Patents

Literature

726 results about "Direct acting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Direct acting means that valves uses a power supply to open and close. Power is transformed into magnetic force,in a plunger type valve,forces a plunger to move and open or close the valve seats. Other direct acting valve operate without a plunger but with same principle...

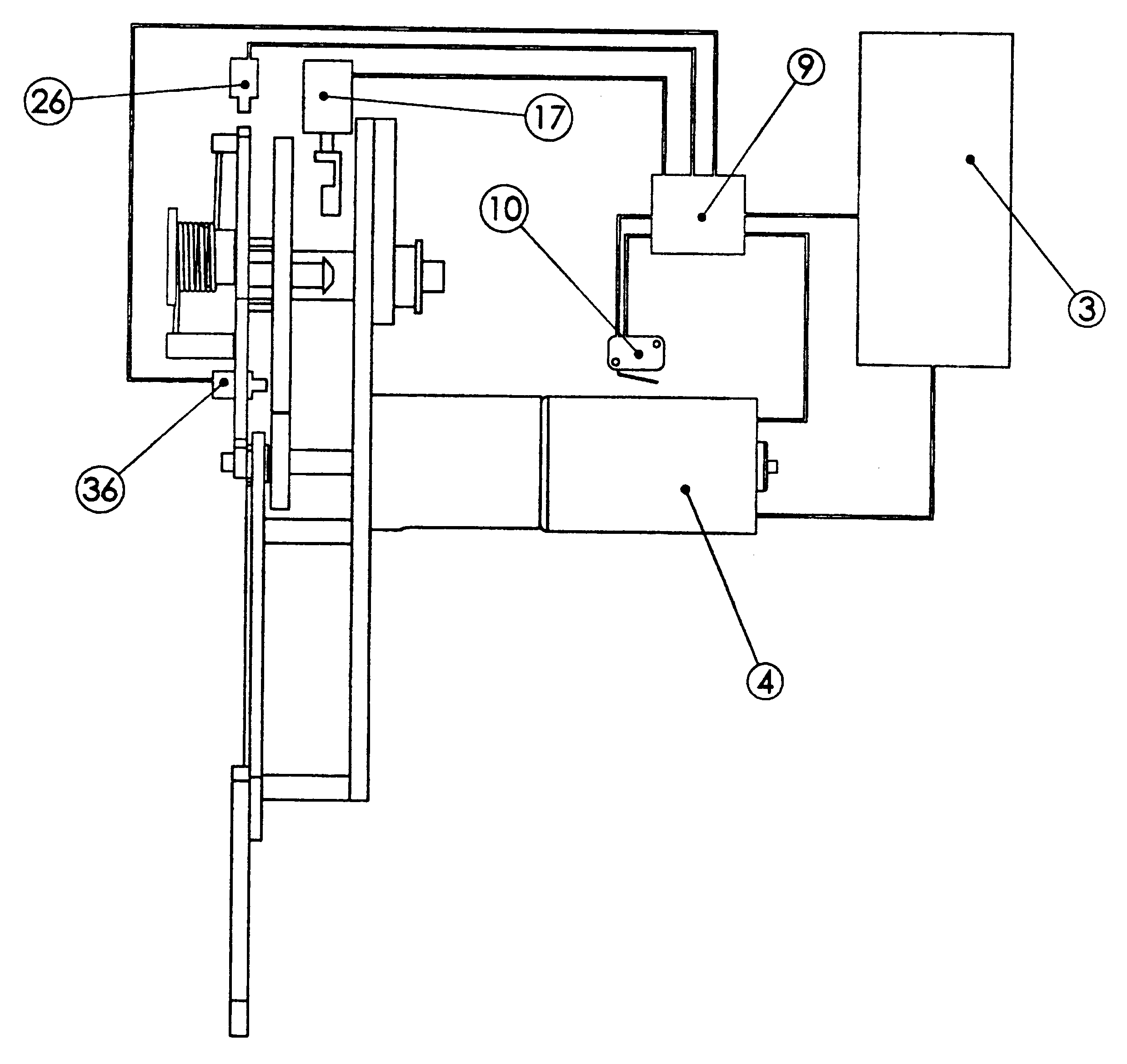

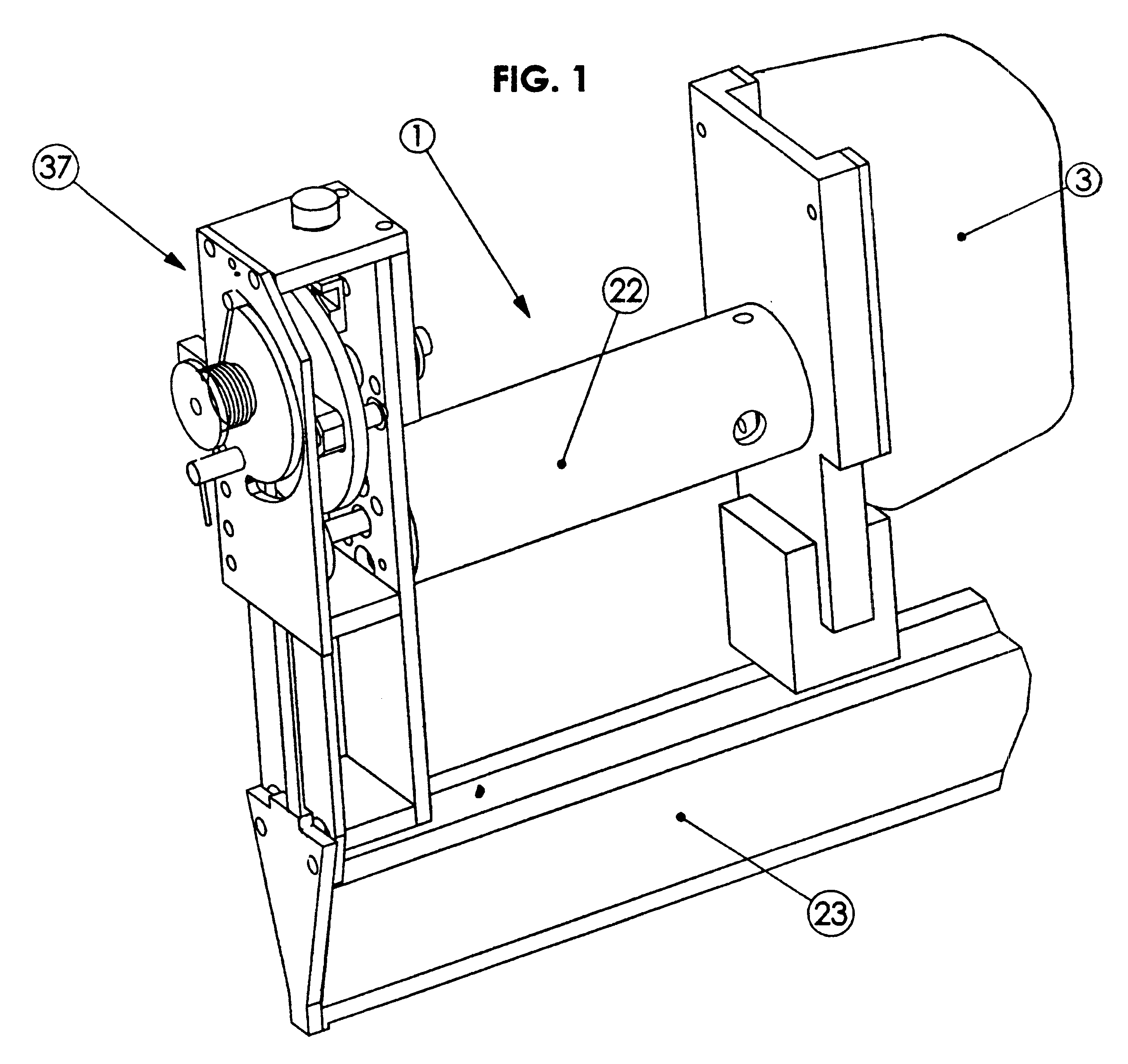

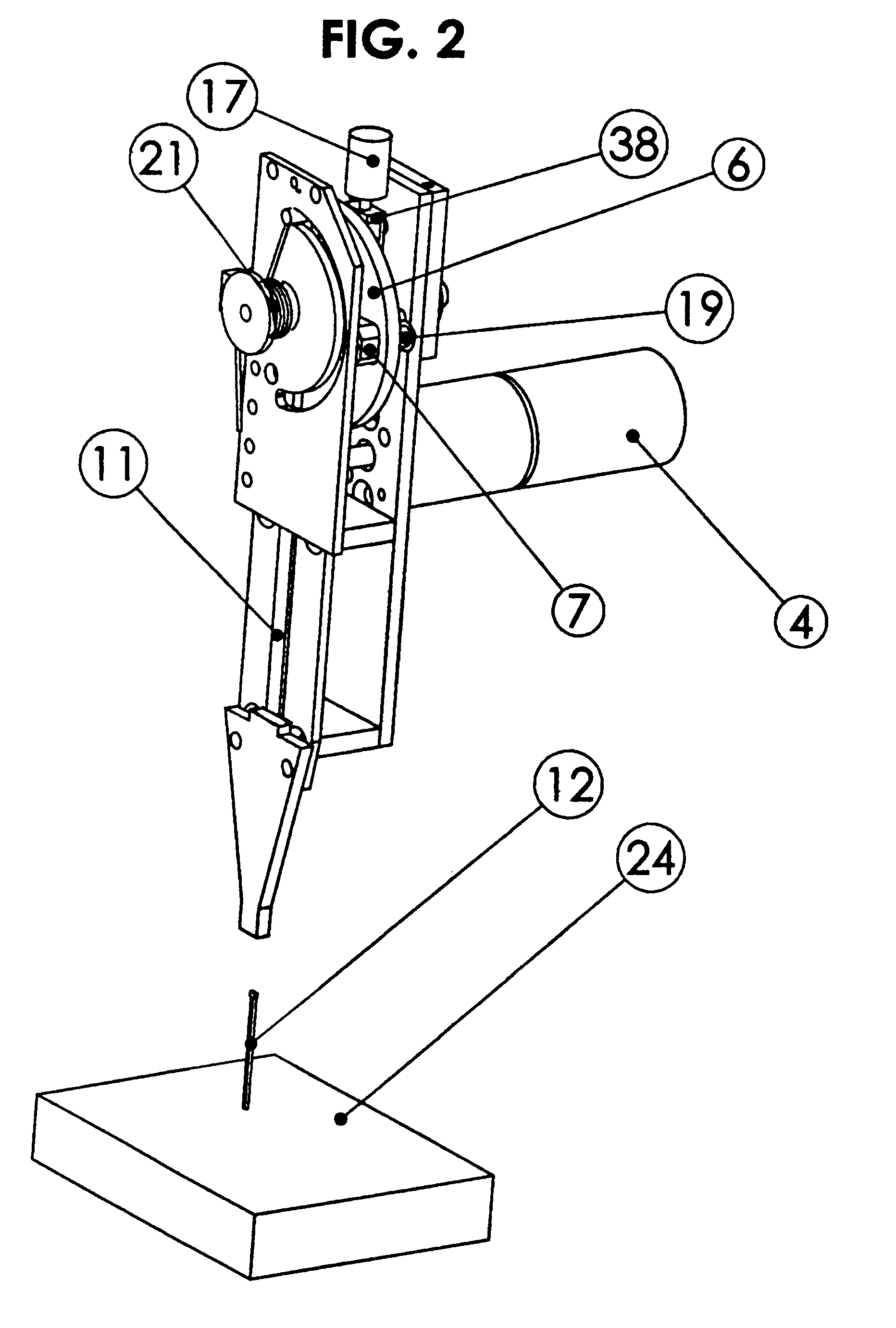

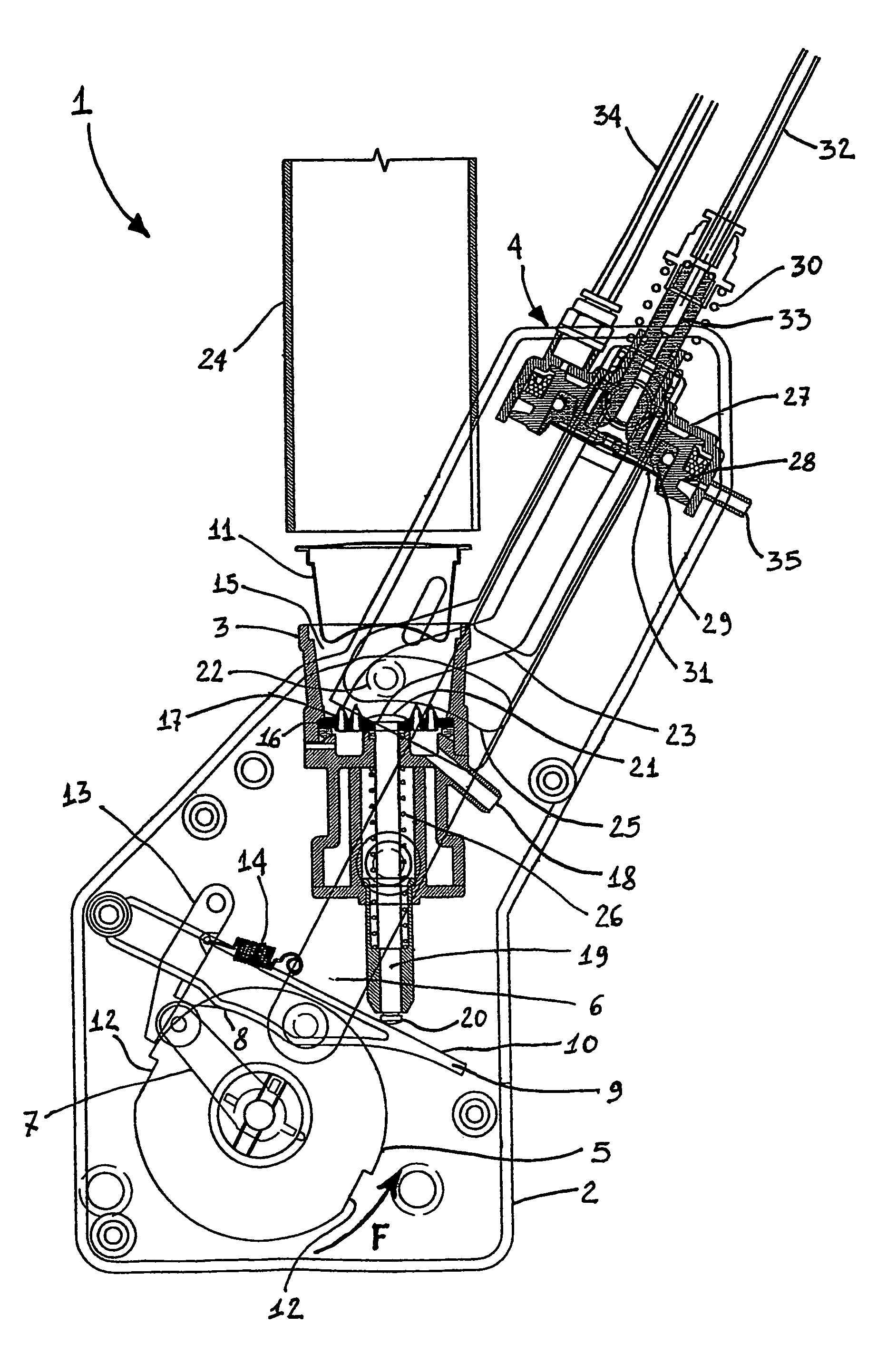

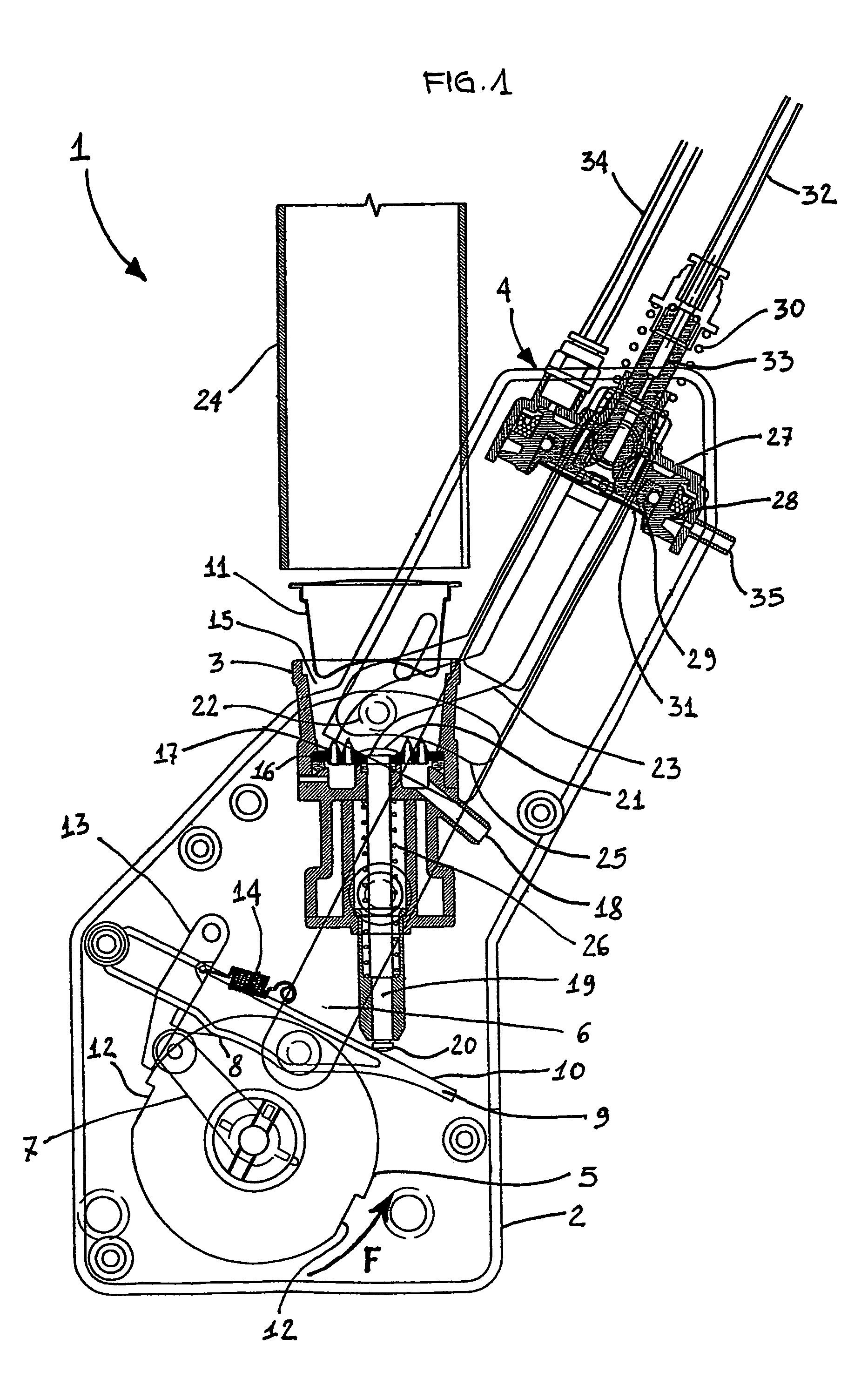

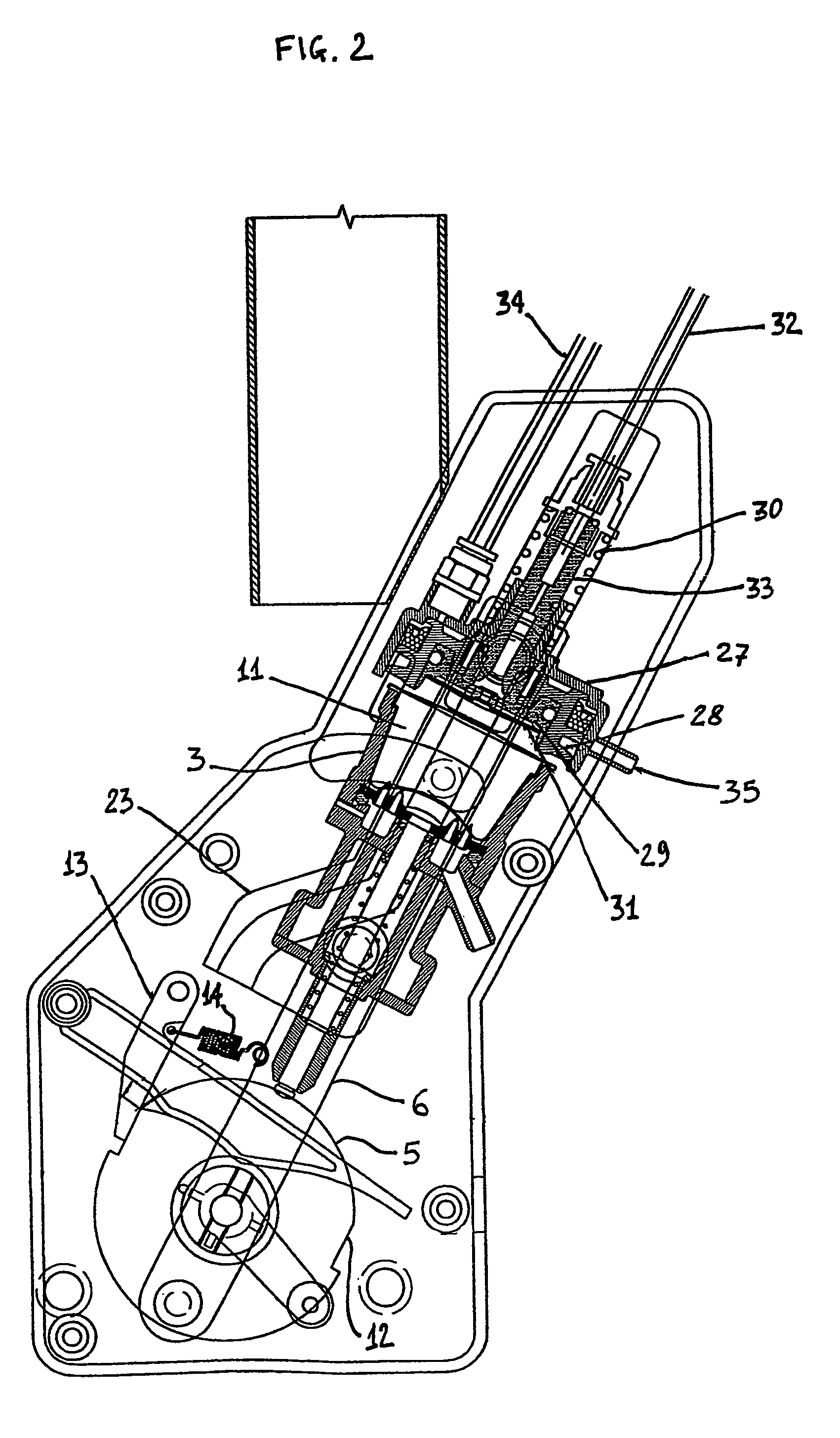

Electrical motor driven nail gun

InactiveUS6705503B1Easy to handleReduce wearStapling toolsReciprocating drilling machinesEngineeringFlywheel

A portable electric nailing gun operating from a power supply. The motor accelerates a flywheel, which at the appropriate energy state is coupled through a mechanism to an anvil acting directly on the nail. The actuation is governed by a control circuit and initiated from a trigger switch. The stored energy delivered from the motor is coupled to the output anvil drives the nail. At least one position of the output anvil is sensed and once the nail is driven, the power is disconnected from the motor. This method uses a direct acting clutch and a harmonic motion nailing mechanism to reduce wear and increase robustness of the nailer. Elastic elements are used to limit stresses during the impact periods. The electrical control circuit and sensors allow precise control and improve safety. The power supply is preferably a rechargeable low impedance battery pack.

Owner:TRICORD SOLUTIONS

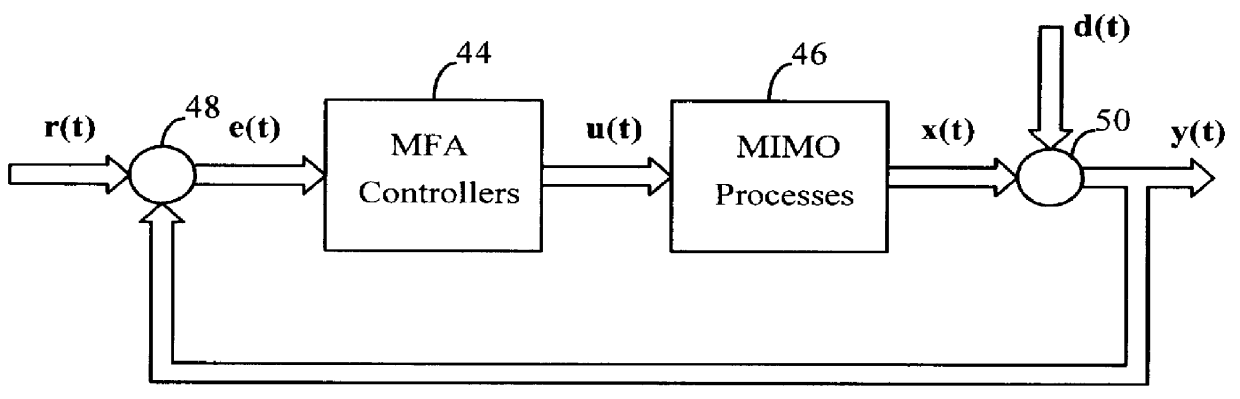

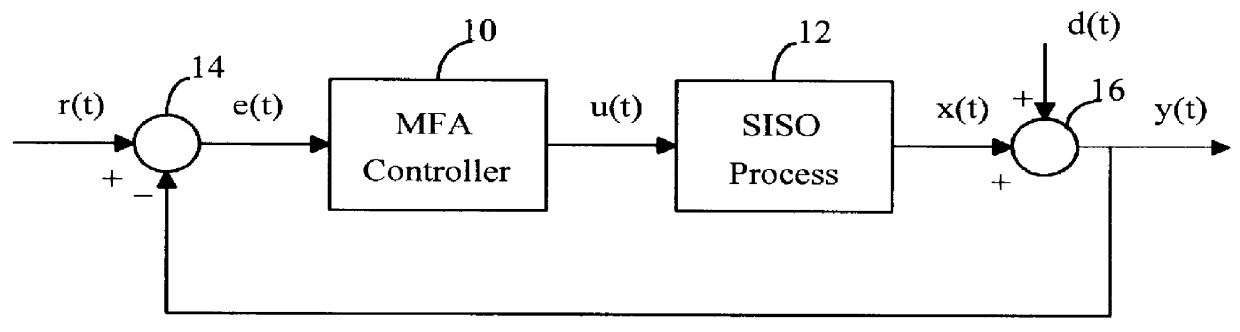

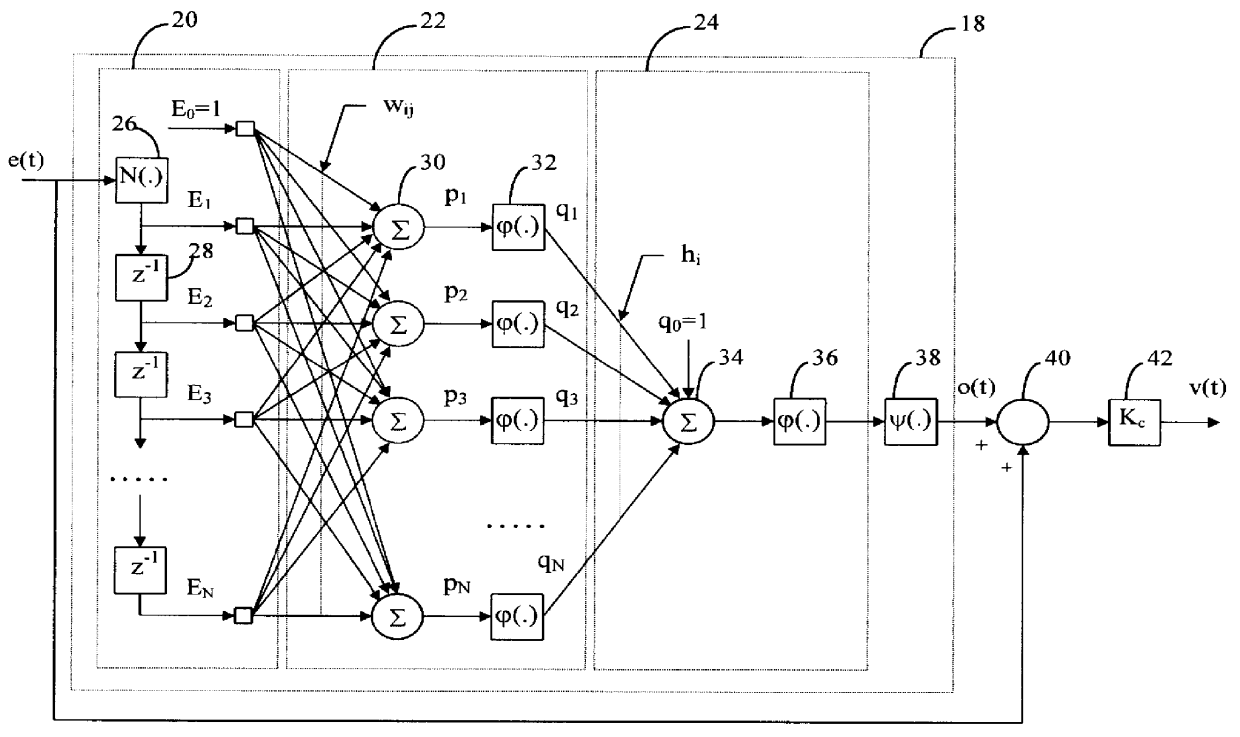

Model-free adaptive process control

InactiveUS6055524ALong response delayOvercome limitationsDigital computer detailsDigital dataData miningSelf adaptive

A model-free adaptive controller is disclosed, which uses a dynamic artificial neural network with a learning algorithm to control any single-variable or multivariable open-loop stable, controllable, and consistently direct-acting or reverse-acting industrial process without requiring any manual tuning, quantitative knowledge of the process, or process identifiers. The need for process knowledge is avoided by substituting 1 for the actual sensitivity function .differential.y(t) / .differential.u(t) of the process.

Owner:GEN CYBERNATION GROUP

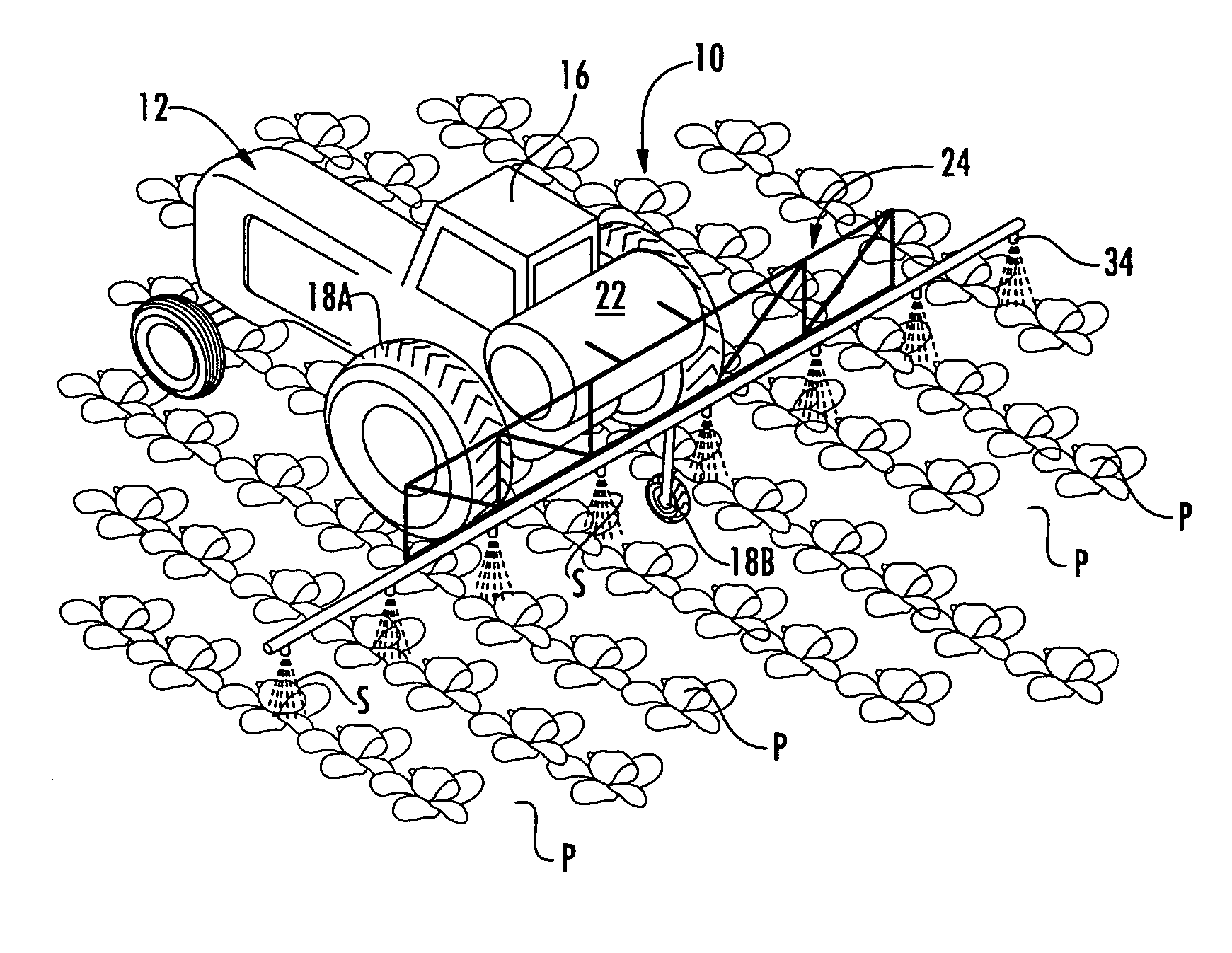

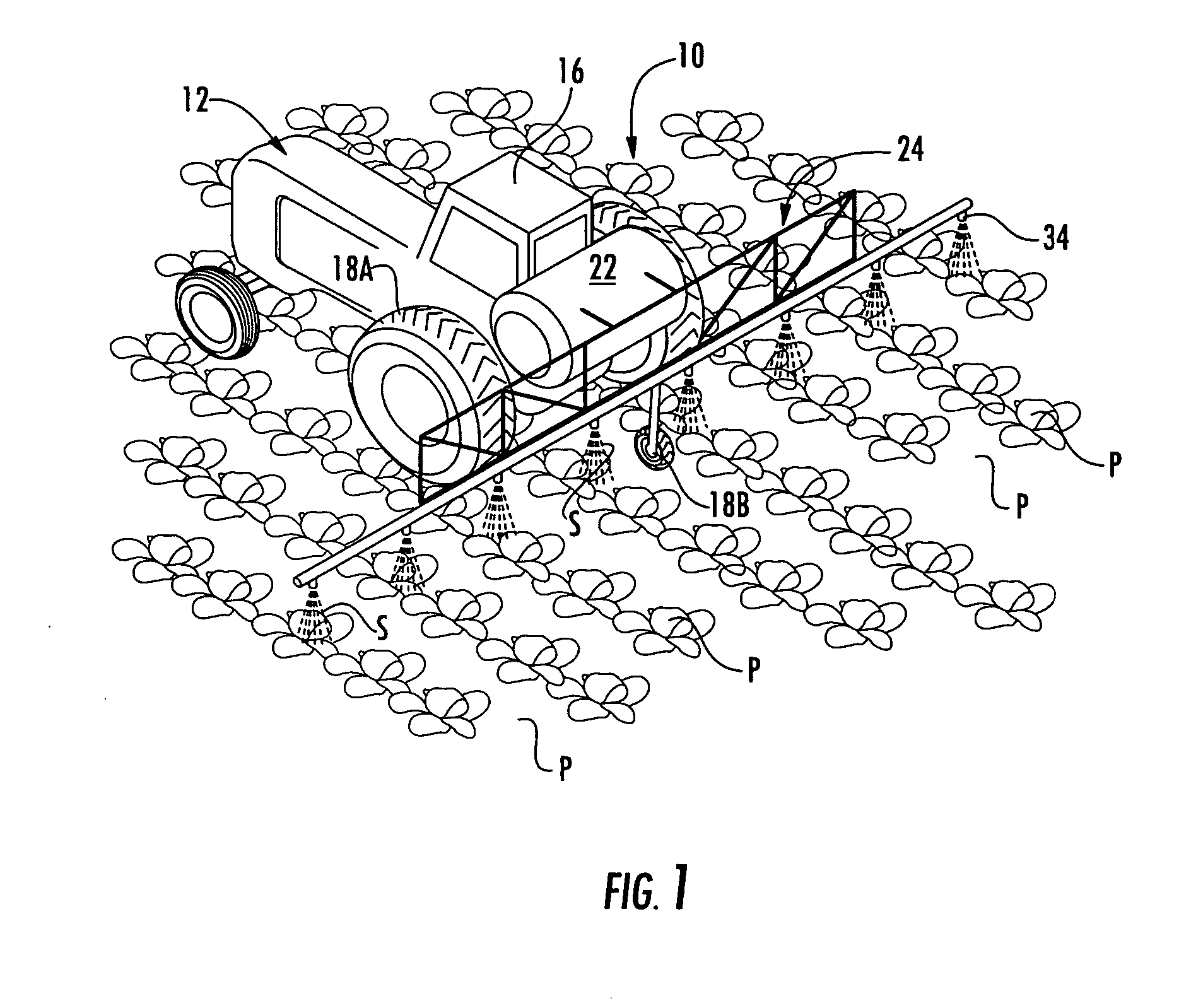

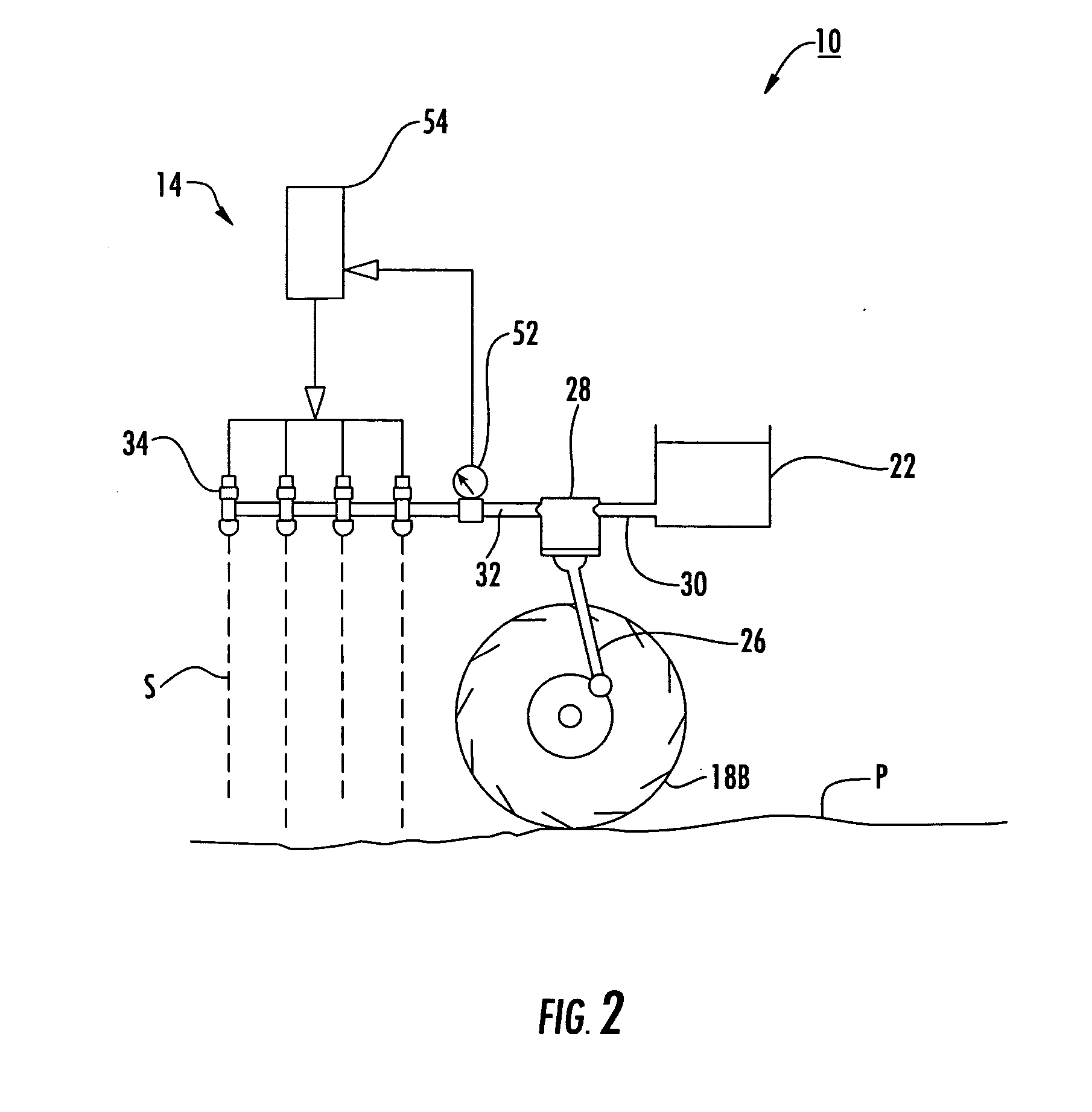

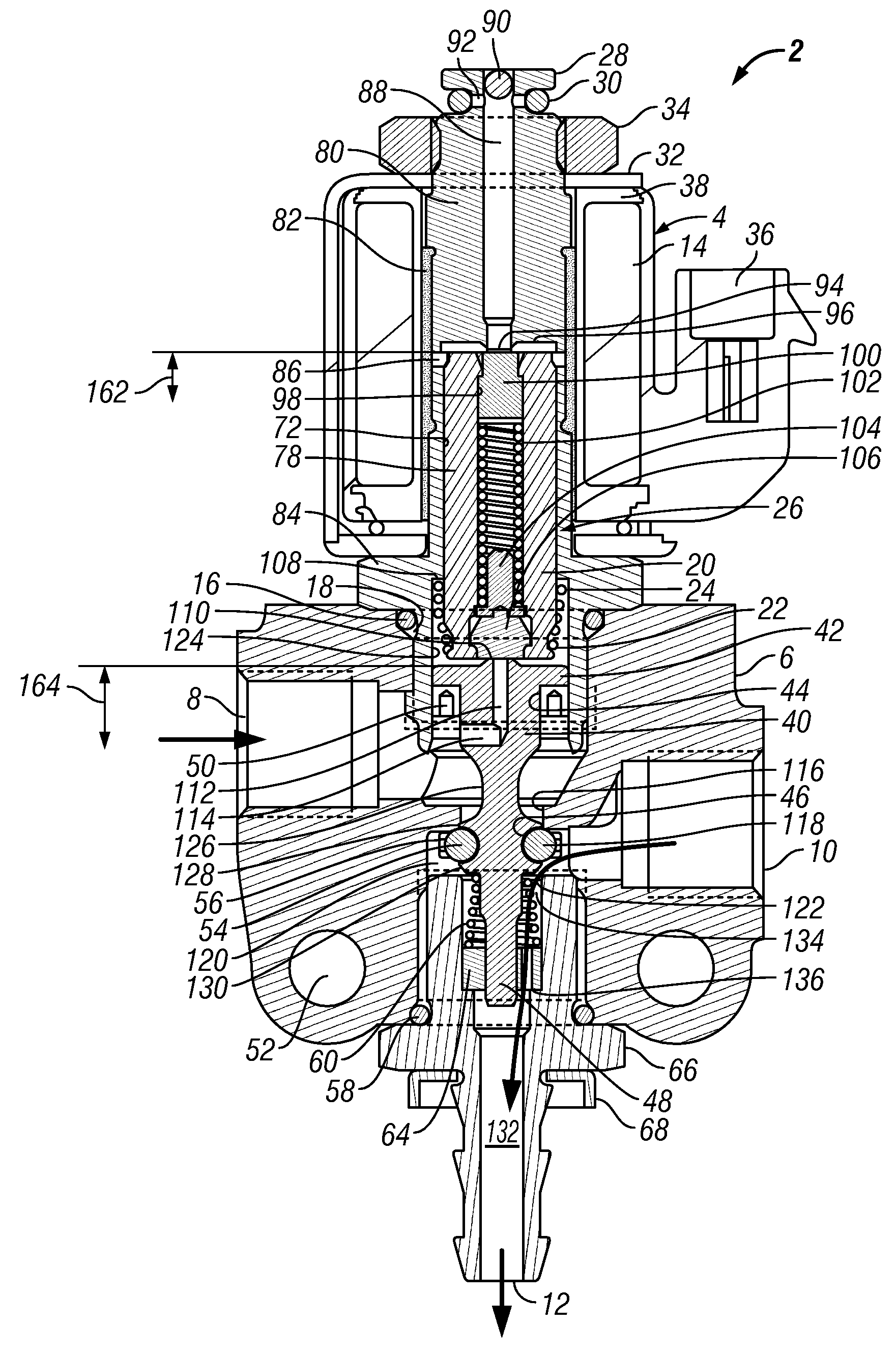

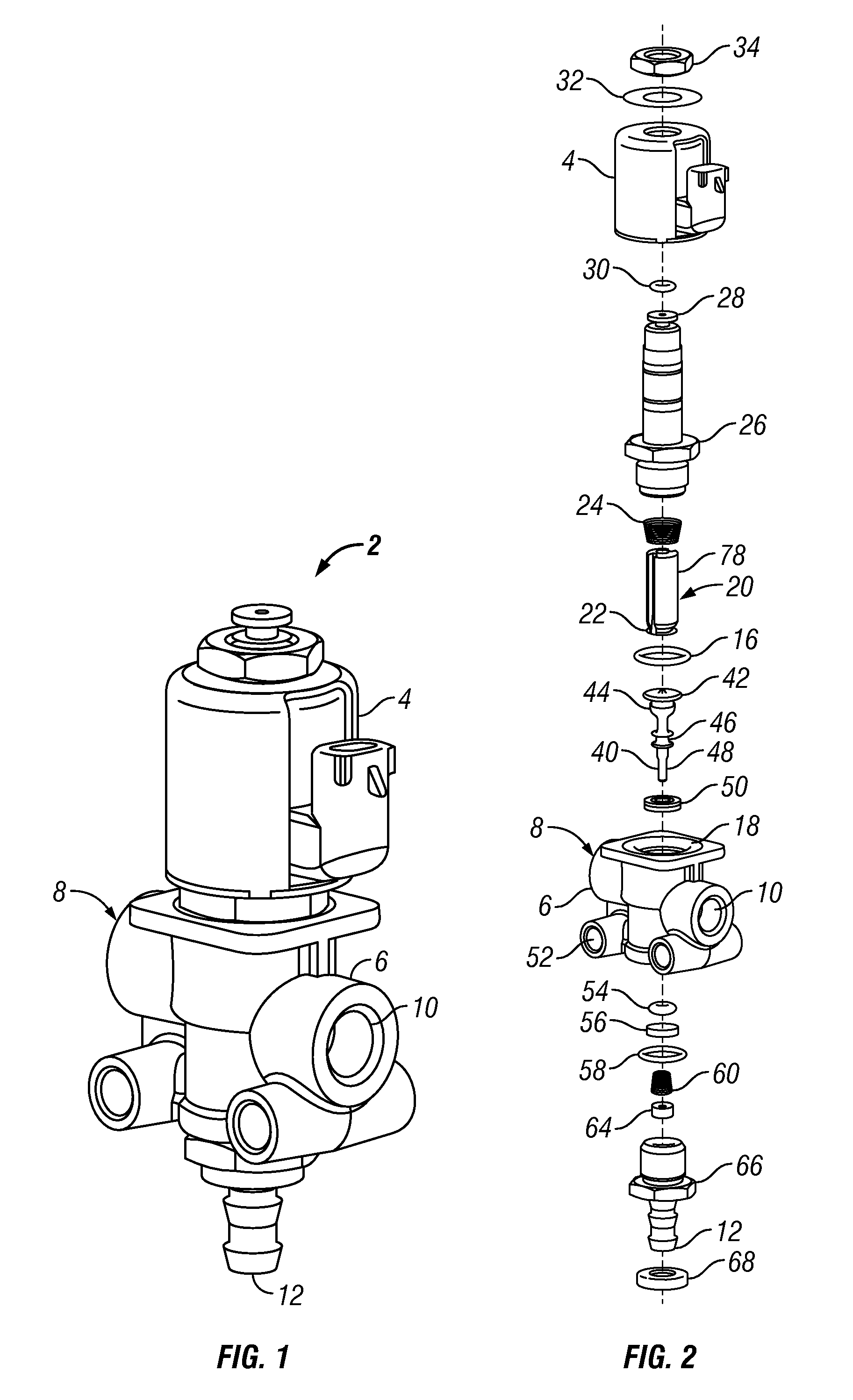

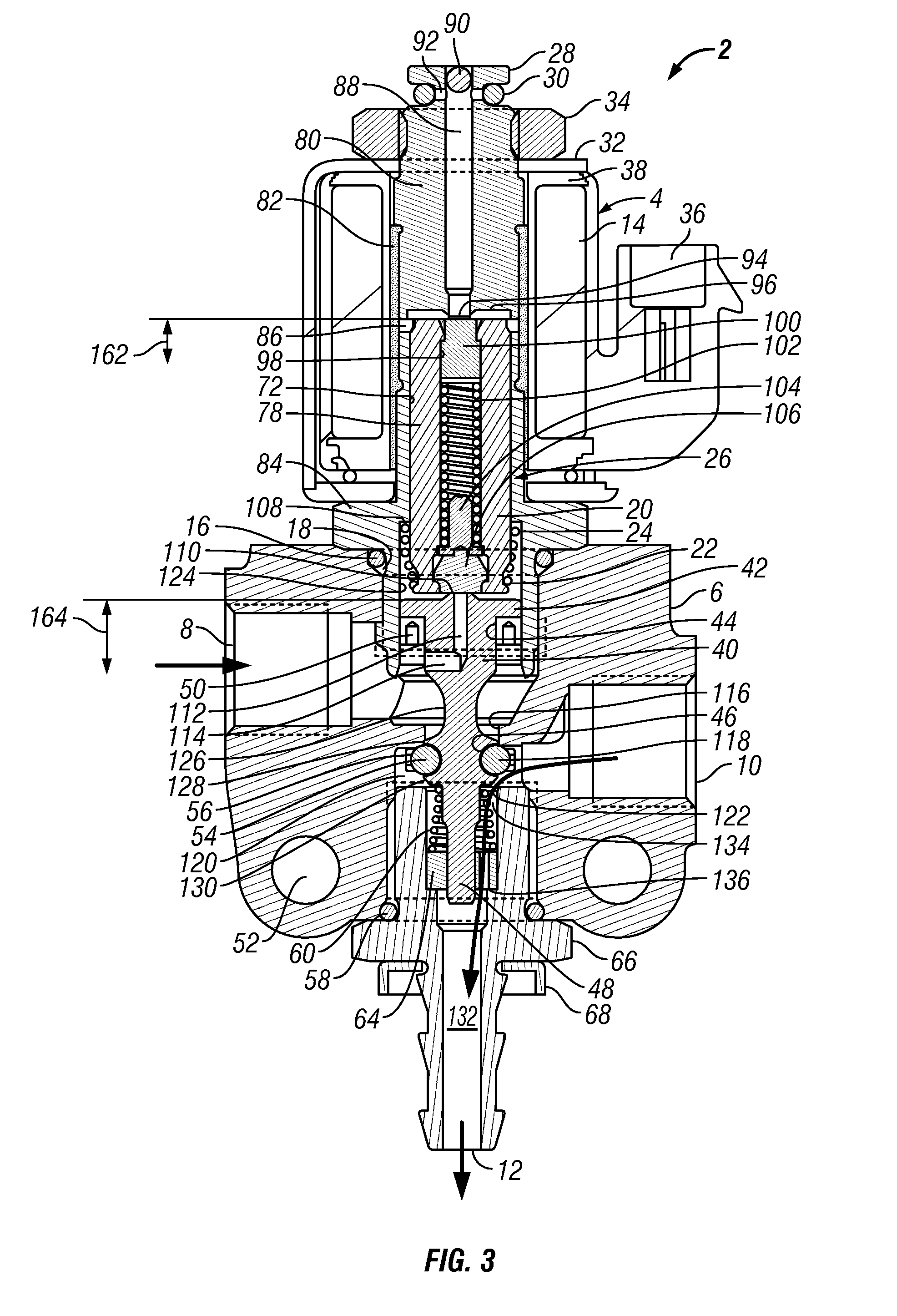

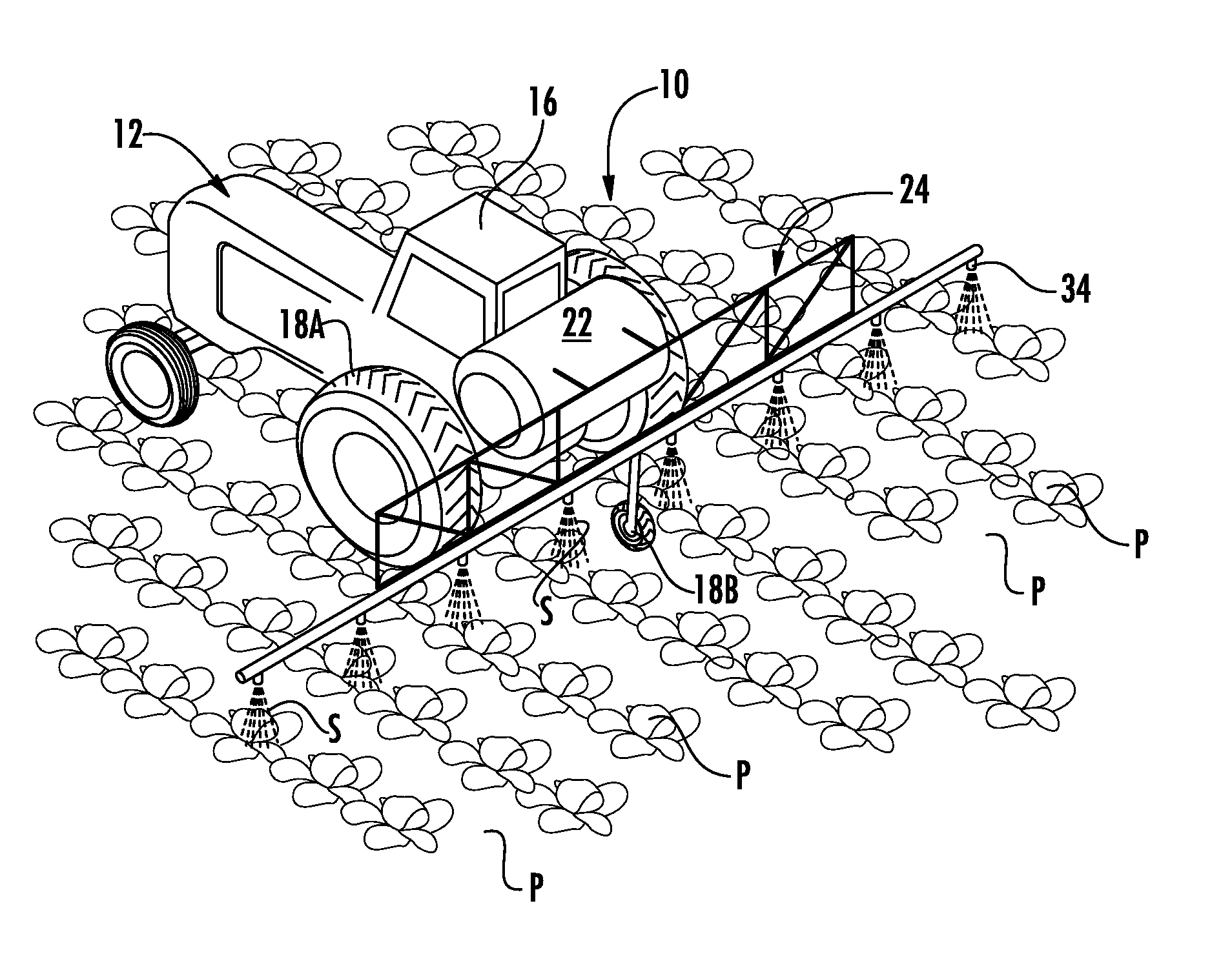

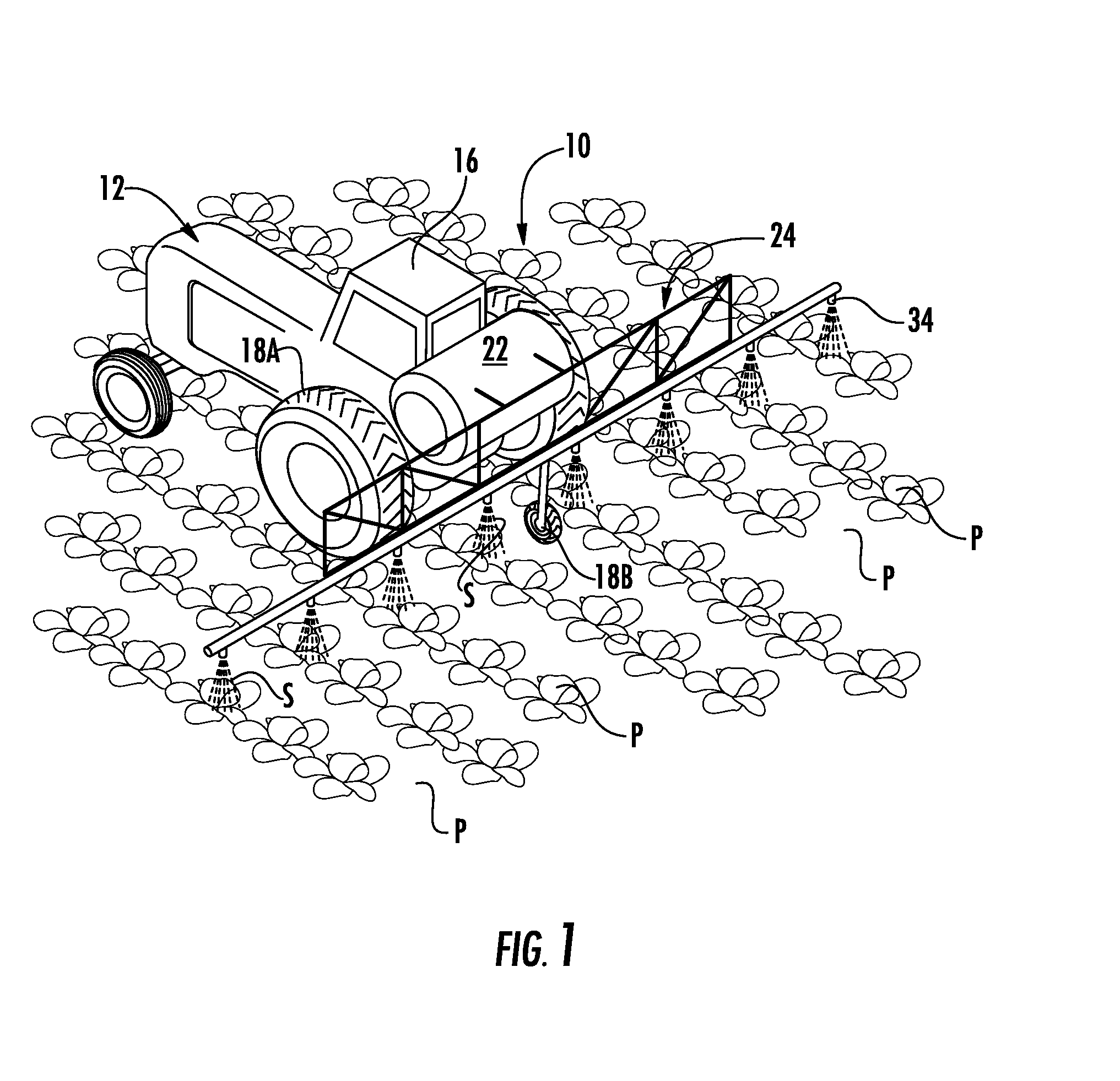

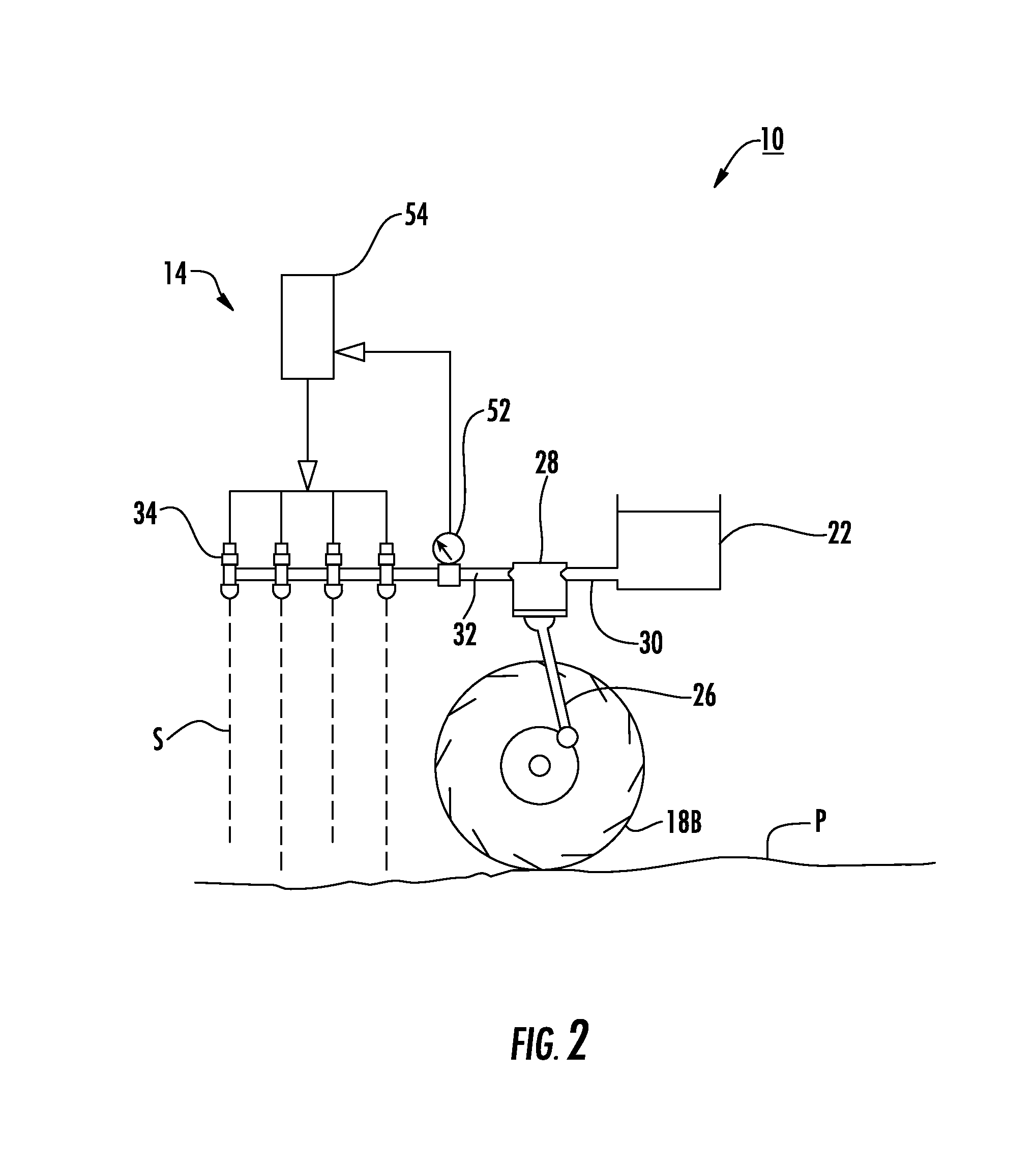

Electrically actuated variable pressure control system

InactiveUS20060273189A1Increase flow resistanceLow flow resistanceOperating means/releasing devices for valvesSelf-acting watering devicesSolenoid valveAtomizer nozzle

An electrically-actuated variable pressure control system for use with flow-controlled liquid application systems. Direct acting solenoid valves are pulsed at varying frequencies and duty cycles to change the resistance to flow encountered by the flow-controlled liquid application system. This pulsing solenoid valve technique preserves a high degree of accuracy and uniformity through a wide range of pressure control. This wide range of pressure control indirectly allows the flow-controlled liquid application system to operate over a wider range of flow control, yielding indirect benefits to performance and productivity. When the solenoid valves are attached to pressure-atomization spray nozzles, control over spray pattern and droplet size is further achieved.

Owner:CAPSTAN

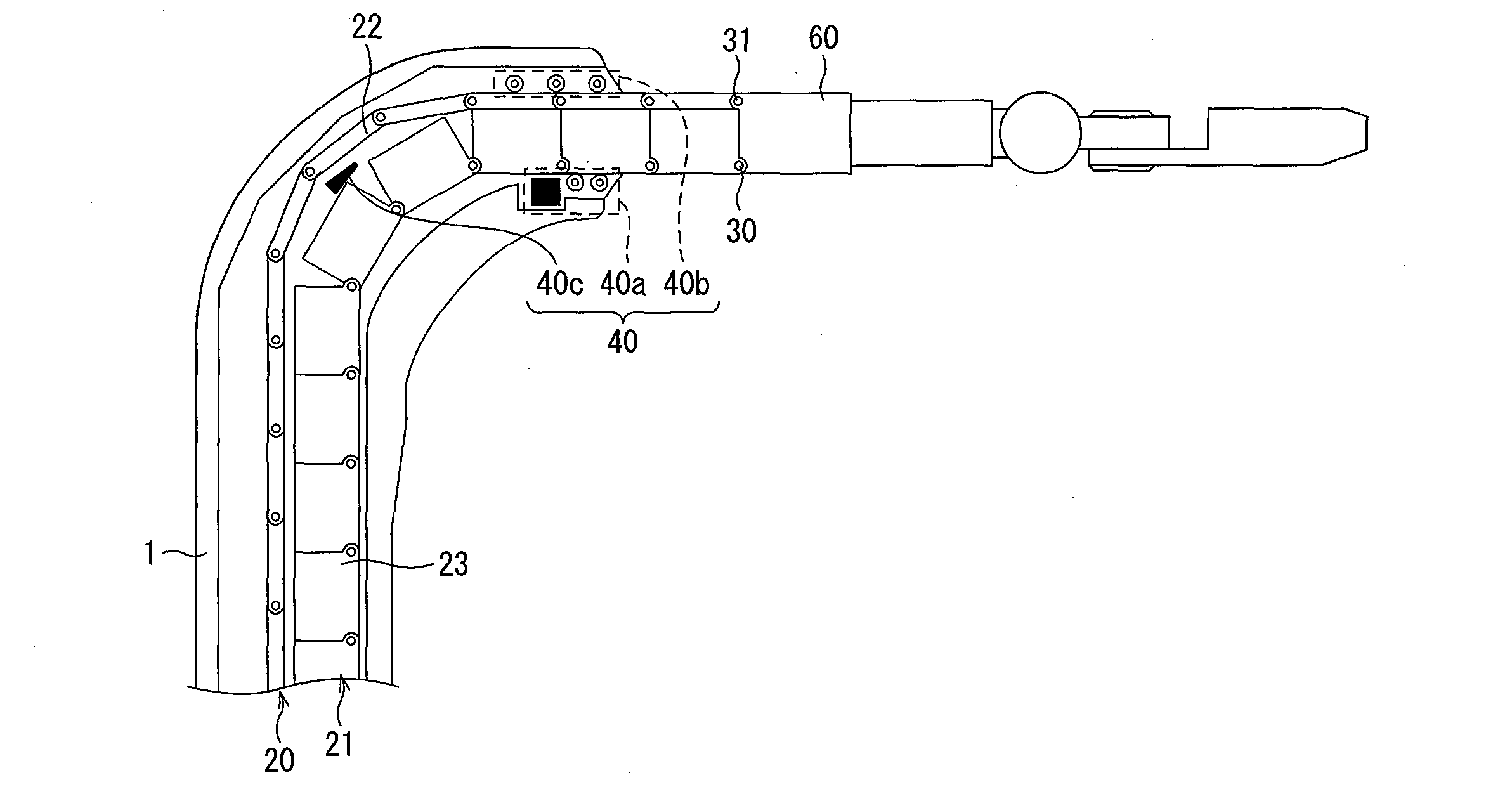

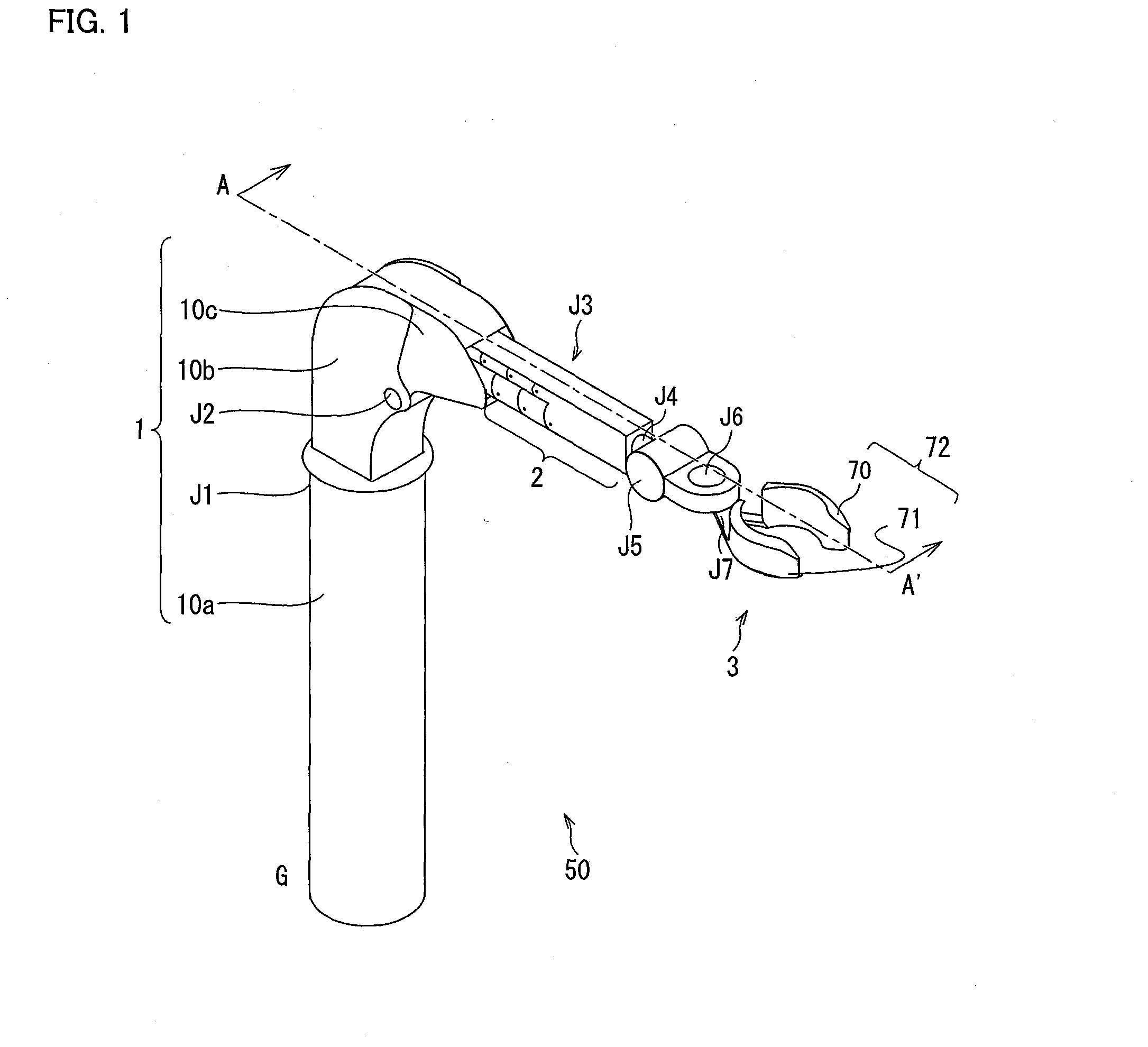

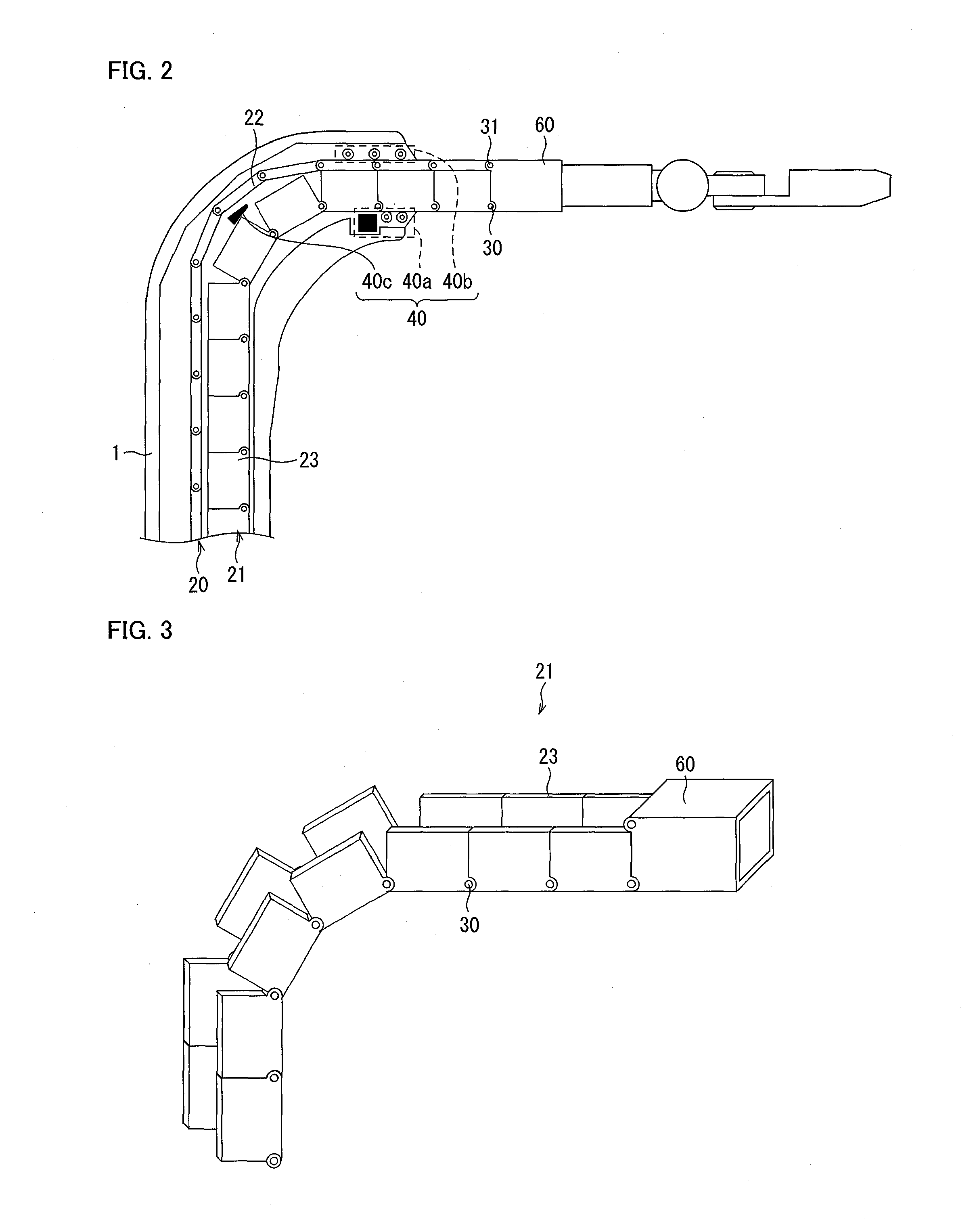

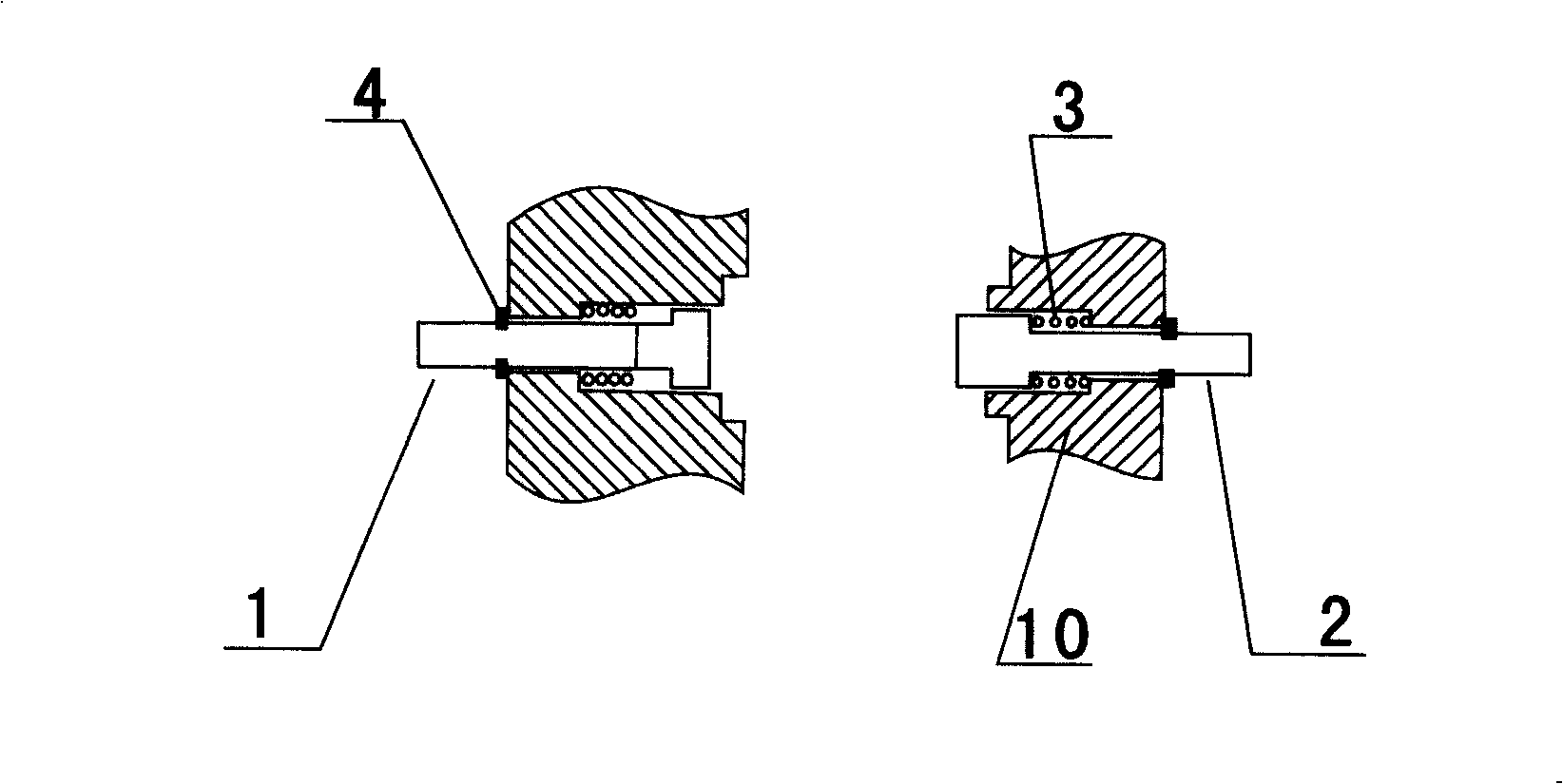

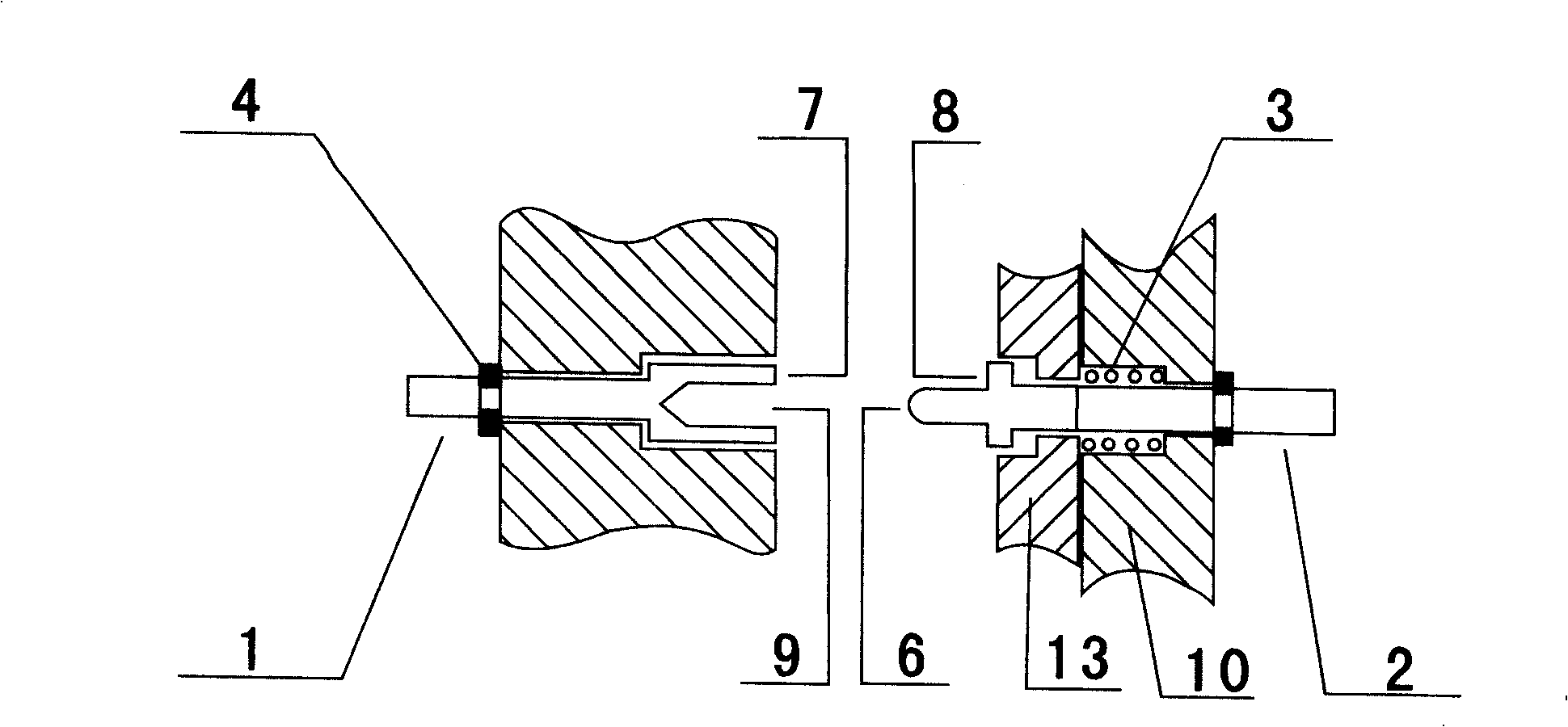

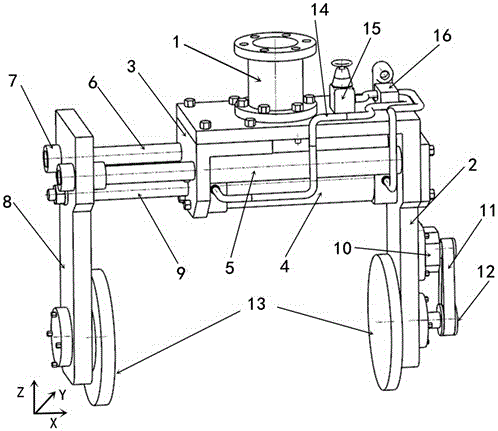

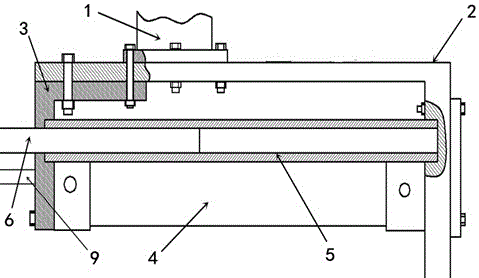

Direct acting extensible and retractable arm mechanism, and robot arm provided with direct acting extensible and retractable arm mechanism

ActiveUS20130068061A1Improve rigiditySmall sizeProgramme-controlled manipulatorJointsRotational axisEngineering

A robot arm (50) of the present invention includes, as a direct acting extensible / retractable joint (J3), an arm section (2) constituted by an upper structure group (20) and a lower structure group (21). Groups (20) and (21), having an arrangement in which structures are connected in series, partially engage so as to form a direct rigid combined structure, and are separated so as to release the rigid structure. An arm length can be adjusted arbitrarily. Section (2) can have a plane surface having no gap to prevent entry of a finger / dust. Separation of Groups (20) and (21) allows an upper structure (22) and a lower structure (23) to rotate around their rotational axes, to realize compact storage inside a robot arm supporting member (1). It is thus possible to prevent significantly entry of a finger / dust, and provide a compact direct acting extensible and retractable arm mechanism.

Owner:FANUC LTD +1

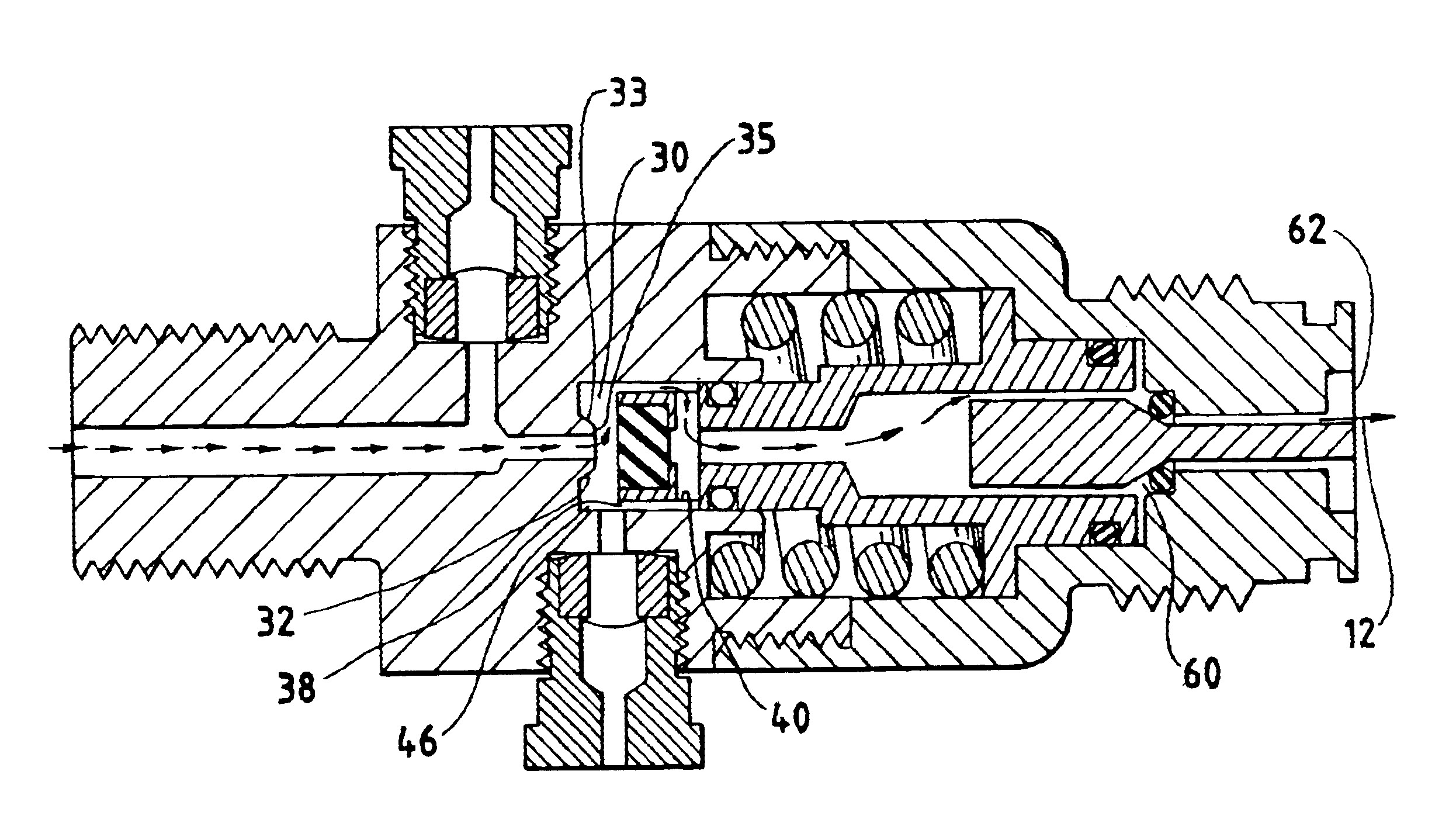

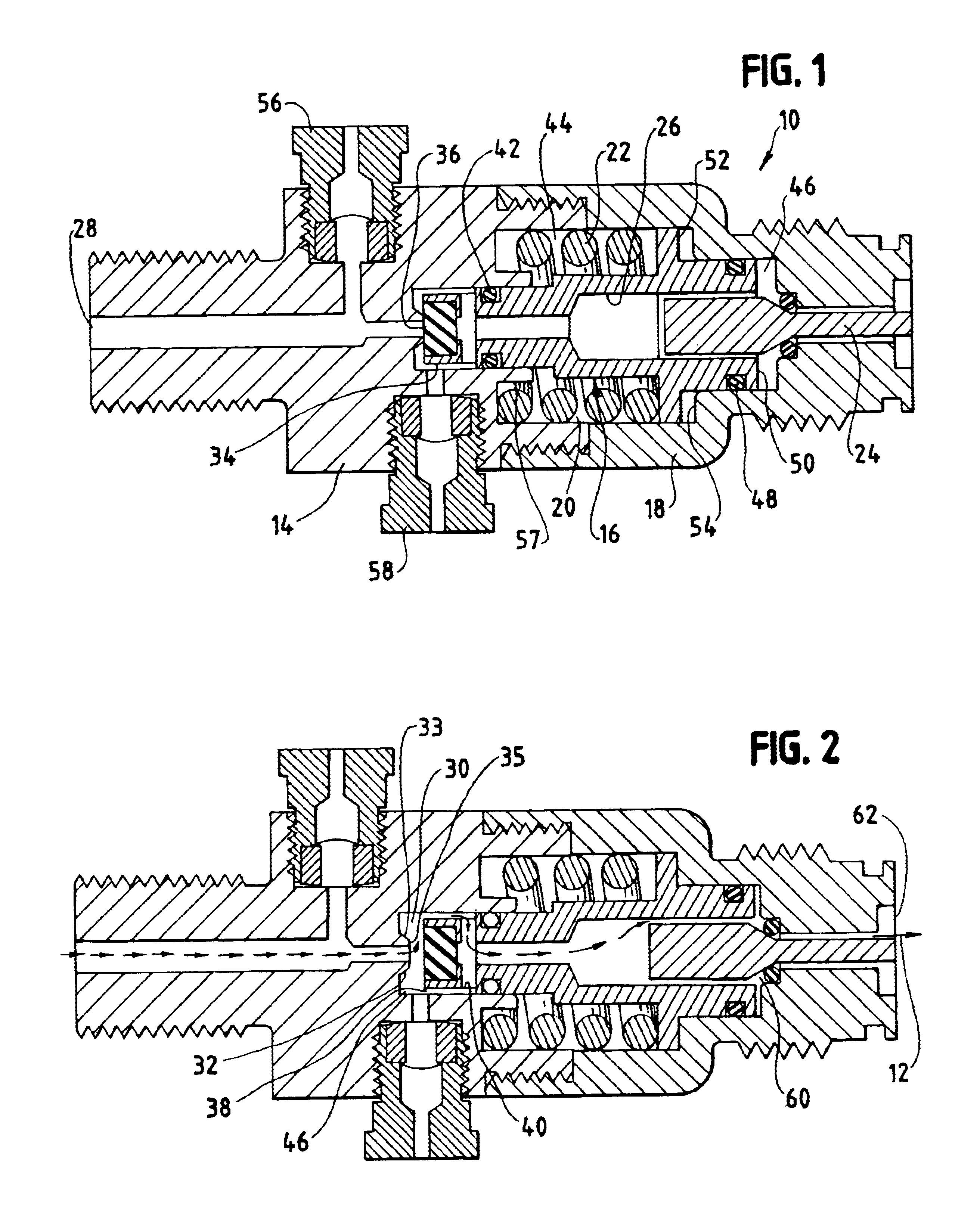

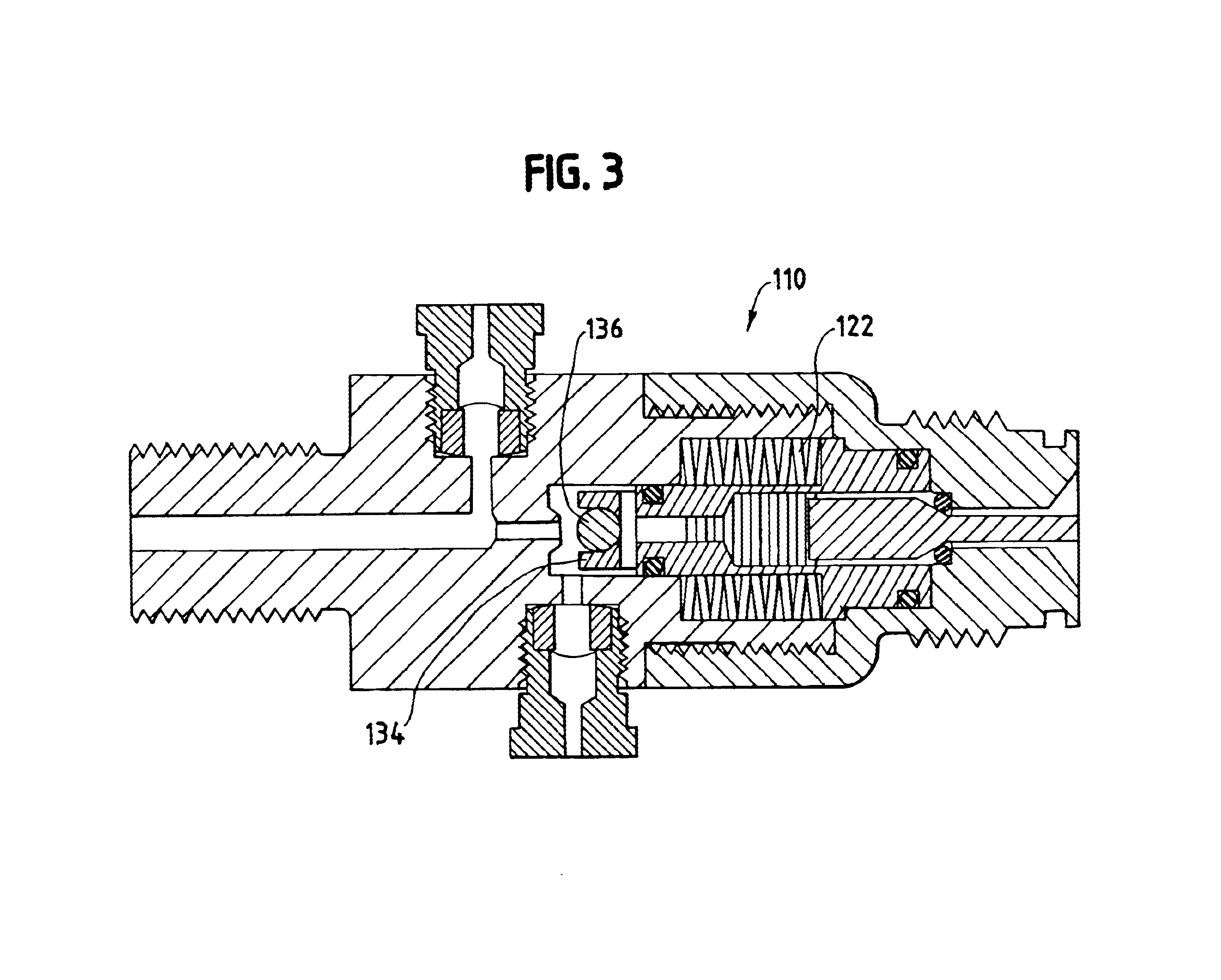

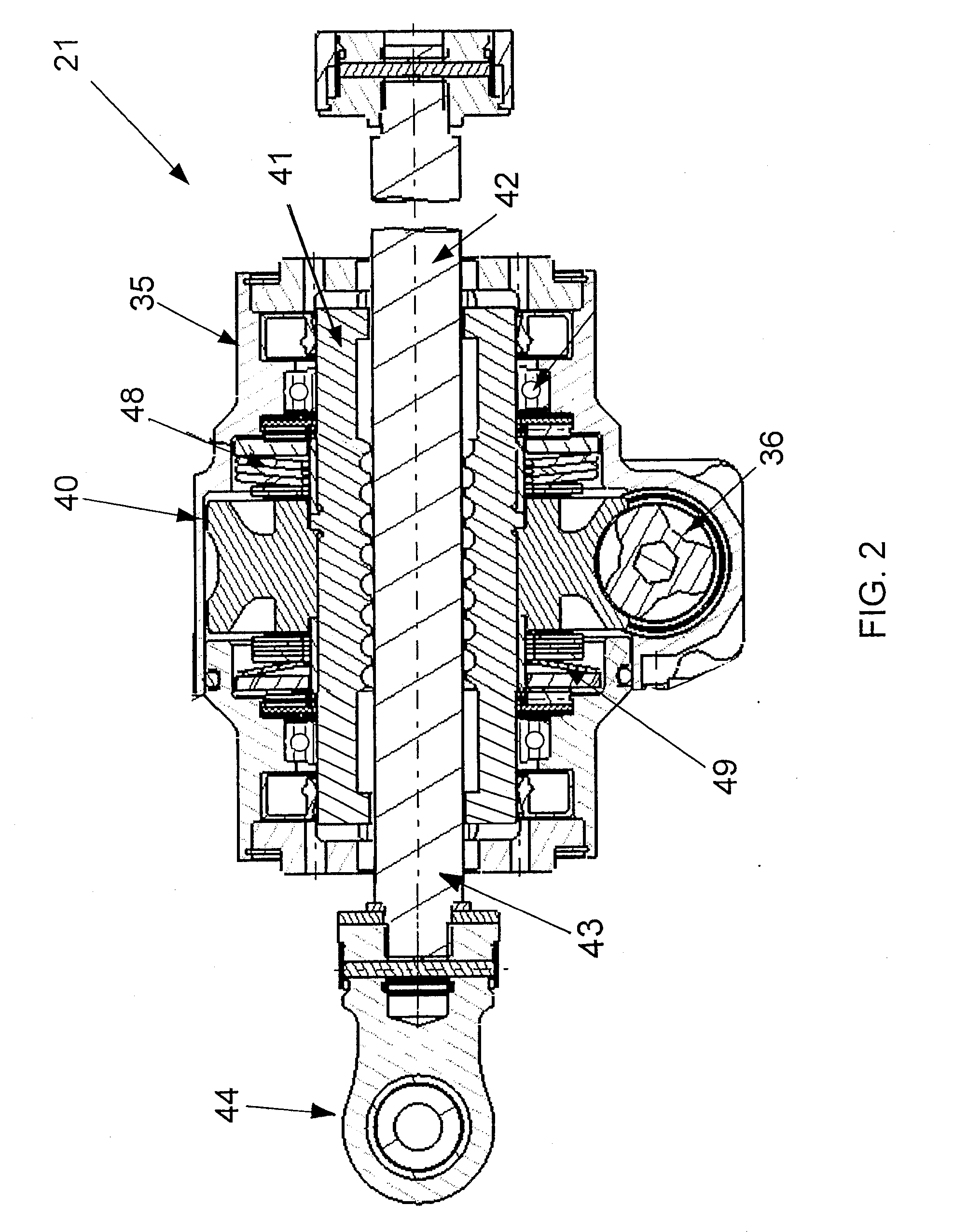

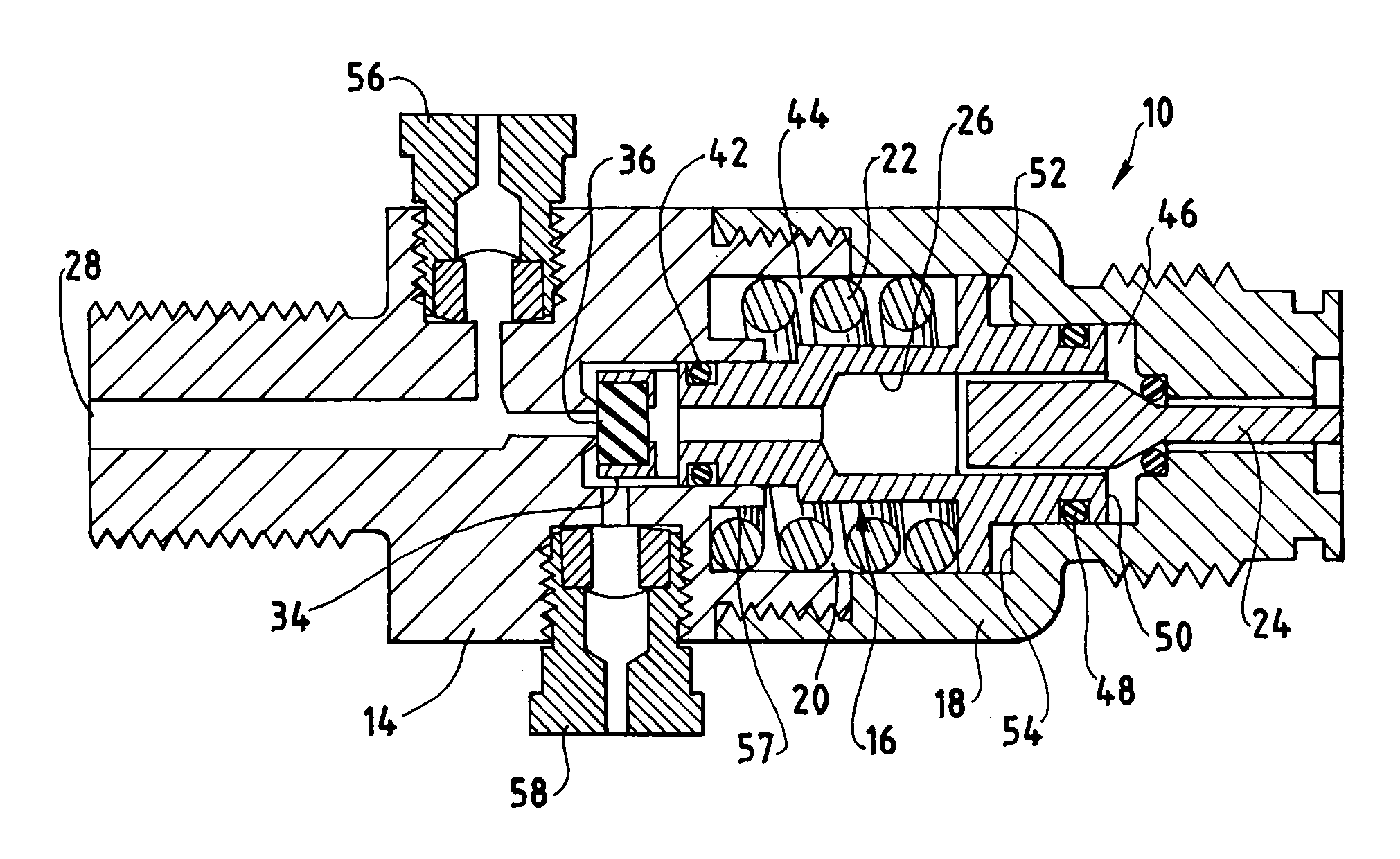

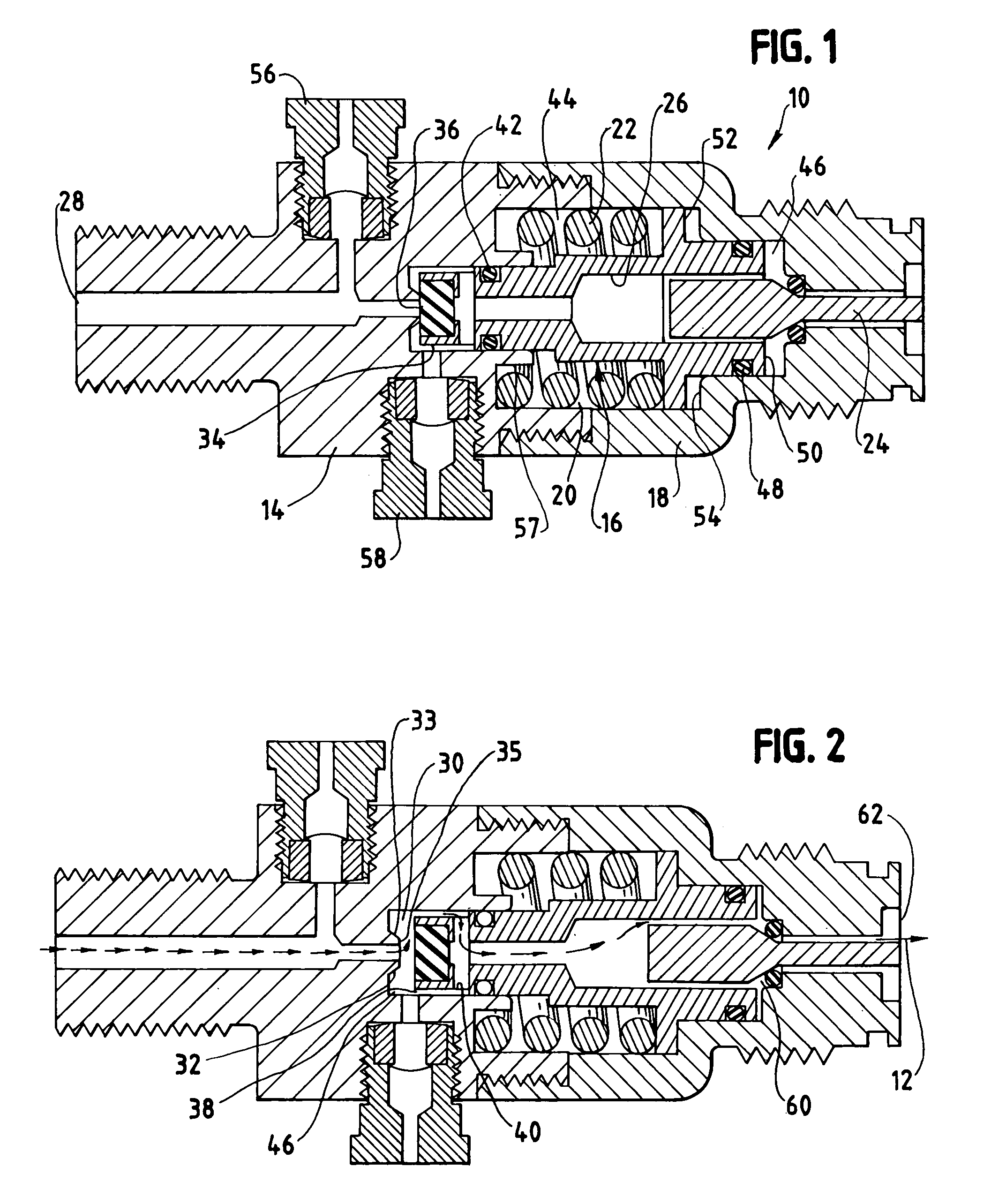

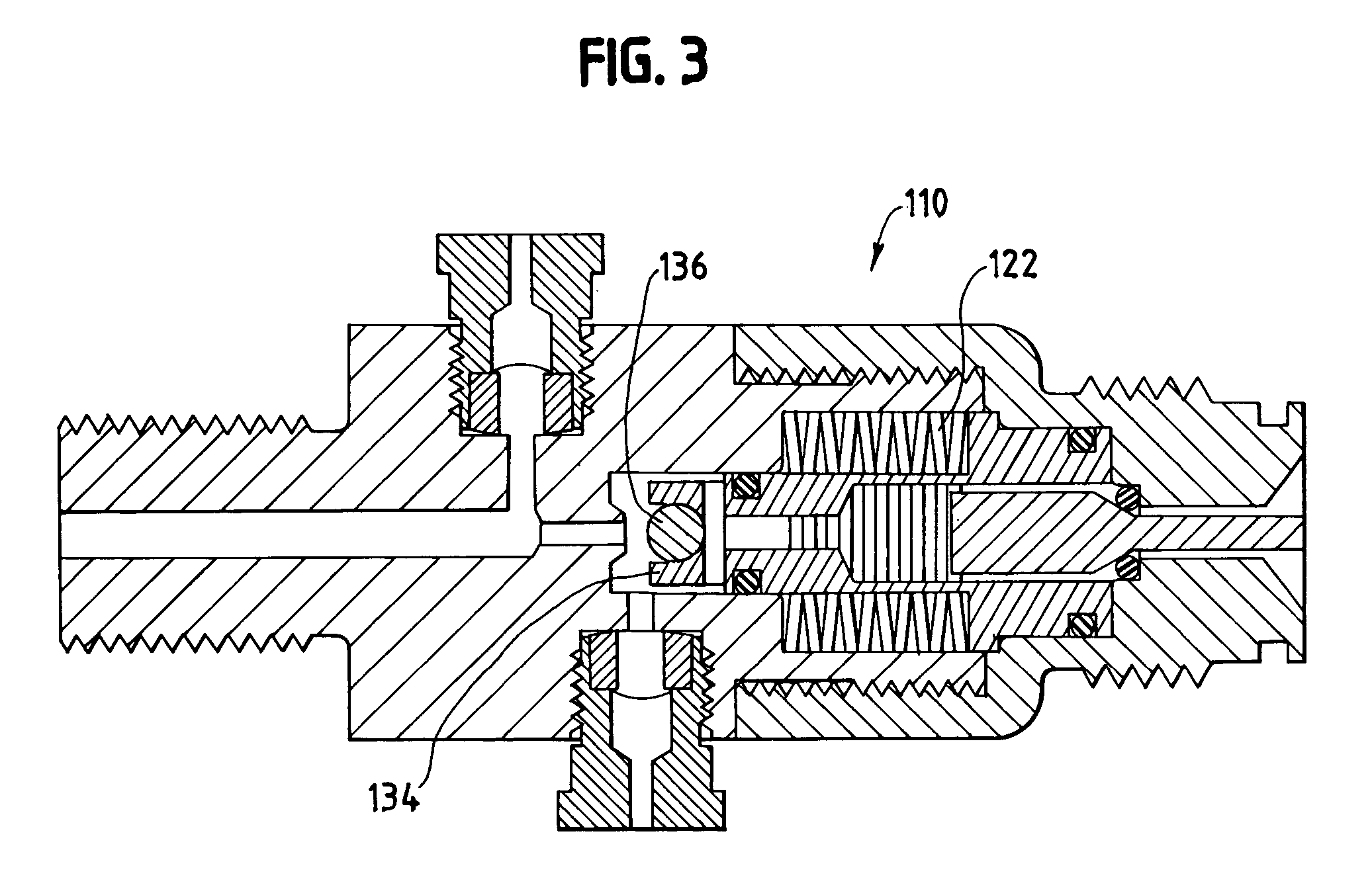

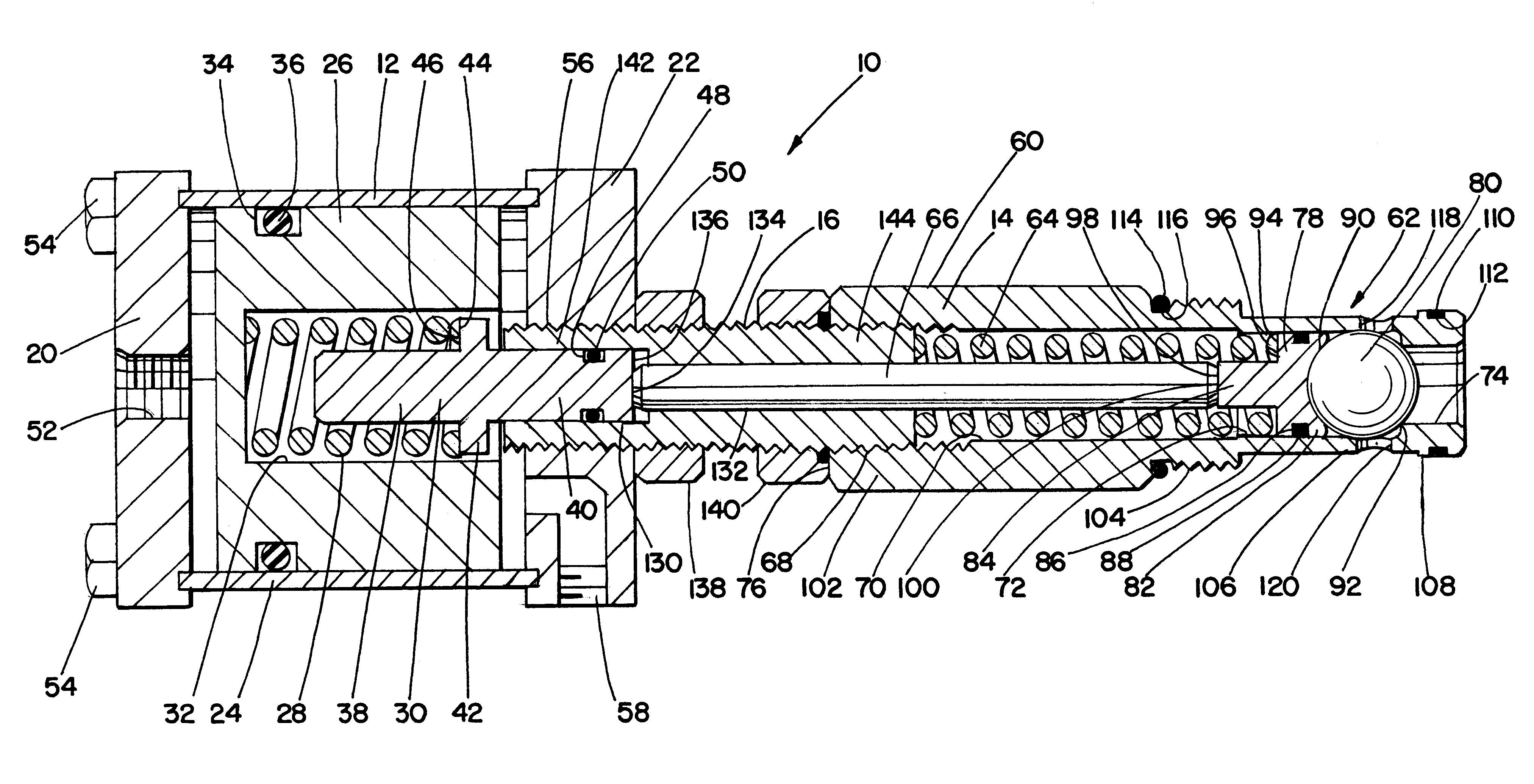

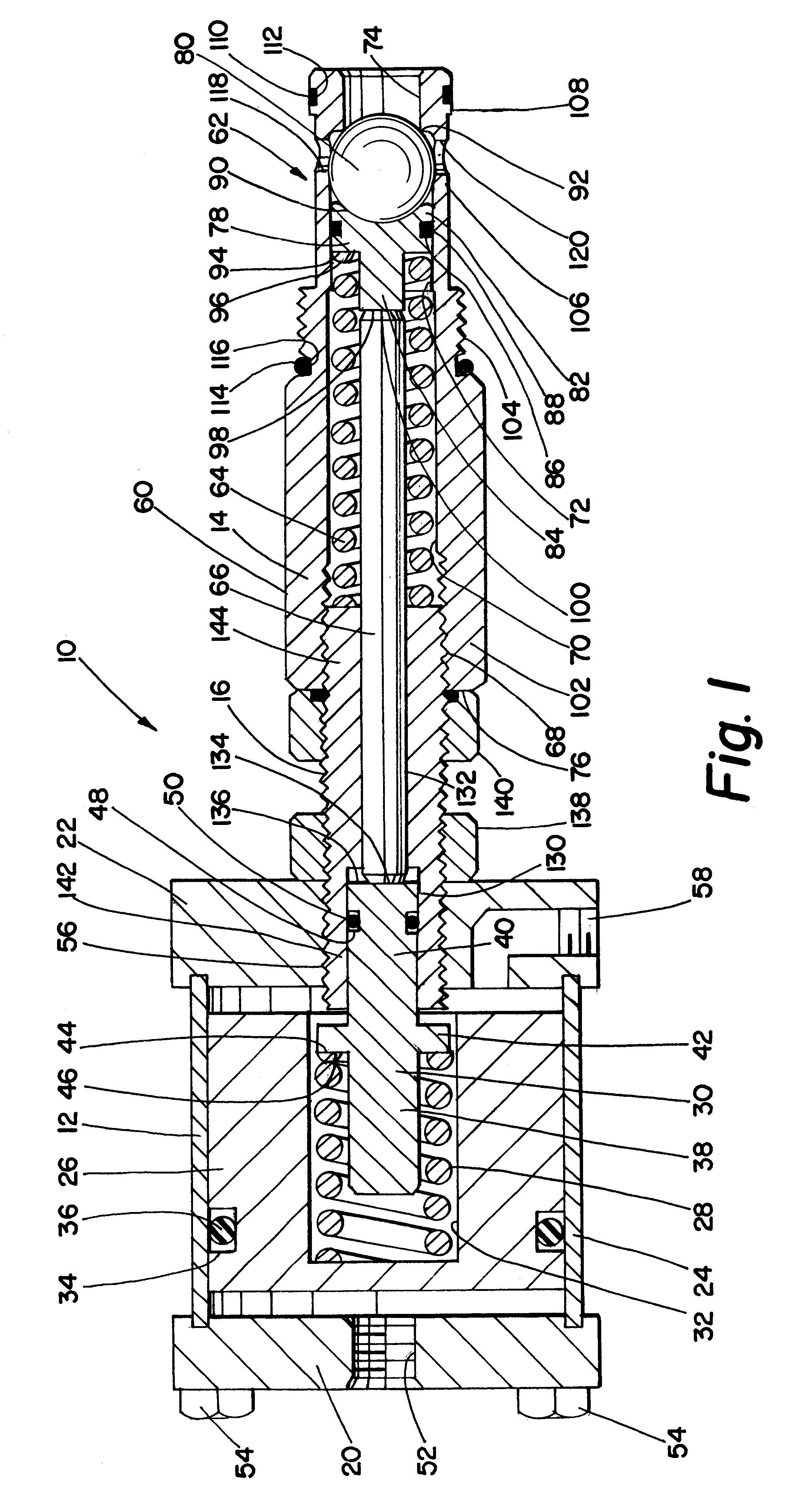

Direct acting gas regulator

InactiveUS6851447B1Improve accuracyLow costOperating means/releasing devices for valvesFluid pressure control without auxillary powerEngineeringHigh pressure

A direct acting pressure regulator controls the flow of a gas from a high pressure source to a low pressure device. Gas is delivered from the regulator at a predetermined outlet pressure. The regulator includes a body having a high pressure inlet and defining a seat. A bonnet is engageable with the body to define a piston chamber within the body and the bonnet. The bonnet has a regulated gas outlet. A piston is disposed within the piston chamber and defines a gap between the piston and a wall defining the chamber. The piston is movable between an open regulator condition and a closed regulator condition. The piston includes a plug having a sealing surface engageable with the seat and movable toward the seat to the closed regulator condition and away from the seat to the open regulator condition. The plug includes axially disposed openings therein for communicating gas from around the plug to a central longitudinal bore in the piston. The piston has an impingement surface in flow communication with the central bore such that gas pressure on the impingement surface exerts a force on the piston to move the piston to the closed regulator condition. A spring urges the piston to the open regulator condition.

Owner:PRESSURE SPECIALIST

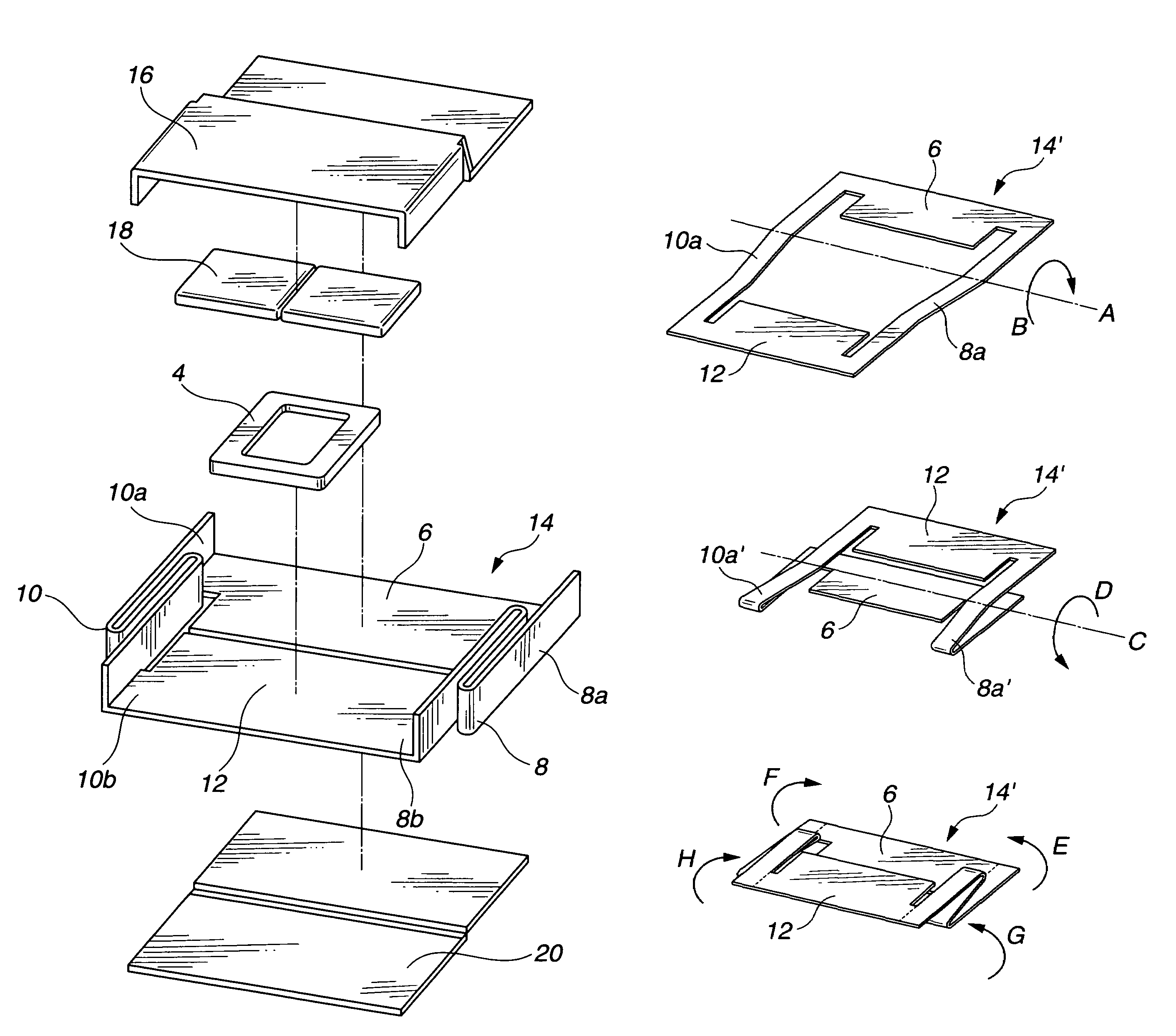

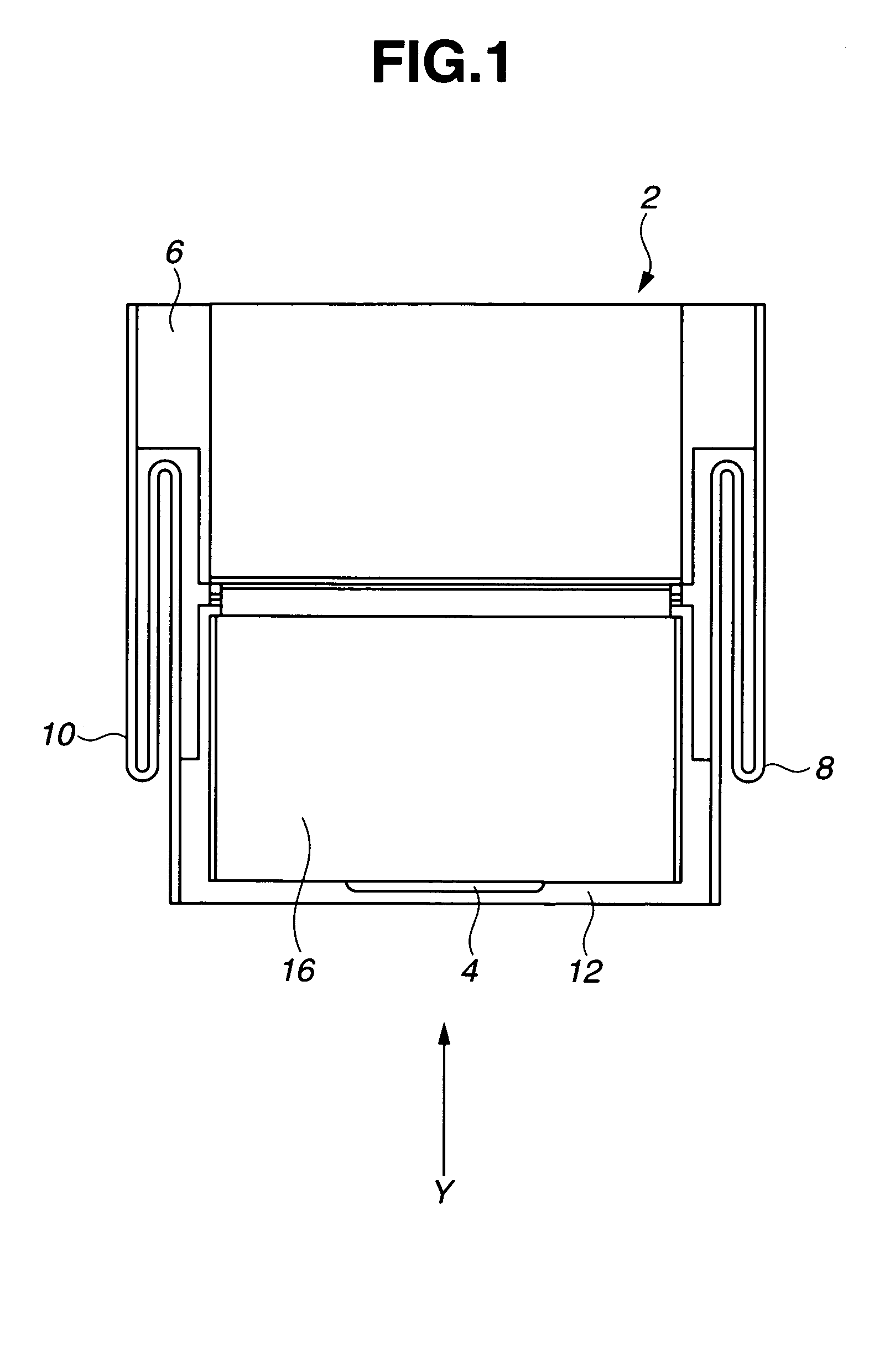

Small-size direct-acting actuator

InactiveUS7355305B2Simple structureSmall sizeTrack finding/aligningRecord information storageEngineeringActuator

A direct-acting actuator is provided comprising a stator section (16), an attachment section (6) secured to the stator section, micro-beams (8, 10) extending from the attachment section, a rotor section (12) supported for swing motion by the micro-beams, a permanent magnet (18) disposed in the stator section, and a coil (4) disposed in the rotor section. Electric current is conducted through the coil in the magnetic field created by the permanent magnet for causing the micro-beams to be displaced for inducing swing motion of the rotor section. The actuator can be assembled to a small size, typically a width of 1-10 mm, a length of 1-10 mm, and a height of 0.1-5 mm.

Owner:SHIN ETSU CHEM IND CO LTD

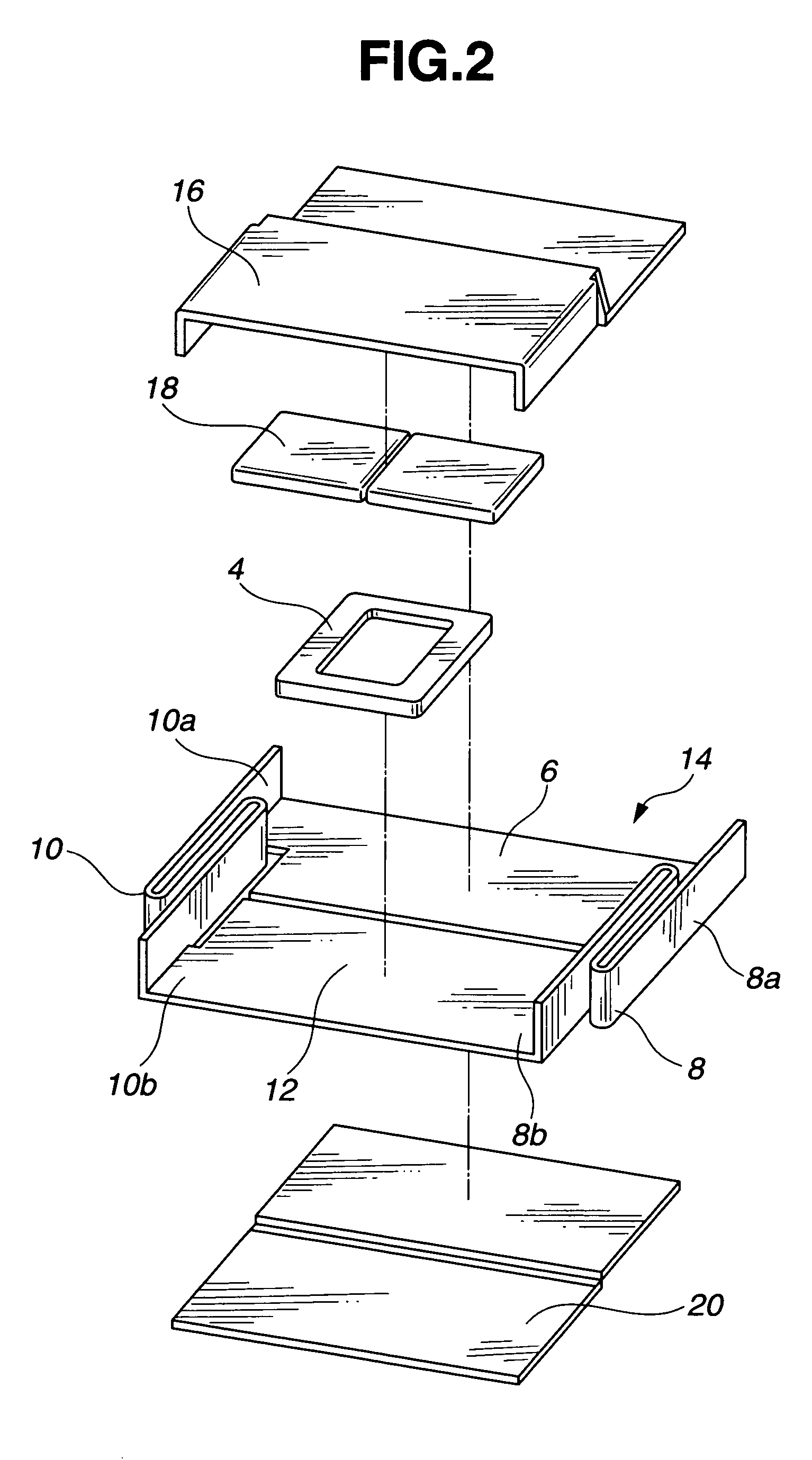

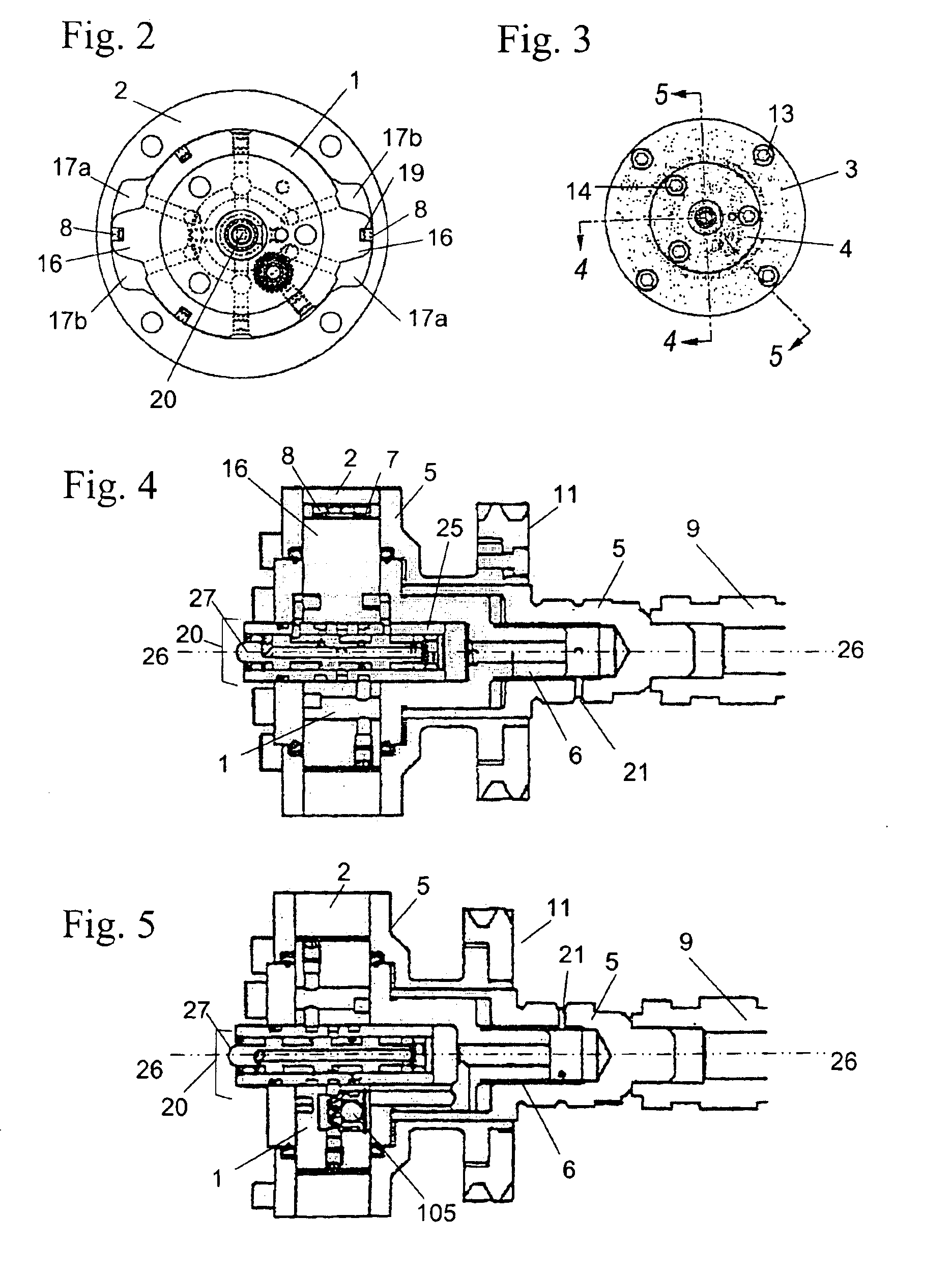

Torsional assisted multi-position cam indexer having controls located in rotor

InactiveUS6883481B2Reduce leakageImprove responseYielding couplingValve drivesControl systemEngineering

An infinitely variable cam indexer utilizes engine oil pressure to actuate a cam and preferably uses an inlet check valve in the oil source to minimize back flow during a torque reversal. The control system is in the center of the rotor and uses an electromechanical actuator, preferably a variable force solenoid, acting directly on the spool to control oil flow. This design reduces leakage and improves the response of the phaser. There are shorter oil passages as compared to a control system mounted at the cam bearing.

Owner:BORGWARNER INC

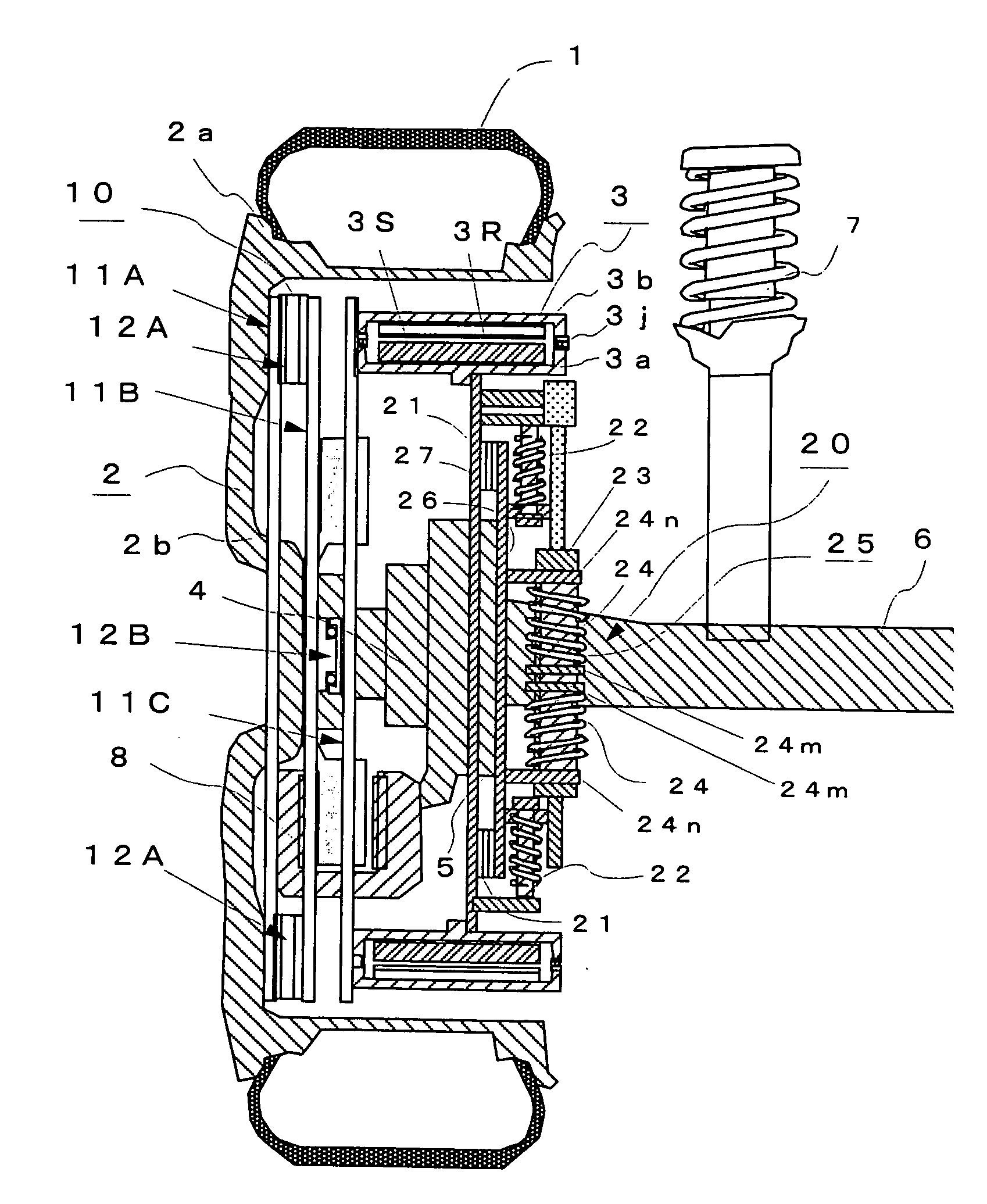

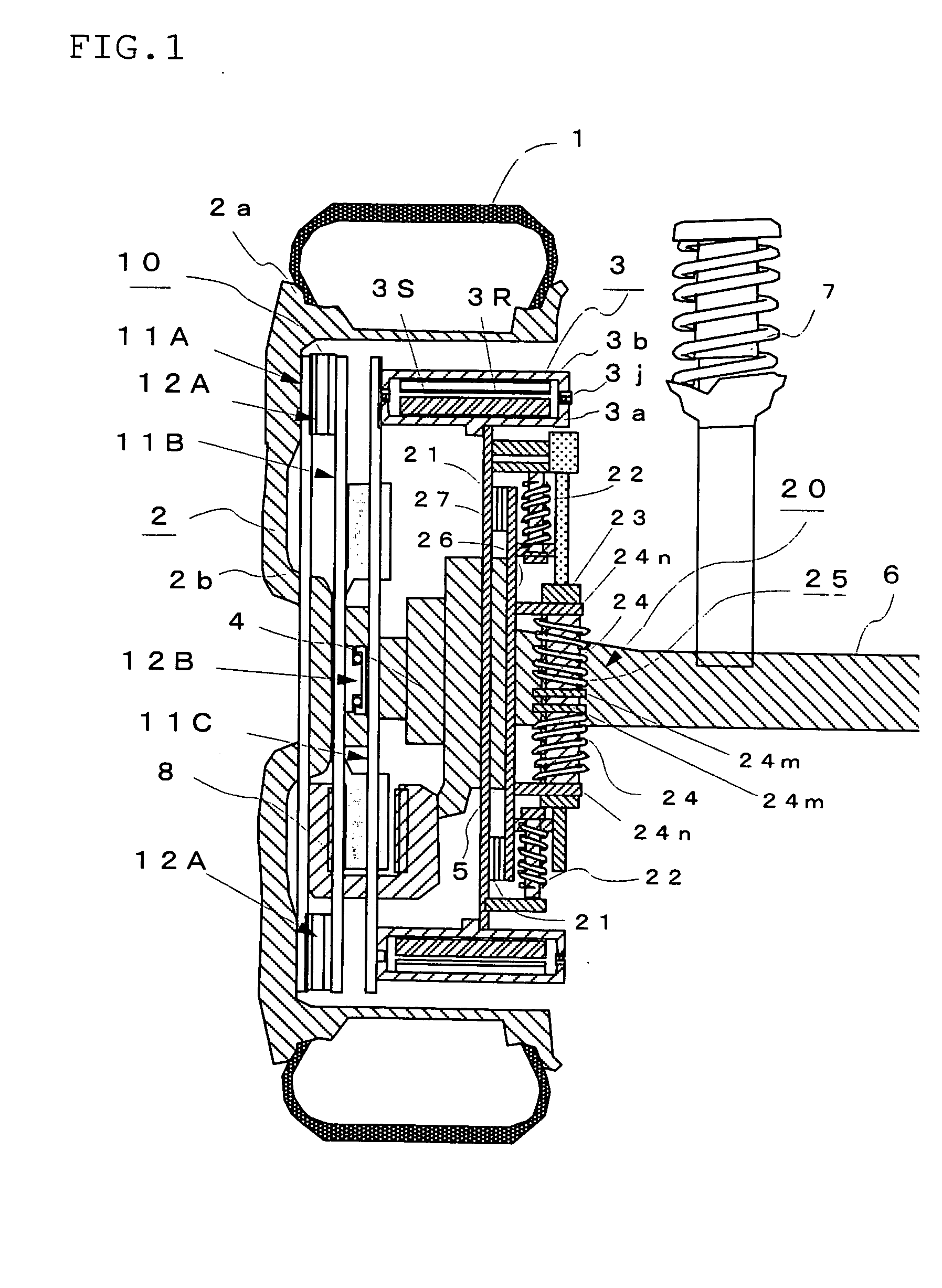

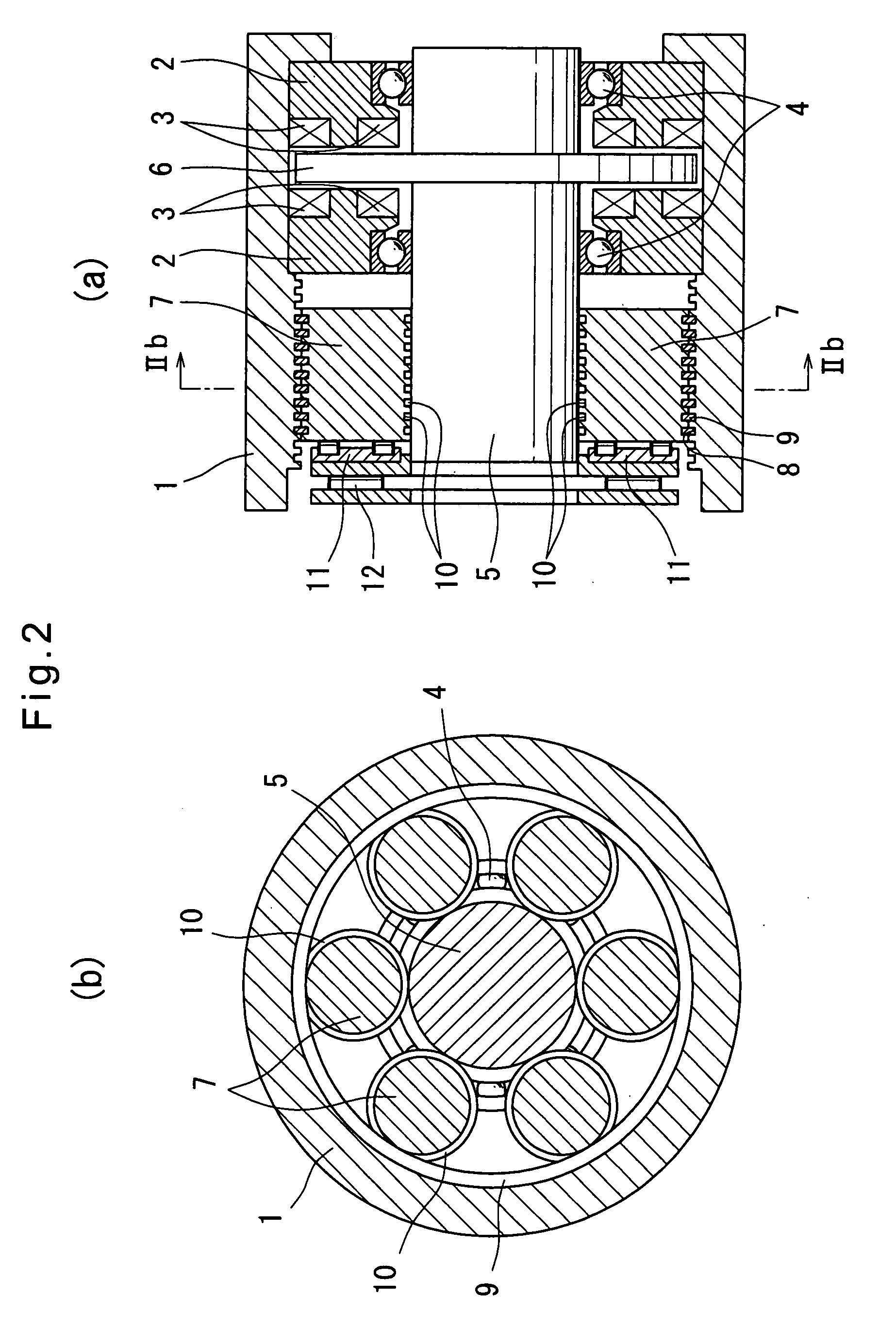

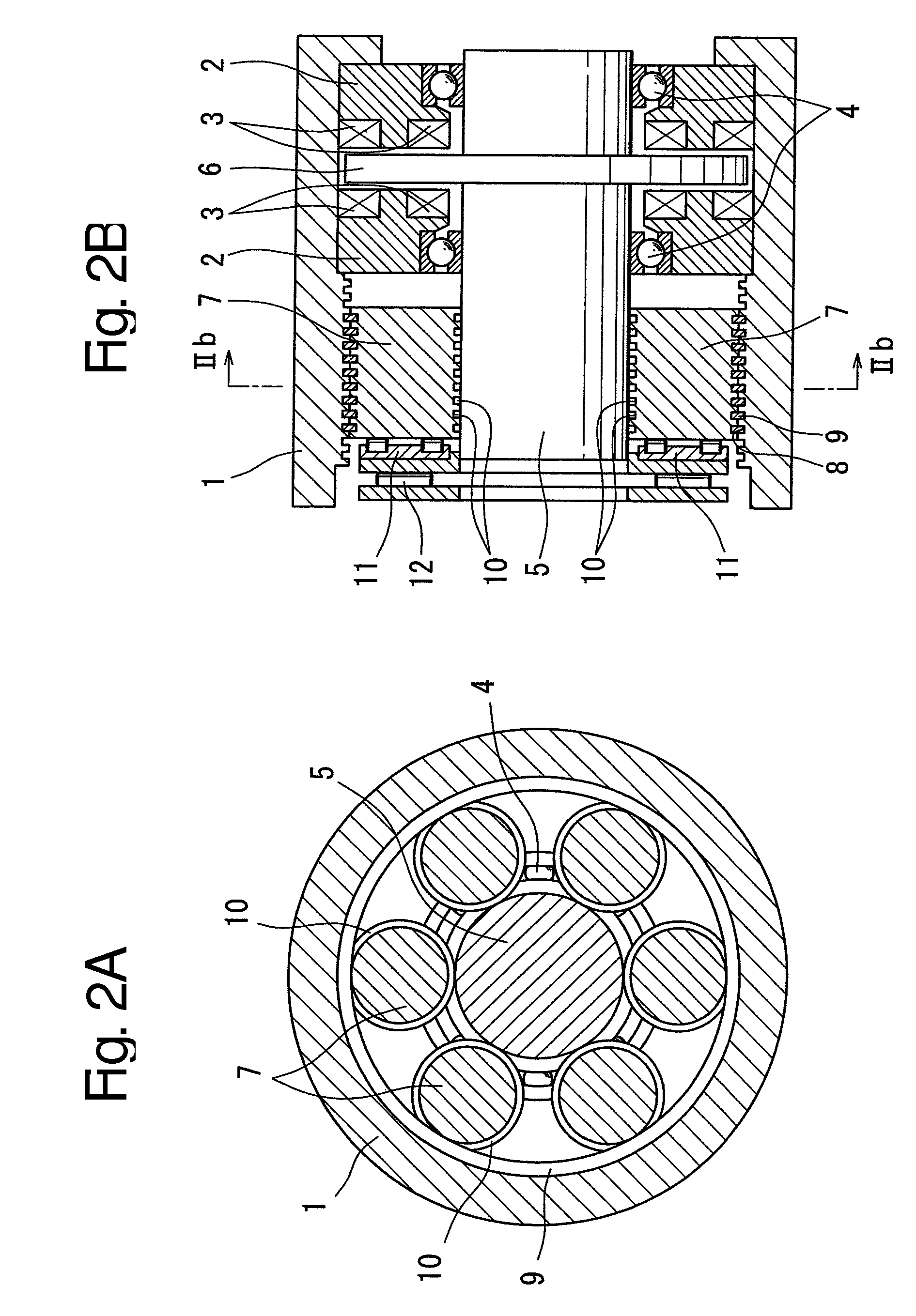

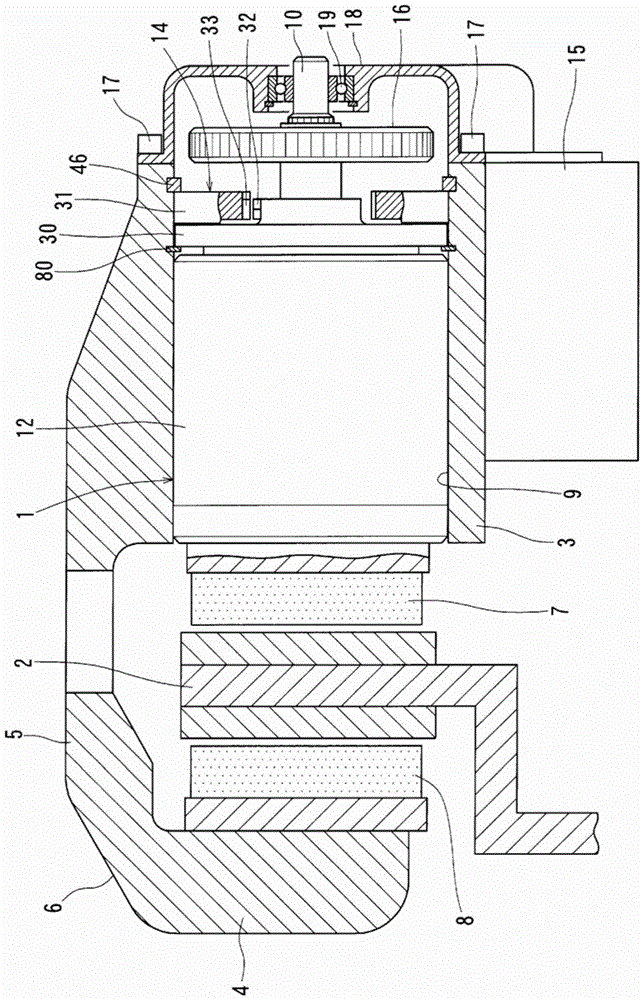

In-wheel motor system

An in-wheel motor system, wherein the rotating side case 3b of an in-wheel motor 3 is connected to a wheel 2 by a flexible coupling 10 comprising a plurality of hollow disk-like plates 11A to 11C and direct-acting guides 12A and 12B, the non-rotating side case 3a of the motor 3 is connected to a knuckle 5 by a damping mechanism 20 for connecting the non-rotating side case 3a of the motor to the knuckle 5 which is a frame dress-up part of the vehicle, comprising two plates 26 and 27 whose moving directions are limited to the vertical direction of the vehicle by direct-acting guides 21 and which are interconnected by first spring elements 22 which move in the vertical direction of the vehicle and dampers 25 with a spring element, each comprising a damper 23 and a second spring element connected to the damper 23 in series and arranged parallel to the first spring elements 22, whereby the drive force of the in-wheel motor 3 can be transmitted to the wheel 2 without fail and the road holding properties of a vehicle can be further improved by greatly reducing variations in the ground-contact load of a tire.

Owner:BRIDGESTONE CORP

Three-way direct pilot valve

InactiveUS20070164243A1High strengthMore compactOperating means/releasing devices for valvesMultiple way valvesEngineeringPilot valve

The present disclosure provides a method, apparatus, and system of an inline direct acting solenoid pilot valve. The valve has a solenoid assembly with a longitudinally moveable core assembly that shifts alternatively between sealing engagement on a lower first end of the core assembly with a pilot port formed in a poppet and sealing engagement on an opposite upper end with a stationary pilot exhaust port in the solenoid assembly. The core assembly can move in the same or opposite direction than the poppet and thus is independently moveable from the poppet to effect the various modes of operation. Because the movement is independent, the core assembly can advantageously operate within the solenoid with a shorter stroke to produce a higher overall force per length relative to a conventional core assembly stroke that is longer than the poppet stroke. The overall design allows a more compact and simplified design.

Owner:ASCO CONTROLS LP

Direct-acting water pressure overflow valve with damping piston

InactiveCN102042432AReduce flow rateReduce noiseValve members for absorbing fluid energyEqualizing valvesLow noiseWater based

The invention relates to a direct-acting water pressure overflow valve with a damping piston. The overflow valve comprises an end cover, as well as a valve seat, a valve core, a left spring seat, a guide sleeve, a spring, a right spring seat and a pressure regulating screw which are arranged in a valve body sequentially; an annular groove and a cross through hole are arranged in the valve seat, the valve core is arranged in an axial through hole of the valve seat, the end part of the valve core is provided with a countersunk groove, a cylindrical surface at the tail part of the valve core and the axial through hole of the valve seat form a guide surface, and cylindrical surface at the tail part of the valve core and a valve port formed by the valve seat form a cone valve structure; the valve core is in contact fit with the left spring seat; the left spring seat is guided by the inner bore of the guide sleeve, the guide sleeve is provided with a small through-flow hole, and the right side of the guide sleeve is provided with the annular groove; the spring is positioned between the left spring seat and the right spring seat; and the pressure regulating screw is connected with the valve body by screw threads. The overflow valve is suitable for a pressure control element in a medium and high-pressure water hydraulic system using seawater, fresh water, a high water base or the like as a working medium. Compared with similar valves, the overflow valve has the advantages of simple structure, convenience for processing, low leakage, small vibration, low noise, good cavitation corrosion resistance and high working stability.

Owner:BEIJING UNIV OF TECH

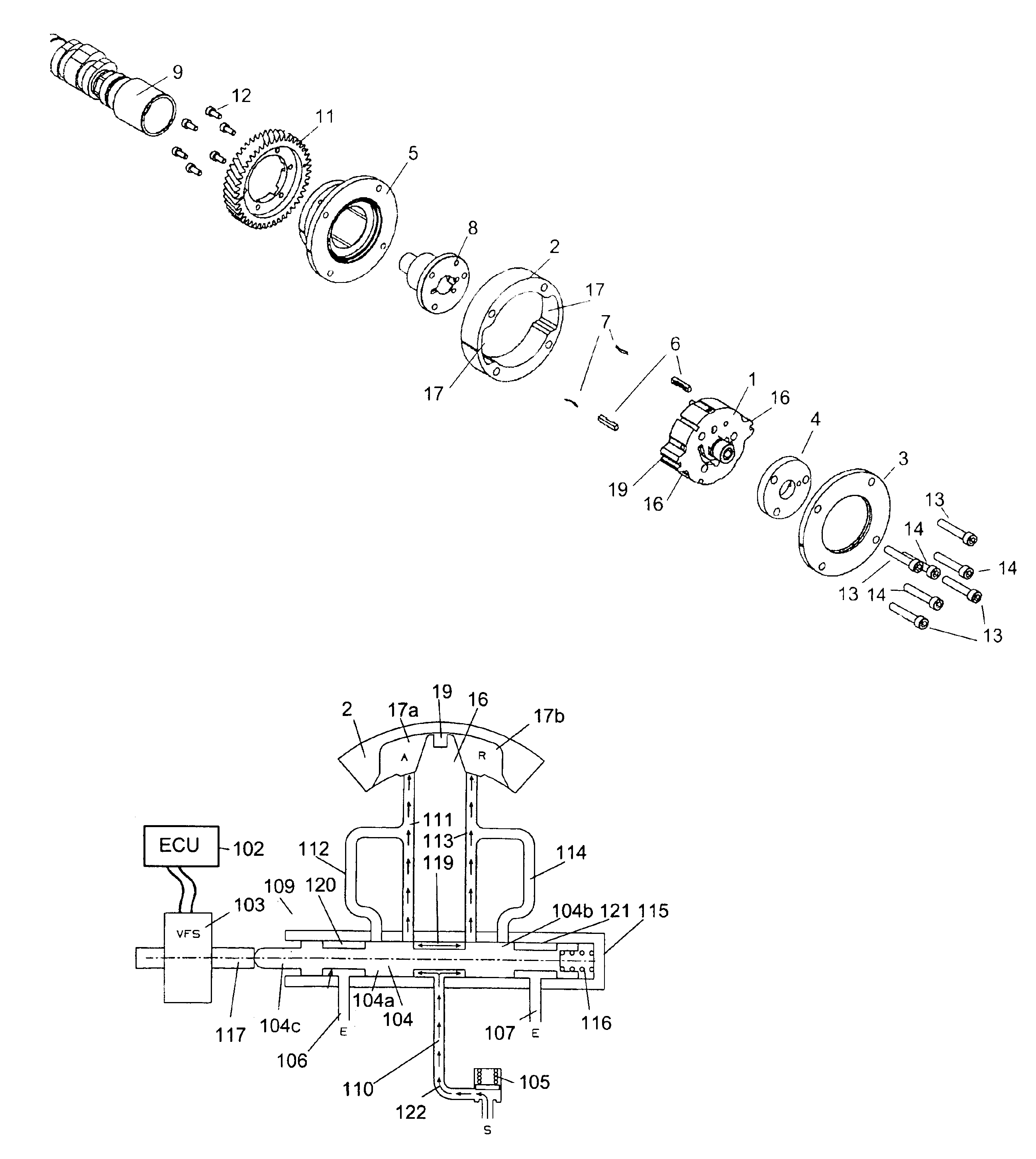

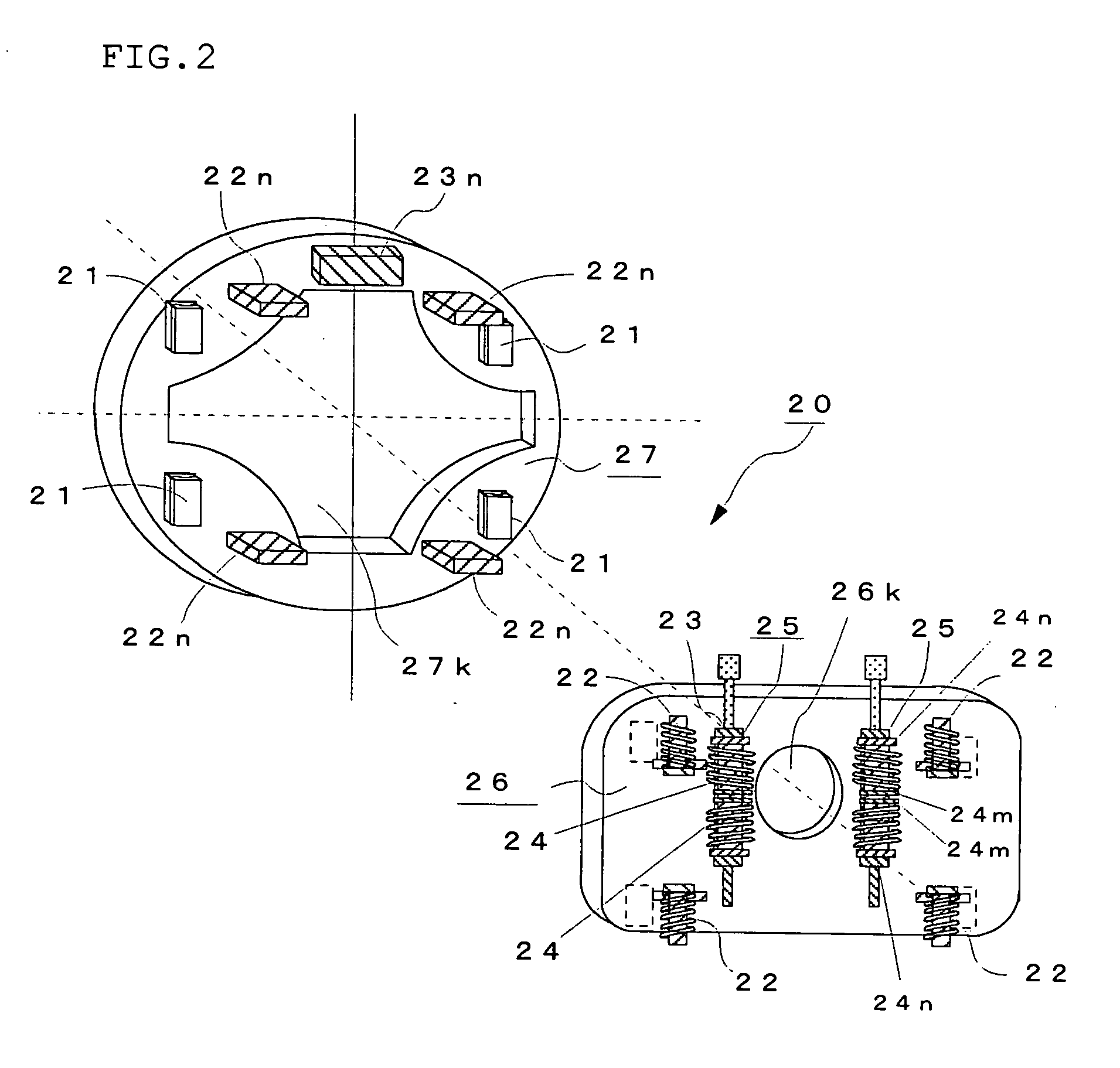

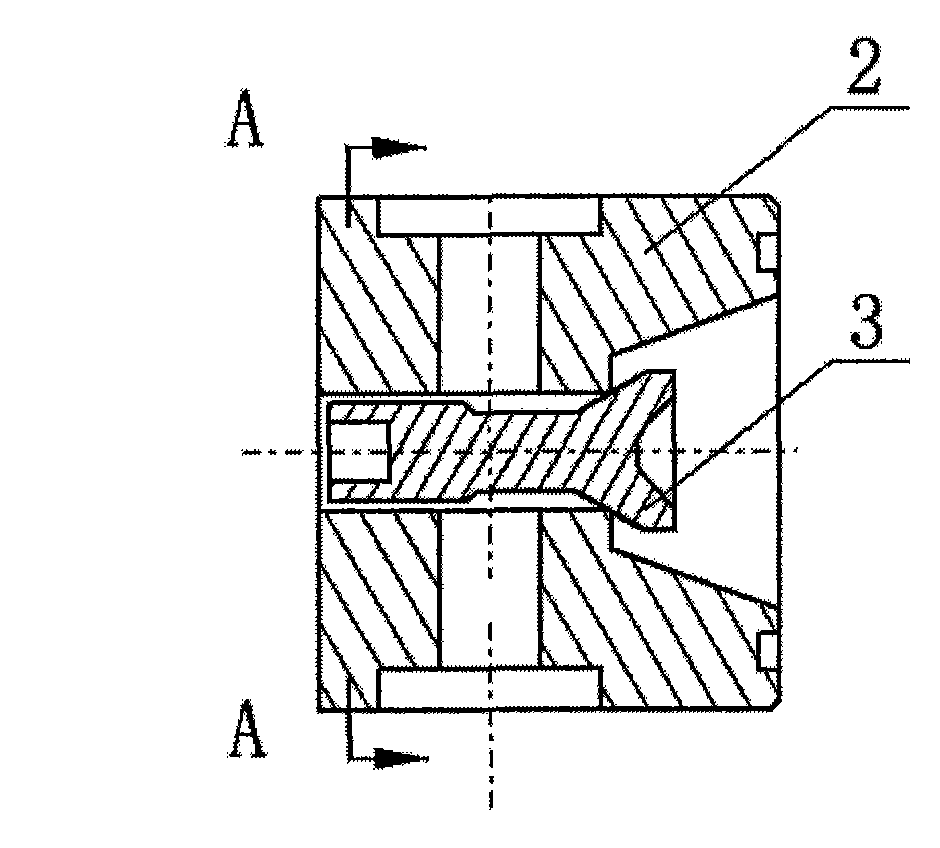

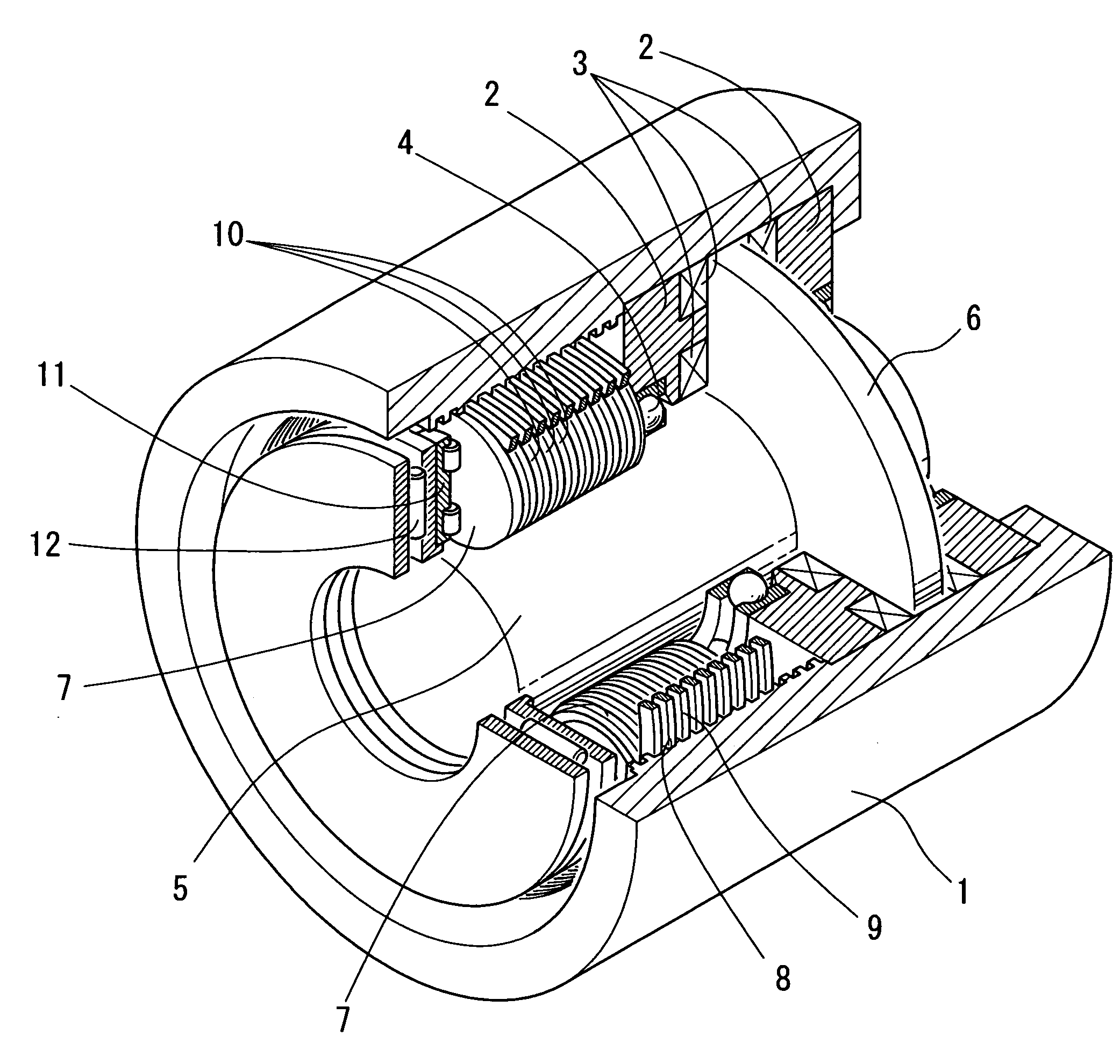

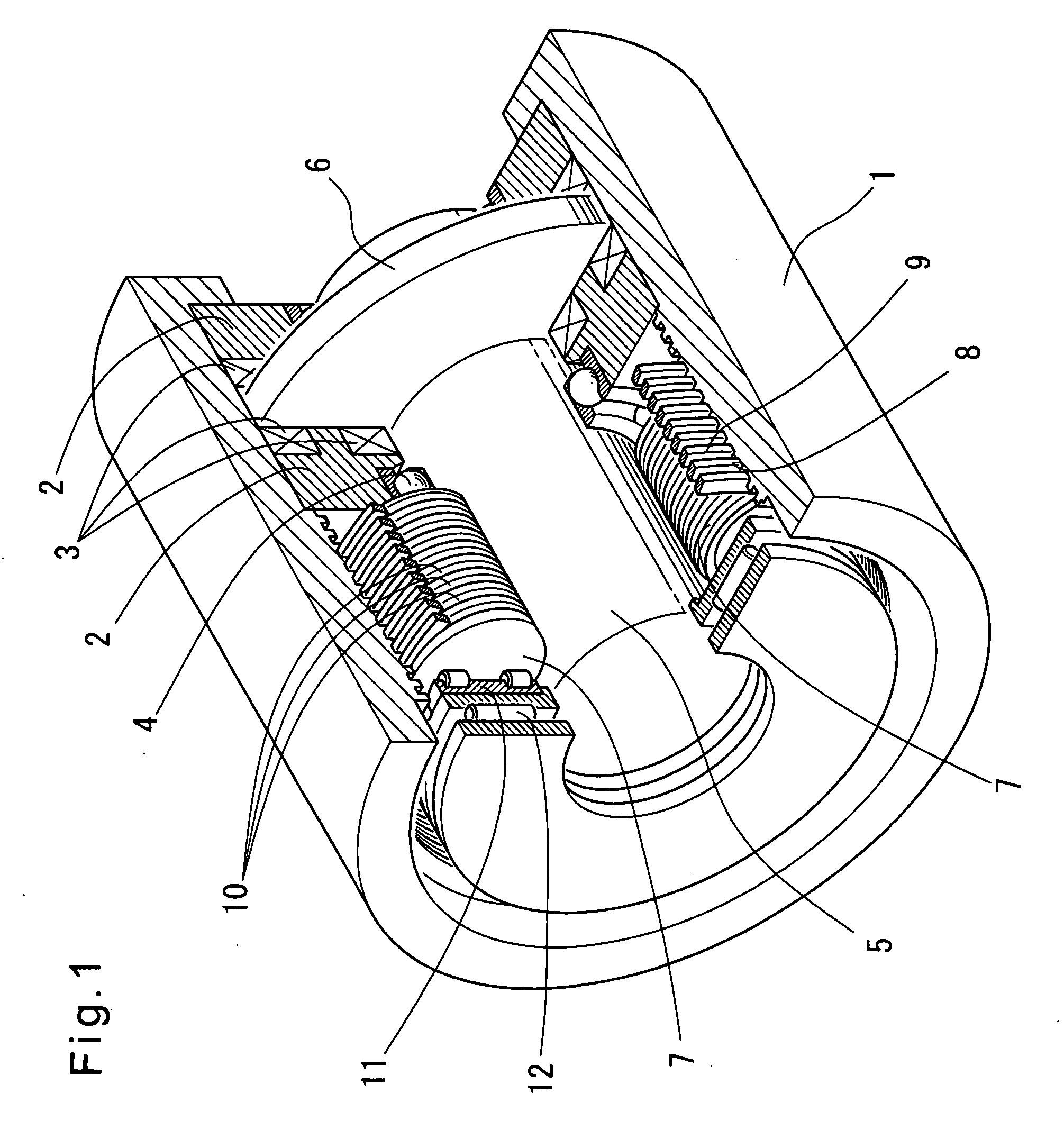

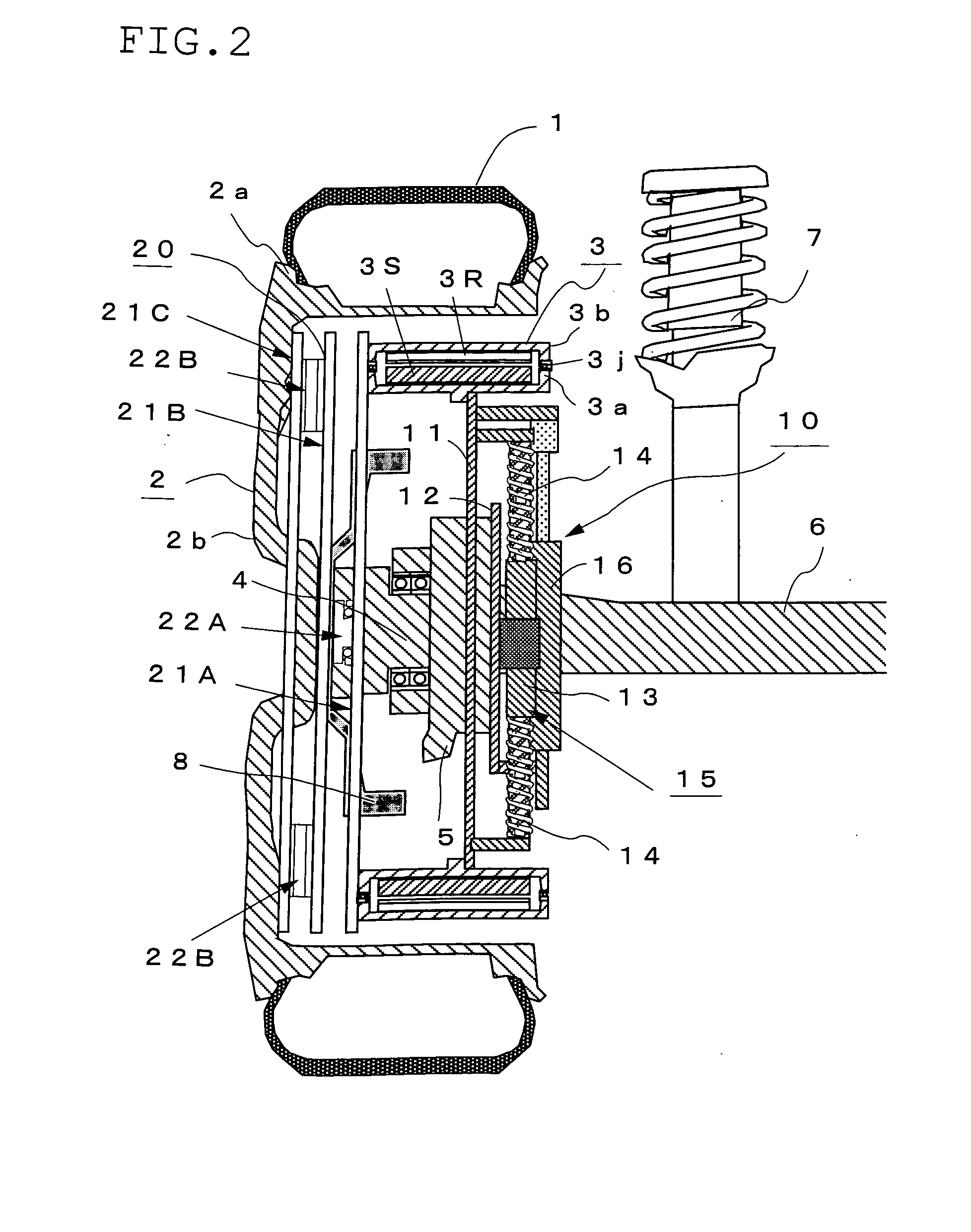

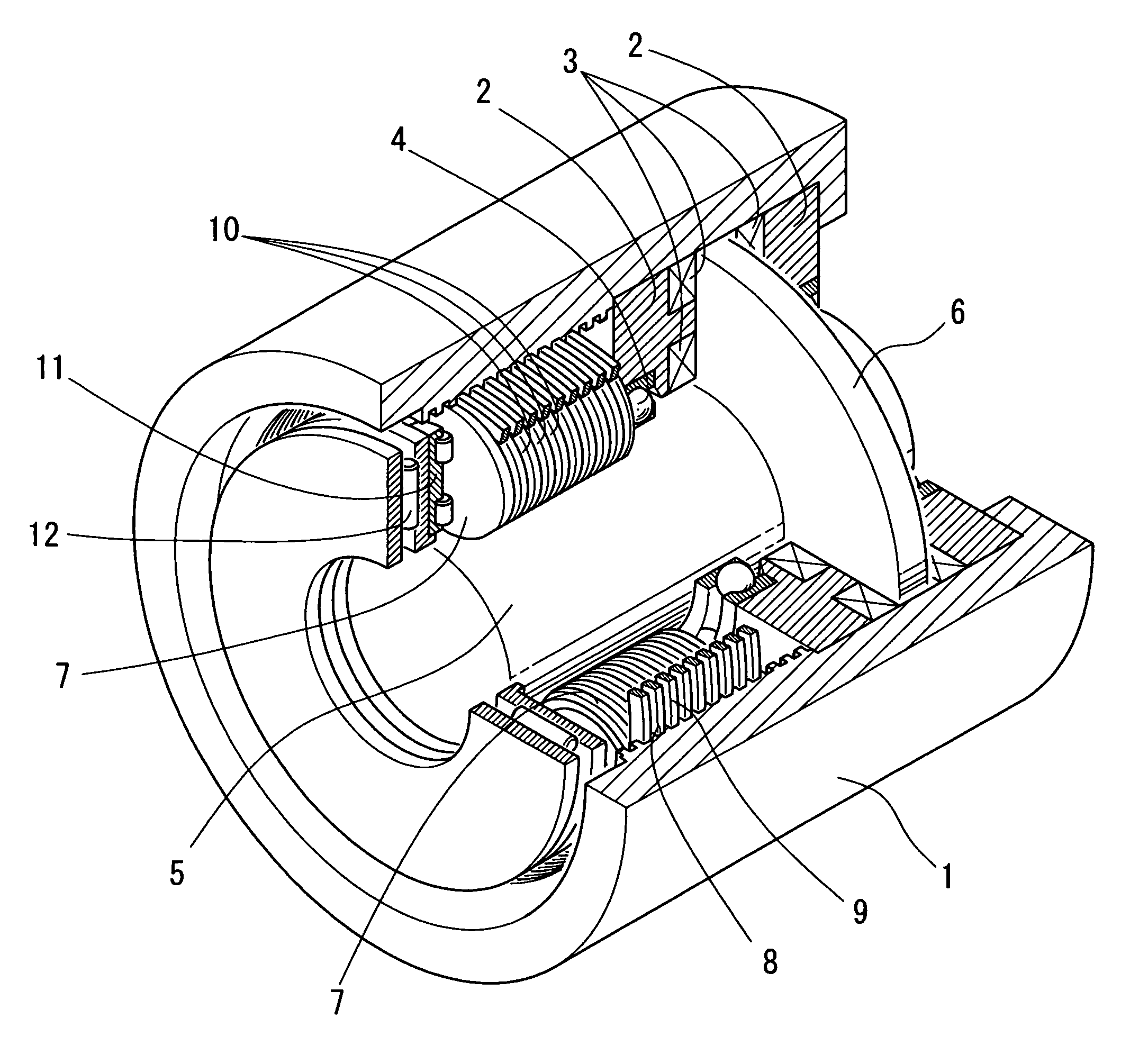

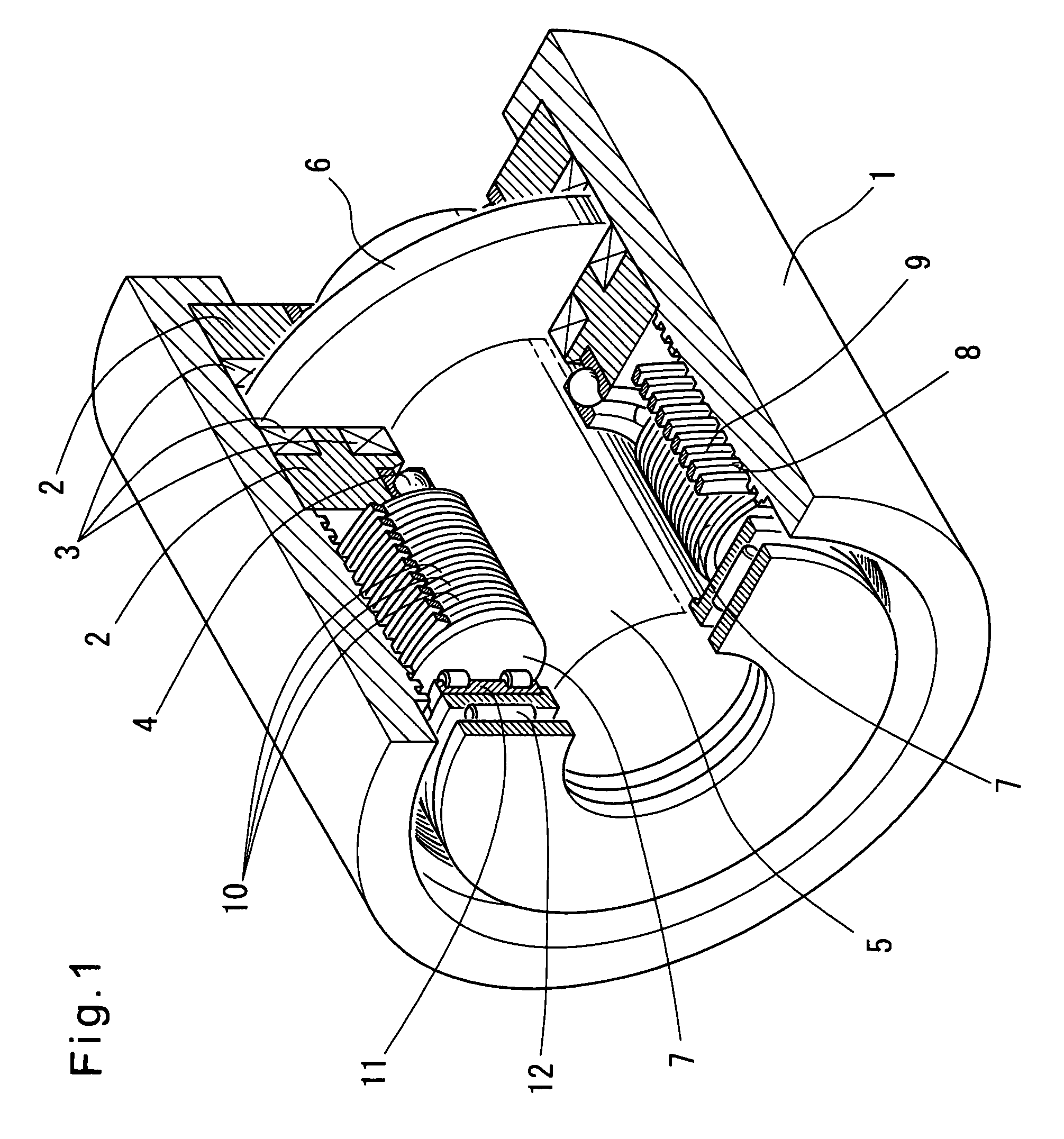

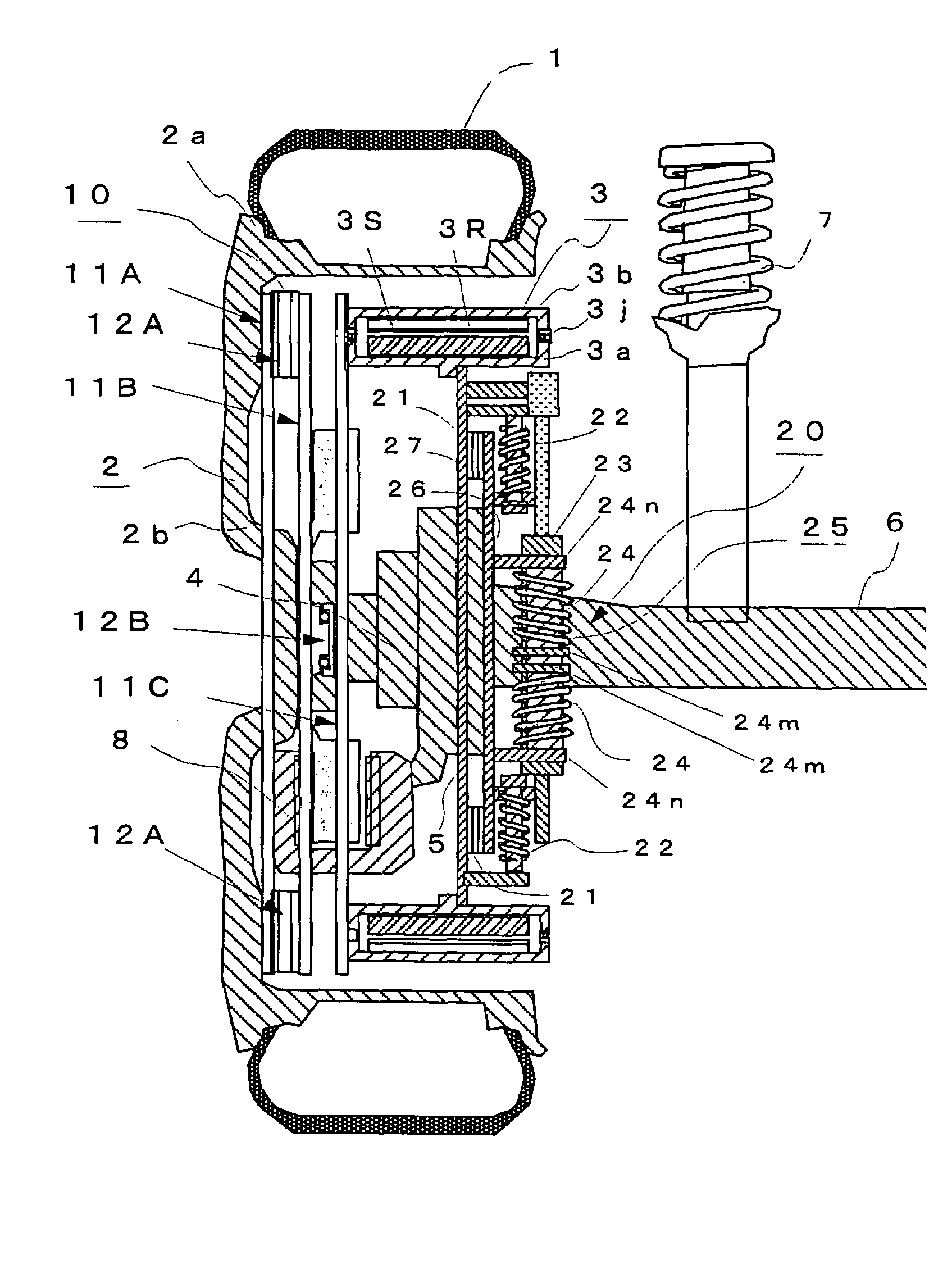

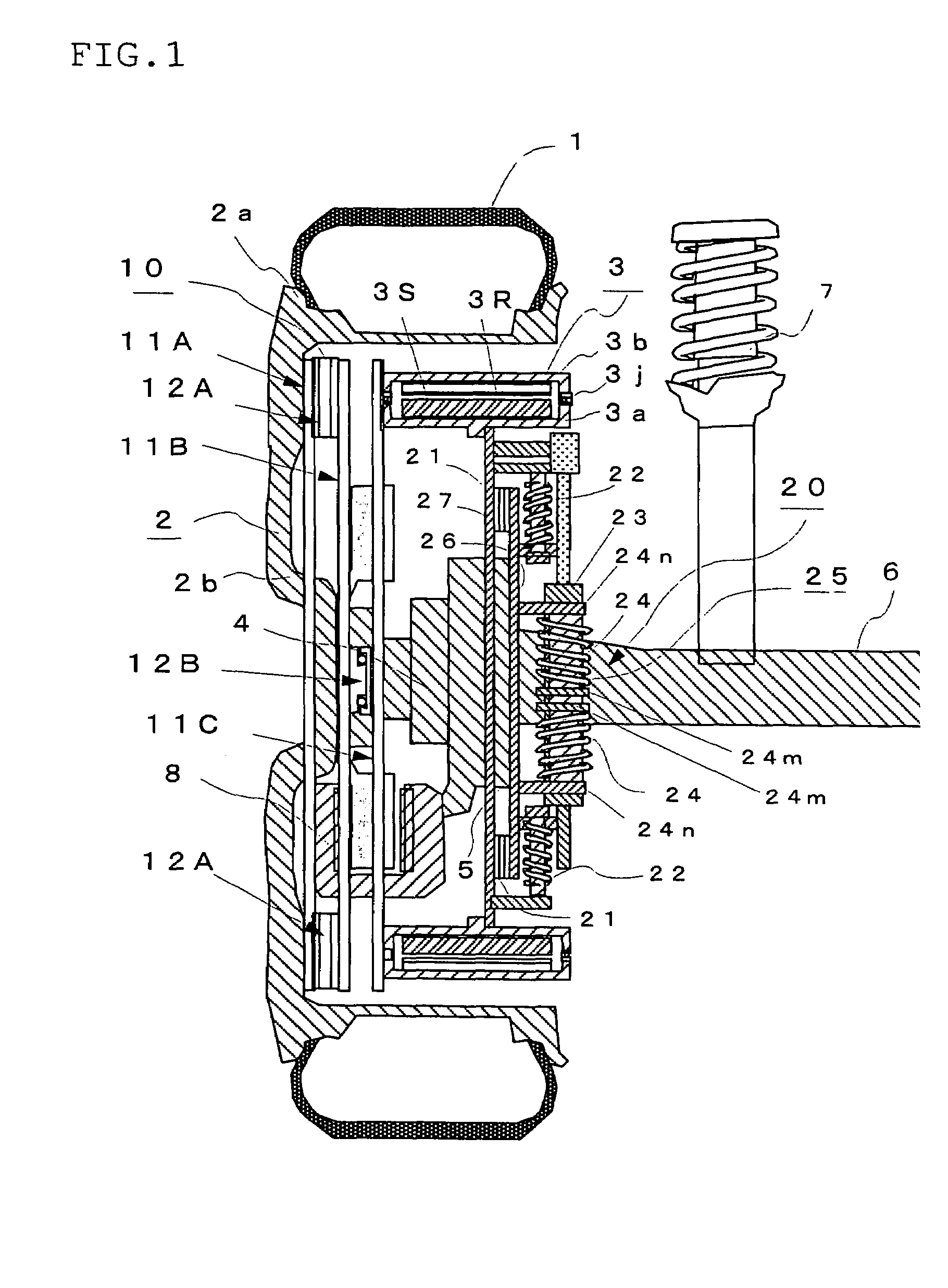

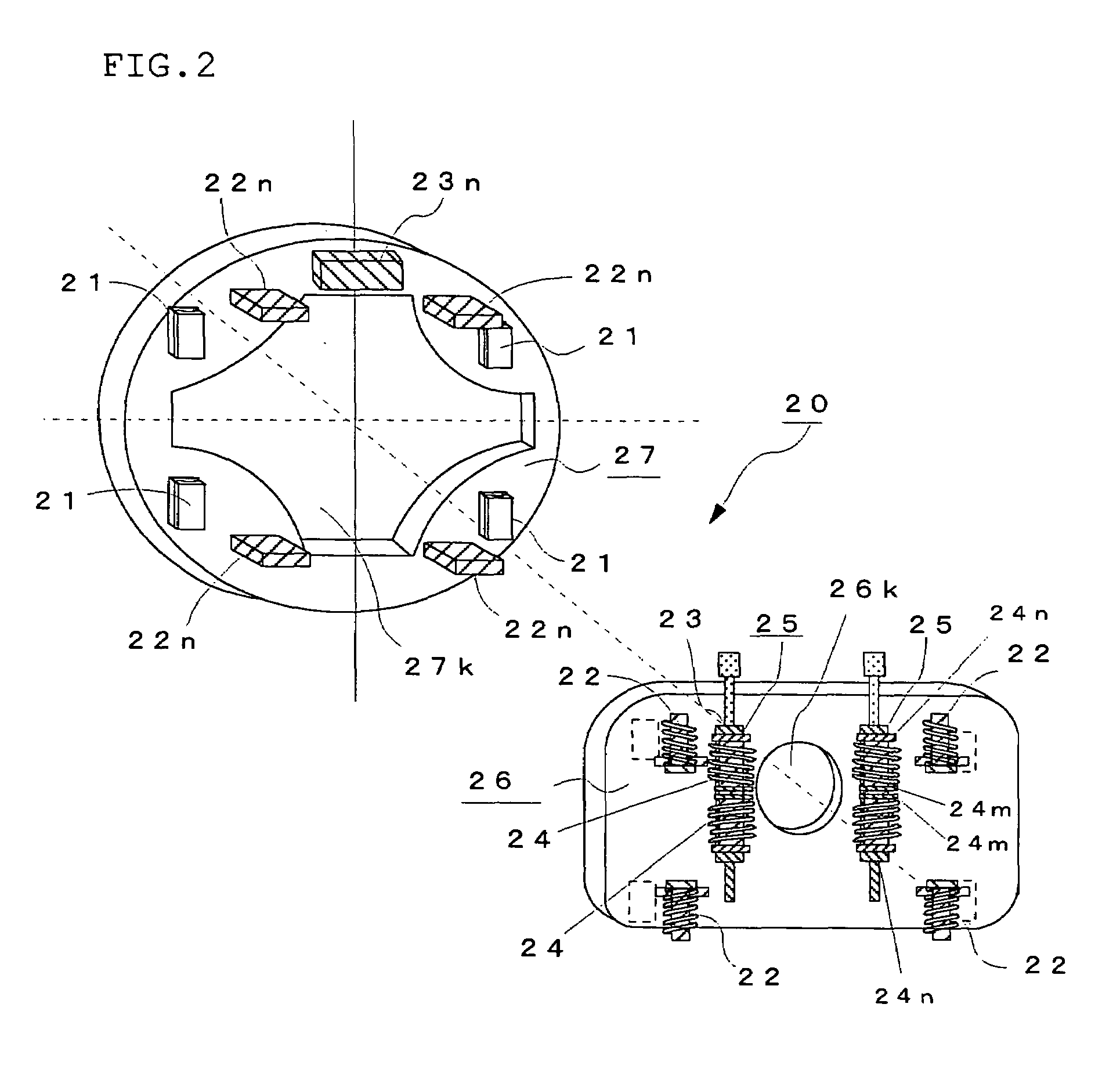

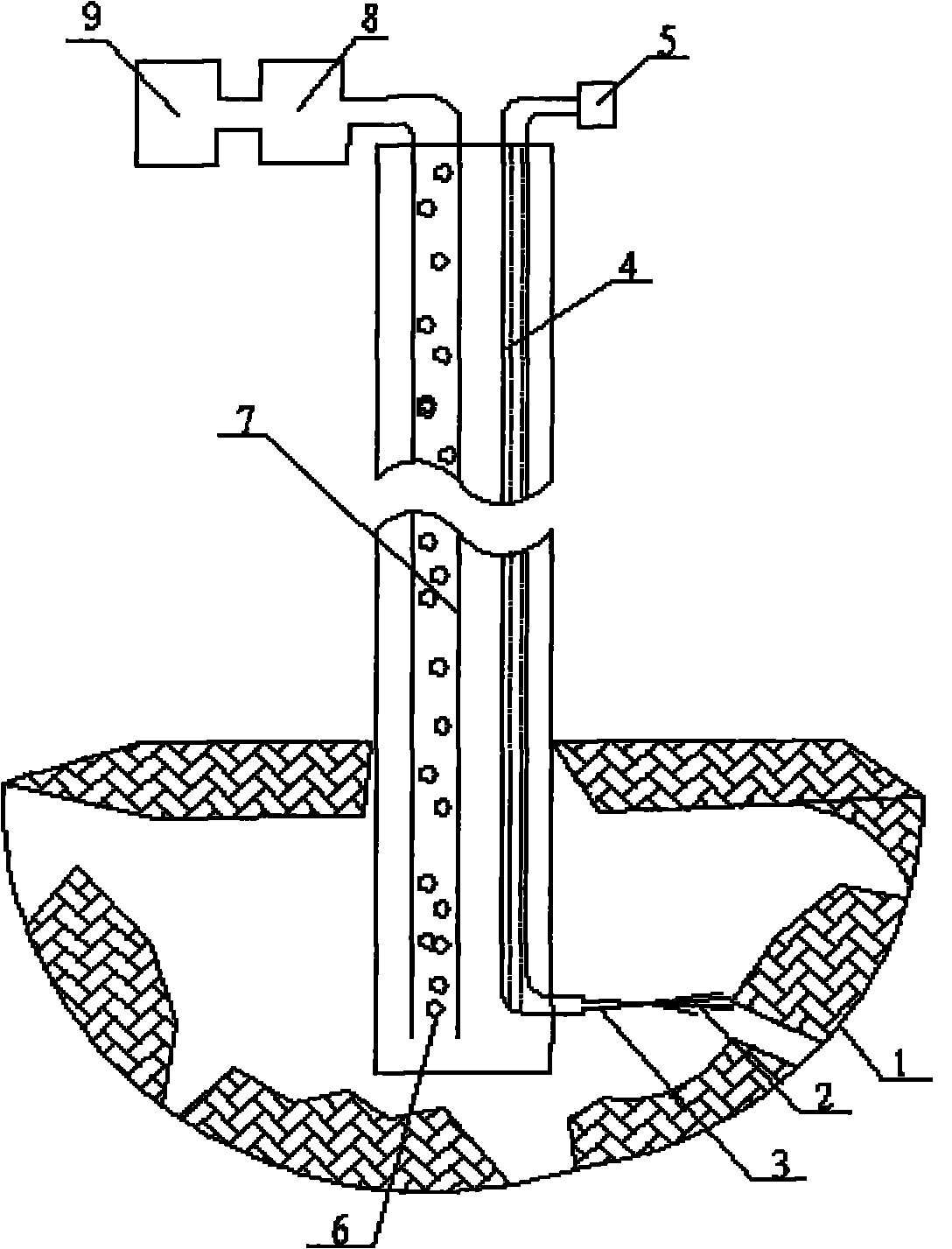

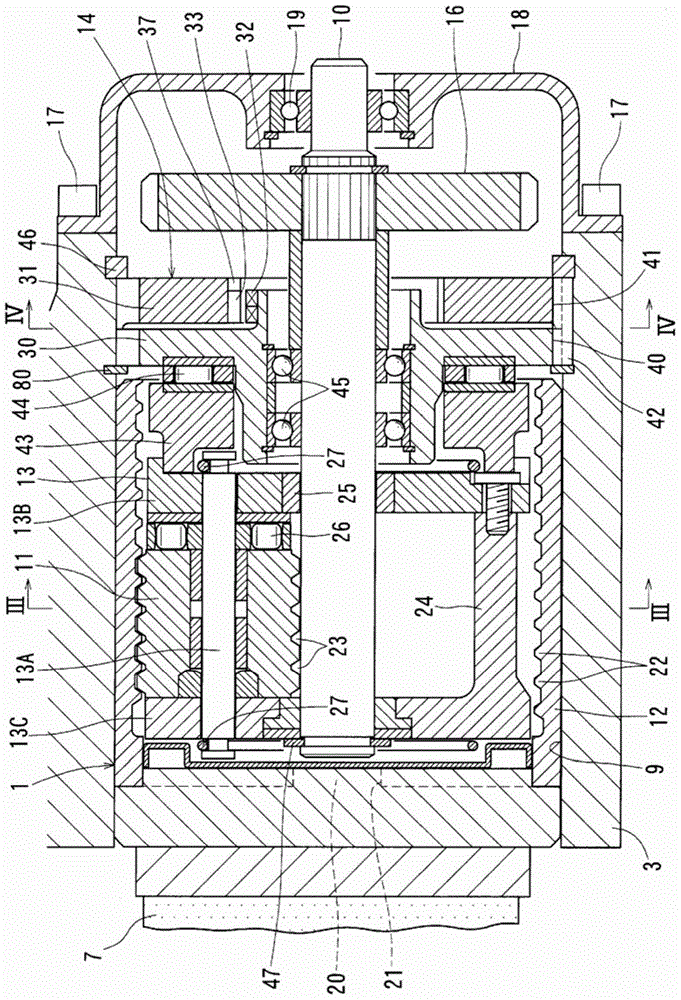

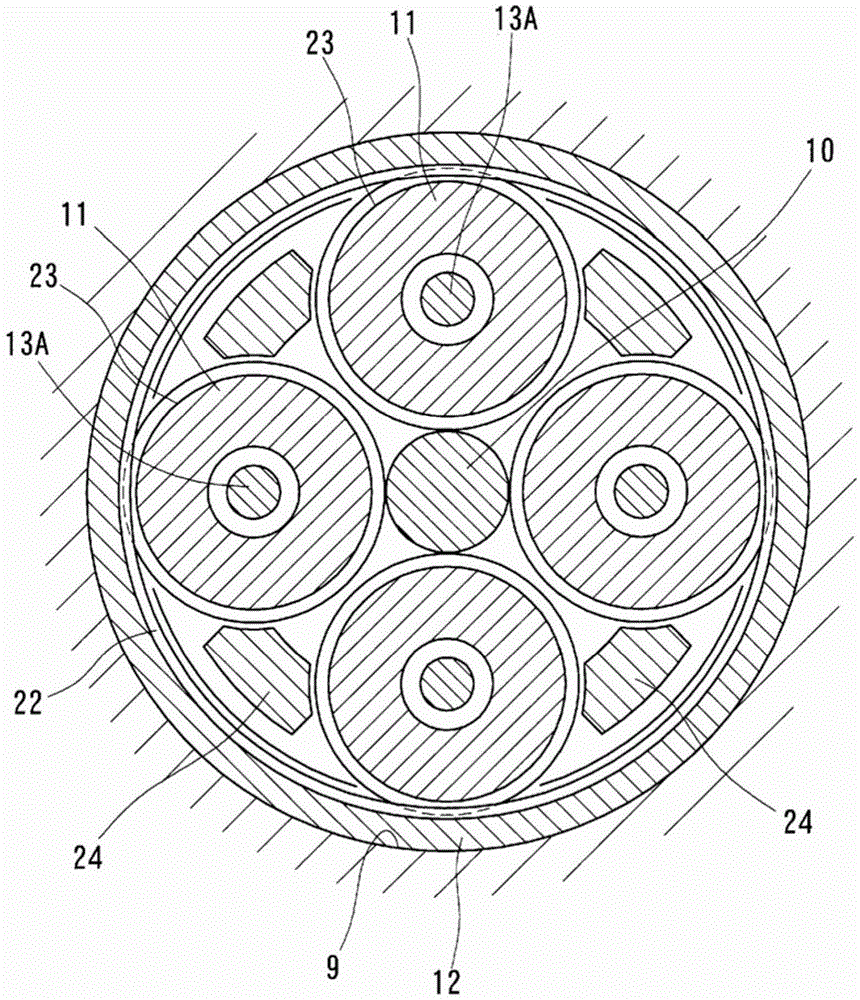

Electric Direct-Acting Actuator and Electric Brake Device

InactiveUS20080110704A1Low costWell formedMechanically actuated brakesElectrodynamic brake systemsLinear motionReducer

An electric direct-acting actuator is proposed which can maintain a large power increasing function without mounting a separate speed reducer.A plurality of planetary rollers 7 are disposed between the radially outer surface of a rotor shaft 5 of an electric motor and the radially inner surface of an outer ring member 1 fixed in position around the rotor shaft 5 so as to be rotatable about the rotor shaft 5 and about their own axes when the rotor shaft 5 rotates. A helical rib is defined by a rib member 9 engaged in a helical groove 8 formed in the radially inner surface of the outer ring member 1. The helical rib is engaged in circumferential grooves 10 formed in the radially outer surface of each planetary roller 7 at the same pitch as the turns of the helical rib. Thus, the rotary motion of the rotor shaft 5 is converted to a linear motion of the planetary rollers 7, so that it is possible to ensure a large power increasing function without mounting a separate speed reducer.

Owner:NTN CORP

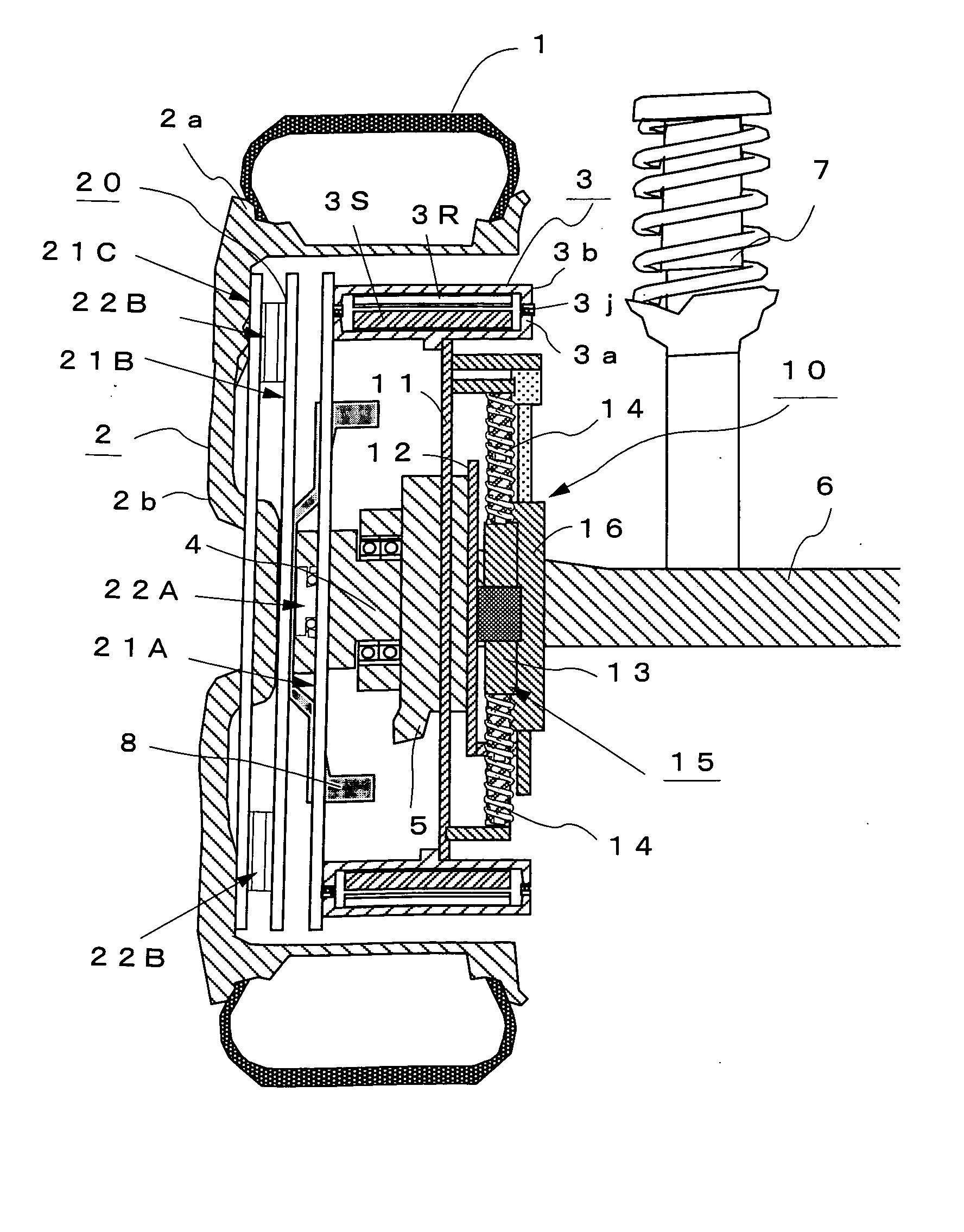

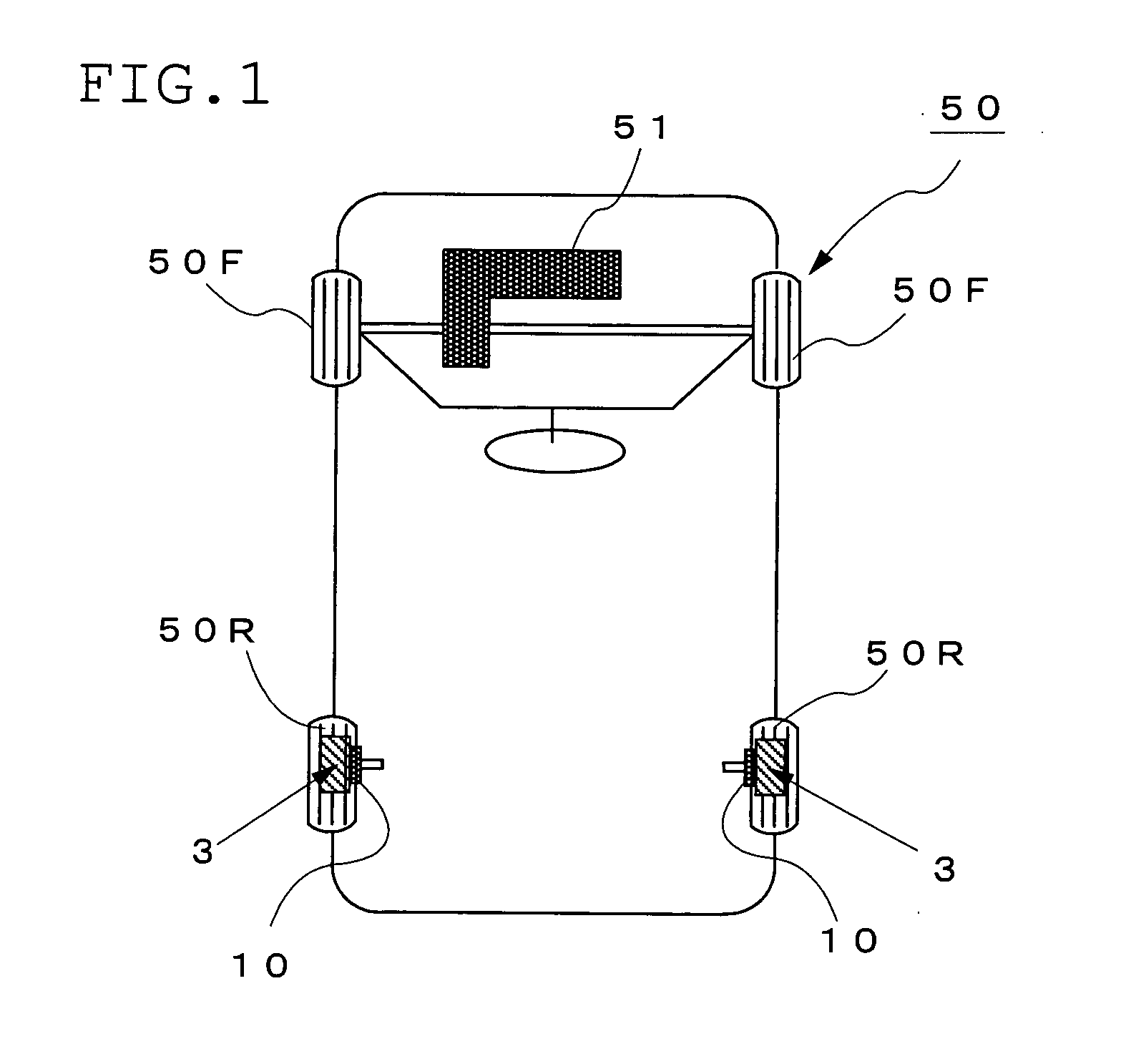

Vehicle Having In-Wheel Motors

InactiveUS20080283315A1Reduce the total massQuality improvementAuxillary drivesElectric devicesInternal combustion engineUnsprung mass

A vehicle having in-wheel motors, wherein when the in-wheel motors are mounted on the vehicle driven by the torque of an internal combustion engine, the in-wheel motors (3) are mounted on wheels on one side of the vehicle opposite to the other side on which the internal combustion engine (51) is mounted. The non-rotating side of the motor and the knuckle (5) are supported by a buffer mechanism (10) having plates (11) and (12) connected to each other by a direct-acting guide (15) with springs composed of a direct-acting guide (13) comprising a linear bearing (13A) and a rod (14) and spring members 14 and 14 moving in the vertical direction of the vehicle and mated with the direct-acting guide (13) and a damper (16) for interconnecting the plates (11) and (12), moving in the vertical direction of the vehicle to support the motor (3) to either one or both of the unsprung mass of the vehicle and the car body by means of the buffer mechanism (10). Thus, the running ability and riding comfort of the vehicle having in-wheel motors can be improved.

Owner:KYB CORP +2

Electrically actuated variable pressure controll system

ActiveUS20140299673A1Simple and economical to manufacture and assemble and useIncrease flow resistanceOperating means/releasing devices for valvesWatering devicesProduction rateControl system

Owner:CAPSTAN

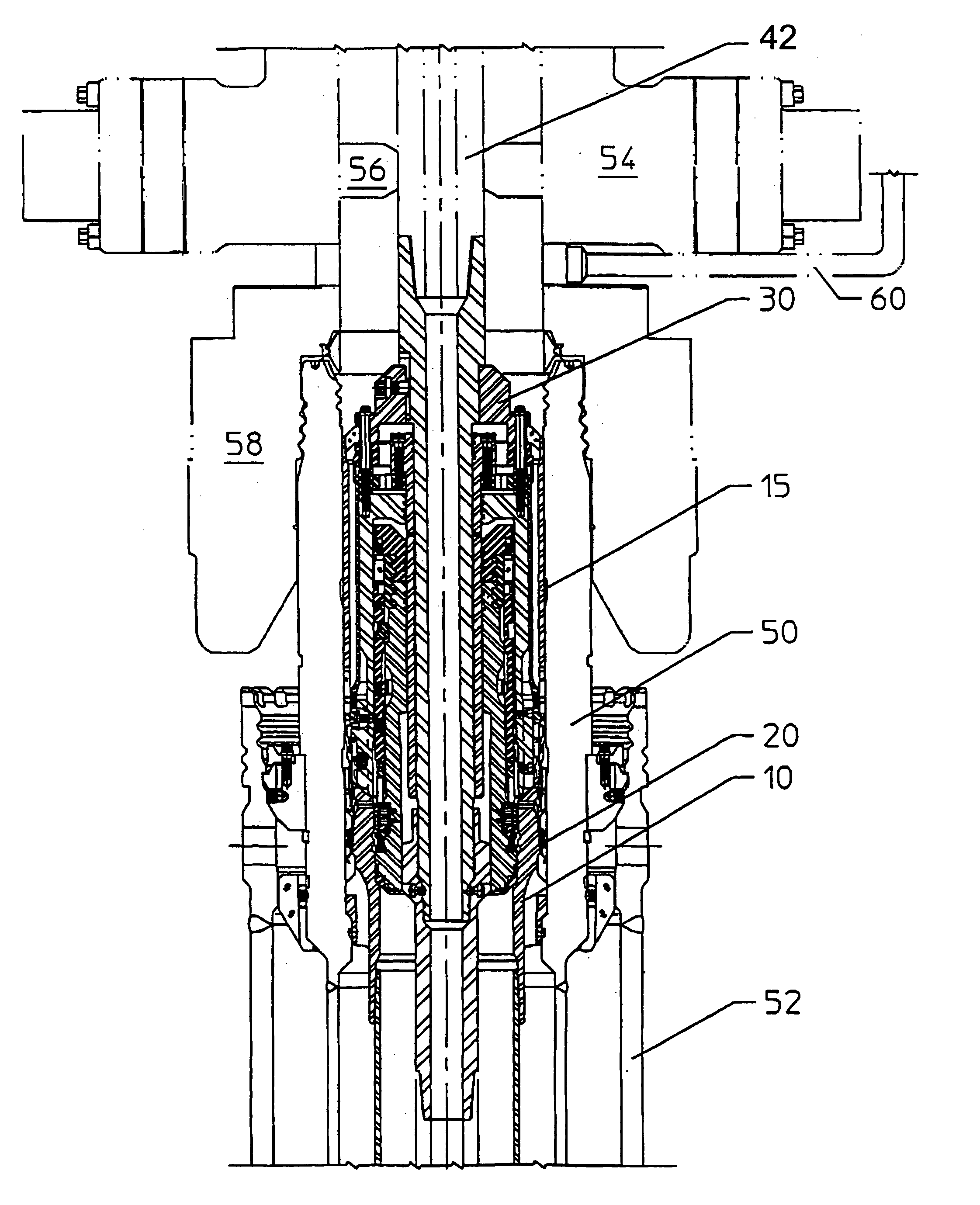

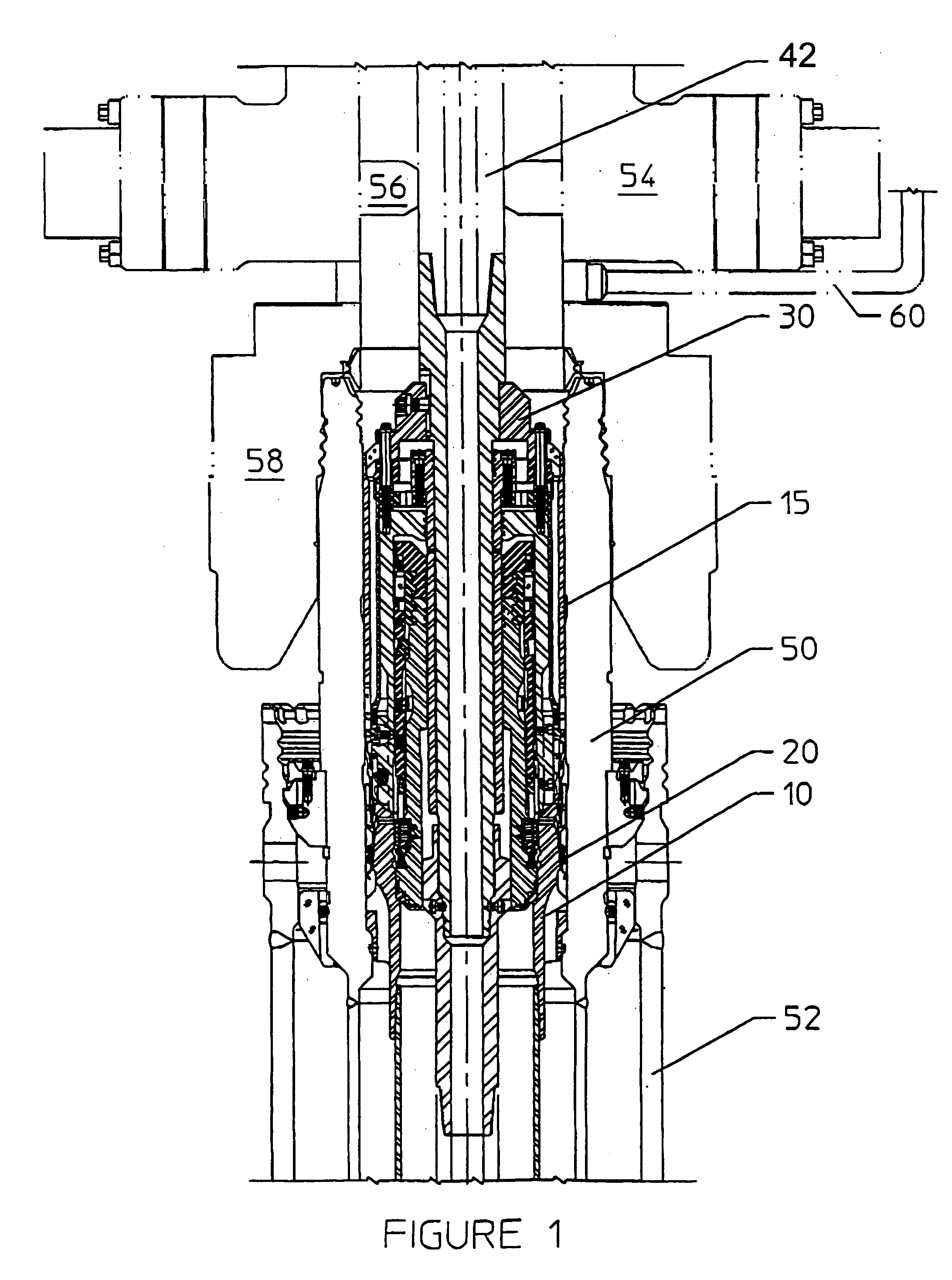

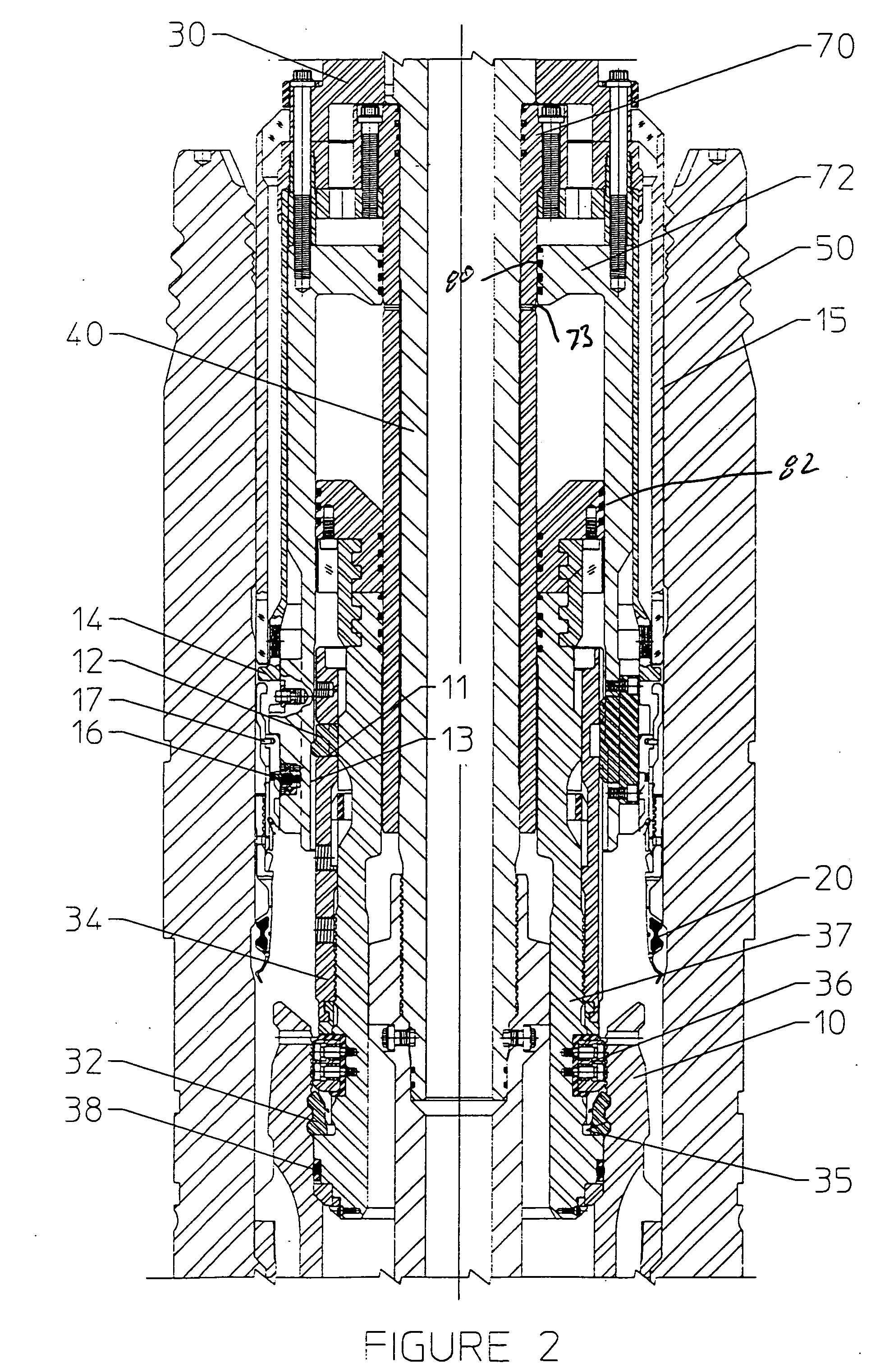

Wellhead assembly with pressure actuated seal assembly and running tool

A subsea well assembly includes a wellhead housing 50 having a cylindrical inner sealing surface and a tubular hanger 10 having a tapered external sealing surface. The running tool 30 includes a central stem 40 connected to the running string. A setting piston 72 is responsive to fluid pressure in the annulus about the running string, and has a radially outer surface and a radially inner surface each for sealing with the running tool body. Fluid pressure to set the seal assembly may be applied to the setting piston through an annulus about the running string, and may also act directly on an initially set seal assembly 20.

Owner:DRIL QUIP

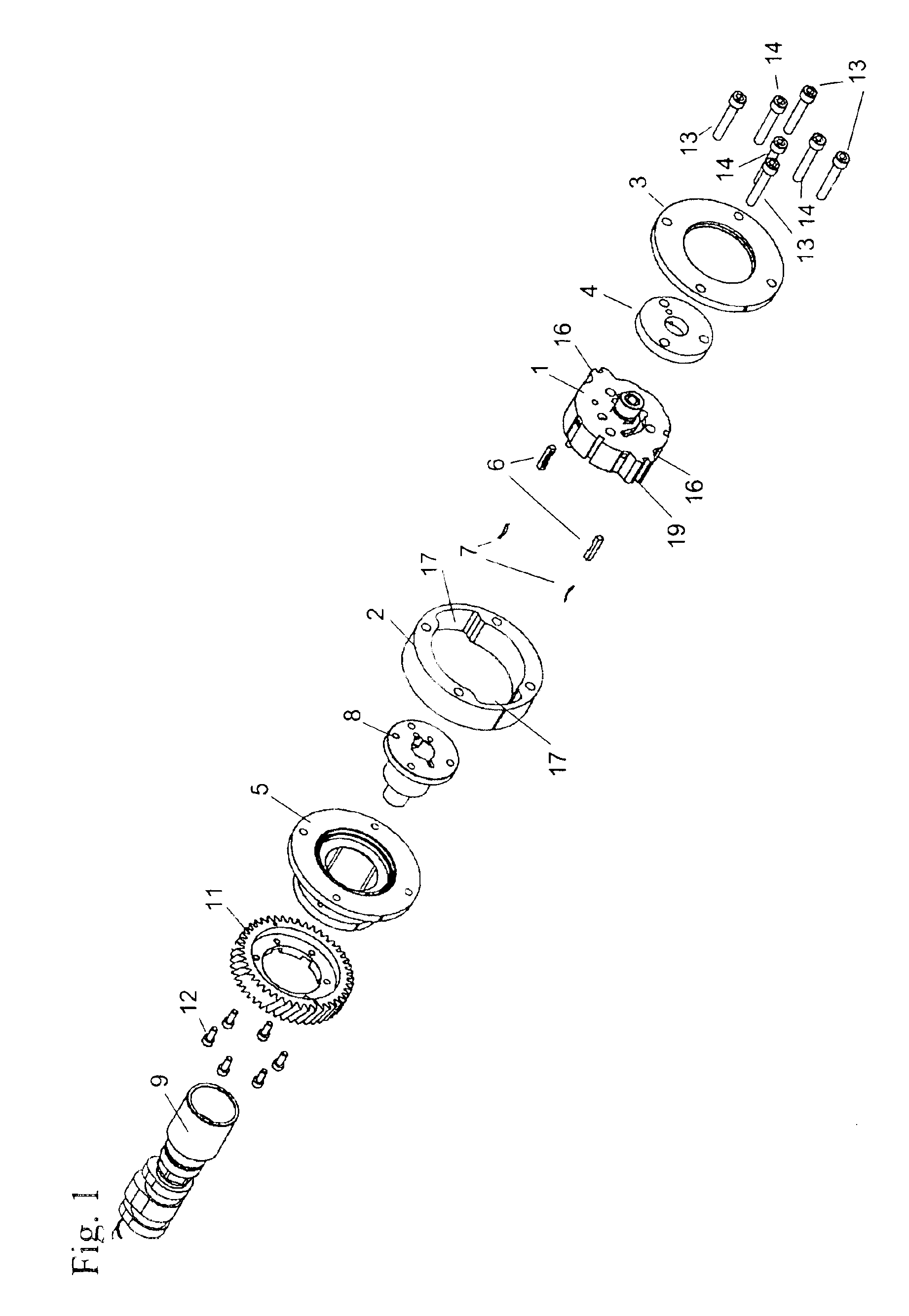

Electric direct-acting actuator and electric brake device

InactiveUS7810616B2Maximum functionCompact designMechanically actuated brakesElectrodynamic brake systemsLinear motionReducer

Owner:NTN CORP

In-wheel motor system

Owner:BRIDGESTONE CORP

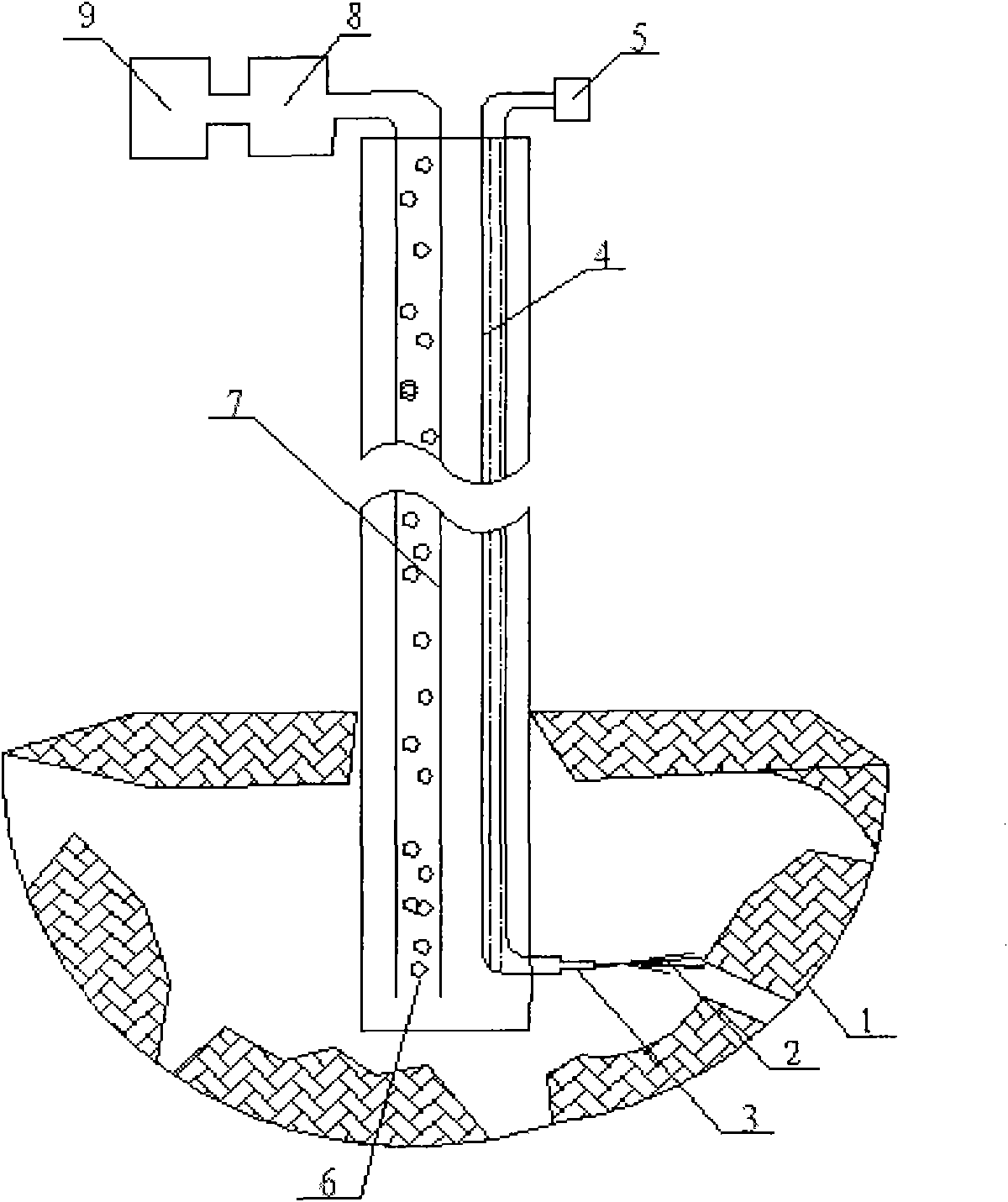

Method for exploiting natural gas hydrates by using high-pressure thermal jetting

InactiveCN101818635ASolve the problem of small mining rangeOvercoming or reducing self-protectionFluid removalJet flowEngineering

The invention relates to a method for exploiting natural gas hydrates by using high-pressure thermal jetting, comprising the following steps of: placing a high-pressure jetting device in an exploiting well; sending thermal fluids into a water injection pipe and a telescopic water gun through a high-pressure pump for spraying; causing high-speed jetting flows to directly act on the natural gas hydrates in the working radii of the high-speed jetting flows to cut and decompose the natural gas hydrates, changing non-decomposed natural gas hydrates into small blocks, bringing the small blocks into an exploiting pipe along with return flows, and then causing the small blocks together with the gas hydrates to rise to a gas-liquid separation device; separating gas and liquid through the gas-liquid separation device, and sending the gas into a gas recovering device. The invention solves the problem of small exploitation range in the exploitation process of the natural gas hydrates, ensures the thermal fluids to act on the surfaces of the non-cracked natural gas hydrates all the time, has a good thermal conduction effect and overcomes or reduces the self protection of the natural gas hydrates; and the telescopic water gun on a nozzle can not only be horizontally rotated, but also can be moved up and down along a vertical shaft by utilizing the power of a drilling machine, thereby ensuring the cutting of large-scale natural gas hydrate ledges.

Owner:JILIN UNIV

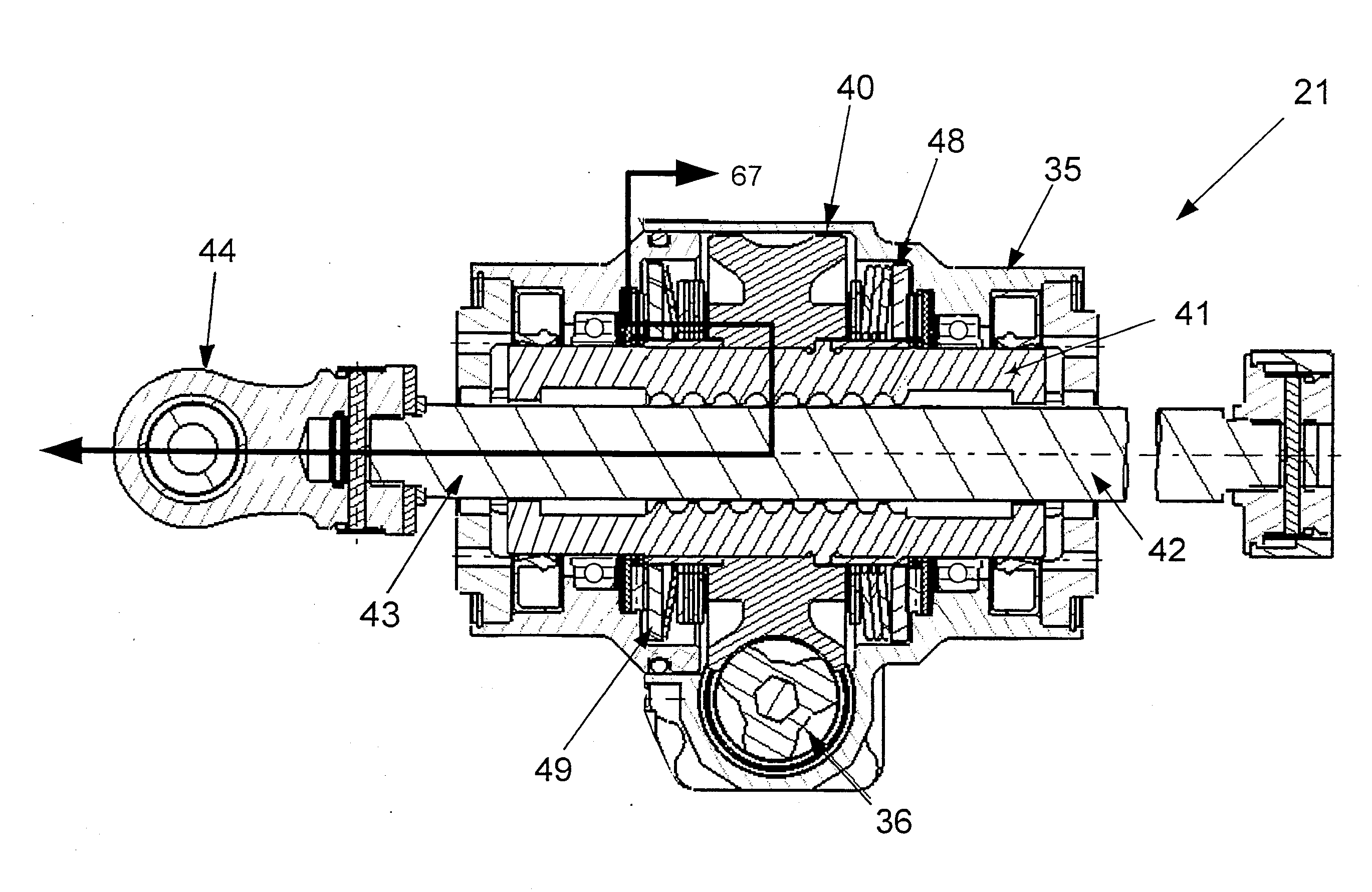

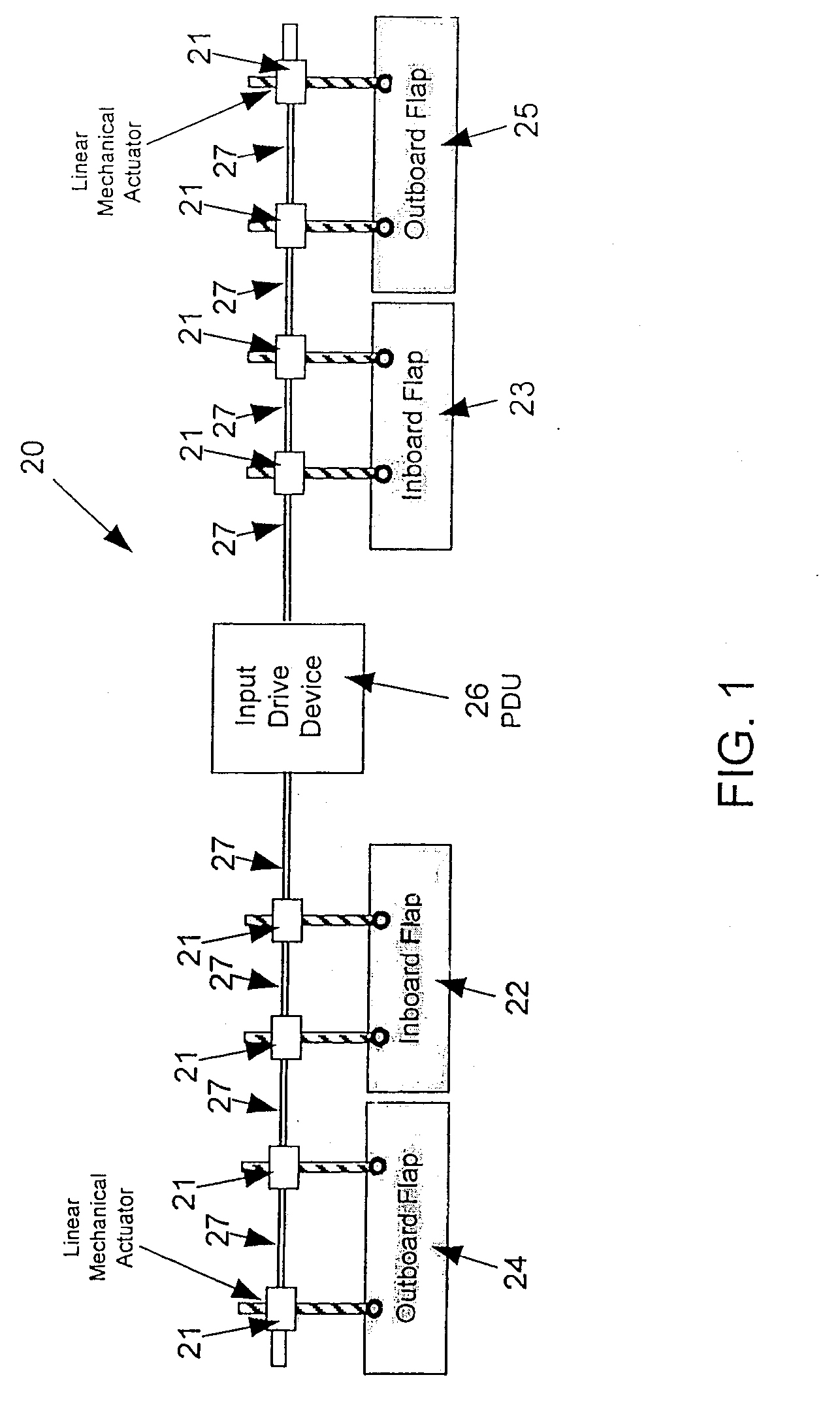

Aircraft flight control actuation system with direct acting, force limiting, actuator

ActiveUS20100096498A1Increase reaction forceSignificant dragAircraft stabilisationWithout power ampliicationEngineeringActuator

A direct acting force limiting actuator wherein the actuator output force either directly or indirectly causes significant drag on a rotary input shaft rather than on the translating output member. Consequently, input energy is dissipated before the actuator gear train mechanical advantage amplifies the reaction forces.

Owner:PARKER INTANGIBLES LLC

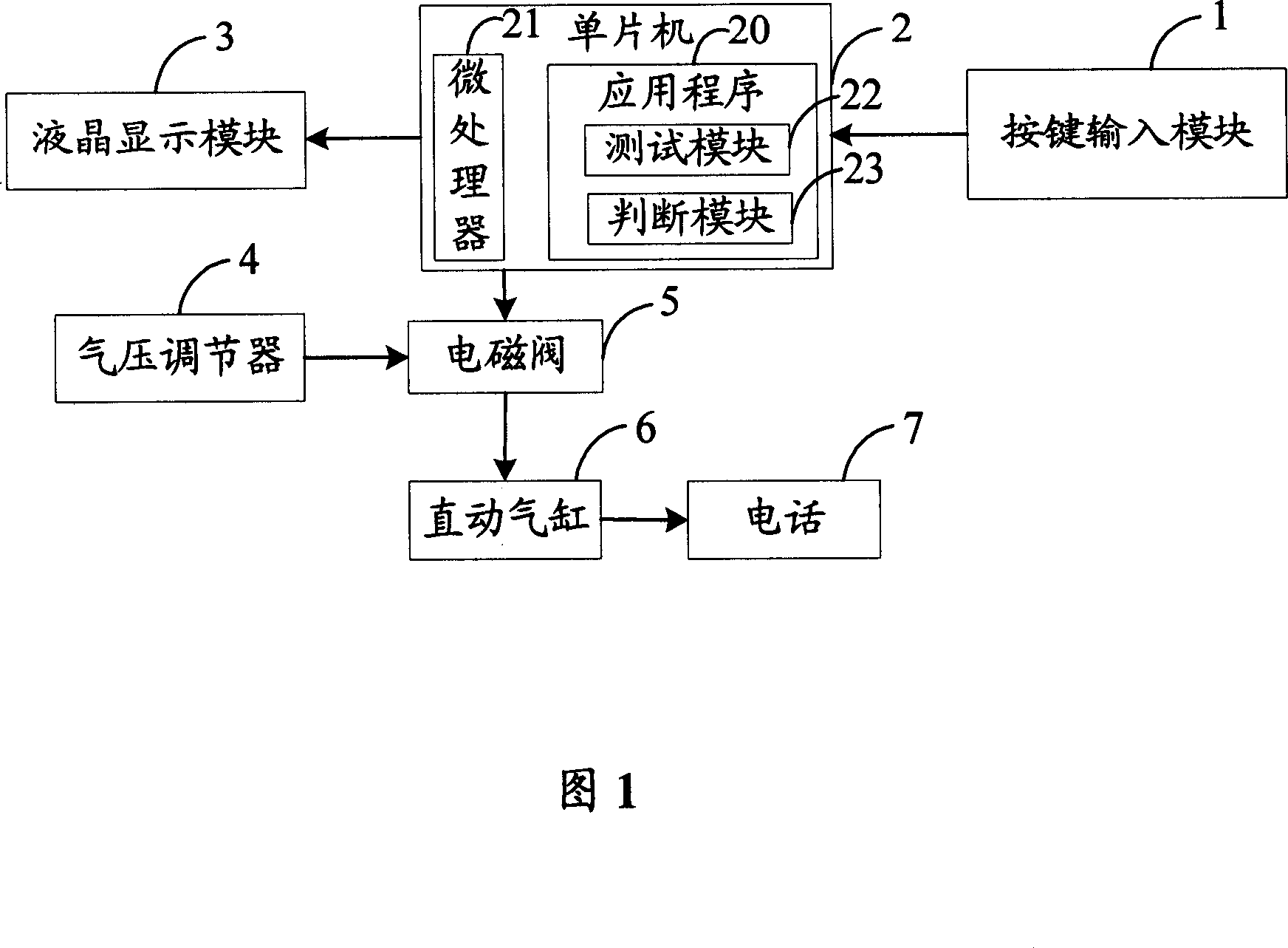

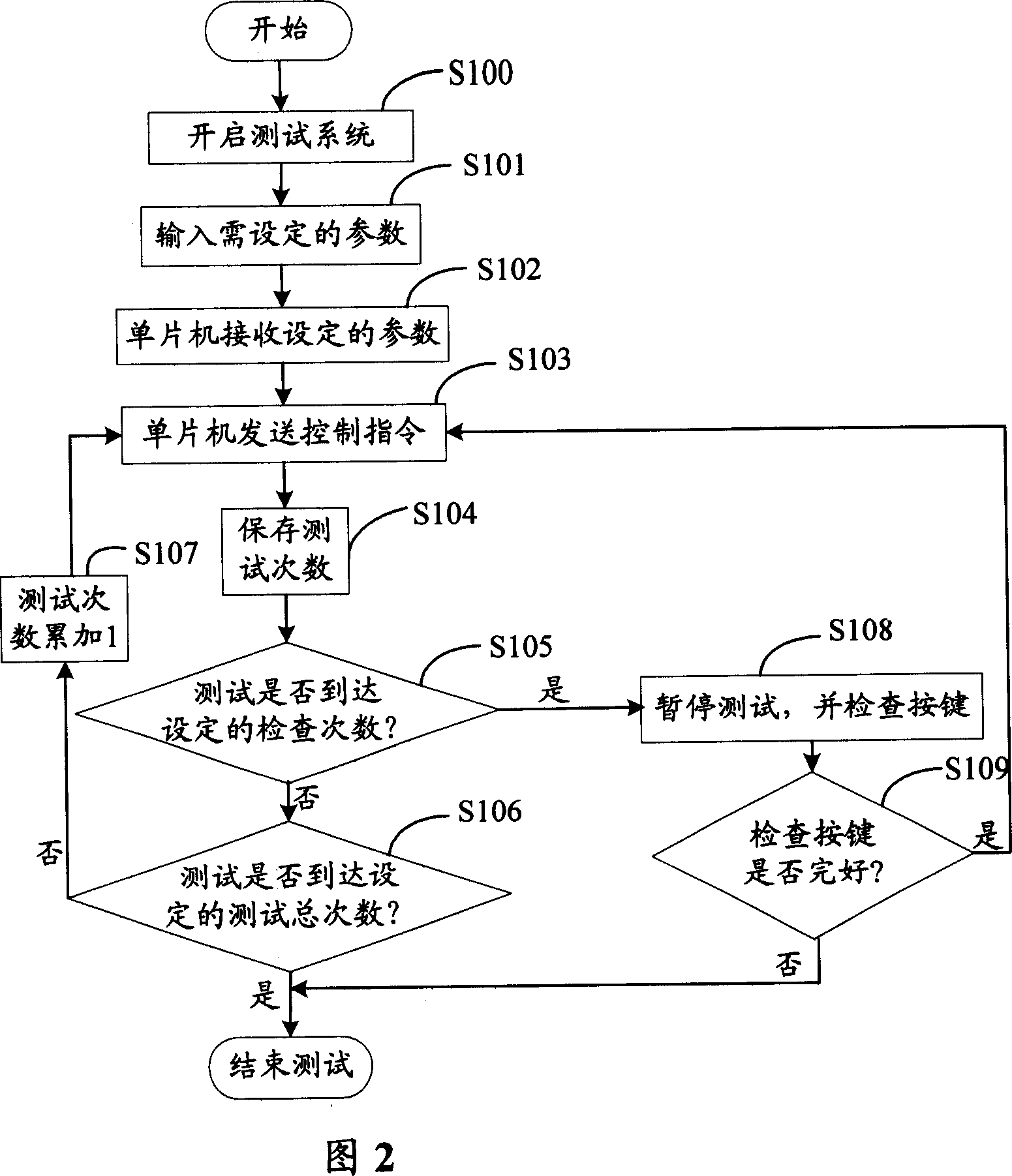

Push-button service-life detection system and method

InactiveCN1936615ARealize power-off protection functionCircuit interrupters testingMicrocontrollerLiquid-crystal display

The invention provides a testing system for the keystroke life including a keystroke input module, a singlechip, a liquid crystal display module, an air pressure regulator, at least one electromagnetic valve and at least one direct-acting air cylinder. The keystroke input module is to incept the order of the starting and closing testing system and incept the testing parameter. The singlechip includes a microprocessor and an application; the microprocessor can order the electromagnetic valve by carrying out the application. The liquid display module is to display the setting testing times and the present testing times. The air pressure regulator supplies the air pressure for the direct-acting air cylinder to make it move up and down by the electromagnetic valve to control the button and test the button life. The invention also provides a method. The invention constructs by the singlechip instead of the PC, so it has the function of speed adjustment and the power-off protection function.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

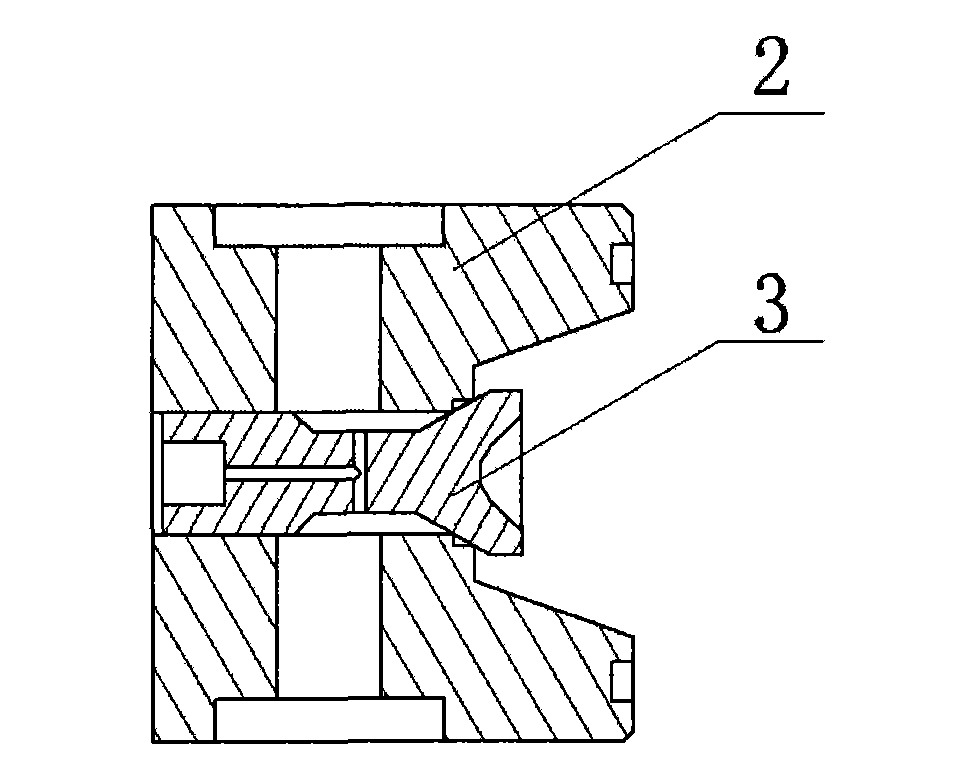

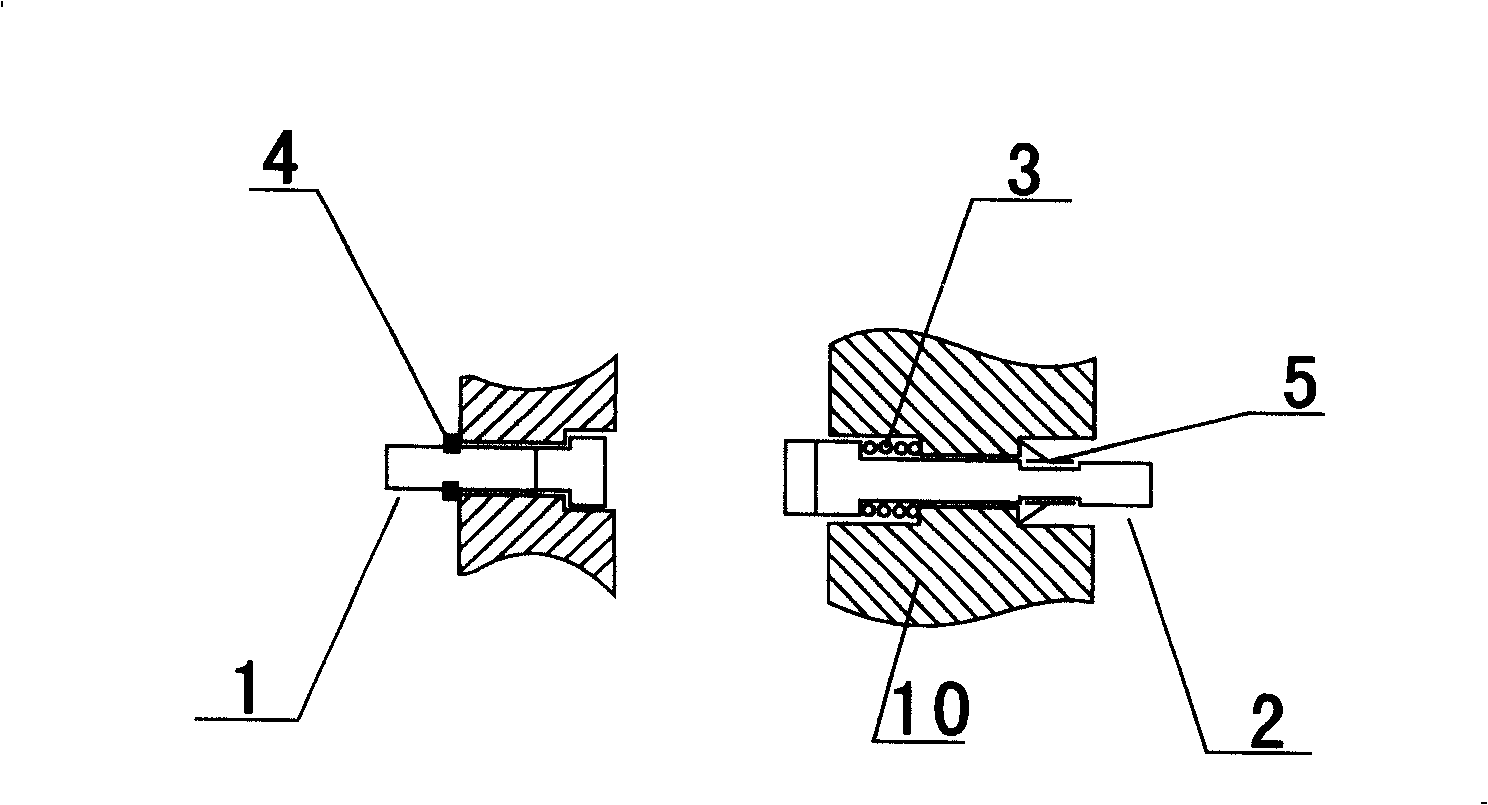

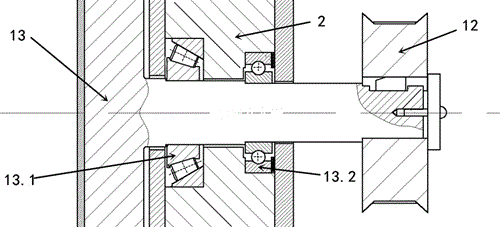

Axial elastic force-applying connection method for electric connector contact pair

InactiveCN101355208AEmission reductionSimple structureCoupling contact membersRelative displacementElectrical resistance and conductance

The invention provides a method for the axial elastic force application connection of electrical connector contact pairs. The method adopts an elastic element to apply axial external force to a contact pair consisting of a contact piece A (1) and a contact piece B (2), so as to combine the two tightly, thereby forming the electric connection with lower conductive resistance. One end of the elastic element is in contact with an insulating base so as to turn into a relative fixed end; and the other end of the elastic element directly acts on a preset fixed end face of an electric conductor contact piece, and is a relative displacement end during axial force application. The contact pair is independently formed by the end planes of the two contact pieces with simple structure. As axial elastic connection can not be affected by shock or other external factors, the connection reliability is higher. The contact pair can be formed by a positive contact piece and a negative contact piece as well, which ensures that the radial and axial directions of the contact pair are uniform in stress and contact.

Owner:徐志

Grabbing manipulator capable of turning over box body

InactiveCN105798894AImprove job stabilityHigh mechanical strengthProgramme-controlled manipulatorGripping headsMotor driveEngineering

The invention provides a grabbing manipulator capable of turning over a box body. The grabbing manipulator is connected with the tail end of a rotating mechanical arm of a right-angle coordinate robot and comprises a supporting mechanism, a displacement adjusting mechanism, a clamping mechanism and a pneumatic control loop. The supporting mechanism is composed of a connecting arm, a fixed clamping plate and a fixing plate. The displacement adjusting mechanism is composed of a movable clamping plate, guide rods, guide sleeves, a pneumatic rod and a pneumatic cylinder. The clamping mechanism is composed of clamping round plates, a servo motor, a synchronous belt and a synchronous wheel. The pneumatic control loop is composed of a pneumatic hose, a direct acting pressure reducing valve and an electromagnetic control reversing valve. According to the grabbing manipulator capable of turning over the box body, the clamping force can be clamped in a whole joint mode through the pneumatic control loop so that grabbing of the heavy box body can be adapted; and the servo motor drives the synchronous wheel to rotate through the synchronous belt, the driving clamping plate can be controlled to forwards and reversely rotate by any angles, the driven clamping plate and the box body rotate along with the driving clamping plate, and hence the posture of the box body can be adjusted after the box body is grabbed by the clamping mechanism.

Owner:HARBIN UNIV OF SCI & TECH

Mechanically and hydrodynamically operated brewing unit

A mechanically and hydrodynamically operated brewing unit (1) for automatic beverage vending machines includes a rotatable base (3) provided with a compartment (15) that acts as a brewing chamber, means to let water under pressure into said compartment, means to connect said compartment with the point at which the brewed beverage is dispensed, and a brewing head (4). This brewing head is comprised of a hollow containment structure (279), a first hollow piston (28) that is housed in said containment structure movably relative thereto, a second piston (29) that is accommodated in said first piston movably relative thereto, and elastic means (30) contrasting the movement of said second piston. The brewing unit is characterized in that said first piston and said second piston are operated by the direct action of a fluid under pressure.

Owner:N& W GLOBAL VENDING

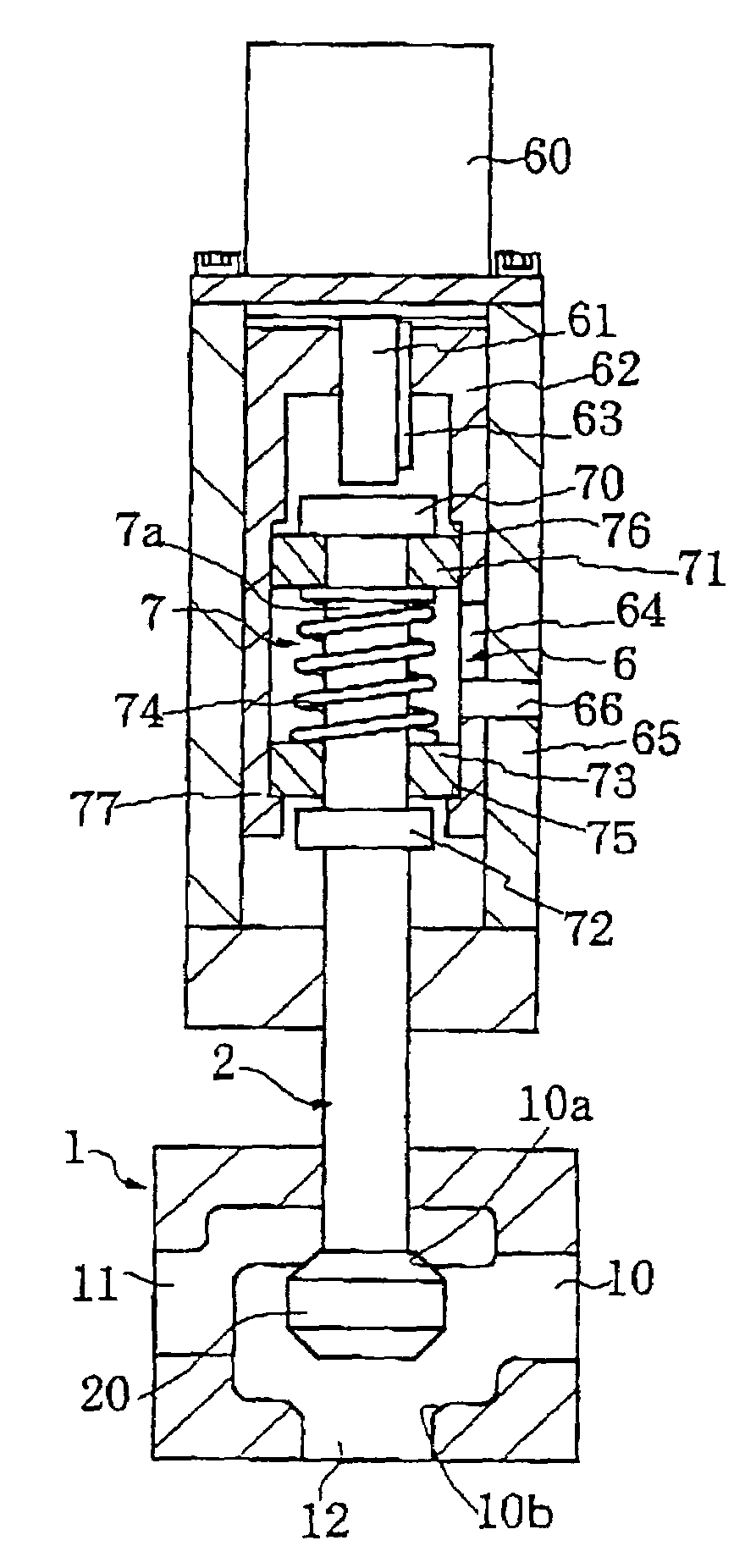

Electric direct-acting actuator and electric brake apparatus

Provided is an electric direct-acting actuator for making it possible to set the clearance for when an electric brake apparatus runs a normal brake operation. The present invention is equipped with a load sensor (14) for detecting the magnitude of the load pressing against a brake disk (2) with a friction pad (7); a temperature sensor (37) for correcting for the effects of temperature on the load sensor (14); and an electronic control device (50). The electronic control device (50) calculates, on the basis of the magnitude of the load detected by the load sensor (14), the rotation angle ([theta]) of an electric motor (15) from the position of the electric motor (15) corresponding to the magnitude of the load to the position of the electric motor (15) where clearance reaches a predetermined magnitude, and causes the electric motor (15) to rotate using the rotation angle ([theta]) as a target value.

Owner:NTN CORP

Direct acting gas regulator

InactiveUS7059343B2Low costAccurate pressureOperating means/releasing devices for valvesOffice automationHigh pressurePressure regulator

A direct acting pressure regulator controls the flow of a gas from a high pressure source to a low pressure device. Gas is delivered from the regulator at a predetermined outlet pressure. The regulator includes a body having a high pressure inlet and defining a seat. A bonnet is engageable with the body to define a piston chamber within the body and the bonnet. The bonnet has a regulated gas outlet. A piston is disposed within the piston chamber and defines a gap between the piston and a wall defining the chamber. The piston is movable between an open regulator condition and a closed regulator condition. The piston includes a plug having a sealing surface engageable with the seat and movable toward the seat to the closed regulator condition and away from the seat to the open regulator condition. The plug includes axially disposed openings therein for communicating gas from around the plug to a central longitudinal bore in the piston. The piston has an impingement surface in flow communication with the central bore such that gas pressure on the impingement surface exerts a force on the piston to move the piston to the closed regulator condition. A spring urges the piston to the open regulator condition.

Owner:PRESSURE SPECIALIST

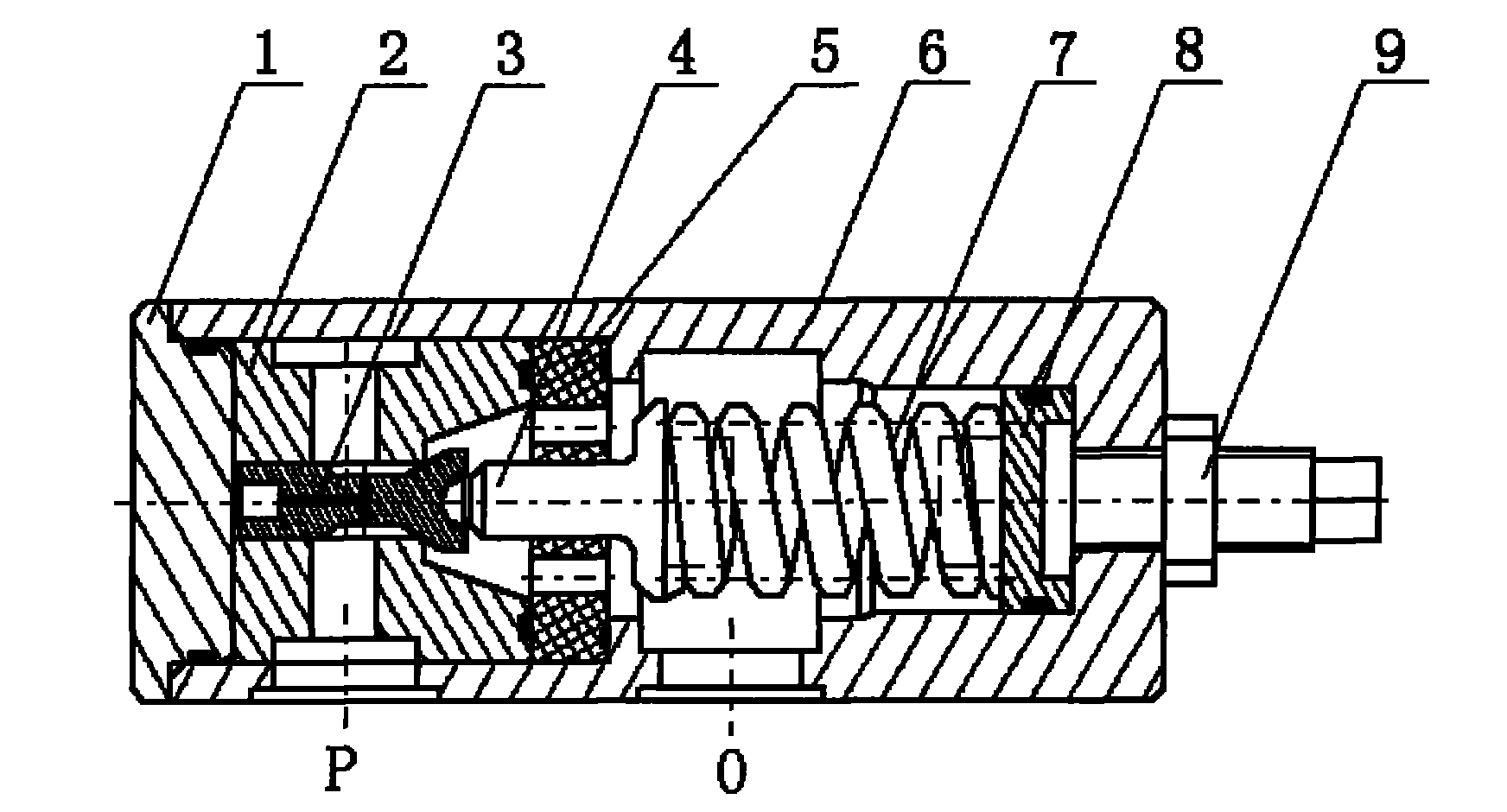

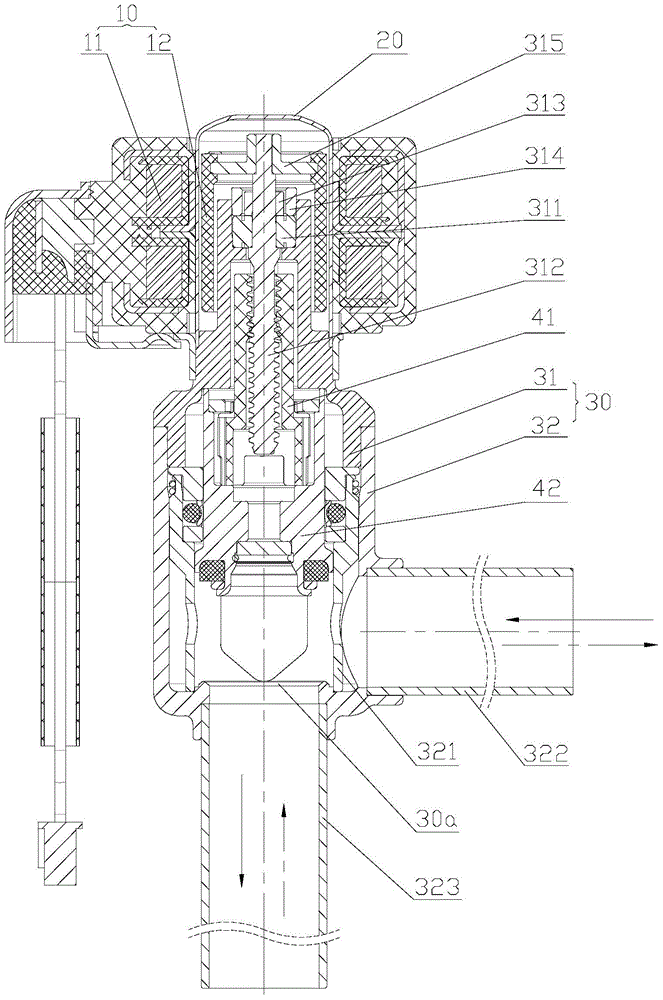

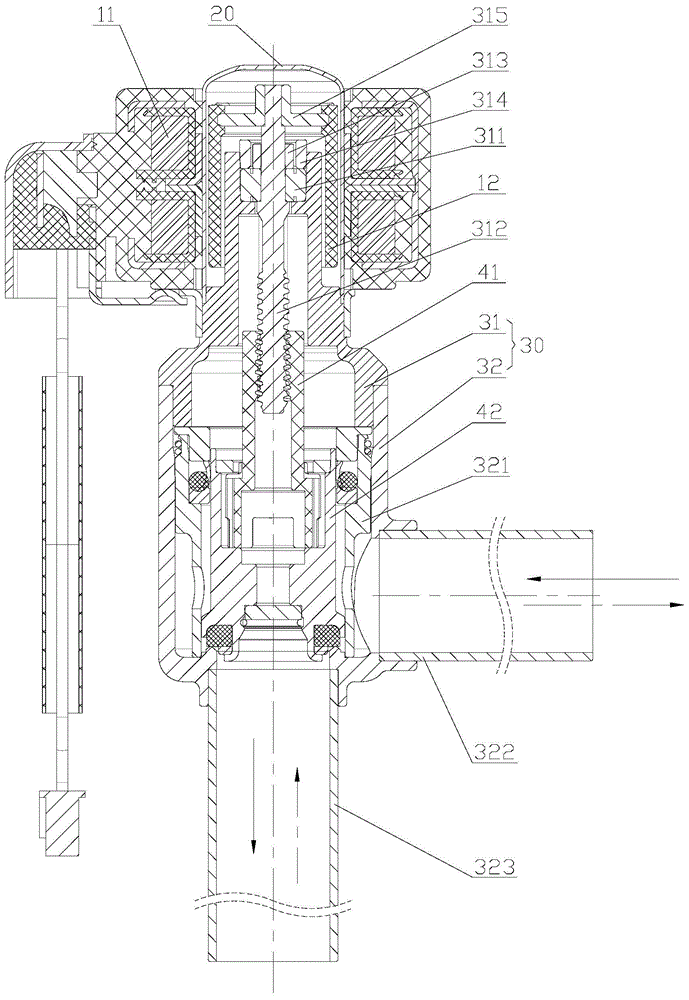

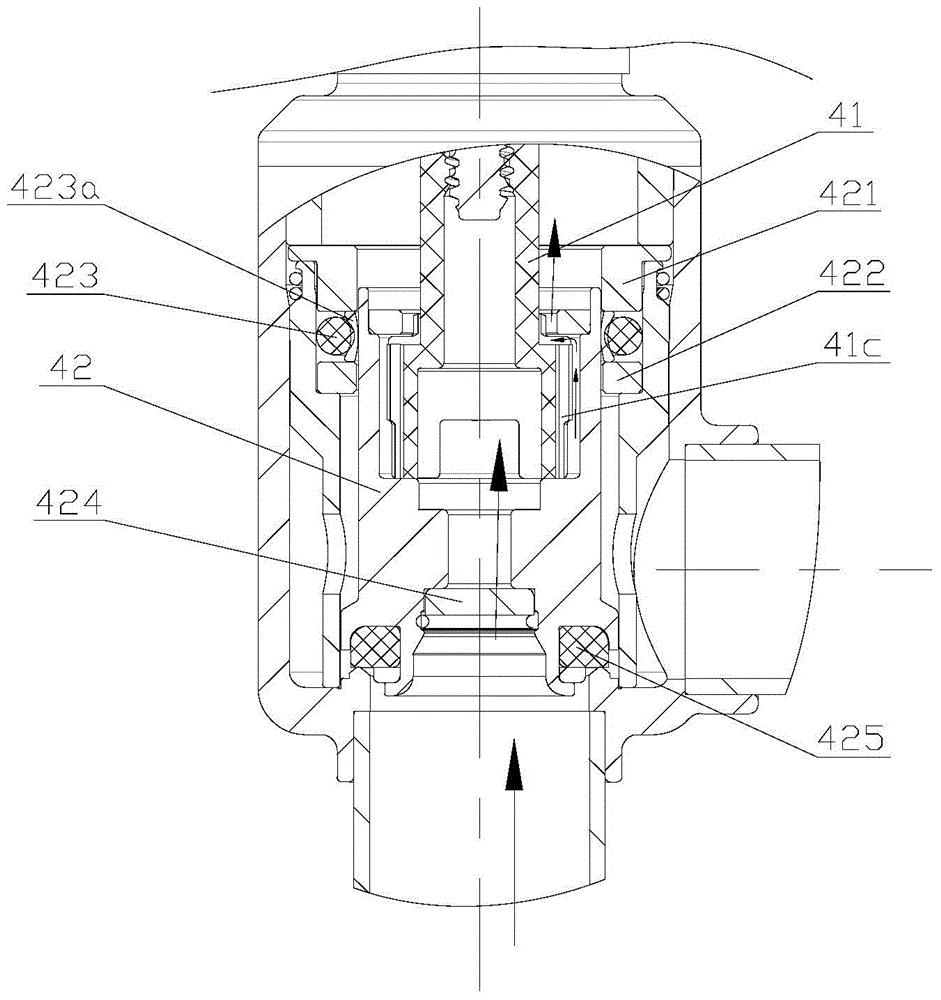

Direct-acting type electric valve

The invention discloses a direct-acting type electric valve. The direct-acting type electric valve comprises a valve seat with a valve cavity, a motor and a lead screw, wherein the motor and the lead screw are mounted at the upper end of the valve seat. The lead screw is connected with a nut in a thread fit manner, and the nut is connected with a valve element; a rotor of the motor and the axial position of the valve seat are relatively fixed, and the upper end of the lead screw is fixedly connected with the rotor; the valve element is driven by the nut to move in the axial direction of the valve cavity to open or close a valve opening in the valve seat; the valve element is of cylindrical structure with a balance channel, and a sealing part for dividing the valve cavity into two independent cavity bodies is arranged on the periphery of the valve element. According to the structure, a gear system is eliminated, and unnecessary transmission is reduced; and friction losses are reduced, and the response is direct, reliable and sensitive. The rotor and the axial position of the valve seat are fixed, that is, in the working process, the opposite positions of the rotor and the coil component are fixed, so that driving force is stable; obviously, for the valve opening of the same size, the size of the motor in the scheme is smaller than that of a motor in the prior art, and the miniaturization large-capacity requirements can be met.

Owner:ZHEJIANG SANHUA CLIMATE & APPLIANCE CONTROLS GRP CO LTD

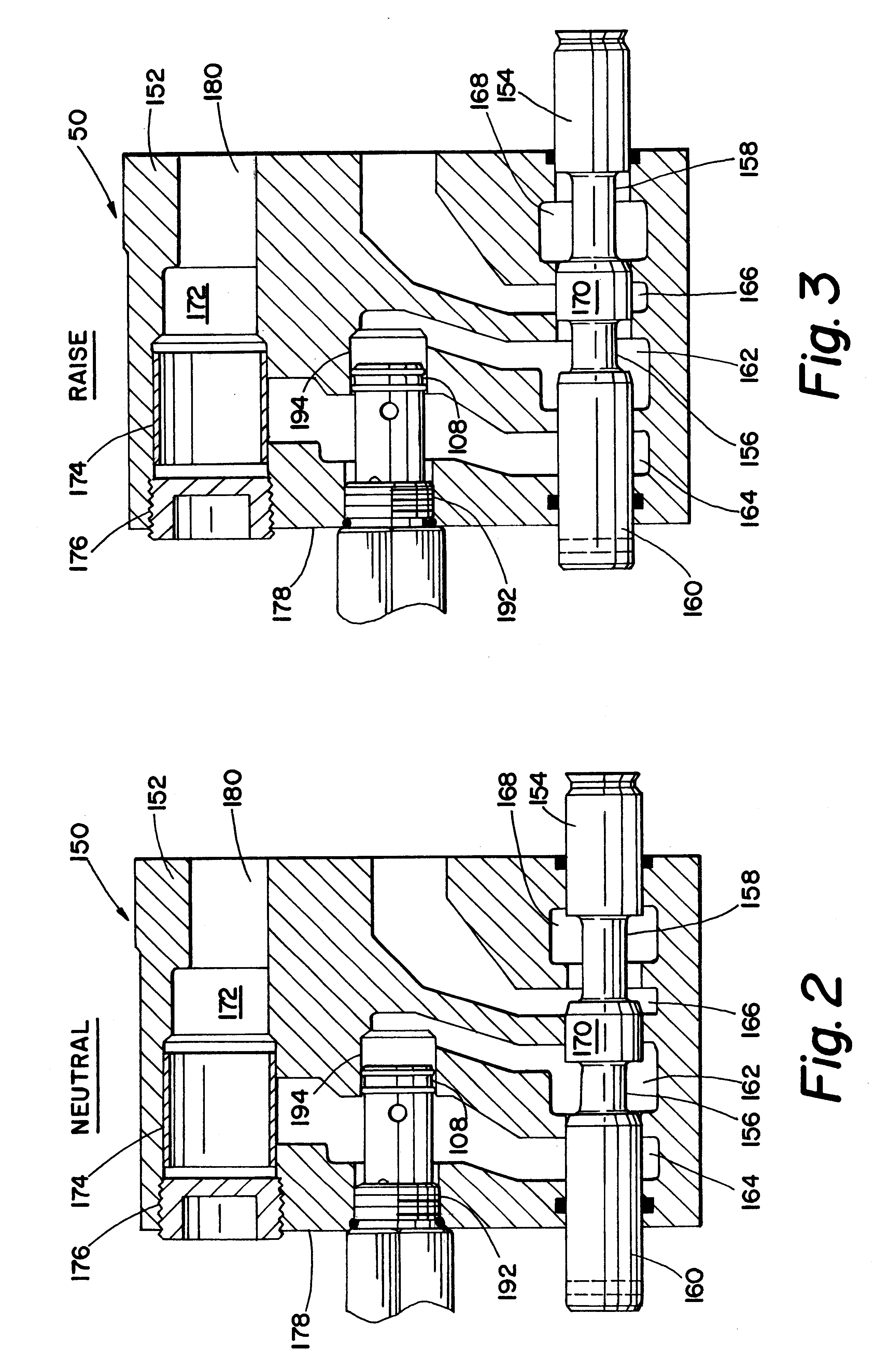

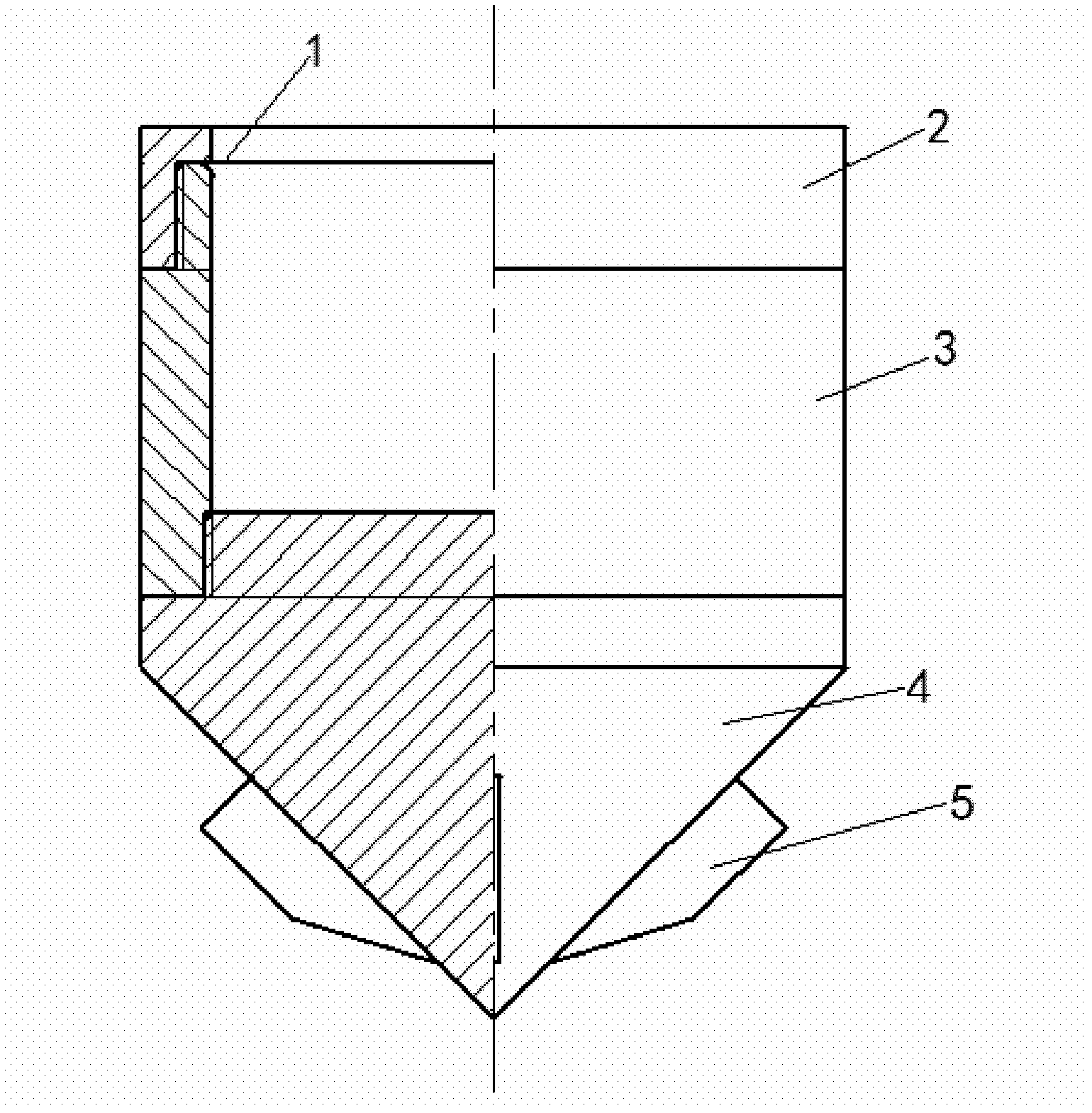

Remotely actuated multiple pressure direct acting relief valve

A multiple pressure direct acting relief valve is disclosed. The multiple pressure relief valve comprises an actuating cylinder, a relief valve and an adjustment screw interconnecting the actuating cylinder and the relief valve. The relief valve includes a low pressure spring which biases a poppet valve arrangement permitting the poppet valve arrangement to be actuatable at a first pre-determined pressure. The actuating cylinder includes a piston that is biased by a high pressure spring causing an additional compressive force to be applied to the poppet valve arrangement through an actuating rod received through the adjustment screw. When pressure is applied to the piston within the actuating cylinder, an additional compressive force is applied by the high pressure spring and the actuator rod to the poppet valve arrangement causing the poppet valve arrangement to be actuatable at a second pre-determined pressure. Lock nuts are provided on the adjustment screw that interconnects the actuating cylinder and the relief valve. When the lock nuts are disengaged, the position of the adjustment screw can be moved relative to the actuating cylinder and the relief valve permitting the adjustment of both pre-determined actuating pressures for the poppet valve arrangement.

Owner:GUYAN INT +1

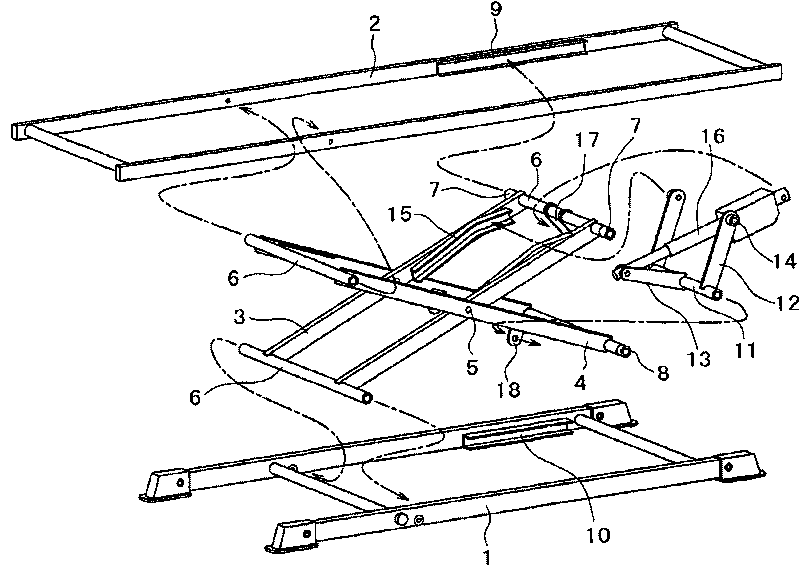

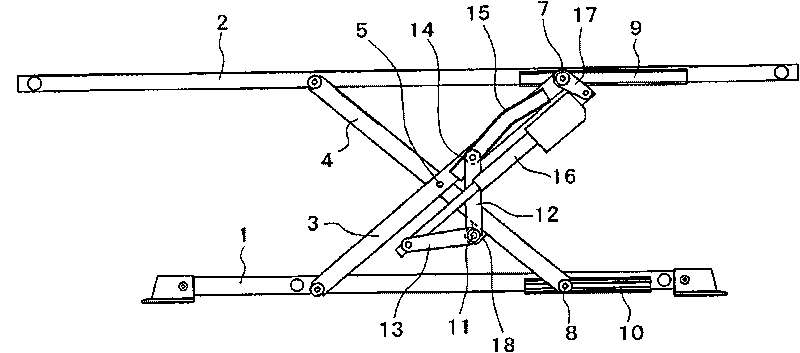

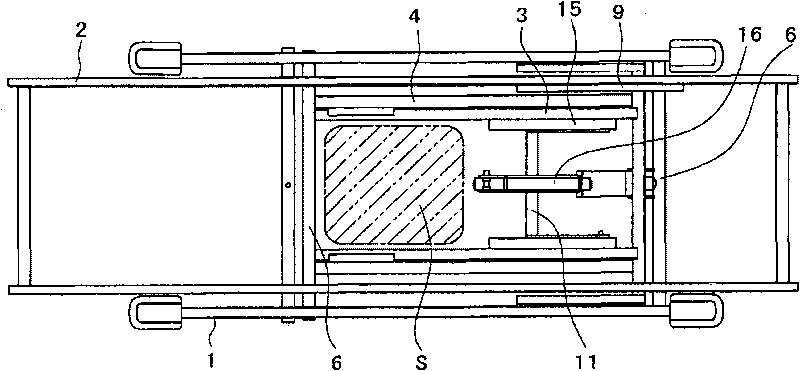

X-linked hoisting mechanism

In a conventional X-linked hoist mechanism, mechanism elements of other functions are difficult to be arranged because hoist drive elements occupy a wide area under a state where a hoist fame is lowered. Such a configuration that the hoist frame is elevated in the operation of a direct acting actuator in the pulling direction is dangerous because the hoist frame drops when the direct acting actuator is damaged. In a hoist mechanism having a first link (3) and a second link (4) constituting an X-linked mechanism between a base frame (1) and the hoist frame (2), a drive member (11) provided rotatably on the other end side of the second link is provided with a push-up arm (12) and a drive arm (13), a member (15) for guiding a moving member (14) provided at the end of the push-up arm (12) is provided on the other end side of the first link in the length direction, and a direct acting actuator (16) is provided between the other end side of the first link and the drive arm, thus constituting an X-linked hoist mechanism.

Owner:PARAMOUNT BED CO LTD

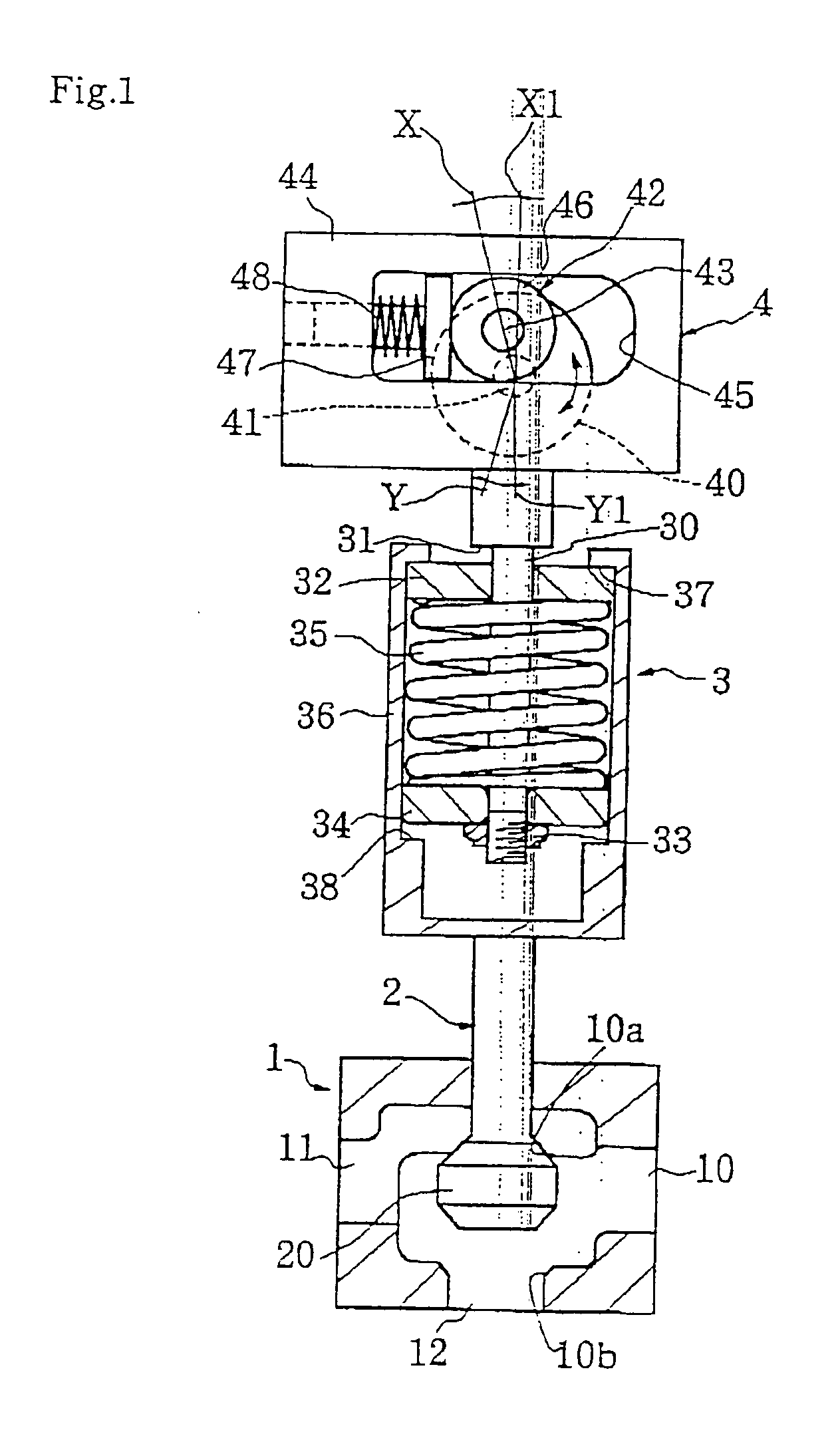

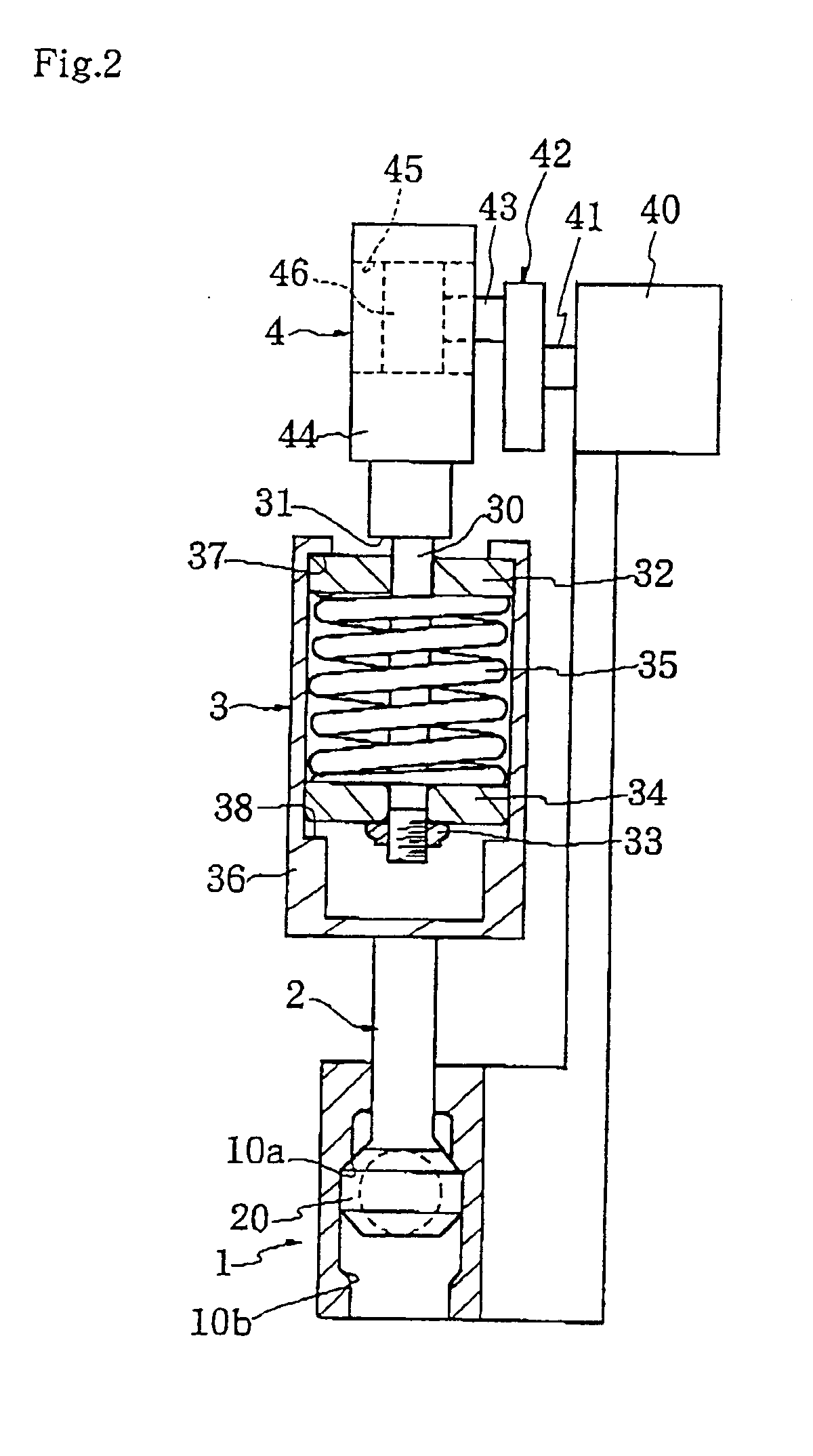

Direct-acting electric operated valve

InactiveUS6971628B2Limit reverse rotationShort strokeOperating means/releasing devices for valvesGearingTop dead centerReciprocating motion

A direct-acting electric operated valve has a stem which reciprocates by an electric motor without using air pressure.In this direct-acting electric operated valve, as the stem 2 vertically reciprocates, a first passage 11 and a second passage 12 are switched over. A cam mechanism 4 is formed for converting rotary reciprocating motion of an eccentric cam 42 which rotary reciprocates by an electric motor 40 into vertical reciprocating motion. The eccentric cam is retained at an upper retaining position X which is slightly exceeding a top dead center X1 and at a lower retaining position Y which is slightly exceeding a bottom dead center Y1. In a state in which an integral coil spring 35 which is previously held between an upper spring seat 32 and a lower spring seat 34 in its compressed state is mounted to a spring shaft 30 which extends from a cam mechanism, the coil spring 35 is accommodated in a spring case 36 connected to the stem.

Owner:ICHIMARU GIKEN

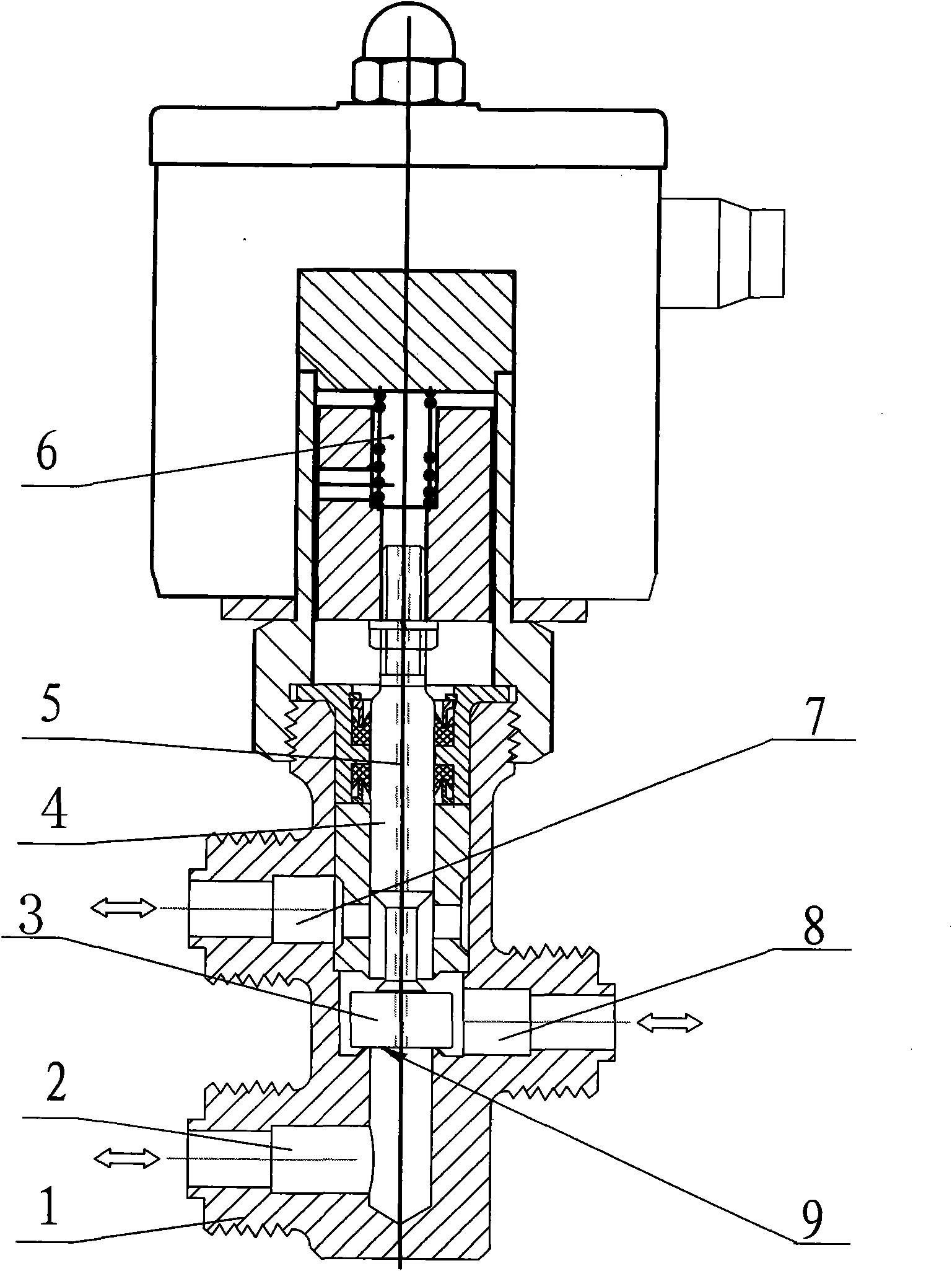

Direct-acting type two-position three-way solenoid valve

InactiveCN101551026AGuaranteed functionRealize functionOperating means/releasing devices for valvesMultiple way valvesSolenoid valveEngineering

The invention relates to a direct-acting type two-position three-way solenoid valve, an inner cavity of which adopts a pressure balancing type sealing structure. The solenoid valve comprises a valve body, valve seats and a valve rod component. The valve body is provided with three ports; a valve disc is fixedly connected with the bottom end of the valve component in the valve body; the bottom end of the valve disc is provided with a through hole which is straight through the valve rod component; the through hole is communicated with an upper cavity channel; when the valve disc falls down, the disc surface of the bottom end of the valve disc can seal a channel port of the valve body, so as to form a sealing structure with communicated valve rods; the medium leads the medium force applied to the valve disc to achieve balance upward and downward by the through hole, so as to form the direct-acting type two-position three-way solenoid valve which adopts the pressure balancing type sealing structure with the communicated valve body. The solenoid valve can work under the condition of vacuum, realize the functions of bearing negative pressure, two-way sealing, random connection and alternation of the ports as an inlet, and work without pressure difference. The solenoid valve can realize direct-acting type control of the solenoid valve with larger diameter in more economic electromagnet range.

Owner:ANSHAN SOLENOID VALVE

Method for measuring explosion shock wave field strength and special-purpose pressure tank thereof

InactiveCN102494830ALow costEasy to operateMeasurement of explosion forceShock wavePlastic materials

The invention provides a method for measuring the explosion shock wave field strength and a special-purpose pressure tank that is used for testing an explosion pressure field. Compared with a traditional pressure sensor measurement method, the provided measuring method is visual, is easy to operate and is more economical. According to a concrete technical scheme, the pressure tank is composed of a membrane, a tank cover and tank body. The tank cover is open and the upper end of the tank cover is provided with a flange. The membrane is a plastic material and is a direct action object at a pressure field; and the deflection of the membrane reflects a pressure level. The tank cover and the tank body are in threaded connection; and the membrane is clampedly placed between a lower end surface of the tank cover flange and an upper end surface of a tank body opening. According to the measuring method provided in the invention, changes of a volume inside the pressure tank before and after explosion as well as before and after deformation of the membrane are measured, so that a pressure filed of an explosion shock wave can be measured.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com