Low-pressure pilot operated safety valve

A pilot-operated safety valve, low-pressure technology, applied in the direction of safety valves, balance valves, valve devices, etc., can solve the problems of response sensitivity, opening speed, return seat closing and sealing stability, fast and reliable, etc., to improve opening response speed, return The seat reset is accurate and reliable, and the effect of enhancing the sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiments of the present invention are further described below in conjunction with the accompanying drawings:

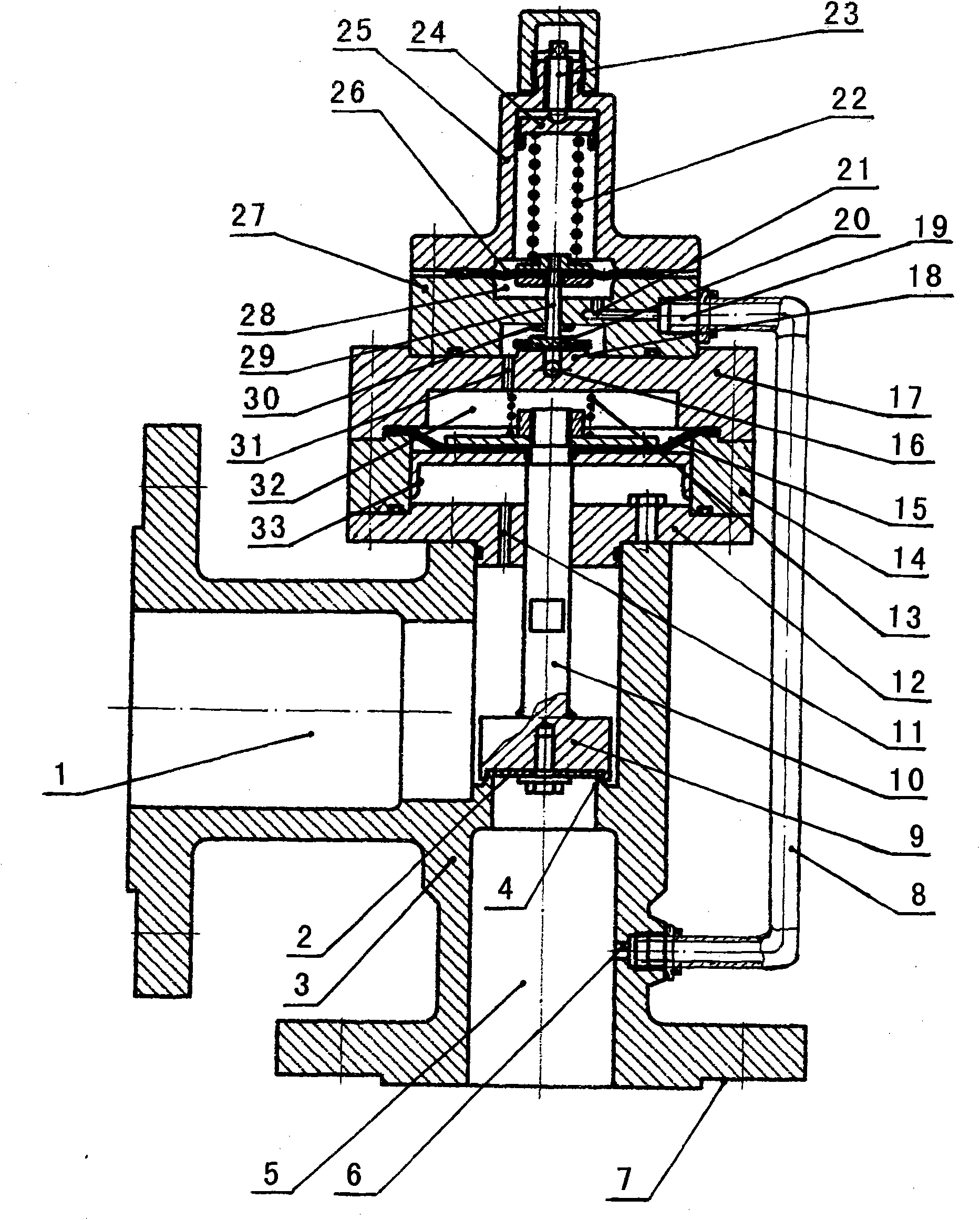

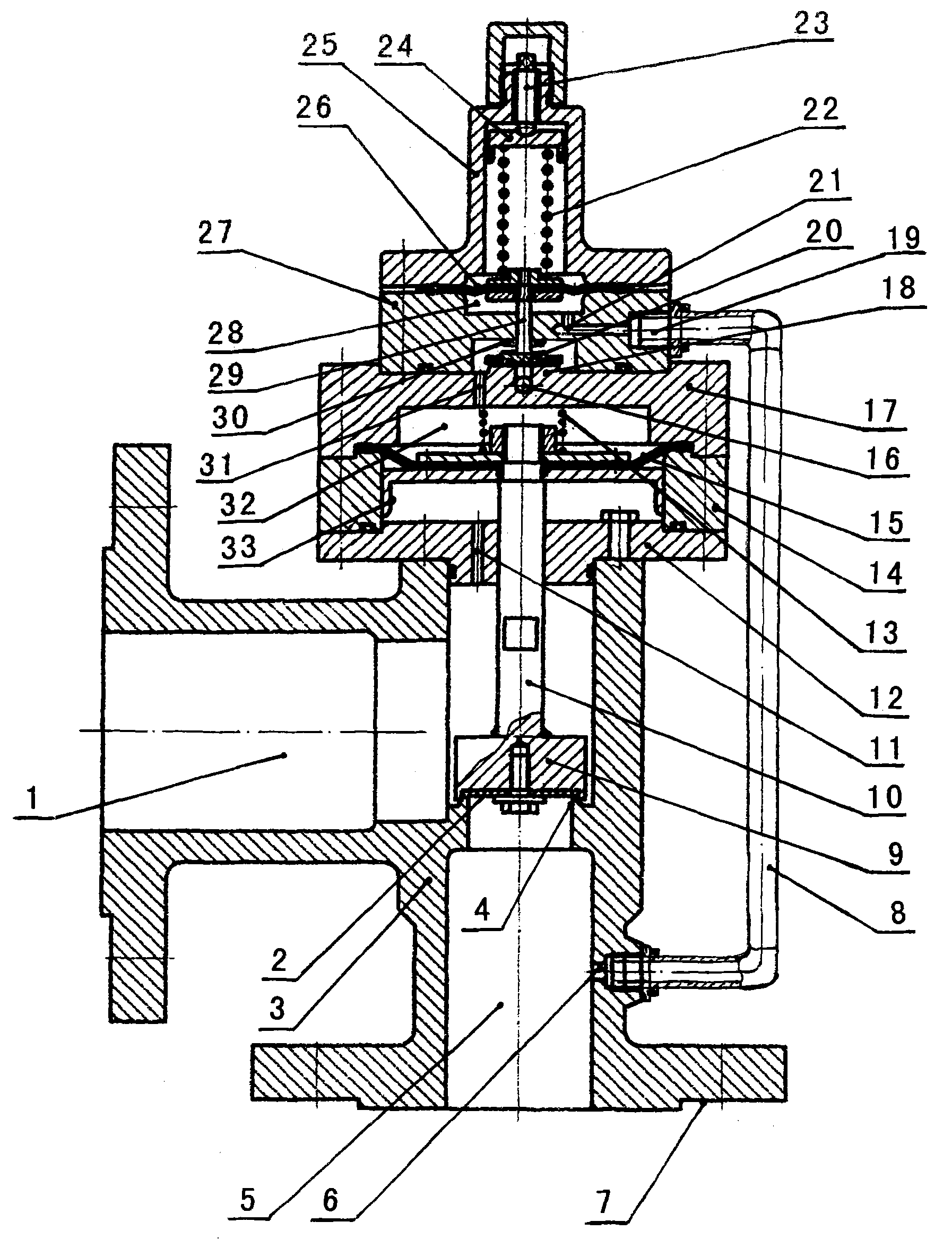

[0037] A low-pressure pilot-operated safety valve proposed by the present invention: it mainly includes a control conversion mechanism, a transmission mechanism and a main valve actuator composed of a main valve body 3, a main valve stem 10 and a main valve core 9. The bottom end of the valve core 9 is embedded with a soft gasket 2 and the main valve port 4 of the main valve body 3 to form a sealing auxiliary structure. The main valve port 4 is made of an alloy surfacing welding inclined plane limit structure, which can improve the sealing performance It can also prevent the main valve spool 9 from being damaged by impact when the seat is closed. The partition plate 12 is provided with a through hole 11 communicating with the lower cavity of the cylinder 14, the main valve stem 10 is connected to the diaphragm assembly 15, and the control switching mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com