Patents

Literature

60results about How to "Overcoming Adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acrylic ester waterproof gasket cement

InactiveCN101525525AOvercome water resistanceOvercoming AdhesionEster polymer adhesivesEmulsionOrganic solvent

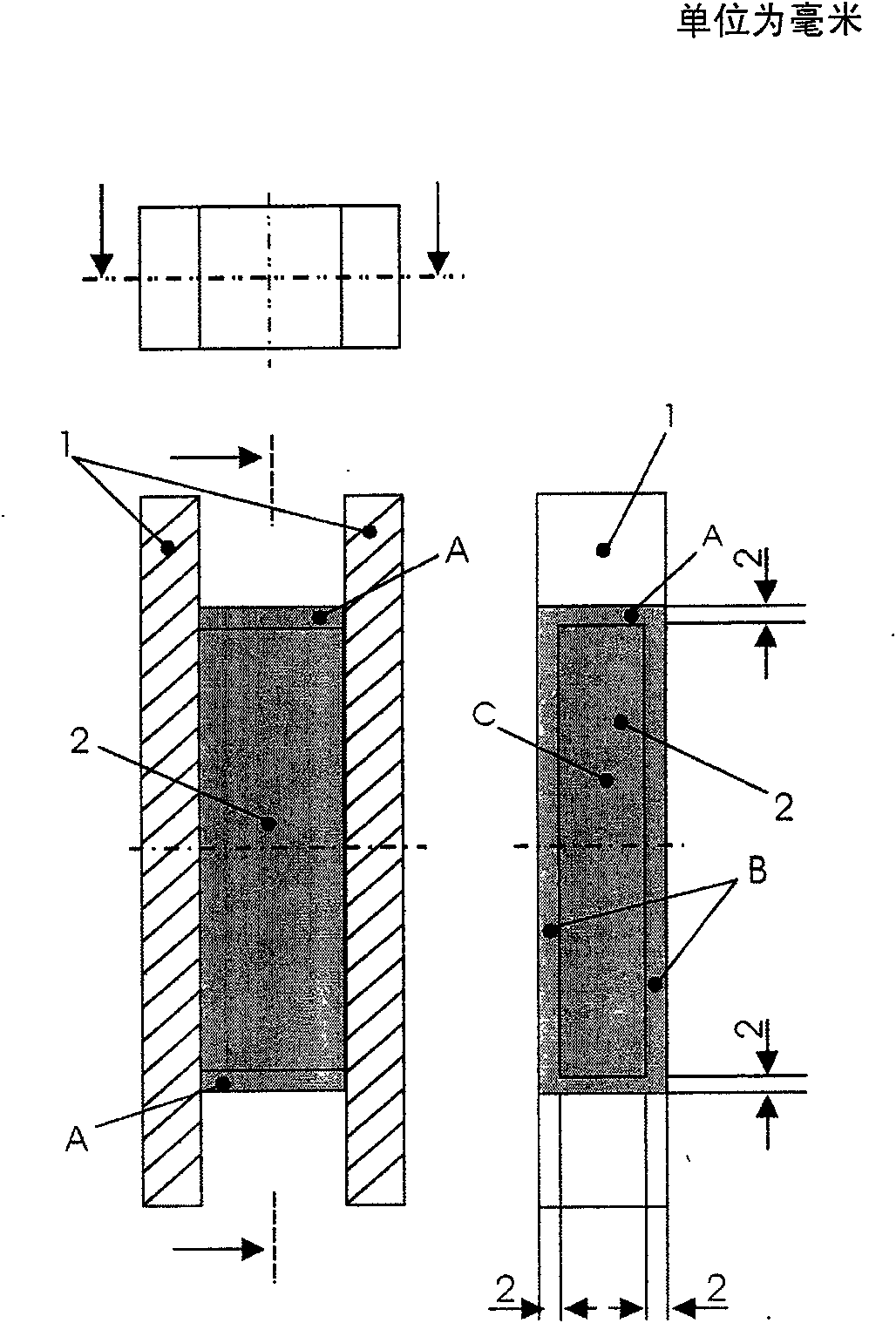

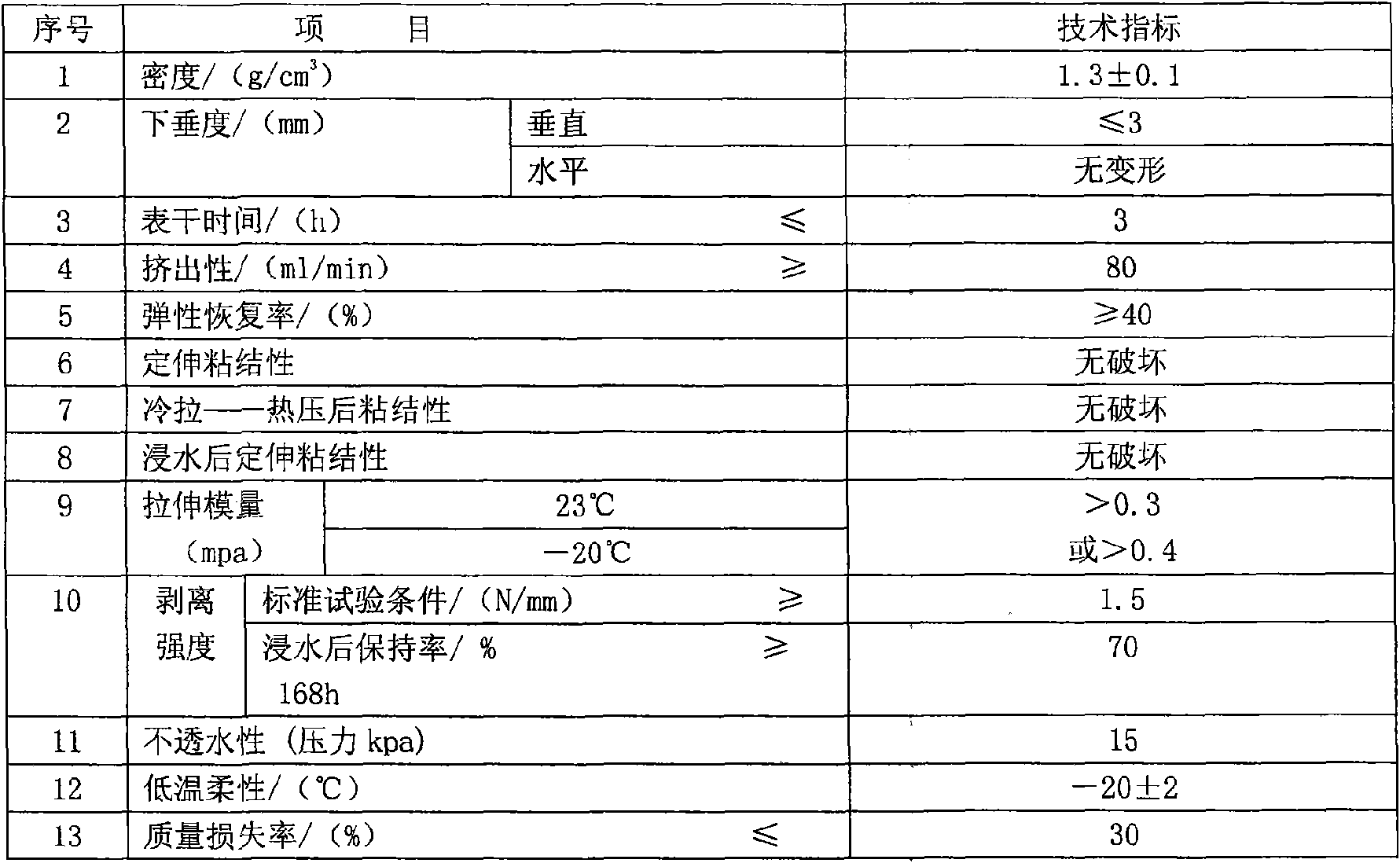

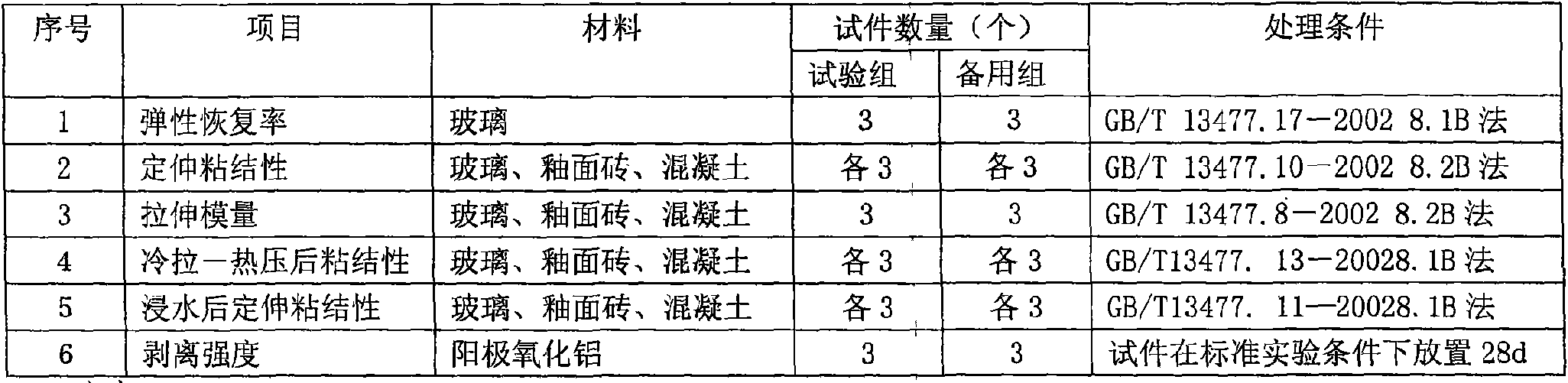

The invention relates to acrylic ester waterproof gasket cement and a preparation method thereof. The acrylic ester waterproof gasket cement includes a technology of environmental-friendly universal glass cement (the patent serial number is 200810083601.8) and comprises the following composition by weight: 30 parts of acrylic ester emulsion, 0.5-3 parts of dispersant, 2-10 parts of silica solution, 0.2-5 parts of coupling agent, 30-80 parts of filling, 0.1-2 parts of pH modifying agent and 0.5-2 parts of coalescing agent. The preparation method of the acrylic ester waterproof gasket cement comprises the following steps: adding one of a plasticizer, the coalescing agent and the coupling agent in a container to be mixed into liquid A, one of the silica solution, the coupling agent is added in another container to be mixed into liquid B, the acrylic ester emulsion is added in the containers, and the dispersant, the liquid A, the liquid B, the filing and the pH modifying agent are added in sequence during stirring the acrylic ester emulsion and the acrylic ester waterproof gasket cement is obtained after the mixture is evenly stirred. The invention overcomes the deficiencies that the aqueous gasket cement is not waterproof and has poor adhesiveness, the solvent-borne type gasket cement has good waterproof performance, but contains over 30 percent of VOC and pollutes the environment seriously, and most of organic solvent belongs to a petrochemical product and causes the waste of energy. The waterproof gasket cement is environmental-friendly and has good waterproof performance and adhesiveness.

Owner:金朝绪

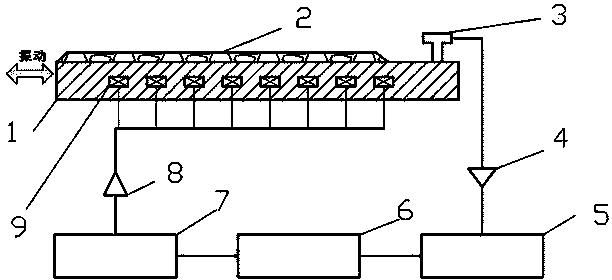

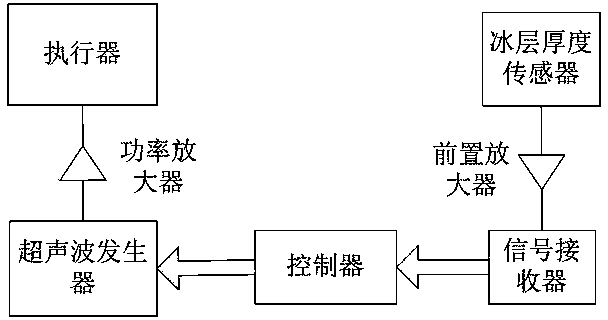

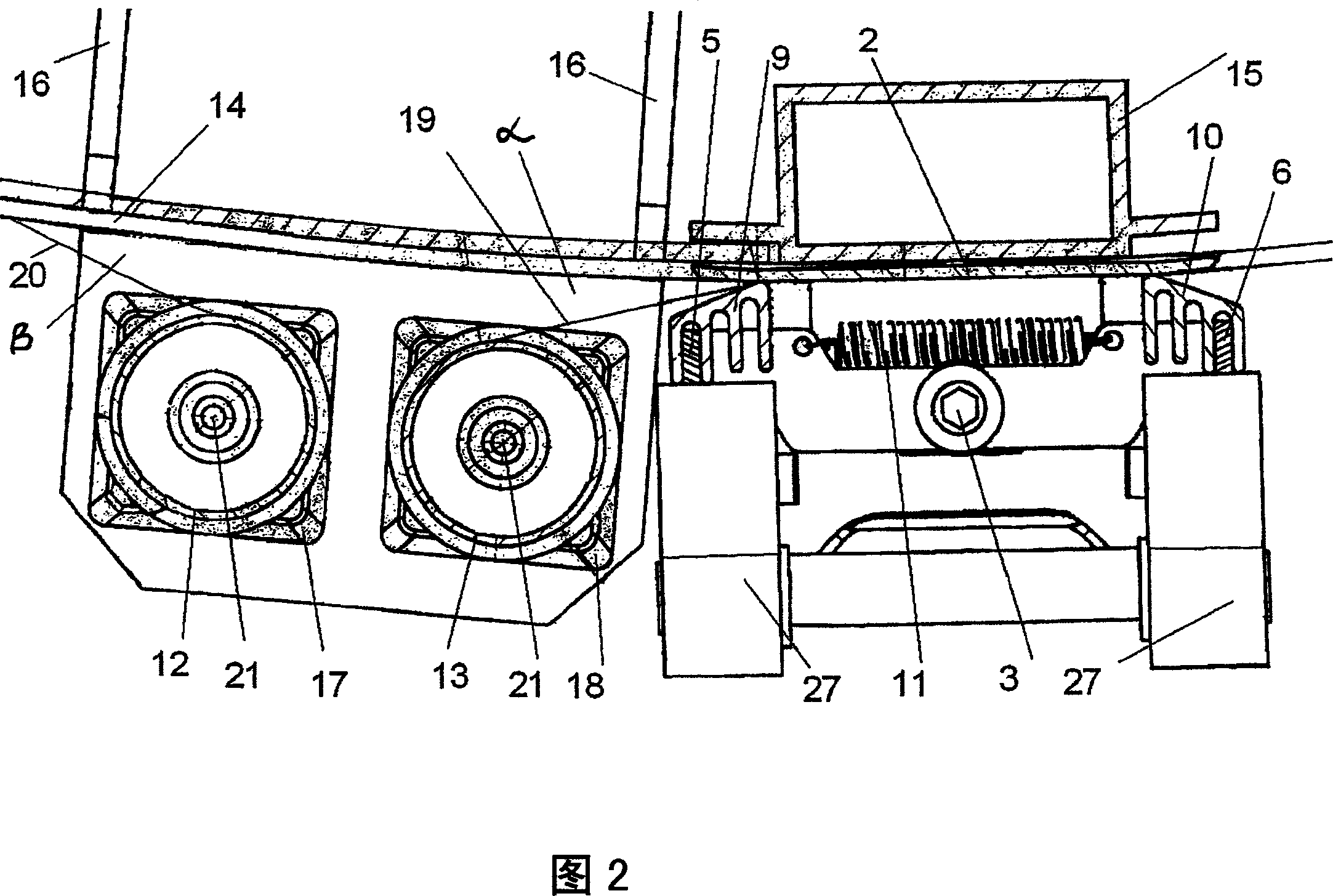

Road surface de-icing device for military airfield

InactiveCN103806401AReduce energy consumptionImprove efficiencySnow cleaningHigh power densityAutomotive engineering

Owner:TSINGHUA UNIV +1

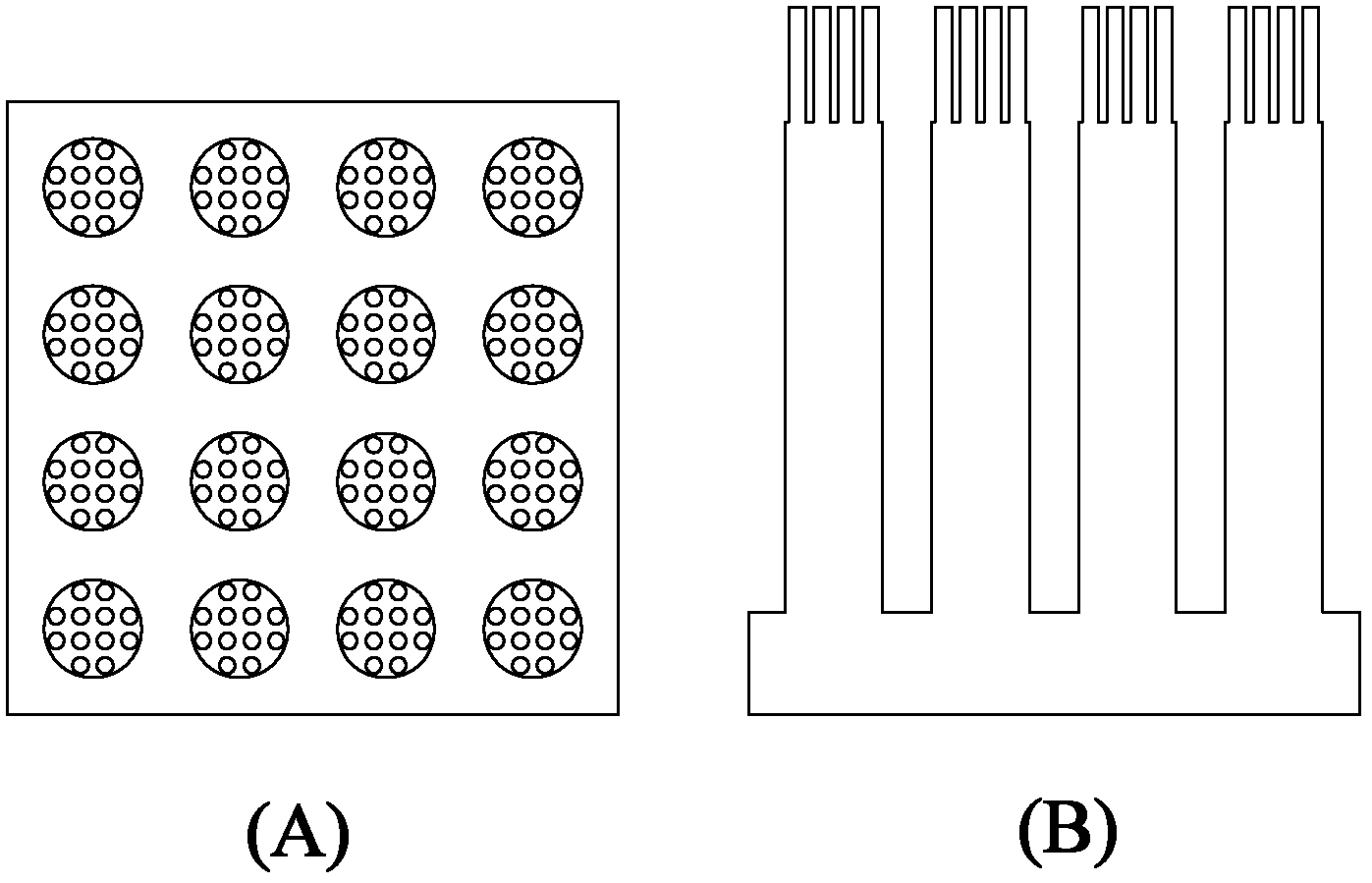

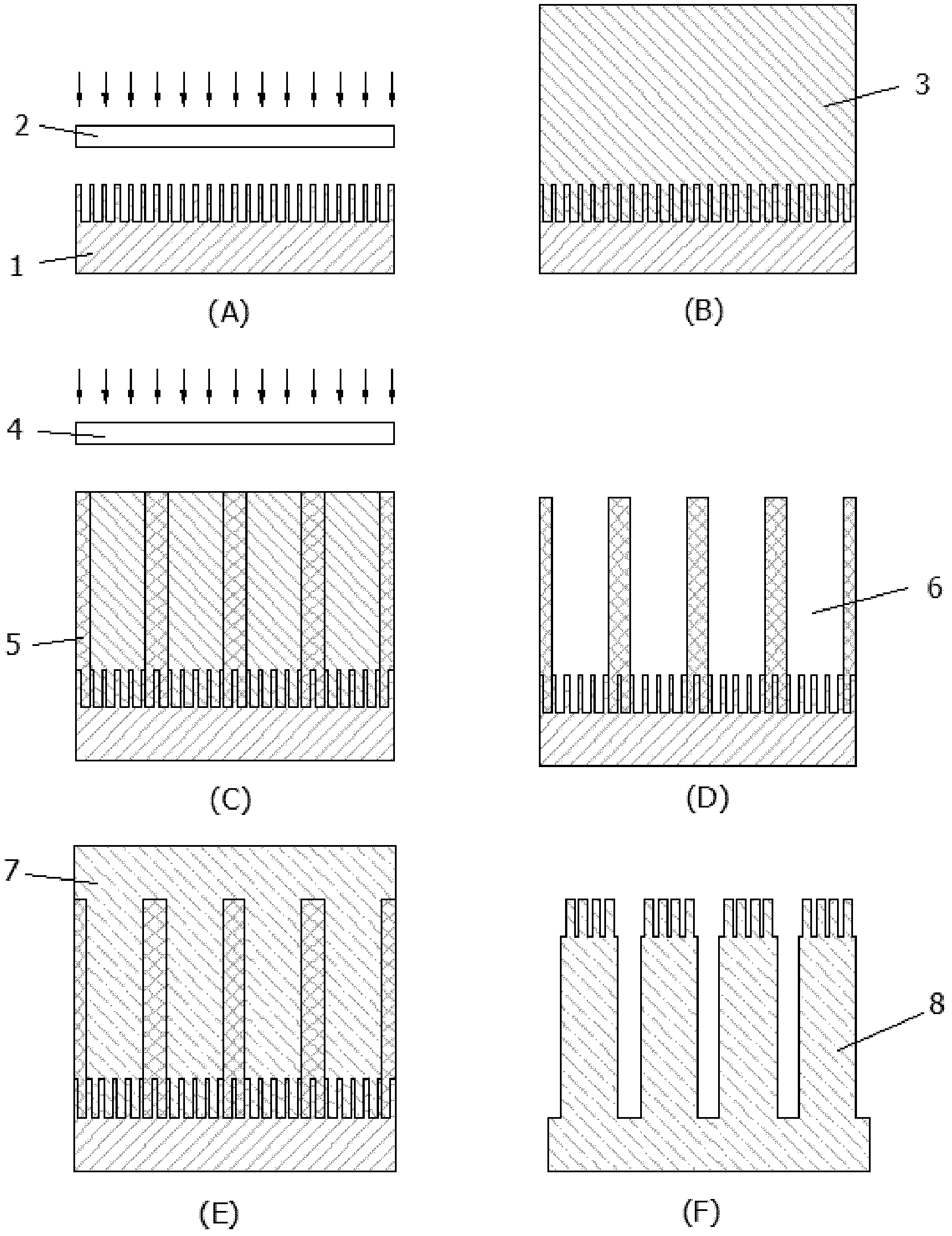

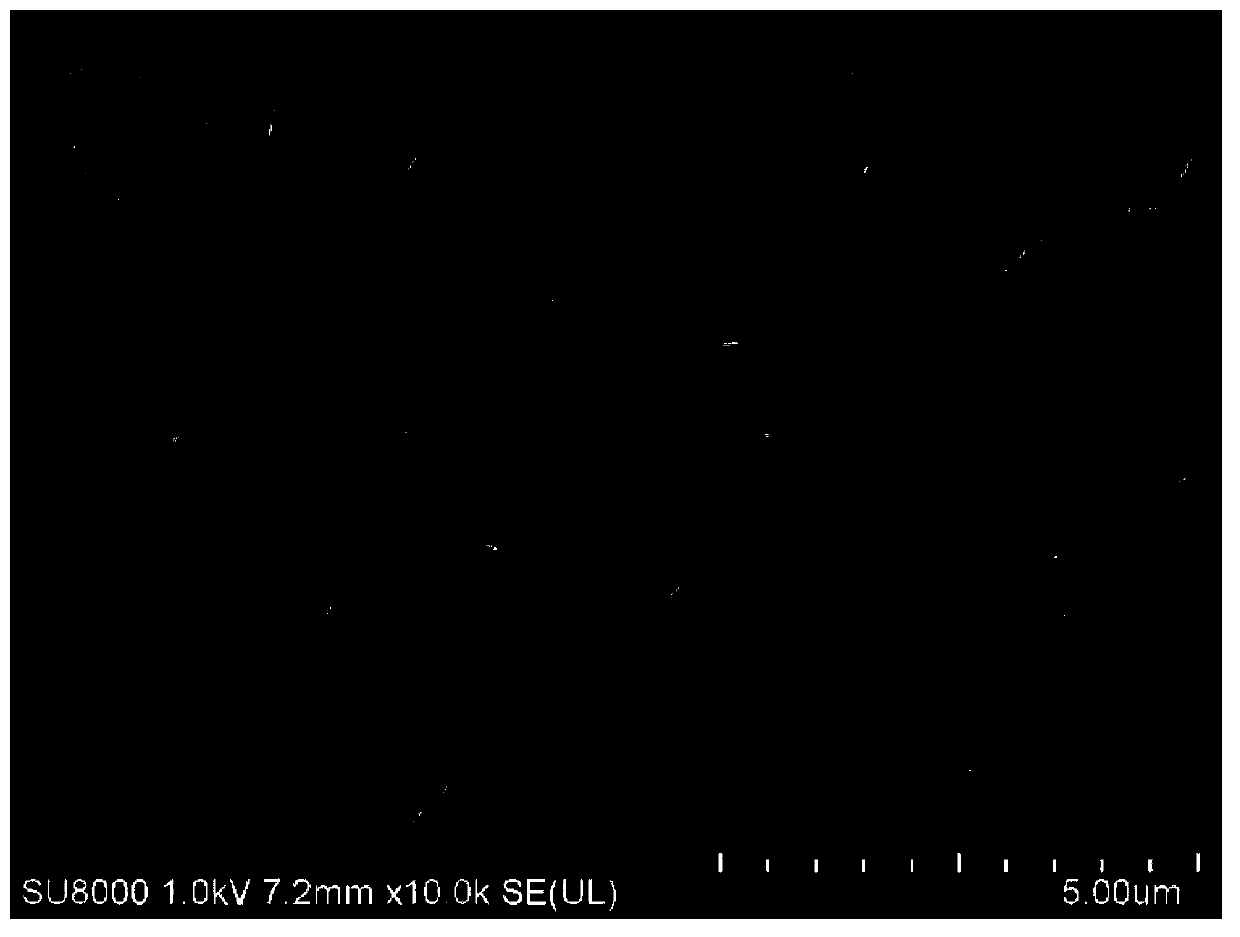

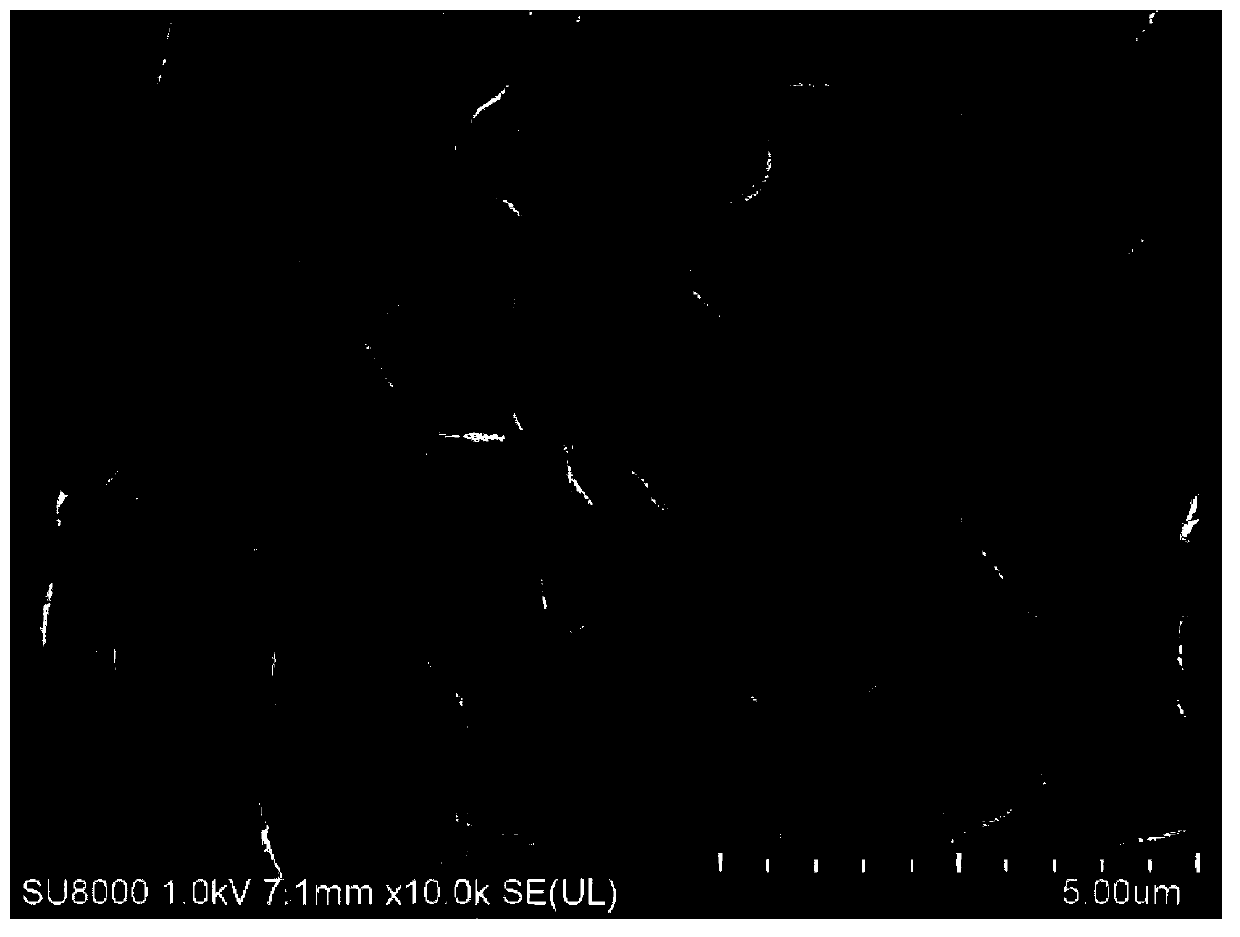

Manufacturing method of gecko hair-imitating dry adhesive

InactiveCN102381679ANot easy to degradeOvercoming pollutionFilm/foil adhesivesDecorative surface effectsMicro nanoResist

A manufacturing method of a gecko hair-imitating dry adhesive. Aiming at disadvantages of easy degradation, easy pollution, and self-adhesion for current wet adhesives, and complicated and tedious manufacturing modes of current dry adhesives, by studying the micro-nano hierarchical structure characteristics of gecko foot hair in the nature, the invention manufactures a composite mold of SU-8 adhesive and silicon by combined ICP etching technology and thick-resist technology; a micro-nano hierarchical structure fiber array with a high depth to width ratio is obtained by one-step forming through a micro-molding mode; the structure imitates the structure characteristics of gecko in the nature, and has a superactive adhesion characteristic. The invention comprises silicon mother board manufacturing based on ICP etching technology, composite mold manufacturing based on thick-resist technology, and bilayer fiber array manufacturing based on micro-molding formation. The invention can manufacture a micro-nano hierarchical structure which has parameters close to parameters of gecko foot hair in the nature; the prepared product is a superactive dry adhesive which not only adapts different surfaces but also is easy to desorb the surfaces actively; the manufacturing cost is low, and the method is simple.

Owner:HUAZHONG UNIV OF SCI & TECH

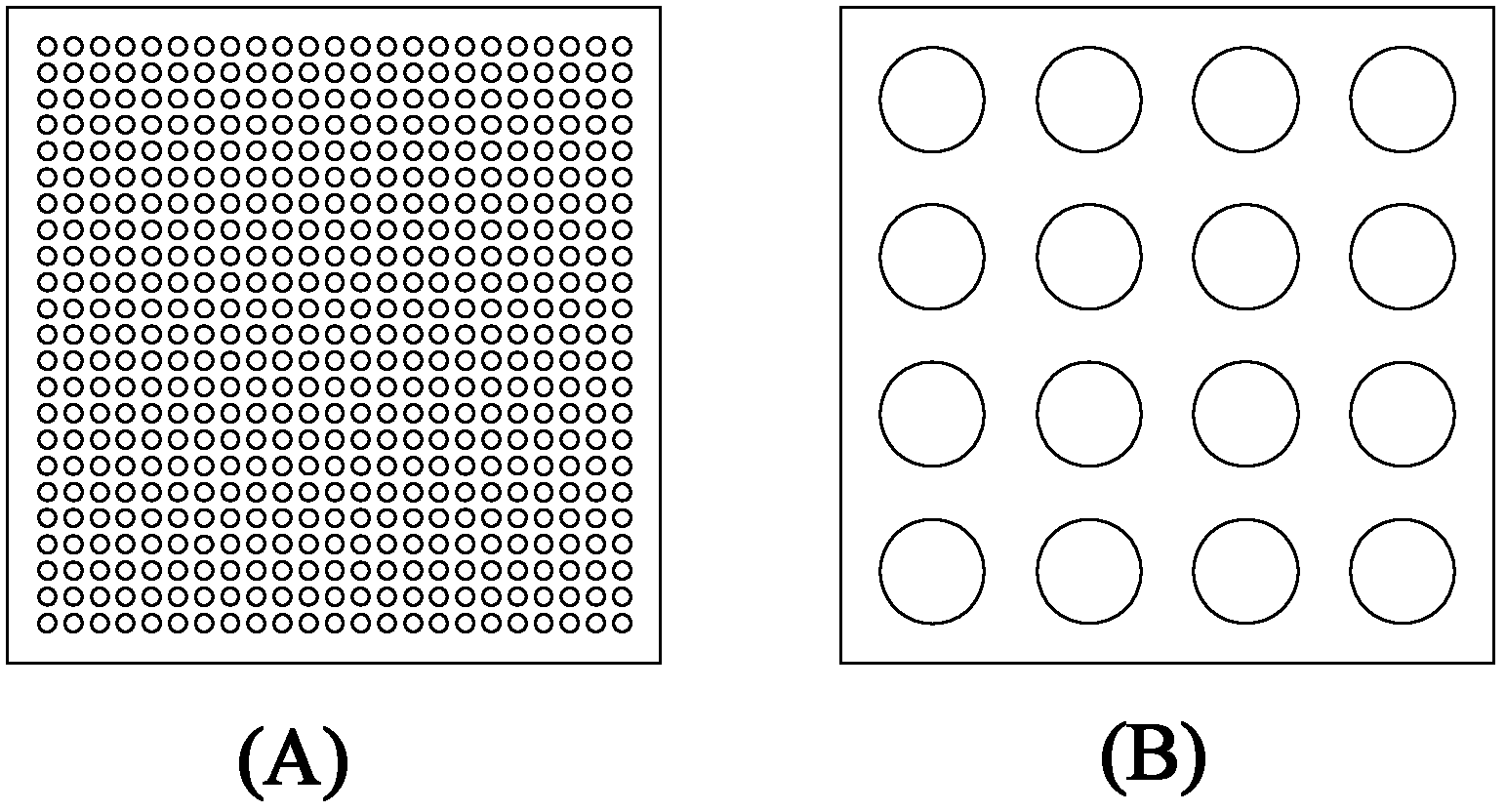

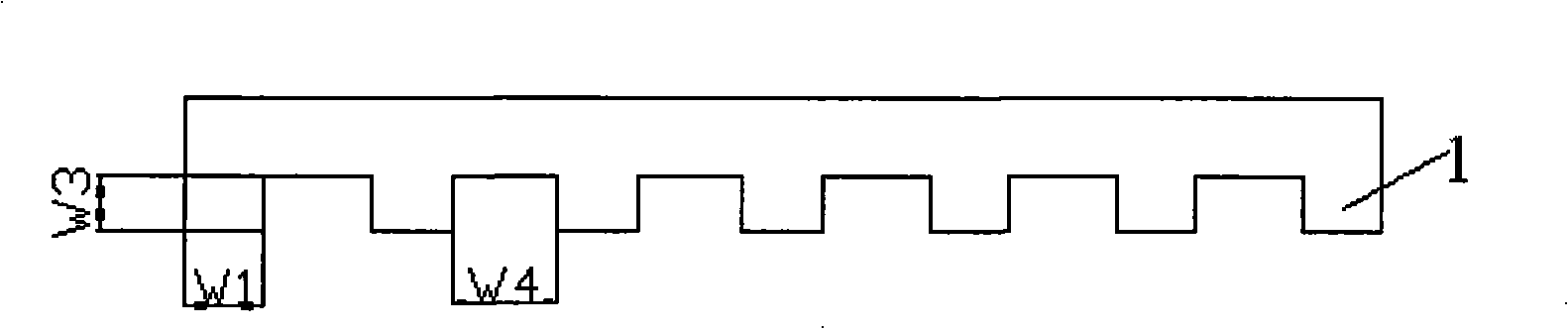

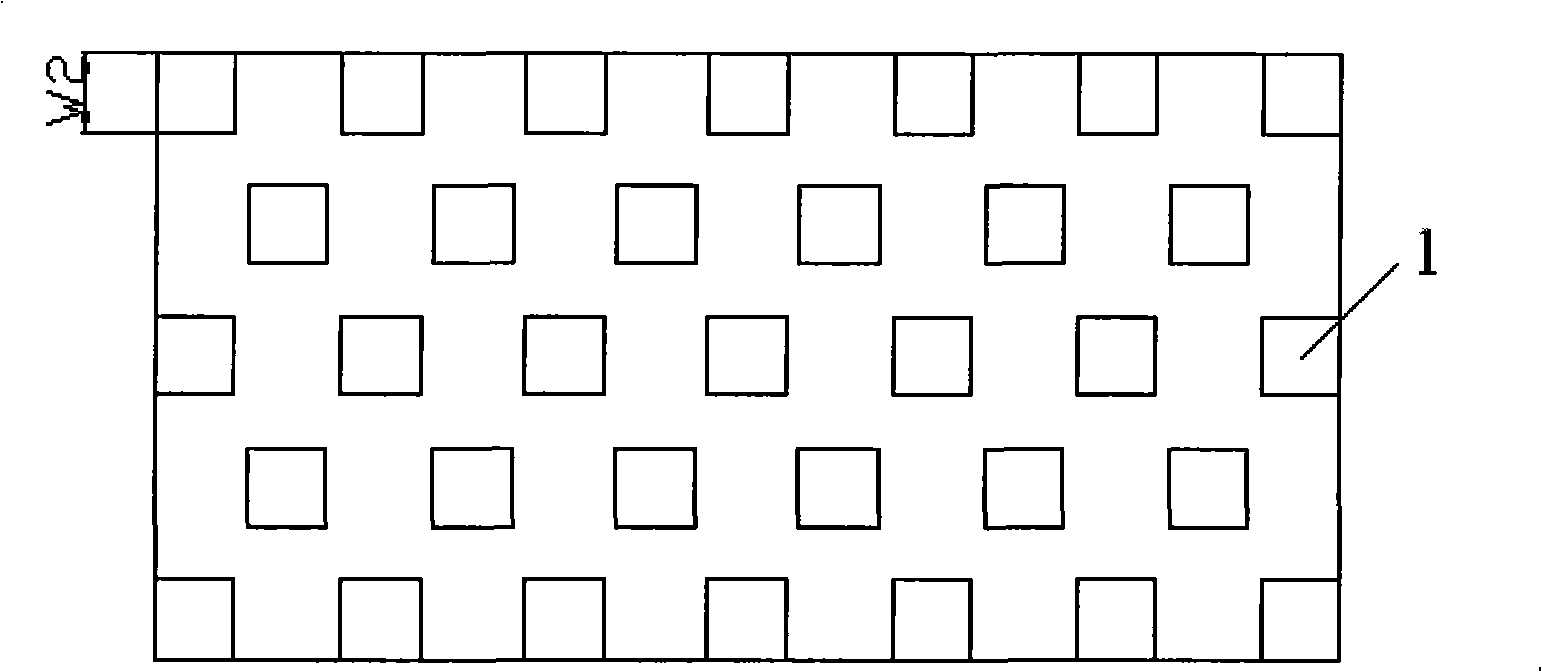

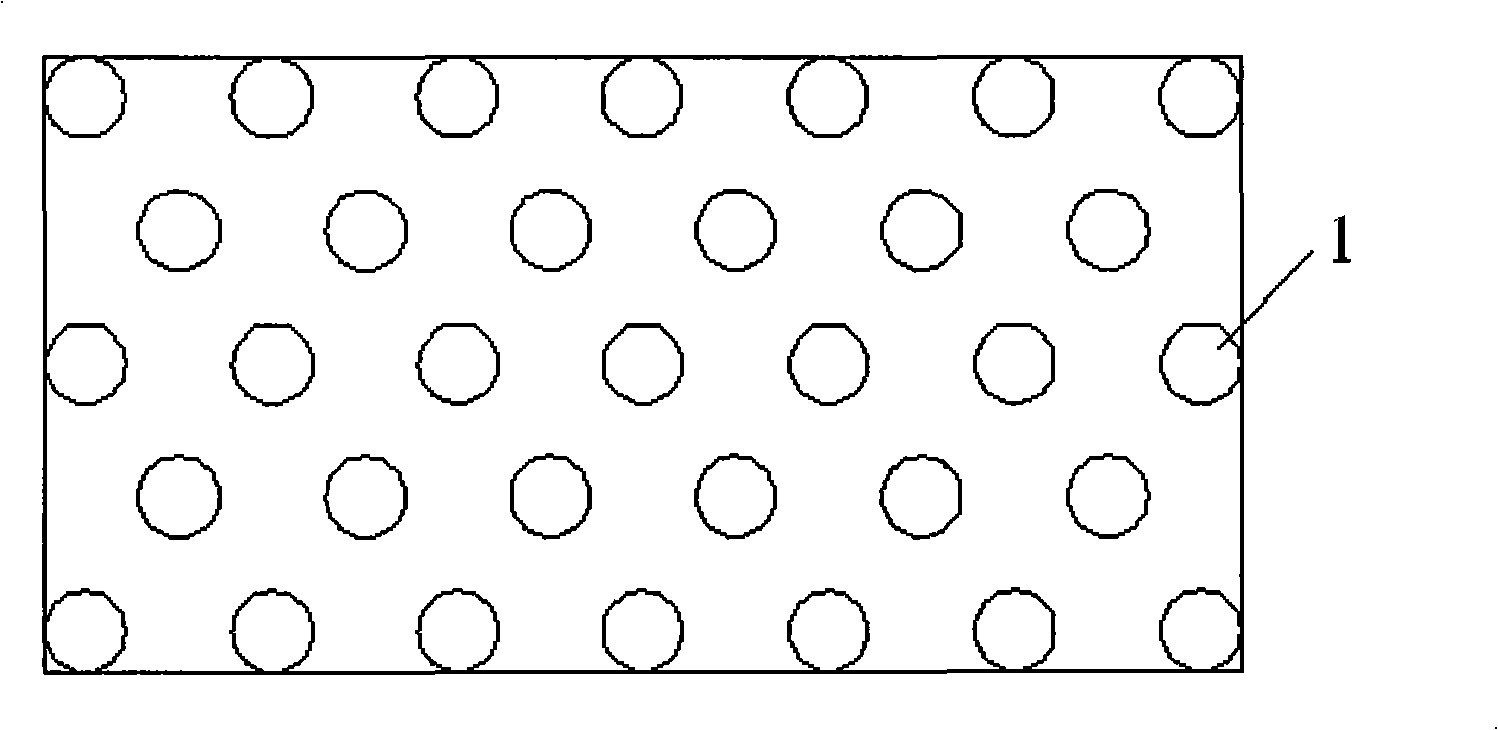

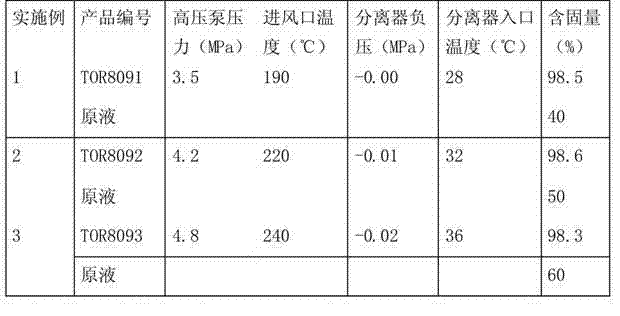

Method for manufacturing drag reduction surface

InactiveCN101402446AReduce pressure loss along the wayLow flow resistanceDecorative surface effectsChemical vapor deposition coatingAviationFlow resistivity

The invention belongs to the technical field of micro-nanometer manufacturing and relates to a method for manufacturing the surface with resistance reduction. Micron level structure arrays in alternate arrangement are designed and manufactured on the surface of a silicon substrate, a silicon dioxide substrate, an engineering plastic substrate or a metal substrate; an ultraviolet stamping photoetching technology is used as a transferring means; a template can be repeatedly used; a fluorination process is used as a surface treatment means to obtain a microstructure substrate with the function of resistance reduction; and the microstructure surface of the substrate has quite low surface energy. The method can be used for the surface of a device for a micro-electromechanical system, and can reduce the surface friction and abrasion as well as the invalidation of adhesion under a microscale; the method can be used for the surface of a conveying pipeline and a microflow device, can reduce the on-way pressure loss of a fluid in a micro-passage and the flow resistance of the fluid, and can increase flow speed; and the method can be used in aviation, spaceflight, navigation, traffic transportation and other fields, and can reduce energy consumption and consequently save energy.

Owner:XI AN JIAOTONG UNIV

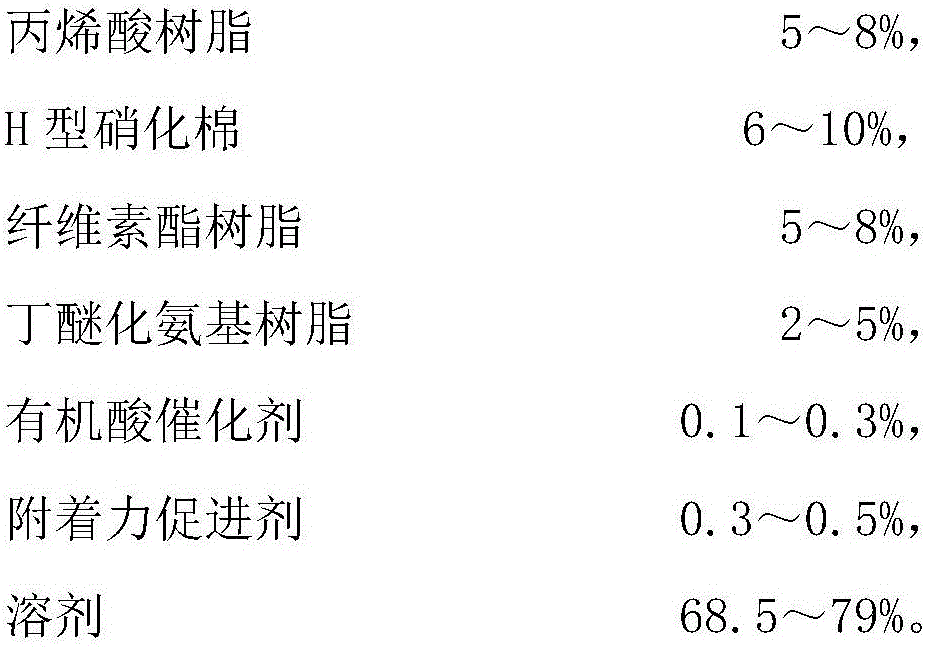

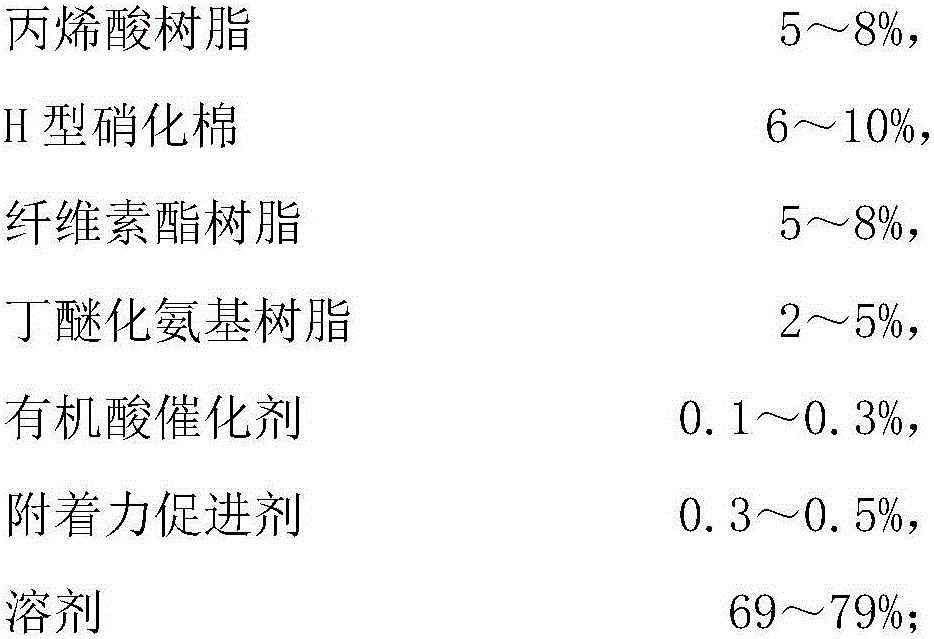

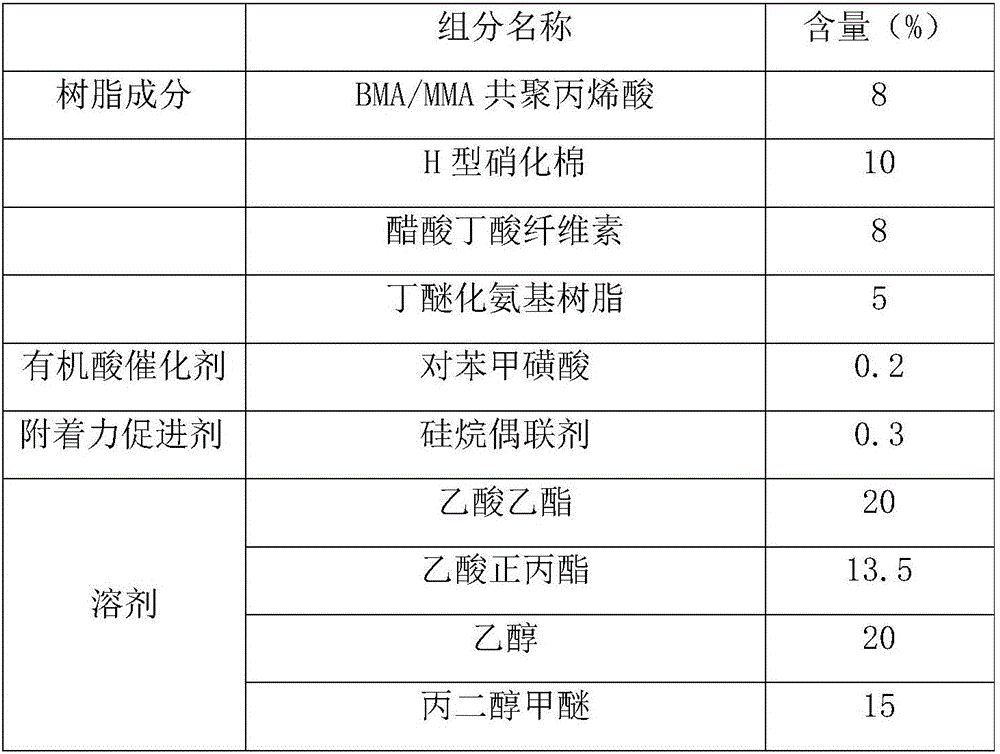

Anti-scratch, fold-resistant and solvent-resistant thermosetting transferring system paint and preparation method thereof

ActiveCN106118256AImprove abrasion resistanceImprove folding resistanceCoatingsCross-linkThermoplastic

The invention discloses anti-scratch, fold-resistant and solvent-resistant thermosetting transferring system paint and a preparation method thereof. The paint comprises the following components by weight percent: 5 to 8 percent of acrylic resin, 6 to 10 percent of H-type nitrocotton, 5 to 8 percent of cellulose ester resin, 2 to 5 percent of butylated amino resin, 0.1 to 0.3 percent of organic acid catalyst, 0.3 to 0.5 percent of adhesive force accelerant, and 68.5 to 79 percent of solvent. By virtue of a thermosetting reaction, the resin of a transferring coating is limitedly cross-linked, so that the hardness and flexibility are improved, and compared with the traditional thermoplastic transferring system, the scratch resistance, fold resistance and solvent resistance are remarkably improved, and the high-performance requirement of a product and a printing process can be better met; and compared with other thermosetting transferring systems, the defects that the transfer is poor and the attachment to aluminum is poor can be overcome. In addition, the resin with appropriate activity is preferred, so that the paint can be directly used as single-component paint, and the operability of the production ingredients is improved.

Owner:SHANGHAI WEIKAI CHEM

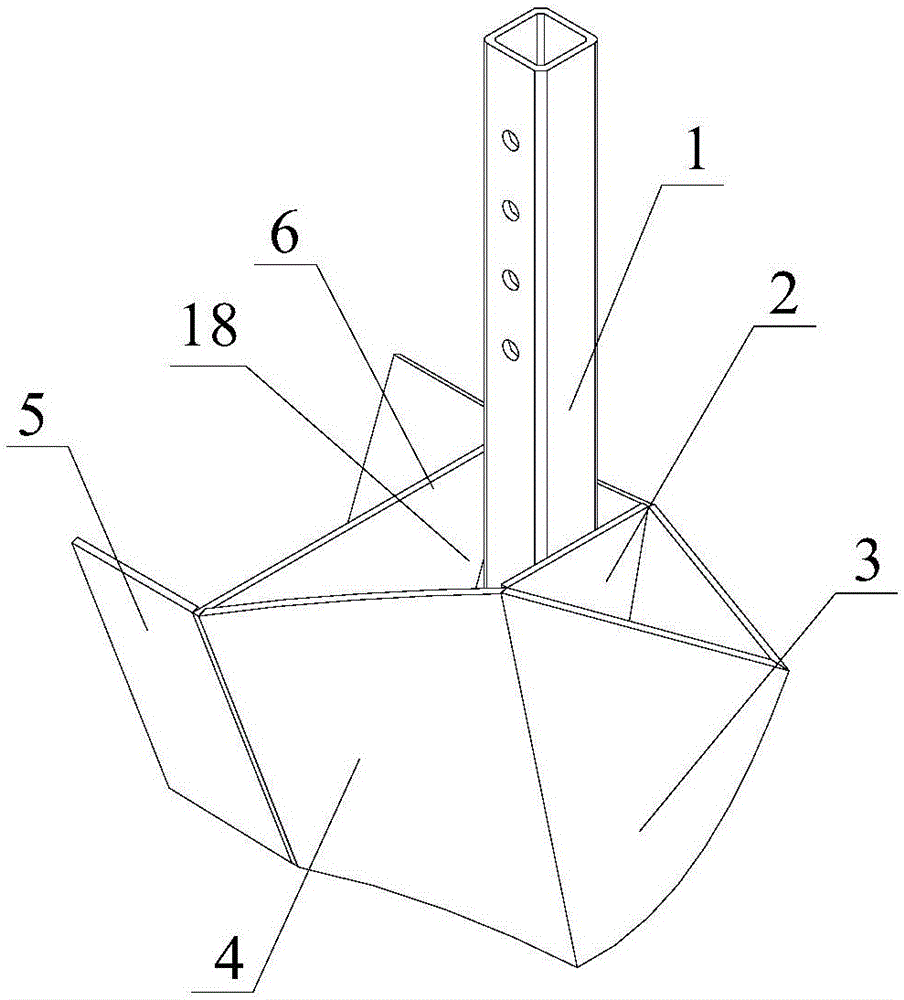

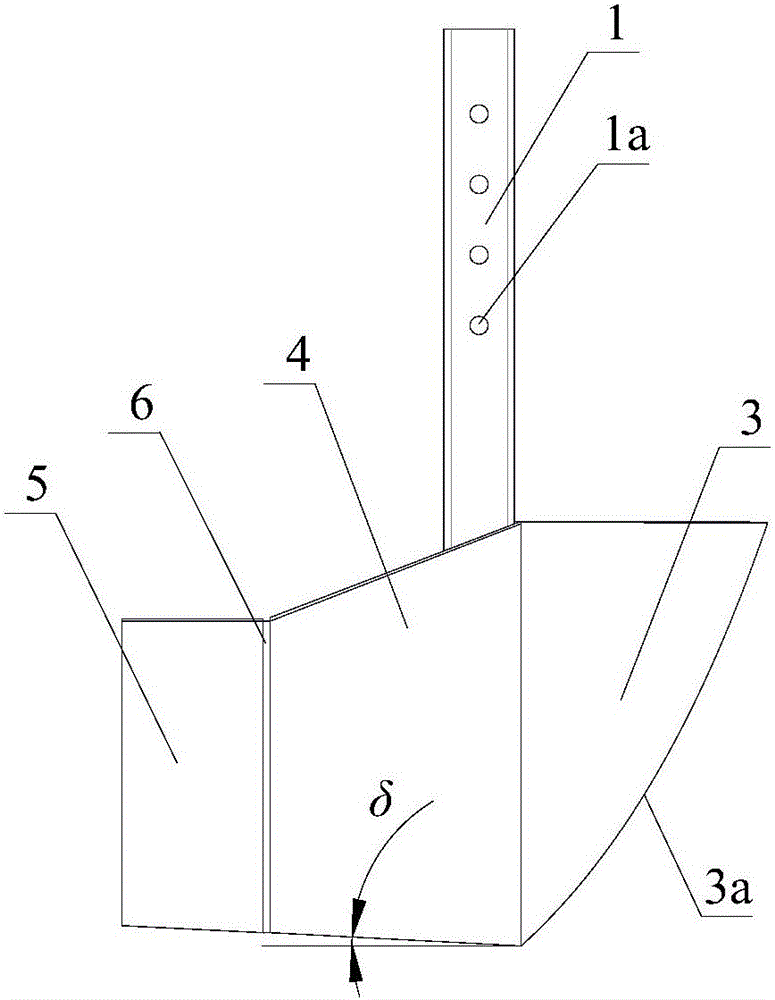

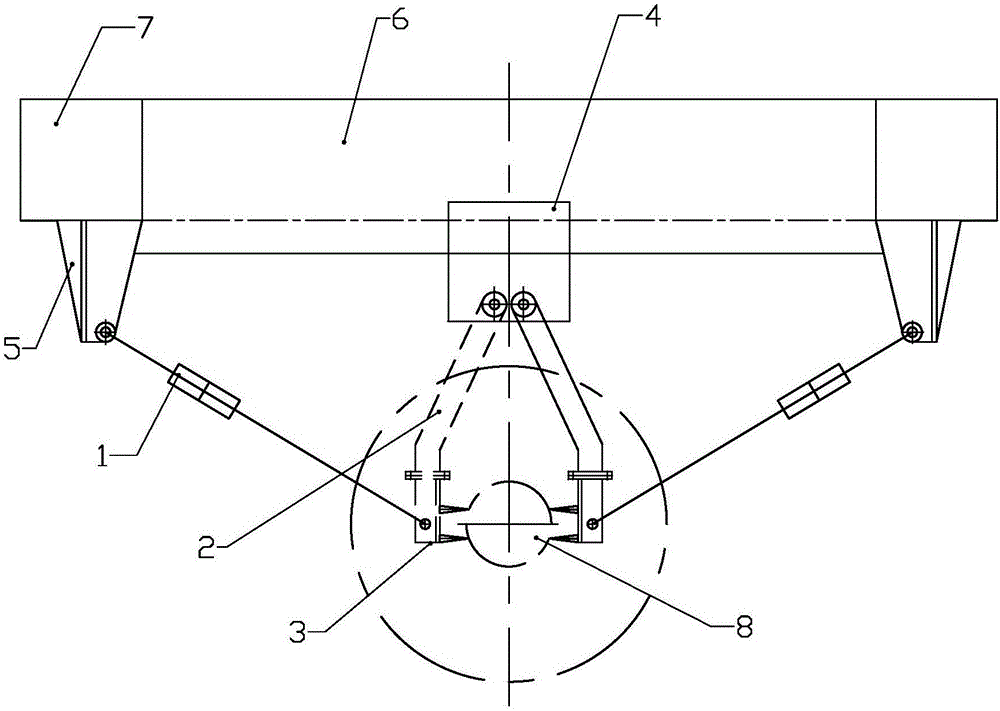

Boat furrow forming device for synchronous furrowing in seeding

ActiveCN106105500AInhibit refluxMeet the requirements for planting furrowsConstructionsSoil drainageEngineeringMoisture

The present invention discloses a boat furrow forming device for synchronous furrowing in seeding, comprising a plow post and a forming frame for mounting the plow post; the forming frame includes two soil breaker plates, two shaping plates and two soil flattening plates, intersecting curves of soil breaking surfaces of the two soil breaker plates are edge curves, and every two of the two soil breaker plates, the two shaping plates and the two soil flattening plates are arranged symmetrically along a plane of the edge curves; the edge curves are exponential function curves, and surfaces of the two shaping plates are each a plow body surface. Furrows are formed through the action of the soil breaker plates, shaping plates and soil flattening plates upon soil, multiple experiments show that made furrows are trapezoidal furrows having clean bottom, smooth walls and uniform depth, and soil reflow can be effectively inhibited; during operation for viscous heavy caked high-moisture-content soil, the boat furrow forming device shows good trafficability, blocking and adhesion during equipment and soil acting are overcome, and the boat furrow forming device is convenient to mount to a combine harvester for use.

Owner:HUAZHONG AGRI UNIV

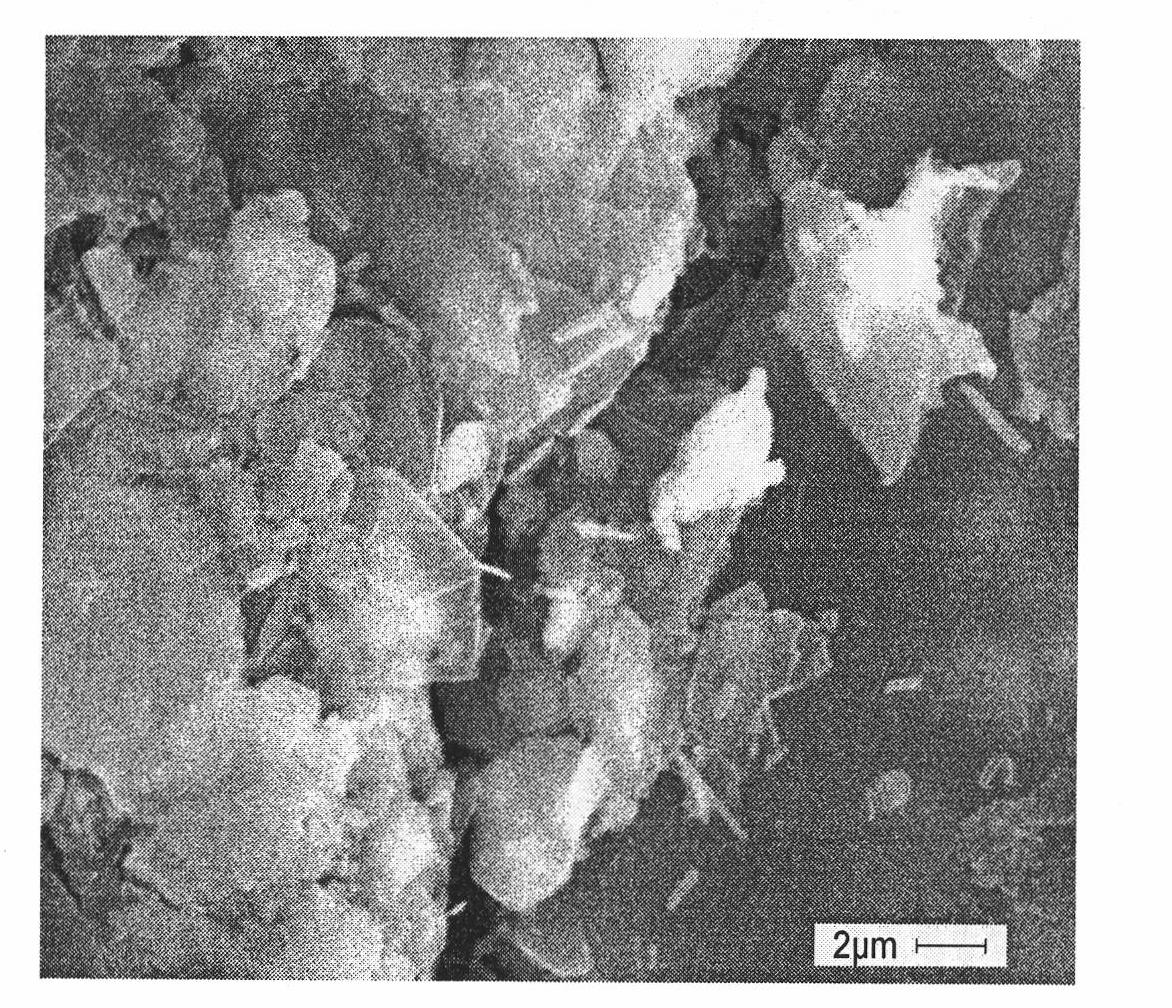

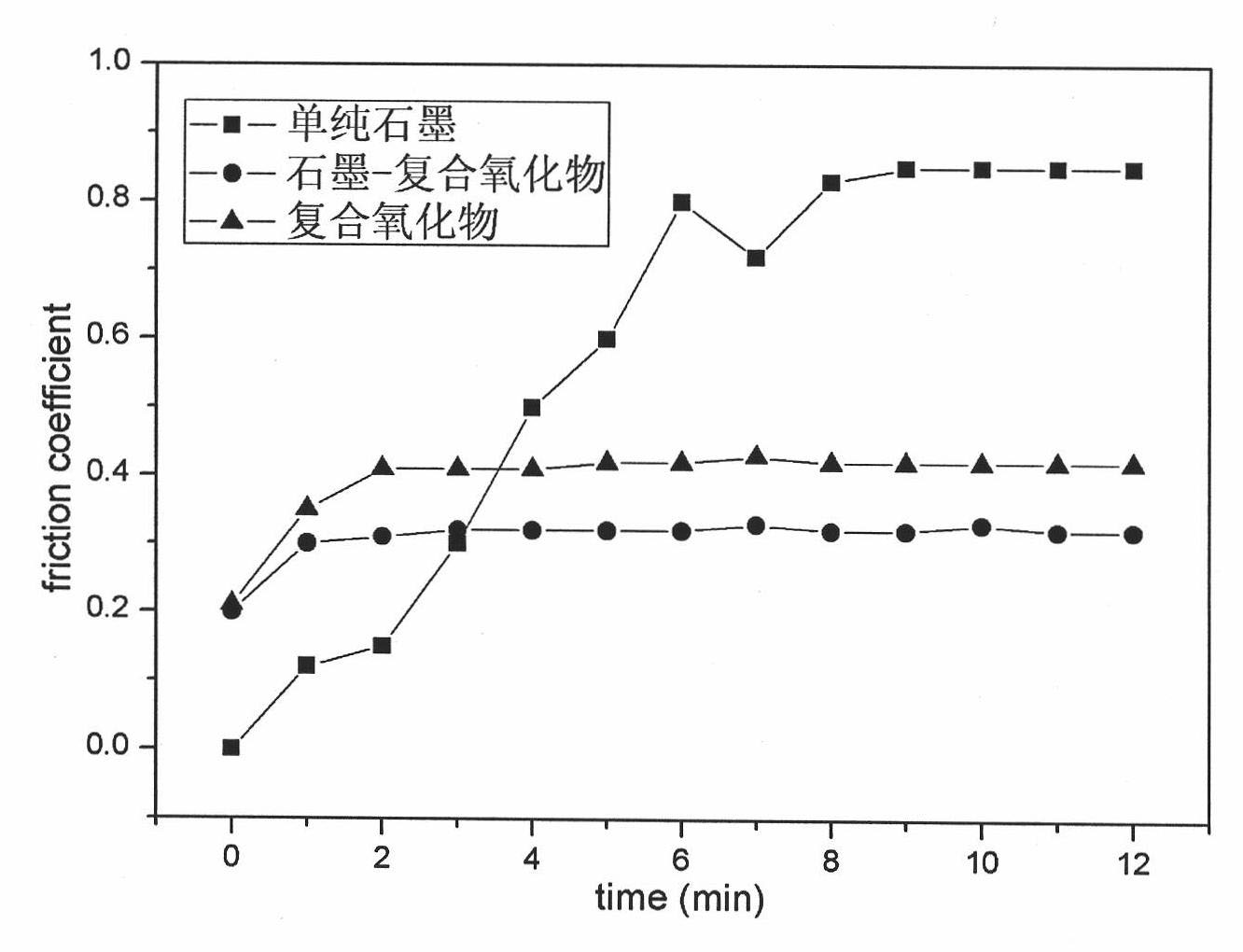

Graphite-oxide composite solid lubricant for hot-rolled seamless steel pipe and preparation method thereof

InactiveCN102093927AImprove carrying capacityGood friction and wear performanceLubricant compositionHigh loadSteel tube

The invention discloses a graphite-oxide composite solid lubricant for a hot-rolled seamless steel pipe and a preparation method thereof. The composite solid lubricant is mainly prepared by taking graphite, boric acid, serpentine, potassium titanate crystal whiskers and mica as main raw material and soluble silicate as adhesive agent by sufficiently stirring and mixing. The composite solid lubricant provided by the invention has high load-carrying capability, good frictional wear reduction performance and long wearing life, and overcomes the following frequently occurring problems of single-graphite solid lubricant: the vibration and noise are large, and the core rod is easy to adhere. During the application process, no noise is detected, the vibration of a rolling mill is small, the steel pipes and the core rods do not adhere, and the rod wrap accident is avoided. In addition, by using the composite solid lubricant, the steel pipe has smooth surface and is suitable for industrial production.

Owner:无锡润鹏复合新材料有限公司

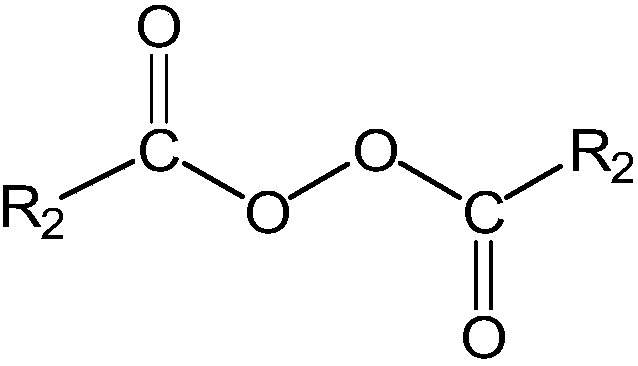

Modified cellulose diacetate as well as preparation method and application thereof

ActiveCN109503892AIncrease melt viscosityFeel comfortableAdditive manufacturing apparatusCellulose diacetateCellulose acetate

The invention belongs to the field of cellulose diacetate products, and particularly relates to a modified cellulose diacetate product as well as a preparation method and application thereof to 3D printing and other fields. The modified cellulose diacetate provided by the invention is prepared by mixing cellulose diacetate, a plasticizer, a hindered phenol antioxidant, a phosphite antioxidant andperoxide. The cellulose diacetate can be used as a 3D printing material for preparing products by adopting a 3D printing method.

Owner:SICHUAN PUSH CELLULOSE ACETATE CO LTD

Advertising tower

The invention relates to an advertising tower for posters to be rolled up and unrolled, said tower consisting of a drive, an inner cylinder, and an outer cylinder comprising a vertical strut. Said inner cylinder is embodied with bearing surfaces for the posters, said surfaces consisting of a transparent material. A turnstile comprising a vertical shaft provided with a pivot drive is arranged at the centre of the inner cylinder. Extension arms carrying receiving elements for poster drums, arranged between the inner cylinder and the outer cylinder, are applied to said shaft. The strut of the outer cylinder and the vertical shaft of the turnstile are arranged on a base plate used as a running surface for supporting and guide rolls. Said rolls are mounted on a cover plate sealing the advertising tower towards the bottom. Clamping devices are arranged on the strut of the inner cylinder, guiding the poster to the bearing surfaces of the inner cylinder. The advertising tower can be erected in a variable manner. The posters are uniformly directly laid on the inner cylinder without an air cushion, and the entire surface of the respective poster is pressed onto said cylinder. Normal paper with a weight of approximately 150 g / m<2> can be used for the posters, without special tear-proof plastic films.

Owner:SWISS TEC MEDIA

Preparation method of nickel oxide/poly(3,4- ethylenedioxythiophene) compound electrochromic film

The invention relates to a preparation method of nickel oxide / poly(3,4- ethylenedioxythiophene) compound electrochromic film. The preparation method comprises following steps: adding nickel acetate tetrahydrate and urea into absolute ethanol to prepare a reaction solution, putting FTO conductive glass, which has been washed by ultrasonic, into a hydrothermal reactor filled with the reaction solution, controlling the temperature in the range of 160 and 180 DEG C, maintaining the temperature for 6 to 12 hours, cooling to the room temperature, washing, burning so as to obtain FTO conductive glass with a NiO layer, dissolving 4- ethylenedioxythiophene monomers into a propylene carbonate solution of lithium perchlorate to obtain deposition liquid, then putting the FTO conductive glass with a NiO layer into the deposition liquid to play as a work electrode, taking a platinum slice as the counter electrode, then performing electro-deposition reactions so as the obtain the product. The preparation method has the advantages of simple technology and low cost, structure design in the micro-nano grade of the inorganic / organic compound electrochromic materials can be achieved, so the respective advantages of the organic and inorganic electrochromic materials can be fully utilized.

Owner:DONGHUA UNIV

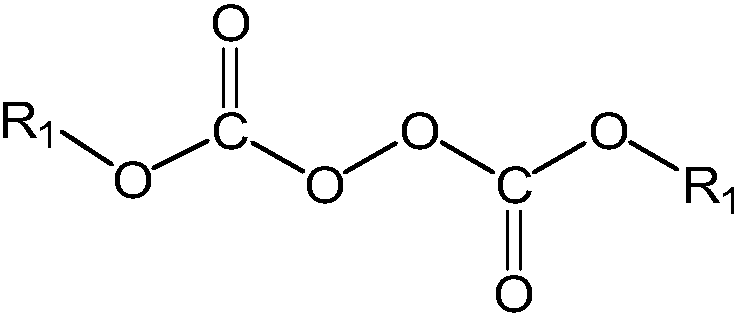

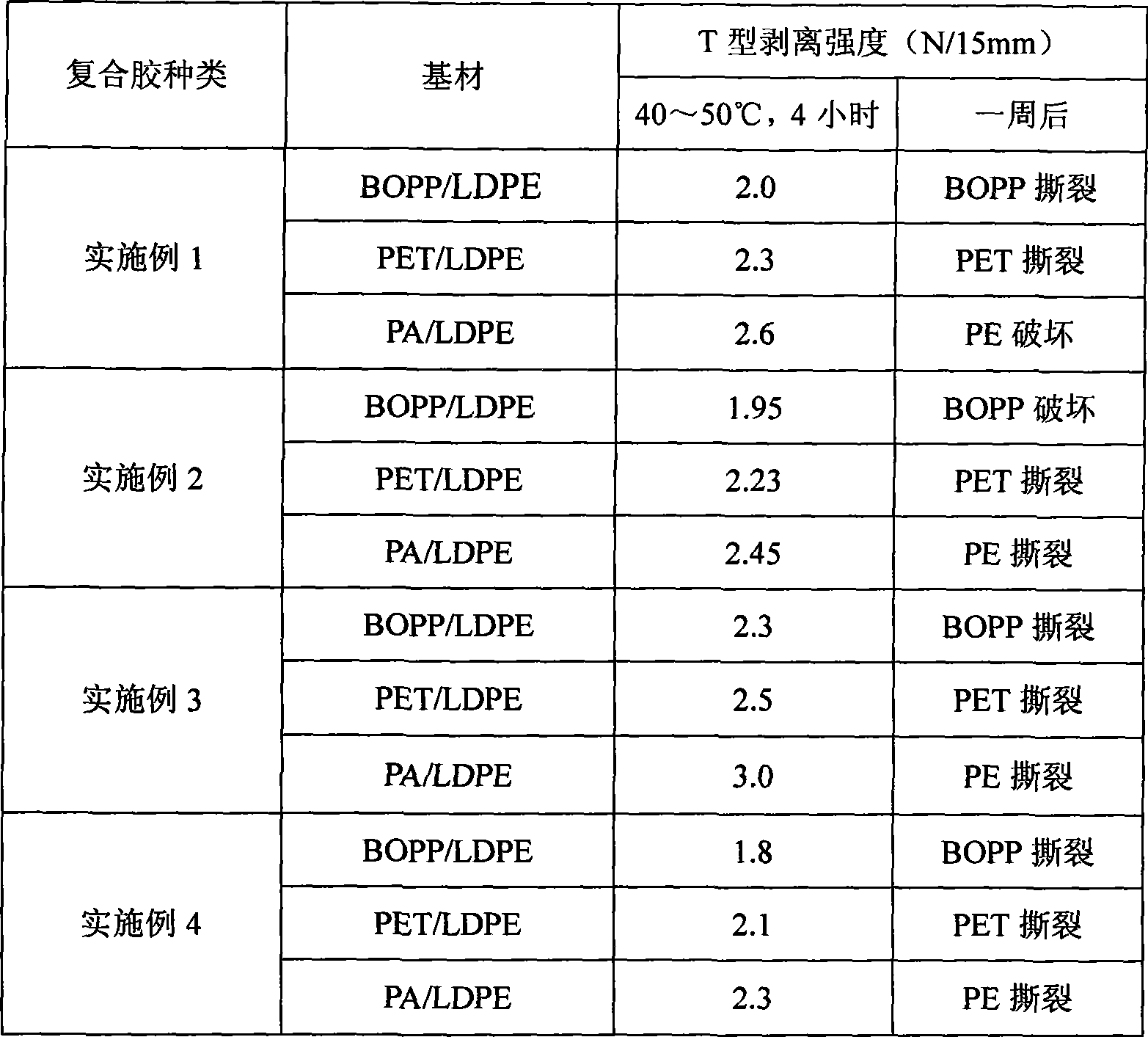

Alcohol water-soluble modified epoxy composite glue and preparation thereof

InactiveCN101497770AAvoid pollutionReduce dosageNon-macromolecular adhesive additivesGraft polymer adhesivesAlcoholPlastic packaging

The invention provides alcohol-soluble modified tygoweld and a preparation method thereof, which belong to the technical field of the plastic packaging composite adhesive. The tygoweld is prepared to bicomponent composite adhesive by alcohol-soluble modified epoxy resin copolymer and firming agent, and the bicomponent composite adhesive can be dissolved in alcohol or mixed solvent of alcohol and water. The invention has better property of plastic-plastic composite adhesive, reduces the consumption of organic solvent and has the characteristics of environment protection. The invention also provides a preparation method of the alcohol-soluble modified epoxy resin copolymer and the firming agent.

Owner:SICHUAN GUOHE NEW MATERIALS

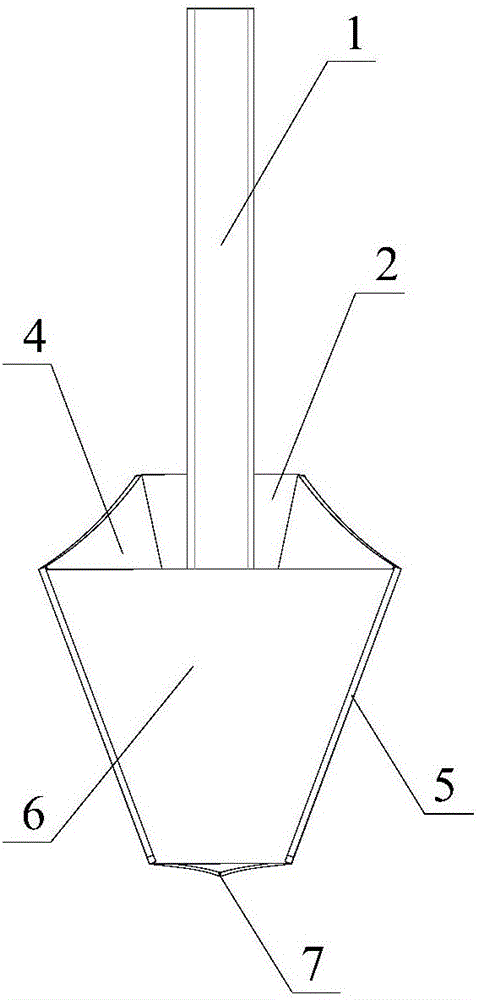

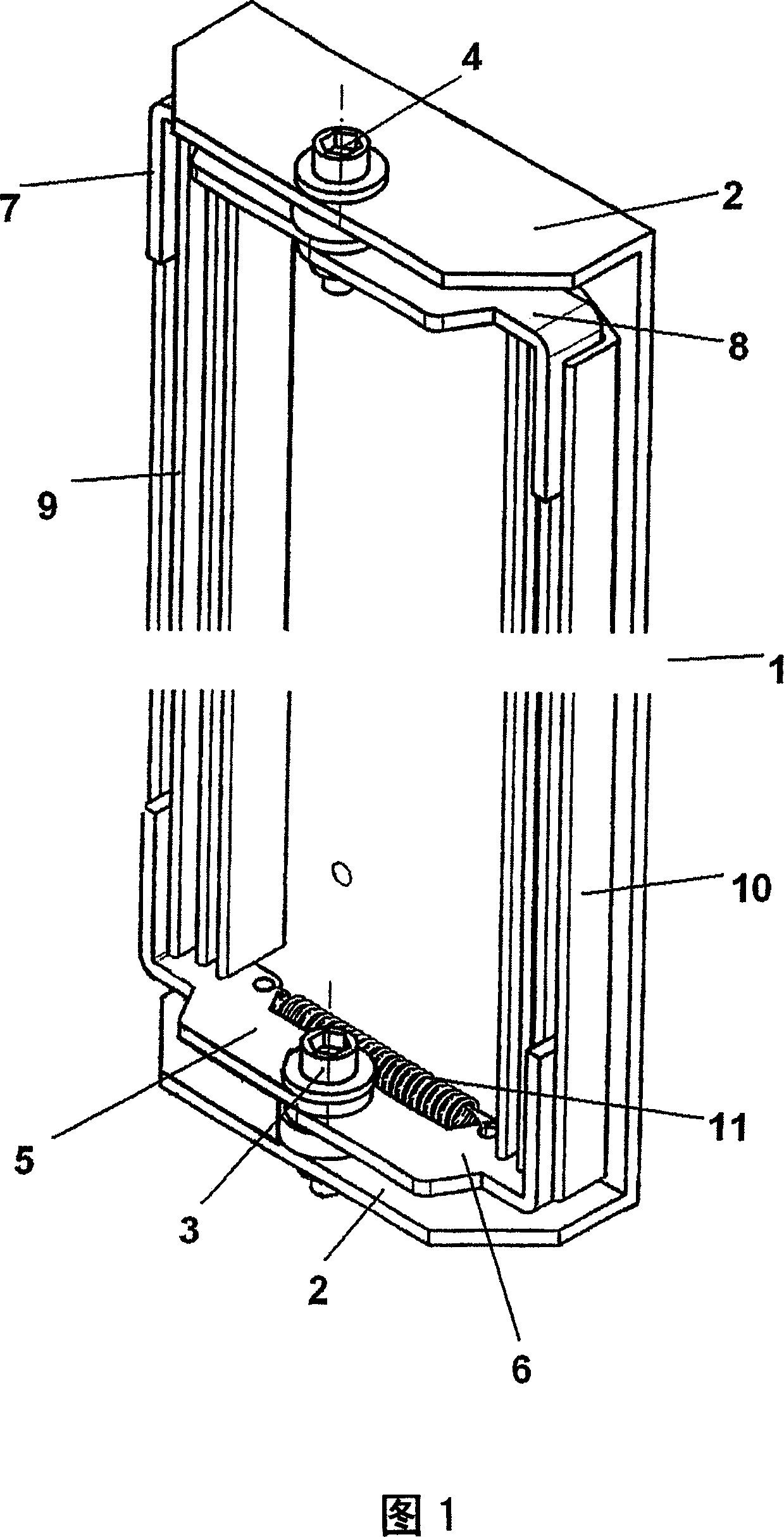

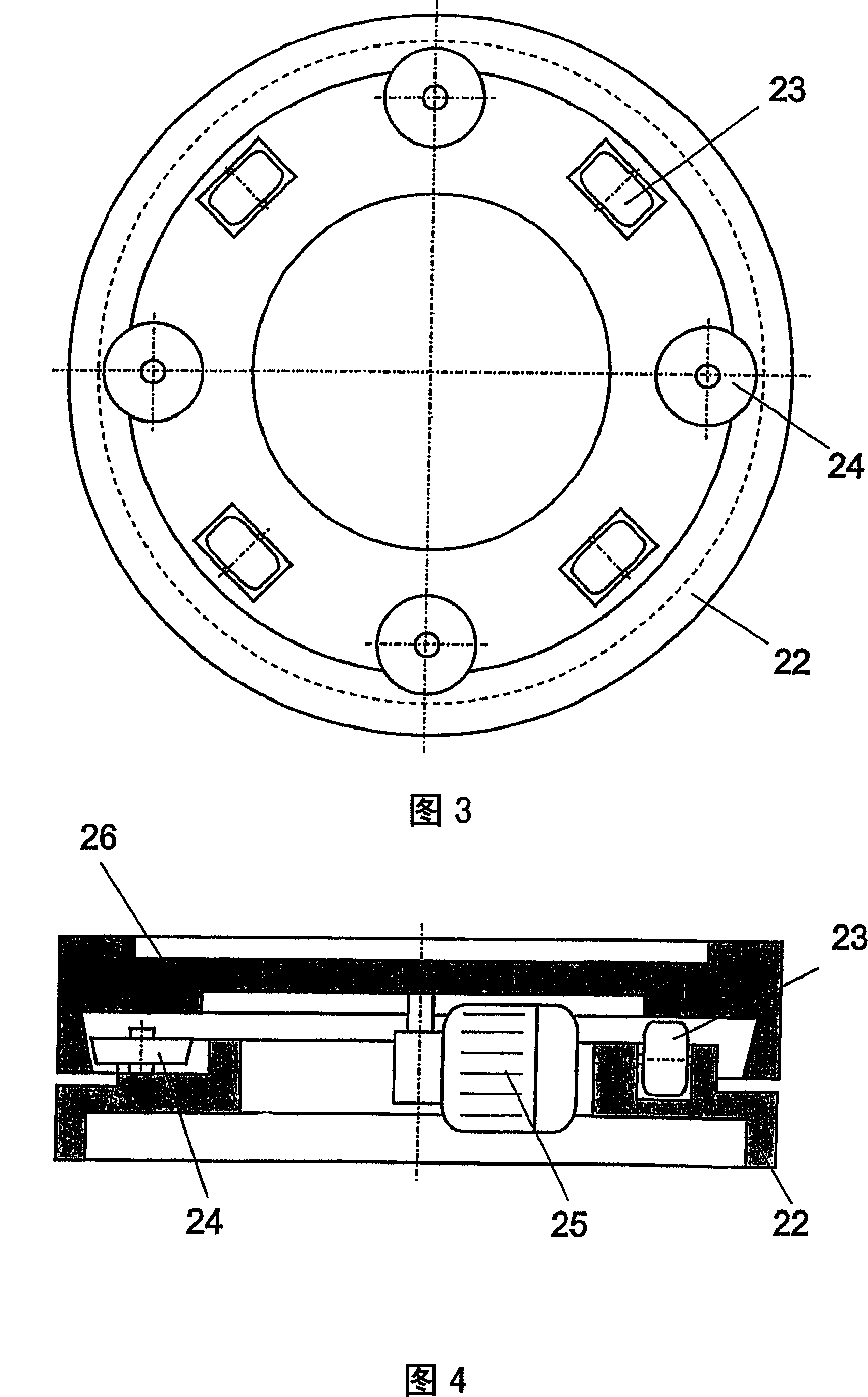

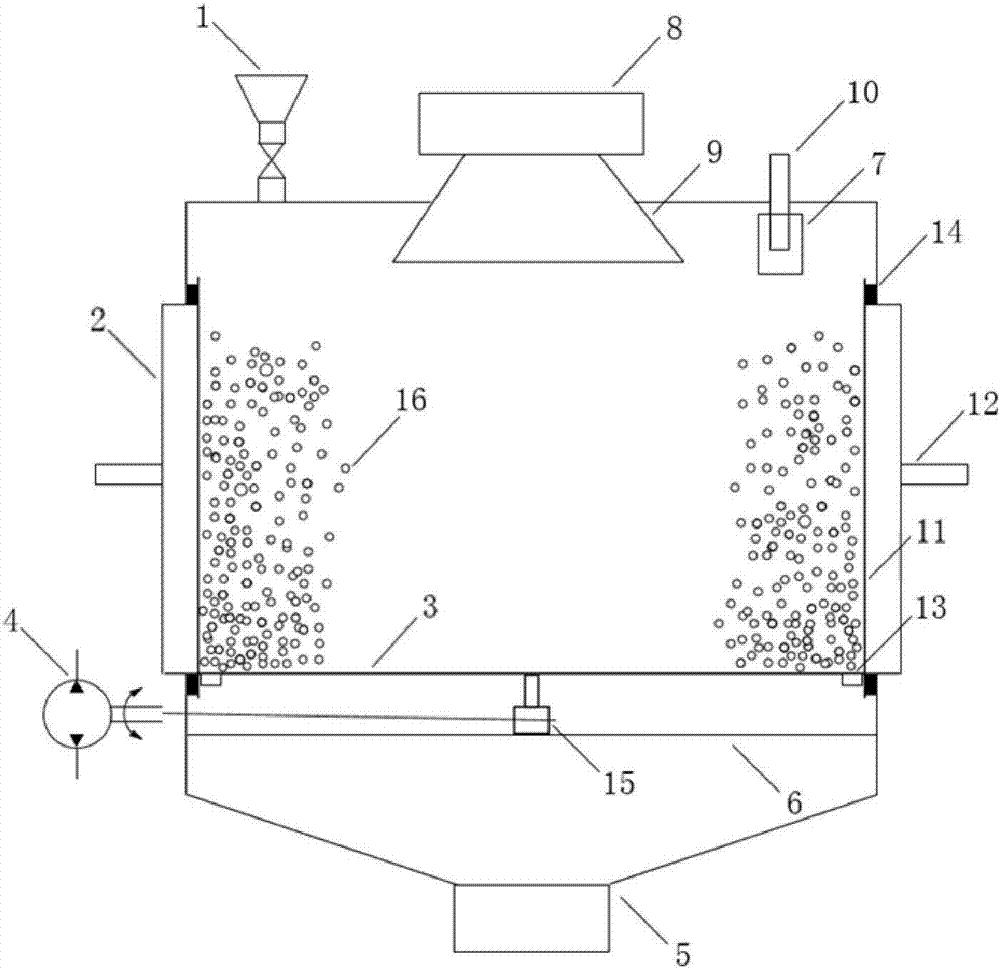

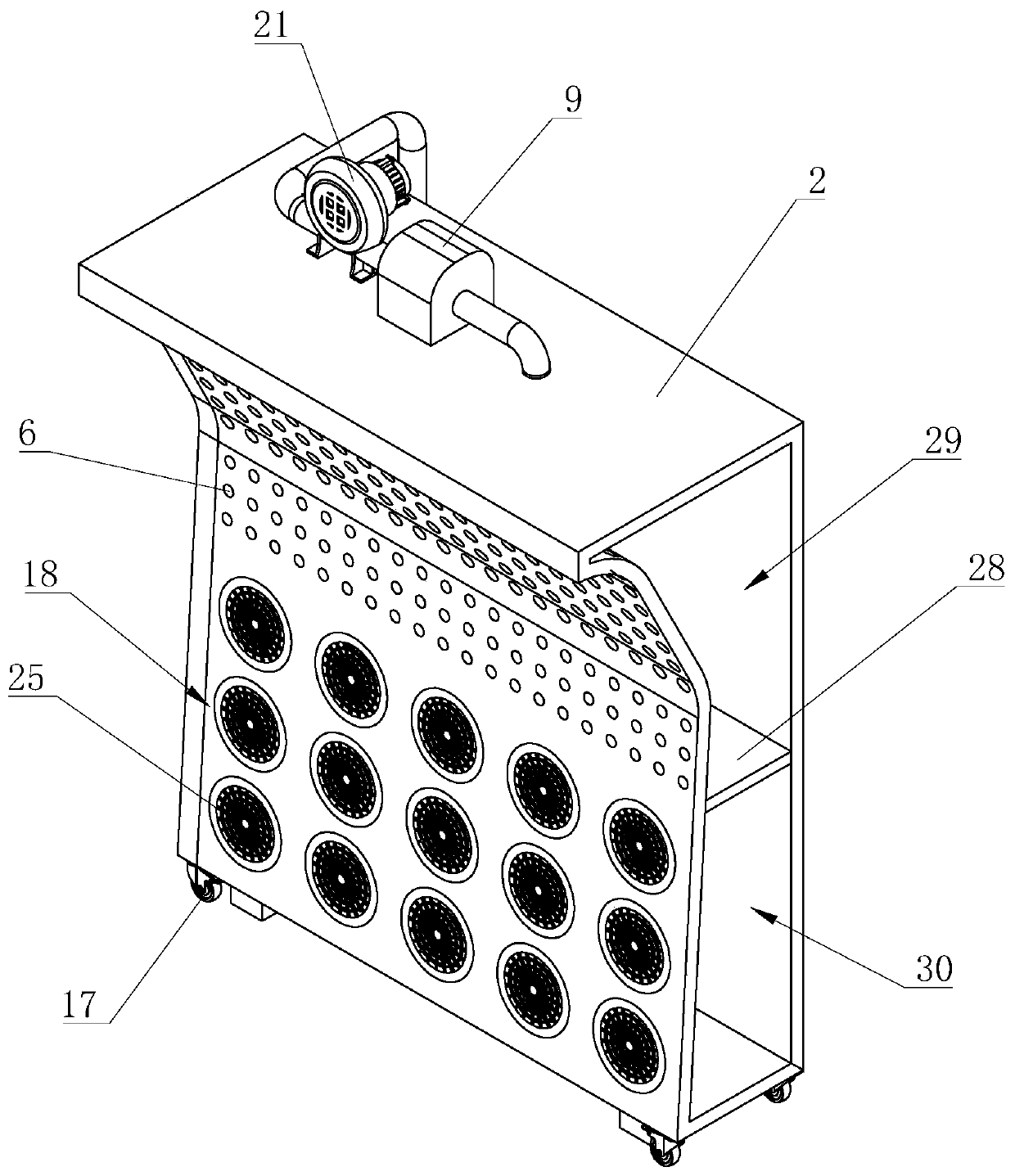

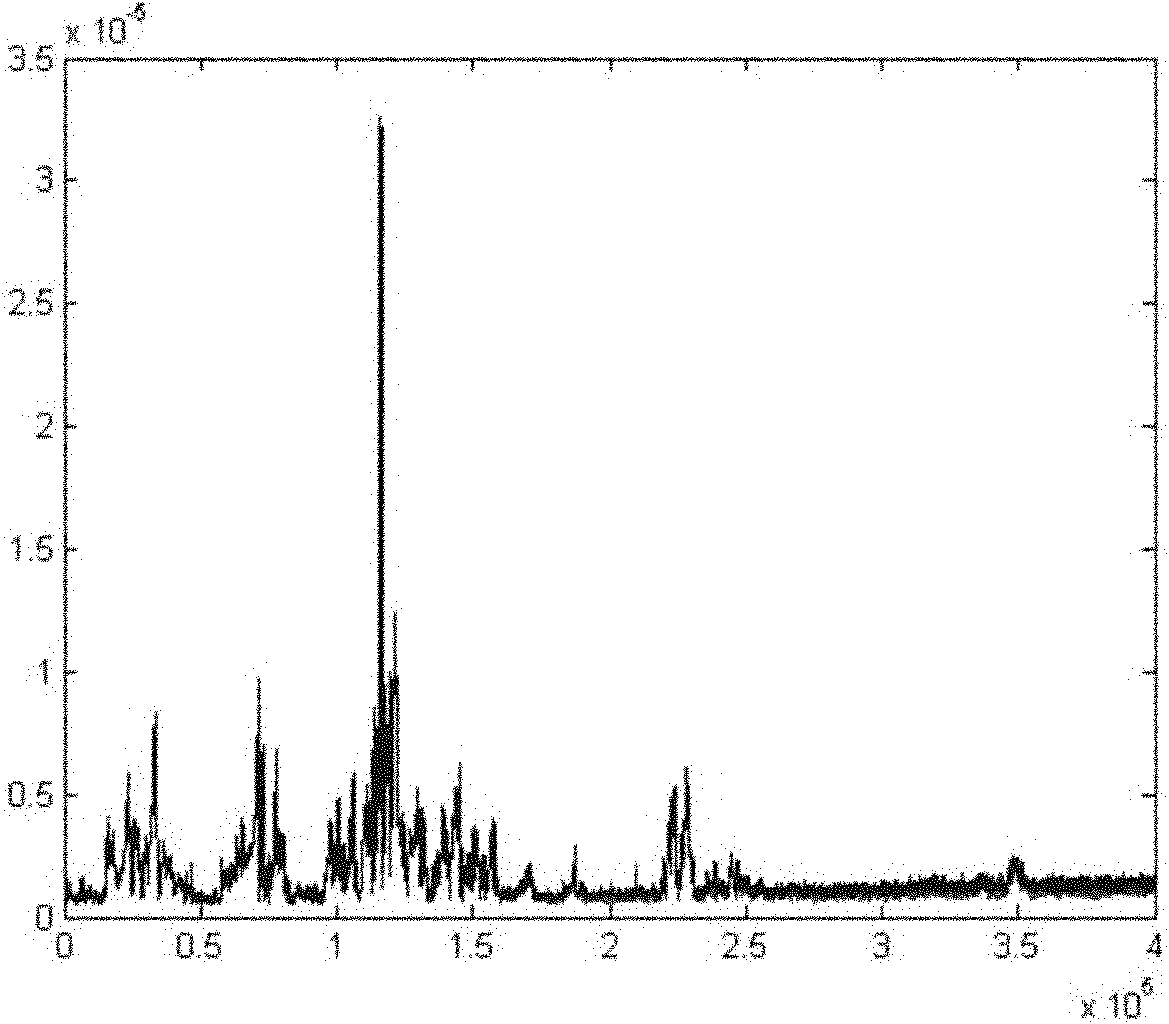

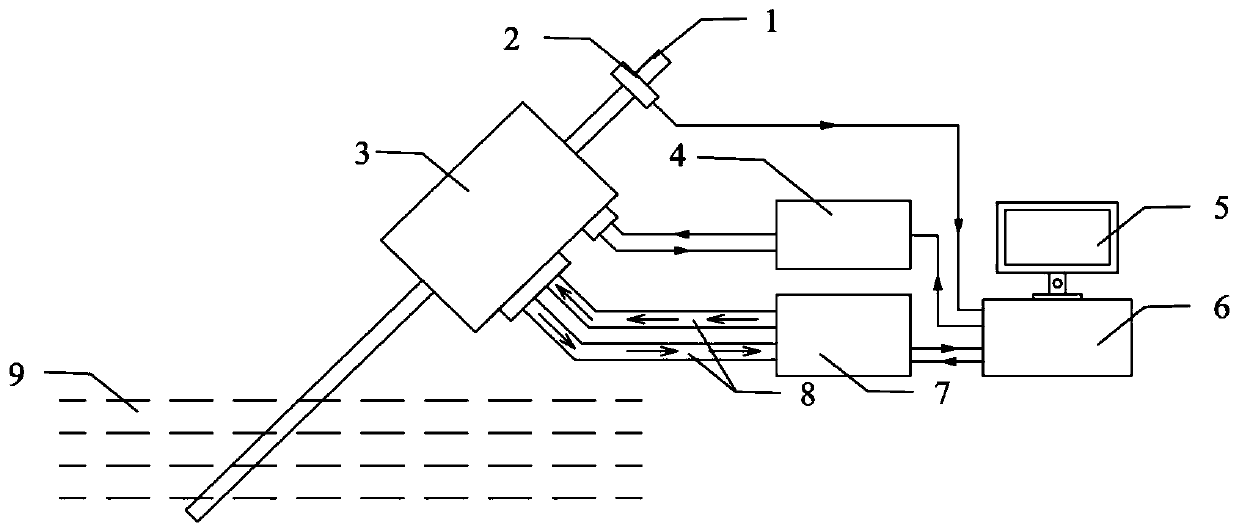

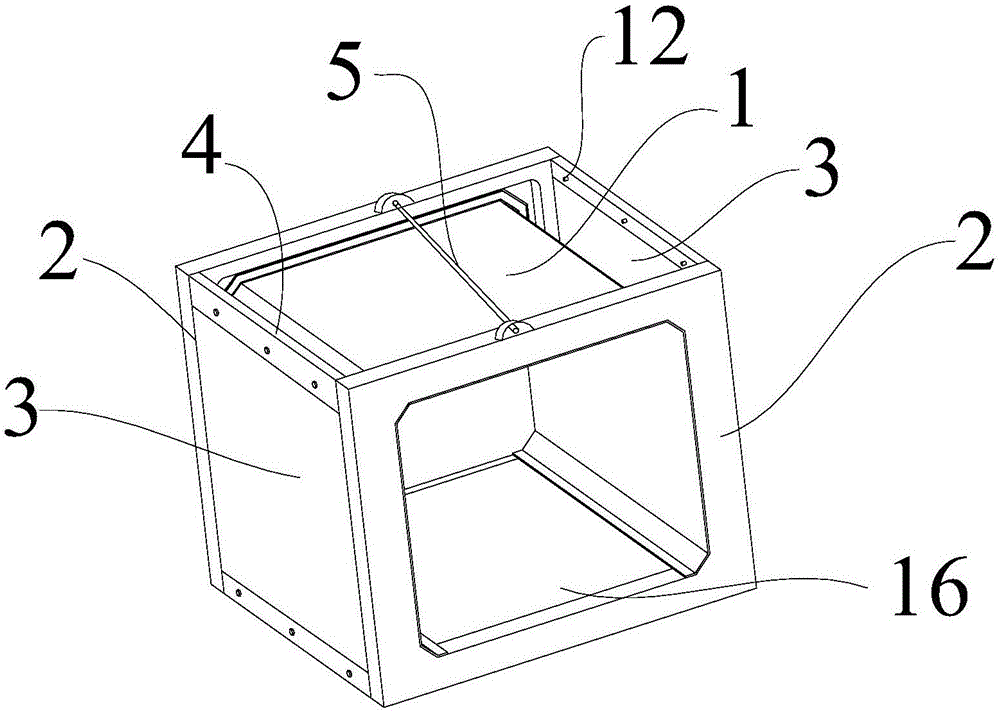

Device for cooperatively enhancing fluidization of nanoparticles by centrifugal field and sound field

InactiveCN106994322AOvercoming AdhesionGood fluidization behaviorEnergy based chemical/physical/physico-chemical processesBaghouseNanoparticle

The invention provides a device for cooperatively enhancing the fluidization of nanoparticles by a centrifugal field and a sound field. The device comprises a feeding hopper (1), an annular air inlet chamber (2), a centrifugal fluidized bed body (3), a stepping motor (4), a discharging hopper (5), a bed body supporting frame (6), a cloth bag dust collector (7), a sounder (8), a loudspeaker (9), an air outlet (10), an annular air distribution plate (11), an air inlet (12), an inner discharging hole (13), a sealing gasket (14) and a right-angle transmission gear box (15). According to the device provided by the invention, the fluidization of the nanoparticles is enhanced through the centrifugal field and the sound field, and abnormal fluidization phenomena including channeling, slugging even normal fluidization and the like of the nanoparticles in a fluidized bed can be effectively eliminated; an agglomeration-crushing process of particle agglomeration is enhanced and mixing between the particles is enhanced; the heat and mass transportation capability between the particles and a main body is improved; process application and amplification are easy to realize; the device has strong operation controllability and is stable to operate.

Owner:SOUTHEAST UNIV

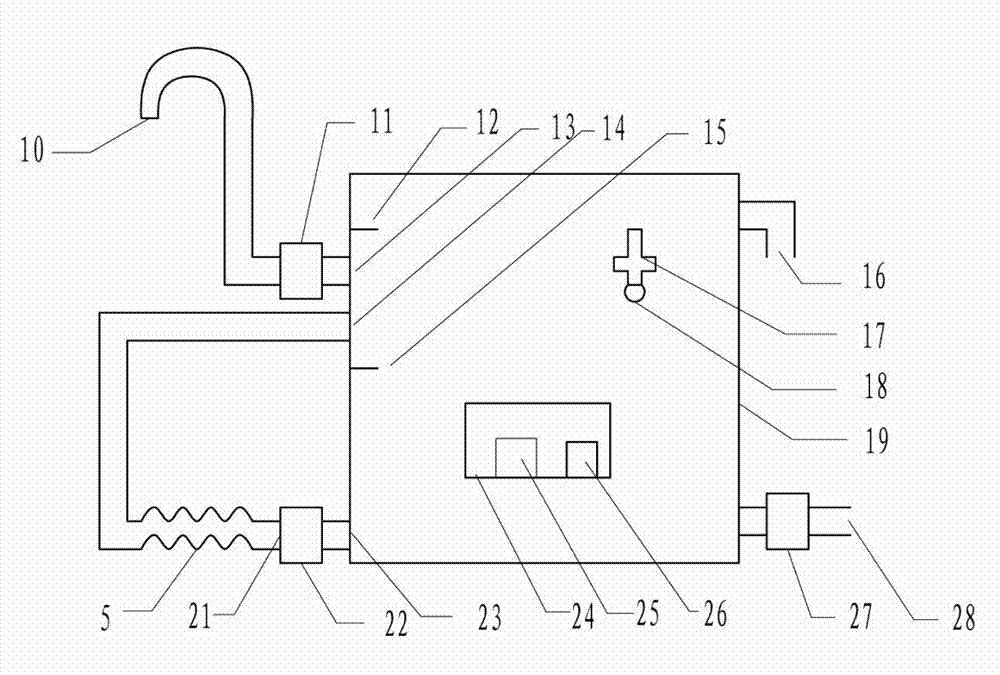

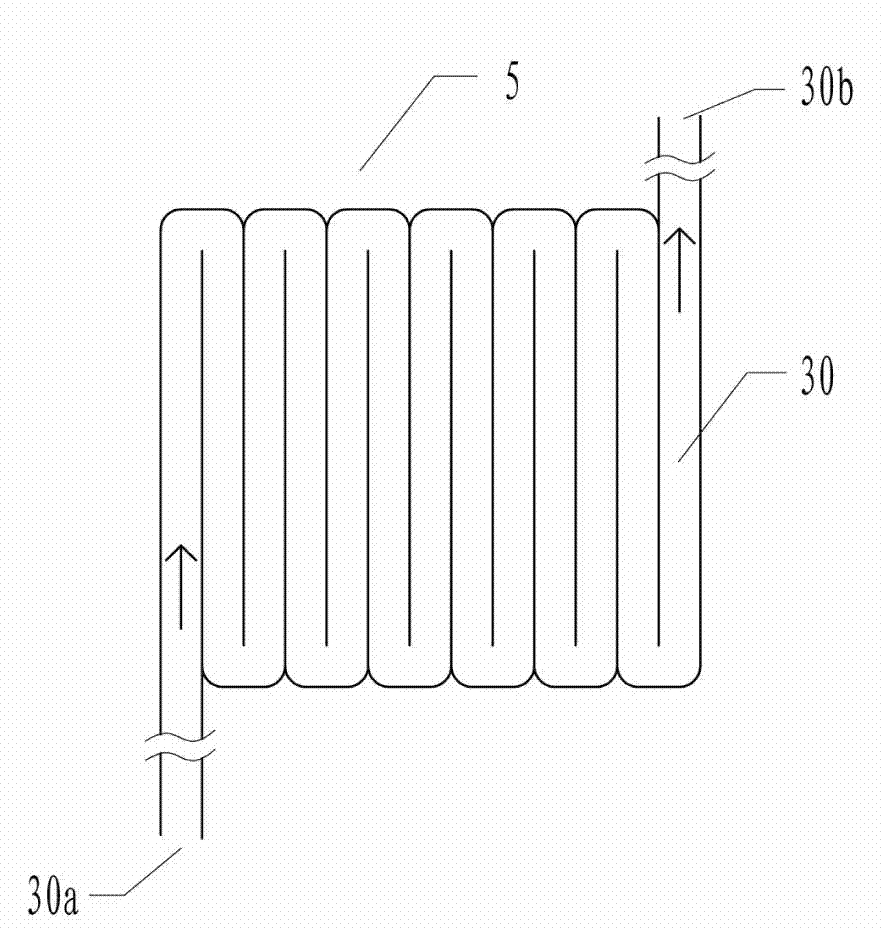

Water cooling control method for high-power electromagnetic oven

InactiveCN102809181AImprove fastnessReasonable structureDomestic stoves or rangesLighting and heating apparatusControl systemNuclear engineering

The invention relates to a water cooling control method for a high-power electromagnetic oven. According to the invention, a water circulation cooling control system, which comprises a water storage tank, a cooling pump, a water level detection device and a water circulation control module, is adopted to control the water circulation exchange of a water cooling device which is in surface contact with an electromagnetic induction wire coil, so as to realize water cooling of the electromagnetic induction wire coil, and the water temperature of the water storage tank can be automatically adjusted so as to quickly cool the electromagnetic induction wire coil. The control method has the advantages of good cooling effect, no noise, safety, durability, high intelligent degree and the like.

Owner:陈梓平

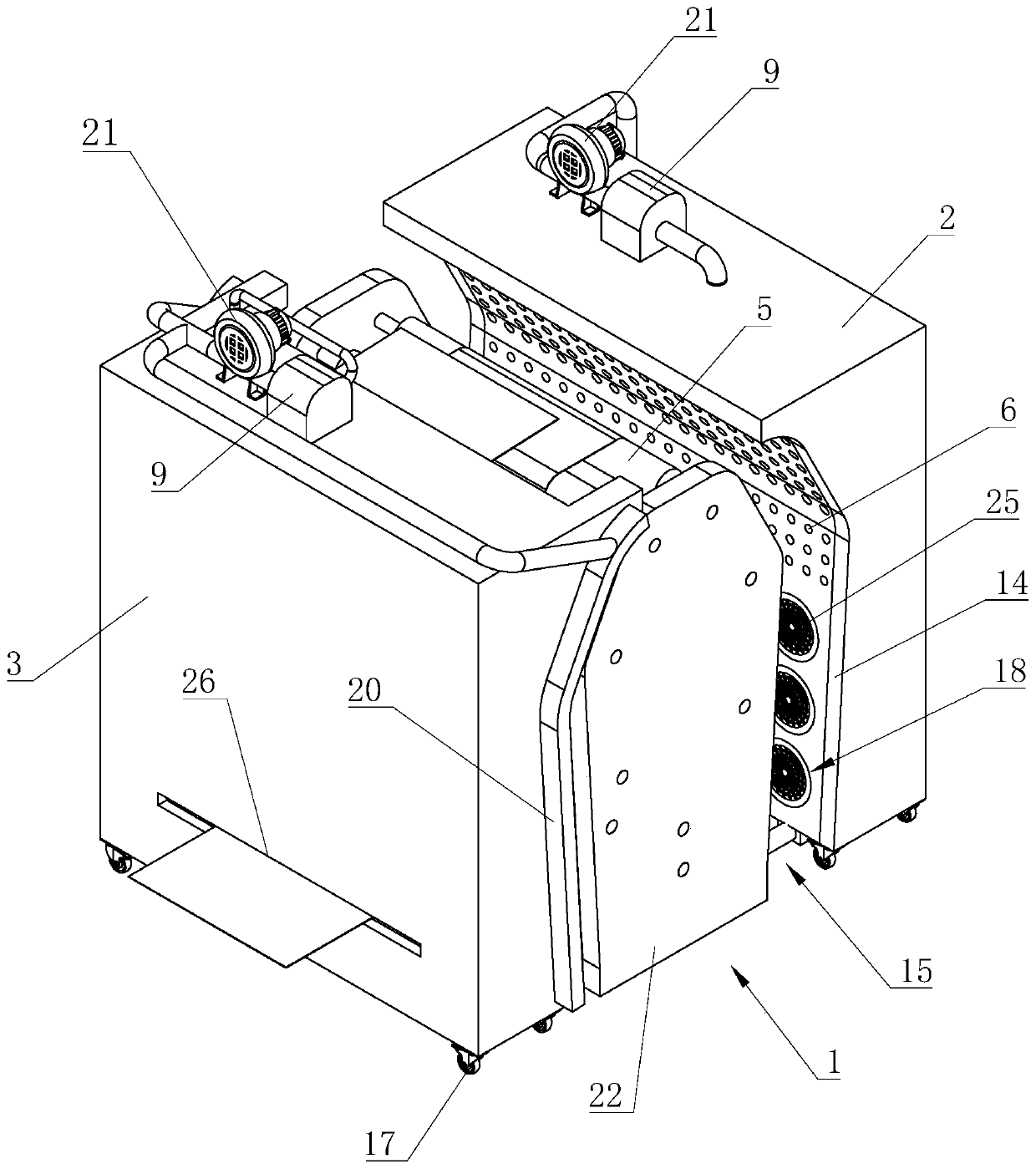

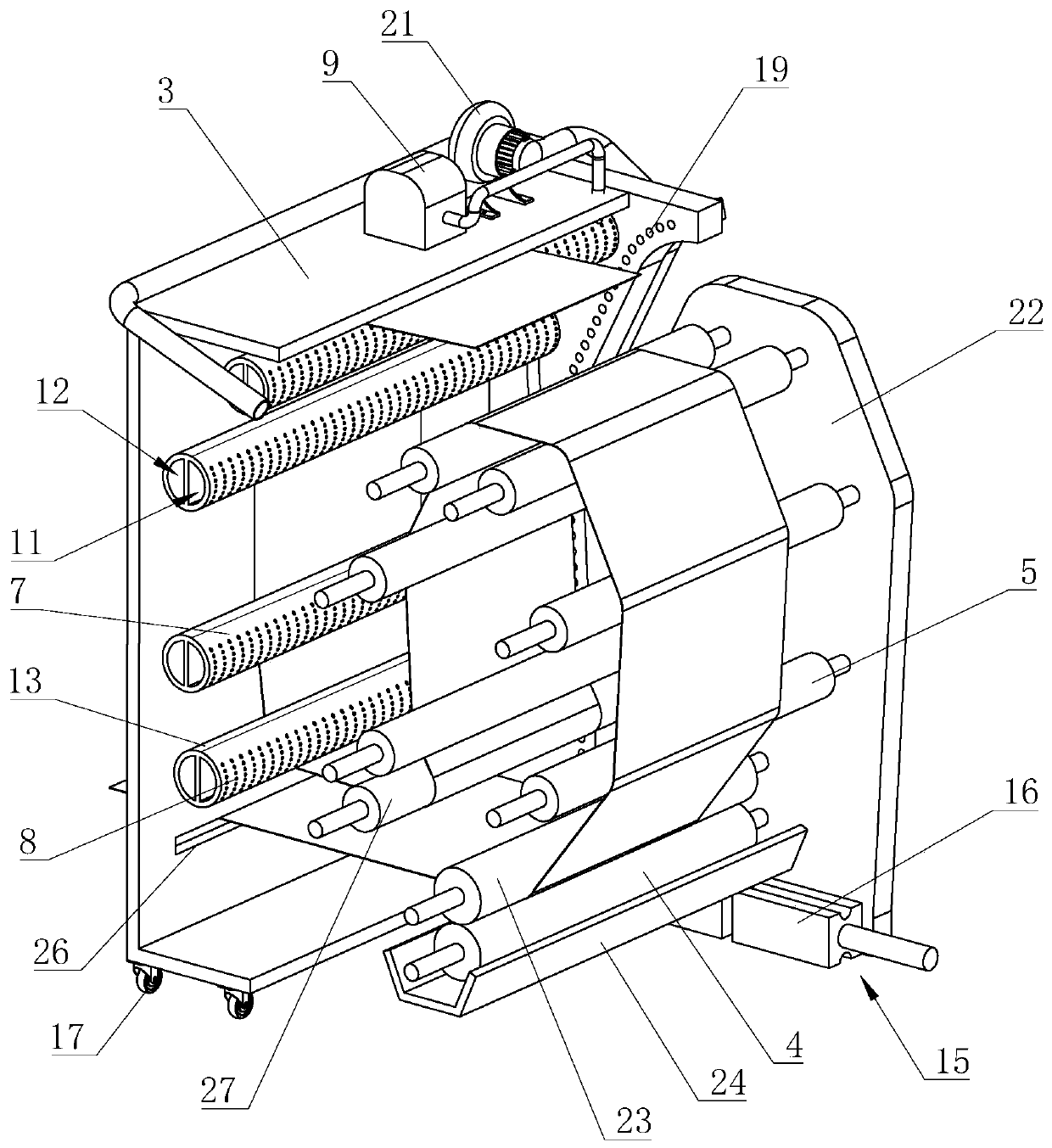

Drying device of film printing machine

ActiveCN110406251AOvercoming associativityOvercoming AdhesionPrinting press partsPrinting inkPulp and paper industry

The invention discloses a drying device of a film printing machine. The drying device comprises a machine frame, a first-stage drying oven and a second-stage drying oven, wherein the first-stage drying oven and the second-stage drying oven are arranged on the two sides of the machine frame, a printing roller is installed at the bottom end of the machine frame, a plurality of first-stage air supplyholes are formed in one side face, facing the material conveying roller, of the first-stage drying oven, a plurality of drying rollers which are hollow are fixed to one side, facing the material conveying roller, of the second-stage drying oven, a plurality of second-stage air supply holes are formed in one side, facing the material conveying roller, of the drying rollers, and electric heating air boxes which communicate with the first-stage air supply holes and the second-stage air supply holes are correspondingly arranged on the first-stage drying oven and the second-stage drying oven. Thedrying device has the technical effects of being high in printing ink drying efficiency and good in drying quality.

Owner:武汉天利包装有限公司

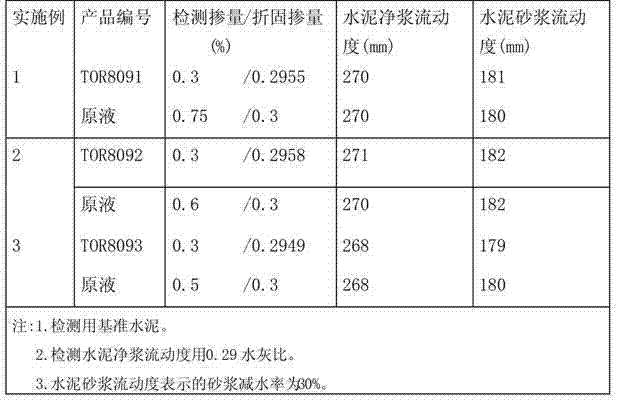

Method for preparing dry high-performance water reducer powder of polycarboxylic acid

A method for preparing dry high-performance water reducer powder of polycarboxylic acid comprises atomizing a polycarboxylic acid water reducer solution and allowing it to enter a drying chamber parallel to hot air under the action of a high-pressure pump; and sucking material under a negative pressure of -0.00--0.02 MPa, cooling via cold air with dew point from -23 DEG C to -17 DEG C, separating, collecting and packaging. The pressure of the high-pressure pump is 3-5 MPa, the temperature of the hot air is 180-250 DEG C, the drying chamber is in a shape of cylinder and has a diameter equal to its height, and the inlet temperature of a separator is 25-40 DEG C. The material in a form of spray quickly flies into the drying chamber via a nozzle under the pressure of 3-5 MPa, to thereby overcome the bond force between the material; the cylindrical drying chamber ensures smooth continuous arc connection between wall surfaces; and negative-pressure suction solves the problem of secondary dusting of the dry powder, further prevents the fine material powder from freely flying in the drying chamber and adhering to the walls, and controls the motion direction of the fine dry powder.

Owner:ZHEJIANG LAOHUSHAN BUILDING MATERIALS

Method for eliminating adhesion phenomenon of suspended structure of micro-electromechanical system (MEMS)

InactiveCN102040188ATechniques to Address Adhesive FailureImprove structural rigidityDecorative surface effectsChemical vapor deposition coatingTemperature controlRoom temperature

The invention provides a method for eliminating the adhesion phenomenon of a suspended structure of a micro-electromechanical system (MEMS). The method is characterized by temperature control: bonding a package layer on the bottom of a chip to form a bonding body, wherein, the thermal expansion coefficient of the package layer is more than that of the chip; and temperature reduction range control: reducing the temperature of the bonding body to room temperature or below room temperature. In the method, the thermal expansion coefficient of the package layer is 5.6*10<-6>-28*10<-6> / DEG C, the adopted material is FR4 (an epoxy glass cloth laminated sheet) or Al-2O3, and the thickness of the material is 50-1000 mu m. In the method, the adhesion phenomenon of the suspended structure of the MEMS can be eliminated only by controlling the size of temperature and tensile stress with a common bonder, therefore, the method has the advantages of simple process, low equipment requirements, strong controllability and capability of realizing mass production.

Owner:SOUTHEAST UNIV

Liquid pollination agent for late autumn yellow pears

The invention discloses a liquid pollination agent for late autumn yellow pears.The liquid pollination agent is prepared from, by weight, 500-700 parts of saccharose, 0.3-0.5 part of rare earth, 2-3 parts of amino acid chelates, 1.5-3 parts of xanthan gum, 1-2 parts of pear flower pollen grains, 1-2 parts of boric acid, 1-2 parts of composite vitamins and 1500-3000 parts of water.The ingredients and a preparation method of the liquid pollination agent are greatly improved compared with a prior art, compared with other pollination agents and pollination methods, the liquid pollination agent has the advantages of being quick effect, high in pollination rate and low in production and labor cost, influence of the natural environmental condition is small, and the liquid pollination agent has quite good popularization value.

Owner:阜阳市颍州区金湖丰种植农民专业合作社

Liquid pollination agent for early-maturing red pears

The invention discloses a liquid pollination agent for early-maturing red pears.The liquid pollination agent comprises, by weight, 500-700 parts of cane sugar, 3-7 parts of potassium dihydrogen phosphate, 2-5 parts of calcium nitrate, 2-3 parts of amino acid chelate, 1.2-2.4 parts of guar gum, 0.3-1 parts of ethylene diamine tetraacetic acid, 1-2 parts of pear pollen particles, 1-2 parts of boric acid, 1-2 parts of multi-vitamin and 2000-2400 parts of water.The components and the preparation method of the liquid pollination agent are improved greatly as compared with those of the prior art.Compared with other pollination agents and pollination methods, the liquid pollination agent has the advantages that the liquid pollination agent is quick in action, high in pollination rate, low in production and labor cost and good in popularization value, and influence of natural environment conditions on the liquid pollination agent is low.

Owner:全椒井府富硒生态牧业有限公司

Continuous casting submerged nozzle

The invention discloses a continuous casting submerged nozzle. Raw materials of the submerged nozzle comprise components, by weight percent, 8 to 10 parts of crystalline flake graphite, 4 to 6 parts of silicon carbide, 3 to 5 parts of silica powder, 6 to 8 parts of fused silica, 20 to 22 parts of fused zirconia mullite, 32 to 34 parts of white corundum and 5 to 7 parts of phenolic resin; the above raw materials are formed under 155 to 165 MPa through a cold isostatic press after being performed mixing granulation and baked under 1220 to 1260 DEG C under the reducing atmosphere to form into the nozzle.

Owner:WUXI SHENJIA HYDRAULIC TECH

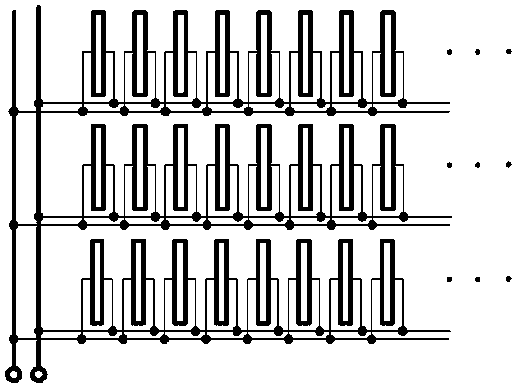

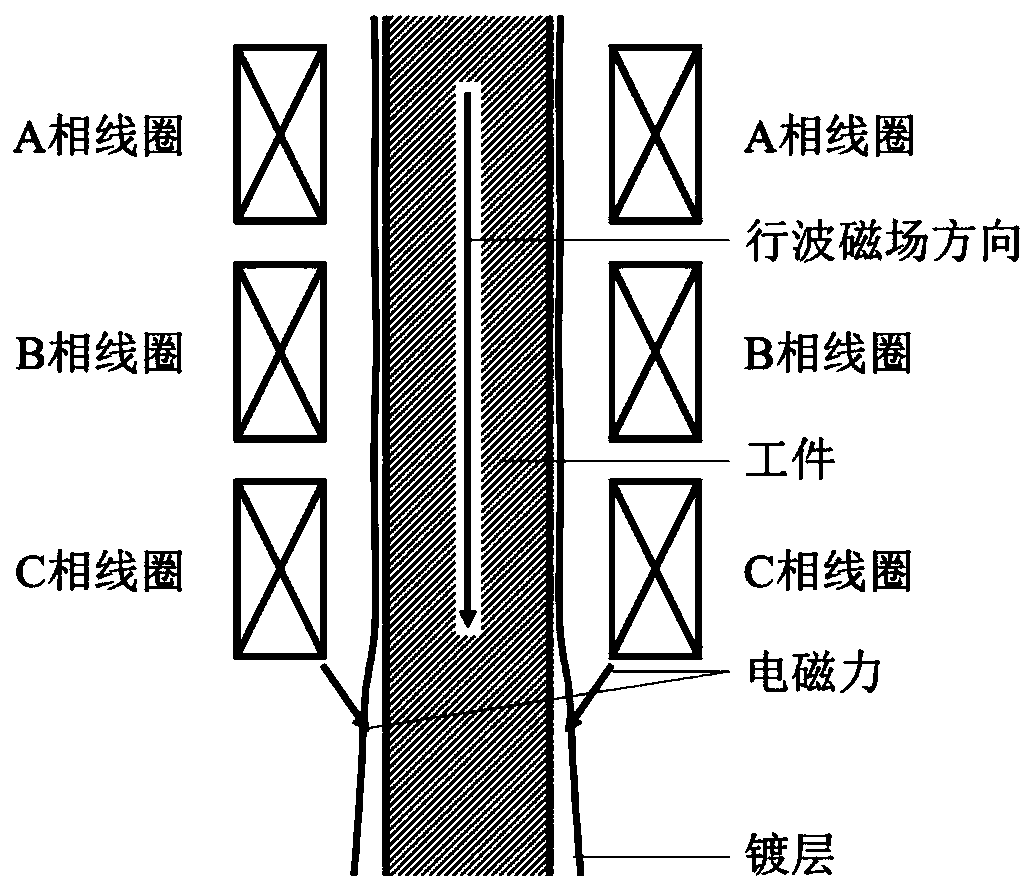

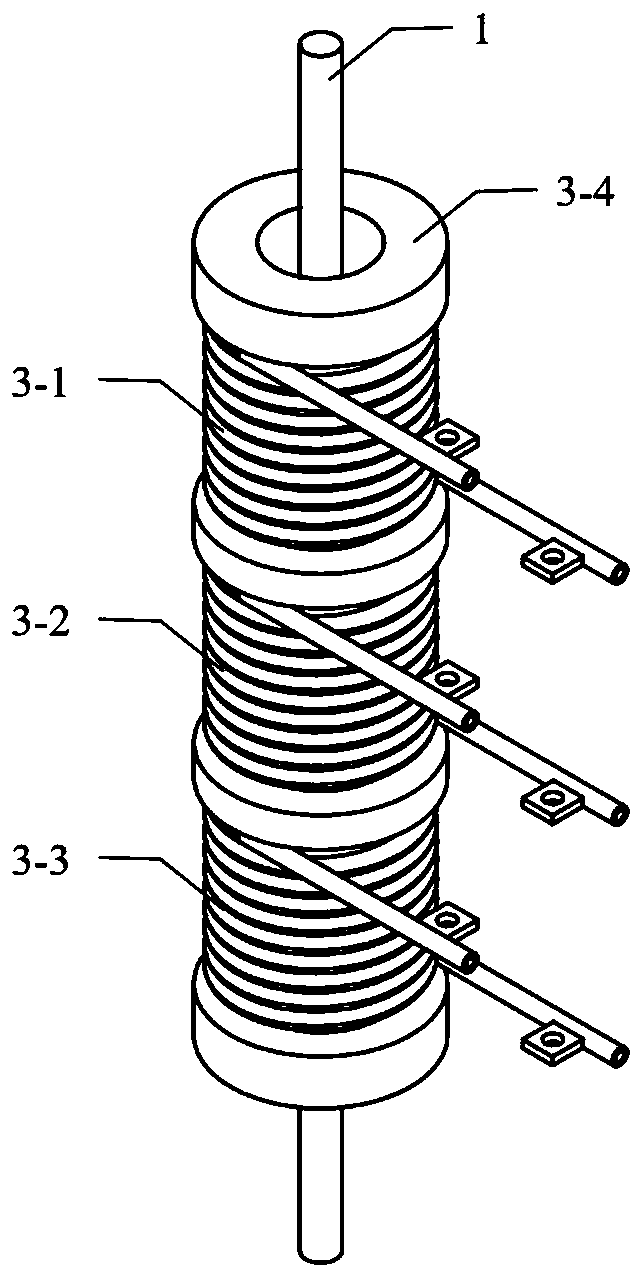

Three-phase electromagnetic wiping device suitable for rod-shaped workpiece

PendingCN110079755AEasy to controlEasy to operateHot-dipping/immersion processesAdhesion forceEngineering

The invention discloses a three-phase electromagnetic wiping device suitable for a rod-shaped workpiece. The three-phase electromagnetic wiping device comprises a coil former and at least one group ofthree-phase coils, wherein a through hole is formed in the center of the coil former, the through hole can allow the rod-shaped workpiece to move upwards and penetrate therethrough, a liquid coatingis adhered to the surface of the rod-shaped workpiece, at least one group of three-phase coils are sequentially wound around the outer side of the coil former in the axial direction, when at least onegroup of three-phase coils are electrified, each phase coil generates an alternating magnetic field, at least one group of three-phase coils form a traveling wave magnetic field at the center of thecoil former, when the rod-shaped workpiece moves upwards in the through hole, under the action of the alternating magnetic field generated by each phase coil, a first electromagnetic force which is obliquely downwards is generated in an induction mode, a second electromagnetic force which is opposite to the movement direction of the rod-shaped workpiece is generated in an induction mode under theaction of the traveling wave magnetic field, the first electromagnetic force and the second electromagnetic force prevent the liquid coating from moving upwards, the adhesion force in the coating is overcome, the coating is compressed, and the surplus coating is wiped, so that the thickness of the coating of the rod-shaped workpiece is controlled. The device has a good wiping effect.

Owner:HUAZHONG UNIV OF SCI & TECH

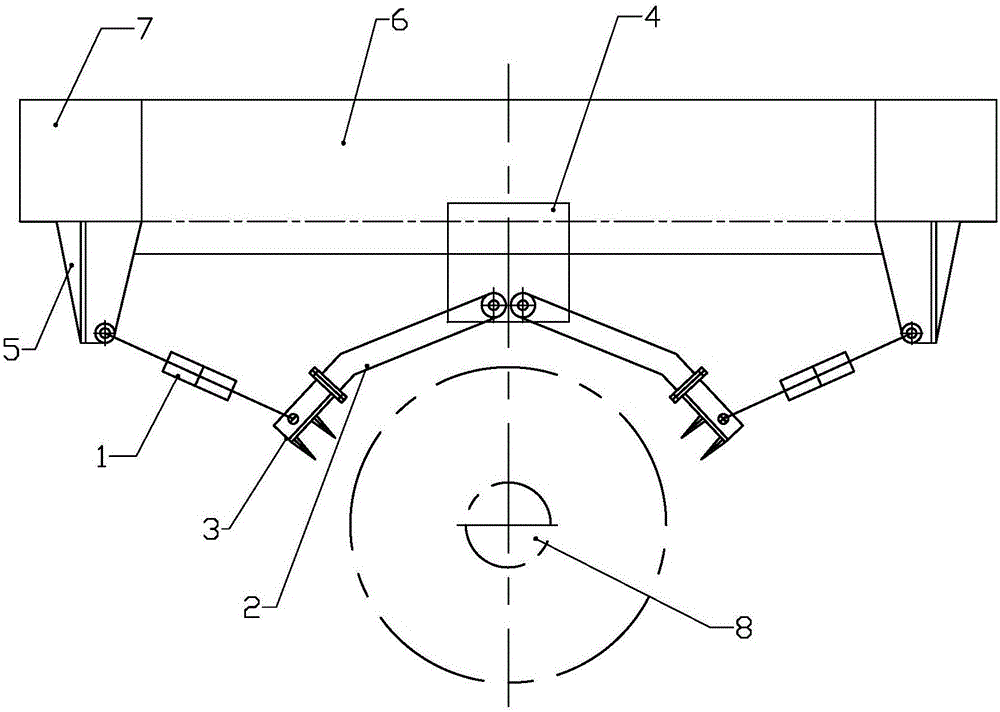

Extrusion-type deslagging device for oxygen lance

The invention discloses an extrusion-type deslagging device for an oxygen lance and belongs to deslagging devices. The extrusion-type deslagging device structurally comprises two oscillating cylinders, two rotating arms, two deslagging tool bits, a fixed support and two oscillating cylinder supports, wherein the oscillating cylinder supports are connected with oxygen lance track columns at the two ends of an oxygen lance track cross beam respectively; the fixed support is arranged at the position, between the two oscillating cylinder supports, on the oxygen lance track cross beam; each oscillating cylinder support is hinged to one of the oscillating cylinders; the other end of each oscillating cylinder is hinged to one of the deslagging tool bits; each deslagging tool bit is hinged to the fixed support through one of the rotating arms; and the two deslagging tool bits are positioned at the left end and the right end of an oxygen lance respectively. The extrusion-type deslagging device for the oxygen lance has the characteristics that potential safety hazards of manual deslagging can be eliminated; the adhesive force between slag and the lance can be overcome by use of extruding and shearing forces, and a steel wire rope of the oxygen lance is free of impulsive load in the deslagging process, so that equipment running is safe; and the deslagging tool bits are stably stressed in the deslagging process, and therefore have low probability of damage.

Owner:SHANDONG IRON & STEEL CO LTD

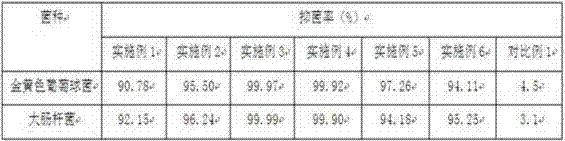

Antibacterial filter paper and preparation method thereof

ActiveCN107503238AHas antibacterial propertiesHas strong antibacterial functionChemical/biochemical paper treatmentFiltration separationBenzene2-dichlorobenzene

The invention provides antibacterial filter paper and a preparation method thereof, relating to the technical field of preparation of filter paper. The preparation method comprises the steps of firstly preprocessing the surface of filter paper by virtue of an amino functional group silane coupling agent, grafting styrene to the surface of the filter paper by taking CuBr / dipyridyl as a catalytic system and 1,2-dichlorobenzene as a solvent, and finally carrying out quaternization on the grafted filter paper by virtue of alkyl bromide, so as to obtain the antibacterial filter paper. The prepared antibacterial filter paper has strong antibacterial funcition and good durability, the defects that the antibacterial components are not uniform and are poor in adhesion property, the use period is short, and the like because formed filter paper is soaked and sprayed with an antibacterial agent in the prior art are overcome, and the antibacterial filter paper has remarkable promotional values.

Owner:HUNAN ZHENGJIA SPECIAL MATERIAL

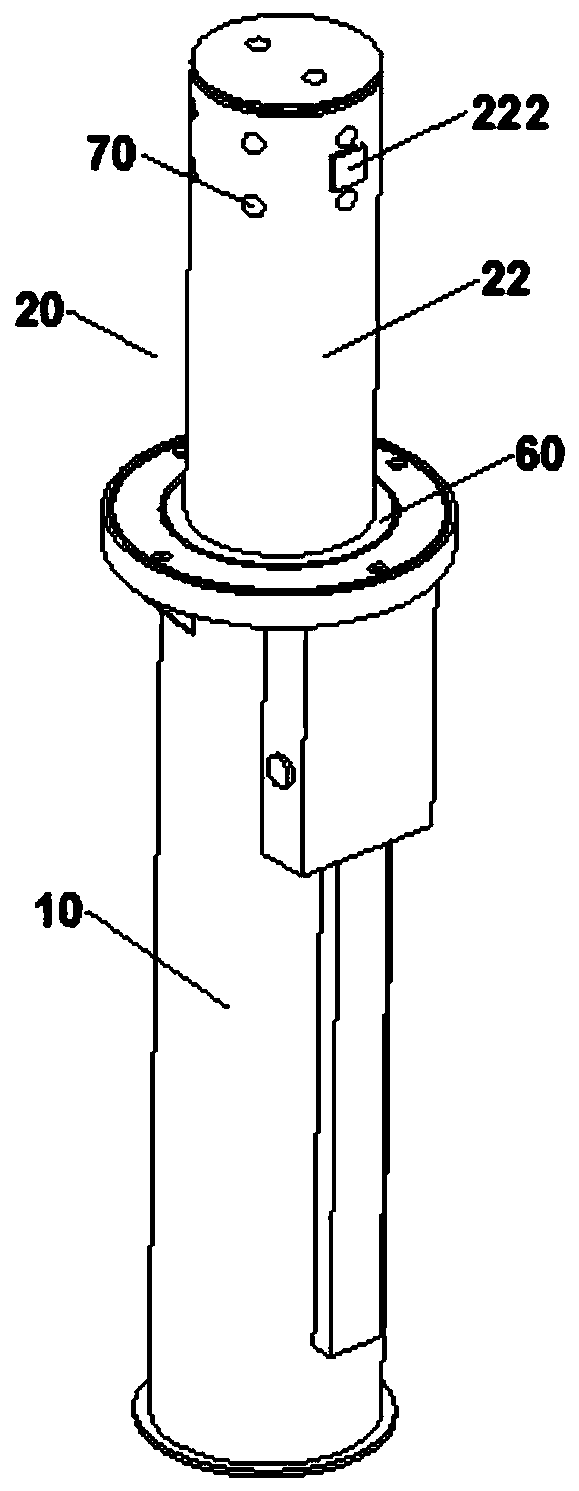

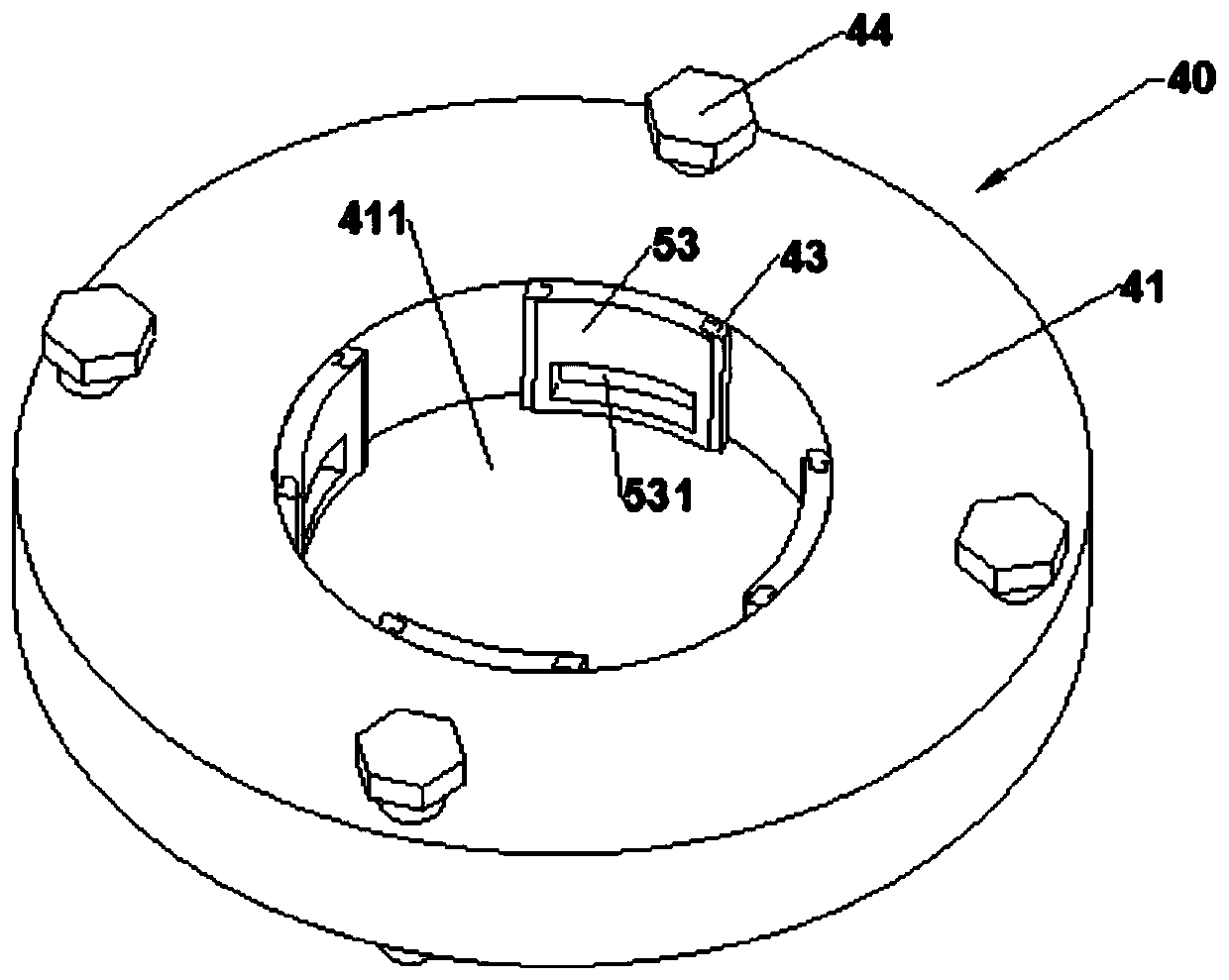

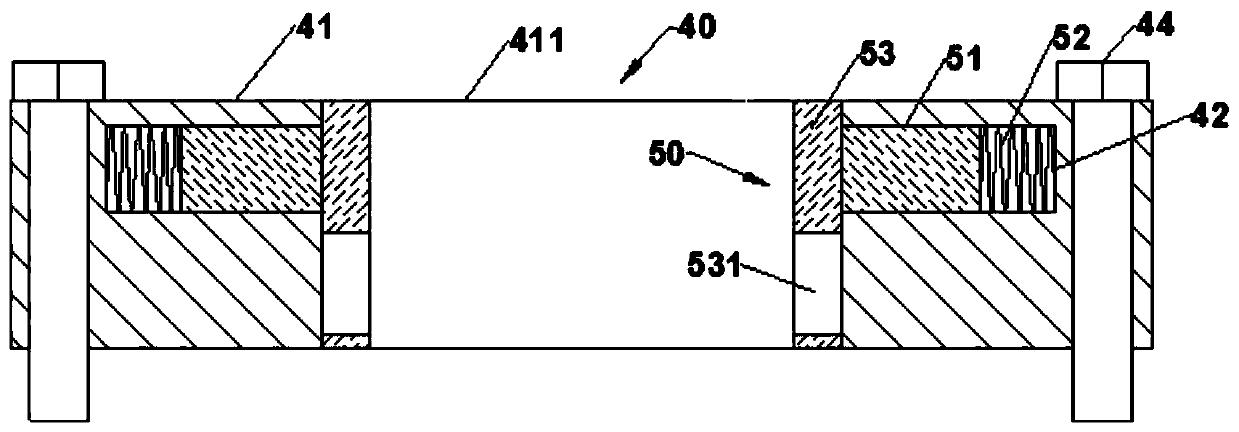

Lifting column convenient to maintain and working method thereof

ActiveCN111560874AEasy maintenanceImprove the blocking effectTraffic restrictionsControl systemEngineering

The invention relates to the technical field of roadblock equipment, and provides a lifting column convenient to maintain and a working method thereof. The lifting column comprises a control system, an outer cylinder and an inner cylinder, wherein the inner cylinder comprises a guide section and an anti-collision section, the anti-collision section is bonded with the guide section, a plurality ofclamping grooves are formed in the anti-collision section, and an infrared sensor is mounted at the upper part of the anti-collision section. The lifting column further comprises a locking mechanism,wherein the locking mechanism comprises a fixing disc, a first through hole is formed in the fixing disc, a plurality of accommodating grooves are formed in the fixing disc, each accommodating grooveis internally provided with a locking assembly, the locking assembly comprises a clamping block, a spring and a baffle, the spring enables the clamping block to have the tendency of leaving the accommodating groove, the baffle is arranged in the first through hole and can slide on the fixing disc, the upper part of the baffle abuts against the clamping block to prevent the clamping block from leaving the accommodating groove, a second through hole is formed in the baffle, and the clamping block can leave the accommodating groove from the second through hole. According to the lifting column convenient to maintain and the working method thereof, the intercepting effect is better, and maintenance is convenient after damage.

Owner:BEIJING ZHUOAOSHIPENG TECH CO LTD

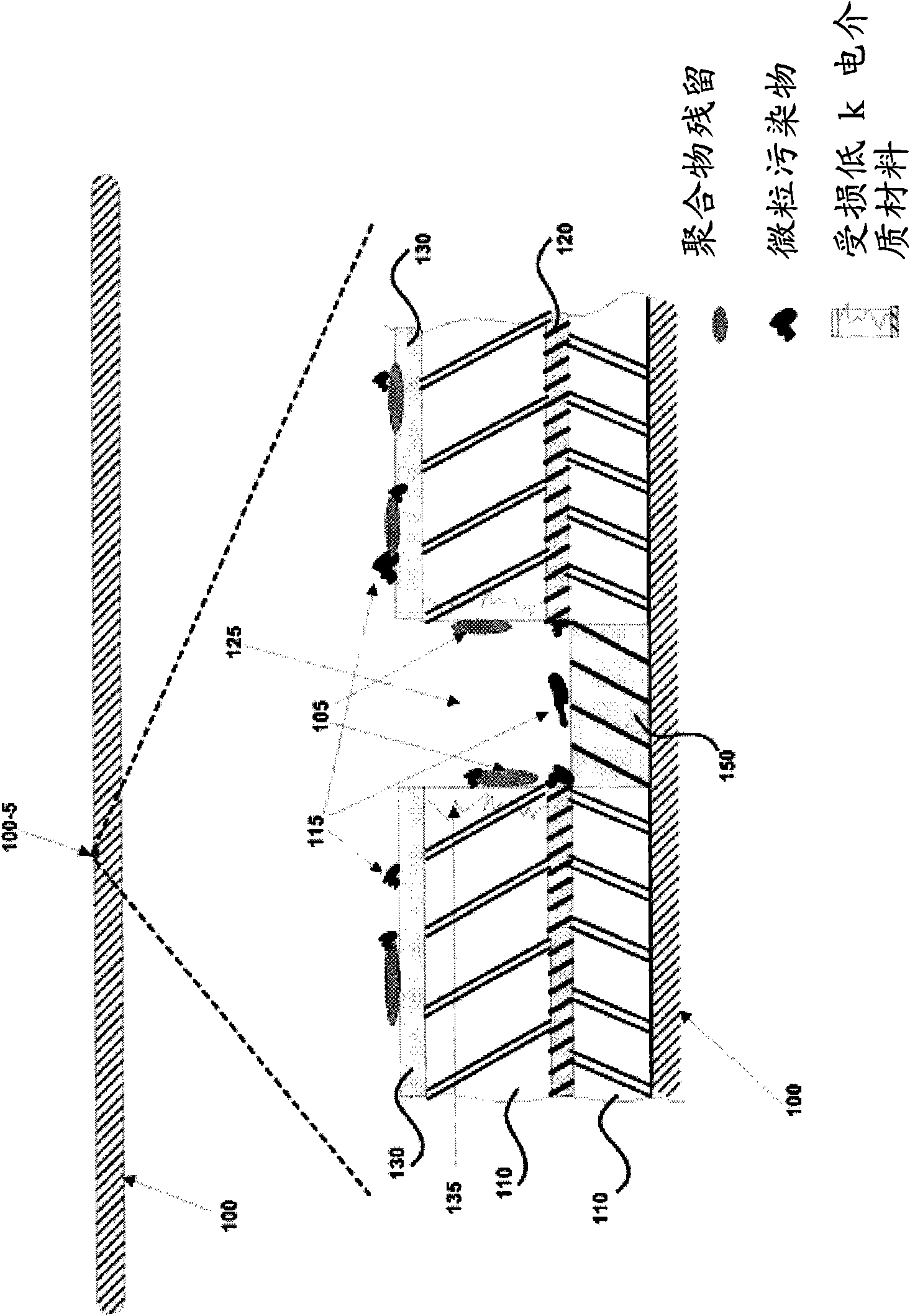

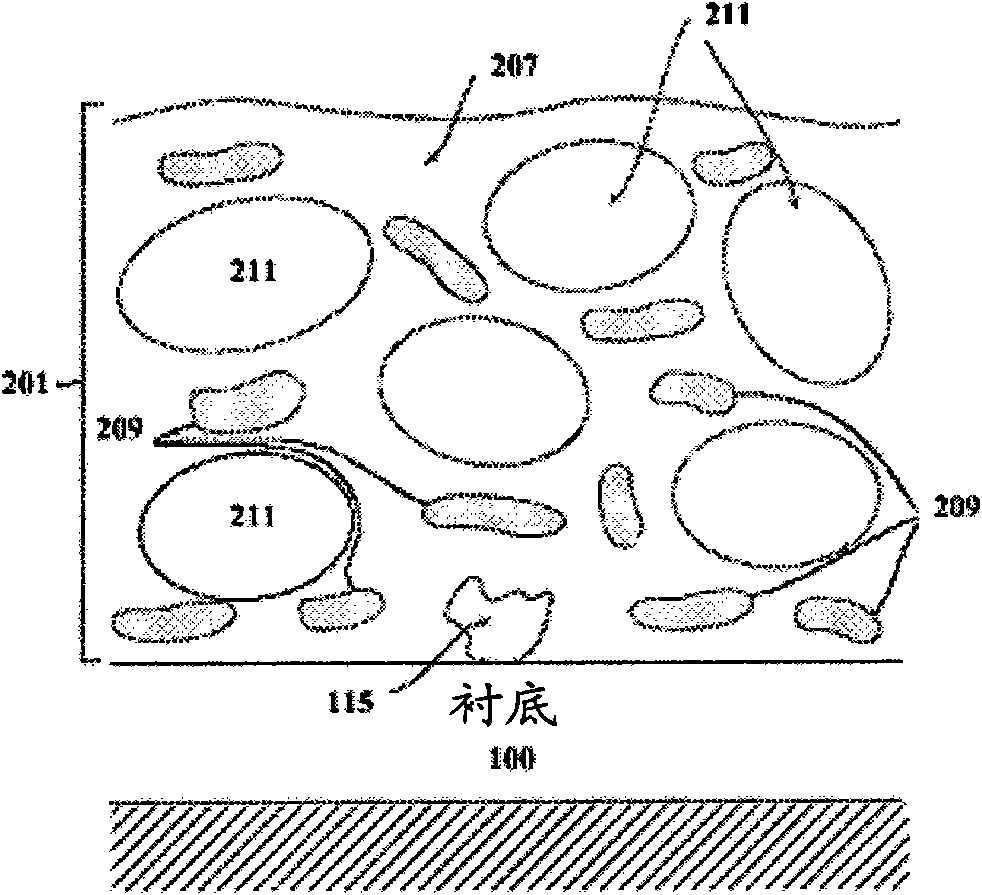

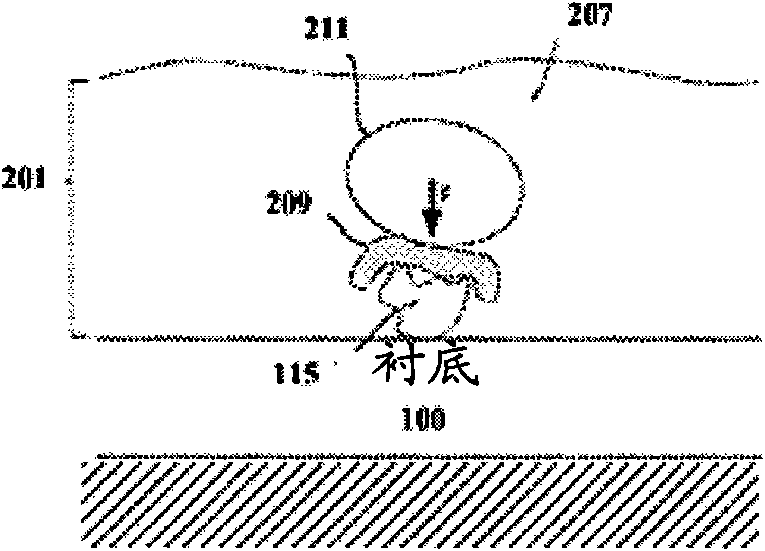

Method of dielectric film treatment

InactiveCN101971297AEasy to understandEasy to cleanSemiconductor/solid-state device manufacturingEmulsionChemical used

A method and system for cleaning a surface of a substrate after an etching operation includes determining a plurality of process parameters associated with the surface of the substrate. The process parameters define characteristics related to the surface of the substrate such as characteristics of the substrate surface to be cleaned, contaminants to be removed, features formed on the substrate and chemicals used in the fabrication operations. A plurality of application chemistries are identified based on the process parameters. The plurality of application chemistries includes a first application chemistry as an emulsion having a first immiscible liquid combined with a second immiscible liquid and solid particles distributed within the first immiscible liquid. The plurality of applicationchemistries including the first application chemistry are applied to the surface of the substrate such that the combined chemistries enhance the cleaning process by substantially removing the particulate and polymer residue contaminants from the surface of the substrate while preserving the characteristics of the features and of the low-k dielectric material through which the features are formed.

Owner:LAM RES CORP

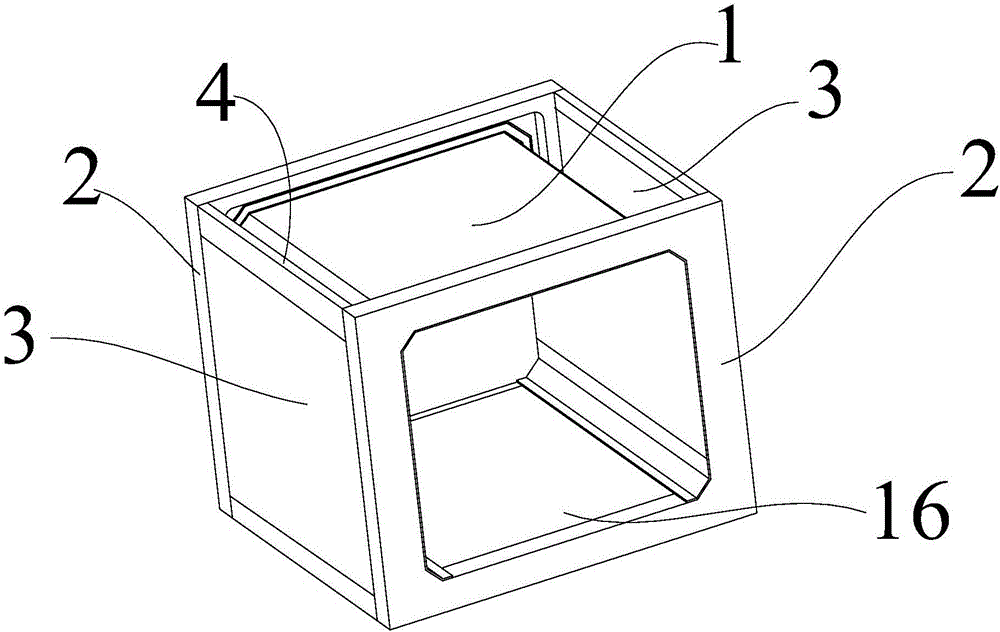

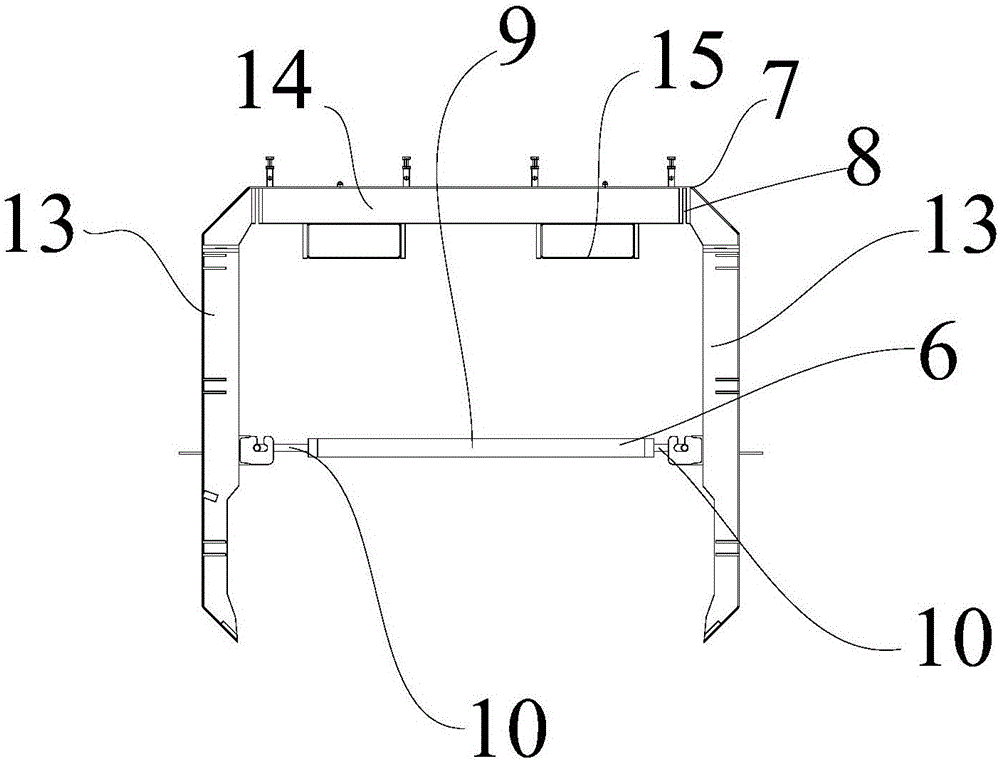

Pipe gallery mold

The invention belongs to the technical field of moulds, and specifically discloses a pipe gallery mould, which includes an inner mold and an outer mold, the outer mold includes a bottom mold, two opposite end molds and two opposite side molds, the inner mold The two ends of the mold are respectively connected with two opposite end forms, the side forms and the bottom form include connecting brackets and concrete prefabricated parts, the two opposite end forms are connected through the connecting brackets, and the concrete prefabricated The component is arranged in the gap formed by the connecting bracket and the end form, and the concrete prefabricated part is connected with the end form and the connecting support and spliced tightly. After the demoulding, the prefabricated part is closely attached to the pipe gallery, which strengthens the side wall and bottom of the pipe gallery, reduces the use of structural steel bars, reduces the amount of concrete used in the pouring process of the pipe gallery, and reduces the cast-in-place concrete in the pipe gallery The volume improves the heat dissipation effect inside the concrete and prevents cracking. At the same time, the side wall and bottom of the pipe gallery do not need to be demoulded, which reduces the difficulty of demoulding and speeds up the construction process.

Owner:中民筑友科技(衡阳)有限公司

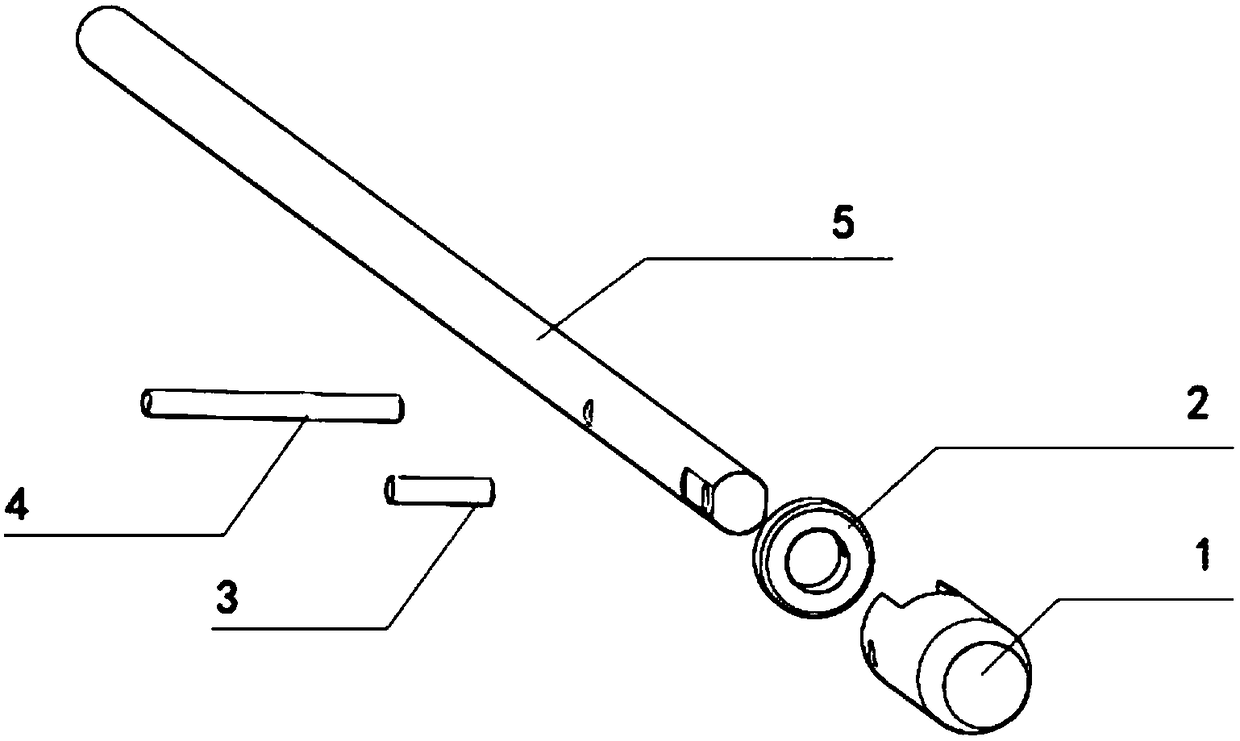

Nuclear power station manhole cover plate assembling and disassembling tool

The invention relates to a nuclear power station manhole cover plate assembling and disassembling tool. The assembling and disassembling tool is used for opening manhole cover plates of nuclear powerplant container equipment. The assembling and disassembling tool comprises a pair of assembling and disassembling rods which are arranged in a complete set, each assembling and disassembling rod comprises a prying rod, a movable supporting ring and a movable head; and for each assembling and disassembling rod, the movable head is arranged at the top end of the prying rod and is hinged to the prying rod, a limiting hole is formed in the middle of the prying rod, a limiting pin is inserted into the limiting hole, and the movable supporting ring sleeves the prying rod and slides between the movable head and the limiting pin. Compared with the prior art, the assembling and disassembling tool has the advantages of being labor-saving, safe, capable of protecting a flange surface, wide in application range and the like.

Owner:CLP CHINA NUCLEAR POWER ENG TECH

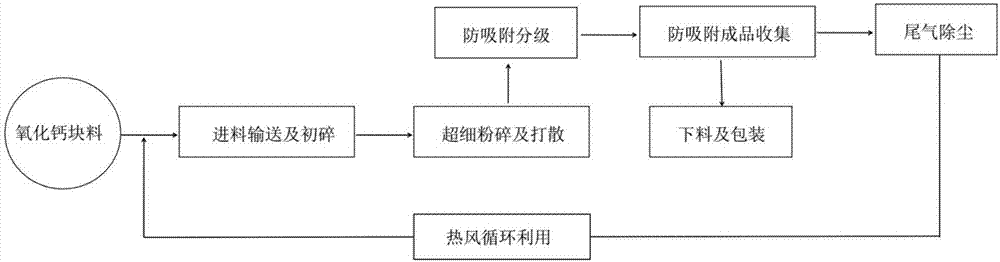

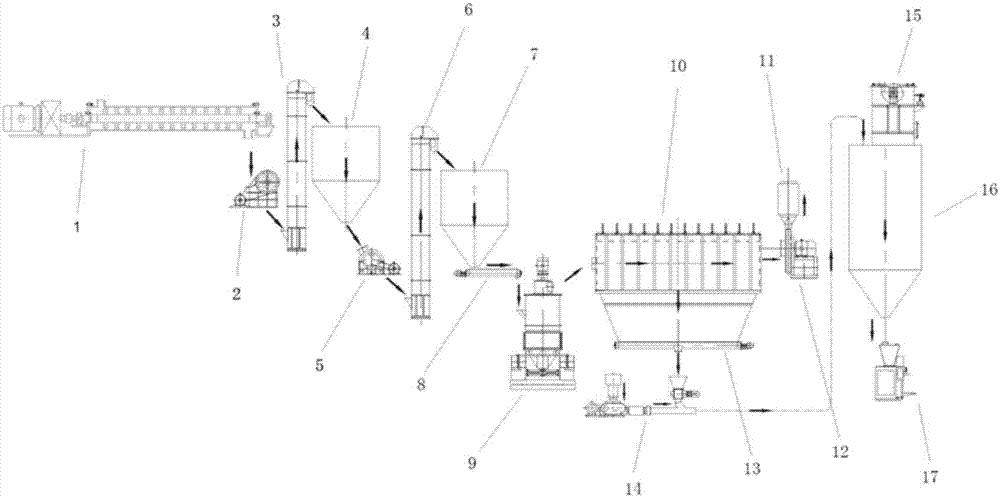

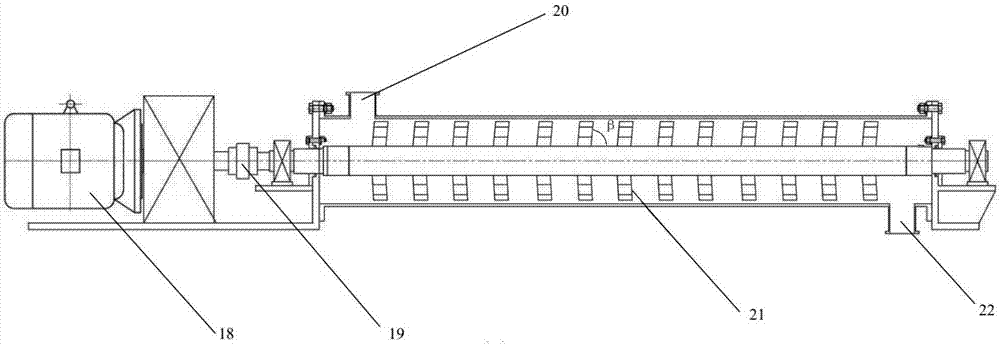

Environment-friendly calcium oxide ultrafine grinding process and complete equipment thereof

ActiveCN107321473AReduce exposureGuaranteed drynessGrain treatmentsEnergy consumptionMaterials science

The invention discloses an environment-friendly calcium oxide ultrafine grinding process and complete equipment thereof. The production process comprises the following steps: 1, feeding and primary crushing: feeding calcium oxide hermetically, and crushing the calcium oxide preliminarily and scattering preliminarily the refined particles at the same time; 2, superfine crushing and scattering: crushing the particles to be 1250 meshes, and crushing the particles while scattering to avoid particles agglomeration; 3, anti-adsorption grading: preventing the powdered particles from being absorbed on blades, and grading the qualified powdered particles at one time; 4, anti-adsorption finished product collection: collecting the powdered particles adhered to inner walls of a collection box through the expansion of a gas bag; 5, ultrafine calcium oxide discharging and packaging. In addition, the process further comprises auxiliary steps of removing dust from tail gas, circulating hot air and the like. According to the environment-friendly calcium oxide ultrafine grinding process and the complete equipment thereof, the whole set of equipment is reasonable in matching, energy consumption is effectively reduced, and dust pollution can be minimized in the production process; and the problem of adhesion and agglomeration of the calcium oxide in production can be solved, the production efficiency is improved, and the calcium oxide with high fineness and high purity is prepared.

Owner:FUJIAN NORMAL UNIV

Preparation method of pouring material with high dielectric property

The invention relates to a preparation method of a pouring material with a high dielectric property. The preparation method comprises steps as follows: high dielectric filler is added to a bifunctional epoxy system and stirred at 130 DEG C for 20 min, a monofunctional epoxy system and nano alumina particles are added at the temperature of 95 DEG C, the mixture is stirred for 130 min, and a glue liquor is obtained; the glue liquor is subjected to vacuum defoamation and added to a mold, and the pouring material with the high dielectric property is obtained after hot-pressing curing. The pouringmaterial has excellent flame retardance and heat resistance and particularly has the outstanding dielectric constant.

Owner:嘉兴立一新材料股份有限公司

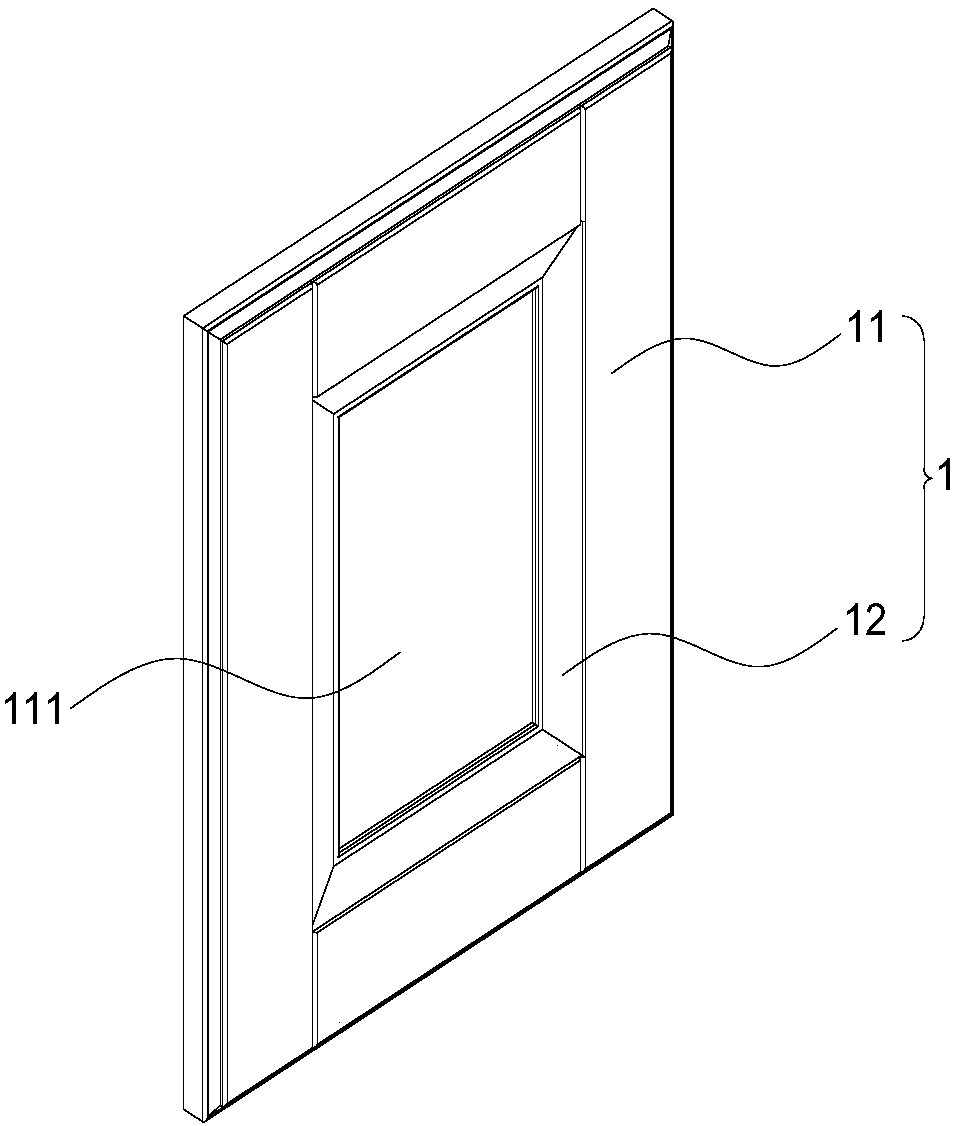

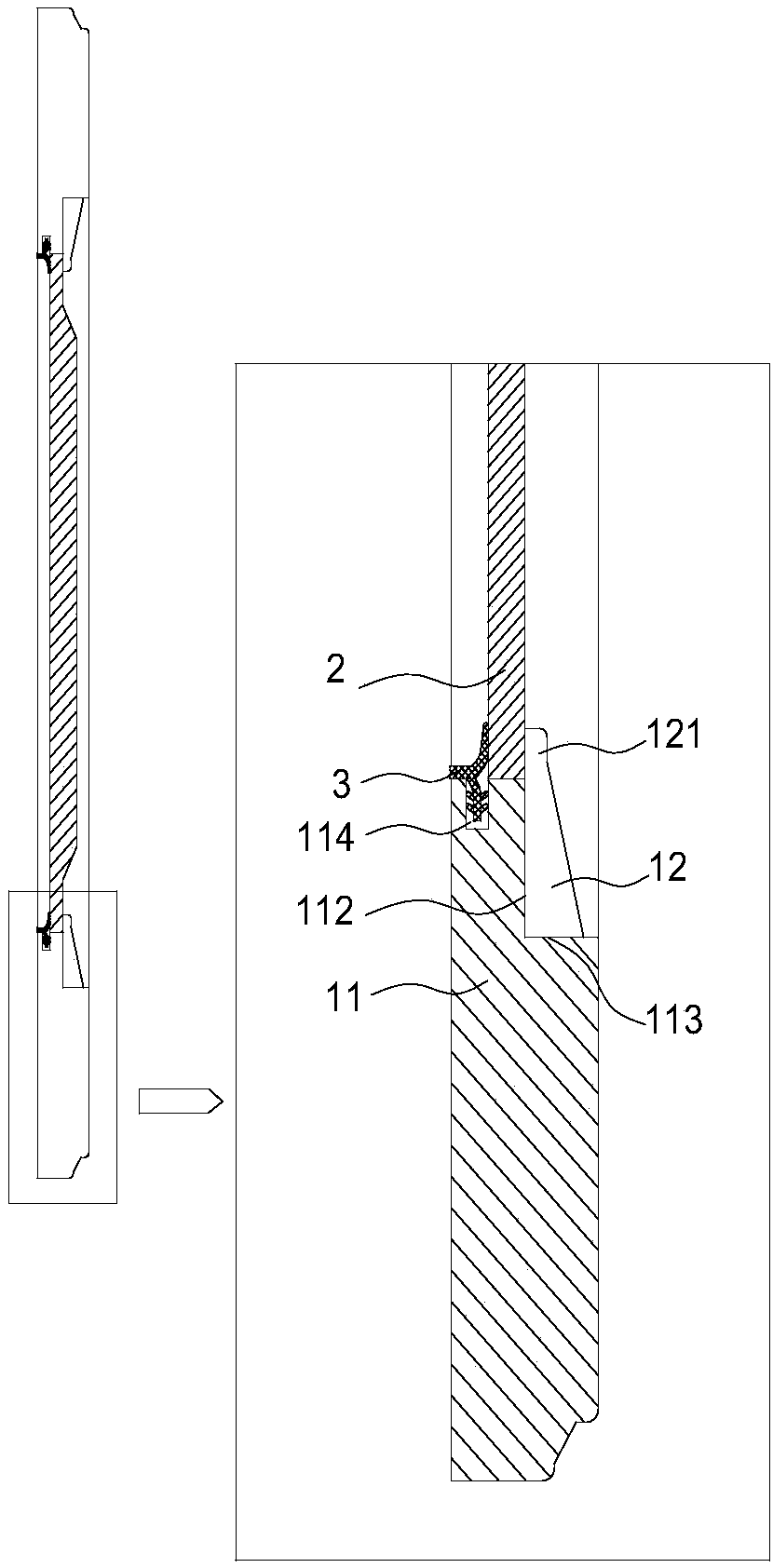

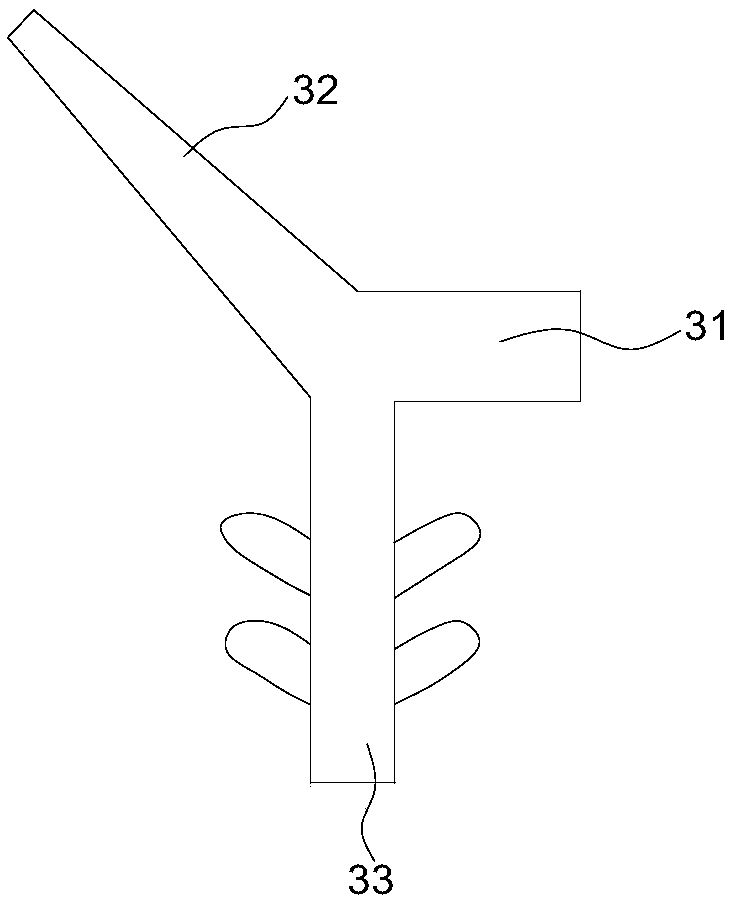

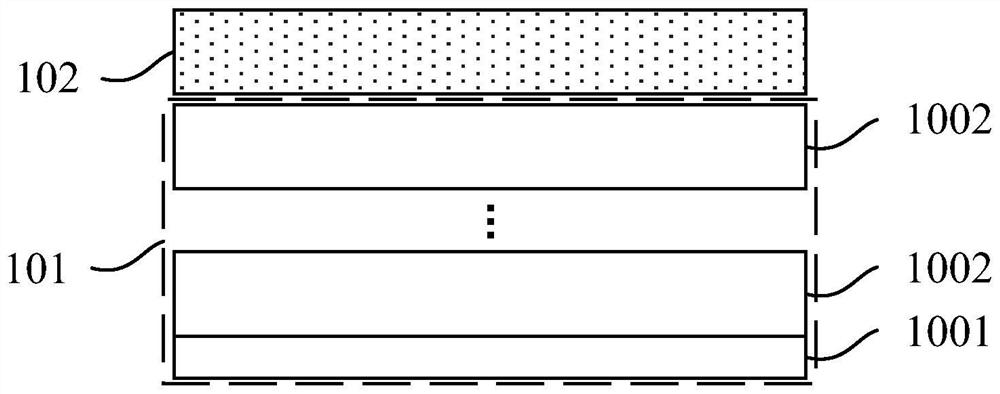

Door frame, preparation method of door frame, and molding press door comprising door frame

InactiveCN108316821AImprove stabilityHigh strengthWood working apparatusDoor leavesEngineeringElectrical and Electronics engineering

The invention discloses a door frame and further discloses a molding press door and a preparation method of the molding press door. The door frame comprises a door frame main body and a side frame. Arectangular opening with the size being matched with that of a rectangular door core is formed in the middle of the door frame main body, and a rectangular right-angle groove surrounding the rectangular opening is formed in the obverse side of the door frame main body. The cross section of the right-angle groove is in an L shape, and the right-angle groove comprises a horizontal groove face parallel to the obverse side of the door frame main body and a vertical groove face perpendicular to the obverse side of the door frame main body. The horizontal groove face is covered with the side frame,and the side frame extends out of the horizontal groove face towards rectangular opening to form an abutting-joint part. The thickness of the side frame is smaller than or equal to the height of the vertical groove face. The molding press door formed by assembling the door frame is overall flat and smooth, the stability and strength of the molding press door are enhanced, and the impact-resistantand extruding-resistant properties of the molding press door are also enhanced.

Owner:SUOFEIYA HOME COLLECTION

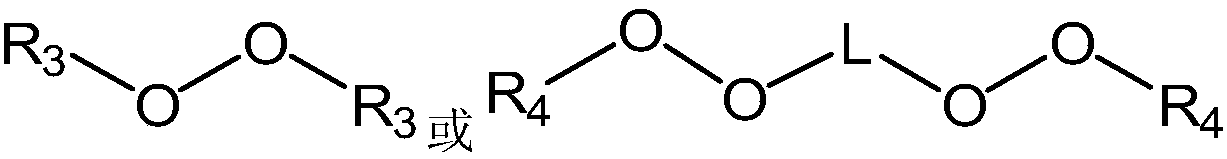

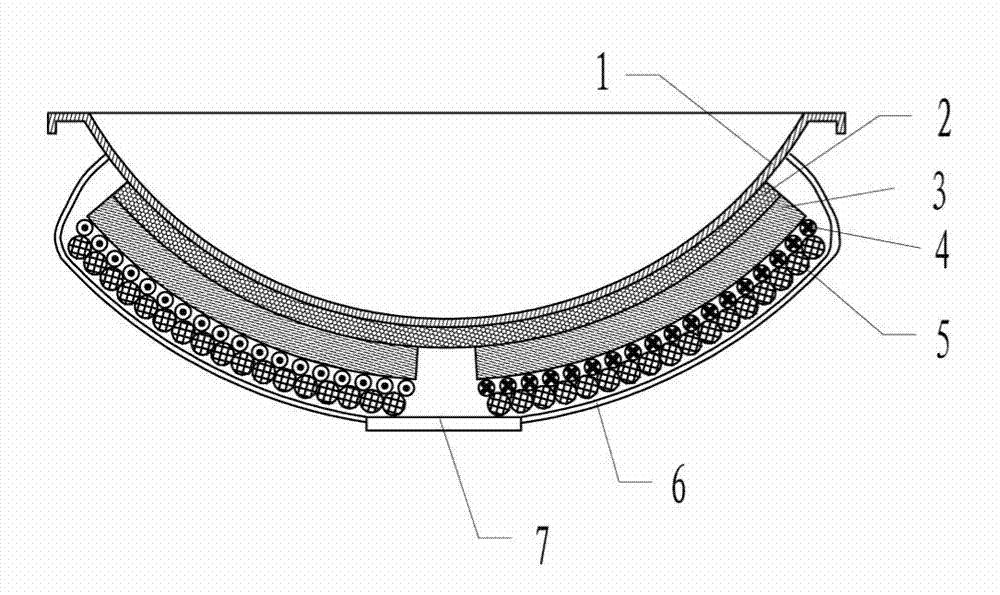

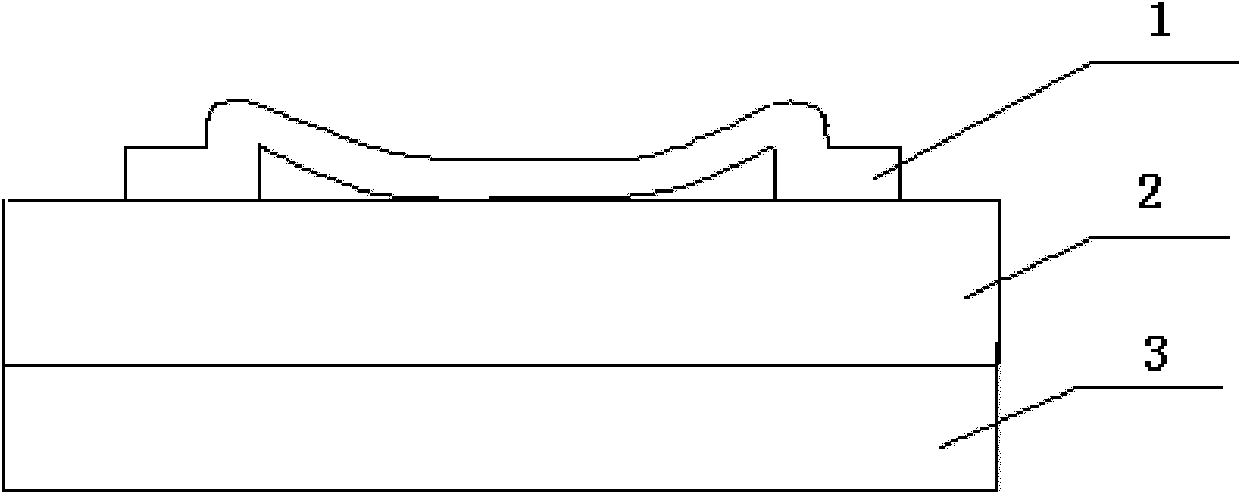

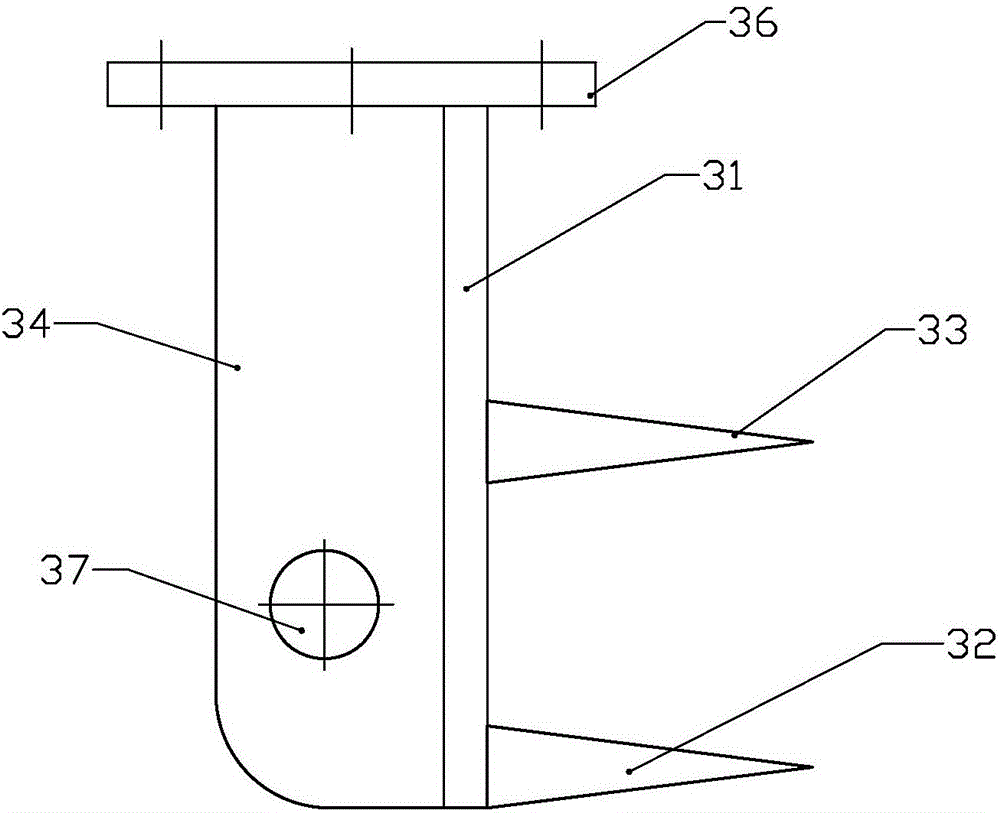

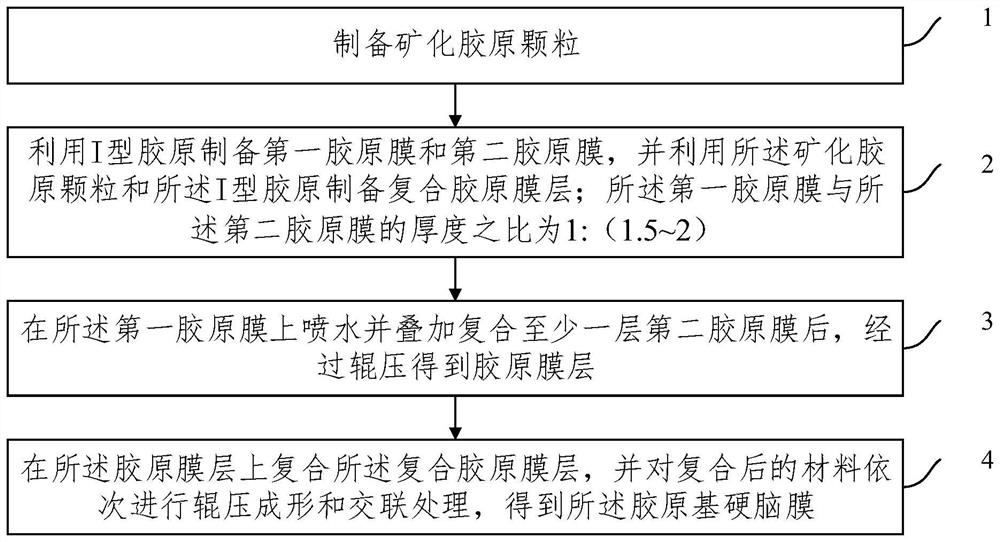

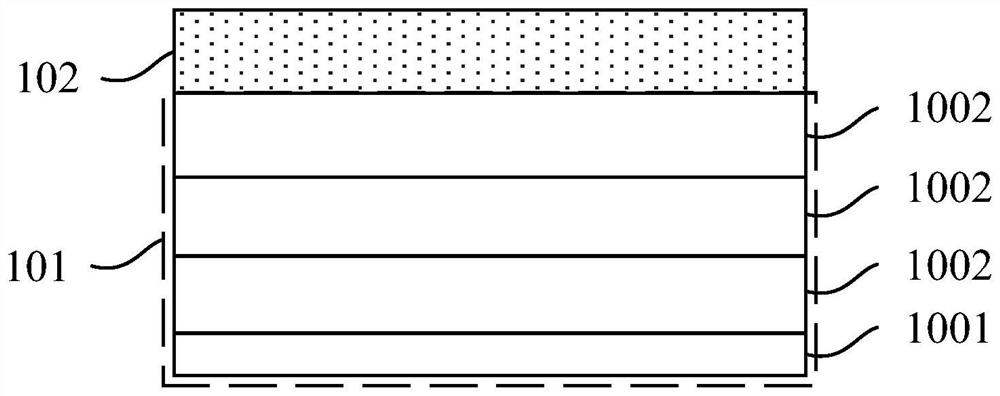

Collagen-based dura mater and preparation method thereof

ActiveCN114225110AOvercome mechanical propertiesOvercoming AdhesionTissue regenerationProsthesisDura mater encephaliMeninges

The invention provides a collagen-based dura mater and a preparation method thereof. The collagen-based dura mater comprises a collagen mater layer facing a brain tissue side and a composite collagen mater layer facing a skull side, the collagen membrane layer comprises at least two layers of collagen membranes, and the collagen membranes are formed by I-type collagen; the collagen film layer is a compact layer obtained by spraying a bonding medium on at least two layers of collagen films, overlapping and compounding, and rolling; the at least two layers of collagen membranes comprise a first collagen membrane and at least one layer of second collagen membrane, and the first collagen membrane faces the brain tissue side; the thickness ratio of the first collagen membrane to the second collagen membrane is 1: (1.5-2); the composite collagen membrane layer is formed by compounding type I collagen and mineralized collagen particles, and the interior of the composite collagen membrane layer is of a porous structure; after the collagen membrane layer and the composite collagen membrane layer are compounded, the compounded material is sequentially subjected to rolling forming and crosslinking treatment, and the collagen-based dura mater is obtained. The collagen-based dura mater provided by the invention has excellent mechanical properties and anti-adhesion performance.

Owner:BEIJING ALLGENS MEDICAL SCI & TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com