Presoak for papermaking and preparation method thereof, and paper industrial packaging production process

A technology of prepreg and prebleach, applied in the field of papermaking, can solve the problems of increasing equipment investment, energy consumption, increasing operators, etc., and achieves the effect of reducing the production process, reducing production costs, and reducing operators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

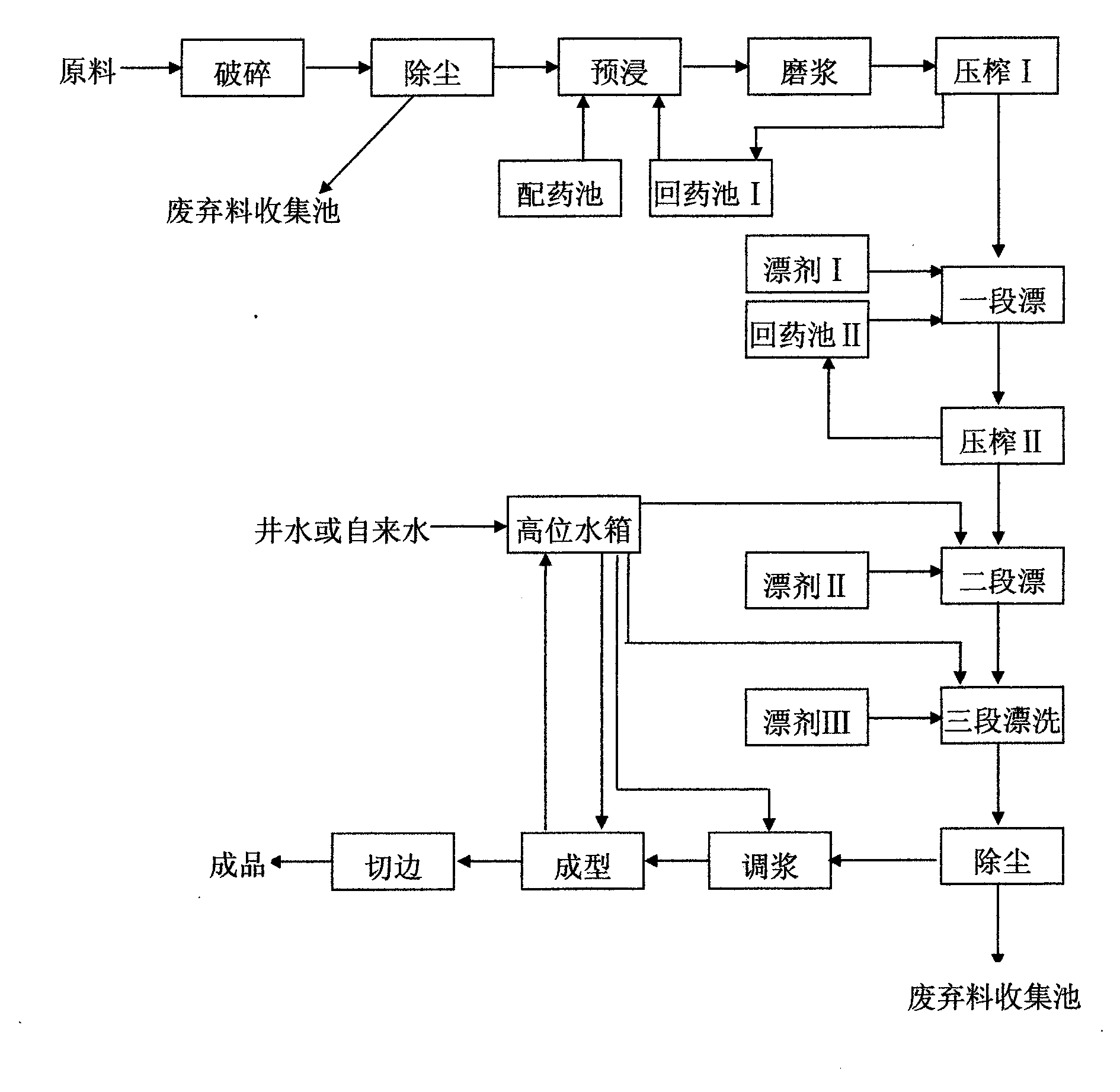

Image

Examples

Embodiment 1

[0069] Recipe 1: a prepreg for papermaking, consisting of the following components in parts by weight:

[0070] The presoaking agent described in this application: consists of 6 parts of chelating agent, 4 parts of penetrating agent, 35 parts of softening agent and 20 parts of pre-bleaching agent,

[0071] Described chelating agent is made up of sulfuric acid, sodium tripolyphosphate and sodium citrate, and wherein mass ratio is: sulfuric acid: sodium tripolyphosphate: sodium citrate=20: 1: 2; The mass concentration of described sulfuric acid is 30%;

[0072] The penetrating agent is composed of alcohol solvent and alkali-resistant penetrating agent OEP-70, wherein the mass ratio is: alcohol solvent: alkali-resistant penetrating agent OEP-70=1.2:1;

[0073] Described softening agent is made up of sodium hydroxide and magnesium oxide, and wherein mass ratio is: sodium hydroxide: magnesium oxide=8: 1;

[0074] The pre-bleaching agent is composed of hydrogen peroxide and a bleac...

Embodiment 2

[0086] The using method of described papermaking prepreg, concrete steps are:

[0087] (1) First, using water as the soaking liquid, add the material to be treated into water, wherein the mass ratio of the material to be treated to water is 1: 5 to obtain the soaking material;

[0088] (2) Next, the chelating agent is added into the soaking material, the dosage of the chelating agent is 7 g / liter of soaking liquid, and the treatment time is 15 to 20 minutes;

[0089] (3) Add the penetrant and softener into the soaking material, the amount of penetrant is 5 g / L of soaking liquid, the amount of softener is 40 g / L of soaking liquid, and the treatment time is 30-45 minutes;

[0090] (4) Finally, add the pre-bleaching agent into the soaking material, the dosage of the pre-bleaching agent is 25 grams per liter of soaking liquid, and the treatment time is 3-4 hours to obtain the prepreg.

Embodiment 3

[0092] A paper-based industrial packaging production process, using cotton stalks as raw materials to make paper-based environmentally friendly tableware as an example:

[0093] Material preparation: use ZCQ 2ZH1 mower to cut the cotton material into pieces with a length of 15-30 mm.

[0094] Dust removal: Use ZCC-2 type dust collector to remove the silt and dust contained in the flakes to obtain clean flakes.

[0095] Prepreg: Use a belt to convey the clean chips to the silo, and add 400 parts of water to 100 parts of clean chips according to the material-to-liquid ratio of 1:4, and then add prepreg. First, the chelating agent is put into the feed bin with an amount of 7 grams per liter, stirred evenly, and the treatment time is 15 minutes. Then put penetrating agent (amount of 5 g / L) and softener (amount of 35 g / L) into the silo, stir evenly, and the processing time is 30 minutes. Finally, put the pre-bleaching agent (amount of 20 g / L) into the silo and stir evenly. The tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com