Patents

Literature

59results about How to "Achieve low carbon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Organic ecological farming system for rice field

InactiveCN105532342ALabor savingRealization costClimate change adaptationFertilising methodsFertilizerDitch

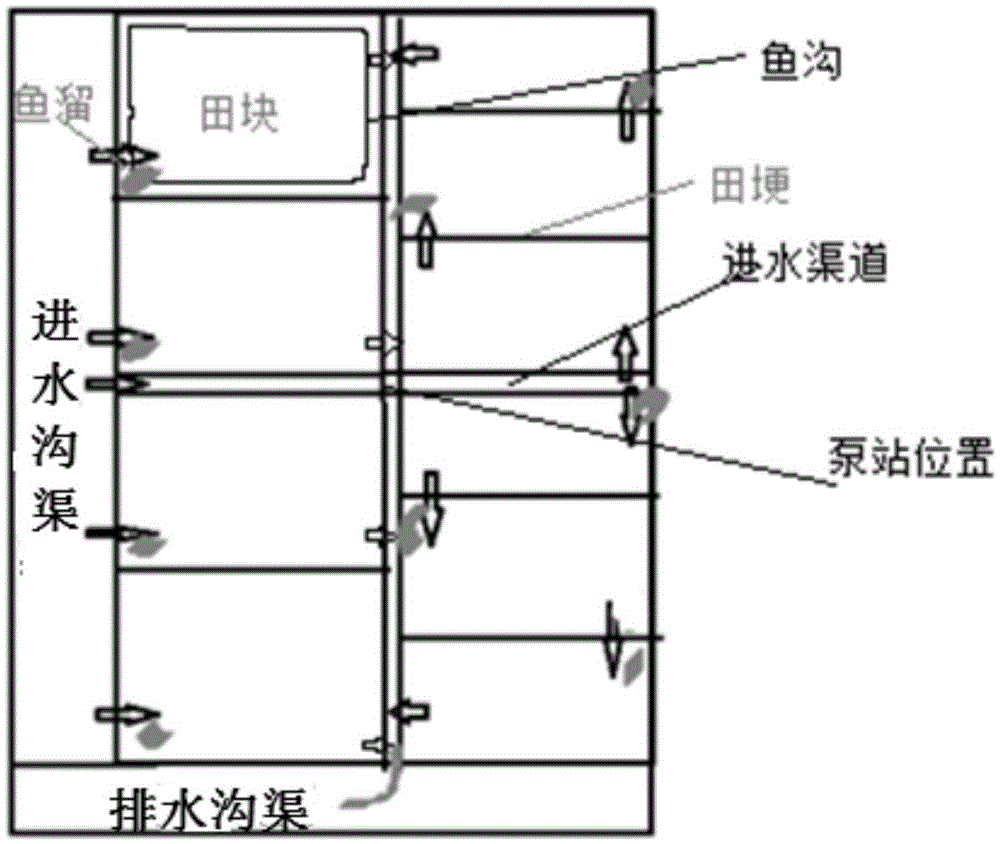

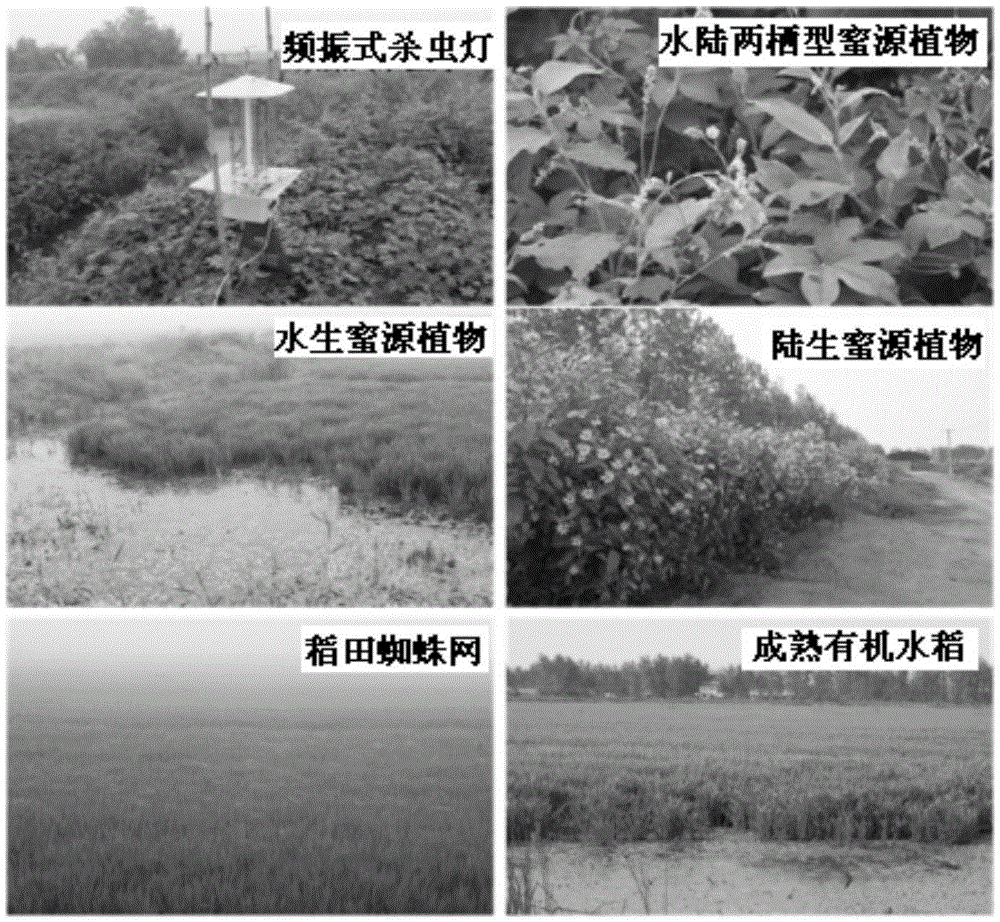

The invention relates to an organic ecological farming system for a rice field. The system is characterized in that a water inlet canal, a drainage canal, a water inlet channel and a drainage channel are crossed to form the cross-shaped drainage rice field, a pump station is arranged at the crossed position of the crossed canals and channels, the rice field is divided into multiple field pieces in the type of plain terraced fields, fish ditches are arranged on the peripheries of the field pieces, and a fish pit is arranged at one corner of each field piece. According to the organic ecological farming system, high harvesting benefits of both rice and fish are achieved, and meanwhile the water conservation fertilizer conservation, low carbon and high ecosystem service functions are achieved; organic ecological farming can be carried out by transforming a common rice field near a good water source appropriately, and the optimized technology for transforming low yield fields and bottom land is achieved.

Owner:HUAIAN SUZE ECOLOGICAL AGRI CO

Method and device for comprehensively utilizing energy of high-pressure natural gas

InactiveCN102383868AImprove the efficiency of pressure energy utilizationImprove system stabilityInternal combustion piston enginesGaseous fuelsCompressed natural gasChemical energy

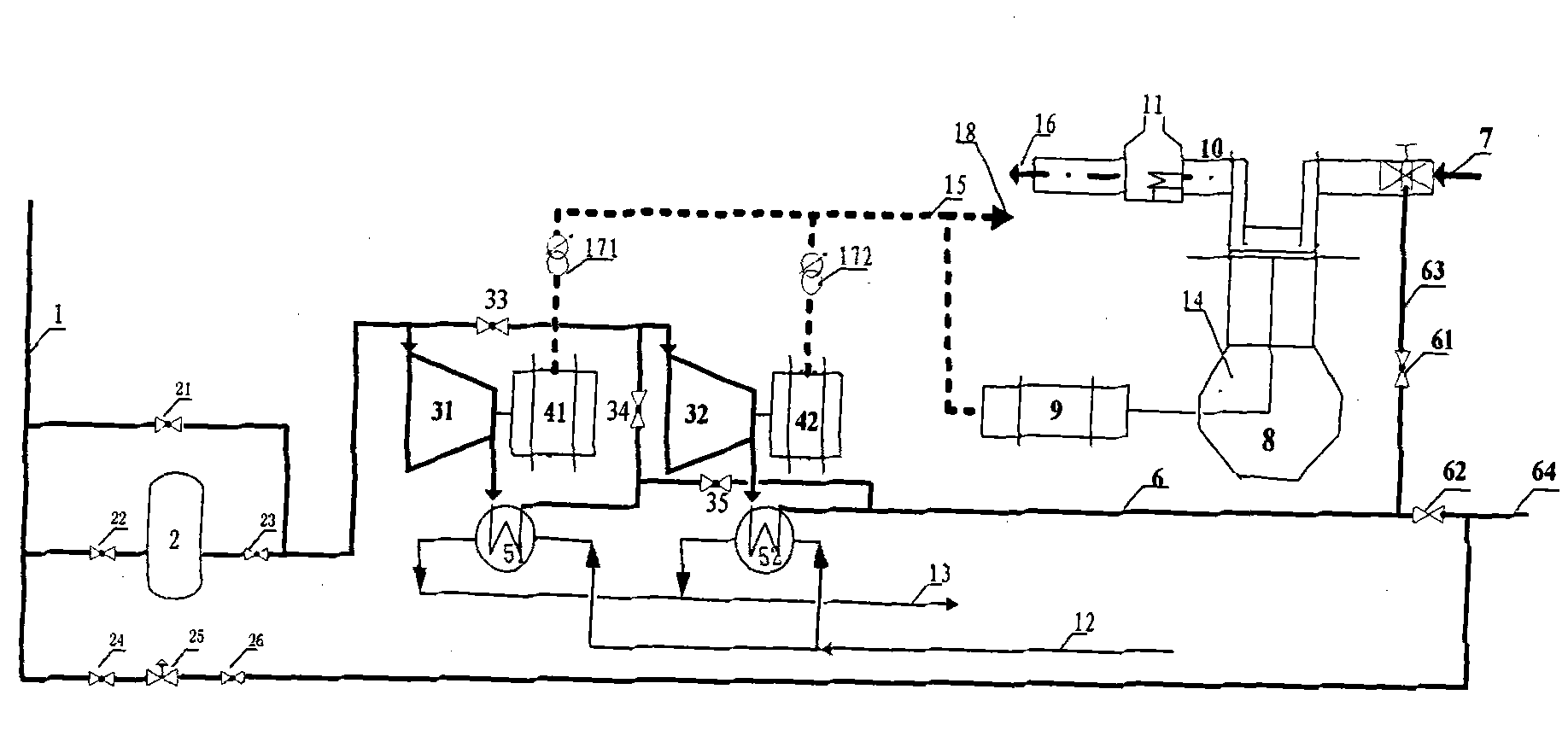

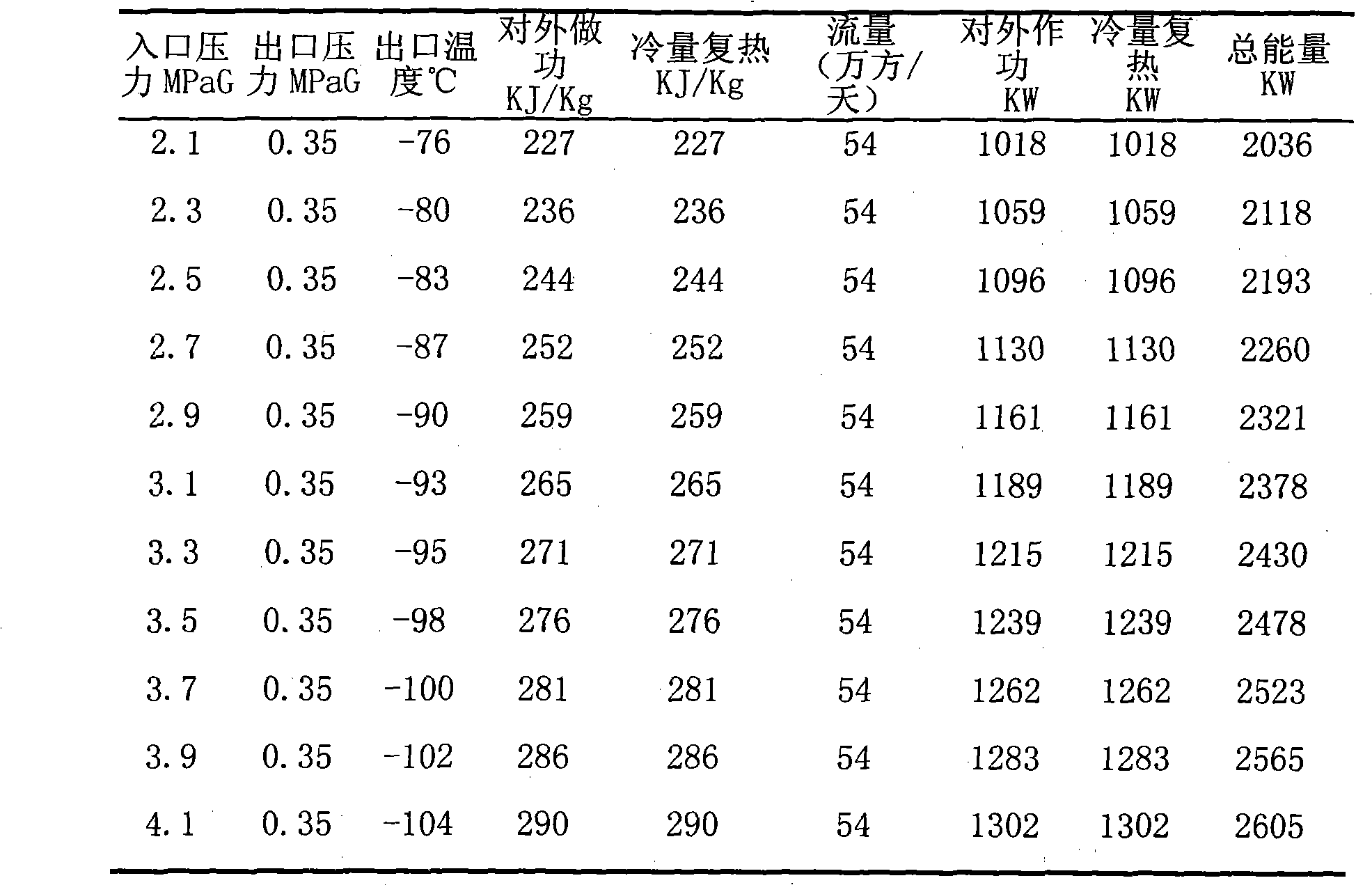

The invention relates to a method and a device for comprehensively utilizing energy of high-pressure natural gas. The method comprises the following steps of: carrying out decarbonization and dehydration on the high-pressure natural gas; reducing a temperature and a pressure of the high-pressure natural gas by turbine expansion; generating electricity by shaft work output by a turbine expansion engine; carrying out cold energy collection on the natural gas subjected to turbine expansion by a heat exchanger, feeding the natural gas subjected to heat exchange by the heat exchanger into an internal combustion engine to generate chemical energy; generating electricity by the chemical energy; and feeding high temperature fume generated by the internal combustion engine into a waste heat boiler to generate steam or hot water. The device comprises a high-pressure natural gas pipeline, a low-pressure natural gas pipeline, a pressure regulator, a valve, the turbine expansion engine, a turbine expansion engine generating set, an internal combustion engine generating set, the heat exchanger, a decarbonization and dehydration mechanism, a frequency converter and the waste heat boiler. The decarbonization and dehydration mechanism is connected with the high-pressure natural gas pipeline and the turbine expansion engine. The turbine expansion engine is connected with a generator and the heat exchanger. The heat exchanger is connected with the low-pressure natural gas transmission and distribution pipeline, thermal fluid and a cold energy pipeline. The internal combustion engine is connected with the generator, the low-pressure natural gas pipeline and the waste heat boiler. Heat energy generated by the waste heat boiler is transferred to thermal equipment. Two types of electric energy are transferred to electric equipment through the frequency converter. The energy utilization rate is improved.

Owner:刘俊德 +2

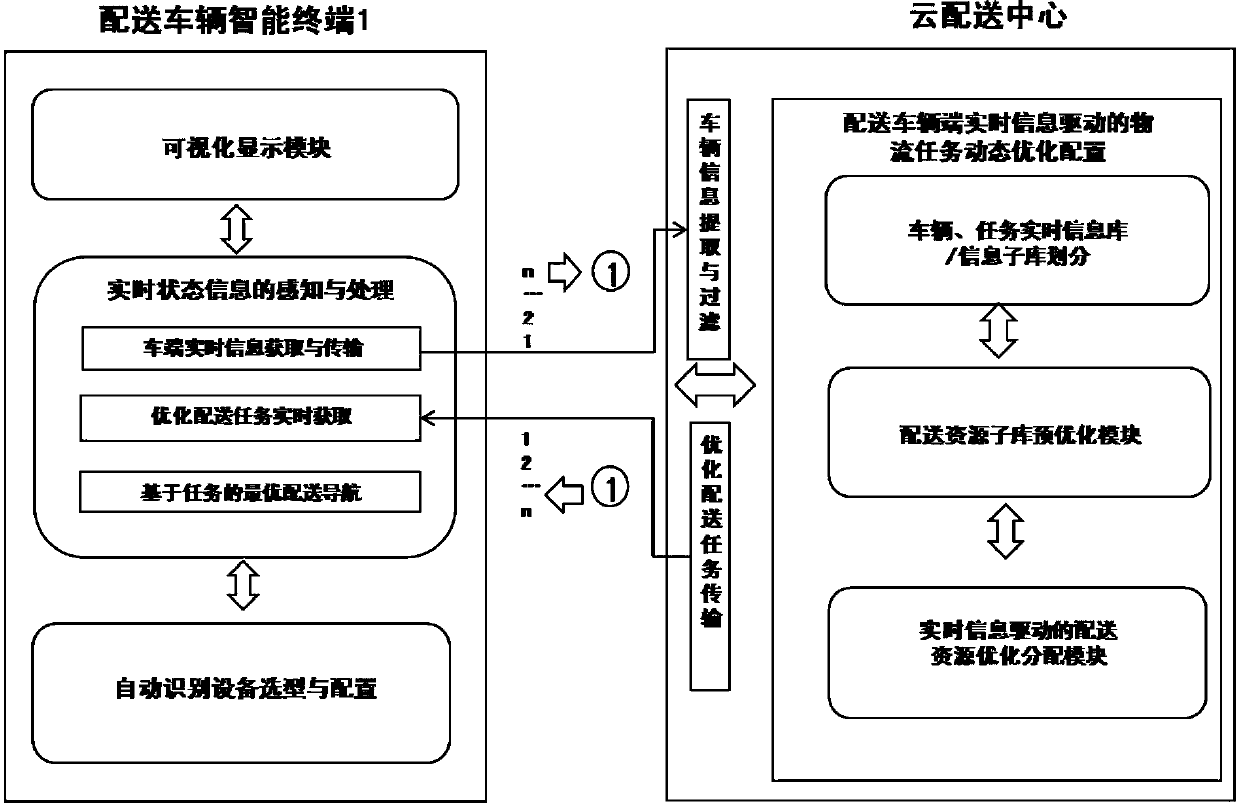

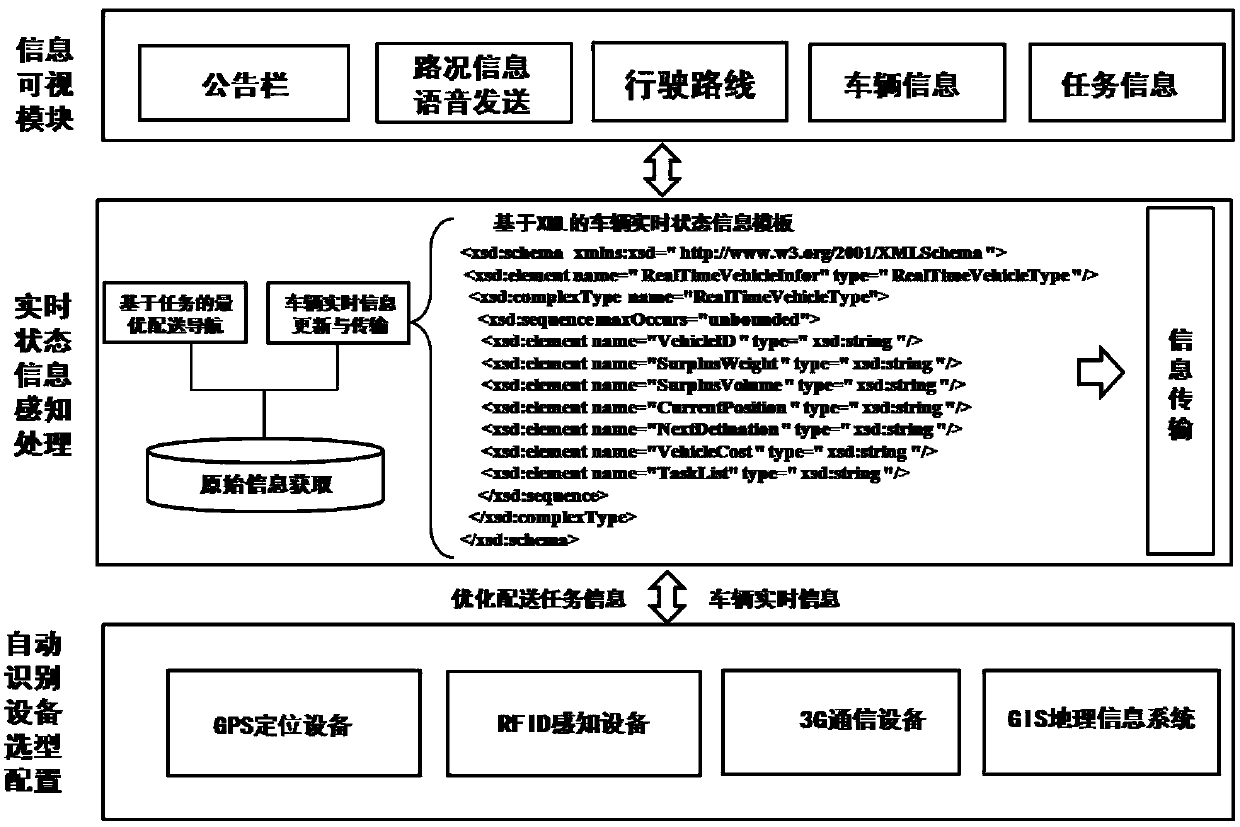

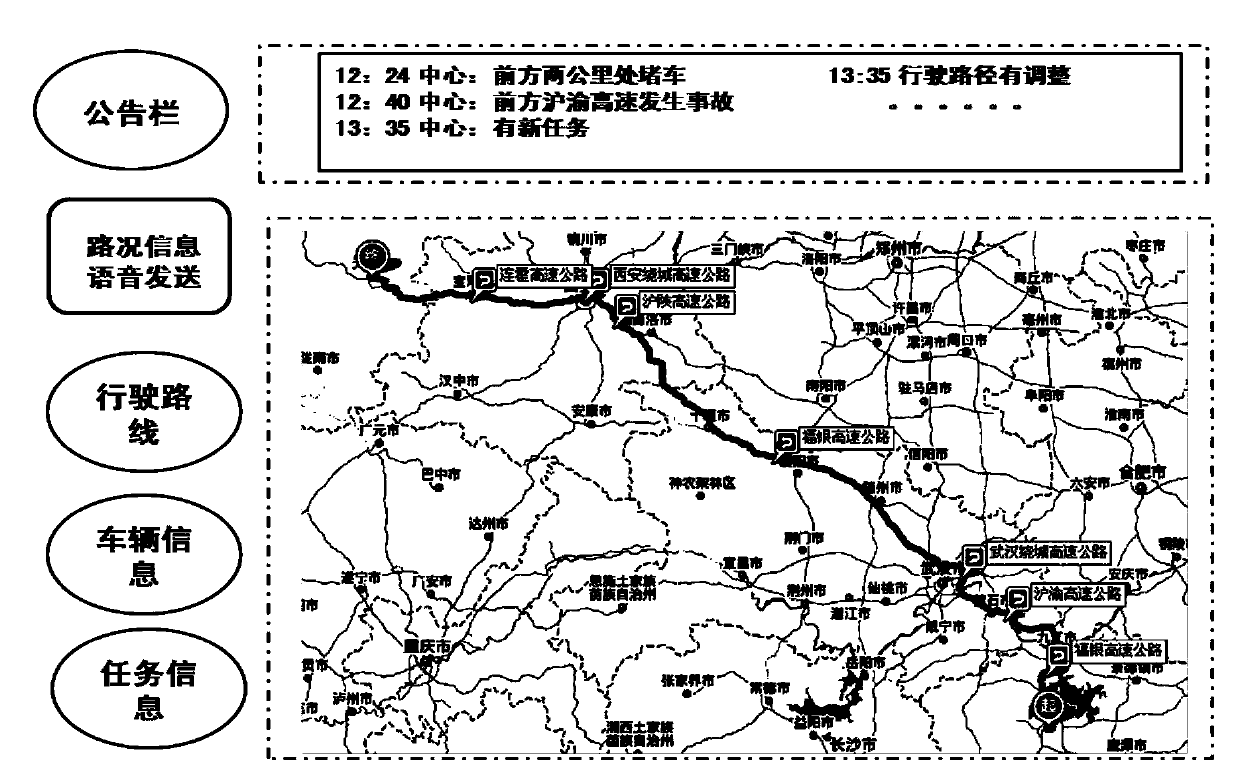

Dynamic optimal distribution method for logistics tasks based on distribution vehicle end real-time state information drive

InactiveCN103473659AIncrease load rateAchieve low carbonForecastingLogisticsTime informationLogistics management

The invention discloses a dynamic optimal distribution method for logistics tasks based on distribution vehicle end real-time state information drive, aiming at solving the technical problem of resource waste caused by low vehicle loading rate in a conventional dynamic logistics task distribution method. According to the technical solution, automatic identification equipment for intelligently acquiring and transmitting real-time state information of a distribution vehicle in logistics distribution activities is configured at the logistics distribution vehicle end, the real-time state information of the vehicle is sensed by the vehicle through using an internet-of-things technology and transmitted to a distribution task management center, and the distribution center performs dynamic optimal distribution on the logistics distribution tasks according to the real-time information of each distribution vehicle and each distribution task, so that the loading rate of the vehicle is improved, and logistics distribution resources are furthest integrated. The method achieves the objectives of reducing the logistics cost and realizing low-carbon, efficient and green logistics.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

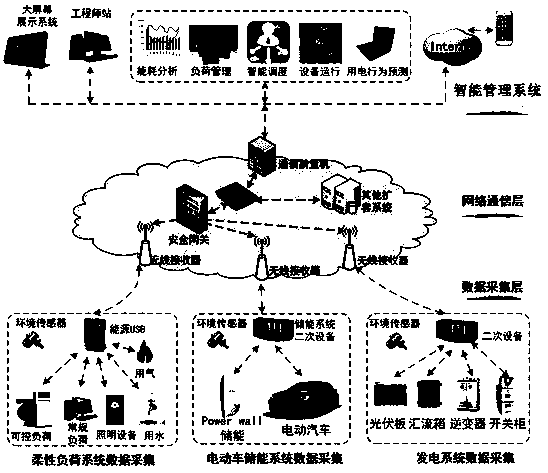

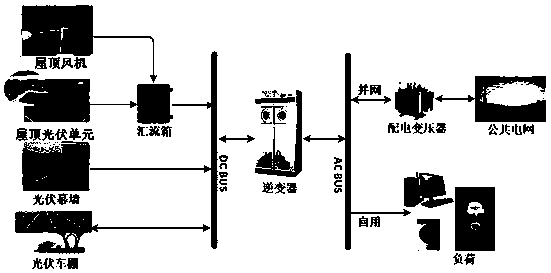

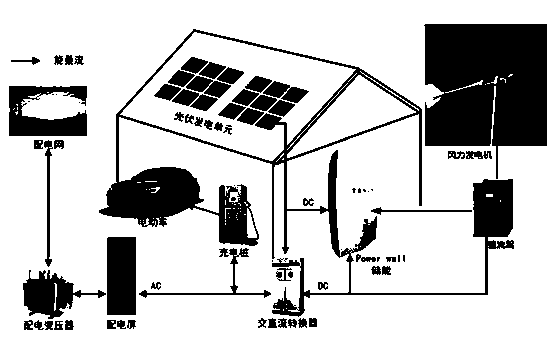

Distributed wind-solar-storage integrated microgrid intelligent control system

InactiveCN109038823AIntelligent managementWaste minimizationSingle network parallel feeding arrangementsAc network load balancingThe InternetNetwork communication

The invention discloses a distributed wind-solar-storage integrated microgrid intelligent control system, which comprises a distributed generation unit, a distributed energy storage unit, a flexible load unit, a control unit and a network communication unit. The monitoring platform receives the flexible load unit through the network communication unit, the signals collected by the distributed energy storage unit and the distributed power generation unit, On the one hand, the monitoring platform stores the received acquisition signals in the database server, on the other hand, the received acquisition signals are fused and processed, and then send control commands to the flexible load unit, the distributed energy storage unit and the distributed power generation unit through the network communication unit after the processing; The monitoring platform displays the processing results on the display screen, and communicates with the workstation in two directions for engineers to control the monitoring platform, and the monitoring platform communicates with the mobile terminal in two directions through the Internet. Through reasonable optimization and dispatching, the utilization rate of clean energy and absorbing capacity are improved, so as to to achieve the optimal power matching of micro-grid system, to achieve efficient energy conservation.

Owner:STATE GRID CORP OF CHINA +1

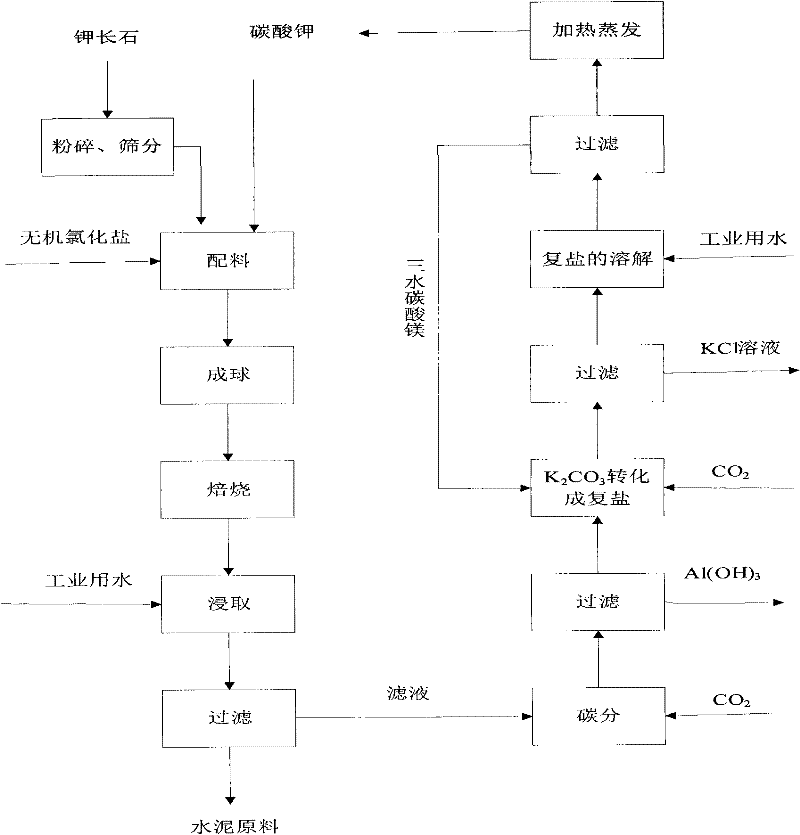

Method for producing potassium fertilizer and aluminum oxide by comprehensively using potassium feldspar

InactiveCN102531710ARealize comprehensive utilizationImprove utilizationAluminium compoundsPotassium fertilisersAluminium hydroxideChloride

The invention relates to a method for producing a potassium fertilizer and aluminum oxide by comprehensively using potassium feldspar. The method comprises the following steps of: (1) smashing potassium feldspar and inorganic chlorate, and burdening potassium feldspar, inorganic chlorate and potassium carbonate in the mass ratio of 1:(1-2):(1-10); (2) pelletizing the prepared material, and sintering at the temperature of 500-1,200 DEG C for 1-5 hours to obtain a sintered material and generate CO2 gas simultaneously; (3) soaking the material obtained in the step (2) into water and filtering; (4) introducing a filtrate obtained in the step (3) into the CO2 gas obtained in the step (2) to obtain an aluminum hydroxide precipitate, and filtering; (5) adding a filtrate obtained in the step (4) into nesquehonite, introducing CO2 gas to obtain a complex salt precipitate, filtering and crystalizing a filtrate to obtain a potassium chloride chemical fertilizer; and (6) adding water for dissolving a complex salt obtained in the step (5) to obtain a solid of nesquehonite, circularly using, heating a potassium bicarbonate solution for decomposing to obtain a potassium carbonate solution for circularly using, and repeating the step (1) to the step (6).

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

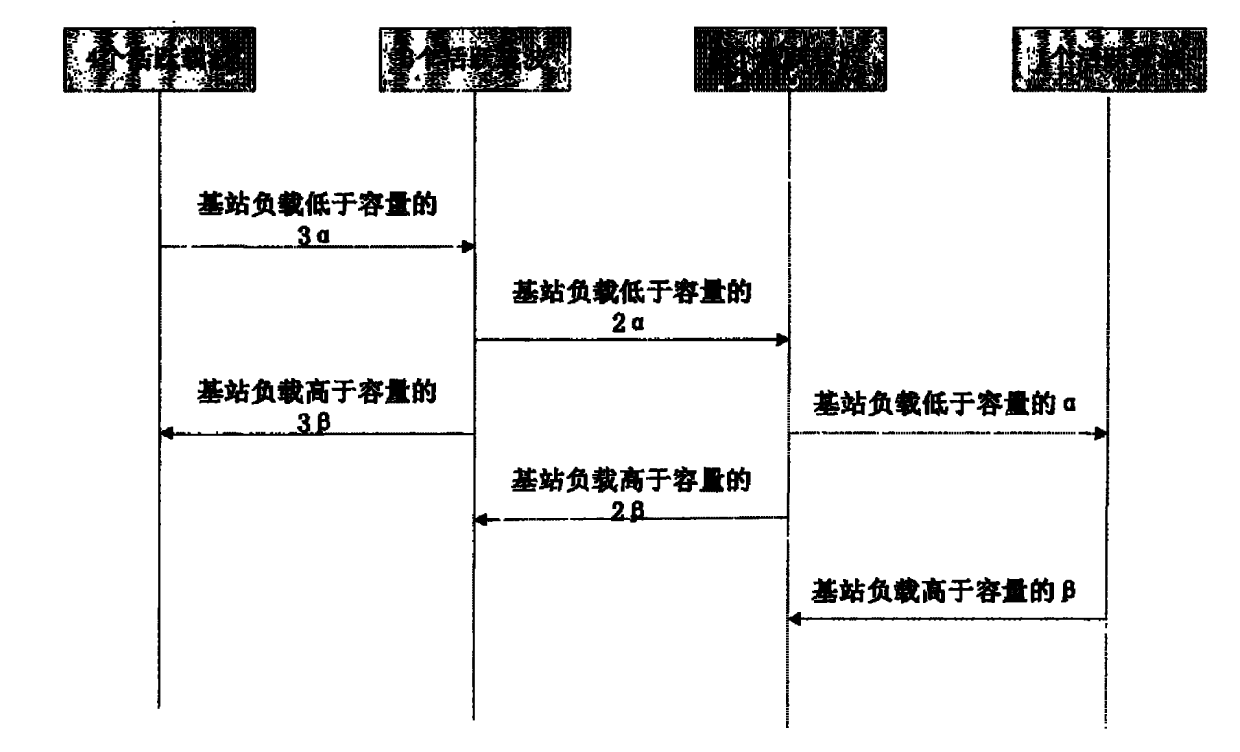

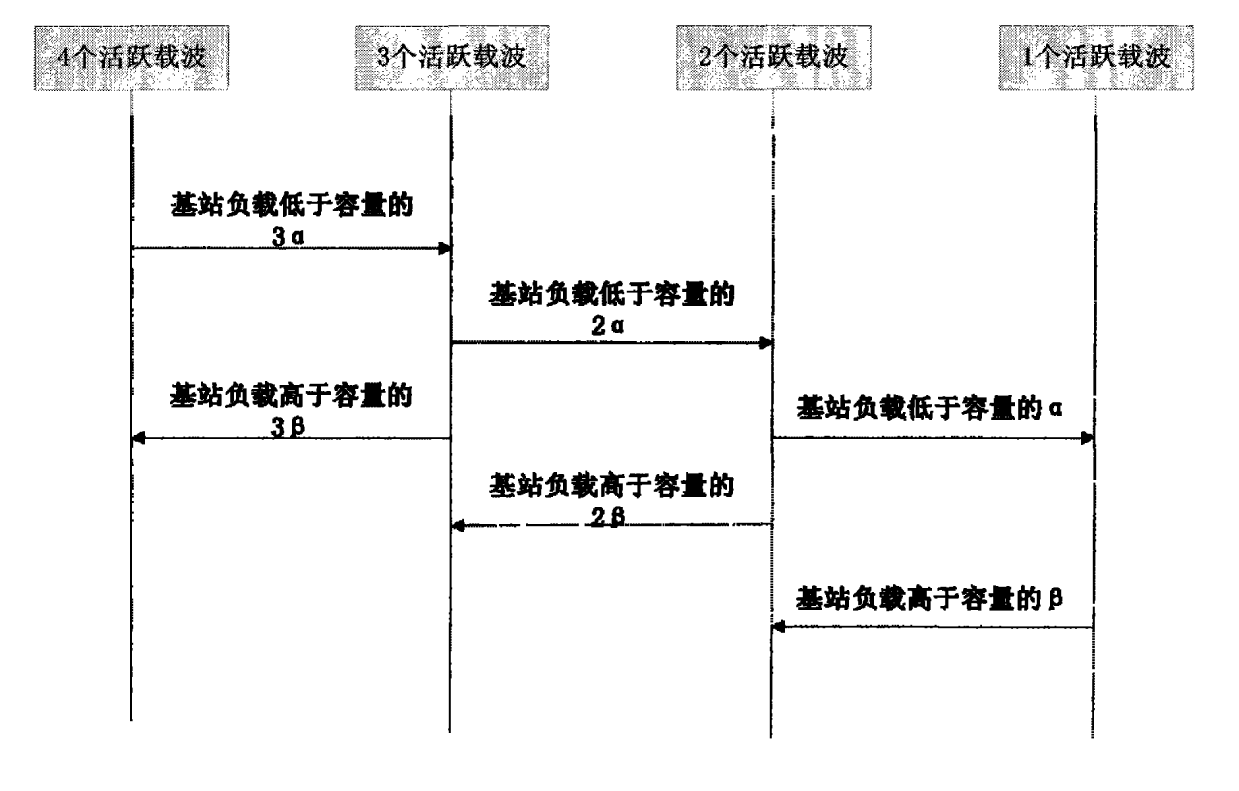

Energy-saving method of wireless communication system

InactiveCN102170685ARealize energy savingAchieve low carbonPower managementEnergy efficient ICTCommunications systemCarrier signal

The invention discloses an energy-saving method of a wireless communication system, and the method is designed for solving the problem that the coverage of base stations is non-overlapped in the deployment of the wireless communication system. The wireless communication system is not always in a full load operation state, and carriers from the base stations are in an idle state in much time, so that one certain carrier is dynamically turned on / off according the change of loads of the base stations in the energy-saving process to save the energy consumption of the base stations for the carrier, thus the low-carbon energy-saving purpose is achieved.

Owner:BEIJING UNIV OF POSTS & TELECOMM

Conductive run board and manufacturing method thereof

InactiveCN102309835ASolve static problemsAvoid adsorptionSynthetic resin layered productsWood layered productsMethyl ethyl ketone peroxideEngineering

The invention discloses a conductive run board and a manufacturing method thereof. No static electricity is generated even if a running belt and the run board mutually rub, so that the conductive run board is safe and reliable to operate. The conductive run board is characterized in that the substrate surface of the run board is covered with a conductive layer. The formula of the conductive run board comprises the following raw materials in parts by weight: 100 parts of unsaturated polyester resin, 15-30 parts of graphite, 0.3-1.2 parts of cobalt promoting agent and 0.5-2 parts of methyl ethyl ketone peroxide. The manufacturing method of the conductive run board comprises the following steps: according to the above formula components, mixing the graphite into the unsaturated polyester resin; dispersing by a three-roll grinder; adding the cobalt promoting agent to evenly mix; then adding the methyl ethyl ketone peroxide to evenly mix; coating on the substrate surface of the run board; and curing at normal temperature.

Owner:吴小凤

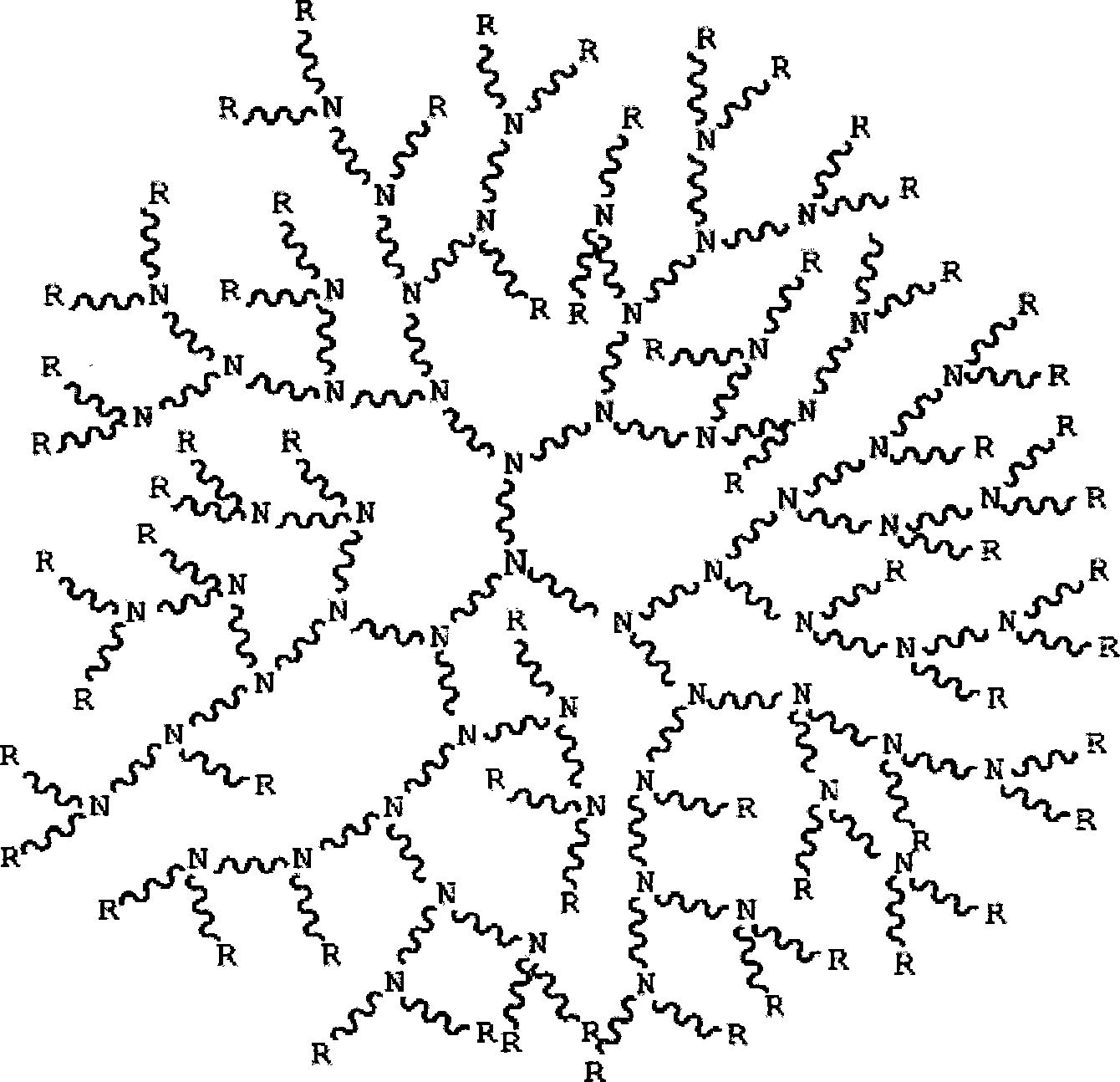

Environmental-friendly water paint and preparation method thereof

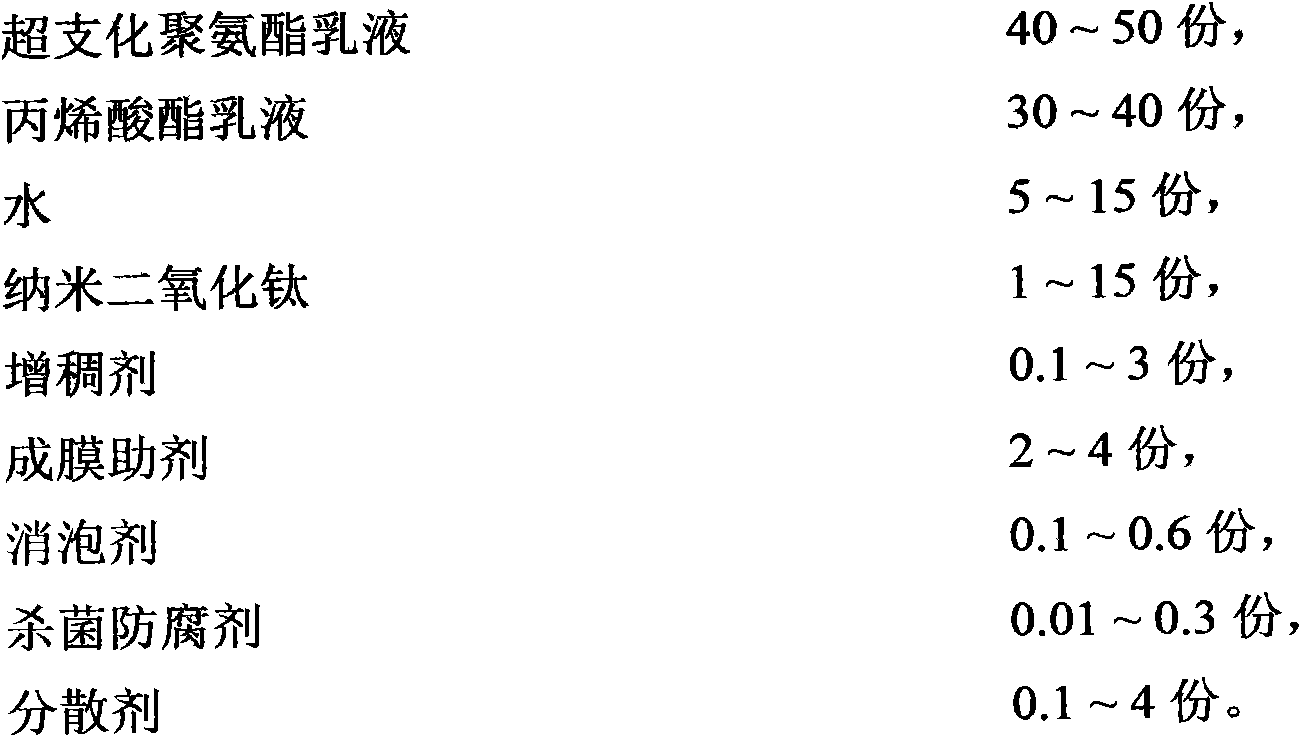

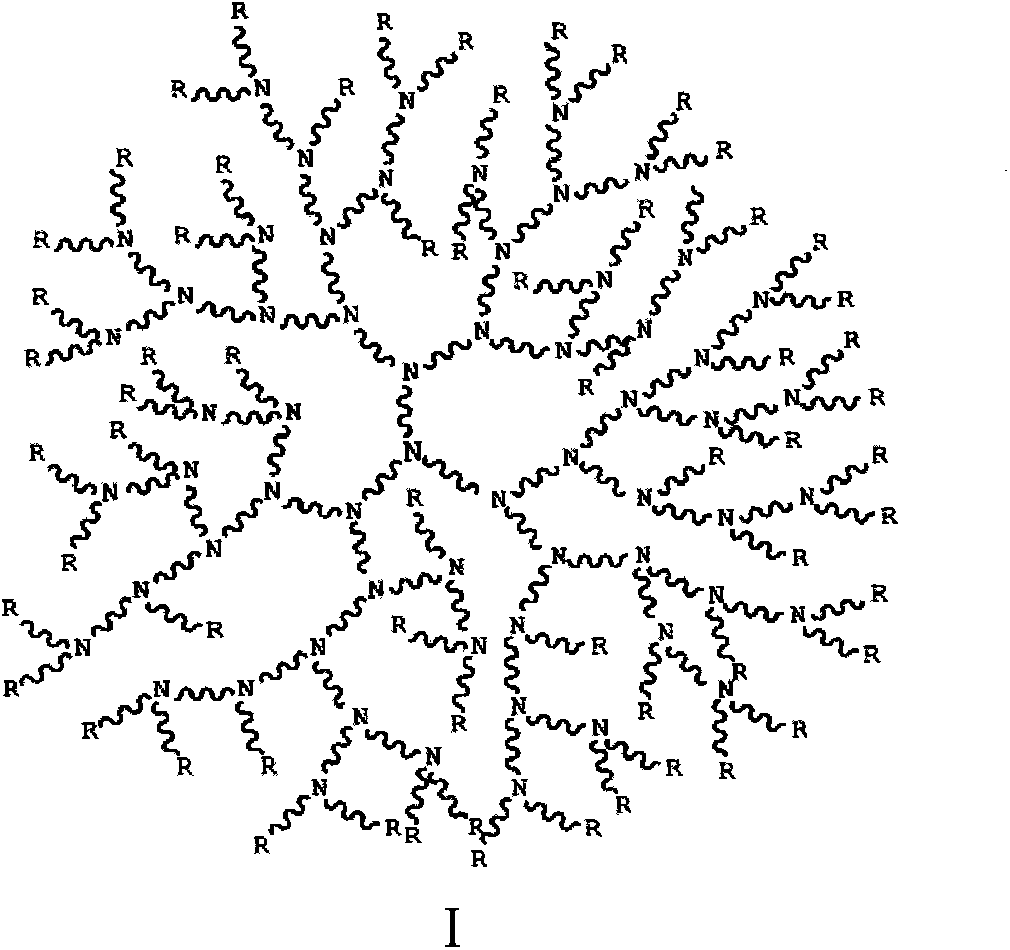

InactiveCN104356920AAvoid secondary pollutionGood for healthAntifouling/underwater paintsPaints with biocidesEmulsionPreservative

The invention relates to environmental-friendly water paint. The water paint comprises the following substances: 40-50 parts of a hyperbranched polyurethane emulsion, 30-40 parts of an acrylic ester emulsion, 5-15 parts of water, 1-15 parts of nanometer titanium dioxide, 0.1-3 parts of a thickening agent, 2-4 parts of a film forming additive, 0.1-0.6 part of an antifoaming agent, 0.01-0.3 part of a disinfecting preservative, and 0.1-4 parts of a dispersing agent. The invention also relates to a preparation method for the water paint. An active group in the water paint is an alpha amino. The invention begins with a film forming substance of a paint film, firstly, the alpha amino is prepared into histidine of which the alpha amino is protected, then the histidine is introduced into film forming resin, and the tail end of the hyperbranched structure of a resin molecule is just the active group alpha amino, so that the active group alpha amino is furthest exposed, effective active groups in the resin molecule are greatly improved, and the effective active groups are in wide contact with methanal; therefore, methanal is converted into a steady nontoxic chemical compound, and the purpose of effectively removing methanal is achieved.

Owner:鹤山市信兴化工有限公司

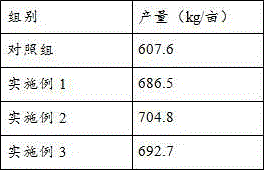

Special compound fertilizer for rice as well as preparation method and applying method of special compound fertilizer

InactiveCN106116937AIncrease organic matterAchieve recyclingSuperphosphatesExcrement fertilisersEcological environmentDrainage basin

The invention discloses a special compound fertilizer for rice. The special compound fertilizer is prepared from the following raw materials of 40-50 parts of an organic fertilizer,10-15 parts of straw, 20-30 parts of a nitrogenous-phosphorus-and potassium fertilizer, 3-5 parts of calcium superphosphate, 3-5 parts of ferrous sulfate, 3-5 parts of zinc sulfate, 3-5 parts of hydroxymethylcellulose, and 0.3-0.5 part of a microorganism microbial population. The invention further discloses a preparation method and applying method of the special compound fertilizer. Through a reasonable fertilizer formula, the simple and easy preparation method and the simple and easy applying method, the finally-obtained fertilizer is rich in various constants and micro nutrients, required by the rice. The fertilizer has remarkable effects in the respects of ecological microbial population adjustment, nutrient feeding, fertilizer utilization and the like of soil, so that the fertilizing amount is greatly reduced, and the cyclic utilization, the low carbon and the high efficiency of the straw are realized. Soil organic matters are markedly increased, the farmland fertility is persistently maintained, the agriculture point source pollution is reduced, the farmland biological diversity is effectively protected, the water resources and the ecological environment of local valleys are effectively protected, and the agricultural sustainable development is promoted.

Owner:JIANGSU SHENHE AGRI SCI & TECH DEV

Plant fiber composite micro-foaming biodegradable hollow plates

The invention discloses plant fiber composite micro-foaming biodegradable hollow plates which are composed of, by weight, 5-15% of natural plant fiber, 40-50% of starch and 35-55% of synthetic biological materials and prepared according to the following method. First, premixing the natural plant fiber and the starch, adding a processing agent in premixed materials, and preprocessing the mixture in a microwave device for 5-6 minutes; then, adding a plasticizing agent and the synthetic biological material, mixing at the temperature of 120-130 DEG C to obtain a modified plant fiber composite base material, and adding 0.5-0.8% of foaming agent in the modified plant fiber composite base material after cooling; and finally low-temperature high shearing, extruding, micro-foaming, sizing and cutting in a same-direction twin screw device to obtain the plant fiber composite micro-foaming biodegradable hollow plates. The raw materials are biodegradable materials, under the premise of guaranteeing use performance of products, wood resource is saved, use amount of plastics is reduced, cost is lowered, and purposes of low-carbon and environmental protection are achieved.

Owner:江西禾尔斯环保科技有限公司

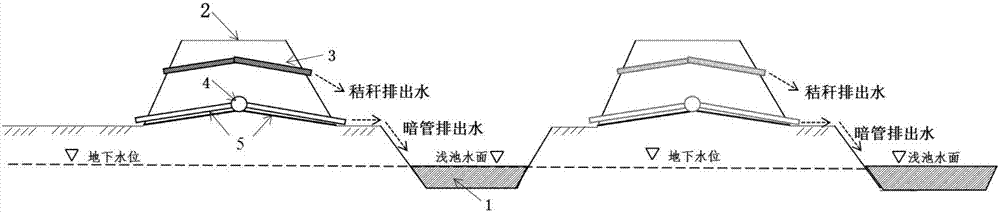

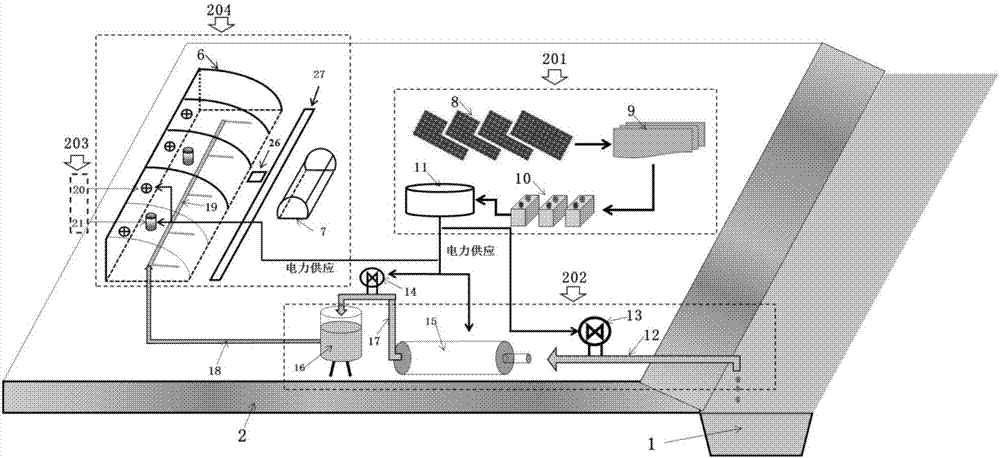

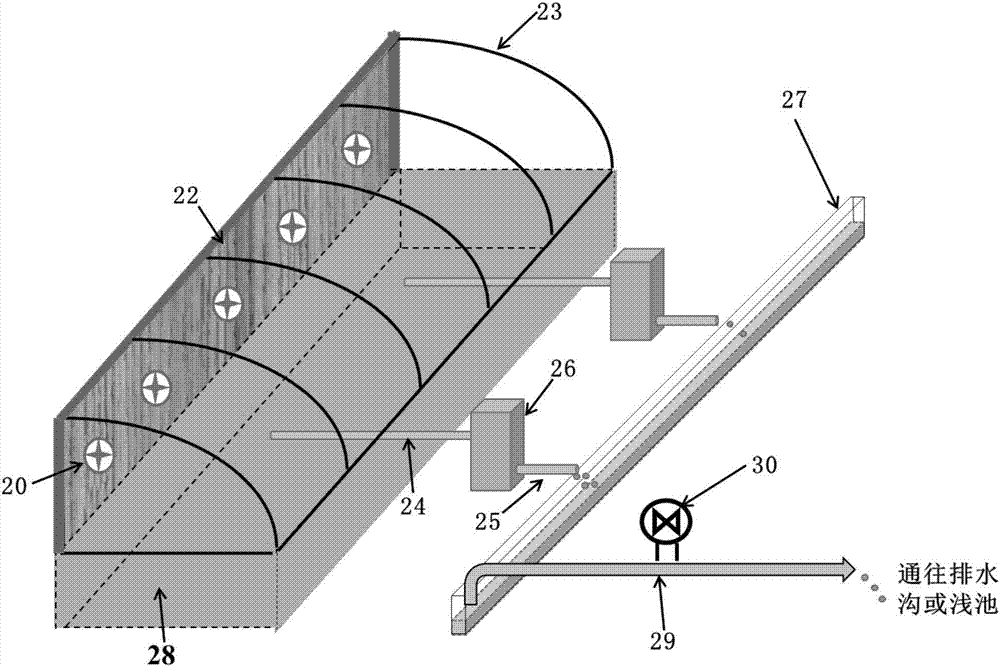

Shallow pool-greenhouse system of raised field of costal saline soil area and application thereof

InactiveCN107114152AConform to the standard of salt contentControl saltClimate change adaptationPisciculture and aquariaElectric powerWater layer

The invention discloses a shallow pool-greenhouse system of a raised field of a costal saline soil area. The system comprises shallow pools, raised fields and a greenhouse system. The raised fields and the shallow pools are alternatively distributed; the raised fields are trapezoidal raised fields. A raised field drainage closed conduit is arranged in the bottom of each raised field, a water isolating layer is arranged in the middle of the raised field, and the greenhouse system is arranged on the shallow pools; the greenhouse system comprises a planting system, an energy system, a water treatment system and a regulating system; the energy system is connected to the water treatment system and the regulating system through a line, the water treatment system is connected to the planting system through a pipeline, and the regulating system is arranged in the planting system. The planting system performs vegetable and fruit planting and agricultural waste fermenting treatment, the energy system provides power to the planting system, the water treatment system and the regulating system, the water treatment system provides water for irrigation for the planting system, and the regulating system controls aeration and temperature increase for the planting system. The system disclosed by the invention has the characteristics of controlling salt of soil, performing agricultural irrigation by means of underground salty water, comprehensively utilizing agricultural wastes, combining vegetable and fruit planting and aquaculture and the like.

Owner:BEIJING NORMAL UNIVERSITY

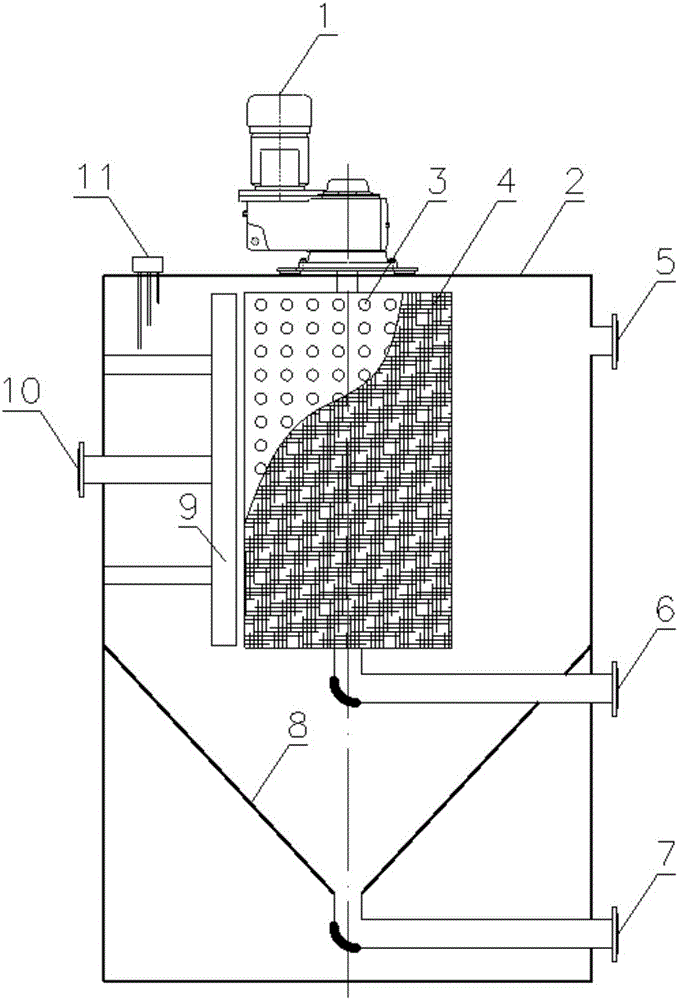

Assembling method for fiber filtration cloth filter and sewage treating method

InactiveCN105148596AReduce energy consumptionAdaptableMoving filtering element filtersFiberFiltration

The invention discloses an assembling method for a fiber filtration cloth filter and a sewage treating method. According to the sewage treating method, fiber filtration cloth is employed as a filter layer; a filtering rotating drum coated by the fiber filtration cloth is vertically arranged in an enclosed pressure vessel; sewage entering the pressure vessel enters the filtering rotating drum after filtration by the fiber filtration cloth and is then discharged from a water outlet; the pressure vessel is employed to increase the flow of sewage passing through the fiber filtration cloth, so work efficiency is improved; and a backwashing apparatus installed at the side of the filtering rotating drum is used for backwashing, and the filtering rotating drum rotates under the driving of a drive unit during backwashing, so 360-degree backwashing of the filtering rotating drum and the fiber filtration cloth is realized. Since a filtering disc is arranged in a shell, influence of the external environment is avoided; due to vertical arrangement of the filtering rotating drum, the fiber filtration cloth filter has the advantages of a small occupied land area, low investment, a simple transmission mechanism, low power of the drive unit and conservation of energy. The fiber filtration cloth filter has good adaptability and is easy to install and adaptive to filtering conditions on various occasions.

Owner:湖南新九方科技有限公司

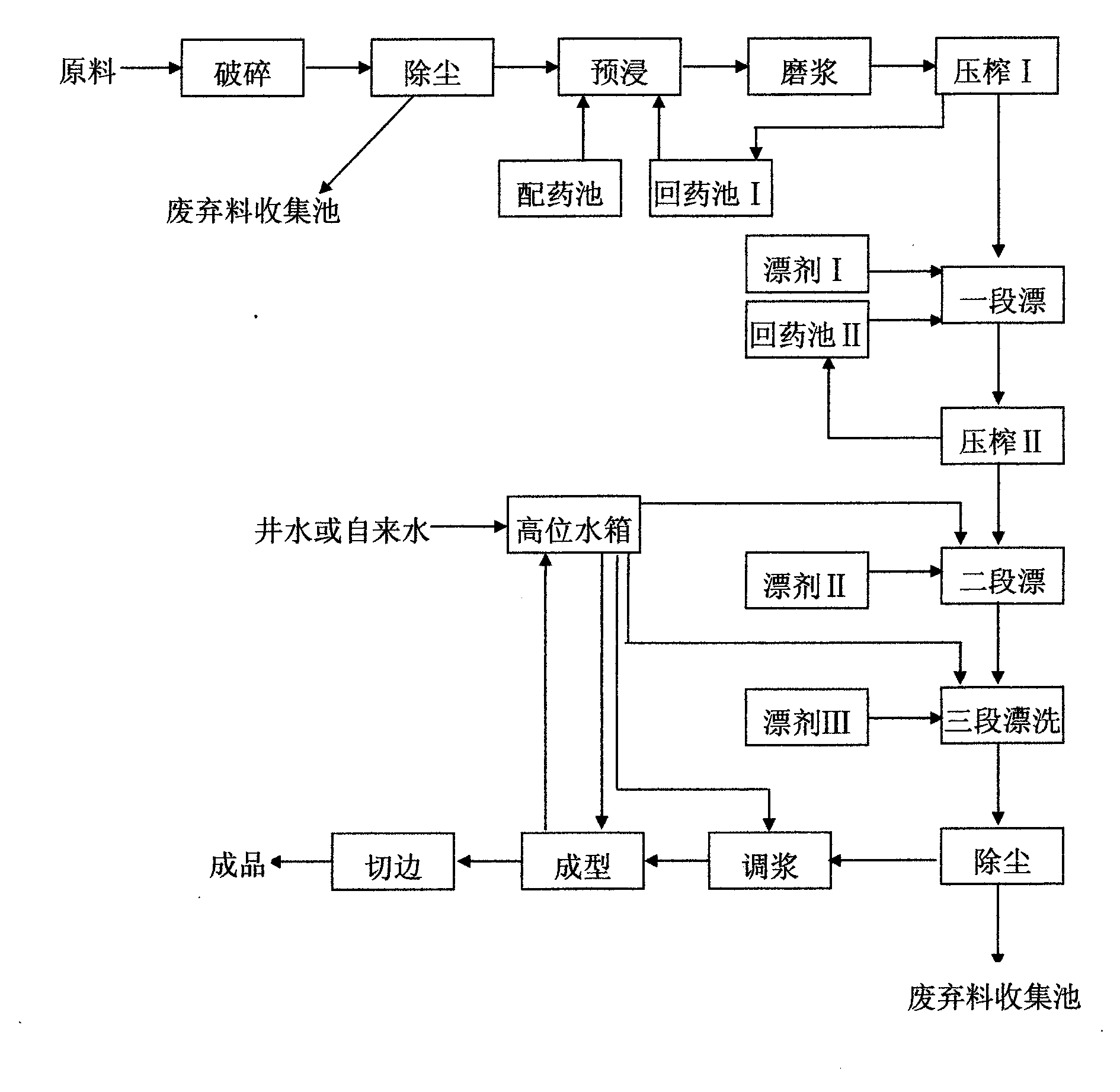

Presoak for papermaking and preparation method thereof, and paper industrial packaging production process

ActiveCN103821030ARealize \"low carbonClean thoroughlyNon-fibrous pulp additionFlexible coversPapermakingProcess engineering

The invention belongs to the technical field of papermaking, and particularly relates to a presoak for papermaking, a preparation method of the presoak, and a paper industrial packaging production process. The presoak comprises the following raw materials in parts by weight: 6 to 8 parts of a chelating agent, 4 to 6 parts of a penetrating agent, 35 to 45 parts of a softening agent and 20 to 30 parts of a prebleaching agent. The prebleaching agent replaces chemicals such as NaOH, Na2S, Cl2 and ClO2 which are needed in conventional pulping, meanwhile a boiler is not needed, chemical stewing is avoided, and the pulping is carried out under the ordinary temperature condition, so that the purpose of low-carbon, clean and environment-friendly pulping is realized. According to the paper industrial packaging product production process, the process of pulping and producing the paper industrial packaging product is combined as one, so that the production process is simplified, unnecessary investment is reduced, and the condition of directly producing the terminal industrial packaging product from raw materials such as straw is realized.

Owner:于翔

Curing agent for stabilizing soil

InactiveCN102086399AEnvironmental protection is goodGood value for moneySolid waste managementBuilding constructionsCelluloseBrick

The invention relates to an environment-friendly curing agent for stabilizing soil, which can improve the bearing capacity of a subgrade. The curing agent for stabilizing the soil is characterized by comprising the following components in parts by weight: 2-18 parts of polyanionic cellulose, 2-6 parts of sodium sulfate or calcium sulphate, 12-50 parts of sulfonic acid, 2-53 parts of granulated blast furnace slag, 1-5 parts of neutral water glass and 38-150 parts of water. The curing agent for stabilizing the soil can remarkably improve the bearing capability of the cured soil and has good antiseepage effect and durability, and the situation of argillization can be reduced after the curing agent is soaked in the water; therefore, the environment-friendly curing agent is suitable for various construction pavements, in particular rural roads developed for travel and agriculture with the requirements of low cost, short construction period and fast effect. The environment-friendly curing agent not only improves the road construction quality, but also makes the material application and the construction process more environment-friendly, can be further applied to the base course and surface course of road and construction engineering and the fields of wind prevention and sand consolidation, canal seepage control, burning-free low-carbon environment-friendly bricks and the like, and is suitable for the semimechanical operation and the large-scale mechanical construction operation in country.

Owner:RUIFUXIANG PHARMA GUANGXI

Carbide slag polymerization fuel and derivative fuel thereof

The invention discloses a carbide slag polymerization fuel and a derivative fuel thereof, which relate to the field of novel fuels. The carbide slag polymerization fuel comprises the following raw materials in percentage by weight: 25-60% of carbide slags, 15-30% of salty mud, 10-40% of fly ash, 5-30% of iron tailings, 1-10% of sodium sulfate, and 0.1-8% of an exciting agent. According to the invention, by mainly using industrial waste residues such as carbide slags, salty mud, fly ash, iron tailings, sodium sulfate and the like which are large in storage quantity and pollute the environment, adding an exciting agent, and drying and crushing the obtained mixture, the polymerization fuel is formed; ad when in use, the polymerization fuel is ignited by using a magnesium rod, and then various materials are subjected to a chemical reaction so as to produce a calorific value of more than 10000 kcal / kg, so that when the fuel is applied to production and life, an effect of changing waste material into things of value is achieved, non-renewable energies are saved, and the pollution caused by industrial solid wastes to the environment is improved, therefore, an effect of energy conservation and environmental protection is achieved, and an effect of low carbon and emission reduction is also achieved, so the fuel contributes to the implementation of national policies of national recycling economy and sustainable development.

Owner:冯恩福

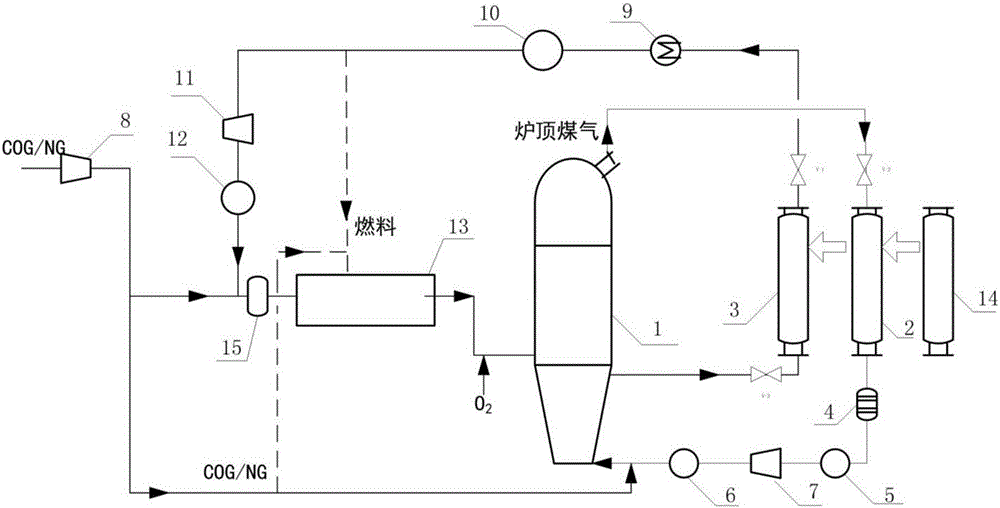

System and method for utilizing top gas of sponge iron produced by reducing shaft furnace

PendingCN106834581AReduce energy consumptionAchieve low carbonShaft furnaceGas emission reductionThermal energyProcess engineering

The invention relates to a system and method for utilizing top gas of sponge iron produced by a reducing shaft furnace. The system comprises a preheating tank, a washing tower, a dehydrator, a decarburization system, a cooling gas input pipe, a cooling gas exhaust pipe and a pre-reducing tank. The preheating tank, the washing tower, the dehydrator and the decarburization system are sequentially connected to the outside of the reducing shaft furnace, and a preheated gas inlet of the preheating tank is connected with a top gas outlet; the cooling gas input pipe and the cooling gas exhaust pipe are arranged on a lower cooling section of the reducing shaft furnace and communicated with the interior of the cooling section, an inlet of the cooling gas input pipe is connected with a cooling gas outlet of the decarburization system, the pre-reducing tank is arranged outside the reducing shaft furnace, and a reduced gas inlet of the pre-reducing tank is connected with an outlet of the cooling gas exhaust pipe. Heat energy included in the high-temperature top gas can be fully utilized for preheating ore, the heat energy of the cooled top gas and CO and H2 reducing gas in coal gas can be utilized for pre-reducing the preheated ore, the energy consumption of the shaft furnace is reduced, and low carbon and environmental friendliness of the shaft furnace ironmaking technology are achieved.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

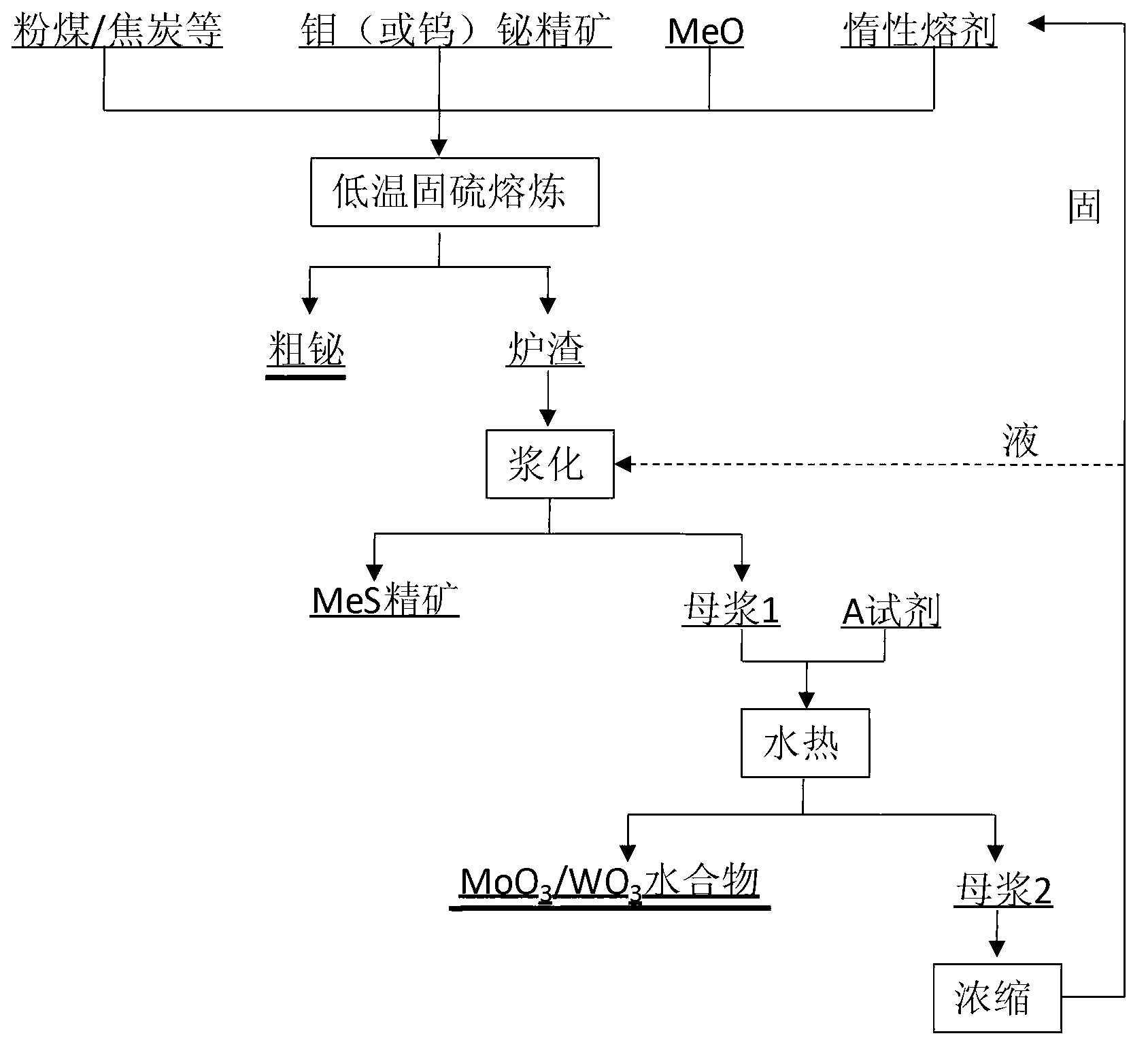

Method for smelting bismuth-molybdenum or bismuth-tungsten concentrates

InactiveCN103305707AReduce energy consumptionLow temperature and high efficiencyProcess efficiency improvementBismuth sulfideHigh energy

The invention provides a method for smelting bismuth-molybdenum or bismuth-tungsten concentrates. The method comprises the following steps of: firstly carrying out low-temperature sulfur fixation smelting on the bismuth-molybdenum or bismuth-tungsten concentrates, and reducing bismuth sulfide and the like in the bismuth-molybdenum or bismuth-tungsten concentrates to metal bismuth; pulping the obtained smelting slag with water; and then putting alkaline liquor obtained through liquid-solid separation of slurry into an autoclave after regulating the pH value of the alkaline liquor to undergo hydrothermal reaction to obtain molybdenum oxide or tungsten oxide. The method has the beneficial effects that problems in existing bismuth-molybdenum or bismuth-tungsten concentrate smelting processes such as heavy pollution of low-concentration SO2 and heavy metal powder, high energy consumption and low efficiency and problems in the processes for extracting molybdenum or tungsten from smelting slag such as long flow, high energy consumption, low recovery rate of molybdenum or tungsten and the like are solved; and the method has the prominent advantages of small environment stress, strong raw material adaptability, simple flow and high recovery rate of metals.

Owner:HUNAN SHIZHUYUAN NON FERROUS METAL

Method for efficient microbial degradation of kitchen waste

InactiveCN111632998AAchieve low carbonEfficient clean conversionFungiBacteriaNutrientMicrobial agent

The invention aims to provide a method for efficient microbial degradation of kitchen waste, and belongs to the technical field of resource utilization of kitchen waste and other organic solid waste.The method comprises the following steps: 1) sorting, crushing and pulpifying the kitchen waste; 2) pretreating auxiliary materials; 3) performing nutrition compounding on the kitchen waste and the auxiliary materials; 4) domesticating and compounding a degradation microbial agent; and 5) performing microbial aerobic degradation on the kitchen waste compounded raw materials. The aerobic degradation method for the kitchen waste aims to solve the problems of high C / N ratio, high salinity, high water content and the like of the kitchen waste, the raw materials with high nitrogen content and highwater absorption are adopted as the auxiliary materials, and the initial solid-to-liquid ratio, the C / N ratio and the like of microbial fermentation of the kitchen waste are adjusted, so that the kitchen waste is adapted to heat and mass transfer in the aerobic microbial fermentation process. Based on the nutrient composition of a fermentation medium formed by nutrition compounding of the kitchenwaste and the auxiliary materials, a composite aerobic microbial agent is formed, so that the purposes of rapid and efficient degradation of the kitchen waste, energy conservation, environmental protection and cost reduction are achieved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

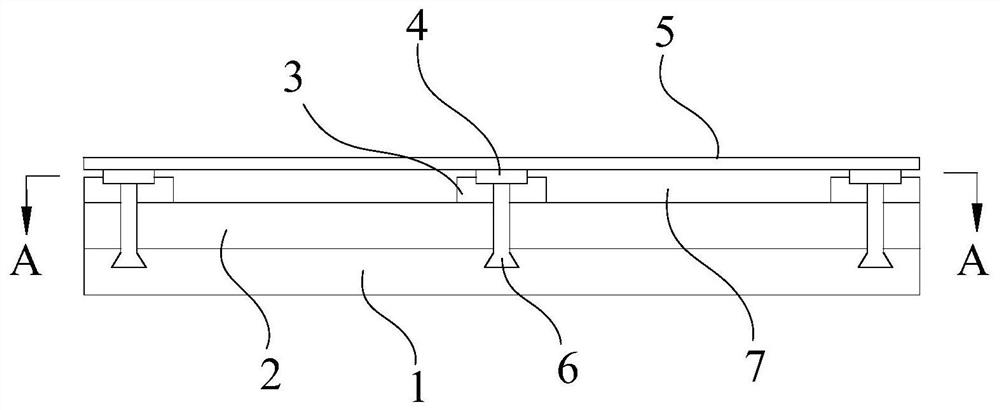

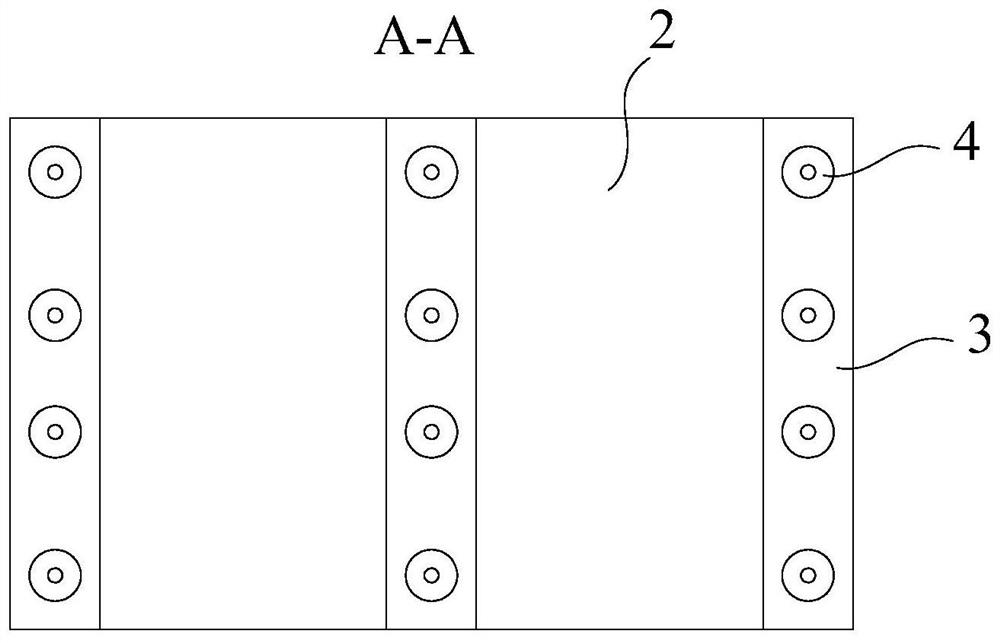

Prefabricated photovoltaic wallboard and manufacturing method thereof

PendingCN113958022AReduce weightImprove power generation efficiencyPhotovoltaic supportsSolar heating energyStructural engineeringMechanical engineering

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

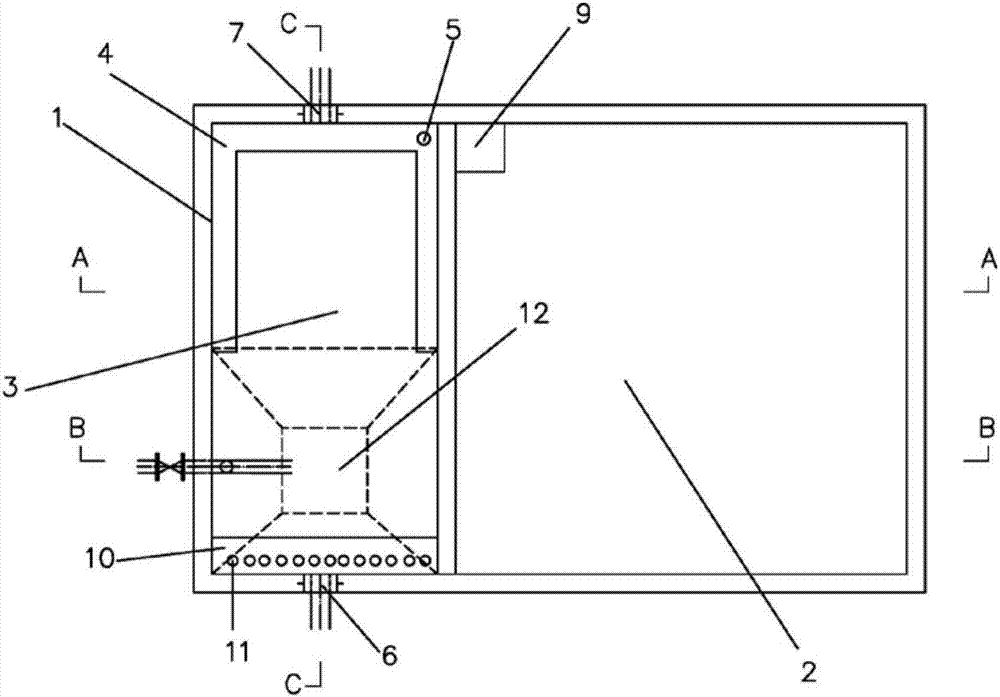

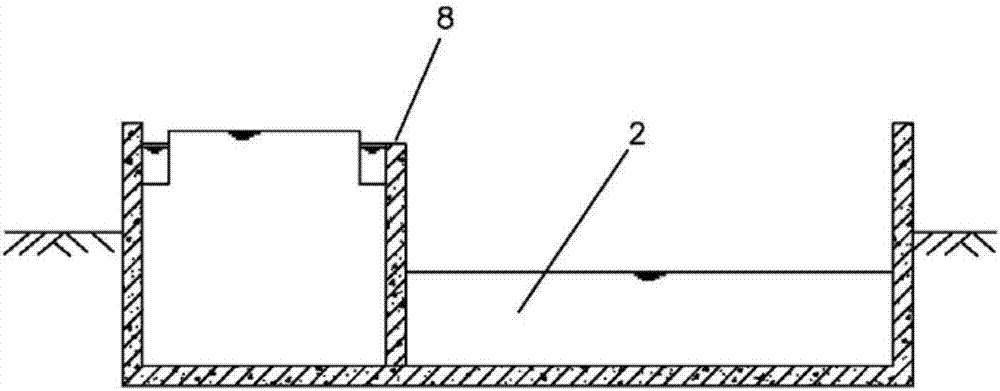

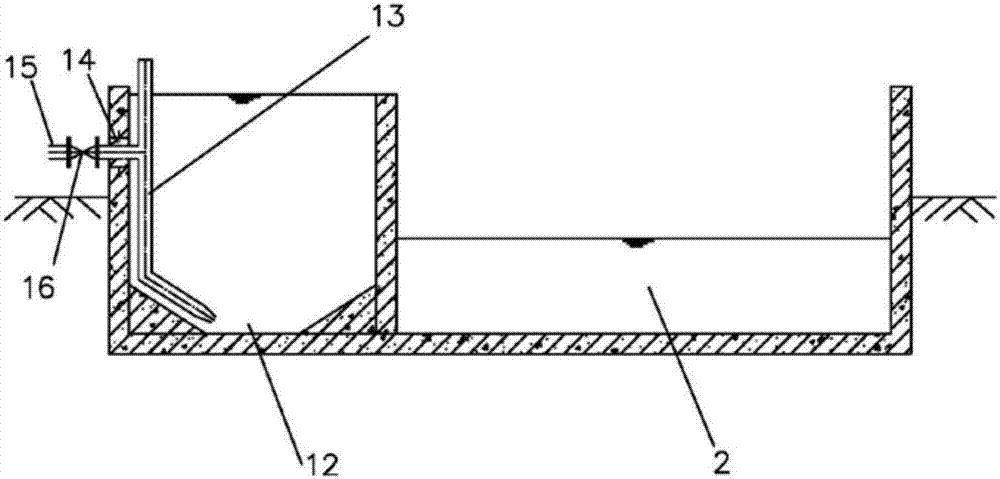

Low-carbon and energy-conservation type settling and adjusting tank

PendingCN107215939ASimple structureEasy construction and maintenanceWater/sewage treatment by flocculation/precipitationOutfallSewage

The invention discloses a low-carbon and energy-conservation type settling and adjusting tank which comprises a primary settling tank and an adjusting tank. The primary settling tank and the adjusting tank are arranged in parallel, the primary settling tank comprises a settling tank body and a water collecting tank, a water level measuring and controlling device is arranged in the water collecting tank, the settling tank body is connected with a water inlet, the water collecting tank is provided with a water outlet and an overflow opening, the water outlet is used for being connected with a biological processing system, the overflow opening is connected with the adjusting tank, a pipe bottom elevation of the overflow opening is the same as the pipe top elevation of the water outlet, a lifting pump is arranged in the adjusting tank, and the water level measuring and controlling device is connected with the lifting pump. The low-carbon and energy-conservation type precipitating and adjusting tank disclosed by the invention is suitable for pretreatment of small and micro sewage treatment facilities of independent industrial and mining enterprises, expressway service stations and the like; as the primary settling tank and the adjusting tank are jointly constructed, the settling and adjusting tank has a simple structure and easiness in water level control; sewage can exceed the adjusting tank according to the average flow to directly enter a subsequent biochemical treatment system, and a part exceeding the average flow is dammed to the adjusting tank; thus, the water volume for the adjusting tank to lift is reduced, and operation energy consumption is reduced.

Owner:桂润环境科技股份有限公司

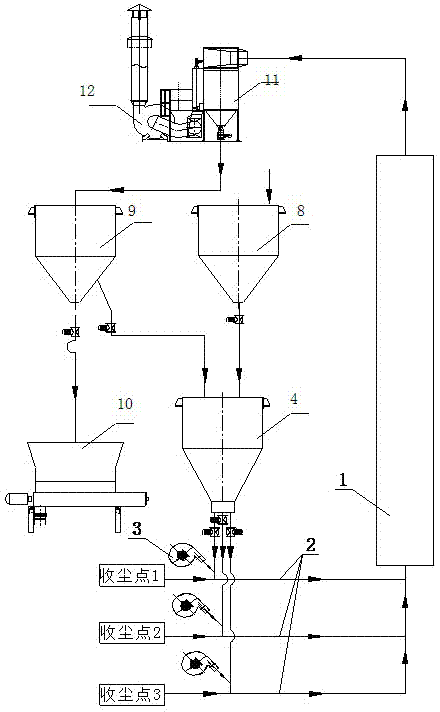

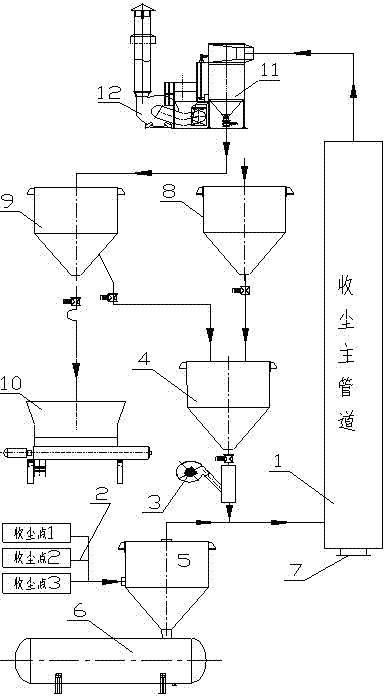

Method and device for purifying asphalt smoke

ActiveCN103028303AReduce the temperatureReduce the amount of adsorptionCombination devicesEnvironmental resistancePurification methods

The invention relates to a purification method for asphalt smoke and a device system for implementing the purification method. The purification method comprises the following steps: (1), performing condensing pretreatment; (2), performing absorption treatment; (3), removing dust and filtering; and (4), recycling the asphalt smoke. The device system comprises a dust-collecting main pipe, an asphalt smoke branched pipe, a high pressure fan, a powder feeding storehouse, a circulating storehouse, a dust collector and an induced draft fan, wherein a cold oil collecting device is mounted between the asphalt smoke branched pipe and the dust-collecting main pipe. According to the invention, the problems of low asphalt smoke dust trapping efficiency and blockage of equipment and pipelines caused by dust accumulation which are difficult to solve by the conventional absorption and purification technology are solved by a condensing pretreatment technology; the service life of the equipment is prolonged; the running rate of the equipment is increased; energy is saved and consumption is reduced; the purification efficiency of the smoke is further improved; separation, collection and recycling of the smoke dust are realized in a closed loop circulation structure; the production environment is improved; and the effects of environmental friendliness, energy conservation and low carbon of the production process are achieved.

Owner:SHANDONG CHENYANG NEW CARBON MATERIALS +1

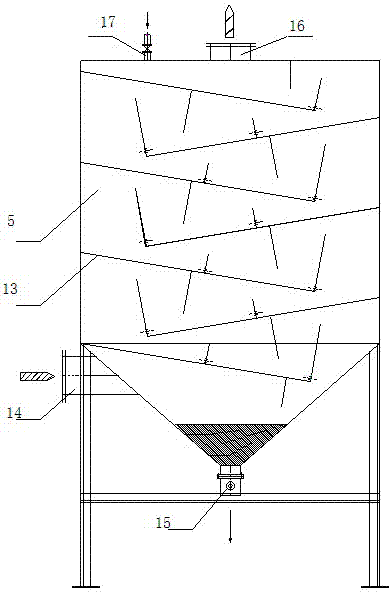

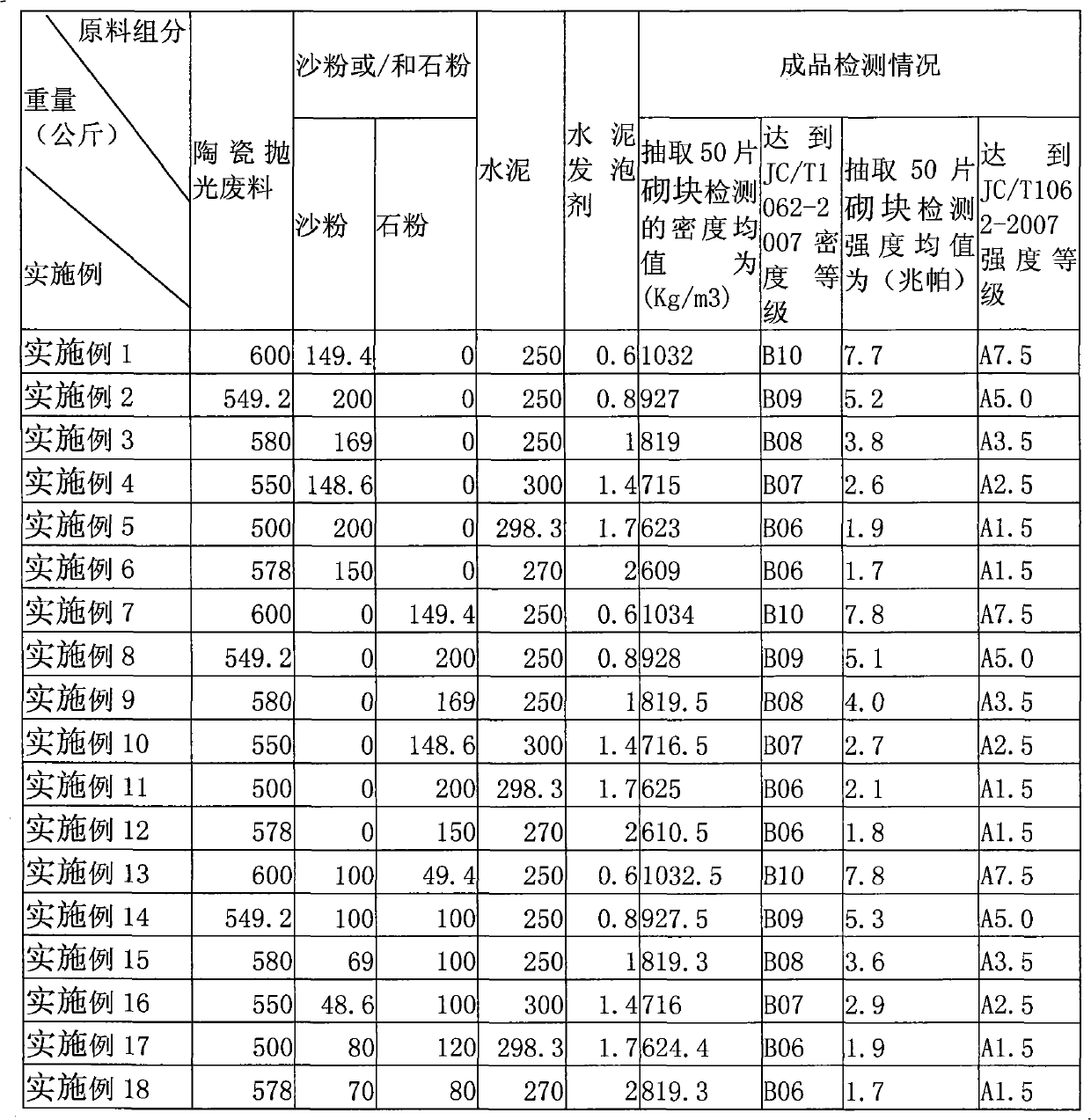

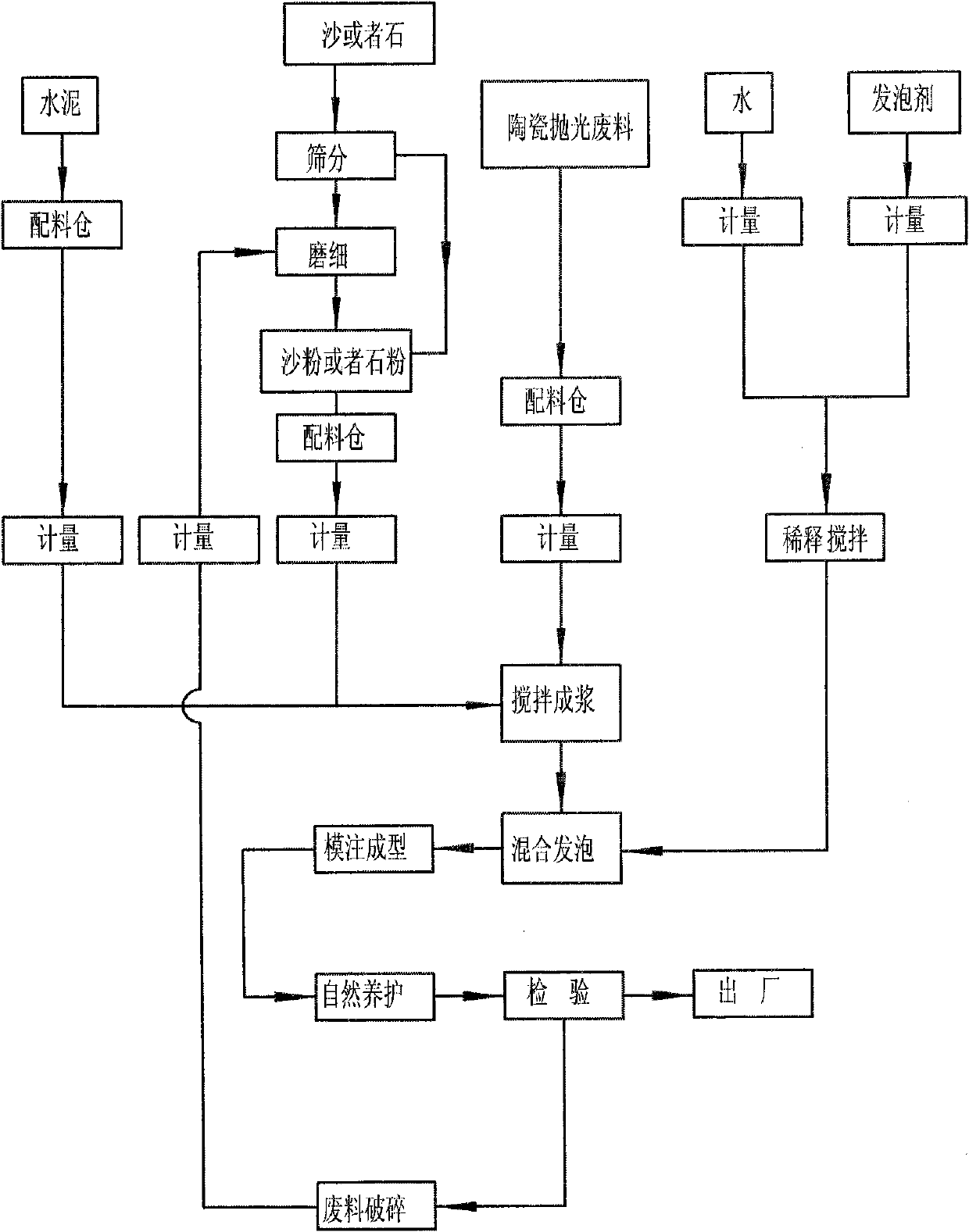

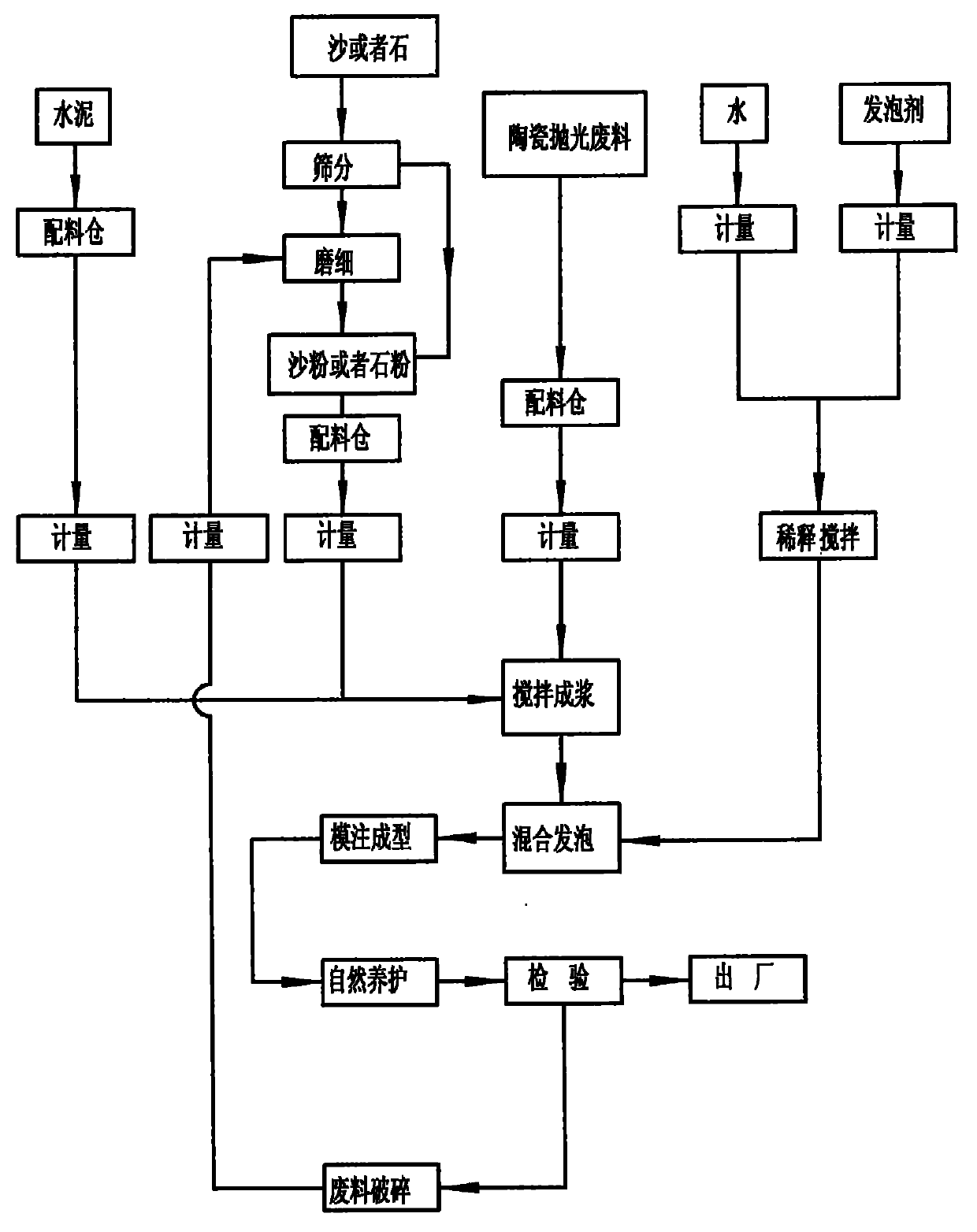

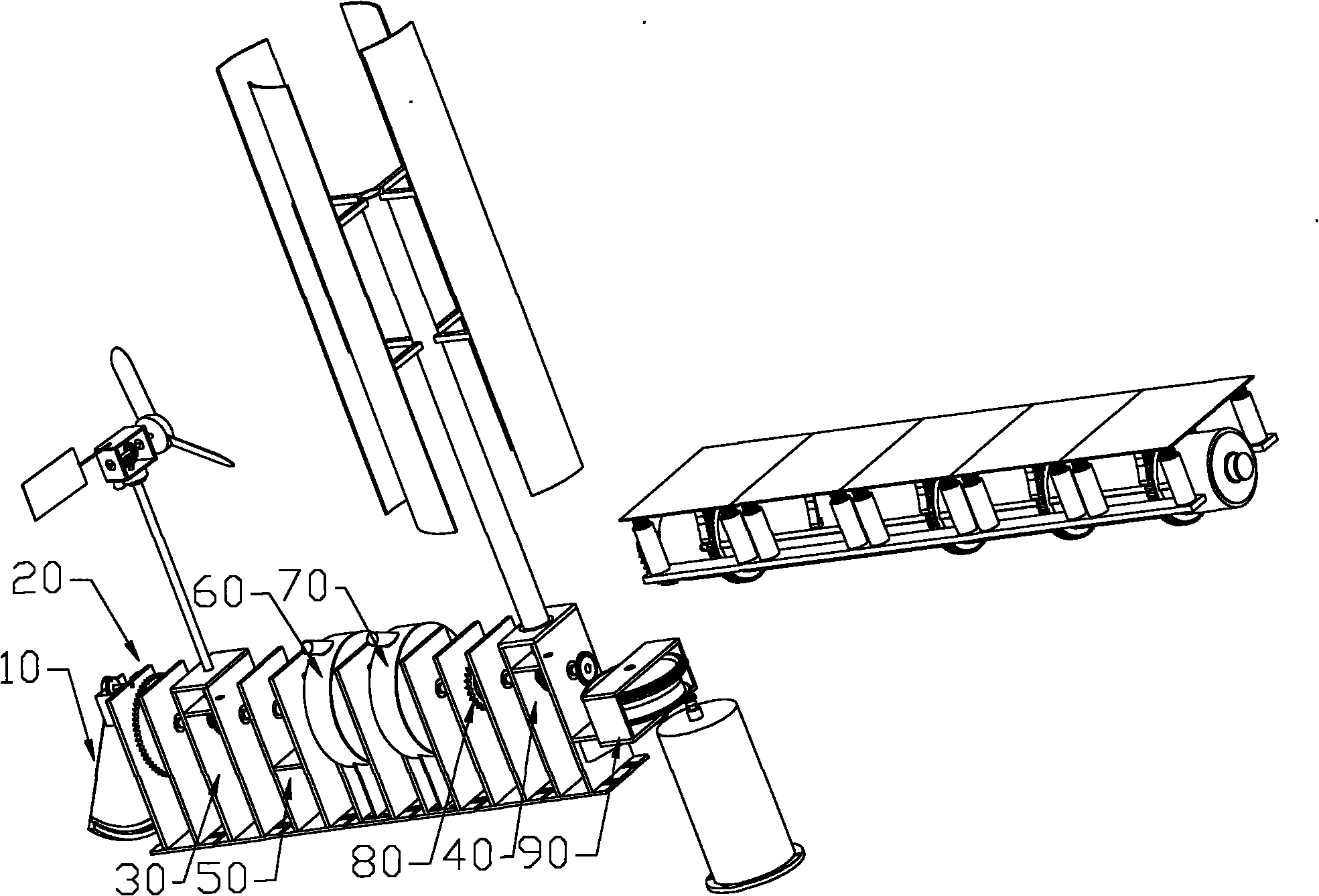

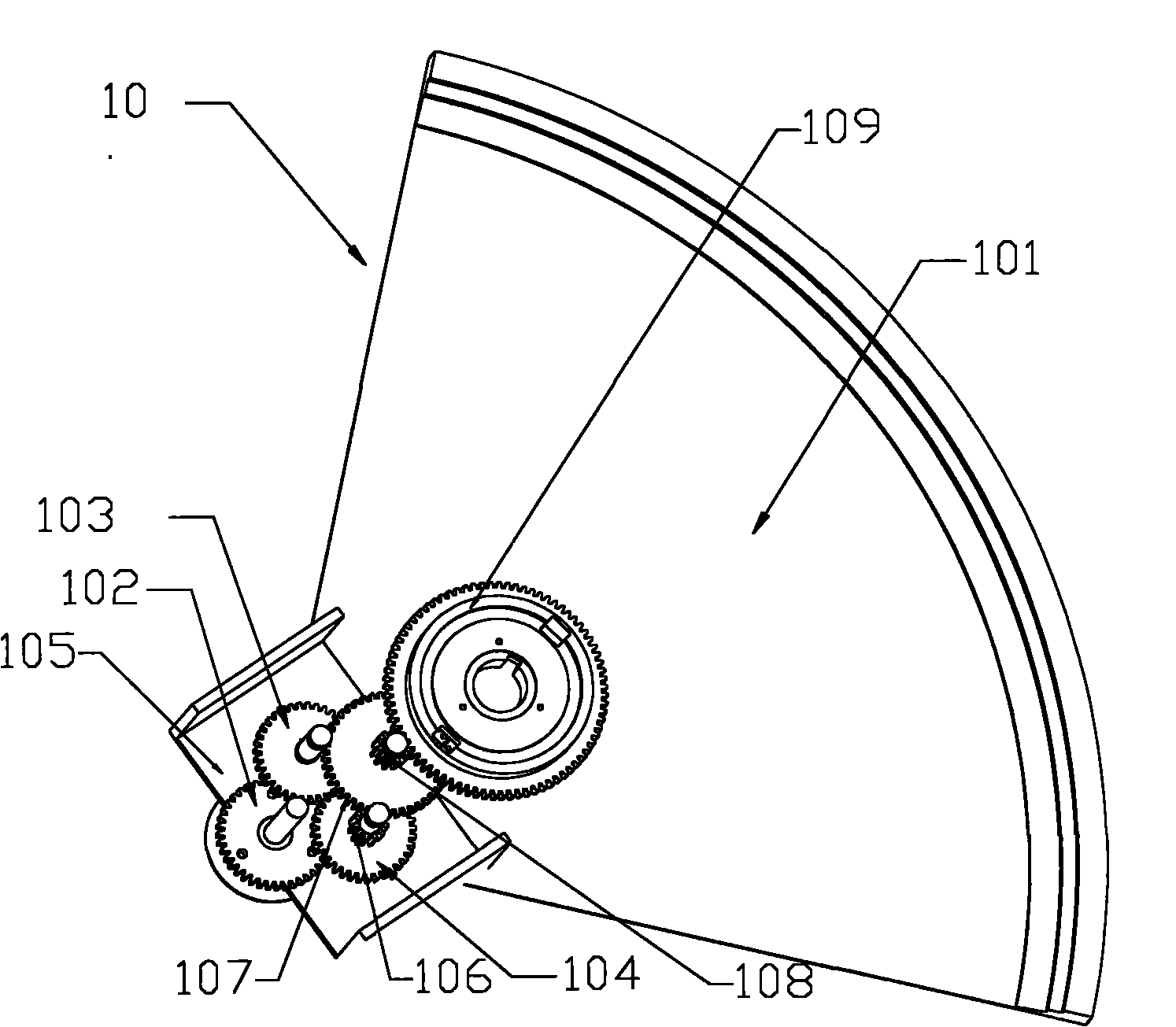

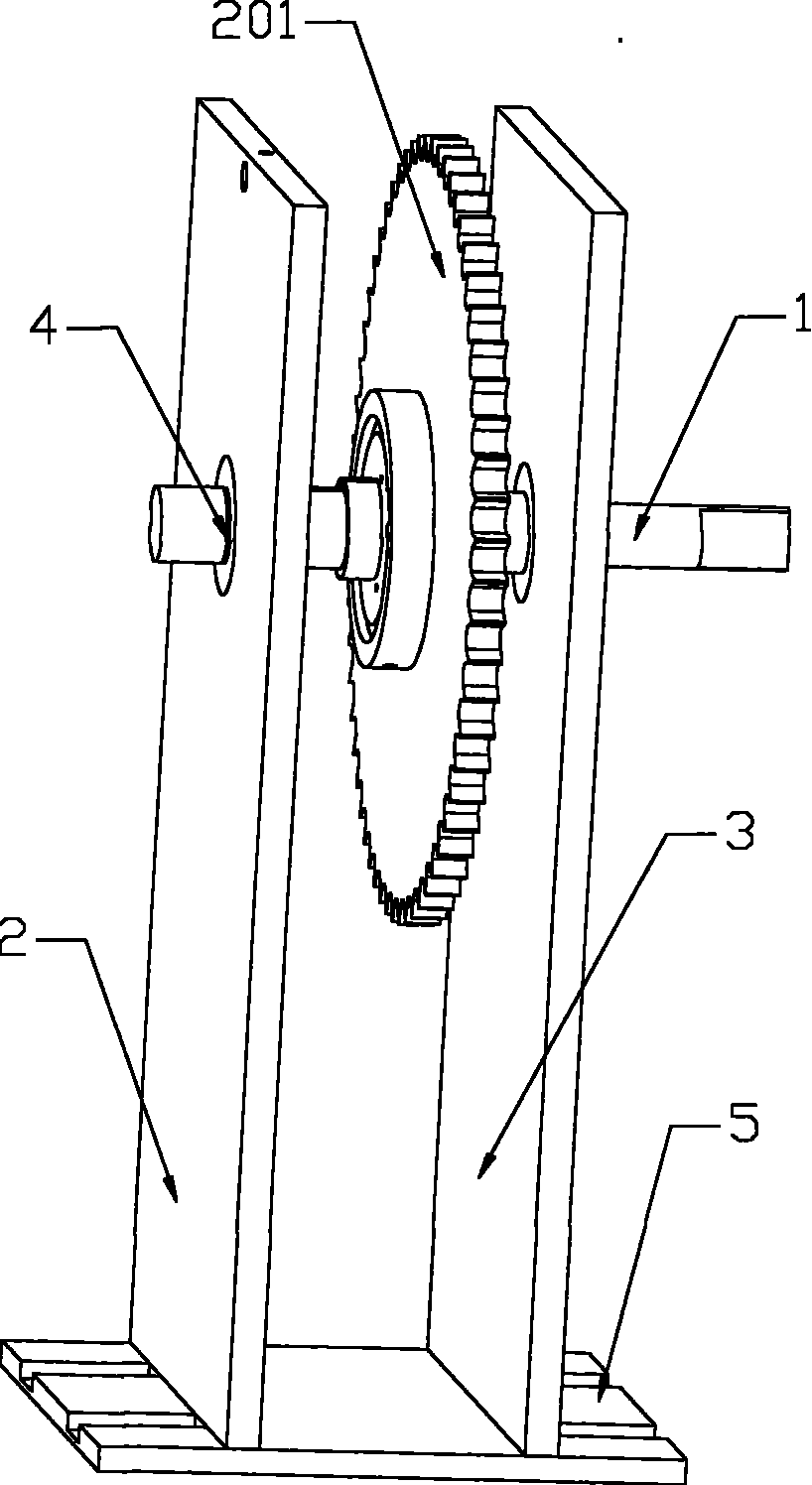

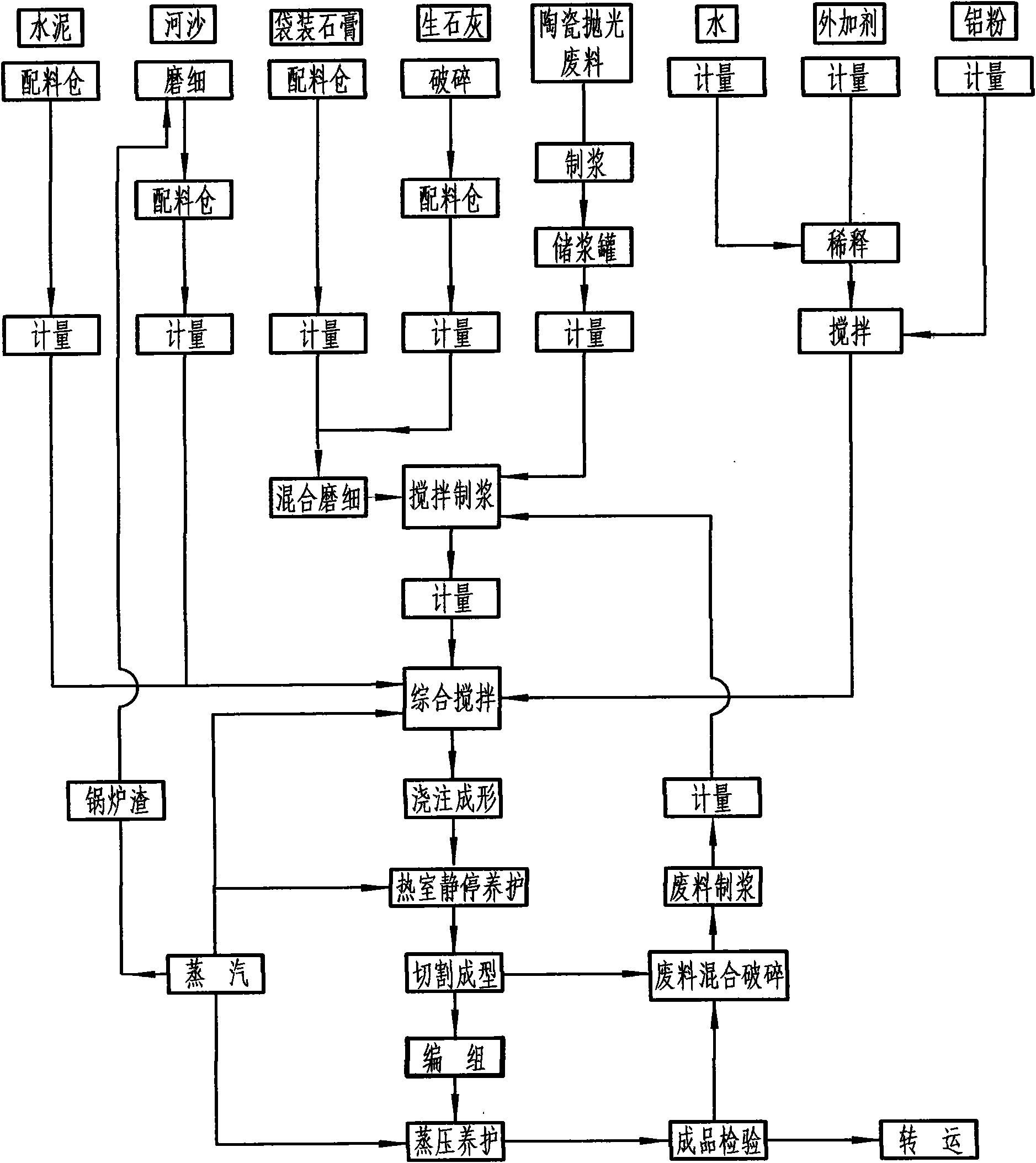

Steam-curing-free foam concrete building block and preparation method thereof

InactiveCN101948332ARealize comprehensive utilizationReduce pollutionCeramicwareFoam concreteFoaming agent

The invention discloses a steam-curing-free foam concrete building block, which is prepared by water and the following raw materials in parts by weight: 50-60 parts of ceramic polishing waste, 15-20 parts of sand flour or / and rock flour, 25-30 parts of cement and 0.06-0.2 part of cement foaming agent. The invention further discloses a preparation method of the building block, comprising the steps of taking the above raw materials, preparing a sizing agent, diluting the foaming agent, preparing pulpy foam concrete, molding, demolding, curing and the like. The steam-curing-free foam concrete building block of the invention has the characteristics of light weight and high strength, good heat preservation and thermal insulation performance, good sound insulation and fireproof performance, low elasticity and seismic resistance, fast construction speed and the like. In addition, the invention can turn waste into wealth and protect the environment.

Owner:周石镭 +3

Energy consumption detection method of single on-line product

The invention relates to an energy consumption detection method of a single on-line product. On the basis of an electricity meter, a gas meter, a fuel meter, a steam meter, a compressed air meter, a new water meter, a circulating water meter, a soft water meter, a nitrogen meter and a non-productive consumption detection instrument which are singly configured on original production equipment, bar code printers and bar code identification devices are randomly configured on all production equipment, and an energy consumption database is singly arranged in a master control computer; computers randomly configured on the production equipment are networked with the master control computer and can directly enter the page of the energy consumption database. The single on-line product is processed through all the production equipment, and read energy consumption data is recorded once in an energy consumption statistical table consistent with an identification code of the single on-line product; and finally, all energy consumption data consumed by the single on-line product for finishing a production processing period is recorded into the energy consumption statistical table, thus the method has intuition, controllability and scientificity.

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

Environmental-friendly wooden anti-glare plate and manufacturing method thereof

InactiveCN105239516ARealize green developmentLow costProtective constructionWood treatment detailsEnvironmental resistanceAging resistance

The invention provides an environmental-friendly wooden anti-glare plate and a manufacturing method thereof, wherein the manufacturing method comprises following steps: immersing wooden single plates into an impregnating agent for immerse processing and the weight ratio between the weight of the wooden single plates before the immerse processing and the weight of the wooden single plates after the immerse process is 1:1.2 to 1.4; processing the sequentially stacked wooden single plates with heat-press after the plurality of the wooden single plates are immersed; the impregnating agent comprises water and phenolic resin; and the weight part ratio of the water and the phenolic resin is 1:1 to 3. The environmental-friendly wooden anti-glare plate provided herein has the advantages of light weight, high strength, strong aging resistance and acid and alkali corrosion resistance; the environmental-friendly wooden anti-glare plate can be used to effectively replace an anti-glare plate on an expressway, thus the problems of poor aging-resistance performance of the anti-glare plate and secondary damage in a car accident; the running efficiency of expressways in our country is improved; the maintenance and running cost are reduced, thus the expressways can be ran with low carbon, safety, high efficiency and low cost; and the sustainable development of the expressways is promoted.

Owner:BEIJING SHOUFA TIANREN ECOLOGICAL LANDSCAPE CO LTD

Nano thermal insulation reflective coating additive for exterior wall

ActiveCN103834216ARealize self-cleaning functionExcellent hydrophobic functionReflecting/signal paintsEmulsionThermal insulation

The invention discloses a nano thermal insulation reflective coating additive for an exterior wall. The nano thermal insulation reflective coating additive comprises the main components in weight ratio: 160-250 parts of water, 1-2 parts of defoaming agent, 8-12 parts of dispersing agent, 0.5-2 parts of hydroxyethyl cellulose, 400-500 parts of thermal insulation reflective powder, 5-10 parts of nano TiO2 powder, 5-10 parts of nano SiO2 powder, 5-12 parts of ethylene glycol, 5-10 parts of film-forming additive, 200-300 parts of AC-261P waterborne acrylic emulsion and 1.0-2.0 parts of thickening agent. The nano thermal insulation reflective coating additive is prepared by stirring all the components according to the weight ratio. The coating additive for the exterior wall can be used for realizing the thermal insulation reflection of a color coating for the exterior wall, and furthermore, the energy conservation of a building is realized; water is used as a solvent, so that the nano thermal insulation reflective coating additive has the advantages of environment friendliness, exterior wall hydrophobicity, self-cleaning and the like.

Owner:深圳市文浩科技有限公司

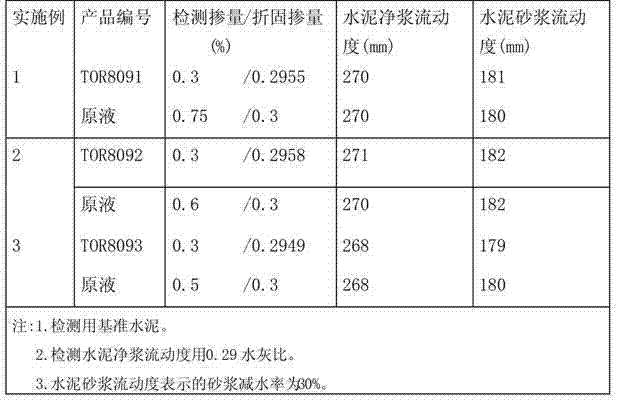

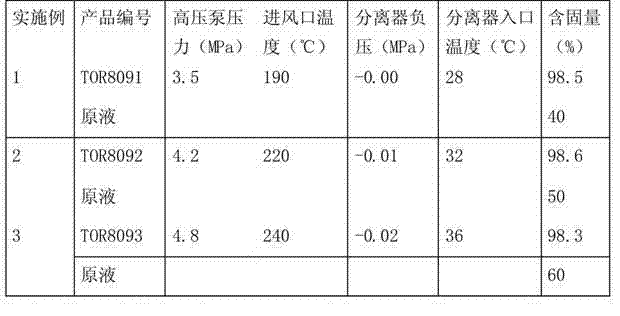

Method for preparing dry high-performance water reducer powder of polycarboxylic acid

A method for preparing dry high-performance water reducer powder of polycarboxylic acid comprises atomizing a polycarboxylic acid water reducer solution and allowing it to enter a drying chamber parallel to hot air under the action of a high-pressure pump; and sucking material under a negative pressure of -0.00--0.02 MPa, cooling via cold air with dew point from -23 DEG C to -17 DEG C, separating, collecting and packaging. The pressure of the high-pressure pump is 3-5 MPa, the temperature of the hot air is 180-250 DEG C, the drying chamber is in a shape of cylinder and has a diameter equal to its height, and the inlet temperature of a separator is 25-40 DEG C. The material in a form of spray quickly flies into the drying chamber via a nozzle under the pressure of 3-5 MPa, to thereby overcome the bond force between the material; the cylindrical drying chamber ensures smooth continuous arc connection between wall surfaces; and negative-pressure suction solves the problem of secondary dusting of the dry powder, further prevents the fine material powder from freely flying in the drying chamber and adhering to the walls, and controls the motion direction of the fine dry powder.

Owner:ZHEJIANG LAOHUSHAN BUILDING MATERIALS

Universal integrated new power-based generator set

InactiveCN102055276AHigh density utilizationHigh penetration rateFinal product manufactureClimate change adaptationNatural sourceNatural resource

The invention discloses a universal integrated new power-based generator set, which comprises a generator, a connecting component and more than two energy components, wherein one end of the generator is provided with shaft head gear; and the energy components are connected and independently arranged. The generator set has the characteristics of high density utilization of various kinds of new energy, convenience for manufacturing, low cost and high popularization degree; and according to the different characteristics of natural sources in different areas and environments, the generator set can regulate the natural energy of various uncertain factors flexibly and very ideally, generate power normally on the basis of overall planning and consideration, realize a strong compensatory function, continuously generate power without stopping, avoid being limited and influenced by the volume of energy, obtain long-time stable-voltage output, saves a large amount of energy, widely supply low-carbon energy, and realize a real green energy world.

Owner:绍兴德慧泵业制造厂

Zero energy consumption automatic vent device for washroom

The invention belongs to a pneumatic energy-saving and environment-protecting device, and particularly relates to a zero energy consumption automatic vent device for a washroom. The zero energy consumption automatic vent device comprises a support saddle, a sleeve, a bearing, a transmission shaft, a pneumatic impeller mechanism and a driven impeller, and is characterized in that the zero energy consumption automatic vent device is mounted on the outer wall surface on a top wall of a vertical shaft used for exhausting peculiar smells or water vapor in a building; and the pneumatic impeller mechanism which comprises a pneumatic impeller, a wheel hub, an impeller rod and a fixing pin is arranged at the top end of the exposed upper shaft section of the transmission shaft. The zero energy consumption automatic vent device converts the wind energy into the mechanical energy, realizes the exhaust of the peculiar smells in the washroom by the transmission shaft which drives the driven impeller in the exhausting vertical shaft to rotate, so as to enable the air flow to ascend, save the electric energy consumed by using an electric exhaust fan, and realize the low-carbon and energy-saving life pattern; and the zero energy consumption automatic vent device has the characteristics of reasonable design, compact structure and the like, and is simple and practical to use, and convenient for installation, manufacture and use,. The zero energy consumption automatic vent device is widely applied to residential buildings, malls, hotels, public buildings, and the like.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Micro-foaming hollow structural plate and processing technique thereof

The invention discloses a micro-foaming hollow structural plate and a processing technique thereof. The plate is prepared from the following raw materials in percentage by weight: 8-10% of biodegradable resin, 2-3% of a foaming agent, 70-80% of plant fiber and 10-20% of inorganic powder. The processing technique comprises the following steps: (1) preparing raw materials according to the formula; (2) mixing and extruding biodegradable resin, plant fiber and inorganic powder under the condition that the temperature is 90-120 DEG C to obtain a modified plant fiber composite base stock; (3) adding the foaming agent into the modified plant fiber composite base stock after the modified plant fiber composite base stock cools down; (4) putting the modified plant fiber composite base stock containing the foaming agent into a co-rotating parallel double-screw device for low-temperature high shearing, micro-foaming extruding, sizing and cutting to obtain the micro-foaming hollow structural plate, The micro-foaming hollow structural plate has the advantages of being high in strength, good in tenacity, low in density, recyclable in leftover materials and the like.

Owner:江西禾尔斯环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com