Grabbing manipulator capable of turning over box body

A technology for grasping manipulators and boxes, applied in manipulators, program-controlled manipulators, chucks, etc., to achieve the effects of high mechanical strength, expanded range and strong working stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

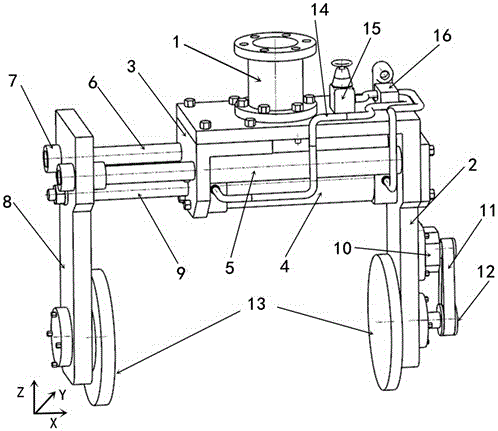

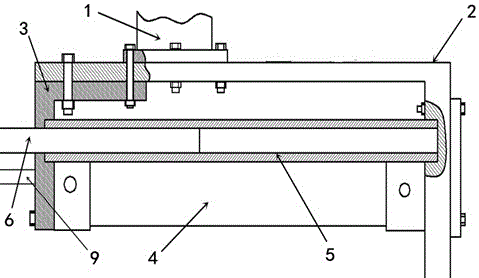

[0017] Embodiment 1: A grabbing manipulator for a reversible box is installed at the end of a rotating manipulator of a Cartesian robot. The Cartesian robot controls the manipulator to reach the specified grabbing position and grabbing angle by moving along the X-axis, Y-axis, and Z-axis and rotating around the Z-axis. The electromagnetic control reversing valve controls the air pressure rod through the air cylinder to drive the movable splint to do horizontal reciprocating movement, which can adjust the clamping width of the manipulator. The movable splint is connected with the guide rod through the sleeve, the guide rod slides in the guide sleeve, and the guide rod and the guide sleeve play the role of guide rail and support. Two pairs of guide rods and guide sleeves are parallel to each other. The sleeve is symmetrically extended and installed on the movable splint, and the sleeve and the guide rod are shrunk fit together to increase the contact area and strengthen the con...

specific Embodiment approach 2

[0019] Specific implementation mode 2: Cartesian coordinate robot controls the manipulator to move to the preset grabbing position, and the mechanical arm rotates at a certain angle, so that the gripping surfaces of the two gripping discs are in contact with the two symmetrical surfaces of the box for gripping. Cartesian coordinates The robot then adjusts the height of the manipulator, moves to the designated position and places it. The work of the pneumatic control circuit is to complete the grabbing and placing of the box body according to the specific embodiment one.

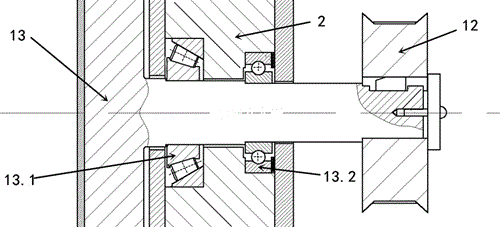

[0020] The active gripping disc is mounted on the fixed clamping plate with a tapered roller bearing and a deep groove ball bearing. The tapered roller bearing offsets the axial force generated by the clamping disc, and the deep groove ball bearing offsets the radial force generated by the clamping disc. This structure makes the structure of the manipulator more compact. The bearing is fixed with the fixed s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com