Method and device for detecting sealing property of seal bearing

A technology of sealing performance and sealed bearings, which is applied in the direction of mechanical bearing testing, liquid tightness measurement using liquid/vacuum degree, and measurement of fluid growth and deceleration rates, etc., which can solve cumbersome inspection methods, complicated test equipment, long time, etc. problems, to achieve the effect of convenient detection means, simple device structure and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

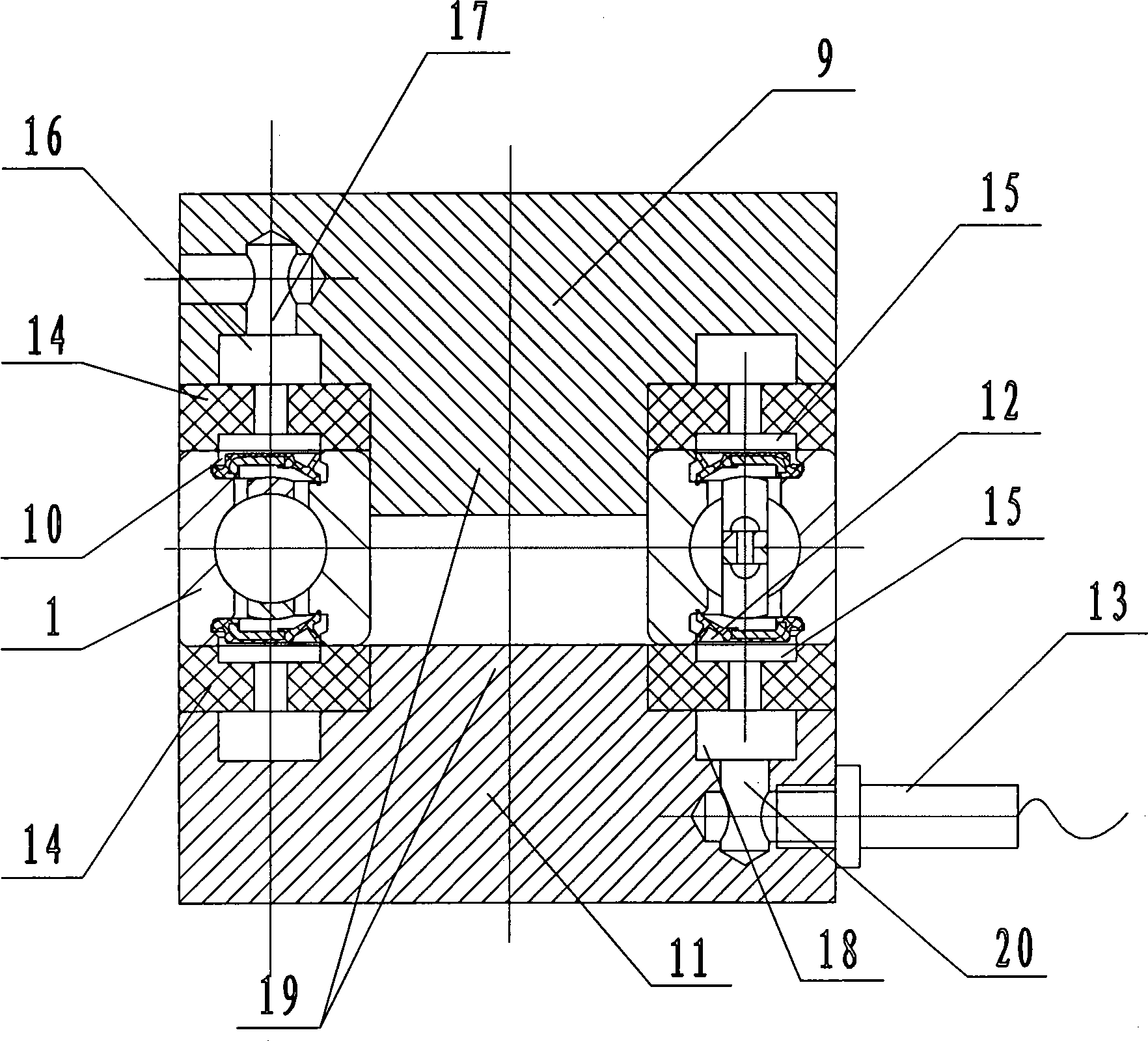

[0021] figure 1 The sealing performance testing device of the sealed bearing shown in the figure has a protruding positioning mandrel 19 under the upper sealing mold 9 and above the lower sealing mold 11 respectively, which fits with the inner hole of the bearing 1, and the shaft shoulders under the upper sealing mold 9 and above the lower sealing mold 11 The ring-shaped rubber sealing gasket 14 is bonded respectively, and the lower part of the upper sealing gasket 14 and the upper part of the lower sealing gasket 14 respectively have a rubber groove 15, and the two rubber grooves 15 are connected with the upper sealing cavity 10 and the upper sealing cavity 10 of the bearing 1 respectively. The lower sealing cavity 12 is connected, and the central through hole of the sealing gasket 14 above is connected to 4 vertical upper air holes 17 of the upper sealing mold 9. There is an upper mold groove 16 below the upper air hole 17, and the center of the sealing gasket 14 below is Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com