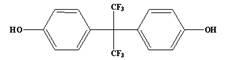

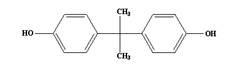

Method for rapidly detecting bisphenol A and bisphenol AF in food

A detection method and food technology, applied in the field of analytical chemistry, can solve the problems of high cost of extraction column, low detection limit, time-consuming operation, etc., and achieve the effect of wide application range, low detection limit and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

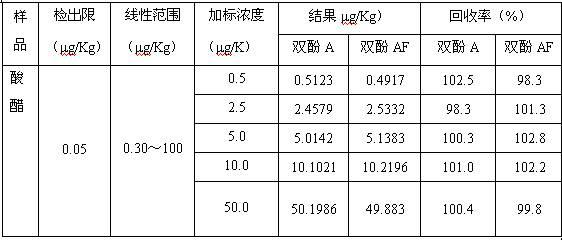

[0028] Example 1 : the rapid detection method of bisphenol A and bisphenol AF in edible acetic acid, concrete steps are as follows:

[0029] (1) Take 10.0 g of edible acid vinegar and centrifuge at 2500 rpm for 5 min, take the supernatant to adjust the pH to 6.0, at this time a small amount of suspended matter appears in the sample, centrifuge at 1500 rpm for 3 min, and inject the supernatant into the extraction device in, spare;

[0030] (2) Mix 20 μL 1-butyl-3-methylimidazolium hexafluorophosphate and 500 μL Triton X-100, quickly inject into the pretreated sample solution, shake well, put in a 75°C water bath for 5 min, and ultrasonicate at 75°C for 3 min (ultrasonic frequency is 60 KHz), cooled to room temperature, centrifuged at 4000 rpm for 5 min, and the lower layer of the extract was removed. Carry out secondary extraction according to the above extraction method, combine the lower layer droplets obtained from the two extractions, and inject them into HPLC for separat...

Embodiment 2

[0033] Example 2: the rapid detection method of bisphenol A and bisphenol AF in edible oil, concrete steps are as follows:

[0034] (1) Take 10.0 g of edible oil and centrifuge at 3000 rpm for 7 minutes. After centrifugation, take the supernatant to adjust the pH to 7.0, then centrifuge at 1600 rpm for 4 minutes, and set aside;

[0035] (2) Mix 15 μL extractant (1-butyl-3-methylimidazolium hexafluorophosphate) and 500 μL dispersion liquid acetone, quickly inject it into the edible oil sample liquid, shake well, put in 75 ℃ water bath for 5 min, and 75 ℃ Sonicate for 5 min (ultrasonic frequency is 70 KHz), cool down to room temperature, centrifuge at 4000 rpm for 5 min, and remove the extract droplet from the lower layer. Carry out secondary extraction according to the above extraction method, combine the lower layer droplets obtained from the two extractions, and inject them into HPLC for separation and analysis. The mobile phase is acetonitrile and water (40:60, V / V), and t...

Embodiment 3

[0038] Example 3 : The rapid detection method of bisphenol A and bisphenol AF in yellow rice wine, concrete operation is as follows:

[0039] (1) Centrifuge 15.0 g rice wine [ethanol content less than 6% (V / V)] for 8 min (3000 rpm), remove the suspended matter in the sample, take the supernatant to adjust the pH to 6.0, centrifuge for 3 min (2000 rpm), To remove the suspended solids produced by adding acid, take the supernatant and inject it into the extraction device for later use;

[0040] (2) Mix 10 μL extractant (1-butyl-3-methylimidazolium hexafluorophosphate) and 500 μL dispersion solution (acetone) and quickly inject it into the pretreated sample, shake well, bathe in 70°C water for 5 min, 70 Sonicate at ℃ for 8 min (ultrasonic frequency is 70 KHz), cool to room temperature, centrifuge at 1500 rpm for 10 min, take out the extract droplet in the lower layer, perform secondary extraction according to the above extraction method, combine the two extract drops, inject HPL...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com