Spray nozzle cleaning method and warm water washlet device

A nozzle and cleaning technology, which is applied in the field of warm water toilet seat device and nozzle cleaning, can solve the problems of accelerated aging, user electric shock, falling off, etc., and achieve the effect of sufficient cleaning and high sterilization level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

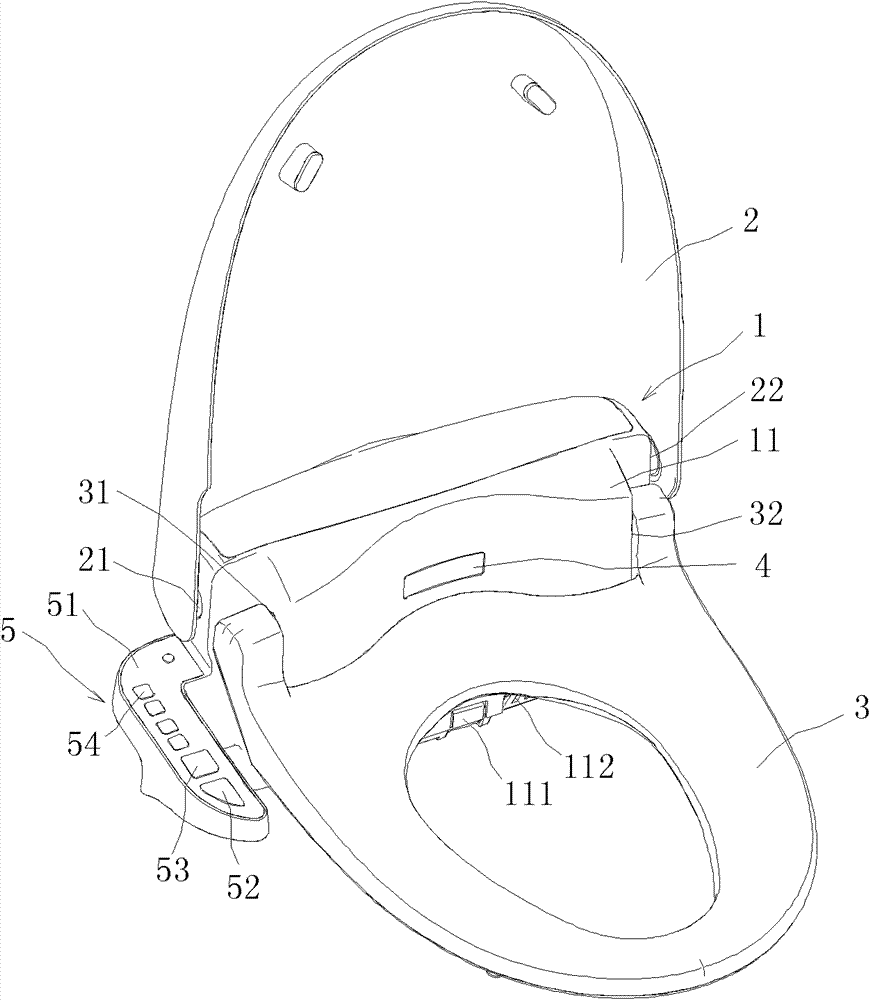

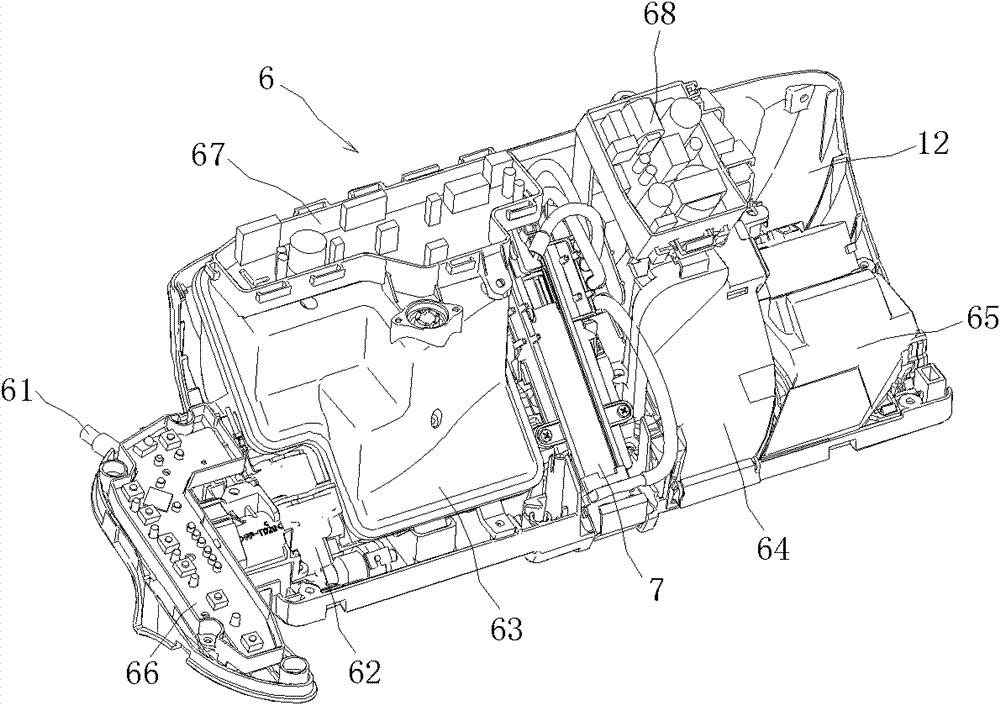

[0050] Such as Figure 1~2 As shown, the warm water toilet seat device provided by the present invention includes:

[0051] The main body shell 1 includes a main body cover 11 and a main body bottom plate 12 for supporting and protecting internal components;

[0052] The toilet cover 2 is rotatably mounted on the main body cover 11 through two rotating shafts 21 and 22 (not shown), and the toilet cover 2 can perform opening and closing rotation around the two rotating shafts 21 and 22;

[0053] The toilet ring 3 is rotatably mounted on the main body cover 11 relative to the rotating shafts 21 and 22 through two rotating shafts 31 and 32 (not shown). The toilet ring 3 is used to support the weight of the user and can rotate around the Rotating shafts 31 and 32 are turned on and off;

[0054] The seating sensor 4 is installed on the front part of the main body cover 11 close to the back and upper part of the toilet ring 3, and is used to detect whether a user is seated;

[00...

Embodiment approach 2

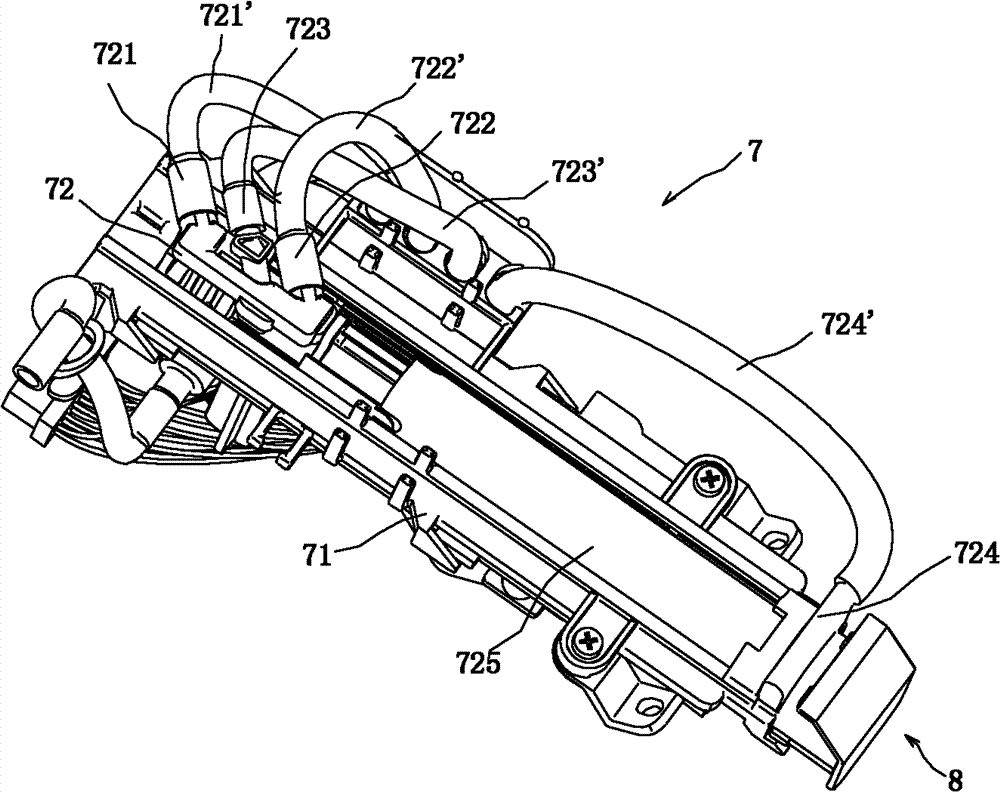

[0081] Such as Figure 8-11 As shown, the principles and effects of the warm water toilet seat device, nozzle assembly 7, bracket 71 and baffle 8 of this embodiment are basically the same as those of the warm water toilet seat device, nozzle assembly 7, bracket 71 and baffle 8 of Embodiment 1, and the baffle 8 It is also movably connected to the front end of the bracket 71, the difference is:

[0082] The baffle 8 is cylindrical, and the front end of the baffle 8 has an opening 86 for the nozzle main body 72 to enter and exit, so that the baffle 8 is rotatably connected to the front end of the bracket 70 around the axial direction of the nozzle main body 72, such as through the baffle Between the inner peripheral surface of 8 and the outer peripheral surface of bracket 71, there is provided a concave-convex structure extending along the circumferential direction with clearance fit to make the two rotatably engaged, so that the reflective part 80 of the baffle 8 is constituted ...

Embodiment approach 3

[0090] see you again Figure 10 , 11 The principles and effects of the warm water toilet seat device, nozzle assembly 7, bracket 71 and baffle 8 of this embodiment are basically the same as those of the warm water toilet seat device, nozzle assembly 7, bracket 71 and baffle 8 of Embodiment 2. The difference is: the baffle plate 8 is fixedly connected to the front end of the bracket 71, and the nozzle body 72 moves in the axial direction to change the distance between the two in the axial direction, that is, the length of the vector, thereby changing the first water flow 91 direction of reflection.

[0091] The fixed connection mentioned in this embodiment can make the baffle 8 detachably connected to the bracket 71 , and of course the baffle 8 can also be connected to the bracket 71 in a non-detachable way such as welding or integral molding.

[0092] In this embodiment, the reflective portion 80 of the baffle 8 includes a reflective portion 80 that changes along the normal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com