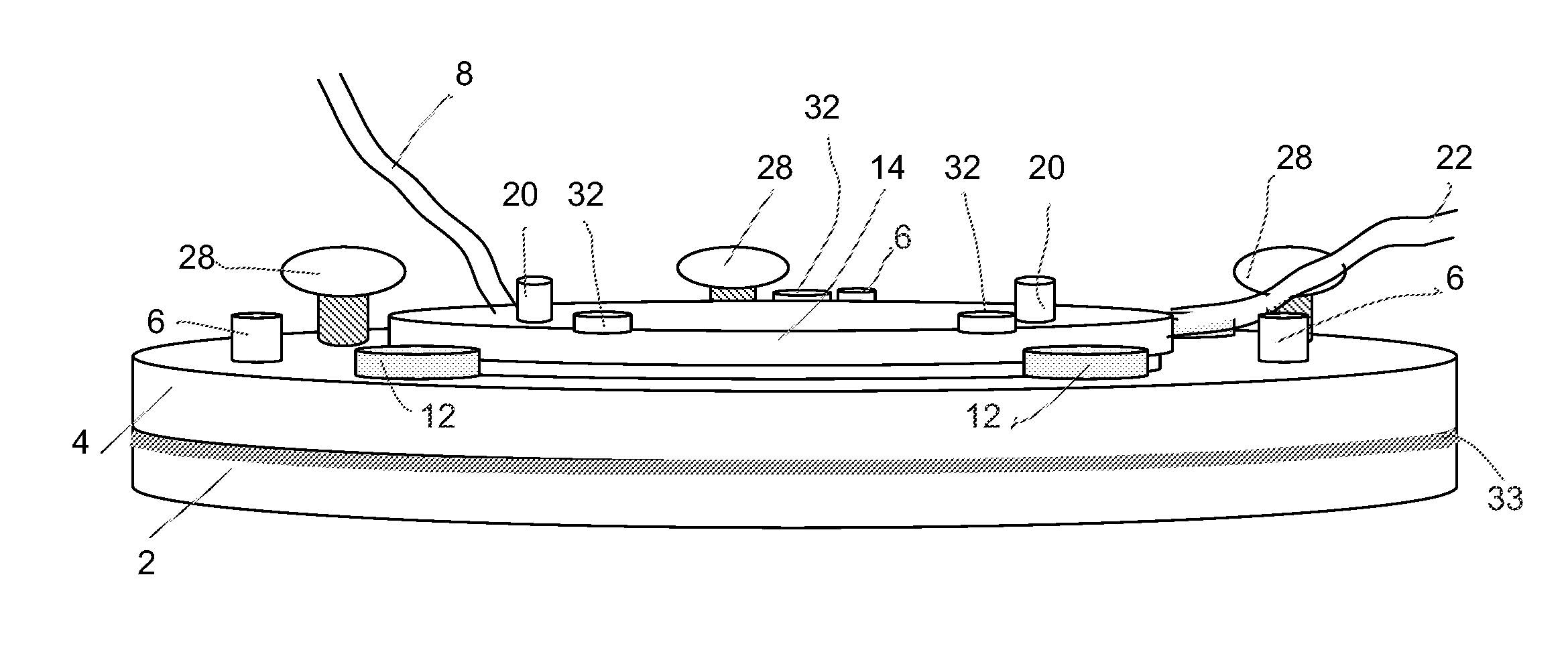

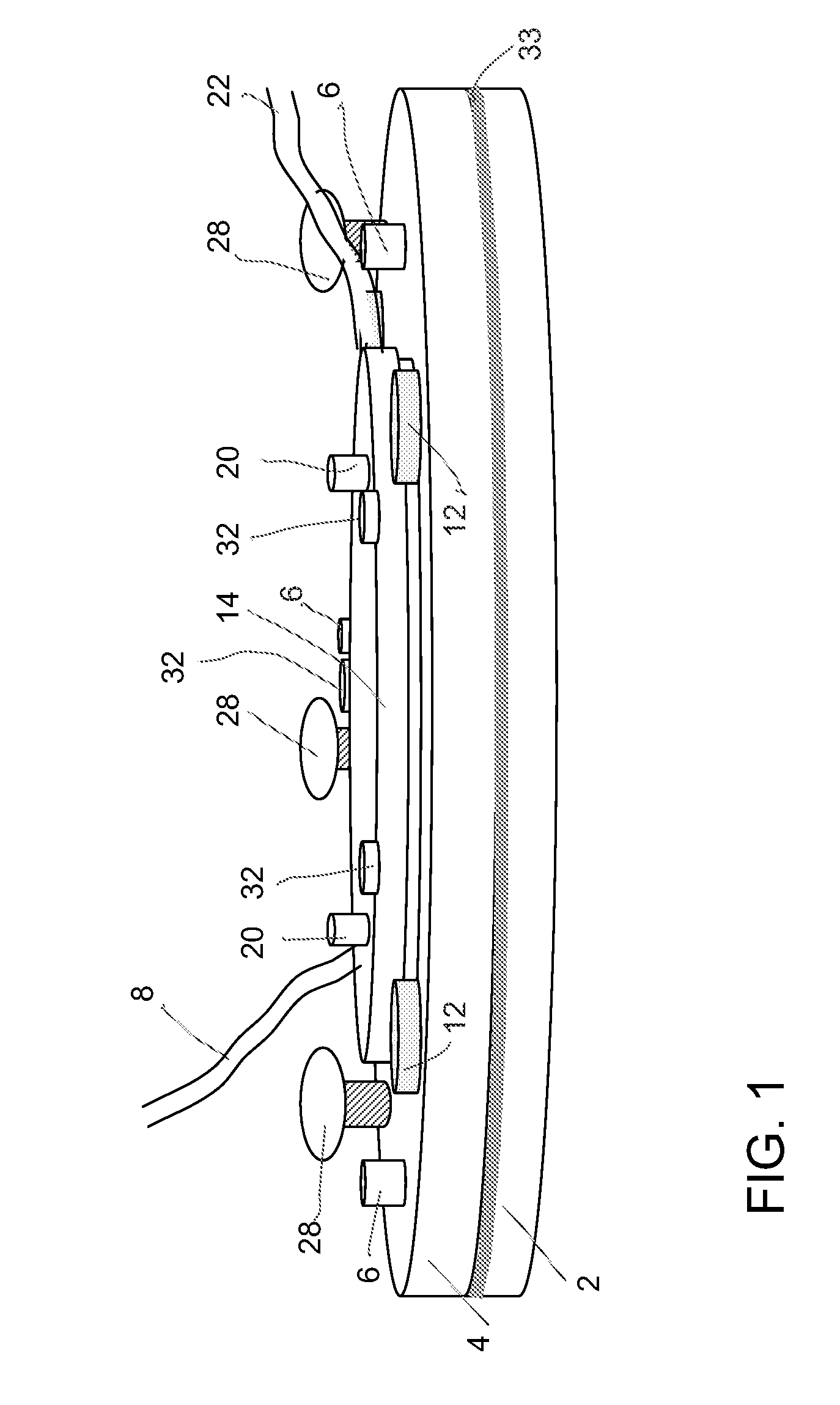

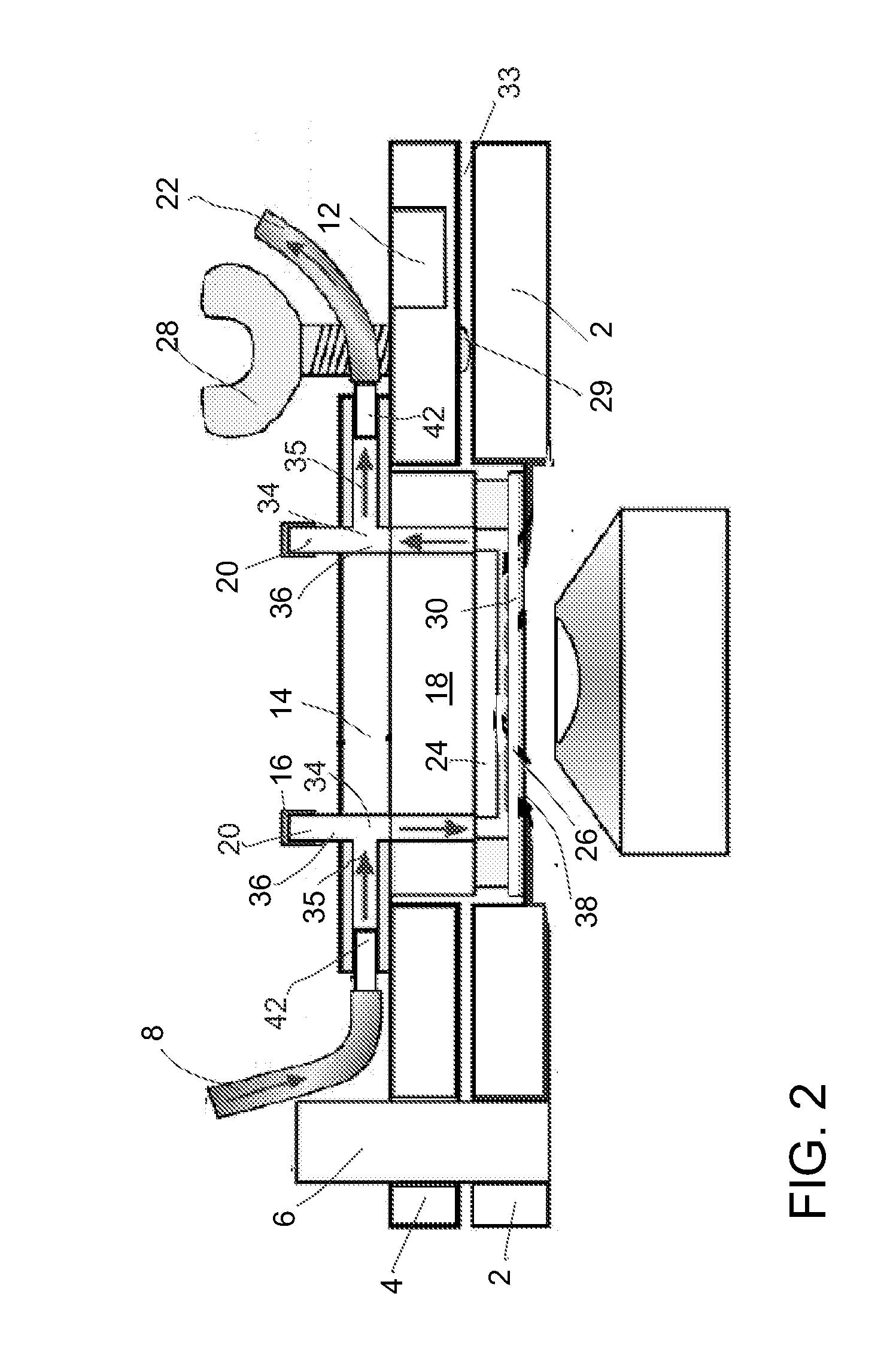

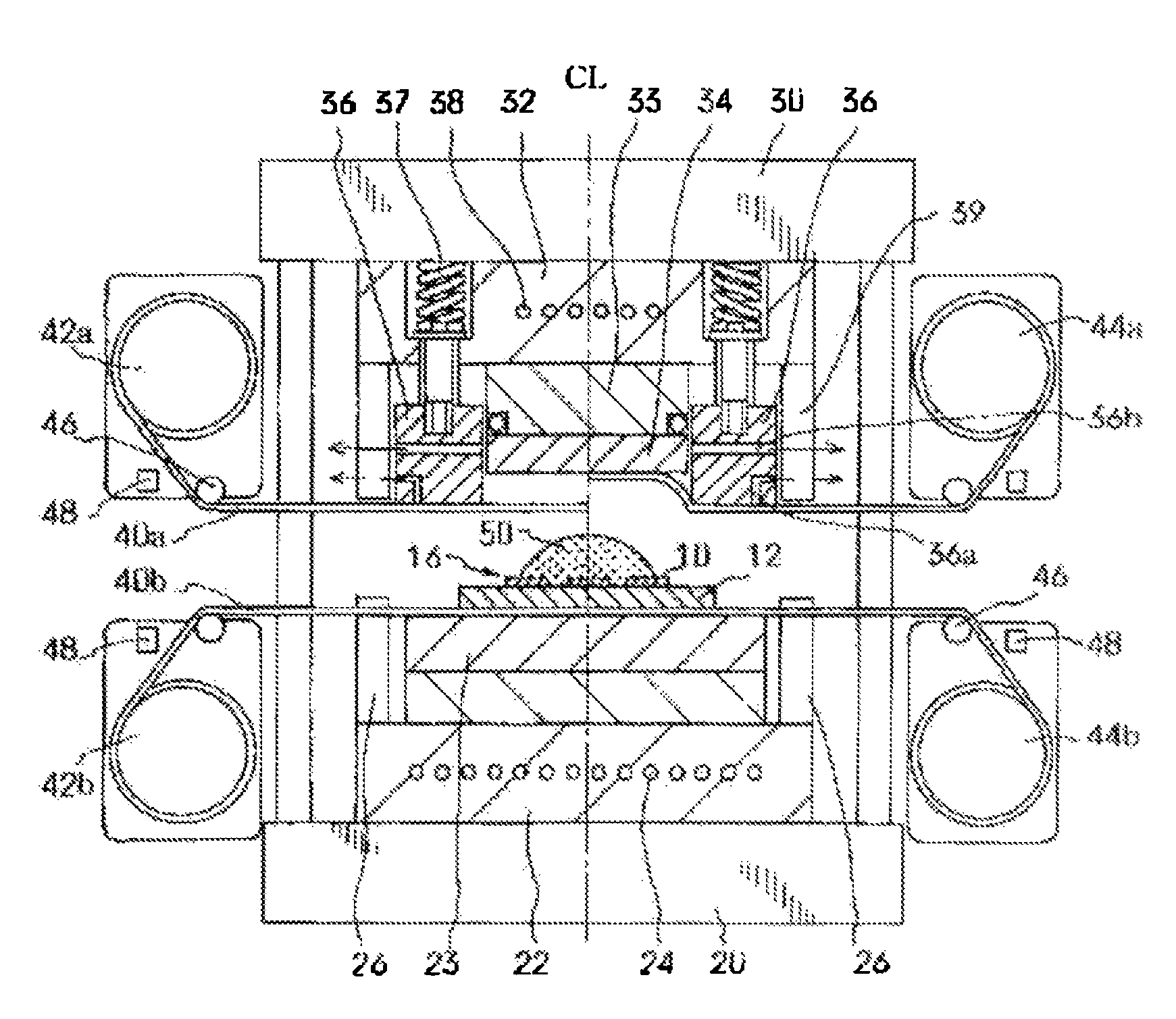

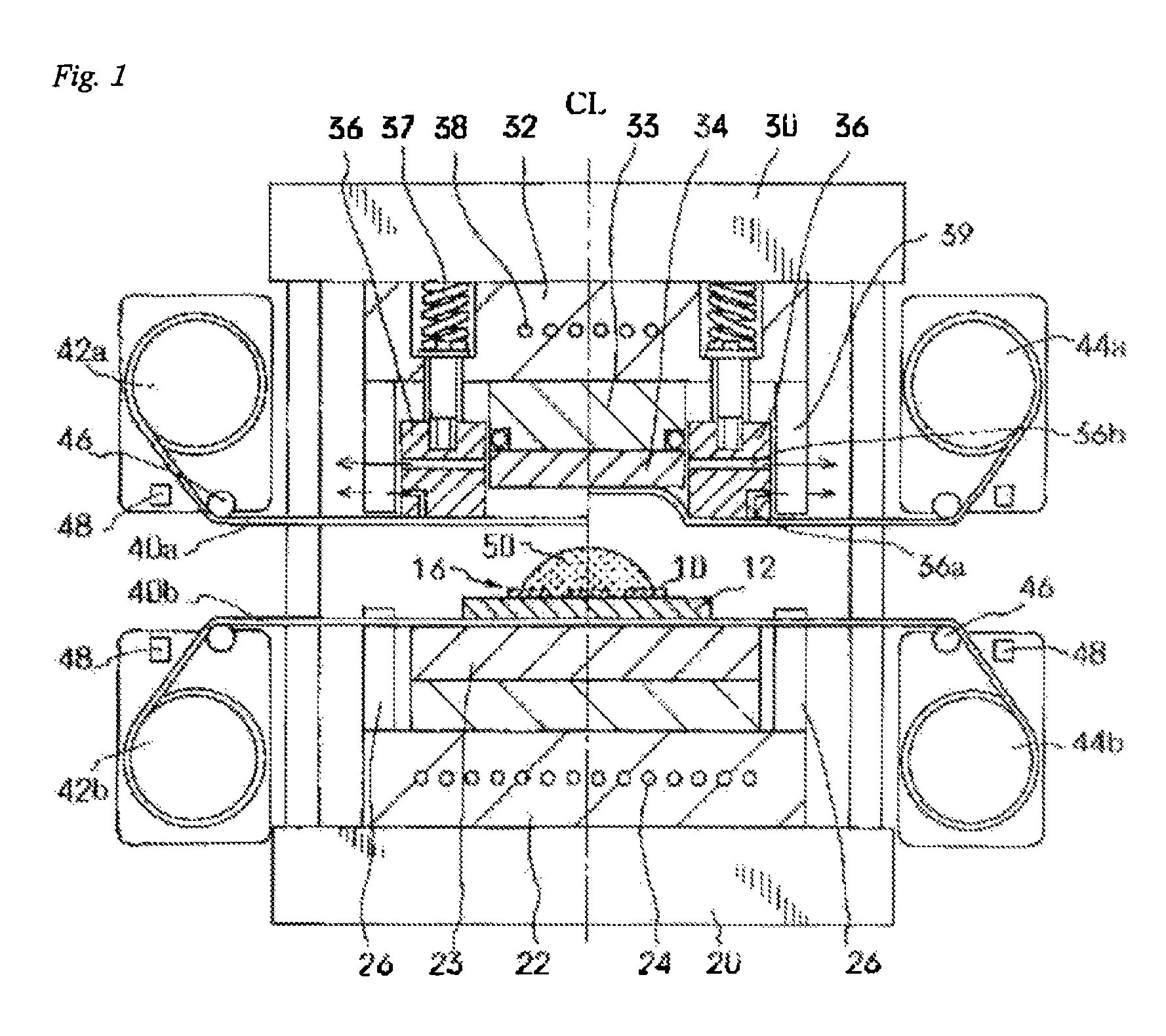

Vascular suction cannula, dilator and surgical stapler

InactiveUS6989016B2Quickly and efficiently closeSimple to manufacture and useSuture equipmentsStapling toolsSurgical departmentDilator

A suction cannula, dilator, stapler and staple are provided herein. The suction cannula is concentrically aligned with a puncture site (e.g., puncture in an artery or vein) and provides vacuum about the periphery of the puncture site so that the puncture hole is always located during a medical procedure, and to thereby permit a surgeon to quickly and efficiently close the puncture using, for example, a stapling device. In the preferred embodiment the suction cannula has a tube-in-tube construction having an inner tube and an outer tube where a vacuum can be applied between the tubes. The dilator (and suction cannula) centers around a guide wire (that is already in place within the venous structure) and follows the path of the guide wire to the puncture site. Preferably, the dilator has a tapered tip on the distal end that enters a hole made in the vein or artery. A blood indicator is provided on the proximal end to provide visual feedback when the surgeon is in the artery (i.e., pulsating blood indicates that the tip of the dilator is in the artery). Also preferably, the dilator includes a tapered tip on the distal end that is radially collapsible so that the dilator can be withdrawn from the artery and the suction cannula is thereby permitted to advance over the dilator to the artery wall. The stapler is provided which holds a multi-pronged staple on a shaft at the distal end. The stapler is constructed to slide into the suction cannula (i.e., the inner tube of the cannula) to approach the puncture in the artery, to permit the stapling of the artery. Preferably, the distal end of the stapler includes a T-flange that holds a staple and a crimping mechanism that crimps the staple into the artery, thereby sealing the puncture. The T-flange permits the staple to be held and inserted into the artery wall. An oval hub on the T-flange is provided that mates with an oval hole in the center of the staple. To hold a staple, a staple is placed on the hub and rotated 90 degrees, thereby affixing the staple to the stapler. Once the staple is crimped onto the artery wall, the shaft can be rotated 90 degrees, thereby aligning the oval hub and the oval hole, so that the stapler can be removed. Preferably, the staple includes a plurality of prongs that are inserted into the vascular wall.

Owner:MEDTRONIC ANGIOLINK

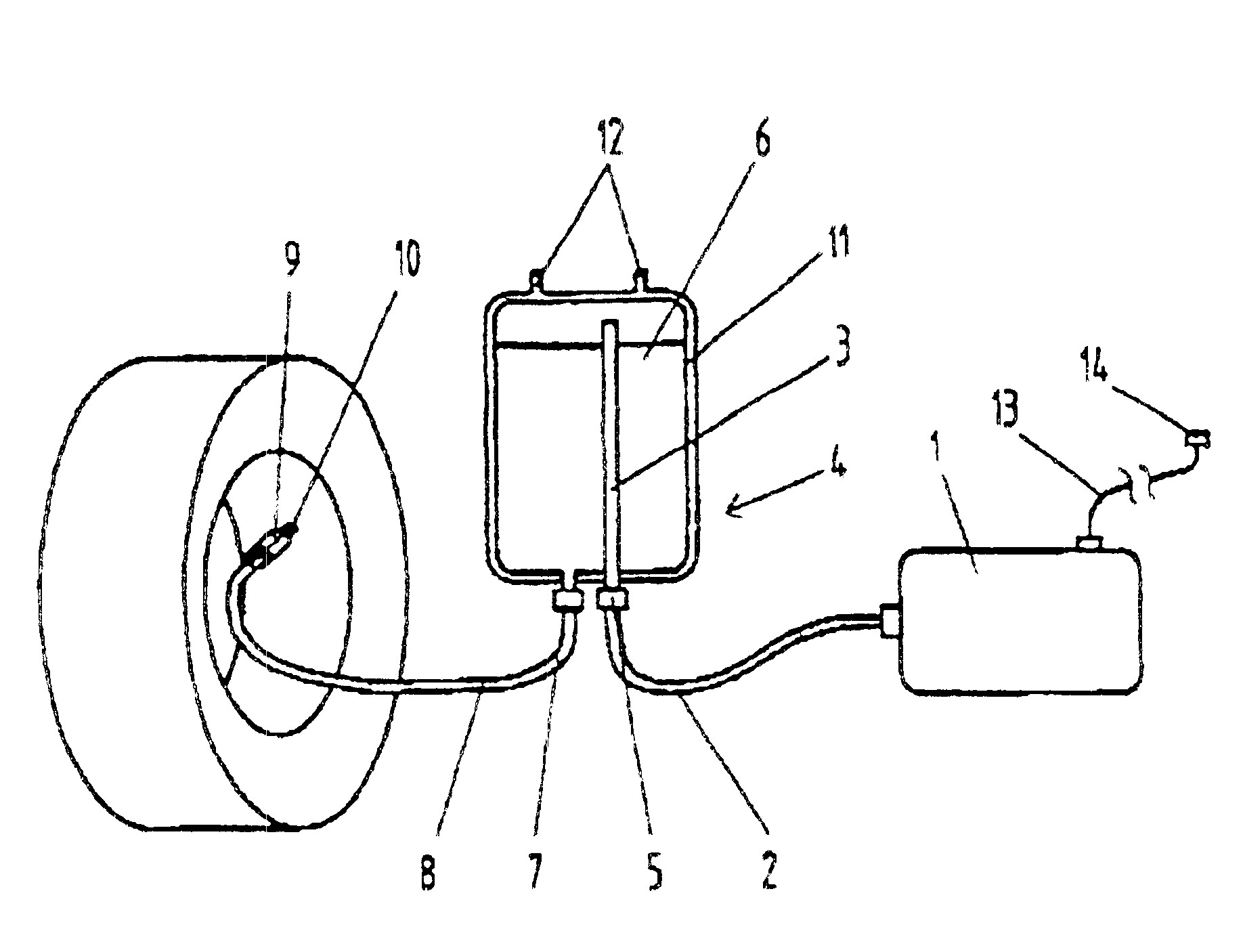

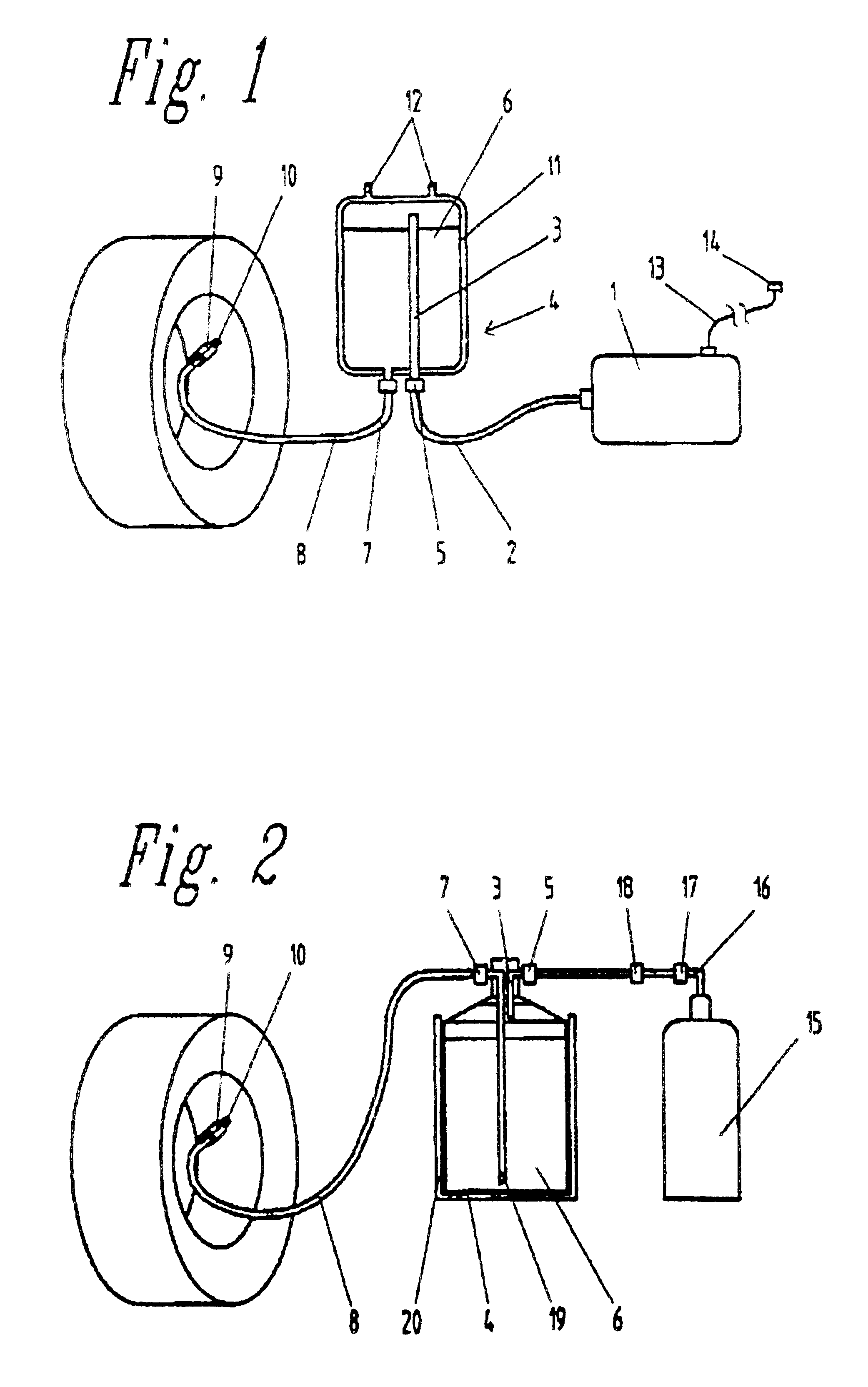

Preparation for sealing punctured tires and apparatus for the sealing and pumping up of tires

InactiveUS6889723B2Avoid easy removalImprove sealingLiquid surface applicatorsTyresSulfur hexafluorideEngineering

A sealing preparation for tire problems is proposed which seals in wet conditions, at low and high temperatures and with defects at the transition between the tread and the side wall of the tire. The sealing preparation contains natural rubber latex or a combination of rubber latex and compatible adhesive resin. Furthermore, various devices are proposed for introducing the sealing preparation into the tire and for the pumping up. An air compressor, or liquefied dinitrogenoxide, or sulphur hexafluoride are preferably used with these devices as a pressure source.

Owner:SUMITOMO RUBBER IND LTD

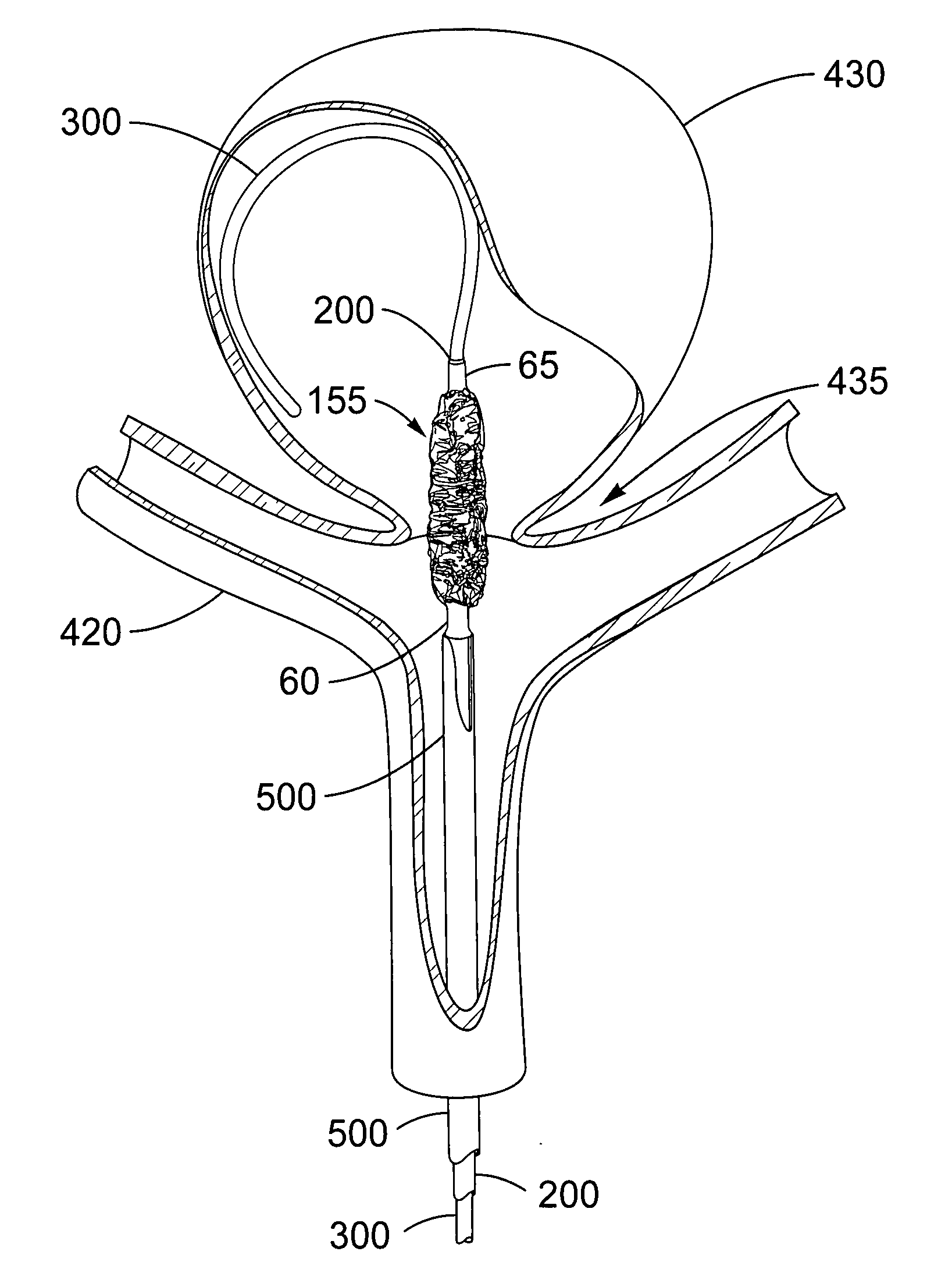

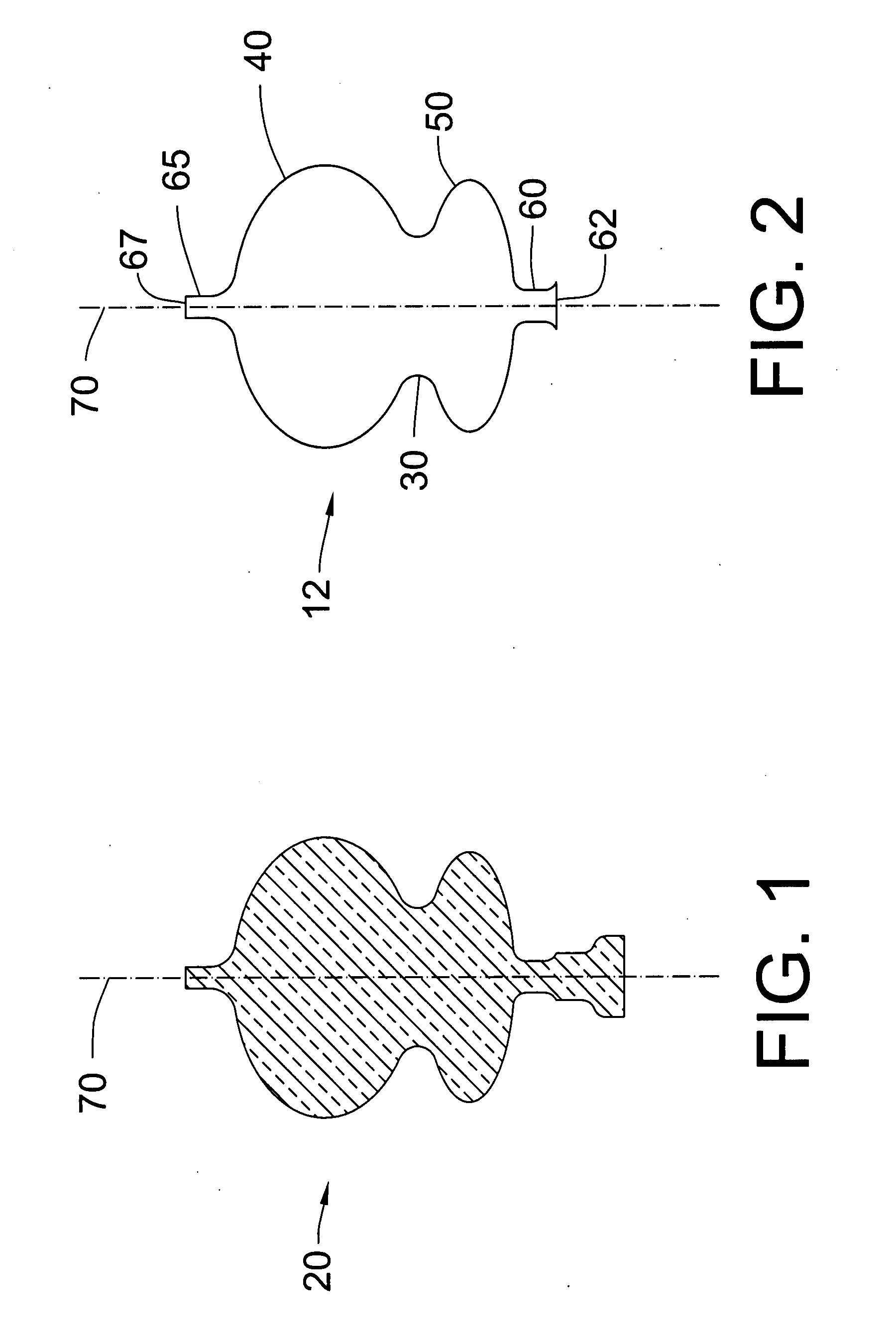

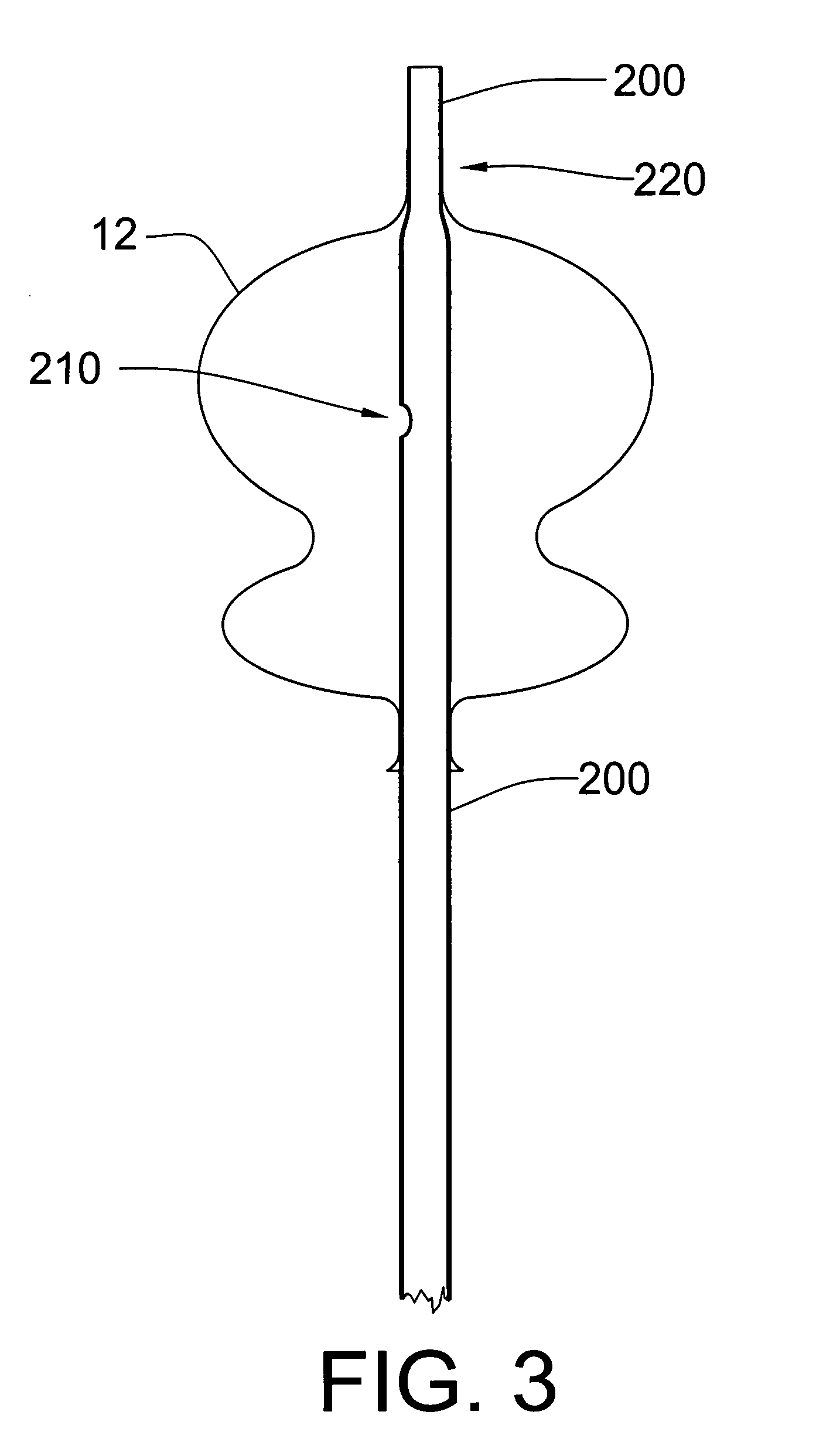

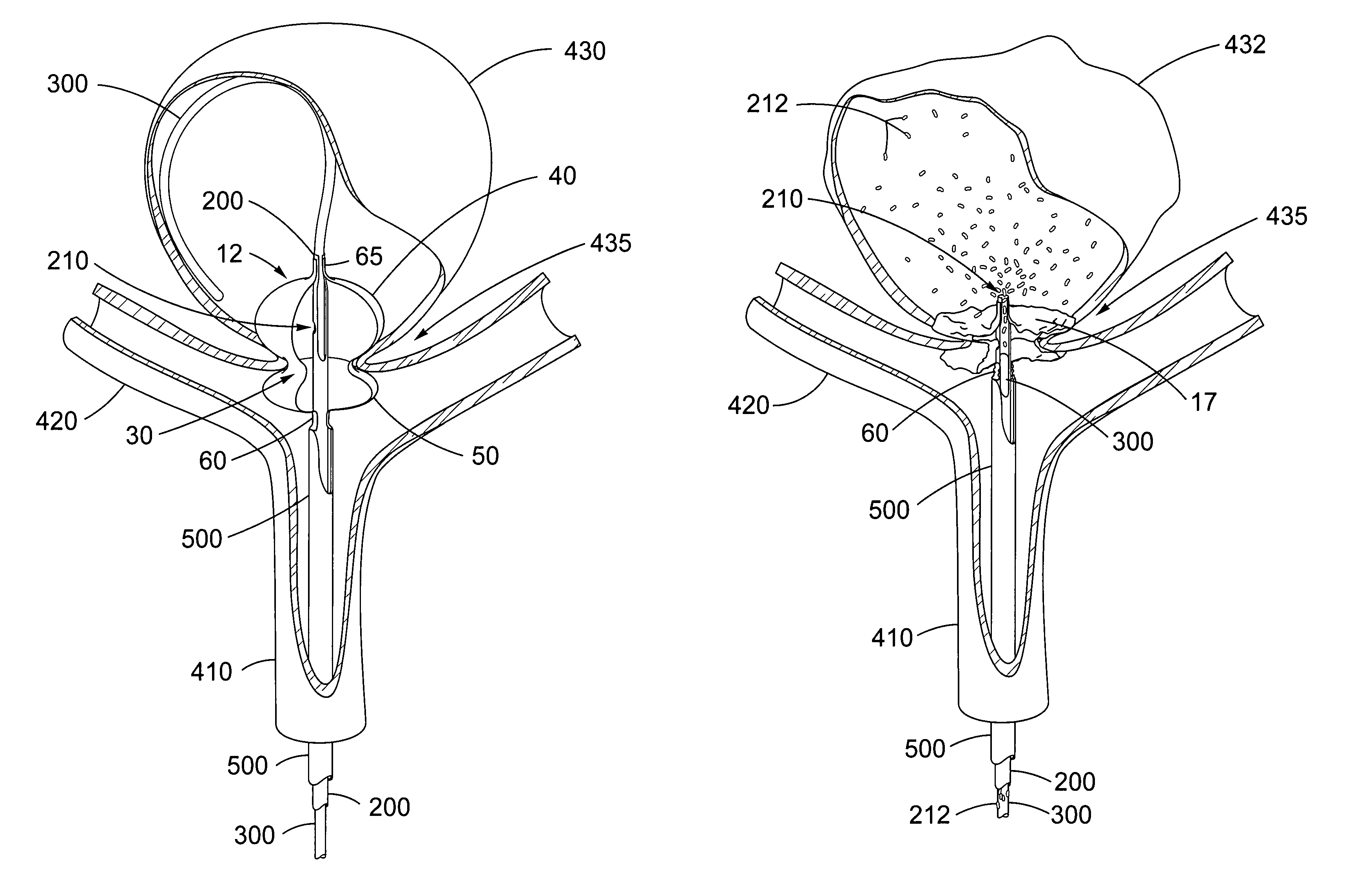

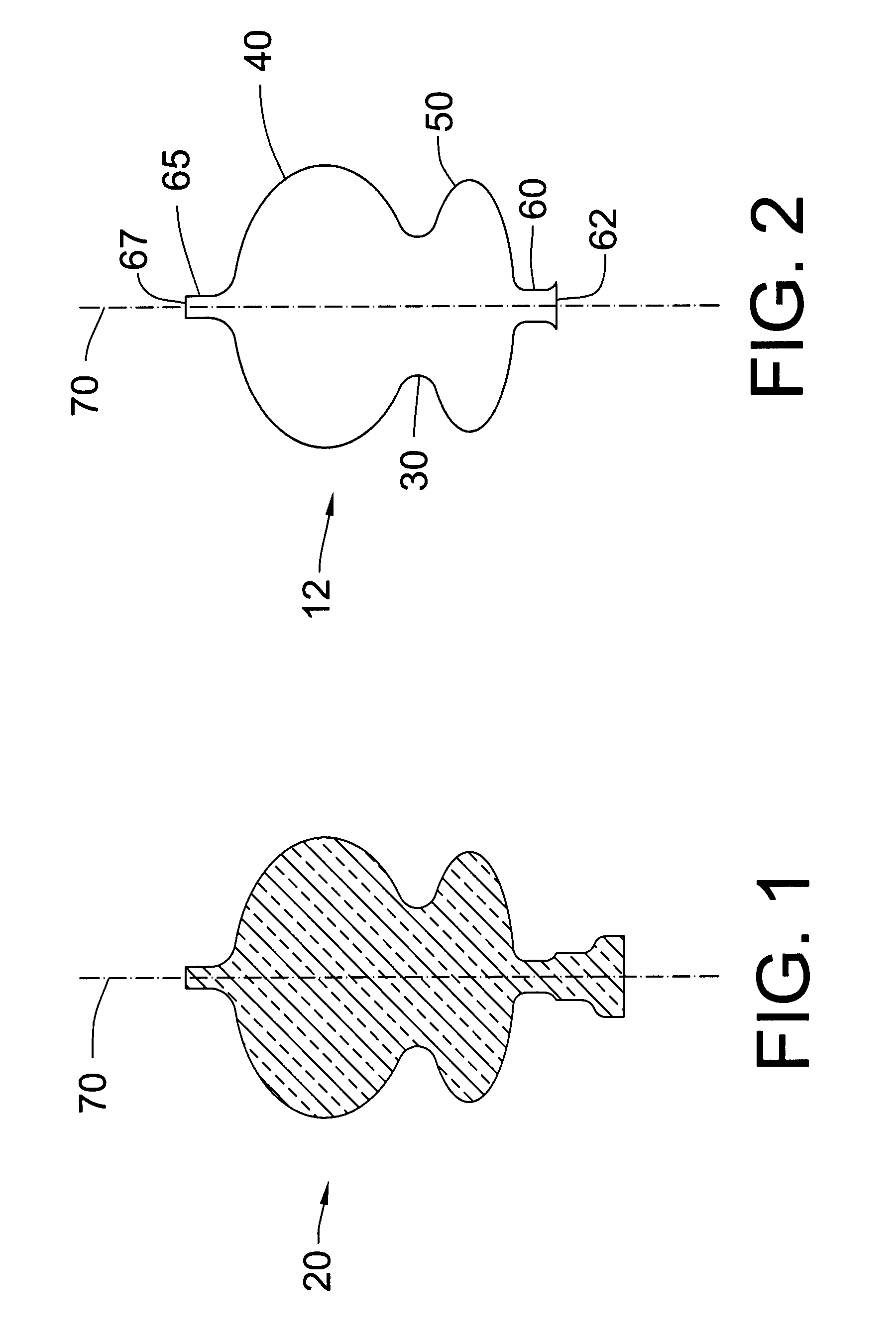

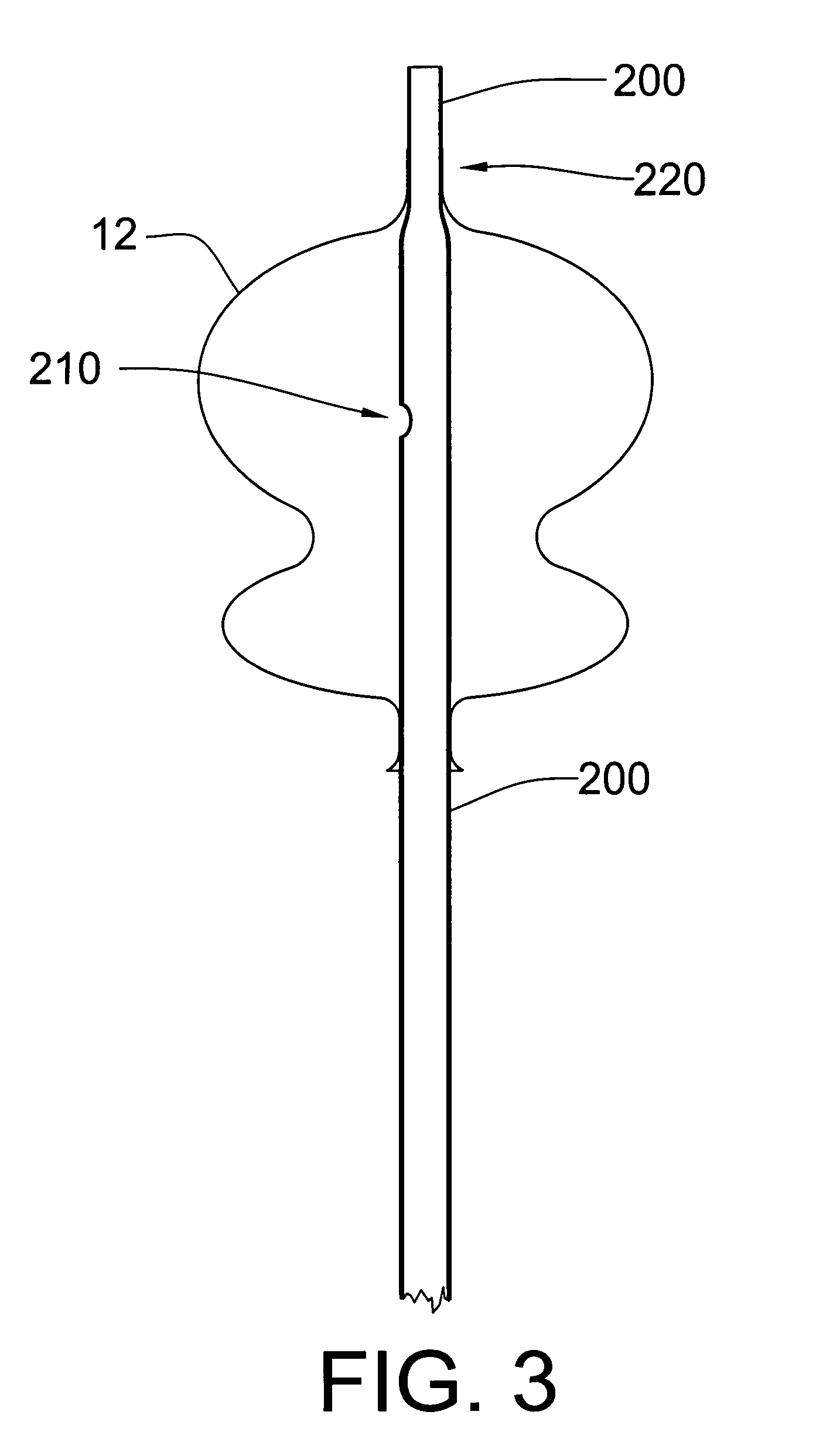

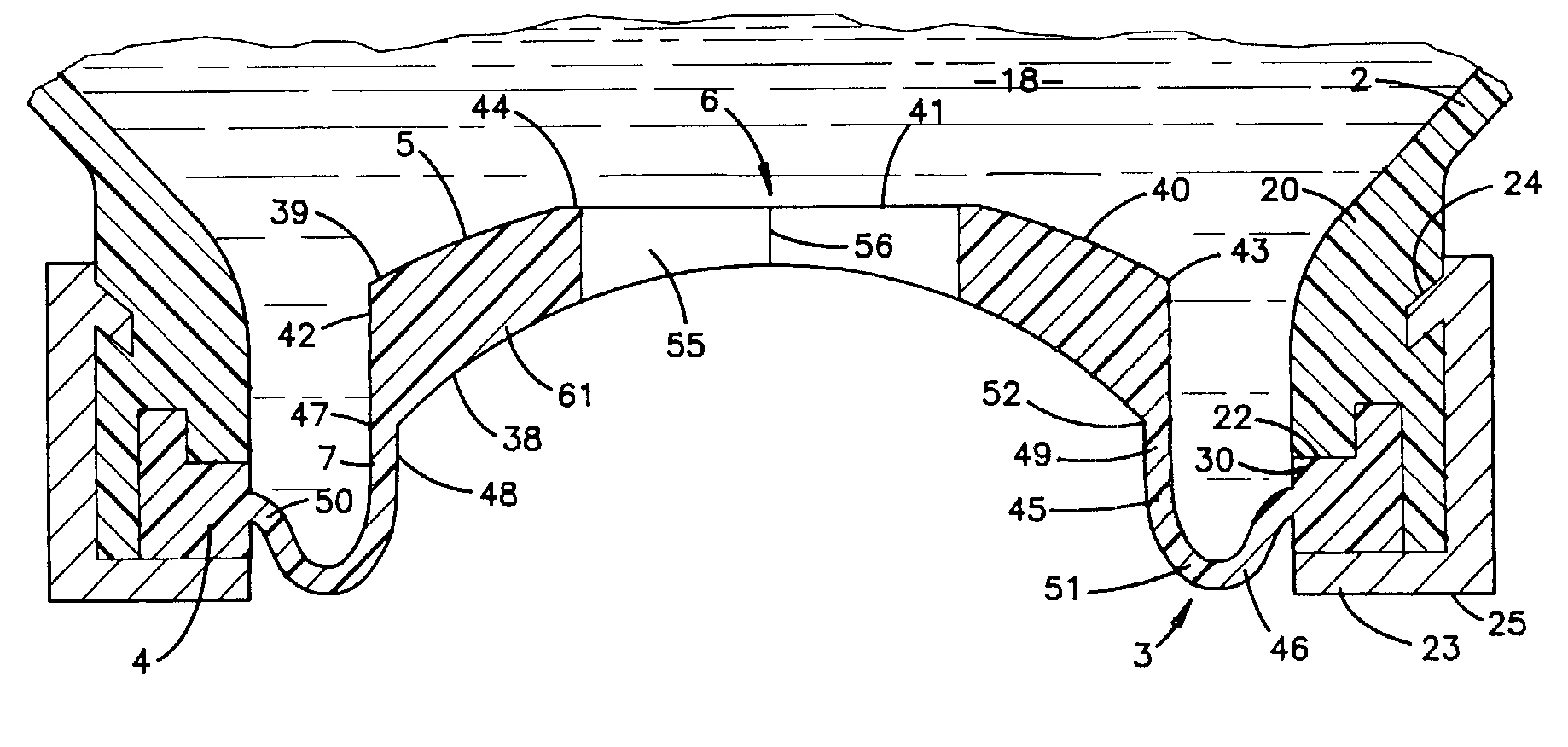

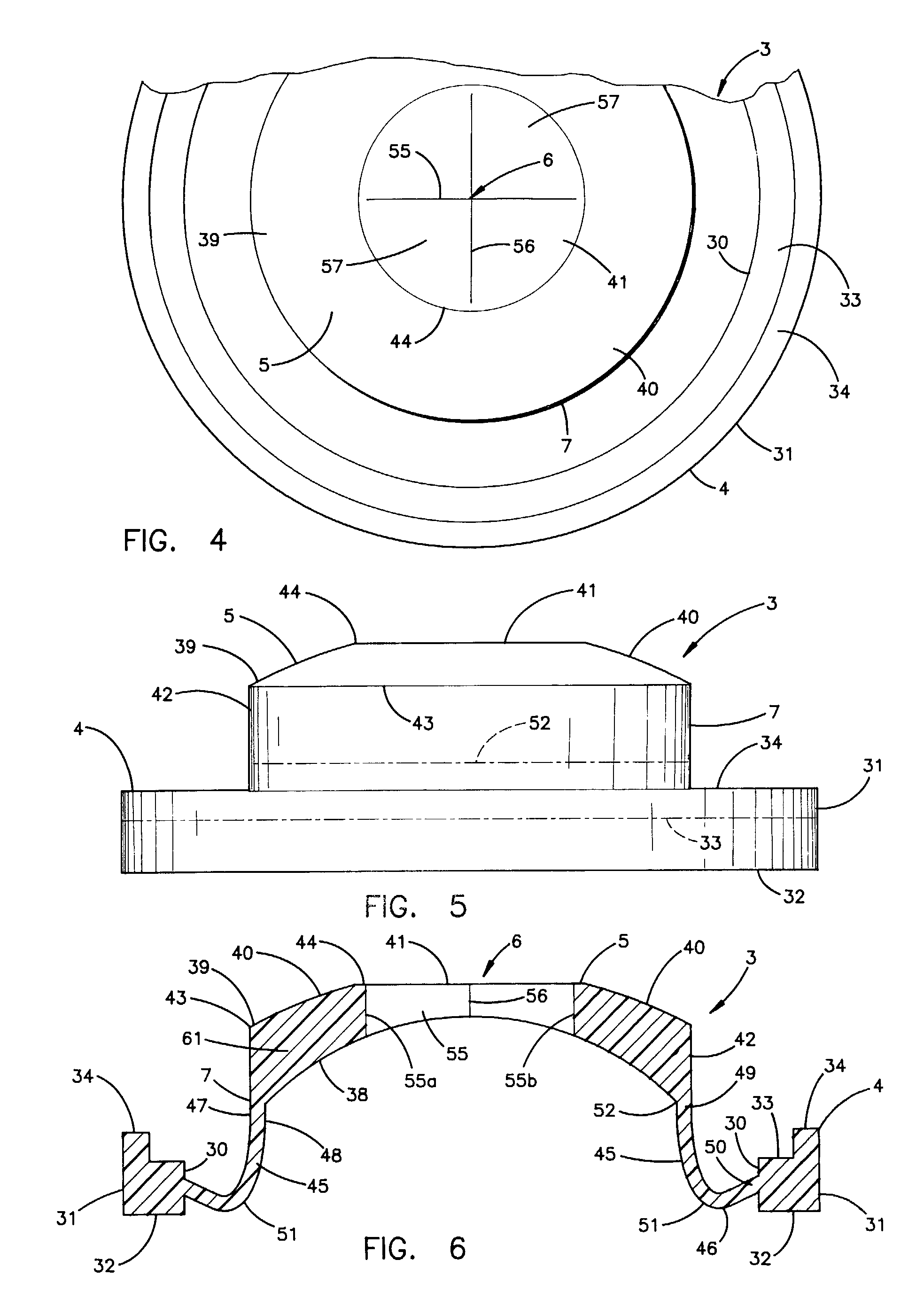

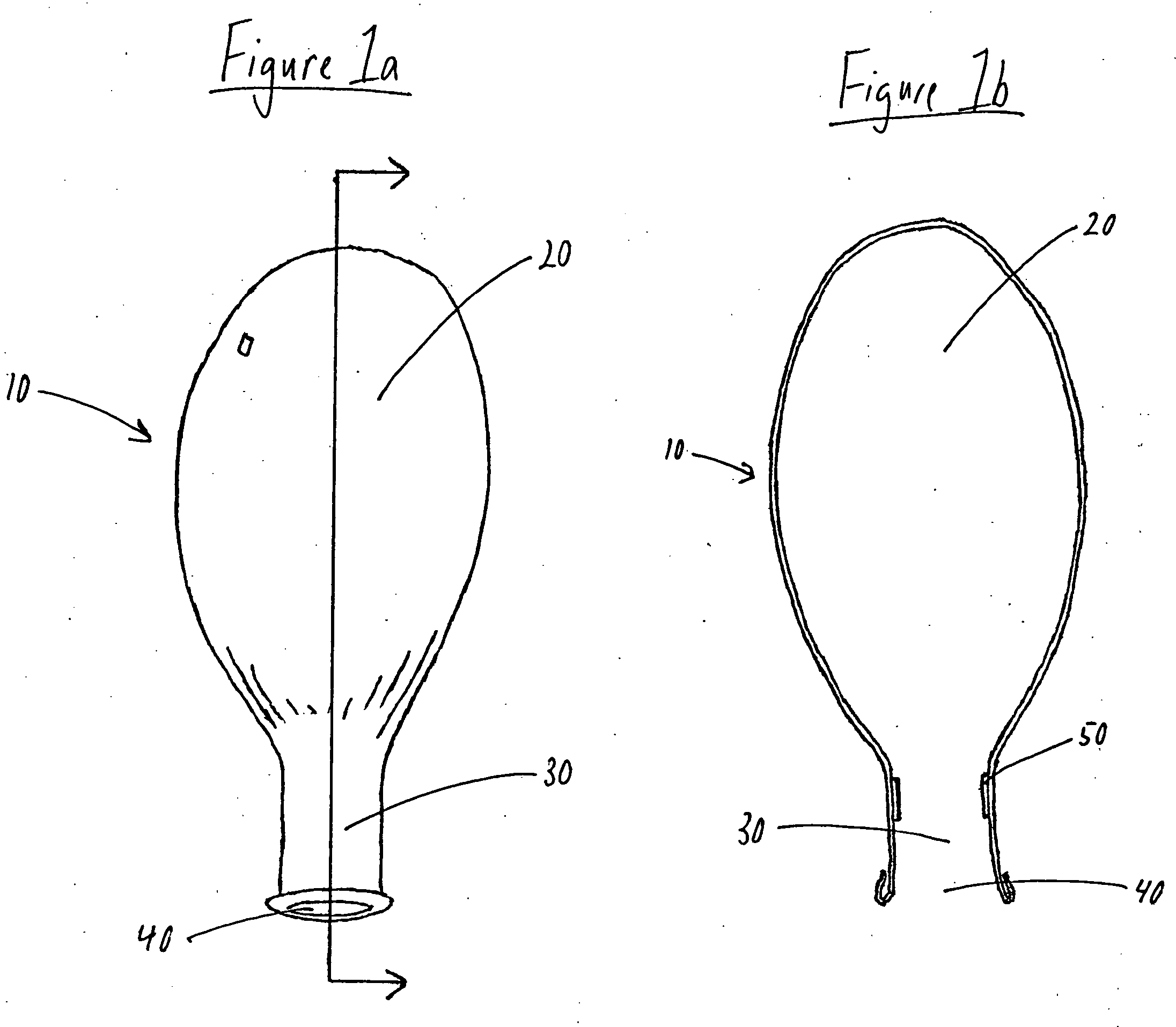

Over-the-wire exclusion device and system for delivery

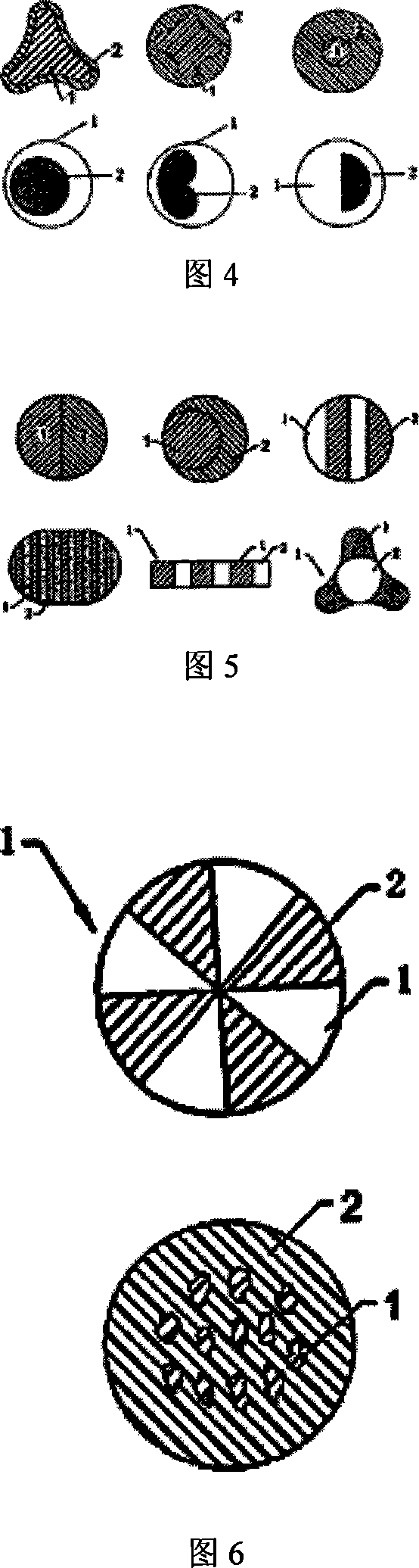

ActiveUS20080140177A1Increase stability , deliverability , and deployabilityReduce flow of fluidEar treatmentDilatorsMechanical forceThin walled

A modification to allow delivery of a two port medical flow restrictor over a guidewire, and a means to mechanically collapse the new device. A thin walled, foil-like shell, is compacted for delivery. The invention includes the device, delivery assemblies, and methods of placing, and using, the device. A device with an aneurysm lobe and an artery lobe self-aligns its waist at the neck of an aneurysm as the device shell is pressure expanded. Mechanical force collapses both the aneurysm lobe and the artery lobe, captivating the neck of the aneurysm and securing the device. The device works for aneurysms at bifurcations and aneurysms near side-branch arteries. The device, unlike endovascular coiling, excludes the weak neck of the aneurysm from circulation, while leaving the aneurysm relatively empty. Unlike stent-based exclusion, the device does not block perforator arteries. This exclusion device can also limit flow through body lumens or orifices.

Owner:ELECTROFORMED STENTS

Over-the-wire exclusion device and system for delivery

ActiveUS8372114B2Reduce flowImprove deliverabilityEar treatmentDilatorsInsertion stentEndovascular coiling

A modification to allow delivery of a two port medical flow restrictor over a guidewire, and a means to mechanically collapse the new device. A thin walled, foil-like shell, is compacted for delivery. The invention includes the device, delivery assemblies, and methods of placing, and using, the device. A device with an aneurysm lobe and an artery lobe self-aligns its waist at the neck of an aneurysm as the device shell is pressure expanded. Mechanical force collapses both the aneurysm lobe and the artery lobe, captivating the neck of the aneurysm and securing the device. The device works for aneurysms at bifurcations and aneurysms near side-branch arteries. The device, unlike endovascular coiling, excludes the weak neck of the aneurysm from circulation, while leaving the aneurysm relatively empty. Unlike stent-based exclusion, the device does not block perforator arteries. This exclusion device can also limit flow through body lumens or orifices.

Owner:ELECTROFORMED STENTS

Microfluidic system and method for using same

InactiveUS20110044865A1Increase flexibilityQuick sealBioreactor/fermenter combinationsBiological substance pretreatmentsElastomerEngineering

In a microfluidic system, a magnetic clamp for sealing a flexible microchannel chip includes a base formed from a magnetically-attractable material. The base supports a window for viewing the face of the microfluidic chip. A ring with magnets uniformly distributed around it is disposed over the base. A transparent disk attached to the top of the ring has an inlet and an outlet for introducing and removing a fluid medium into a cavity defined the disk, the window, the center opening of the ring and the base. An elastomer cushion is attached to the inner surface of the disk. The magnetic force between the base and the magnets on the ring compresses the cushion against the microfluidic chip so that the microchannels are sealed against the window with a uniform and reproducible pressure.

Owner:RGT UNIV OF CALIFORNIA

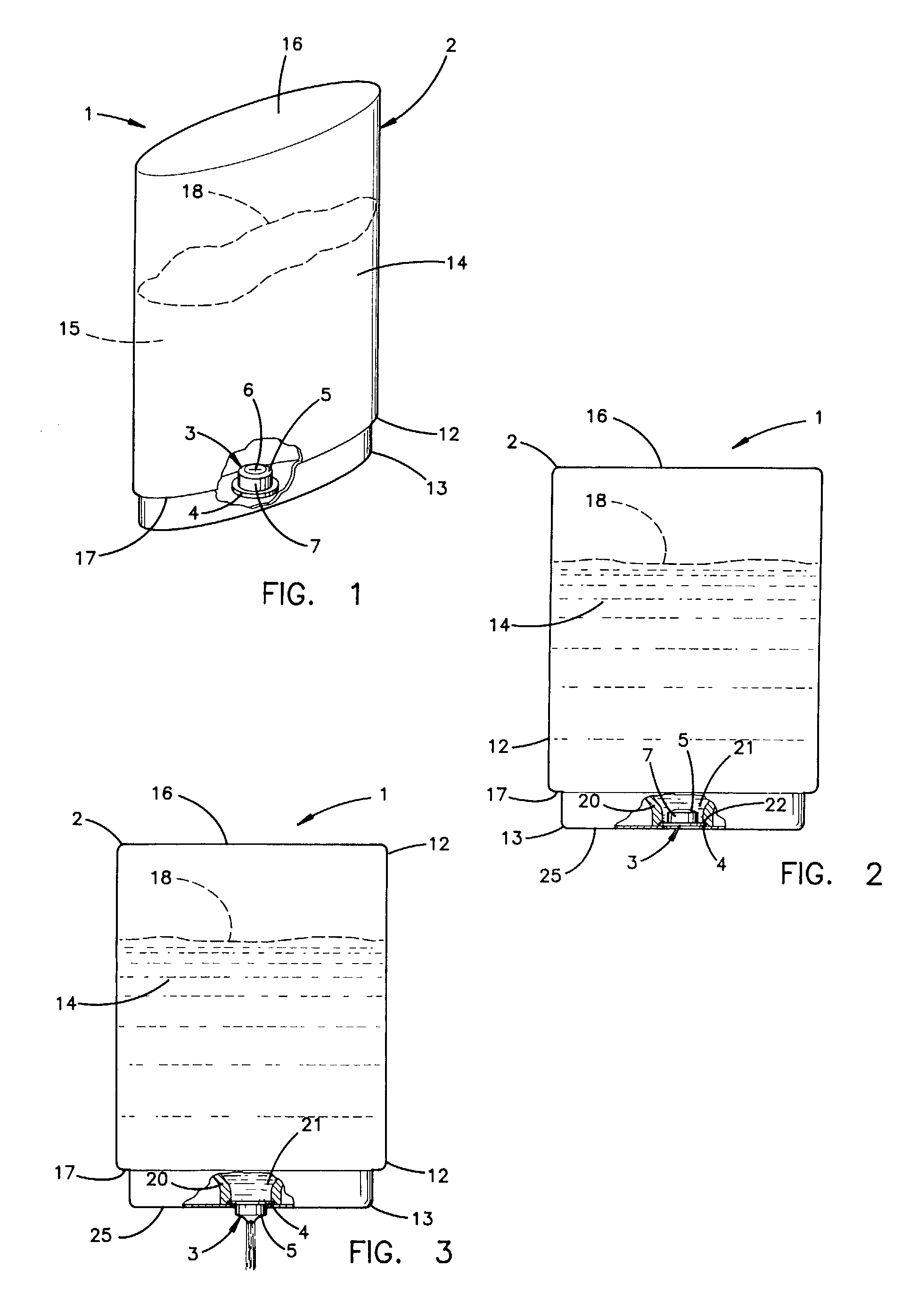

Dispensing valve

InactiveUS7077296B2Easily and neatly dispensingSufficient flexibilityClosuresCheck valvesBiomedical engineeringMechanical engineering

A dispensing valve is provided for dispensing fluid products. The valve includes a marginal portion, a flexible valve head with a discharge orifice therein, and a flexible connector sleeve having one end connected with the marginal portion and the opposite end connected with the valve head adjacent a marginal edge thereof.

Owner:APTARGROUP INC

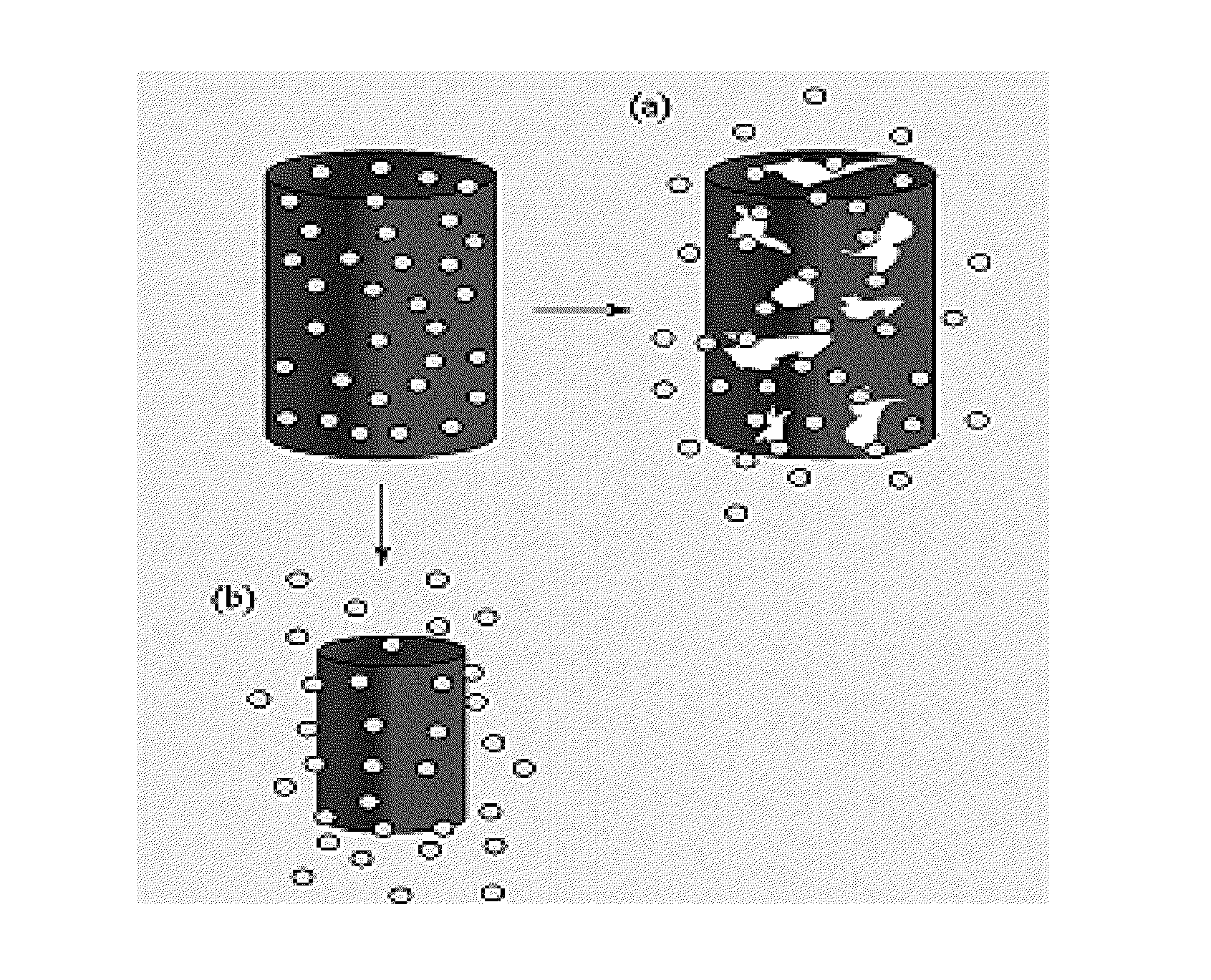

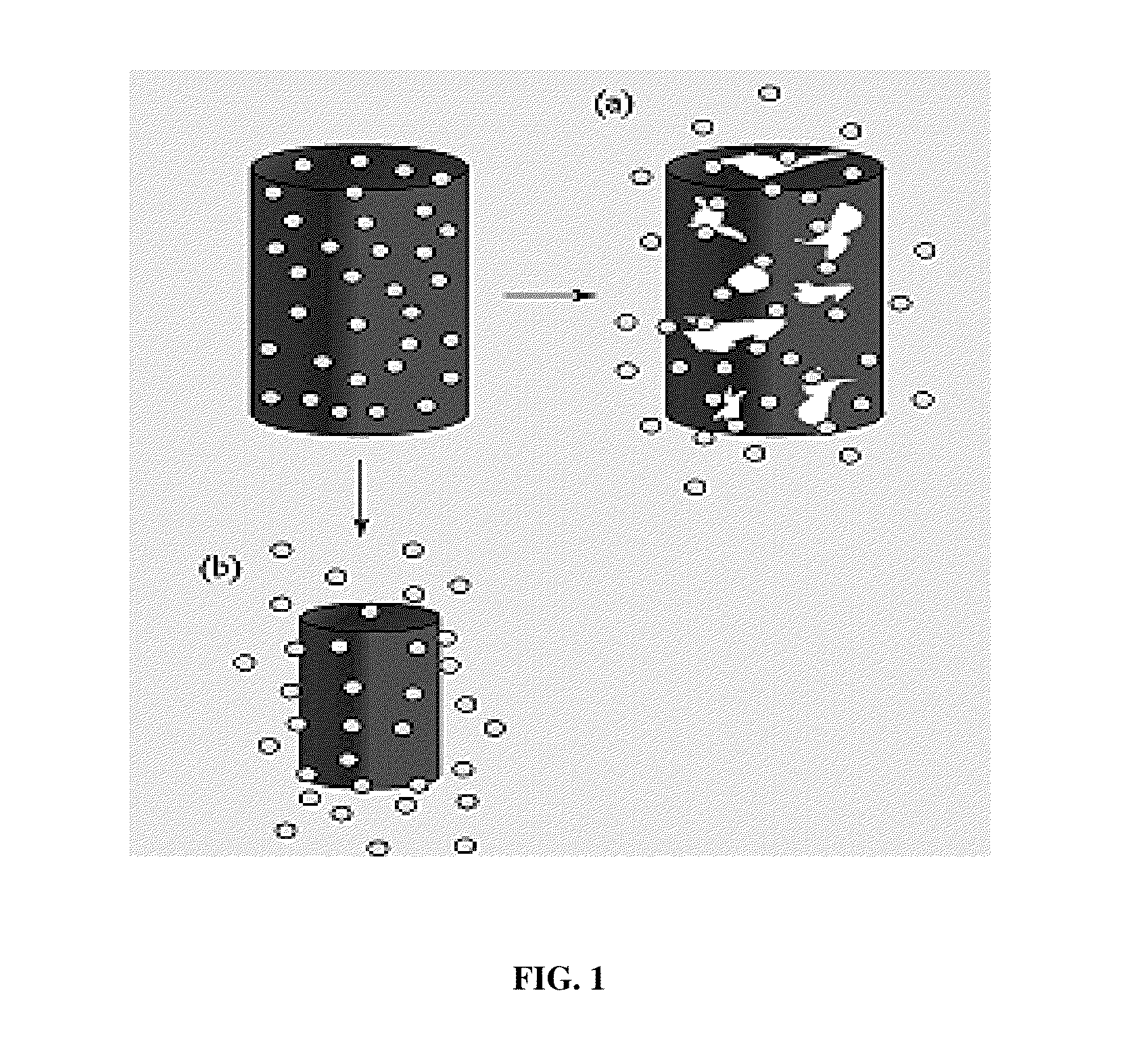

System and method for electrospun drug loaded biodegradable chemotherapy applications

InactiveUS20110038936A1Good coagulationImprove adhesionPowder deliveryHeavy metal active ingredientsBiomedical engineeringPolymer

Biodegradable resorbable drug delivery systems characterized by an electrospun biodegradable resorbable polymeric fiber matrix with at least one therapeutic agent incorporated into the fibers of the matrix, wherein the fiber matrix has an interfibrillar space of at least 65% by volume. Therapeutic methods for delivering a chemotherapeutic agent to body cavities from which a tumor has been excised and for strengthening weakened blood vessel walls are also disclosed.

Owner:GRISWOLD KIMBERLY A +1

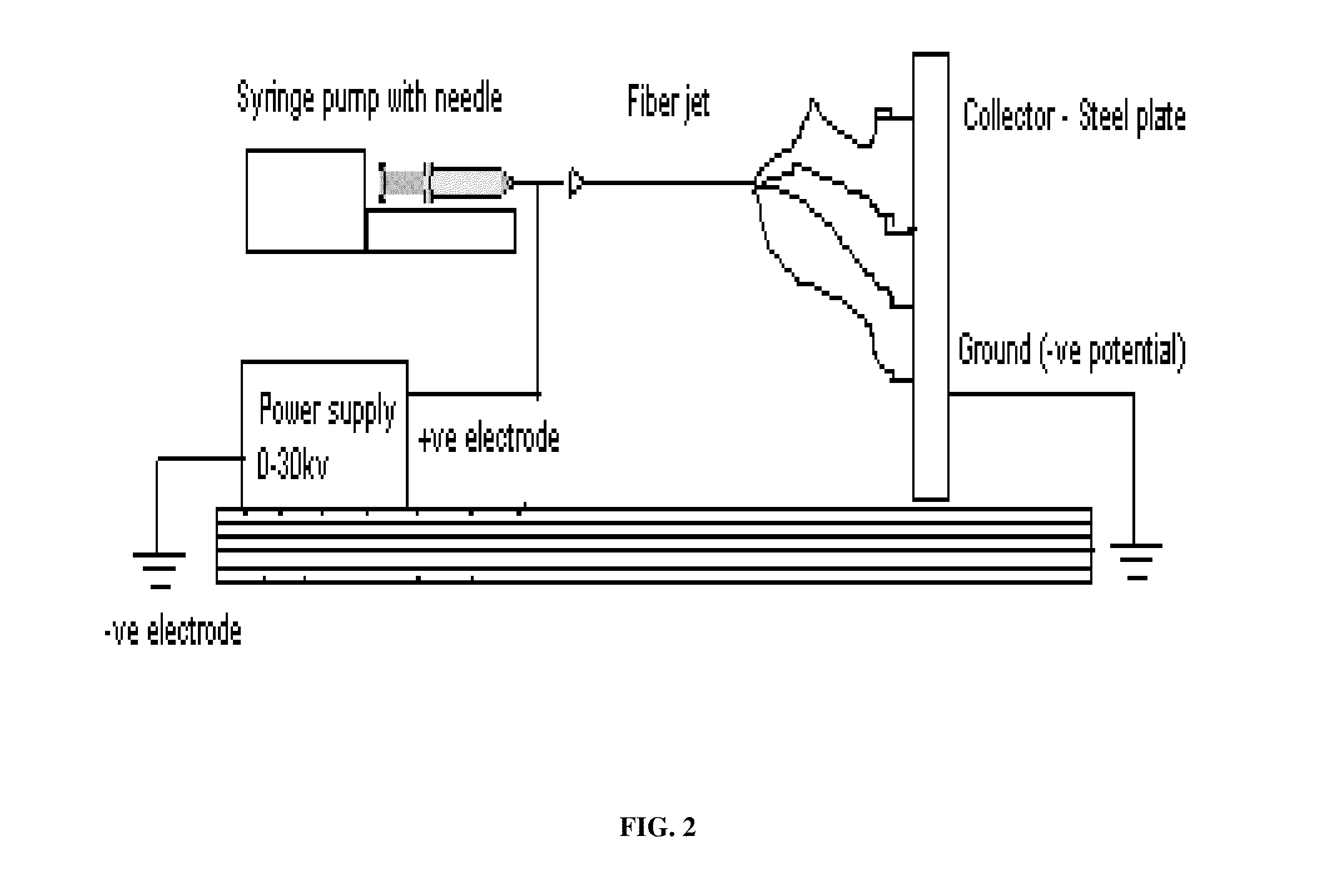

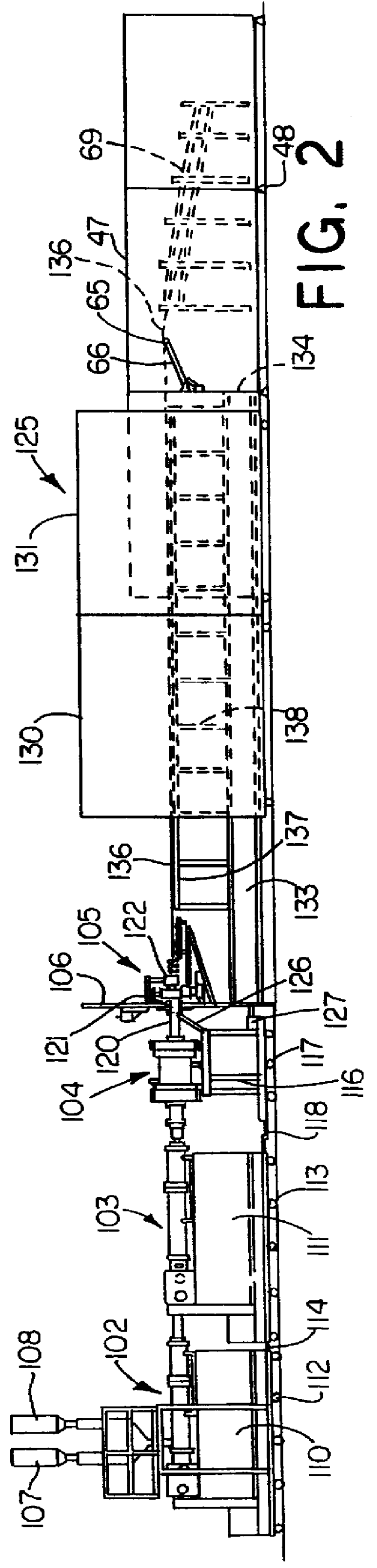

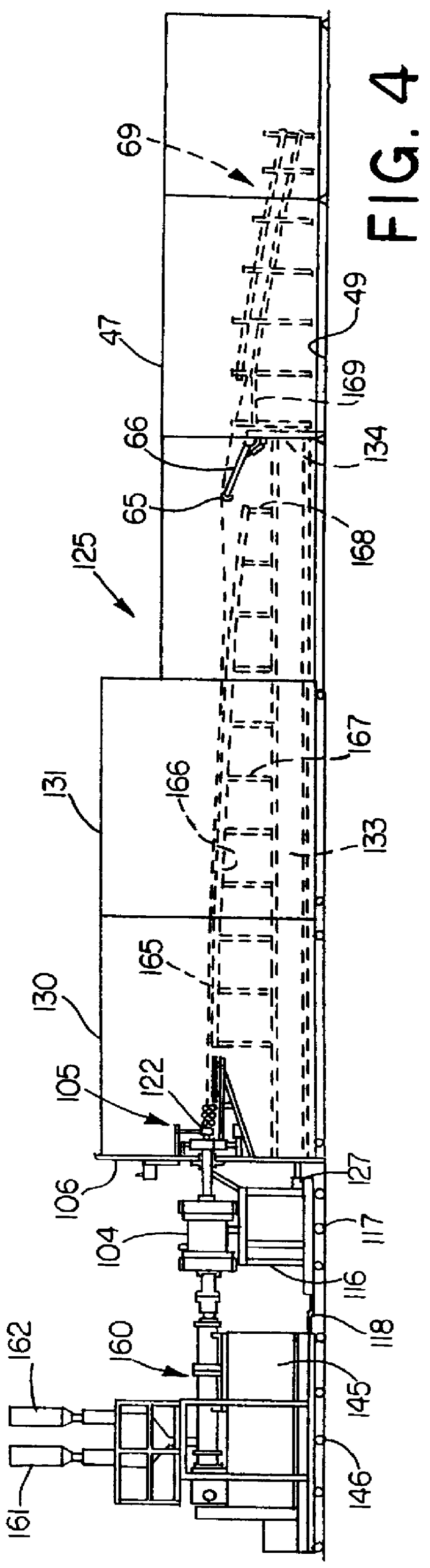

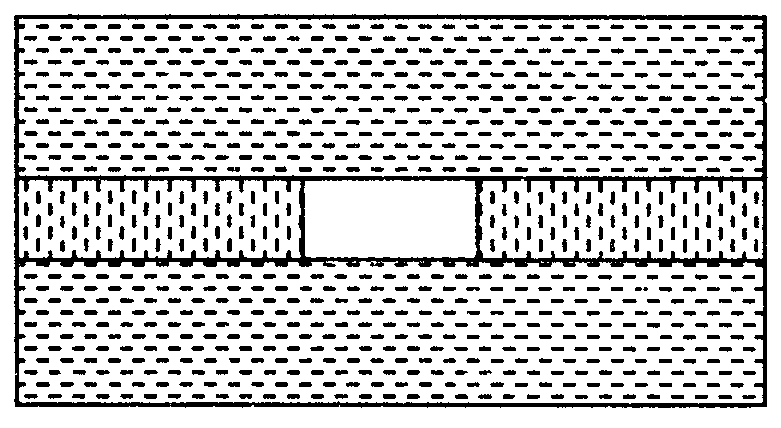

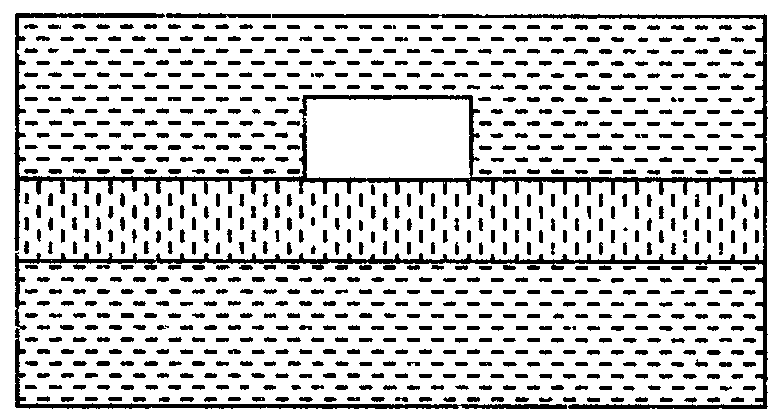

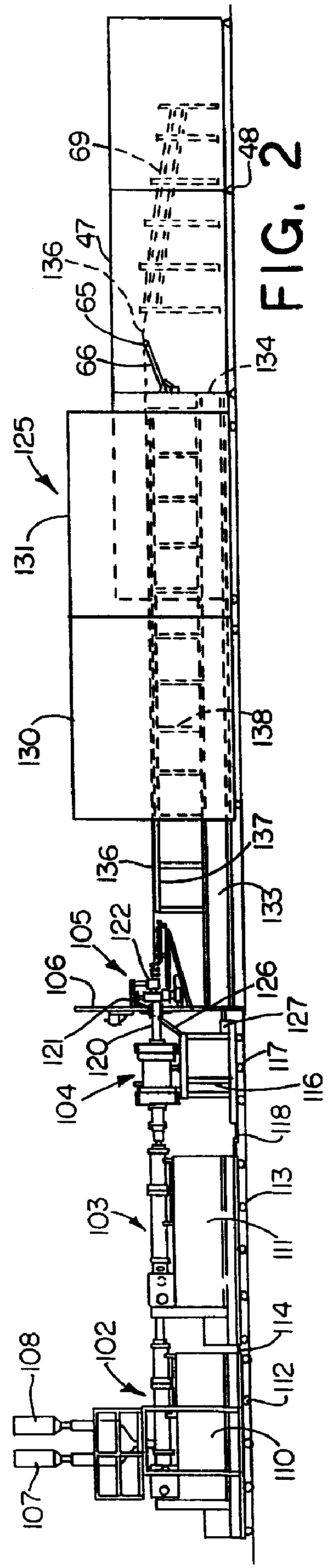

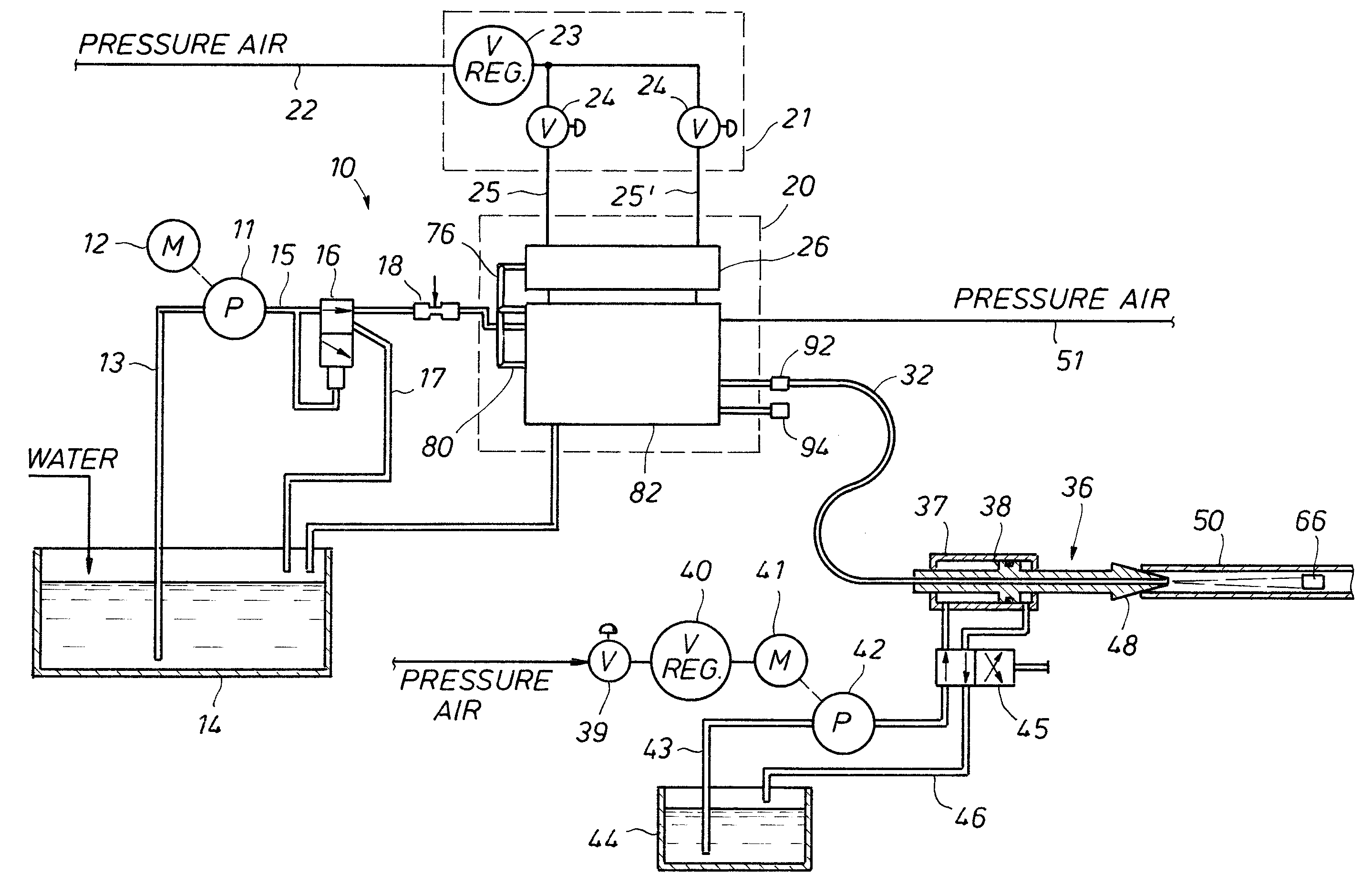

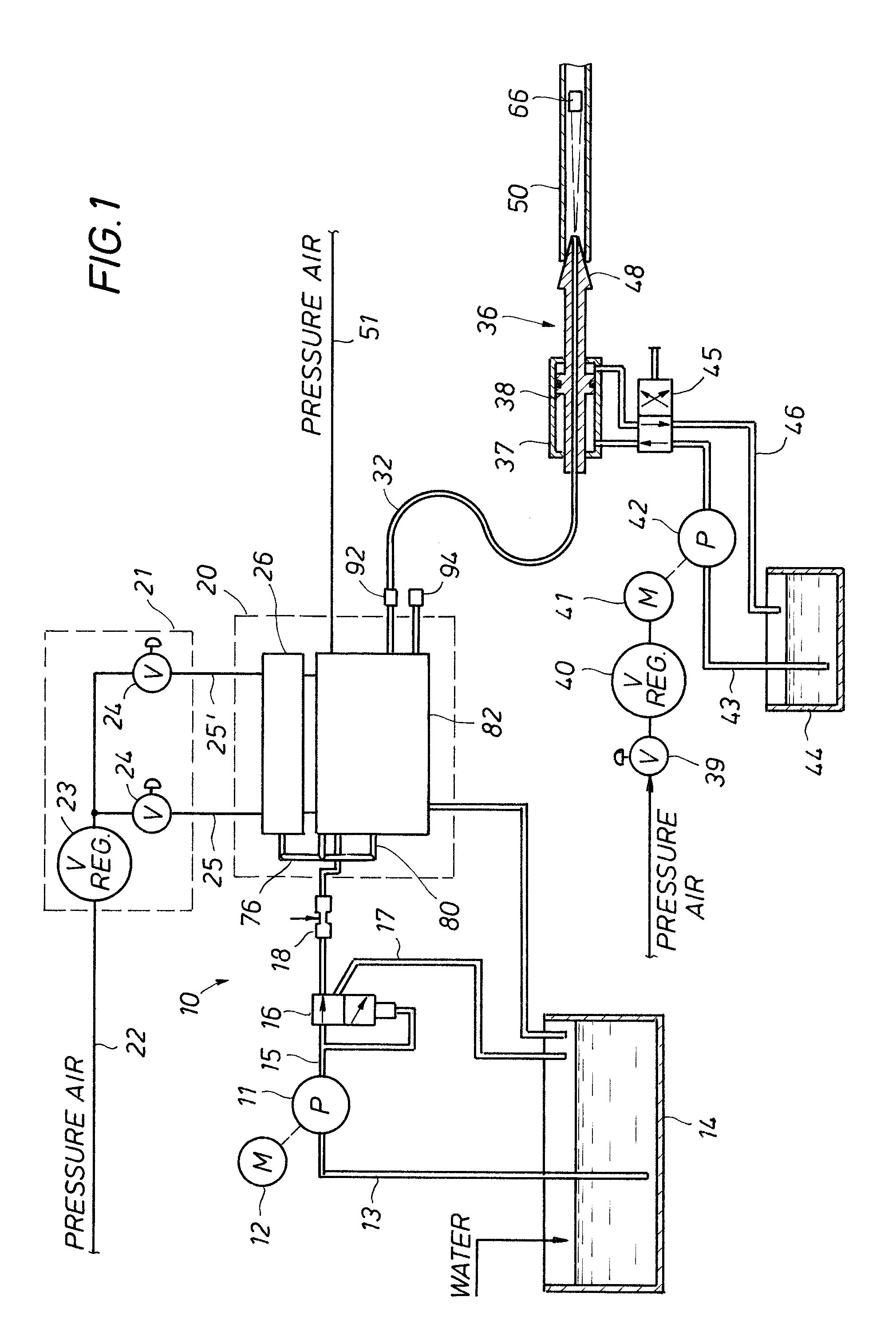

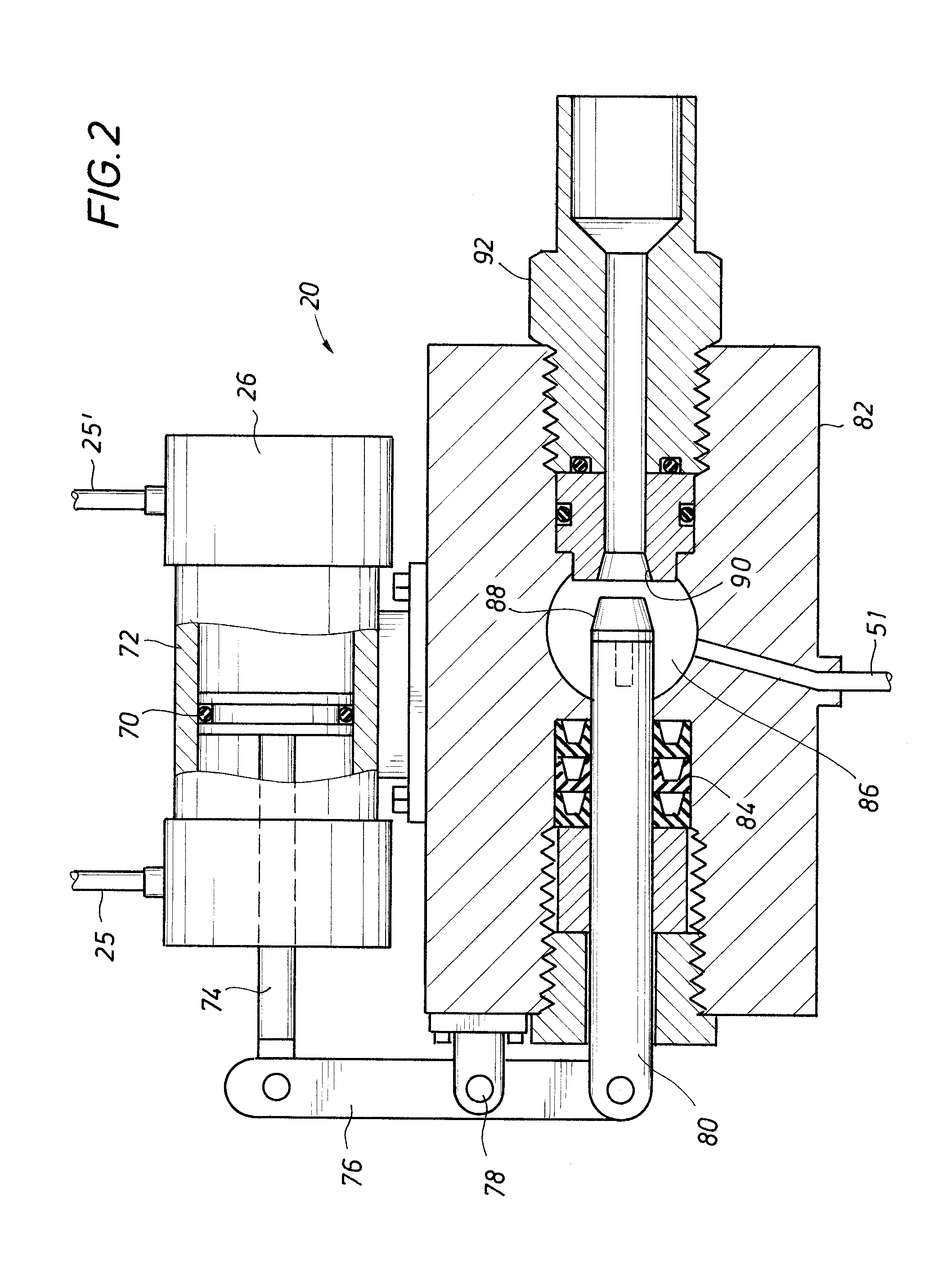

Foam extrusion apparatus

InactiveUS6113374AEasy to disassembleIncrease the sectionConfectionerySweetmeatsNarrow rangeFree rotation

An extrusion system utilizes single or tandem extruders and a mixer-cooler to extrude a foamable extrudate through a die in a sealable chamber. The foamable extrudate is shaped and calibrated within the chamber. The die is mounted on the end of a gel tube projecting through a gland seal in a fixed bulkhead forming the upstream end of the chamber. The gel tube and mixer-cooler are mounted on a movable carriage, movement of which may be used to adjust the die with respect to shaping and calibrating equipment inside the chamber. The mixer-cooler achieves a selected narrow range of uniform viscosity of the melt at the die depending on the size of the product and density. The chamber is preferably a vacuum chamber producing low density foams. The product exits the chamber to atmosphere on a continuous basis through a submerged orifice in a water baffle immersion seal. The mixer-cooler enables a large size low density product to be produced with uniform cellular structure without cell collapse or density gradients, as the product is subjected to the pressure and temperature transformations passing from the chamber to atmosphere through the water. The seal includes the submerged orifice with a free wheeling guiding system upstream of the orifice. Immediately ahead of the guiding system, the parameters of the foam extrudate are sensed to control the configuration of the orifice on a continuous basis. Before the extrudate passes into the water baffle seal it moves over a floating dancer roll, the position of which controls a haul-off such as a vacuum belt at the tail end of the system. This avoids pushing on the extrudate.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

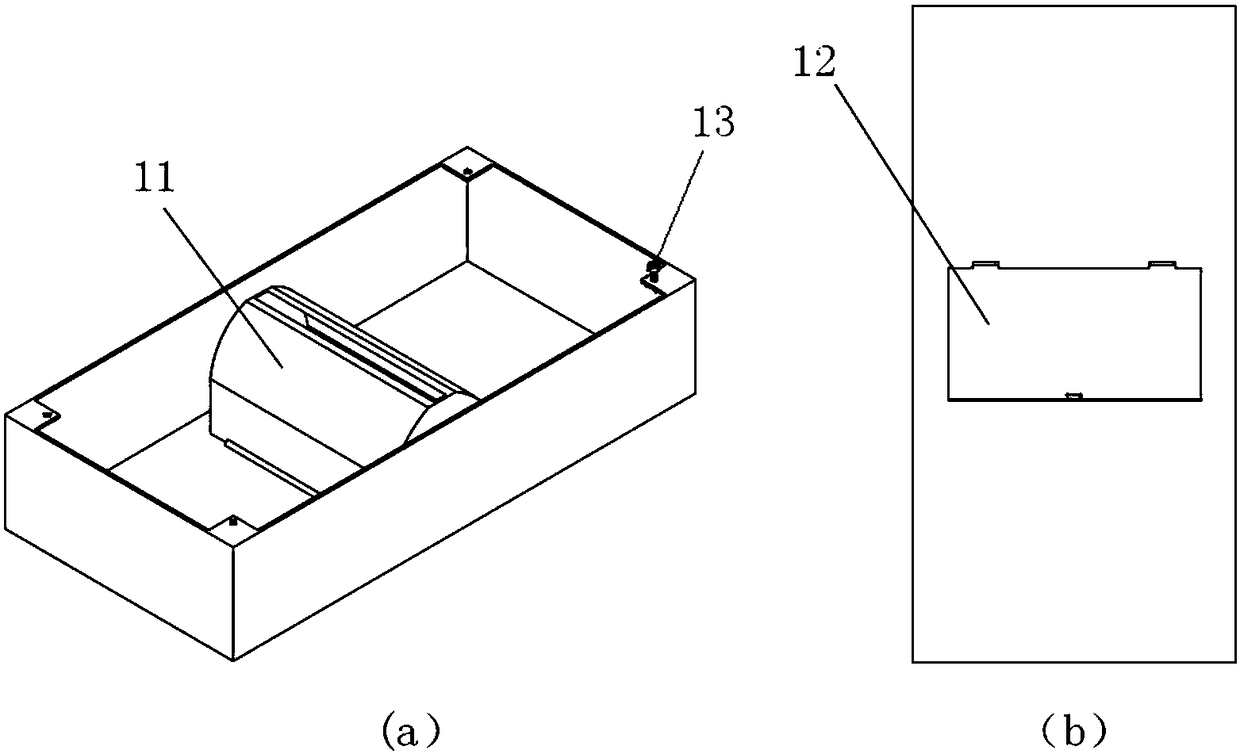

Polydimethylsiloxane micro-fluidic chip and preparation method thereof

InactiveCN103055981AQuick sealAchieve reversible bondingLaboratory glasswaresMicrofluidic chipMicro fluidic

The invention relates to a polydimethylsiloxane micro-fluidic chip and a preparation method thereof. The polydimethylsiloxane micro-fluidic chip is characterized in that the polydimethylsiloxane micro-fluidic chip consists of three layers of base materials, wherein the upper layer is a polydimethylsiloxane cover layer, the middle layer is a double-sided rubber layer, and the lower layer is a polydimethylsiloxane basal layer; and the micro-fluidic chip is prepared by adhering the upper and lower layers of base materials and the middle layer. The preparation method is characterized by comprising the following steps in sequence: (1) designing and drawing micro-channels of the micro-fluidic chip by using computer-aided design software; (2) processing the micro-channels as well as sample inlets on the base materials of the chip through a micro-processing technology; and (3) aligning, pressing and sealing the three layers of base materials to prepare the micro-fluidic chip. The polydimethylsiloxane micro-fluidic chip and the preparation method thereof have the advantages that no generator or ultraviolet irradiation equipment needs to be used in the preparation of the polydimethylsiloxane micro-fluidic chip provided by the invention, and rapid sealing of the polydimethylsiloxane can be realized.

Owner:SUZHOU WENHAO MICROFLUIDIC TECH CO LTD

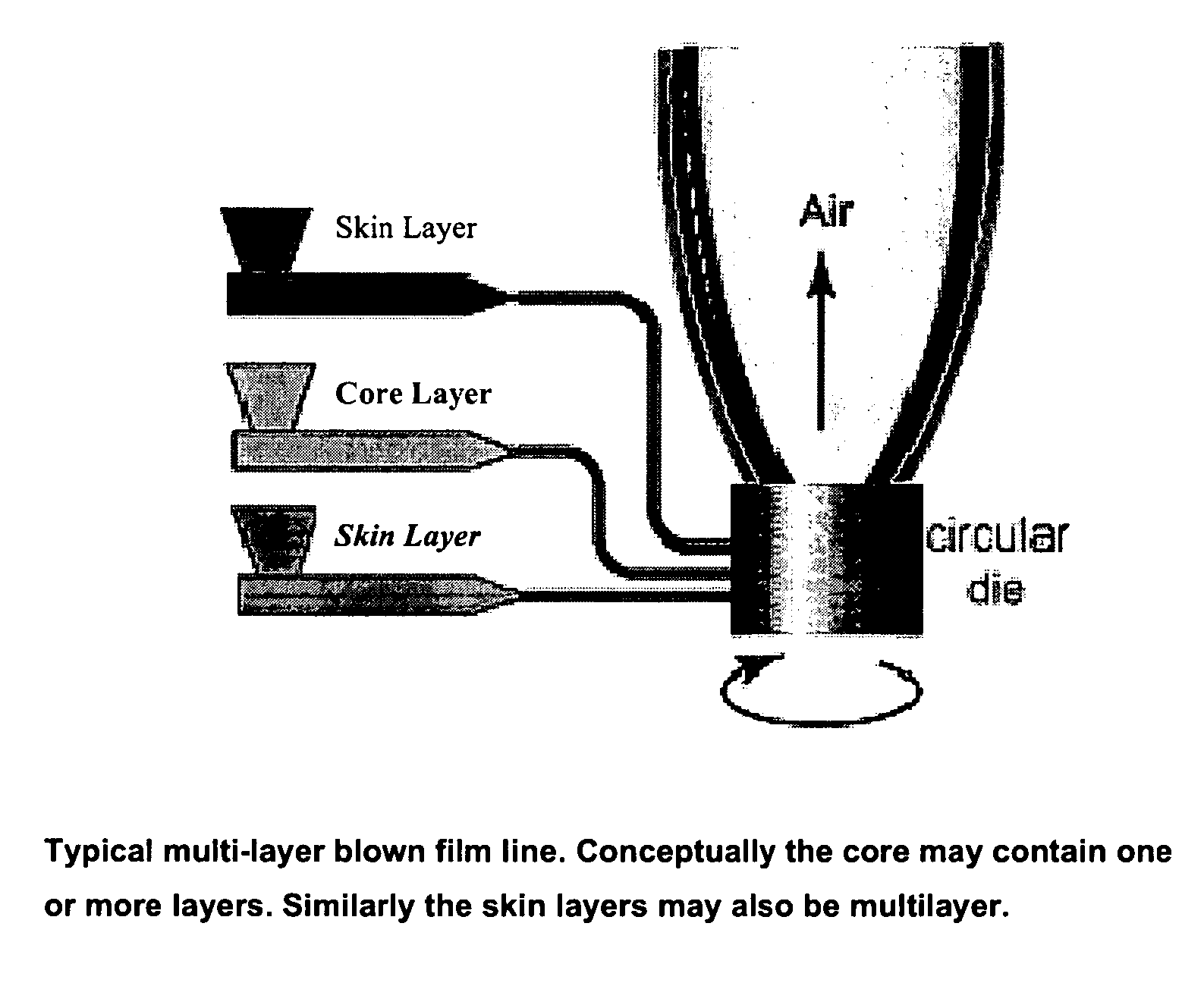

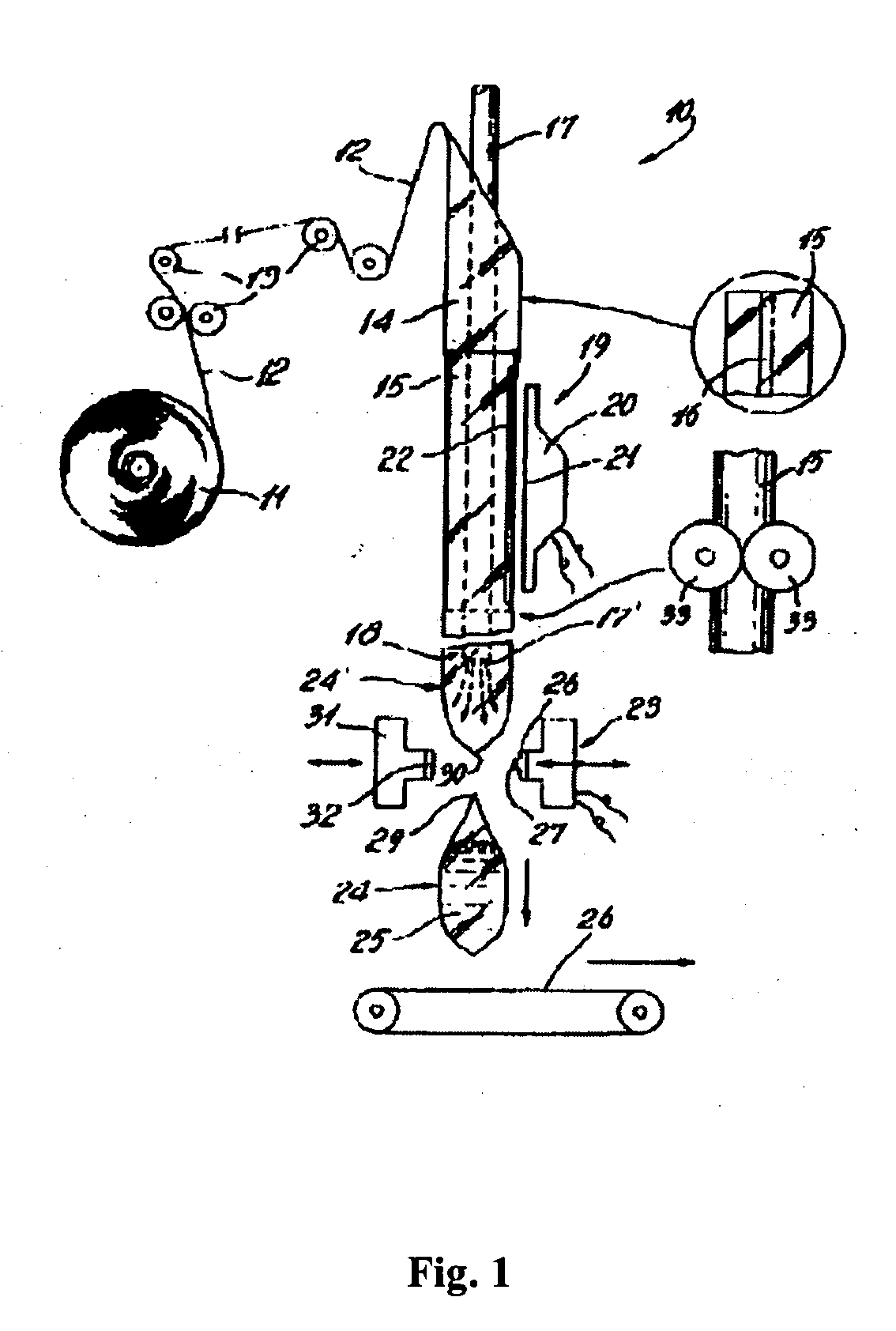

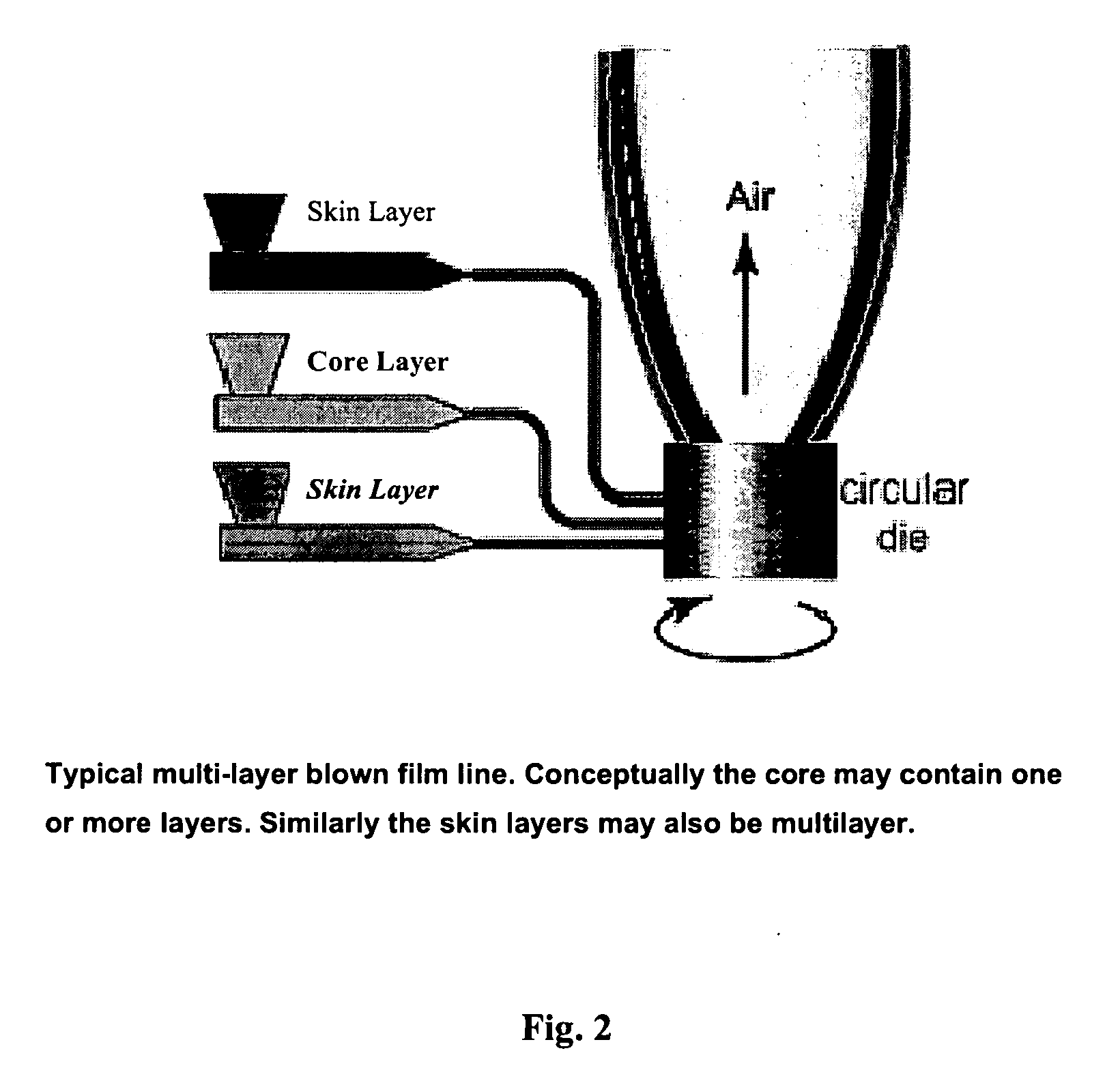

Thin film for vertical form fill and seal packaging of flowable materials

InactiveUS20070252276A1Quick sealImprove heat transfer characteristicsSemiconductor/solid-state device detailsSynthetic resin layered productsPolypropyleneLow-density polyethylene

A multi-layer film for vertical form, film and seal systems for liquid, powder, granules and / or other flowables packaging, said multi-layer comprising: an inner layer made of polyethylene, a blend of polyethylenes or ethylene copolymers; a core, comprising one or more than one layer, made from a blend of polypropylene, linear low density polyethylene, a polymer compatibilizer or tie-layer resin, and / or low density polyethylene, said core being applied against the inner layer; and an outer layer (same or different from the inner layer or the core layer) is made of a polyethylene or a blend of polyethylenes with or without ethylene copolymers, said outer layer being applied against the core and opposite the inner layer; said multi-layer film having an overall thickness of lower or equal to 2.5 mil and at least one of the properties listed hereinafter: a stiffness (as measured by 1% secant modulus in the film direction) varying from 79000 psi to 140000 psi; a tensile strength at yield of from 2100 psi to 3300 psi; (measured in film machine direction) and a tensile strength at break of from 4700 to 6700 psi (measured in film machine direction). A method of forming, sealing and filling a pouch with said film, a pouch formed with said film and use of said film to form a pouch.

Owner:LLOYD GEORGE IAN

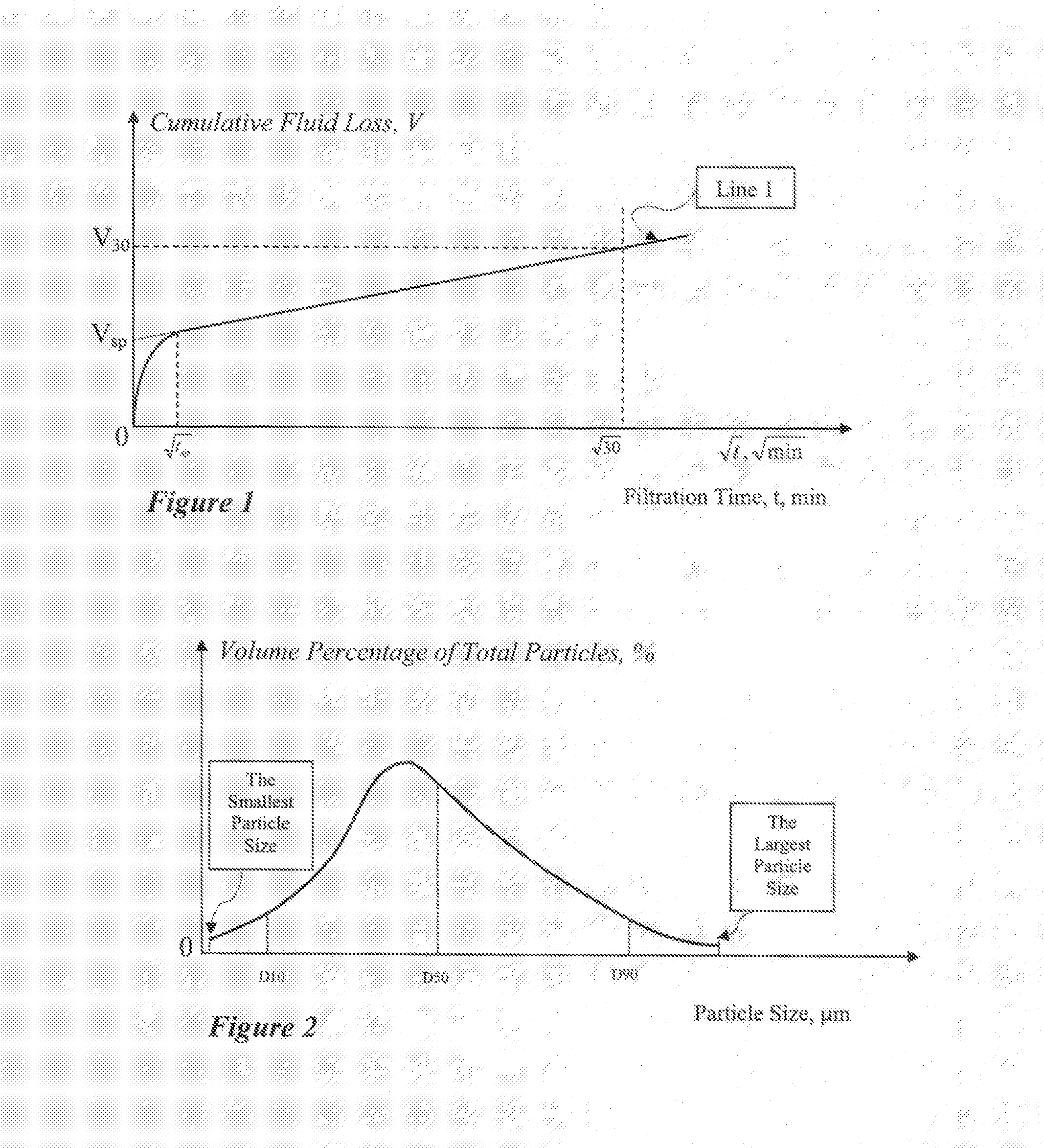

Method of Stopping Lost Circulation

InactiveUS20150292279A1Fast strengthening of its initially formed sealQuick upgradeFlushingDrilling compositionParticulatesLost circulation

A method for forming a seal to subterranean fractures or other voids penetrated by a wellbore comprises a particulate sealing formulation of fast sealing and / or fast strengthening. To achieve fast sealing, the particulate formulation is comprised of multiple groups of particulates of a narrow particle size distribution. Furthermore, the method comprises minimizing the spurt loss of a formulation by adjusting its particulates larger than D30, based on evaluation with a slot disk test method. The fast strengthening of the formulation is achieved by fast accumulation of particulates. Furthermore, the method comprises maximizing the fluid loss after spurt of a formulation by adjusting its particulates smaller than D30 or adding some diatomaceous earth or selecting particulates of a D75 larger than 75 microns and with a narrow particle size distribution. At least 5% of the sealing particulates by weight of the total particulates are smaller than 200 micron and acid soluble.

Owner:SHARP ROCK TECH

Normal-temperature sealer for anodic oxide film of aluminum and aluminum alloy and sealing method thereof

InactiveCN101665970AQuick sealImprove sealing efficiencySurface reaction electrolytic coatingTetramineDodecylsulfonic acid

The invention provides a normal-temperature sealer for an anodic oxide film of aluminum and aluminum alloy. The sealer is characterized by comprising the following components in concentration (g / L): Ni<2+>0.8-1.3, F<-> 0.4-0.8, triethanolamine 0.1-5.0, hexamethylene tetramine 0.1-1.0, sodium dodecanesulphonate0.001-0.1, bloom inhibitor 0.01-2.0 and the balance of water. The invention also discloses a sealing method for the sealer. Compared with the prior art, the sealer has the advantages of low cost, easy preparation, easy operation, and great improvement on the surface anti-pollution ability, the anti-corrosion property and the electric insulativity of the anodic oxide film of the aluminum alloy.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

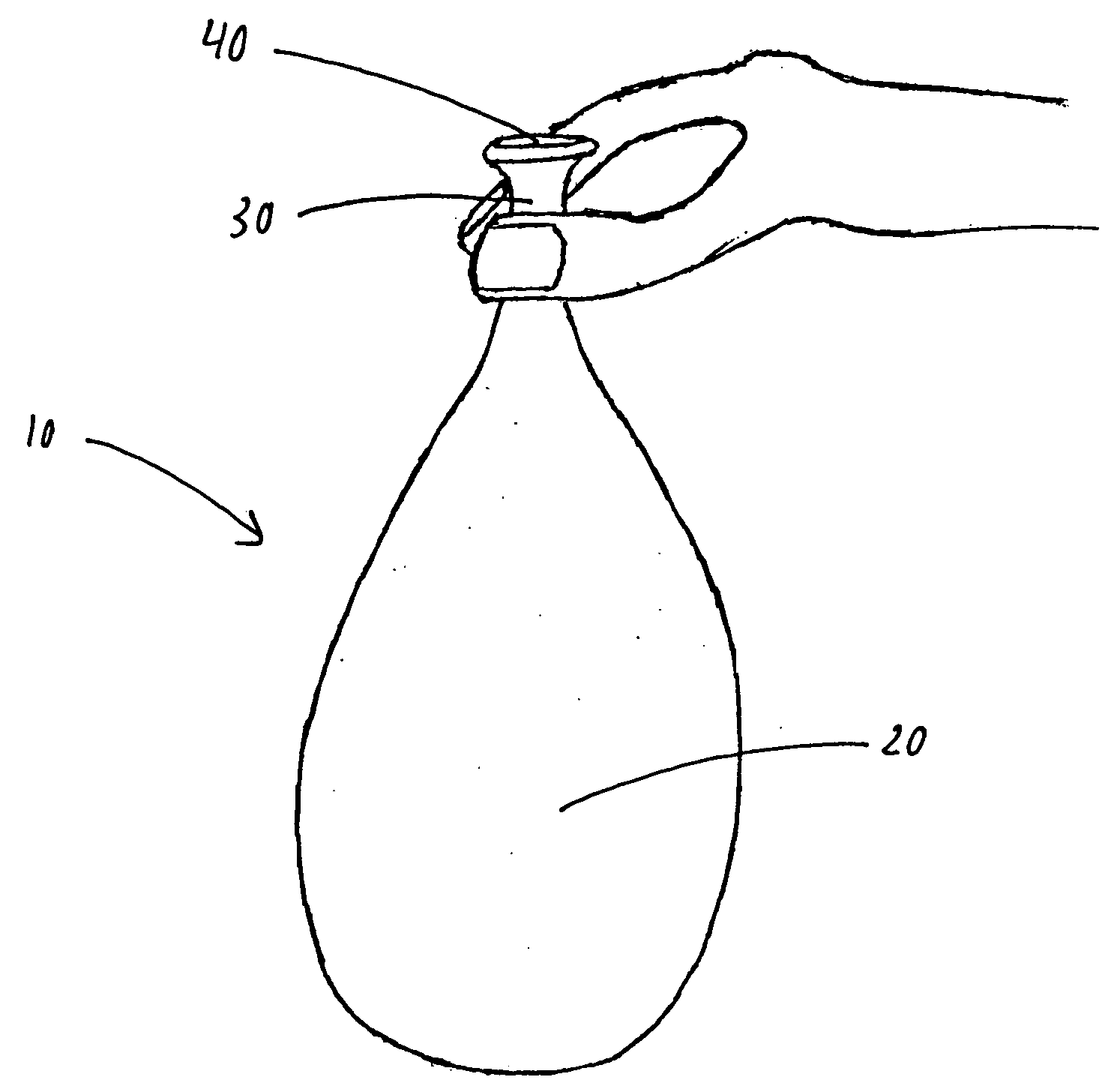

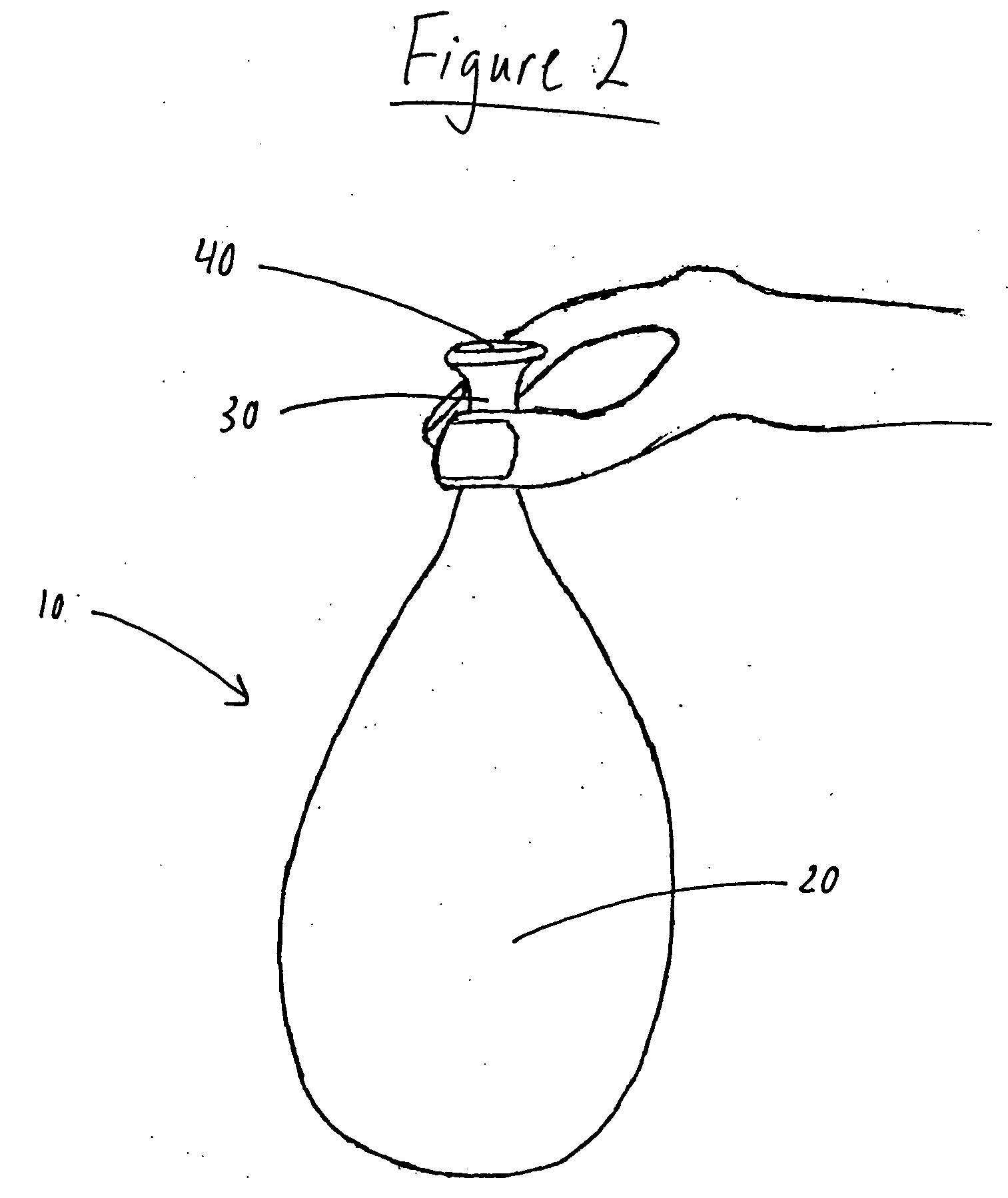

Toy water balloon

InactiveUS20050176339A1Easy and painless and quickEfficient and cost-effective designDollsToy aircraftsGeneral surgery

The present invention provides a water balloon with a quick, easy, and low-cost means for sealing the balloon orifice. For example, the water balloon may comprise a liquid-activated closure mechanism along the inside of the balloon neck. A user then activates the closure mechanism while filling the balloon with water and may then seal the balloon orifice by pinching the balloon neck.

Owner:CUISINIER JARRET P

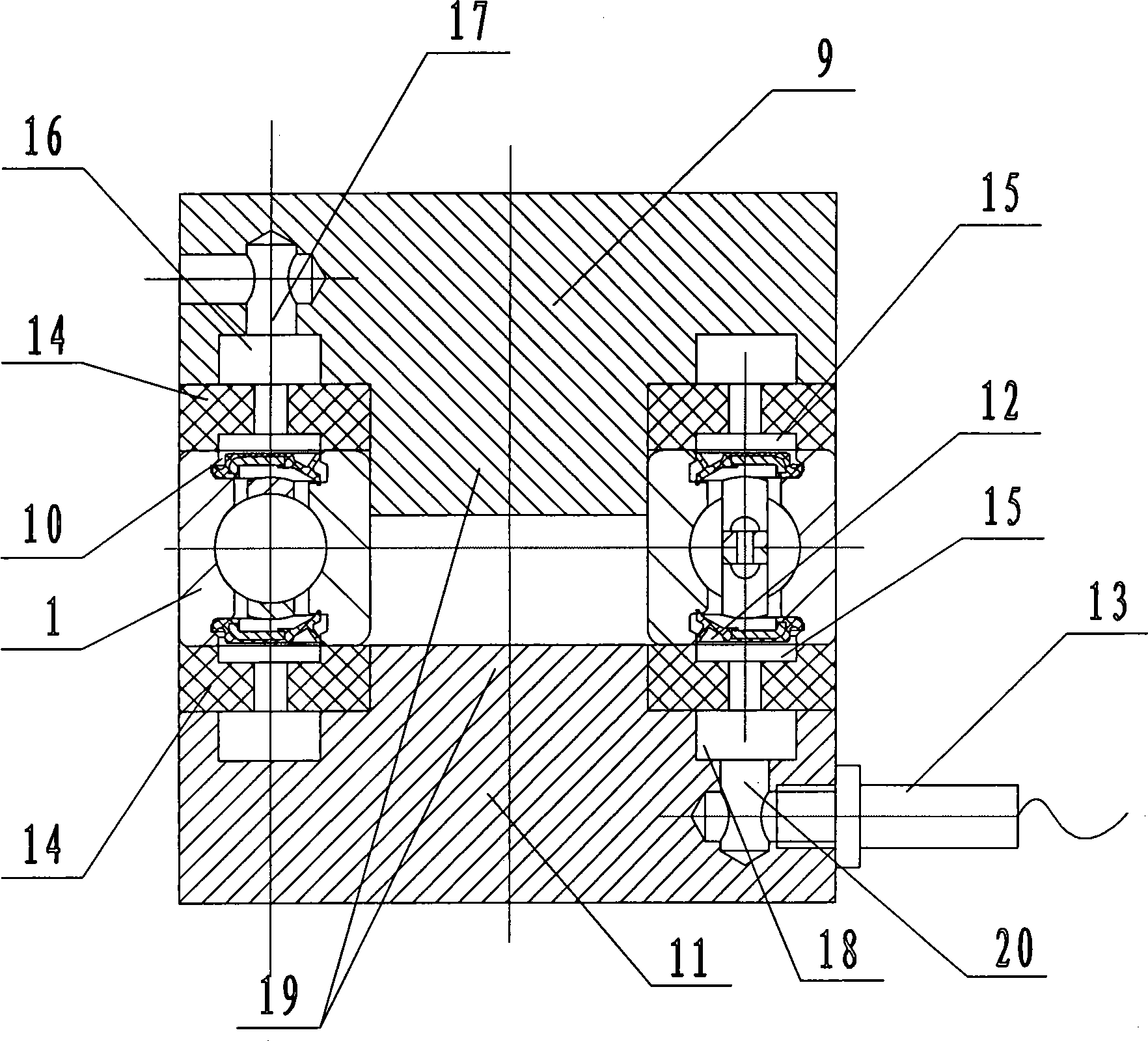

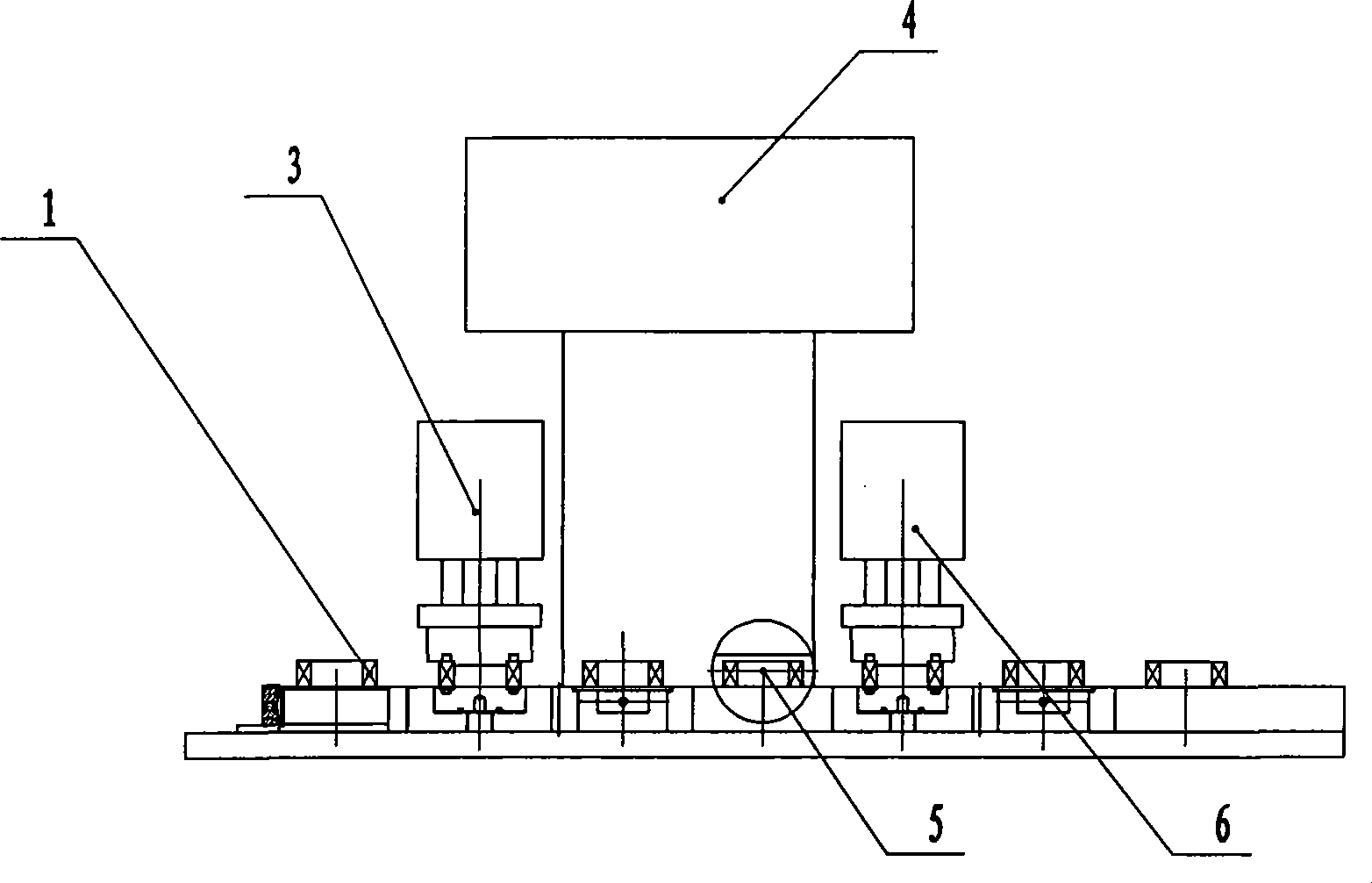

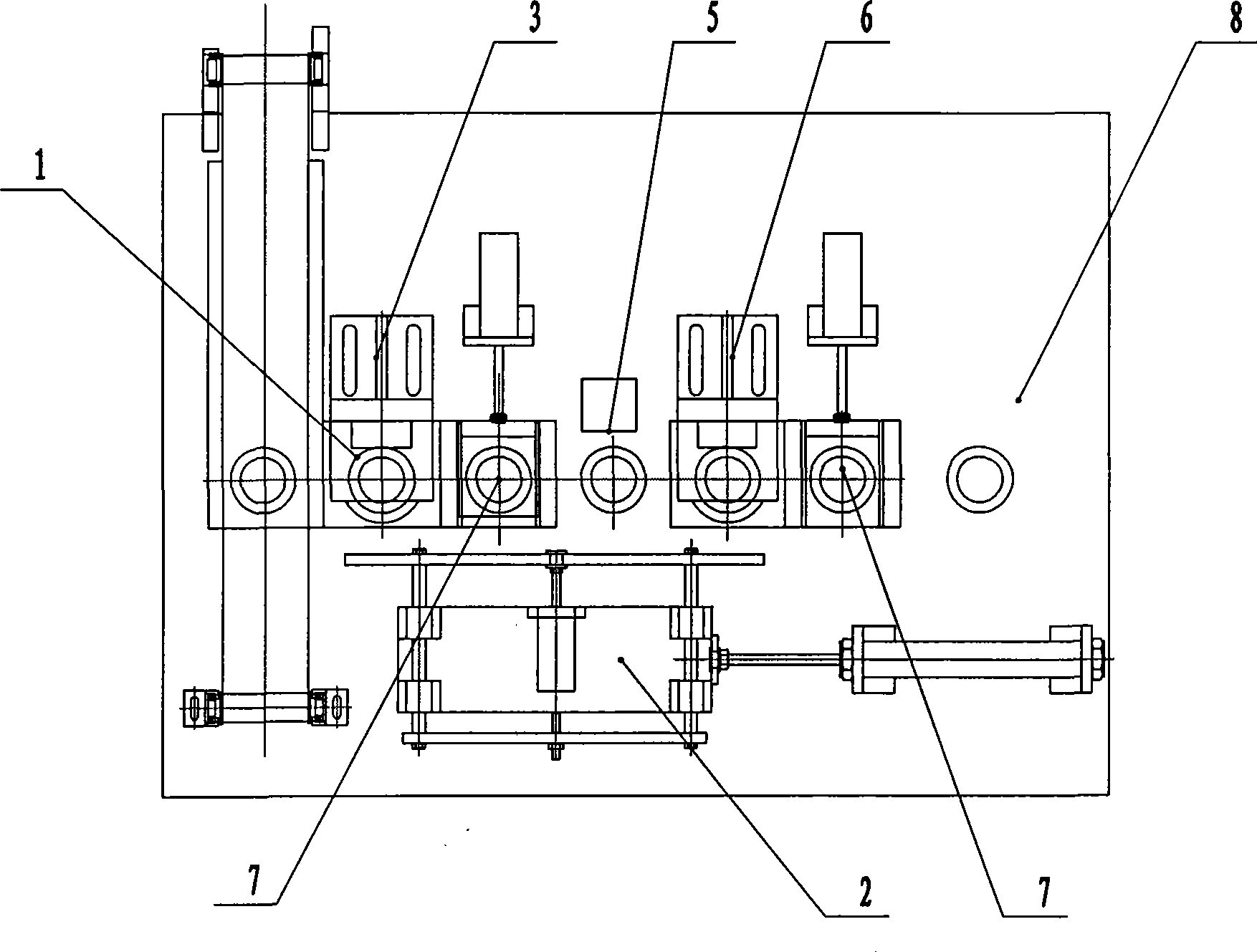

Method and device for detecting sealing property of seal bearing

ActiveCN101435735AThe detection method is simpleEasy to installMeasurement of fluid loss/gain rateMachine bearings testingInformation controlEngineering

The invention relates to a device and a method for detecting sealing property of a sealed bearing. An upper sealed mould hermetically contacts an inner ring and an outer ring on one end face of a bearing to be detected, and the upper sealed mould is provided with an upper sealed air vent communicating the end face of the bearing; a lower sealed mould hermetically contacts an inner ring and an outer ring on the other end face of the bearing to be detected, and the lower sealed mould is provided with a lower sealed air vent communicating the end face of the bearing; and the upper air vent is connected with compressed air, and the lower air vent is connected with a sensor which is connected with an information control processing device. The device has the advantages of simple structure, convenient detection means and accurate result. When the upper sealed mould is connected with a power driving mechanism, the device achieves semiautomatic detection. A sealed gasket makes seal of the inner ring and the outer ring on the end face of the bearing more reliable. A positioning mandrel ensures that detection of the bearing is quicker and installation of the bearing accurate. Under the control of the information control processing device, the device matched with other auxiliary devices, and can achieve automatic detection.

Owner:QINGDAO TAIDE AUTOMOBILE BEARING

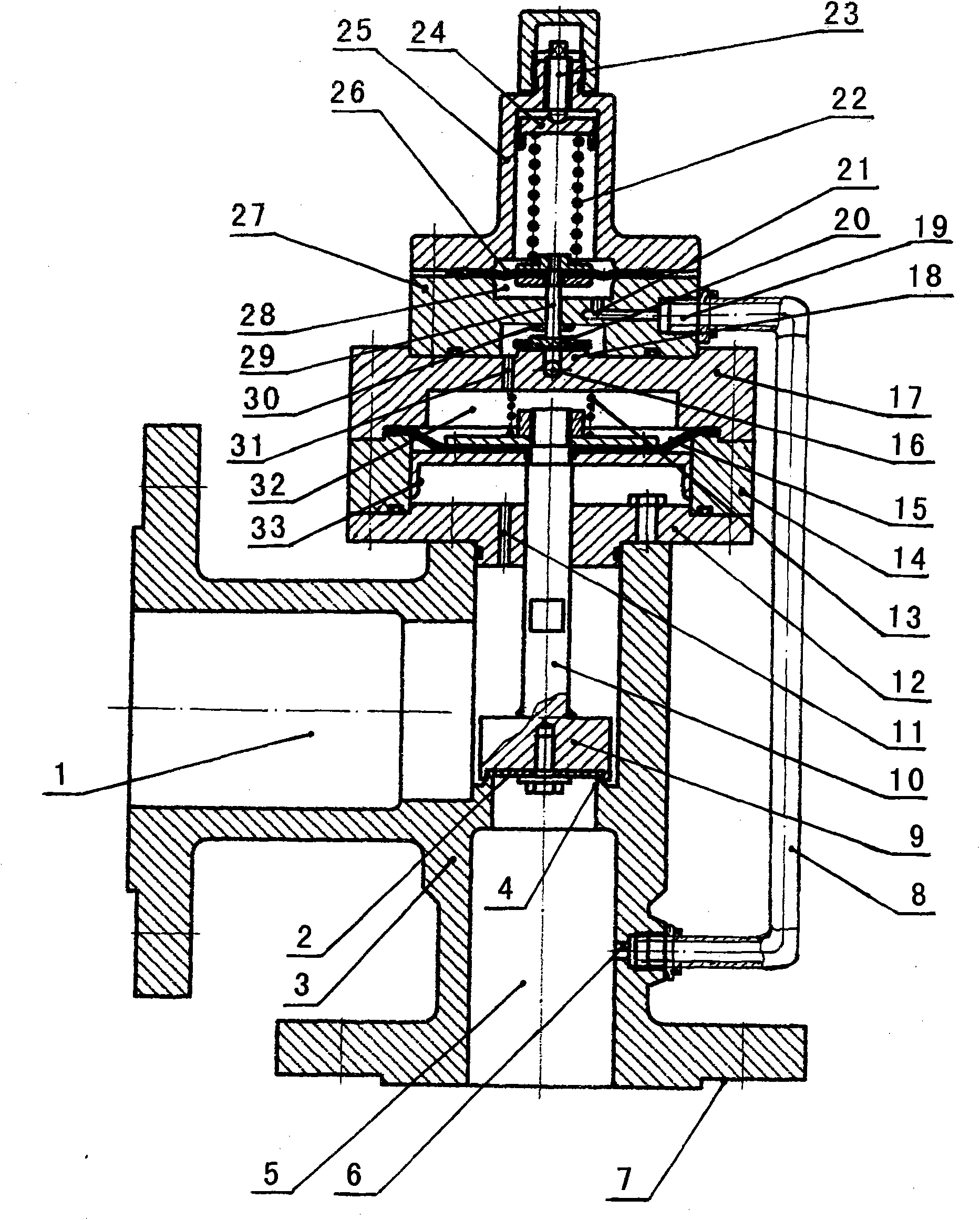

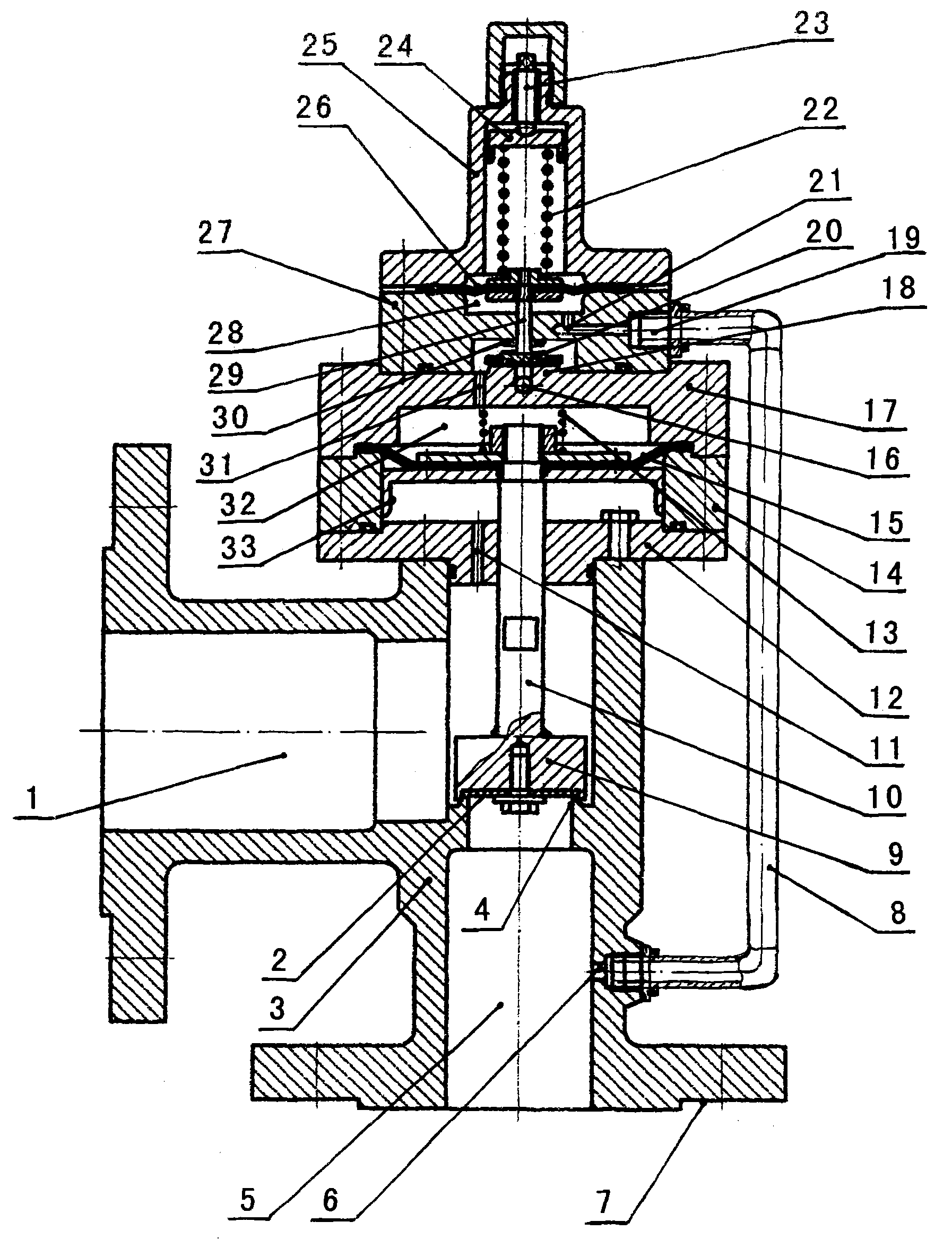

Low-pressure pilot operated safety valve

ActiveCN102147028AAccurate and reliable return to seatQuick conversionEqualizing valvesSafety valvesEngineeringReaction speed

The invention discloses a low-pressure pilot operated safety valve. The valve comprises an execution mechanism, a transmission mechanism and a conversion mechanism, wherein the execution mechanism consists of a main valve body, a valve rod and a valve core; the transmission mechanism of a balance air chamber consists of a partition board, a cylinder, a piston and a diaphragm assembly; the conversion mechanism of a control air chamber consists of a pilot valve seat, a valve core cover, a diaphragm assembly and a pilot valve core; the pilot valve core can quickly perform air chamber sealing conversion between the pilot valve seat and the valve core cover when sensing the pressure change and moving up and down, and pressure in the control air chamber and the balance air chamber is quickly converted by switching an external drain hole; and by increasing and reducing the area of the air chambers, the main valve can be quickly opened to exhaust air and relieve pressure so as to ensure the safety, and the main valve can be accurately and stably seated and tightly closed. The valve has novel design and simple structure, the excessive pressure is only 1 to 3 percent, the opening precision is very high, the response speed is very high, the seating pressure range is a fixed value, the seating reset is accurate and reliable, and the valve has very good market prospect.

Owner:四川长仪油气集输设备股份有限公司

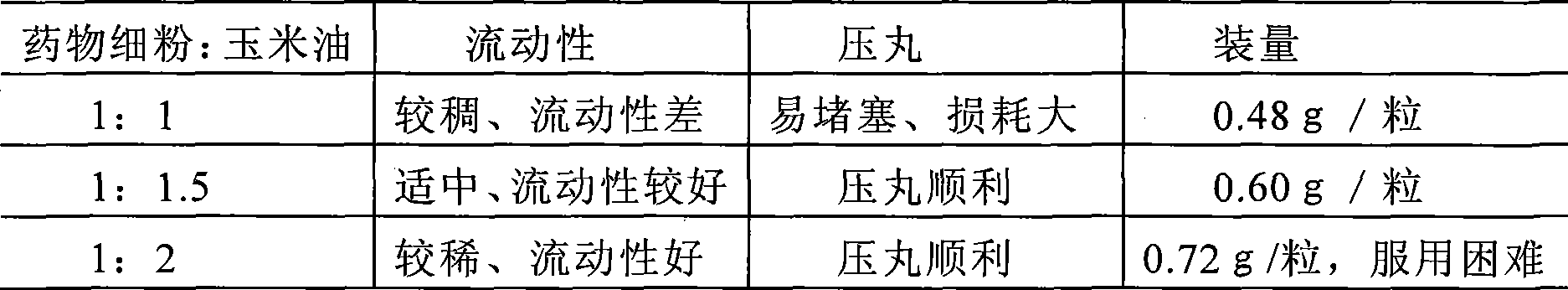

Niuhuangshangqing soft capsule and preparation method thereof

ActiveCN101444570AAvoid volatile lossPrevent oxidationHydroxy compound active ingredientsComponent separationVegetable oilMoisture absorption

The invention relates to a Niuhuangshangqing soft capsule and a preparation method thereof, as well as a quality control method of capsule contents. The Niuhuangshangqing soft capsule comprises contents and capsule shell. The contents include an extent of Chinese medicinal materials in Niuhuangshangqing prescription and a dispersion medium with a weight ratio of 1:(1-2), wherein, the dispersion medium is vegetable oil. The soft capsule is prepared by extracting effective components from Chinese medicinal materials in Niuhuangshangqing prescription in accordance with the properties of the effective components by using different modern extraction techniques and making into soft capsule. The soft capsule has embedding and masking effects, and can prevent volatilization loss of oil components and oxygenation or photodecomposition of effective components. The soft capsule also has the advantages of rapid disintegration, uniform dispersion, high bioavailability, good stability of effective components, low liability of moisture absorption, good air tightness, direct intestinal absorption after disintegration, masking of unpleasant odors of effective components, convenience for administration and carrying, and so on.

Owner:TAIJI GROUP

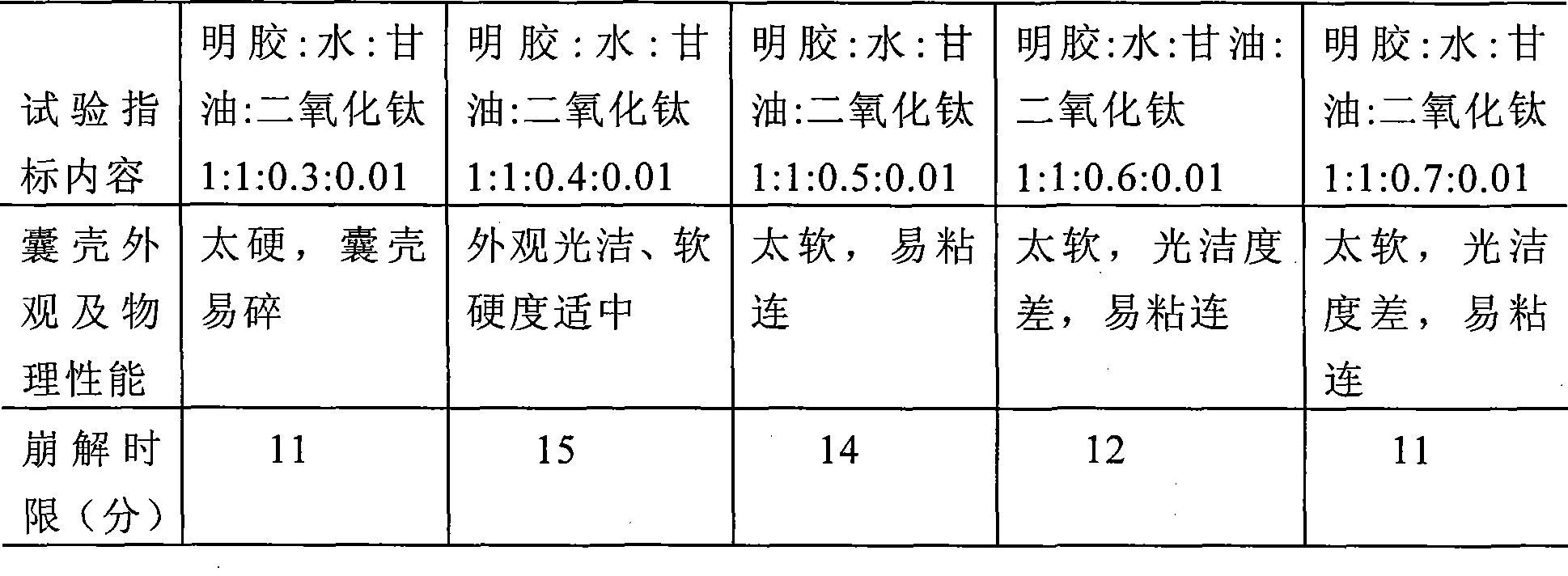

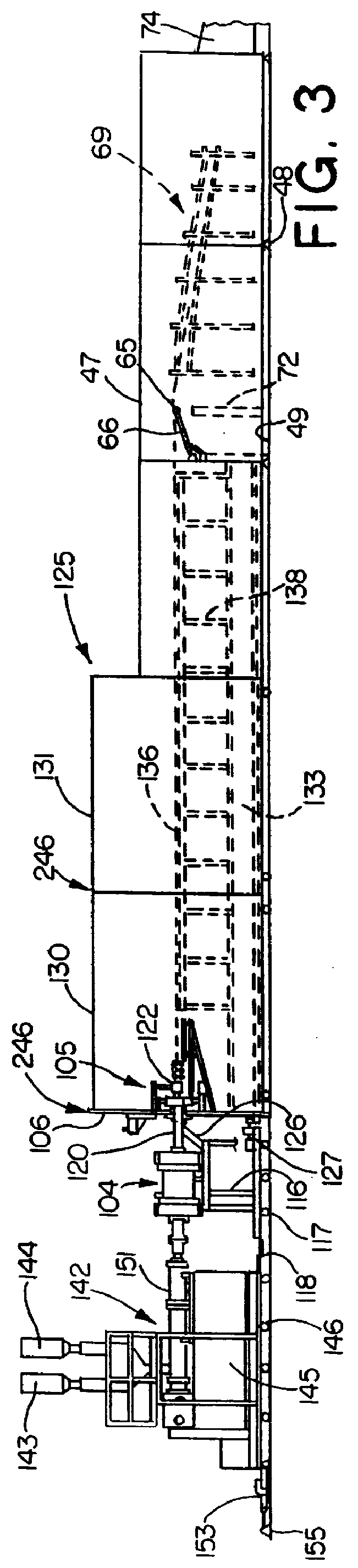

Sealable chamber extrusion apparatus with seal controls

InactiveUS6116882AReadily removeIncrease cross-sectional areaConfectionerySweetmeatsHoneycomb structureEngineering

An extrusion system utilizes single or tandem extruders and a mixer-cooler to extrude a foamable extrudate through a die in a sealable chamber. The foamable extrudate is shaped and calibrated within the chamber. The die is mounted on the end of a gel tube projecting through a gland seal in a fixed bulkhead forming the upstream end of the chamber. The gel tube and mixer-cooler are mounted on a movable carriage, movement of which may be used to adjust the die with respect to shaping and calibrating equipment inside the chamber. The mixer-cooler achieves a selected narrow range of uniform viscosity of the melt at the die depending on the size of the product and density. The chamber is preferably a vacuum chamber producing low density foams. The product exits the chamber to atmosphere on a continuous basis through a submerged orifice in a water baffle immersion seal. The mixer-cooler enables a large size low density product to be produced with uniform cellular structure without cell collapse or density gradients, as the product is subjected to the pressure and temperature transformations passing from the chamber to atmosphere through the water. The seal includes the submerged orifice with a free wheeling guiding system upstream of the orifice. Immediately ahead of the guiding system, the parameters of the foam extrudate are sensed to control the configuration of the orifice on a continuous basis. Before the extrudate passes into the water baffle seal it moves over a floating dancer roll, the position of which controls a haul-off such as a vacuum belt at the tail end of the system. This avoids pushing on the extrudate.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

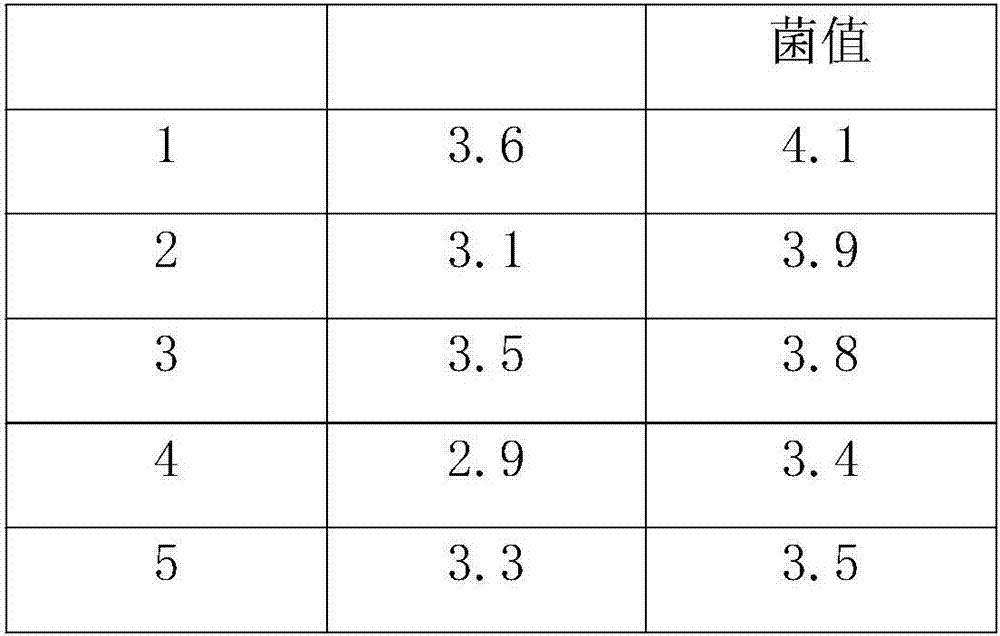

High-strength antibacterial aluminum alloy for aluminum alloy ladder and preparation method thereof

ActiveCN107201469AHigh hardnessImprove toughnessAnodisationMicro arc oxidationPlasma electrolytic oxidation

The invention relates to the technical field of aluminum alloy ladder preparation, and particularly relates to high-strength antibacterial aluminum alloy for an aluminum alloy ladder and a preparation method thereof. The aluminum alloy comprises a high-strength aluminum alloy matrix and a micro-arc oxidation film, wherein the micro-arc oxidation film is arranged on the surface of the aluminum alloy matrix, the weight of a hole sealing agent on the micro-arc oxidation film is 0.15 g / cm<2> to 0.90 g / cm<2>, and the hole sealing agent covers at least 92% of micropores in the micro-arc oxidation film. The preparation method comprises the steps of smelting metal, modifying, refining and degassing, pouring and forming and performing quenching treatment, aging treatment, micro-arc oxidation and hole sealing treatment, wherein in the step of modifying, nanometer modificators are uniformly dispersed into liquid alloy obtained by smelting; in the step of refining and degassing, 0.23% to 0.38% of hexachloroethane is added to the modified liquid alloy so as to refine and degas; and the aging treatment is divided into four-stage aging treatment. The aluminum alloy prepared by adopting the preparation method has the characteristics of high hardness, high strength, wear resistance, corrosion resistance, good anti-cracking performance, good antibacterial effect, difficulty in aging and deformation and long service life.

Owner:浙江洋铭实业有限公司

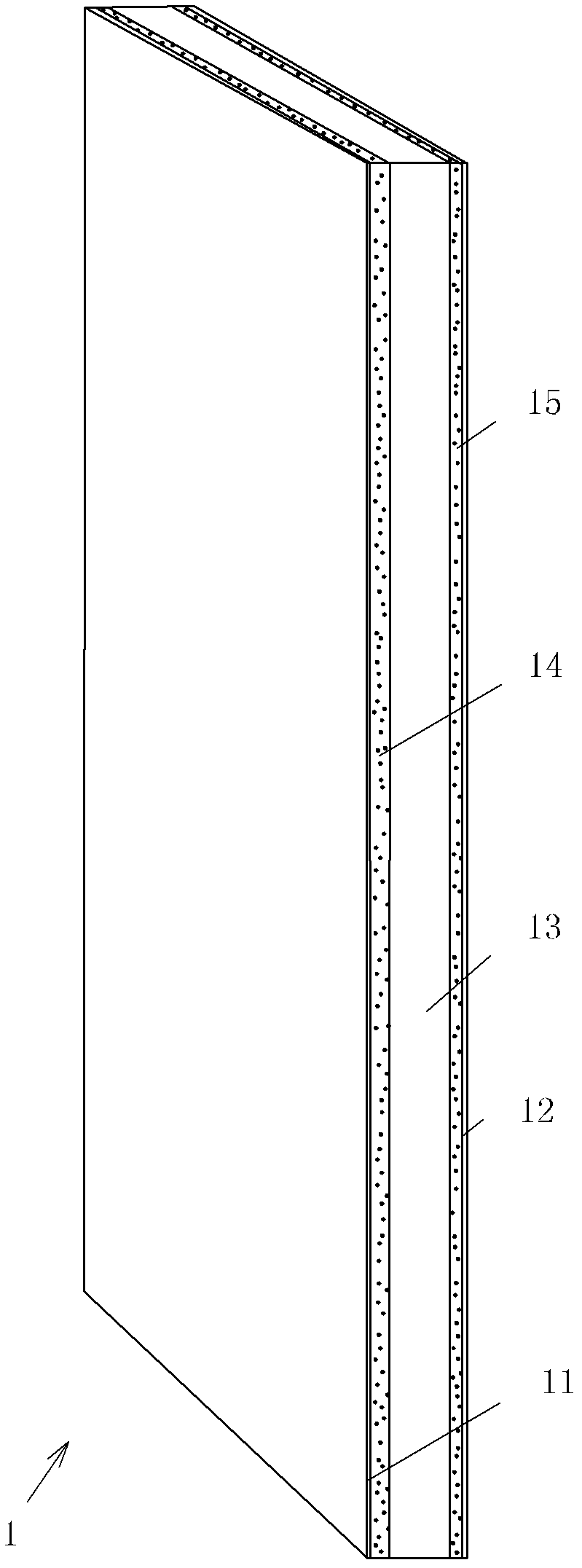

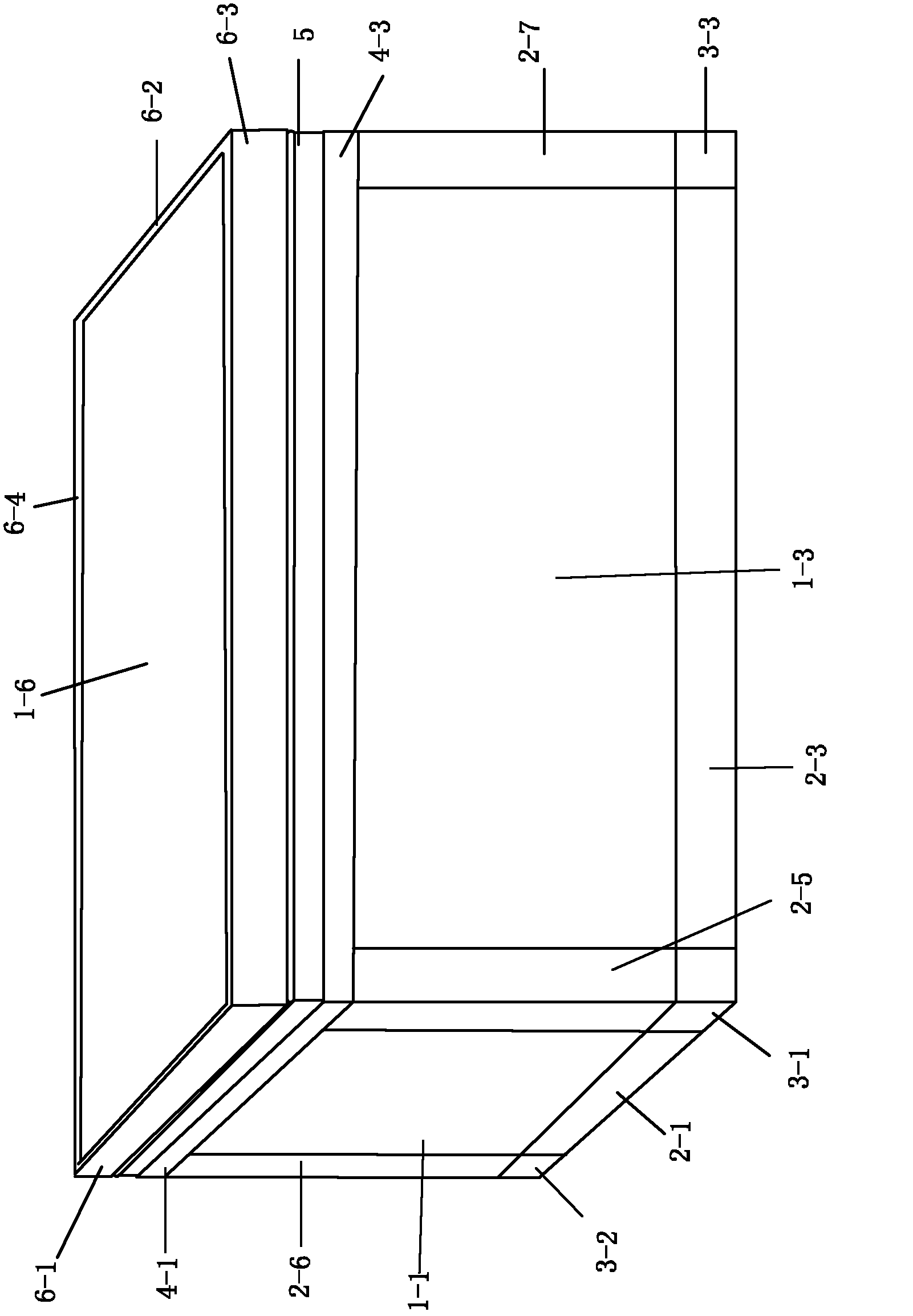

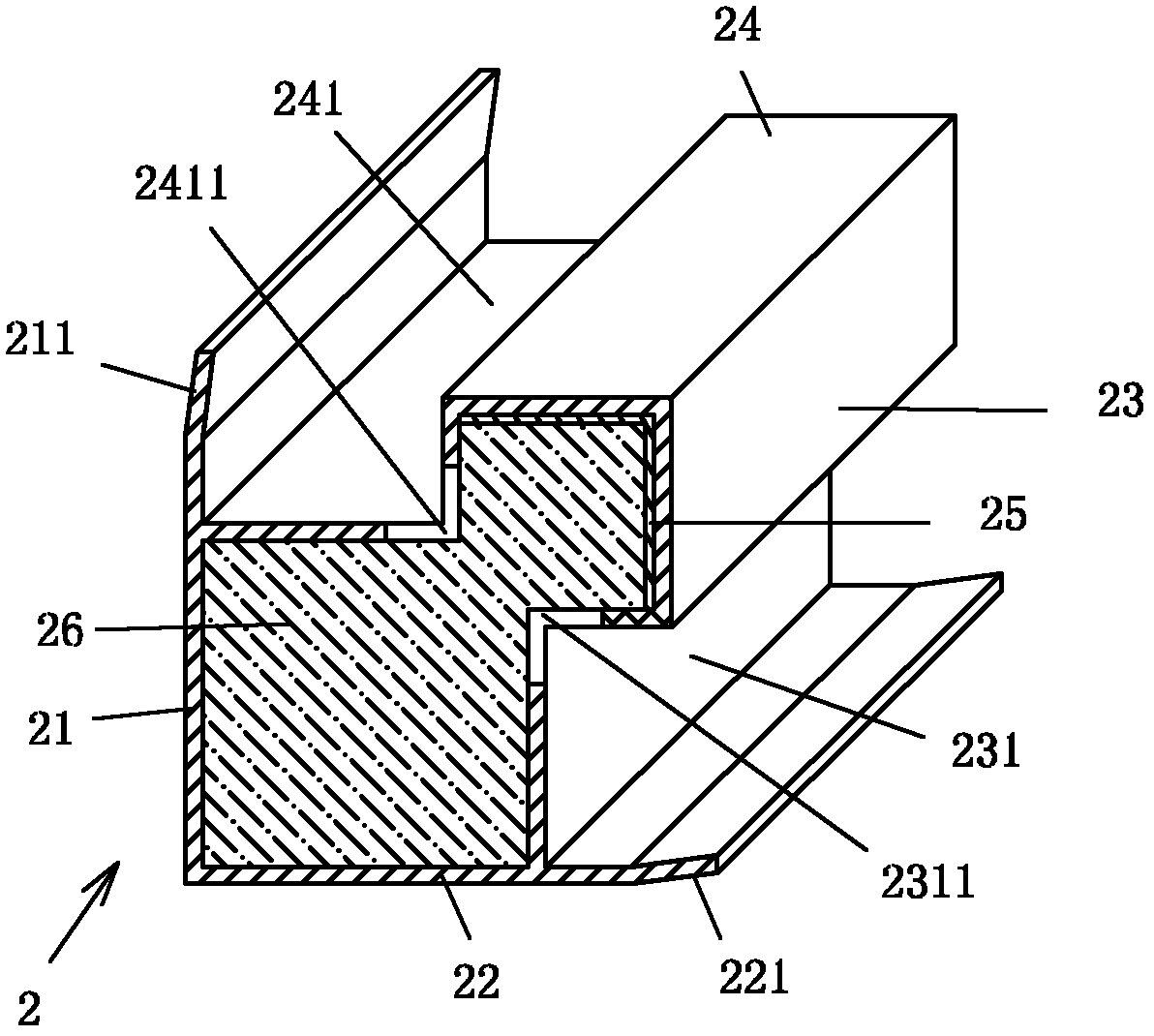

Rectangular vacuum insulation structural board and heat preservation box assembled by same

ActiveCN103174913AMaximize insulation capacityExert thermal insulation abilityThermal insulationDomestic cooling apparatusAdhesiveEngineering

The invention discloses a rectangular vacuum insulation structural board and a heat preservation box assembled by the rectangular vacuum insulation structural board. According to the structural board, a vacuum insulation board is arranged between a rigid inner side face board and a rigid outer side face board which are identical in size through polyurethane (PU) expanded plastics or other insulated adhesives in a clamping mode, side edge strips are not arranged on the periphery between the inner side face board and the outer side face board. According to the heat preservation box, a rectangular box frame is formed by four rectangular angle connecting blocks, eight seamed edge section bars and four box opening section bars. The bottom of the box frame and four side faces of the box frame are respectively provided with rectangular vacuum insulation structural boards, and a box body with an opening at the upper end is formed. A rectangular ring-shaped door sealing strip is arranged on the periphery of the opening of the box body in a sleeved mode, and four sides of the rectangular ring-shaped door sealing strip are provided with magnet strips. A rectangular vacuum insulation structural board forms a door board which is buckled on the opening of the box body and seals the opening of the box body, wherein four sides of the rectangular vacuum insulation structural board are provided with edge sealing section bars, a steel board strip is arranged on the surface, facing the box body, of each edge sealing section bar of the door board, and each steel board strip is absorbed with each magnet strip corresponding to the door sealing strip. The rectangular vacuum insulation structural board is good in rigidity, high in appearance size precision, good in decorative performance and convenient to assemble and install.

Owner:FUJIAN SUPERTECH ADVANCED MATERIAL

SMS many component compound packing material and producing method with same

The invention relates to an SMS composite packaging material with multi-components and a production method thereof. The material includes two layers of spun-bonded fiber MINERVA and an interlayer which is a layer of melt-blown fiber. The MINERVA layers are bonded with a melt-blown layer through heat boning, acupuncture, spun-lace or ultrasonic; the MINERVA layers comprise two-component fiber and the melt-blown layer comprises one-component fiber. The production method includes the following processes: the fiber ejected by a spun-bonded machinery forms a web; when a web curtain moves to a melt-blown machinery, the melt-blown machinery ejects filaments to the moved web curtain; the web curtain continues to move to the spun-bonded machinery and the filaments are spread on the web curtain by the spun-bonded machinery ejects; at last, the process of strengthening the fiber and the web is carried out to obtain the martial in the invention. The invention not only can be widely used in the packaging material, but also can be used in the aspects of composition, surface-covering, a series of medical composite cloth and electrical wipes. Besides, the invention has the advantages of low melting point, fast sealing, high intensity and uneasy material spilling as well as favorable permeability and low cost.

Owner:DONGHUA UNIV

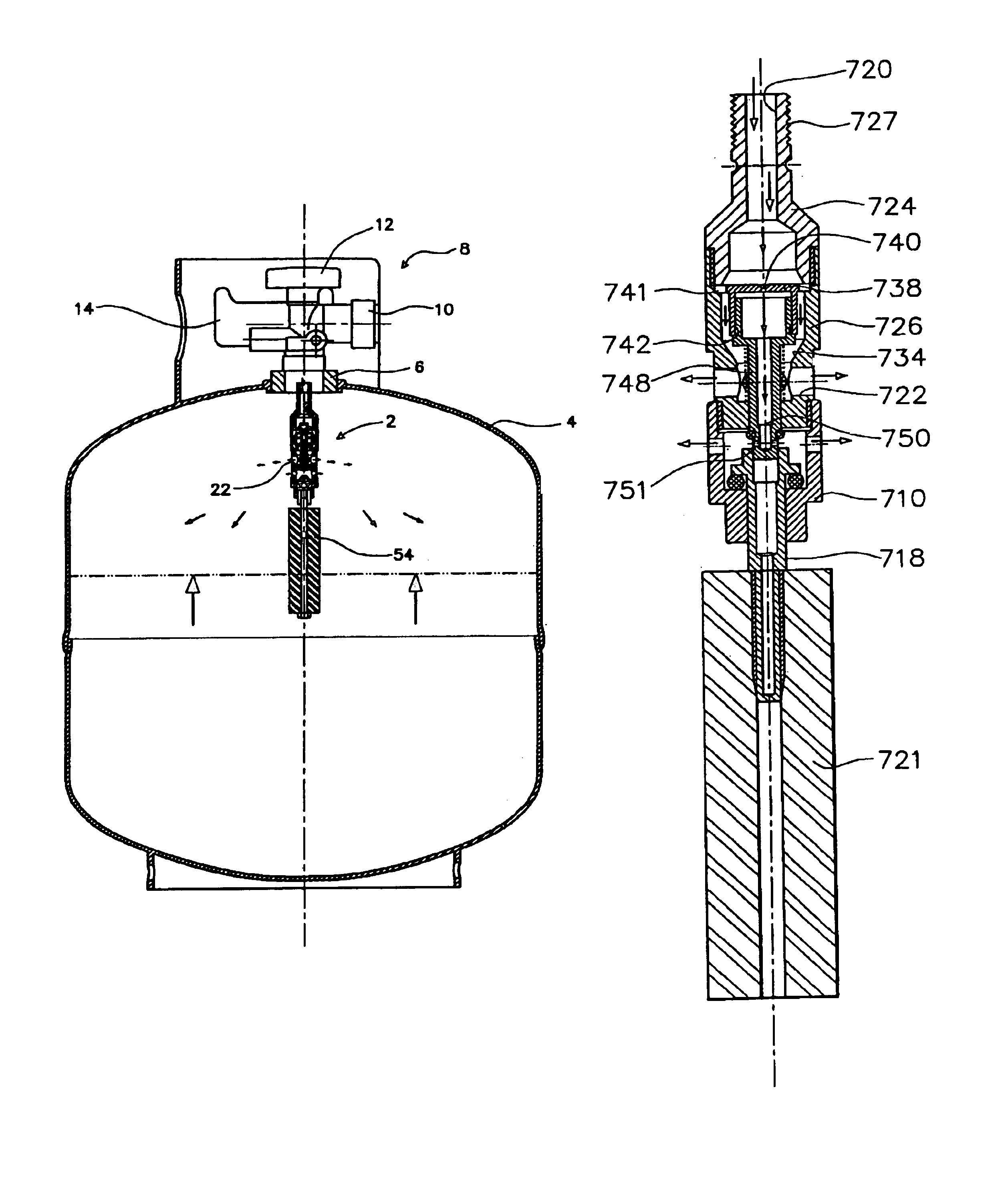

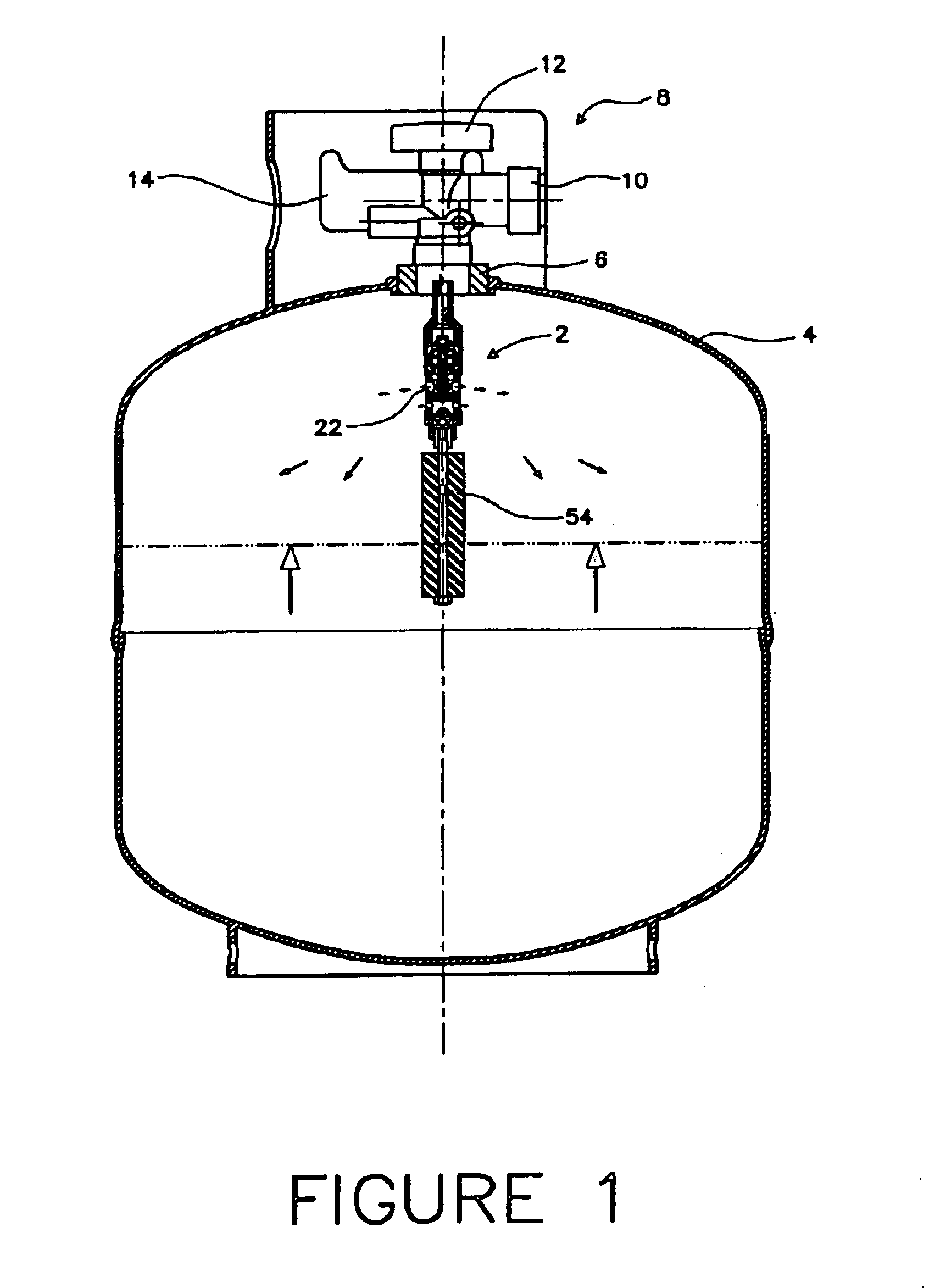

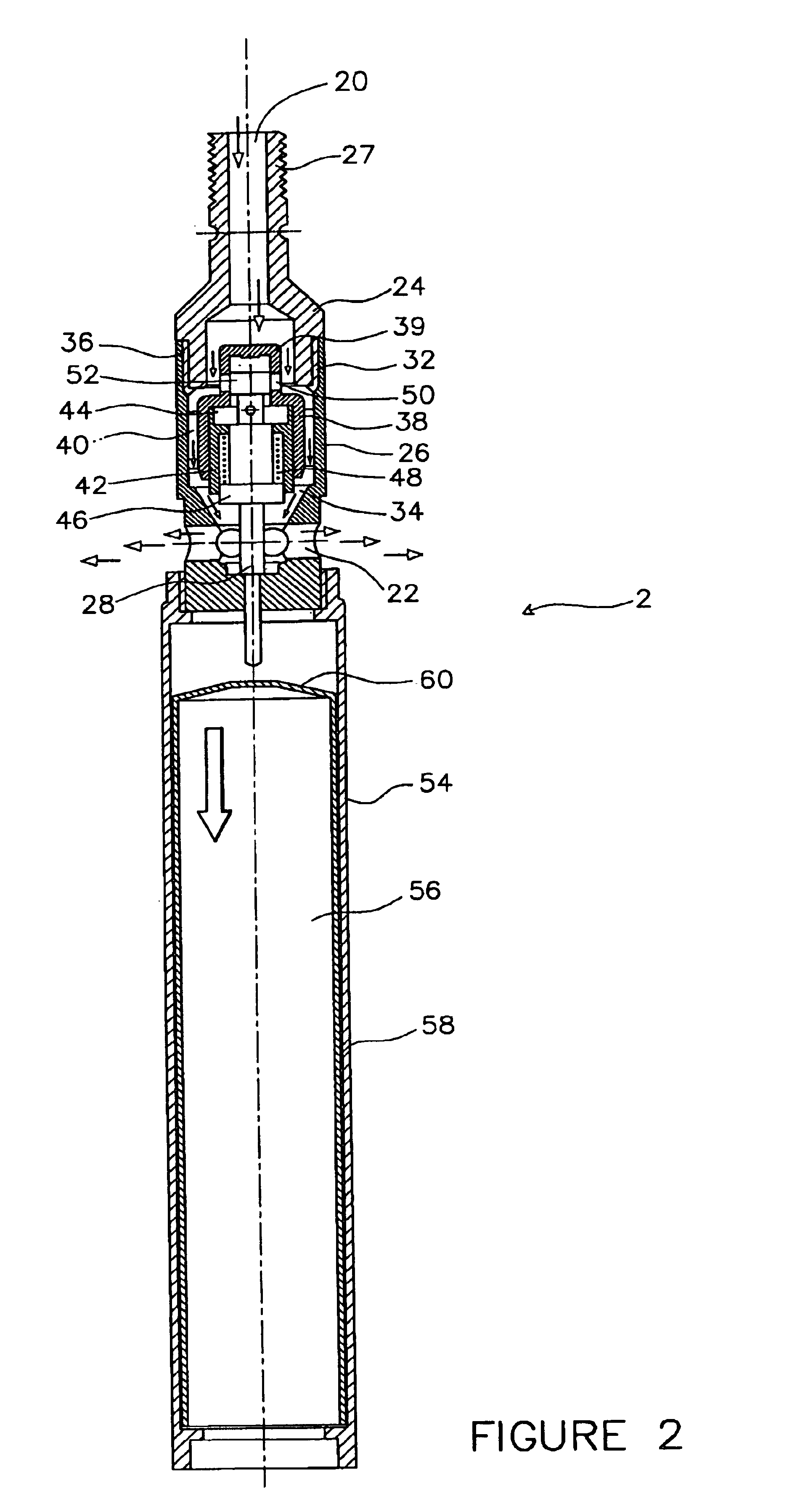

Valve assembly for pressurized fluid vessel

InactiveUS6910499B2Quick sealConvenient ArrangementOperating means/releasing devices for valvesSolid materialFluid levelPressure difference

A valve assembly for a pressurized fluid vessel such as a propane tank has a housing defining a main fluid passageway therebetween with a valve seat (734) defined in the main passageway, a main valve member (742) movable against the valve seat (734) to block the passageway, an insert (738) defining an internal chamber within the interior of the housing within which the main valve member (742) is disposed, a secondary fluid flow passageway through the insert (738), through a conduit (748) connected to the main valve body, and through openings (751) in an end of the conduit (748) facing second ports opening into the vessel, and a secondary valve member (760) movable to block the openings (751) under the action of a float (721) on a predetermined fluid level being reached, thereby exposing the main valve member (742) to a pressure differential to close the valve.

Owner:FOSTER ASSETS CORPORATION

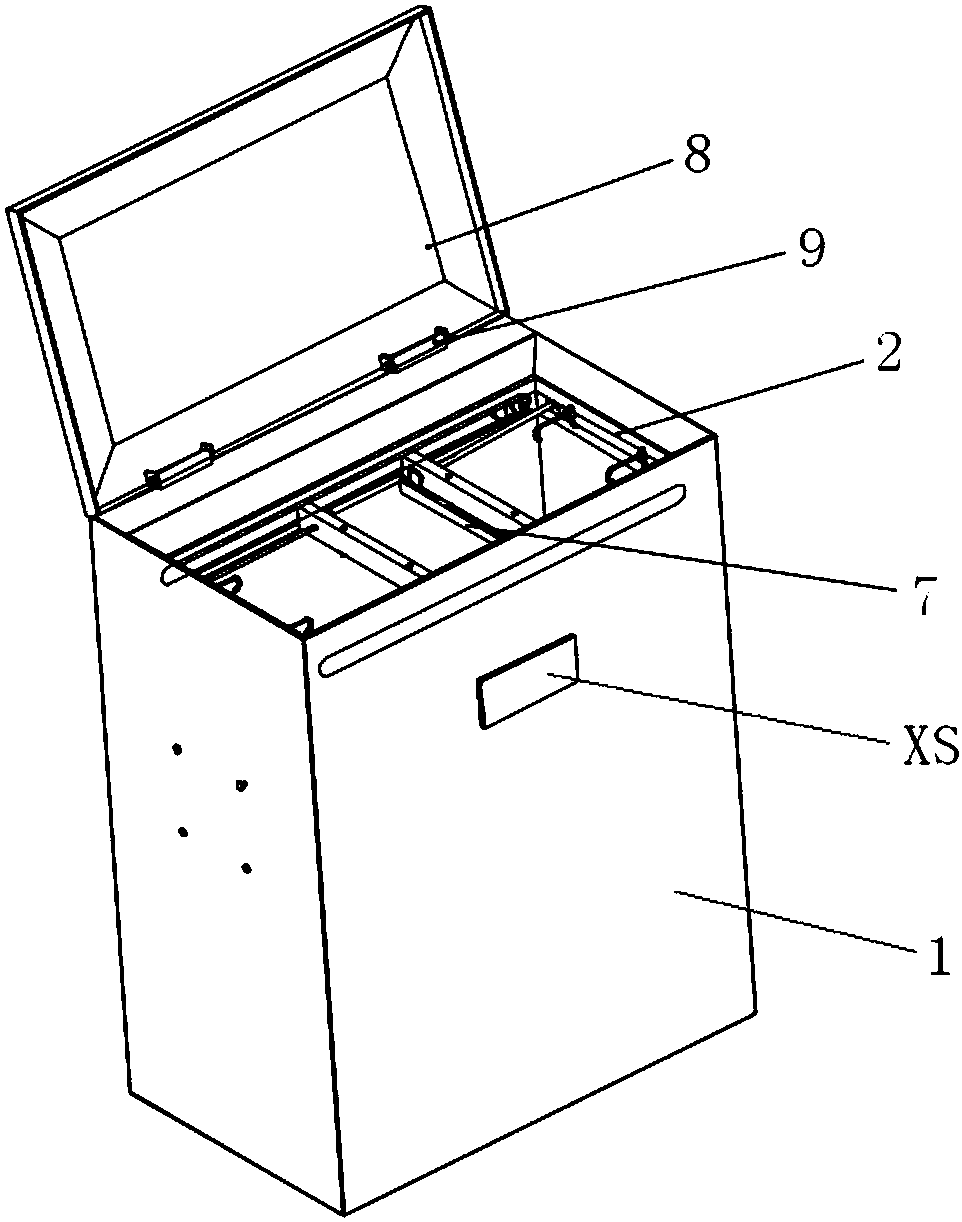

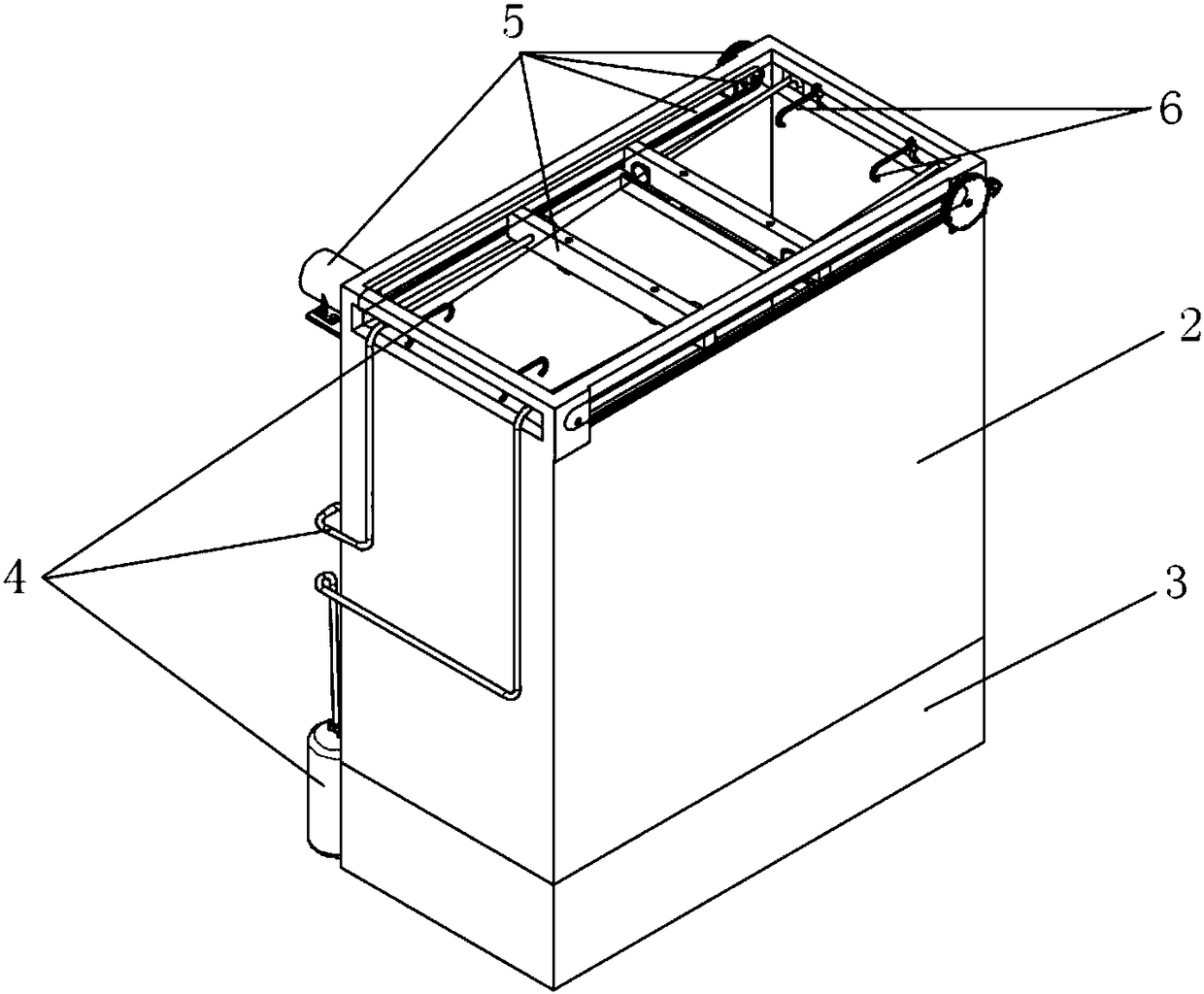

Multifunctional intelligent garbage can

The invention discloses a multifunctional intelligent garbage can. The multifunctional intelligent garbage can comprises an outer can, an inner can, a garbage bag opening and closing device and an intelligent controller, wherein the inner can is sleeved with the outer can, the garbage bag opening and closing device comprises a grabbing device and an opening and closing mechanism, the opening and closing mechanism comprises two parallel push rods and a push rod driving mechanism, the two ends of each push rod correspond to the upper edges of the front and rear walls of the inner can respectively, the grabbing device comprises vacuum pumps and multiple suckers, and the suckers are distributed and installed on the opposite surfaces of the two push rods and connected with the vacuum pumps through flexible air pipes. According to the multifunctional intelligent garbage can, a garbage can body is internally provided with the garbage bag opening and closing device controlled by the intelligent controller, so that automation of garbage bag opening and closing is achieved, not only are replacement and sealing of garbage bags convenient and fast, but also there is no need for a user to touchgarbage directly, and thus the life quality of the user is greatly improved; the garbage can is low in production cost and suitable for application and popularization.

Owner:TANGSHAN COLLEGE

Pump valve mechanism

InactiveUS7421757B1Quick sealQuick indexSuction cleanersHollow article cleaningShock waveEngineering

A method for cleaning tubes and heat exchangers provides an oscillating pump / valve mechanism to provide a periodic waveform of shocks to fouled tubes. Preferably, a pair of pneumatic control valves operates an actuator to oscillate a valve within a valve block, and isolation of a fluid within a manifold in the block creates a pumping action from the valve, to create an intense fluid shock wave to clean interior surfaces tubes.

Owner:AIMM TECH

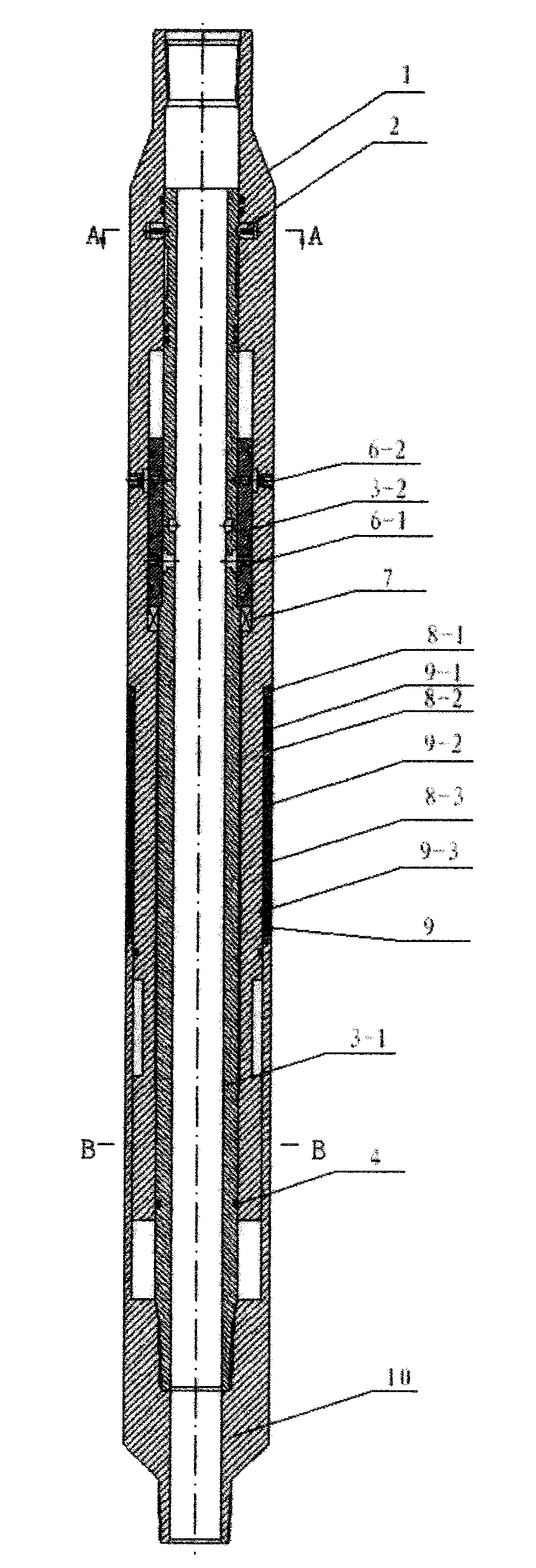

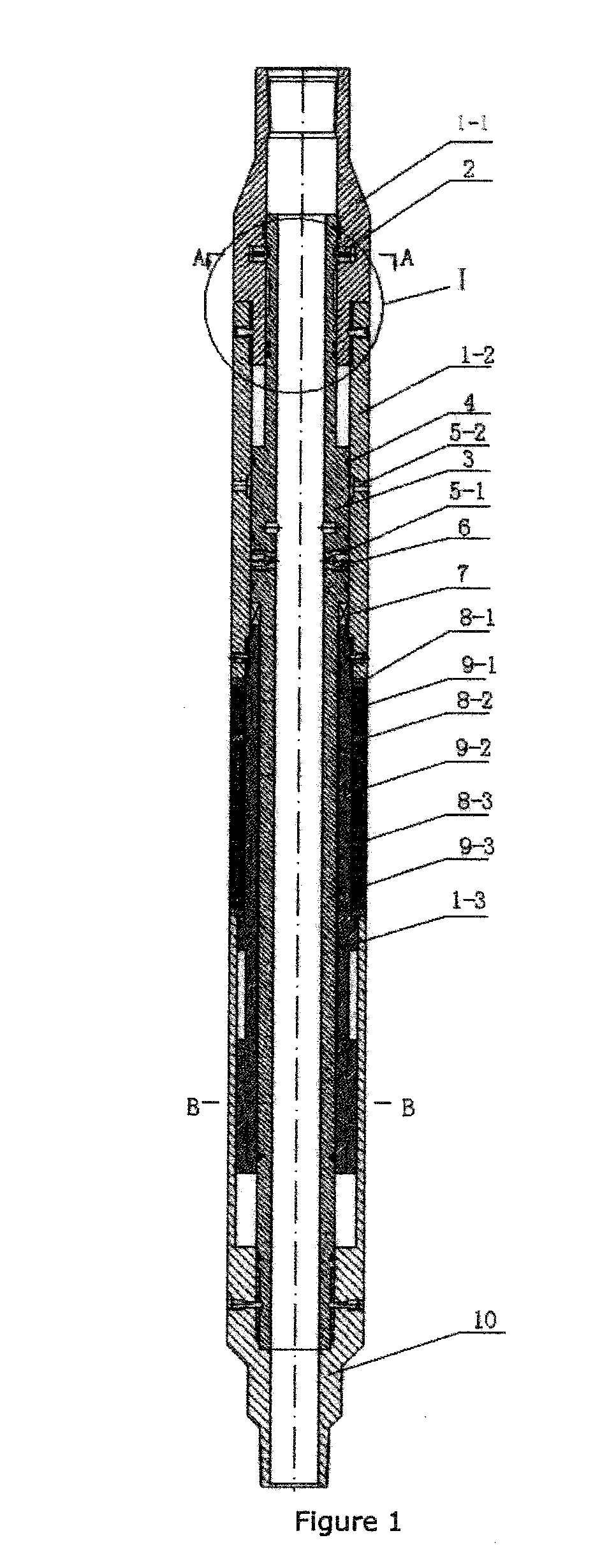

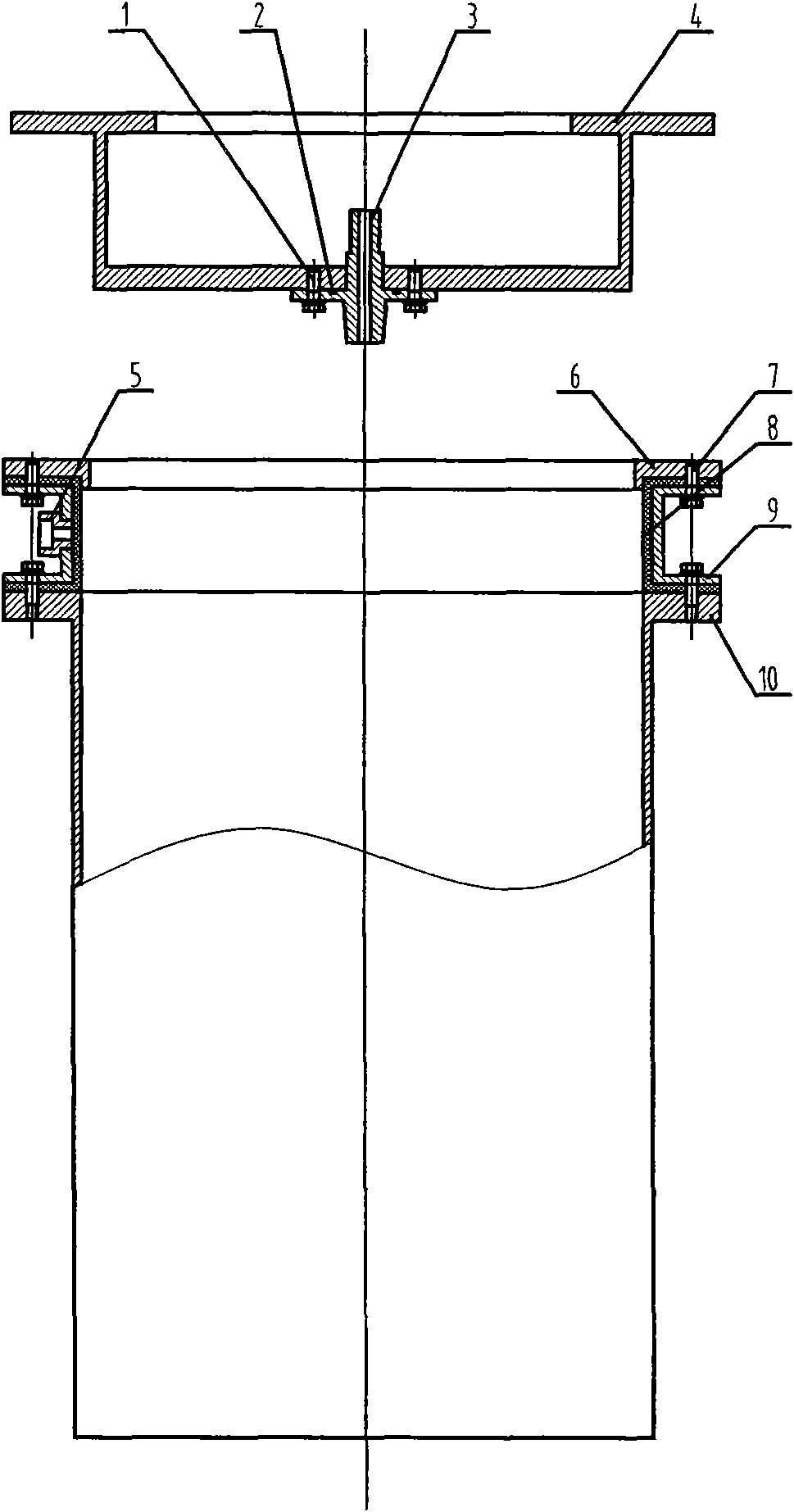

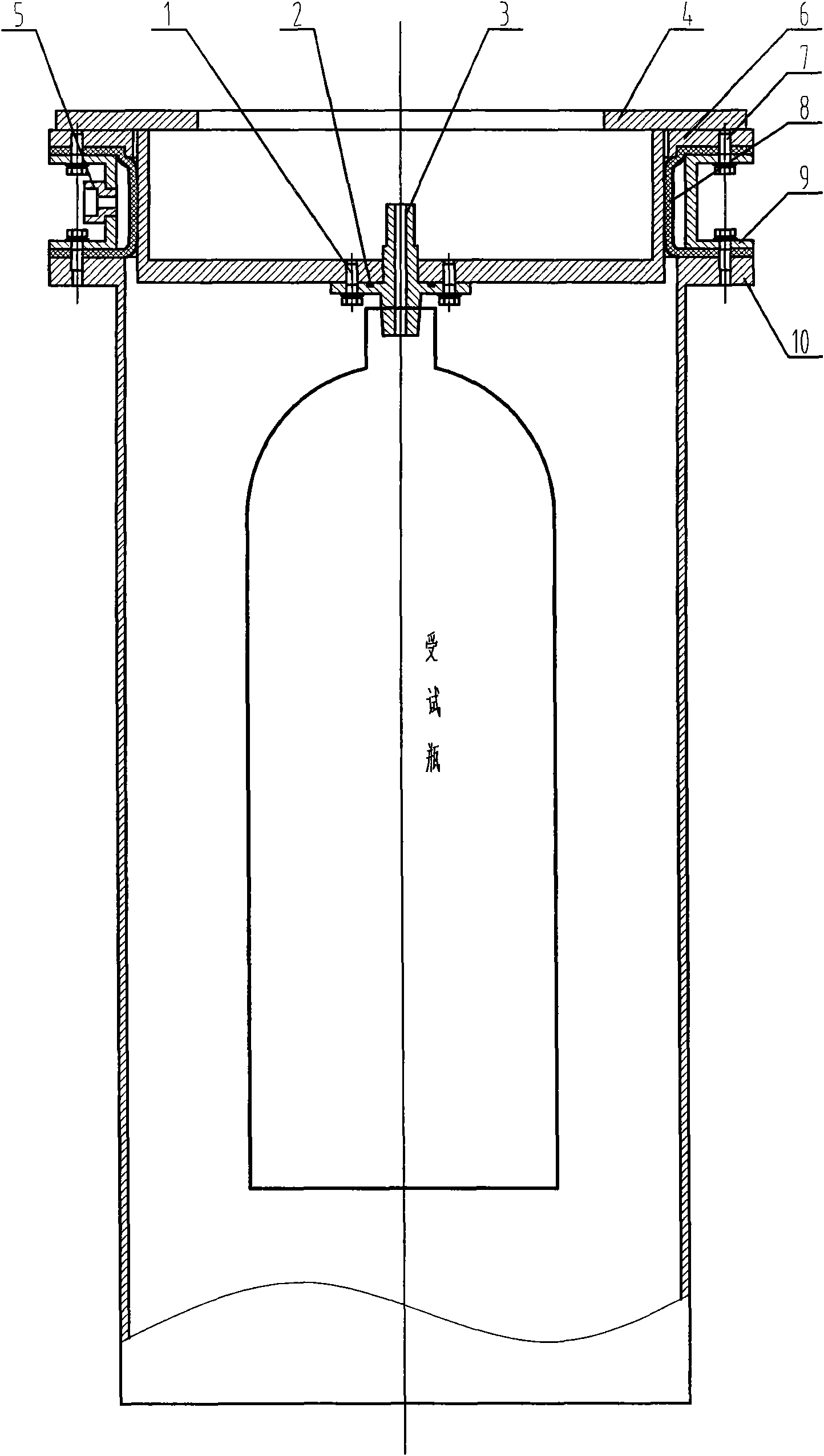

Underground Annular Blowout Preventer and Assembly Process Thereof

ActiveUS20130153796A1Simple structureDesign innovationValve arrangementsFlushingUpper jointWell drilling

An underground annular blowout preventer, which belongs to the technical field of underground blowout prevention, includes an upper joint and a lower joint are sleeved outside a central barrel. The lower end of the central barrel is fixedly connected with the lower joint. The lower end of the upper joint is sleeved on the inner side of the upper end of the lower joint. The upper joint is matched with the lower joint through a spline. The lower end of the upper joint can freely move relative to the lower joint along a spline pair. At least one rubber barrel is sleeved on the outer side of the upper joint. The rubber barrel can be extruded and expanded by the upper joint and the lower joint. The underground annular blowout preventer of the present invention can transmit large torque, has a simple structure, long service life, is convenient to use, and can be repeatedly used. The underground annular blowout preventer is used in coordination with a check valve of a near drill in the well drilling process, so that quick sealing of a well can be ensured, and well blowout accidents can be effectively prevented. A pipe column is lowered to seal the well and is lifted to open the well, and the inside of the drill rod is in communication with an annular space after the well is sealed, which facilitates replacement for heavy mud lubrication operations.

Owner:SOUTHWEST PETROLEUM UNIV

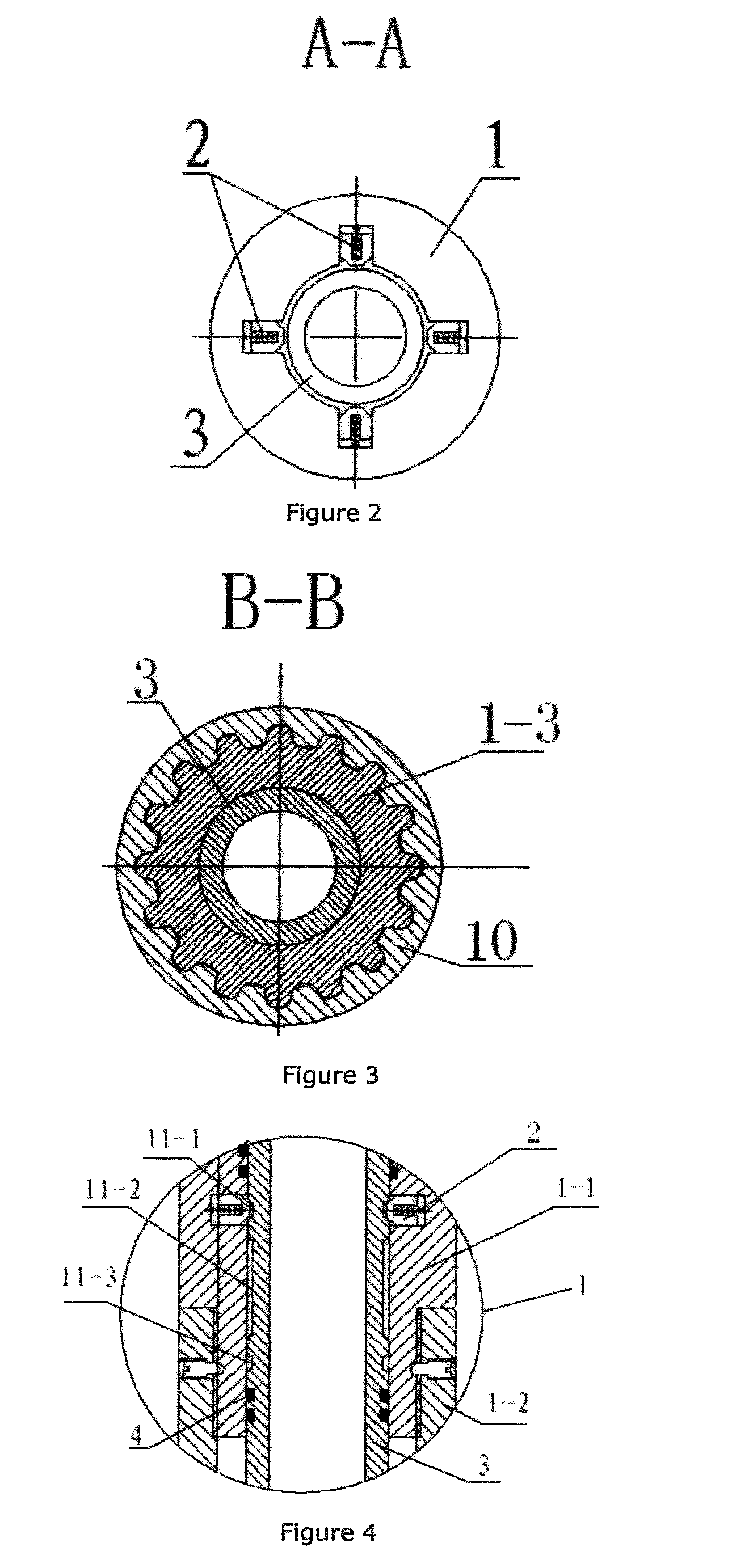

Water jacket and air bag type sealing device for hydraulic test of air bottle outside measuring method

InactiveCN101581643AQuick sealImprove sealingMaterial strength using tensile/compressive forcesGas cylinderEngineering

The invention relates to a water jacket and air bag type sealing device for hydraulic test of an air bottle outside measuring method, in particular to a test container for forming seal between a water jacket and a water jacket cover. The sealing device mainly comprises a pressure test joint, the water jacket cover, a pneumatic joint, a flange, a rubber air bag, a connecting flange and the water jacket, wherein the pressure test joint is fixedly connected with the water jacket cover through a connecting bolt and an O-shaped ring which seals the connecting part; the pneumatic joint is fixedly connected to an outer circular face of the connecting flange; the rubber air bag and the connecting flange are placed between the flange and the water jacket and fixed through the connecting bolts; and the connecting faces of the connecting flange, the flange and the water jacket are sealed through an upper end face and a lower end face of the rubber air bag. The sealing device has a simple, compact and reasonable structure, has simple and convenient operation, is quick, effective and reliable to form a water jacket seal, can ensure smooth hydraulic test of the air bottle outside measuring method, and greatly improves the production efficiency.

Owner:无锡昌华机电制造有限公司

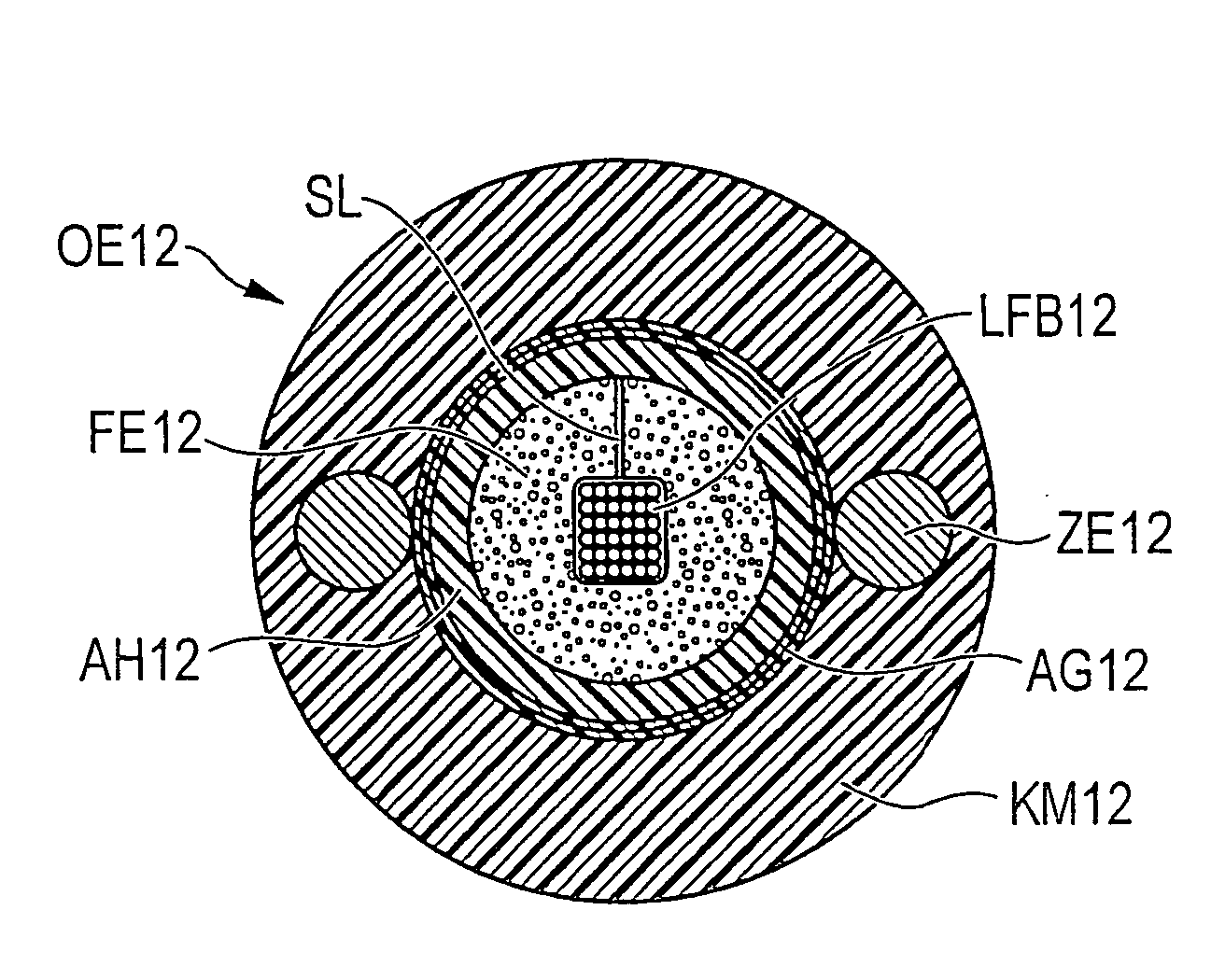

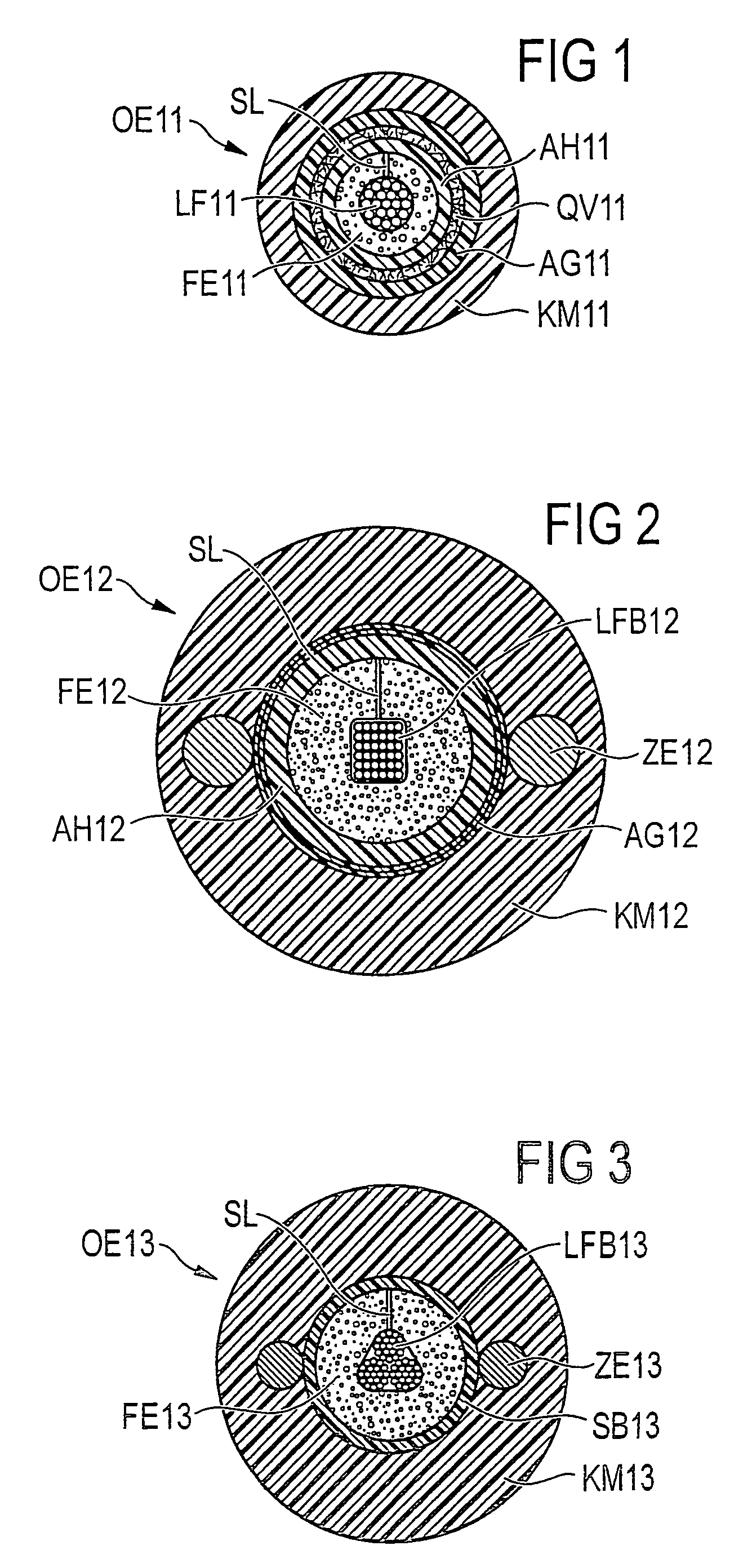

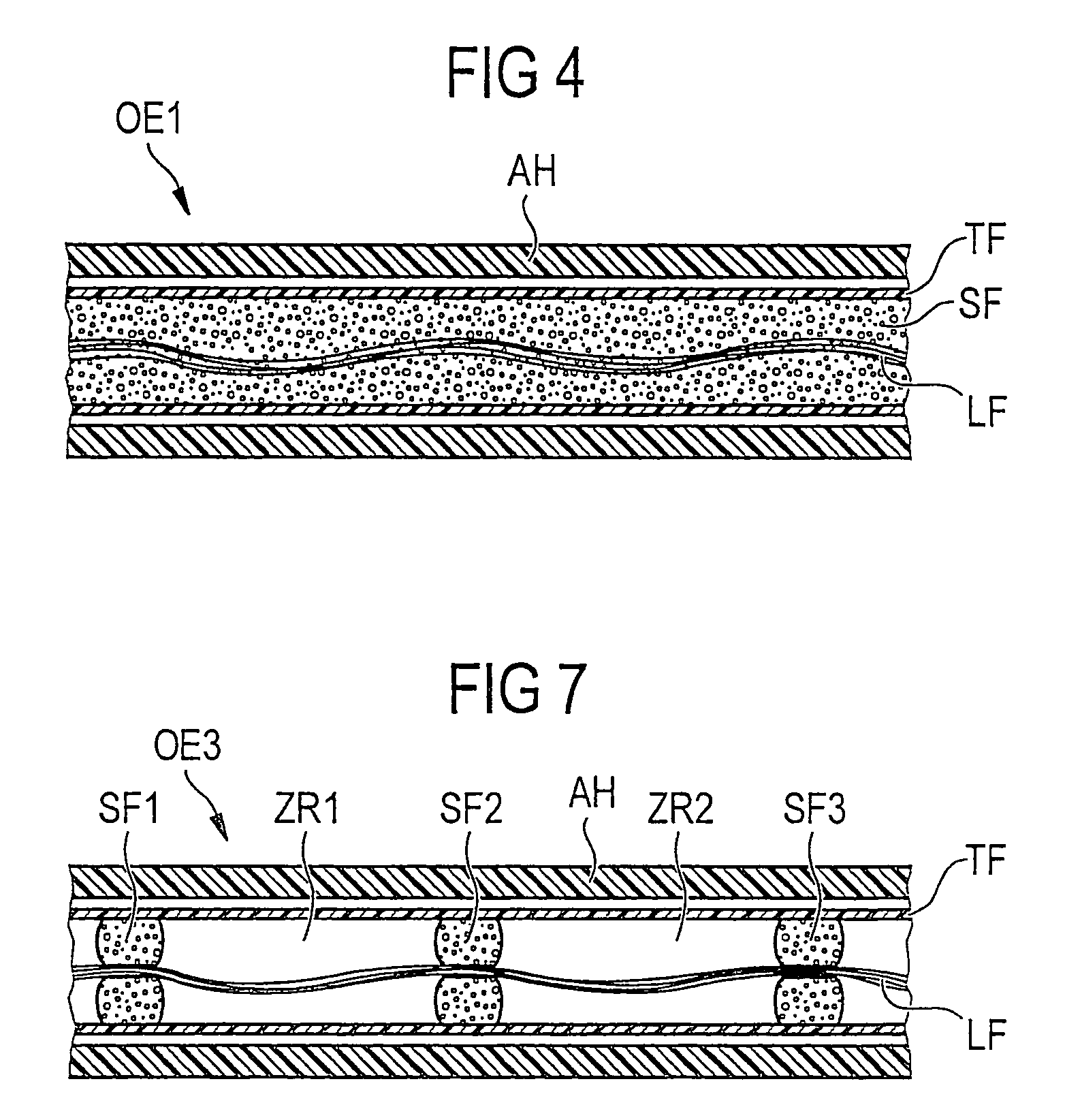

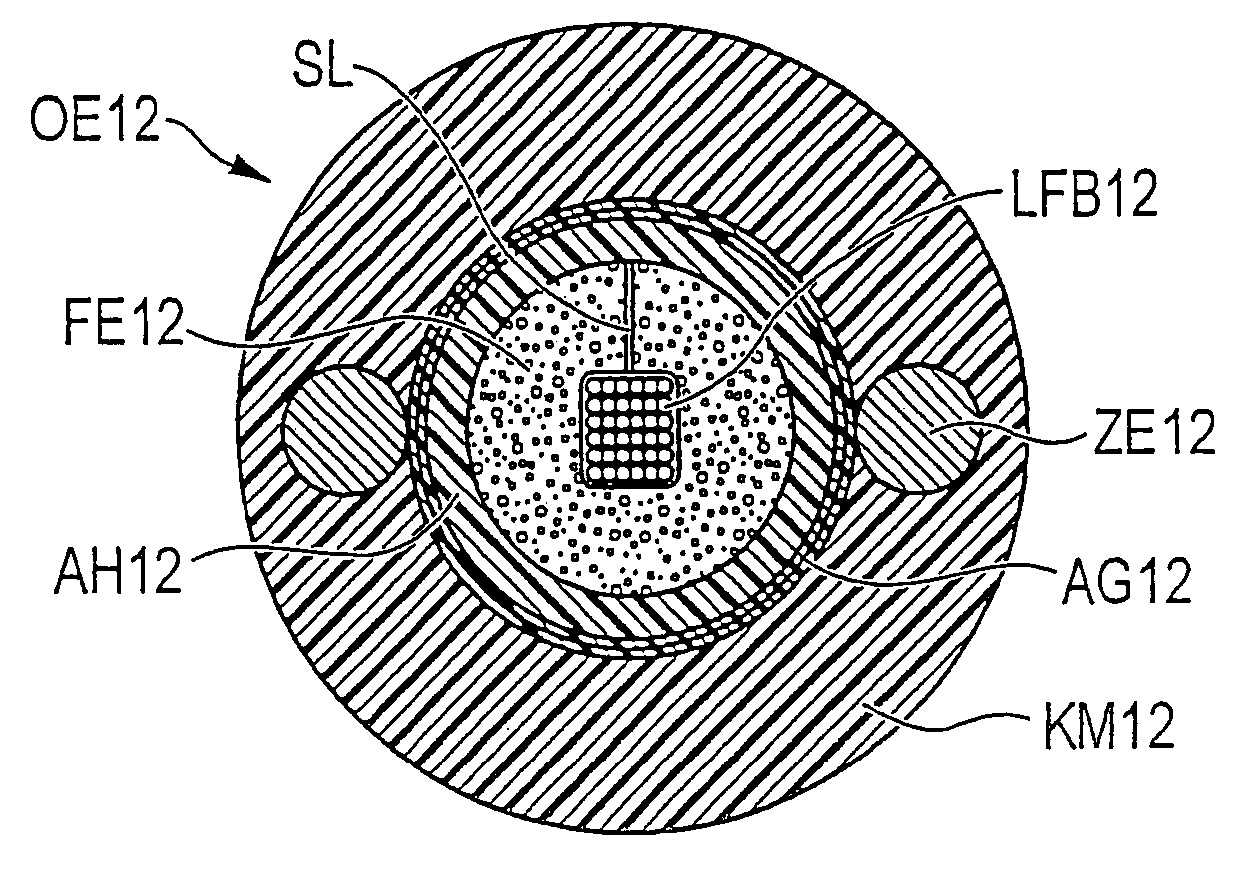

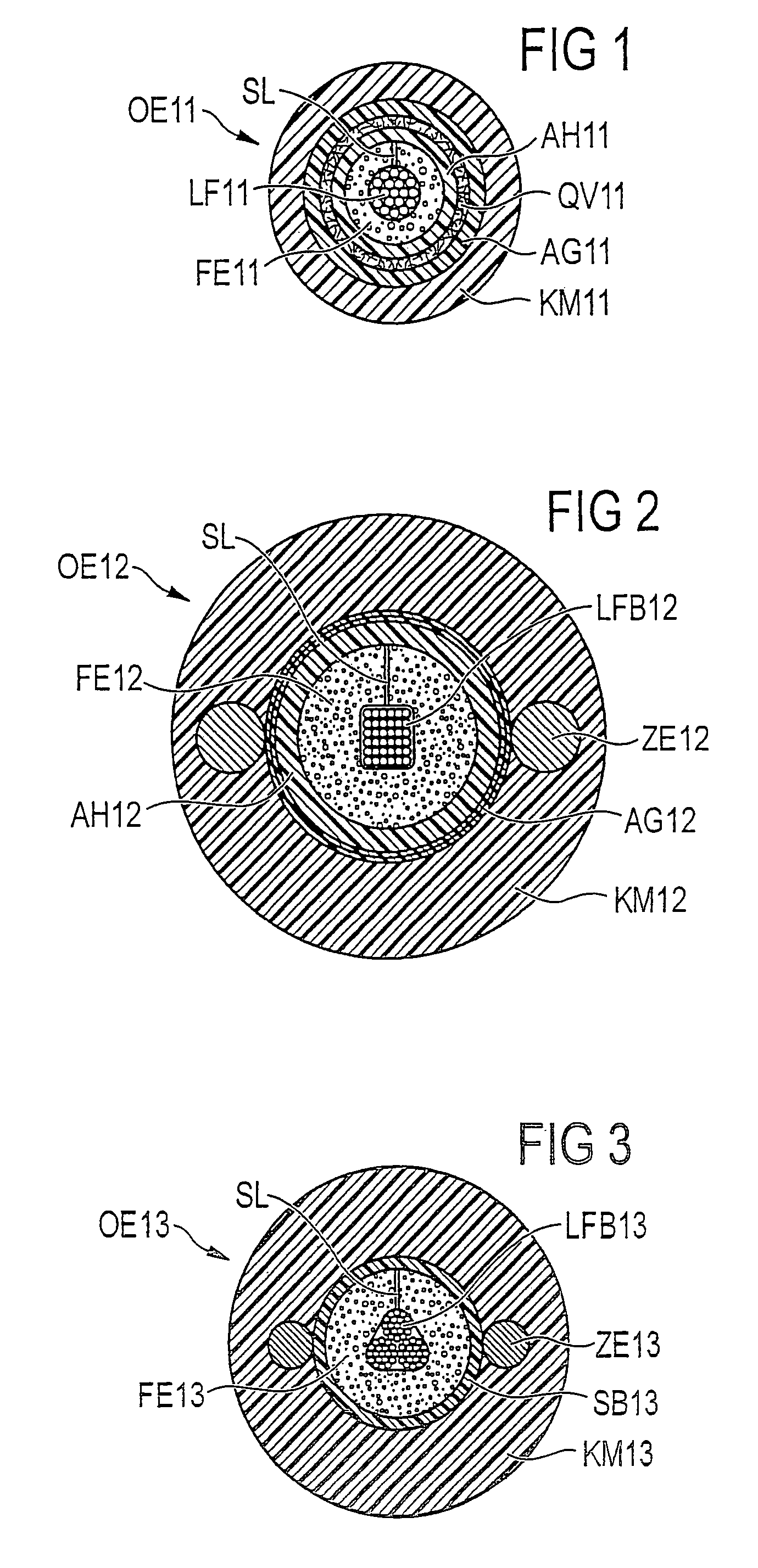

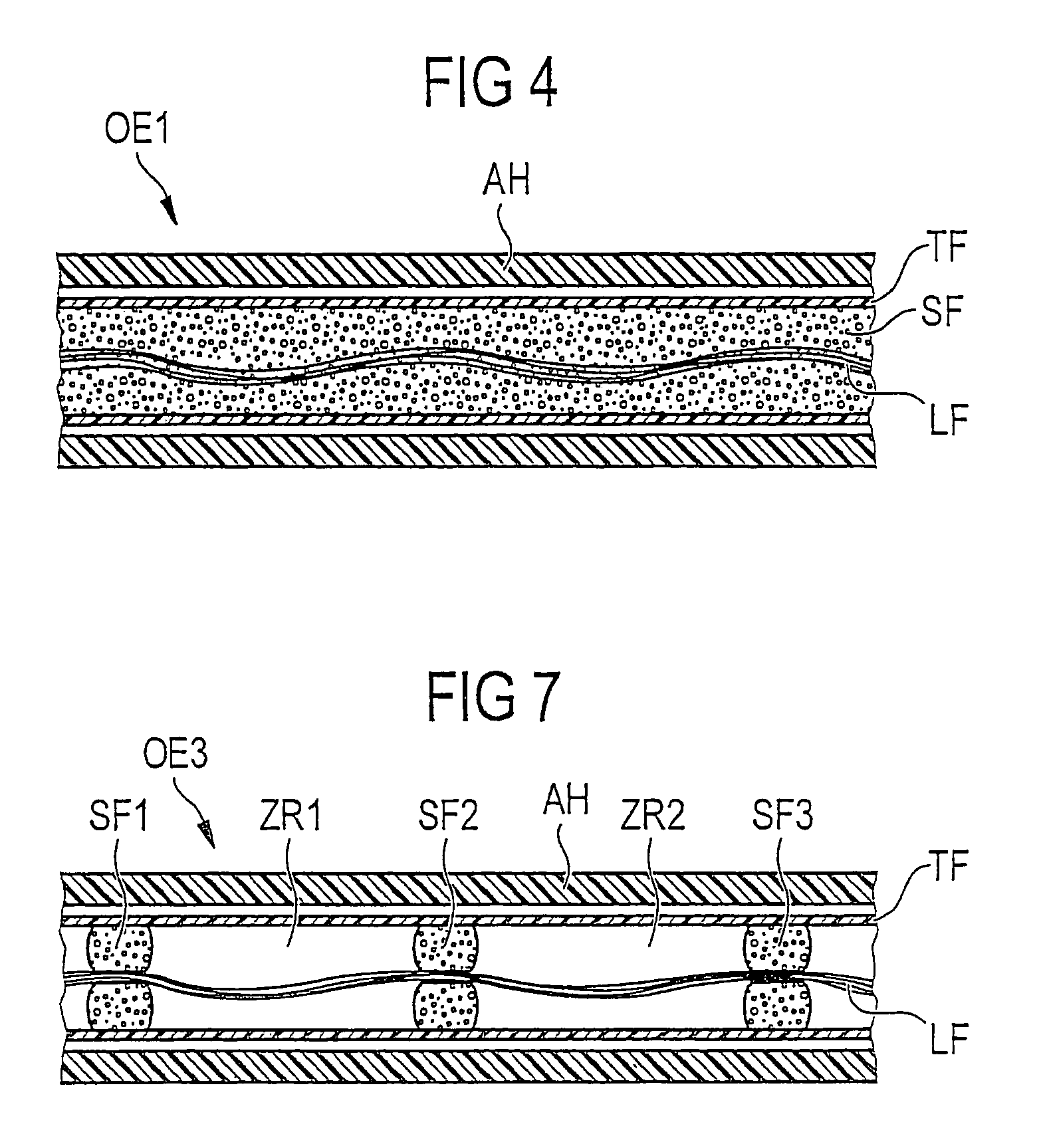

Optical transmission element

InactiveUS7349607B2Improve adhesionRelative density is smallFibre mechanical structuresPressesUltrasound attenuationContact pressure

Between an optical fiber (LF11, LFB12, LFB13) and a surrounding core covering (AH11, AH12, SB13) of an optical transmission element (OE11 to OE13) there is at least one dry and compressible fixating element (FE11 to FE13), which surrounds the optical fiber totally or partially, and which exerts a defined contact pressure against the core covering and against the optical fiber for fixating the optical fiber in the longitudinal direction of the transmission element. The fixating element is further formed and positioned in such a way, that position changes of the optical fiber due to bending or elongation are possible. In this way, unallowable attenuation increases in the optical fiber due to bending or position changes can be avoided.

Owner:CORNING CABLE SYST LLC +1

Optical transmission element

InactiveUS7471861B2Relative density is smallIncrease flexibilityFibre mechanical structuresPressesUltrasound attenuationContact pressure

Between an optical fiber (LF11, LFB12, LFB13) and a surrounding core covering (AH11, AH12, SB13) of an optical transmission element (OE11 to OE13) there is at least one dry and compressible fixating element (FE11 to FE13), which surrounds the optical fiber totally or partially, and which exerts a defined contact pressure against the core covering and against the optical fiber for fixating the optical fiber in the longitudinal direction of the transmission element. The fixating element is further formed and positioned in such a way, that position changes of the optical fiber due to bending or elongation are possible. In this way, unallowable attenuation increases in the optical fiber due to bending or position changes can be avoided.

Owner:CORNING CABLE SYST LLC

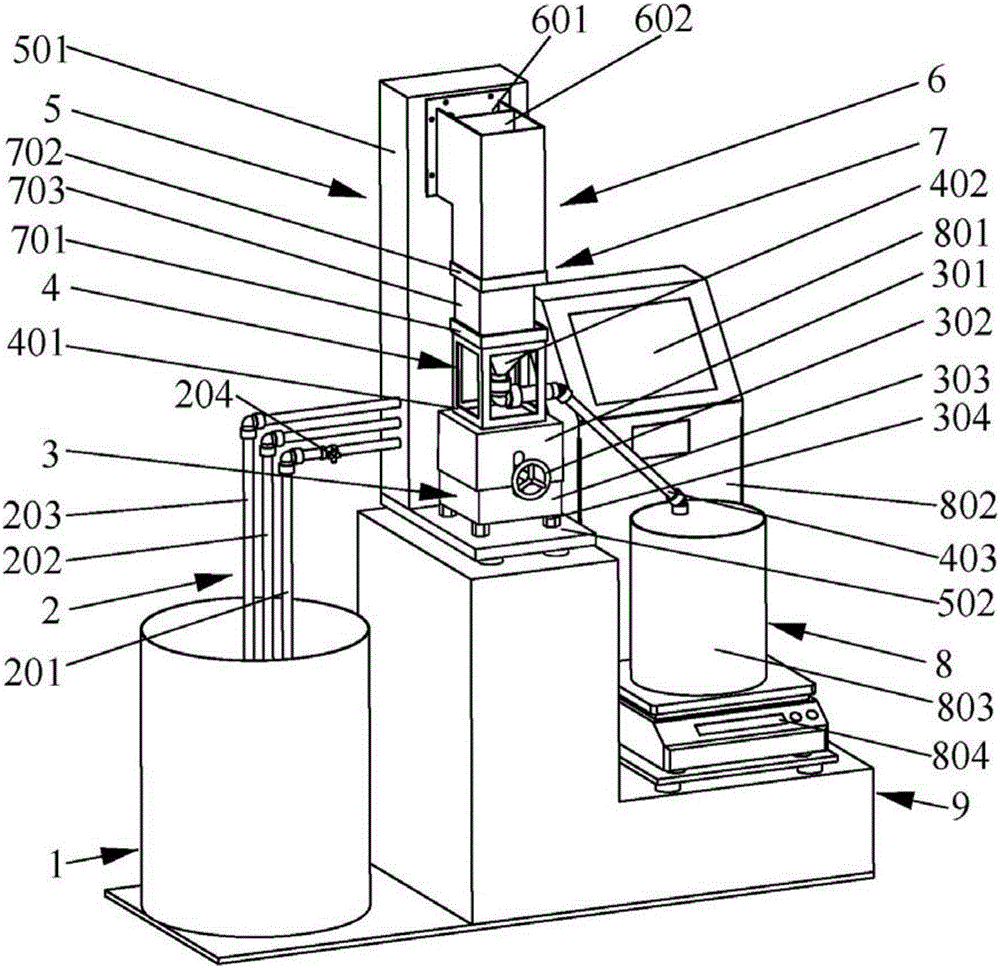

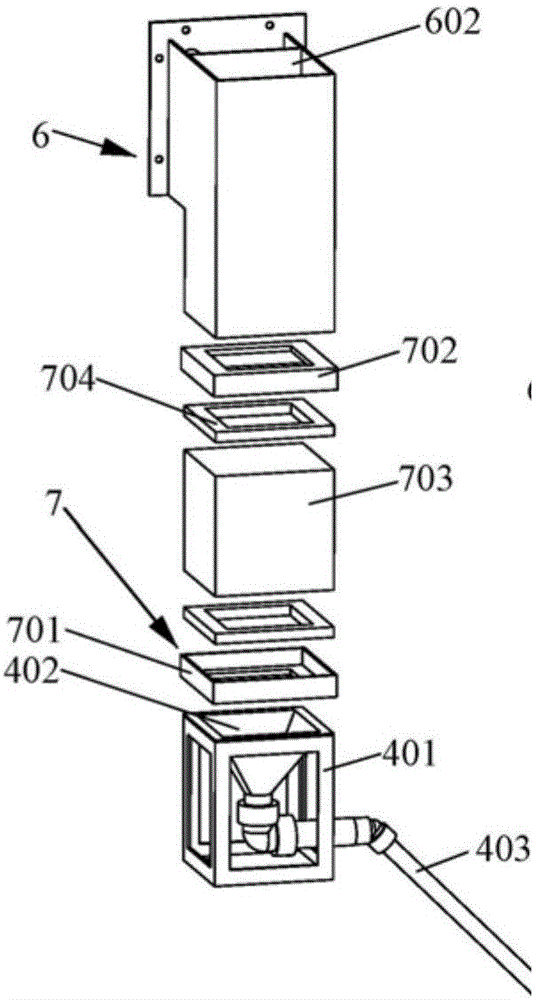

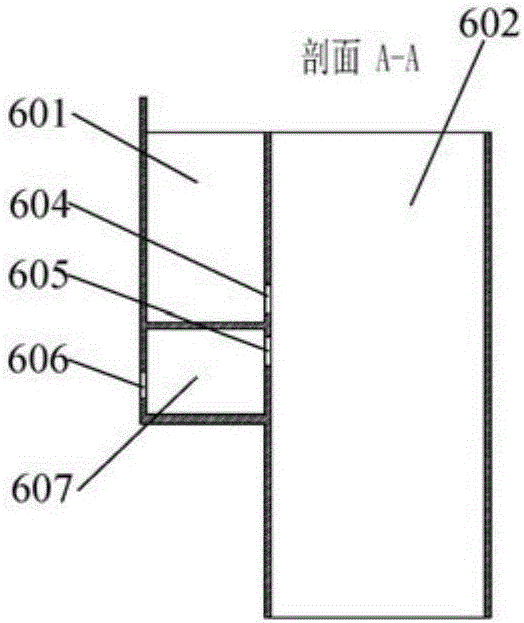

Measuring device for concrete permeation coefficient and measuring method

ActiveCN106769782AQuick sealQuick disassemblyPermeability/surface area analysisWater storageWater quality

The invention provides a measuring device for a concrete permeation coefficient. The device comprises a water injecting chamber, a water inlet pipe, an overflow pipe, a water storage container, an upper annular tray, a lower annular tray, a support frame, a lifting mechanism, a permeating water collecting funnel, a permeating water guiding pipe, a weighting container and an intelligent measuring system, wherein the water injecting chamber is communicated with the water storage container through the water inlet pipe and the overflow pipe; the support frame is respectively fixedly connected with the lower annular tray on the upper side and the lifting mechanism on the lower side; the upper annular tray is fixedly connected with the lower edge of the water injecting chamber; a sealing cushion is arranged on the lower surface of the upper annular tray; the lower annular tray is fixedly connected with the upper end of the support frame; a sealing gasket is arranged on the upper surface of the lower annular tray; the permeating water collecting funnel is arranged in the support frame; the bottom of the permeating water collecting funnel is connected with the weighting container through the permeating water guiding pipe; the intelligent measuring system is used for calculating the permeation coefficient of a test piece according to a fixed formula based on the measured time, and corresponding permeating water quality. The measuring device provided by the invention has a simple structure, high measurement precision and high measurement repeatability; the measuring method is quick and convenient and is suitable for the measurement for the concrete permeation coefficient in any places; and the invention also provides a method for measuring the concrete permeation coefficient by adopting the measuring device.

Owner:BEIJING NELD INSTR

Semiconductor device and method of manufacturing thereof

ActiveUS8262970B2Reduce warpageQuick sealSemiconductor/solid-state device detailsSolid-state devicesCompression moldingShell molding

A method of manufacturing a semiconductor device sealed in a cured silicone body by placing an unsealed semiconductor device into a mold and subjecting a curable liquid silicone composition that fills the spaces between the mold and the unsealed semiconductor device to compression molding under a predetermined molding temperature, wherein said curable liquid silicone composition has viscosity of 90 Pa·s or less at room temperature, a time interval from the moment directly after measurement of a torque with a curometer at the molding temperature to the moment when the torque reached 1 kgf·cm is not less than 1 min., while the time interval during which the torque grows from 1 kgf·cm to 5 kgf·cm is not more than 1 min.

Owner:DOW TORAY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com