SMS many component compound packing material and producing method with same

A technology of composite packaging materials and production methods, applied in the field of packaging materials, to achieve the effects of good air permeability, not easy to leak materials, and low surface melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

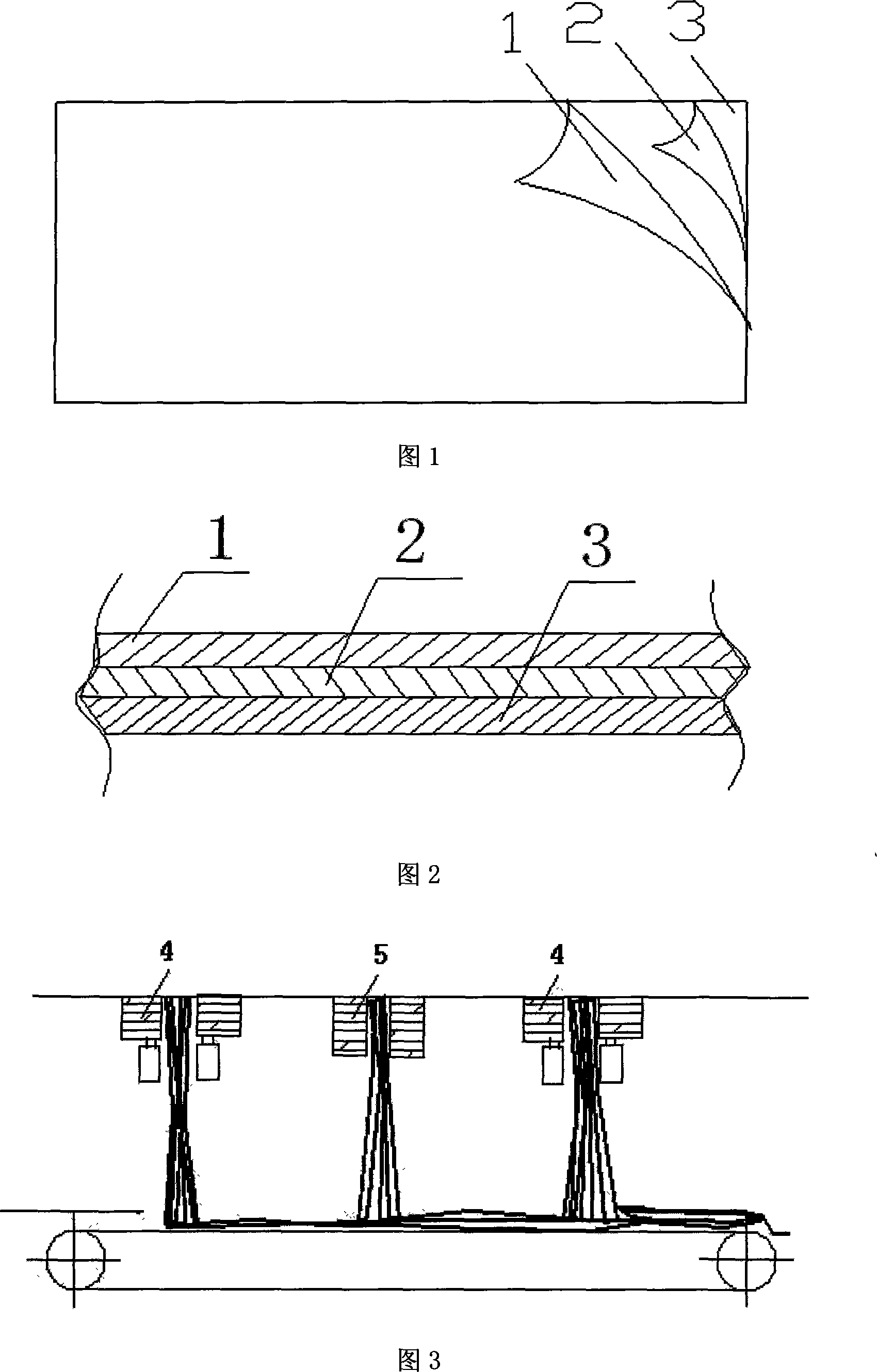

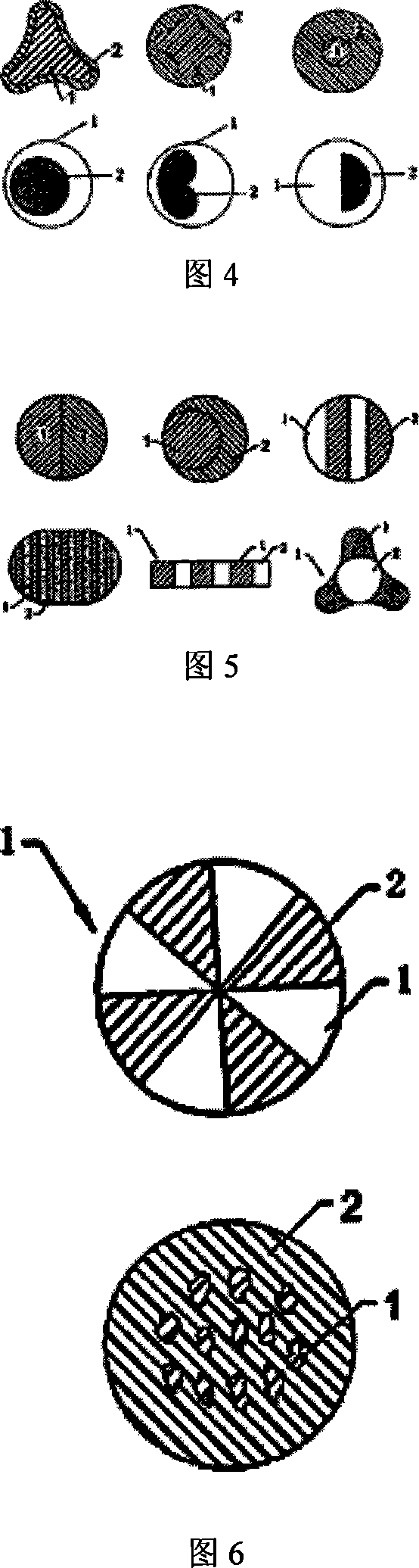

[0056] The MINERVA layer is a continuous multi-component spunbond fiber, the fiber is selected from a skin-core structure (see Figure 4), the skin layer is PE, which can be HDPE (high-pressure polyethylene) or LDPE (low-pressure polyethylene), and the core layer is PET. The proportion of PE components is 10%-90%, and the proportion of PET components is 90%-10%; the M-layer structure is a single-component or two-component structure; the composite method is hot rolling, or ultrasonic, or Spunlace, or acupuncture and other composite processes.

Embodiment 2

[0058] The MINERVA layer is a continuous multi-component spunbond fiber, the fiber is selected from the skin-core structure (see Figure 4), the skin layer is PE, which can be HDPE (high-pressure polyethylene) or LDPE (low-pressure polyethylene), and the core layer is PP. The proportion of PE components is 10%-90%, and the proportion of PP components is 90%-10%; the M-layer structure is a single-component or two-component structure; the composite method is hot rolling, or ultrasonic, or Spunlace, or acupuncture and other composite processes.

Embodiment 3

[0060] The MINERVA layer is a continuous multi-component spunbond fiber, the fiber is selected from a side-by-side structure (see Figure 5), the first component is PE, which can be HDPE (high-pressure polyethylene) or LDPE (low-pressure polyethylene), the other component for PET. The proportion of PE components is 10%-90%, and the proportion of PET components is 90%-10%; the M-layer structure is a single-component or two-component structure; the composite method is hot rolling, or ultrasonic, or Spunlace, or acupuncture and other composite processes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com