Method and device for comprehensively utilizing energy of high-pressure natural gas

A natural gas and high-pressure technology, applied in the field of comprehensive utilization of high-pressure natural gas energy, can solve the problems of limited practical application, power output pressure, frequency and power instability, and inability to adapt to the supply pressure of natural gas users' consumption, etc., to improve system stability, The effect of preventing icing and improving the efficiency of pressure energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

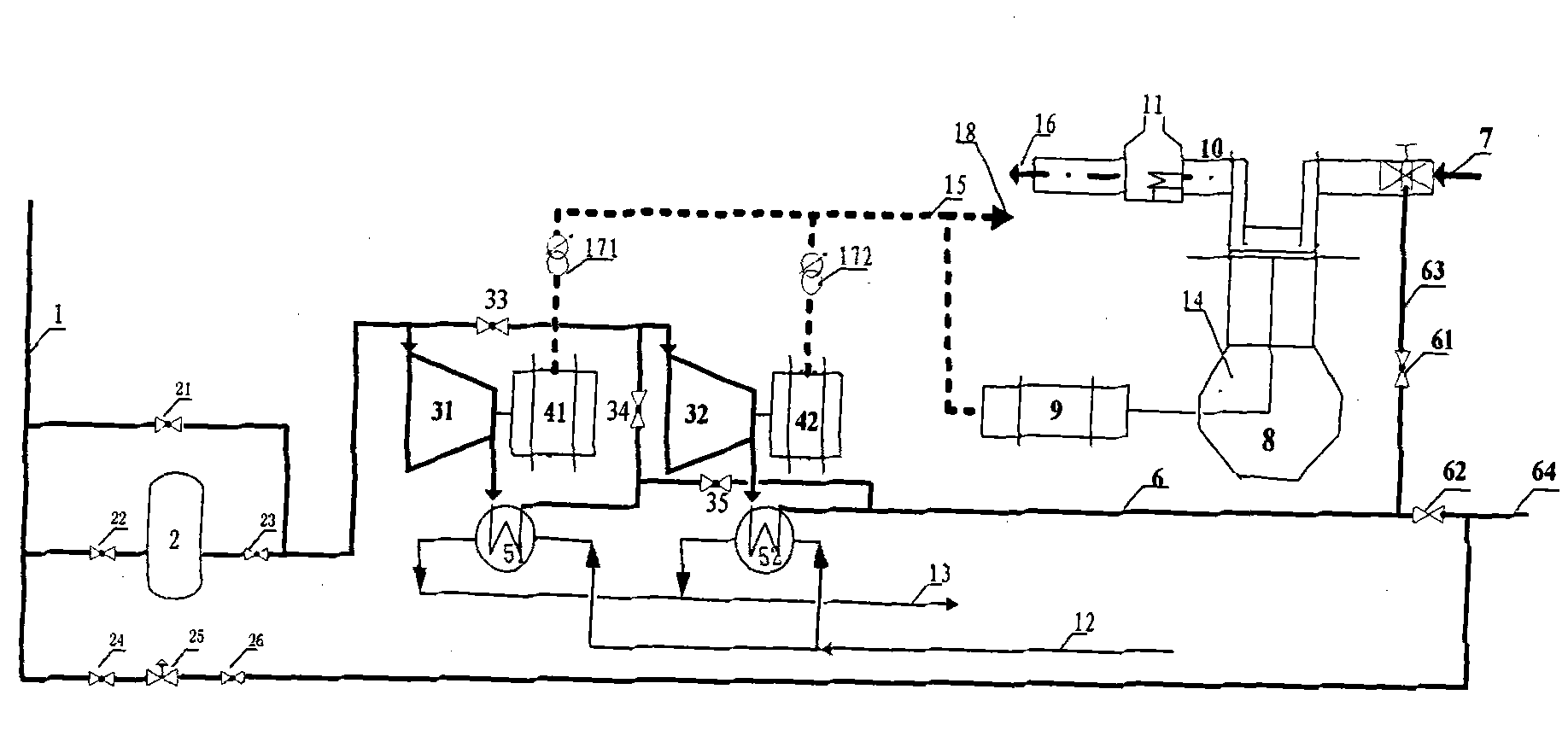

[0066] Such as figure 1 As shown, the high-pressure natural gas transported through the high-pressure natural gas pipeline network 1 has a pressure fluctuation range of 1.6 to 3.5Mpa, a temperature of about 25°C, contains 0.2% carbon dioxide and saturated water, and a flow rate of 20,000 Nm3 / H. It is decarbonized by molecular sieves After the dehydration tower 2, the dew point temperature drops to -35°C, the carbon dioxide content drops to 50PPM, and enters the turbo-expansion depressurization process. This process can have two operating modes according to the changes in the flow and pressure of natural gas used by downstream users:

[0067] 1. Turbo expanders run in series:

[0068] When the natural gas pressure is 2.0-3.5Mpa and the flow rate is 2000--6000Nm 3 When / H, the series operation mode of the turbo expander is adopted. At this time, the valves 33 and 35 are closed, and the valve 34 is opened. The clean natural gas first passes through the turbo expander 31 of model...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com