Environmental-friendly water paint and preparation method thereof

A water-based paint, environmental protection technology, applied in paints containing biocide, anti-fouling/underwater coatings, coatings, etc., can solve the problems that water-based paints have insignificant and ineffective removal of formaldehyde, and achieve the goal of eliminating secondary Effects of pollution, strong formaldehyde removal ability, and reliable living environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

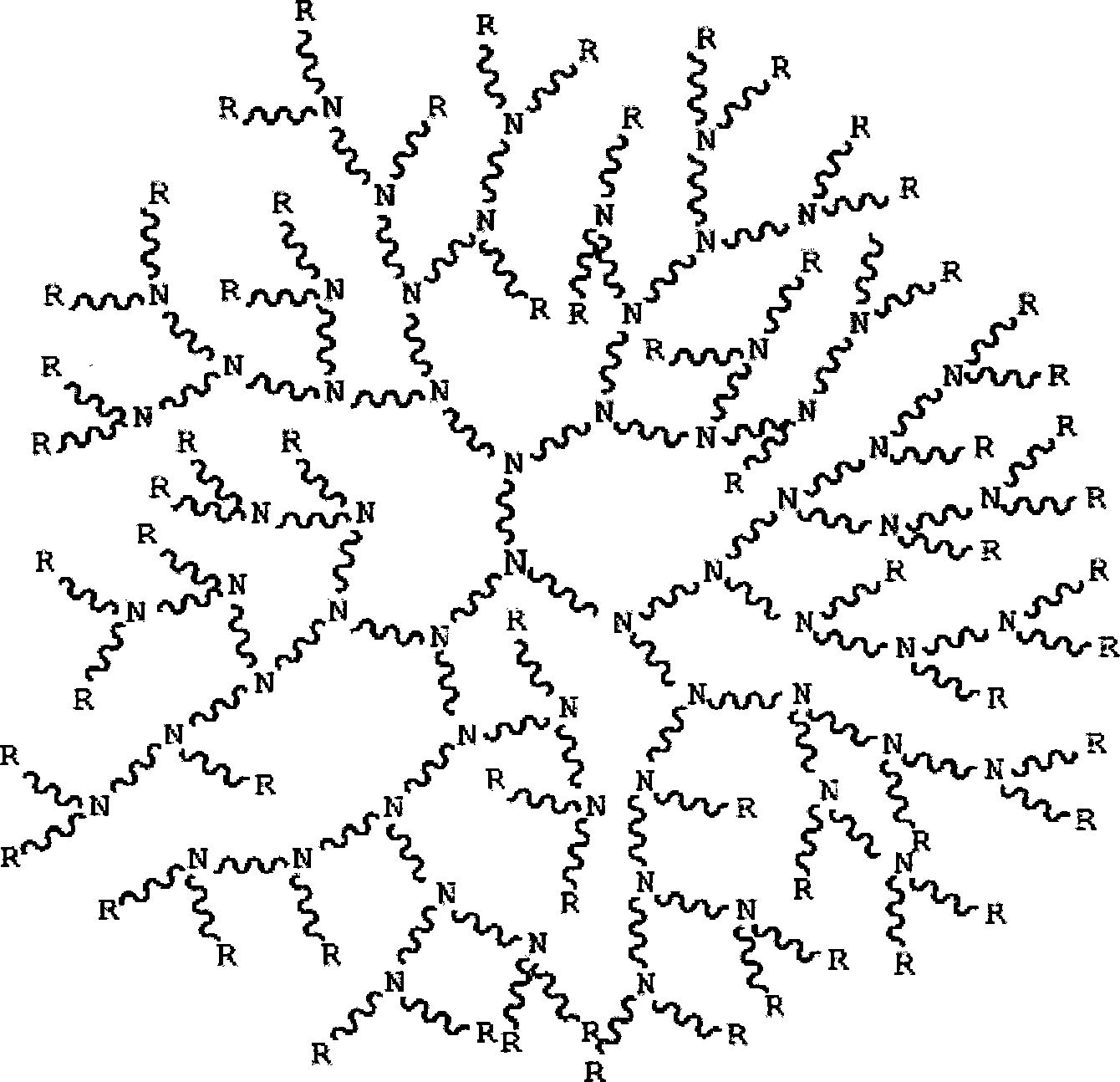

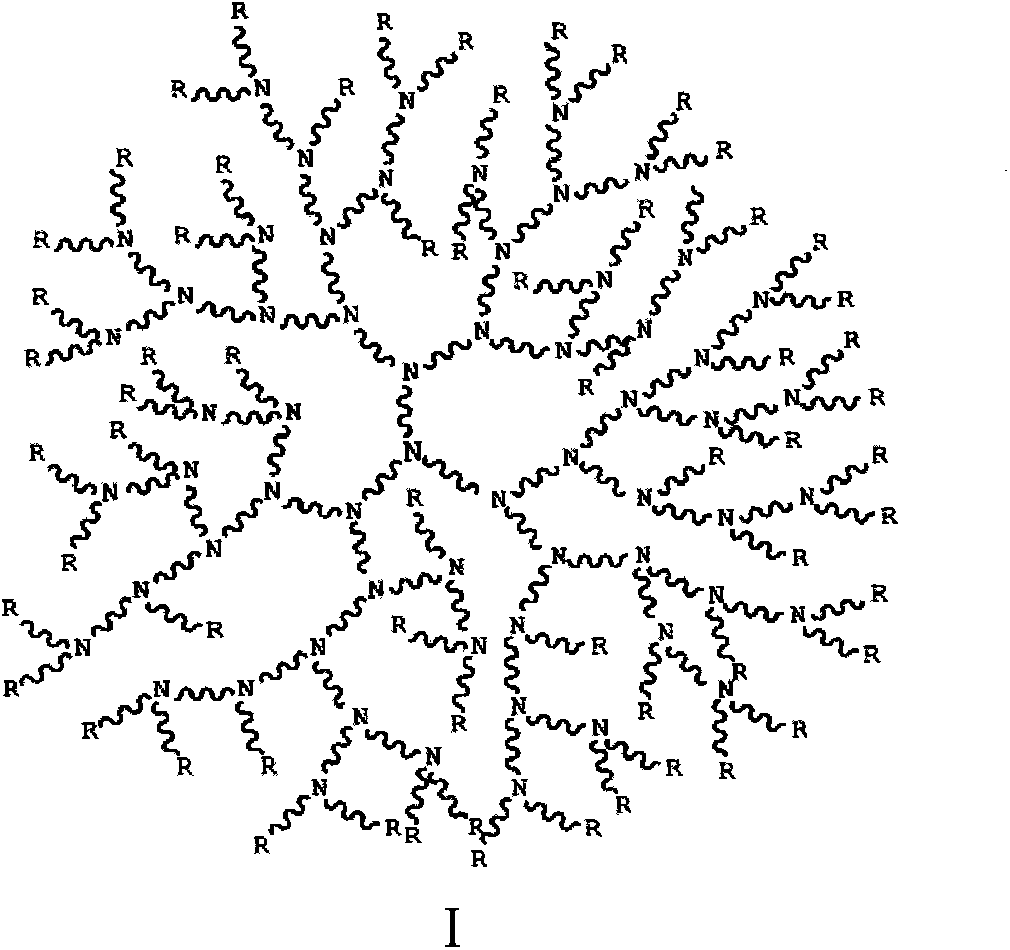

Image

Examples

Embodiment 1

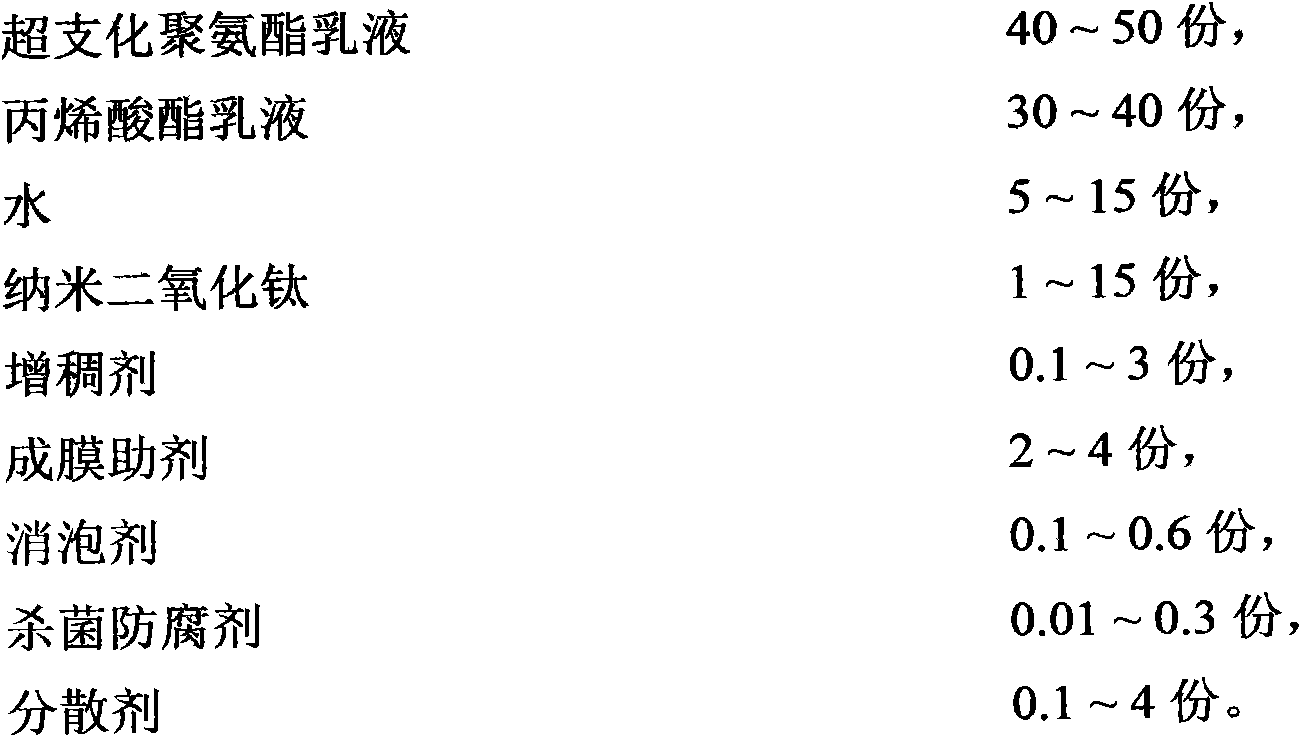

[0036] The environment-friendly water-based paint of the present embodiment comprises the following materials by weight:

[0037]

[0038]

[0039] The preparation method of the environment-friendly water-based paint of the present embodiment may further comprise the steps:

[0040] (1) Preparation of hyperbranched polyurethane emulsion:

[0041] a. Dissolve 10.5g of histidine in 25ml of deionized water, adjust its pH value to 9-10 with 8mol / L NaOH solution; slowly add acetic anhydride dropwise at 0°C, and add NaOH solution appropriately to control the pH of the system The pH value is in the range of 9 to 10. After the mixture continues to be stirred for 4 hours, it is acidified with concentrated hydrochloric acid to a pH value of 2; the solvent and excess acetic anhydride are removed by distillation under reduced pressure, and the residue is dissolved in 20ml of methanol. After filtration, α Amino-protected histidine;

[0042]b. Add 46.68g of toluene diisocyanate and ...

Embodiment 2

[0049] The environment-friendly water-based paint of the present embodiment comprises the following materials by weight:

[0050]

[0051] The preparation method of the environment-friendly water-based paint of the present embodiment may further comprise the steps:

[0052] (1) Preparation of hyperbranched polyurethane emulsion:

[0053] a. Dissolve 10.5g of histidine in 25ml of deionized water, adjust its pH value to 9-10 with 8mol / L NaOH solution; slowly add acetic anhydride dropwise at 0°C, and add NaOH solution appropriately to control the pH of the system The pH value is in the range of 9 to 10. After the mixture continues to be stirred for 4 hours, it is acidified with concentrated hydrochloric acid to a pH value of 2; the solvent and excess acetic anhydride are removed by distillation under reduced pressure, and the residue is dissolved in 20ml of methanol. After filtration, α Amino-protected histidine;

[0054] b. Add 46.68g of toluene diisocyanate and 4.69g of N,...

Embodiment 3

[0061] The environment-friendly water-based paint of the present embodiment comprises the following materials by weight:

[0062]

[0063] The preparation method of the environment-friendly water-based paint of the present embodiment may further comprise the steps:

[0064] (1) Preparation of hyperbranched polyurethane emulsion:

[0065] a. Dissolve 10.5g of histidine in 25ml of deionized water, adjust its pH value to 9-10 with 8mol / L NaOH solution; slowly add acetic anhydride dropwise at 0°C, and add NaOH solution appropriately to control the pH of the system The pH value is in the range of 9 to 10. After the mixture continues to be stirred for 4 hours, it is acidified with concentrated hydrochloric acid to a pH value of 2; the solvent and excess acetic anhydride are removed by distillation under reduced pressure, and the residue is dissolved in 20ml of methanol. After filtration, α Amino-protected histidine;

[0066] b. Add 46.68g of diphenylmethane diisocyanate and 4.6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com