Electric direct-acting actuator and electric brake apparatus

An electric, actuator technology, applied in the direction of transmission, friction transmission, brake type, etc., can solve the problem of difficult to stably capture the timing and instability of sudden changes in differential value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

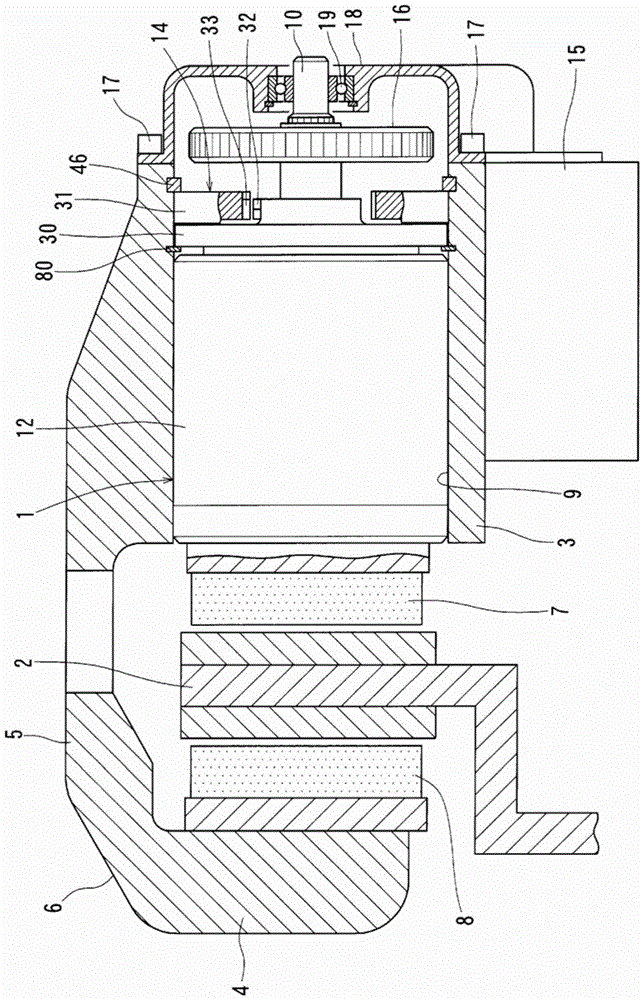

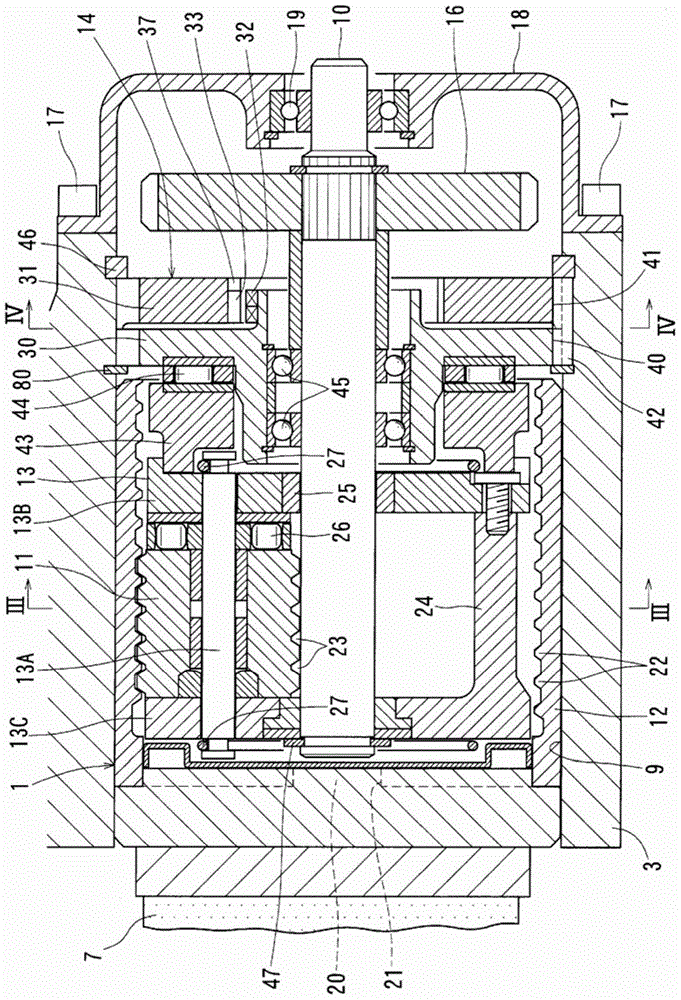

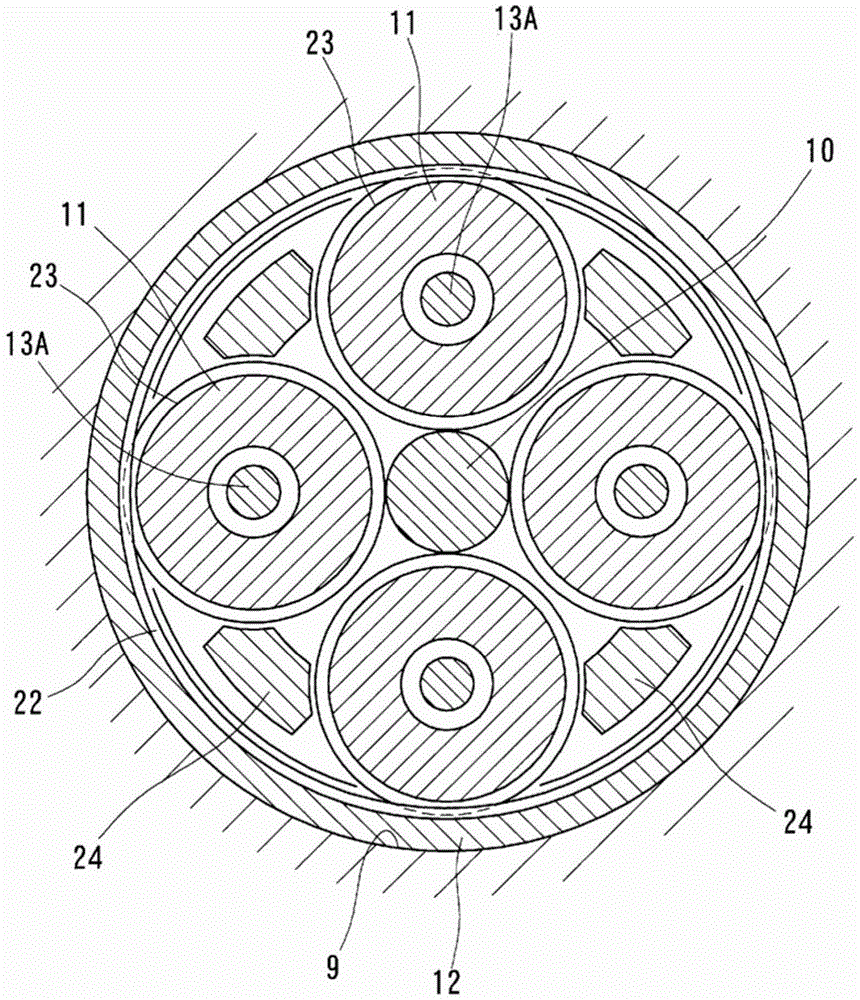

[0039] exist figure 1 An electric braking device for a vehicle using the electric linear actuator 1 according to the embodiment of the present invention. This electric braking device has a brake caliper body 6 in the shape of connecting opposing plates 3, 4 by a bridge 5, and a pair of left and right friction pads 7, 8, wherein the opposing plates 3, 4 are spaced between them with the wheel. The integrally rotating brake discs 2 are arranged facing each other. Furthermore, the electric linear actuator 1 is assembled into the housing hole 9 opened on the surface of the facing piece 3 facing the brake disc 2 .

[0040] The friction pads 7, 8 are respectively provided between the opposing plates 3, 4 and the brake disc 2, and are supported so as to be able to be aligned with a fixing member (not shown) fixed to a steering knuckle (not shown) supporting the wheel. Axial movement of the disc 2. In addition, the caliper body 6 is also supported by the fixture so as to be slidable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com