Polydimethylsiloxane micro-fluidic chip and preparation method thereof

A technology of polydimethylsiloxane and polydimethylsiloxane materials, which is applied in the field of preparation of polydimethylsiloxane microfluidic chips, can solve the problem of poor bonding strength, easy leakage, Expensive and other issues, to achieve the effect of fast sealing and reversible bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

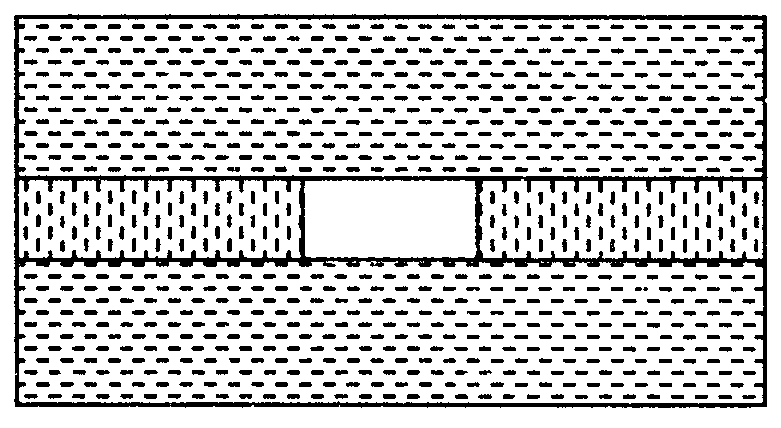

[0024] figure 1 It is a schematic cross-sectional structure diagram of a polydimethylsiloxane microfluidic chip in Example 1 of the present invention.

[0025] exist figure 1 In the middle, the upper layer is a polydimethylsiloxane cover sheet layer, the middle layer is a double-sided adhesive layer, and the lower layer is a polydimethylsiloxane base layer. The microchannel of the microfluidic chip is directly processed on the double-sided adhesive material of the middle layer. The specific method is: using laser etching method on the commercialized A transparent microchannel pattern is processed on the Tape type double-sided adhesive tape. The cover sheet layer and the base sheet layer are mixed and degassed by polydimethylsiloxane prepolymer and initiator in a ratio of 10:1. Obtained by pouring on a sheet of flat glass. After punching out the inlet and outlet of the solution on the cover sheet layer, the upper and lower layers of polydimethylsiloxane substrates are align...

Embodiment 2

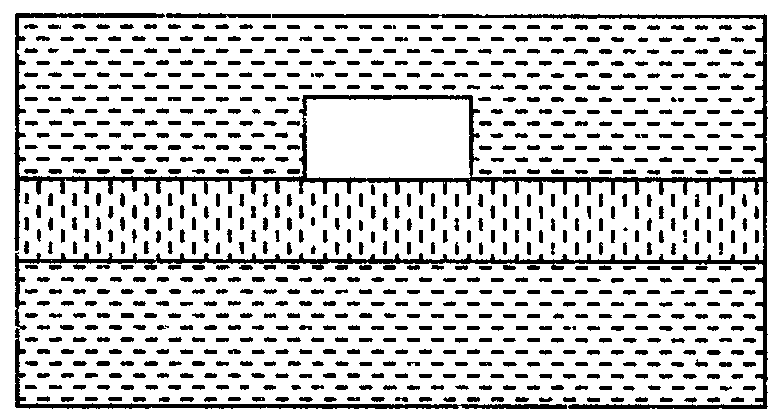

[0027] figure 2 It is a schematic cross-sectional structure diagram of a polydimethylsiloxane microfluidic chip according to Example 2 of the present invention.

[0028] exist figure 2 In the middle, the upper layer is a polydimethylsiloxane cover sheet layer, the middle layer is a double-sided adhesive layer, and the lower layer is a polydimethylsiloxane base layer. The microchannel of the microfluidic chip is directly processed on the upper layer of polydimethylsiloxane siloxane material. The specific method is: a silicon template with micro-protrusion patterns on the silicon substrate is prepared by traditional micro-processing methods, and the The polydimethylsiloxane prepolymer and the initiator are mixed at a ratio of 10:1, degassed, and cast on a silicon template to obtain a microchannel substrate with a microgroove structure. The polydimethylsiloxane-based sheet of the lower layer is directly obtained by mixing the polydimethylsiloxane prepolymer and the initiator ...

Embodiment 3

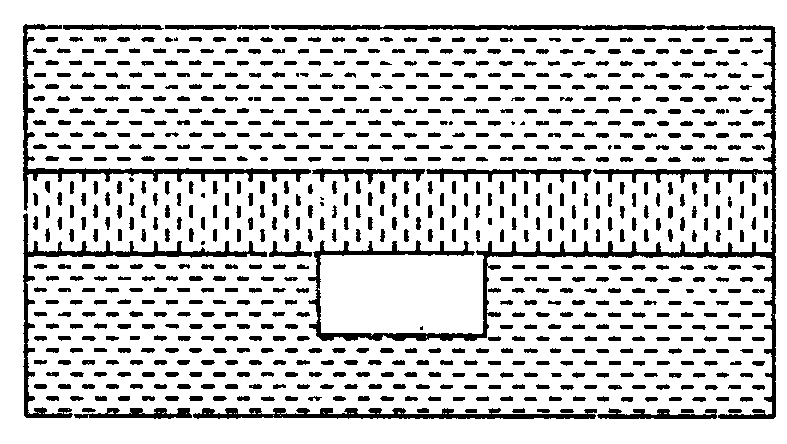

[0030] image 3 It is a schematic cross-sectional structure diagram of a polydimethylsiloxane microfluidic chip according to Example 2 of the present invention.

[0031] exist image 3 In the middle, the upper layer is a polydimethylsiloxane cover sheet layer, the middle layer is a double-sided adhesive layer, and the lower layer is a polydimethylsiloxane base layer. The microchannel of the microfluidic chip is directly processed on the underlying polydimethylsiloxane siloxane material. The specific method is: a silicon template with micro-protrusion patterns on the silicon substrate is prepared by traditional micro-processing methods, and the The polydimethylsiloxane prepolymer and the initiator are mixed at a ratio of 10:1, degassed, and cast on a silicon template to obtain a microchannel substrate with a microgroove structure. The polydimethylsiloxane-based sheet on the upper layer is directly obtained by mixing the polydimethylsiloxane prepolymer and the initiator in a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com