Method for eliminating adhesion phenomenon of suspended structure of micro-electromechanical system (MEMS)

A technology of micro-electronic machinery and suspended structure, applied in micro-structure technology, micro-structure device, manufacturing micro-structure device, etc., can solve the problems of high magnetic field strength, limited application range, limited application surface, etc., to improve structural rigidity and recovery The effect of strong force, controllability and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention takes the MEMS surface-processed double-end fixed-support beam device as an example to specifically illustrate the detailed content of the present invention.

[0019] 1. Construction of MEMS suspended structure with adhesion:

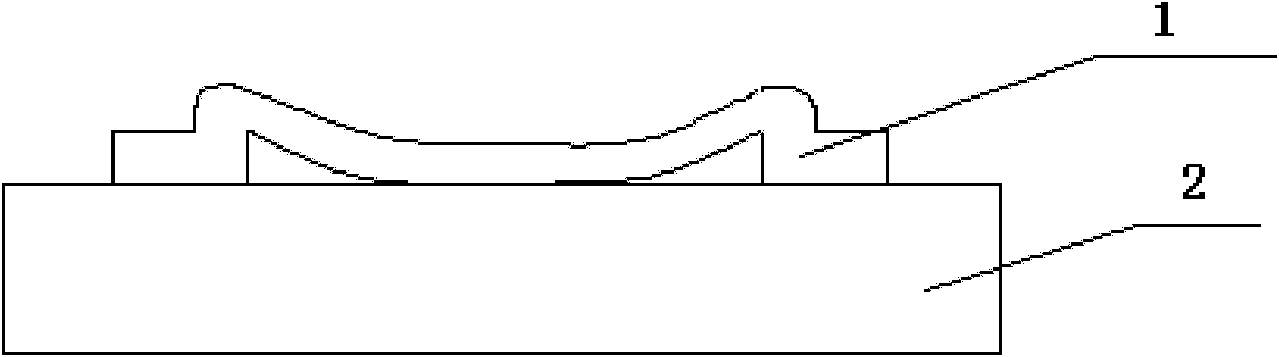

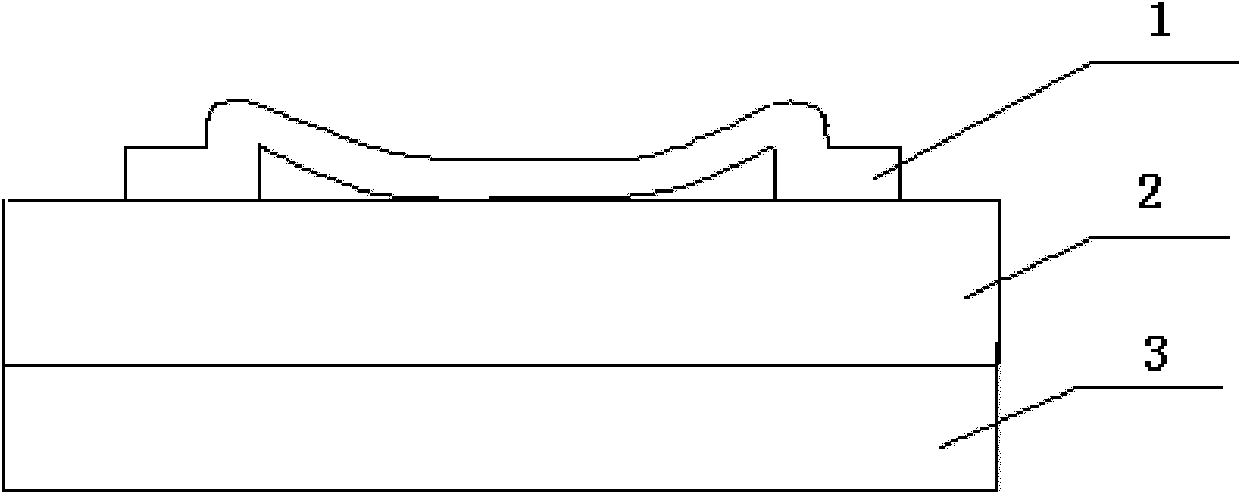

[0020] (1) Loading a double-ended fixed beam 1 with a length of 100-1000 μm on the rectangular silicon test chip 2 .

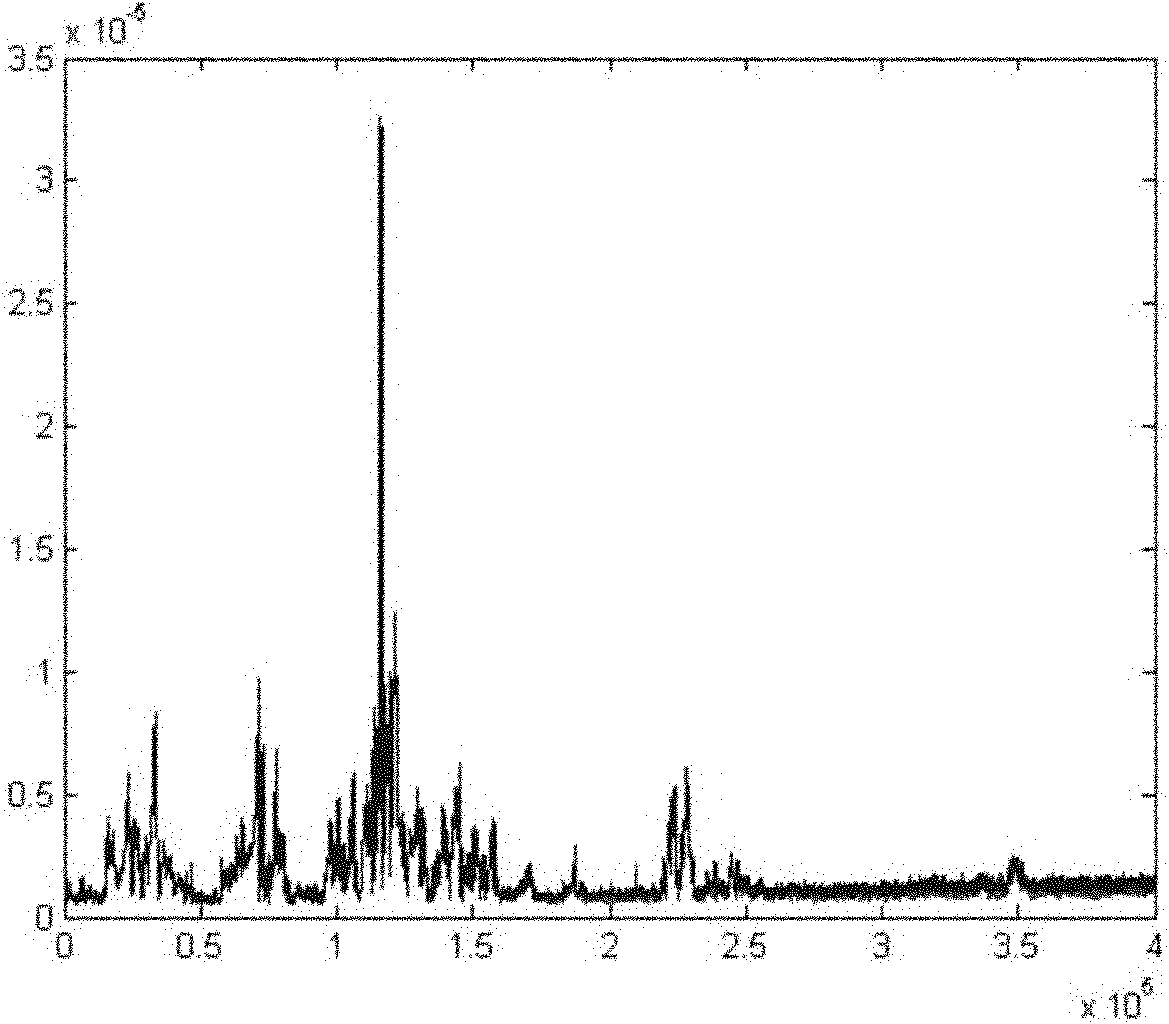

[0021] (2) Configure release solution, mix 25ml of 40% HF (hydrogen fluoride) solution, NH 4 F (ammonium fluoride) 40g, glycerin 20ml, water 46ml mixed evenly, put in 40 C in a water bath for heating. Then, the chip with the double-end fixed beam is placed in the release liquid and released by wet method, so that the beam 1 is adhered to the surface of the chip, see figure 1 . The beam can also be forced to adhere to the substrate without recovery using an atomic force probe. Use the Doppler instrument to detect the vibration wave of the cantilever beam and the chip to check the adhesion of the beam, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com