Patents

Literature

1389 results about "Thermal fluids" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermofluids is a branch of science and engineering encompassing four intersecting fields...

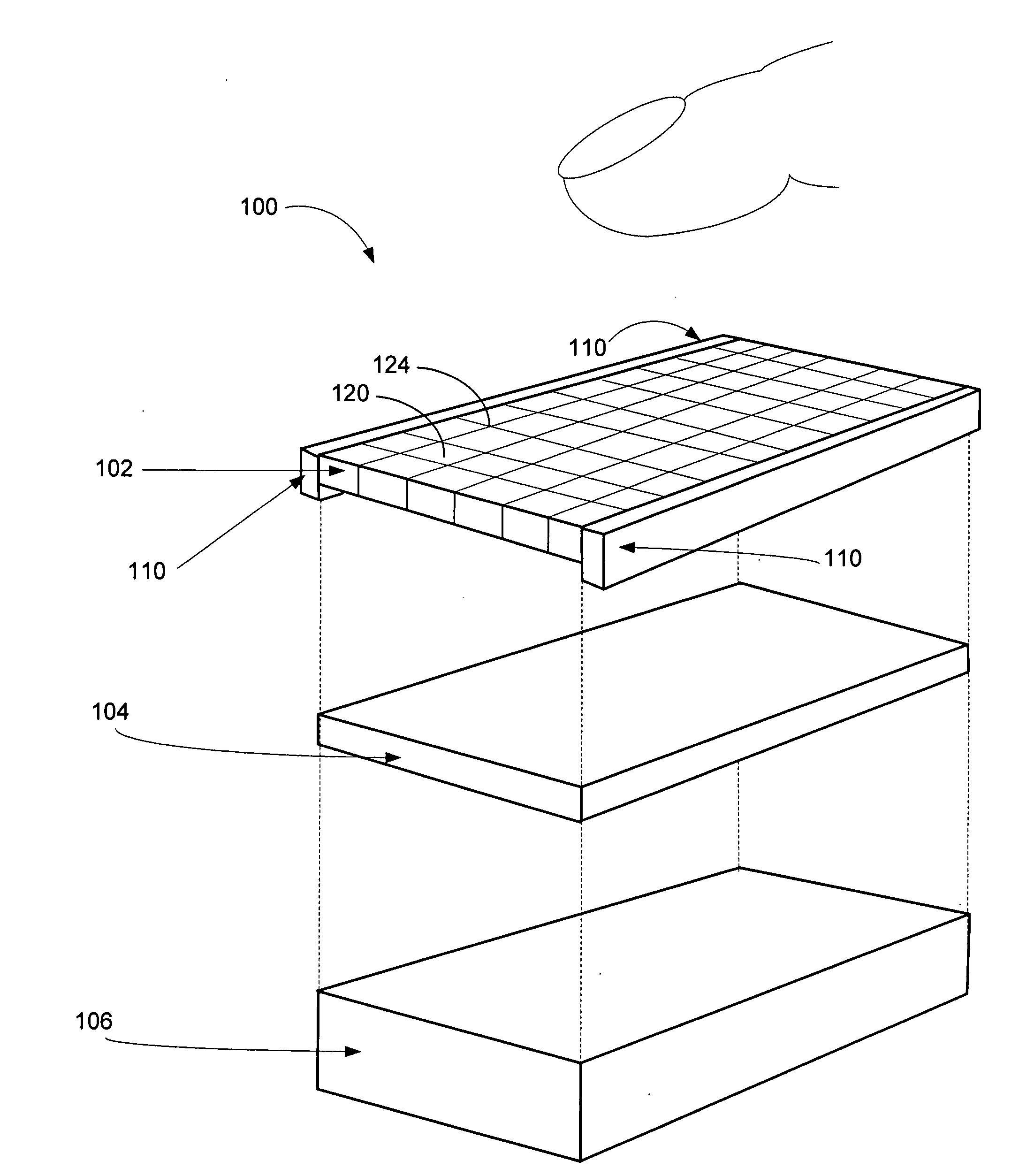

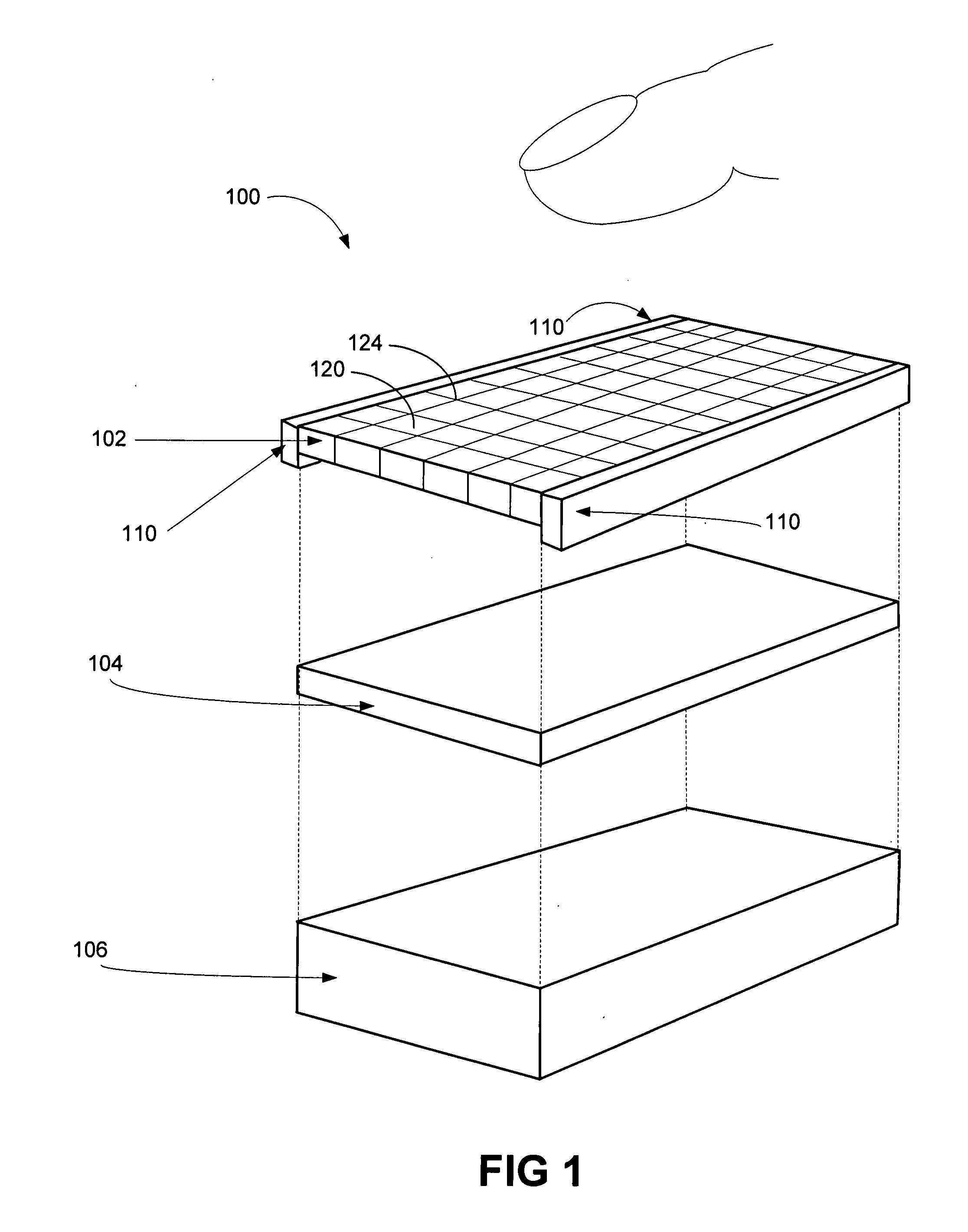

Method and apparatus for multi-touch tactile touch panel actuator mechanisms

A method and apparatus of actuator mechanisms for a multi-touch tactile touch panel are disclosed. The tactile touch panel includes an electrical insulated layer and a tactile layer. The top surface of the electrical insulated layer is capable of receiving an input from a user. The tactile layer includes a grid or an array of haptic cells. The top surface of the haptic layer is situated adjacent to the bottom surface of the electrical insulated layer, while the bottom surface of the haptic layer is situated adjacent to a display. Each haptic cell further includes at least one piezoelectric material, Micro-Electro-Mechanical Systems (“MEMS”) element, thermal fluid pocket, MEMS pump, resonant device, variable porosity membrane, laminar flow modulation, or the like. Each haptic cell is configured to provide a haptic effect independent of other haptic cells in the tactile layer.

Owner:IMMERSION CORPORATION

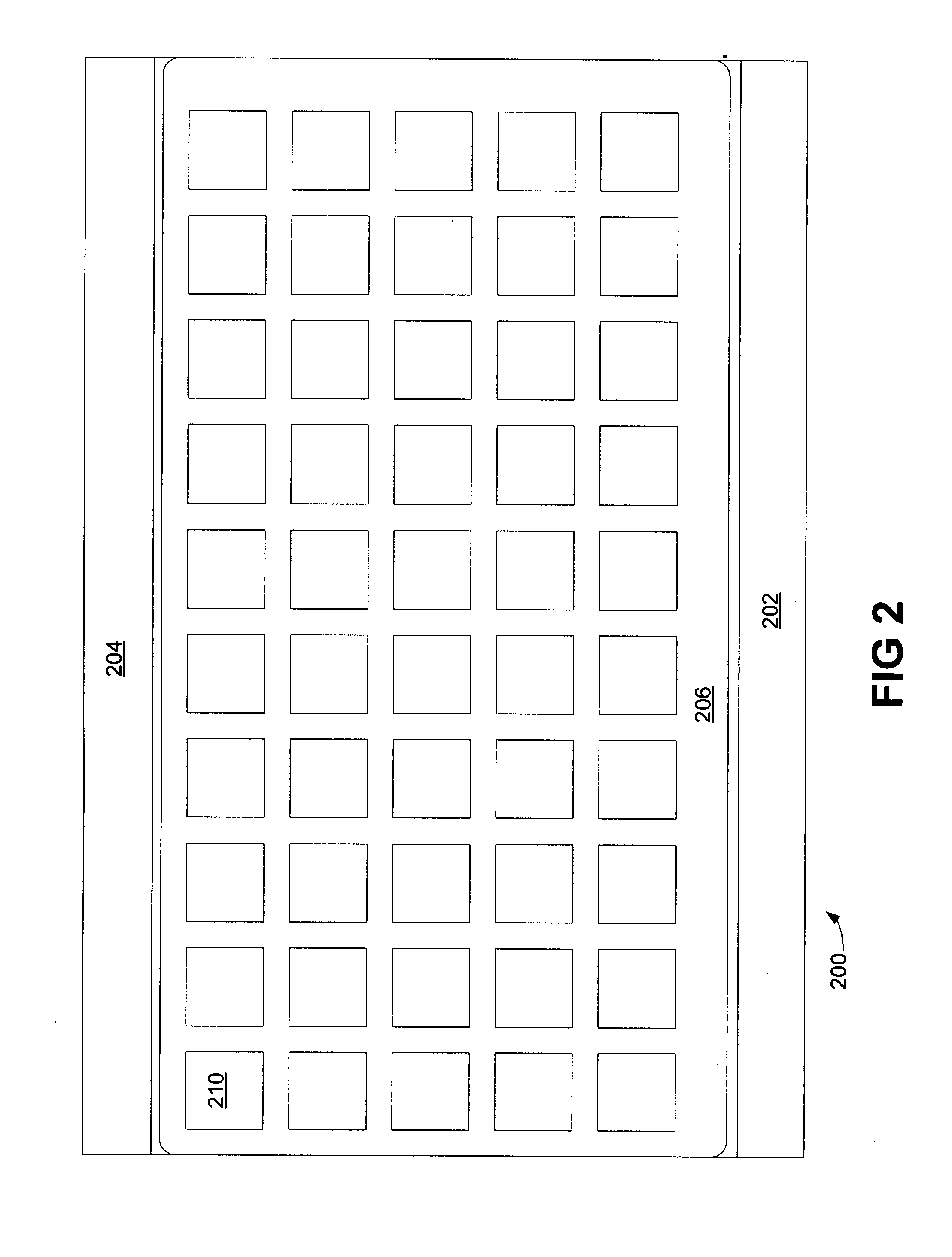

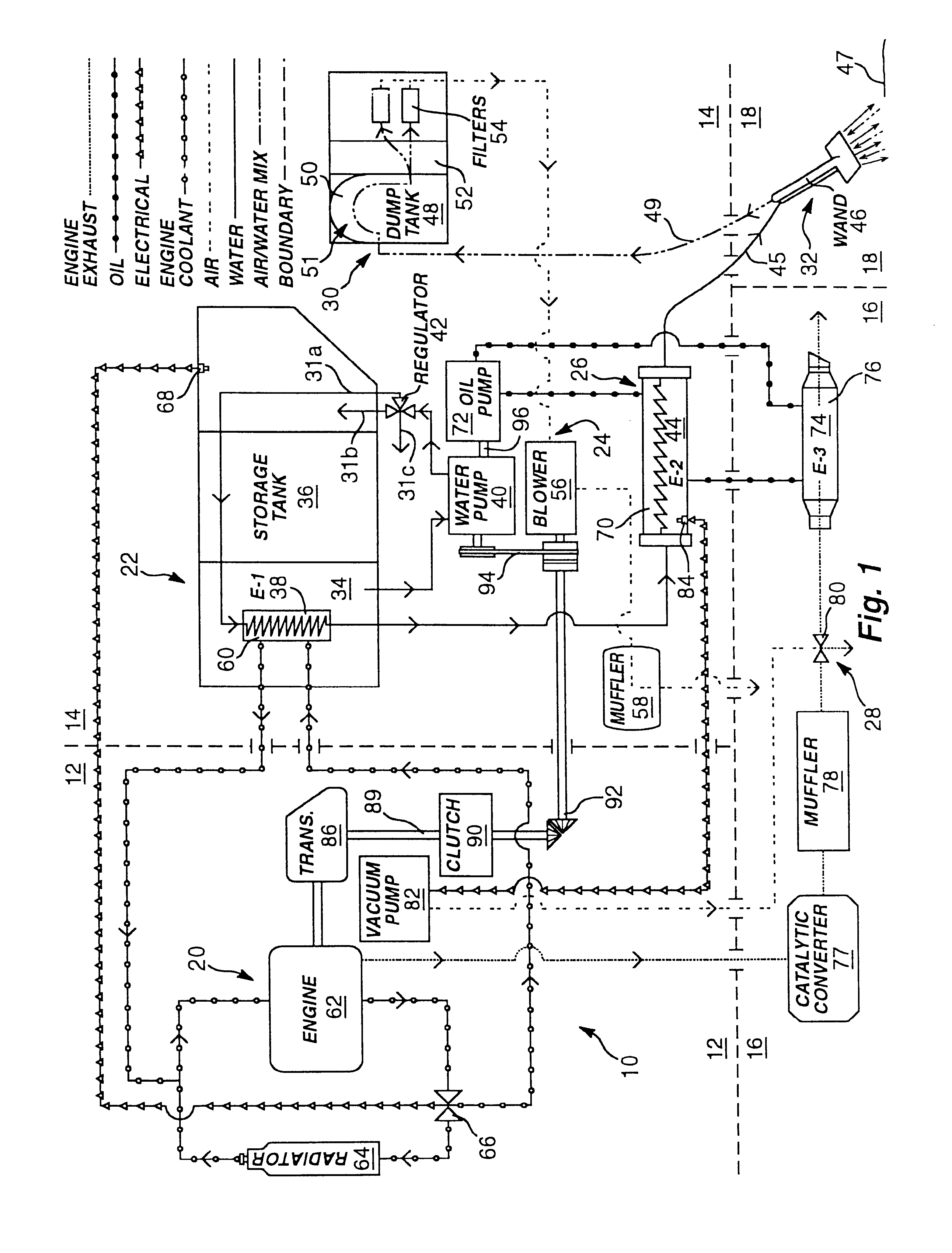

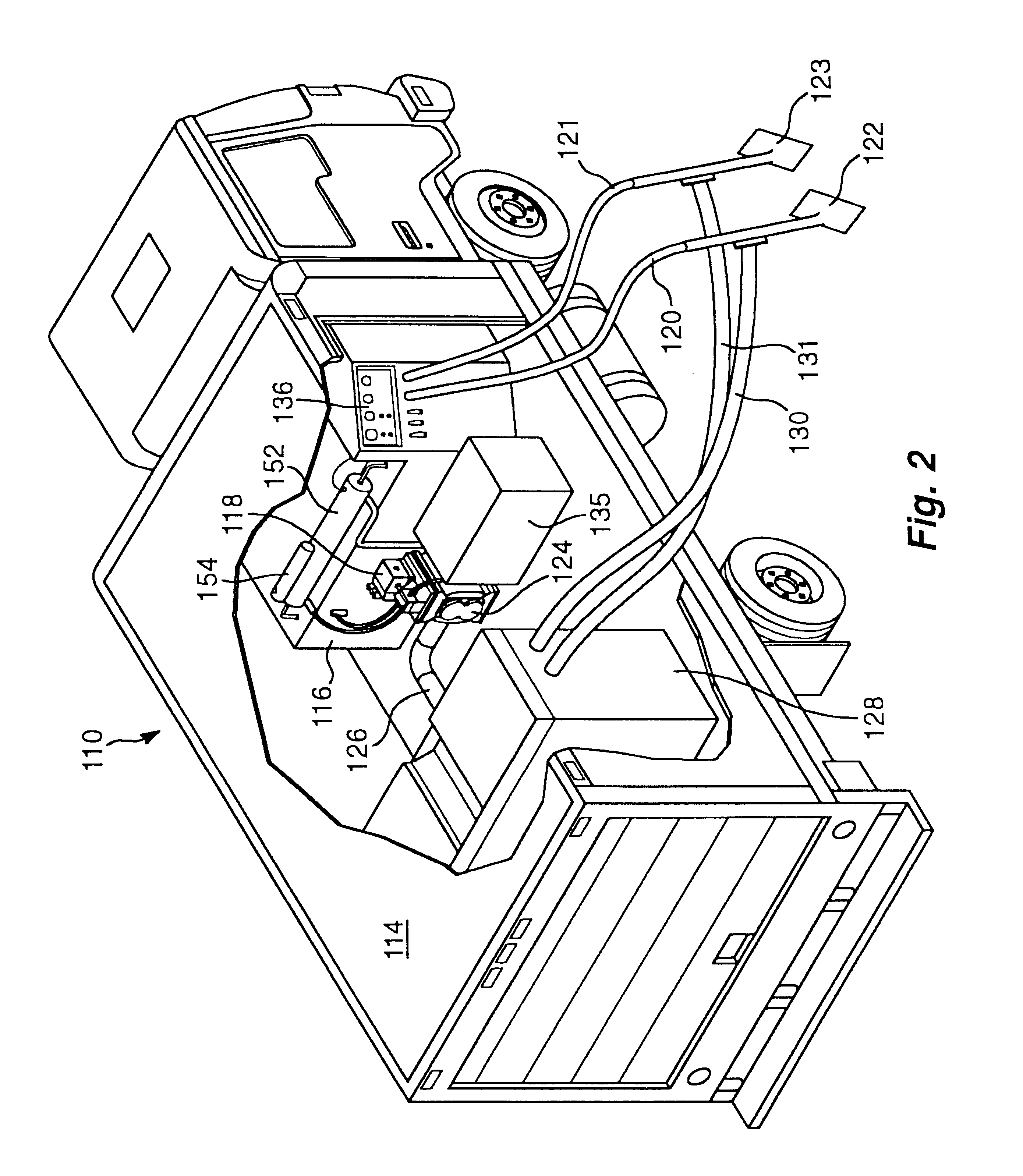

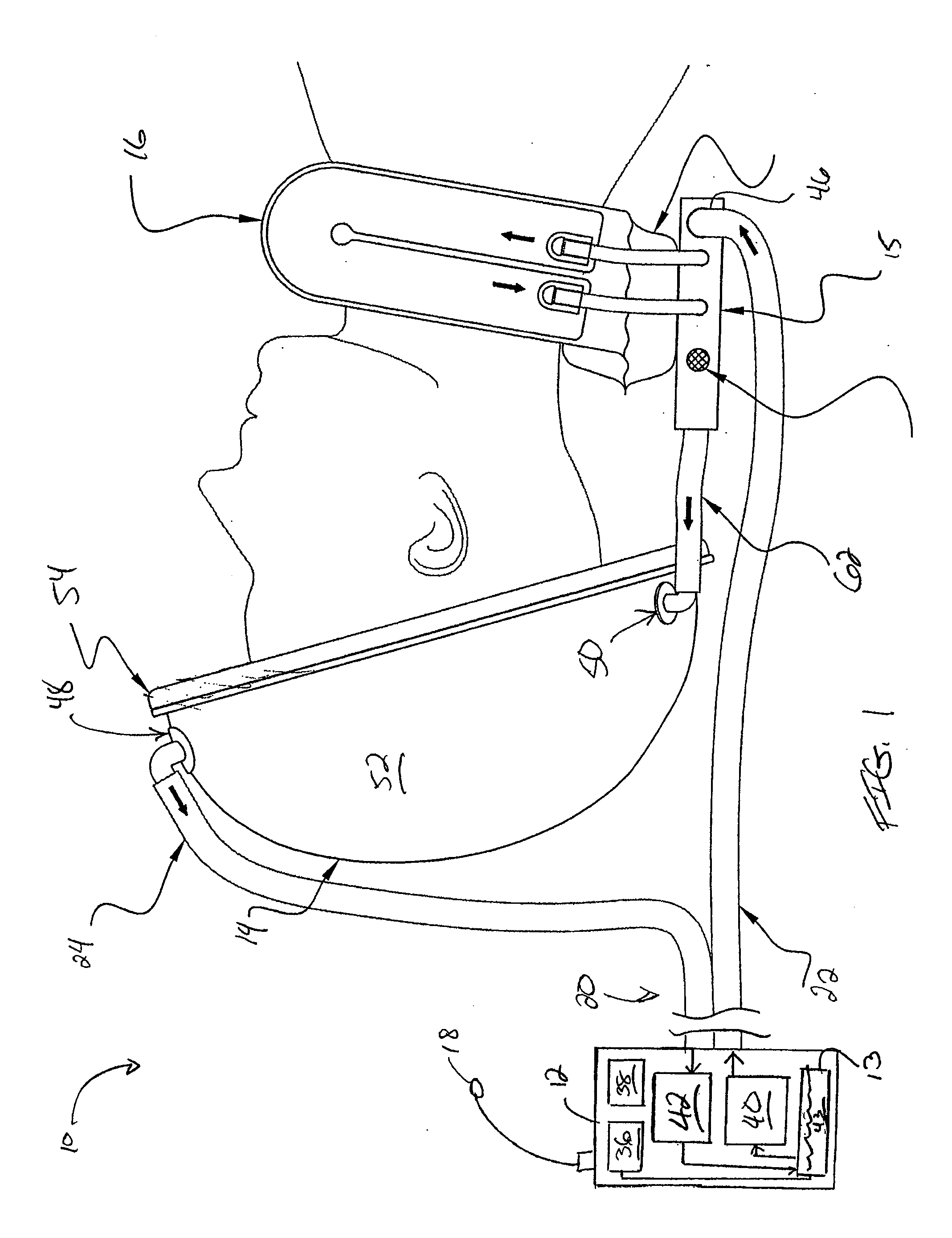

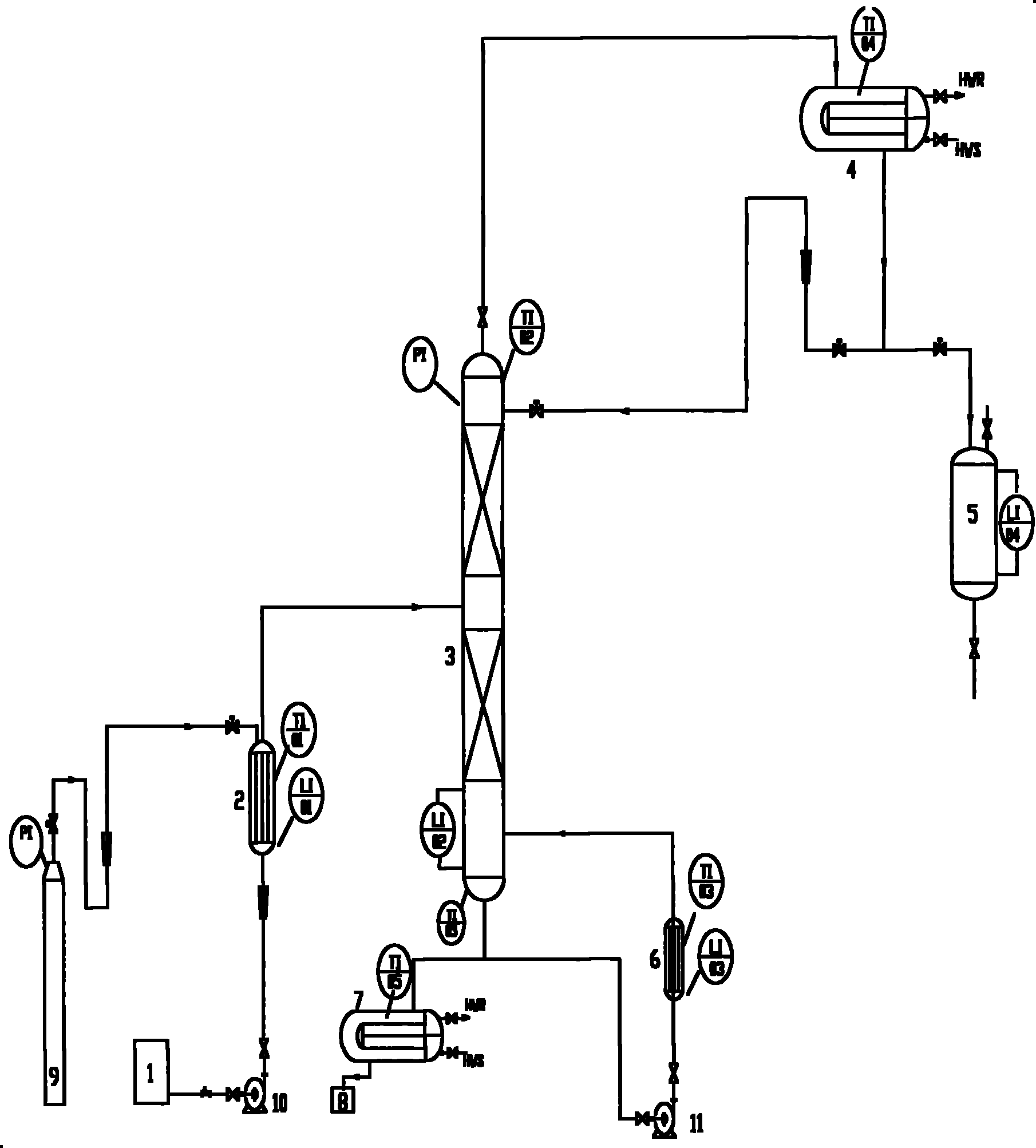

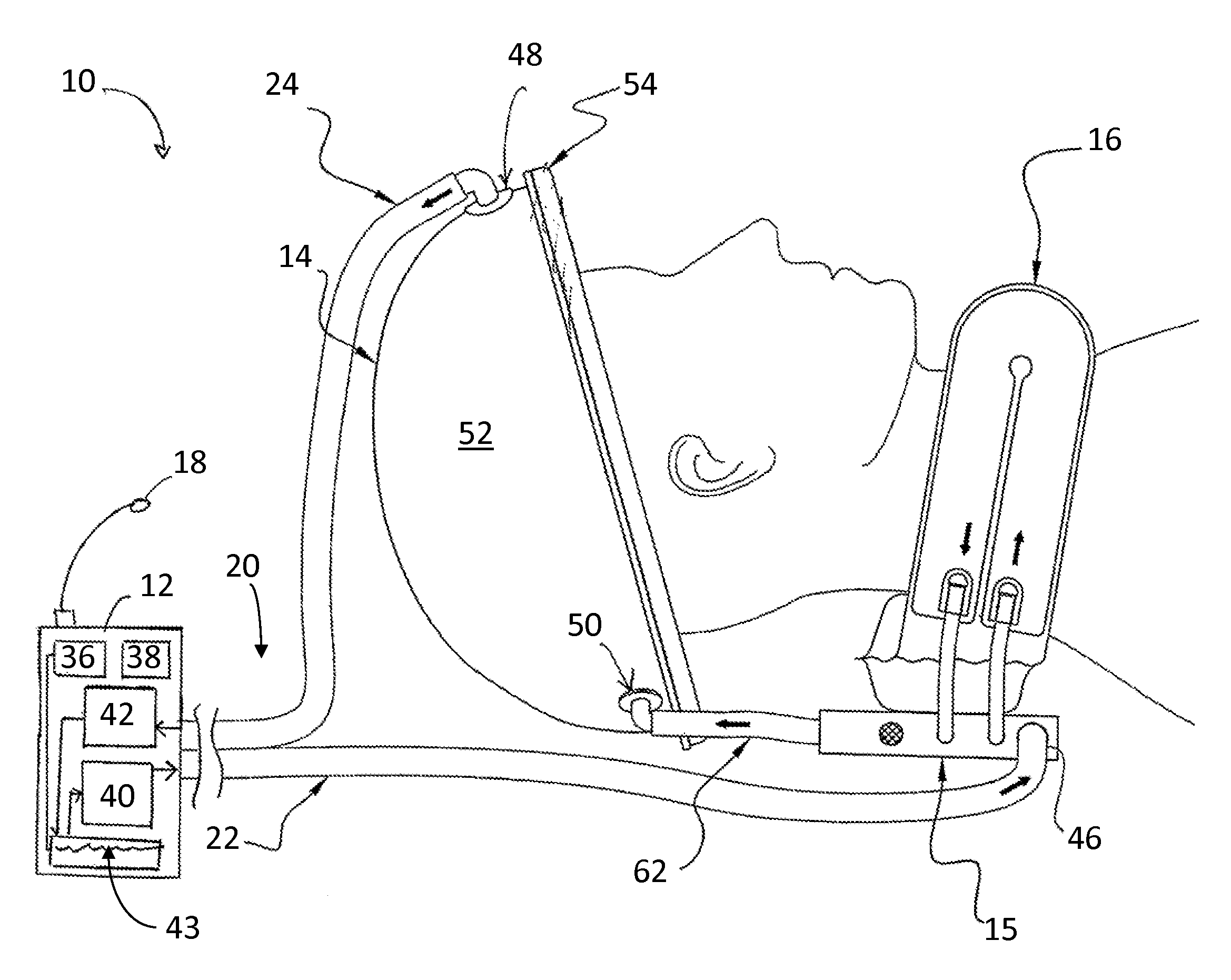

Portable high-temperature, high-pressure washing plant

InactiveUS6675437B1Reliable outputIncrease temperatureInternal combustion piston enginesRecuperative heat exchangersProcess engineeringThermal contact

A washing system for high temperature cleaning applications, such as carpet-cleaning, is disclosed that provides a consistent cleaning fluid temperature. The washing system utilizes multiple heat exchangers and multiple heat paths. The heating and power source is provided by a medium duty, diesel cycle engine. Multi-stage heating involves heat transfer from the engine's coolant to the cleaning fluid and heat transfer from the exhaust of the engine to the cleaning fluid via an intermediate medium. The system also includes a fluid clutch used to engage a power takeoff from the engine to operate the pump and blower of the washing plant. A failsafe source cutoff diverts the exhaust flow from thermal contact with an intermediate heat transfer oil.

Owner:BLUE LINE EQUIP

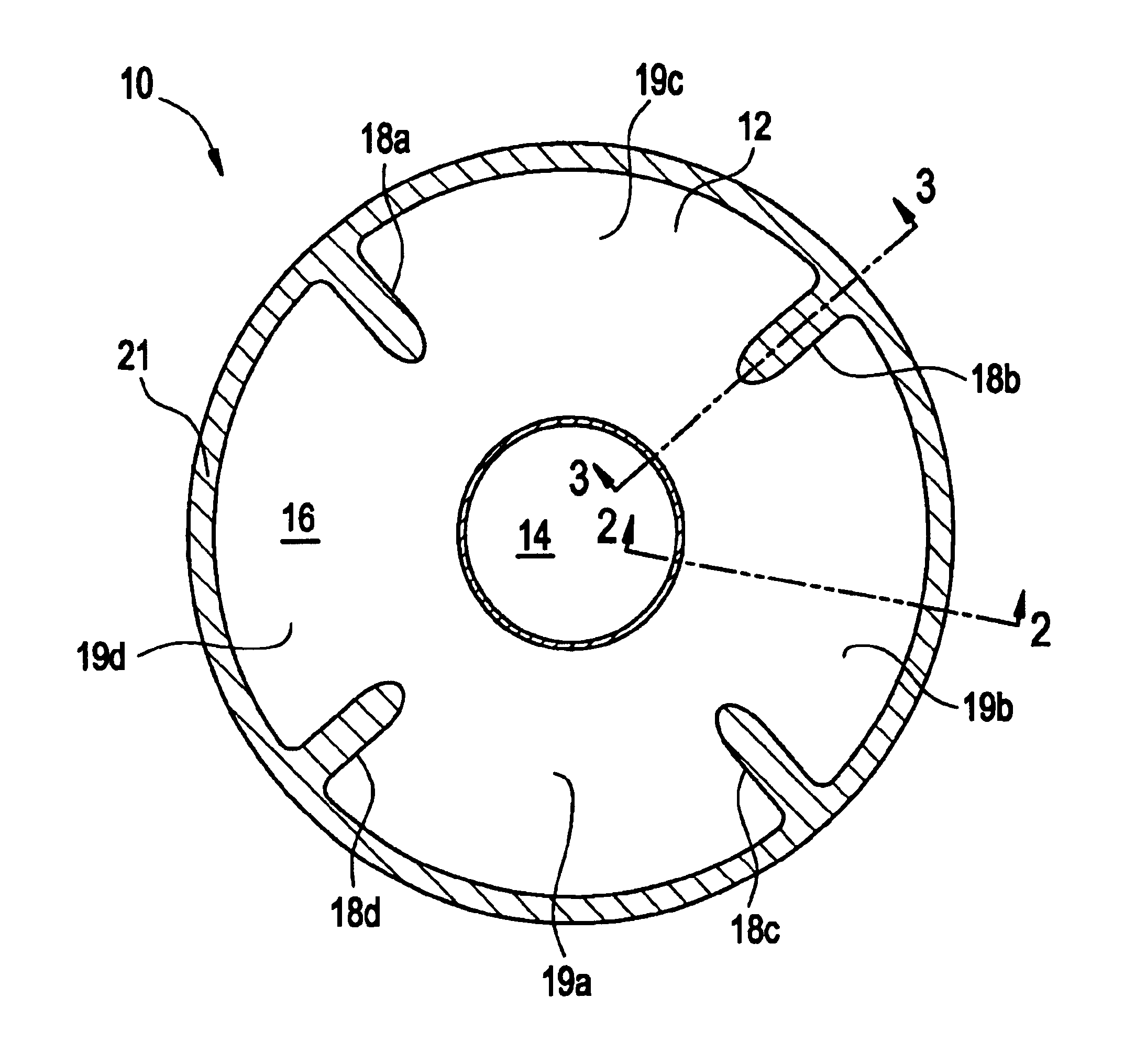

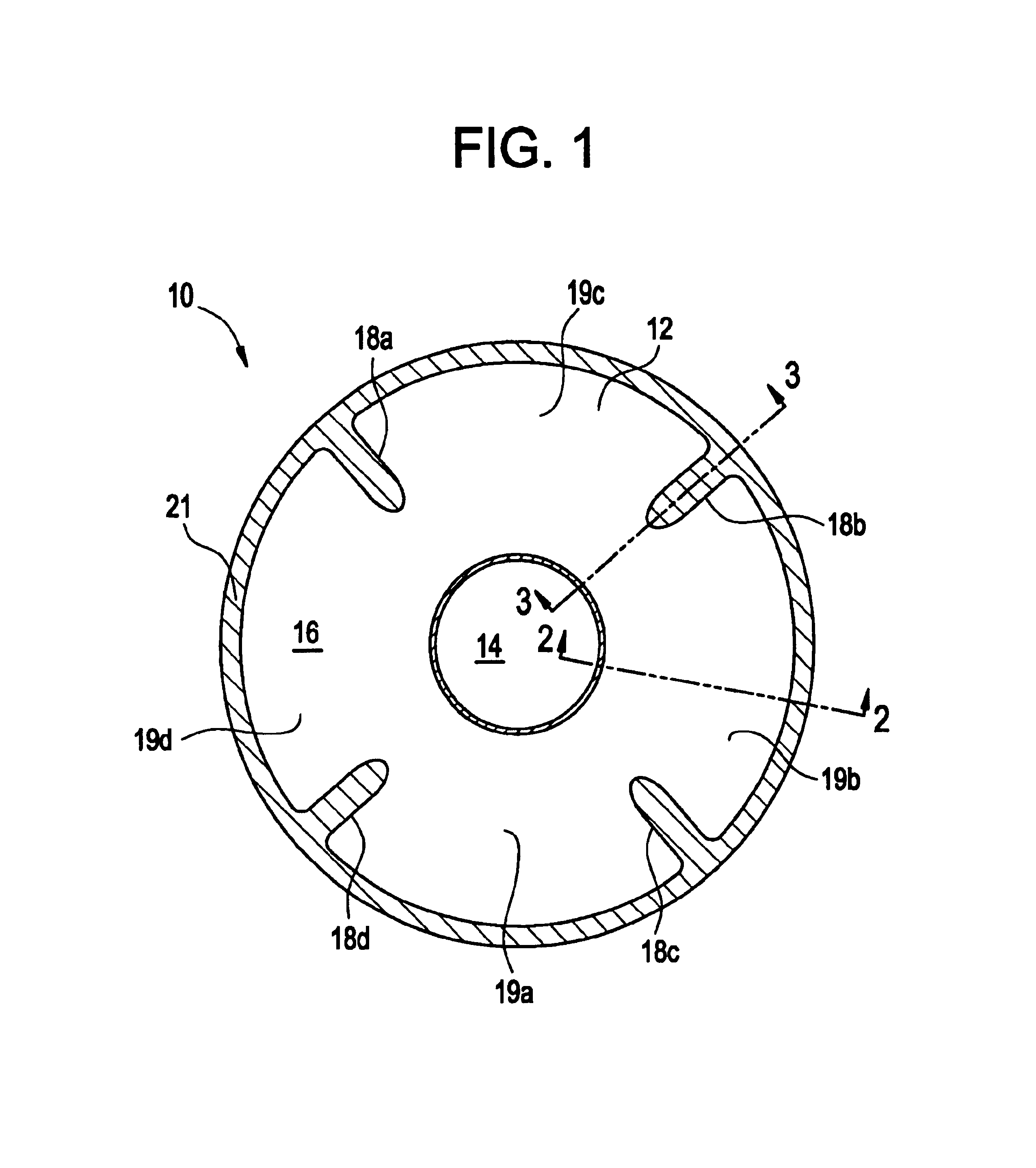

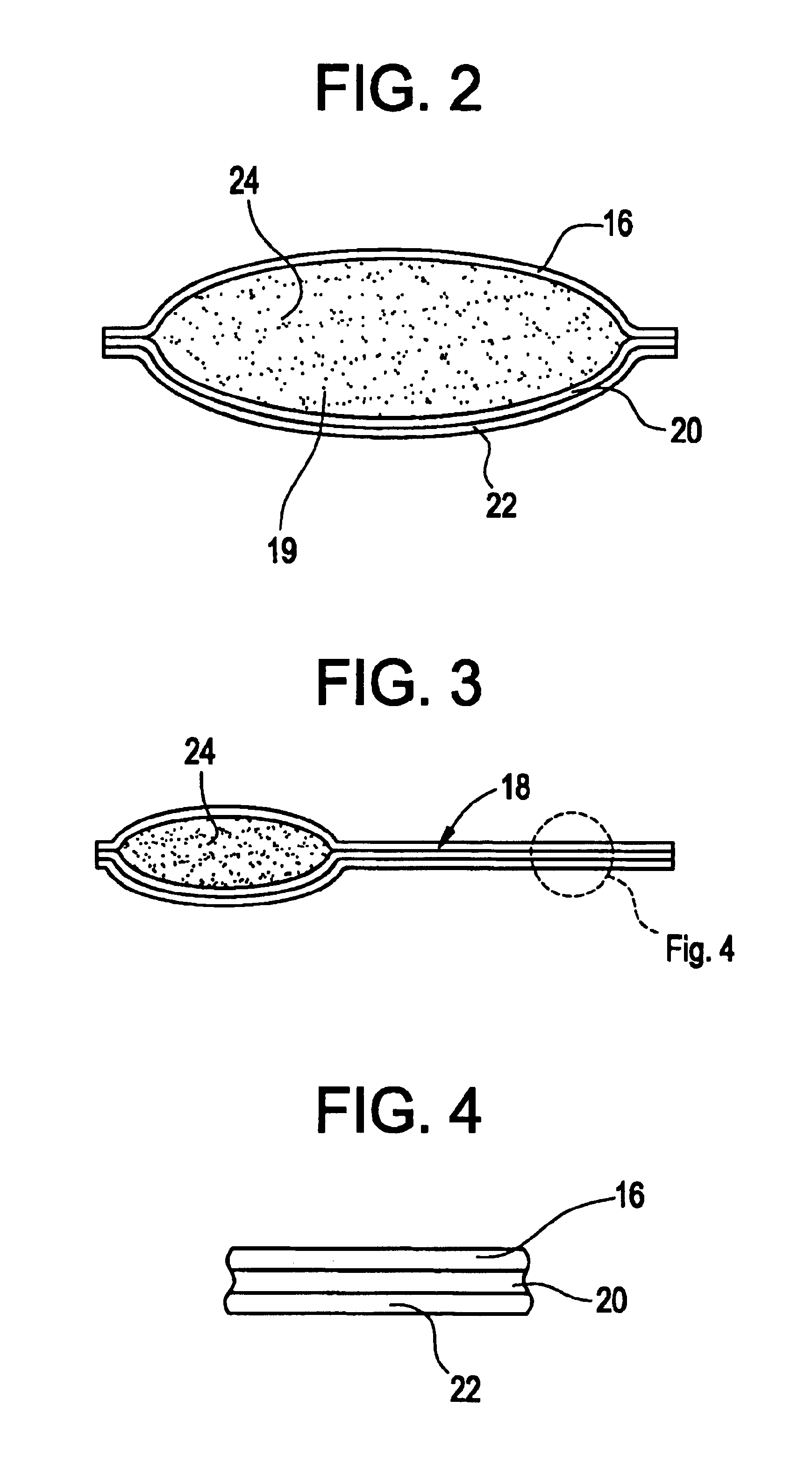

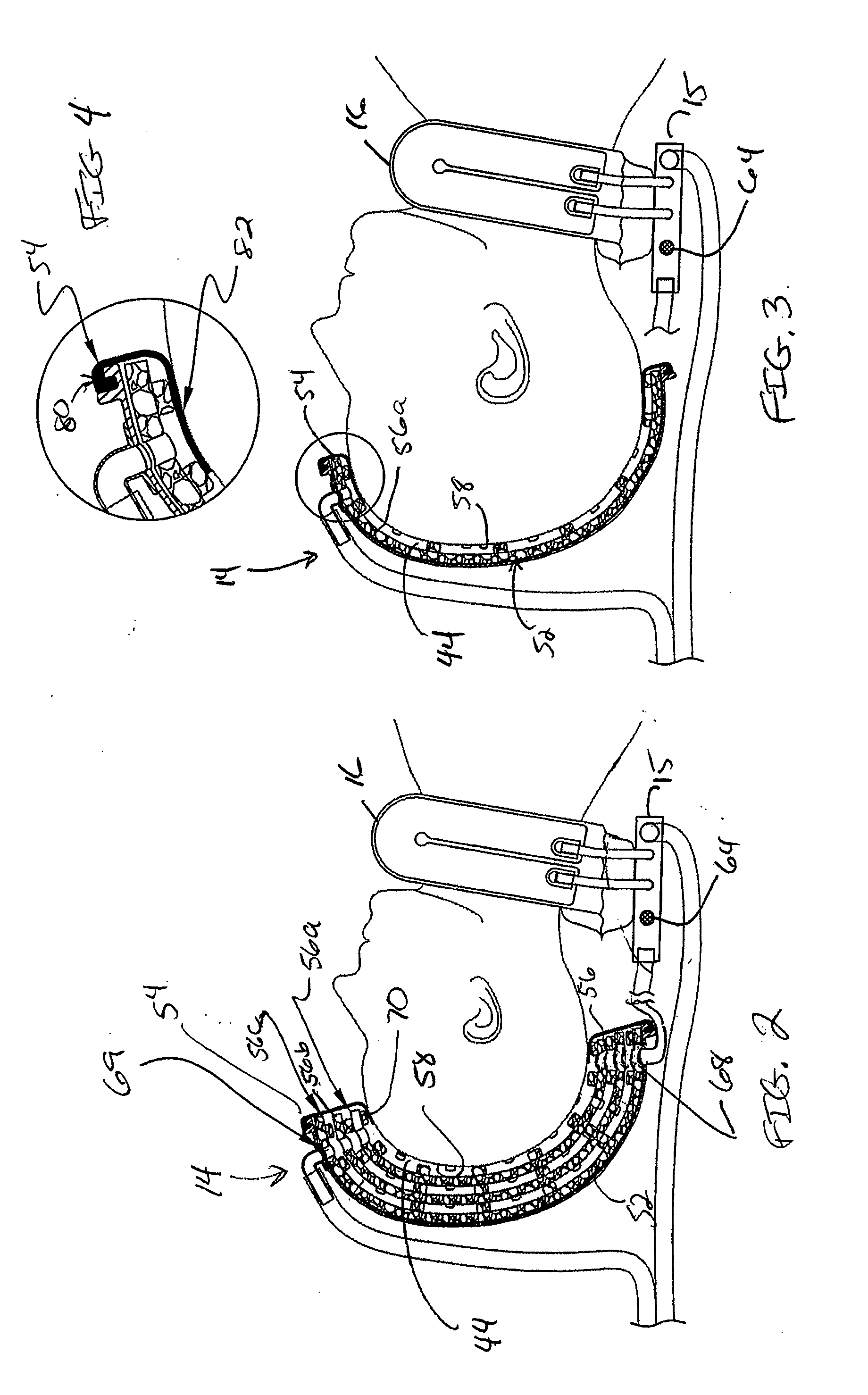

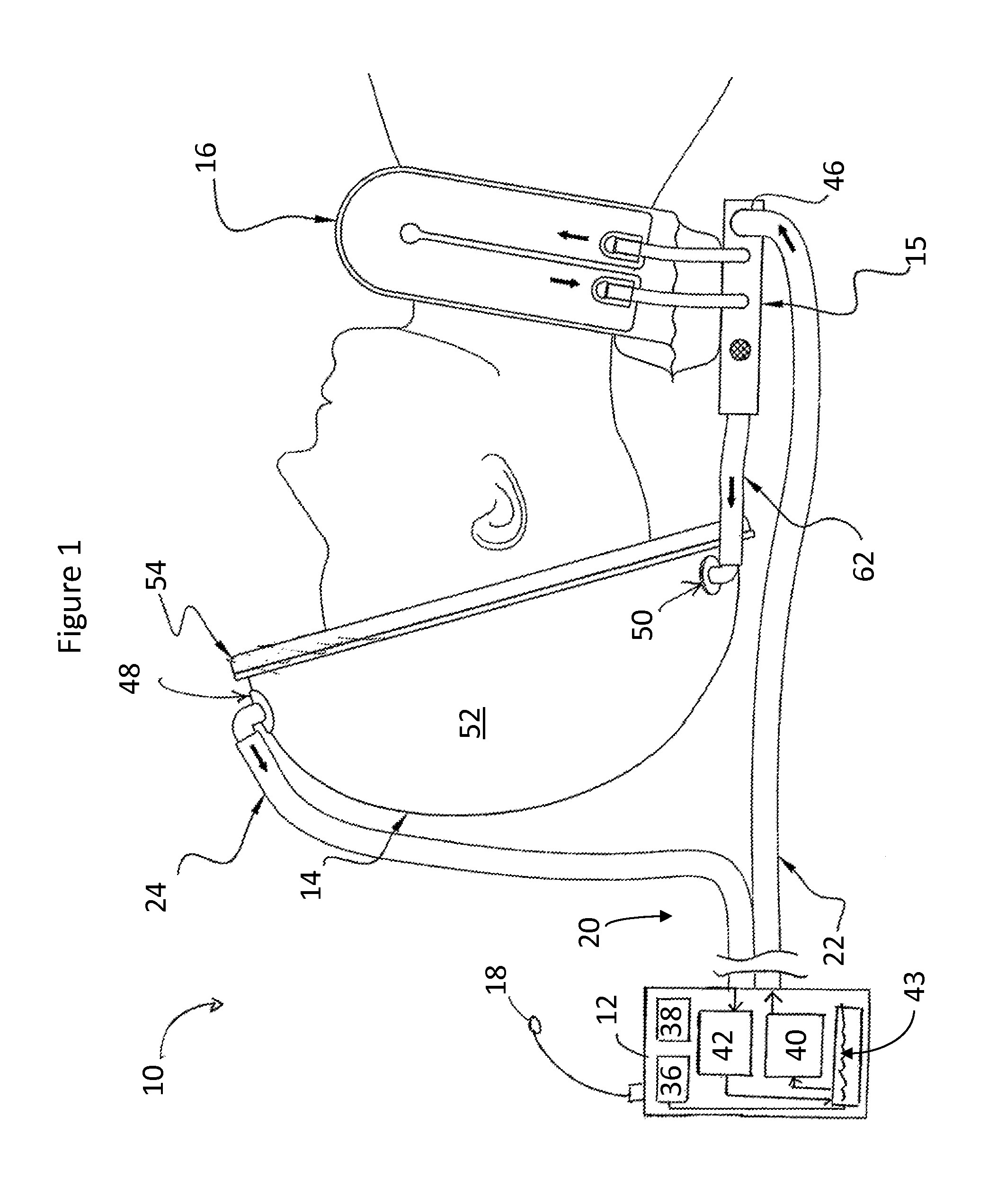

Thermal pack for the female breast

A thermal pack is provided for application to a female breast for therapeutic application of heat or cold to the breast, comprises a pliable, disk-shaped body having an aperture extending approximately through the center of the body, the body comprising a top wall having an outer surface and an inner surface, an opposed bottom wall having an outer surface and an inner surface, wherein the inner surface of the top wall and the inner surface of the bottom wall define at least one fluid tight cavity therebetween; and a thermal fluid, such as a gel, contained in the at least one cavity. The thermal pack may have a single cavity wherein the body further comprises two or more baffles which restrict the flow of fluid through to keep the thermal fluid dispersed substantially uniformly in each cavity region between the baffles when the thermal pack is secured against the breast.

Owner:THERAPEARL

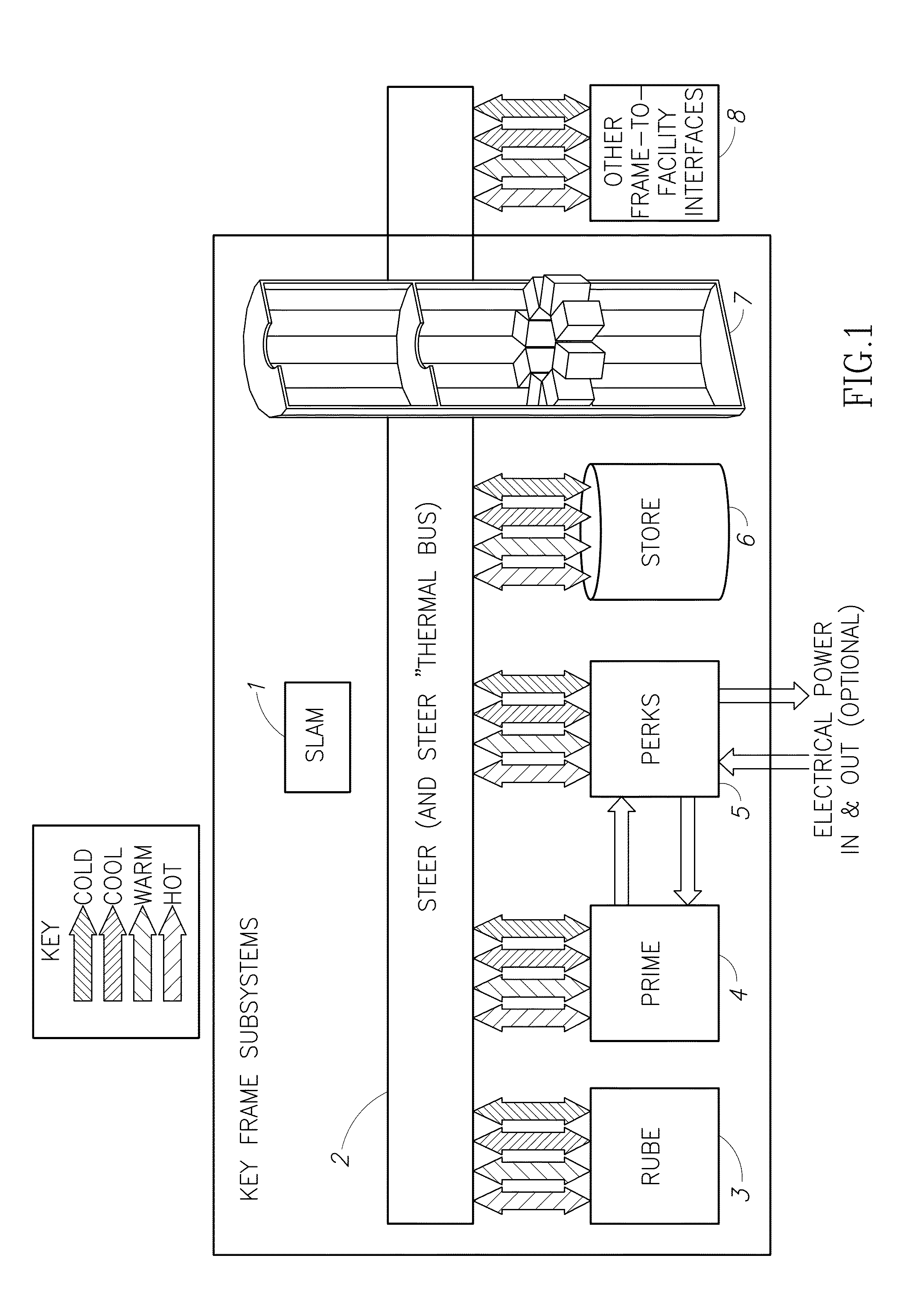

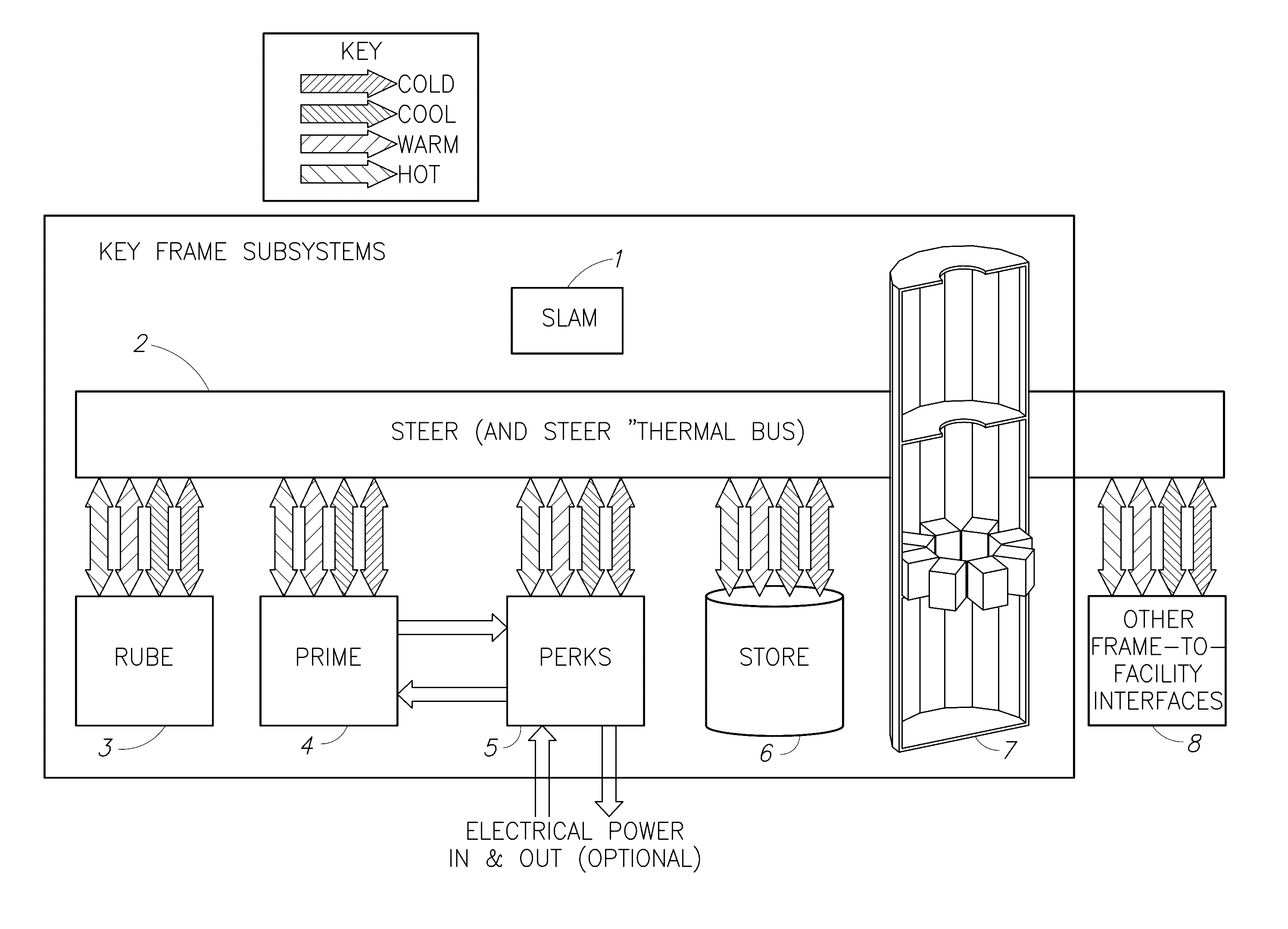

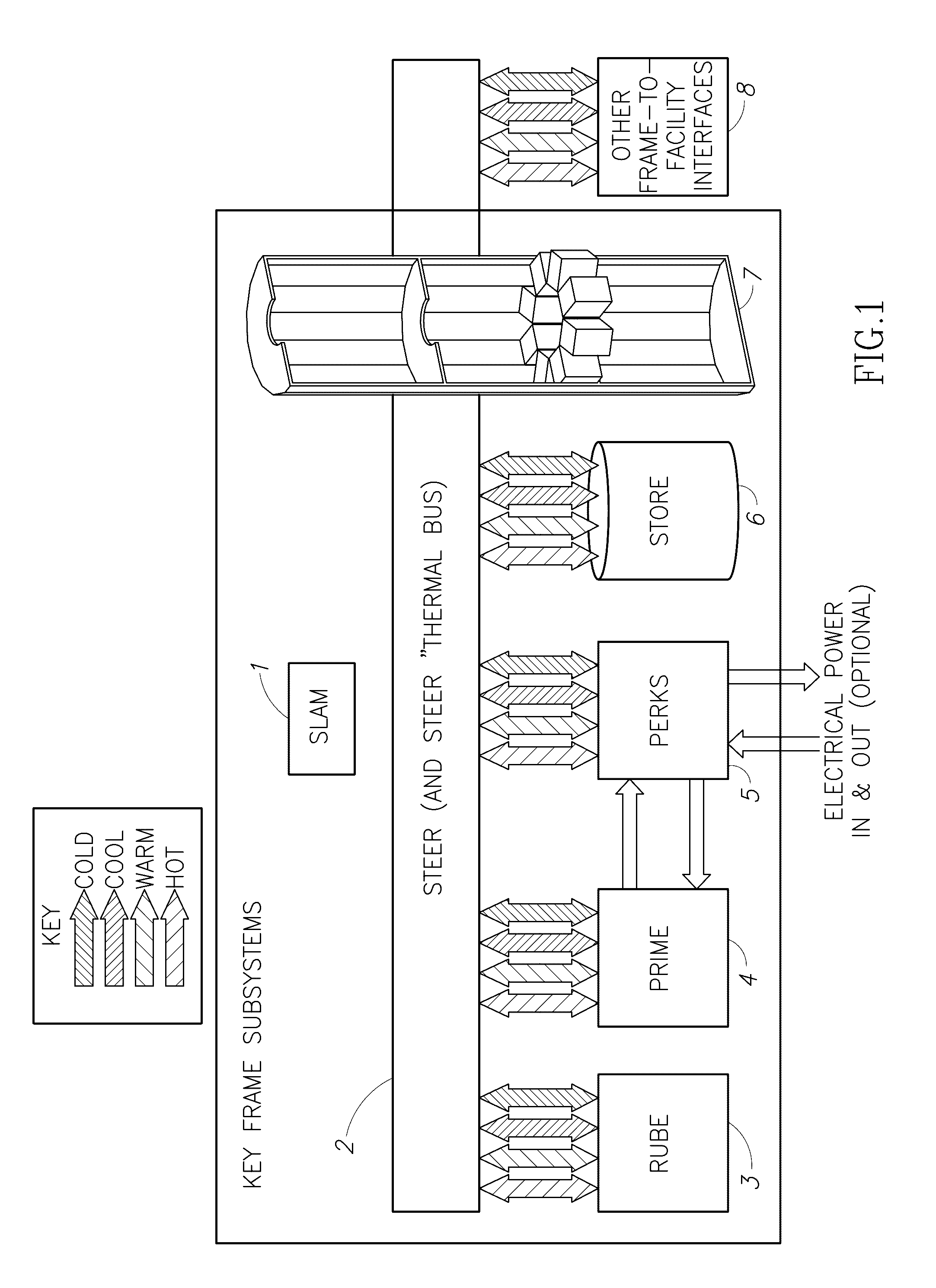

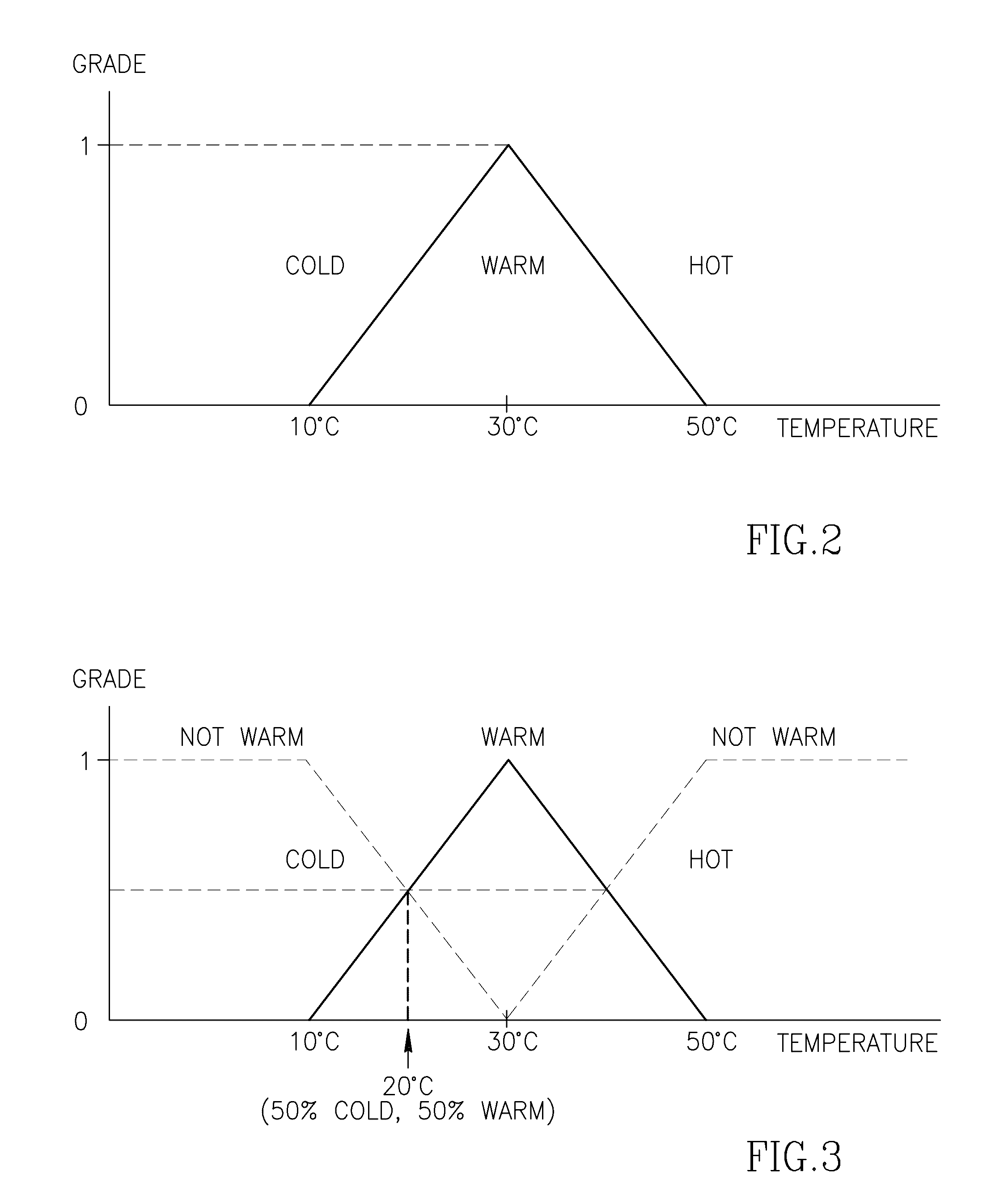

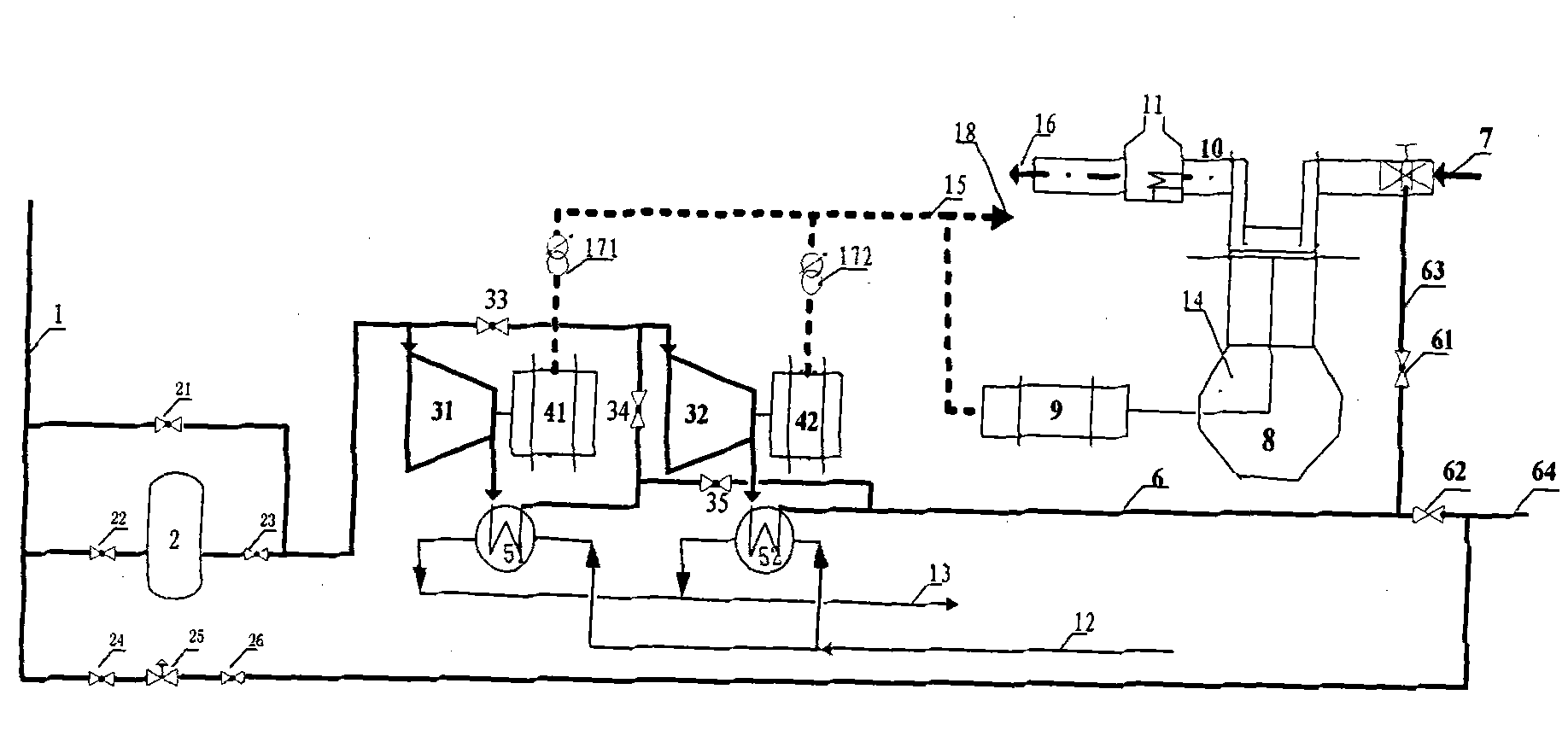

FRAME (Forced Recuperation, Aggregation and Movement of Exergy)

ActiveUS20140183957A1Convenience to workReduce internal pressureBatteries circuit arrangementsSteam generation heating methodsData centerPower usage

The present invention is directed to an apparatus for more efficient exergy and power usage in data centers. Denominated FRAME (standing for “Forced Recuperation, Aggregation & Movement of Exergy”), the apparatus is a power production and exergy management system (exergy being energy available to do useful work, as opposed to energy, which can be changed to a form, usually heat, rendering it unavailable). The apparatus integrates generally isothermal operation with phase-change and single-phase liquid cooling having variable operating temperatures and pressures, aided by a dynamically reconfigurable “thermal bus” comprising multi-fluid thermal fluid transport channels, virtual plumbing, and associated support devices. The apparatus minimizes exergy use through efficient operation and by recuperating and aggregating useful exergy that may then be dynamically repurposed to meet energy or power needs that would otherwise have to be met via external means.

Owner:SCRUTINY

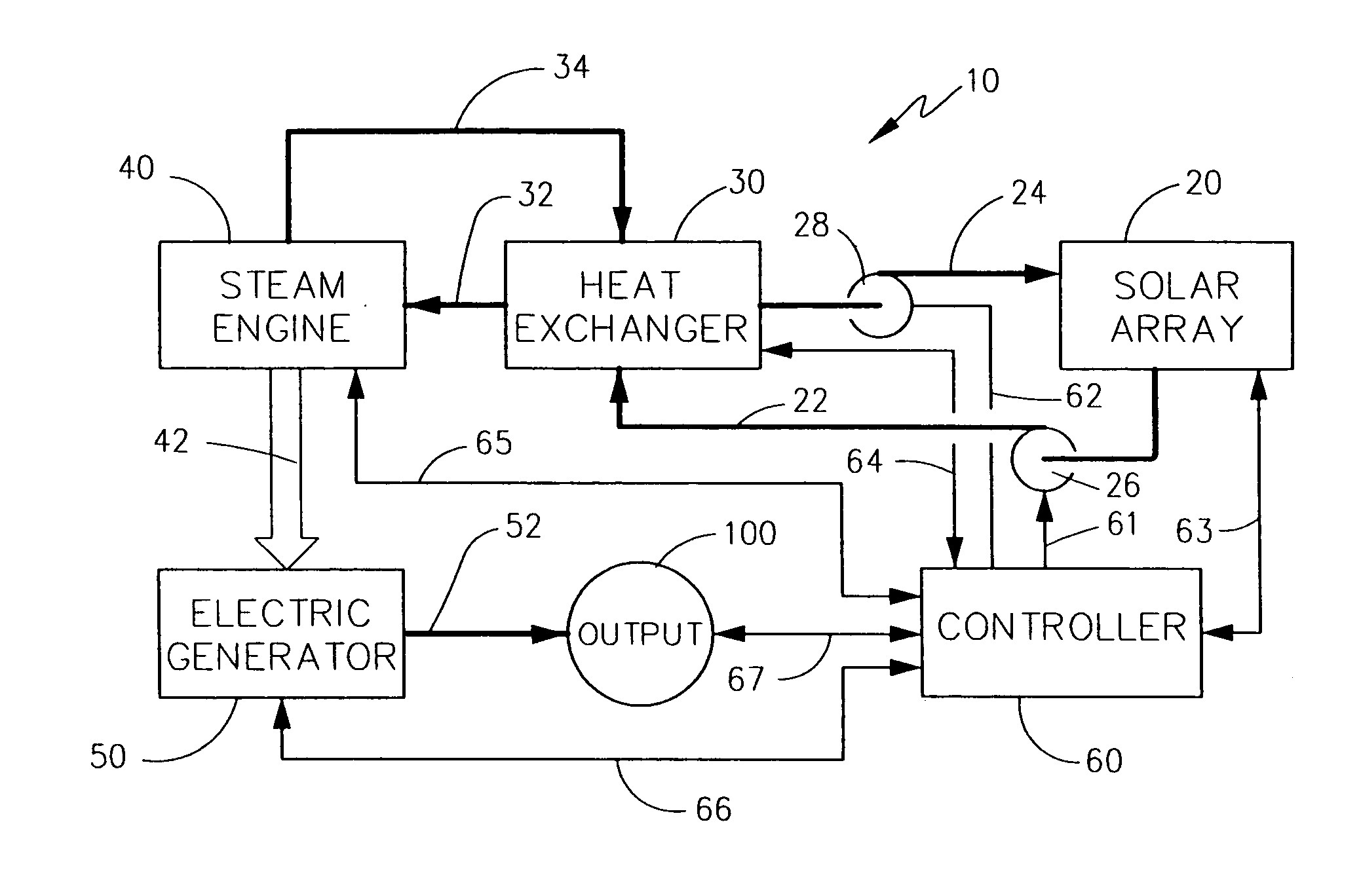

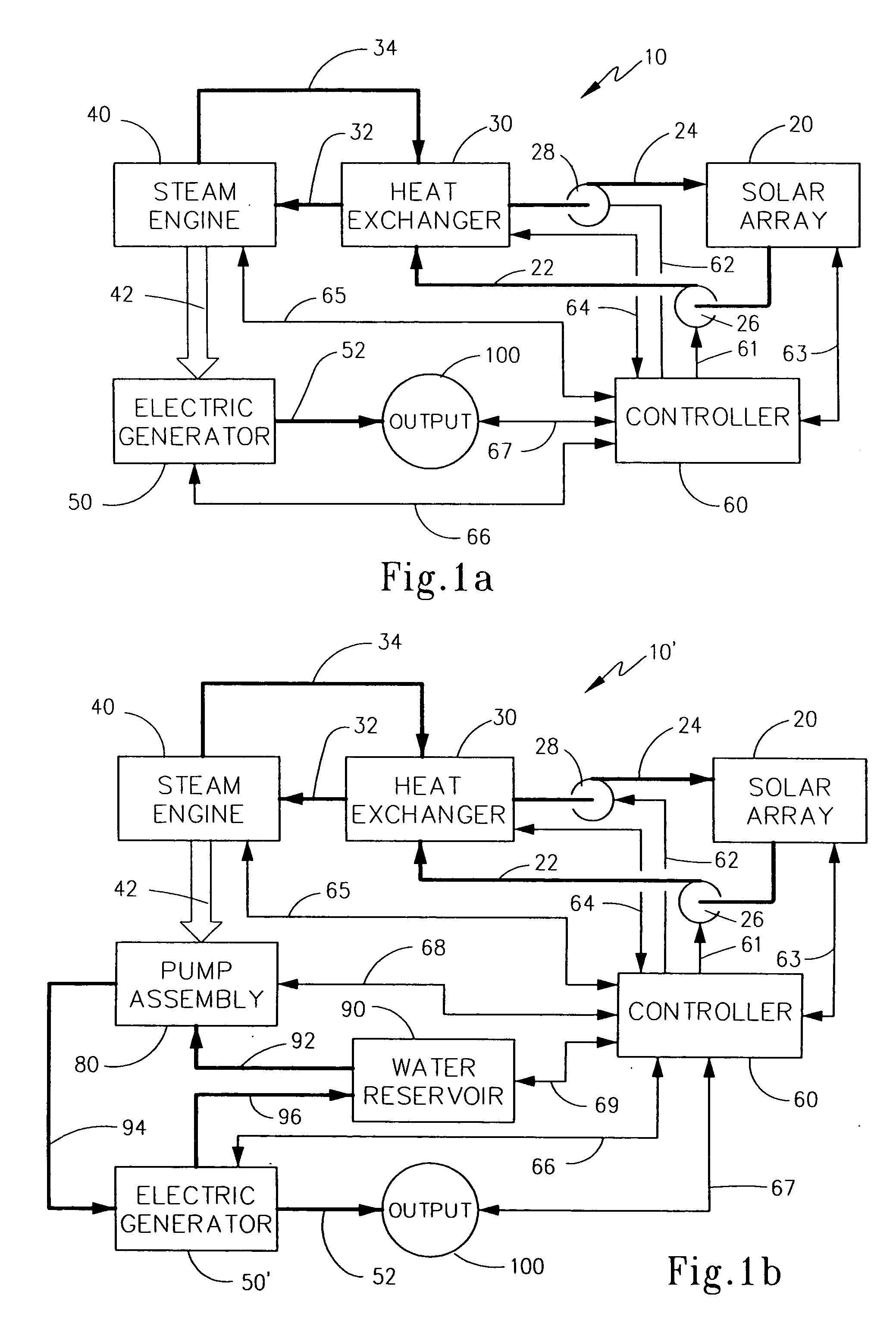

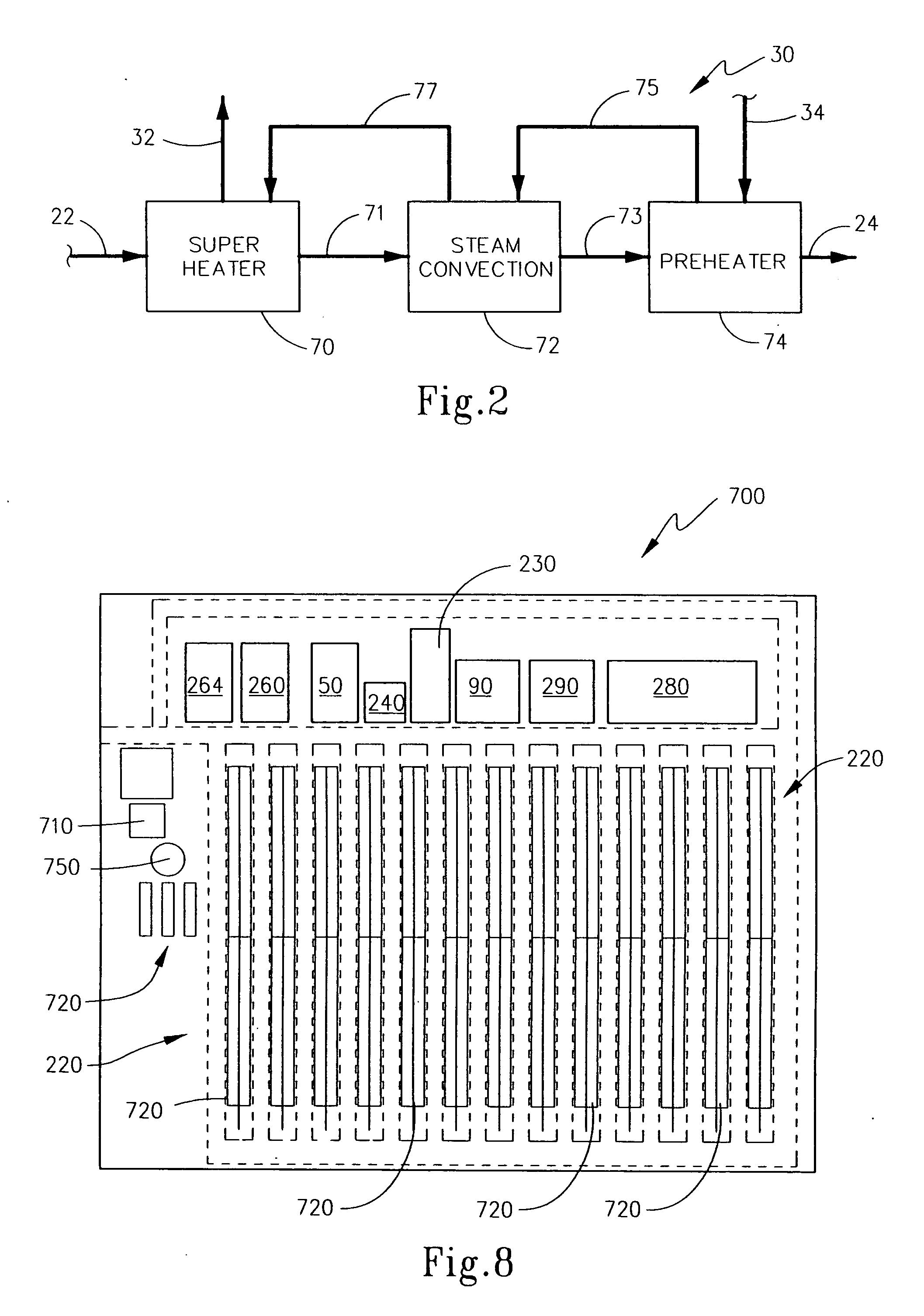

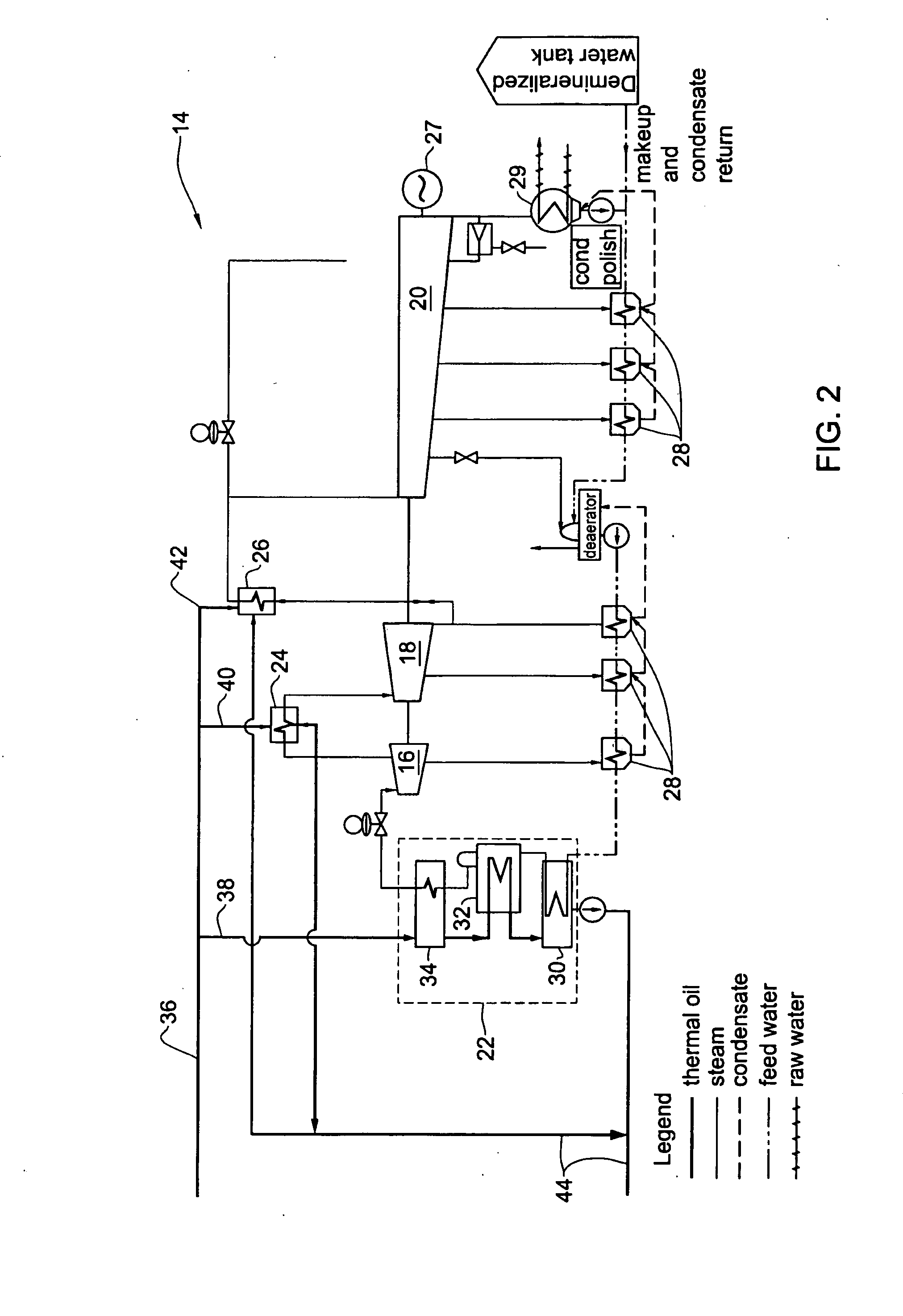

Electric generation facility and method employing solar technology

An electric generation station employs a solar array to heat a thermal transfer fluid that is supplied to a heat exchanger to produce steam. The heated steam drives a steam engine that operates either an electric generator to produce electricity or a pump assembly. The pump assembly can pump water to an elevated location for use during peak times by flowing water downwardly past an electric generator. The electric generators can be pelton turbines. One or more thermal fluid storage facilities can be used to store heated fluid, and heat may also be stored in a heat retaining material. Additional optional features and combinations of optional assemblies are disclosed. A method of generating electricity with these systems is also described.

Owner:POWERSTREAMS

Adjustable thermal cap

A thermal cap that can fit a variety of head sizes is disclosed. The cap can include a shell having a fluid inlet and outlet, a sealing mechanism and removable sizing layers disposed within the shell. Depending upon the size of a patient's head, sizing layers can either be added to or removed from the outer shell to maintain a fluid circulation space between the head and the rigid shell and allow substantially even distribution of a thermal fluid about the scalp of the patient during operation. The shell is preferably rigid and an elastomeric member can seal the periphery of the cap to the patient's head to prevent leakage. Other types and aspects of thermal cap systems are also disclosed.

Owner:MEDCOOL

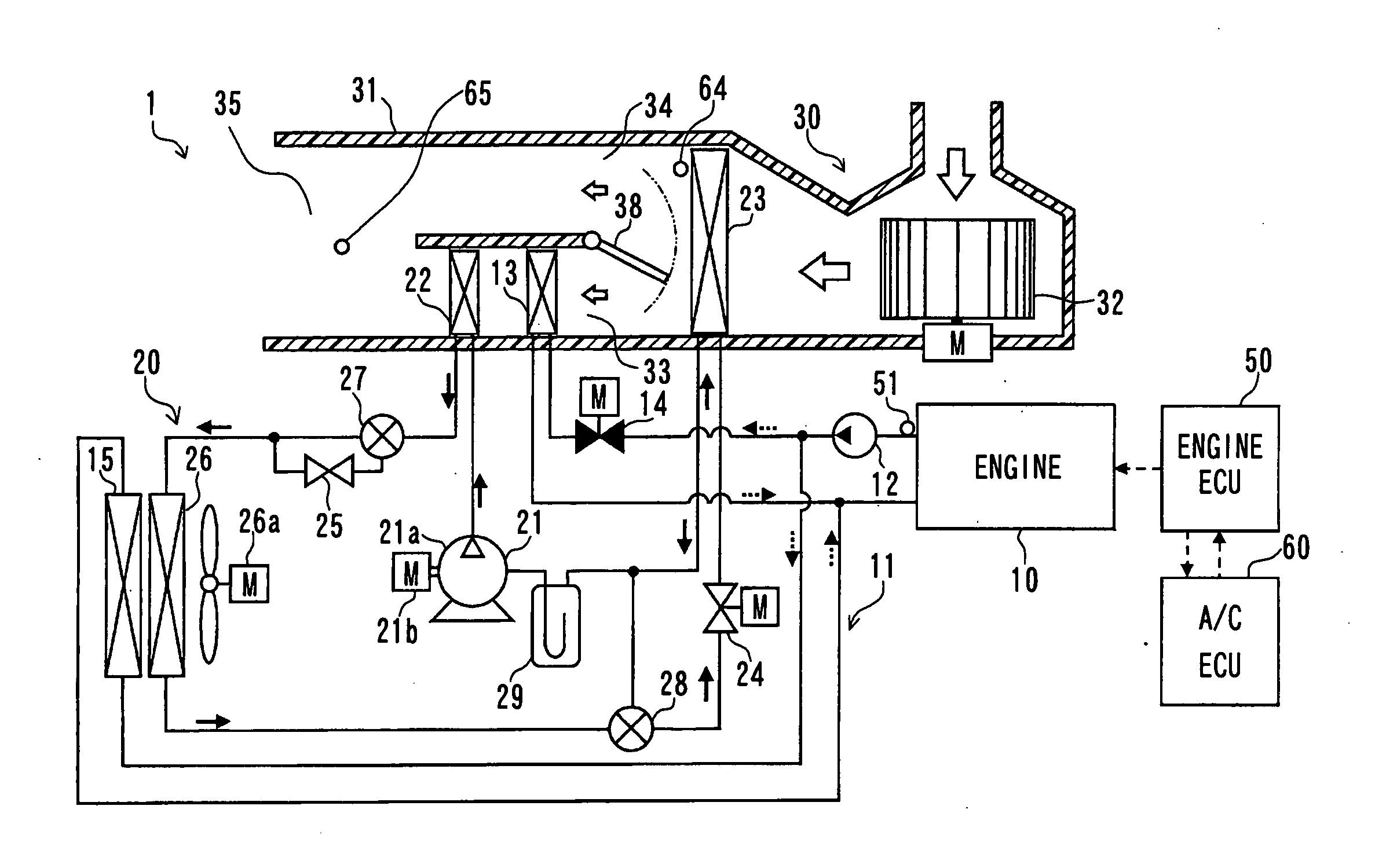

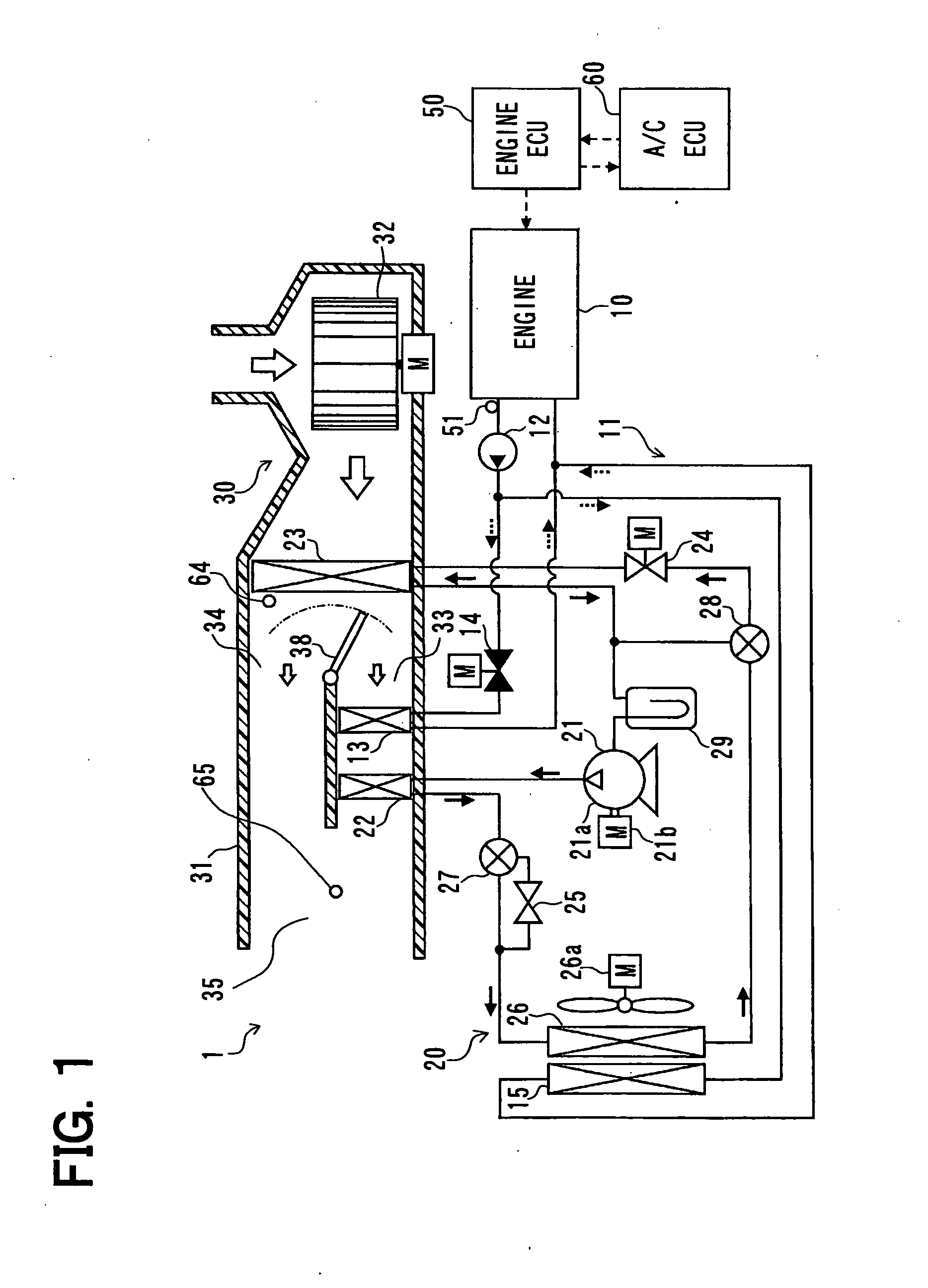

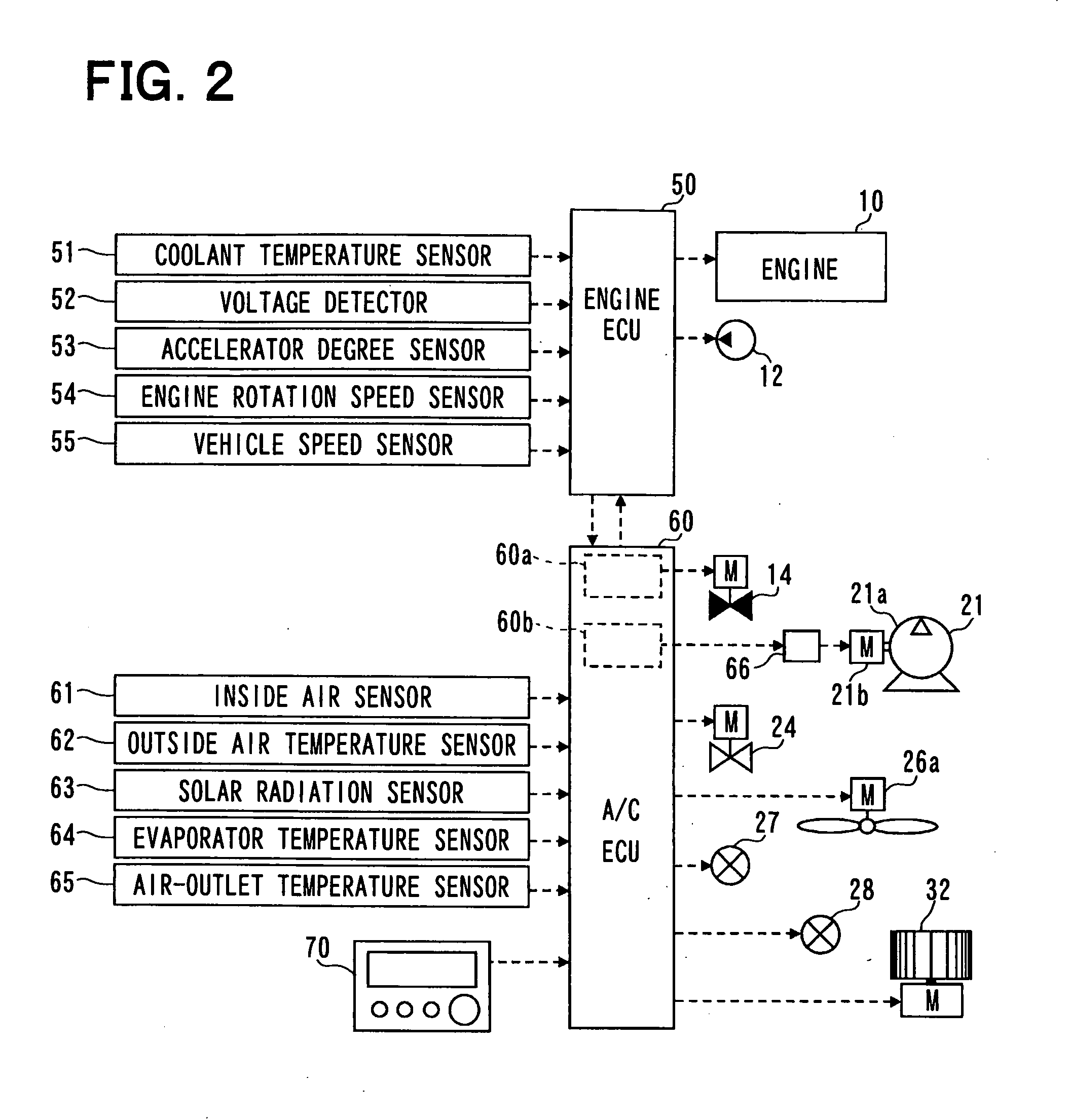

Air conditioner for vehicle

InactiveUS20110048671A1Deterioration can be suppressedIncrease temperatureAir-treating devicesRailway heating/coolingEngineeringThermal fluids

In an air conditioner for a vehicle with an equipment controlled in accordance with a traveling state of the vehicle, a first heater is disposed to heat air to be blown into a vehicle compartment by using a coolant of the equipment as a heat source, and a second heater is adapted as an auxiliary heater to further heat the air heated by the first heater. A heating capacity of the first heater is controlled such that a temperature of the equipment is approached to a predetermined temperature when the thermal fluid after passing through the first heater returns the equipment, and a heating capacity of the second heater is controlled such that a temperature of air to be blown into the vehicle compartment becomes a desired temperature.

Owner:DENSO CORP

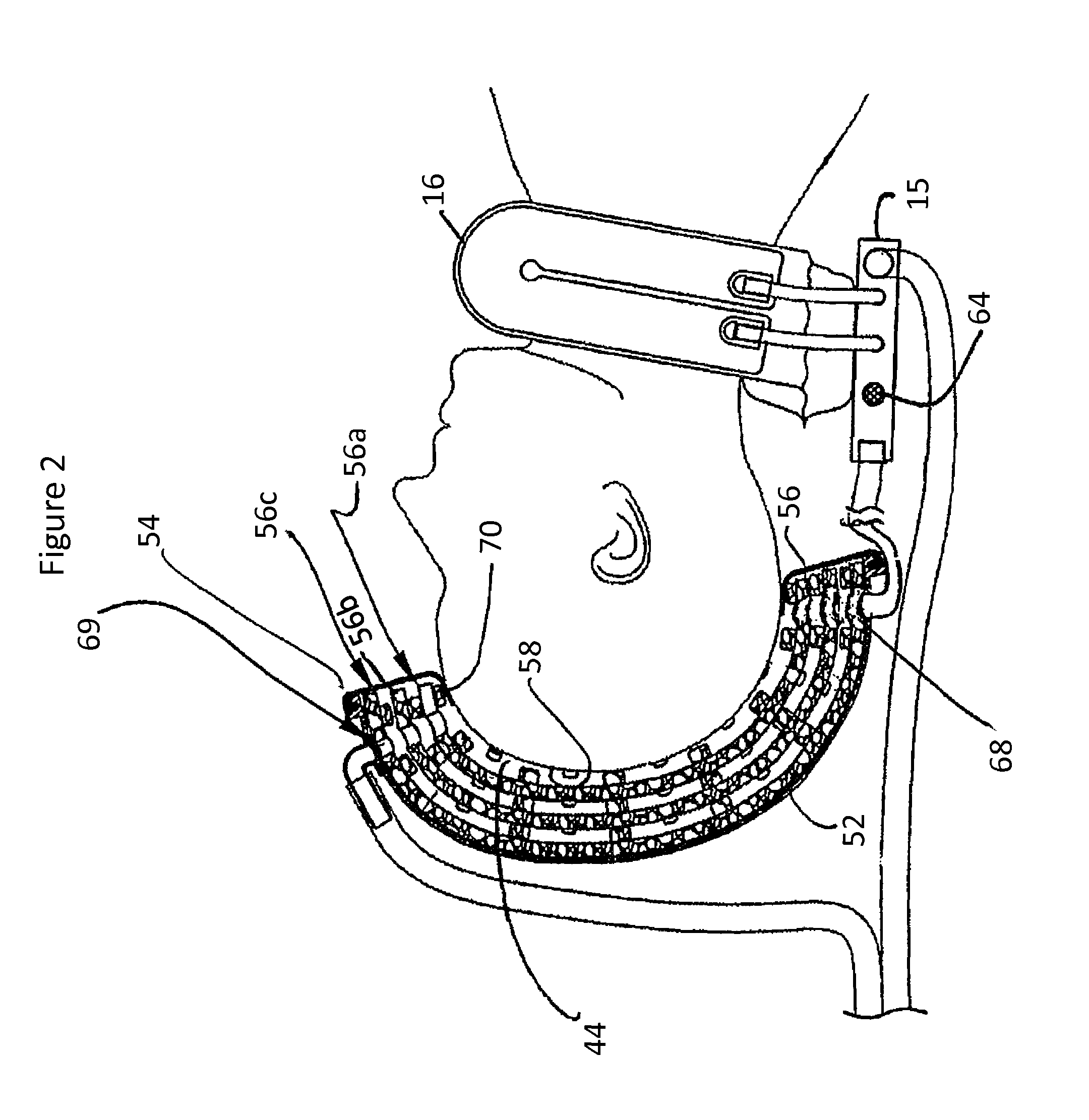

Solar energy comprehensive utilization apparatus

ActiveCN102487255ASolve the cooling problemShort lifeOther heat production devicesPV power plantsThermal energyEngineering

The invention discloses a solar energy comprehensive utilization apparatus that comprises a photovoltaic generating assembly, a temperature difference generating assembly, and a cooling device. The photovoltaic generating assembly receives solar radiation and converts solar energy into electric energy. The temperature difference generating assembly, which is arranged at a backlight side of the photovoltaic generating assembly, is used for converting heat energy that is from the photovoltaic generating assembly into electric energy; besides, the temperature difference assembly includes a hot end and a cold end that is at an opposite side of the hot end, wherein the hot end is contacted with the backlight side of the photovoltaic generating assembly. The cooling device, which contains fluid medium, is arranged at one side of the temperature difference generating assembly and is contacted with the cold end of the temperature difference generating assembly; moreover, the cooling device enables the cold end of the temperature difference generating assembly to be cooled by circulating the fluid medium as well as thermal fluid medium is generated for utilization. According to the invention, a modularized solar energy generating and heat recovery and utilization apparatus is established, thereby realizing high efficient solar energy generating efficiency and electric heating comprehensive utilization efficiency.

Owner:ENN SCI & TECH DEV

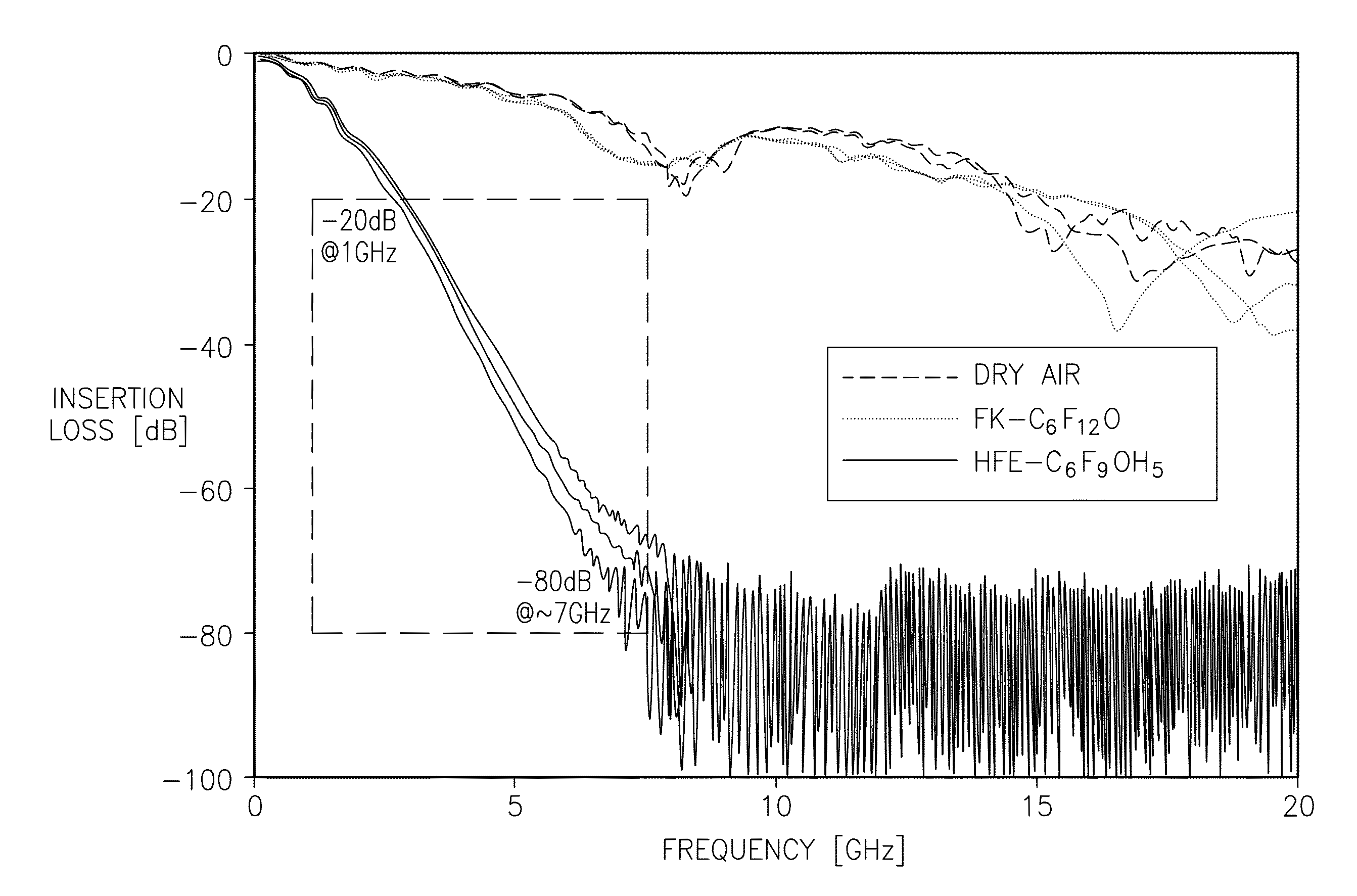

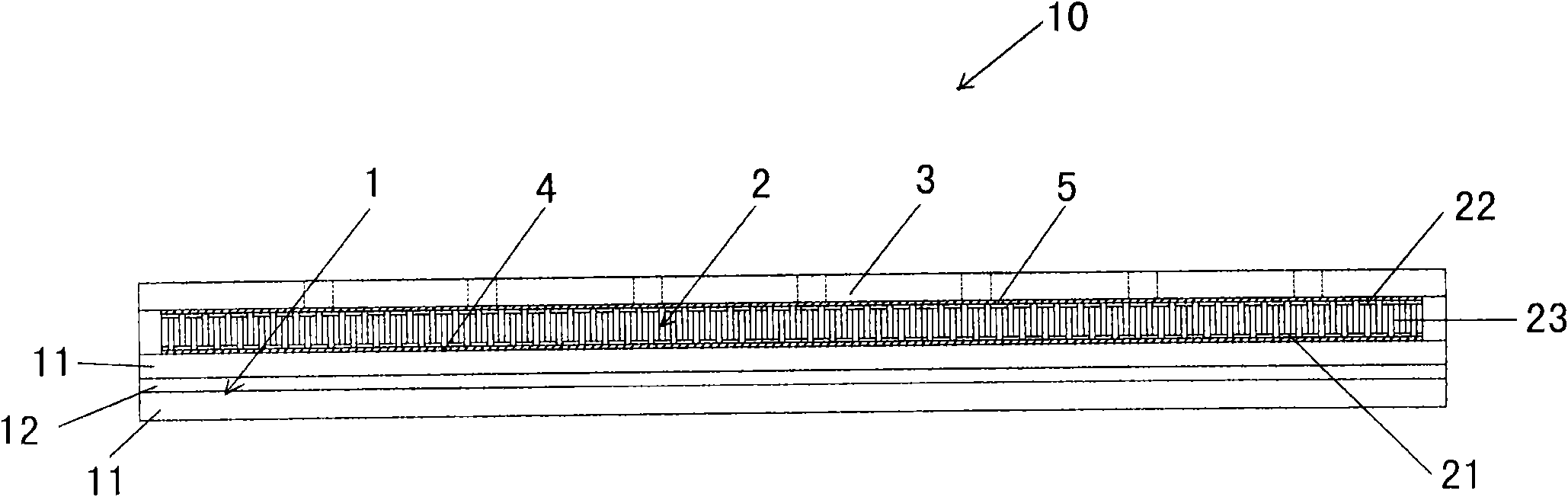

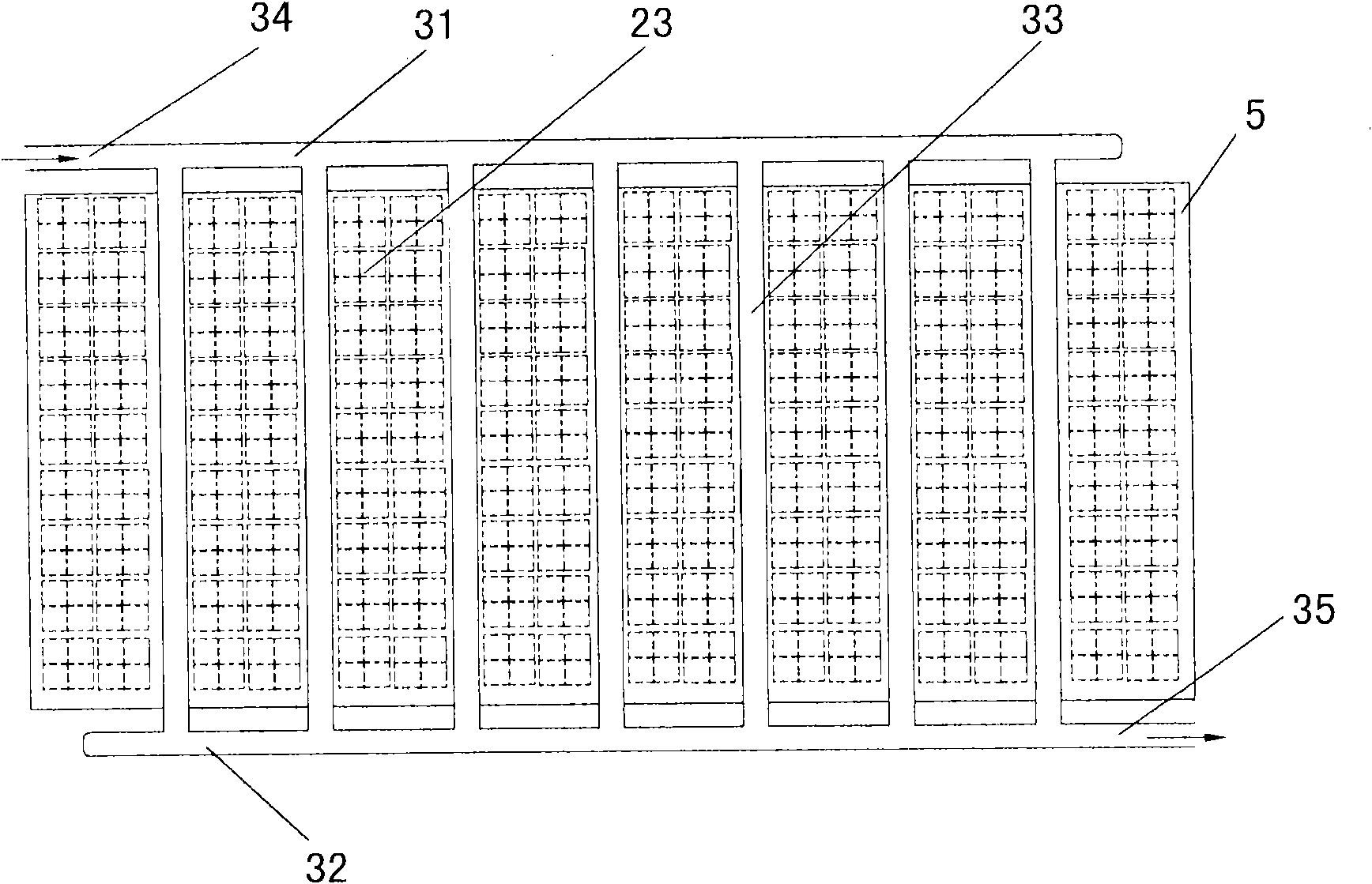

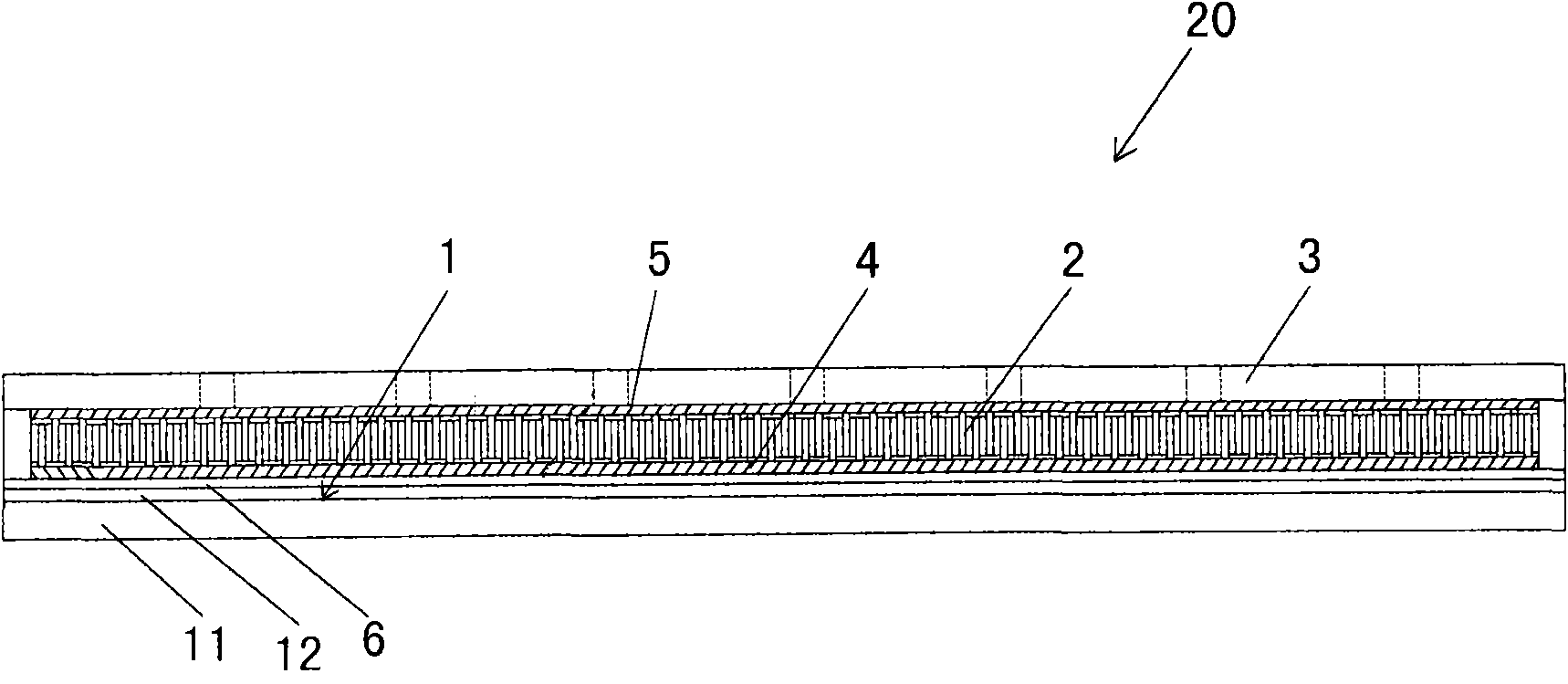

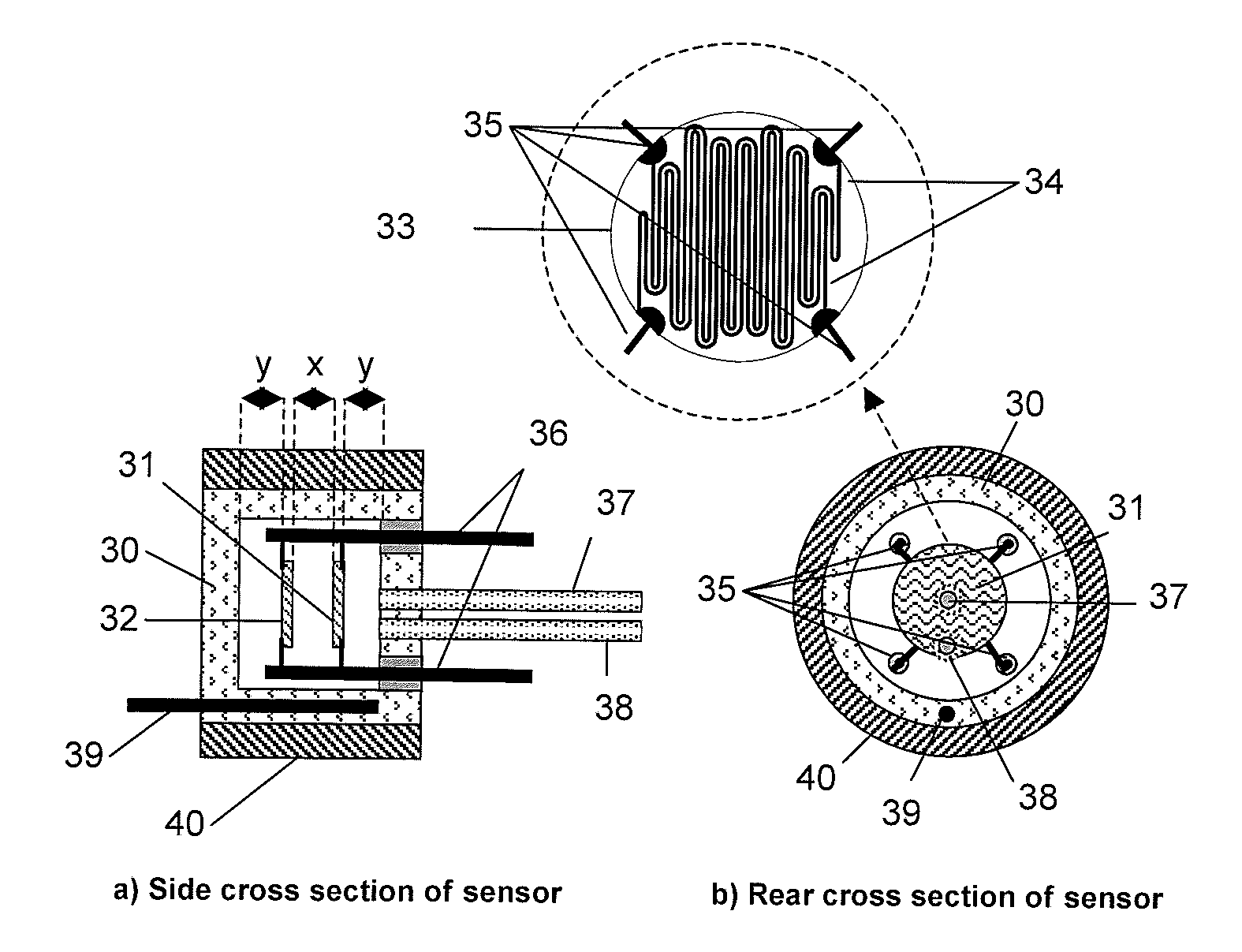

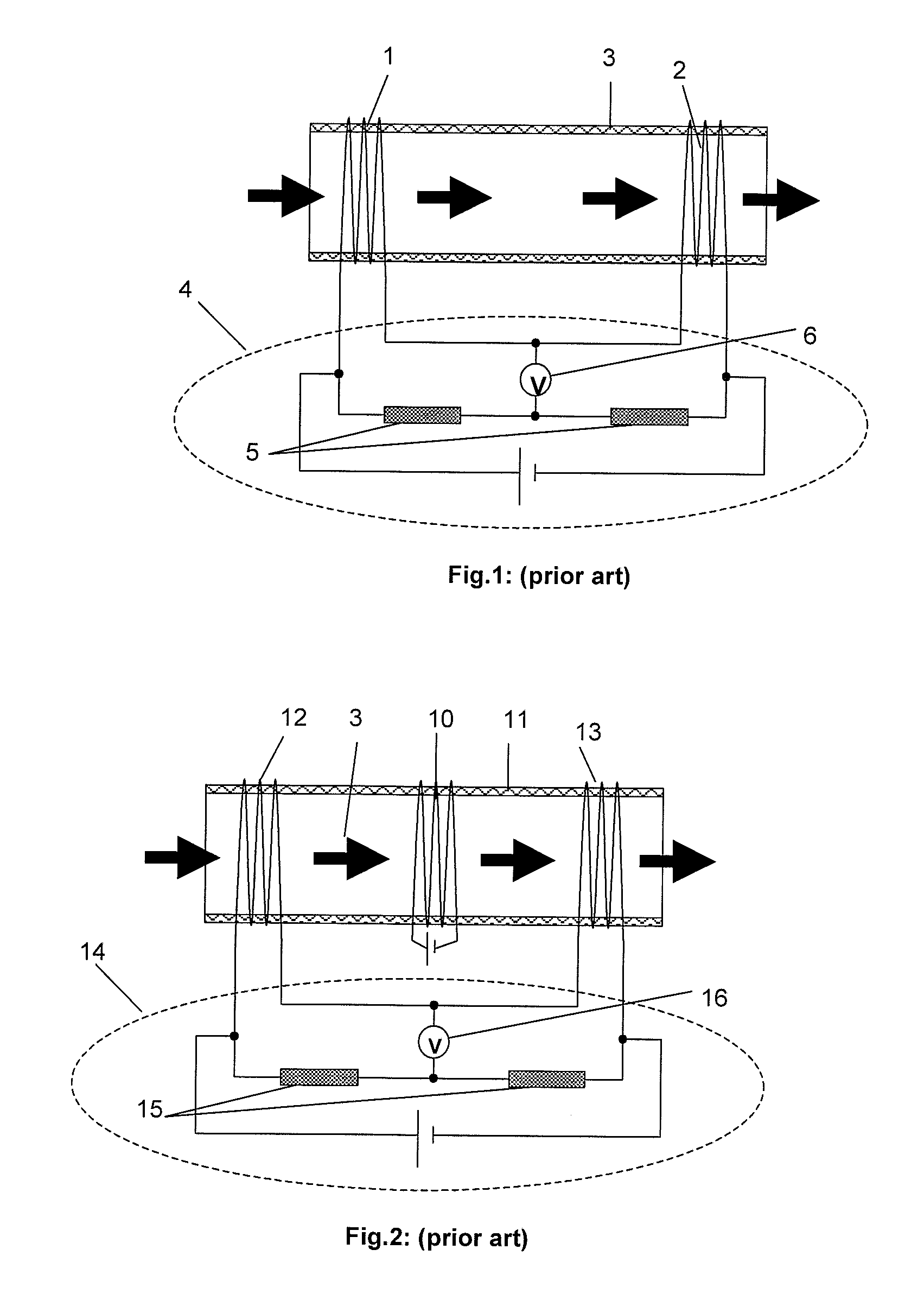

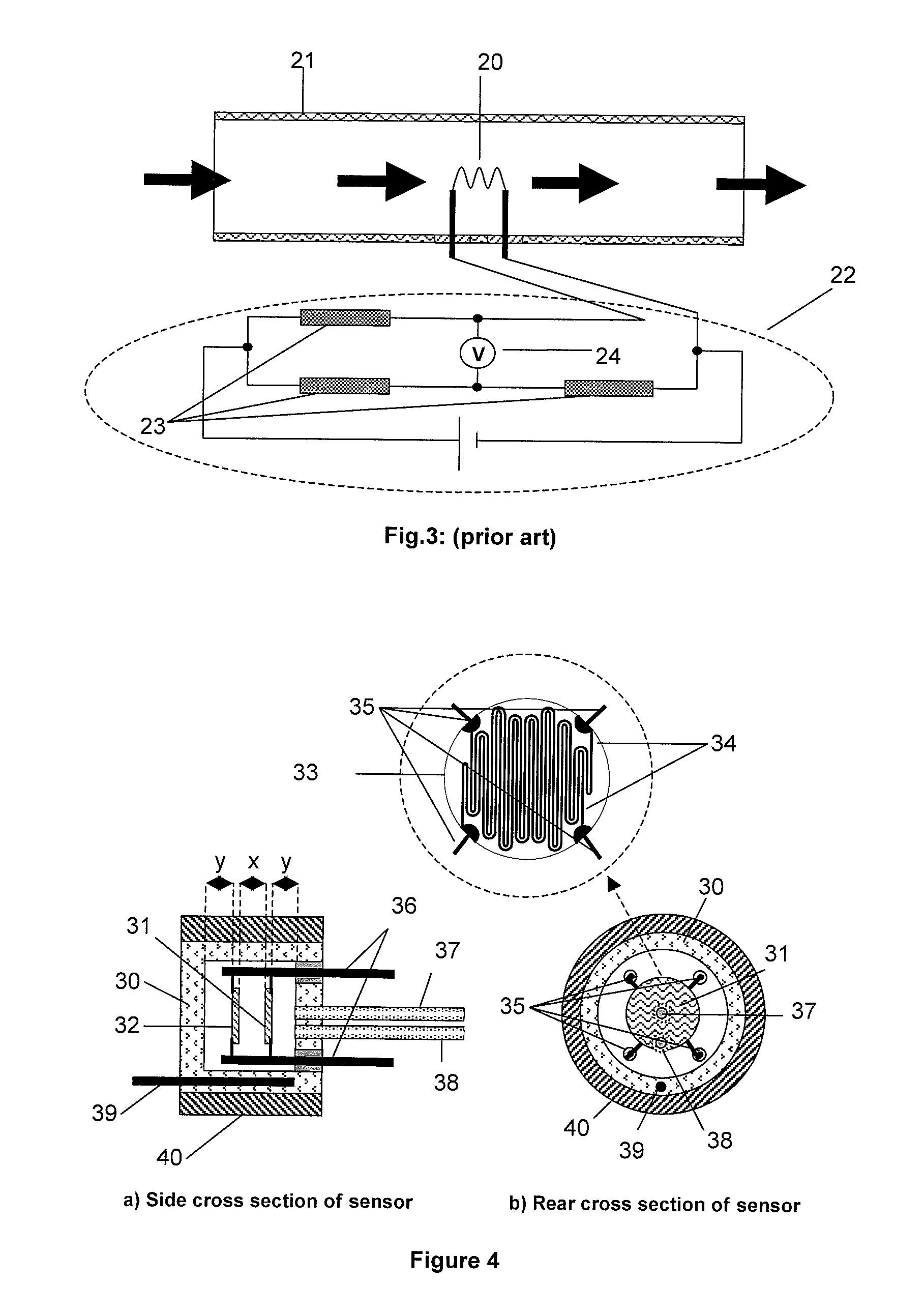

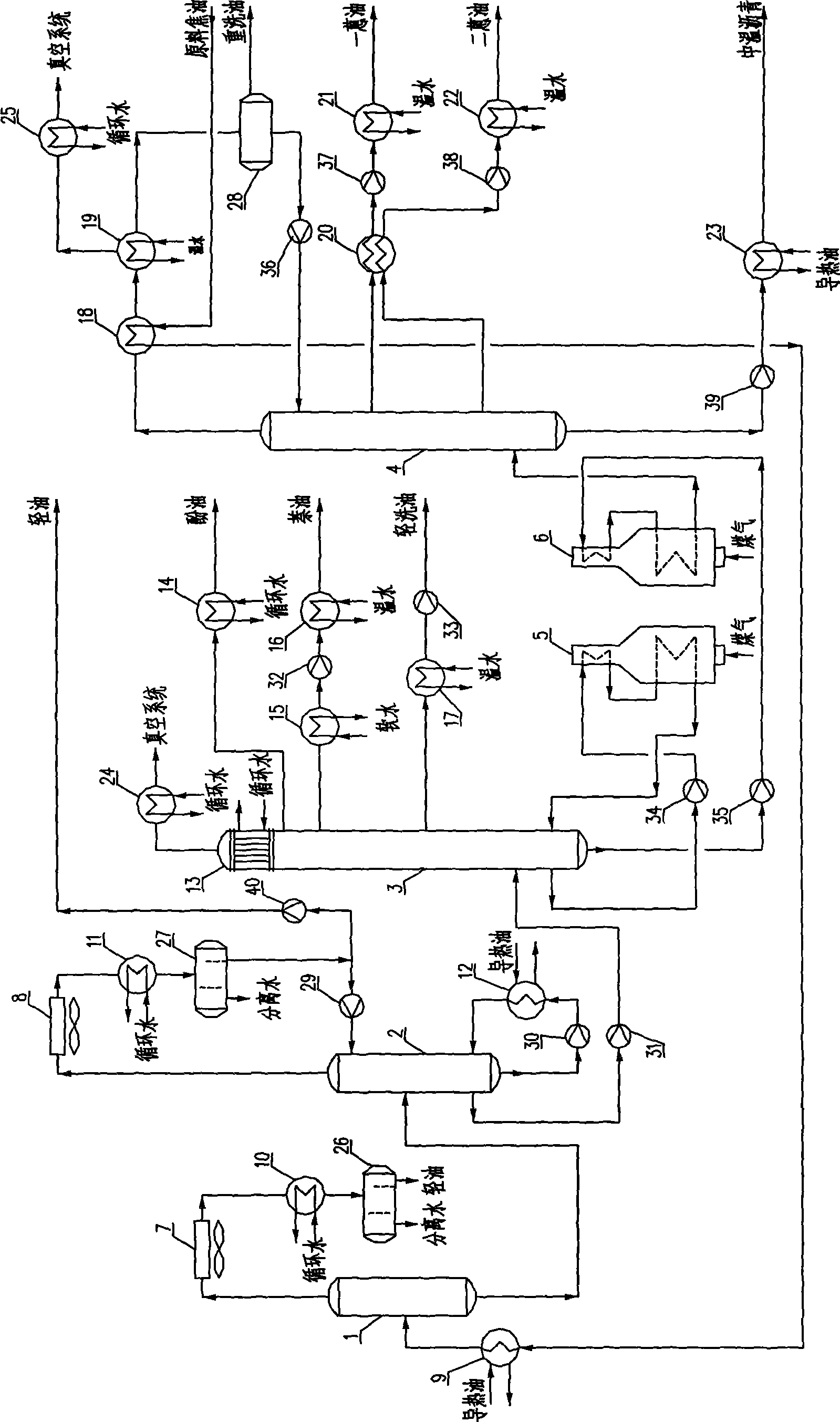

Thermal fluid flow apparatus

ActiveUS20110296910A1Large specific surface areaImproved noise suppressionVolume/mass flow by thermal effectsElectricityEngineering

Provided is a compact apparatus for measuring the flow rate of a fluid. The apparatus includes a heated measure element and a heated reference element which are in substantially the same thermal environment within a measure cell, except that the measure element is situated in the path of the cooling fluid flow and the reference element is sheltered from this direct fluid flow. These elements are arranged as parallel and concentric planar elements that are essentially identical to each other with matching thermal characteristics. The elements are electrically connected in a Wheatstone bridge arrangement. Thermal exchange between the reference and measure elements is used to optimise noise rejection due to common mode background thermal effects. Measured parameters from the bridge can be used to derive the fluid flow rate.

Owner:SERVOMEX GRP LTD

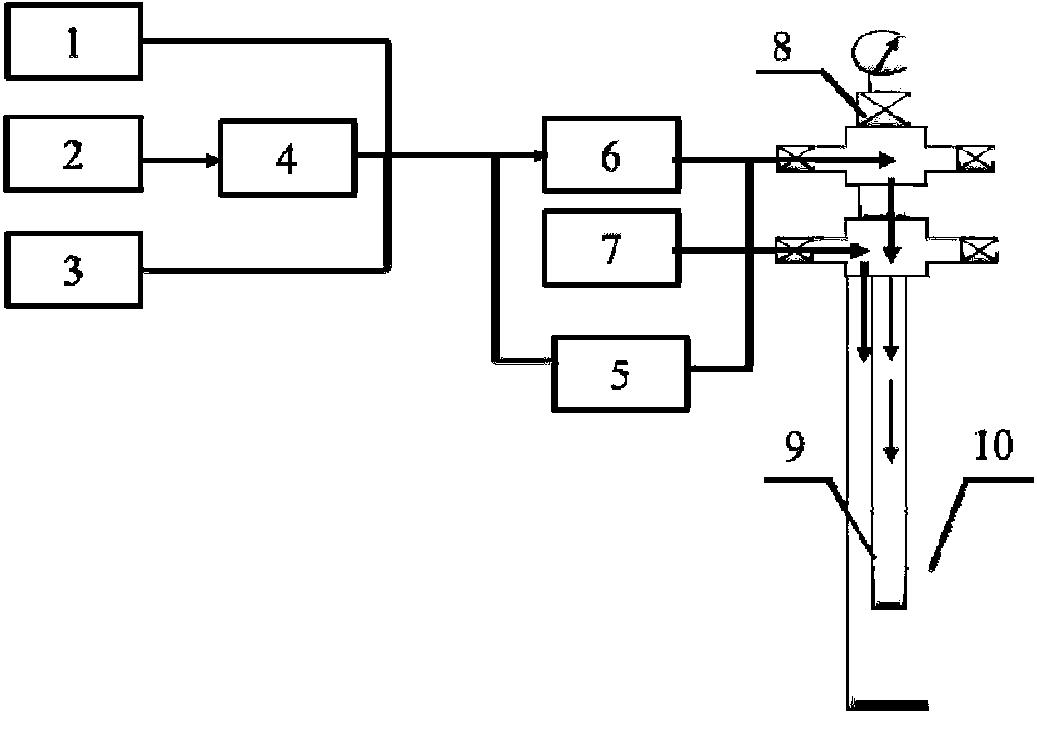

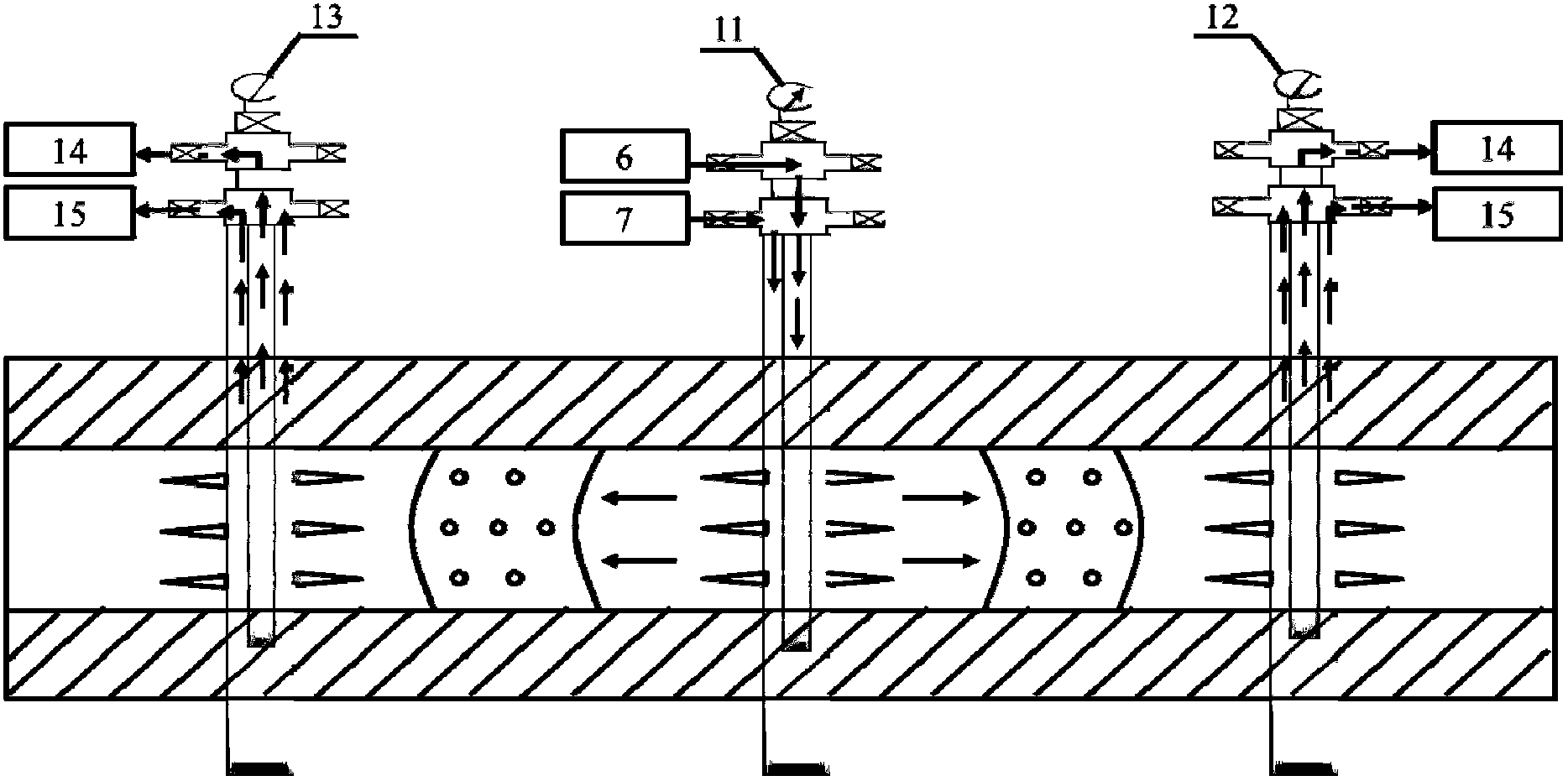

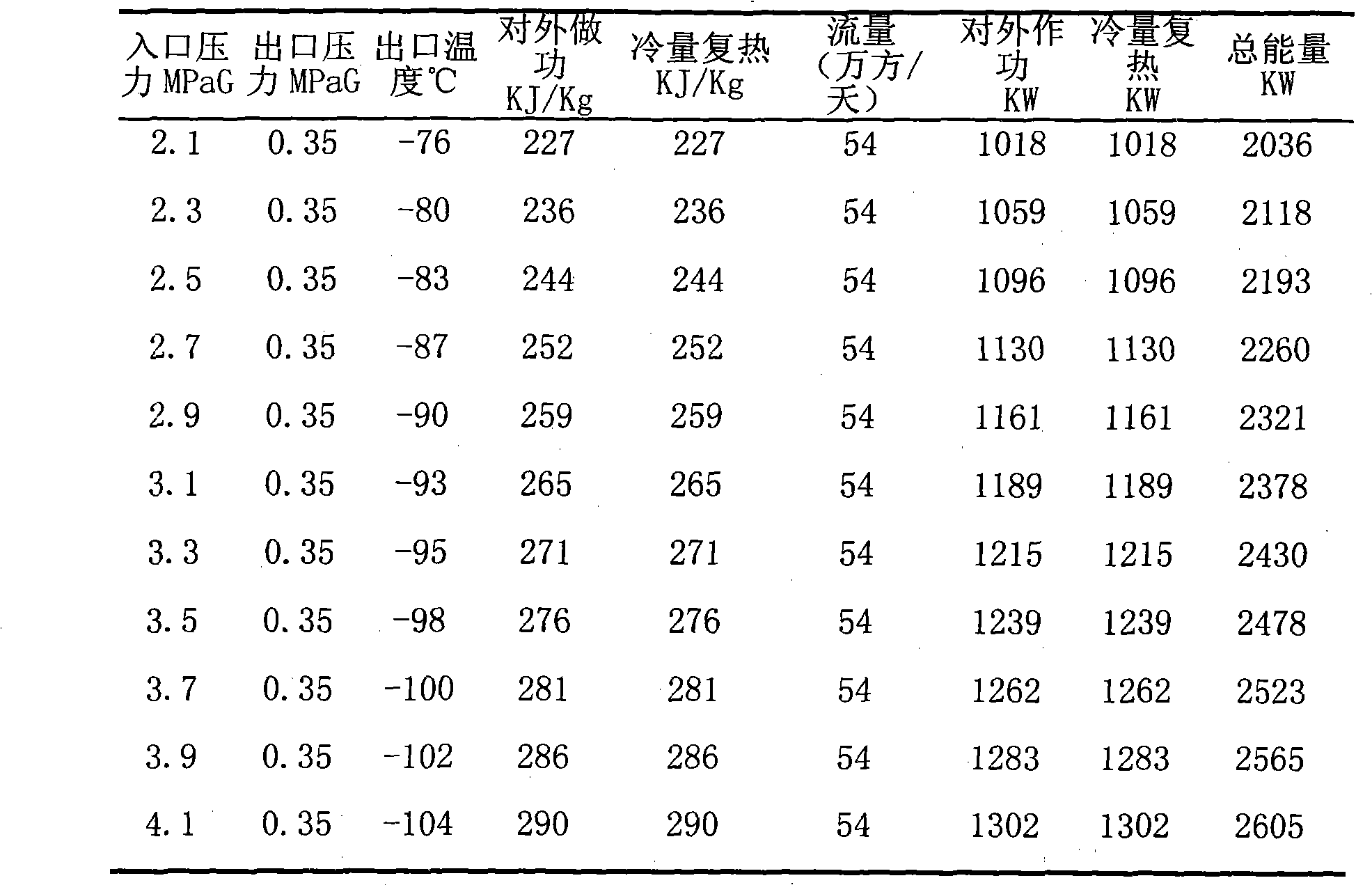

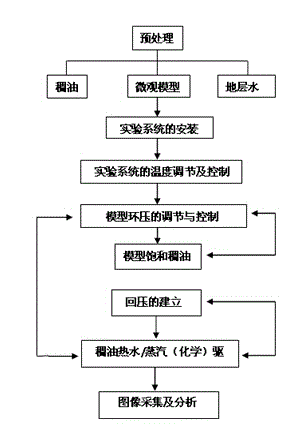

Method for coal bed methane mining by multi-element thermal fluid foam displacement

ActiveCN103061730AImprove permeabilityHard to getOther gas emission reduction technologiesFluid removalHigh pressure waterHigh pressure

The invention discloses a method for coal bed methane mining by multi-element thermal fluid foam displacement. Multi-element thermal fluid is injected into a coal bed of an injection-production well group through an injection well, and foaming agent is injected at intervals. A multi-element thermal fluid foam slug is formed in the coal bed to displace the coal bed methane in order to improve the recovery efficiency of the coal bed methane. The method specifically includes that extracted coal bed methane is compressed and mixed with compressed air, and then the mixture is injected into a multi-element thermal fluid generation device for ignition, extracted processed ground water is mixed to produce the multi-element thermal fluid mainly with high-temperature and high-pressure water vapor and mixed gas of carbon dioxide and nitrogen, the produced multi-element thermal fluid is injected into the underground coal bed through the injection well, a foaming system composed of preferred alkyl ether sulfonate and corrosion inhibitor is injected from an oil jacket annulus at intervals, the multi-element thermal fluid foam slug is formed under the ground to displace the coal bed methane, and water is drained and gas is recovered from a production well. The method has the advantages that fuel is easy to obtain, principles are clear and distinct, and the like, and can provide guidance for implementation of well stimulation of the coal bed methane.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Thermal recovery technology of multielement thermal fluid of thickened oil well

The invention relates to a thermal recovery technology of a multielement thermal fluid of a thickened oil well, comprising the step of injecting a multielement thermal fluid and annular injection nitrogen into an oil layer together. The invention relates to a thermal recovery technology of a multielement thermal fluid of an offshore thickened oil well.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Method for preparing high-purity cyclopentadiene

ActiveCN102060649AMild reaction conditionsControllableHydrocarbon by depolymerisationReboilerNitrogen gas

The invention relates to a method for preparing high-purity cyclopentadiene, which comprises the following steps of: heating a thermal decomposer containing purified conduction oil and a composite inhibitor and a rectifying reboiler to a specified temperature; adding dicyclopentadiene serving as a crude product into the thermal decomposer continuously and stably; allowing the depolymerized cyclopentadiene to enter a rectifying column; extracting high-purity cyclopentadiene from a tower top, heating a small amount of dicyclopentadiene and by-products by the reboiler at the tower bottom to rectify the small amount of dicyclopentadiene and by-products again, and recycling kettle liquid. The method has the advantages of simple equipment, high production capacity, little coking and long service life of the conduction oil serving as a raw material and the equipment.

Owner:PETROCHINA CO LTD

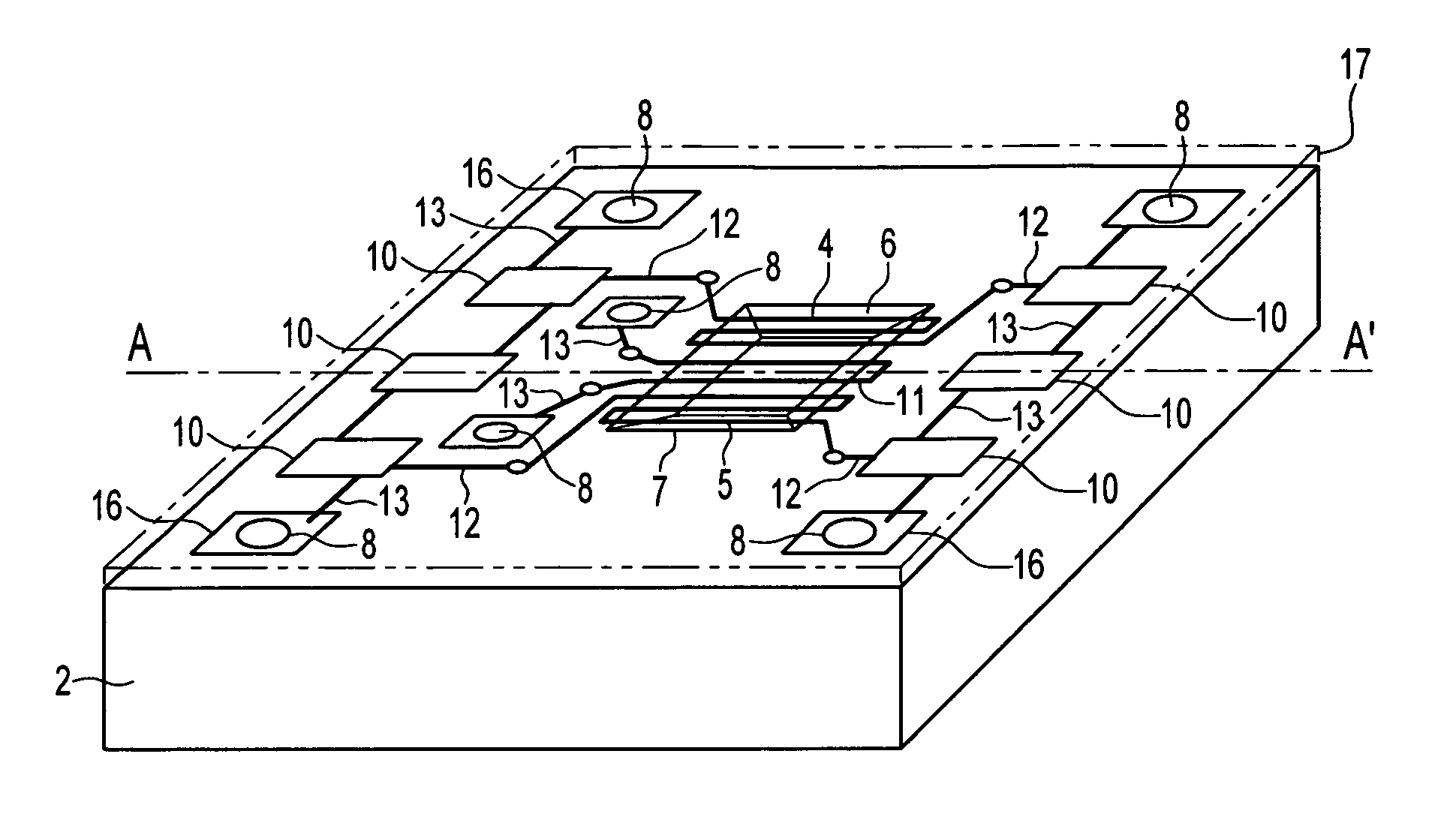

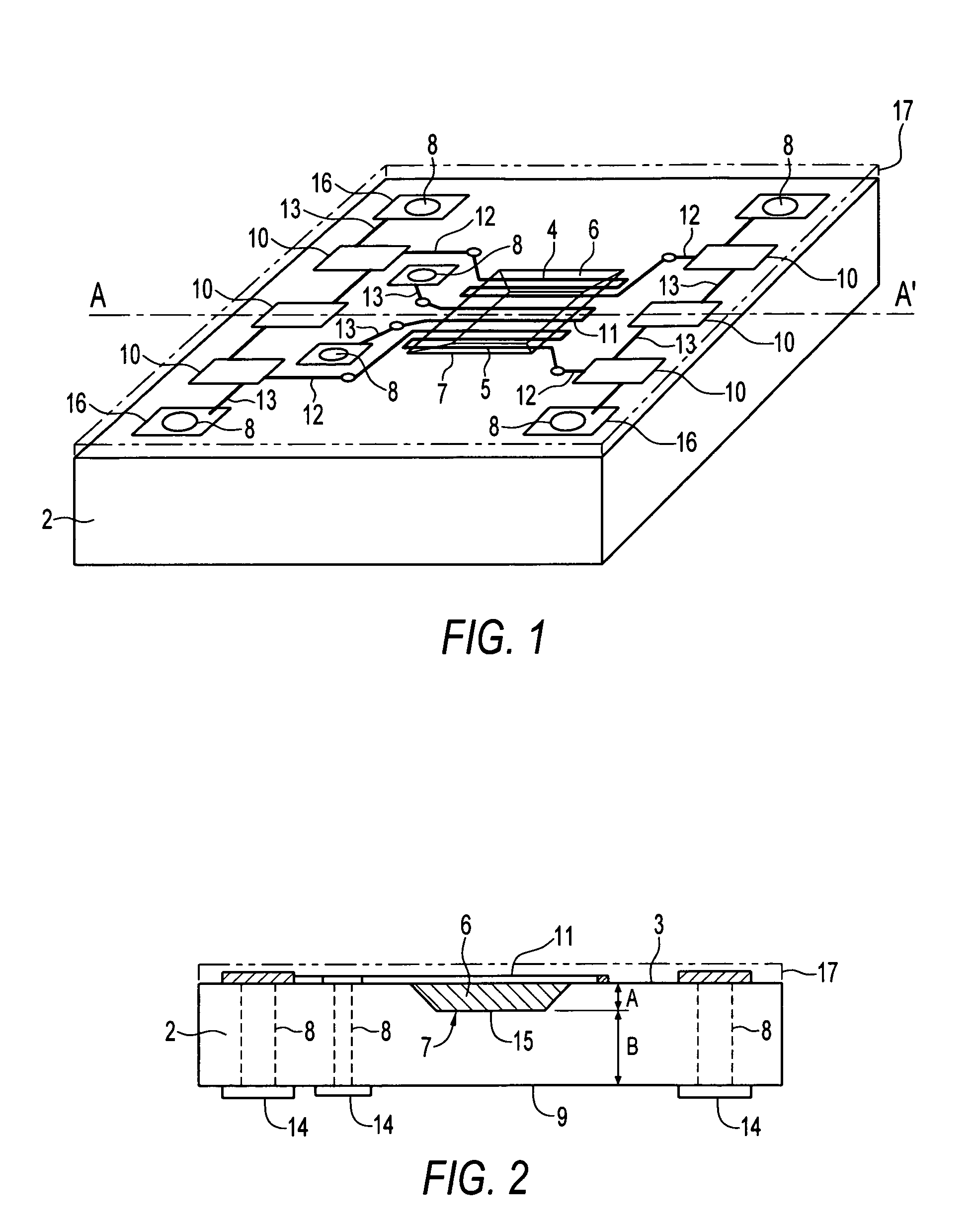

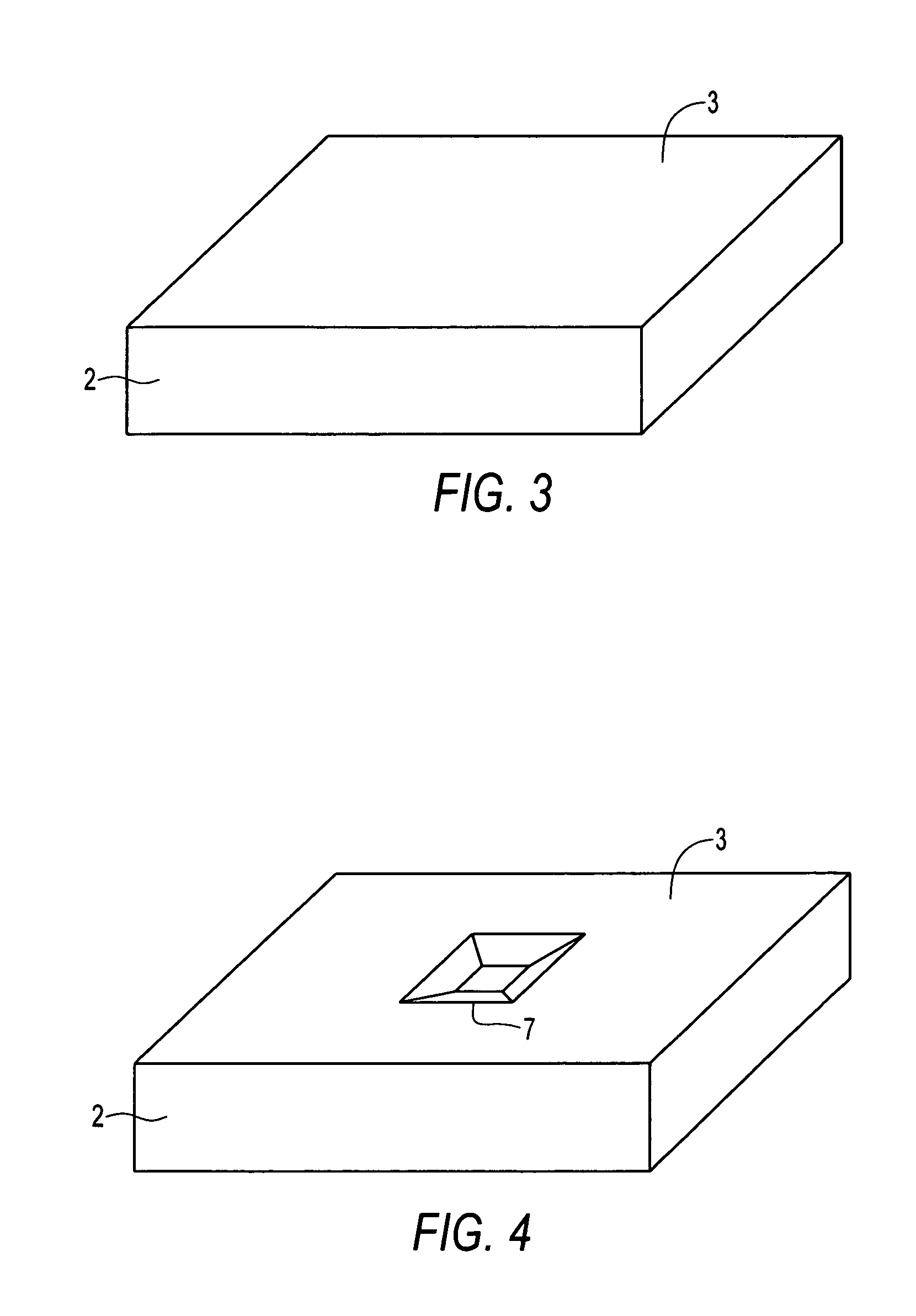

Thermal fluid flow sensor and method of forming same technical field

InactiveUS7255001B1Improve sensor performancePath resistanceVolume/mass flow by thermal effectsSignal conditioningThermal fluids

A thermal fluid flow sensor and method of forming same. The flow sensor has an integrated circuit substrate, such as a silicon substrate, and a region of low thermal conductivity material carried on the top surface of the integrated circuit substrate. One or more pairs of temperature sensing elements are disposed on the low thermal conductivity region together with a heating element so that a robust flow sensor can be provided at low cost. Signal conditioning circuitry is disposed on the same surface as the temperature sensing elements and connected to the sensing elements thereby further reducing costs and improving the flow sensor sensitivity.

Owner:HONEYWELL INT INC

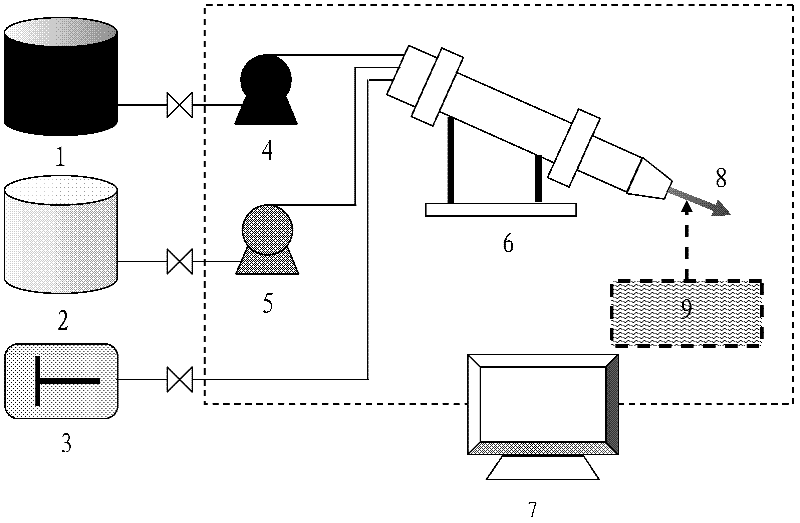

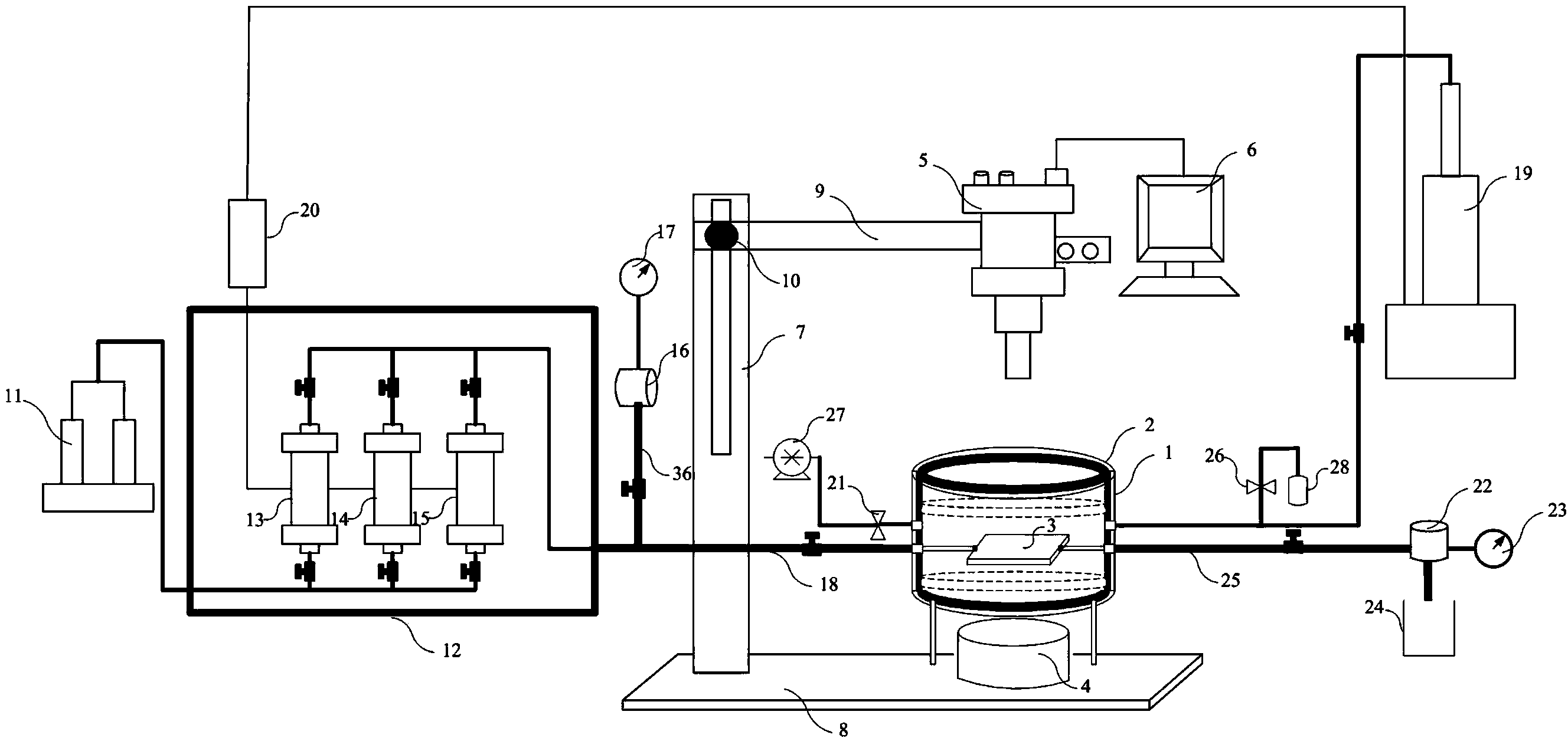

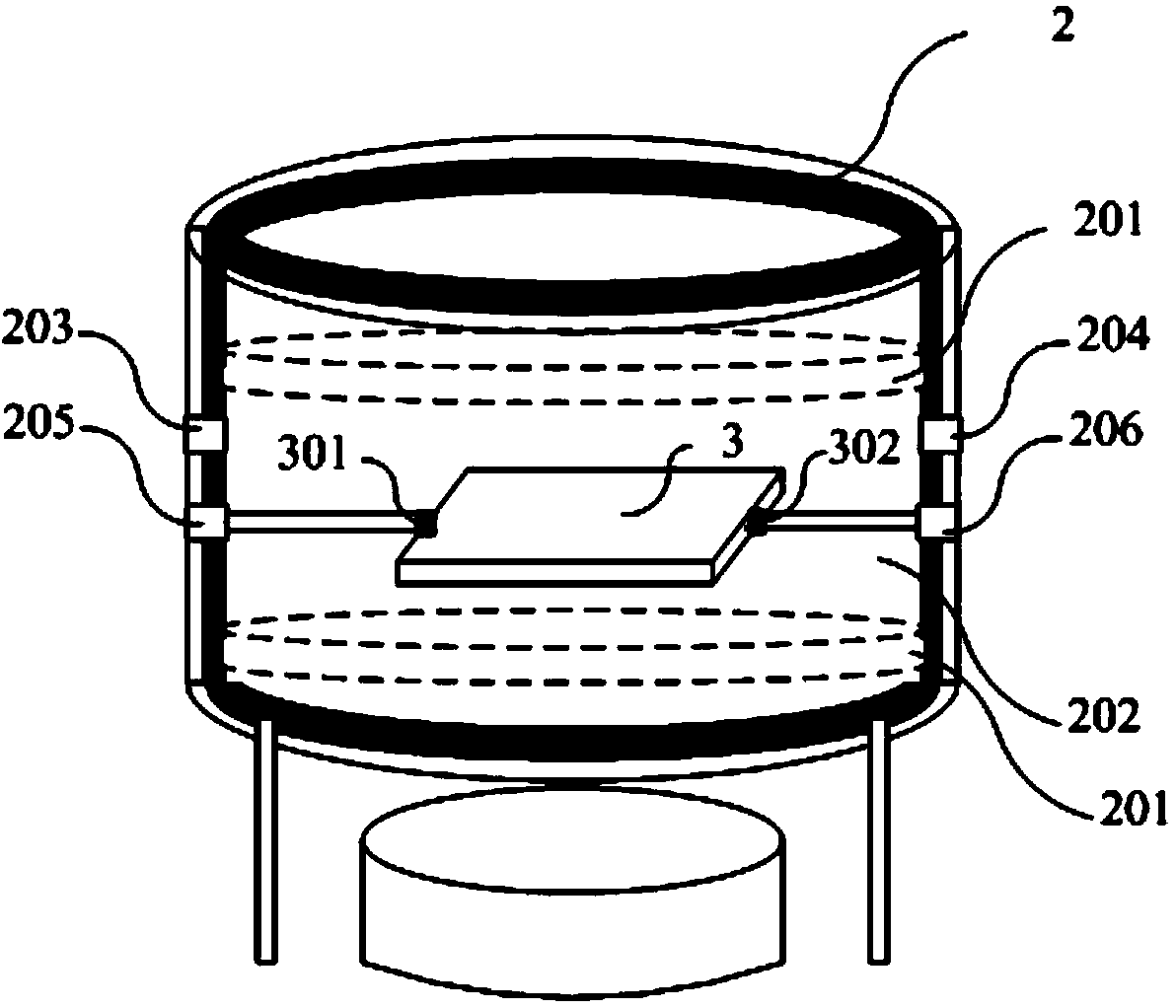

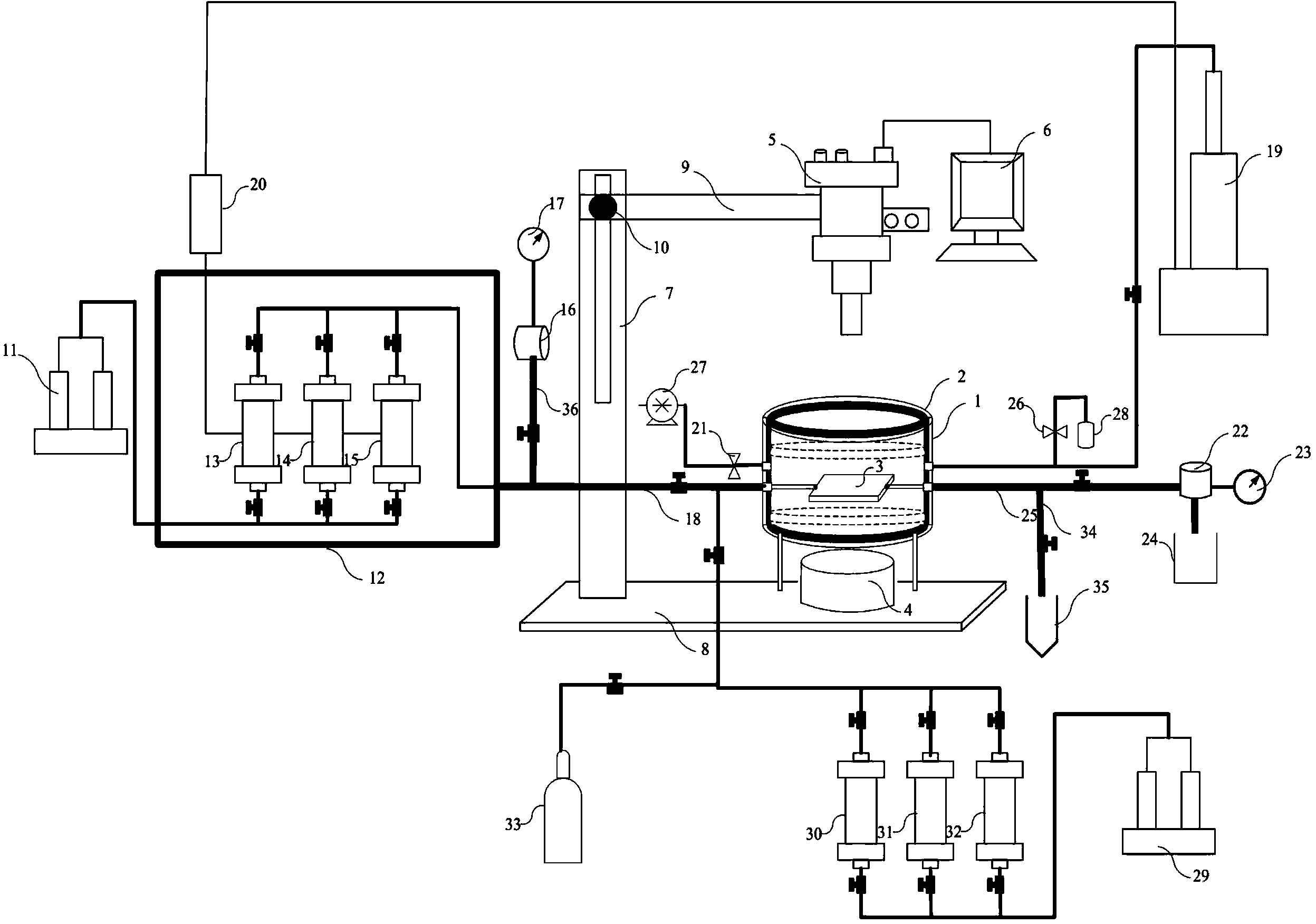

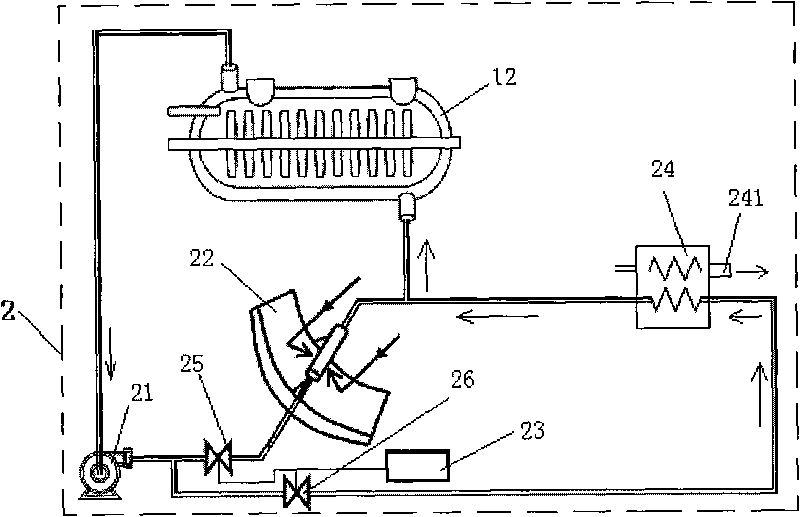

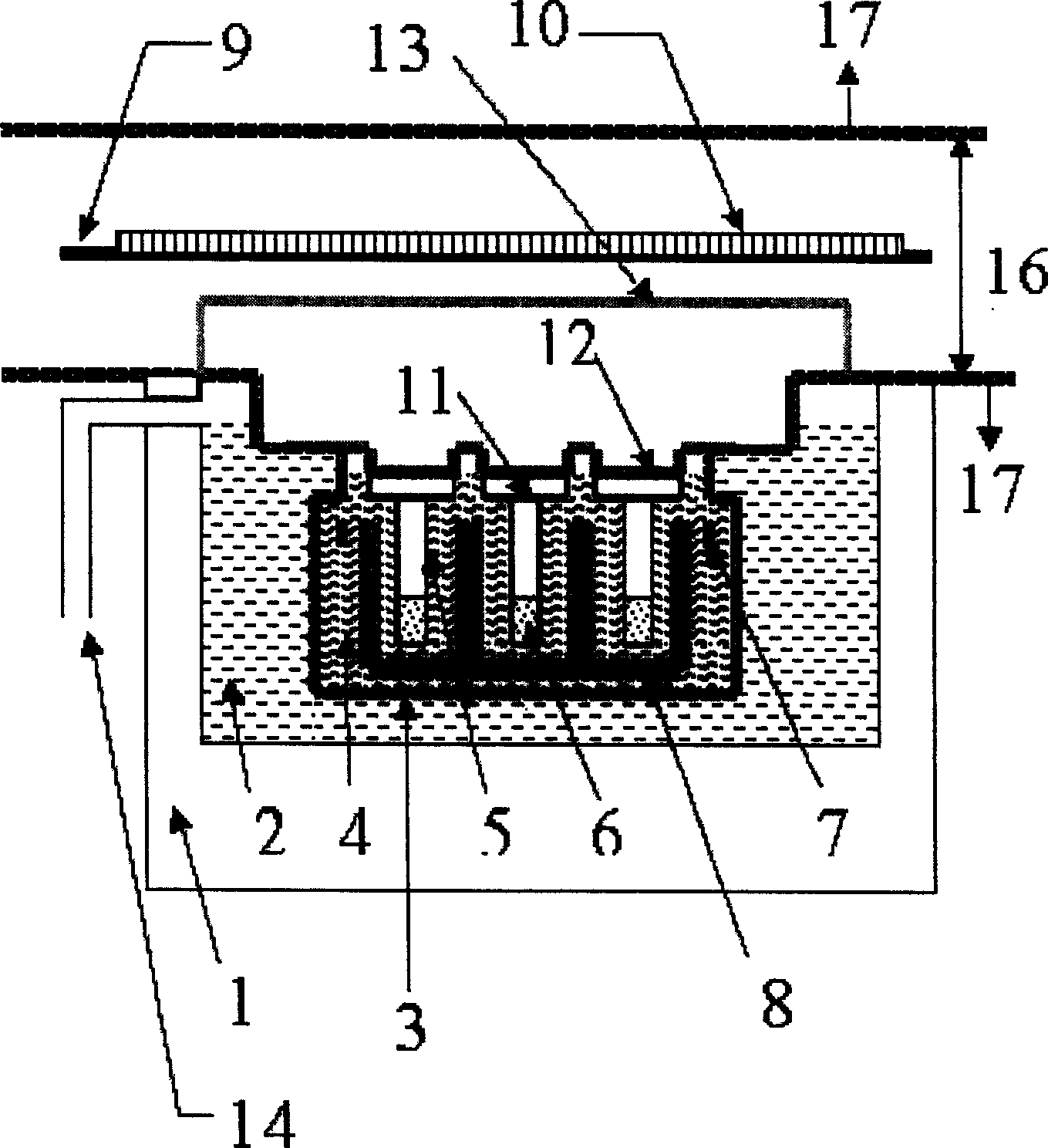

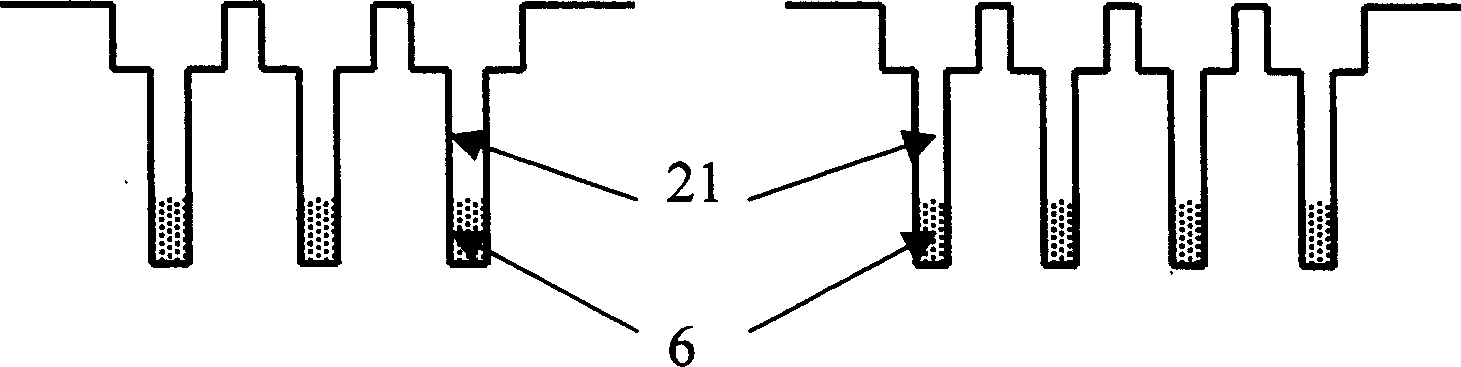

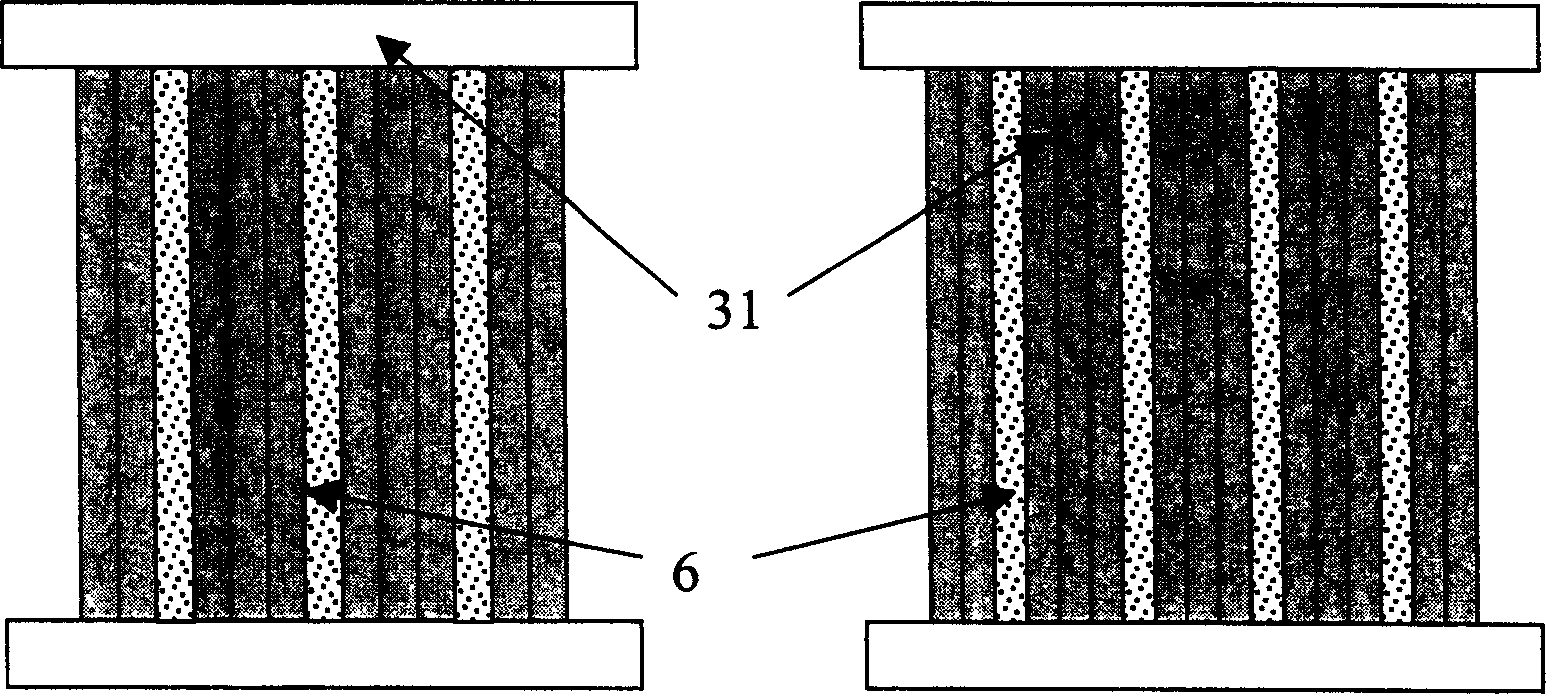

Two-dimensional microcosmic visual thickened oil replacement simulation experiment system and use method thereof

ActiveCN104265255AMeet the needs of development researchReduce experiment costFluid removalFlat glassLine tubing

The invention provides a two-dimensional microcosmic visual thickened oil replacement simulation experiment system and a use method thereof. The two-dimensional microcosmic visual thickened oil replacement simulation experiment system comprises a microcosmic simulation experiment device, a visual data acquisition device, a support device, a multivariate thermal fluid injection device, a confining pressure tracking device and a metering device, wherein the microcosmic simulation experiment device comprises a heating jacket, a clamper and a plate glass microcosmic model; the visual data acquisition device comprises a microscopic shooting device and a computer; the multivariate thermal fluid injection device comprises an ISCO injection pump, an oven and a replacement medium intermediate container, a water intermediate container, a thickened oil intermediate container, a first heat traced pipeline and a bypass pipeline; the confining pressure tracking device comprises an annular pressure tracking pump, an annular pressure tracking pump pressure meter, a vacuum pump and a first vacuum valve. The two-dimensional microcosmic visual thickened oil replacement simulation experiment system give full consideration to characteristics of the thickened oil reservoirs, provides convenience for research on a thickened oil replacement mechanism through microcosmic experiments, has the advantages of low experiment cost, high work efficiency and the like, and can meet with demands on development and research of the thickened oil reservoirs.

Owner:PETROCHINA CO LTD

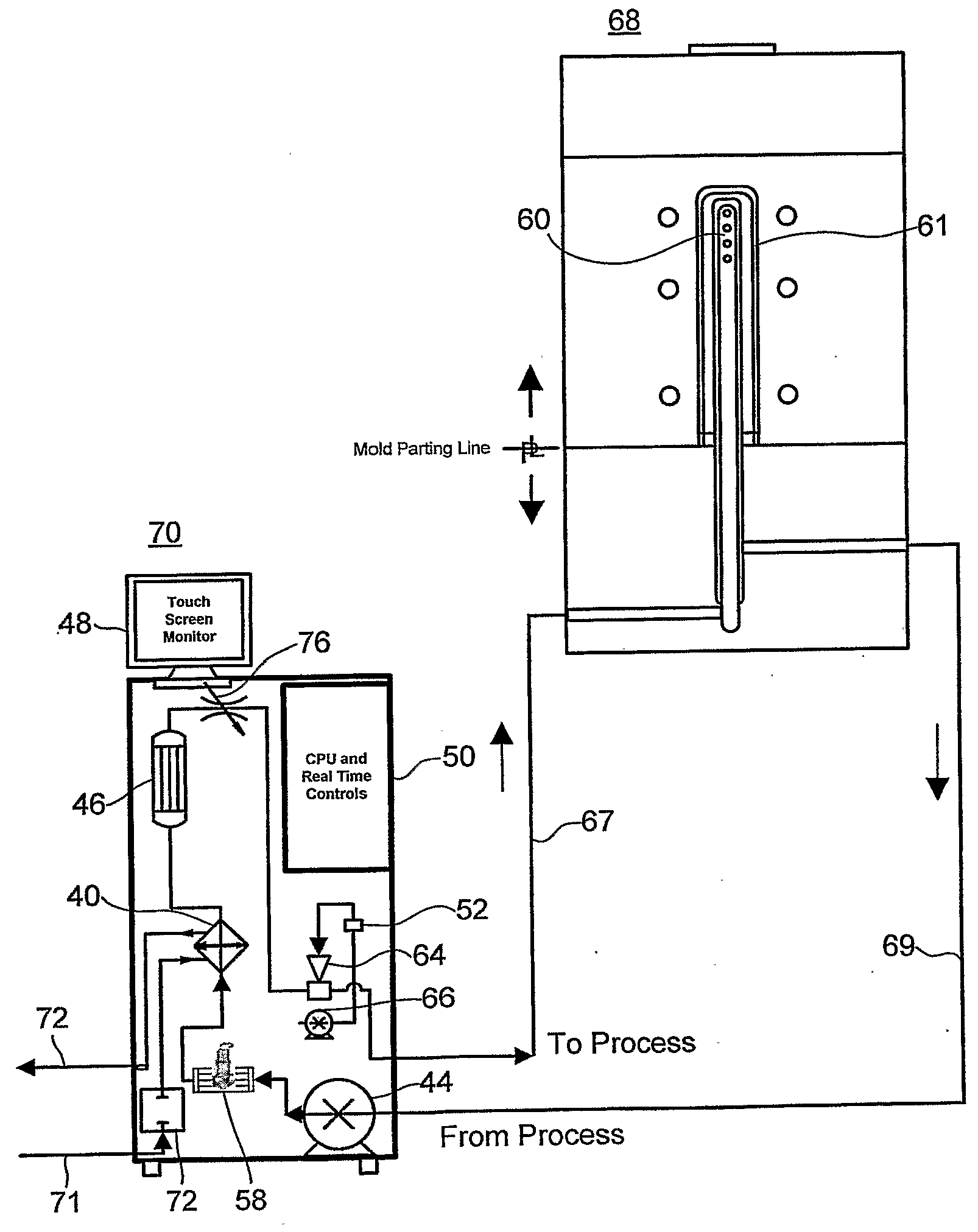

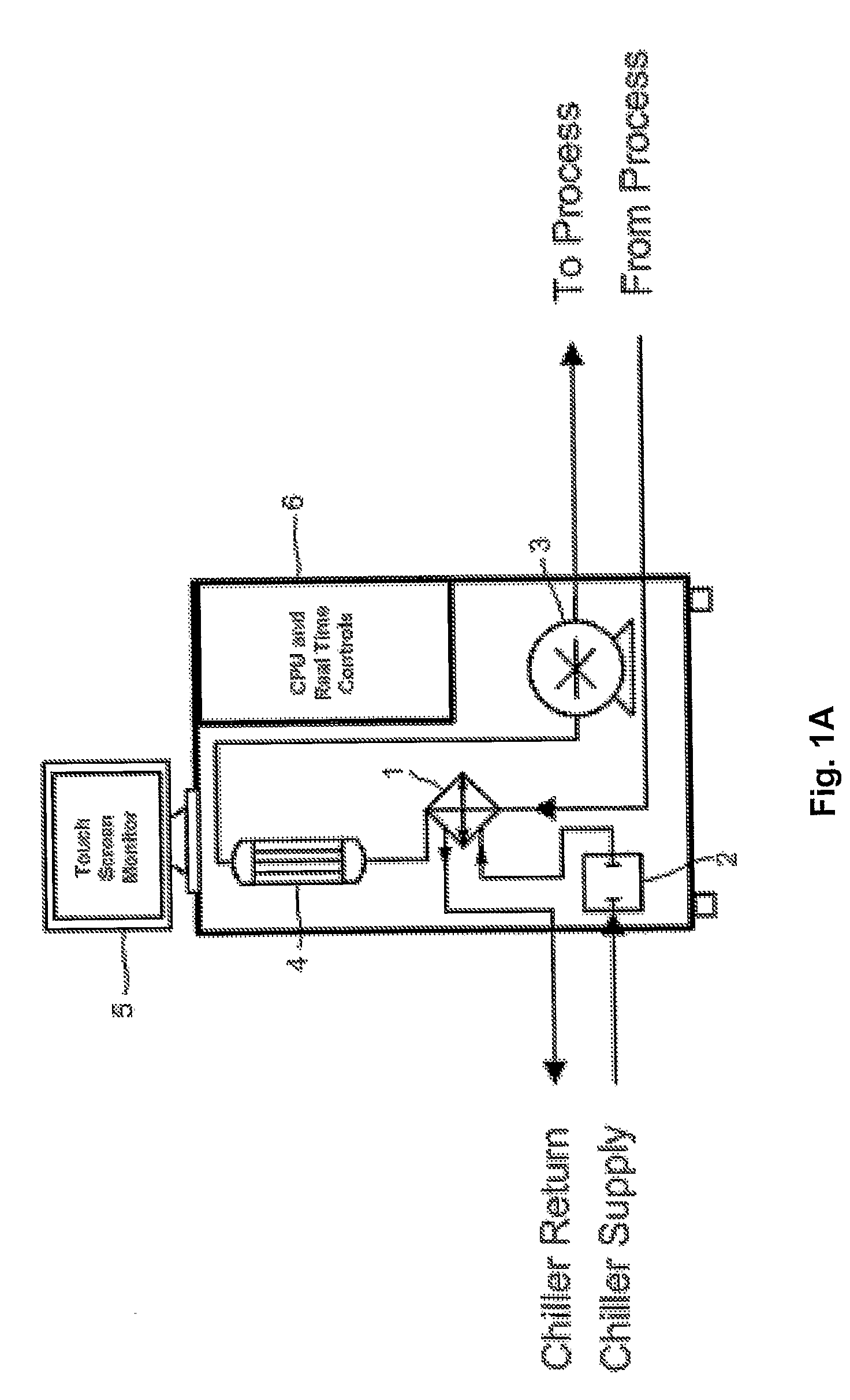

Method and apparatus for controlling the temperature of molds, dies, and injection barrels using fluid media

ActiveUS20090174101A1Limit precision and reliabilityLack of precisionTemperatue controlAuxillary shaping apparatusMolding machineDie casting

For controlling temperature in the molding of plastics, metal, ceramic, or die-casting, a circulator supporting a molding machine includes a fixed displacement pump driven by an electronic servo motor for volumetric metering of thermal fluid to or from the molding machine. A pre-set or dynamically controlled volume and flow rate profile matches the heating and cooling requirement of a molding machine and process. Volumetric metering may be based on parameters such as time, machine cycle status, temperature, pressure, and / or flow rate. Fluid may be circulated through the mold at positive or negative pressure at fixed, variable, or pulsed flow. The supply side in a fluid loop may be restricted so as to cause a pressure drop in or upstream of the mold, die or barrel, and seed bubbles may be injected into the fluid flow to excite vaporization and lowering of the fluid temperature.

Owner:MOLDCOOL INT

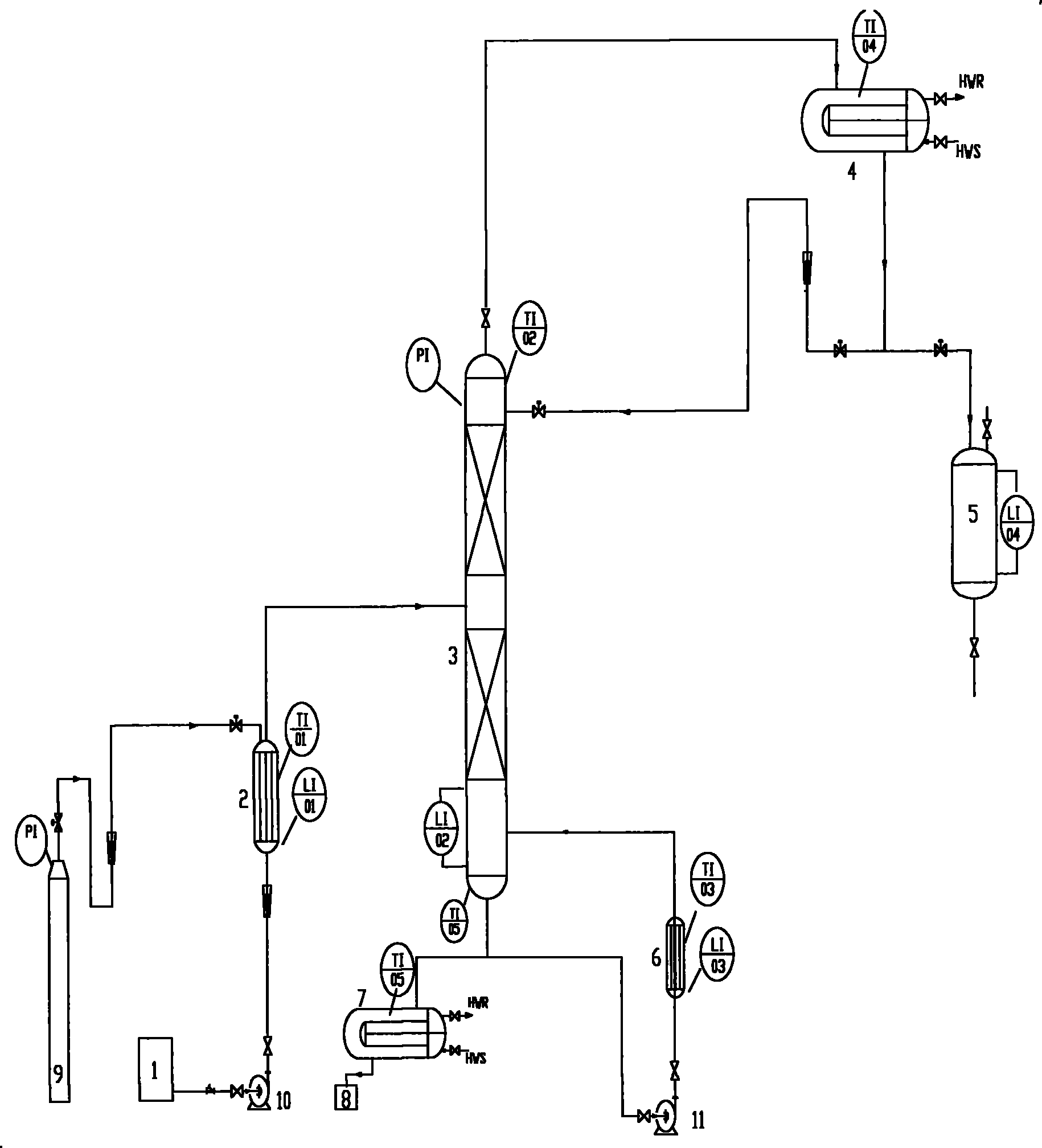

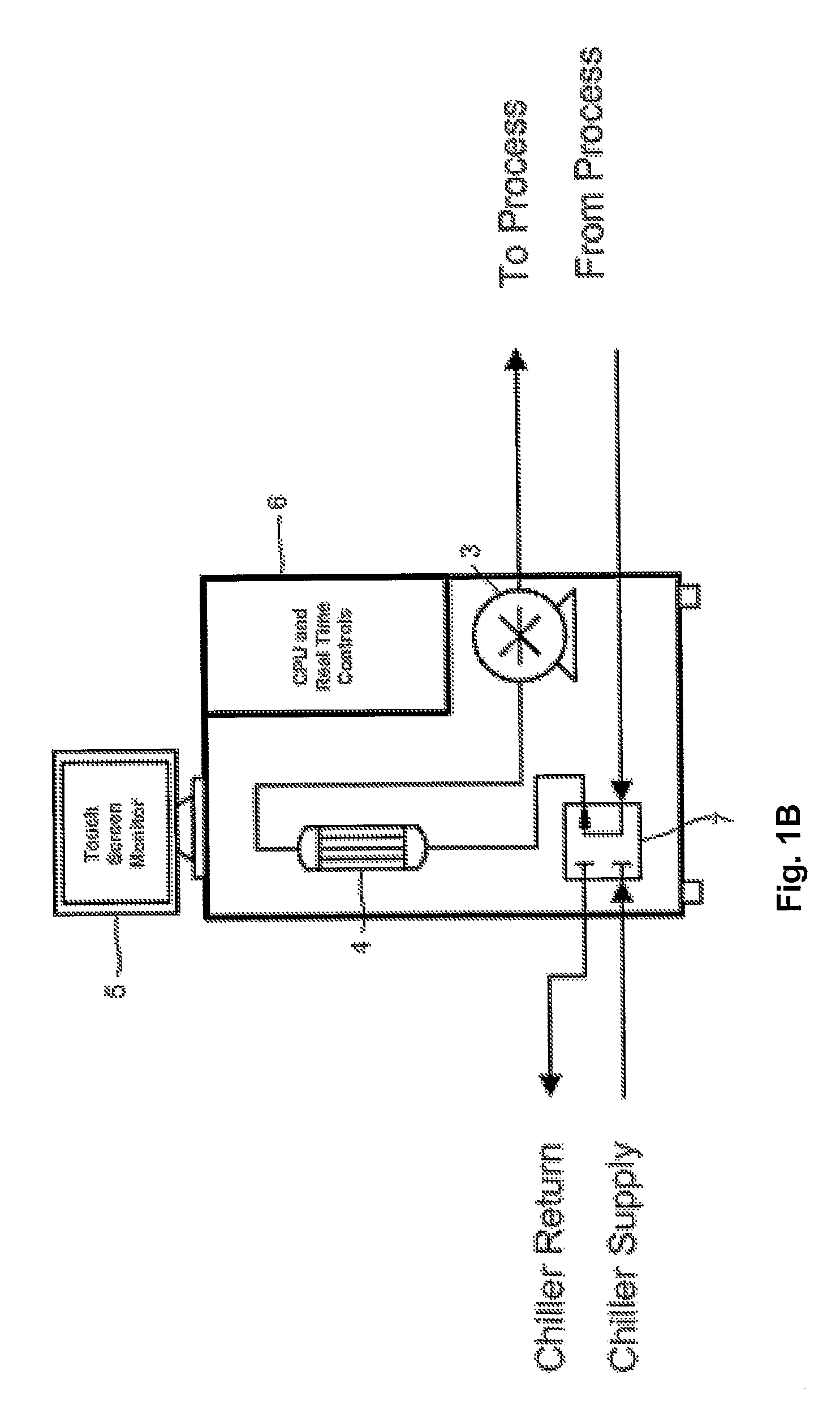

Two-tower type pressure reducing coke tar distillation process and apparatus therefor

ActiveCN101475819ASolve the technical problems of dealing with large-scale tarShort processTar working-up by distillationReboilerHeat conducting

The invention relates to a two-tower type process for distilling vacuum tar and a device thereof. The process comprises the following steps: removing the moisture and light oil distillate of raw tar in a pre-dehydration tower and a dehydration tower at normal pressure; performing decompressing operations in a No.1 distillation tower to obtain carbolic oil, naphthalene oil and light washing oil distillate; and performing decompressing operations in a No.2 distillation tower to obtain heavy washing oil, first anthracene oil, second anthracene oil and mid-temperature pitch. The heat for the pre-dehydration tower and the dehydration tower is supplied by heat conducting oil; the heat for the No.1 distillation tower is supplied by heating the mixed oil on the bottom of the tower circularly in a No.1 tubular heating furnace; and the heat for the No.2 distillation tower is supplied by heating the mixed oil on the bottom of the No.1 distillation tower in a No.2 tubular heating furnace and then performing flash distillation on the mixed oil on the bottom of the No.2 tower. The main devices comprise the dehydration tower, the No.1 distillation tower, the No.2 distillation tower, a dehydration tower reboiler, the No.1 tubular heating furnace, the No.2 tubular heating furnace, a heat exchanger for each distillate, a cooler, a steam generator and the like. The process has the advantages of short technological flow, less device investment, and less energy consumption, thus the process is applicable to large scale coal tar processing engineering.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

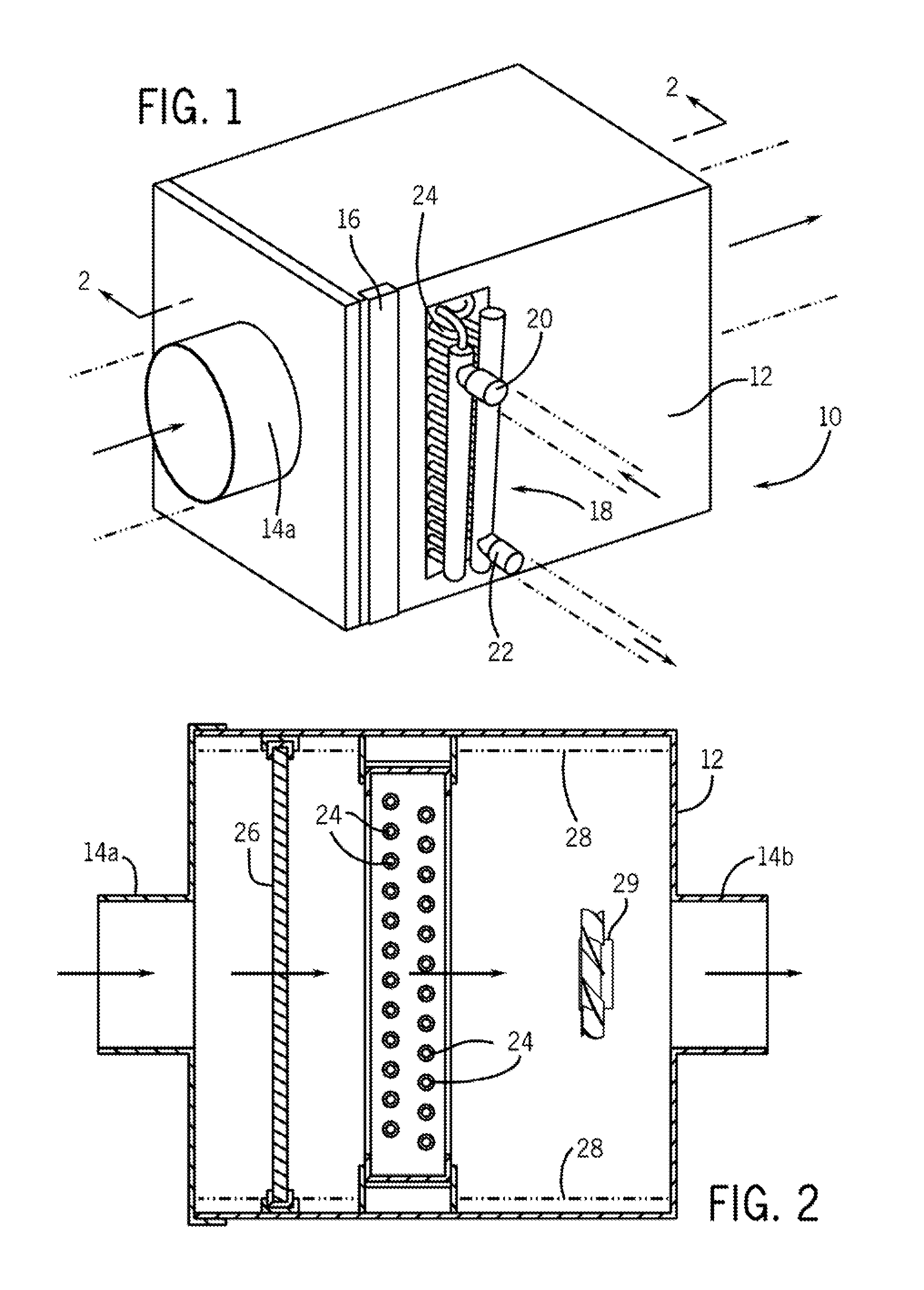

Thermal fluid temperature converter

A thermal fluid temperature converter uses temperature from a thermal fluid to preheat or precool incoming air prior to entering a household / workplace / building / appliance. The thermal fluid temperature converter includes a hollow housing, a filter placed inside the hollow housing, and a temperature exchanger placed inside the hollow housing. The temperature exchanger is adapted to receive a thermal fluid that circulates through the coils. The air enters the hollow housing, interchanges temperature with the thermal fluid circulating through the coils, and leaves the hollow housing as a heated air or a cooled air.

Owner:CULLEN FREDRICK THOMAS +1

Solar thermal power plants

InactiveUS20100212318A1Improve efficiencyLow costAuxillary drivesFrom solar energyWorking fluidCollection system

A solar thermal power plant is provided comprising a solar collection system and a steam-electric power plant. The solar collection system comprises one or more tube radiation absorbers containing a thermal fluid therewithin, the system being configured to heat the thermal fluid by passing the thermal fluid through the one or more tube radiation absorbers while the absorbers are irradiated with solar radiation. The steam-electric power plant comprises an intermediate-pressure steam turbine, a low-pressure steam turbine, at least one additional steam turbine having an inlet pressure higher than that of the intermediate-pressure steam turbine, and piping containing a working fluid. Each turbine is associated with a heat exchange system adapted to transfer heat from the thermal fluid to the working fluid.

Owner:SIEMENS CONCENTRATED SOLAR POWER

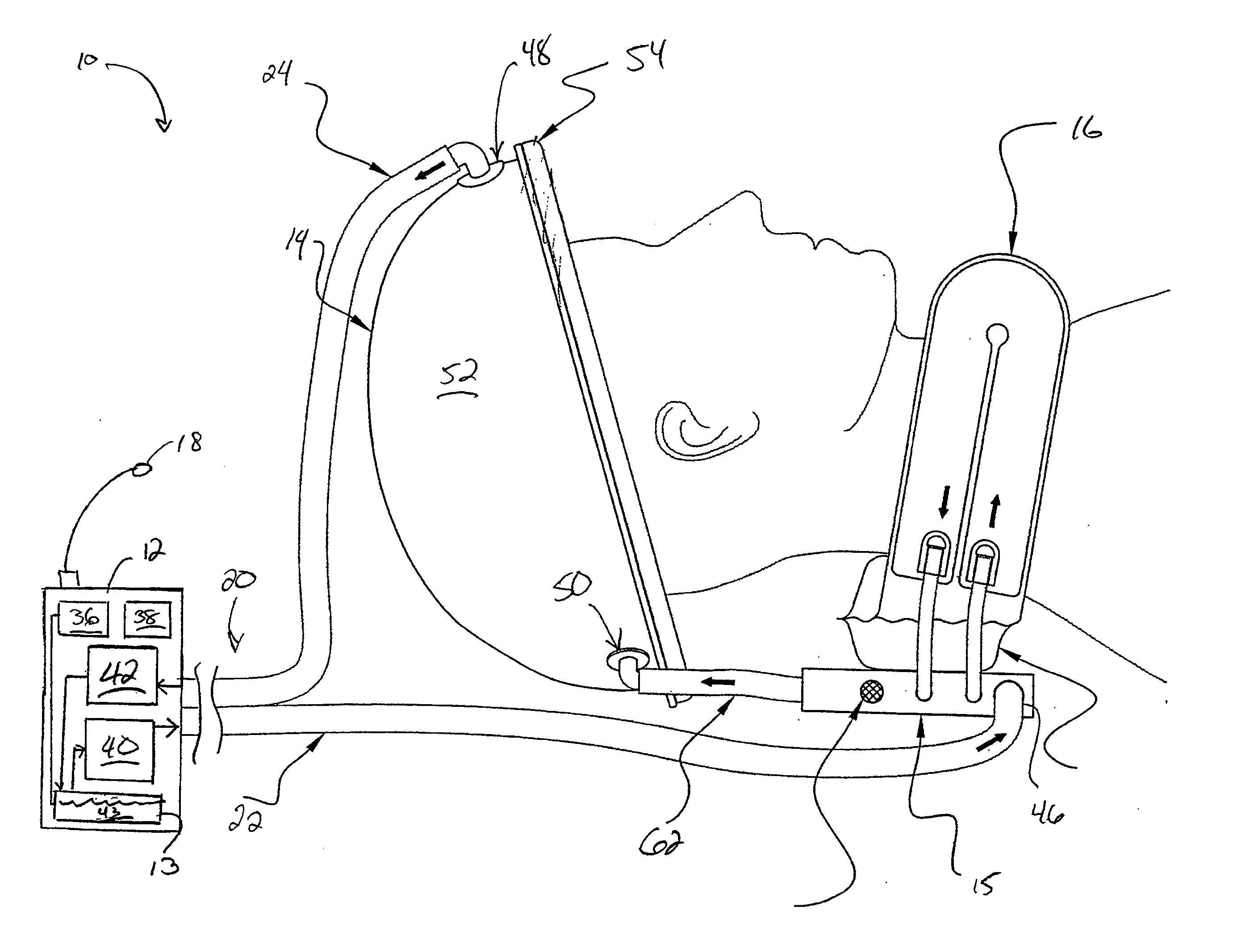

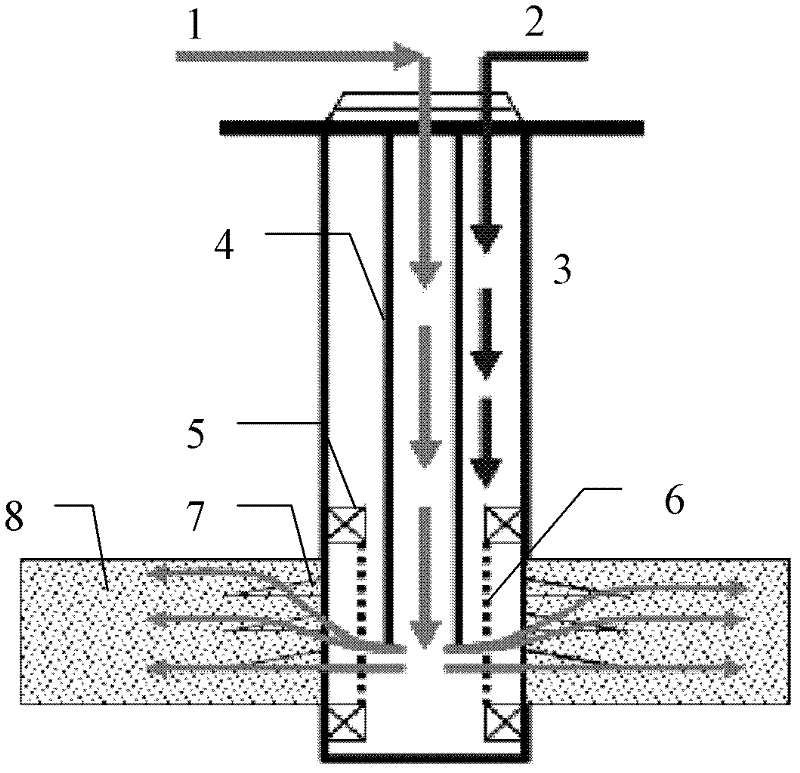

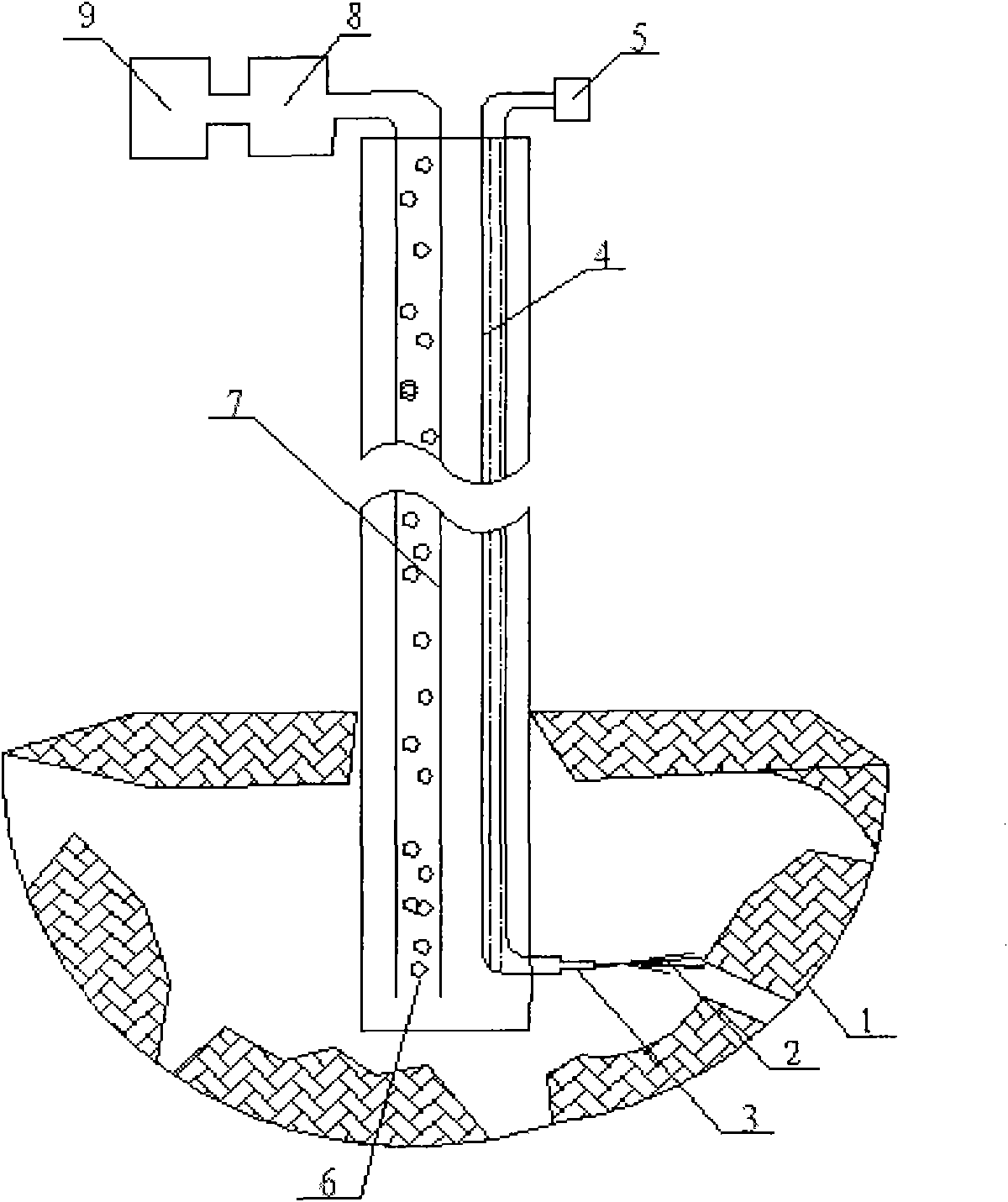

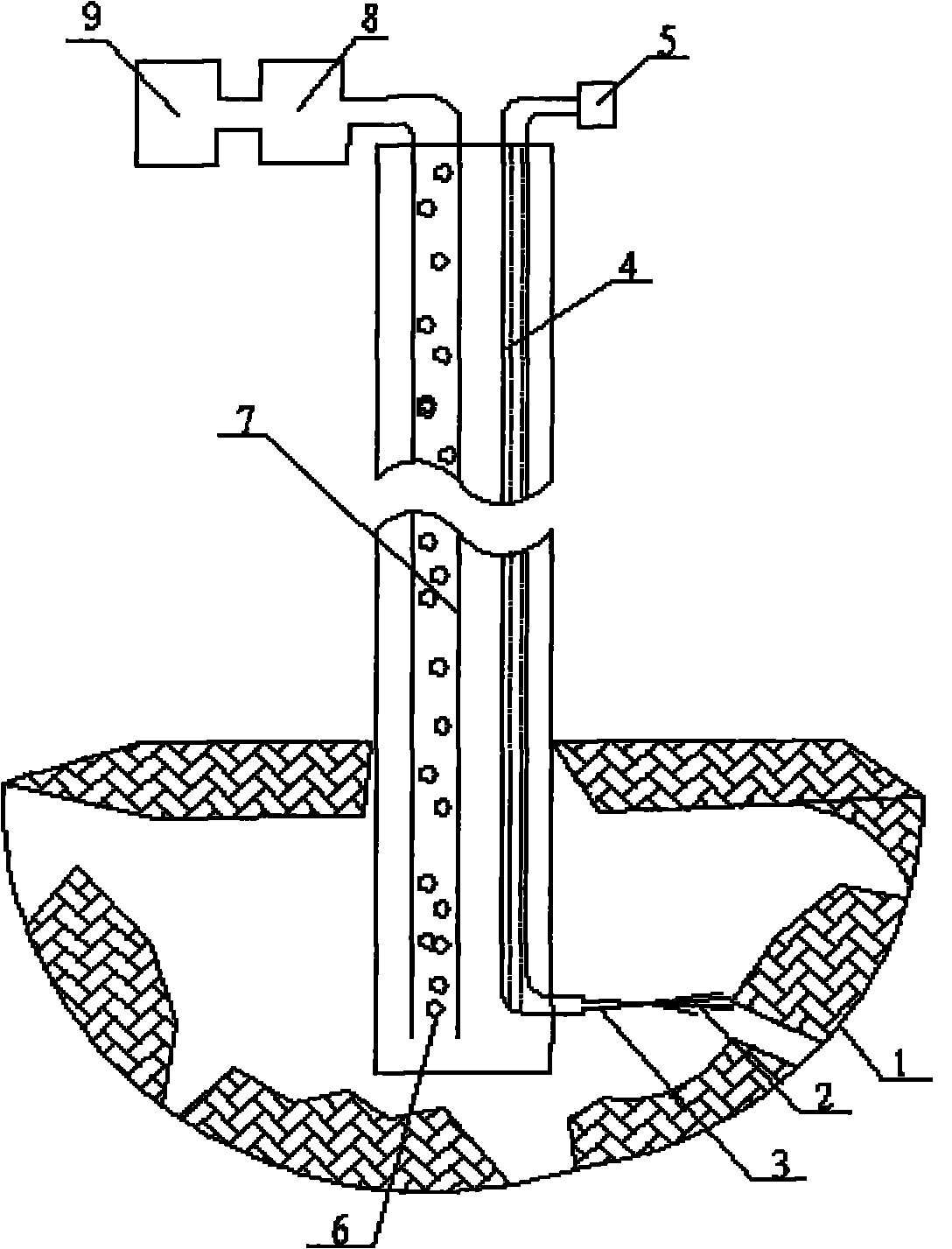

Method for exploiting natural gas hydrates by using high-pressure thermal jetting

InactiveCN101818635ASolve the problem of small mining rangeOvercoming or reducing self-protectionFluid removalJet flowEngineering

The invention relates to a method for exploiting natural gas hydrates by using high-pressure thermal jetting, comprising the following steps of: placing a high-pressure jetting device in an exploiting well; sending thermal fluids into a water injection pipe and a telescopic water gun through a high-pressure pump for spraying; causing high-speed jetting flows to directly act on the natural gas hydrates in the working radii of the high-speed jetting flows to cut and decompose the natural gas hydrates, changing non-decomposed natural gas hydrates into small blocks, bringing the small blocks into an exploiting pipe along with return flows, and then causing the small blocks together with the gas hydrates to rise to a gas-liquid separation device; separating gas and liquid through the gas-liquid separation device, and sending the gas into a gas recovering device. The invention solves the problem of small exploitation range in the exploitation process of the natural gas hydrates, ensures the thermal fluids to act on the surfaces of the non-cracked natural gas hydrates all the time, has a good thermal conduction effect and overcomes or reduces the self protection of the natural gas hydrates; and the telescopic water gun on a nozzle can not only be horizontally rotated, but also can be moved up and down along a vertical shaft by utilizing the power of a drilling machine, thereby ensuring the cutting of large-scale natural gas hydrate ledges.

Owner:JILIN UNIV

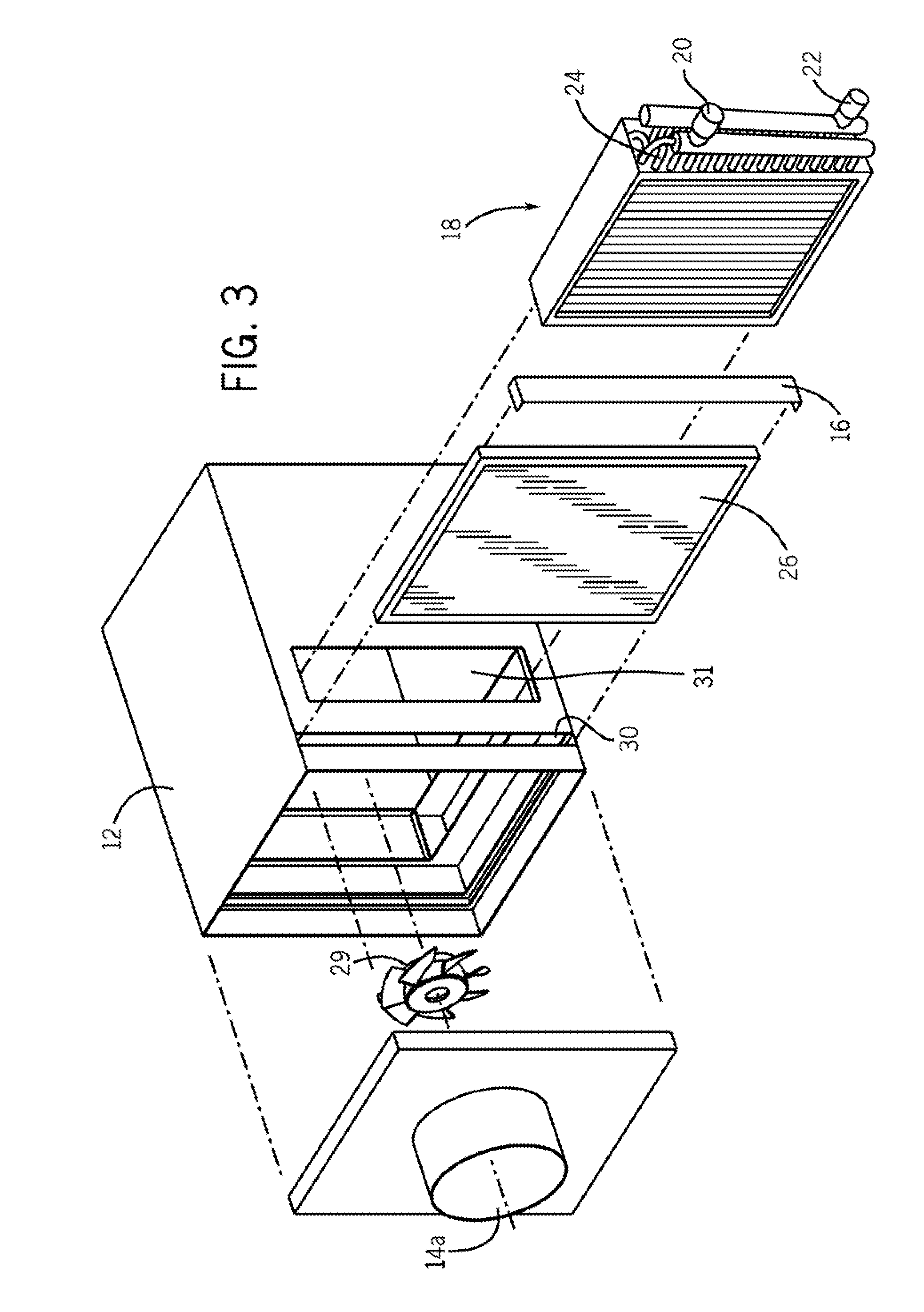

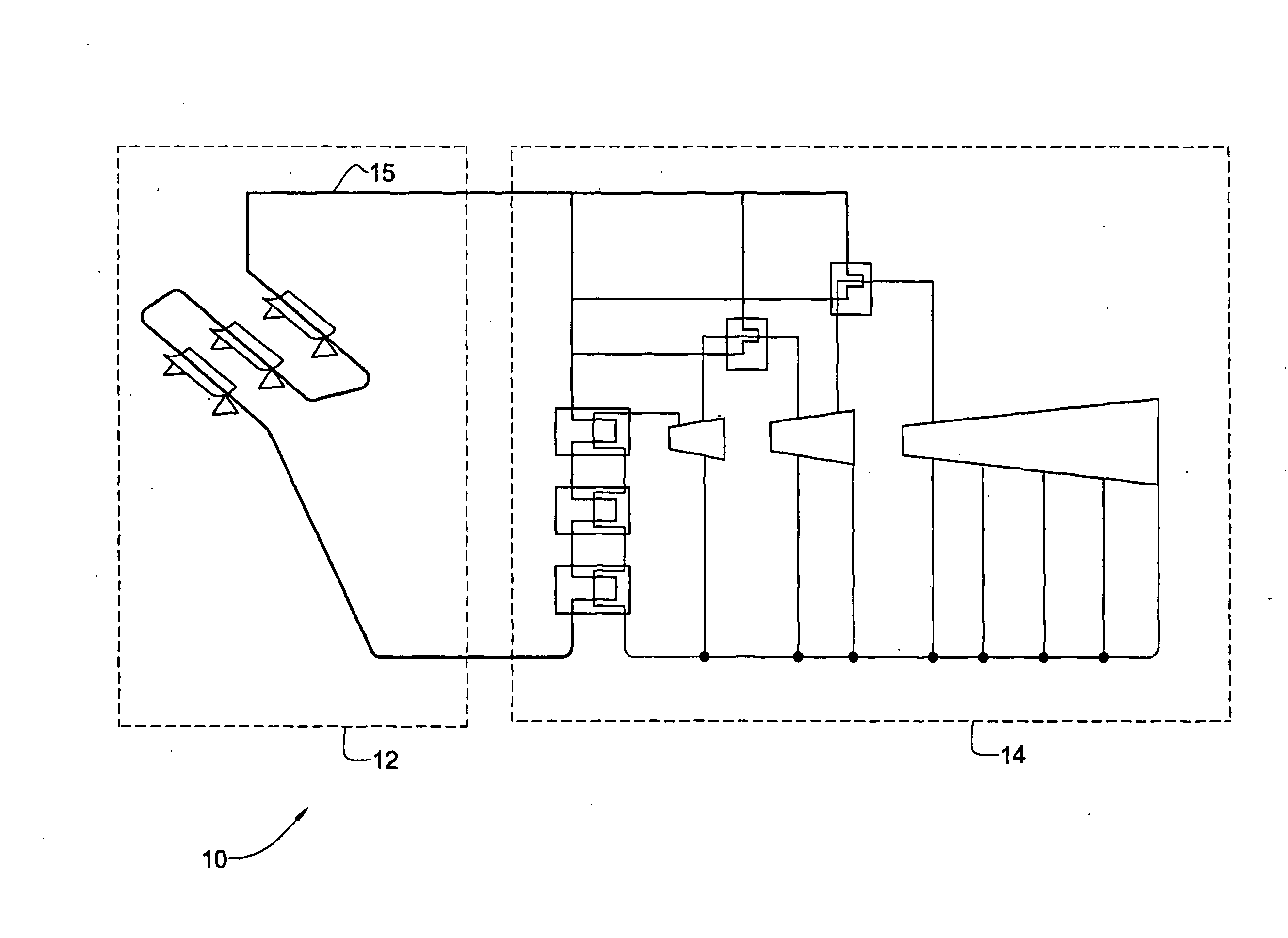

FRAME (forced recuperation, aggregation and movement of exergy)

ActiveUS9543787B2Readily givesReadily and efficiently acceptEnergy efficient ICTElectric signal transmission systemsData centerPower usage

The present invention is directed to an apparatus for more efficient exergy and power usage in data centers. Denominated FRAME (standing for “Forced Recuperation, Aggregation & Movement of Exergy”), the apparatus is a power production and exergy management system (exergy being energy available to do useful work, as opposed to energy, which can be changed to a form, usually heat, rendering it unavailable). The apparatus integrates generally isothermal operation with phase-change and single-phase liquid cooling having variable operating temperatures and pressures, aided by a dynamically reconfigurable “thermal bus” comprising multi-fluid thermal fluid transport channels, virtual plumbing, and associated support devices. The apparatus minimizes exergy use through efficient operation and by recuperating and aggregating useful exergy that may then be dynamically repurposed to meet energy or power needs that would otherwise have to be met via external means.

Owner:SCRUTINY

Method and device for comprehensively utilizing energy of high-pressure natural gas

InactiveCN102383868AImprove the efficiency of pressure energy utilizationImprove system stabilityInternal combustion piston enginesGaseous fuelsCompressed natural gasChemical energy

The invention relates to a method and a device for comprehensively utilizing energy of high-pressure natural gas. The method comprises the following steps of: carrying out decarbonization and dehydration on the high-pressure natural gas; reducing a temperature and a pressure of the high-pressure natural gas by turbine expansion; generating electricity by shaft work output by a turbine expansion engine; carrying out cold energy collection on the natural gas subjected to turbine expansion by a heat exchanger, feeding the natural gas subjected to heat exchange by the heat exchanger into an internal combustion engine to generate chemical energy; generating electricity by the chemical energy; and feeding high temperature fume generated by the internal combustion engine into a waste heat boiler to generate steam or hot water. The device comprises a high-pressure natural gas pipeline, a low-pressure natural gas pipeline, a pressure regulator, a valve, the turbine expansion engine, a turbine expansion engine generating set, an internal combustion engine generating set, the heat exchanger, a decarbonization and dehydration mechanism, a frequency converter and the waste heat boiler. The decarbonization and dehydration mechanism is connected with the high-pressure natural gas pipeline and the turbine expansion engine. The turbine expansion engine is connected with a generator and the heat exchanger. The heat exchanger is connected with the low-pressure natural gas transmission and distribution pipeline, thermal fluid and a cold energy pipeline. The internal combustion engine is connected with the generator, the low-pressure natural gas pipeline and the waste heat boiler. Heat energy generated by the waste heat boiler is transferred to thermal equipment. Two types of electric energy are transferred to electric equipment through the frequency converter. The energy utilization rate is improved.

Owner:刘俊德 +2

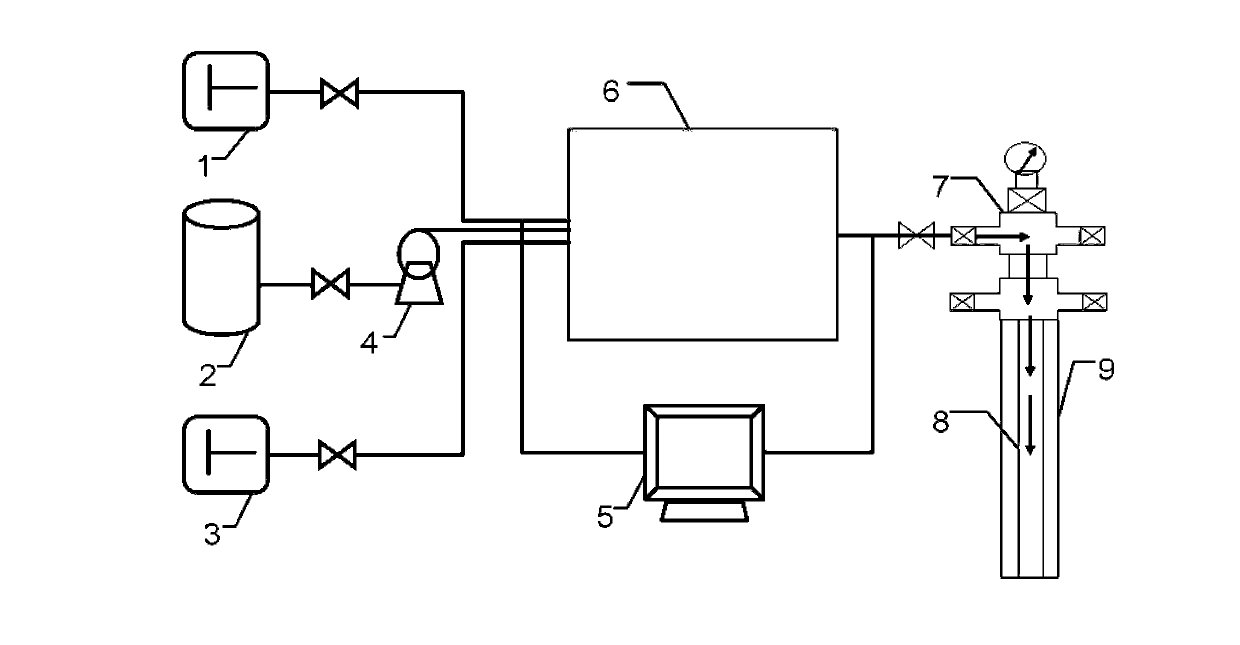

Device and method for exploiting natural gas hydrates by means of thermal fluid fracturing

ActiveCN103206199AEfficient decompositionImprove mining efficiencyFluid removalFracturing fluidPressure difference

The invention belongs to the technical field of unconventional oil and gas exploitation, and particularly relates to a device and a method for exploiting natural gas hydrates by means of thermal fluid fracturing. The device for exploiting the natural gas hydrates by means of thermal fluid fracturing comprises a fracturing fluid injection system, a natural gas exploitation system and a well system; the fracturing fluid injection system is used for providing high-pressure thermal fracturing fluid and injecting the high-pressure thermal fracturing fluid into the well system; the natural gas exploitation system is used for controlling the pressure difference between a hydrate reservoir stratum and the ground so that the hydrates can be exploited in a depressurization manner; and the well system is used for opening the hydrate reservoir stratum and guiding the fluid to flow into or flow out of the reservoir stratum. The method for exploiting the natural gas hydrates by means of thermal fluid fracturing is implemented by the device. The device and the method have the advantages that a plurality of processes for exploiting hydrates can be combined and used together, the hydrate exploitation efficiency is improved, and the method for exploiting the hydrates is high in prospect.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

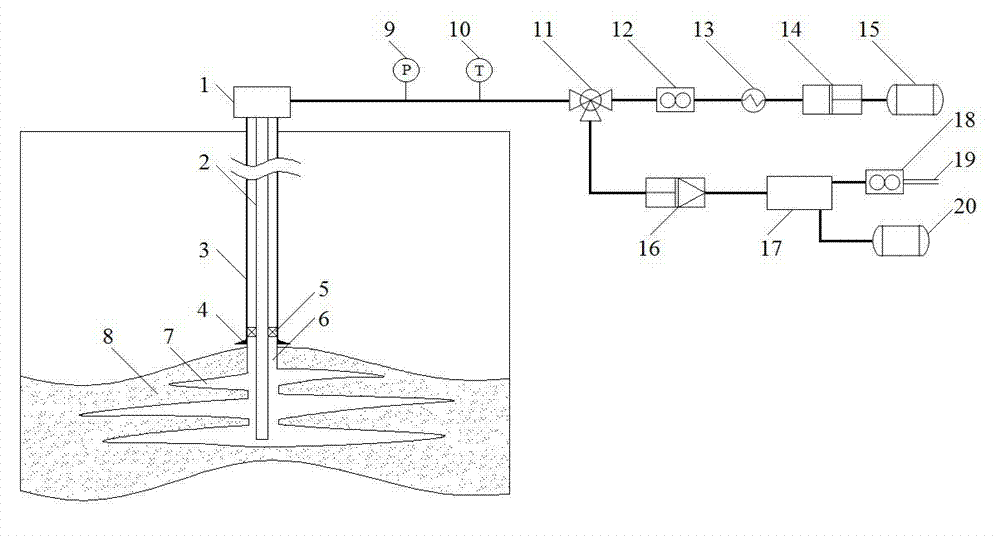

Experimental apparatus for exploiting natural gas hydrate reservoir by means of thermal fluid fracturing

The invention belongs to the technical field of unconventional oil and gas exploitation, and particularly relates to an experimental apparatus for exploiting natural gas hydrate reservoir by means of thermal fluid fracturing. The experimental apparatus for exploiting the natural gas hydrate reservoir by means of thermal fluid fracturing comprises a hydrate core three-axis fracturing system, a fracturing fluid injection system, a natural gas exploitation system and an acoustic emission monitoring system, and is characterized in that the hydrate core three-axis fracturing system is used for fracturing a hydrate core to form hydraulic fracture; the fracturing fluid injection system provides high-pressure thermal fracturing fluid in a hydrate fracturing procedure; the natural gas exploitation system is used for exploiting the natural gas hydrate core in a depressurization manner; and the acoustic emission monitoring system is used for detecting an expansion procedure of the fracture and flowing states of multiple phases of fluid in the fracture. The experimental apparatus has the advantages that a ground stress state of the actual natural gas hydrate reservoir can be truly simulated, and mechanism study and effectiveness evaluation for exploitation for the natural gas hydrate reservoir by means of thermal fluid fracturing can be implemented.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

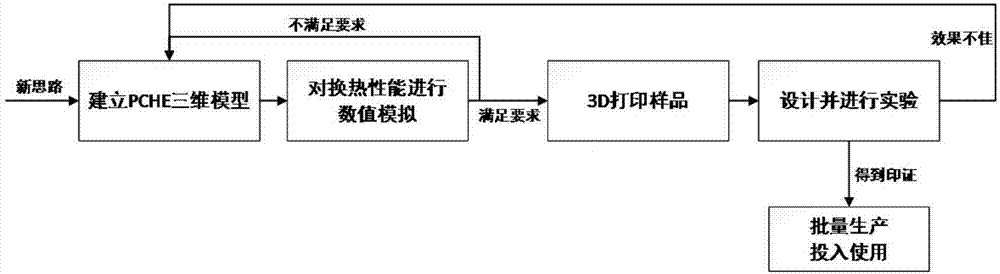

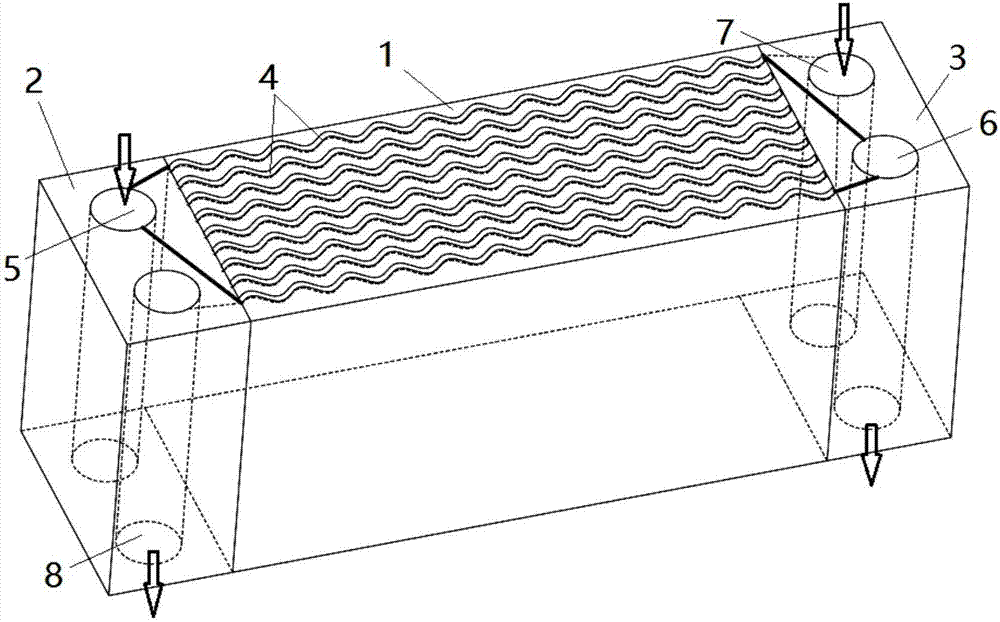

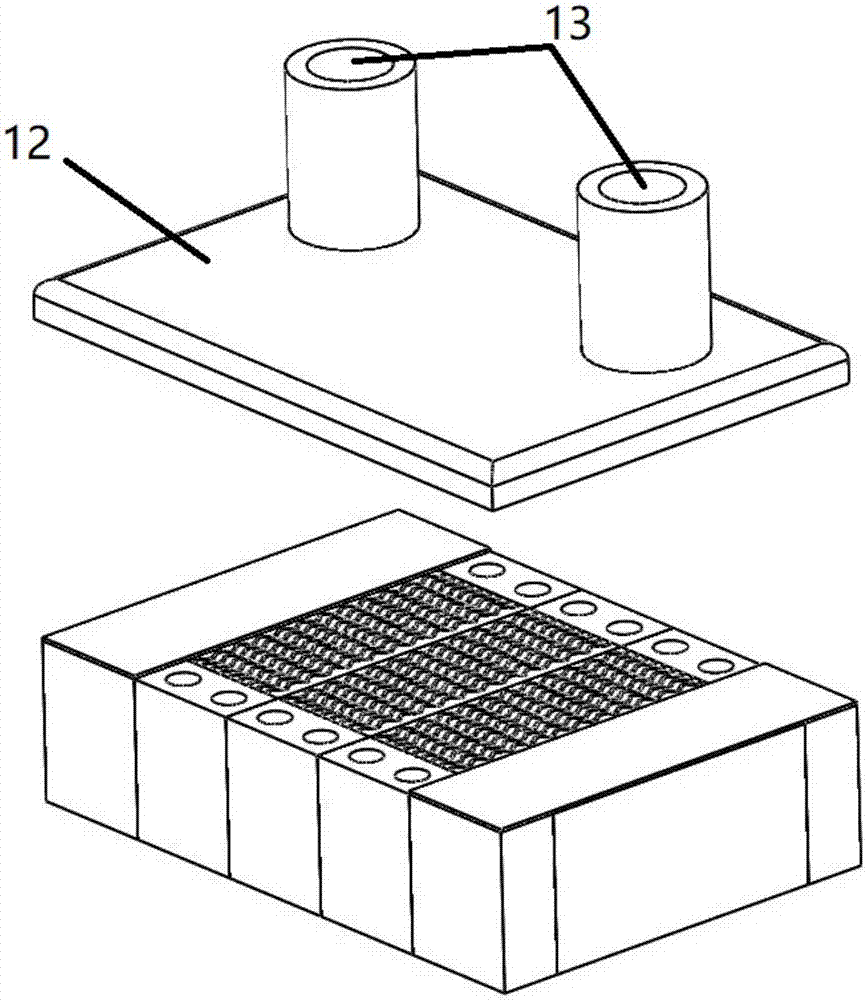

Novel printed circuit board type heat exchanger based on 3D printing technology

InactiveCN107388854AImprove work performanceSimple designHeat exchanger casingsStationary tubular conduit assembliesInlet channelEngineering

The invention discloses a novel printed circuit board type heat exchanger based on a 3D printing technology. The novel printed circuit board type heat exchanger based on the 3D printing technology comprises a heat exchange main body formed on the basis of the 3D printing technology, wherein two ends of the heat exchange main body are a first heat exchanger inlet and outlet section and a second heat exchanger inlet and outlet section separately; a thermal fluid inlet channel and a cold fluid outlet channel are formed in the first heat exchanger inlet and outlet section in the vertical direction; a thermal fluid outlet channel and a cold fluid inlet channel are formed in the second heat exchanger inlet and outlet section in the vertical direction; a plurality of layers of periodic heat exchange channels are formed in the middle of the heat exchange main body from bottom to top; part of the periodic heat exchange channels communicate with the thermal fluid inlet and outlet channel; and the rest of periodic heat exchange channels communicate with the cold fluid inlet and outlet channel. The 3D printing technology is adopted, the whole heat exchanger is formed integrally, and loss of drainage, resistance and the like due to manufacturing errors can be reduced.

Owner:XI AN JIAOTONG UNIV

Adjustable thermal cap

A thermal cap that can fit a variety of head sizes is disclosed. The cap can include a shell having a fluid inlet and outlet, a sealing mechanism and removable sizing layers disposed within the shell. Depending upon the size of a patient's head, sizing layers can either be added to or removed from the outer shell to maintain a fluid circulation space between the head and the rigid shell and allow substantially even distribution of a thermal fluid about the scalp of the patient during operation. The shell is preferably rigid and an elastomeric member can seal the periphery of the cap to the patient's head to prevent leakage. Other types and aspects of thermal cap systems are also disclosed.

Owner:MEDCOOL

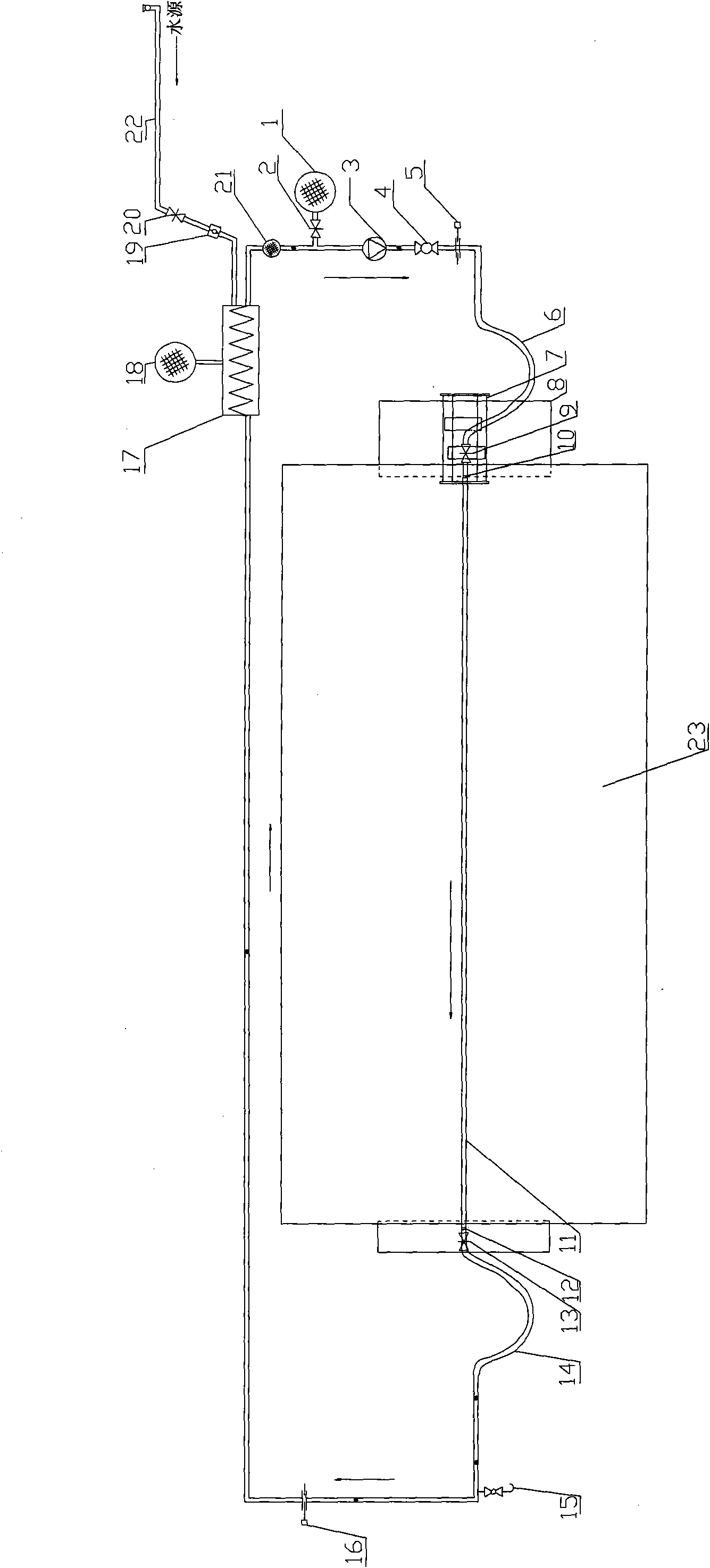

Quick test device and method for performances of trough type solar thermal collector

ActiveCN101666704AQuick measurementSimple structureTesting optical propertiesExpansion tankFast measurement

The invention discloses a quick test device for performances of a trough type solar thermal collector, which comprises a fuel tank, a valve arranged at the port of the fuel tank, a fuel pump, a thermal collector, a heat interchanger, a vapor tank, an expansion tank, a water pipe and a direct radiometer which is fixed with the thermal collector in the same direction, wherein the focusing point of the thermal collector is provided with a thermal collecting pipe; the fuel tank is filled with heat conducting fuel; the thermal collector, the heat interchanger and the expansion tank are connected bypipelines in sequence to form a loop; the thermal collecting pipe is connected on the left of the valve, and the expansion tank is connected on the right thereof; and the water pipe and the vapor tank are respectively connected at the inlet and the outlet of the heat interchanger. The quick test device has the advantages of simple and easily-implemented structure and capability of realizing quicktest of performances of the thermal collector. The invention also discloses a quick test method for the performances of the trough type solar thermal collector.

Owner:深圳市汇元佳实业发展有限公司

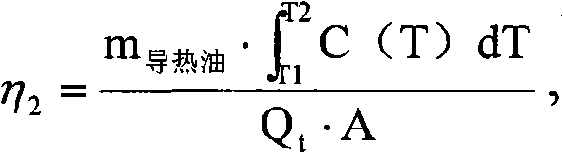

Sludge drying system and using method thereof

ActiveCN101708942AImprove protectionAvoid the "sticky phase" phenomenonSludge treatment by de-watering/drying/thickeningEnergy based wastewater treatmentThermal energySludge

The invention relates to a sludge drying system and a using method thereof. The system is characterized by comprising a sludge drying incineration loop, a conduction oil heat supply circulation loop and a high temperature smoke loop, wherein the sludge drying incineration loop comprises a dry sludge back-mixing device, a sludge drier, a sludge incinerator, a dry sludge storage bin and a dry sludge regulating valve; the conduction oil heat supply circulation loop comprises a conduction oil pump, a solar thermal collector, a solar radiation survey meter, a high temperature heat exchanger and two conduction oil regulating valves; and the high temperature smoke loop comprises an air blower. The sludge drying method comprises the following steps: firstly, drying wet sludge in the sludge drier to obtain dried sludge; returning and inputting the sludge to the sludge back-mixing device; mixing and re-inputting the dried sludge and the wet sludge to the sludge drier for drying; incinerating the dried sludge in the sludge incinerator, wherein heat energy released by high temperature smoke which is generated by incineration provides energy for drying with solar energy so as to avoid primary energy consumption. The system and the method can be widely applied to sludge drying treatment engineering.

Owner:TSINGHUA UNIV +3

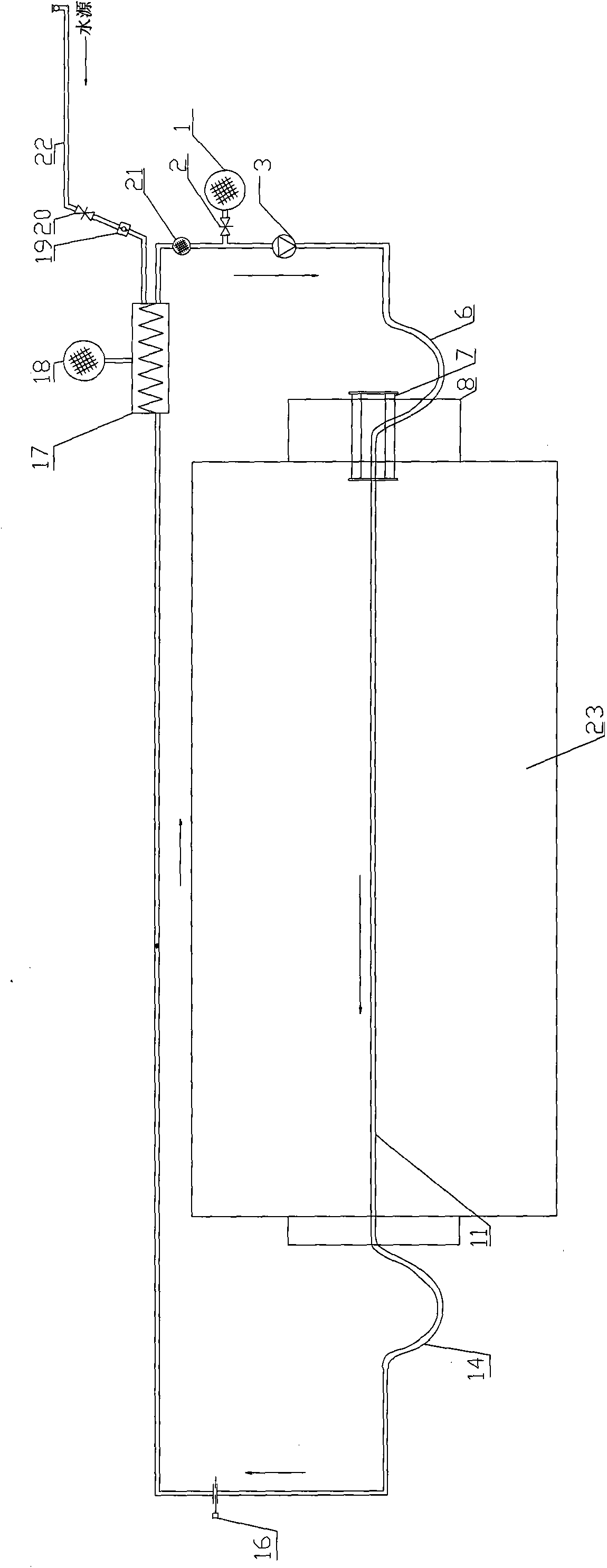

Coal bed gas well multiple thermal fluid strengthening mining method

The invention discloses a coal bed gas well multiple thermal fluid strengthening mining method. Coal bed gas mined in other gas wells is compressed to be fuel, then mixed with pressed air, filled into a multiple thermal fluid generating device and combusted to generate high-temperature high-pressure mixed gas such carbon dioxide and nitrogen. Mined underground water filled with the mixture and processed is vaporized by the high-temperature high-pressure mixed gas to generate a multiple thermal fluid mainly comprising mixed gas of the high-temperature high-pressure steam, the carbon dioxide and the nitrogen. The generated multiple thermal fluid is filled into an underground coal bed along an oil pipe from a well mouth, shut-in and soak are performed and after sleeving pressure goes stable, the well is opened for production. The coal bed gas well multiple thermal fluid strengthening mining method solves the problem that a carbon dioxide source is hard to obtain.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

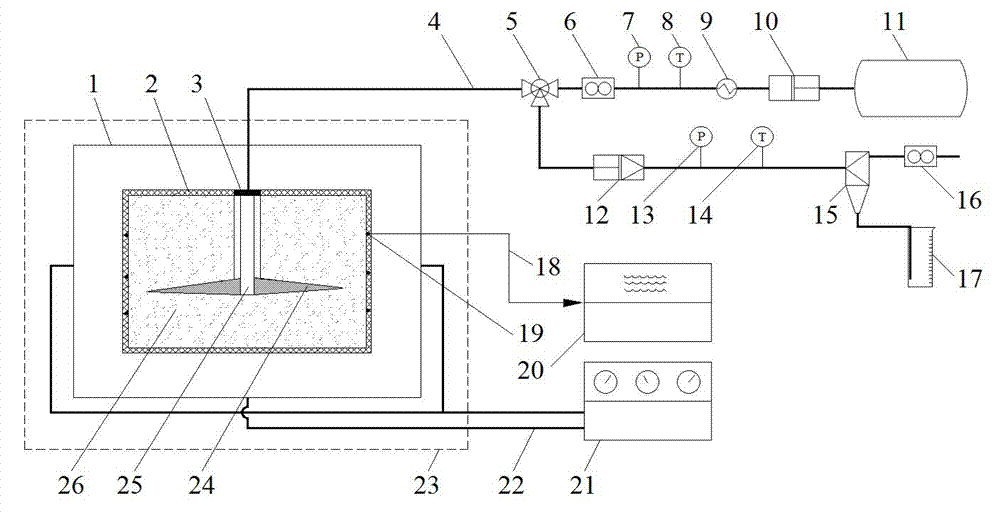

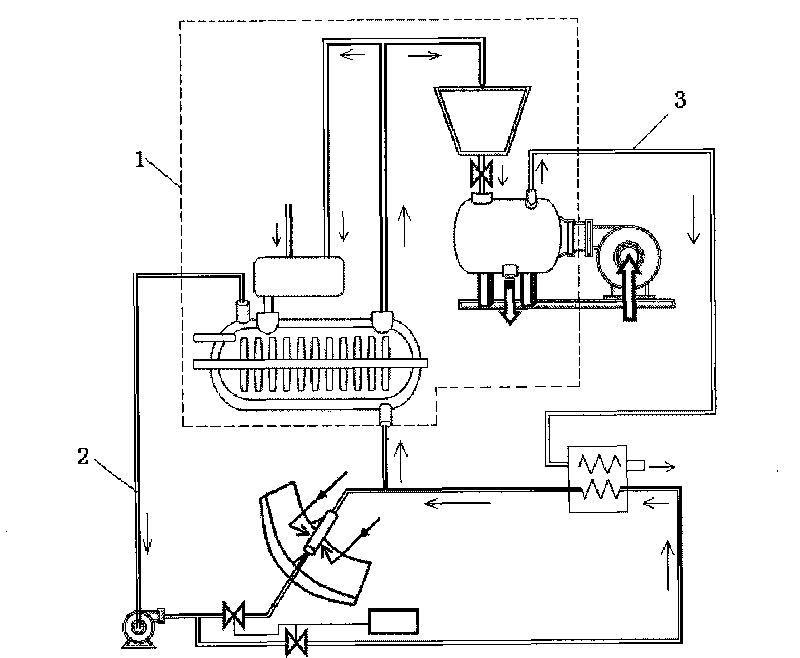

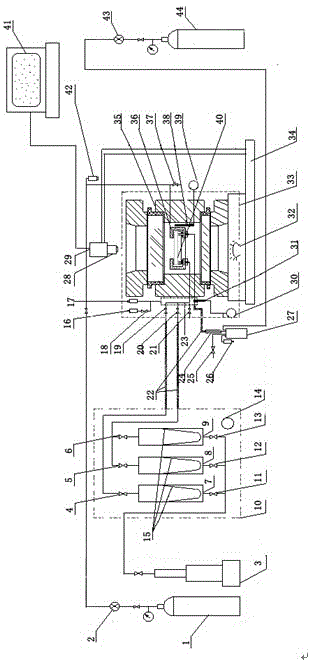

Heavy oil thermal recovery microscopic displacement experiment system

InactiveCN105569637AAvoid reflux fluctuationsImprove insulation effectSurveyConstructionsModel systemEngineering

The invention provides a heavy oil thermal recovery microscopic displacement experiment system. The heavy oil thermal recovery microscopic displacement experiment system comprises an injection system, a model system, an output system, and an image acquisition and analysis system. The injection system is provided with a power source to provide displacement thermal fluid. The model system receives the displacement thermal fluid provided by the injection system, and uses an inert gas to apply and control circling pressure on the periphery of a micro model, so as to carry out a displacement experiment on heavy oil by the thermal fluid. The output system receives output liquid after the displacement experiment, and maintains certain return pressure. The image acquisition and analysis system performs dynamic observation and shooting on a microscopic displacement process, and researches microscopic percolation characteristics and displacement mechanism. Through improving heating heat-retaining property and sealing property of the experiment system and return pressure control design, the heavy oil thermal recovery microscopic displacement experiment system makes an experiment process and an experiment method more reliable. The system can carry out heavy oil thermal recovery microscopic displacement experiments, and researches displacement effect analysis and displacement mechanism.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for vacuum linear source evaporation coating film and its apparatus

InactiveCN1598042AIncrease heating contact areaImprove effective utilizationVacuum evaporation coatingSputtering coatingMulti materialTemperature control

The method and the equipment of vacuum linear-source vapor filming relate to the technology of vacuum filming. The equipment of the invention is composed of exact heater, vapor cavity filling liquid, vapor boat with concavo-convex trough, milling arm, narrow slot cover board, baffle resisting pollution, switch baffle, thermoscope and so on. Different materials can be put in the flute, processing the basic-quality vapored, intermingled, braized together. The exact heater of the equipment is placed out of the vacuum system. The invention can guarantee the vapor boat and the materials in the boat be heated with symmetrical temperature, stable vapor speed. This invention can improve not only the efficient utilizing rate of vapor materials, but also the vapor plating quality of the thin film.

Owner:成建波

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com